Patents

Literature

1247 results about "N-Butanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

N-Butanol or n-butyl alcohol or normal butanol is a primary alcohol with a 4-carbon structure and the chemical formula C₄H₉OH. Its isomers include isobutanol, 2-butanol, and tert-butanol. Butanol is one of the group of "fusel alcohols" (from the German for "bad liquor"), which have more than two carbon atoms and have significant solubility in water.

Fermentive production of four carbon alcohols

Owner:GEVO INC

Alternative fuel and fuel additive compositions

InactiveUS20090013591A1Reduce concentrationReduce severityBiofuelsLiquid carbonaceous fuelsParticulatesAlternative fuels

Alternative gasoline, diesel fuel, marine diesel fuel, jet fuel, and flexible fuel compositions are disclosed. The compositions include an alcohol and / or a glycerol ether or mixture of glycerol ethers, which can be derived from renewable resources. When combined with gasoline / ethanol blends, the glycerol ethers can reduce the vapor pressure of the ethanol and increasing the fuel economy. When added to diesel fuel / alcohol blends, glycerol ethers improve the cetane value of the blends. All or part of the diesel fuel in the compositions described herein can be biodiesel fuel and / or synthetic fuel derived from a Fischer-Tropsch synthesis process. Fischer-Tropsch synthesis can also use feedstocks derived from sources other than crude oil, such as methane, methanol, ethanol, lignin and glycerol, which can further reduce reliance on foreign sources of crude oil. When used in jet fuel, glycerol ethers can replace all or part of conventional deicing additives, thus lowering skin toxicity, and glycerol ethers ability to reduce particulate emissions can lower the appearance of contrails. When used in marine diesel, the reduction in particulate emissions can be environmentally significant. In another embodiment, the alternative compositions comprise gasoline, ethanol, and n-butanol, and in one aspect, the ethanol and / or n-butanol can be derived from renewable resources. Fuel additive compositions, including glycerol ethers and hydrocarbons and / or alcohols, are also disclosed.

Owner:BRADIN DAVID +2

Carbon nano material/metal nano material composite nano ink

InactiveCN102993820AReduce manufacturing costLow costConductive layers on insulating-supportsInksCyclohexanoneKetone

The invention provides a carbon nano material / metal nano material composite nano ink which comprises solvent, an additive, a carbon nano material and a metal nano material. The carbon nano material / metal nano material composite nano ink is characterized in that the solvent can comprise water, alcohol organic solvent (ethanol(alcohol), isopropanol, n-butanol and the like), ester organic solvent (ethyl acetate, butyl acetate, ethylene-propylene acetate and the like), benzene organic solvent (methylbenzene, dimethylbenzene and the like) and ketone organic solvent (cyclohexanone, acetone, methylethylketone, butanone and the like); the additive comprises surfactant, pH value stabilizer, defoaming agent, diluter, reinforcer and the like; the carbon nano material comprises a single-layer carbon nanotube, a double-layer carbon nanotube, a multi-layer carbon nanotube and graphene; the metal (copper, silver, gold, platinum, nickel and the like, also including an alloy nano material, an ITO metal composite nano material and the like) nano material further comprises a metal nanoparticle, a metal nanowire or a metal nanotube; the components of the nano ink must include one carbon nano component and one metal nano component, such as a single-layer carbon nanotube and copper nanowire composite ink, a double-layer carbon nanotube and silver nanowire composite ink, a single-layer carbon nanotube and silver nanoparticle composite ink or any other possible combination; the components can be regulated according to specific applications; and a composite nano conductive film can be formed on different bases through different electronic printing processes. The ink can be used in the printing of a flexible base material and can be conveniently prepared into a flexible conductive film.

