Active carbon supported copper-metal oxide catalyst, preparation method and applications thereof

A technology of activated carbon and oxides, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as weak interactions, improve selectivity and ethanol removal Hydrogen activity, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

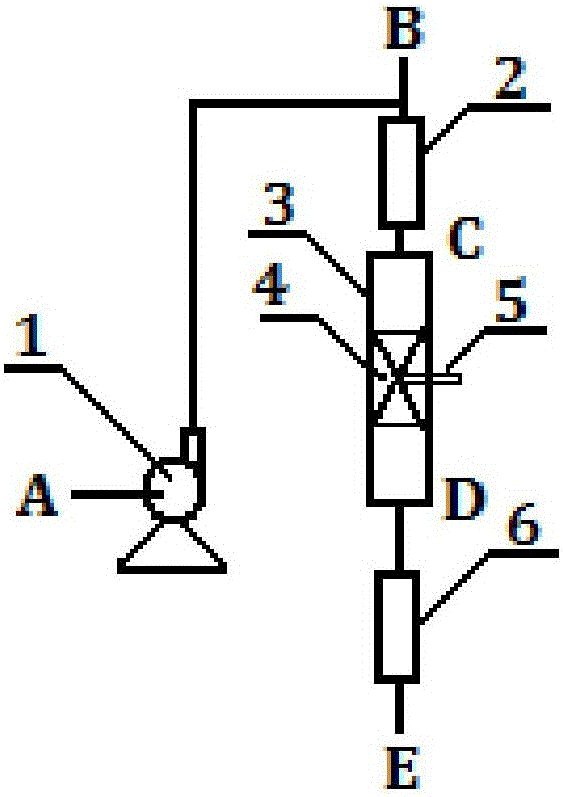

Method used

Image

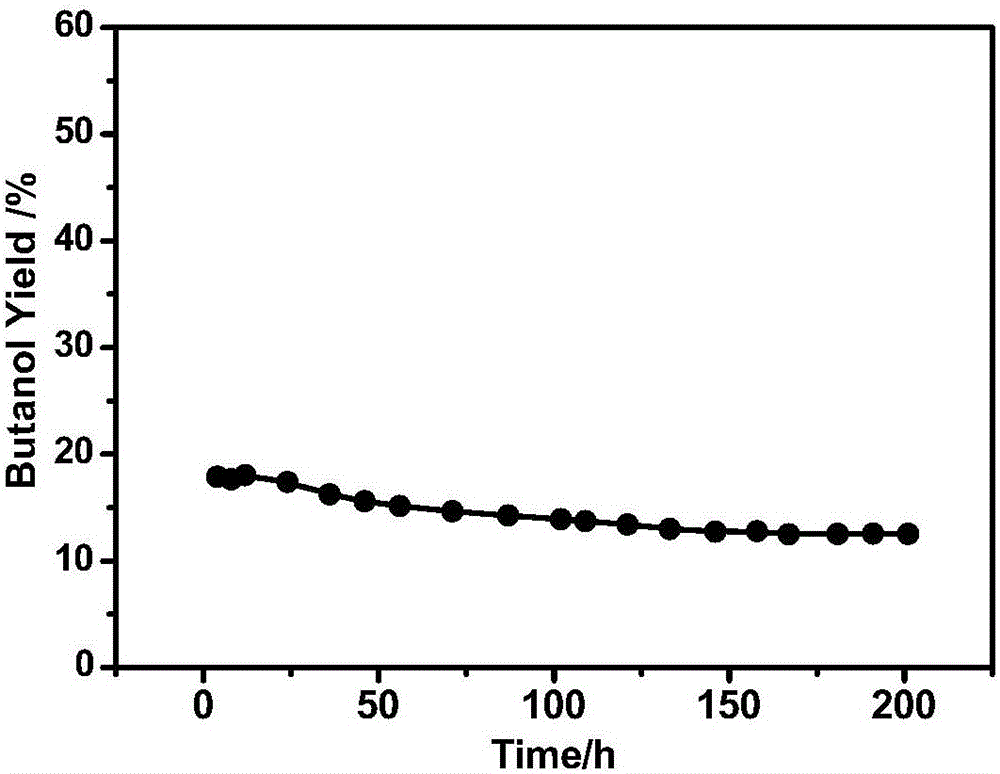

Examples

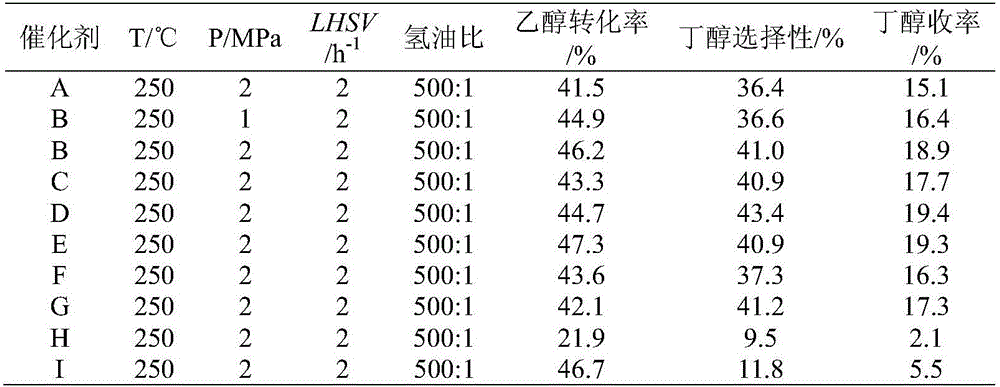

Embodiment 1

[0046] 0.7603g copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) and 0.4555g cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O) Added into 10ml of deionized water, after it was dissolved and mixed uniformly, 2g of columnar activated carbon particles were added therein and soaked for 4h. The above mixture was first dried on a rotary evaporator at 50° C. and 0.09 MPa for 3 hours, and then dried at 80° C. and 0.09 MPa for 2 hours. The dried solid matter was calcined in a tube furnace at 450° C. for 3 h in a nitrogen atmosphere to obtain catalyst A. Its metal Cu loading is 8.4wt%, CeO 2 The loading capacity of the catalyst is 7.6wt%, and the rest is an activated carbon carrier; the obtained catalyst is a columnar particle with a diameter of 0.8mm and a length of 3-8mm, and the radial average strength of the particle is 124.2N / cm; its specific surface area is 1001.3m 2 / g, the most probable pore diameter is 2.9nm, and the pore volume is 0.49ml / g.

Embodiment 2

[0048] The preparation method of catalyst B is the same as in Example 1, but the impregnating solvent is changed into dehydrated alcohol. Its metal Cu weight content is 8.4wt%, CeO 2 The loading capacity of the catalyst is 7.6wt%, and the rest is activated carbon carrier; the obtained catalyst is a columnar particle with a diameter of 0.8mm and a length of 3-8mm, and the radial average strength of the particle is 123.5N / cm; its specific surface area is 1005.8m 2 / g, the most probable pore diameter is 2.8nm, and the pore volume is 0.49ml / g.

Embodiment 3

[0050] The preparation method of catalyst C is the same as embodiment 2, but cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O) has a mass of 0.6833g. Its metal Cu weight content is 8.1wt%, CeO 2 The loading capacity of the catalyst is 10.9wt%, and the rest is activated carbon carrier; the obtained catalyst is a columnar particle with a diameter of 0.8mm and a length of 3-8mm, and the radial average strength of the particle is 117.1N / cm; its specific surface area is 988.4m 2 / g, the most probable pore diameter is 2.9nm, and the pore volume is 0.45ml / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com