Patents

Literature

47results about How to "Improve crystallization properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

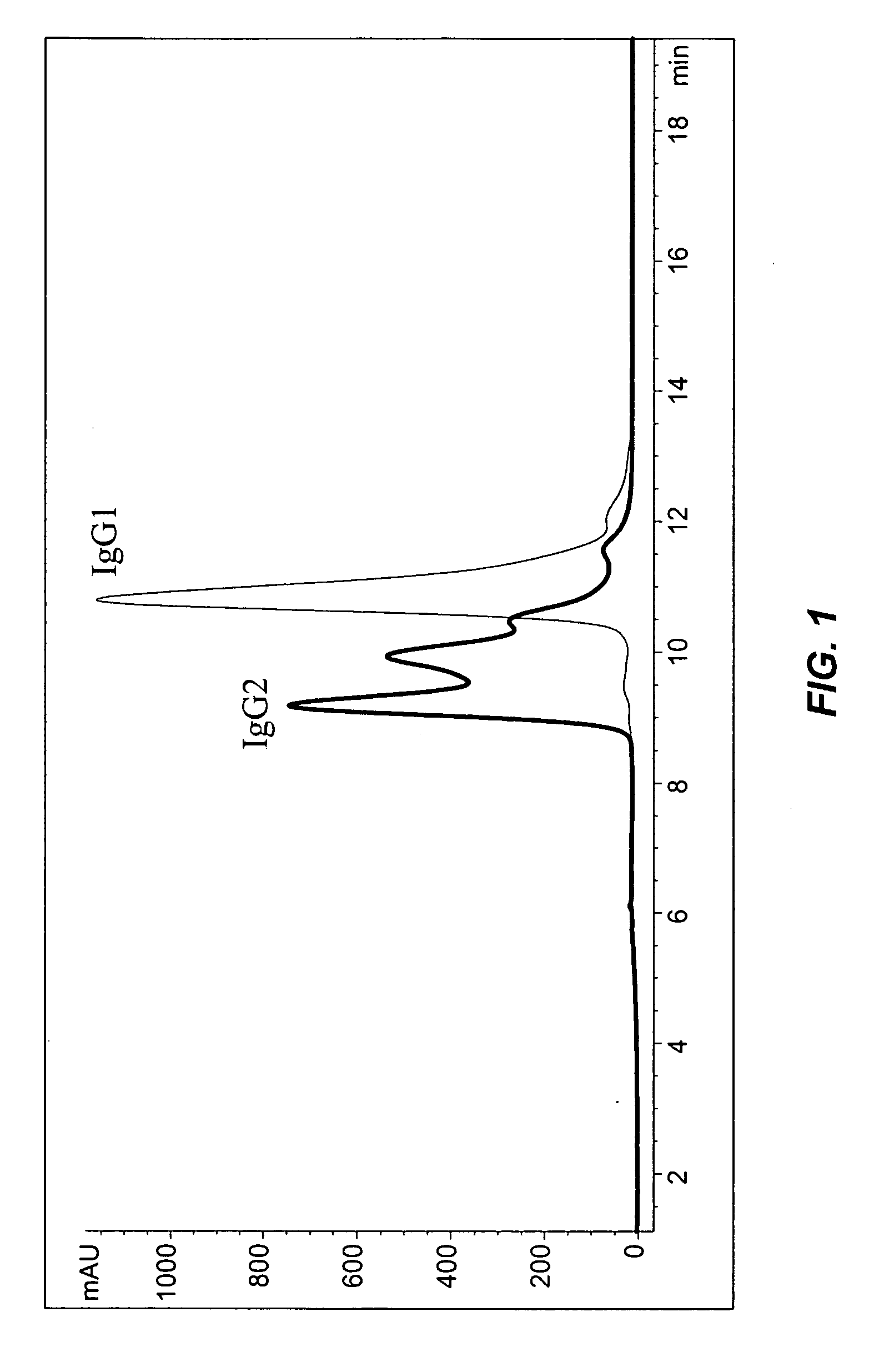

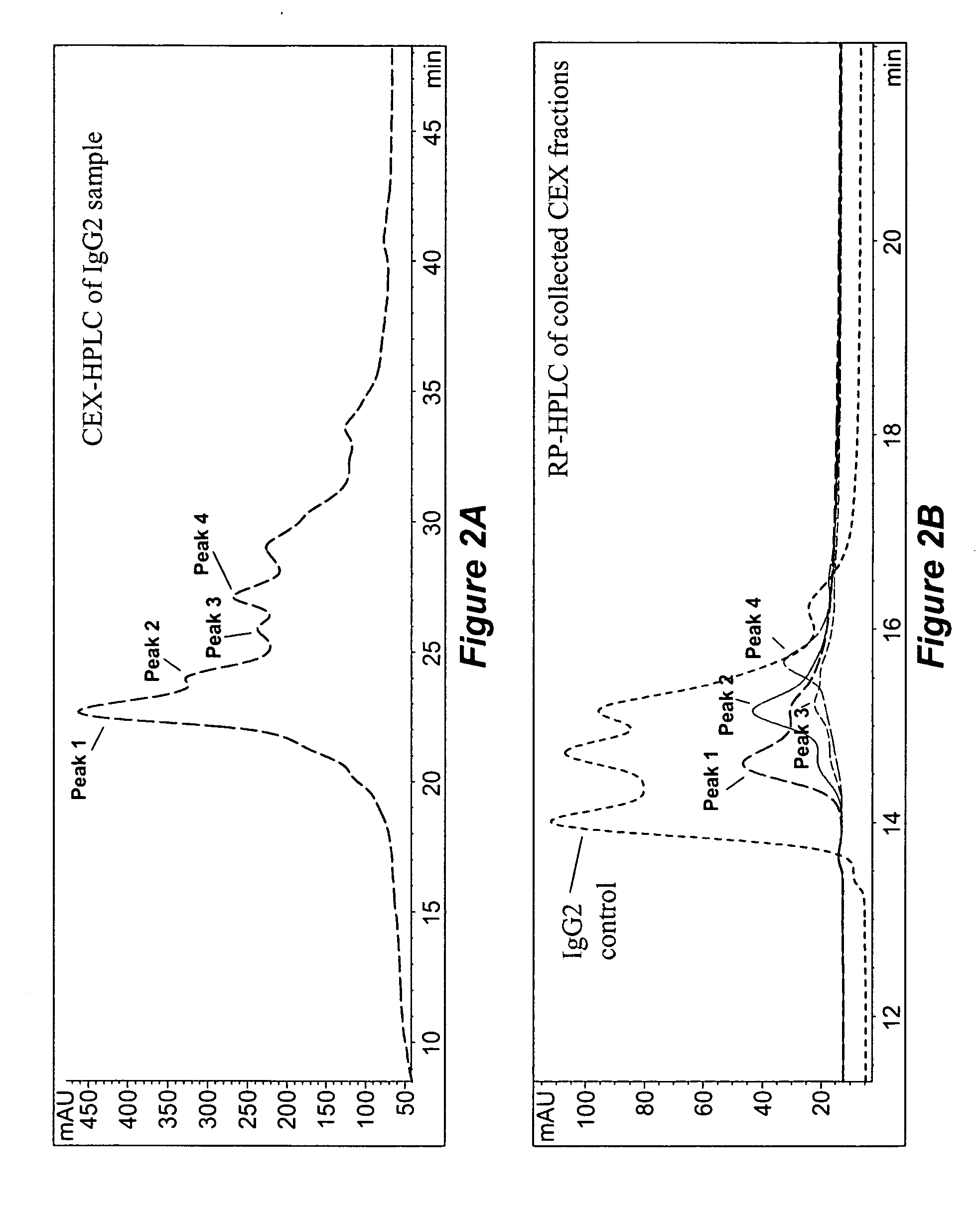

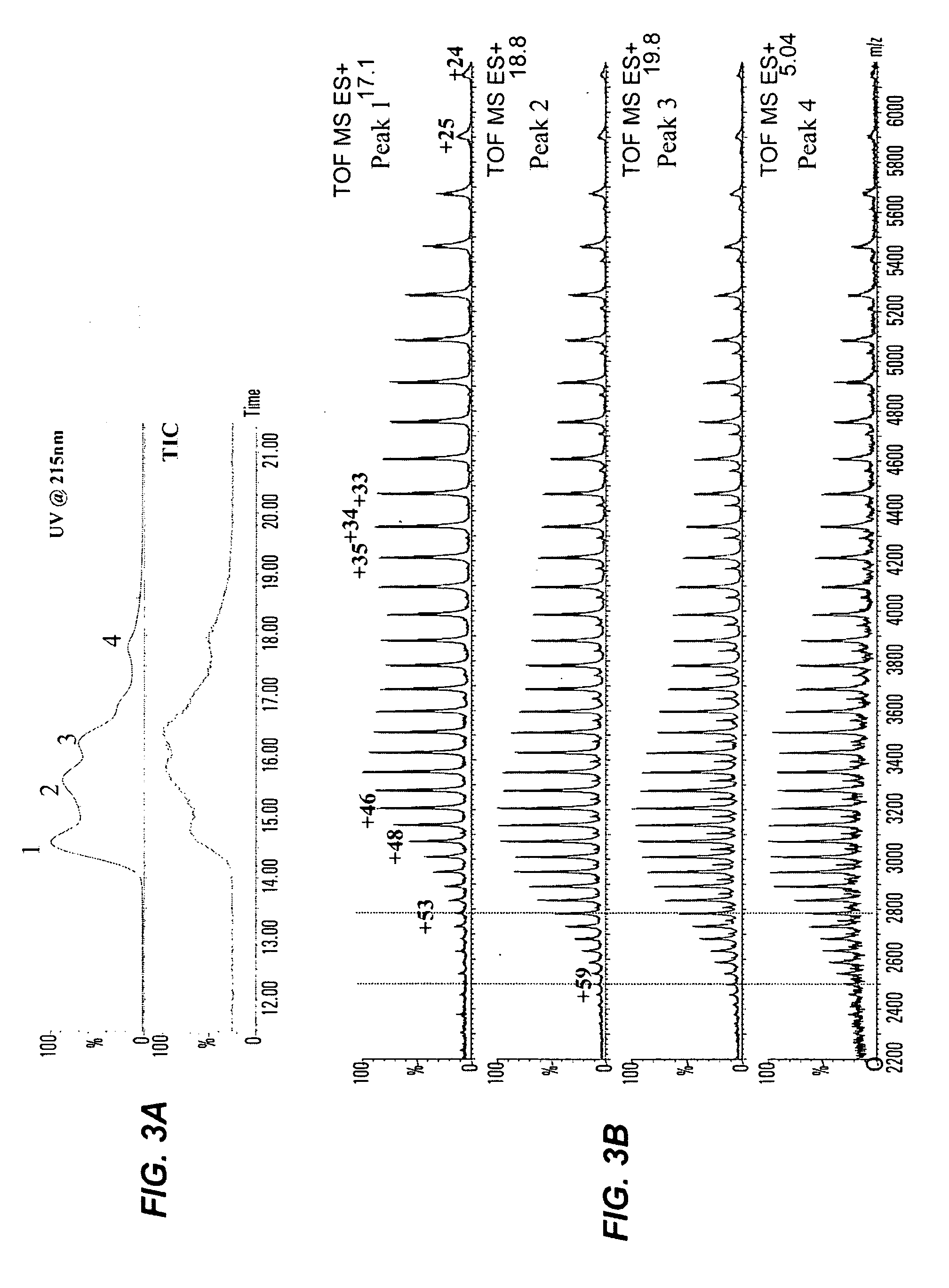

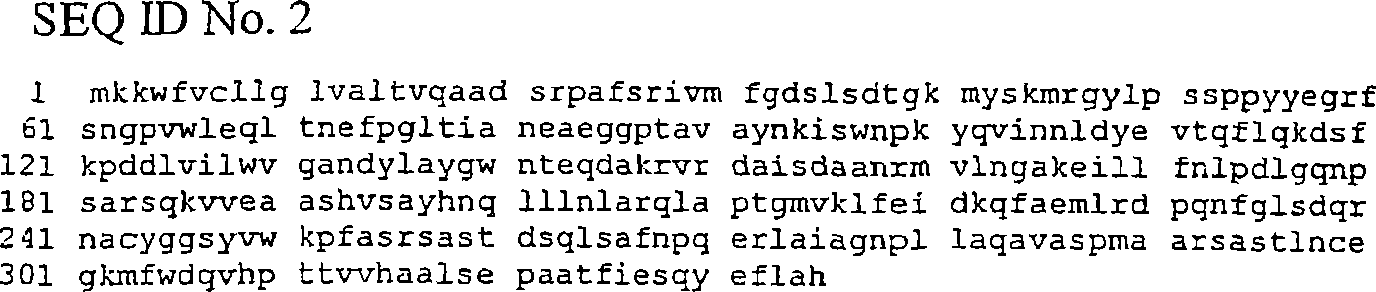

Methods for refolding of recombinant antibodies

ActiveUS20060194280A1Efficient and economic productionImproved pharmaceuticalImmunological disordersFermentationRecombinant antibodiesCoupling reagent

The present invention is generally directed to methods of producing an increase in the enrichment or recovery of preferred forms of IgG proteins. More particularly, the invention relates to subjecting preparations of such recombinant IgG proteins with a reduction / oxidation coupling reagent and optionally a chaotropic agent.

Owner:AMGEN INC

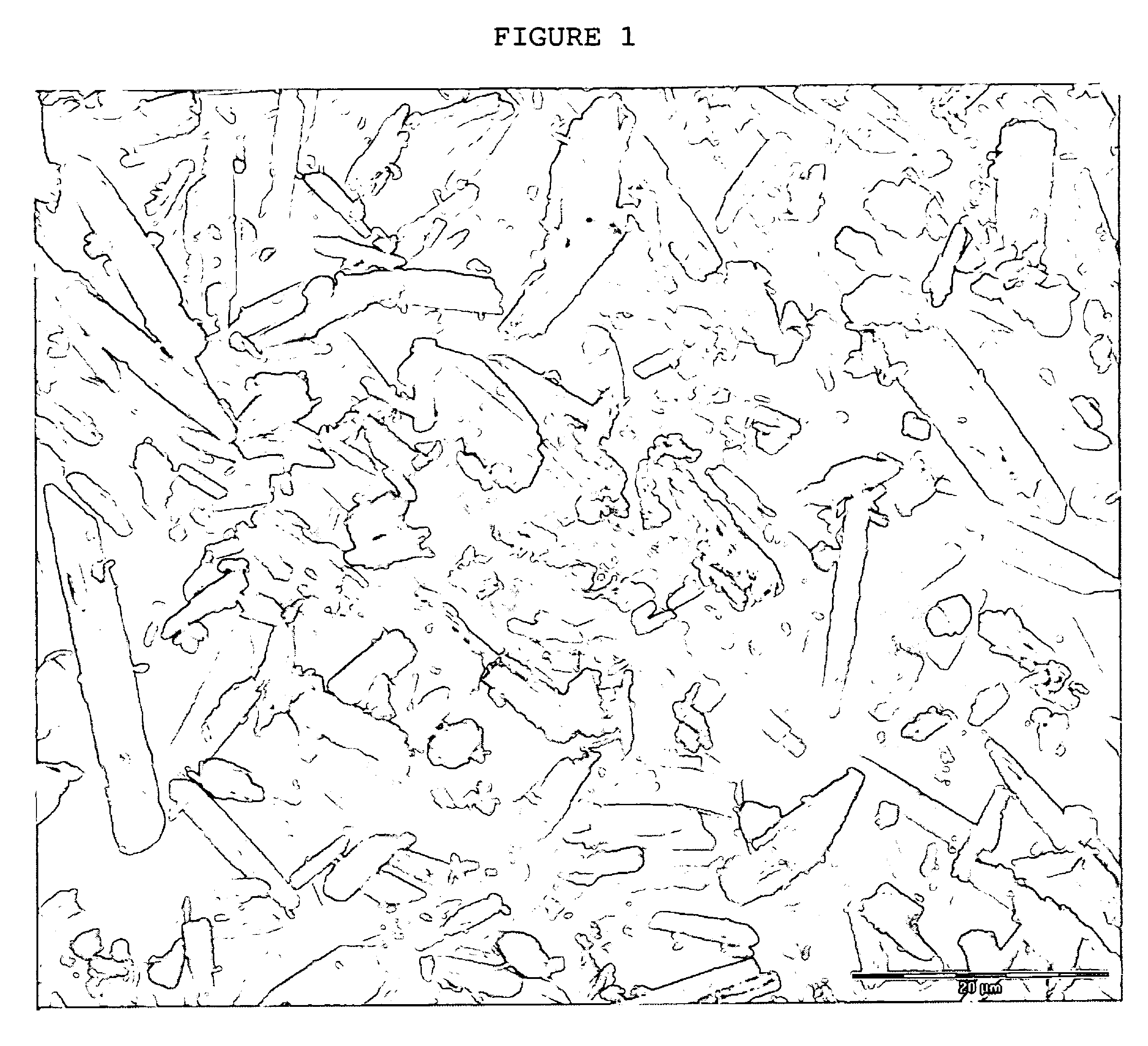

Crystals of laquinimod sodium, and process for the manufacture thereof

InactiveUS7884208B2High purityImprove crystallization propertiesBiocideNervous disorderImpurityLaquinimod Sodium

Disclosed is a process for the preparation of laquinimod sodium which removes the impurities after the salt formation step, thus resulting in crystals of higher purity as well as crystals having improved crystalline characteristics.

Owner:TEVA PHARMA IND LTD

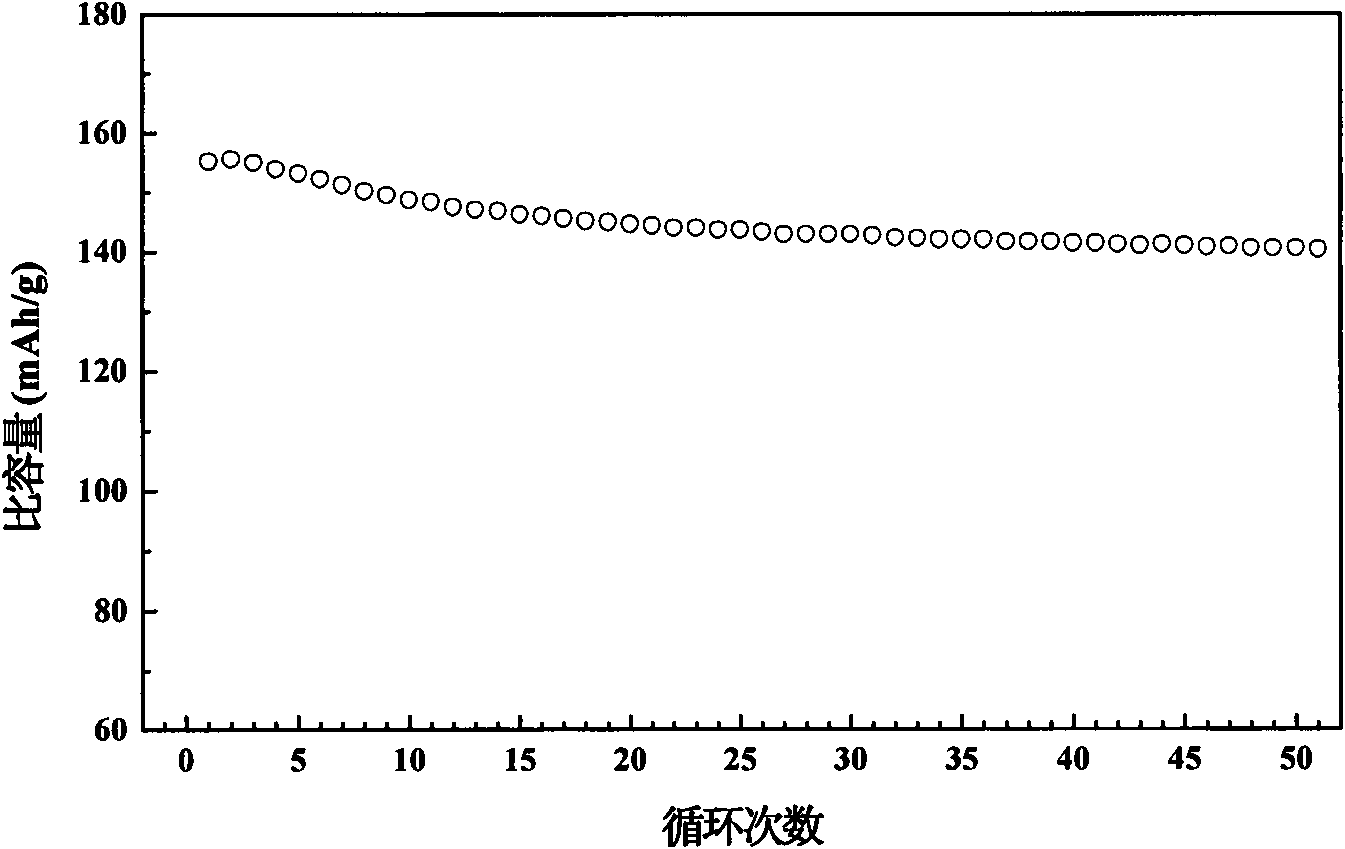

Modified lithium manganese oxide electrode material for lithium ion secondary battery and synthesizing method thereof

