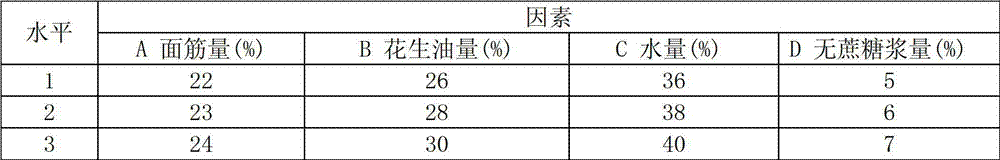

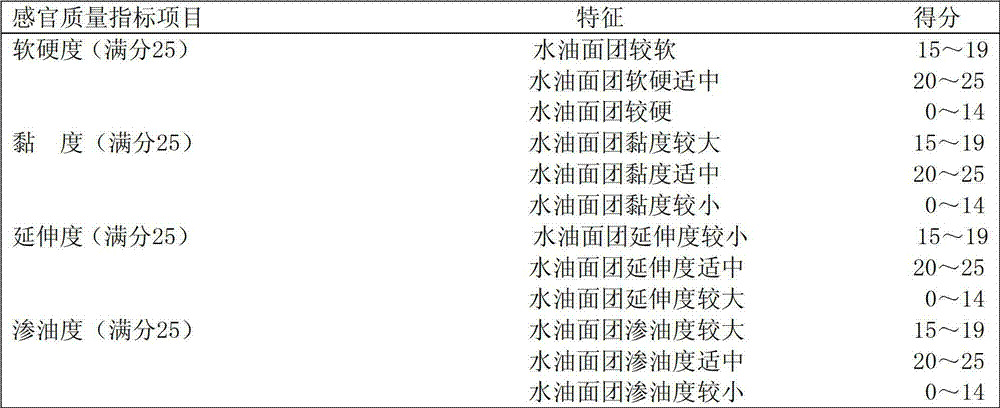

Patents

Literature

158 results about "Puff pastry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Puff pastry, also known as pâte feuilletée, is a flaky light pastry made from a laminated dough composed of dough (détrempe) and butter or other solid fat (beurrage). The butter is put inside the dough (or vice versa), making a paton which is repeatedly folded and rolled out before baking.

Non-hydrogenated vegetable oil based margarine for puff pastry containing an elevated diglyceride emulsifier

ActiveUS20070148313A1Sufficient structureHigh than usual level of diglycerides functionDough treatmentFatty acid esterificationGreek letter betaGlycerol

A mono-, di-, and triglyceride emulsifier is provided that is obtained by the interesterification or glycerolysis of triglycerides with glycerol. The diglyceride portion w / w is at least about 65% to about 80%, and most preferably from about 70% to about 80%. The high diglyceride emulsifier is useful in preparing a margarine from a selected quantity a non-hydrogenated vegetable oil and from an amount of saturated fat for use in puff pastry products. The puff pastry is trans fat free and a less than usual percentage of saturated fats. A preferred structured puffpastry margarine is prepared by mixing on a weight to weight basis about 14 parts of the high diglyceride emulsifier that is in predominantly stable beta crystal form, from about 14 to 27 parts of a non-hydrogenated vegetable oil, and from about 40 to about 52 parts of a saturated fat.

Owner:CARAVAN INGREDIENTS

Agaric and black sesame puff pastry

InactiveCN103689034ASimple preparation processFull of nutritionDough treatmentBakery productsBiotechnologyAgaric

