Patents

Literature

101results about How to "Limit growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

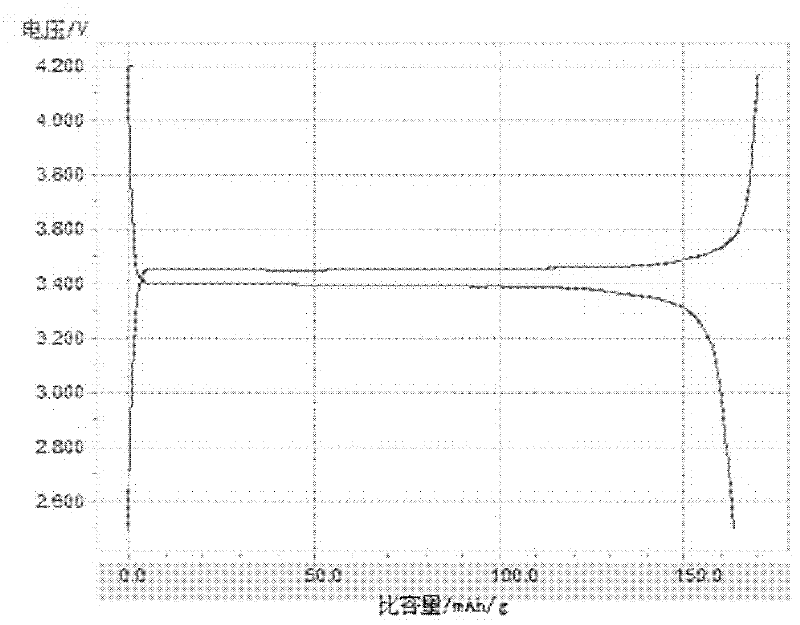

Preparation method of carbon-coated sodium-micron-scale lithium titanate composite anode material

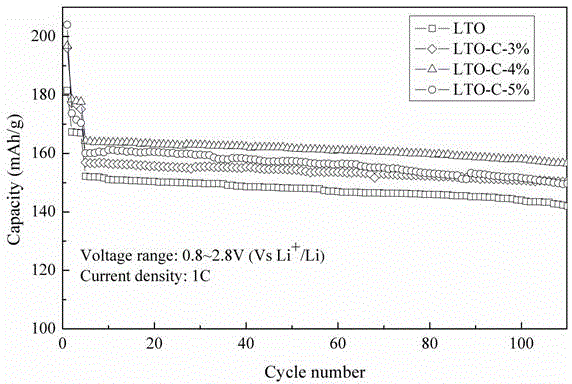

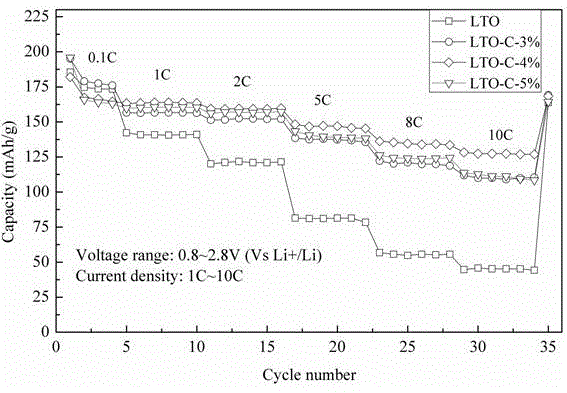

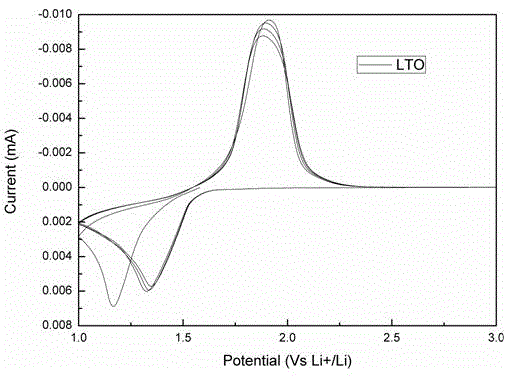

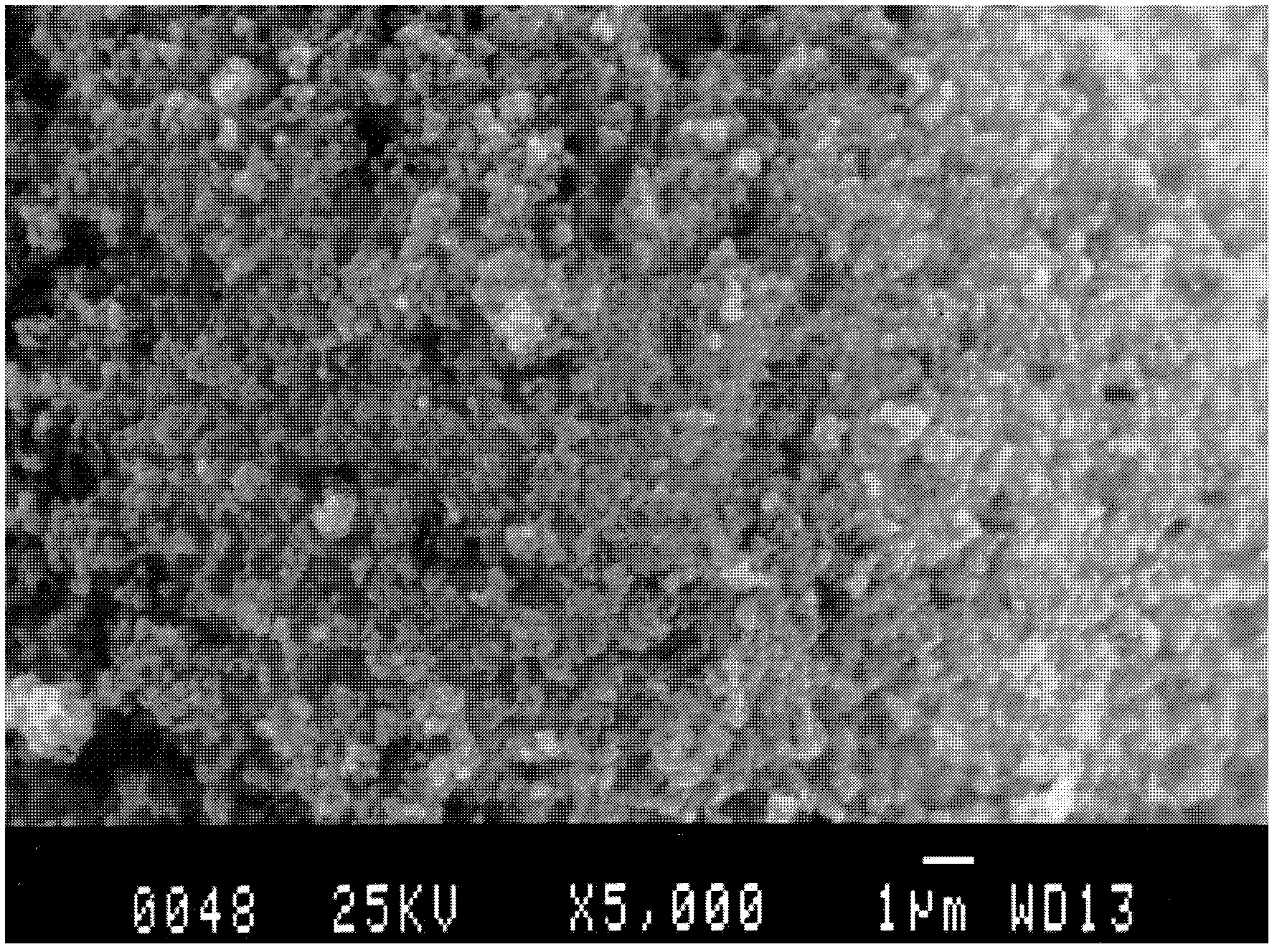

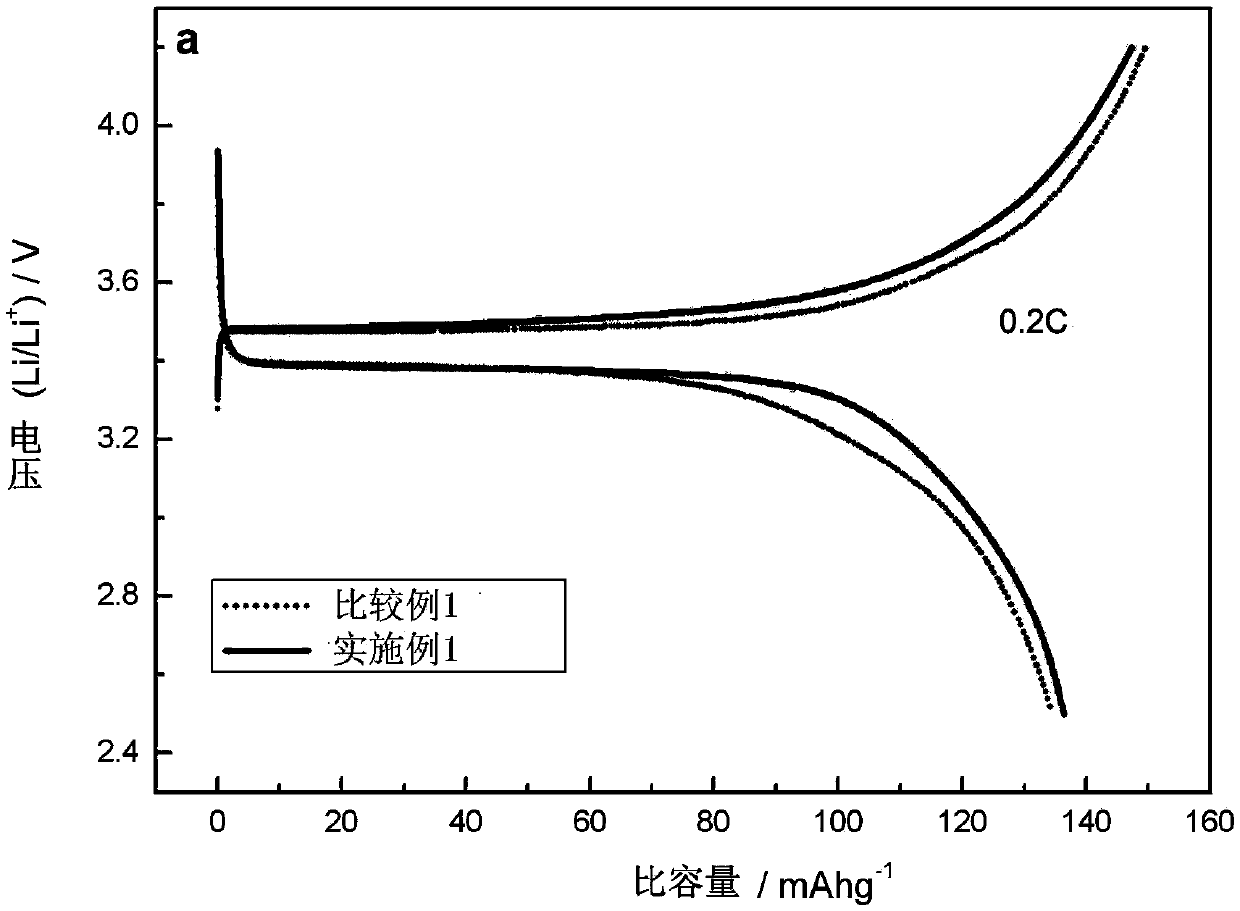

ActiveCN105591079AGuaranteed stabilityLoose particle structureMaterial nanotechnologyCell electrodesMicron scaleOrganotitanium compound

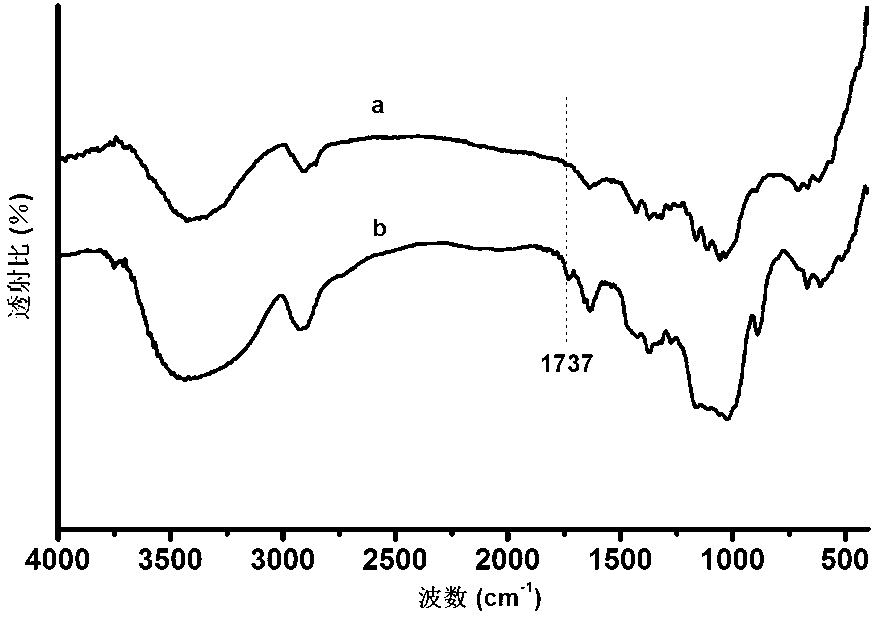

The invention relates to a preparation method of a carbon-coated sodium-micron-scale lithium titanate composite anode material. The method comprises steps as follows: lithium salt is dissolved in an aqueous solution of absolute ethyl alcohol, and the solution is marked a solution a; an organic titanium compound and a carbon source are dissolved in absolute ethyl alcohol, and the solution is marked a solution b; a chelating agent M is dissolved in absolute ethyl alcohol, ultrasonic dispersion is performed, and the solution is marked a solution c; the solution c is slowly dropwise added to the solution b while stirring, and white sol is obtained; then the solution a is slowly dropwise added to the white sol; after the sol is aged, heating, stirring, drying, grinding, sieving and calcination are performed, and the carbon-coated lithium titanate composite anode material is obtained. Lithium titanate has narrower particle size distribution and more uniform particle distribution, and sodium-micron-scale particles are uniformly inlaid to form particles with high tap density; the particle structure is loose and porous, the specific surface area of a formed electrode is larger, getting off of lithium ions in the lithium titanate material is facilitated, and the stability of the crystal structure of the lithium ions in the charge and discharge process is guaranteed.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

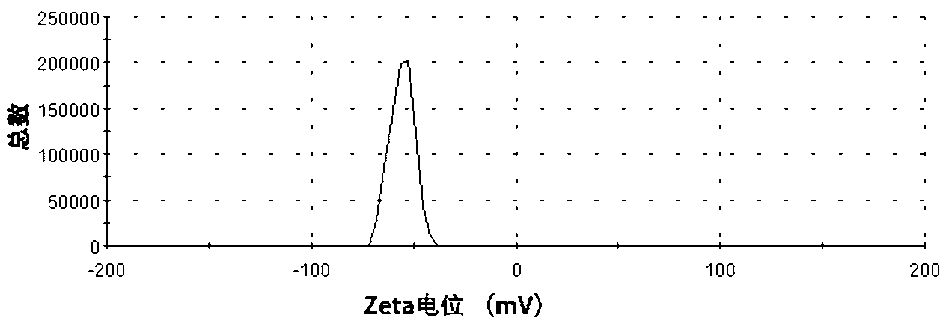

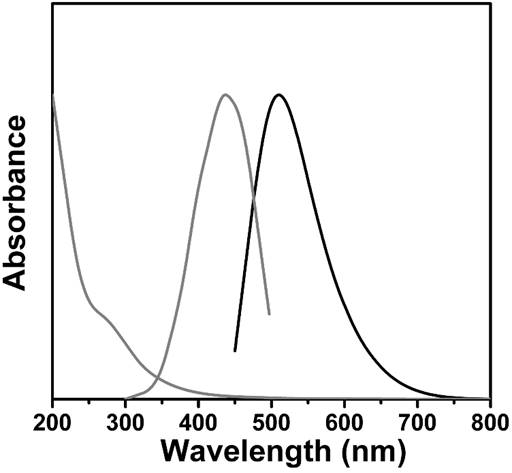

Preparation method of colloidal solution of nano-ZnO

InactiveCN103318945AImprove water solubilityLow viscosityMaterial nanotechnologyZinc oxides/hydroxidesHydroxypropylmethyl celluloseChemistry

The invention discloses a preparation method of a colloidal solution of nano-ZnO. The method comprises the following steps: mixing an aqueous modified cellulose solution having a concentration of 0.001-100g / L with a zinc salt solution having a concentration of 0.01-100g / L according to a volume ration of 1:10-100:1, wherein the modified cellulose is dialdehyde hydehydroxypropyl methyl cellulose obtained through the selective oxidation of the secondary hydroxyl groups in the C2 and C3 positions of hydroxypropyl methyl cellulose; and slowly adding an alkaline solution for adjusting the pH value to 8.5-11.5, and stirring at 20-90DEG C for 1-600min until reaction completion in order to obtain the colloidal solution of nano-ZnO having an average particle size of 1-100nm. The prepared nano-ZnO has the advantages of ultrahigh stability, antibiosis and ultraviolet resistance, good biocompatibility and good biodegradability, and can be applied to the coat field, the textile field, the medical health field and the like.