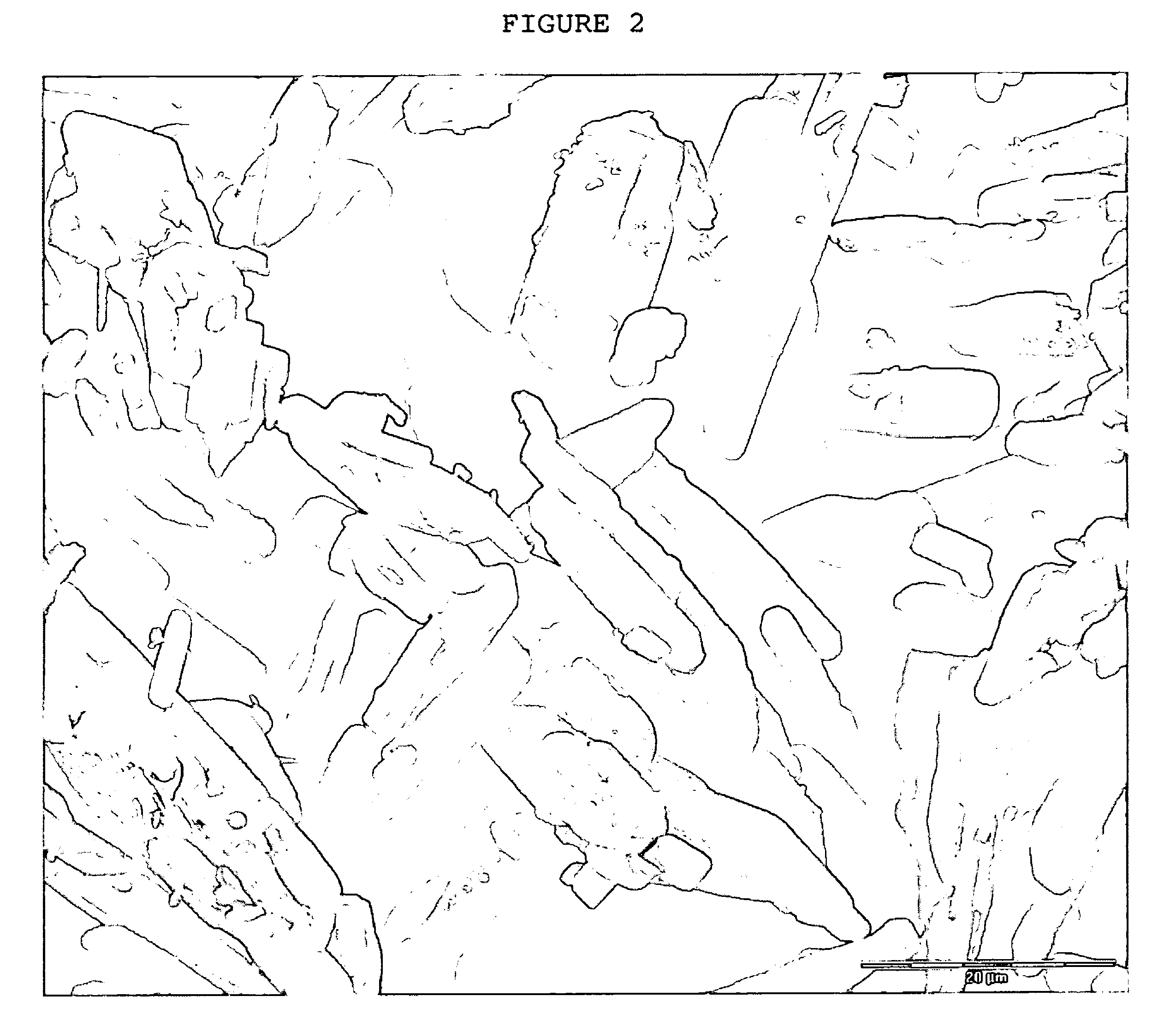

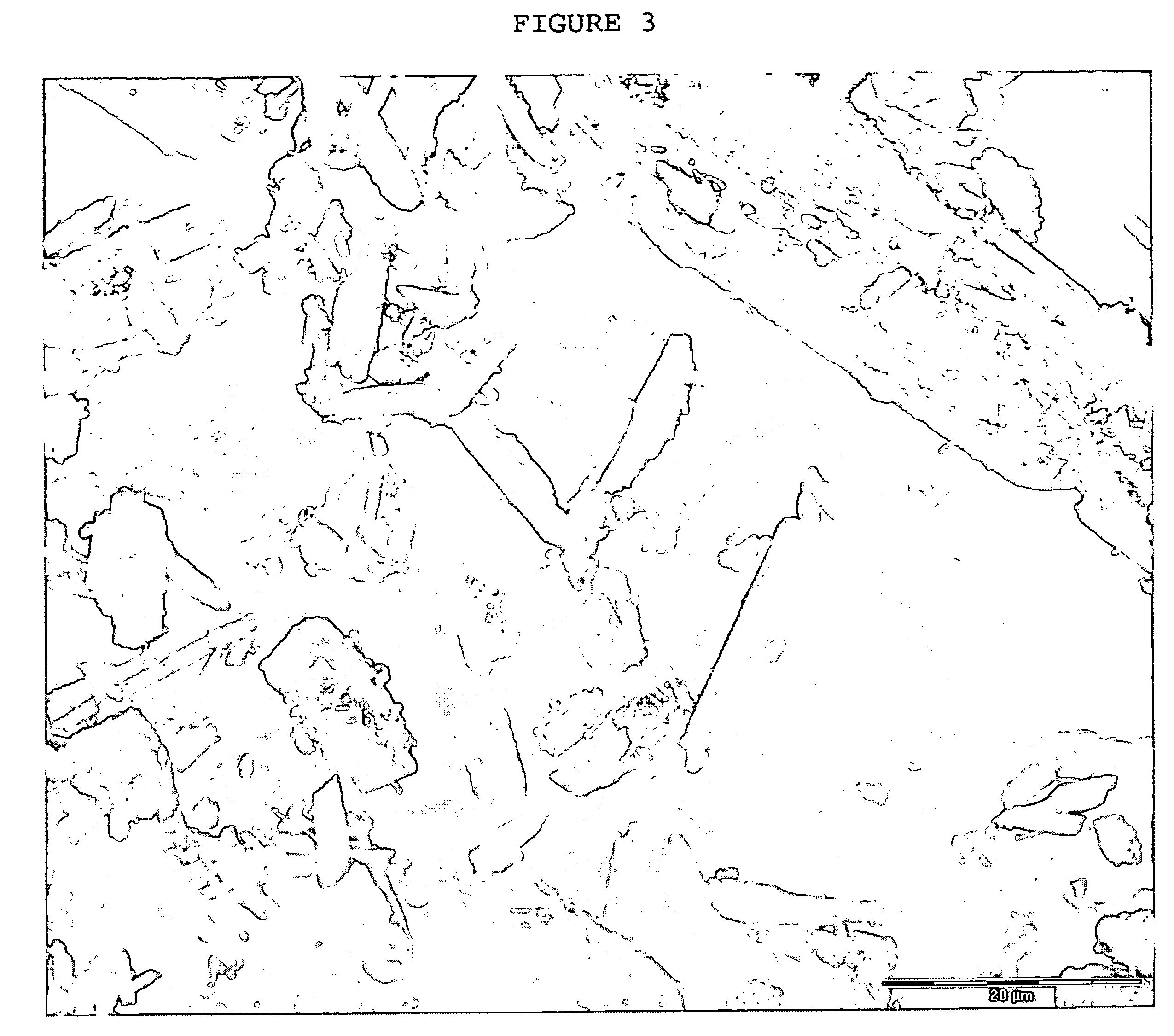

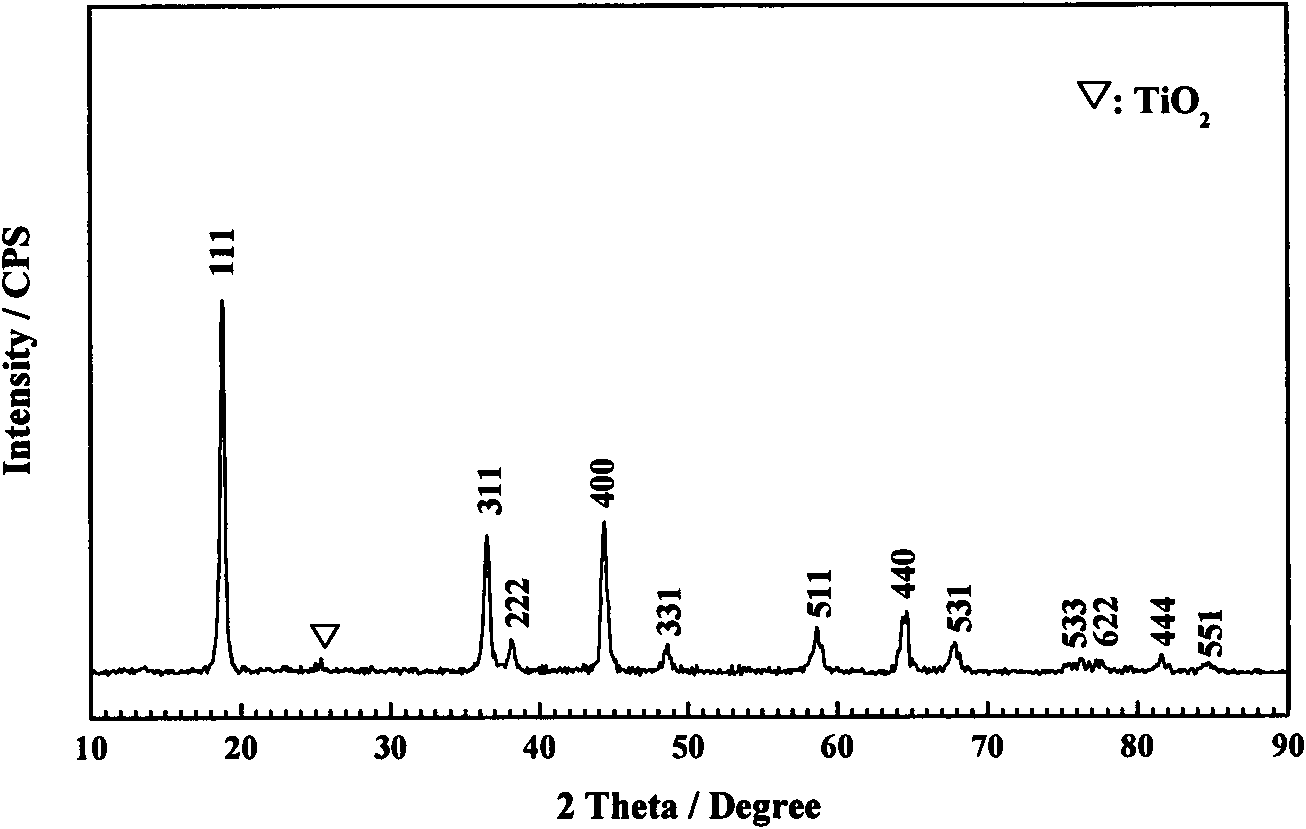

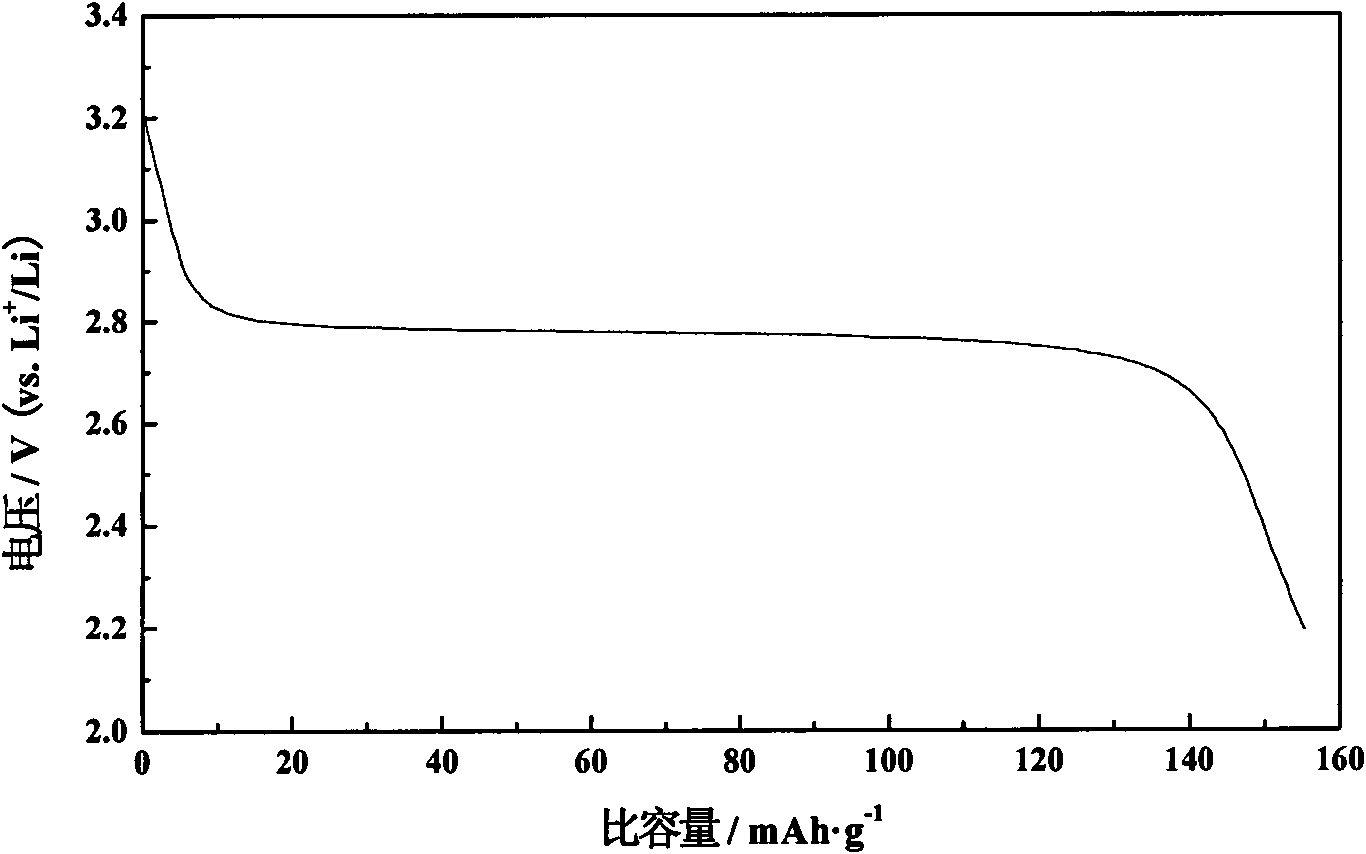

InactiveCN102208640AImprove featuresImprove crystallization propertiesCell electrodesAluminium-ion batterySodium-ion battery

The invention provides a modified lithium manganese oxide electrode material for a lithium ion secondary battery, which is characterized in that the general formula is Li(4-x)A(x+y)Mn(5-y)O12.epsilonBOz. The synthesizing method comprises the following steps: weighing and mixing raw materials evenly in accordance with the stoichiometric ratio in the general formula and then adding the mixture of the raw materials to a container; adding an oxidizing solution, evening mixing and reacting for over 10 minutes, and then taking the materials out, washing and drying; and then carrying out high-temperature calcination and reaction for 1-30 hours at a temperature of 400-1200 DEG C under an oxygen-contained atmosphere, and cooling to obtain the modified lithium manganese oxide electrode material. Compared with an existing electrode material and a synthesizing technology, the modified lithium manganese oxide electrode material produced in the production process can improve the crystalline characteristic and the purity of products as well as the specific capacity, the initial coulomb efficiency, the cyclical stability and other characteristics in electrochemical property; and the modified lithium manganese oxide electrode material improves performances of the lithium ion battery, promotes the wider applications of the lithium ion battery and has significant economic meanings and practical value.