The invention provides agaric and black sesame puff pastry, which is prepared from the following ingredients in parts by weight: 280 to 300 parts of flour, 30 to 40 parts of black bean meal, 30 to 40 parts of pawpaw powder, 40 to 50 parts of coco powder, 20 to 30 parts of celery powder, 5 to 6 parts of yeast powder, 25 to 30 parts of agaric, 40 to 50 parts of black sesame, 40 to 50 parts of coffee, 4 to 5 parts of astragalus, 5 to 6 parts of schisandra chinensis, 5 to 6 parts of polygonum multiflorum, 4 to 5 parts of angelica, 4 to 5 parts of rehmannia glutinosa, 5 to 6 parts of medlar, 4 to 5 parts of lagochilus leiacanthus, 3 to 4 parts of frankincense, 3 to 4 parts of roselle, 70 to 80 parts of white granulated sugar and a proper amount of common salt, sesame oil and water. The agaric and black sesame puff pastry provided by the invention has the advantages that the manufacturing process is simple, the nutrition is rich, the mouth feeling is unique, the chocolate and fruit fragrance can be realized, the agaric and black sesame puff pastry is more popular by people, in addition, extracts of traditional Chinese medical materials of astragalus membranaceus, schisandra chinensis, polygonum multiflorum, angelica and the like are added, the effects of relaxing tendons, activating collaterals, prolonging the life, realizing the beautification effect, benefiting the kidney, nourishing yin to realize the beautification effect and the like can be realized, and the agaric and black sesame puff pastry belongs to healthy leisure health care food.

Owner:李宝军

Low Trans Puff Pastry Composition, Method of Use and Puff Pastry Products

InactiveUS20080206413A1Elimination of trans unsaturationLess saturated fatBaking mixturesFood coatingSolid contentAnimal fat

Disclosed are improvements in puff pastry preparation, which reduce, and preferably eliminate, trans unsaturated fatty acids by the use of a new puff pastry fat comprised principally of palm olein, which is preferably interesterified. The puffed pastry fats exhibit low levels of trans fatty acids. The puff pastry fats and products are highly functional without resort to high solids contents, hydrogenation or butter or other animal fats.

Owner:AARHUSKARLSHAMN USA INC

Making method of crispy cream custard bun

A making method of crispy cream custard bun belongs to the food processing technology and mainly includes firstly, making moist crust, oiled crust and crispy crust; secondly, grinding cooked salted egg yolk, adding sugar, butter and the like and mixing well to obtain stuffing; and thirdly, finishing wrapping and placing wrapped buns in an oven for baking. The making method is characterized by including making of the moist crust, the oiled crust, the crispy crust and the stuffing and includes: mixing cake flour, beaten egg, cold boiled water and granulated sugar in cotton form, and adding shortening to make dough to obtain the moist crust; mixing cake flour, butter and lard oil and rolling to obtain dough which is made into the oiled crust; rolling two pieces of the dough into sheets in equal thickness, wrapping the oiled crust with the moist crust, rolling flat and folding the dough for rolling again, and doing fold-and-roll for three times; rolling flat to obtain a thin crust, and wrapping the thin crust with plastic wrap before placing in a refrigerator for cold storage for 30 minutes; using a spoon to grind the cooked salted egg yolk, adding sugar, butter and the like into mince of the egg yolk, mixing well, and adding carrot juice to obtain the stuffing; and finishing wrapping and placing on a middle rack of an oven for baking for eating.

Owner:诸葛洁婧

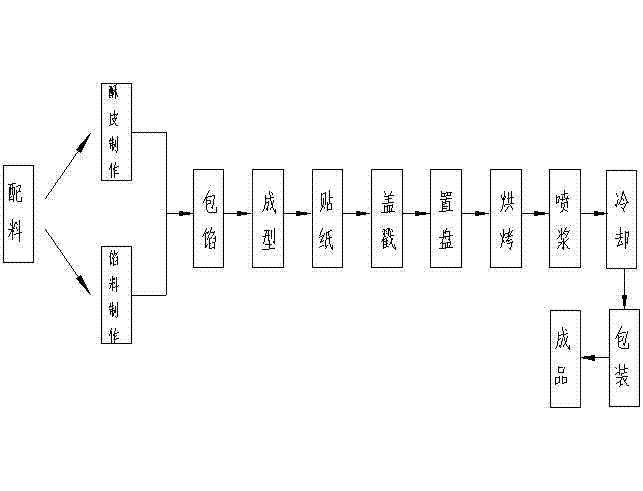

Suzhou-style mooncake with good cake crust sensation quality and production technology of mooncake