Owner:杨阳

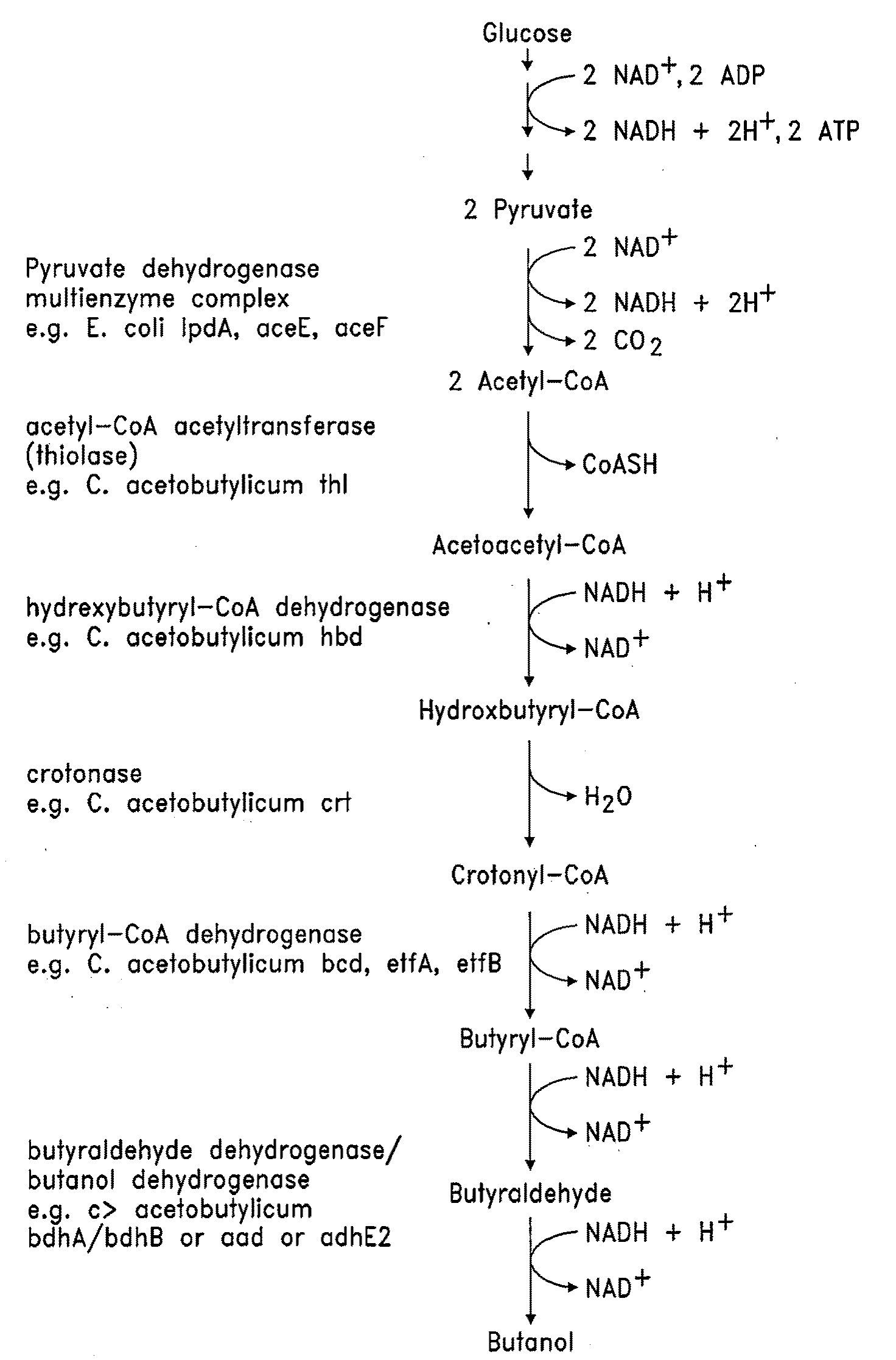

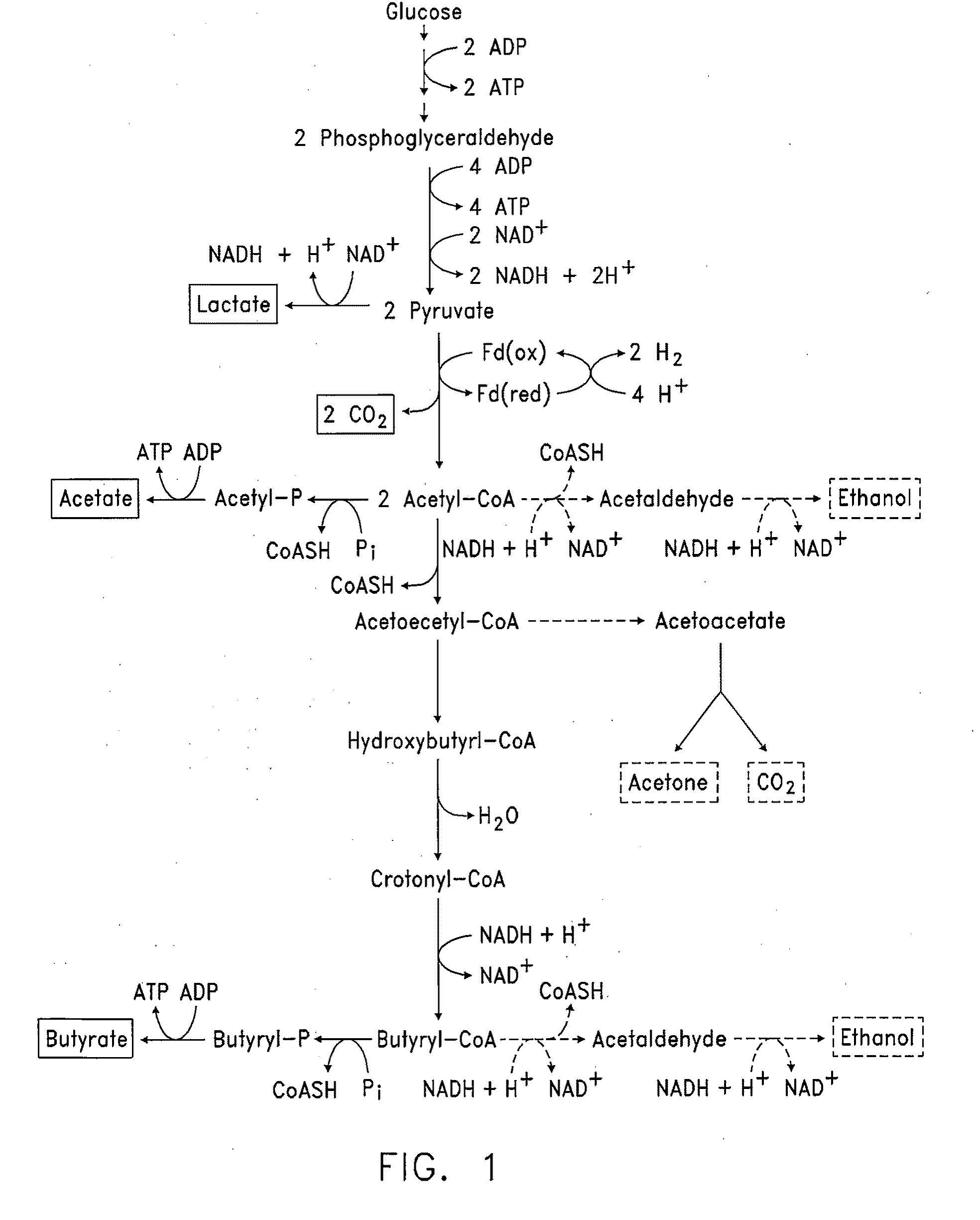

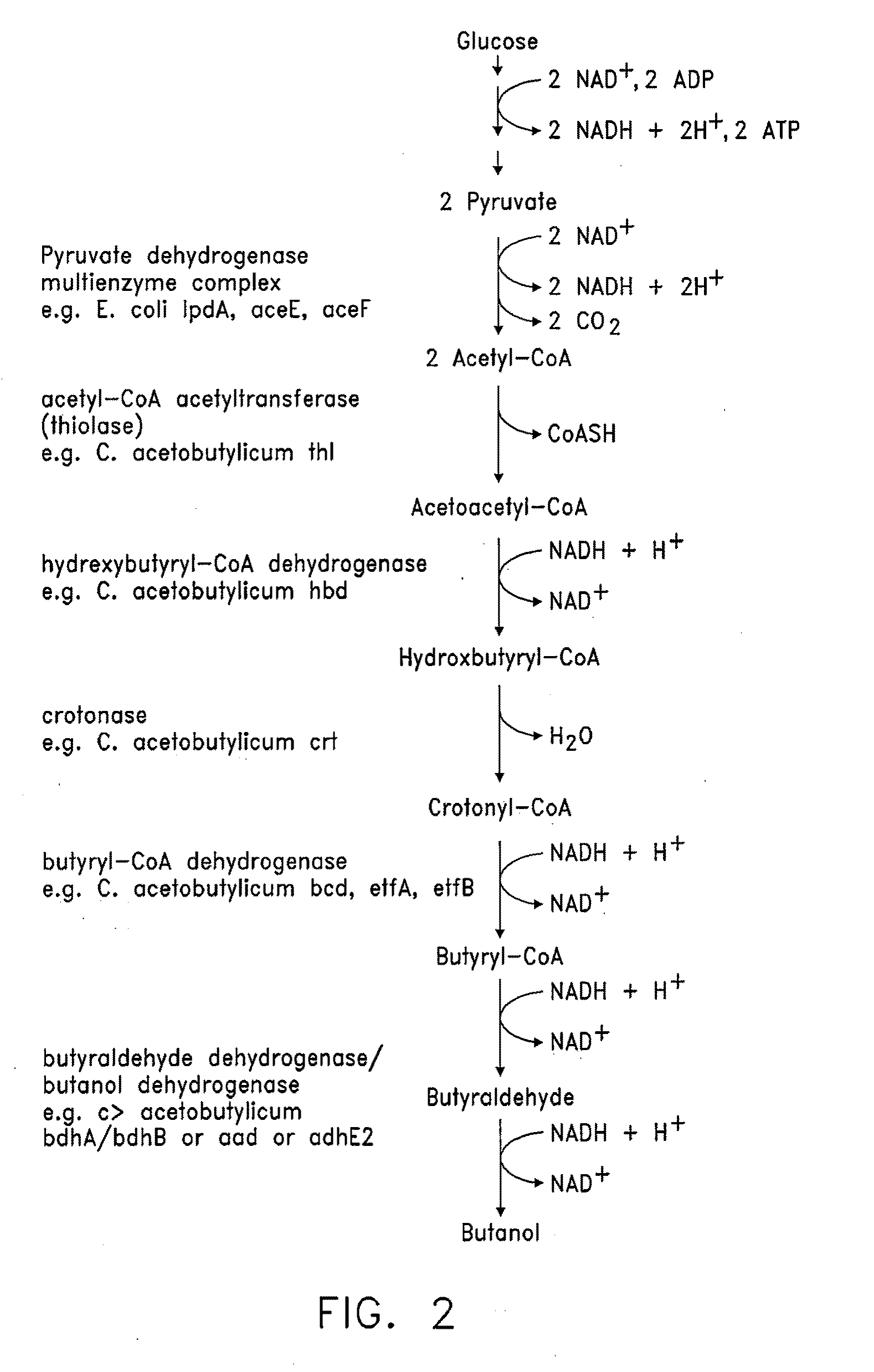

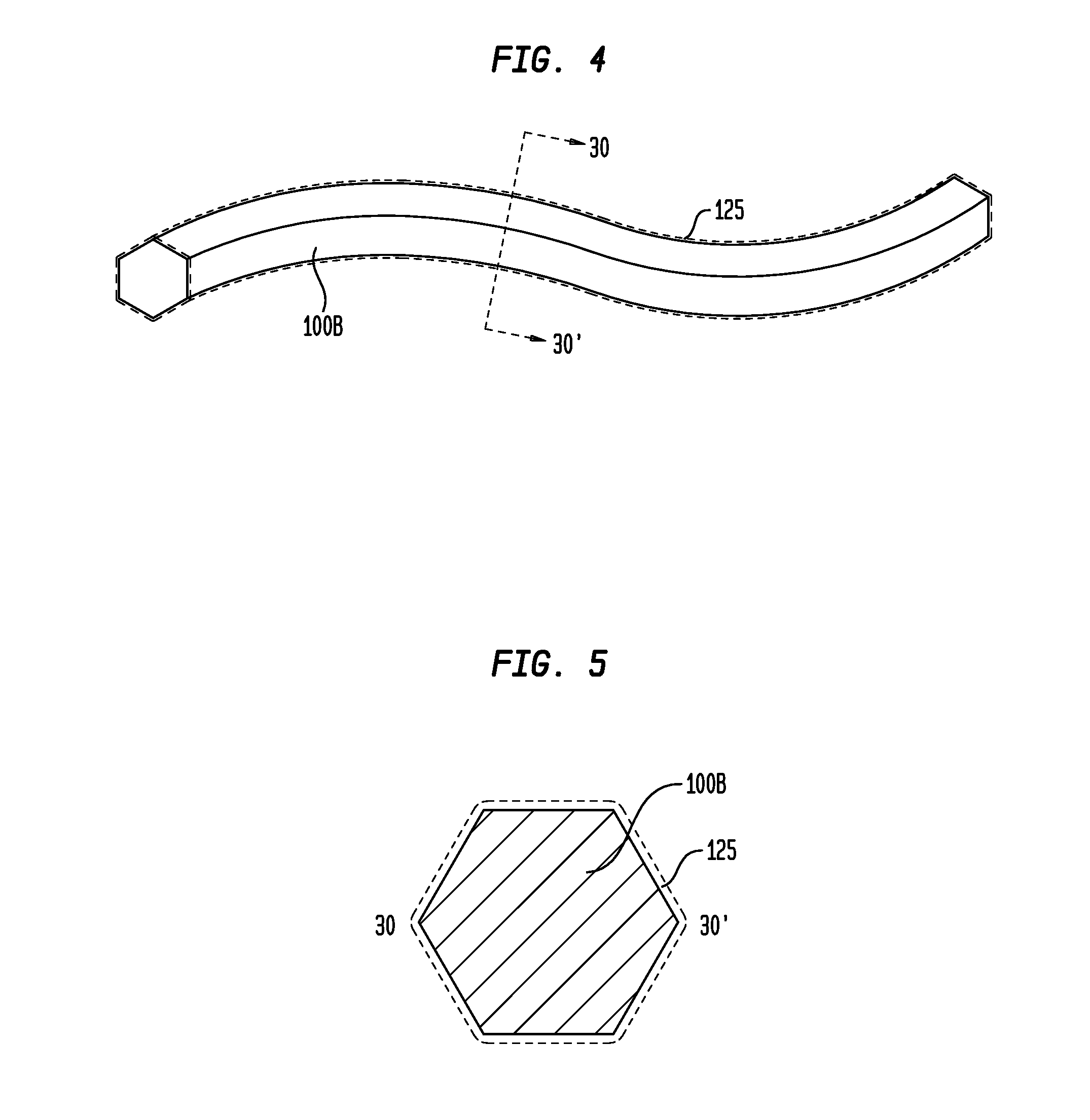

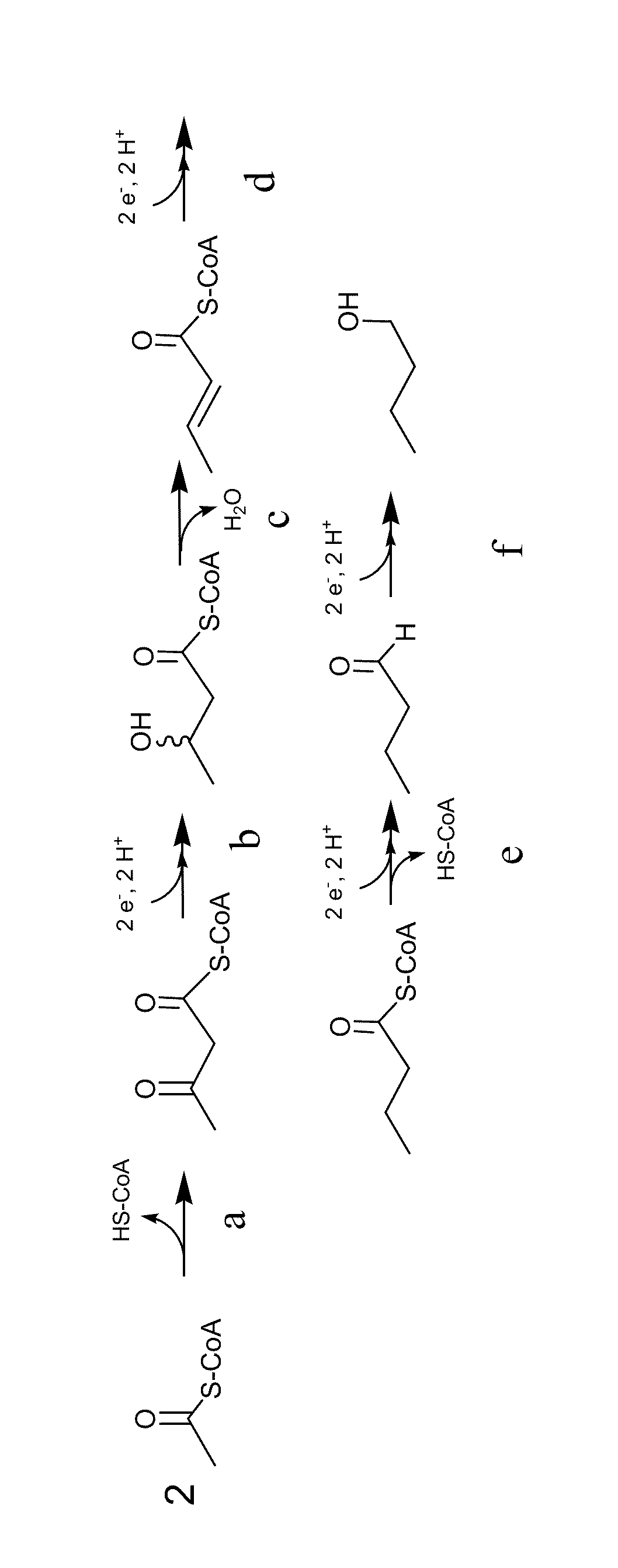

Butanol production by metabolically engineered yeast

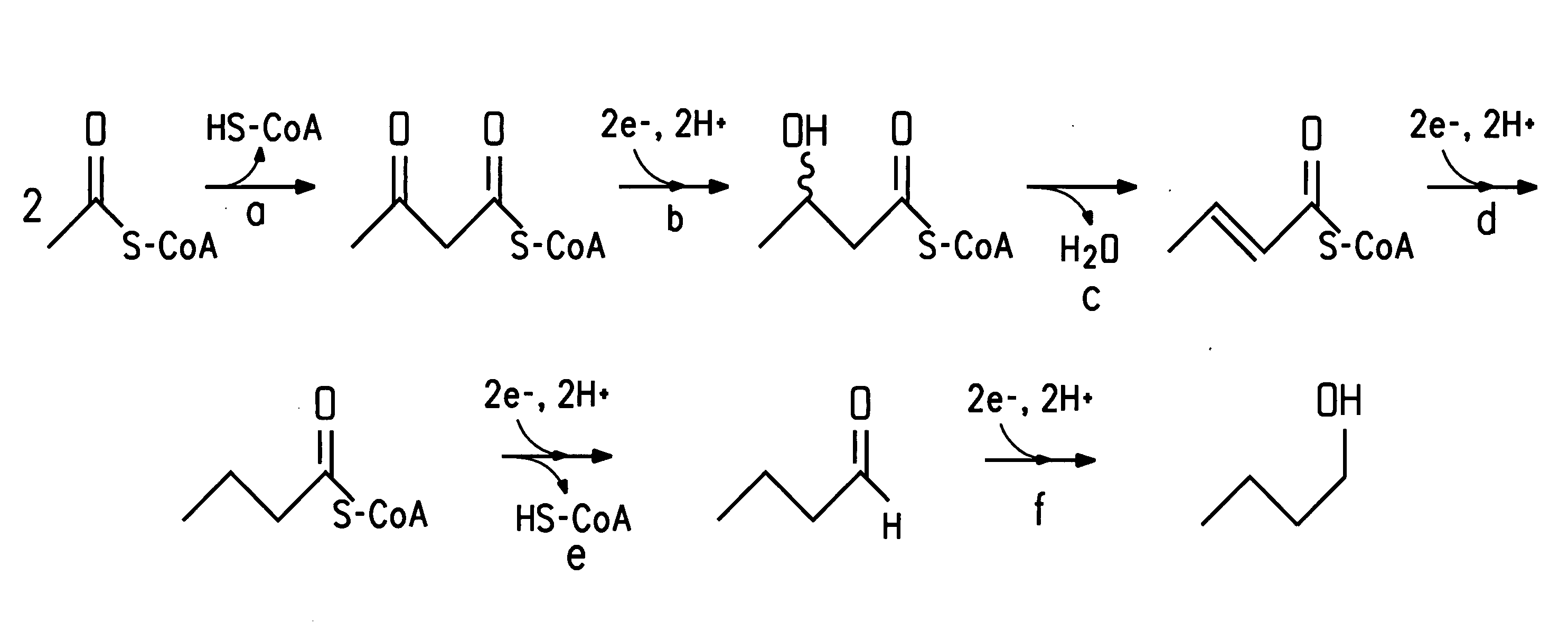

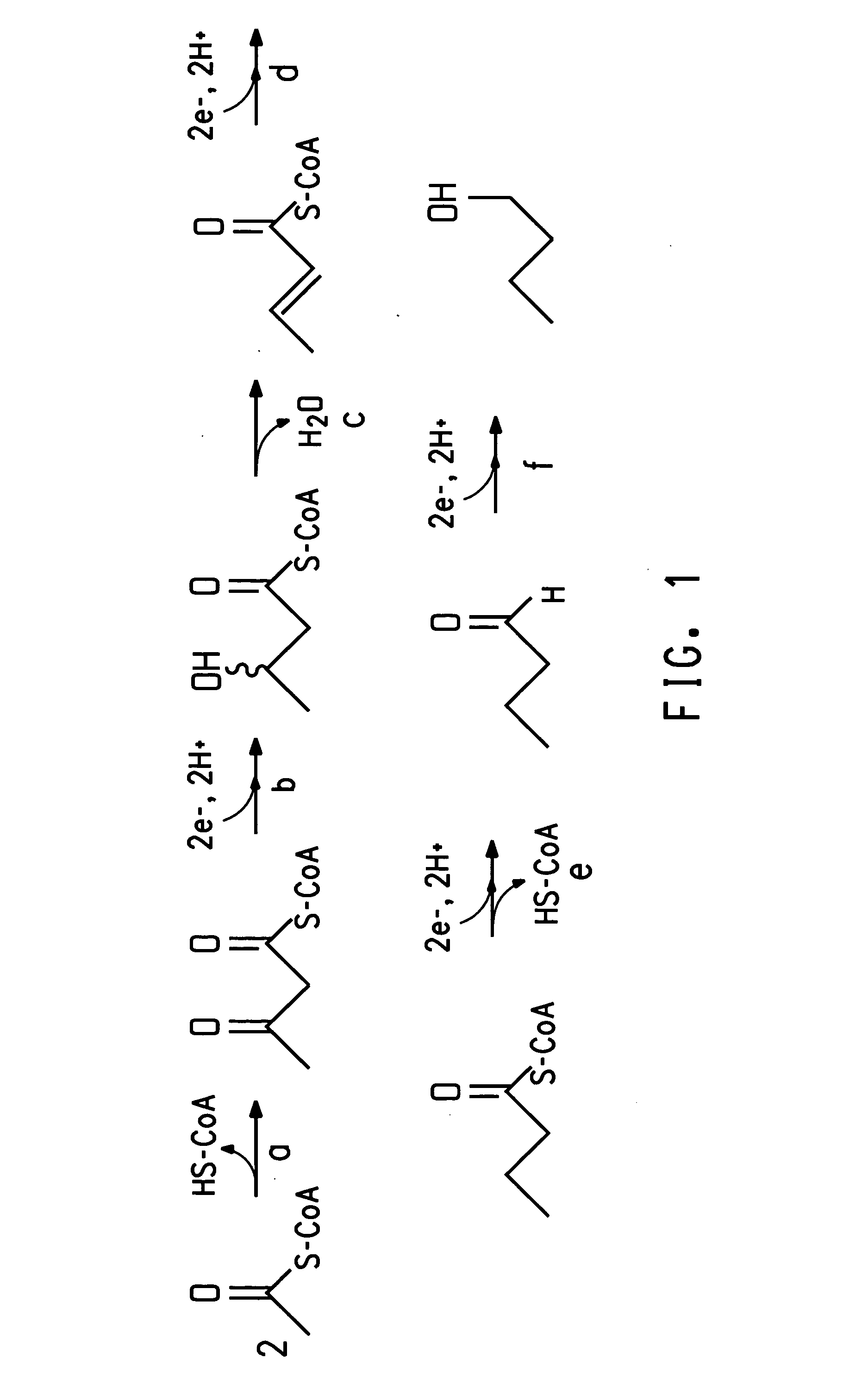

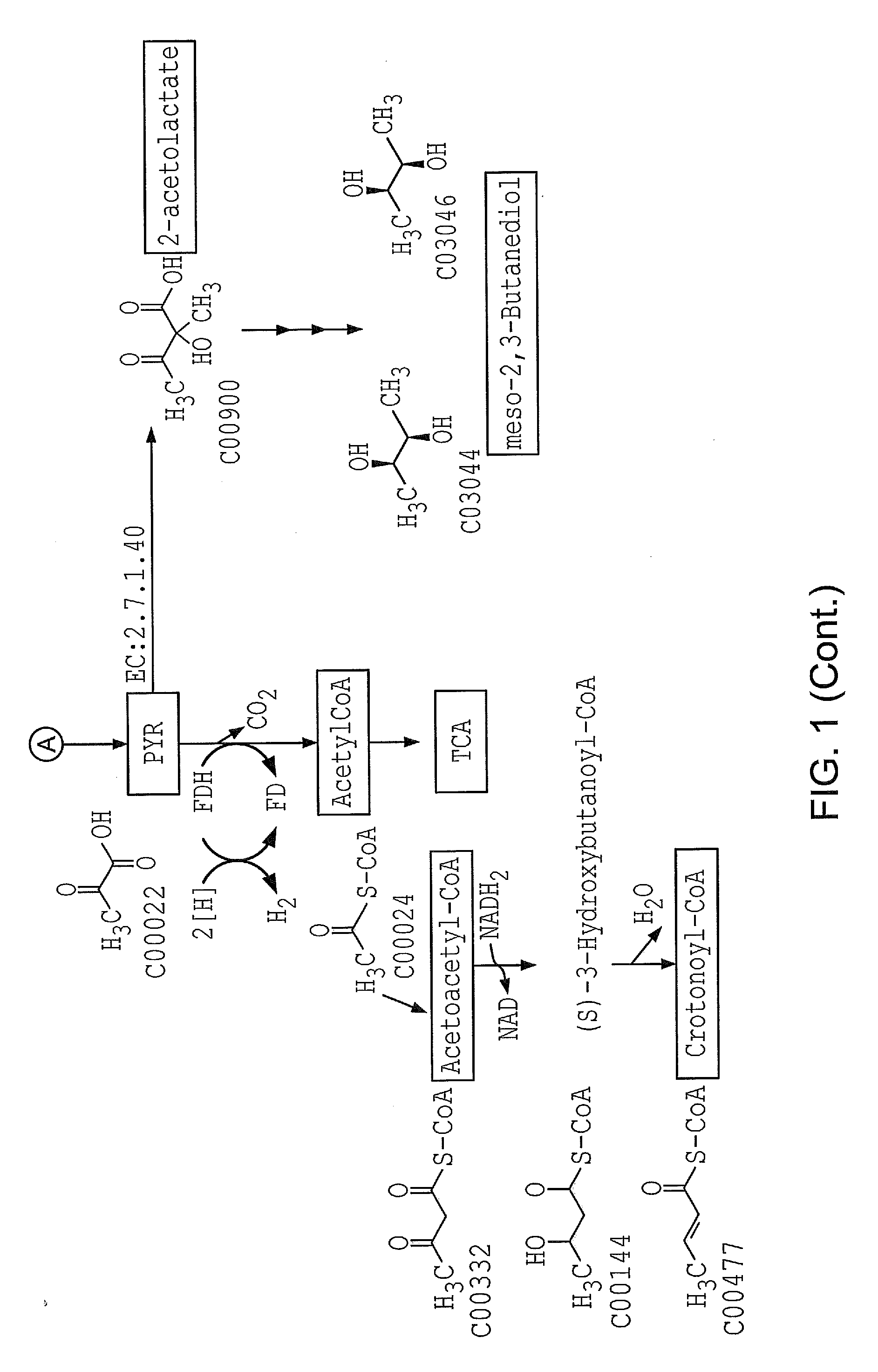

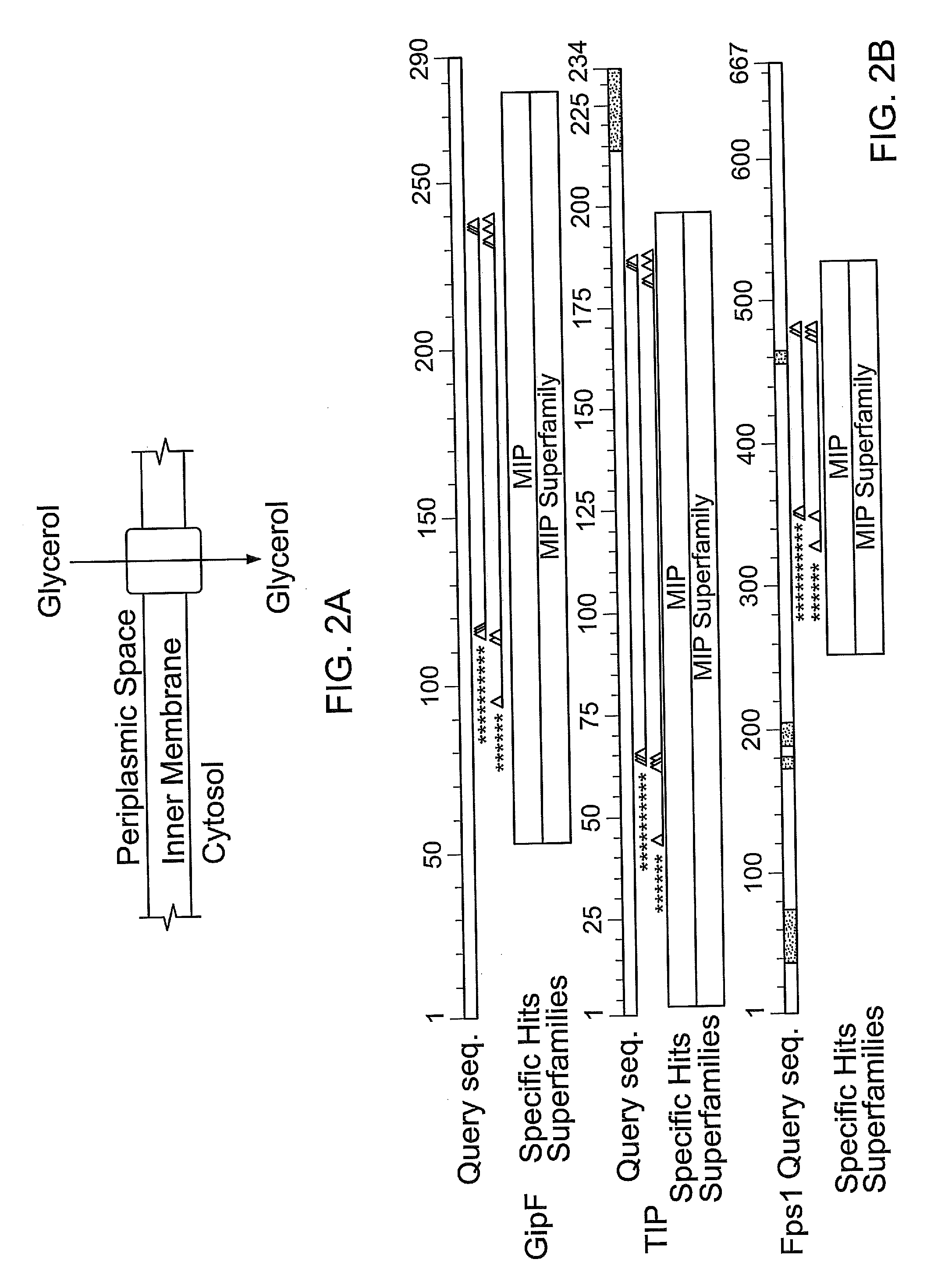

InactiveUS20100062505A1Improve metabolic activityIncreased amount of acetyl-CoAFungiBiofuelsHeterologousYeast

There are disclosed metabolically-engineered yeast and methods of producing n-butanol. In an embodiment, metabolically-engineered yeast is capable of metabolizing a carbon source to produce n-butanol, at least one pathway produces increased cytosolic acetyl-CoA relative to cytosolic acetyl-CoA produced by a wild-type yeast, and at least one heterologous gene encodes and expresses at least one enzyme for a metabolic pathway capable of utilizing NADH to convert acetyl-CoA to n-butanol. In another embodiment, a method of producing n-butanol includes (a) providing metabolically-engineered yeast capable of metabolizing a carbon source to produce n-butanol, at least one pathway produces increased cytosolic acetyl-CoA relative to cytosolic acetyl-CoA produced by a wild-type yeast, and at least one heterologous gene encodes and expresses at least one enzyme for a metabolic pathway utilizing NADH to convert acetyl-CoA to n-butanol; and (b) culturing the yeast to produce n-butanol. Other embodiments are also disclosed.