Owner:王明月

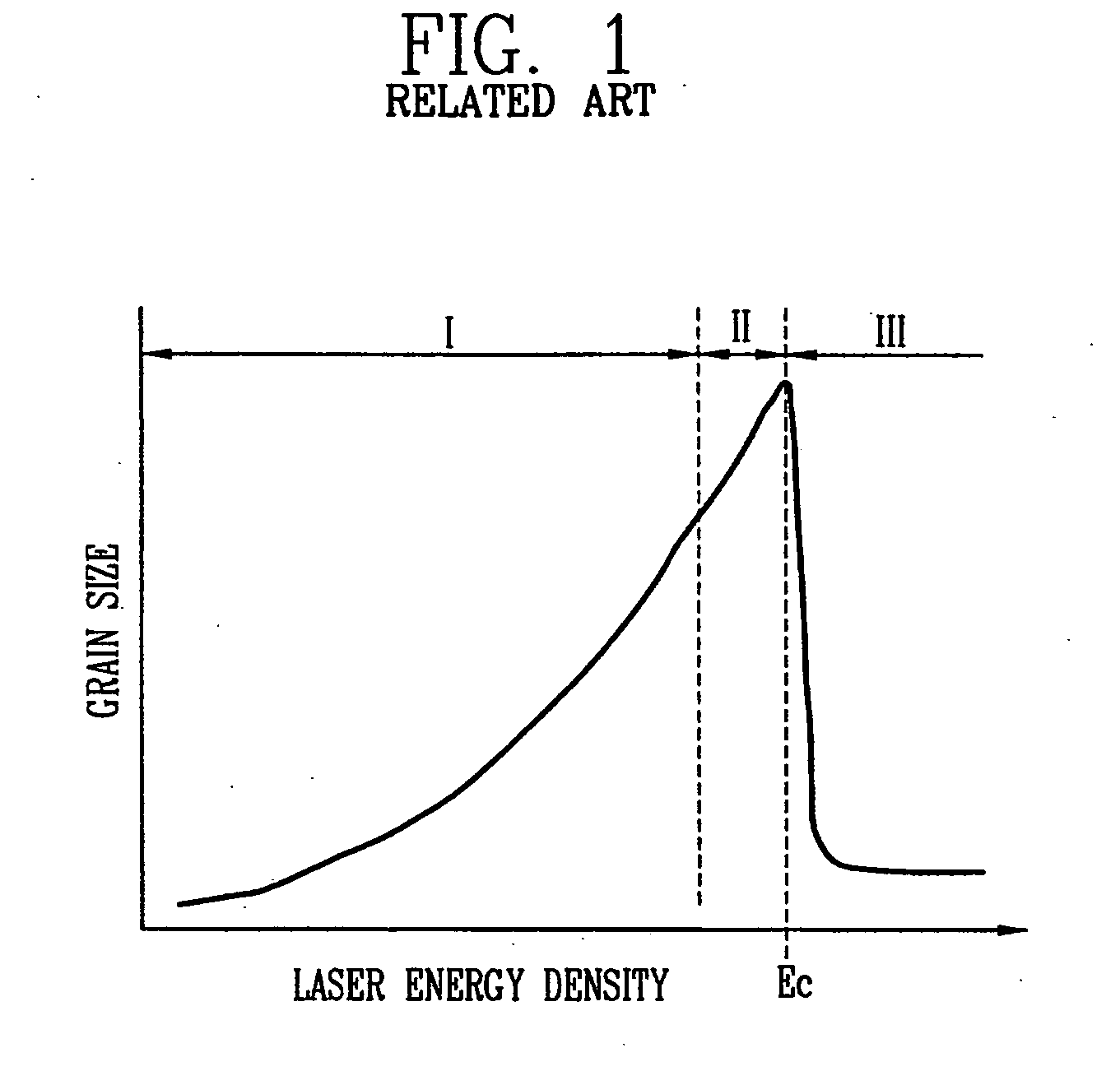

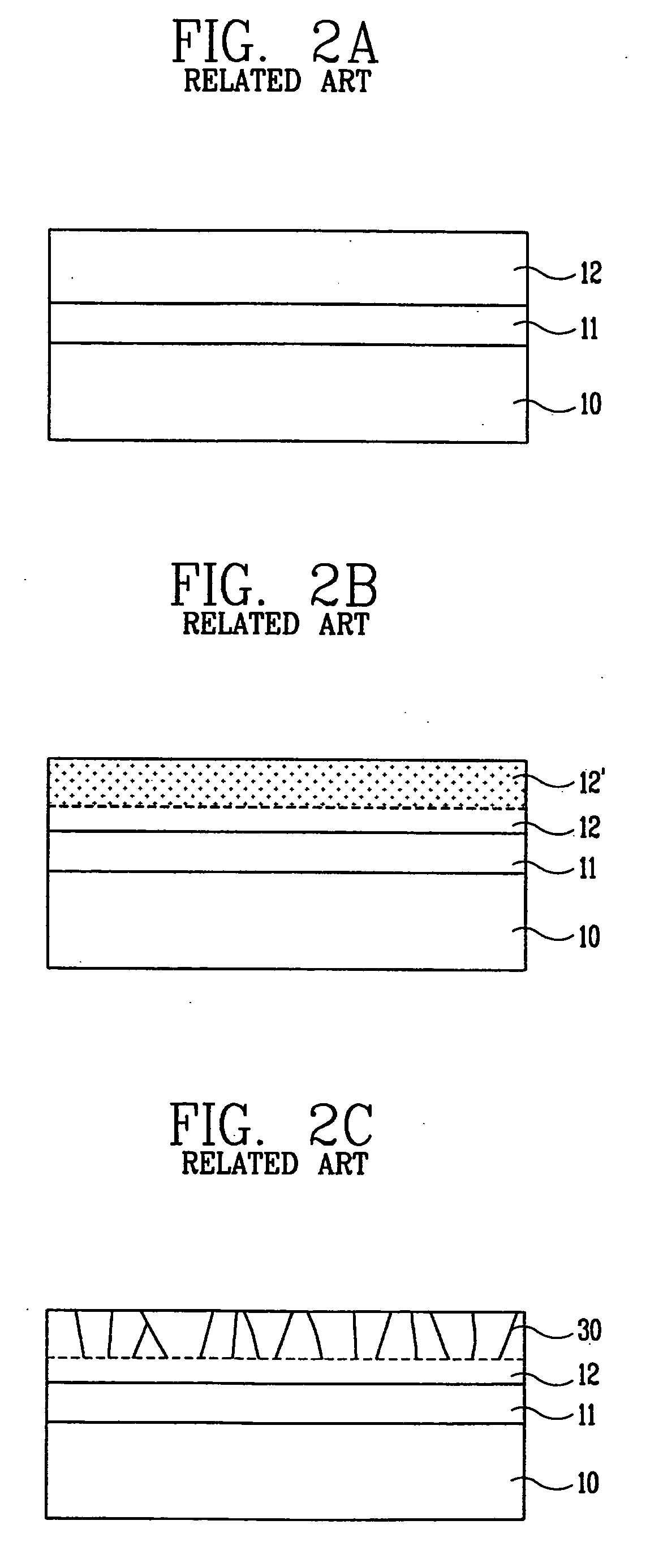

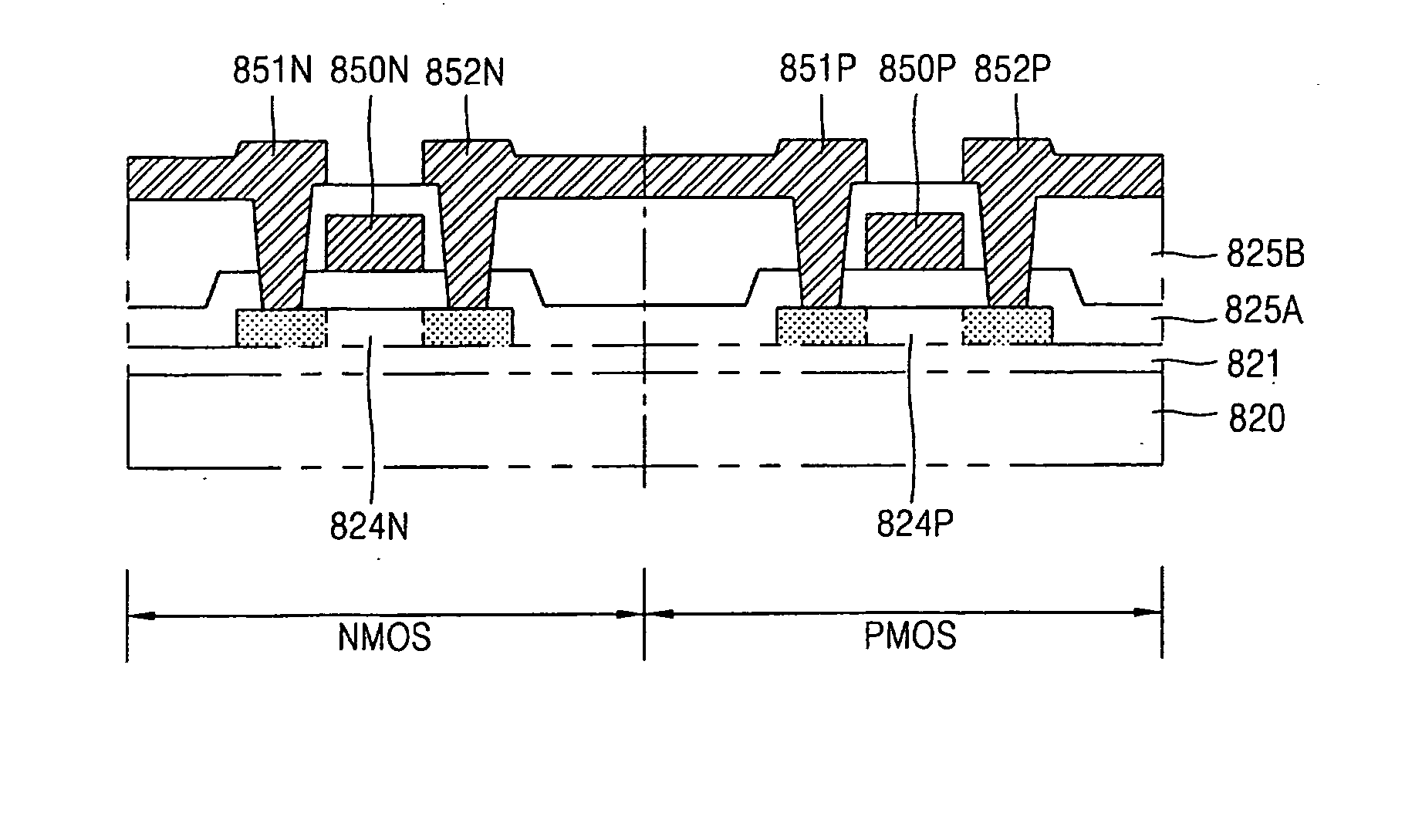

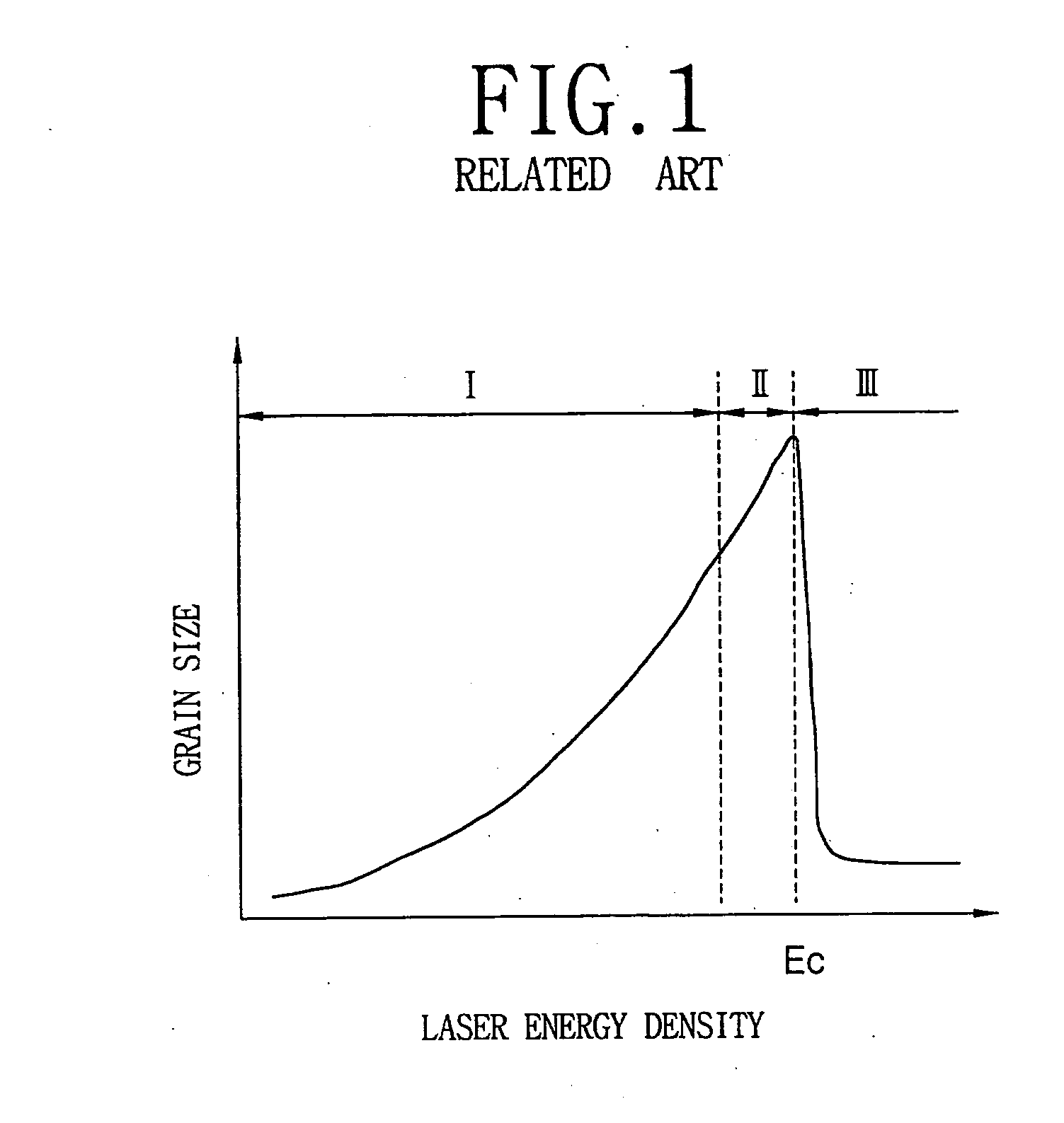

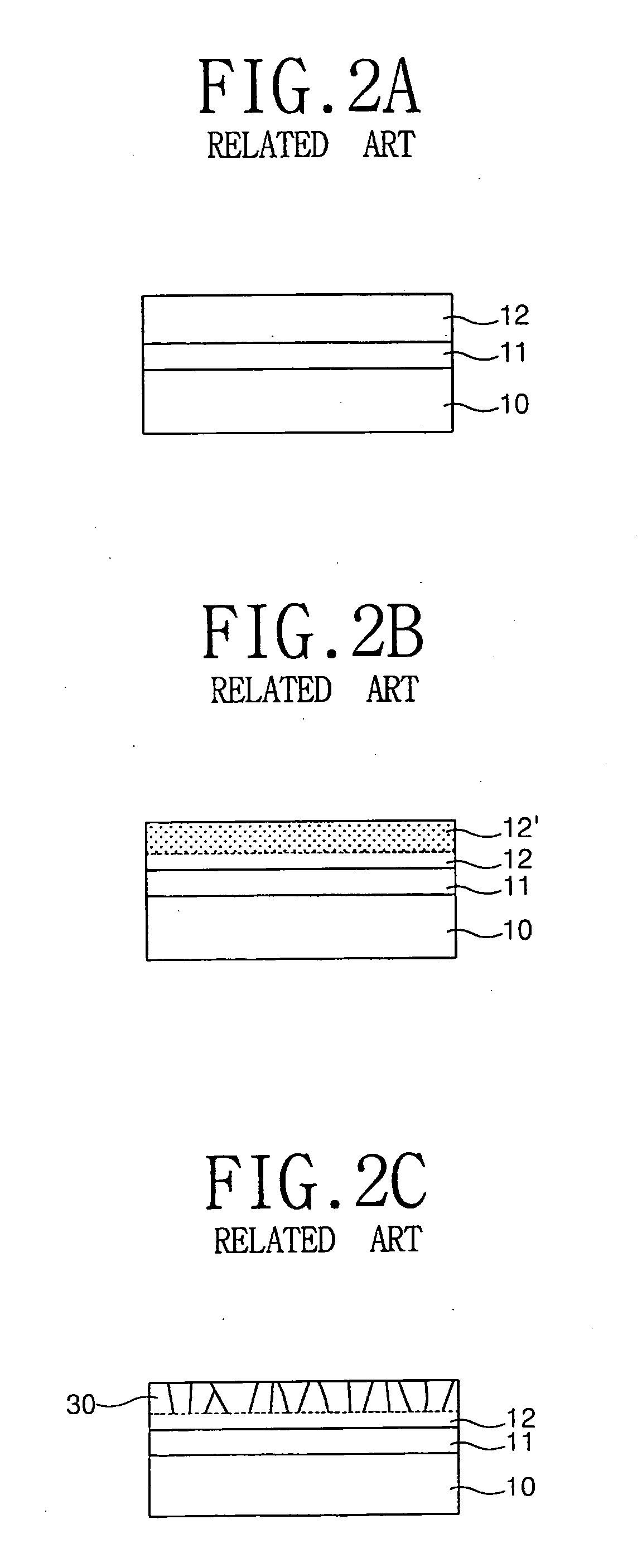

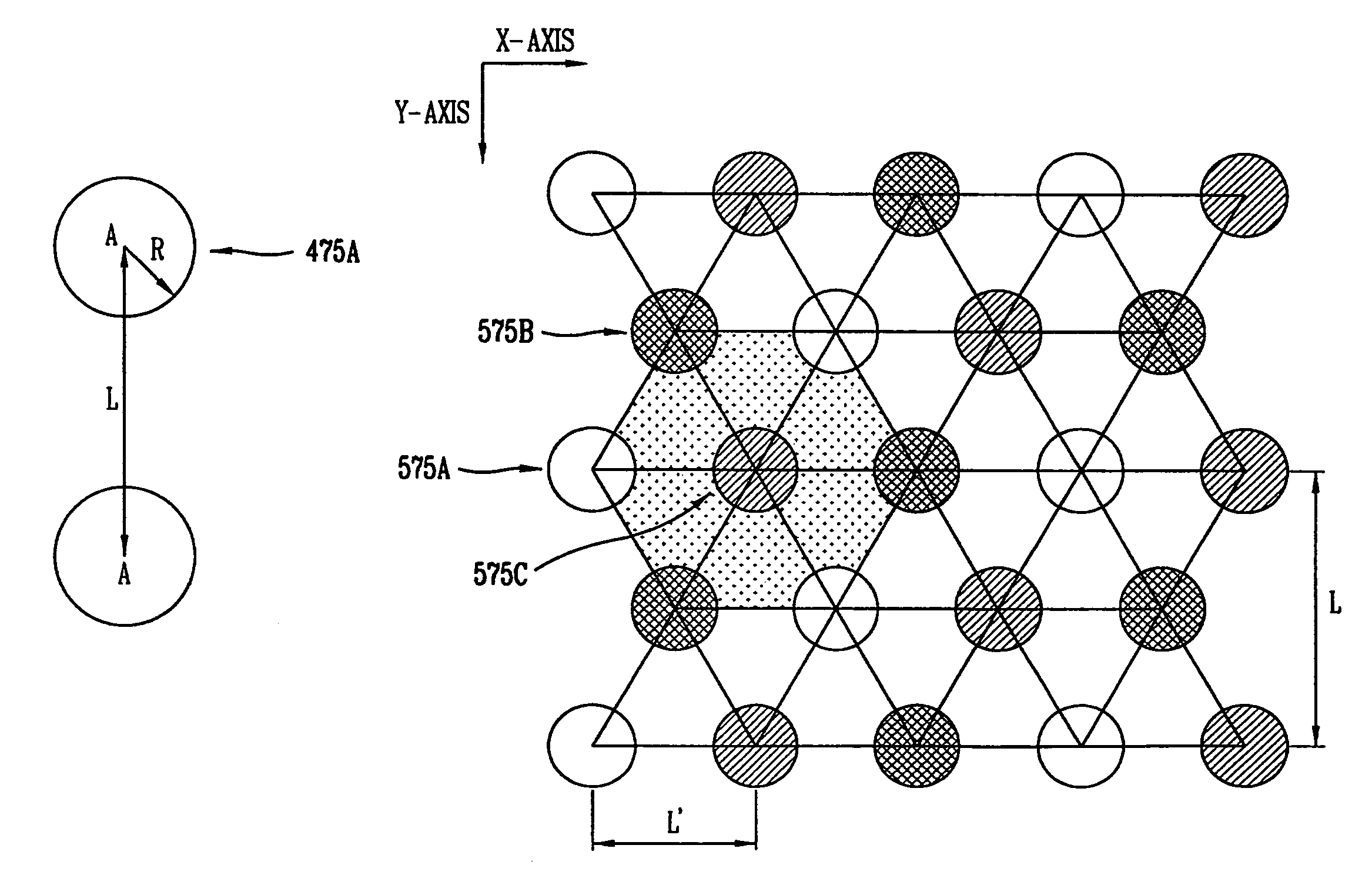

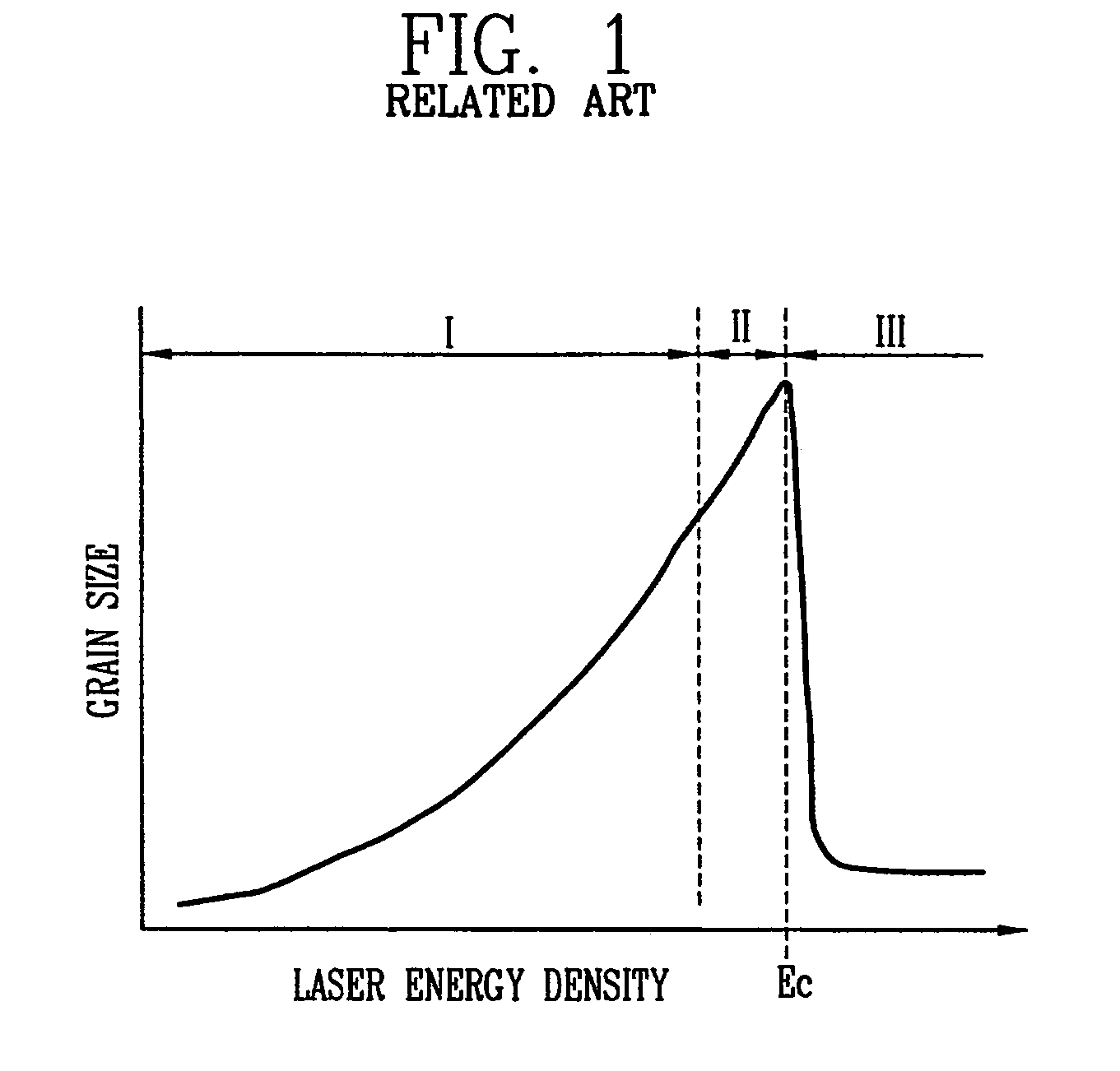

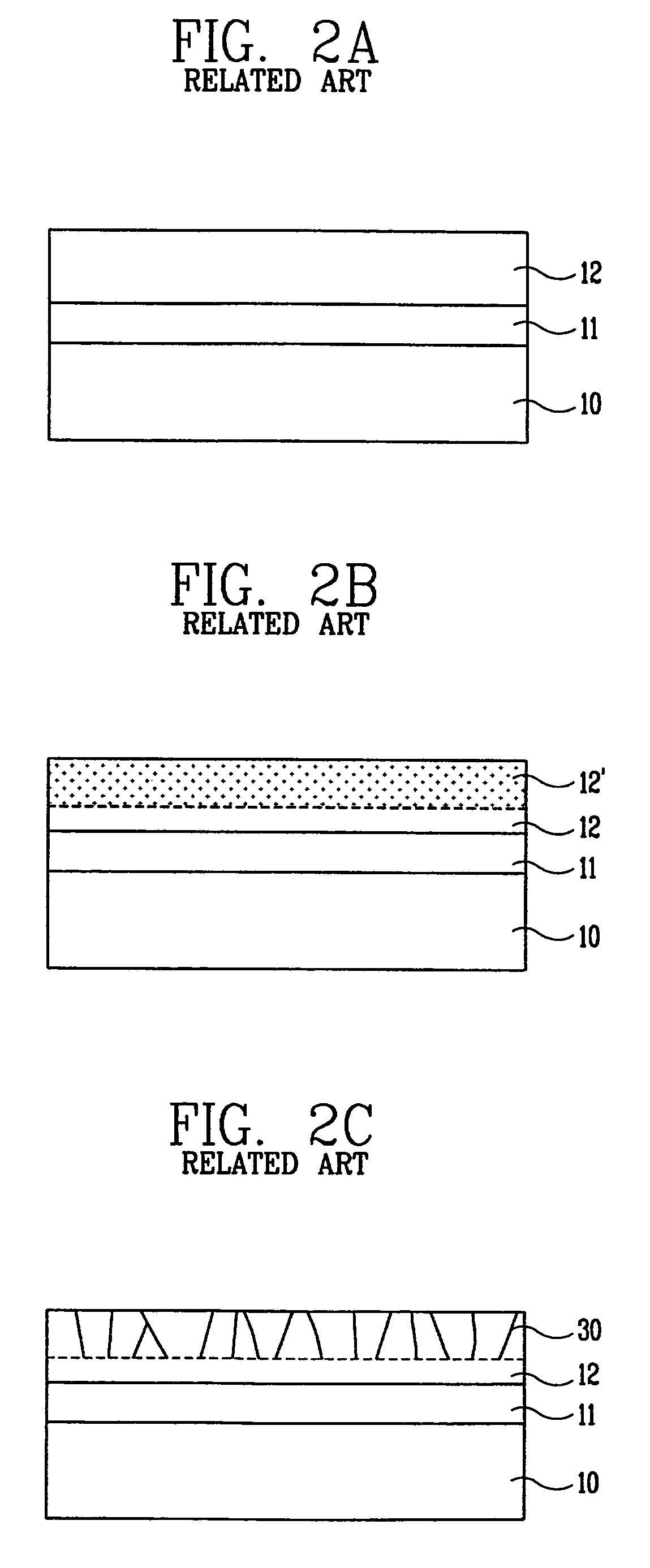

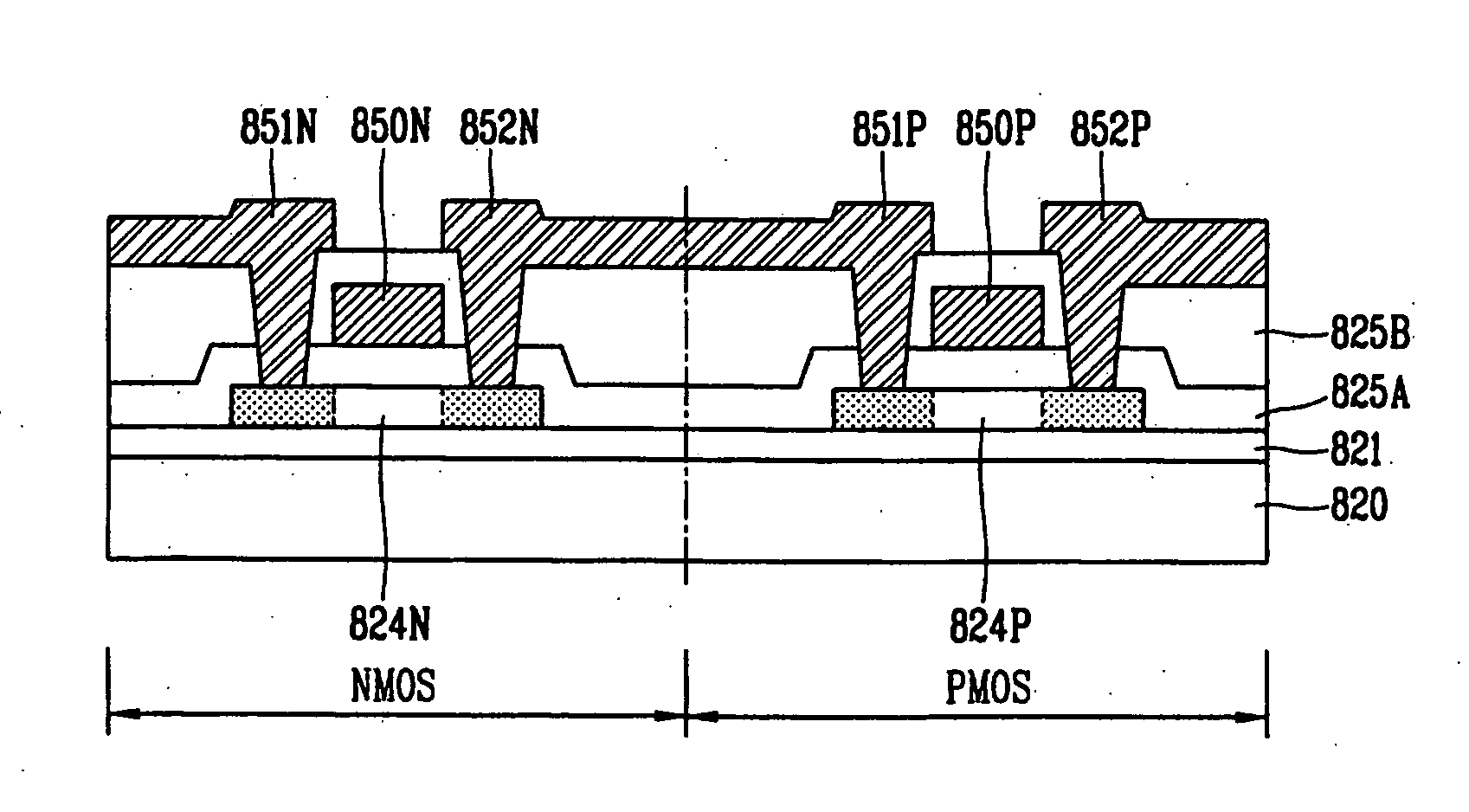

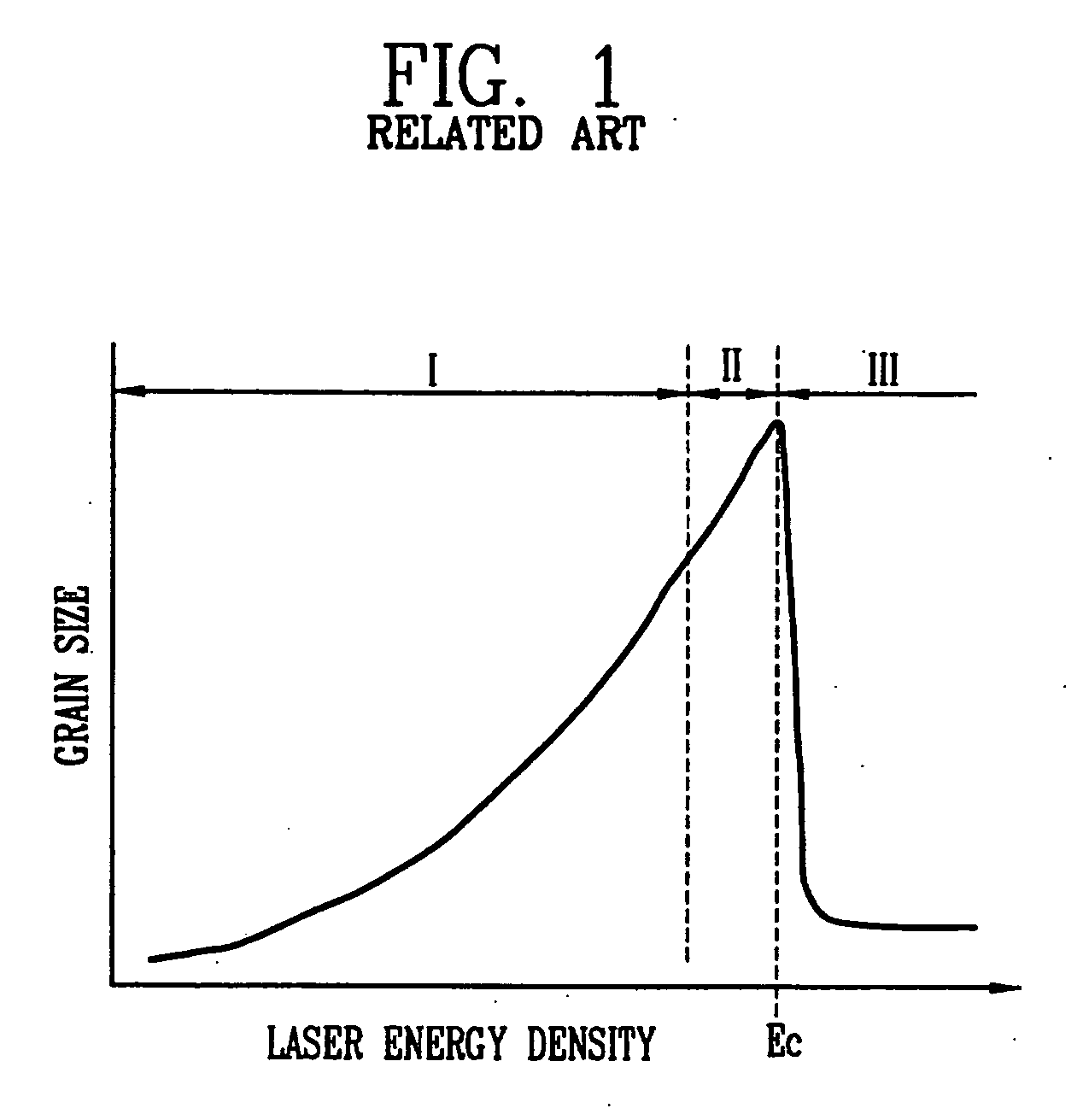

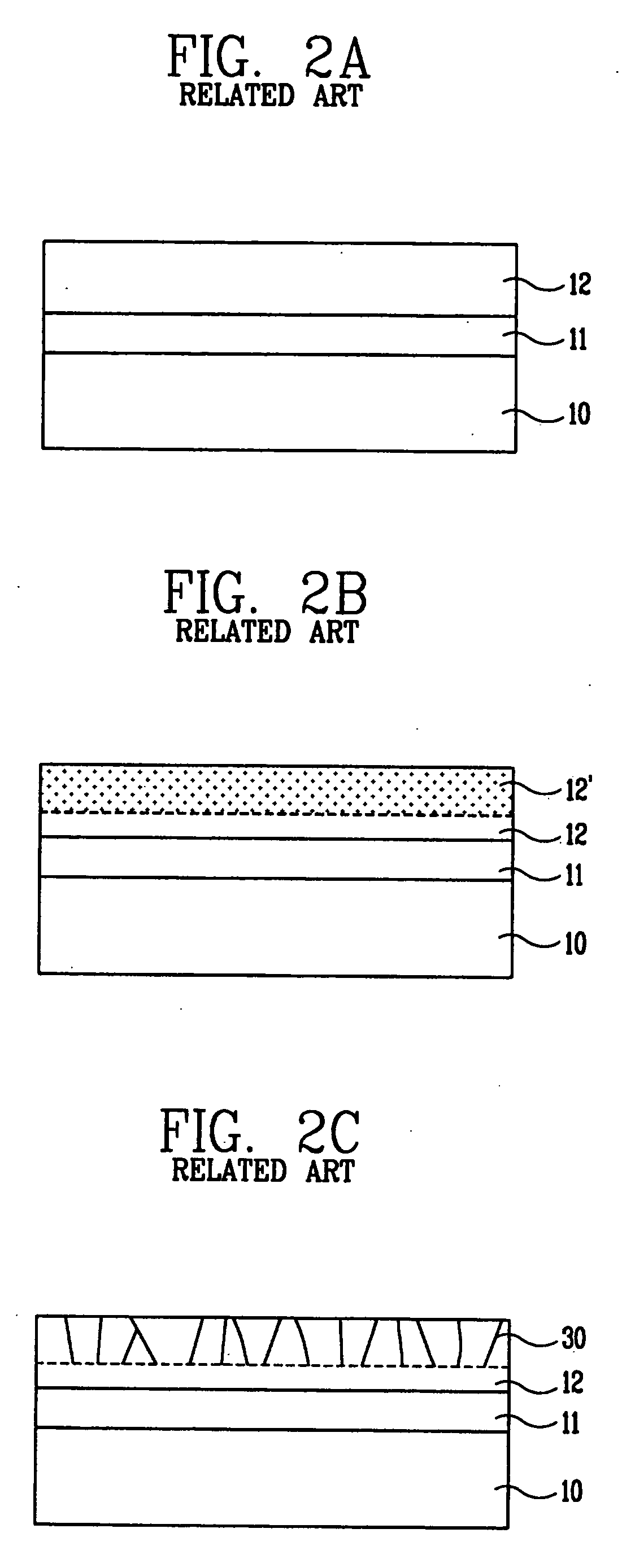

Laser mask and crystallization method using the same

InactiveUS20050139788A1Improve crystallization characteristicImprove crystallization propertiesTransistorElectric discharge tubesLaser beamsSemiconductor

A crystallization method using a mask includes providing a substrate having a semiconductor layer; positioning a mask over the substrate, the mask having first, second and third blocks, each block having a periodic pattern including a plurality of transmitting regions and a blocking region, the periodic pattern of the first block having a first position, the periodic pattern of the second block having a second position, the periodic pattern of the third block having a third position, the first, second and third positions being different from each other; and crystallizing the semiconductor layer by irradiating a laser beam through the mask.