Owner:SUZHOU UNIV

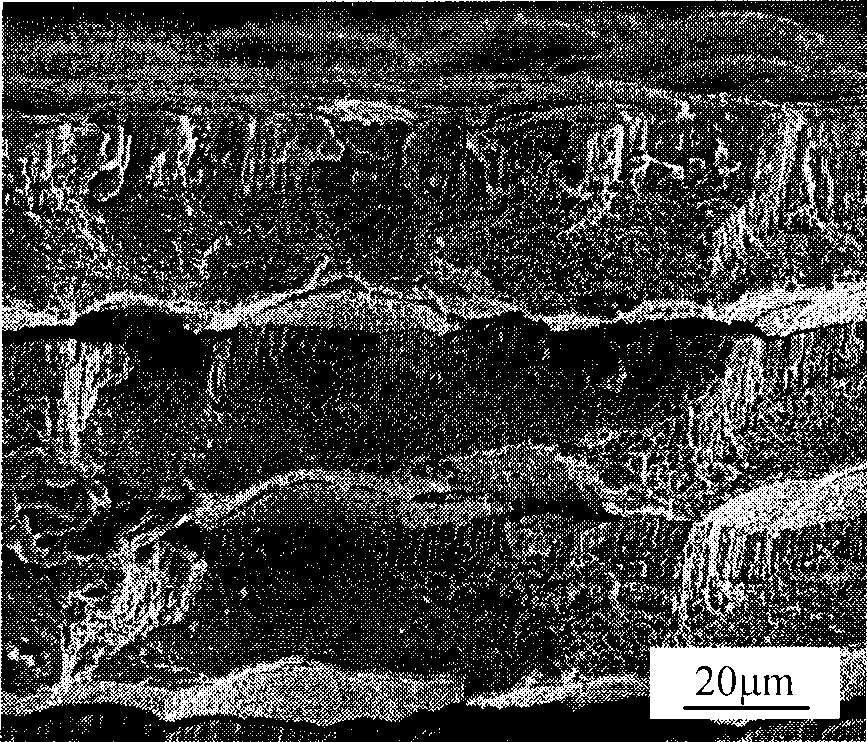

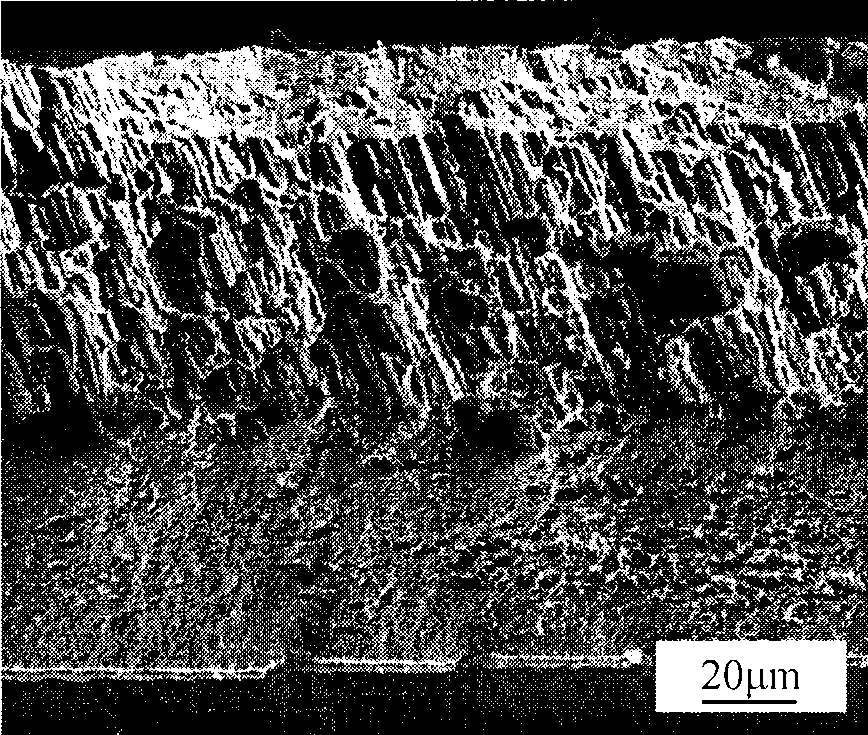

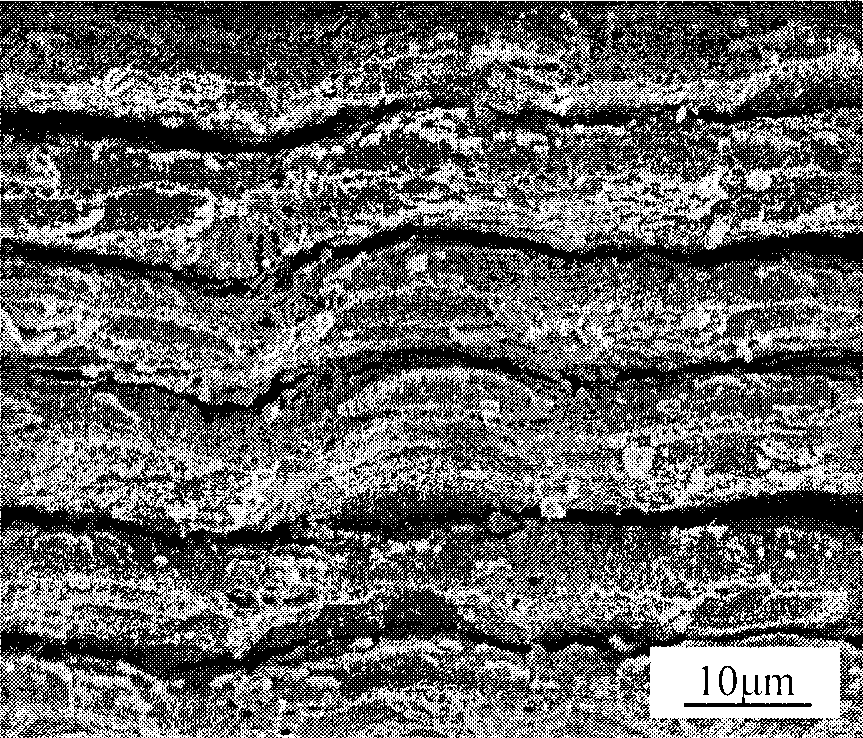

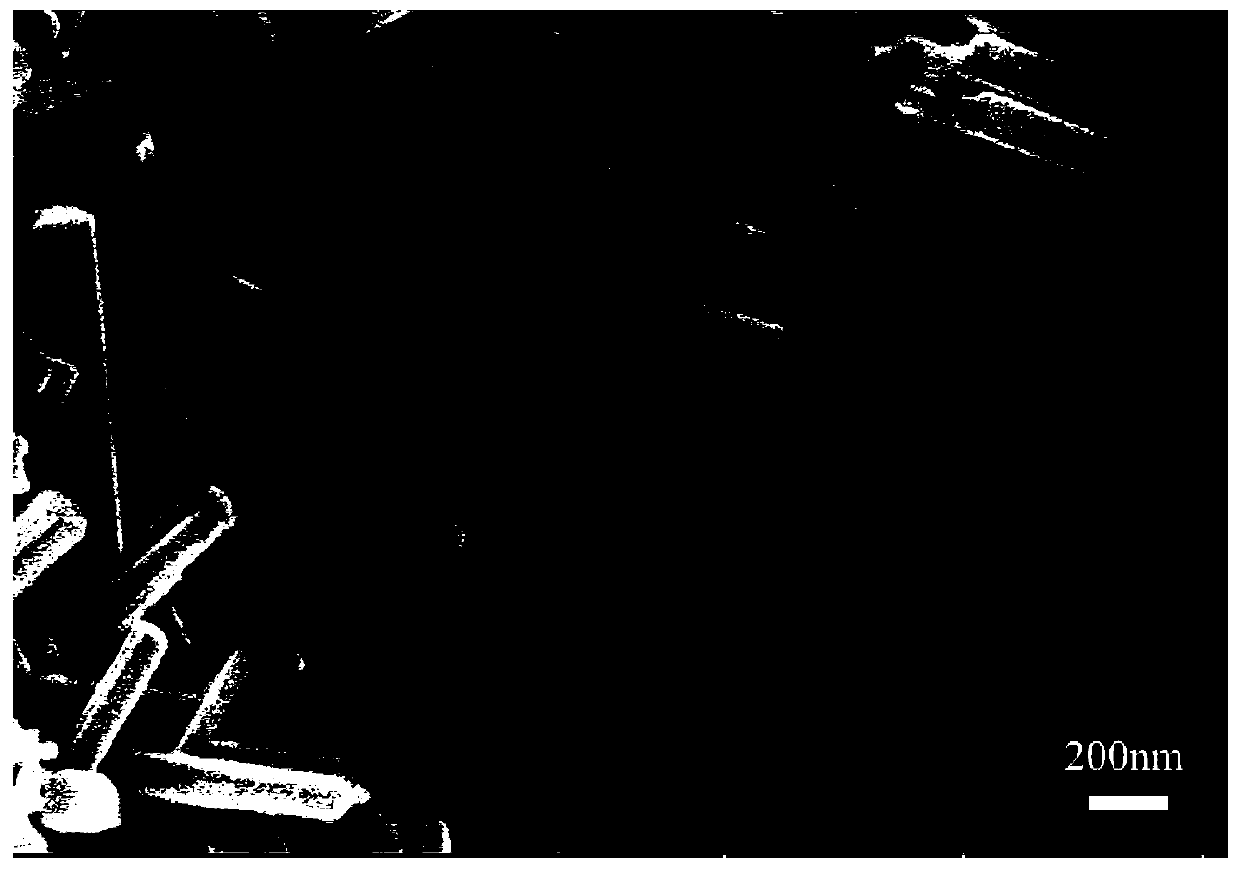

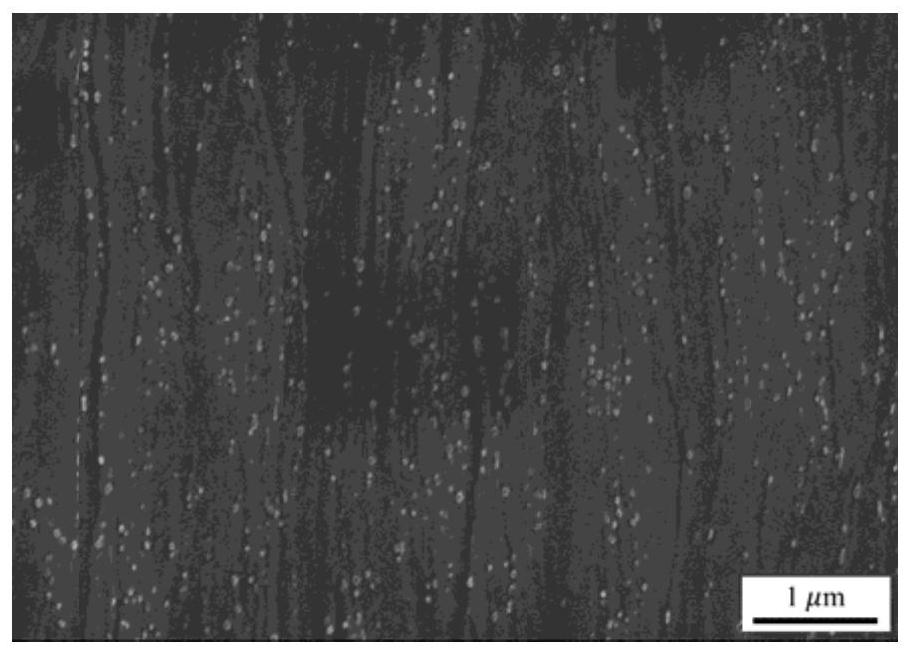

Metal / ceramic microlaminate material and preparation thereof

InactiveCN101413101AImprove toughnessReduce toughnessVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionMetal sheet

The invention provides a metal / ceramic micro-lamination material and a preparation method thereof. The method adopts an electron beam physical vapor deposition technology and alternately evaporates a metal target material and a ceramic material through an electron gun to prepare the metal / ceramic micro-lamination material. The thickness of a ceramic layer is 1 mu m; and the thickness of a metal layer is between 10 and 35 mu m, and the volume fraction ratio of the metal layer and the ceramic layer, namely the thickness ratio or the thickness ratio of layers is between 10 and 35. The metal target material is Ni-20Co-12Cr-4Al (weightt percent); and the ceramic target material is ZrO2(YSZ) containing 8 weight percent of Y2O3. The metal / ceramic micro-lamination material has large thickness ratio of layers; therefore, the material can keep the characteristic of good toughness of the metal material to a great extent. Simultaneously, the existence of a lamination structure limits the growth of columnar crystals in the metal layer and reduce the possibility that crack expands along the metal grain boundary. Compared with a monolayer EB-PVD metal sheet, the metal layer of the micro-lamination material has less probability of brittle intergranular fracture and higher strength.

Owner:HARBIN INST OF TECH

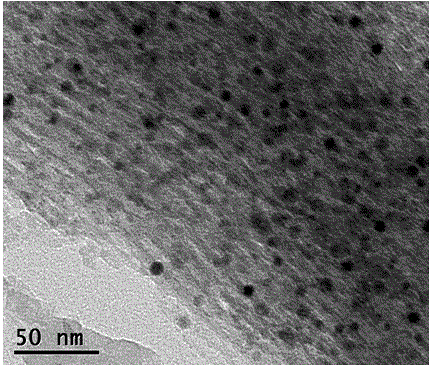

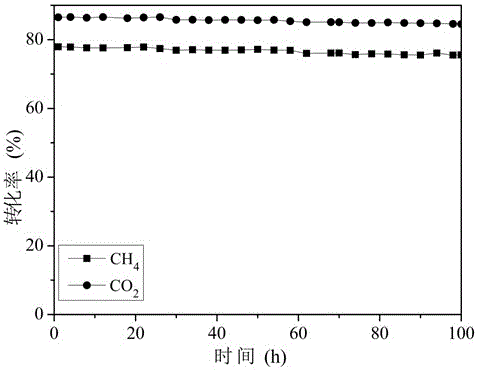

Preparation method for rapidly preparing highly-dispersed nickel-based catalyst for methane reforming with carbon dioxide

InactiveCN106000444ASimple preparation processShorten evaporation timeHydrogenMolecular sieve catalystsNickel catalystHigh carbon

The invention discloses a preparation method for rapidly preparing a highly-dispersed nickel-based catalyst for methane reforming with carbon dioxide. A high-temperature-resistant mesoporous material with a large specific surface area and ordered mesoporous passages is adopted as a carrier of the catalyst, a nickel precursor salt and the mesoporous material are ground and stirred to uniformly disperse the nickel precursor salt on the surface of the mesoporous material carrier which is not de-molded by adopting a solid-state grinding method, and during drying, the nickel precursor salt enters the passages to obtain a nickel catalyst with highly-dispersed active ingredients and high carbon deposition resistance and sintering resistance by calcination and H2 reduction. The preparation method has the advantages of simple preparation process, high catalysis efficiency, energy saving (calcination is not required during preparation of the carrier), uniform distribution of the active ingredients and the like.

Owner:KUNMING UNIV OF SCI & TECH

Ultra-fine titanium aluminum composite oxide and preparation method thereof

The invention discloses ultrafine titanium-aluminum composite oxide and a preparation method thereof. The method comprises the following steps: aluminum salt and titanium salt are dropped into the mixture of hydrocarbon component and surfactant with the VB value less than 1 to form an ultra solubilization micellar system, so as to react under the existence of precipitant and or catalyst; and the obtained reaction product is baked and / or roasted to obtain the ultrafine titanium-aluminum composite oxide. The titanium-aluminum composite oxide hole has a more rational structure, the pore volume with the hole diameter of 4 nm to 20 nm occupies 75 percent to 95 percent of the whole pore volume, thereby being favorable for improving the selectivity and the activity of the catalyst. The amount of the surfactant and the hydrocarbon component used for the method is little, the cost is low, the ultrafine particles are in a single dispersed state, the process is simple, and the invention can be used for the mass industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing tungsten-cobalt hard alloy

The invention discloses a manufacturing method for tungsten cobalt hard alloy, it includes following steps: mixing, wetmilling, drying, mixing with forming agent, pressing and forming, eliminating forming agent, sintering, it selects Co powder whose Fisher particle size is (1.0-2.5) mu m, Cr3C2 powder whose Fisher particle size is (4.0-4.6) mu m and WC powder with (1.2-1.8) Fisher particle size. The weight percentage of Co Powder, Cr3C2 powder, WC powder are (7.0-7.5)%, (0.7-1.0)% and the residue. The hard alloy in the invention has excellent density and rigidity and the price is low.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

