Modified lithium manganese oxide electrode material for lithium ion secondary battery and synthesizing method thereof

A secondary battery and electrode material technology, applied to battery electrodes, circuits, electrical components, etc., to achieve the effect of improving crystallization characteristics and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

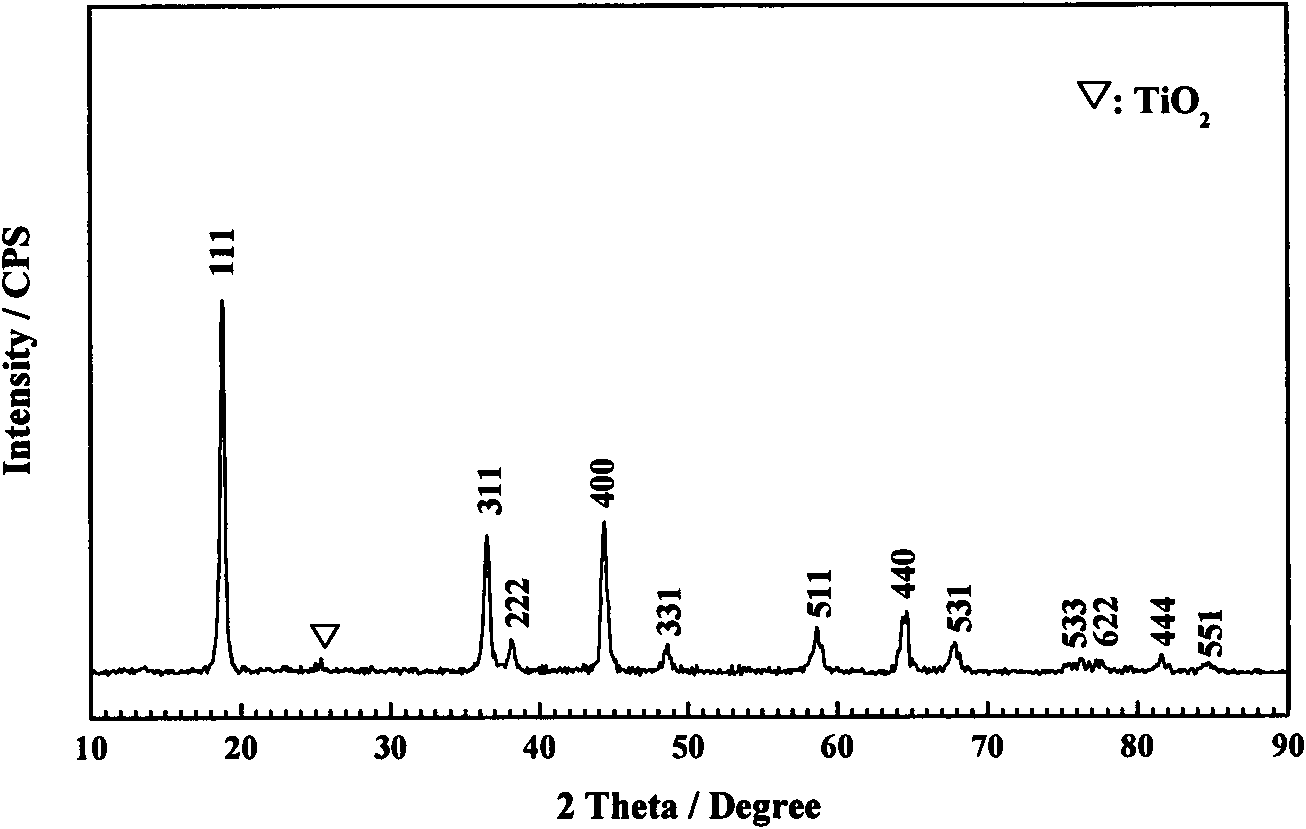

[0033] 230.1gLi 2 CO 3 , 691.6gMnO 2 , 78.3gCo(CH 3 COO) 2 4H 2 O solid powder is added in the beaker, adding concentration is 15wt.% H 2 o 2 The aqueous solution was stirred continuously at 50°C, reacted for about 12 hours, and then filtered. After the filter cake was washed and dried, it was added into a ball mill tank together with 500ml of absolute ethanol, the mass ratio of Φ10 stainless steel balls to the above raw materials was 0.55, and the speed of the planetary ball mill was 150r / min, and ball milled for 1h. The ball-milled mixture was raised to 650°C at 5°C / min in an atmosphere with an oxygen content of 30%, and then calcined with heat for 12h to obtain 750g of the final product doped lithium manganate solid powder. Rigaku-D / MAX-2550PC X-ray diffractometer (Cu target K-ray wavelength: 0.154nm) was used to test the sample crystal X-ray diffraction pattern at a rate of 0.02° / s.