Owner:GEVO INC

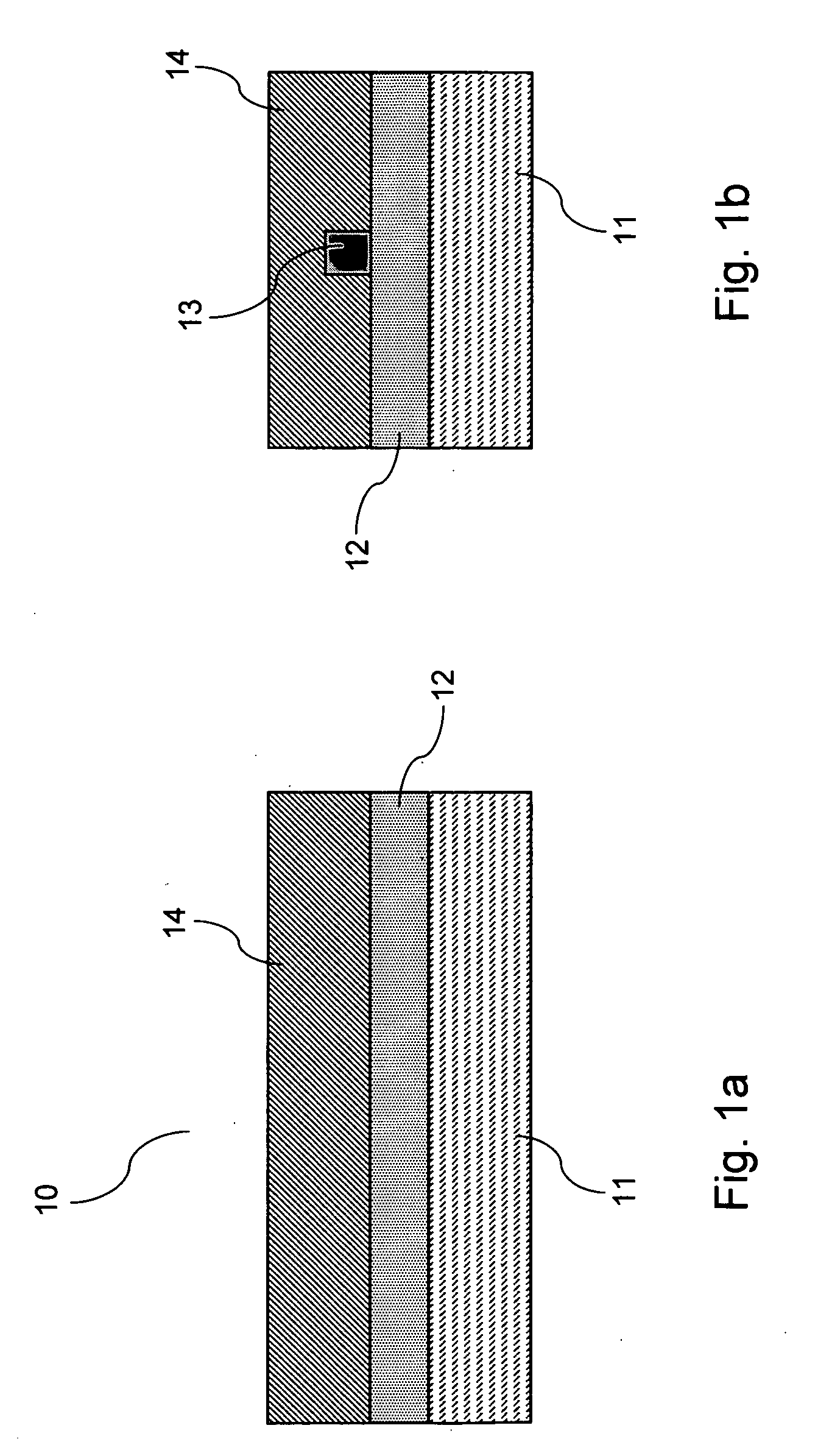

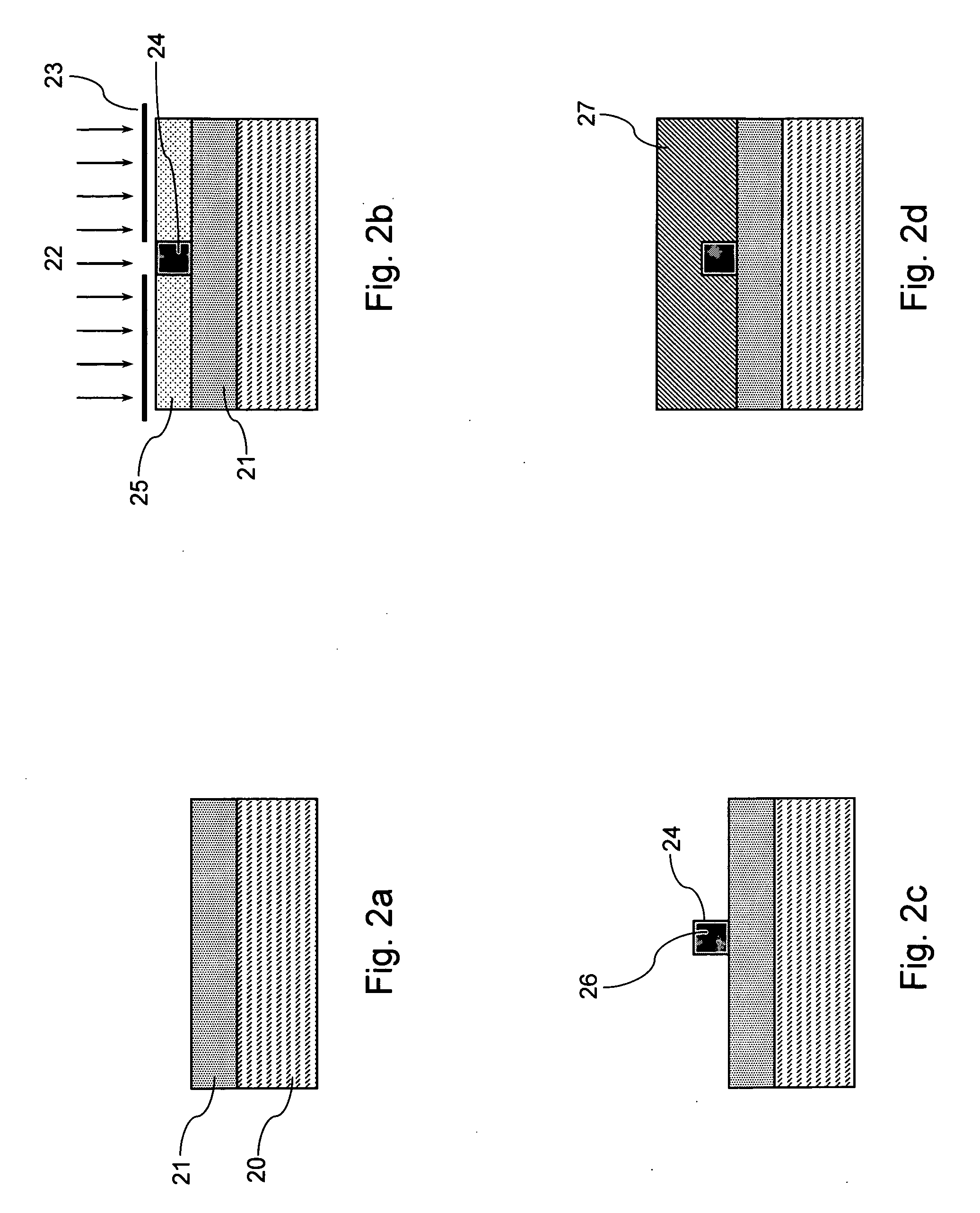

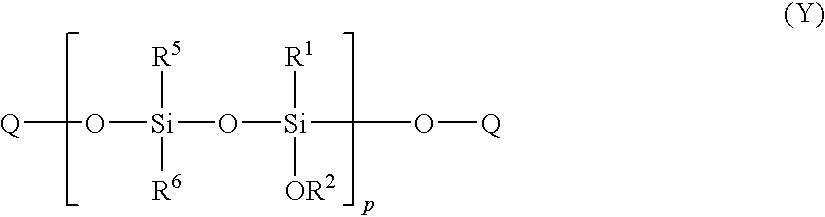

Process for producing polysiloxanes and use of the same

A process for the preparation of an organosilicon condensate which comprises reacting together a silicon containing compound having at least one silanol group and a silicon containing compound having at least one —OR group or at least one silanol group (or a compound having both groups) in the presence of strontium oxide, barium oxide, strontium hydroxide or barium hydroxide and optionally a solvent such as water, methanol, ethanol, 1-propanol, 2-propanol, 1-butanol and 2-butanol, acetone or toluene.

Owner:ZETTA RES & DEV LLC RPO SERIES

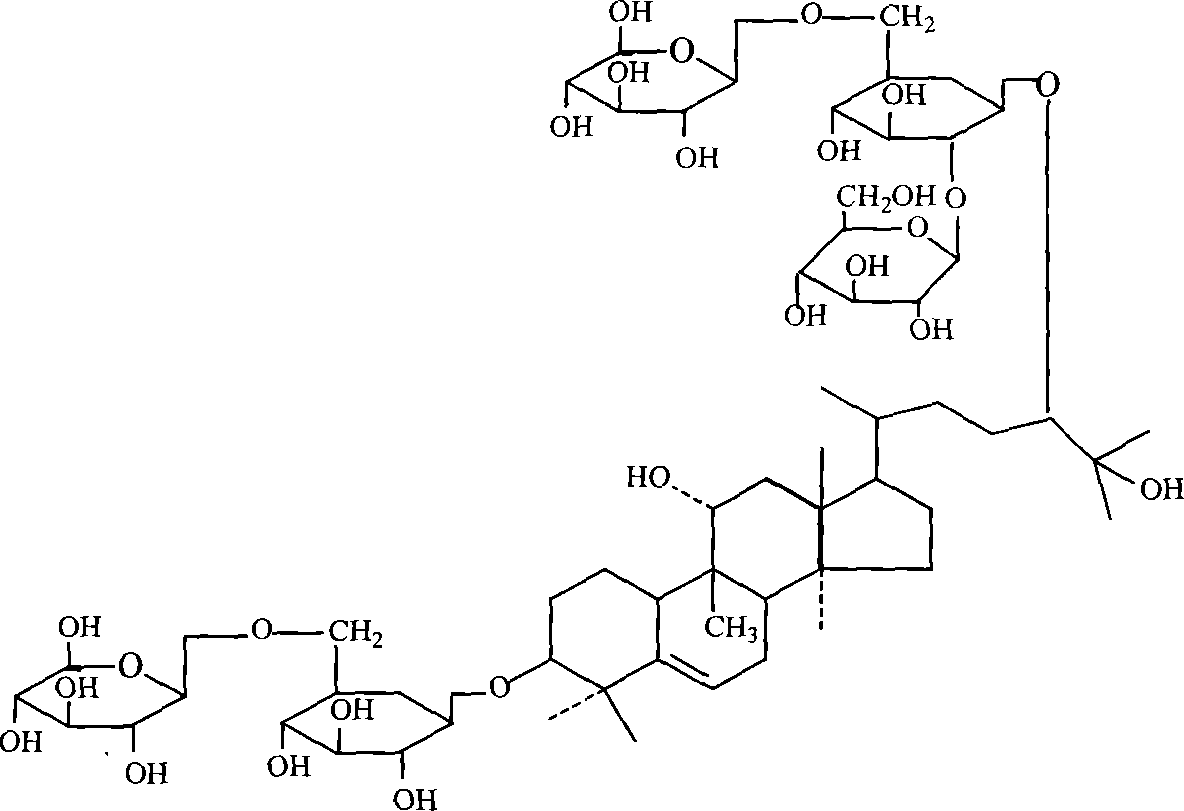

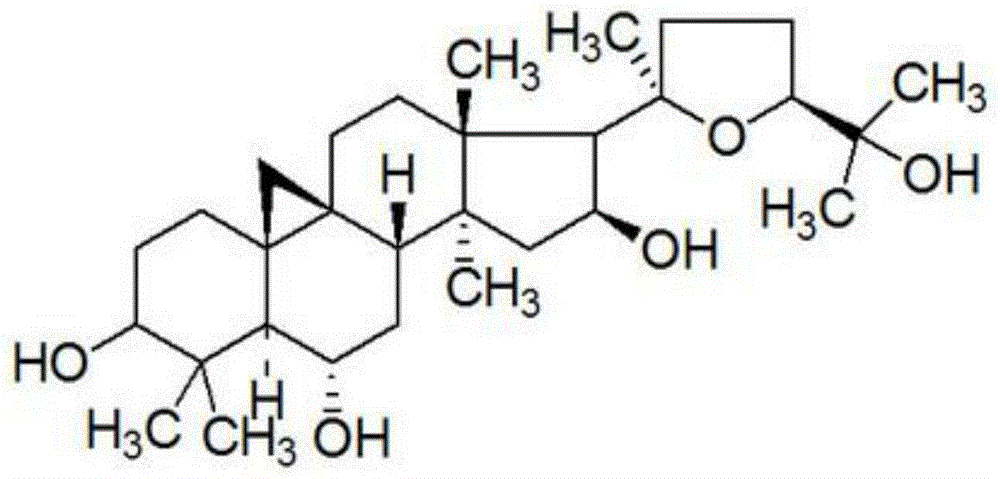

Method for preparing high-purity Momordia grosvenori aglycone from Momordia grosvenori

A process for preparing high-purity momordicoside from fructus momordicae includes such steps as pulverizing, reflux extracting in alcohol, filtering to obtain extract A, suspending it in water, extracting in ethyl acetate 1-3 times, recovering ethyl acetate mother liquid, extracting in n-butanol 1-3 times, recovering n-butanol to obtain extract B, passing it through polyamide column, water washing, concentrating to obtain coarse saponin, chromatography by silica gel column, eluting with chloroform-methanol-water, collecting coarse momordicoside V, chromatography, water washing, eluting with alcohol, and collecting product.

Owner:SHANGHAI JIAO TONG UNIV

Methods of making nylon intermediates from glycerol

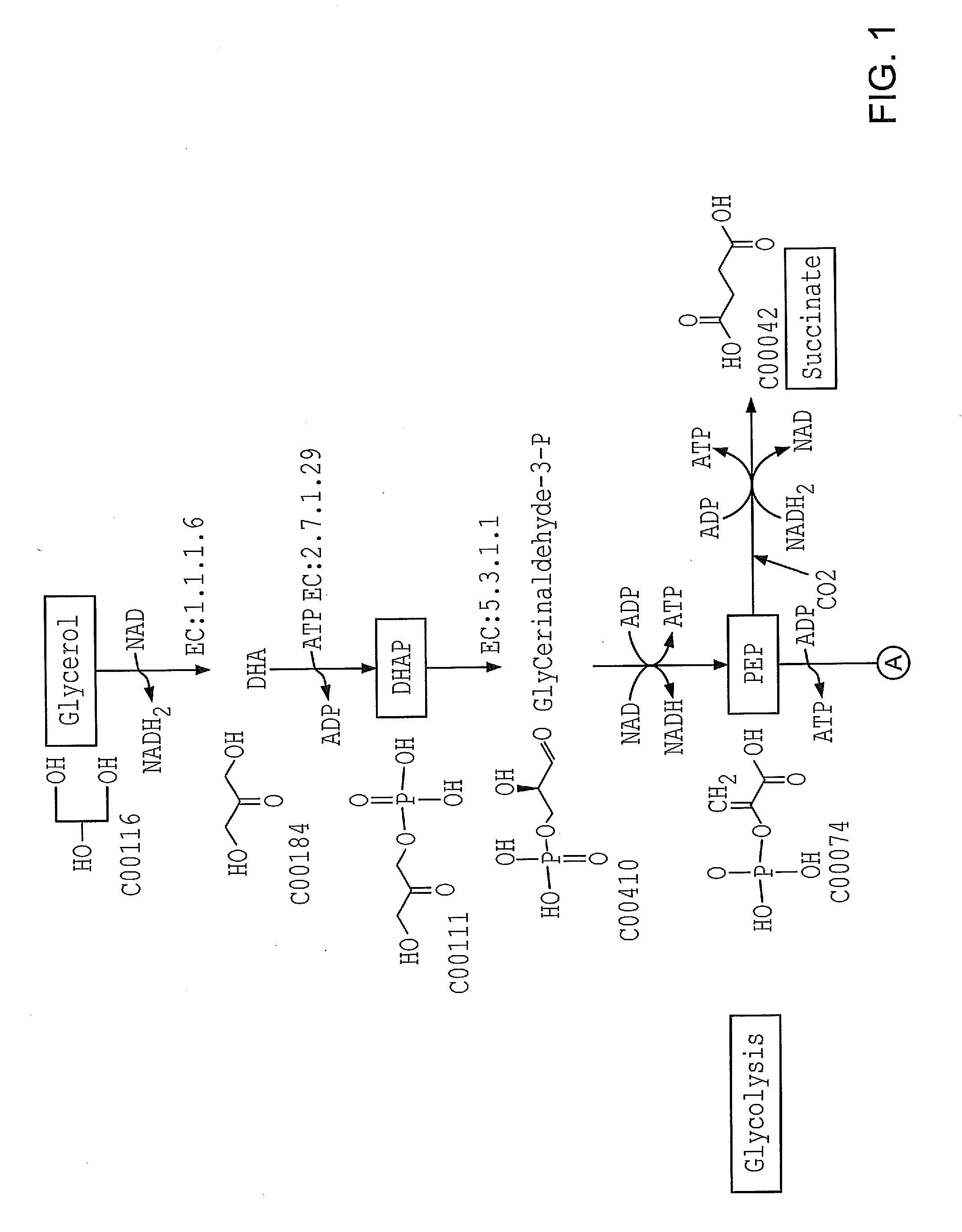

ActiveUS20130210090A1Reduce usageRate minimisedBacteriaHydrolases3-Hydroxypropionic acid2,3-Butanediol

Embodiments of the invention relate to the enzymatic conversion of bioderived feedstocks to commercially valuable chemicals. The enzymatic conversions of the embodiments of the invention offer the potential for lower cost routes to these value-added chemicals. Some of the chemicals that are useful include nylon intermediates such as caprolactam, adipic acid, 1,6-hexamethylene diamine; butanediols such as 1,4-butanediol, 1,3-butanediol, and 2,3-butanediol; butanols such as 1-butanol, and 2-butanol; succinic acid, butadiene, isoprene, and 3-hydroxypropanoic acid.