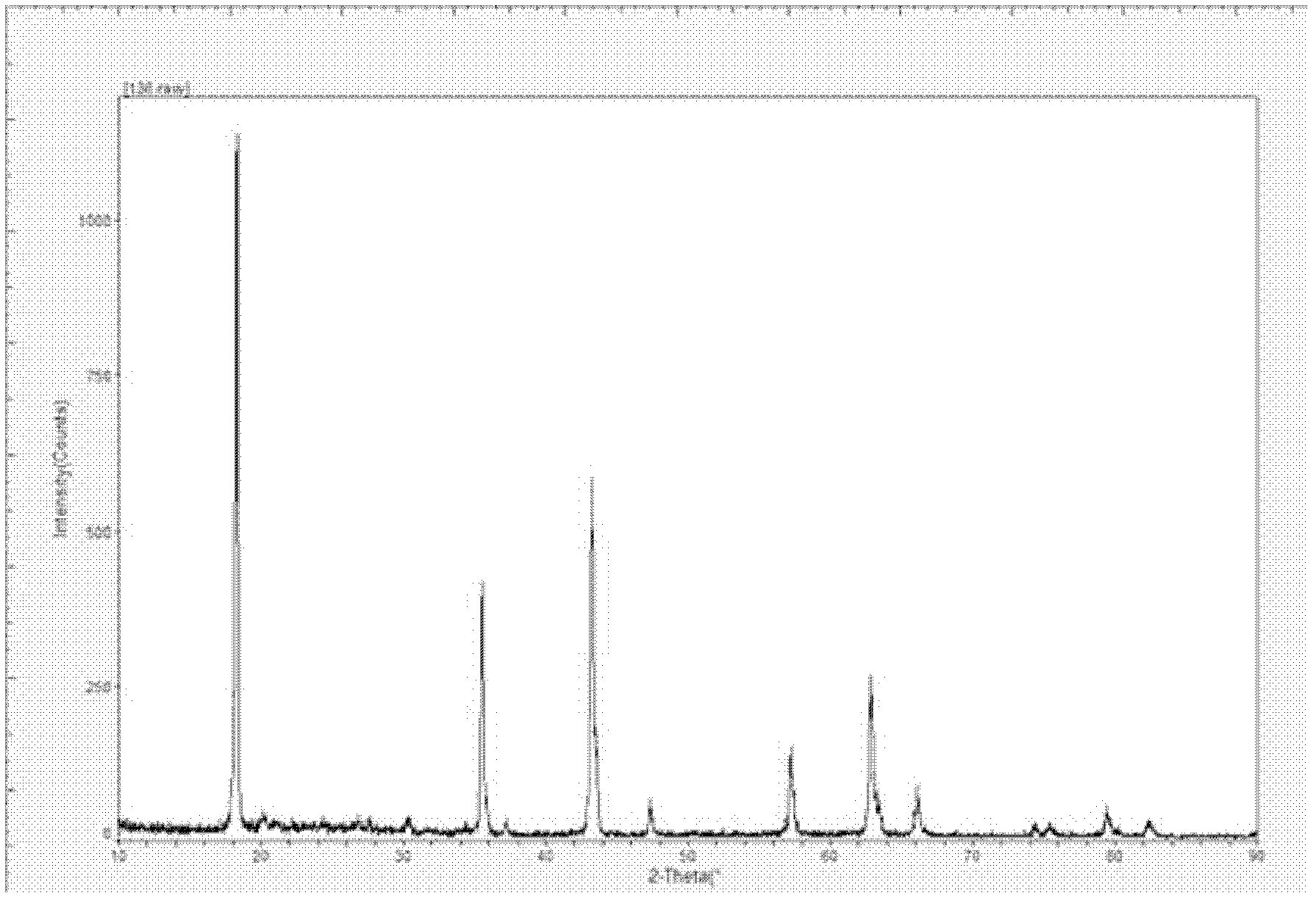

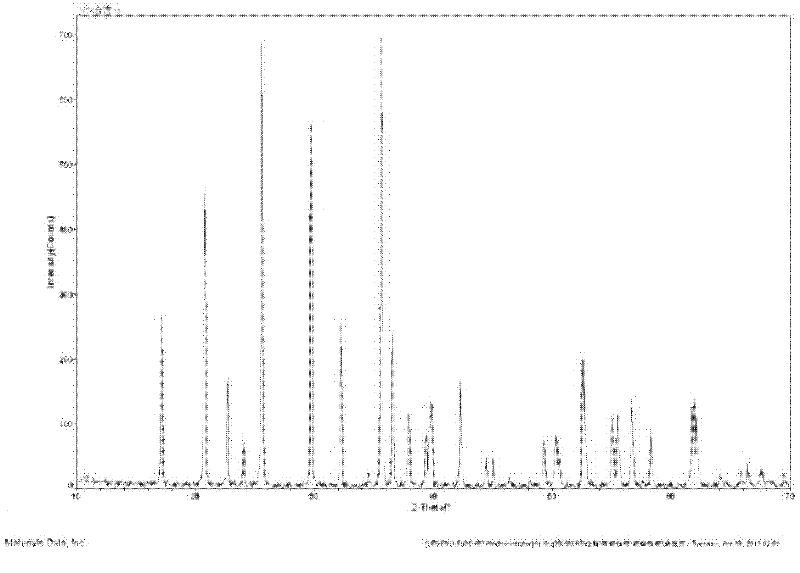

Modified lithium titanate material used for lithium ion battery and manufacturing method thereof

The invention relates to a modified lithium titanate material used for a lithium ion battery and a manufacturing method thereof. The modified lithium titanate material is manufactured by the following steps through a molten-salt growth method: adopting a lithium source and a titanium source as raw materials and taking a molten salt as a fusing agent; doping a compound containing a magnesium element, an aluminum element, a neodymium element, a rubidium element, a gallium element, a cesium element, a silicon element, a tin element or a carbon element for modification; and grinding and calcining. The modified lithium titanate material has the advantages of nano particles, clear crystal structure and integral crystallization shape; the manufacturing method using the molten-salt growth method is used to ensure the homogeneity of products; and the electrical conductivity and cycle performance of the lithium ion battery with the modified lithium titanate cathode can be improved greatly.

Owner:青岛瀚博电子科技有限公司

Preparation method of novel high-selectivity acetone gas sensitive sensor

The invention relates to a preparation method of a novel high-selectivity acetone gas sensitive sensor and is suitable for the field of preparing a gas sensing apparatus with a high selective characteristic on acetone steam. The preparation method comprises the following steps: by adopting a sol-gel method, adding hexadecyl trimethyl ammonium bromide in a process of preparing Zn(OH)2 colloid; thendrying and grinding the colloid, cleaning the colloid and carrying out annealing at high temperature; coating a ceramic tube with the prepared material through hexadecyl trimethyl ammonium bromide; and preparing a gas sensitive sensor after low-temperature annealing; and then carrying out aging. In the colloid preparation process, hexadecyl trimethyl ammonium bromide is added to generate a stablecolloid favorably; the ceramic tube is coated with the mateiral by using hexadecyl trimethyl ammonium bromide which plays a binding role; moreover, through low-temperature annealing, the selectivityof the gas sensitive element can be improved by means of hexadecyl trimethyl ammonium bromide. The gas sensitive element prepared by the method has a sensitive characteristic on acetone steam, and candetect the acetone steam from much organic steam.

Owner:HEBEI UNIV OF TECH

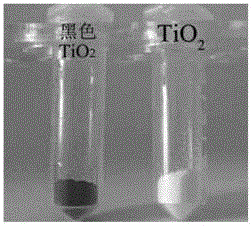

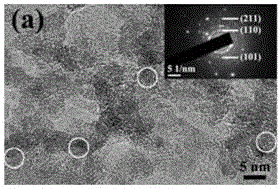

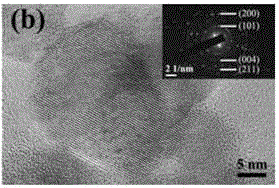

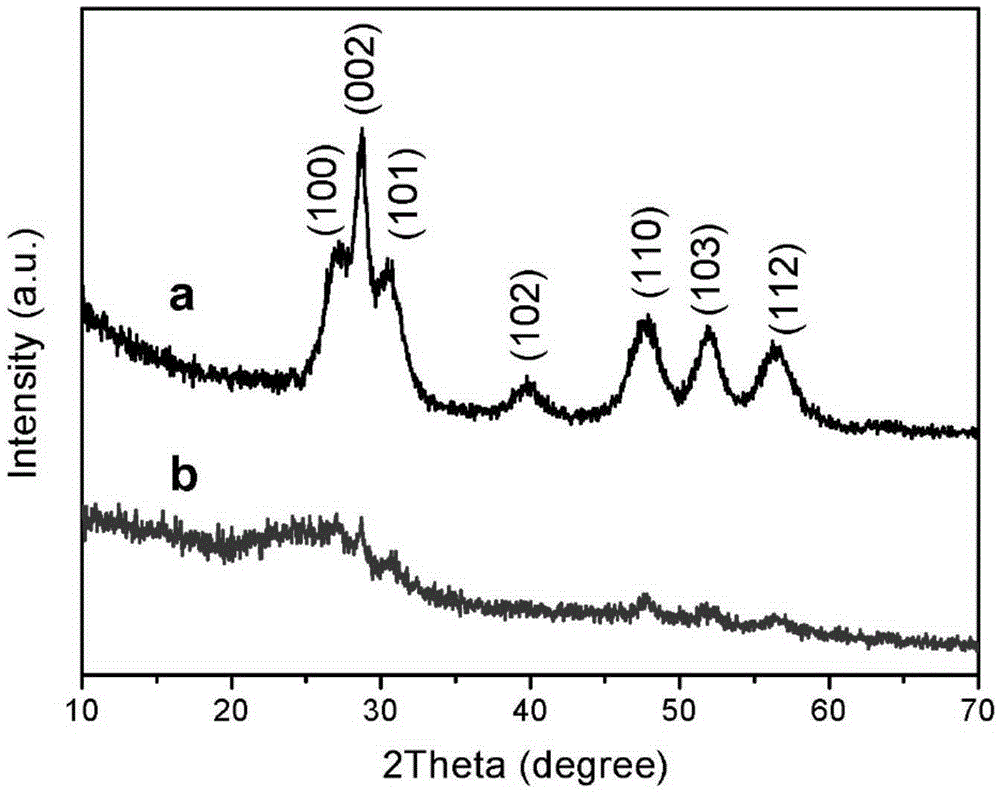

Method for preparing black titanium dioxide powder by pulse laser sputtering deposition under negative-pressure environment

InactiveCN106756788AImprove production efficiencyMake fastPhysical/chemical process catalystsVacuum evaporation coatingInternal pressureOptoelectronics

The invention discloses a method for preparing black titanium dioxide powder by pulse laser sputtering deposition under negative-pressure environment. The method comprises the following steps: firstly, white titanium dioxide powder is pressed as a piece to obtain a target with the pressure of 140-200 Mpa; then, the target is put in a vacuum tank, and the vacuum tank is vacuumized to reach the internal pressure of 1*10-6-1*104 Pa; an angle between an incident laser beam of a pulse laser and the target is adjusted within 10-45 degrees, and a distance from a substrate of the laser to the target is 15-50 mm; and the pulse laser is started, the laser pulse width, the laser energy, the laser wave length and the frequency are adjusted, the target in the vacuum tank is focused and irradiated by laser for a certain time to obtain a black titanium dioxide film on the substrate, and black titanium dioxide on the black titanium dioxide film is scraped off to obtain the black titanium dioxide powder. The method is simple and fast in preparation process, low in raw material cost and short in reaction time.

Owner:TIANJIN UNIV

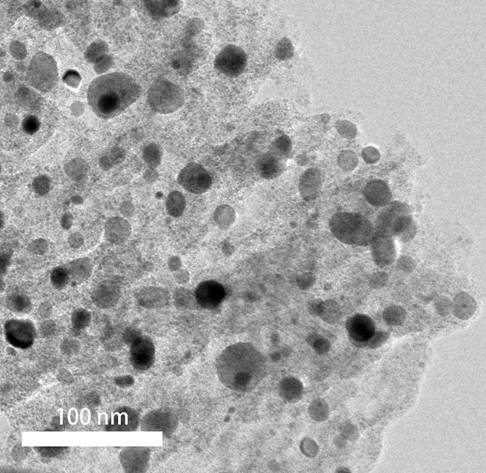

Preparation method for zinc sulfide-graphene nanocomposite

ActiveCN105347388ALower charge transfer resistanceImprove featuresMaterial nanotechnologyZinc sulfidesGraphene nanocompositesSulfur containing

The invention discloses a preparation method for a zinc sulfide-graphene nanocomposite. The preparation method is characterized by comprising the following steps: (1) preparation of a mercaptozinc complex: a step of dissolving sulfur-containing ligand and zinc salt in a proper amount of deionized water or an organic solvent for a hybrid reaction, carrying out stirring, then successively carrying out centrifugal washing with an organic solvent and deionized water, collecting a precipitate and drying the precipitate in vacuum so as to obtain the mercaptozinc complex; (2) preparation of a sintered body: weighing a certain amount of the mercaptozinc complex, sintering the mercaptozinc complex in a vacuum sintering furnace, introducing nitrogen into the vacuum sintering furnace and then carrying out natural cooling to room temperature so as to obtain black solid with white powder on its surface; and (3) acid treatment: a step of soaking the sintered body in an acid solution and then carrying out filtering and drying so as to obtain the zinc sulfide-graphene nanocomposite. The preparation method has the characteristics of simple process and synthesis equipment, a short synthesis period, good product homogeneity and easiness in realization of industrialization.

Owner:嘉兴长蒿新材料科技有限公司

Modified lithium iron phosphate material for lithium ion battery and preparation method thereof

InactiveCN102390825AImprove consistencyEnsure consistencyCell electrodesNanotechnologyRubidiumLithium-ion battery

The invention relates to a modified lithium iron phosphate material for a lithium ion battery and a preparation method thereof. The modified lithium iron phosphate material is prepared by a molten salt method: adding a compound containing magnesium, aluminum, neodymium, rubidium, gallium, cesium, silicon, tin or carbon element for modification by taking a lithium source, an iron source and a phosphorus source as raw materials and molten salt as a flux; and grinding and then calcining. The modified lithium iron phosphate material has nano-sized granularity, a clear crystal structure and a complete crystal shape; the electron conductivity and ion diffusivity are high; and the lithium ion battery using the modified lithium iron phosphate material as a positive electrode has high cycle performance.

