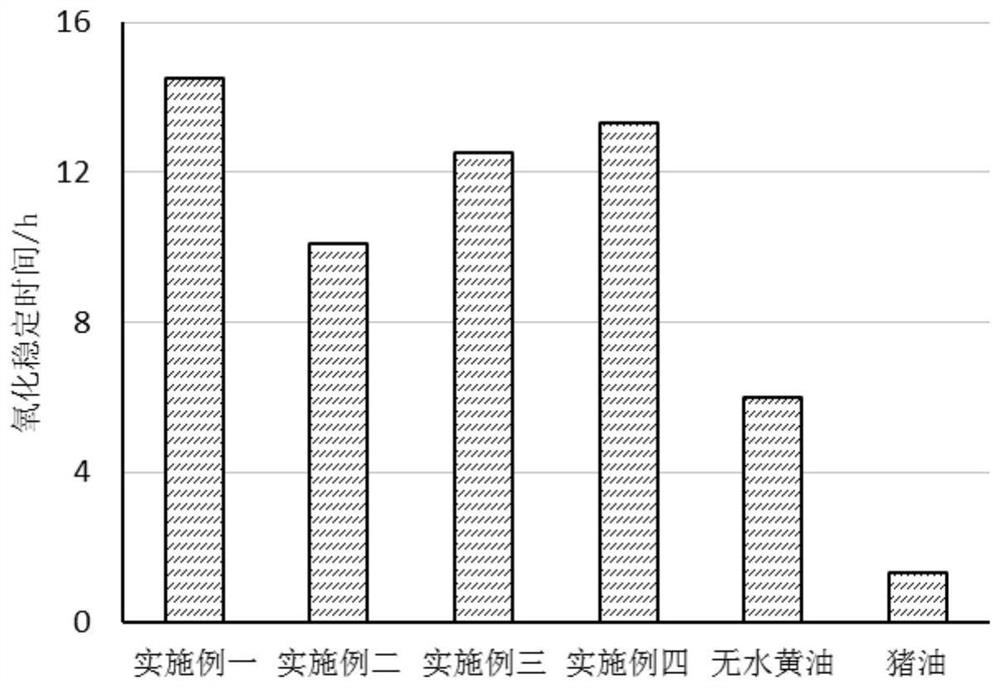

Baking oil suitable for pastry and preparation method of baking oil

A pastry and oil technology, which is applied in the directions of edible oil/fat, application, food science, etc., can solve the problem of insufficient shortening, ductility stability, flavor oil cost, health, and comprehensive performance of baking oil. Comprehensive and other issues, to achieve good plasticity, good crystallization characteristics, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0049] Preparation example one first transesterified oil

[0050] In this preparation example, the first transesterification grease is obtained by chemical transesterification method, and this method comprises the following steps:

[0051] Heating: stirring and mixing palm olein with a mass percentage of 70% and palm stearin with a mass percentage of 30% to obtain a mixed oil, heating the mixed oil to 100-110°C, and removing moisture and oxygen in the mixed oil;

[0052] Transesterification reaction: Add sodium methoxide to the mixed oil, keep the vacuum strength at 1-3mbar, and carry out the transesterification reaction for 30 minutes, wherein the added mass of sodium methoxide accounts for 0.1% of the mass of the mixed oil;

[0053] Neutralization: After the reaction, add citric acid solution to carry out neutralization reaction for 30 minutes, and acidify the soap fraction generated by the transesterification reaction to obtain crude transesterified oil, wherein the mass co...

preparation example 2

[0056] Preparation Example 2 Second transesterification grease

[0057] In this preparation example, the second transesterified oil is obtained by a chemical transesterification method, and the method comprises the following steps:

[0058] Heating: stirring and mixing 75% palm stearin and 25% coconut oil by mass evenly to obtain a mixed oil, heating the mixed oil to 100-110°C, and removing moisture and oxygen in the mixed oil;

[0059] Transesterification reaction: Add sodium methoxide to the mixed oil, keep the vacuum strength at 1-3mbar, and carry out the transesterification reaction for 30 minutes, wherein the added mass of sodium methoxide accounts for 0.1% of the mass of the mixed oil;

[0060] Neutralization: After the reaction, add citric acid solution to carry out neutralization reaction for 30 minutes, and acidify the soap fraction generated by the transesterification reaction to obtain crude transesterified oil, wherein the mass concentration of the citric acid solu...

Embodiment 1

[0063] This embodiment provides a kind of baking fat suitable for puff pastry, by mass percentage, this baking fat comprises the following components:

[0064] Base oil: 40.3% palm olein, 15% anhydrous butter, 13% palm stearin, 10% coconut oil, 20% first transesterified fat;

[0065] Emulsifier: 0.4% propylene glycol fatty acid ester, 0.4% mono- and diglyceride fatty acid ester;

[0066] Flavor enhancer 0.8% and food flavor 0.1%. Wherein, the first transesterified fat is the first transesterified fat of Preparation Example 1.

[0067] The present embodiment also provides a method for preparing the above-mentioned baking fat suitable for puff pastry, comprising the following steps:

[0068] Prepare the oil phase: by mass percentage, mix 40.3% palm olein, 13% palm stearin, 10% coconut oil, and 20% first transesterified fat and heat to 60-65°C, then add anhydrous butter 15%, stirred at a speed of 60rpm to obtain an oil phase;

[0069] Dissolving emulsifier: by mass percentage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com