Boron nitride composite mesoporous oxide nickel-based catalyst and preparation method thereof

A boron nitride composite mesoporous, nickel-based catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to improve anti-sintering performance and low cost , Solve the effect of sintering and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

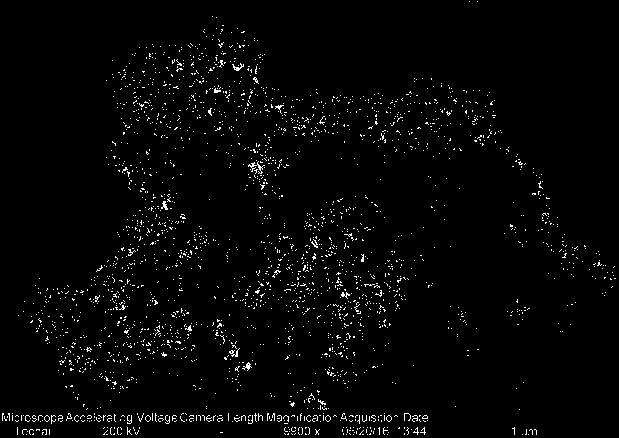

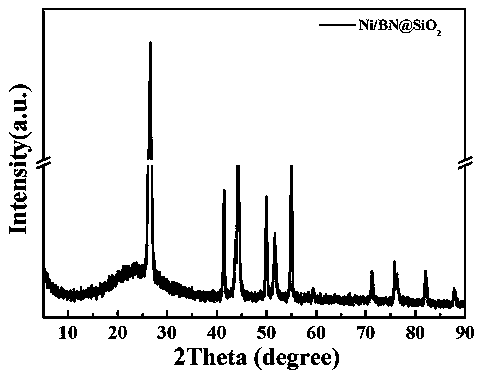

[0029] Weigh 0.400 g of boron nitride and 0.150 g of nickel nitrate and dissolve them in a mixed solution of water and ethanol, add 0.600 g of surface modifier CTAB and 1.80 mL of ammonia water, stir ultrasonically for 1 h, and dissolve 0.6 g of mesoporous oxide precursor TEOS Added dropwise and stirred vigorously for 6 h. The nickel loading was 6.5 wt%. Centrifugal washing with water and alcohol 3 times each, 60 o C drying for 12 h. The heating rate in the air atmosphere is 2 o C / min, 600 o C calcined for 4 h. Use hydrogen to program temperature reduction, first pass N 2 at 300 o C for 30 min, cooled to room temperature with 10 vol% H 2 / N 2 Mixed gas (30mL / min) 750 o C reduction for 1 h, a new structure nickel-based catalyst of boron nitride composite mesoporous oxide was obtained.

[0030] Test the catalytic activity of the above catalyst: Weigh 0.120 g (40-60 mesh) of the prepared catalyst and put it into a fixed bed quartz tube reactor for catalyst performance t...

Embodiment 2

[0032]Weigh 0.400 g of boron nitride and 0.150 g of nickel nitrate and dissolve them in a mixed solution of water and ethanol, add 0.600 g of surface modifier CTAB and 1.80 mL of ammonia water, stir ultrasonically for 1 h, and add 0.6 g of mesoporous oxide precursor TEOS dropwise Add and stir vigorously for 1 h. The nickel loading was 6.5 wt%. Centrifugal washing with water and alcohol 3 times each, 60 o C drying for 12 h. The heating rate in the air atmosphere is 2 o C / min, 600 o C calcined for 4 h. Use hydrogen to program temperature reduction, first pass N 2 at 300 o Pretreatment at C for 30 min, cooled to room temperature and treated with 10 vol% H 2 / N 2 Mixed gas (30mL / min) 750 o C reduction for 1 h, a new structure nickel-based catalyst of boron nitride composite mesoporous oxide was obtained.

[0033] Test the catalytic activity of the above catalyst: Weigh 0.120 g (40-60 mesh) of the prepared catalyst and put it into a fixed bed quartz tube reactor for catal...

Embodiment 3

[0035] Weigh 0.400g of boron nitride and 0.130g of nickel acetylacetonate and dissolve in the mixed solution of water and ethanol, add 0.600g of surface modifier CTAB and 1.80mL of ammonia water, stir ultrasonically for 1 h, and add 0.6g of mesoporous oxide precursor TEOS dropwise Add and stir vigorously for 6 h. The nickel loading was 6.5 wt%. Centrifugal washing with water and alcohol 3 times each, 60 o C drying for 12 h. The heating rate in the air atmosphere is 2 o C / min, 600 o C calcined for 4 h. Use hydrogen to program temperature reduction, first pass N 2 at 300 o Pretreatment at C for 30 min, cooled to room temperature and treated with 10 vol% H 2 / N 2 Mixed gas (30mL / min) 750 o C reduction for 1 h, a new structure nickel-based catalyst of boron nitride composite mesoporous oxide was obtained.

[0036] Test the catalytic activity of the above catalyst: Weigh 0.120 g (40-60 mesh) of the prepared catalyst and put it into a fixed bed quartz tube reactor for cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com