Owner:青岛瀚博电子科技有限公司

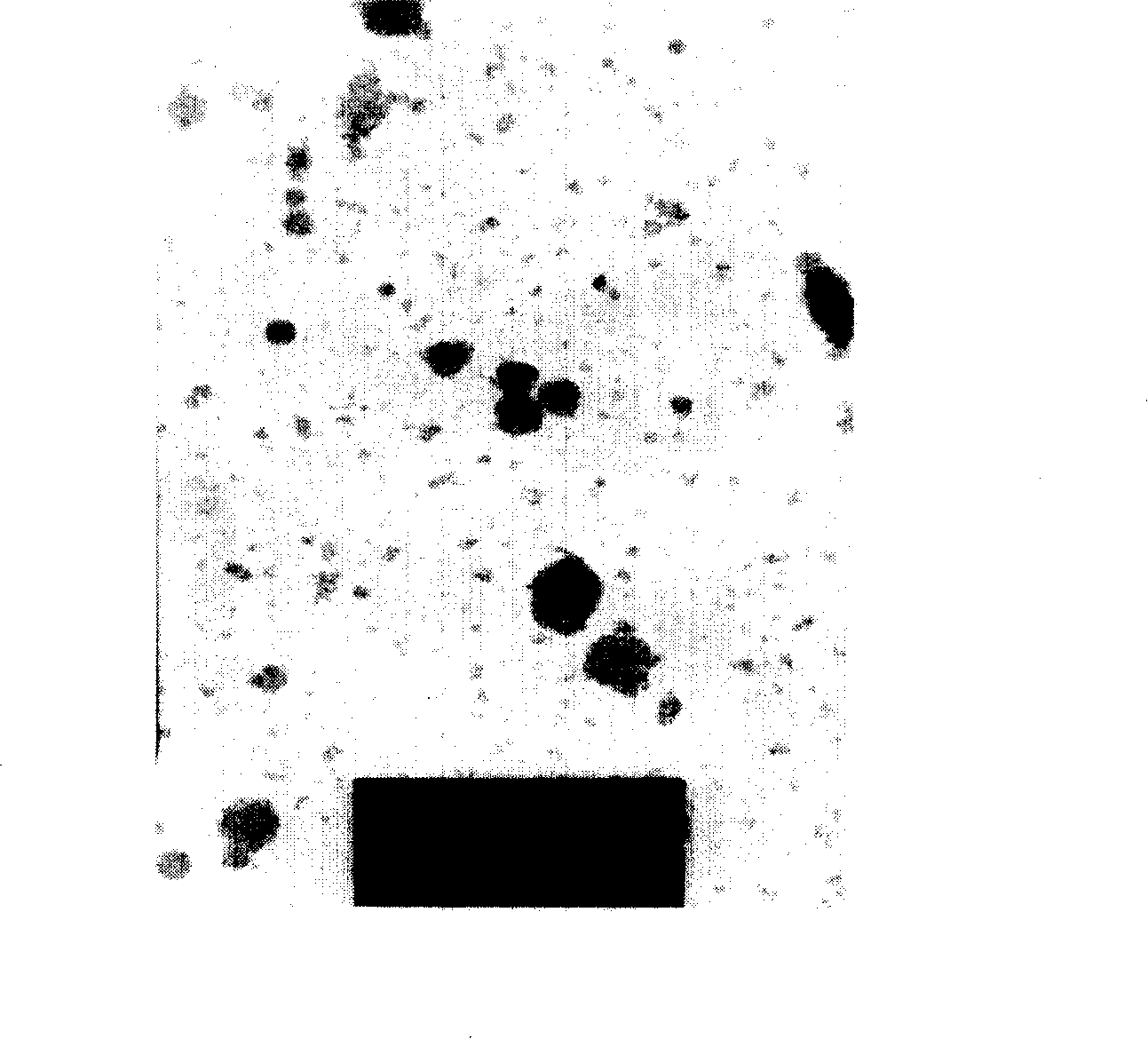

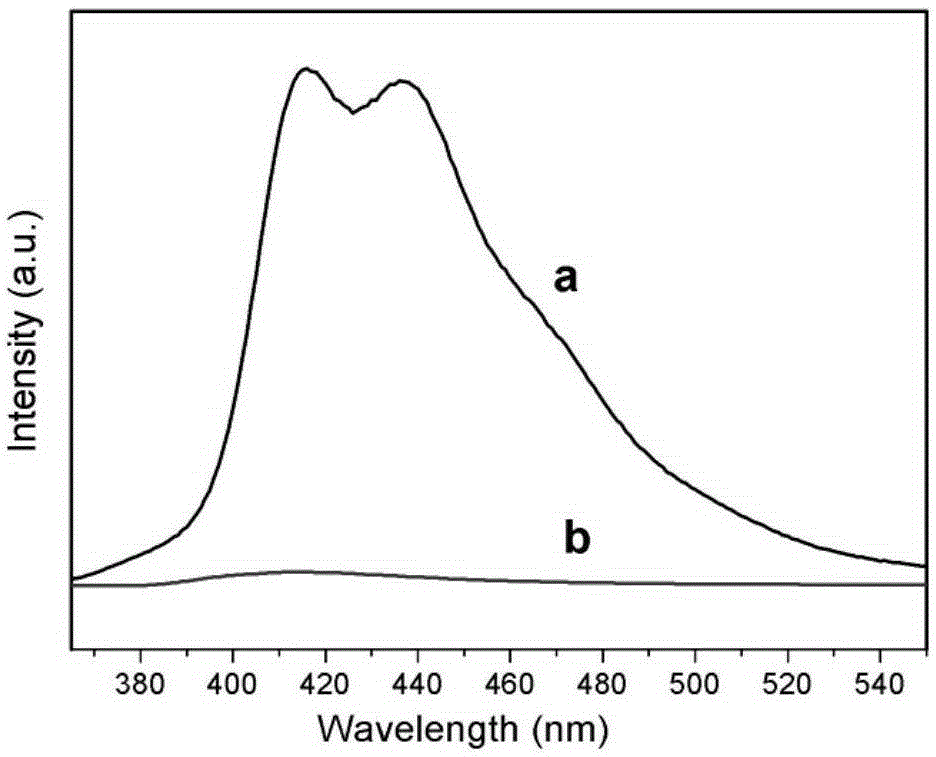

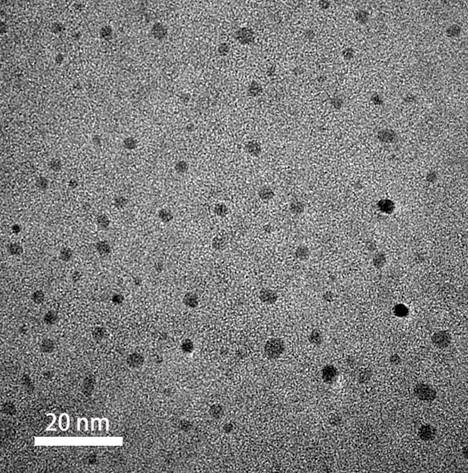

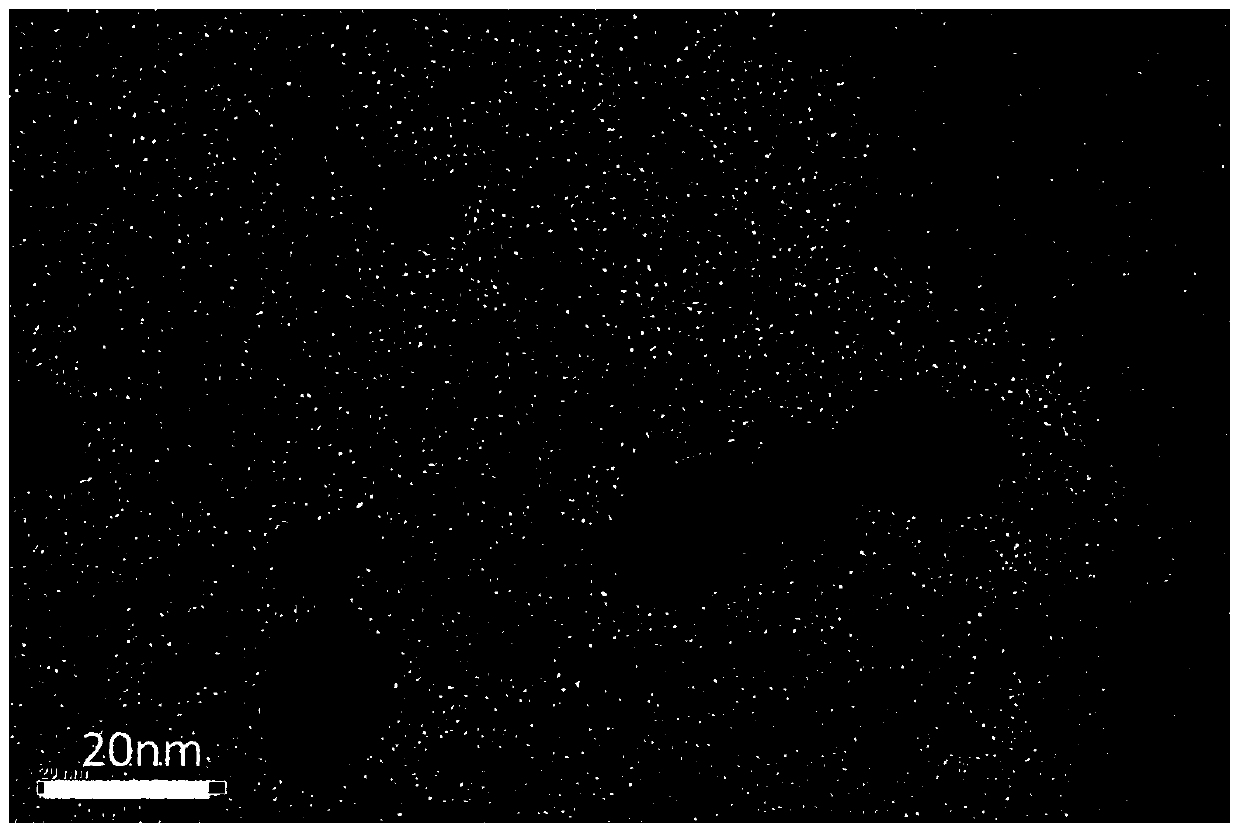

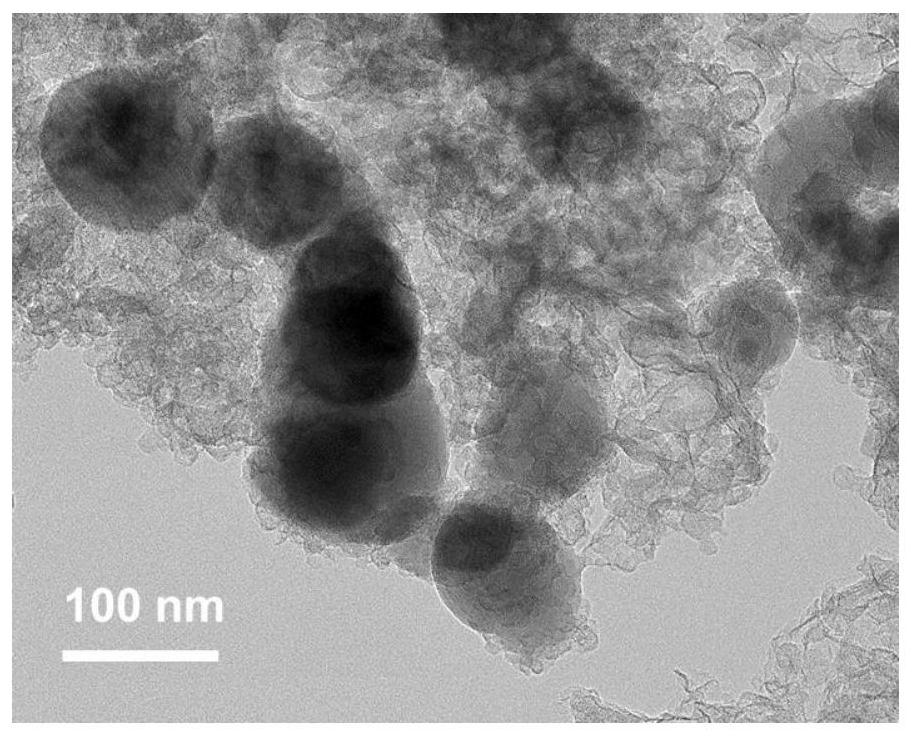

Carbon quantum dot loaded cobalt-ruthenium alloy composite material, preparation method and application thereof

ActiveCN111939930ALimit growthRealize synergistic catalysisHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsCarbon filmPtru catalyst

The invention belongs to the technical field of ammonia borane hydrolysis, and discloses a carbon quantum dot loaded cobalt-ruthenium alloy composite material, a preparation method and application thereof. The method comprises: preparing a carbon quantum dot solution with the concentration of 26 g / L; fully dissolving a water-soluble salt of Co and a water-soluble salt of Ru in a carbon quantum dotsolution according to a molar ratio of Co to Ru of 1:(1-0.1), carrying out hydrothermal treatment at 160-200 DEG C for 4-10 hours, centrifuging, and drying to obtain precursor powder; and placing theprecursor powder in an inert atmosphere, and roasting for 4-8 hours at a temperature of 400-800 DEG C to obtain the carbon quantum dot loaded cobalt-ruthenium alloy composite material. The inventiondiscloses application of a carbon quantum dot loaded cobalt-ruthenium alloy composite material as an ammonia borane hydrogen production catalyst. According to the invention, by compounding carbon quantum dots and cobalt-ruthenium alloy nanoparticles, a large specific surface area can be provided, so that the metal nanoparticles are more uniformly dispersed on the surface of the material, and the supporting effect of the carbon film can effectively prevent the particles from growing up and agglomerating after long circulation; and the catalytic activity is improved by utilizing the mutual synergistic effect of the carbon quantum dots and the cobalt-ruthenium alloy.

Owner:ZHENGZHOU UNIV

Graphitized active carbon-based composite additive, preparation method and applications thereof

InactiveCN108123103AHigh specific surface areaImprove electronic conductivityElectrochemical generatorsHybrid capacitor electrodesActive carbonCharge and discharge

The invention relates to a graphitized active carbon-based composite additive, a preparation method and applications thereof, wherein the additive is metal-element-containing graphitized active carbonparticles, the carbon particles contain 0.1-50 wt% of carbon with a graphite structure, the specific surface area of the active carbon particles is 100-3000 m<2> / g, the electric conductivity of the active carbon particles is 0.01-100 S / cm, the metal element is one or more than two selected from Sn, Pb, Bi, Ce, In and Zn, and the metal element content in the additive is 0.01-30 wt%. According to the present invention, the lead-carbon battery negative electrode prepared by using the graphitized active carbon as the additive has advantages of high charge and discharge reversibility, high chargeand discharge cycle life and high charge acceptance compared to the conventional lead acid battery negative electrode.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Preparation method of lithium iron phosphate cathode material

InactiveCN106848261AGood hole conductivityIncreased electronic conductivity and ion diffusion rateSecondary cellsPositive electrodesCarbon coatingDispersed media

The invention discloses a preparation method of a lithium iron phosphate cathode material. The preparation method comprises the following steps of (1), dispersing iron phosphate into a dispersing agent, so as to obtain dispersion liquid A of the iron phosphate; (2), dispersing a lithium carbonate and magnesium chloride doping agent into a dispersing agent, so as to obtain lithium source-magnesium source doping agent dispersion liquid B; (3), slowly adding the dispersion liquid A of the iron phosphate into the lithium source-magnesium source doping agent dispersion liquid B, enabling an obtained first mixture to react to make a coarse material of a lithium iron phosphate material; (4), grinding and uniformly mixing the coarse material of the lithium iron phosphate material and carbon-source glucose in a dispersing medium ethanol, drying an obtained second mixture, sintering the second mixture for 12h to 24h at a temperature of 700 to 750 DEG C in a protective atmosphere of a nitrogen gas, and naturally cooling the second mixture to a room temperature, so as to obtain the lithium iron phosphate cathode material. The non-in-situ carbon coating is adopted by the preparation method; meanwhile, the carbon coating is carried out in a sintering process; the increment of a crystal particle of the lithium iron phosphate material in a long-time high-temperature sintering process is limited; the electronic conductivity and the ion diffusion rate of the material are further improved; the lithium iron phosphate cathode material has better rate charging and discharging performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY CO LTD CO LTD

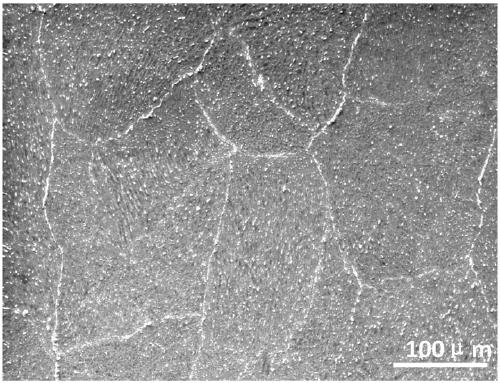

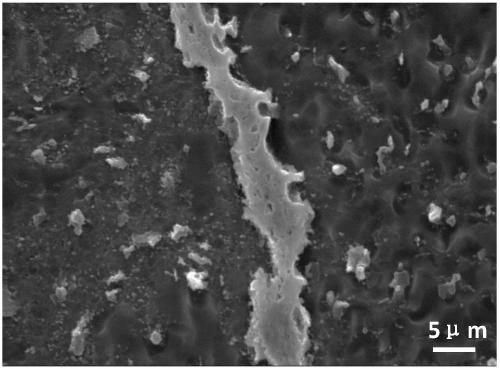

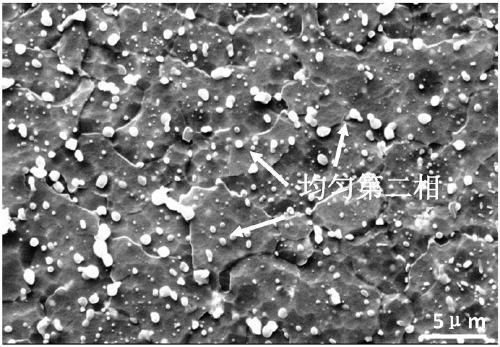

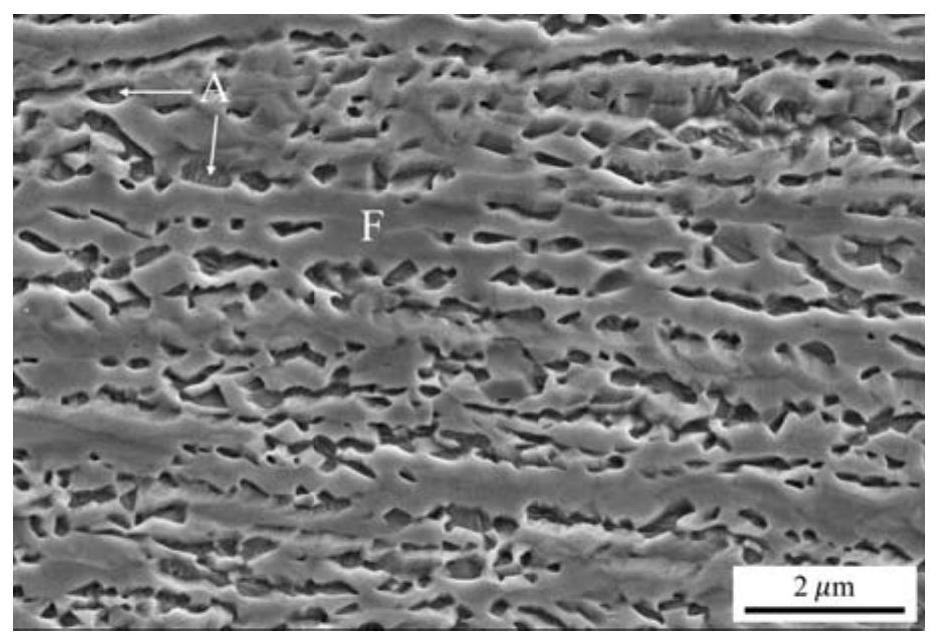

Method for preparing and controlling second phase homogenization in high-aluminum-content cast-rolled magnesium alloy plate

The invention relates to a method for preparing and controlling a second phase homogenization in a high-aluminum-content cast-rolled magnesium alloy plate. The method comprises the following steps ofheating stepped solid solution treatment, high-temperature multi-pass rolling deformation, cooling multi-pass rolling deformation and recrystallization annealing treatment. By means of the method, a mesh-strip-shaped segregation second phase of a millimeter-scale size in an initial tissue is eliminated, a fine near-spherical second phase with uniform dispersion distribution is obtained, and the fine crystal structure is obtained at the same time. According to the method, a method combining heat treatment and common rolling is adopted, and no barrier is implemented in industrial production. Theproblem that the high-aluminum-content cast-rolled magnesium alloy is difficult to deform and serious in rolling cracking is solved, so that a magnesium alloy sheet material which is good in macroscopic morphology, uniform in microstructure and super-close in comprehensive performance is obtained.