Owner:LG DISPLAY CO LTD

Laser mask and crystallization method using the same

ActiveUS20050139925A1Improve crystallization propertiesTransistorSolid-state devicesIrradiation laserSilicon thin film

A crystallization method includes providing a substrate having a silicon thin film; positioning a laser mask having first to fourth blocks on the substrate, each block having a periodic pattern including a plurality of transmitting regions and a blocking region; and crystallizing the silicon thin film by irradiating a laser beam through the laser mask. A polycrystalline silicon film crystallized by this method is substantially free from a shot mark, and has uniform crystalline characteristics.

Owner:LG DISPLAY CO LTD

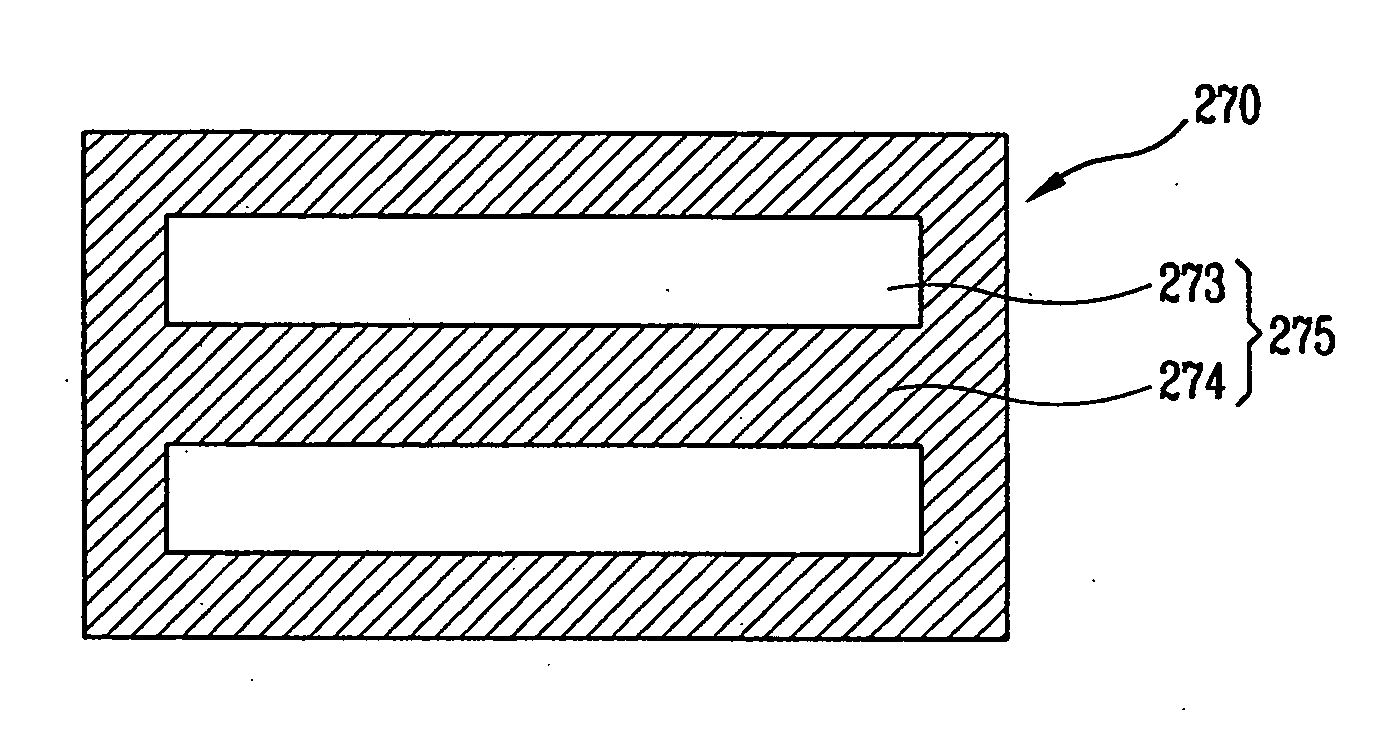

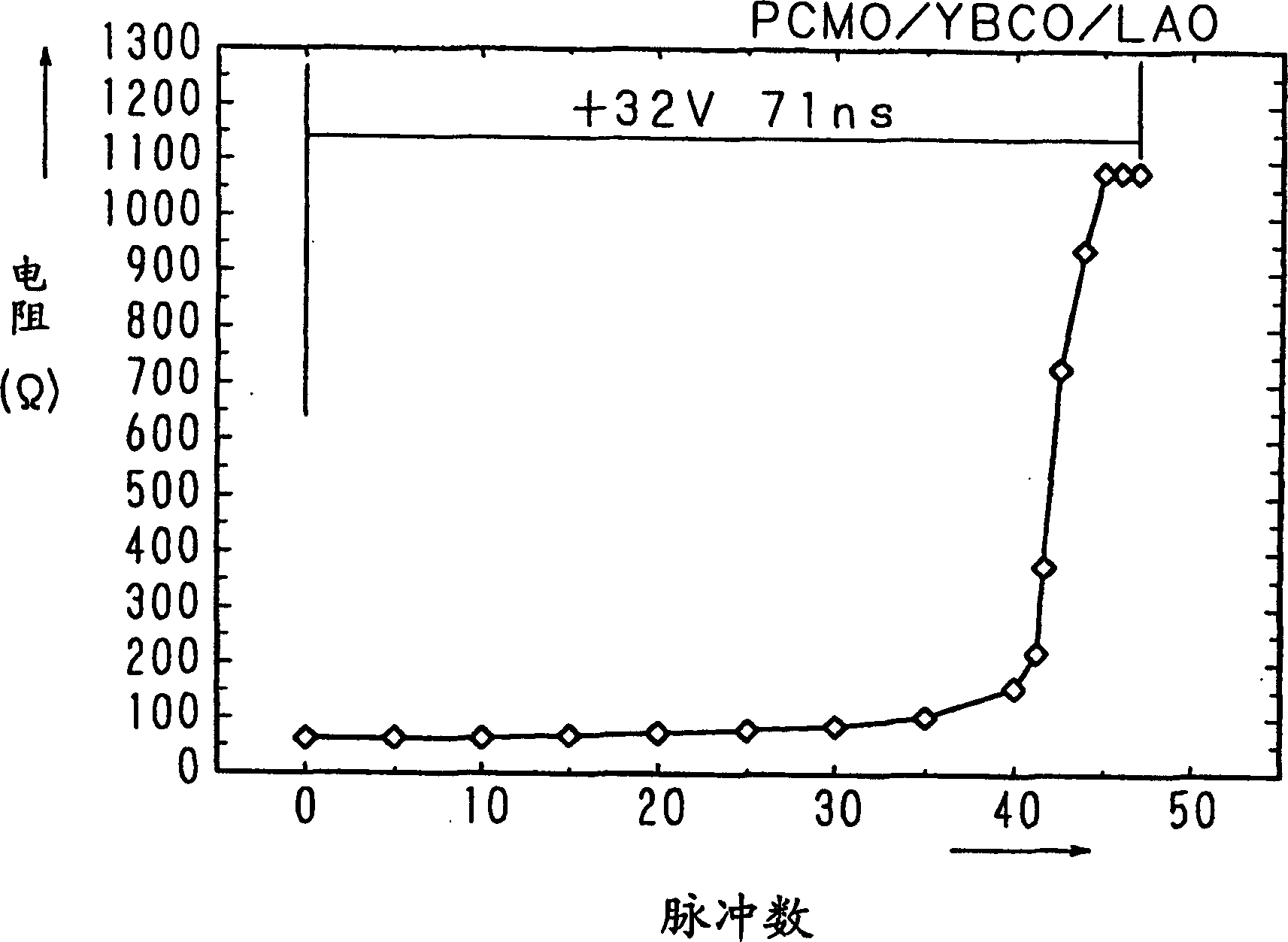

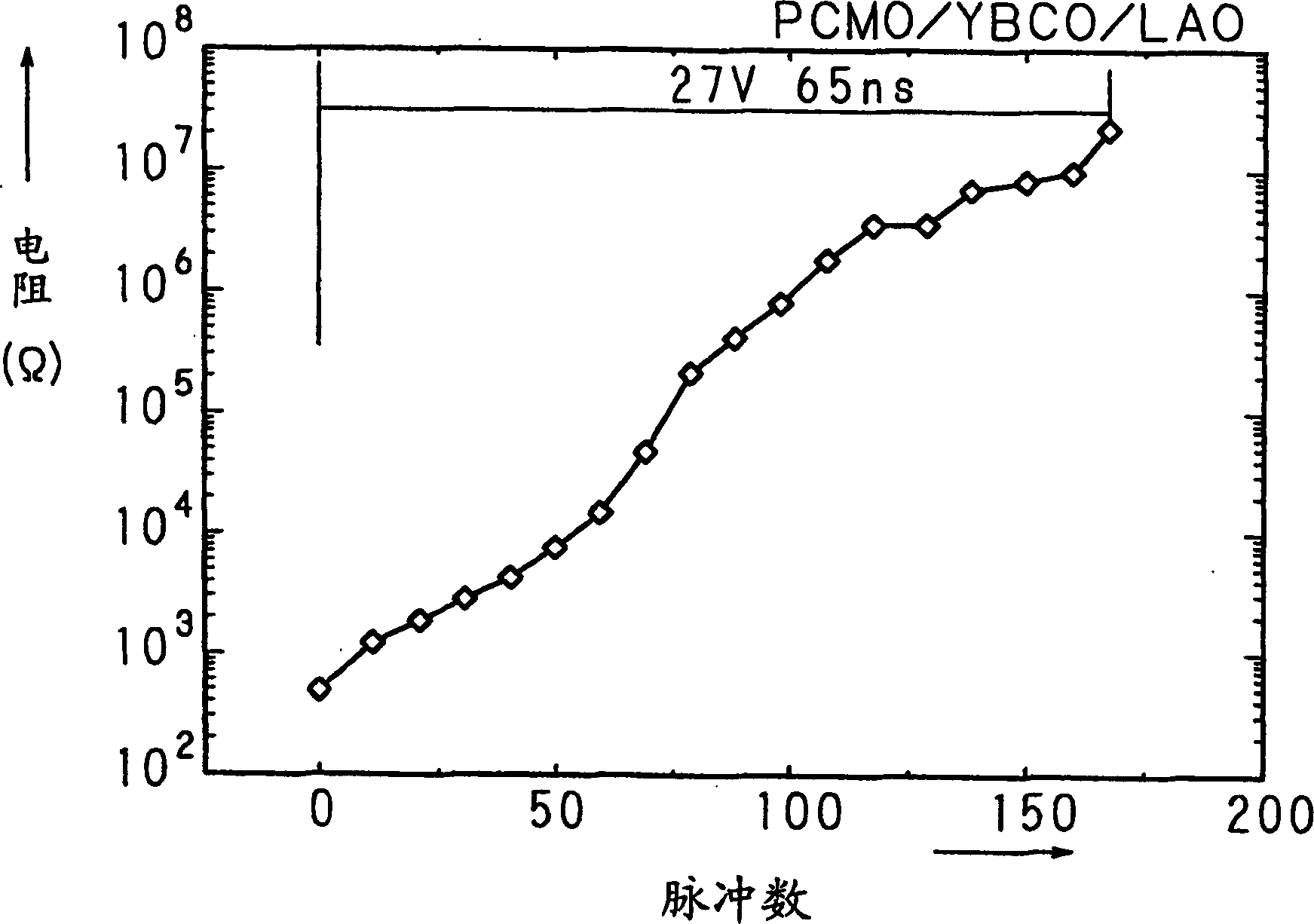

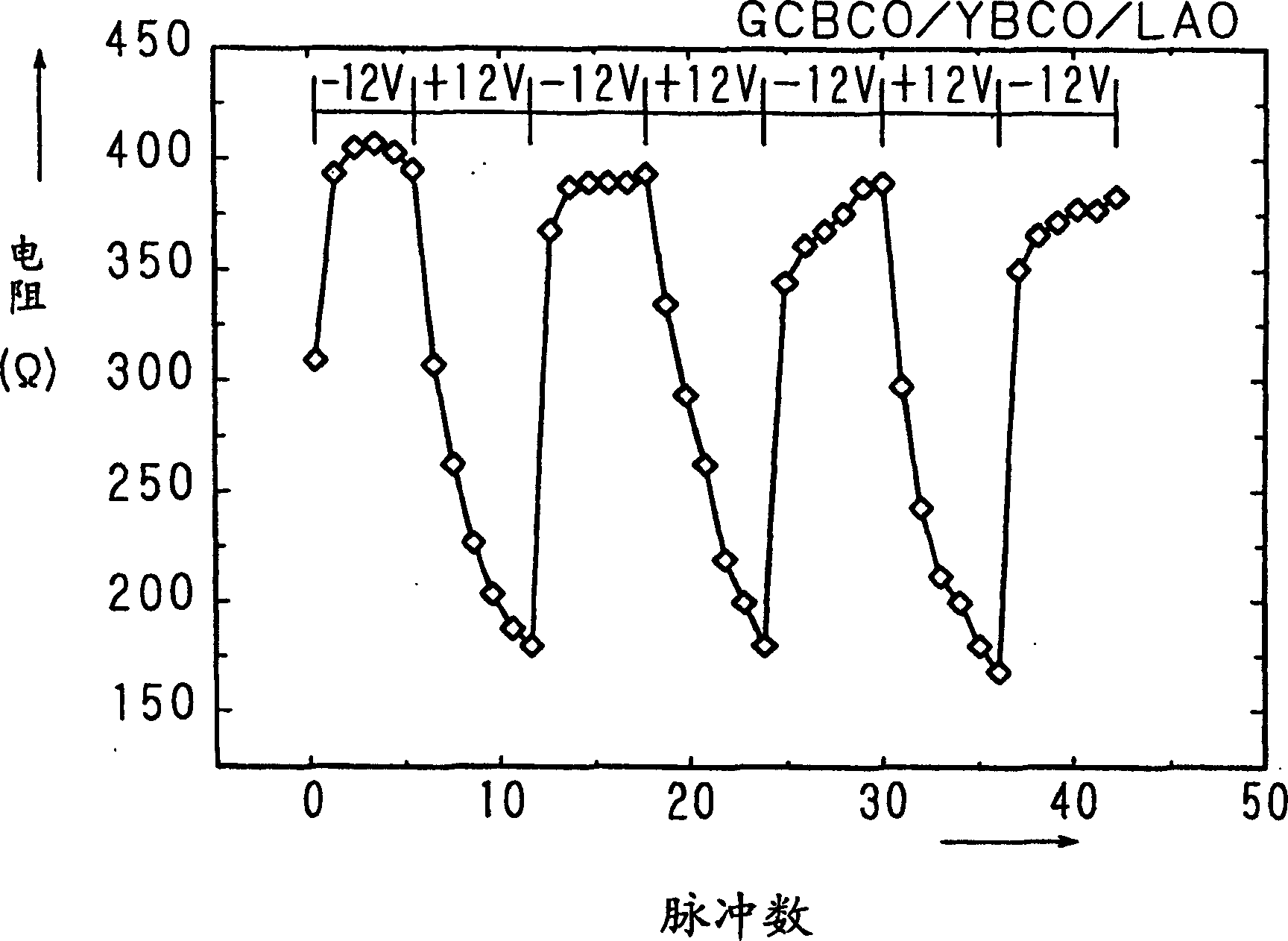

Memory cell, memory device and manufacturing method of memory cell

InactiveCN1542848APositive-going threshold voltage reductionLess prone to read disturbSolid-state devicesDigital storageBit lineComputer architecture

A memory cell (33) in which a variable resistive element (31) and a Schottky diode (32) are connected in series to each other. In a memory device, bit lines (BL0, BL1 and BL2) are arranged in a column direction, one end of the bit line (BL) is connected to a bit line decoder (34), and the other end thereof is connected to a reading circuit (37). Word lines (WL0, WL1 and WL2) are arranged in a row direction so as to intersect with the bit lines (BL), and both ends of the word line (WL) are connected to word line decoders (35 and 36). In other words, the bit line (BL) and the word line (WL) are arranged in a matrix and a memory cell (33) is located at a position where the bit line (BL) and the word line (WL) intersect with each other, which constitutes the memory device. An influence of a reading disturbance in the memory cell (33) and the memory device is reduced.

Owner:SHARP KK

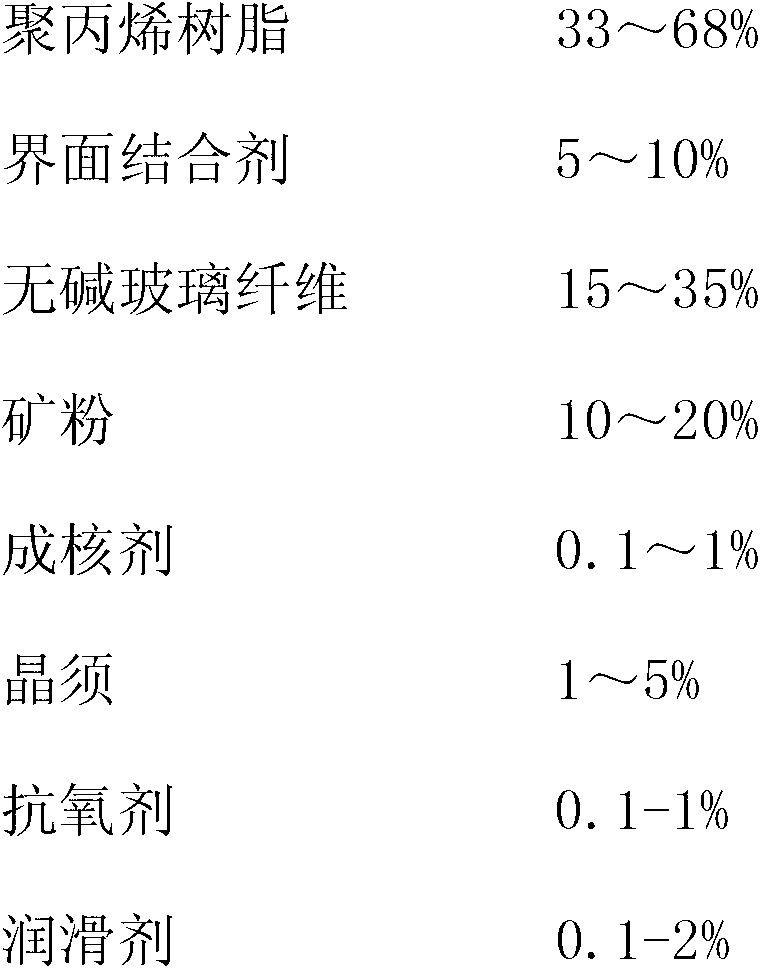

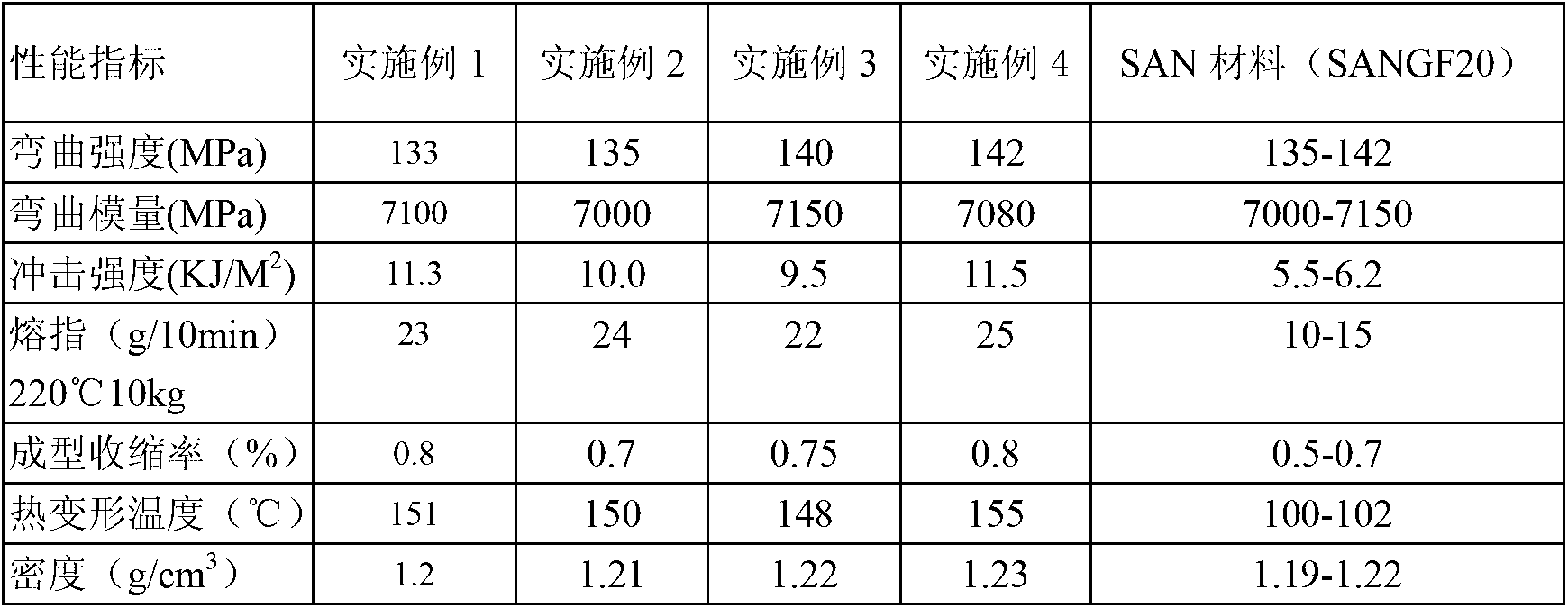

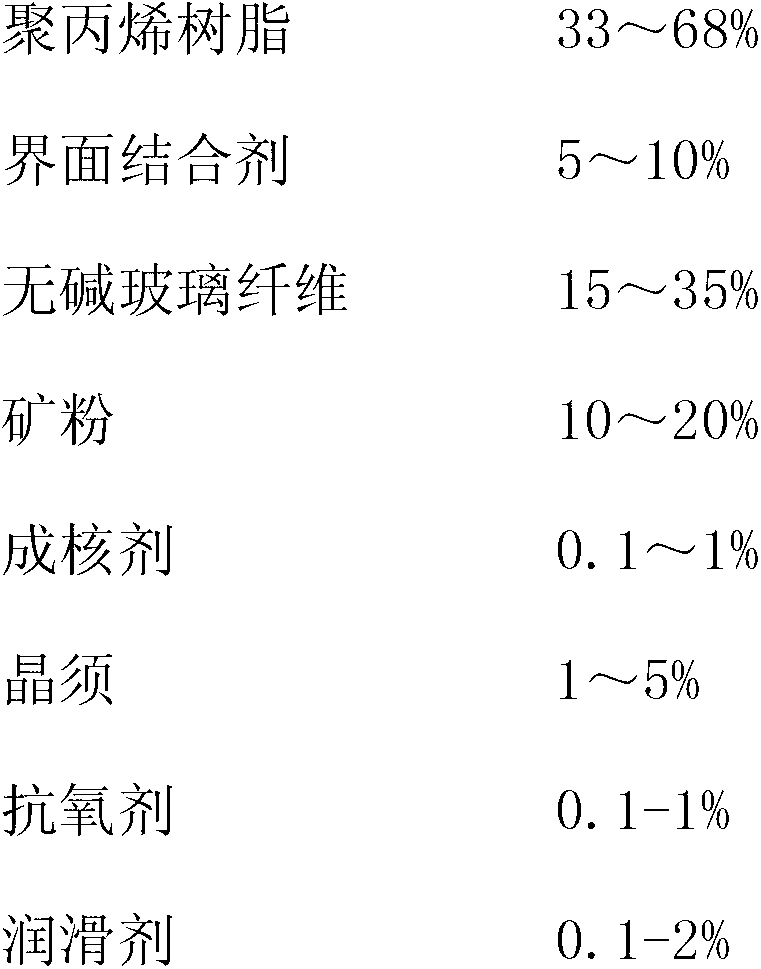

Special air conditioner wind wheel material with high rigidity, high heat resistance and low shrinkage, and preparation method of special air conditioner wind wheel material

ActiveCN103073794AOvercome Die Adaptability DifficultiesImprove crystallization propertiesPolypropyleneInterface bonding

The invention discloses a special air conditioner wind wheel material with high rigidity, high heat resistance and low shrinkage, and a preparation method of the special air conditioner wind wheel material. The special air conditioner wind wheel material is composed of the following materials by weight: 33-68% of polypropylene resin, 5-10% of interface bonding agent, 15-35% of alkali-free glass fiber, 10-20% of mineral powder, 0.1-1% of nucleating agent, 1-5% of crystal whisker, 0.1-1% of antioxygen, and 0.1-2% of lubricant. The rigidity index of the wine wheel material is up to 7000Mpa, the molding shrinkage is 0.6%, both the rigidity index and the molding shrinkage are about the same as those of a universal SAN material wind wheel, and the best advantage is that the molding liquidity, the heat resistance and the toughness are all better than those of the SAN material wind wheel. All selected materials of the invention meet the environmental requirement of European Union ROSH. The raw materials of the special air conditioner wind wheel material are easy to get, the energy consumption is low, the machine wear rate is small, the cost is low, the recycling is easy, and the special air conditioner wind wheel material is suitable for replacing the SAN material wind wheel.