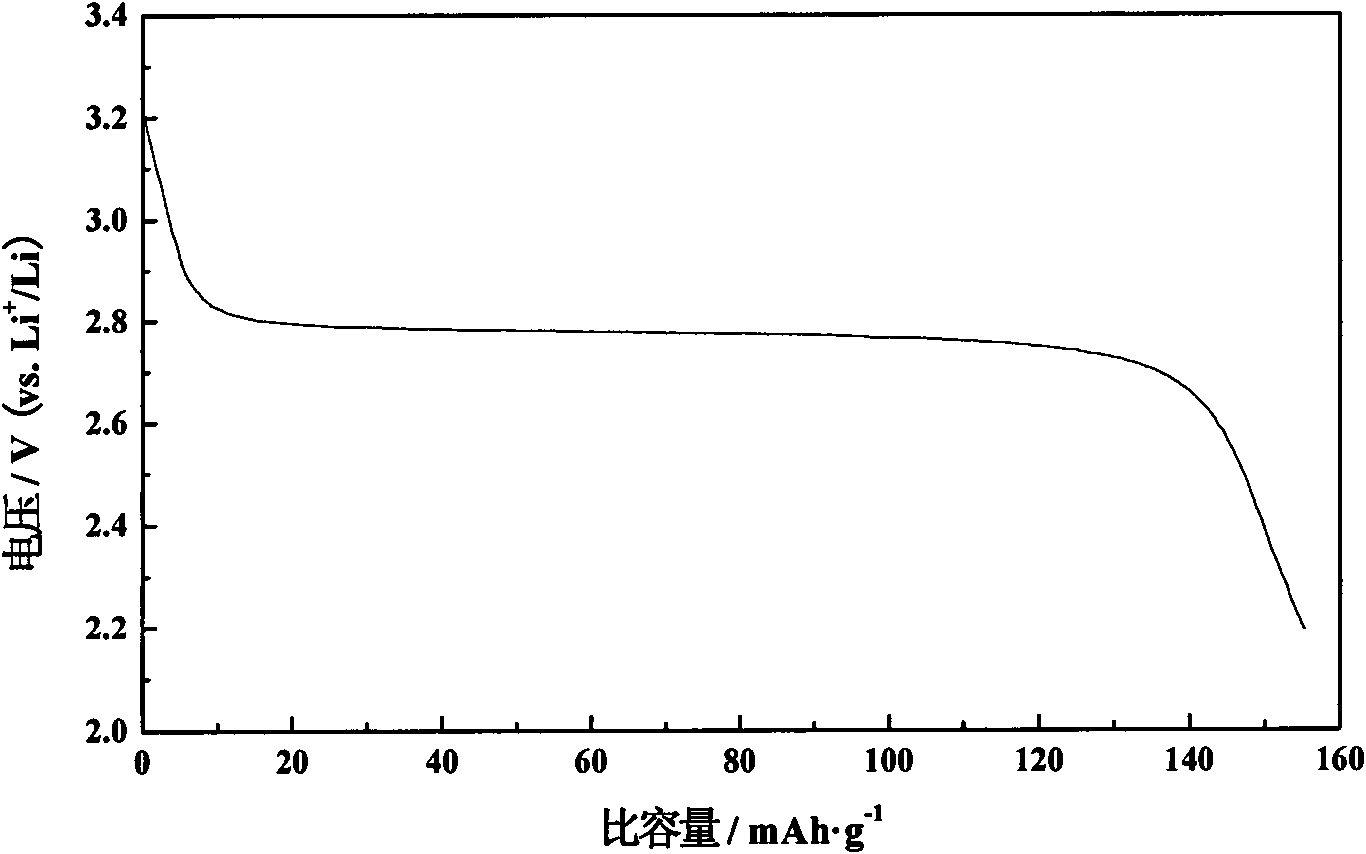

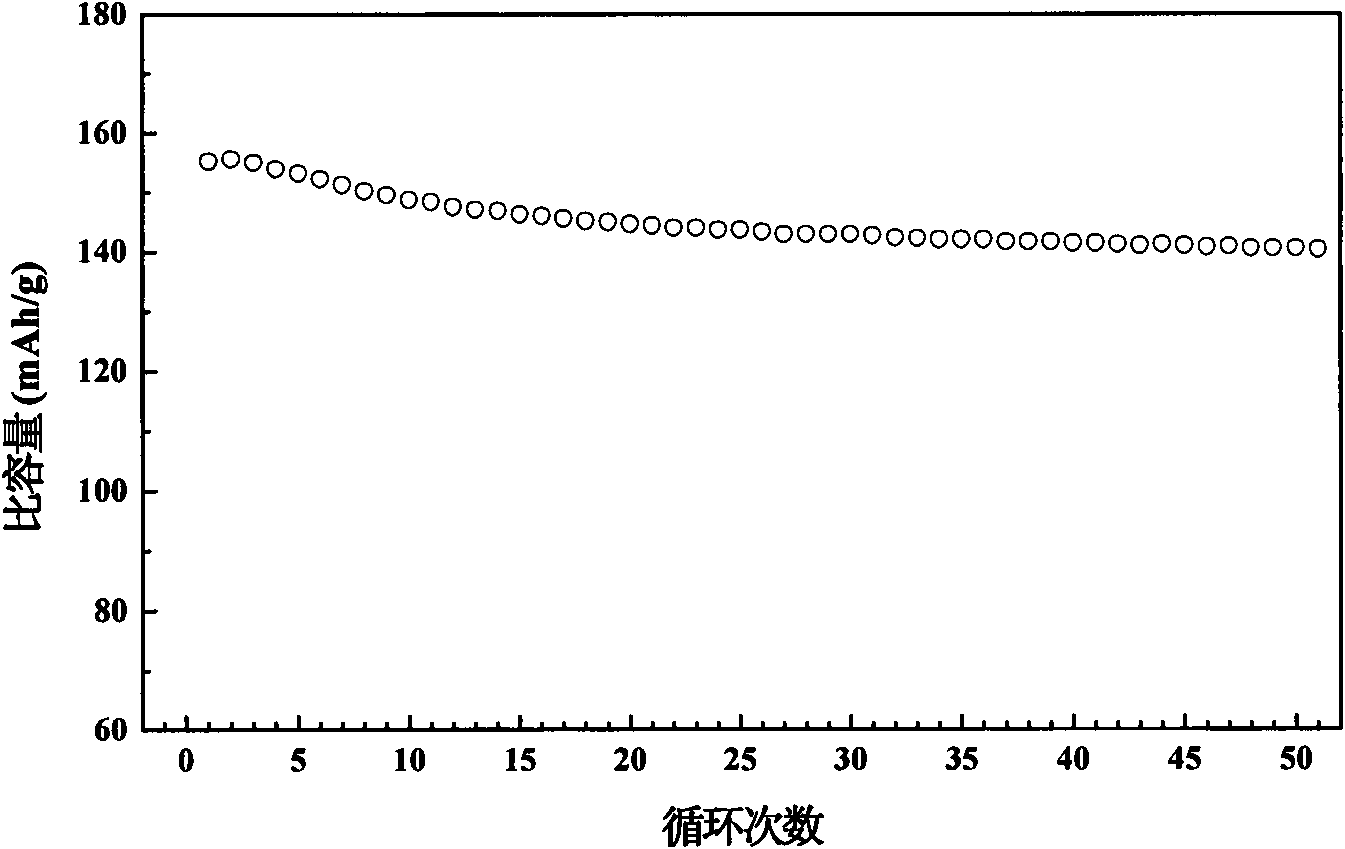

[0034] The above products lithium manganate, acetylene black, and polyvinylidene ...

Embodiment 2

[0036] Weighing 220.8gLi 2 CO 3 , 663.7gMnO 2 , 75.2gCo(CH 3 COO) 2 4H 2 O, 38.6gTiO 2 Solid powder, mixed with 500ml concentration of 15wt.% H 2 o 2 Add the aqueous solution into the ball mill tank together, the mass ratio of Φ10 stainless steel balls to the above-mentioned raw materials is 0.55, the speed of the planetary ball mill is 150r / min, and perform ball milling for 1h. The above ball-milled mixture was raised to 650°C at 5°C / min in an atmosphere with an oxygen content of 30%, and then kept and calcined for 12h to obtain 760g of a final product containing TiO 2 5wt.% doped lithium manganate solid powder. Carry out X-ray diffraction test and make 2032 button battery and carry out charge and discharge test according to the method described in Example 1.

[0037] The main phase diffraction peaks of the XRD spectrum of the product sample are consistent with those in the literature (Takada, T., Hayakawa, H., Akiba, E.J.Solid State Chem., 1995, 115:420), and TiO 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com