Owner:JILIN UNIV

Welding wire for high-strength 7xxx aluminum alloy and composite material, and preparation method thereof

InactiveCN111139384AReduce the risk of reunionsLimit growthWelding/cutting media/materialsSoldering mediaAluminum matrix compositesAluminium alloy

The invention discloses a welding wire for a high-strength 7xxx aluminum alloy and a composite material, and a preparation method thereof. The welding wire is a 7xxx-series aluminum matrix composite material and comprises the following elements in percentage by weight: 6.7 to 12 percent by weight of Zn, 2.0 to 2.8 percent by weight of Mg, 2.0 to 2.5 percent by weight of Cu, 0.1 percent by weight of Si, 0.1 percent by weight of Fe, 0.1 percent by weight of Sc, 4 to 8 percent by weight of reinforced-phase TiB2, and the balance Al.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing a silver-based electric contact material

The invention discloses a method for preparing a silver-based electric contact material, which comprises the following steps of: adopting a method for performing injection and atomization on both solid phase powder and a liquid phase metal to obtain reinforced phase composite powder coated with a metal; and adopting a preparation means of subsequent sintering, hot pressing and squeezing to densify the composite powder so as to form the silver-based electric contact material. In the electric contact material, the reinforced phase form is granular, the reinforced phase average particle size is between 0.1 and 100 mum, and the reinforced phase weight content in the electric contact material is less than or equal to 20 percent. The electric contact material prepared by the method has the advantages of good arc ablation resistance, high conductivity and excellent mechanical properties, and the arc resistance, the conductivity, and the strength of the electric contact material are improved respectively compared with those of a same-system material prepared by the conventional powder metallurgy method.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

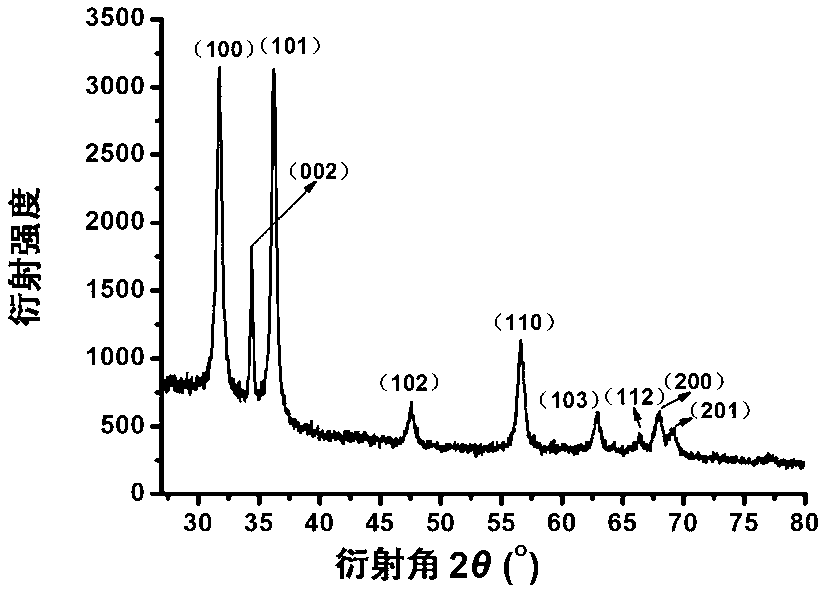

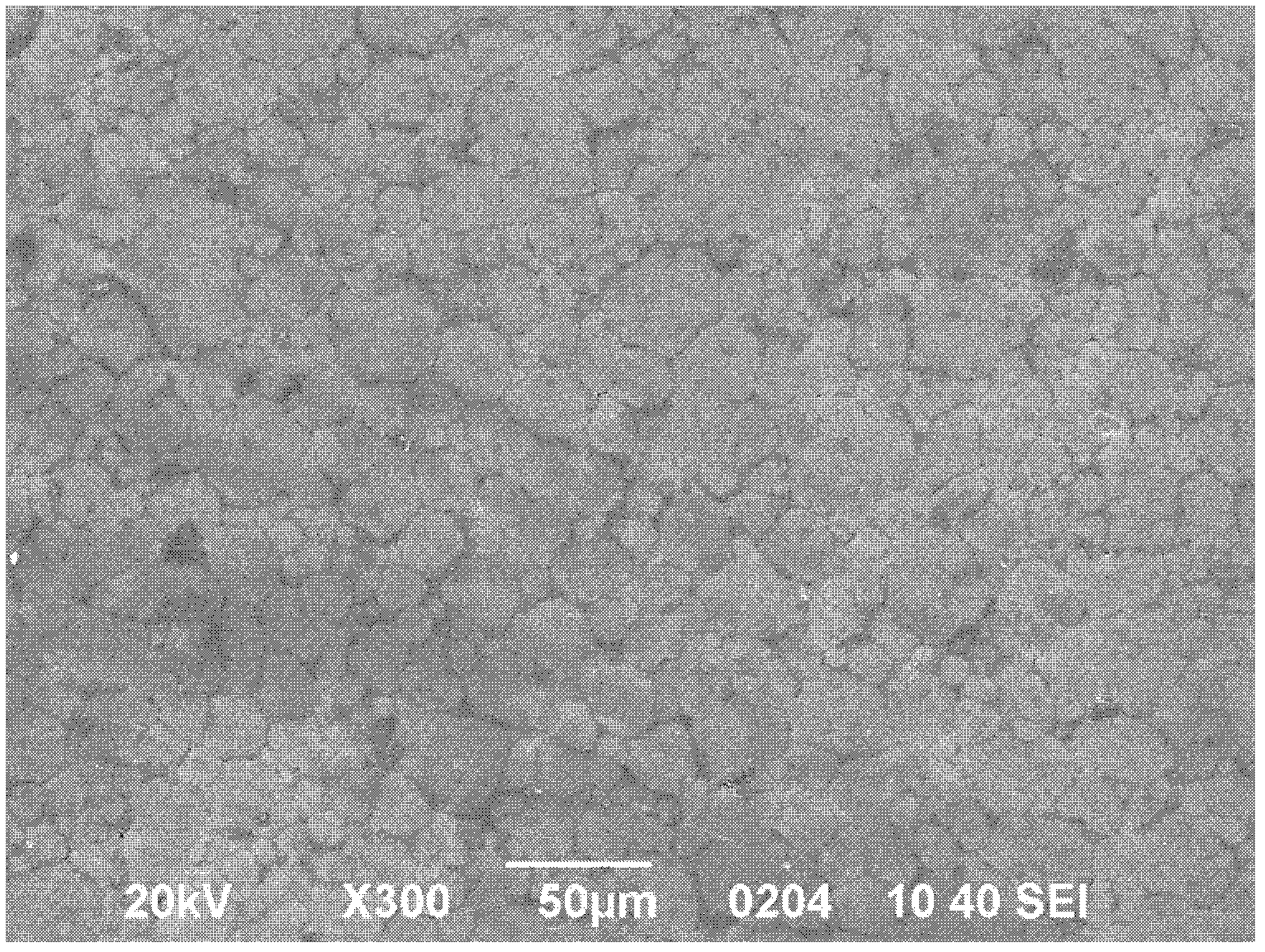

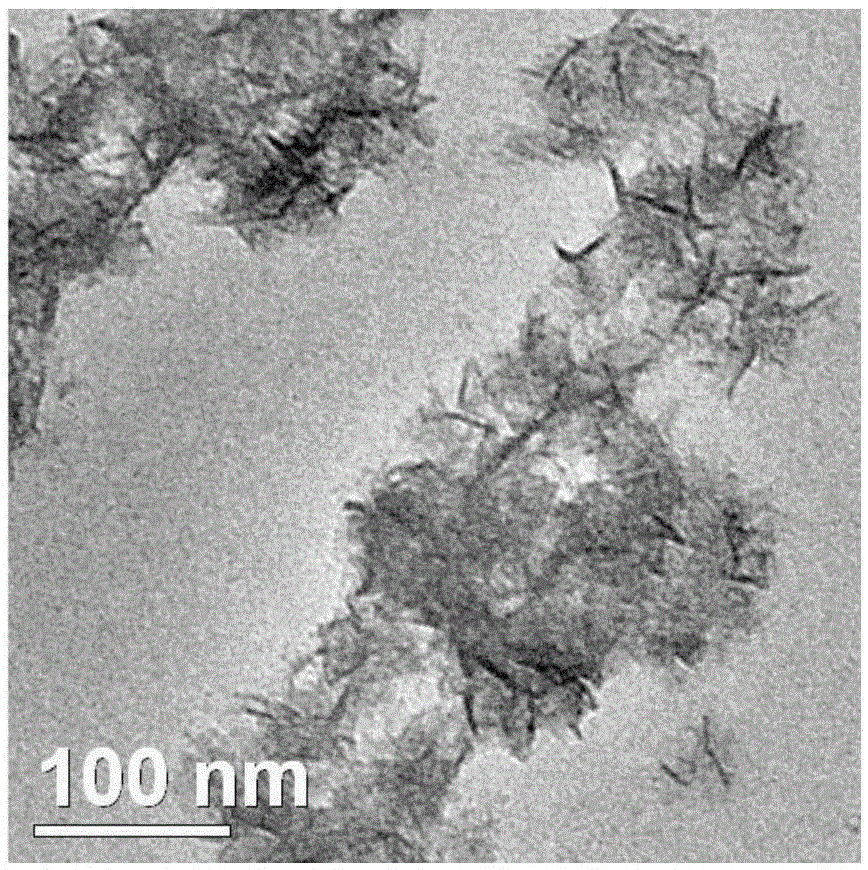

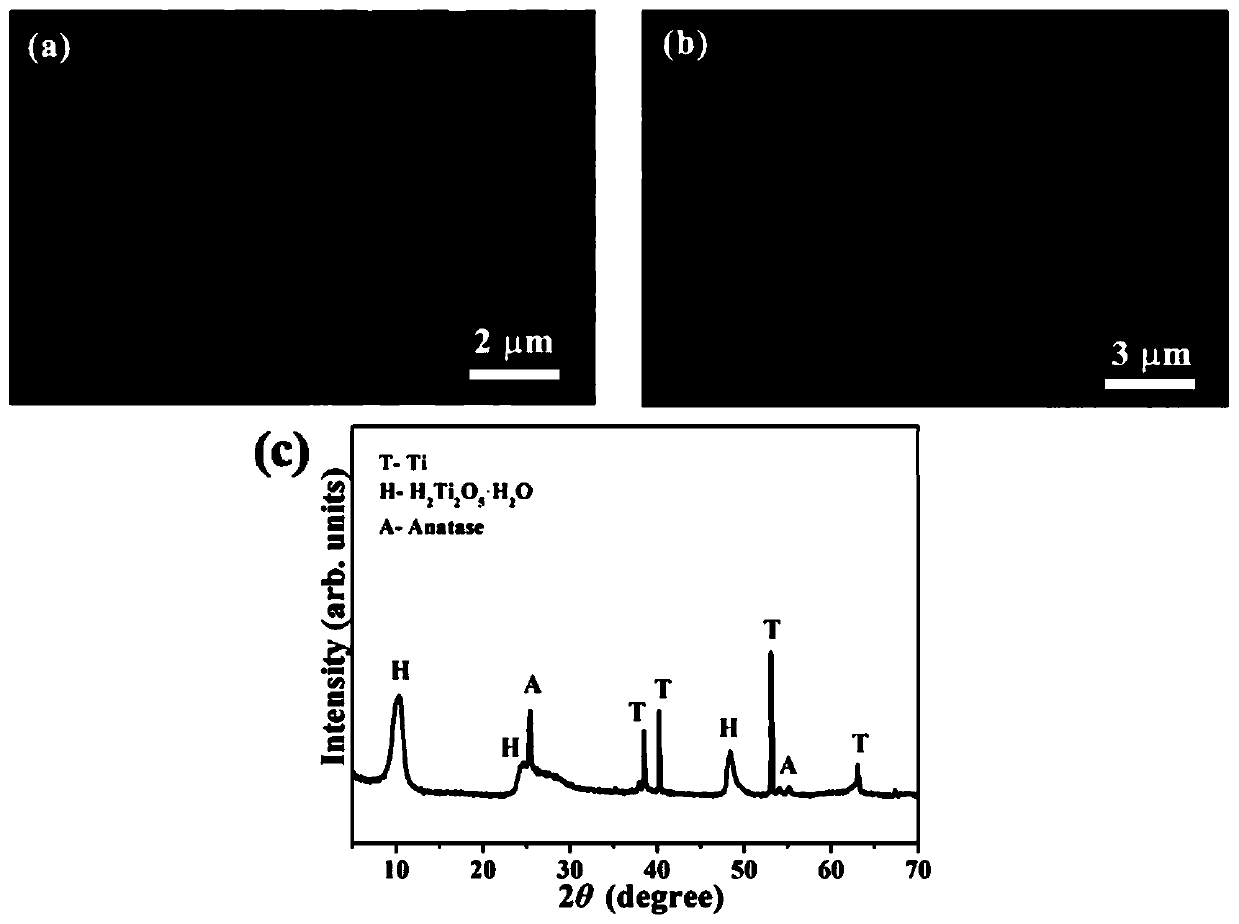

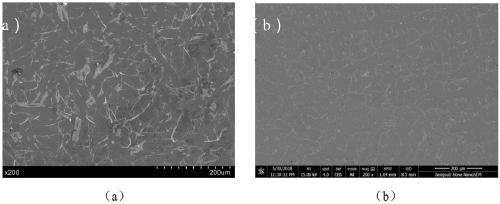

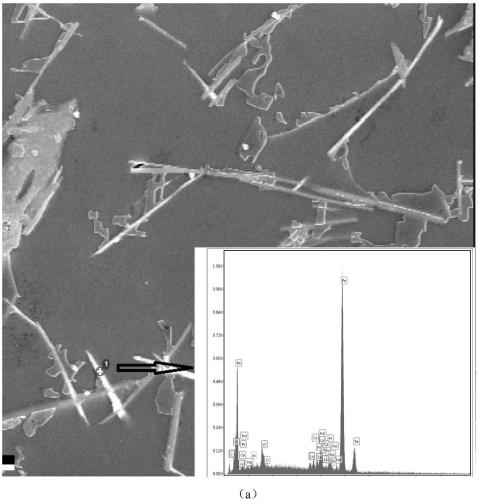

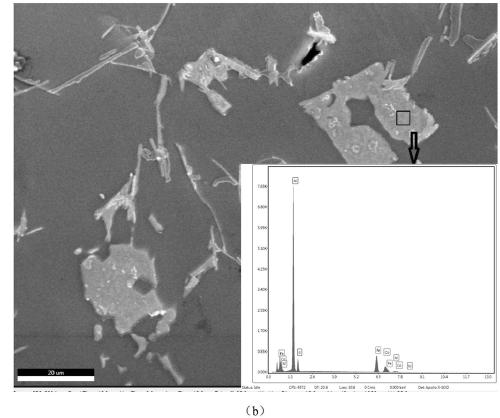

In-situ preparation method of titanium dioxide-based metal oxide composite nano-catalyst material

InactiveCN110833829AMature technologyLow costMetal/metal-oxides/metal-hydroxide catalystsNano catalystPtru catalyst

The invention relates to the fields of in-situ growth, morphology and density regulation of titanium dioxide-based metal oxide catalysts, environmental catalytic purification, oxidation film formation, nano-materials and nanotechnology, and concretely relates to an in-situ preparation method of a titanium dioxide-based metal oxide composite nano-catalyst material. A metal oxide seed layer directlygrows on the surface of a metal substrate by using a liquid-phase plasma discharge technology, the metal substrate can be in any shape, a nano-material directly grows on the surface of the seed layerby combining hydrothermal and ion exchange processes, and surface modification is carried out. The prepared titanium dioxide-based metal oxide catalyst material has the advantages of strong film-substrate binding force, good crystallinity, large active area, uniform material size, uniform growth distribution, adjustable morphology and high catalytic activity, and can be applied to the fields of photocatalytic degradation of organic pollutants, automobile tail gas treatment, denitration and desulfurization treatment, industrial waste gas treatment, CO catalytic oxidation and related environment catalytic purification.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for synthesizing carbon-coated lithium ferrous pyrophosphate by hydrothermal method

ActiveCN103985870ALow costSave the wrapping processCell electrodesSecondary cellsWater bathsSynthesis methods

The invention discloses a method for synthesizing carbon-coated lithium ferrous pyrophosphate by a hydrothermal method. The method comprises the following steps of (1) weighing raw materials, dissolving a carbon source into distilled water or deionized water, and heating, stirring and dissolving in a water bath at the temperature of 50-90 DEG C; respectively dissolving a lithium source, an iron source and a phosphorus source into the deionized water, uniformly stirring the sources, sequentially adding the iron source and the lithium source into a solution dissolved with the carbon source, adding ammonia water to adjust the pH of the mixed solution to 4-6, adding the phosphorus source, heating the mixed solution in the water bath at the temperature of 50-90 DEG C, and stirring for 1-2 hours; (2) performing reaction on the mixed solution at 150-350 DEG C and the pressure of 1-10MPa for 3-10 hours, cooling to room temperature after the reaction is finished, and performing solid-liquid separation to obtain a solid which is a precursor solid-phase product; (3) drying the precursor solid-phase product, and then sintering to obtain the carbon-coated lithium ferrous pyrophosphate. The method has the advantage that the reaction temperature is relatively low, and the synthesis method is simple; the prepared carbon-coated lithium ferrous pyrophosphate serving as a positive electrode material is excellent in electrochemical performance.

Owner:CENT SOUTH UNIV

Magnetic particle reinforced Al matrix composite and preparation method thereof

ActiveCN109402455AHigh strengthImprove magnetic permeabilityMagnetic materialsSynthesis methodsThermal expansion

The invention provides a magnetic particle reinforced Al matrix composite and a preparation method thereof. The composite is prepared from submicron sized Nd2Fe14B particles as a reinforcing phase with a melt direct synthesis method, that is, submicron Nd-Fe-B powder is added to pure Al or Al alloy melt. The magnetic particle reinforced Al matrix composite has the characteristics of high magnetism, low cost, high strength, high wear resistance, low thermal expansion and low residual stress, and is a novel magnetic function and structure reinforced material. The preparation method is simple andefficient, and is worthy of development and popularization.