Owner:武汉顺威赛特工程塑料有限公司

Laser mask and crystallization method using the same

InactiveUS7316871B2Improve featuresImprove crystallization propertiesTransistorSemiconductor/solid-state device manufacturingEngineeringIrradiation laser

A crystallization method using a mask includes providing a substrate having a semiconductor layer; positioning a mask over the substrate, the mask having first, second and third blocks, each block having a periodic pattern including a plurality of transmitting regions and a blocking region, the periodic pattern of the first block having a first position, the periodic pattern of the second block having a second position, the periodic pattern of the third block having a third position, the first, second and third positions being different from each other; and crystallizing the semiconductor layer by irradiating a laser beam through the mask.

Owner:LG DISPLAY CO LTD

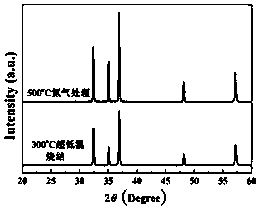

Method for preparing high-conductivity zinc oxide ceramic at ultralow temperature

ActiveCN108546110ALower densification temperatureImprove crystallization propertiesEnvironmental resistanceOxide ceramic

The invention discloses a method for preparing high-conductivity zinc oxide ceramic at ultralow temperature. The method comprises the following steps: taking zinc oxide powder as a raw material and anorganic acid solution or a zinc acetate solution as a solvent, grinding, pelleting, performing ultralow temperature sintering, and thermally treating in an inert atmosphere, thereby obtaining the zinc oxide ceramic. The densification temperature of the zinc oxide ceramic prepared according to the preparation method is far lower than that in a traditional sintering method, the density of the zincoxide ceramic prepared according to the preparation method can reach 99.0% or above, the crystalline grain size can be controlled to be below 2 mu m, and the conductivity can reach 1.5 S / cm or higher.The preparation method has the advantages of being simple in process, low in energy consumption, greens environmental protection, high practicability and good application prospect.

Owner:GUANGXI UNIV

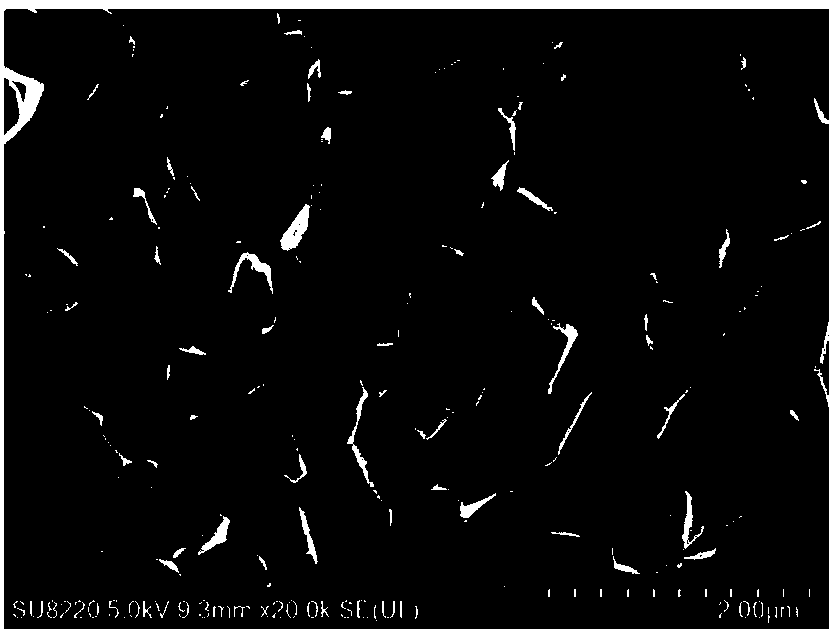

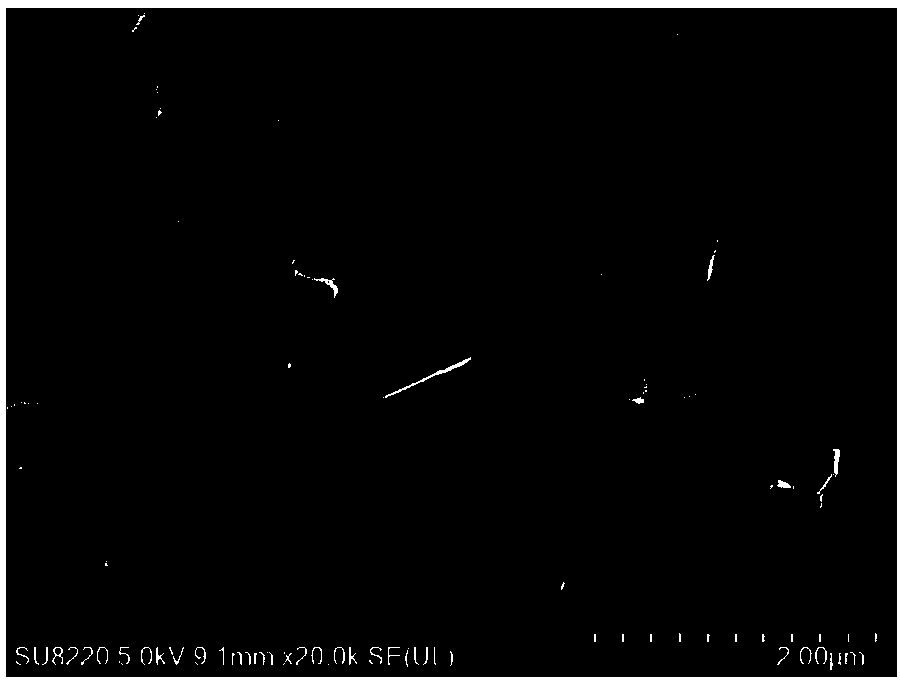

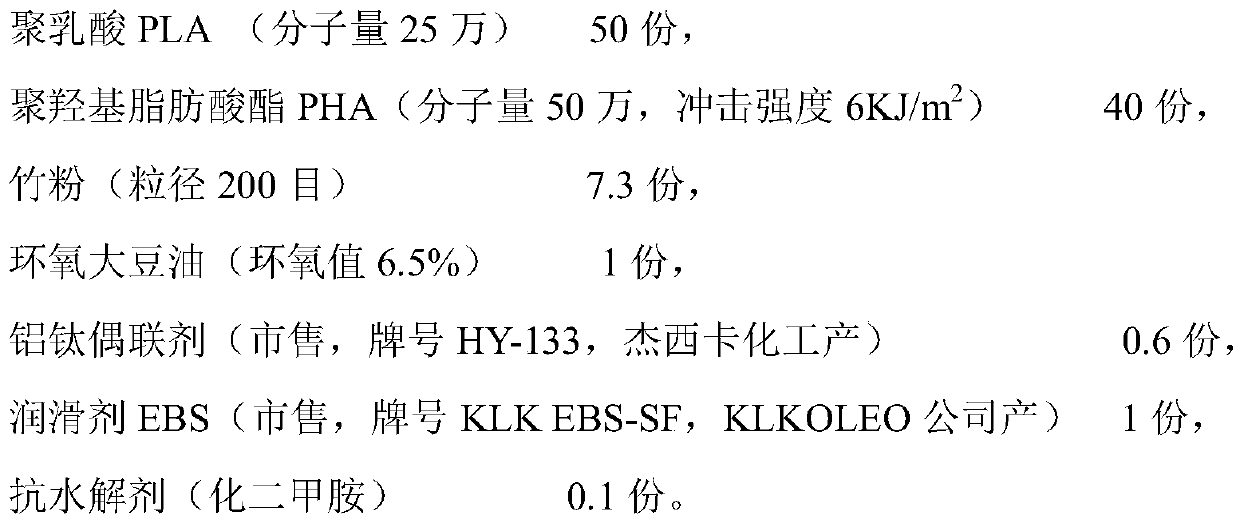

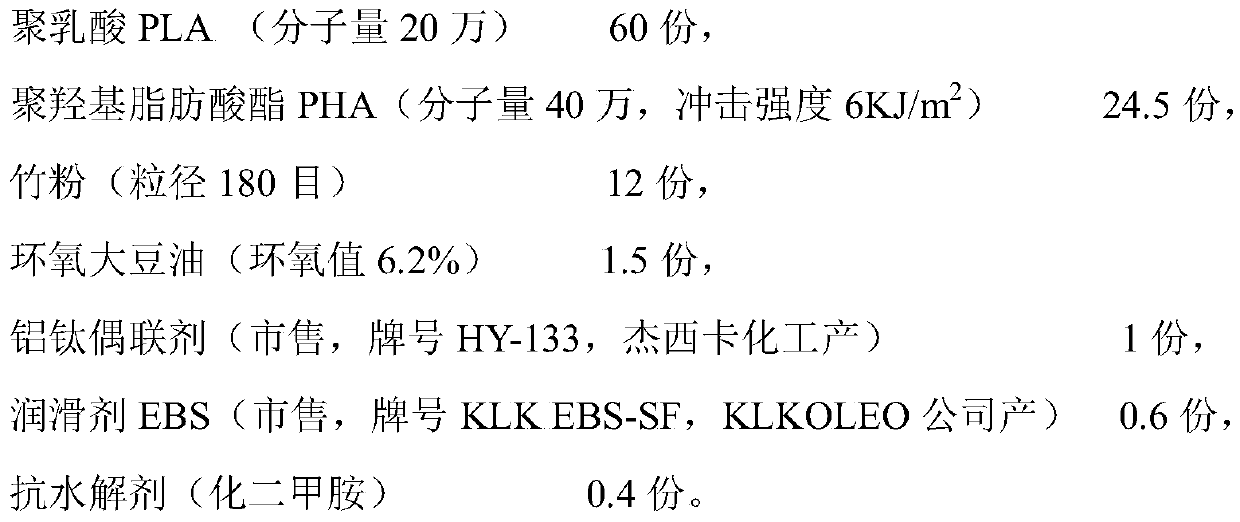

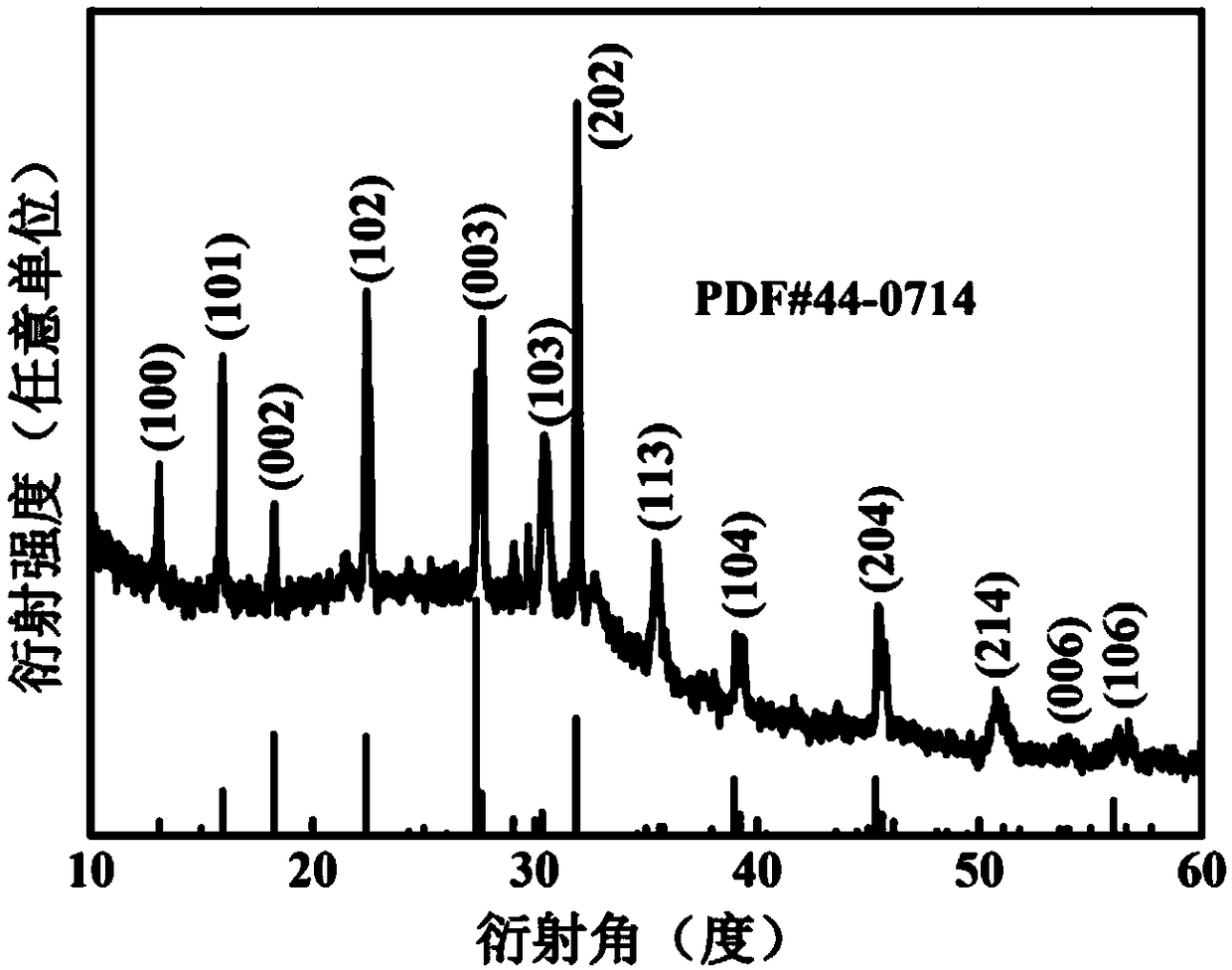

Biodegradable straw and preparation method thereof

ActiveCN111040398AImprove crystallization propertiesIncrease glass transition temperature and thermal stabilitySOYBEAN SEED OILSoybean oil

The invention discloses a biodegradable straw and a preparation method thereof. The straw comprises, by mass, 50%-80% of polylactic acid, 10%-40% of polyhydroxyalkanoate, 3%-12% of bamboo powder, 1%-2% of epoxidized soybean oil, 0.3%-1% of an aluminum-titanium coupling agent, 0.1%-1% of a lubricating agent and 0.1%-1% of an anti-hydrolysis agent. The preparation method comprises the following steps: uniformly stirring the bamboo powder and the aluminum-titanium coupling agent to obtain a bamboo powder pretreated material for later use; sequentially adding the epoxidized soybean oil, the bamboopowder pretreated material, the lubricant and the anti-hydrolysis agent into a resin mixture of the polylactic acid and the polyhydroxyalkanoate at a stirring speed of 100-250 r / min, and uniformly stirring to form a polylactic acid mixture; and adding the polylactic acid mixture into double-screw extrusion equipment, extruding a straw blank, and sequentially carrying out water cooling, air cooling, water removal and cutting on the straw blank under the traction of traction equipment to obtain the biodegradable straw product. The biodegradable straw material can effectively prolong the degradation time of the PLA straw, improve the mechanical properties of the PLA straw, and effectively improve the harmful bacterium inhibition ability of the straw.

Owner:NANJING PRIDE PLASTIC TECH

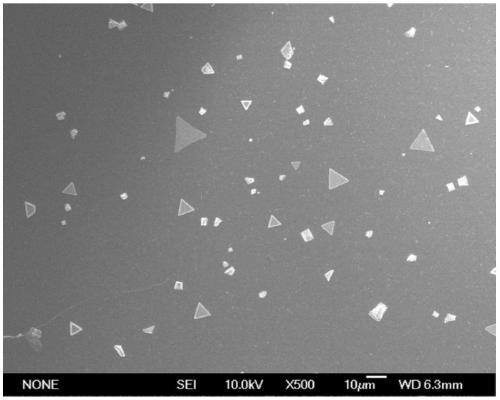

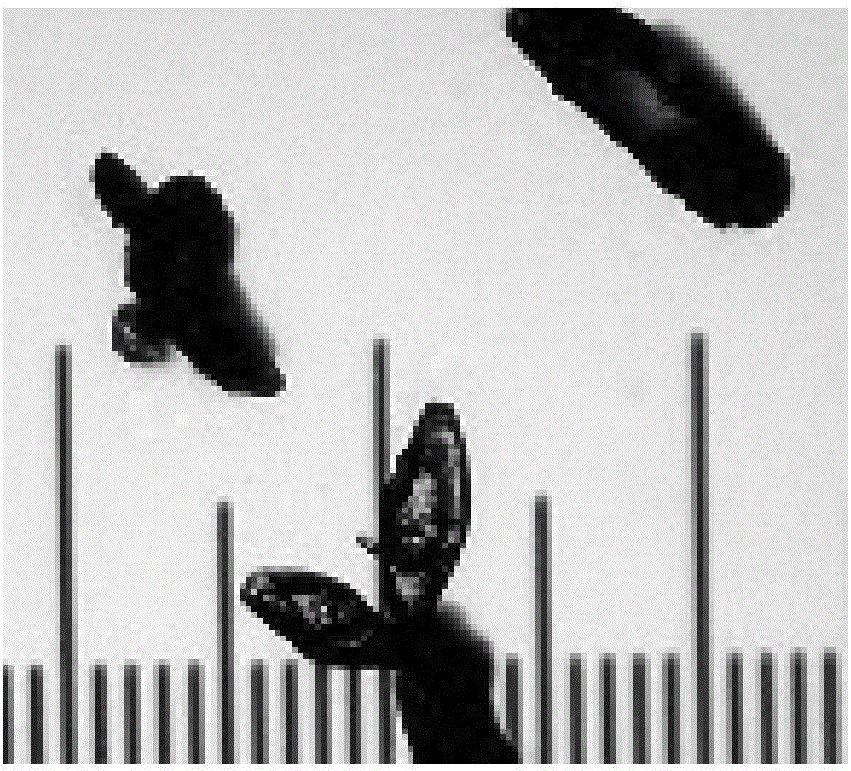

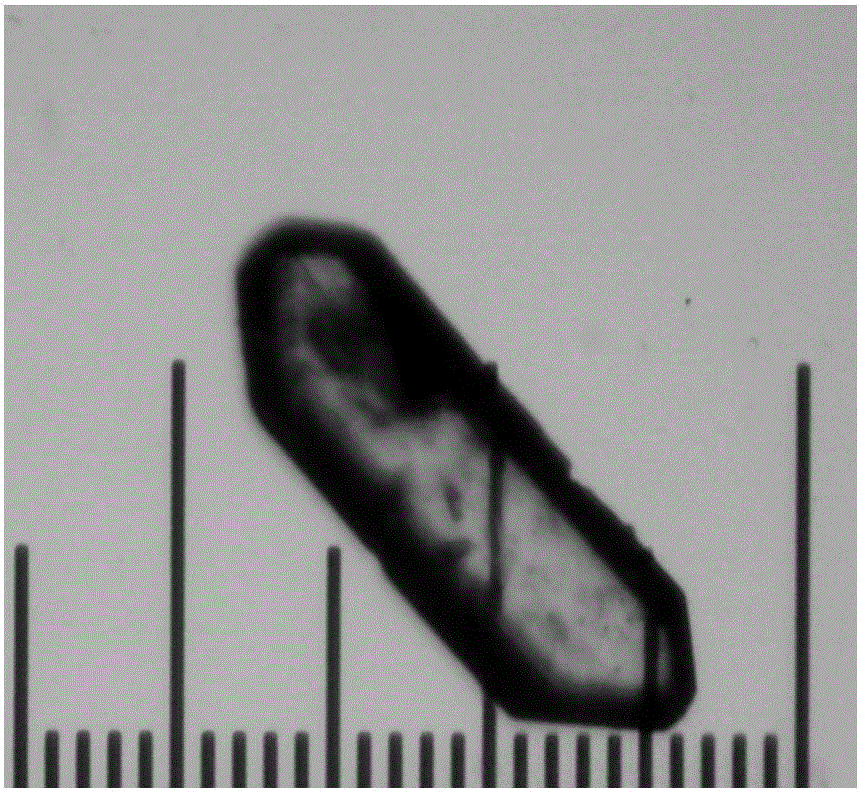

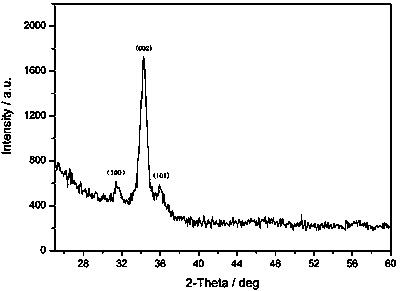

Inorganic non-lead caesium bismuth halogen Cs3Bi2X9 perovskite micrometer disc and synthesis method thereof

ActiveCN109052470ASolve easily decomposable puzzlesSimple processMaterial nanotechnologyBismuth compoundsHalogenSynthesis methods

The invention discloses an inorganic non-lead caesium bismuth halogen Cs3Bi2X9 perovskite micrometer disc and a synthesis method thereof. The synthesis method comprises the following steps: (1) cleaning a liner; (2) preparing mixed powder of CsX and BiX3, wherein X=Cl, Br, or I; (3) putting the cleaned liner and the prepared mixed powder into a double-temperature zone horizontal tubular furnace; (4) setting the temperature, the temperature keeping time and the pressure intensity of the horizontal tubular furnace; (5) introducing high-purity argon as a carrier gas, thereby obtaining the inorganic non-lead caesium bismuth halogen Cs3Bi2X9 perovskite micrometer disc. The inorganic non-lead caesium bismuth halogen Cs3Bi2X9 perovskite micrometer disc disclosed by the invention is regular in shape, good in crystallization property, high in stability, and capable of solving the problems that the conventional lead-based perovskite material has toxicity and is easy to decompose in an atmosphereenvironment, and can be applied to preparation of novel photoelectric devices.