Owner:INV NYLON CHEM AMERICAS LLC

Aqueous ink for inkjet recording

ActiveUS20080282932A1Good dispersionMaintain good propertiesDuplicating/marking methodsInksOrganic solventWater soluble

An aqueous ink for inkjet recording is provided, which includes water, pigment, a water-soluble organic solvent incorporated at a content of not less than 30% by weight, a surfactant, and 3-methoxy-3-methyl-1-butanol. The surfactant is formed of at least one selected from the group consisting of acetylene glycol-based surfactant and a fluorinated surfactant.

Owner:TOSHIBA TEC KK

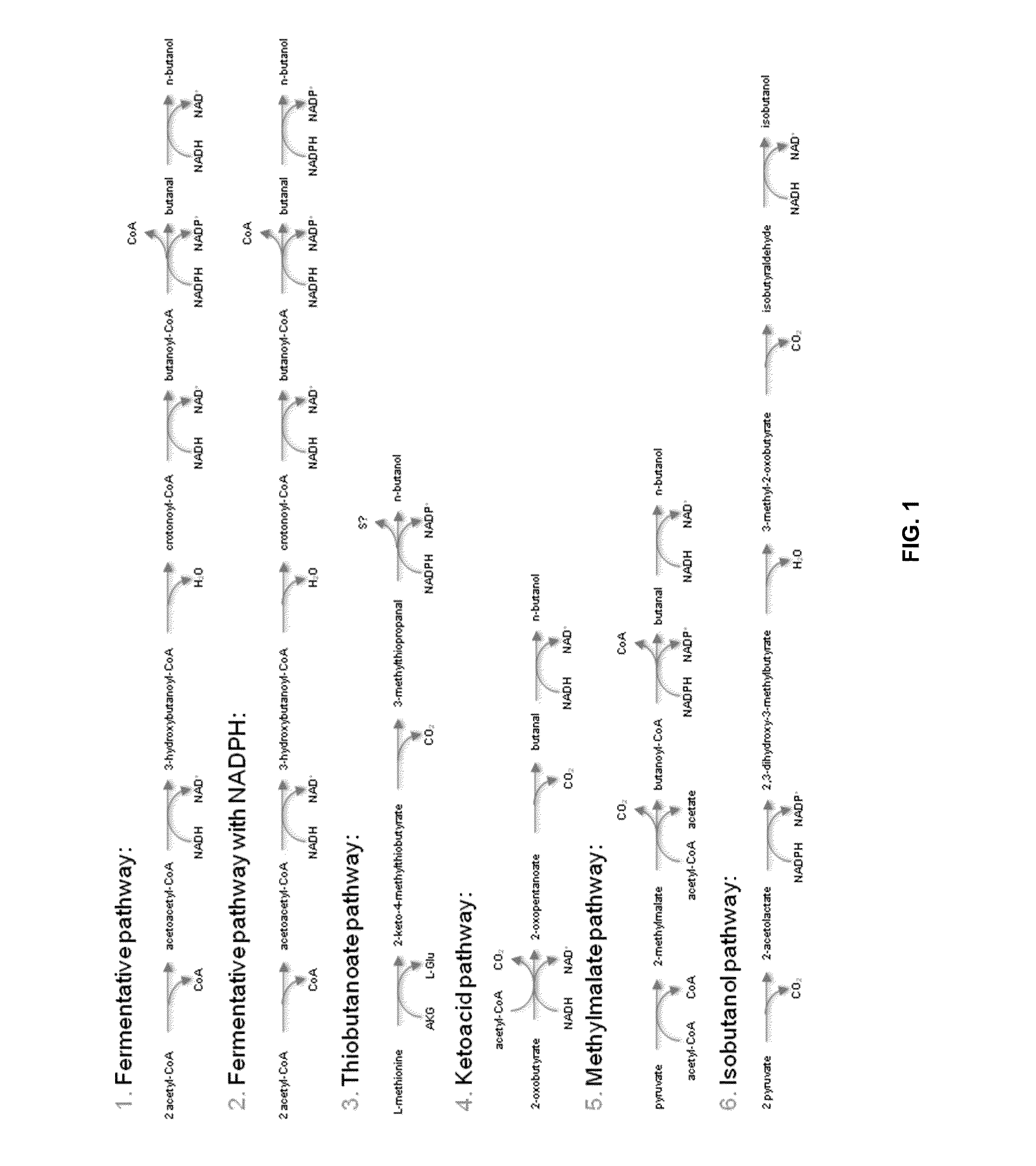

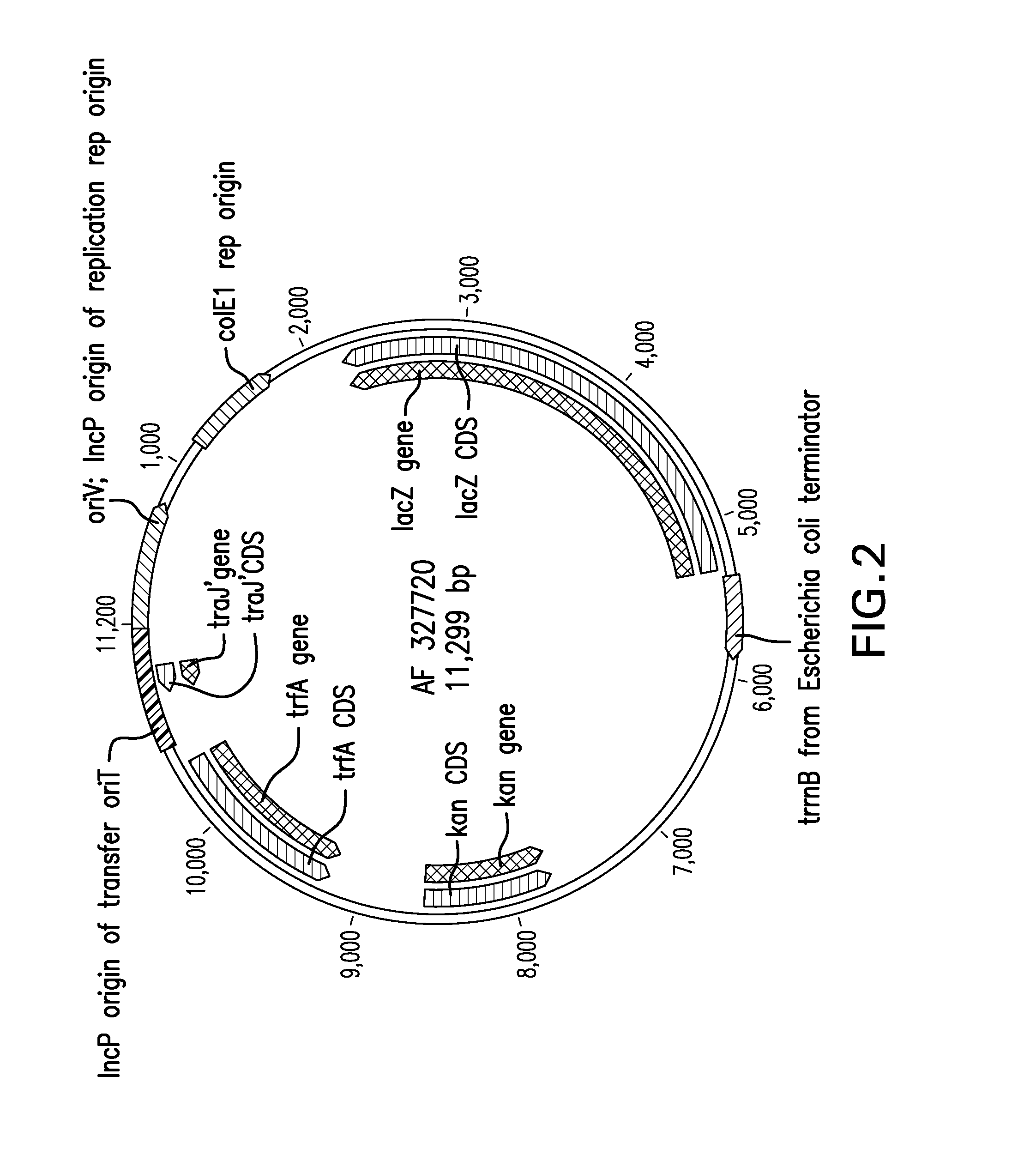

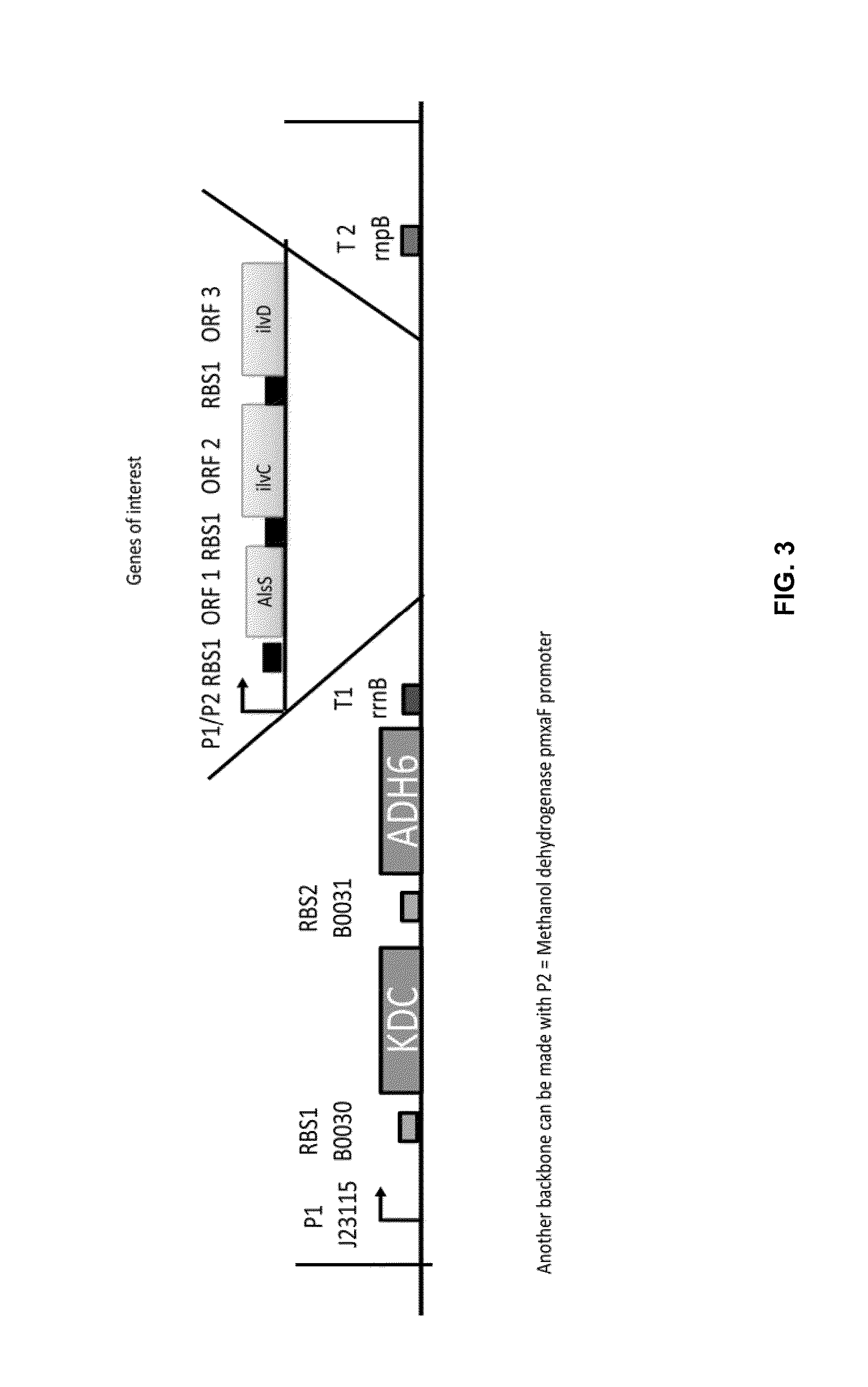

Biological Conversion of Multi-Carbon Compounds from Methane

Multi-carbon compounds such as ethanol, n-butanol, sec-butanol, isobutanol, tert-butanol, fatty (or aliphatic long chain) alcohols, fatty acid methyl esters, 2,3-butanediol and the like, are important industrial commodity chemicals with a variety of applications. The present invention provides metabolically engineered host microorganisms which metabolize methane (CH4) as their sole carbon source to produce multi-carbon compounds for use in fuels (e.g., bio-fuel, bio-diesel) and bio-based chemicals. Furthermore, use of the metabolically engineered host microorganisms of the invention (which utilize methane as the sole carbon source) mitigate current industry practices and methods of producing multi-carbon compounds from petroleum or petroleum-derived feedstocks, and ameliorate much of the ongoing depletion of arable food source “farmland” currently being diverted to grow bio-fuel feedstocks, and as such, improve the environmental footprint of future bio-fuel, bio-diesel and bio-based chemical compositions.

Owner:PRECIGEN INC

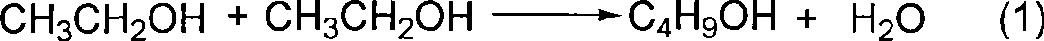

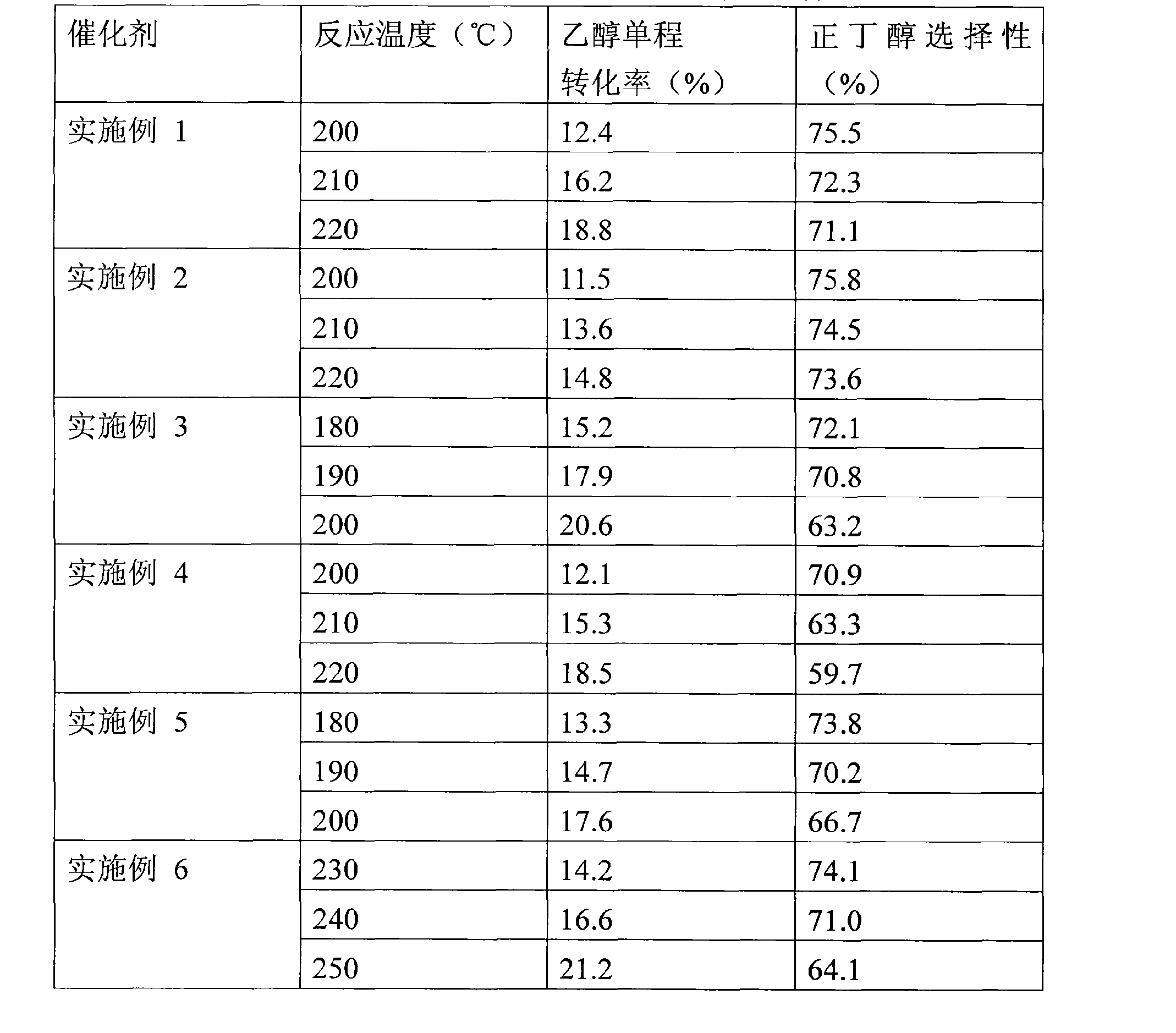

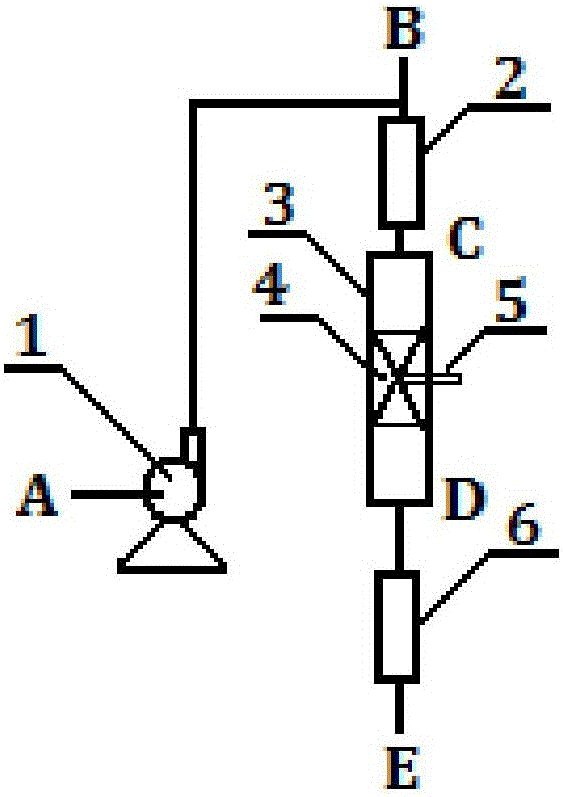

Bi-component supported catalyst of ethanol condensed n-butanol and a method of preparing thereof

InactiveCN101530802ASimple methodLow costOrganic compound preparationHydroxy compound preparationPotassium fluorideGram

The invention discloses a bi-component supported catalyst of ethanol condensed n-butanol and a method of preparing thereof. The main active ingredients of the catalyst are as follows by weight percentage content: 2%-10% nickel, 0.5%-9% cocatalyst MgO or KF. The preparing method comprises the steps of: directly dipping 30-50 grams of granulose gamma-Al2O3 into nickel acetate or nickel nitrate aqueous solution with consistency being 0.5-1.0 mol / L, dipping for 2 to 4 days, occasionally stirring, evaporating, drying under 130 degrees centigrade, then dipping into magnesium nitrate or potassium fluoride aqueous solution with consistency being 0.1-1.0 mol / L for 2 to 3 days, evaporating, drying under 130 degrees centigrade to prepare the bi-component supported catalyst of ethanol condensed n-butanol. The method of preparing bi-component supported catalyst in the invention is simple and has low cost; the catalytic activity is higher than that of the single component nickel supported catalyst; the selectivity of the n-butanol in the products can achieve above 70% and has wildly industrialized application prospect.