Owner:JIANGSU UNIV

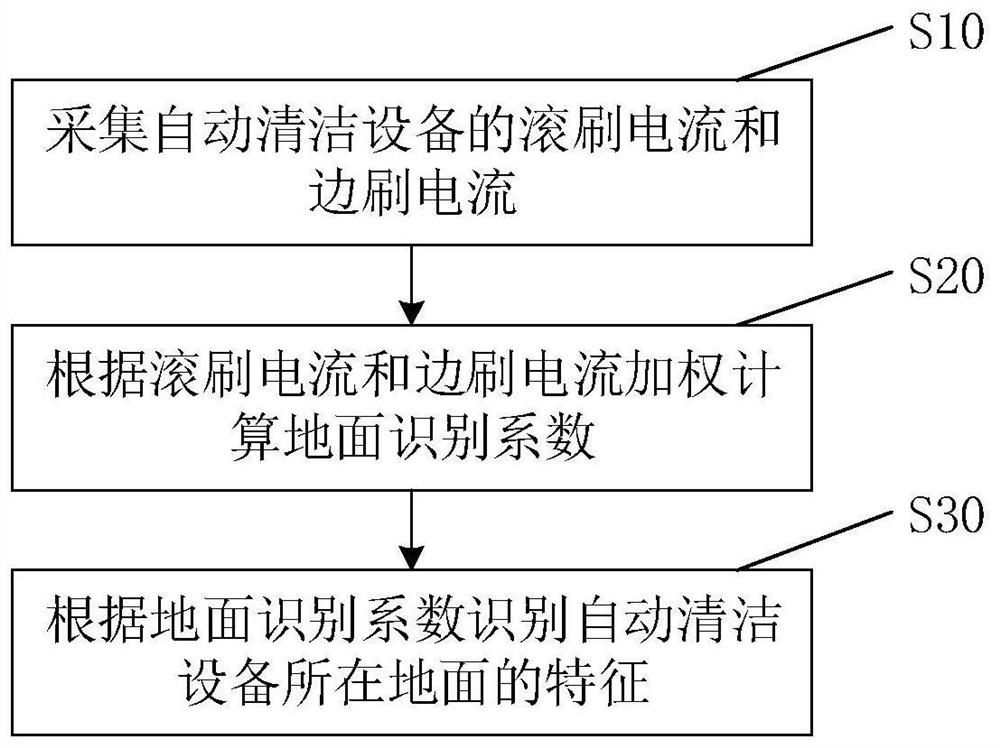

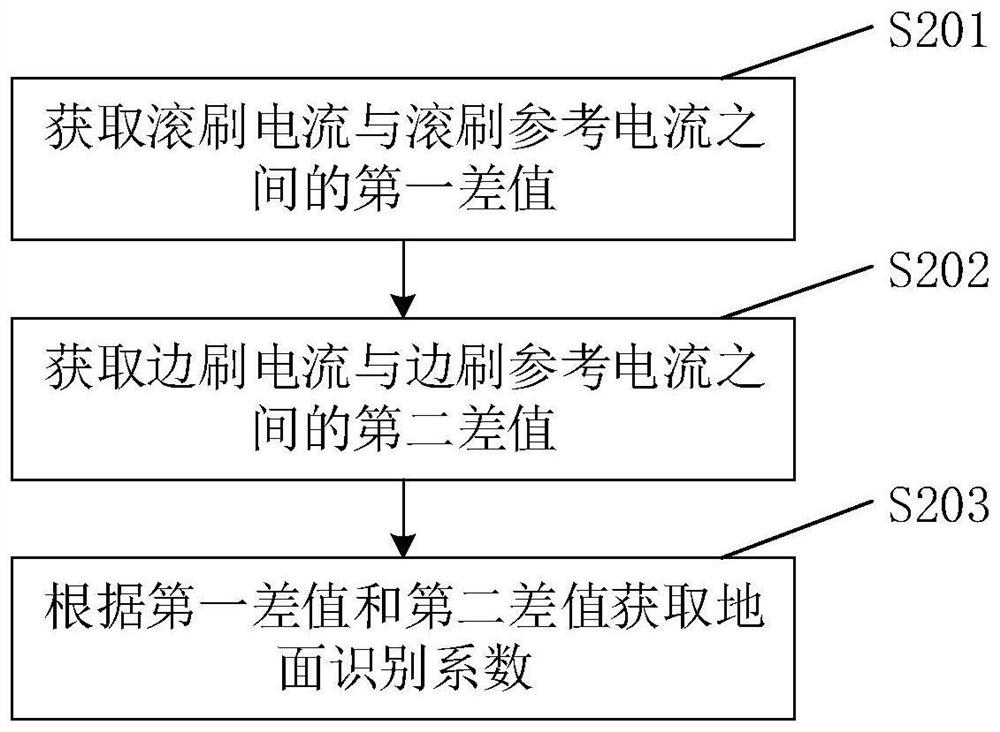

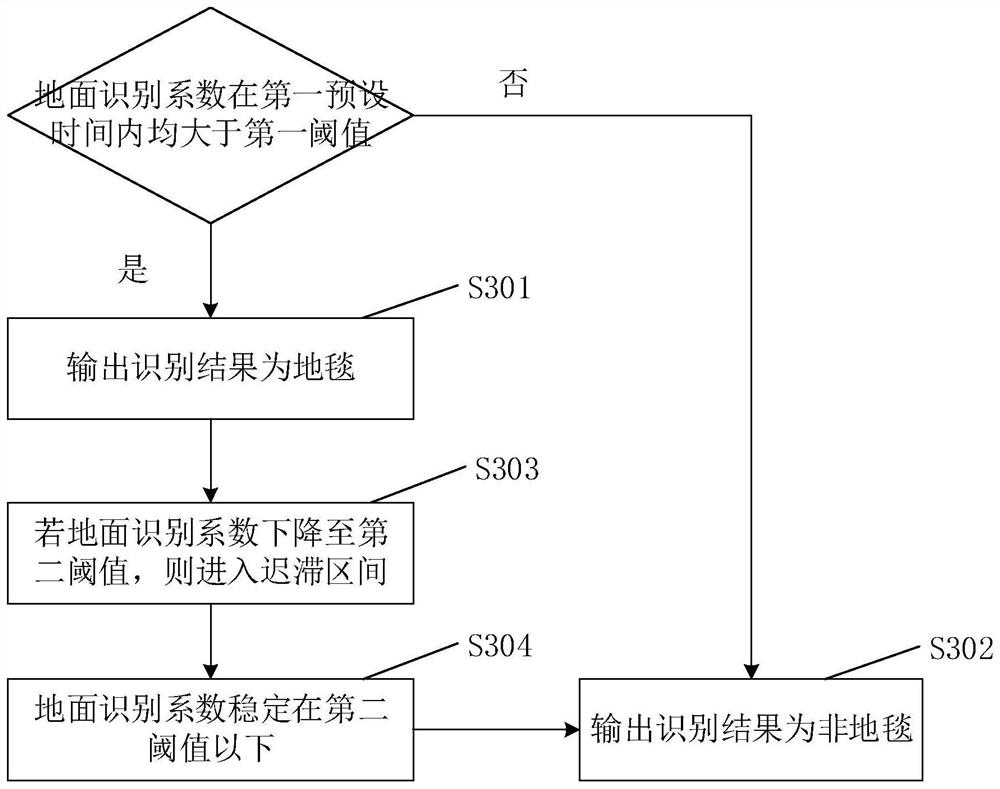

Method and device for recognizing ground features by automatic cleaning equipment

ActiveCN112137505ALimit growthImprove accuracyCarpet cleanersCleaning action controlProcess engineeringBrush

The invention discloses a method and a device for identifying ground features by automatic cleaning equipment. The method comprises the following steps: collecting rolling brush current and side brushcurrent; calculating a ground recognition coefficient according to the rolling brush current and the side brush current in a weighted manner; and identifying the characteristic that the ground wherethe automatic cleaning equipment is located is a carpet or non-carpet medium surface according to the ground identification coefficient. Software optimization is carried out on the basis of the current detection technology, and the false identification rate is reduced while no extra cost exists.

Owner:DREAM INNOVATION TECH (SUZHOU) CO LTD

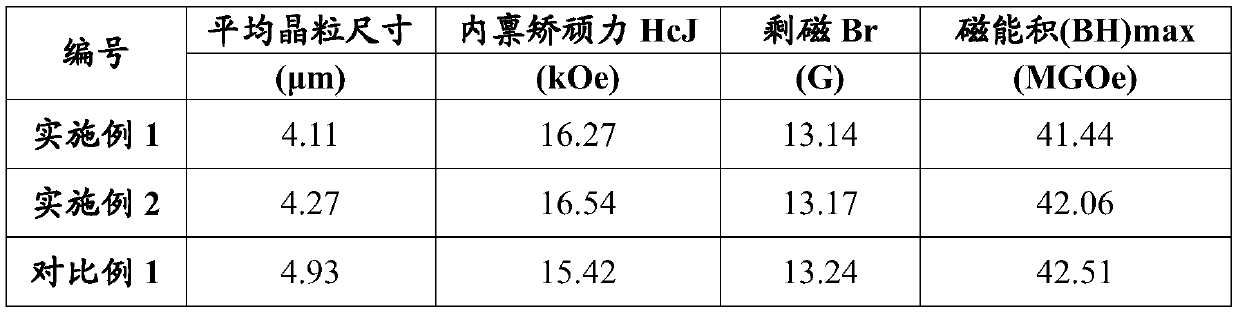

Method for improving coercive force of sintered neodymium iron boron magnet

ActiveCN110033914AGood wettabilityFacilitate liquid phase flowInductances/transformers/magnets manufactureMagnetic materialsTungstenNeodymium iron boron

The invention discloses a method for improving coercive force of a sintered neodymium iron boron magnet. The method comprises the following steps that (1) neodymium-iron-boron fine powder is preparedfrom the following components: 26-35wt% of Pr-Nd alloy, 0.1-0.8wt% of Al, 0.01-0.3wt% of Cu, 0.5-1.5wt% of B and the balance of Fe, wherein the average particle size of the neodymium-iron-boron fine powder is 0.5-10 microns; and (2) the neodymium-iron-boron fine powder, tungsten powder and Cu-Ga alloy are mixed uniformly and then magnetic field orientation compression molding, isostatic pressing,vacuum sintering and tempering treatment are carried out to obtain the sintered neodymium iron boron magnet. According to the method disclosed by the invention, the sintered neodymium iron boron magnet with relatively small grain size and relatively high coercive force can be obtained and free of heavy rare earth can be obtained.

Owner:BAOTOU RES INST OF RARE EARTHS

Preparation method for active carbon loaded tungsten carbide nanometer composite powder used as electrocatalyst

ActiveCN110368970AShort processLow costPhysical/chemical process catalystsCarbonizationTransfer Ability

The invention discloses a preparation method for an active carbon loaded tungsten carbide nanometer composite powder used as an electrocatalyst. The preparation method comprises the following steps: synthesizing an active carbon loaded violet tungsten oxide precursor powder through a liquid phase method, then placing the precursor into a mixed atmosphere of methane and hydrogen, and carrying out carbonization so as to obtain a active carbon loaded nanometer tungsten carbide nanometer composite powder. The nanometer composite powder provided by the invention has high loading efficiency and large loading capacity, realizes uniform distribution of tungsten carbide in the pore channels of active carbon, and can inhibit growth of tungsten carbide crystalline grains; through the porous structureof the active carbon, the specific surface area, transfer ability and stability of the composite powder are improved; and the nanometer composite powder has high oxygen reduction reaction (ORR) catalytic performance and long-term stability.

Owner:HEFEI UNIV OF TECH

Preparation method of high-dispersibility silicon dioxide micro-powder

InactiveCN108529636AHigh adsorption activityImprove adsorption capacityMaterial nanotechnologySilicon compoundsAmmonium hydroxideSilicon dioxide

The invention relates to the technical field of preparation of silicon micro-powder and particularly relates to a preparation method of high-dispersibility silicon dioxide micro-powder. The preparation method comprises the following steps: firstly, taking animal blood as a raw material, and performing enzymolysis and heating to remove impure protein to obtain biomass extract rich in heme iron; reducing the heme iron to ferrous ions with hydrochloric acid to obtain protein reaction liquid rich in ferrous ions; then, precipitating parts of ferrous ions with ammonium hydroxide, performing etherification reaction with hydroxyl in the reaction liquid through an etherifying agent, and introducing a propyl sulfonate group into the reaction liquid to obtain home-made functional liquid; and addingthe home-made functional liquid to the reaction liquid of sodium silicate and hydrochloric acid to finally obtain the high-dispersibility silicon dioxide micro-powder. The prepared silicon dioxide micro-powder has excellent dispersibility, is not easy to agglomerate, is uniform in particle size and has wide application prospects.

Owner:FOSHAN GAOMING DISTRICT ZHUAHE NEW MATERIAL TECH CO LTD

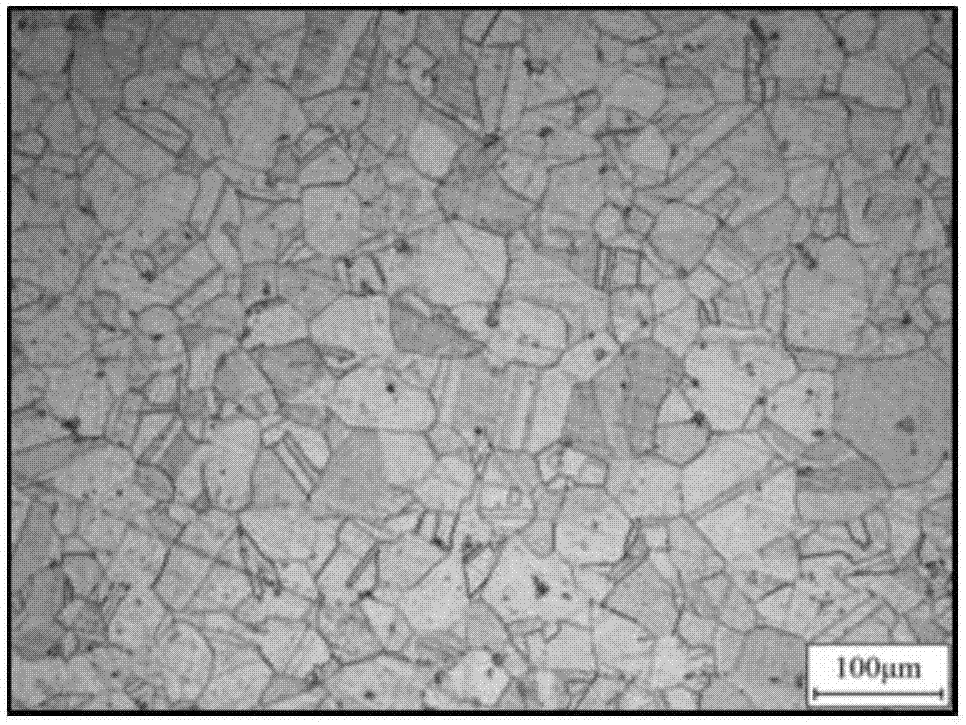

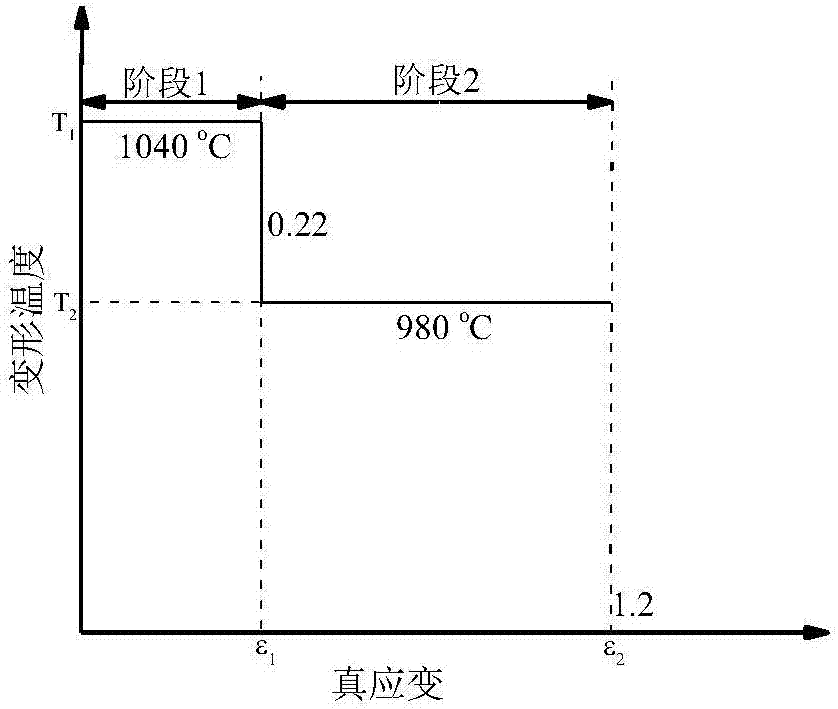

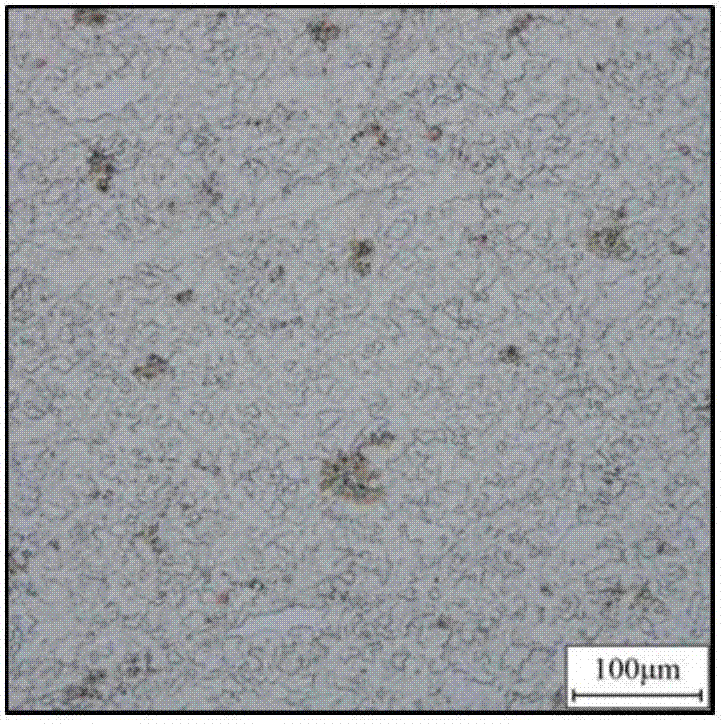

Method for refining grain structure of nickel-based alloy forging by regulating and controlling deformation temperature

The invention discloses a method for refining the grain structure of a nickel-based alloy forging by regulating and controlling the deformation temperature. The method comprises the following steps: (1) performing solid solution treatment on the nickel-based alloy forging stock and quenching; (2) performing plastic deformation on the nickel-based alloy forging stock on the condition that the strain rate is 0.001 s[-1]-0.1 s[-1]: firstly, heating the forging stock to a deformation temperature of 1030-1050 DEG C, and secondarily performing deformation after performing heat preservation on the forging stock until the forging stock is uniform in temperature, wherein the deformation process comprises two stages, the deformation amount at the first stage is 20%-40%, the deformation temperature is reduced to 950-1010 DEG C after the completion of deformation, the second-stage deformation is carried out until the forging stock after heat preservation is uniform in temperature, and the total deformation amount of the forging stock at the two stages is 60%-70%; and (3) immediately quenching the forging after the completion of deformation. According to the method for refining the grain structure of the nickel-based alloy forging by regulating and controlling the deformation temperature, the grain structure of the nickel-based alloy forging is refined by regulating and controlling the deformation temperature, and an effective means is provided for the manufacture of high quality forgings.

