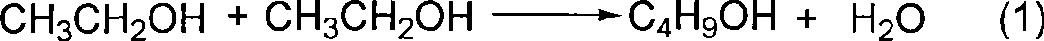

Bi-component supported catalyst of ethanol condensed n-butanol and a method of preparing thereof

A technology of supported catalyst and n-butanol, which is applied in the direction of catalyst activation/preparation, preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of low selectivity of n-butanol and high reaction temperature, and achieve simple and catalytic The effect of high activity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

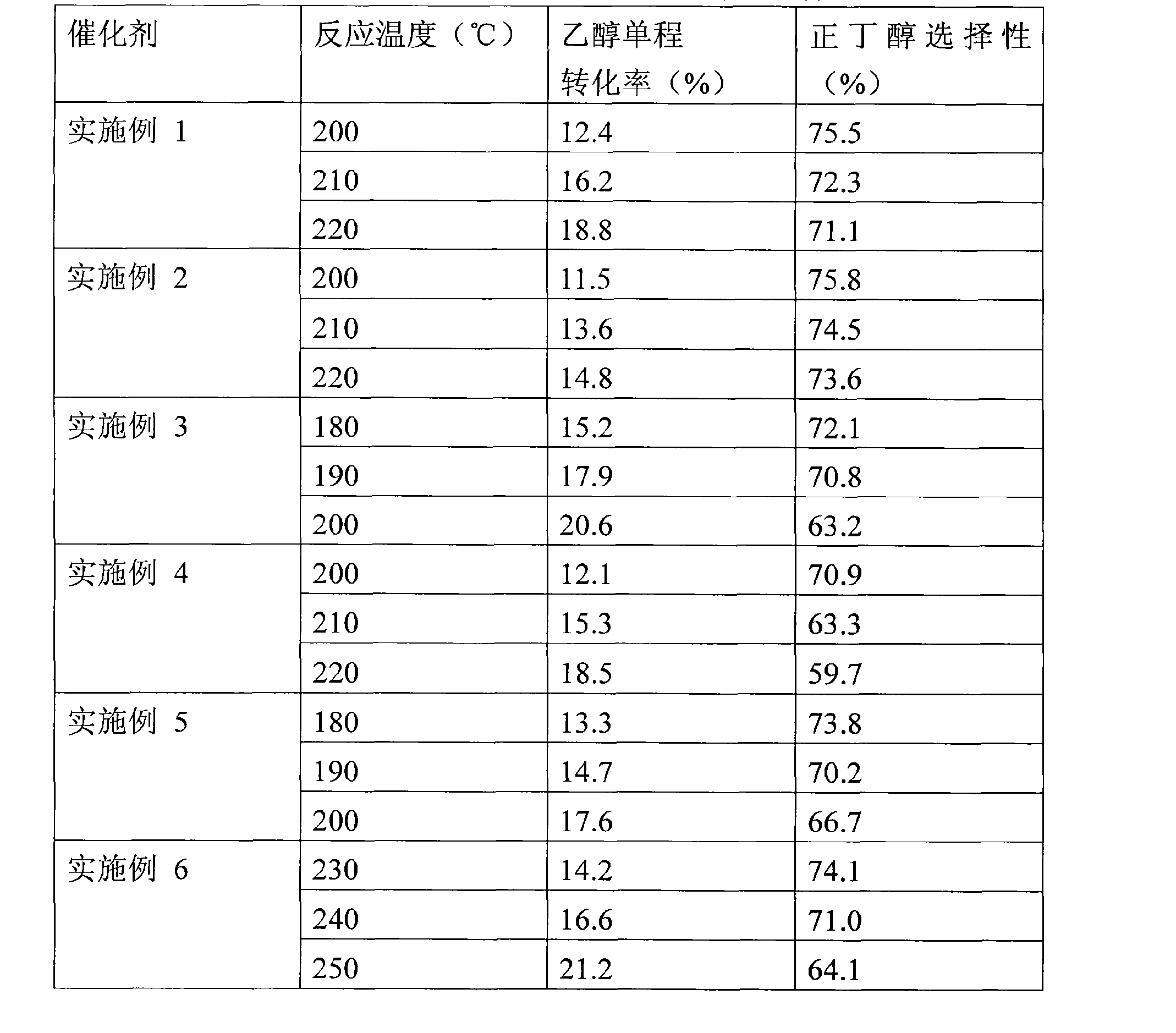

Embodiment 1

[0014] Weigh 7.43 grams of nickel nitrate hexahydrate and dissolve it in 60 mL of water. After it is completely dissolved, add 36 grams of formed γ-Al with a particle size of 4-6 mm 2 o 3 After soaking for 3 days, the solution was evaporated to dryness, and then dried overnight at 130°C. Then weigh 4.87 grams of magnesium nitrate hexahydrate and dissolve it in 60 mL of water. 2 o 3 Immerse in it, evaporate the solution to dryness after immersing for 2 days, and then dry it at 130° C. to obtain a two-component supported catalyst. Put the catalyst into a tubular reactor with an inner diameter of 16 mm, fill the upper and lower parts of the reaction tube with ceramic beads, inject hydrogen gas at 80 mL / min, raise the temperature to 160 ° C for half an hour, then maintain the temperature at 260 ° C for 1 hour, and then raise the temperature to Restore at 430°C for 4 hours, continue to pass hydrogen to lower the temperature to 180°C, stop hydrogen flow, and directly pump 95% eth...

Embodiment 2

[0016] The first step is to load nickel nitrate (7.43g) on the formed carrier γ-Al 2 o 3 (36g) The steps are the same as in Example 1; In the second step, take 3.20 grams of potassium fluoride dihydrate and dissolve it in 60mL of water. 2 o 3 Immerse in the potassium fluoride solution again, and the subsequent treatment is the same as the step of adding the second component in Example 1. The reaction conditions for hydrogen pretreatment before catalyst reaction and ethanol condensation are the same as in Example 1. In the presence of the catalyst, at a reaction temperature of 220° C., the conversion rate of ethanol is 15%, and the selectivity of n-butanol is 74%, as shown in the table 1.

Embodiment 3

[0018] The first step is to weigh 4.72 grams of nickel acetate tetrahydrate and dissolve it in 60 mL of water. After it is completely dissolved, add 36 grams of formed (particle size: 4-6mm) γ-Al 2 o 3 After soaking for 2 days, the solution was evaporated to dryness, and then dried at 130°C. In the second step, weigh 8.28 grams of nickel acetate tetrahydrate and dissolve it in 60 mL of water. After it is completely dissolved, dry the product obtained in the first step and then immerse it in the solution. After 2 days of immersion, the solution is evaporated to dryness, and then the drying. In the third step, 5.07 grams of magnesium nitrate hexahydrate was weighed and dissolved in 60 mL of water, and then the dried product obtained in the second step was immersed in the solution. After 2 days of immersion, the solution was evaporated to dryness. The hydrogen flow treatment of catalyzer and ethanol condensation reaction conditions are as embodiment 1. Under this catalyzer effe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com