Owner:ZHENGZHOU UNIV

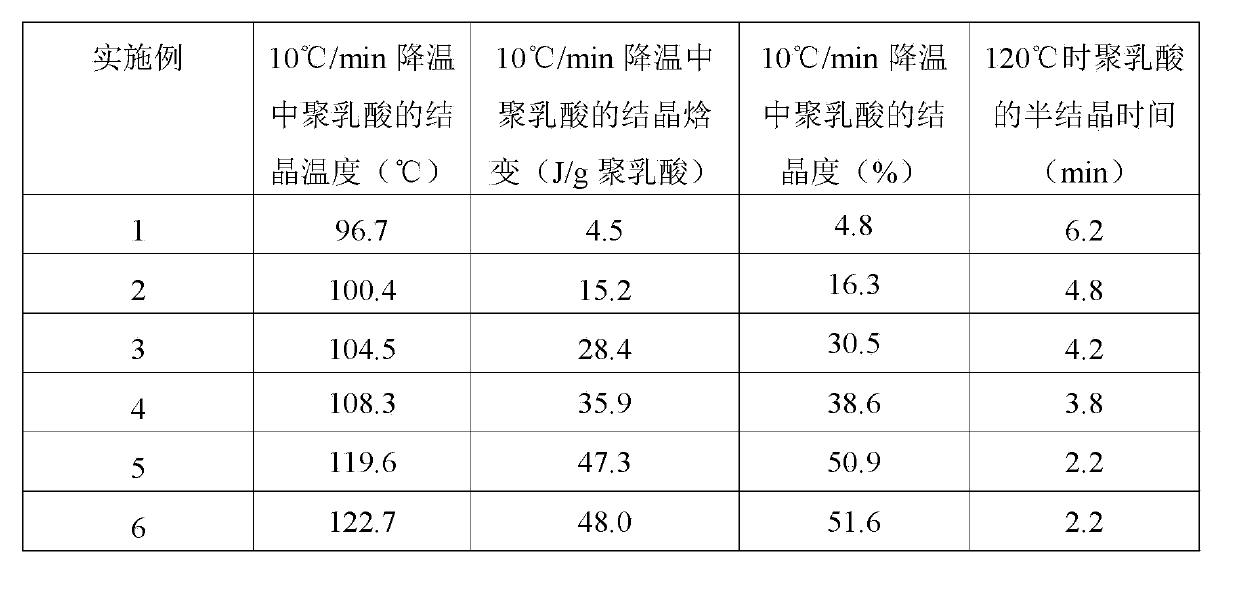

Method for accelerating crystallization of polylactic acid resin

ActiveCN103396659AImprove crystallization propertiesIncreased crystallinity and crystallization speedPolyvinylidene fluoridePolylactic acid

The invention relates to the technical field of polylactic acid modification and aims to provide a method for accelerating crystallization of polylactic acid resin. The method comprises the specific steps of: adding a semi-crystalline polylactic acid resin and a polymer-type crystallization promoter into a mixing apparatus; then mixing well in the mixing apparatus; and extruding for granulation, so as to obtain a rapid crystallization modification polylactic acid resin. The method employs organic high-molecular polymer-type crystallization promoter to improve crystallization performance of the polylactic acid, and the promoter has good compatibility with polylactic acid, improves nucleation effect, accelerates crystallization of polylactic acid, and improves processability and thermal behavior of the polylactic acid. Furthermore, a commercialized semi-crystalline polymer polyvinylidene fluoride having similar melting point as polylactic acid is used as the crystallization promoter for polylactic acid, and a melt blending method can be employed. The method provided by the invention has simple process, low cost and can realize large-scale industrialized production.

Owner:ZHEJIANG UNIV

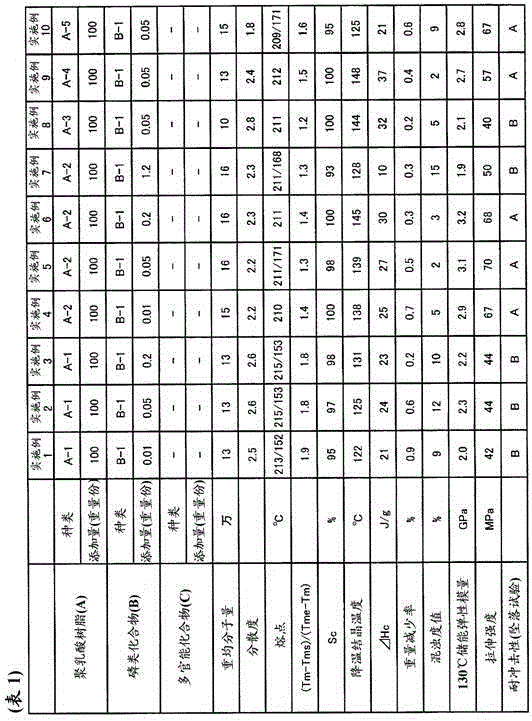

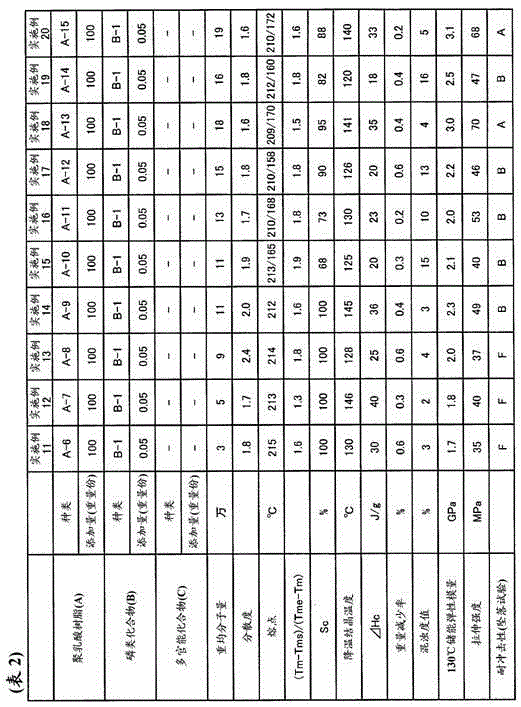

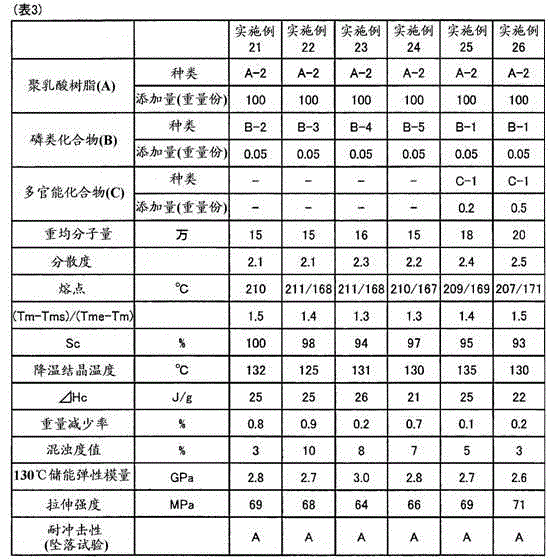

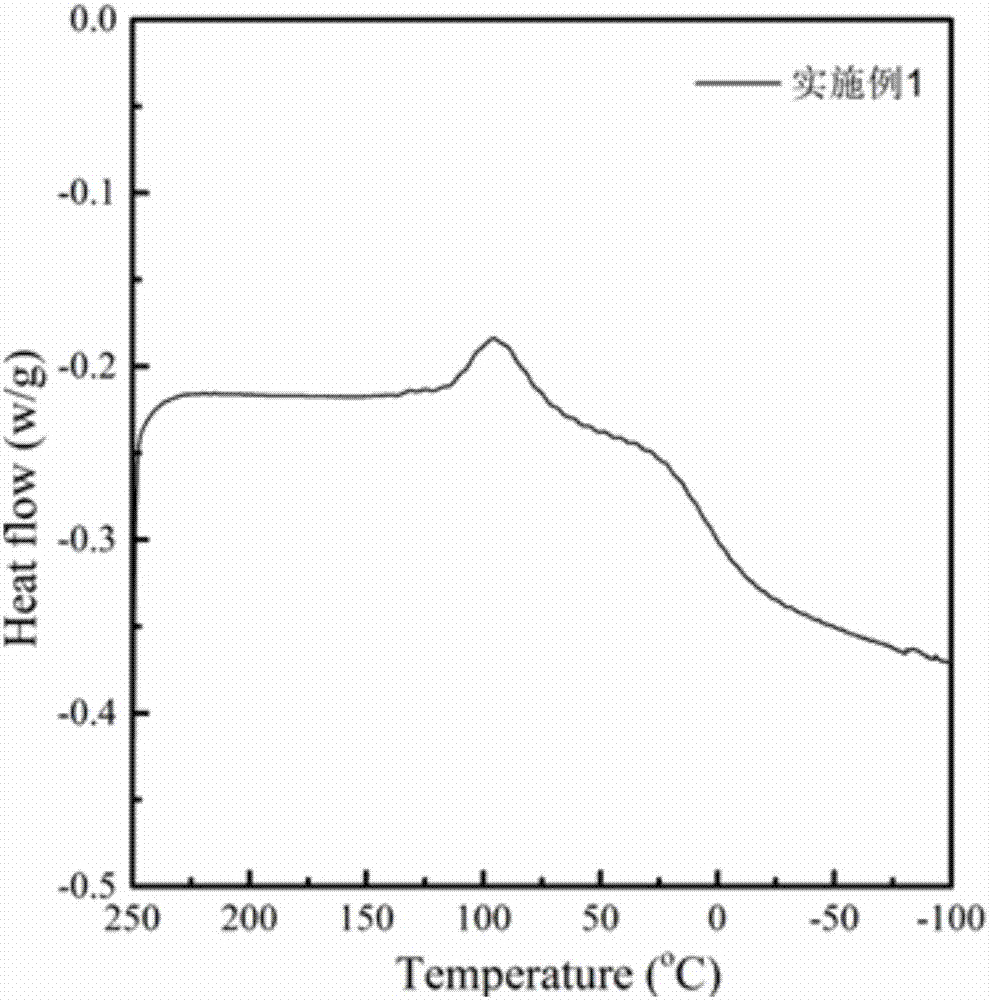

Polylactic acid resin composition, and method for producing molded article and polylactic acid resin composition

InactiveCN104704050AImprove heat resistanceImprove crystallization propertiesAlkaline earth metalPhosphoric acid

A polylactic acid resin composition containing from 0.005 part by weight to 1.2 parts by weight of a phosphoric acid metal salt represented by general formula MxHyPOz ((where M represents an alkali metal atom or alkaline earth metal atom; and x, y, and z are integers that satisfy 1≰x≰2, 1≰y≰4, and 2≰z≰8, respectively) per 100 parts by weight of polylactic acid resin comprising a poly-L-lactic acid component and a poly-D-lactic acid component, the heat of crystallization being 5 J / g or higher in differential scanning calorimetry when the polylactic acid resin composition is heated to 250°C, held in a constant-temperature state for 3 minutes, and then cooled at a cooling rate of 20°C / min.

Owner:TORAY IND INC

Production method of high-density ammonium metavanadate

ActiveCN106430305AHigh bulk densityIncrease surface tensionPolycrystalline material growthFrom normal temperature solutionsApparent densityHigh density

The invention discloses a production method of high-density ammonium metavanadate. The production method comprises the following main steps: (1) pre-adding an aid into a vanadium-containing solution; (2) heating the solution; (3) adding ammonium salt, so as to obtain an ammonium metavanadate precipitate; (4) cooling to completely precipitate vanadium; and (5) drying. The production method has the advantages that produced ammonium metavanadate is a perfect single crystal with thick particles, and the apparent density is higher than 1g / cm<3>, so that the dust problem in the operation can be effectively solved.

Owner:DALIAN RONGKE ENERGY STORAGE GRP CO LTD

Method for preparing zinc oxide electronic film at low temperature

ActiveCN103757613ALow deposition temperatureLow costLiquid/solution decomposition chemical coatingOrganic filmThermal decomposition method

The invention provides a method for preparing a zinc oxide electronic film at low temperature, which adopts a spray thermal decomposition process. The method comprises the following steps: precursor solution preparation and film deposition. The method is characterized in that the precursor solution is a [(Zn(NH3)4](OH)2 solution. By using the alkaline [(Zn(NH3)4](OH)2 solution as the precursor solution and a movable heating platform as a heating source and adopting the spray thermal decomposition process, the method can prepare the ZnO film with excellent crystallinity at 130 DEG C or so, has the advantages of no damage on the substrate, low cost, no pollution, no toxicity or harm and simple technique, and can implement large-area film preparation. The substrate material in the technique has wider selection range and small limits; and if a flexible organic film is used as the substrate, a special conveyor can be utilized to implement roll-to-roll production.