Owner:CENT SOUTH UNIV

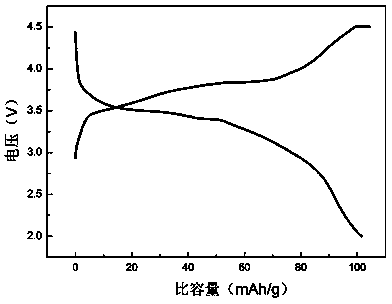

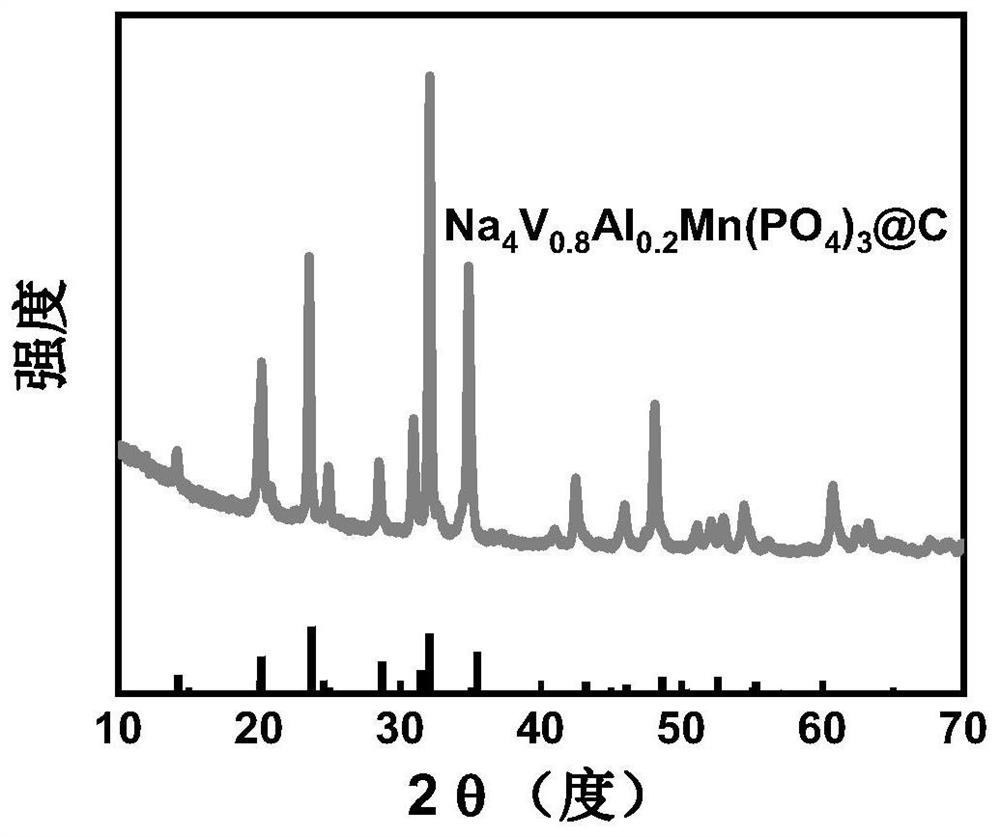

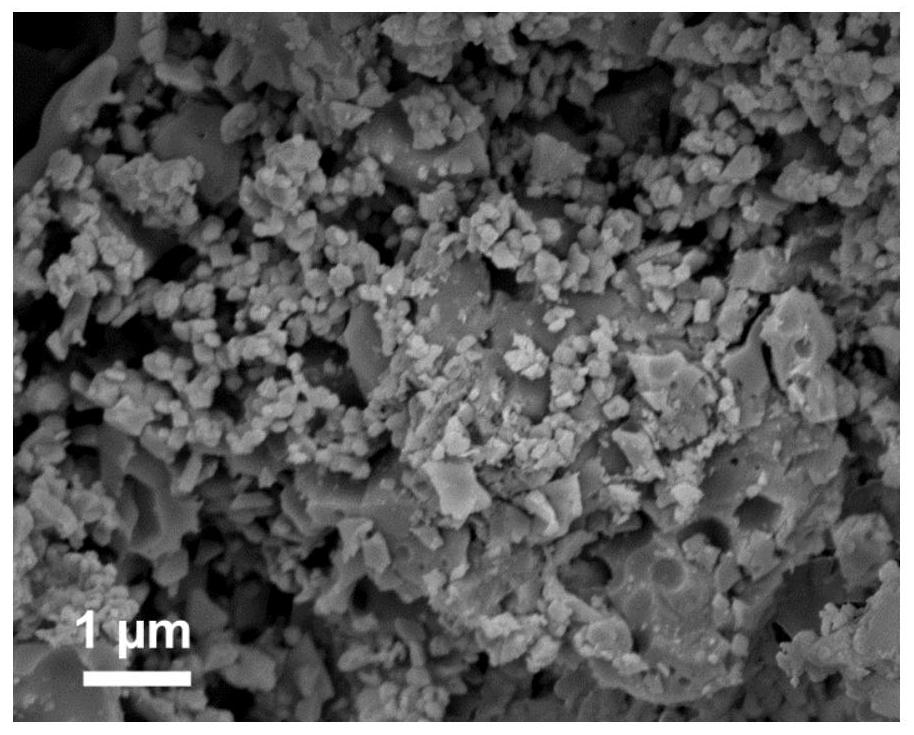

Phosphate positive electrode material and preparation method and application thereof

InactiveCN112421040AIncrease discharge voltageImproved magnification performanceSecondary cellsPositive electrodesCarbon coatingElectrical conductor

The invention provides a phosphate positive electrode material and a preparation method and application thereof. The phosphate positive electrode material comprises an inner core and a carbon coatinglayer formed on the surface of the inner core, wherein the inner core comprises Na4+deltaV1-xMxMn(PO4)3. The chelating effect between an organic carbon source and metal ions is utilized to realize uniform mixing of raw materials and in-situ introduction of a carbon coating layer, so the overall conductivity of the material is improved; half of manganese is introduced to replace vanadium, so that the working voltage of the material is increased while the use amount of vanadium is reduced; then a trace amount of stable metal elements are doped to replace part of vanadium, the use amount of vanadium is further reduced, meanwhile, a solid solution structure is formed by vanadium and manganese, ginger Taylor structure distortion caused by manganese ions is reduced, the three-dimensional sodiumsuper-ion conductor structure of the material can be maintained, and the rate capability of the material is improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

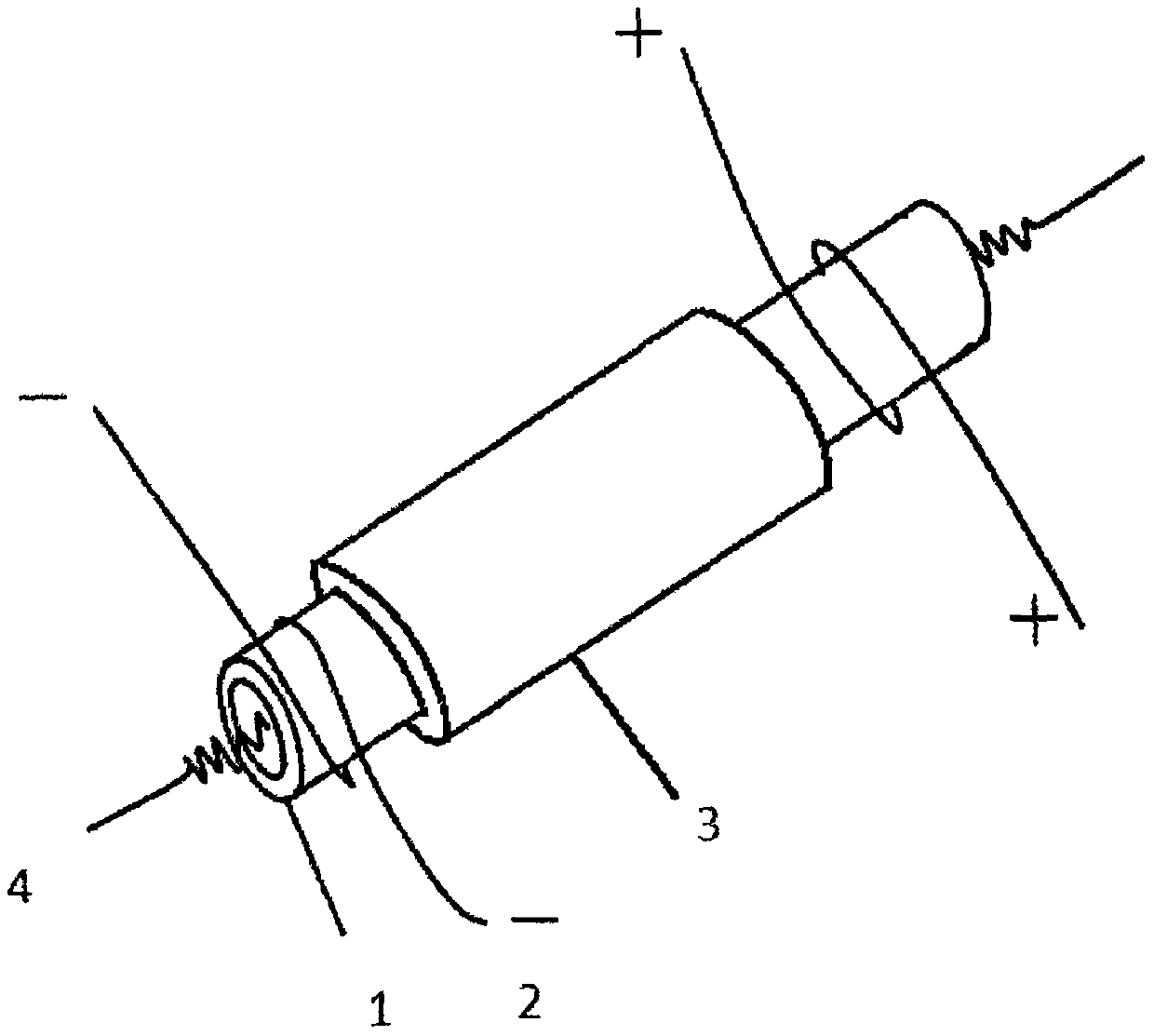

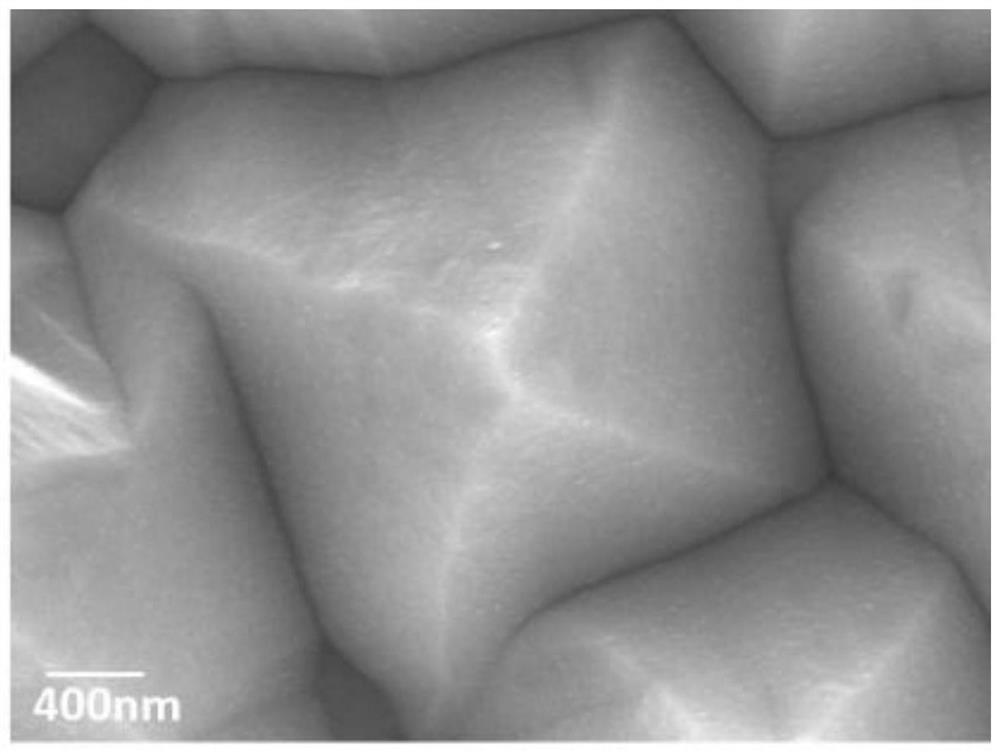

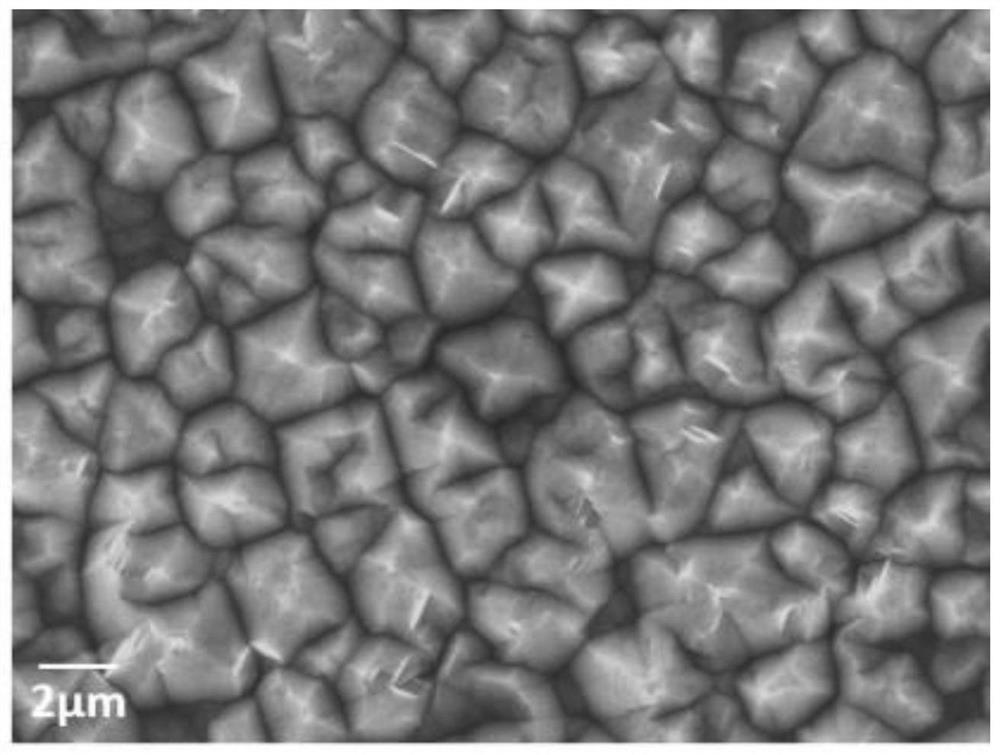

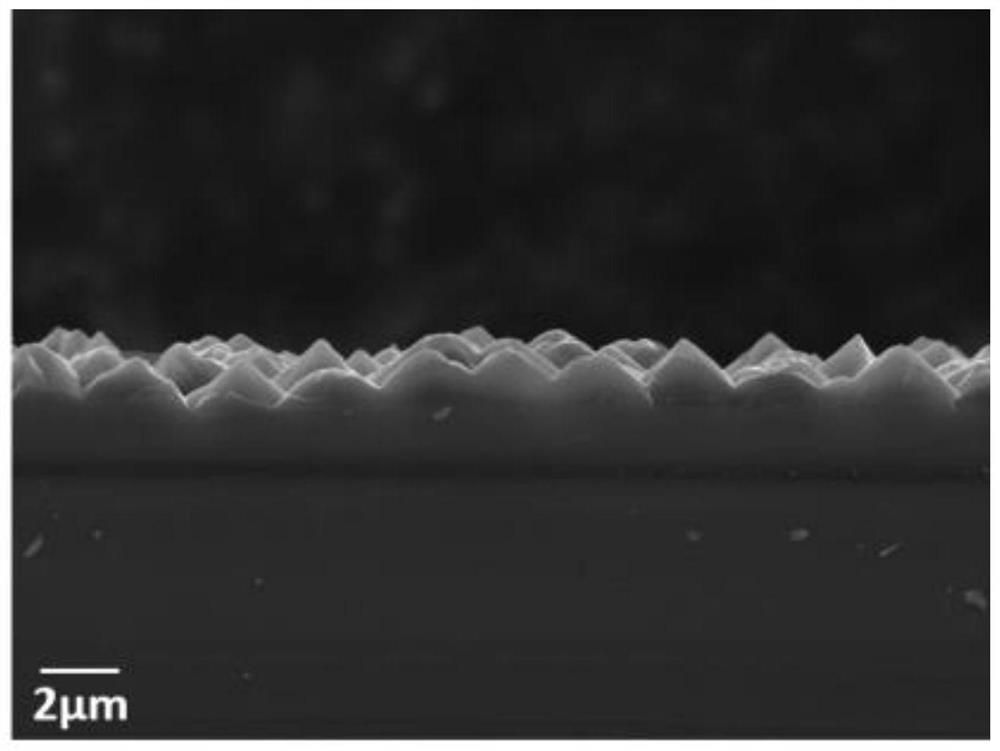

Pyramid rapid texturing solution and texturing method and silicon wafer product thereof

ActiveCN112442739ALow costReduce the effect of sedimentationPolycrystalline material growthAfter-treatment detailsCu2 ionsSilver ion

The invention discloses a pyramid rapid texturing solution and a texturing method and silicon wafer product thereof. The pyramid rapid texturing solution comprises the following main components: a silver ion source, a copper ion source, a fluorine ion source, an oxidant and deionized water. The pyramid rapid texturing solution can be used for rapidly texturing the surface of a silicon wafer at room temperature, an independent, complete, uniform and tightly arranged positive pyramid textured structure can be formed on the surface of the silicon wafer within an extremely short time, the size ofthe structure is 0.5-2 microns, and the surface reflectivity is 8-20%. Compared with existing line production pyramid structures, the pyramid rapid texturing solution has the advantages that: the tower tip is smooth and more uniform in distribution, is very beneficial to back polishing and passivation, and is particularly suitable for existing PERC, HIT, IBC and other efficient battery structures.The pyramid texturing method provided by the invention has the advantages that: the overall reaction time is controlled within 5 minutes, the time cost and the equipment cost can be greatly reduced,and the wide popularization and application are facilitated.