Owner:ZHEJIANG UNIV

Method for preparing solid acid catalyst of esterification

InactiveCN101703940AHigh activityGood choiceOrganic compound preparationCarboxylic acid esters preparationSolid acidN-Butanol

The invention relates to a method for preparing a solid acid catalyst used in esterification. The method takes organic titanium ester and silicone ester as raw materials and prepares a SO42- / TiO2-SiO2 novel solid acid by a hydrothermal method. If the solid acid catalyst is used in a reflux device to catalyze acetic acid / n-butanol esterification reaction, the yield and selectivity of n-butyl acetate can reach 98.9 percent and 99.5 percent respectively. The catalyst is characterized in simple preparation process, low cost, high activity and selectivity, long lifespan and the like, overcomes the disadvantage that concentrated sulfuric acid used as the catalyst is poor in selectivity, low in esterification yield, severe in equipment corrosion, large amount of waste liquid produced, environmental pollution and the like, and has good industrial application prospect.

Owner:CHINA NAT OFFSHORE OIL CORP +1

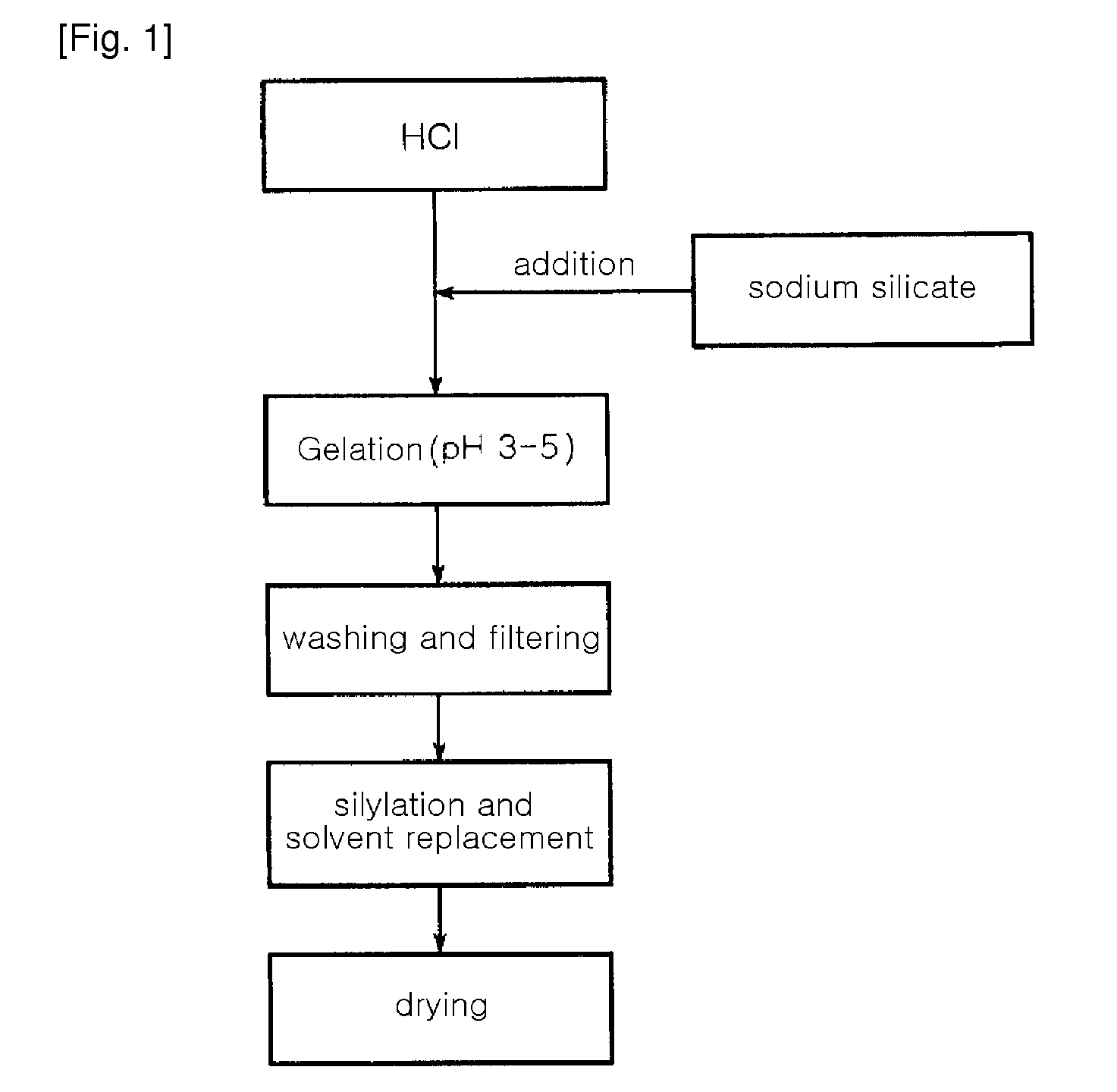

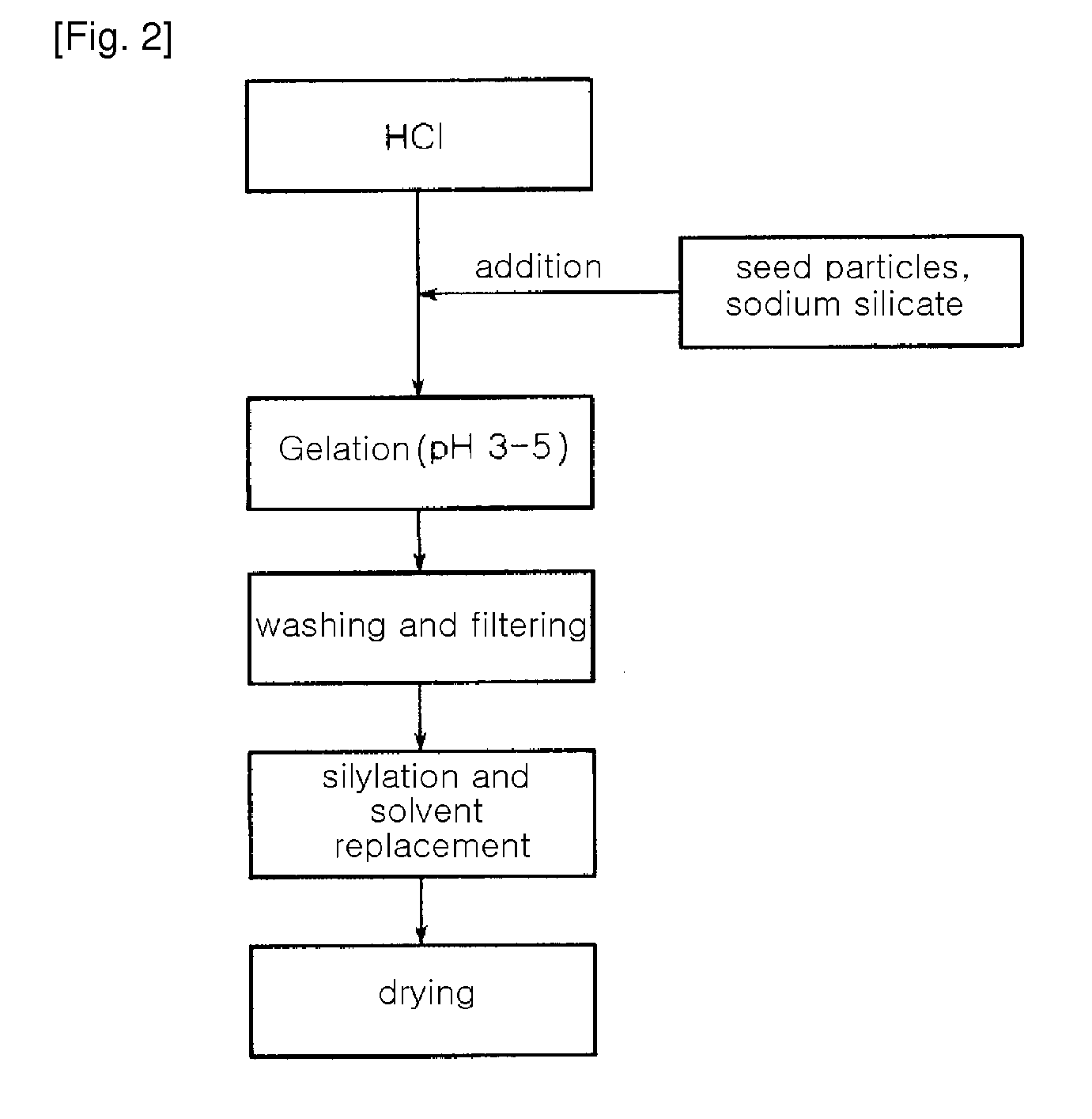

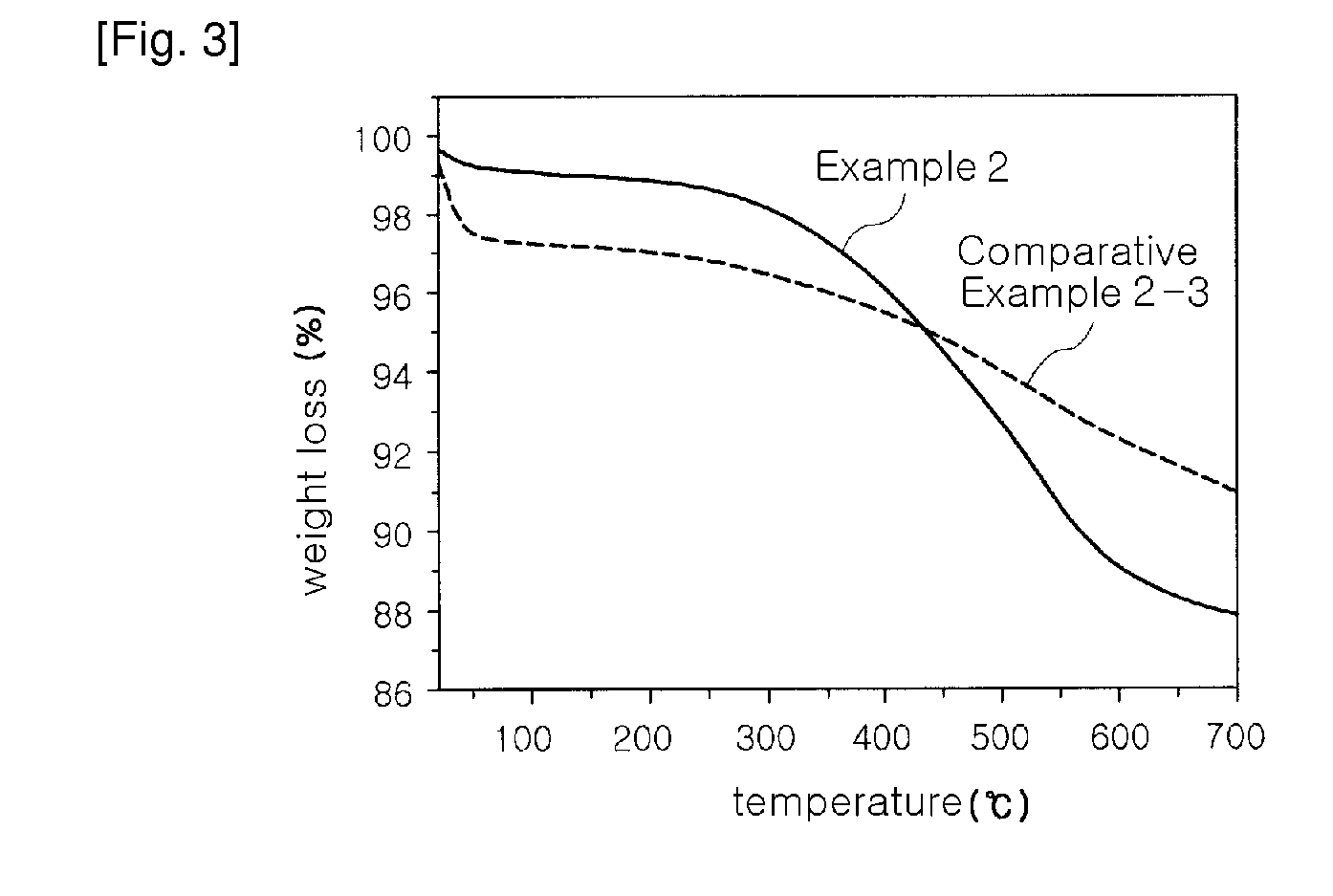

Method for preparing permanently hydrophobic aerogel and permanently hydrophobic aerogel prepared by using the method

A method for preparing permanently hydrophobic aerogel and permanently hydrophobic aerogel prepared by the method. The method comprises adding sodium silicate to HCl at 30 to 90° C. until an acidity reaches pH 3-5, to form silica hydrogel under acidic conditions of pH 3-5, washing the silica hydrogel with distilled water using a mixer, followed by filtering, adding the silica hydrogel to a silylating solution of silylating agent in n-butanol at pH 1-5 using an acid selected from hydrochloric acid, sulfuric acid, phosphoric acid and nitric acid, to simultaneously conduct silylation and solvent replacement, and drying the silica hydrogel; The method has the following advantages; i) silylation and solvent replacement can be simultaneously conducted, ii) n-butanol is used as a reaction solvent instead of methanol upon silylation, thus obtaining a thermal conductivity comparable to conventional aerogel powders, iii) silylation is conducted under improved conditions, i.e., strong acidic conditions of pH 1-5, and as a result, all of the aerogel powders can be reacted with a silylating agent, thereby obtaining permanently hydrophobic aerogel, iv) the washing with a mixer makes the amount of removed sodium ions uniform, thus it is suitable for mass-production, and v) the method provides a relatively simplified procedure and the use of the silylating agent in a small amount enables low costs and mass-production.

Owner:KOREA INST OF IND TECH

Method and Composition for Disinfecting Hard Surfaces

Aqueous hard surface treatment compositions necessarily comprise an alcohol constituent selected from the group consisting of methanol, ethanol, n-propanol, isopropanol, n-butanol, benzyl alcohol, and mixtures thereof which alcohol constituent comprises from about 40 and 70 weight percent (“% wt”) of the total weight of the composition of which it forms a part. Preferably however the alcohol constituent is present in an amount of from about 50% wt to about 70% wt, more preferably is present in amounts of from about 60% wt to about 70% wt.

Owner:RECKITT BENCKISER INC

Metallic Nanowire Ink Composition for a Substantially Transparent Conductor

An exemplary printable composition comprises a liquid or gel suspension of a plurality of metallic nanofibers or nanowires; a first solvent; and a viscosity modifier, resin, or binder. In various embodiments, an exemplary metallic nanowire ink which can be printed to produce a substantially transparent conductor comprises a plurality of metallic nanowires at least partially coated with a first polymer comprising polyvinyl pyrrolidone having a molecular weight less than about 50,000; one or more solvents such as 1-butanol, ethanol, 1-pentanol, n-methylpyrrolidone, cyclohexanone, cyclopentanone, 1-hexanol, acetic acid, cyclohexanol, and mixtures thereof; and a second polymer or polymeric precursor such as polyvinyl pyrrolidone or a polyimide, having a molecular weight greater than about 500,000.

Owner:NTHDEGREE TECH WORLDWIDE

Method for separation of lincomycin

InactiveCN102746348AModerate consumptionSimple and fast operationSugar derivativesSugar derivatives preparationFiltrationPolystyrene

Owner:SHANGHAI INST OF PHARMA IND

Method for the production of 1-butanol

ActiveUS8426173B2Robust toleranceReduce the temperatureBiofuelsOxidoreductasesMicroorganismN-Butanol

A method for the production of 1-butanol by fermentation using a microbial production host is disclosed. The method employs a reduction in temperature during the fermentation process that results in a more robust tolerance of the production host to the butanol product.

Owner:GEVO INC

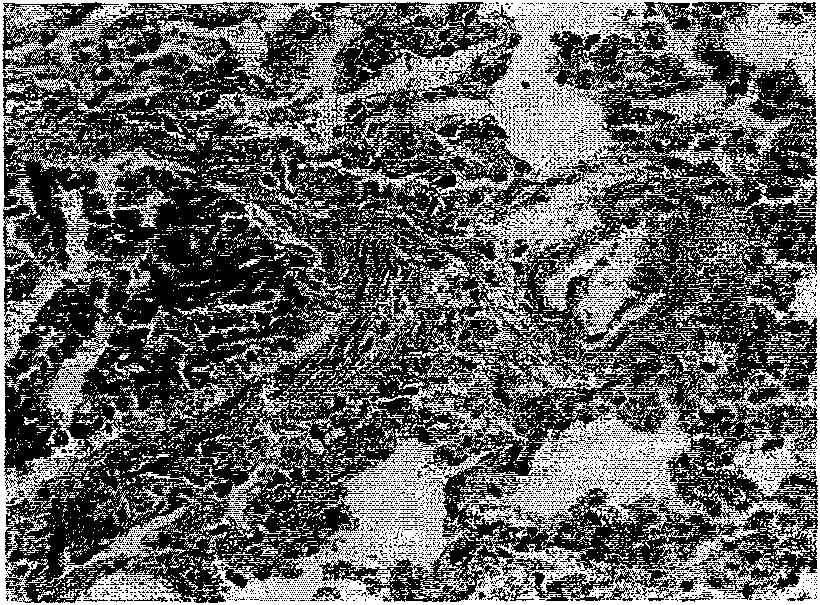

Green making technology of animal tissue paraffin section

A green making technology of animal tissue paraffin section disclosed in the invention aims at providing a technique of making a paraffin section of animal tissue applied to the agricultural university medicine and other majors, characterized by that the type of chemical reagents that are used is limited, the chemical reagents have no toxicity, and dehydrate the tissue thoroughly, accelerate making sections but not lead to excessive contraction and increasement of hardness of the tissue, and substitute dimethyl benzene used in the traditional making technology of the paraffin section which isharmful to human body, so as to eliminate the occupational diseases and environmental pollution caused by dimethyl benzene. The making technology comprises the following steps: carrying out fixation with a fixative solution (100ml of the fixative solution comprises 91 ml 85% alcohol, 4 ml methanol and 5 ml glacial acetic acid ), dehydrating the tissue with graded ethanol, then putting the fixative and dehydrated tissue in a mixed transparent reagent (comprising 14wt% of analytically pour n-butanol, 29wt% of acetone and 57wt% of absolute alcohol ) for standing for 3 hours, then carrying out normal waxing and embedding, using analytically pour turpentine (60 DEG C) for section staining, carrying out dewaxing twice, carrying out hydration under normal temperature, using haematoxylin for staining nuclei, decoloration and bluing, and using eosin for staining, dehydrating until get absolute alcohol, then carrying out air drying, and directly using the gum diluted by turpentine to sealing the section.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Method for preparing micron SiO2 gas gel small ball

The present invention relates to the process of preparing micron level SiO2 aerogel ball as the stuffing of chromatographic column for separating biological macromolecule. The process includes the following steps: preparing alcohol sol of SiO2 via mixing silicon gel and nitric acid in the volume ratio of 1 to 0.5-20, and adding anhydrous ethanol; mixing n-heptane, span-80, Tween-85 and n-butanol in certain volume proportion through stirring to obtain oil phase; adding the sol of SiO2 into the oil phase in certain volume ratio to form W / O emulsion; stirring, adding concentrated ammonia water to alkaline for depositing gel, further stirring, and liquid-solid separation to obtain SiO2 gel microballoon; washing with acetone and drying to obtain micron level SiO2 aerogel ball. The process has normal pressure, easy control, low cost, and other advantages.