Owner:重庆鼎旺科技有限公司

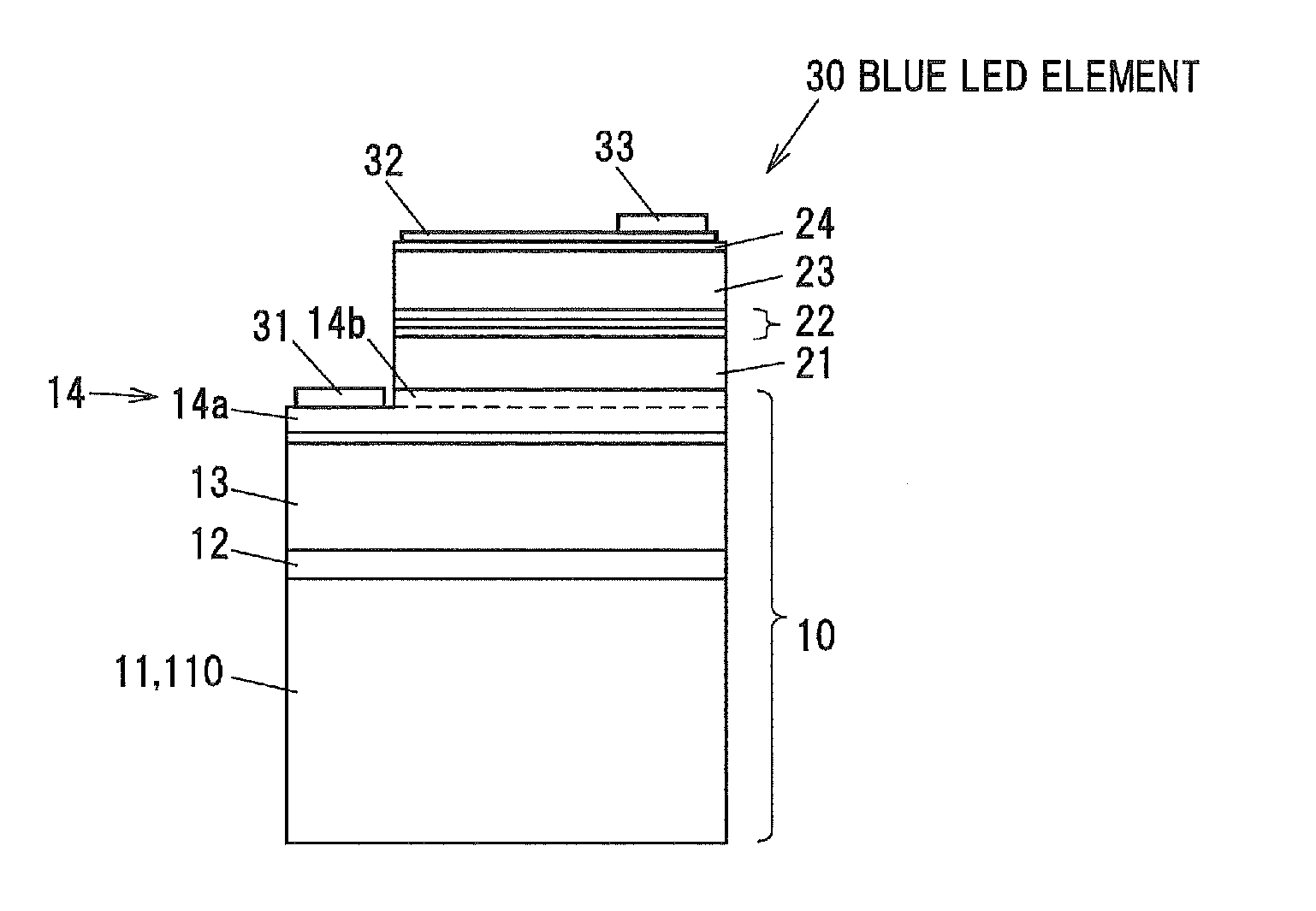

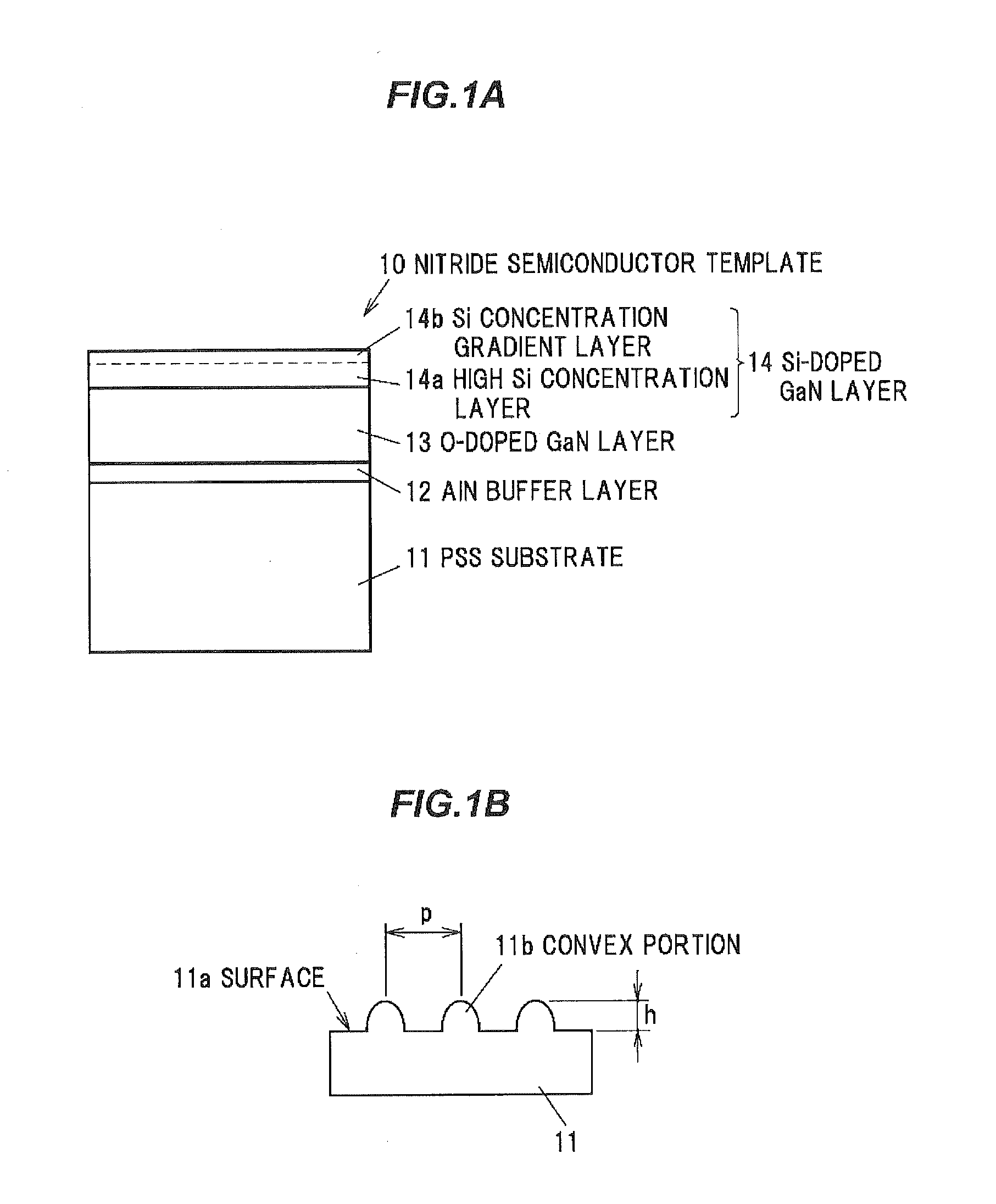

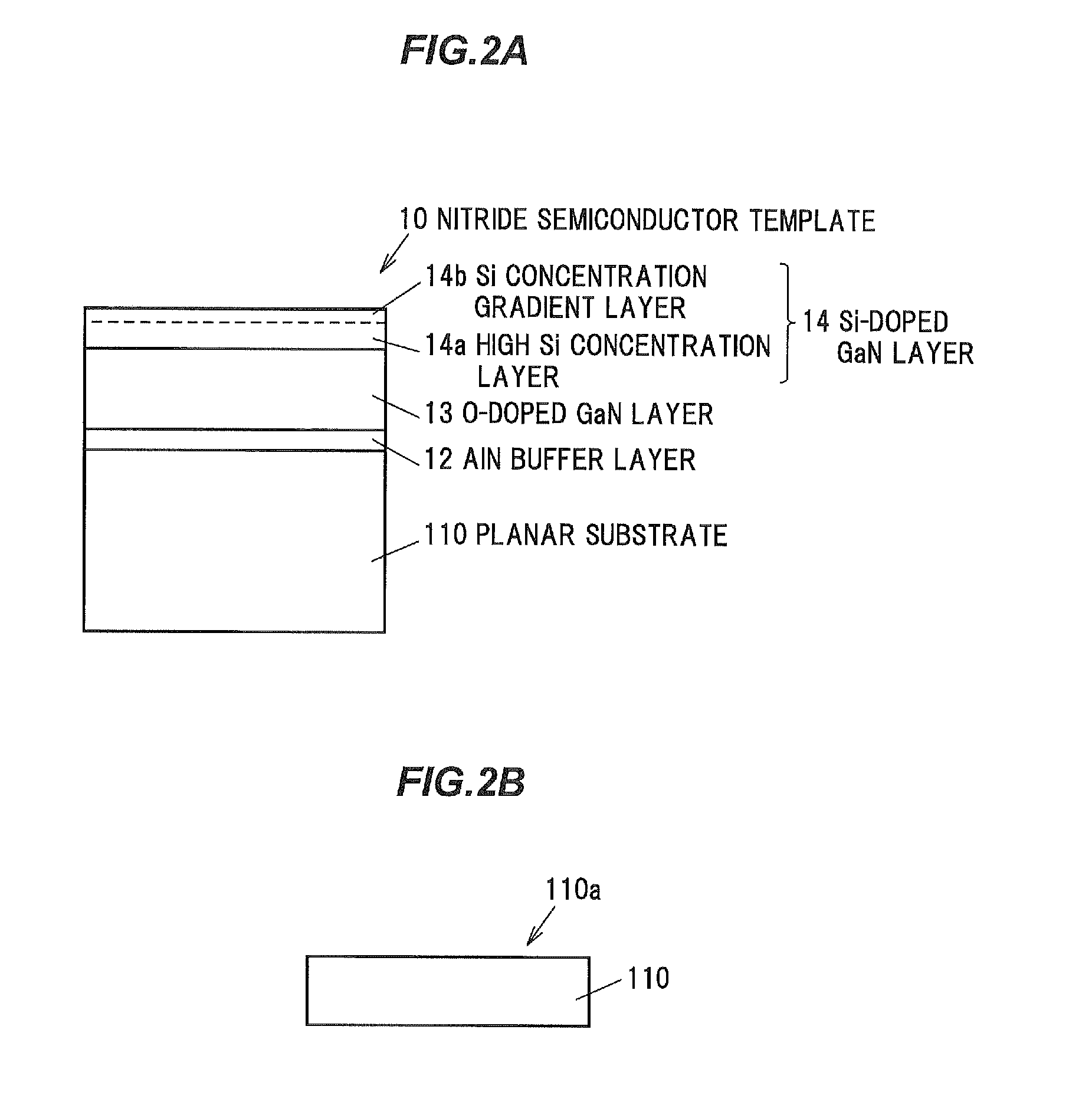

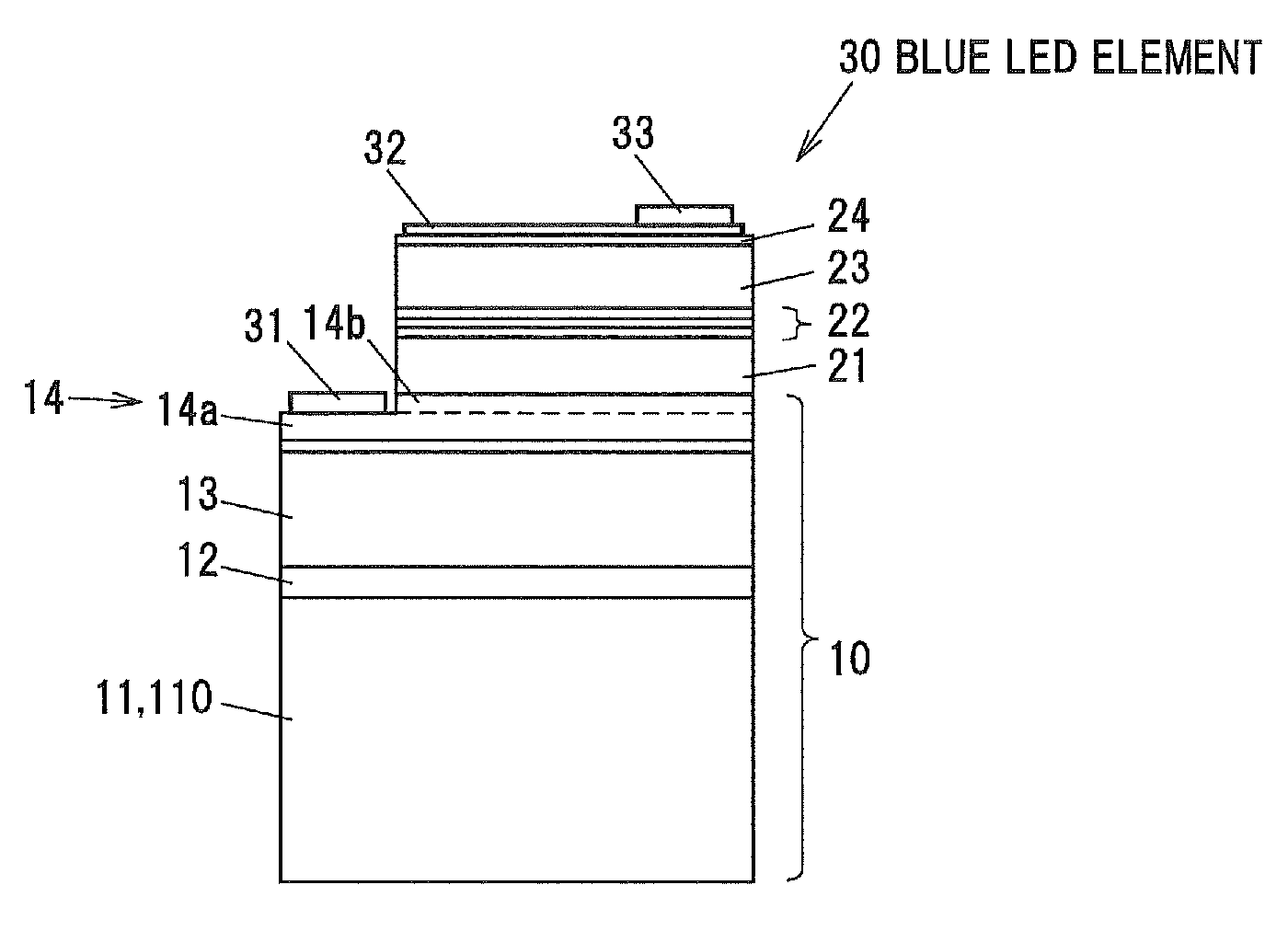

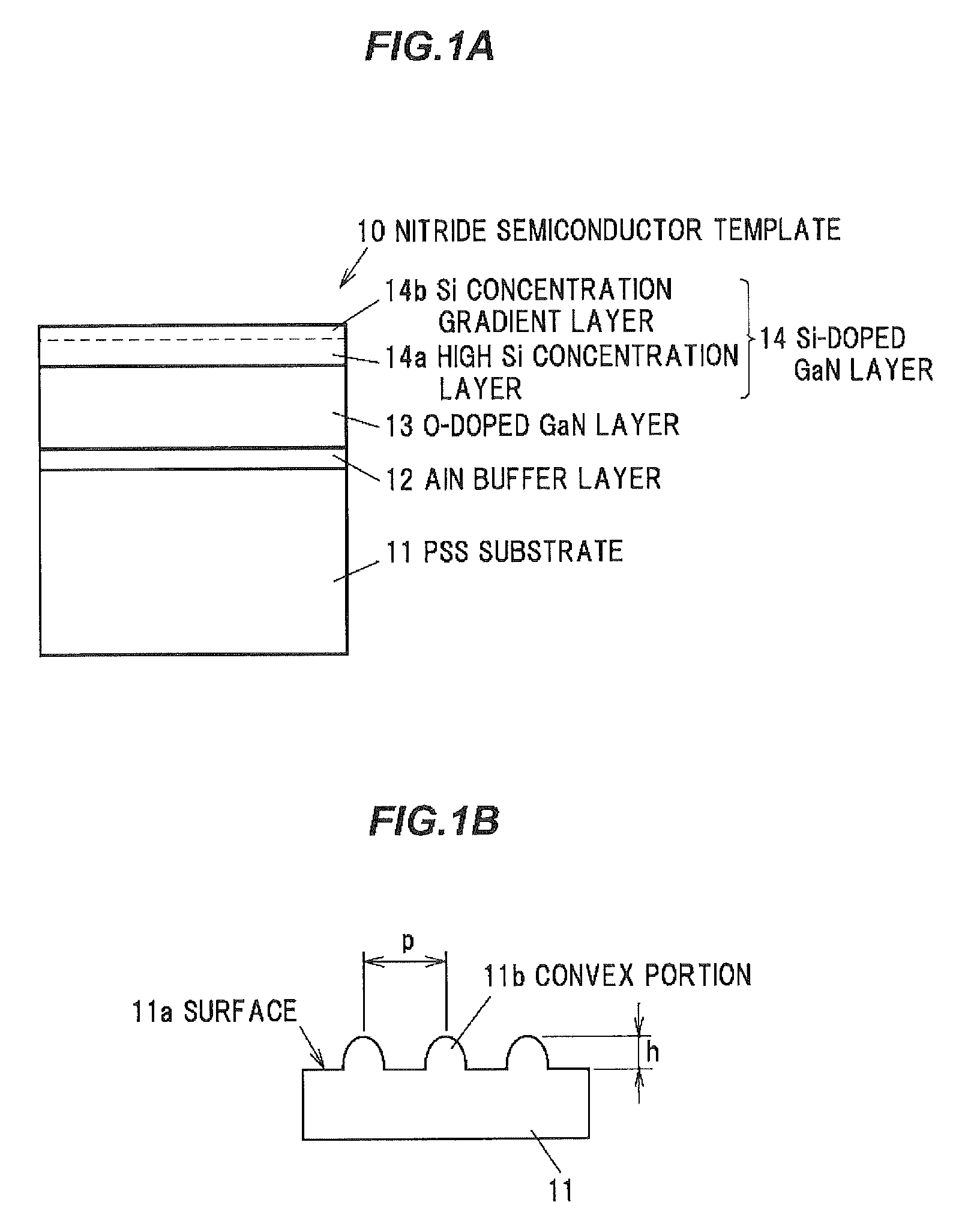

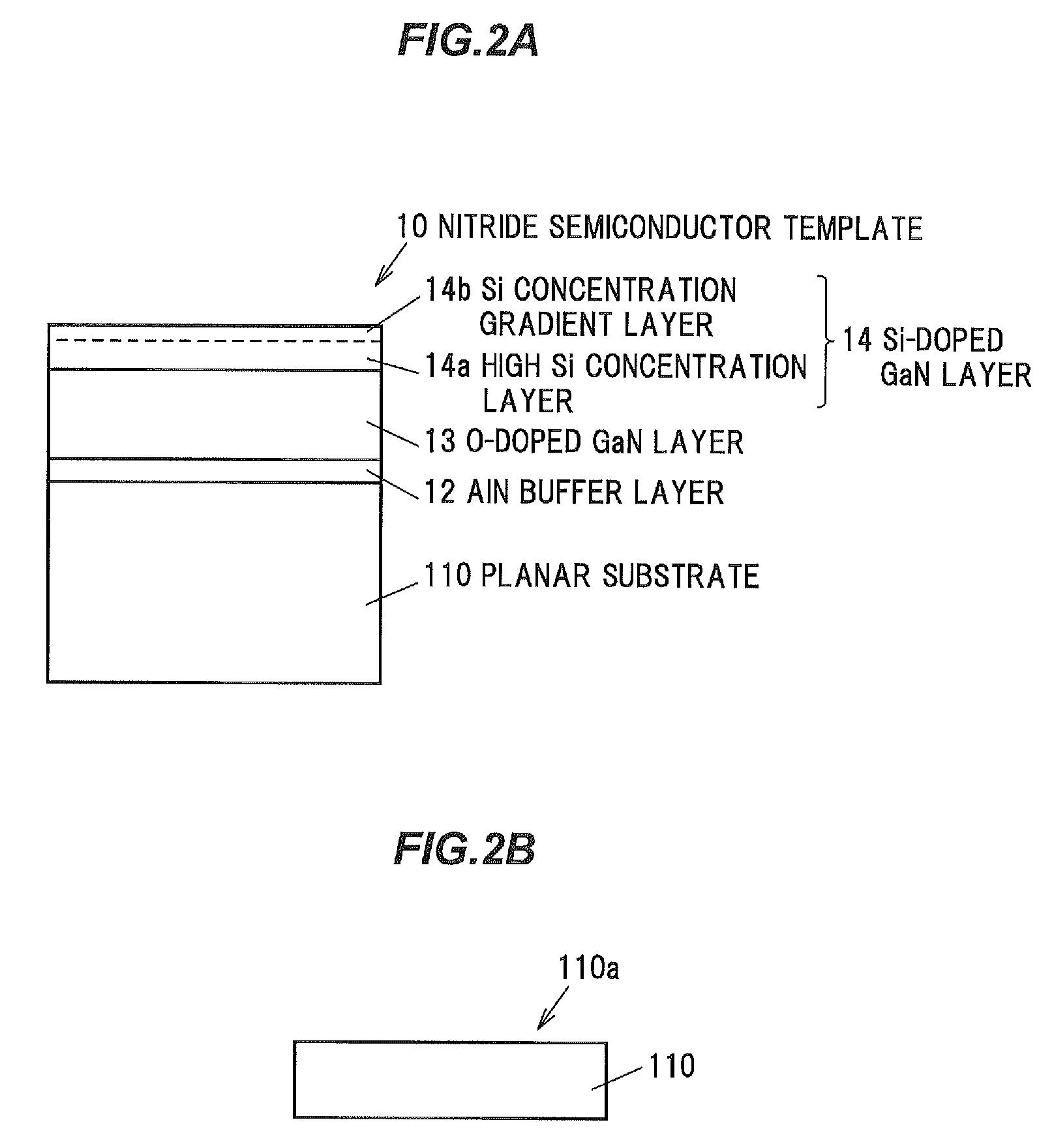

Nitride semiconductor template and light-emitting diode

ActiveUS20130153858A1Lower resistanceImprove crystallization propertiesSemiconductor/solid-state device manufacturingSemiconductor devicesConcentration gradientTotal thickness

A nitride semiconductor template includes a substrate, and a group III nitride semiconductor layer formed on the substrate and including a Si-doped layer doped with Si as an uppermost layer thereof. The group III nitride semiconductor layer has a total thickness of not less than 4 μm and not more than 10 μm. The Si-doped layer includes a Si concentration gradient layer having a carrier concentration that gradually decreases toward an outermost surface thereof so as to be not less than 1×1017 cm−3 and not more than 5×1017 cm−3 at the outermost surface of the group III nitride semiconductor layer.

Owner:SUMITOMO CHEM CO LTD

Thermoplastic polyurethane elastomer composite material, preparation method and application thereof

ActiveCN107880531ALow shrinkageImprove crystallization propertiesAdditive manufacturing apparatusSelective laser sinteringElastomer composites

The invention relates to a thermoplastic polyurethane elastomer composite material, a preparation method and an application thereof. The composite material comprises the following components: a hypocrystalline thermoplastic polyurethane elastomer and filler through surface treatment. The filler is a mixture of layered filler and granular filler in a mass ratio of 0.1: 1 to 5: 1, preferably 0.5:1 to 3:1. The composite material is prepared by fusing and blending, so that the crystallizing characteristic of a thermoplastic polyurethane elastomer product is improved, a low shrink thermoplastic polyurethane elastomer is obtained, the property of the material is ensured stable, and the obtained composite material can be used for a quick forming method of fused processing, for example, a fusing deposition quick forming method or a selective laser sintering method.

Owner:WANHUA CHEM GRP CO LTD

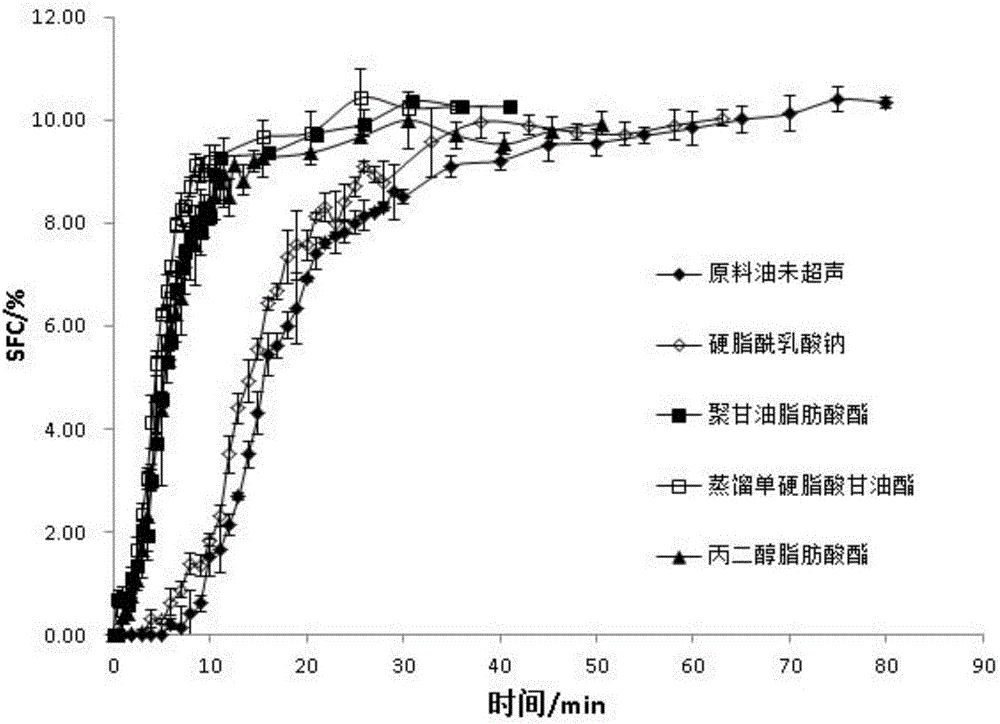

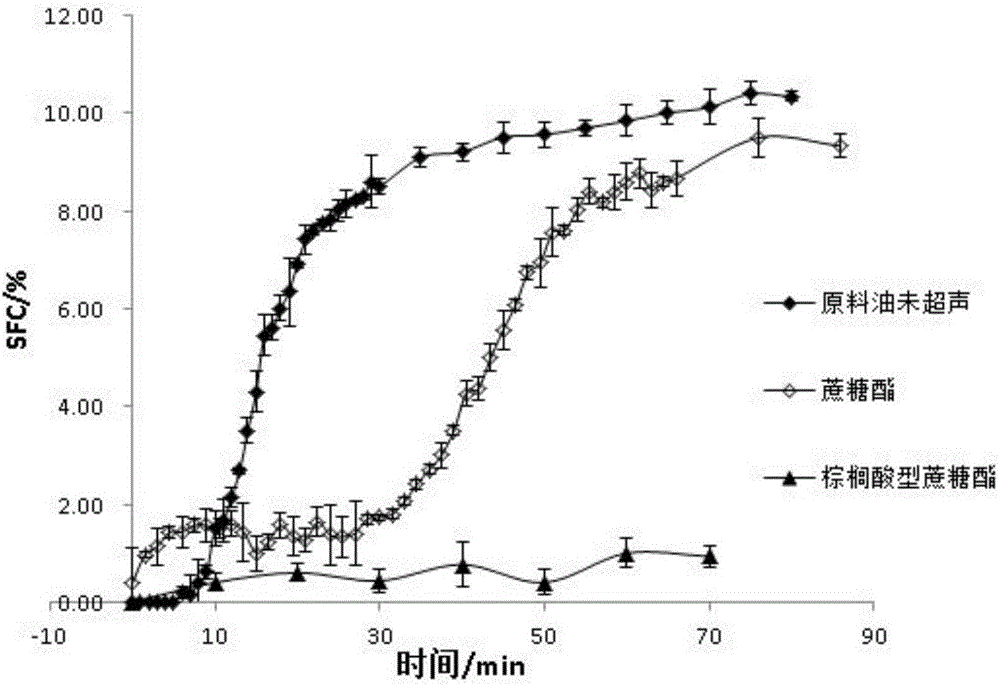

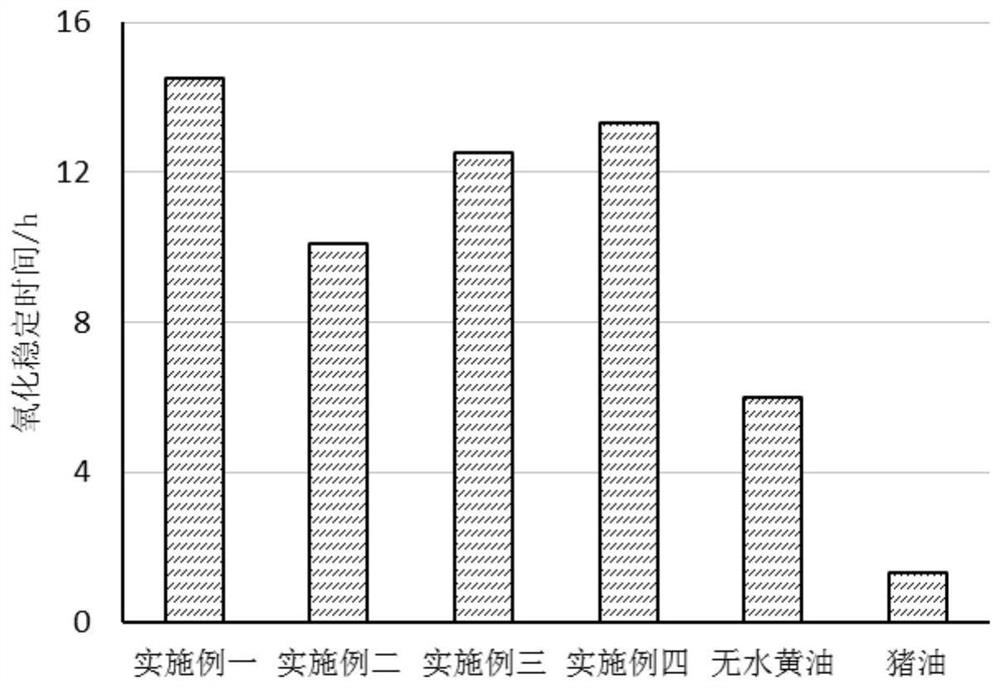

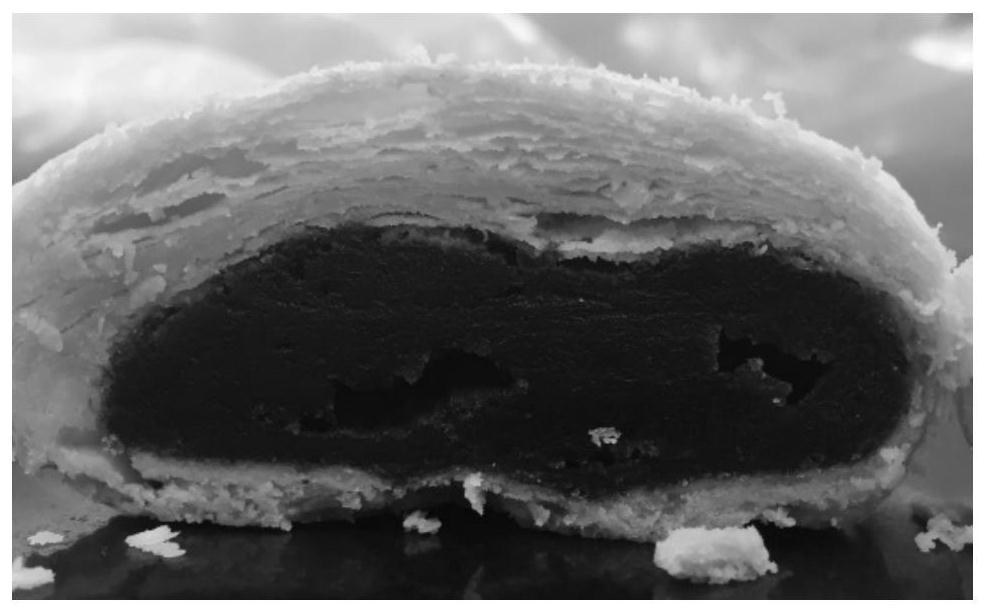

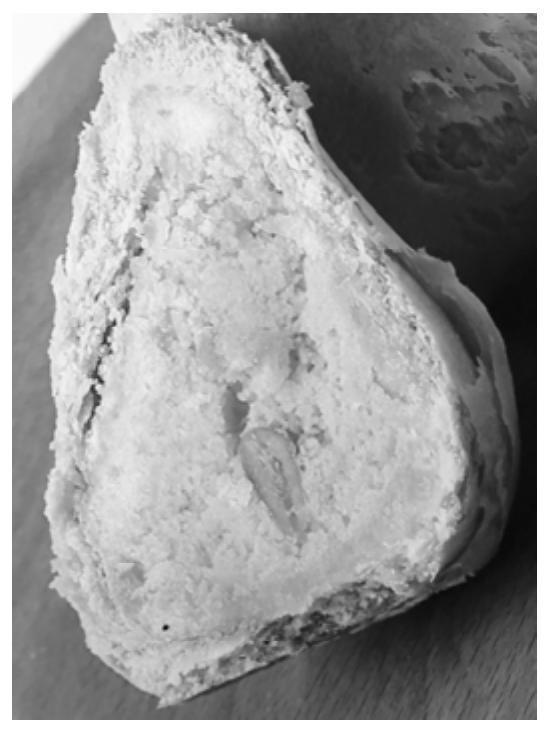

Method for promoting grease crystallization with high-strength ultrasonic coupling emulsifier

ActiveCN106497674AGood effectImprove crystallization propertiesFatty-oils/fats refiningHigh intensityPalm oil

The invention discloses a method for promoting grease crystallization with a high-strength ultrasonic coupling emulsifier, belonging to the field of grease crystallization improvement and control. The method disclosed by the invention comprises the following steps of: heating palm oil and palm oil-based compound grease to certain temperature to eliminate crystallization memory; adding different emulsifiers and heating and stirring for certain time; cooling to ultrasonic temperature; and performing ultrasonic treatment to obtain grease with improved crystallization property. In the invention, the crystallization rate of the obtained palm oil and palm oil-based compound grease is accelerated, the crystallization quantity after storage in the same conditions is increased, the particle size of the crystal is reduced, and the method has a good application prospect.

