Lithium ion battery SiO composite material as well as preparation method and application thereof

A lithium-ion battery, silicon oxide technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of less than 75% first time efficiency, less than 70% first time efficiency, difficult to control crystal grains, etc. Improve the first coulombic efficiency and capacity, and improve the effect of the first coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) SiO x (0.9x In the modified SiO x Block;

[0064] (2) Modified SiO x The block is crushed, crushed at ultra-low temperature, and SiO is controlled x The volume of powder below 1.0μm accounts for less than 15.0% of the total, 3.090 / D 10 90 max <50.0μm;

[0065] (3) Take 100g of SiO x The powder is placed in a rotary furnace, the temperature is raised to 600°C at 3°C / min, acetylene gas is introduced at a flow rate of 0.2L / min, and N 2 Protective atmosphere, control the flow rate to 0.1L / min, react for 10h, to the precursor;

[0066] (4) Put the above precursor into a mechanical fusion machine, control the speed at 1800r / min, fuse for 10min, and control SiO x Median particle size D before and after carbon coating 50 The change is 0.5~2.0μm;

[0067] (5) mixing, sieving, demagnetizing, drying and packaging to obtain silicon oxide composite material.

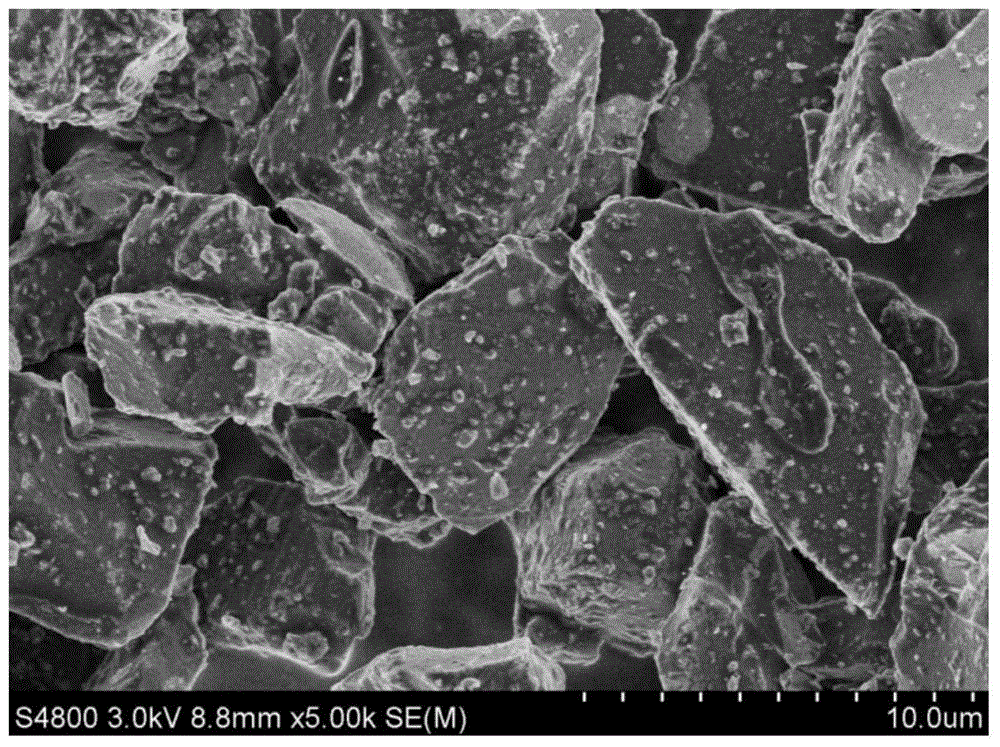

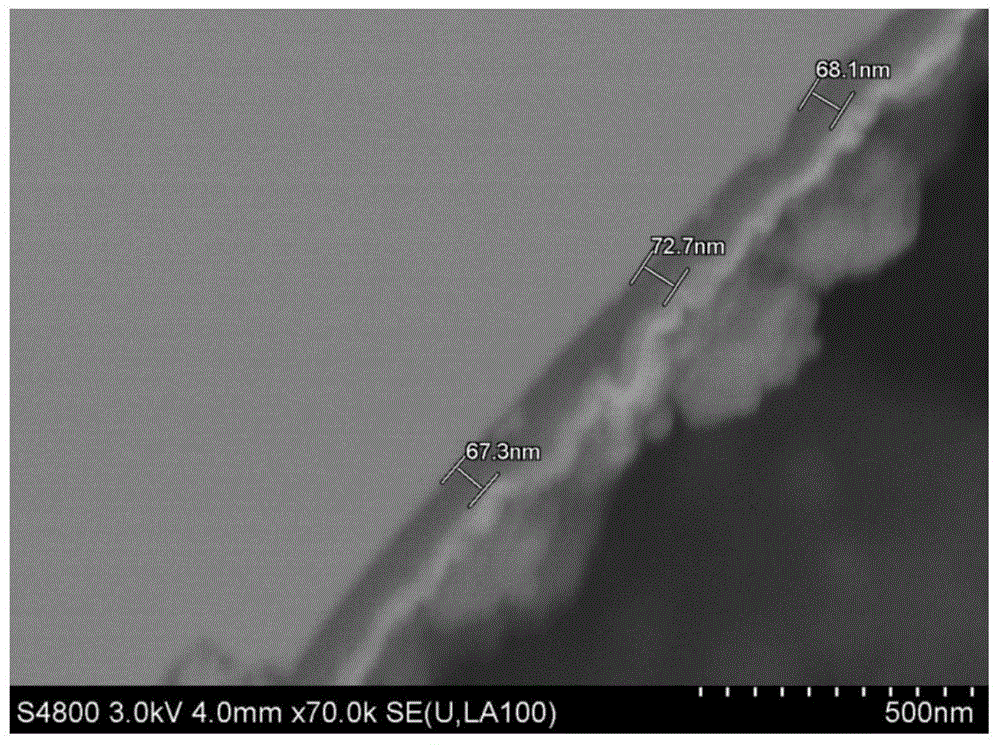

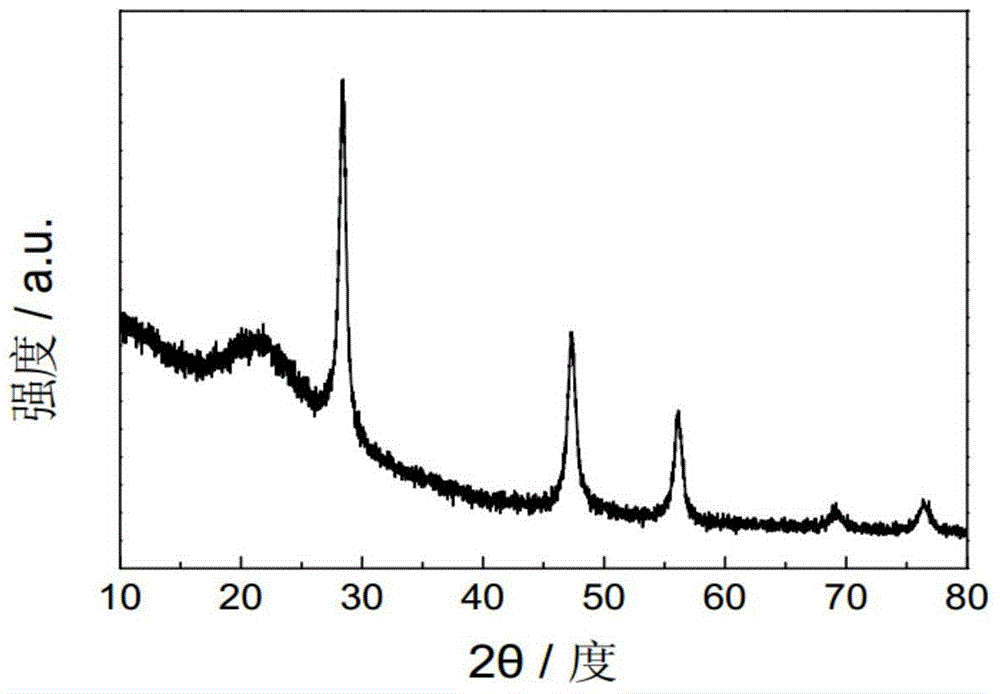

[0068] figure 1 It is an electron microscope picture of the silicon oxide composite material in Example 1 of...

Embodiment 2

[0071] (1) SiO x The block is placed in a roller kiln, filled with an argon protective atmosphere, and heated at a rate of 3°C / min to 900°C for 10 hours, so that Si crystallites are evenly dispersed in SiO x In the modified SiO x Block;