Owner:TONGJI UNIV

Method for extracting and separating curcumin

InactiveCN103570517AHigh purityLow costCarbonyl compound separation/purificationOrganic layerN-Butanol

The invention discloses a method for extracting and separating curcumin. The method comprises the following steps: (1) extraction: crushing curcuma longa, adding 2-10% alkaline water to extract to obtain an alkaline water extracting solution; (2) degreasing: adding an organic solvent petroleum ether, 6# solvent oil, cyclohexane, benzene, methylbenzene or ethyl acetate into the alkaline water extracting solution, stirring and extracting for 1-2h, and then, standing for 1-2h to separate out an organic layer; (3) acid deposition: regulating the pH value of the extracting solution to 1-2 by using hydrochloric acid to separate out the curcumin, filtering, and drying to constant weight to obtain a crude product of the curcumin; and (4) dissolving the crude product of the curcumin by using an organic solvent methanol, ethanol, acetone, n-butanol or isopropanol, filtering, adding distilled water into the filtrate, carrying out freezing crystallization at the temperature of 0-5 DEG C for 2-8h, filtering, and drying to obtain a curcumin product. The method is low in production cost; the prepared curcumin product is high in purity up to over 98.5%.

Owner:HUNAN KEYUAN BIO PRODS

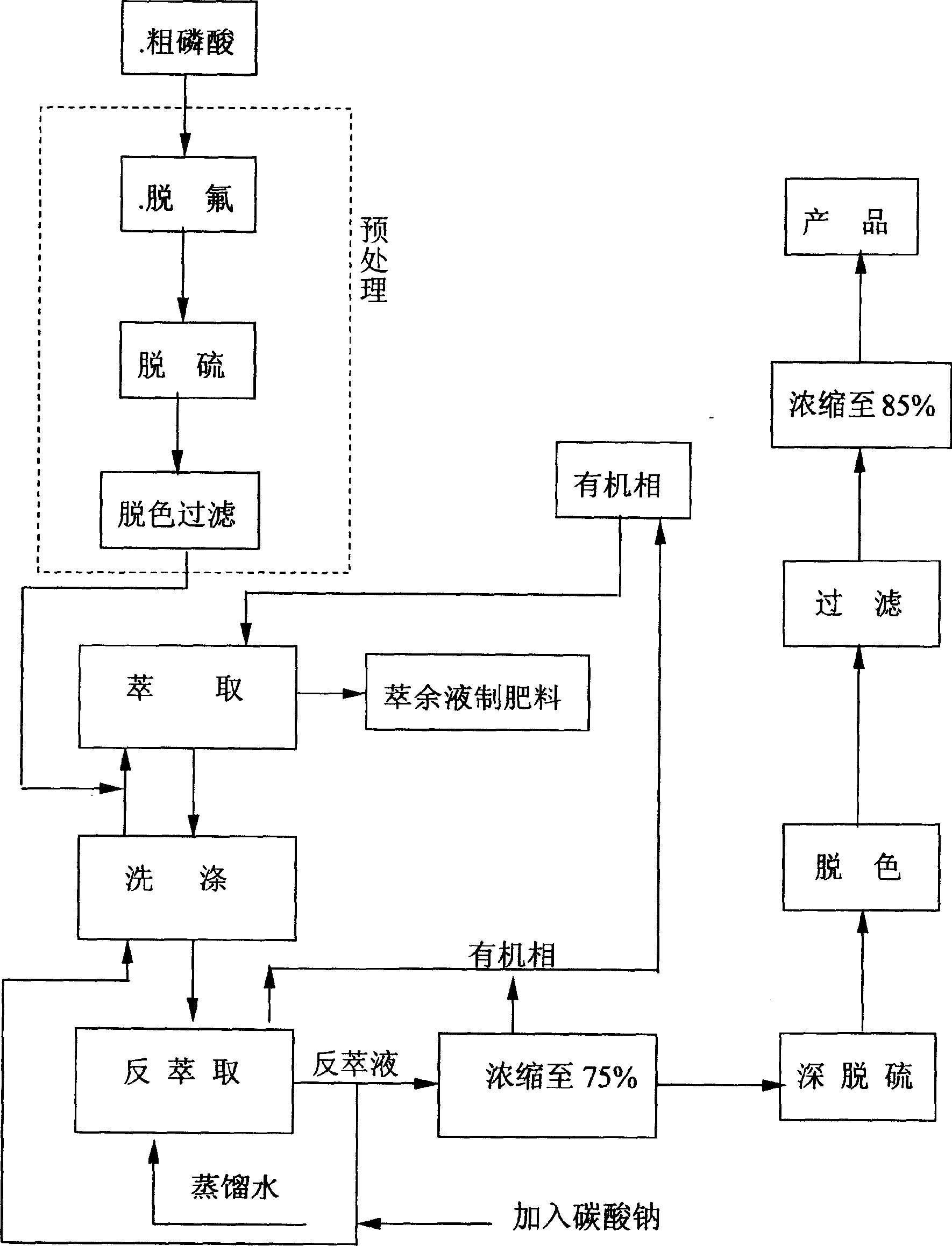

Method of solvent extraction purification of wet method phosphoric acid produced from medium and low grade phosphosus ore

ActiveCN1751987AReduce the concentration of ortho acidThe extraction and purification process is continuousPhosphorus compoundsPhosphoric acidN-Butanol

A process for preparing wet phosphoric acid from medium-or low-grade phosphorus are through solvent extracting and purifying includes such steps as concentrating the crude wet phosphoric acid, defluorinating, desulfurizing, decoloring, filtering, counter current extracting in the mixture of n-butanol, methylisobutyl ketone and synergist by 7-10 stages while adding sulfuric acid at the 3rd or the 7th stage, counter current washing with phosphoric acid solution containing Na salt by 4-5 stages, counter-current reverse extracting of organic phase with distilled water by 3-5 stages, concentrating, recovering solvent, decoloring, filtering, adding the phosphoric acid solution of BaCO3 for removing ''SO4'' radicals, decoloring, filtering and concentrating.

Owner:HUAZHONG NORMAL UNIV

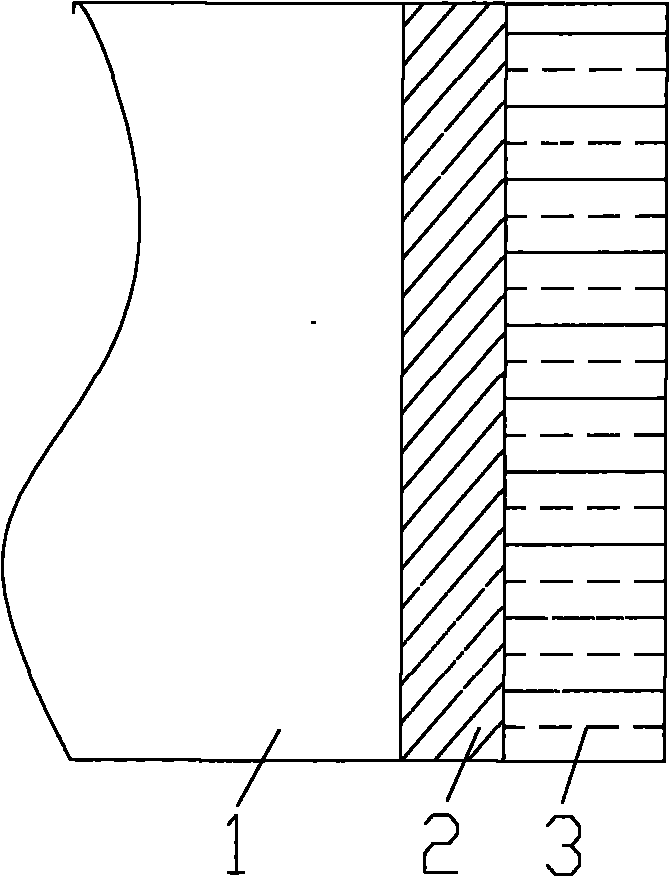

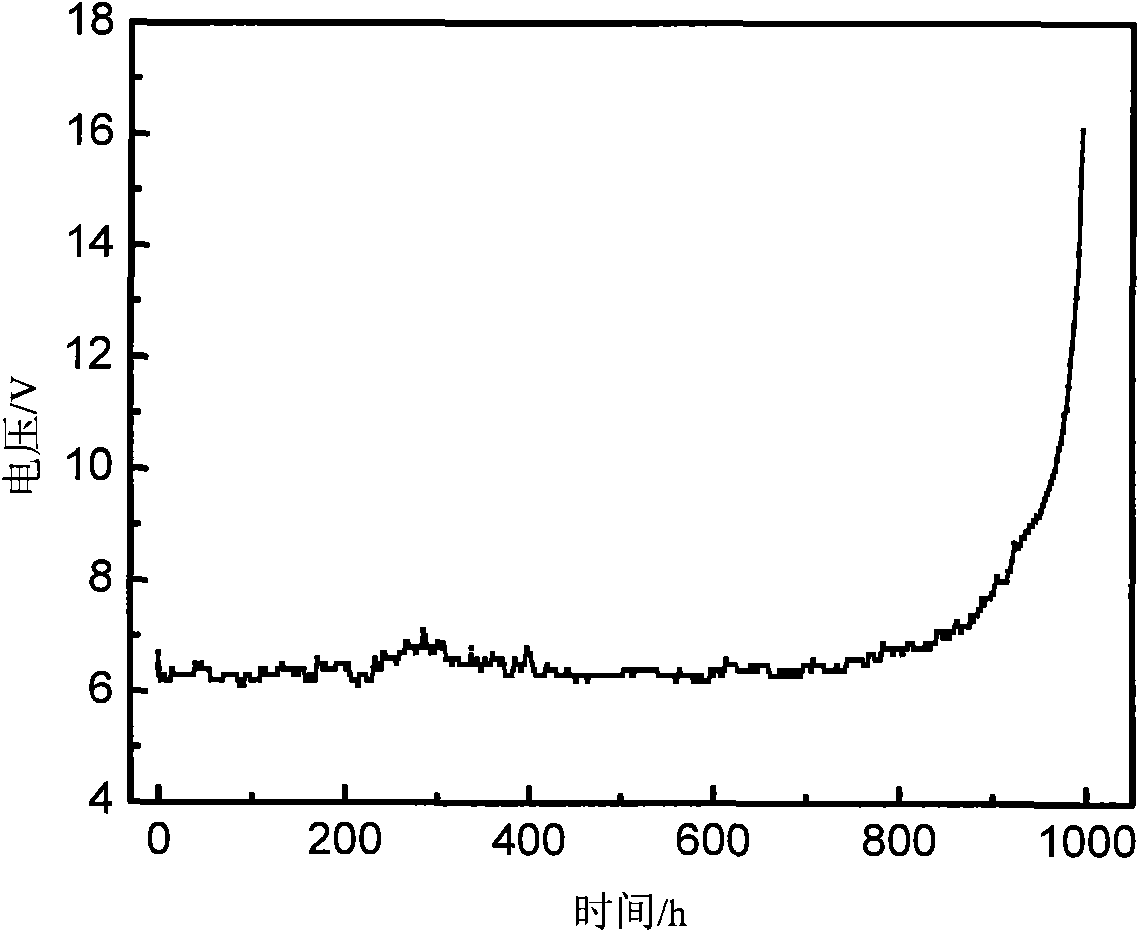

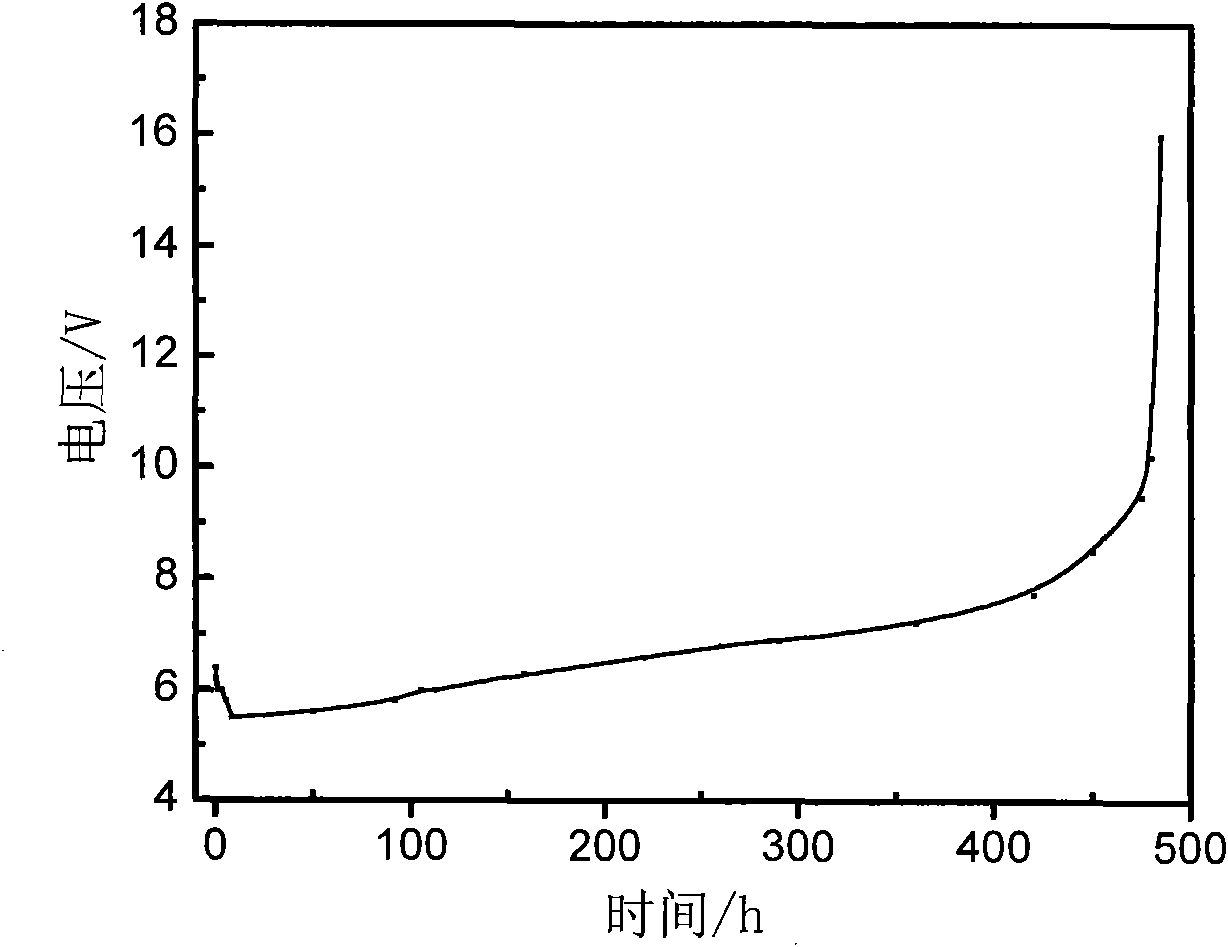

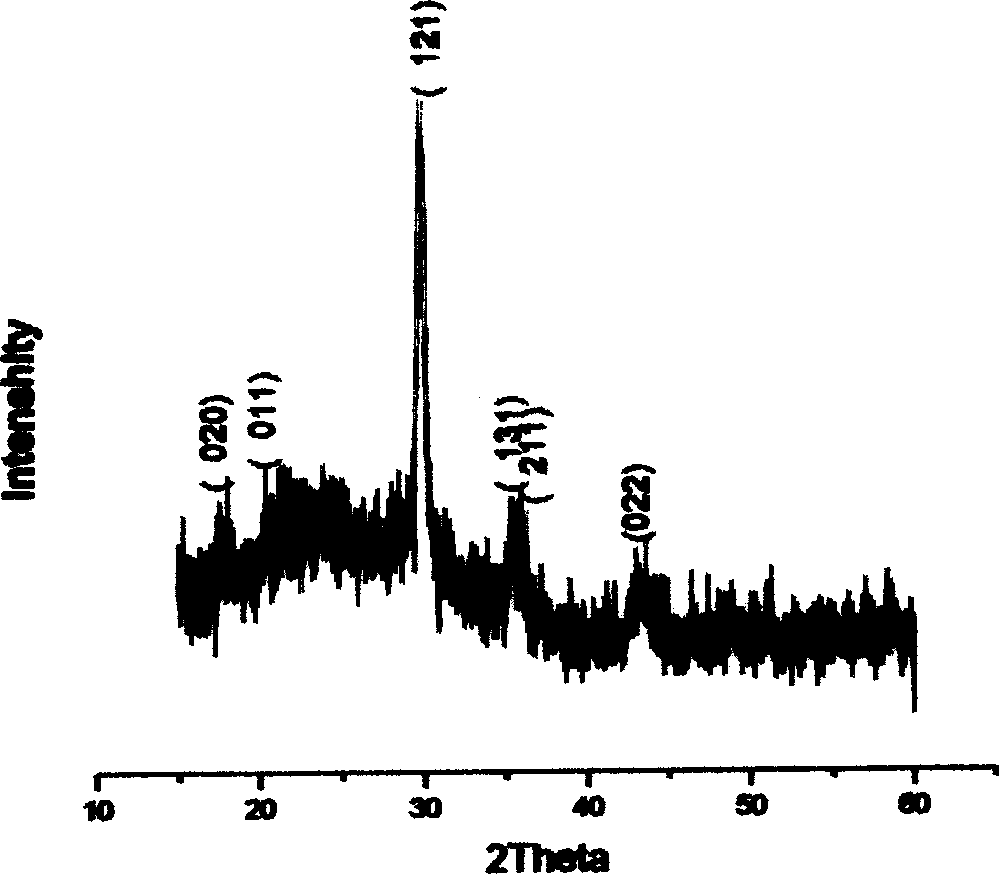

High-stability DSA anode for preparing chlorine by electrolysis and preparation method thereof

The invention relates to a high-stability DSA anode for preparing chlorine by electrolysis and a preparation method thereof. The anode comprises a titanium substrate, a middle layer and a surface active layer, wherein the IrxM (1-x) O2 middle layer is arranged between the titanium substrate and the surface layer, and M is Co, Mn or a CoTa mixture; and the components of the surface active layer are RuO2, IrO2, TiO2 and SnO2. The preparation method comprises the following steps: dissolving the components of the middle layer in proportion in isopropanol or n-butanol and other organic solvents, evenly coating on the pretreated substrate, and drying under an infrared lamp or in a drying box; then placing in a muffle furnace for thermal oxidation, and repeating the step for 1 to 10 times; and then coating the blended surface layer solution on the middle layer, repeating the preparation steps for 10 to 20 times, and holding in the muffle furnace. The service life of the anode is greatly prolonged based on the existing industry standards (20h), and the anode can be widely used in electrolyzing seawater antifouling, chlor-alkali industry and cathodic protection and other fields.