Owner:JIANGNAN UNIV

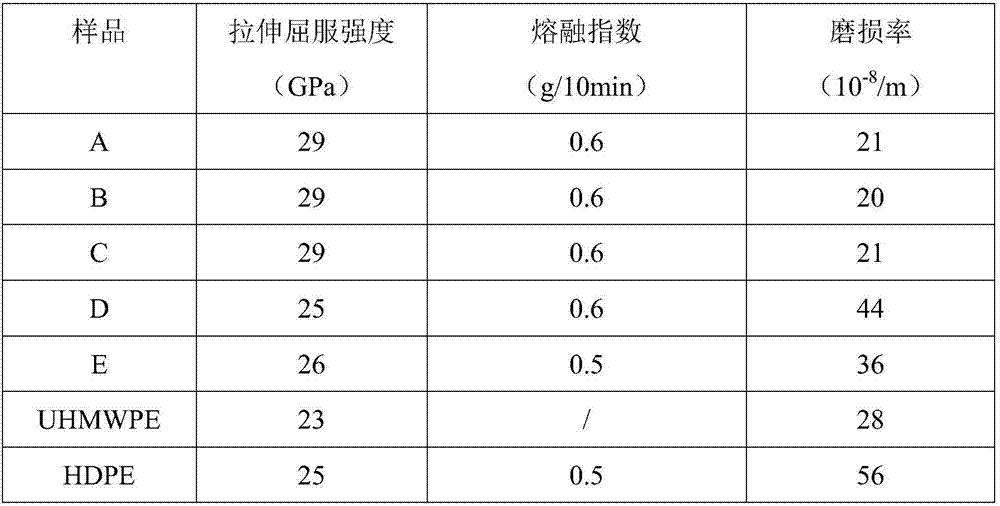

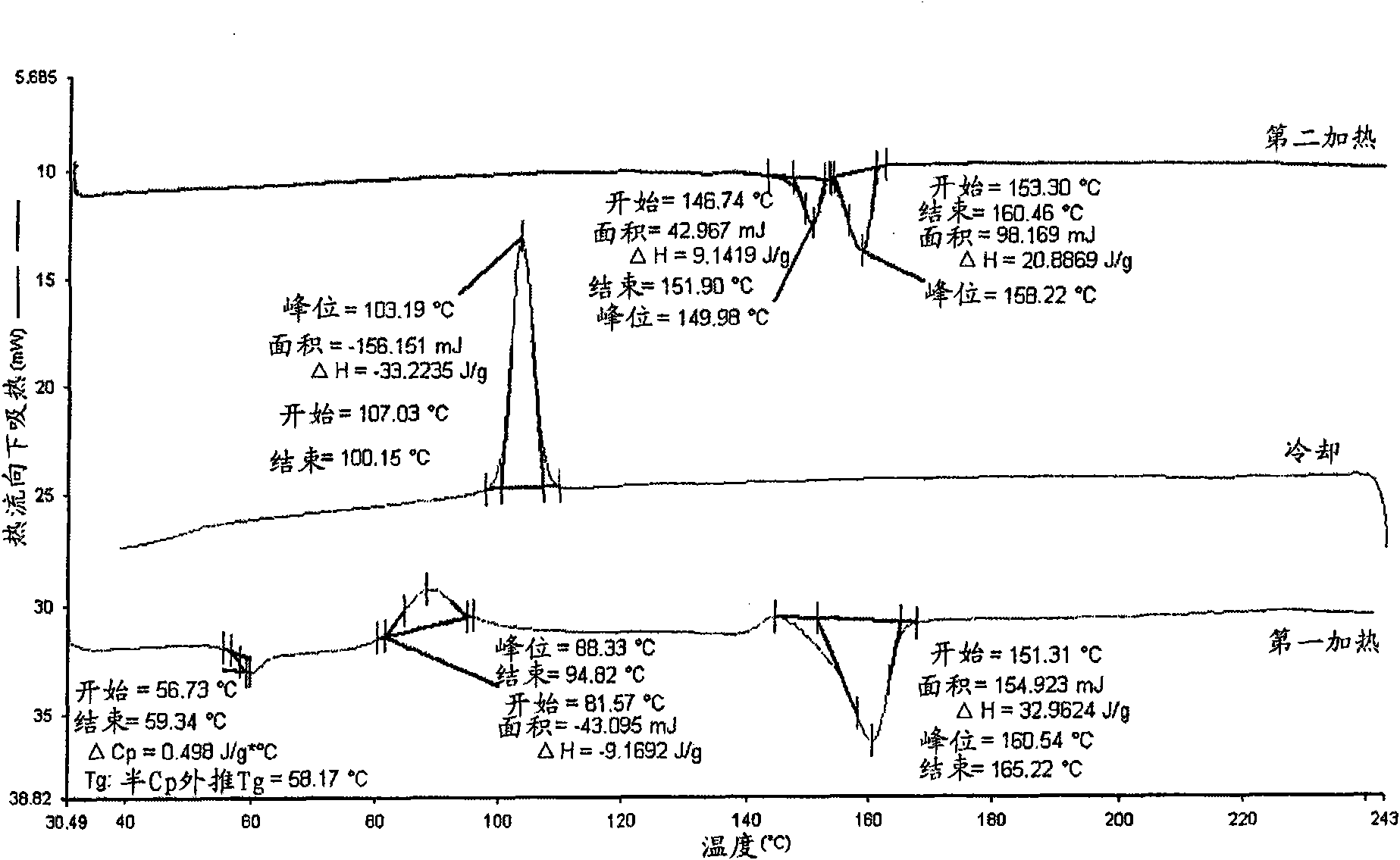

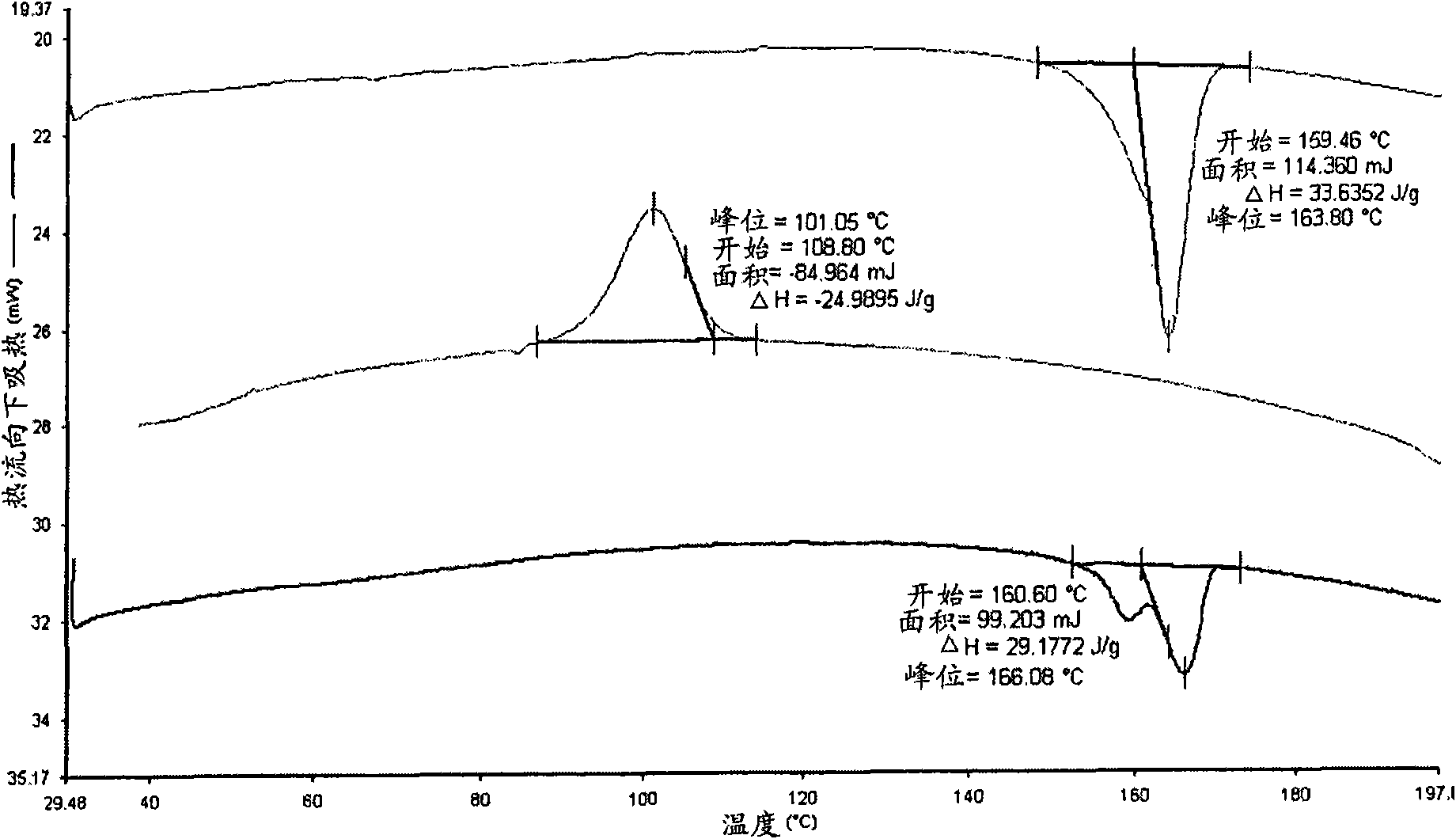

C60 fullerene modified abrasion-resistant polyethylene composite material and preparation method thereof

InactiveCN106995545AImprove crystallization propertiesImprove wear resistanceAntioxidantC60 fullerene

The invention belongs to the field of macromolecule materials, and particularly relates to a C60 fullerene modified abrasion-resistant polyethylene composite material and a preparation method thereof. The C60 fullerene modified abrasion-resistant polyethylene composite material is characterized by being prepared from the following components in parts by mass: 1 to 10 parts of C60 fullerene, 1 to 10 parts of silane coupling agent, 75 to 100 parts of high density polyethylene, 5 to 10 parts of maleic anhydride grafted polyethylene, 1 to 10 parts of coupling agent with high molecular weight, 1 to 3 parts of antioxidant, and 1 to 3 parts of heat stabilizer.

Owner:YANGZHOU POLYTECHNIC INST +1

High-barrier PE material and preparation technology thereof

InactiveCN107400286AImprove crystallization propertiesImprove barrier propertiesNano sio2Fire retardant

The invention discloses a high-barrier PE material. The high-barrier PE material comprises, by weight, 60-80 parts of polyethylene, 5-10 parts of hydroxyethyl acrylate, 1-5 parts of triphenyl phosphite, 10-20 parts of a polymer / nano-SiO2 composite material and 2-6 parts of a flame retardant. The PE is modified with the polymer / nano-SiO2 composite material, so the barrier property of the PE material is improved.

Owner:SICHUAN HUILI IND

Polylactic acid forming body and making method thereof

InactiveCN101554763AWith heat-resistant effectImprove heat resistanceCoatingsHeat resistanceMachining process

The invention relates to a making method of polylactic acid forming body, which enables polylactic acid to be continuously ejected to form the polylactic acid forming body with heat resistance. The making method is characterized in that at the time of the ejection of polylactic acid, the thermoform of the polylactic acid is performed in a metal die, the polylactic acid in the metal die is crystallized at constant temperature so as to achieve the effects of crystallization and heat resistance, and a finished product formed by die sinking ejection keeps good shape and does not deform. The making method can adopt a continuous method to produce polylactic acid products with heat resistance, all ejection products using the polylactic acid as materials can be made by the forming and processing process, and the polylactic acid after forming and processing has heat resistance and favorable mechanical characteristics.

Owner:鸿福鑫有限公司

Method for improving frost resistance of edible fat

InactiveCN106889211AAdjust crystallization propertiesImprove fractionationEdible oils/fatsFrostFractionation

The invention provides a method for improving frost resistance of edible fat by the inventor. In the process of refining edible fat particularly in the process of producing palm oil, a method of performing refinement and then performing fractionation is adopted, and a deodorizing technology in the refining process is specially adjusted, so that the purpose of adjusting the crystallization characteristics of palm liquid oil raw materials is achieved, so that the fractionation effect is obviously improved, and the quality of products is improved.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Nitride semiconductor template and light-emitting diode

ActiveUS8829489B2Lower resistanceImprove crystallization propertiesSemiconductor/solid-state device manufacturingSemiconductor devicesConcentration gradientTotal thickness

Owner:SUMITOMO CHEM CO LTD

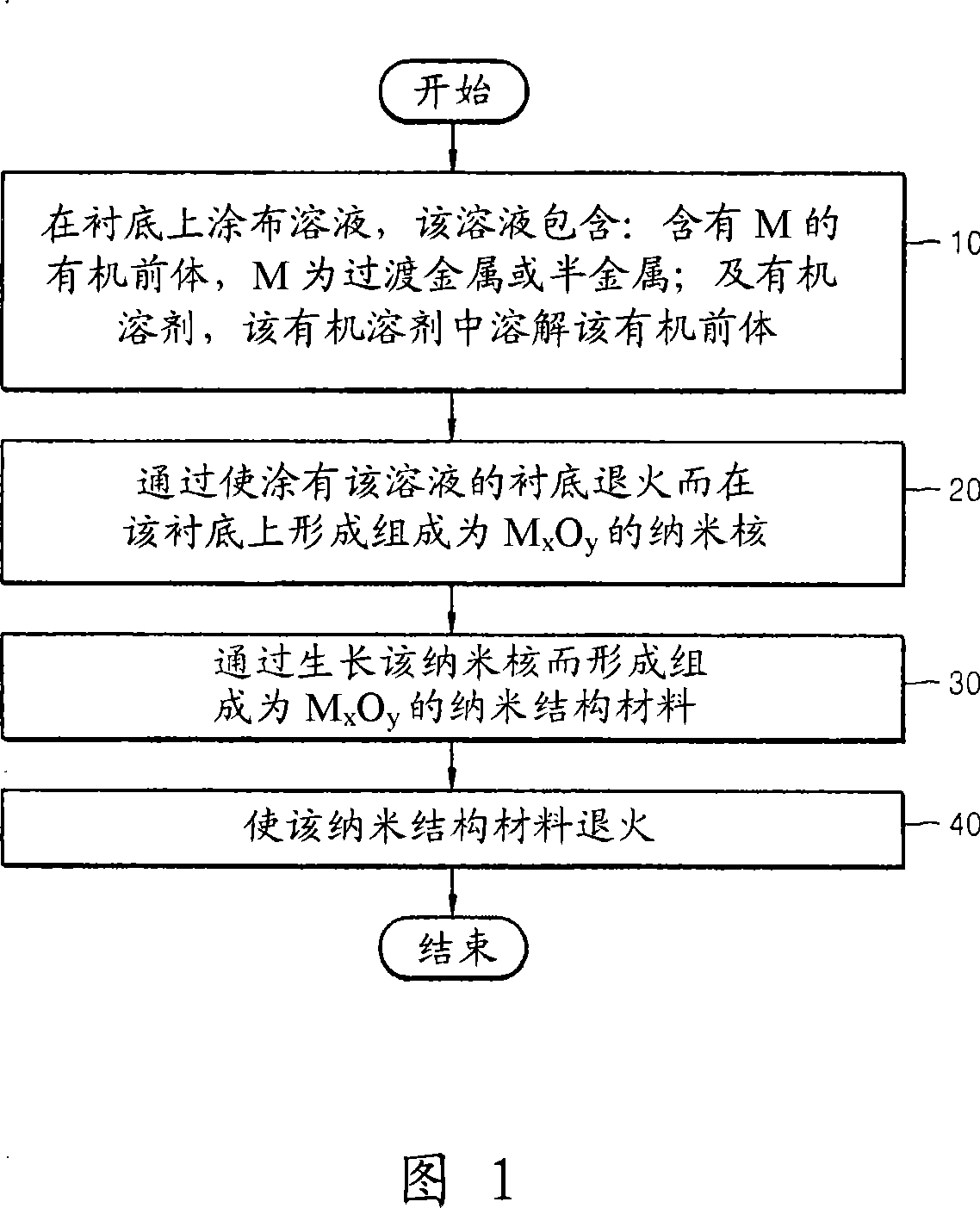

Method of forming oxide based nano structures

InactiveCN101219777AImprove crystallization propertiesSmooth connectionMaterial nanotechnologyLiquid surface applicatorsNano structuringOrganic solvent

Provided is a method of forming an oxide-based nano-structured material including growing a nano-structured material using a nano-nucleus having the same composition as the desired oxide-based nano-structured material. A solution is coated on a substrate, the solution including: an organic precursor containing M which is a transition metal or a semi metal; and an organic solvent in which the organic precursor is dissolved. A nano-nucleus having a composition of MxOy is formed on the substrate by annealing the substrate. A nano-structured material having a composition of MxOy is formed by growing the nano-nucleus while supplying a reaction precursor containing M into the nano-nucleus, and the nano-structured material is annealed.

Owner:ELECTRONICS & TELECOMM RES INST

Laser mask and crystallization method using the same

InactiveUS20080106686A1Improve crystallization propertiesTransistorSemiconductor/solid-state device manufacturingLaser beamsSemiconductor

A crystallization method using a mask includes providing a substrate having a semiconductor layer; positioning a mask over the substrate, the mask having first, second and third blocks, each block having a periodic pattern including a plurality of transmitting regions and a blocking region, the periodic pattern of the first block having a first position, the periodic pattern of the second block having a second position, the periodic pattern of the third block having a third position, the first, second and third positions being different from each other; and crystallizing the semiconductor layer by irradiating a laser beam through the mask.

Owner:LG DISPLAY CO LTD

Enzymatic treatment of oils

The present invention relates to a method of reducing and / or removing diglyceride from an edible oil, comprising a) admixing an edible oil with an acyl acceptor substrate and a fatty-acid CoA independent diglyceride: glycerol acyltransferase, wherein the fatty-acid CoA independent diglyceride: glycerol acyltransferase is characterized as an enzyme which in an edible oil is capable of transferring an acyl group from a diglyceride to glycerol. Preferably, the diglyceride: glycerol acyltransferase comprises the amino acid sequence motif GDSX, wherein X is one or more of the following amino acid residues L, A, V, I, F, Y, H, Q, T, N, M or S. Furthermore the present invention relates to the use of a fatty-acid CoA independent diglyceride: glycerol acyltransferase characterized as an enzyme which in an edible oil is capable of transferring an acyl group from a diglyceride to glycerol, in the manufacture of an edible oil, for reducing and / or removing (preferably selectively reducing and / or removing) diglyceride from said edible oil, and to the use of said enzyme in the manufacture of a foodstuff comprising an edible oil for improving the crystallization properties of said foodstuff.

Owner:AS DE DANSKE SUKKERFABRIKKER

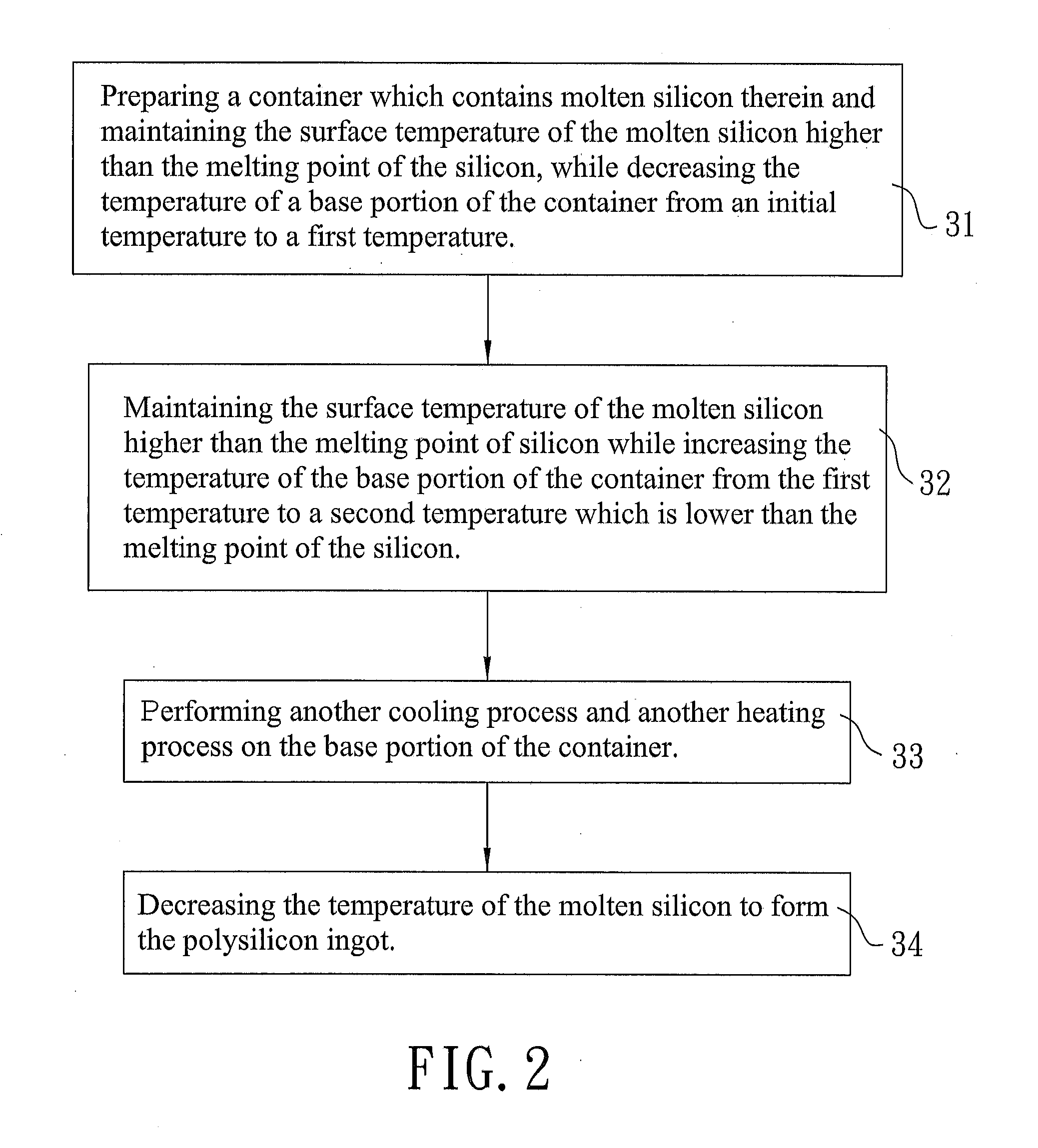

Method for manufacturing a polysilicon ingot

InactiveUS20140007621A1Reduce temperatureLarge particlesPolycrystalline material growthGlass drawing apparatusMolten siliconPolycrystalline silicon

A method for manufacturing a polysilicon ingot includes: (a) providing molten silicon in a container; (b) maintaining a surface temperature of the molten silicon higher than its melting point while decreasing the temperature of a base portion of the container to a temperature (T1) lower than the melting point at a rate of at least 2.6° C. / min; (c) increasing the temperature of the base portion to a temperature (T2) lower than the melting point; (d) maintaining the surface temperature of the molten silicon higher than the melting point while decreasing and then increasing the temperature of the base portion to a temperature lower than the melting point of silicon; and (e) reducing the temperature of the molten silicon to form the polysilicon ingot.

Owner:MOTECH INDUSTRIES

Flame-retardant polypropylene plastic

InactiveCN105885217AHigh flame retardant efficiencyImprove crystallization propertiesMaleic anhydrideAmmonium polyphosphate

The invention discloses flame-retardant polypropylene plastic. The flame-retardant polypropylene plastic comprises the following component in parts by weight: 70-80 parts of polypropylene resin, 40-50 parts of a fire retardant, 10-20 parts of terpene resin, 8-12 parts of nano-titania and 0.2-0.8 part of an antioxidant. By adding the fire retardant prepared by mixing ammonium polyphosphate, grafted maleic anhydride and nano-clay into the flame-retardant polypropylene plastic, ammonium polyphosphate and nano-clay in a compound flame-retardant polypropylene system can be uniformly dispersed, so that the flame-retardant efficiency is obviously improved, the crystallization property of a polypropylene matrix can be improved, and the tenacity of a material is improved.

Owner:林建君

Baking oil suitable for pastry and preparation method of baking oil

PendingCN112237220AAppropriate SFC valueImprove crystallization propertiesEdible oils/fatsBiotechnologyPalm stearin

The invention relates to the technical field of baking oil, in particular to baking oil suitable for pastry and a preparation method of the baking oil. The baking oil is prepared from the following components in percentages by mass: 0-60% of palm liquid oil, 10-40% of anhydrous butter, 0-30% of palm stearin, 0-20% of coconut oil, 0-10% of soybean oil, 0-60% of first ester exchange oil, 0-30% of second ester exchange oil, 0-1% of propylene glycol fatty acid ester, 0-0.5% of mono-and diglycerides of fatty acids, 0-2% of a flavor enhancer, 0-0.4% of essence and 0-0.003% of pigment. The baking oilhas a proper SFC value at the temperature of 10-20 DEG C, has good crystallization characteristics, is good in comprehensive performance and is suitable for the pastry.

Owner:上海南侨食品有限公司 +2

Polyester resin composition, application thereof and molded product

PendingCN111849128AImprove crystallization propertiesShort curing timeSemiconductor devicesLed packagingInjection molding process

The invention discloses a polyester resin composition, application thereof and a molded product. The polyester resin composition comprises the following components: 0-55 parts of polyester resin A with the melting temperature being more than 280 DEG C and less than 290 DEG C; 5-60 parts of polyester resin B with the melting temperature being greater than 290 DEG C and less than 300 DEG C; 5-60 parts of a white pigment; 0.1-5 parts of an inorganic nucleating agent; and 1-40 parts of filler. According to the invention, the polyester resin B with high crystallization capacity is compounded with the inorganic nucleating agent, so that the crystallization performance of the polyester resin composition can be greatly improved, the minimum curing time required by normal cooling and demolding of the molded product in the injection molding process is greatly shortened, and the development requirements of ultra-multi-mold-cavity and rapid cooling of a LED reflection support material can be wellmet; and meanwhile, the problem of interface micro-stripping between LED packaging silica gel and a metal material belt in the functional area can be well solved, and the ultrasonic scanning layeringresistance and the long-term use reliability are greatly improved.

Owner:KINGFA SCI & TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com