Owner:SONGSHAN LAKE MATERIALS LAB +1

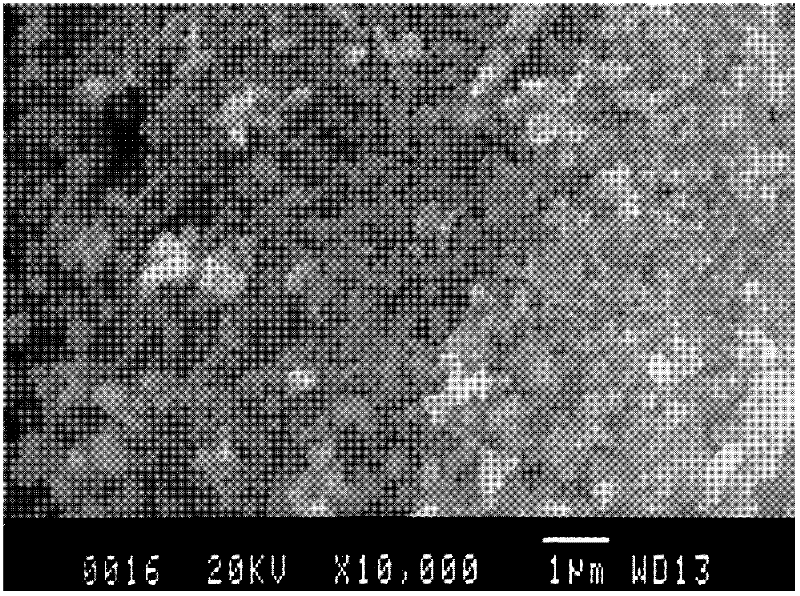

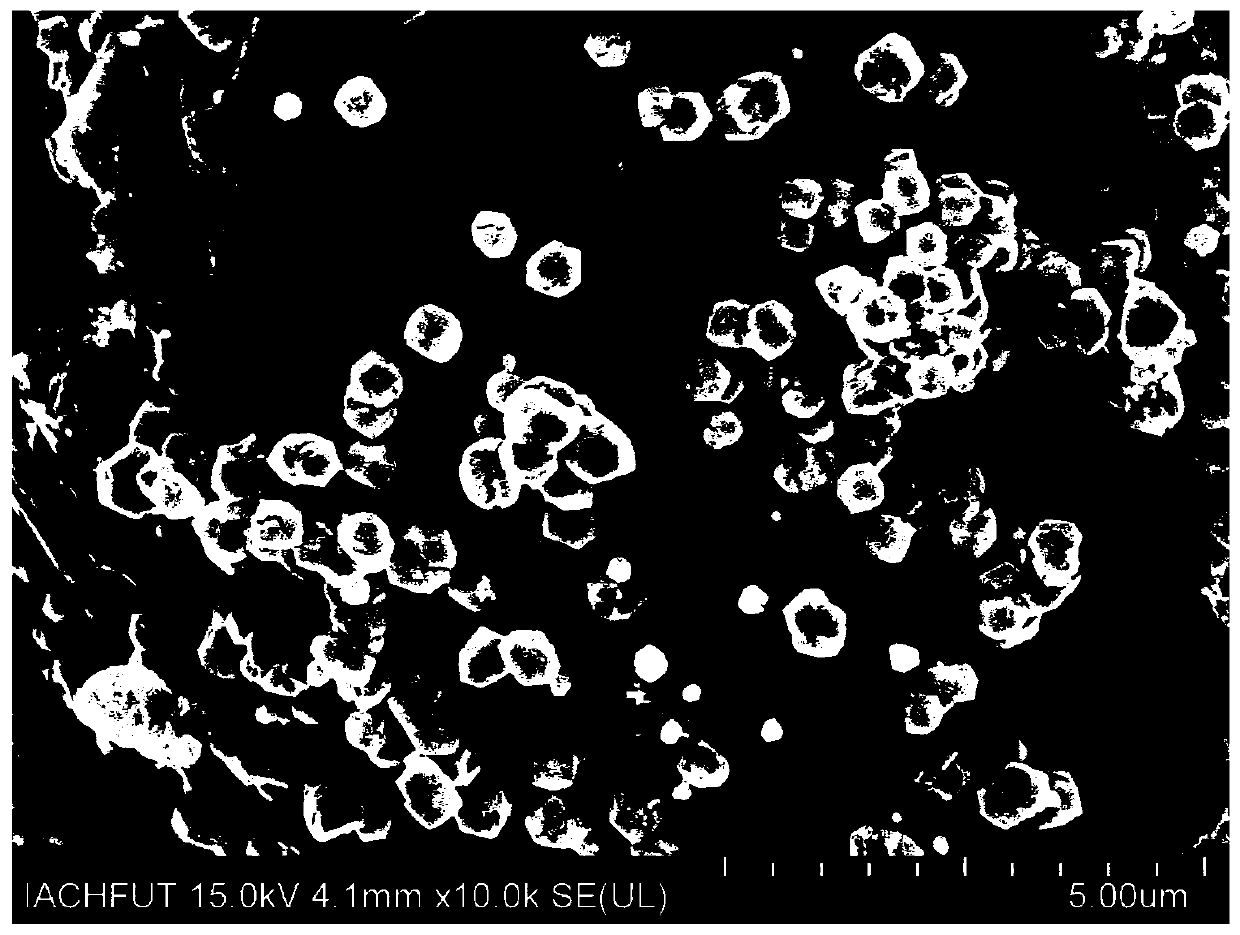

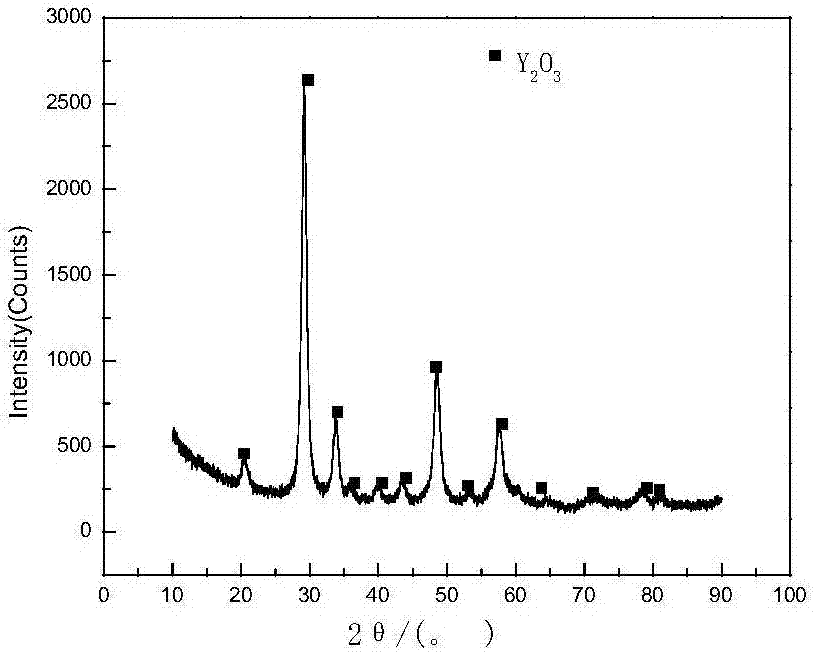

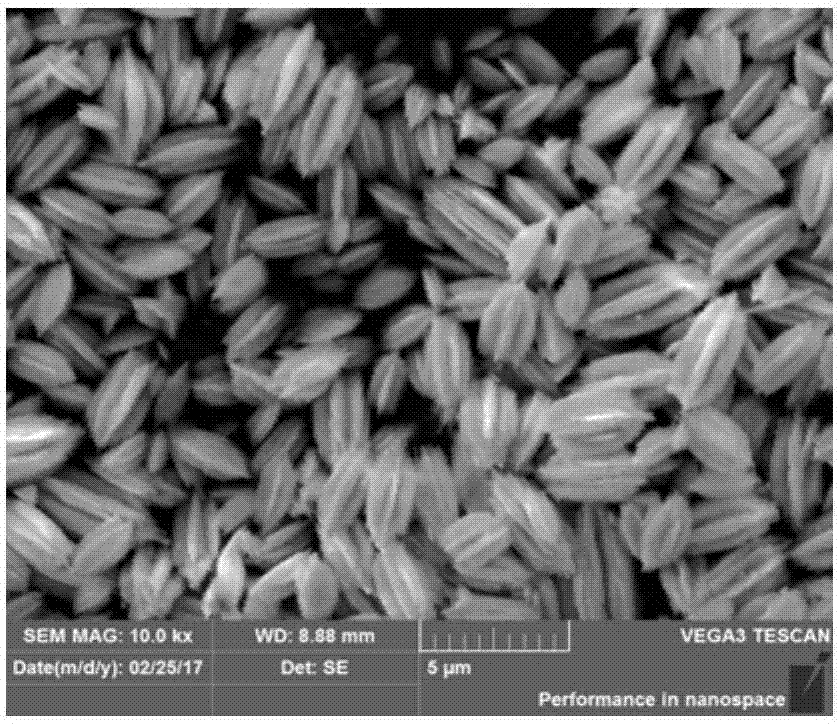

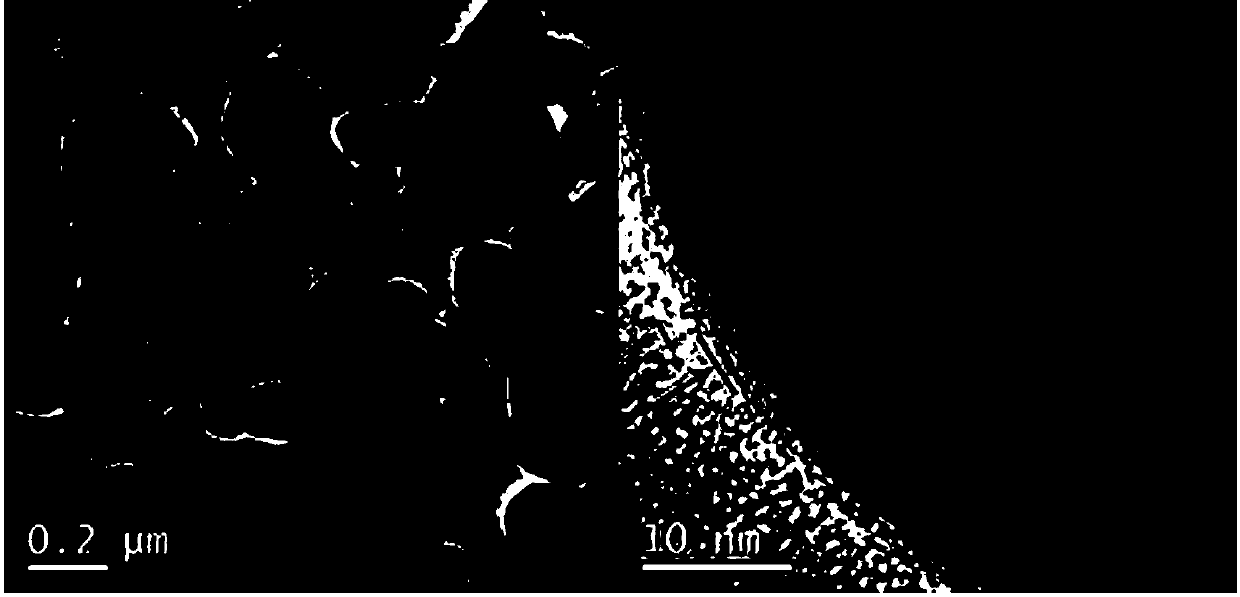

Yttrium oxide powder and preparation method thereof

ActiveCN107021520ALarge specific surface areaStrong binding abilityRare earth metal oxides/hydroxidesCrystalliteGlycerol

The invention relates to yttrium oxide powder and a preparation method thereof, and belongs to a material preparation process. The preparation method of the yttrium oxide powder comprises the following steps: 1) dissolving yttrium nitrate into glycerol and water, adjusting the pH value to be 8 to 10, and reacting at 160 to 170 DEG C for 14 to 16 hours to obtain reaction liquid; 2) filtering the reaction liquid obtained in the step 1), and washing and drying the obtained precipitate to obtain precursor powder; 3) calcining the precursor powder obtained in the step 2) at 600 to 700 DEG C for 2 to 3 hours to obtain the yttrium oxide powder. The submicron-grade carambola-shaped yttrium oxide powder obtained by the preparation method provided by the invention has large specific surface area; when the submicron-grade carambola-shaped yttrium oxide powder serves as a reinforced phase of a metal material, the special groove structure of the carambola-shaped yttrium oxide can be fixed in the matrix of the metal material well, increment of the matrix can be limited effectively, the crystalline grain is fine, and the yttrium oxide powder can be applied widely.

Owner:HENAN UNIV OF SCI & TECH

Method for synthesizing LiFePO4/C positive material of lithium ion battery

InactiveCN104009231AImprove conductivityGood cycle charge and discharge performanceCell electrodesSecondary cellsHydrothermal synthesisLithium electrode

The invention relates to a hydrothermal synthesis method of a LiFePO4 / C positive material of a lithium ion battery. The method comprises the following steps: respectively weighing a lithium salt and a phosphate salt according to the molar ratio of 3:1 and respectively dissolving in distilled water so as to respectively form 3mol / L of lithium salt solution and 1mol / L of phosphate salt solution for later use; adding aniline into the phosphate salt solution obtained in the step (1); secondly, adding the completely dissolved lithium salt solution into a mixed solution of the aniline and the phosphorus salt so as to instantaneously generate a white Li3PO4 precipitate; dripping an iron salt solution containing an antioxidant into the system obtained in the step (2); stirring the solution obtained in the step (3) and then transferring into a reaction kettle, washing the precipitate obtained in a separating manner in the distilled water, then putting an drying oven at 60 DEG C for drying and obtaining LiFePO4 / PANI powder after the drying; and cooling the LiFePO4 / PANI powder to a room temperature so as to obtain the LiFePO4 / C anode material.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

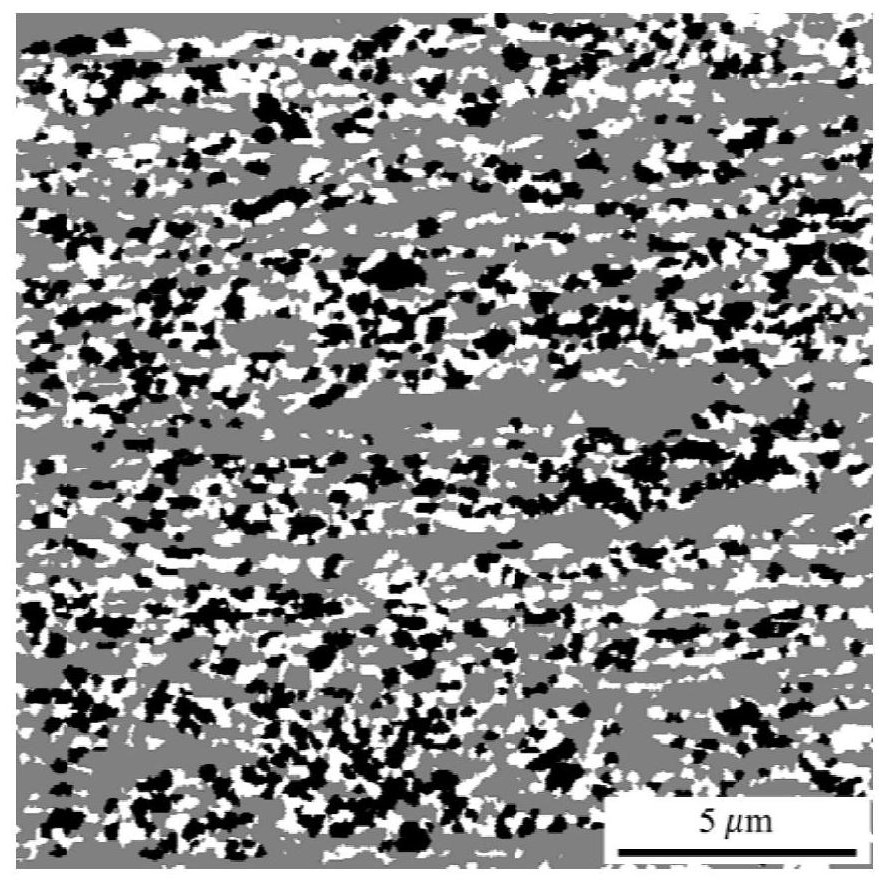

A kind of low-carbon, medium-manganese, high-para austic, high-strength and tough steel and heat treatment method thereof

ActiveCN112063931BHigh yield strengthHigh tensile strengthProcess efficiency improvementTemperingChemical composition

The invention belongs to the technical field of heat treatment of materials, and in particular relates to a low-carbon, medium-manganese, high-residue, high-strength and tough steel and a heat treatment method thereof. The mass percentage ratio of the chemical composition of the steel is: C: 0.10-0.25%, Mn: 4.0-8.0%, Al: 1.0-2.5%, and the balance is Fe and other unavoidable impurities. In this method, after the steel smelting, continuous casting, hot rolling and other processes, the hot-rolled steel plate is subjected to the following heat treatment: low temperature tempering-cold rolling-rapid heating-two-phase zone isothermal for a very short time-rapid cooling. The average grain size of retained austenite in the final high-strength steel is less than 200nm, the volume fraction can reach 15%-40%, and the matrix is a heterogeneous structure of equiaxed recrystallized ferrite + strip unrecrystallized ferrite; The yield strength is in the range of 800MPa‑1200MPa, the tensile strength is in the range of 1200MPa‑1500MPa, and the uniform elongation can be achieved at 10%‑20%. The invention obtains excellent mechanical properties and realizes high-efficiency heat treatment at the same time by improving the morphology of the ferrite matrix and the volume fraction and grain size of the retained austenite.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com