Owner:DALIAN UNIV OF TECH

Fabric detergent with colour-preserving function and preparation method thereof

InactiveCN101798552AReduced or diminished appearanceReduce or reduce lossesOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsBetaineN-Butanol

The invention provides a fabric detergent with colour-preserving function and preparation method thereof. The detergent contains sodium fatty alcohol ether sulphate, laurylamide propyl betaine, alkyl glucoside, fatty alcohol polyoxyethylene (9) ether, sodium alpha-olefin sulphonate, 3-methooxyl-3-methyl-1-butyl alcohol, 1-vinyl pyrrolidone, 1-vinyl copolymer, sodium chloride, 1, 2-benzisothiazolin-3-one, essence, citric acid monohydrate and deionized water. The invention obtain favourable detergency in clothing washing process while realizing colour-preserving effect; the detergent is environmentally friendly, cleaning and colour-preserving are completed in one step, the detergent is non-toxic and non-irritant, and resource is saved.

Owner:北京绿伞科技股份有限公司

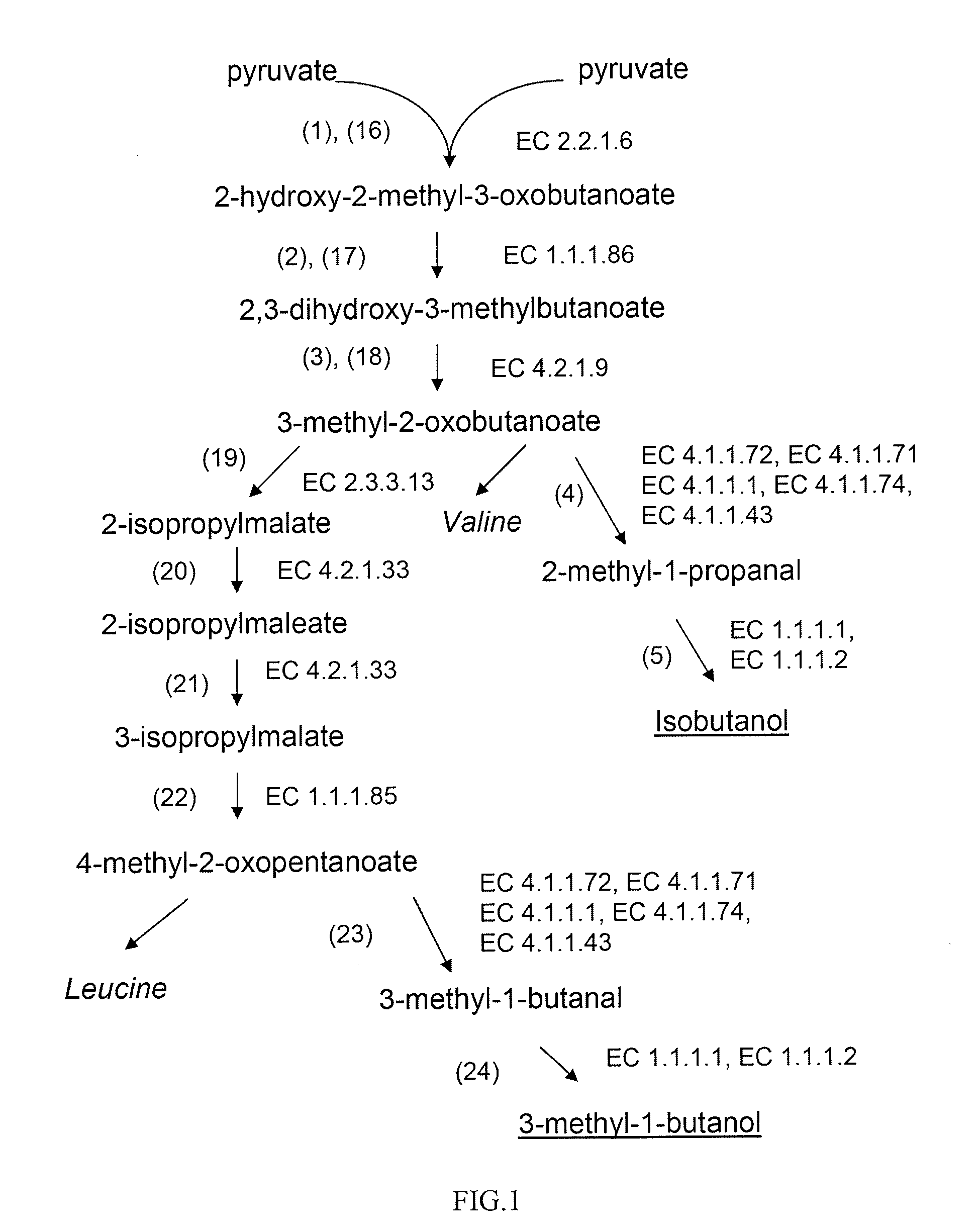

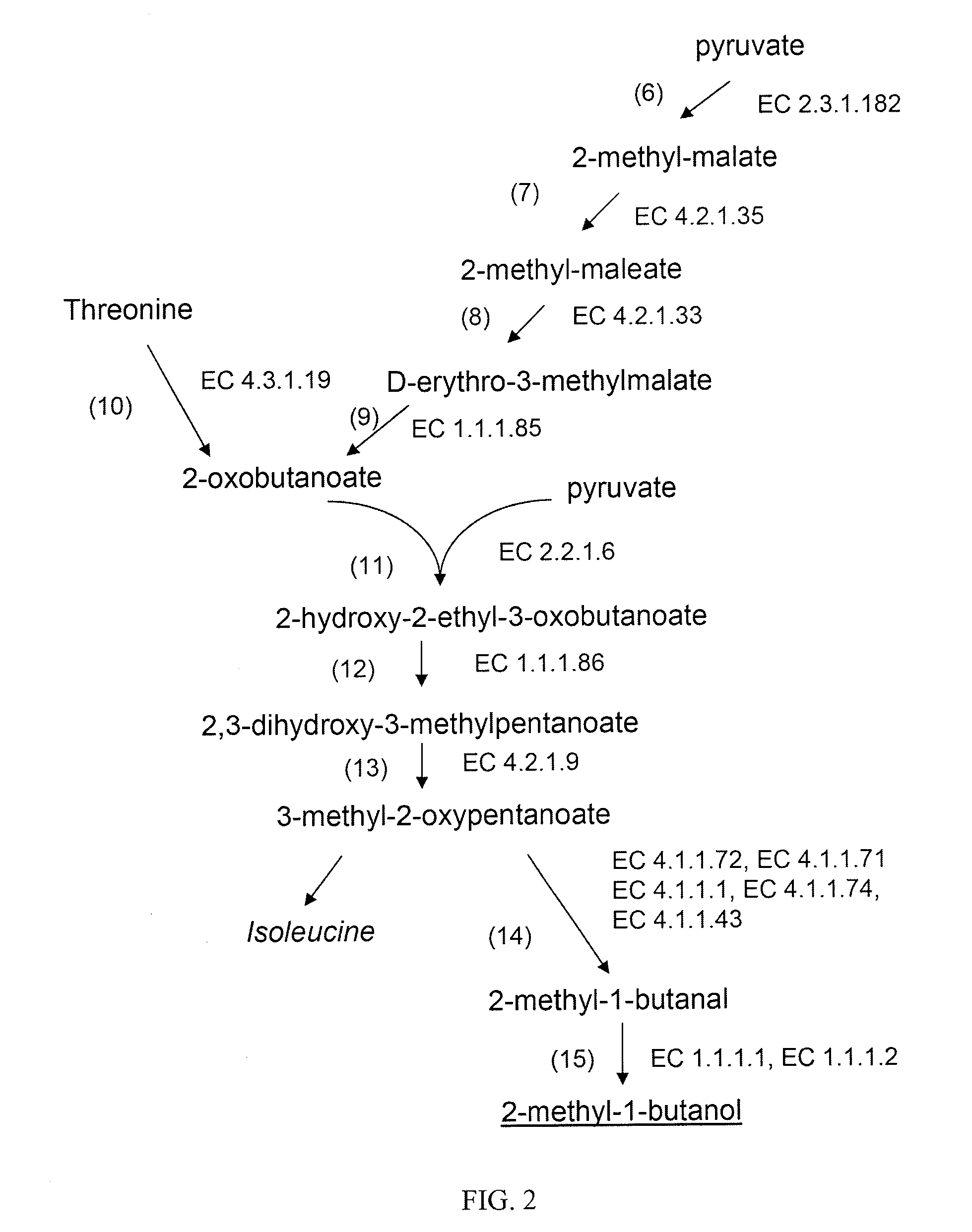

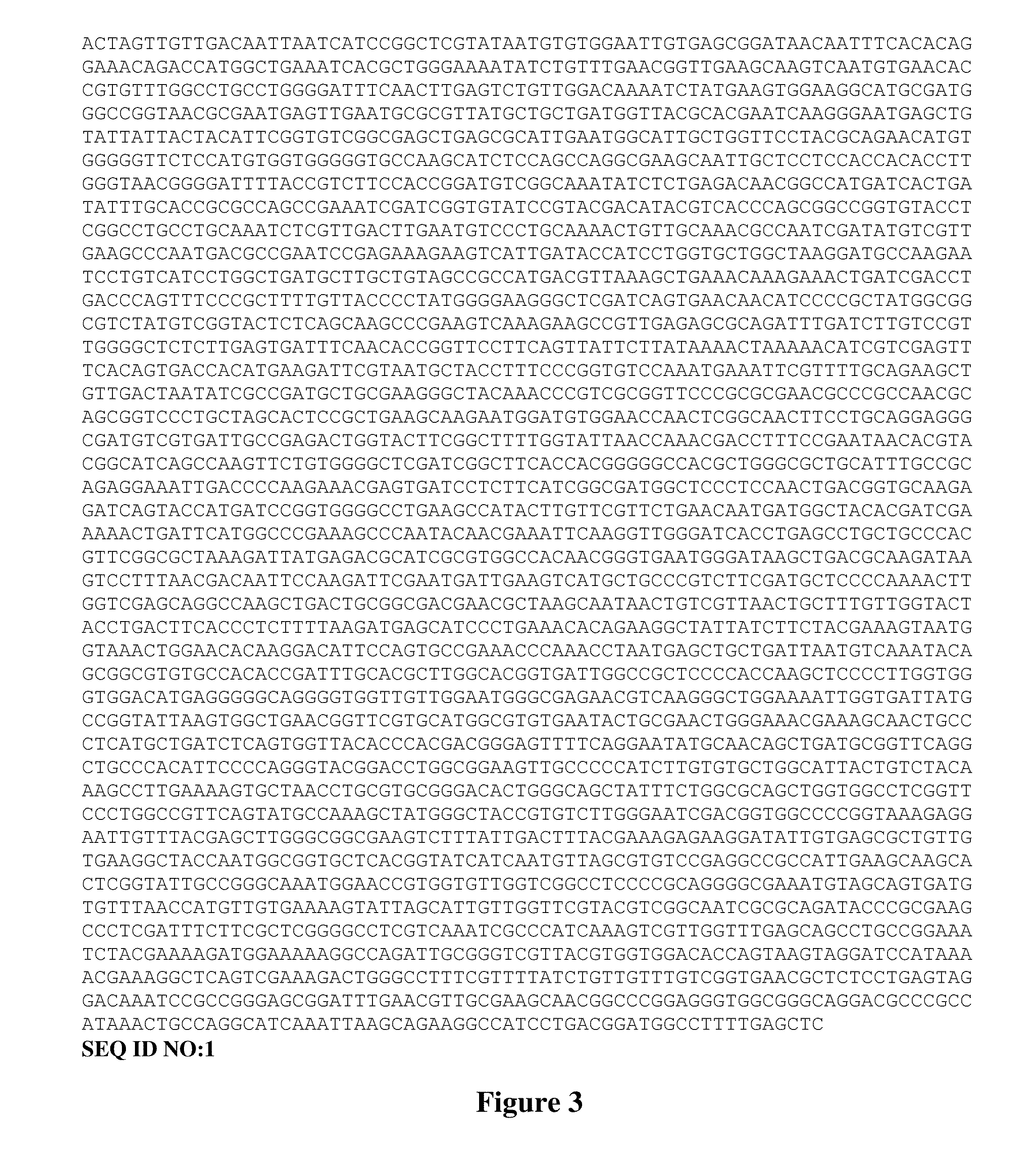

Production of branched-chain alcohols by photosynthetic microorganisms

The present invention provides genes, polypeptides and expression constructs therefor, recombinant photosynthetic microorganisms, and method of use thereof, such as for the production of branched-chain alcohols (including 2-methyl-1-butanol, 3-methyl-1-butanol, and isobutanol) and derivatives thereof for a variety of uses.

Owner:SYNTHETIC GENOMICS INC

Titanium dioxide sol and coating type denitration catalyst

InactiveCN104030347AImprove quality scoreHigh coating loadDispersed particle separationTitanium dioxideCeriumPolyethylene glycol

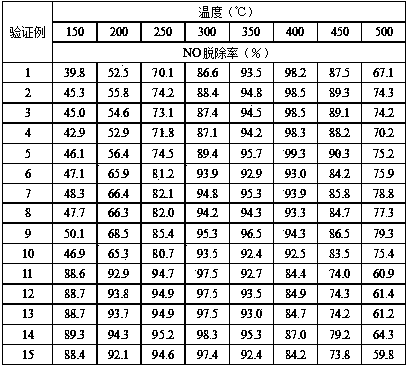

The invention discloses a titanium dioxide sol and a coating type denitration catalyst. The titanium dioxide sol is prepared from a titanium dioxide precursor, a dispersing agent, organic chelating agents, alcohol solvents, deionized water and auxiliaries, wherein the organic chelating agents include one or two of acetylacetone, tert-butyl ketone and 1,3-diphenyl-1,3-propanedione, the alcohol solvents include one or two of methanol, ethanol, isopropanol and n-butanol, and the auxiliaries include one or two of methylcellulose, polyethylene glycol-400, sodium dodecyl sulfate, hexamethylene tetramine, tetrahydrofuran and ethanolamine. A substrate of the coating type denitration catalyst is made of cordierite honeycomb ceramics, and the substrate is coated with active components of a vanadium-tungsten impregnation solution, an iron-cerium impregnation solution or a manganese-cerium impregnation solution with the titanium dioxide sol as a carrier. The grain size of the titanium dioxide sol is at the nanometer level. A coating formed by the coating type denitration catalyst has high bonding fastness, coating capacity and solid content.

Owner:CHONGQING UNIV

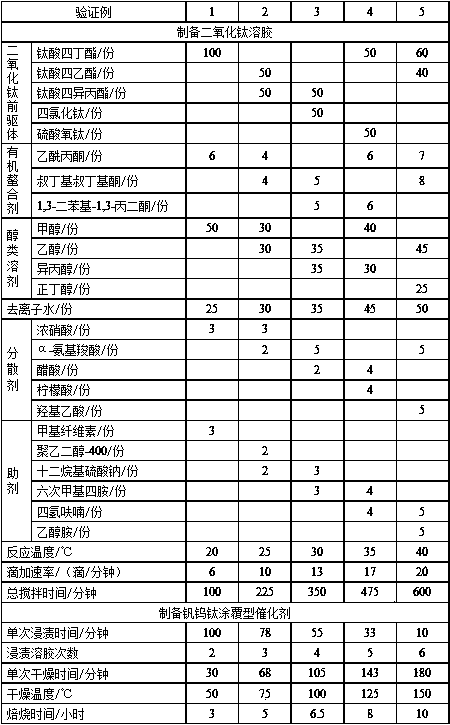

Method for preparation of Cycloastragenol by sulfuric acid hydrolysis

The invention relates to a method for preparation of Cycloastragenol by sulfuric acid hydrolysis. The method provided by the invention utilizes sulfuric acid to hydrolyze the Chinese medicine astragalus crude extract astragaloside, and realizes conversion of astragaloside to Cycloastragenol under certain hydrolysis condition, then performs impurity separation on the Cycloastragenol crude extract obtained by acid hydrolysis by chloroform and n-butanol extraction, and further makes use of silica gel column chromatography purification to finally obtain high purity Cycloastragenol. The invention aims to provide the method that can overcome the disadvantages of complex production process, low yield, high cost and the like of Cycloastragenol production and is suitable for large-scale production of different purity Cycloastragenol.

