Preparation method of lithium iron phosphate cathode material

A technology of lithium iron phosphate and positive electrode material, applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problem of low electronic conductivity and ion mobility of lithium iron phosphate material, high temperature cycle capacity decay, poor physical processing performance, etc. problems, to achieve the effect of improving electron conductivity and ion diffusion rate, improving electrical properties, and good hole conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

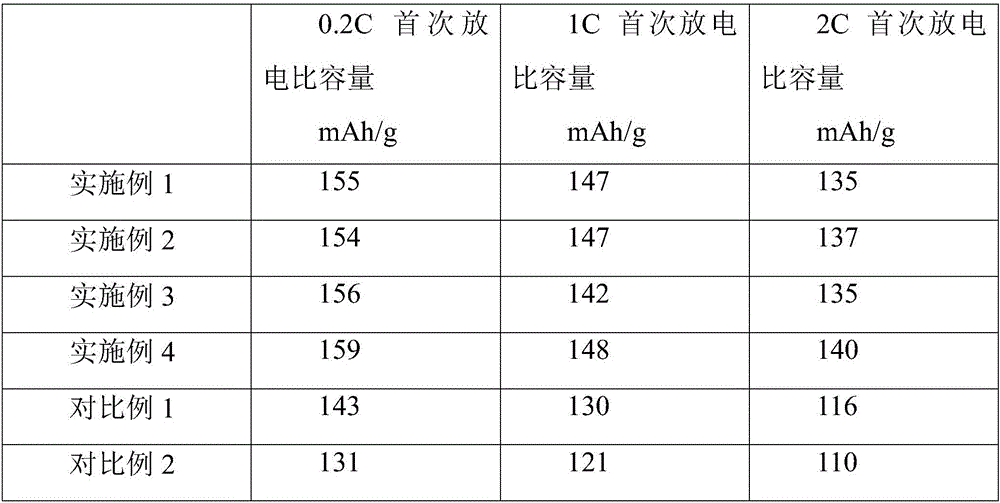

Examples

Embodiment 1

[0025] (1) Prepare the dispersion of iron phosphate: dissolve 17g of AEO-9 in 1L of ethanol under stirring, then add 1mol of iron phosphate, and disperse at high speed for 1h to obtain the dispersion of iron phosphate, denoted as A;

[0026] (2) Preparation of lithium source-magnesium source dopant dispersion: dissolve 17g of AEO-9 in 1L of ethanol under stirring, then add 8.4977mol of lithium carbonate, disperse at high speed for 28min, then add 8.887mol of magnesium chloride, and continue stirring 48min, obtain lithium source-magnesium source dopant dispersion liquid, denoted as B;

[0027] (3) Add liquid B into the autoclave, then slowly add liquid A into liquid B, control the flow rate of liquid A to 88ml / min, after adding liquid A, seal the autoclave, Under certain conditions, raise the temperature to 178°C and react for 18 hours. After the reaction is completed, cool down to room temperature, open the reaction kettle, release the suspended matter, and filter with suction...

Embodiment 2

[0031] (1) Prepare the dispersion of iron phosphate: dissolve 7g of AEO-9 in 1L of methanol under stirring, then add 1mol of iron phosphate, and disperse at high speed for 1h to obtain the dispersion of iron phosphate, denoted as A;

[0032] (2) Preparation of lithium source-dopant magnesium source dispersion: dissolve 18g of AEO-9 in 1L of methanol under stirring, then add 8.499mol of lithium carbonate, disperse at high speed for 28min, then add 8.882mol of magnesium chloride, and continue stirring 48min, obtain lithium source-magnesium source dopant dispersion liquid, denoted as B;

[0033] (3) Add liquid B to the autoclave, then slowly add liquid A to liquid B, control the flow rate of liquid A to 78ml / min, after adding liquid A, seal the autoclave, Under certain conditions, raise the temperature to 278°C and react for 6 hours. After the reaction is completed, cool down to room temperature, open the reaction kettle, release the suspended matter, and filter with suction to o...

Embodiment 3

[0037] (1) Prepare the dispersion of iron phosphate: dissolve 28g of AEO-9 in 1L of ethanol under stirring, then add 1mol of iron phosphate, and disperse at high speed for 1h to obtain the dispersion of iron phosphate, denoted as A;

[0038] (2) Preparation of lithium source-magnesium source dopant dispersion: dissolve 28g of AEO-9 in 1L of ethanol under stirring, then add 8.4977mol of lithium carbonate, disperse at high speed for 28min, then add 8.887mol of magnesium chloride, and continue stirring 48min, obtain lithium source-magnesium source dopant dispersion liquid, denoted as B;

[0039] (3) Add liquid B into the autoclave, then slowly add liquid A into liquid B, control the flow rate of liquid A to 188ml / min, after adding liquid A, seal the autoclave, Under certain conditions, raise the temperature to 288°C and react for 12 hours. After the reaction is completed, cool down to room temperature, open the reaction kettle, discharge the suspended matter, and filter with suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com