Method of solvent extraction purification of wet method phosphoric acid produced from medium and low grade phosphosus ore

A wet-process phosphoric acid, low-grade technology, used in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as large liquids, reduced equipment capacity, inability to carry out, etc., to improve extraction rate, reduce burden, The effect of increasing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

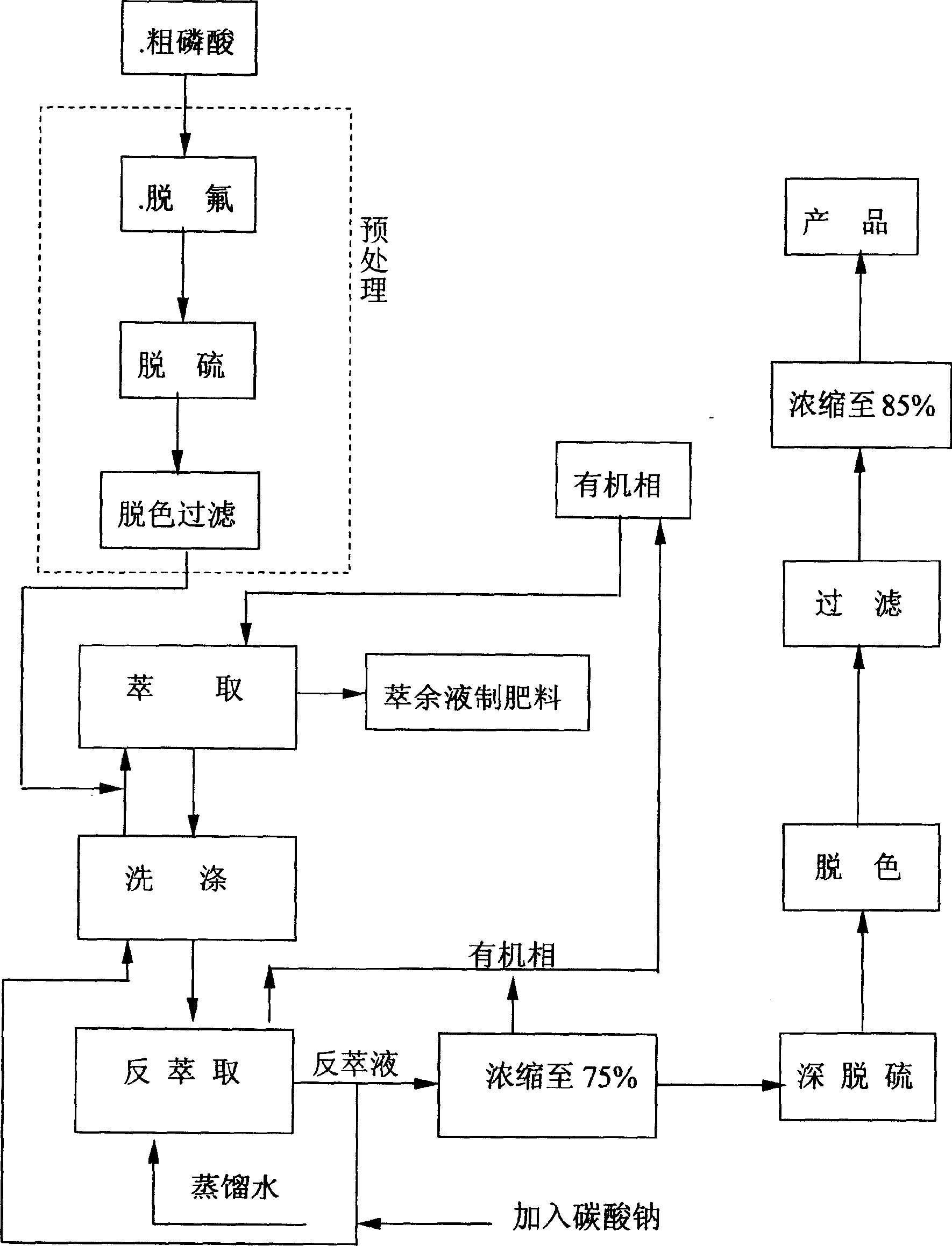

[0037] The pretreated 42wt%P 2 o 5 The wet-process phosphoric acid is extracted with a mixed solvent of n-butanol and methyl isobutyl ketone, and the volume ratio of n-butanol: methyl isobutyl ketone in the mixed solvent is 3: 7, adding 3% isoamyl alcohol to increase the volume of the mixed solvent of alcohol and ketone Efficacy agent, after seven-stage countercurrent extraction, the extraction ratio O:A is 6:1, four-stage countercurrent washing, washing water with 600g / l H 3 PO 4 +60g / l Na 2 CO 3 The aqueous solution, washing ratio O:A is 6:1, three-stage countercurrent back extraction, back extraction ratio O:A is 6:1, concentration, deSO 4 2- , decolorized, filtered, and concentrated again to obtain 85wt% phosphoric acid. The test process conditions and product quality are shown in Table 1.

Embodiment 2

[0039] The pretreated 43wt%P 2 o 5 The wet-process phosphoric acid is extracted with a mixed solvent of n-butanol and methyl isobutyl ketone, and the volume ratio of n-butanol in the mixed solvent: methyl isobutyl ketone is 2: 8, adding 5% isoamyl alcohol to increase the volume of the mixed solvent of alcohol and ketone Efficacy agent, after seven-stage countercurrent extraction, the extraction ratio O:A is 2.5:1, five-stage countercurrent washing, washing water with 600g / l H 3 PO 4 +60g / l Na 2 CO 3 The aqueous solution, washing ratio O:A is 8.5:1, five-stage countercurrent back extraction, back extraction ratio O:A is 4:1, concentration, deSO 4 2- , decolorized, filtered, and concentrated again to obtain 85wt% phosphoric acid. The test process conditions and product quality are shown in Table 1.

Embodiment 3

[0041] The pretreated 43wt%P 2 o 5 The wet-process phosphoric acid is extracted with a mixed solvent of n-butanol and methyl isobutyl ketone, and the volume ratio of n-butanol in the mixed solvent: methyl isobutyl ketone is 3: 7, adding 4% isoamyl alcohol by volume of the mixed solvent of alcohol and ketone, After ten stages of countercurrent extraction, the extraction ratio O:A is 3:1, five stages of countercurrent washing, washing water with 600g / l H 3 PO 4 +60g / l Na 2 CO 3 , washing ratio O:A is 6.5:1, four-stage countercurrent back extraction, back extraction ratio O:A is 6:1, concentration, deSO 4 2- , decolorized, filtered, and concentrated again to obtain 85wt% phosphoric acid. The test process conditions and product quality are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com