Owner:BEIJING UNIV OF CHEM TECH

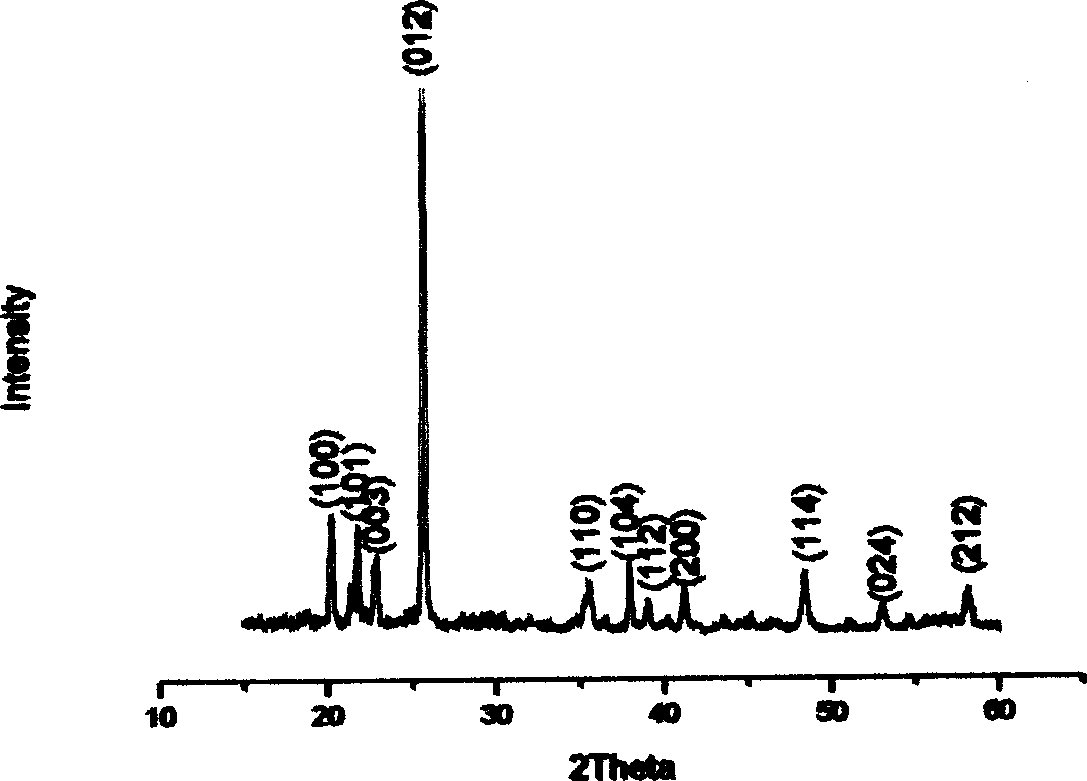

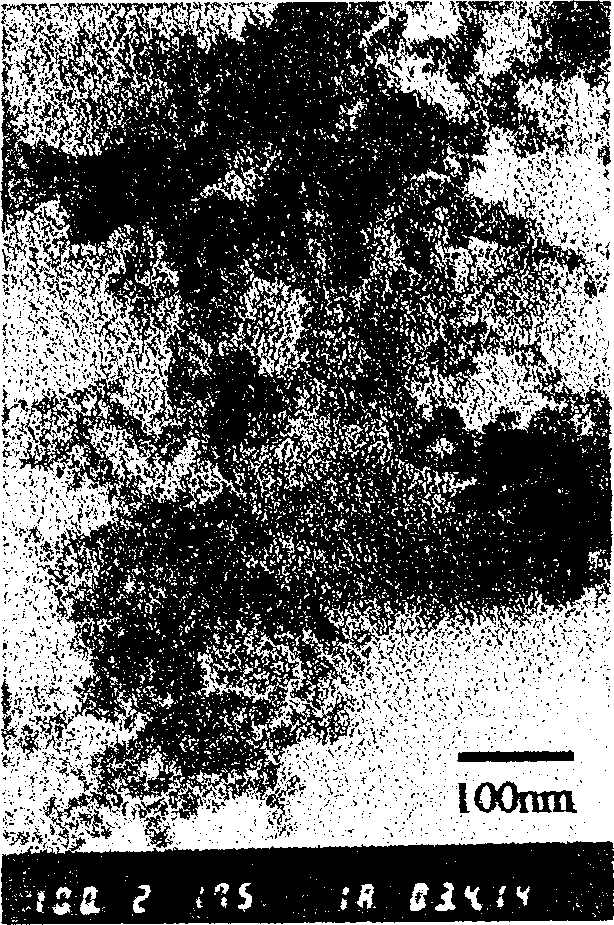

Reversed phase lithium inserting process of preparing polycrystal LiFePO4 nano powder material

InactiveCN1469499APromote generationNo precipitation reactionAlkaline accumulatorsActive material electrodesN-ButanolNanoscopic scale

The present invention is reversed phase lithium inserting process of preparing polycrystal nano LiFePO4 powder material. Mixed surfactant ST of Span-80 and Tween-80 is added slowly into n-heptane, and mixed water solution of FeCl3 and glacial acetic acid and n-butanol are added to reversed phase microemulsion of FeCl3; the mixed solution of NH4H2PO4 and anhydrous glacial acetic acid and the microreactor of the microemulsion is utilized to prepare deposited nano size FePO4 grains; and LiI is inserted to obtain nano LiFePO4 powder finally. The present invention has the advantages of low synthesis temperature, and small size, great specific surface area and high activity of the synthesized material. The LiFePO4 powder material is suitable for use in producing lithium ion cell.

Owner:TSINGHUA UNIV

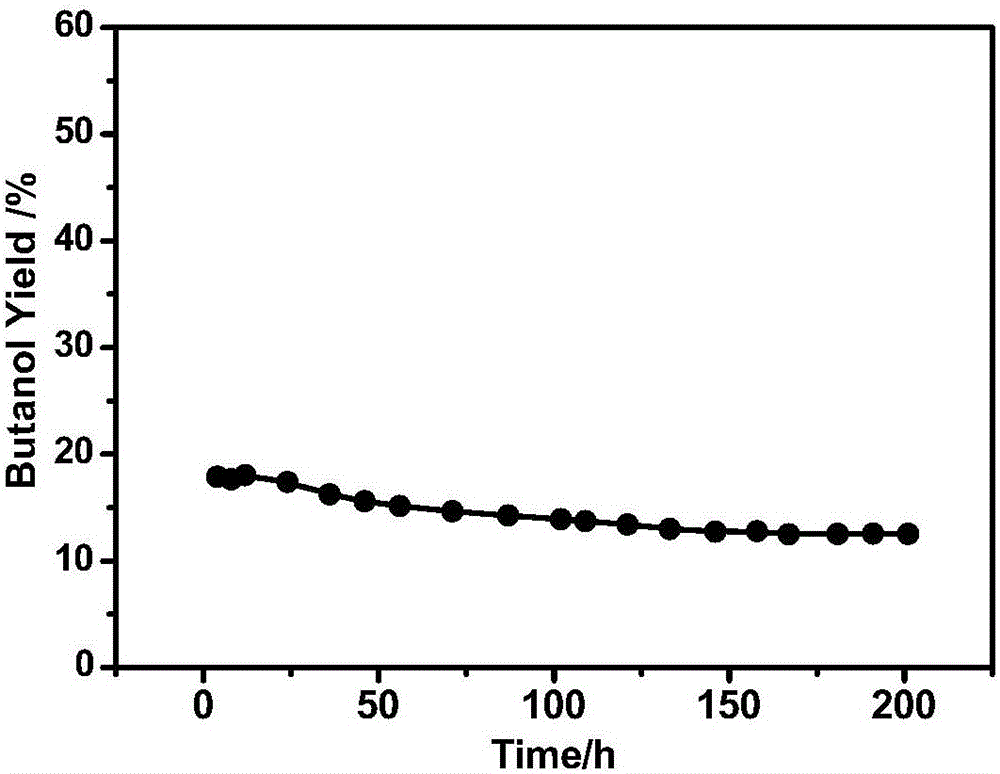

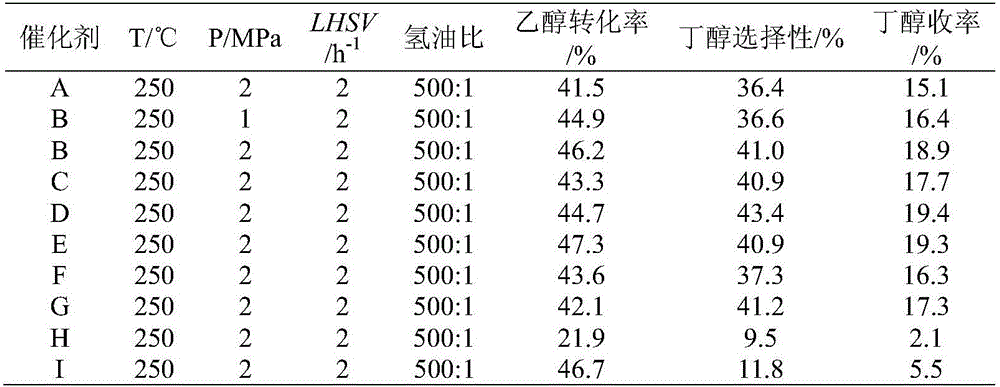

Active carbon supported copper-metal oxide catalyst, preparation method and applications thereof

ActiveCN106076344AAchieve a high degree of dispersionProcess stabilityOrganic compound preparationHydroxy compound preparationActivated carbonDehydrogenation

The invention provides an active carbon supported copper-metal oxide catalyst, a preparation method and applications thereof, wherein the catalyst comprises, by mass, 55-98% of a carrier active carbon, 1-20% of a metal Cu, and 1-25% of a metal oxide MOx. According to the present invention, the catalyst has characteristics of convenient preparation and low cost, and can be used in the n-butanol preparation reaction using ethanol dehydrogenation condensation, wherein the fixed-bed continuous reaction is adopted during the application, the process is simple, the reaction conditions are relatively mild, The yield of the n-butanol in the product achieves 10-30 wt%, and the unreacted ethanol can be reused after the product separation.

Owner:ZHEJIANG UNIV OF TECH

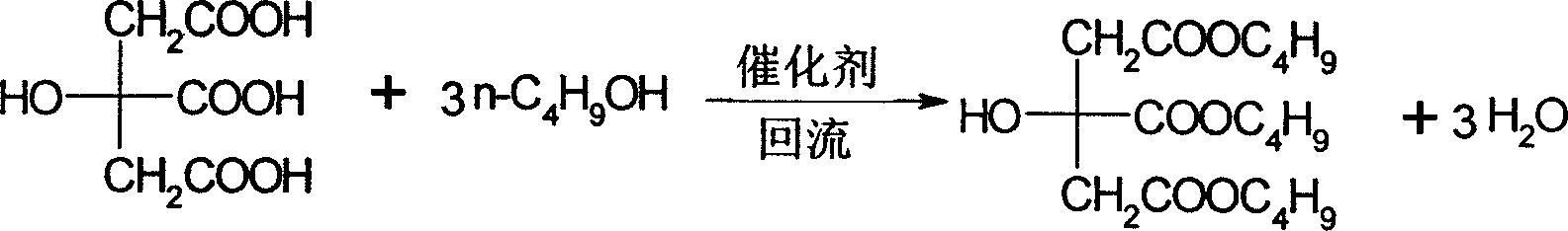

Method for preparing tributyl citrate using mesoporous molecular sieve as catalyst

InactiveCN1762969AReduce dosageNo pollution in the processMolecular sieve catalystsOrganic compound preparationMolecular sieveDistillation

The tributyl citrate preparing process features using mesoporous molecular sieve as catalyst for the synthesis of tributyl citrate, filtering out the catalyst from the reacted product after reaction for reuse, and treating the filtrate through distillation, water washing, alkali washing, and re-distillation to obtain tributyl citrate. The catalyst has relatively high catalytic activity on the esterification of citric acid and n-butanol. The present invention has the advantages of high yield, cheap catalyst, small catalyst consumptlion, mild reaction condition, short reaction period, reusability of the catalyst, no environmental pollution, direct use of non-toxic reactant n-butanol as water entrainer, etc.

Owner:EAST CHINA NORMAL UNIV

Ceramic product having alcoholic drink alcoholization function and preparation method thereof

InactiveCN102690102AGood colorSpicy and violent tasteAlcoholic beverage preparationClaywaresIsobutanolSilicic acid

The invention relates to an alcoholic drink storage utensil and a preparation method thereof. The alcoholic drink storage utensil is a ceramic product having an alcoholic drink alcoholization function and is composed of purple sand, an alcoholic drink purifying solvent, an energy activator and an environment-imitating solvent, wherein the purple sand accounts for 70-80% of the raw materials, the alcoholic drink purifying solvent accounts for 5-20% of the raw materials s, the energy activator accounts for 5-20% of the raw materials s, and the environment-imitating solvent accounts for 2-6% of the raw materials. The alcoholic drink purifying solvent contains major elements of potassium, sodium, calcium, magnesium and phosphorus and further contains zinc, iron, selenium, copper, strontium, iodine, fluorine and metasilicic acid; the energy activator can be tourmalinite or negative ion powder or a mixture of the tourmalinite and the negative ion powder; the environment-imitating solvent is diatomite. The function of the ceramic products is that parameters such as acetaldehyde, methanol, n-propanol, sec-butyl alcohol, isobutanol, n-butanol and isoamyl alcohol, and the like can be reduced to a different degree; parameters such as ethyl acetate, ethyl butyrate, ethyl lactate and ethyl caproate, and the like can be raised to different degrees. According to the invention, the alcoholic drink has good shade, virgin whiteness, no thickness, no pungent smell and no other off-flavors.

Owner:冯政

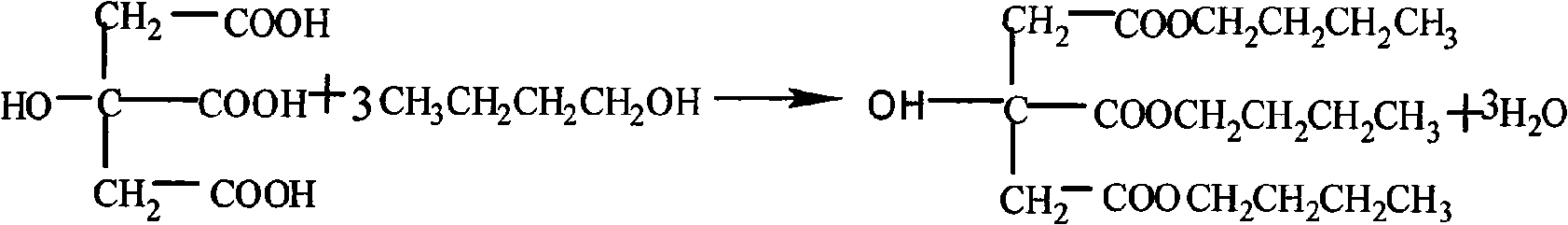

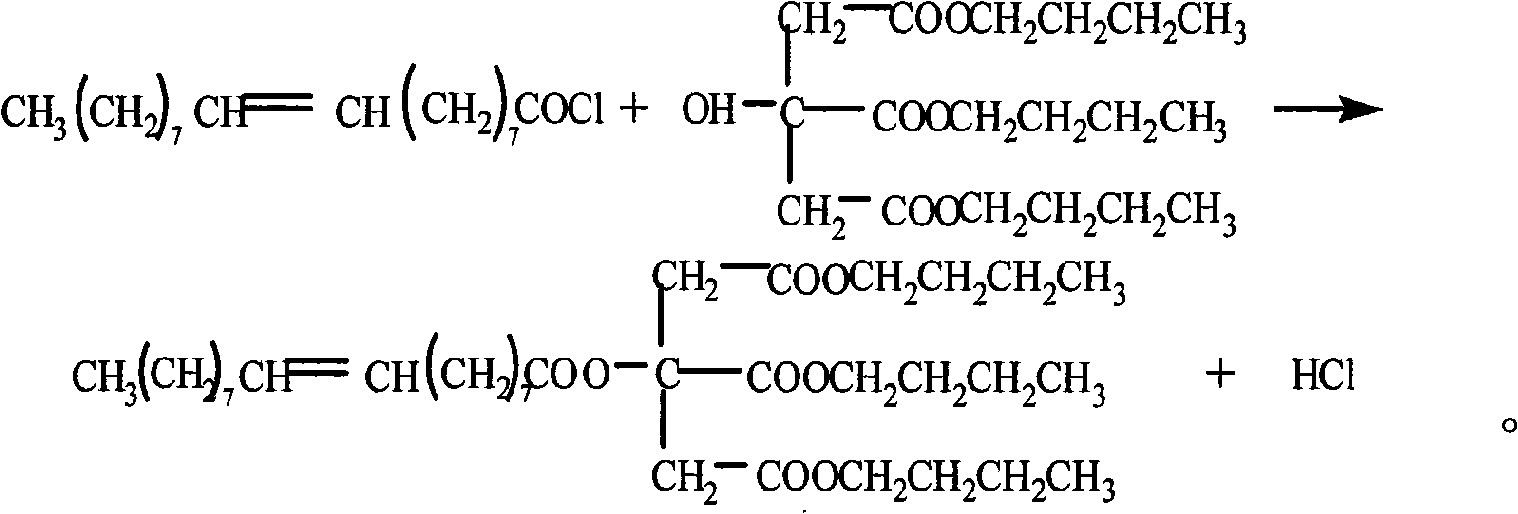

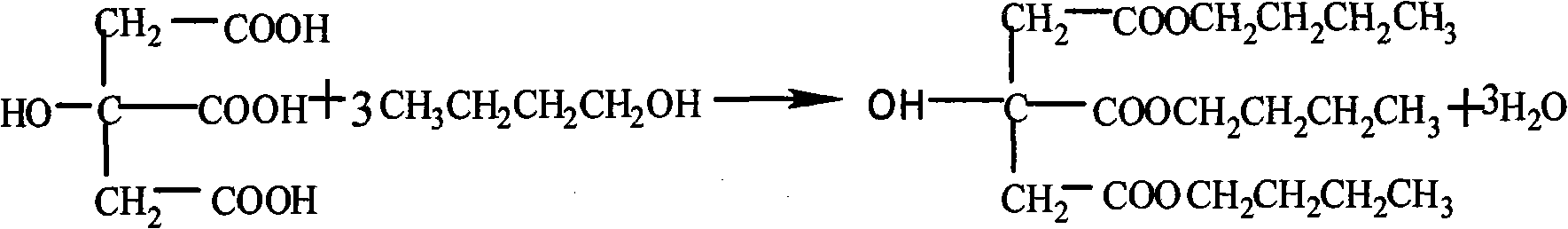

Method for preparing oleoyl tributyl citrate plasticizer

InactiveCN101255114AOrganic compound preparationCarboxylic acid esters preparationRoom temperatureChloride

The invention provides a method for preparing oleoyl tributyl citrate plasticizer, comprises: adding citric acid, n-butanol, water-carrying agent and catalytic agent into a reactor, stirring and heating up, controlling the temperature for reaction at 96 degree C until no water is generated again, and obtaining tributyl citrate; adding oleate into the reactor, stirring and heating up, dropping phosphorus trichloride into the reactor, reacting for 3h at 60 degree C, cooling to room temperature, standing for 2h, and separating to obtain; and a step 3, synthesizing oleoyl tributyl citrate; adding tributyl citrate and a catalytic agent into the reactor, stirring and heating up to 70 degree C, dropping oleoyl chloride, absorbing the generated hydrogen chloride by introducing the drier into base, stopping the reaction until the pH value of base has no change, and obtaining oleoyl tributyl citrate by neutralizing with sodium carbonate solution, water washing, and vacuum filtrating.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com