[0072] (2) Modified SiO x Blocks are mechanically pulverized and graded pulverized to control SiO x The volume of powder below 1.0μm accounts for less than 15.0% of the total, 3.090 / D 10 90 max <50.0μm;

[0073] (3) Take 100g of SiO x The powder is placed in a rotary furnace, the temperature is raised to 900°C at 5°C / min, methane gas is introduced at a flow rate of 0.2L / min, and N 2 Protective atmosphere, control the flow rate to 0.1L / min, react for 2h, to the precursor;

[0074] (4) Put the above precursor into the VC mixer, control the rotation speed to 400r / min, disperse for 10min, and control the SiO x Median particle size D before and after carbon coating 50 The change is 0.5~2.0μm;

[0075] (5) mixing, sieving, demagnetizing,...

Embodiment 3

[0077] (1) SiO x (0.9x In the modified SiO x Block;

[0078] (2) Modified SiO x The block is crushed, crushed at ultra-low temperature, and SiO is controlled x The volume of powder below 1.0μm accounts for less than 15.0% of the total, 3.090 / D 10 90 max <50.0μm;

[0079] (3) Take 100g of SiO x The powder is placed in a rotary furnace, and the temperature is raised to 850°C at a rate of 5°C / min. Propane gas is introduced at a flow rate of 5.0L / min. During the entire reaction process, N 2 Protective atmosphere, the control flow is 1.5L / min. Reaction 10h, to the precursor;

[0080] (4) Put the above precursor into a mechanical fusion machine, control the speed at 1800r / min, fuse for 10min, and control SiO x Median particle size D before and after carbon coating 50 The change is 0.5~2.0μm;

[0081] (5) mixing, sieving, demagnetizing, drying and packaging to obtain silicon oxide composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com