InactiveCN102919332AImprove qualityConducive to processBakery productsClear LayerAdditive ingredient

The invention relates to a production technology of a Suzhou-style mooncake with good cake crust sensation quality. The production technology of the Suzhou-style mooncake with good cake crust sensation quality comprises the following steps of: (1) preparing ingredients; (2) making crisp crust and fillings, wherein the crisp crust making comprises the following step of preparing water and oil doughs, oil crisp doughs and crisp crust doughs; (3) wrapping the fillings and forming; (4) baking; and (5) cooling. According to the production technology, the cake crust formulation is adjusted appropriately; the cake crust of the prepared Suzhou-style mooncake has favorable comprehensive sensory quality, and the Suzhou-style mooncake with good cake crust sensation quality has the advantages of low sweetness, clear layers, crisp taste, complete cake crust and nutrition and health.

Owner:苏州稻香村食品工业有限公司

Pastry moon cake and preparation method thereof

The present invention aims to provide a pastry moon cake and a preparation method thereof. The preparation method includes water-oiled dough production, pastry production, a pastry filling process, filling production, raw cake production and a baking process, wherein warm water is used in the production of water-oiled dough, and the temperature of the warm water is controlled at 40-80 DEG C, and green tea powder is added in the production process of fillings. Beneficial effects of the pastry moon cake: grease contents and sugar contents in moon cakes are reduced by using vegetable oil instead of traditional animal oil and using xylitol instead of sucrose in the moon cake production process, so that the pastry moon cake can inhibit the increase of blood sugar and fat accumulation in the human body, and is suitable for diabetics and the elderly to eat; and the introduction of green tea powder into the traditional five-kernel fillings makes the pastry moon cake light in taste and delicate in fragrance, healthy and nutritional.

Owner:TIANJIN YOUHAO INTERCONNECTION TECH CO LTD

Multilayer crispy mooncake and making method thereof

The invention relates to a multilayer crispy mooncake and a making method thereof. The mooncake comprises a mooncake crust and stuffing, and the mooncake crust comprises a wrapper and a crispy wrapper. The wrapper comprises, by weight, 15-25 parts of flour, 5-10 parts of animal oil, 0.01-0.03 part of syrup and 5-10 parts of water. The crispy wrapper comprises, by weight, 1-3 parts of flour and 1-2 parts of animal oil. The multilayer crispy mooncake is made through the steps of wrapper making, crispy wrapper making, shortening, stuffing adding and baking, and the making method is low in cost, high in operability and suitable for popularization, and the multilayer crispy mooncake is loose in structure, fragrant, crispy, loose and soft in mouthfeel, agreeably sweet and oily but not greasy, has no additive, is green and healthy and has high economic value.

Owner:董斌

Puff pastry and method for preparing same

InactiveCN102669240AThe crust is crispy and lightTaste full of elasticityBakery productsBiotechnologyBENINCASA HISPIDA FRUIT

The invention discloses a puff pastry and a method for preparing the same. The puff pastry consists of oily leather, pastry and stuffing, wherein the stuffing consists of cake flour, starch, sugar, processed sesame, salad oil, pork lard, desiccated coconut, water and winter melon; the oily leather consists of the following components: low gluten flour, high gluten flour, pork lard, granulated sugar and water; and the pastry consists of the following components: low gluten flour and pork lard. The crust of the puff pastry is fragrant, crisp, light and thin, the stuffing is well tasty, fully elastic and tough, the puff pastry has a pure taste and is quite characterized, and people should want more while chewing and eating the puff pastry. The preparation method is simple and easy to implement.

Owner:开平市三埠小麦田西饼店

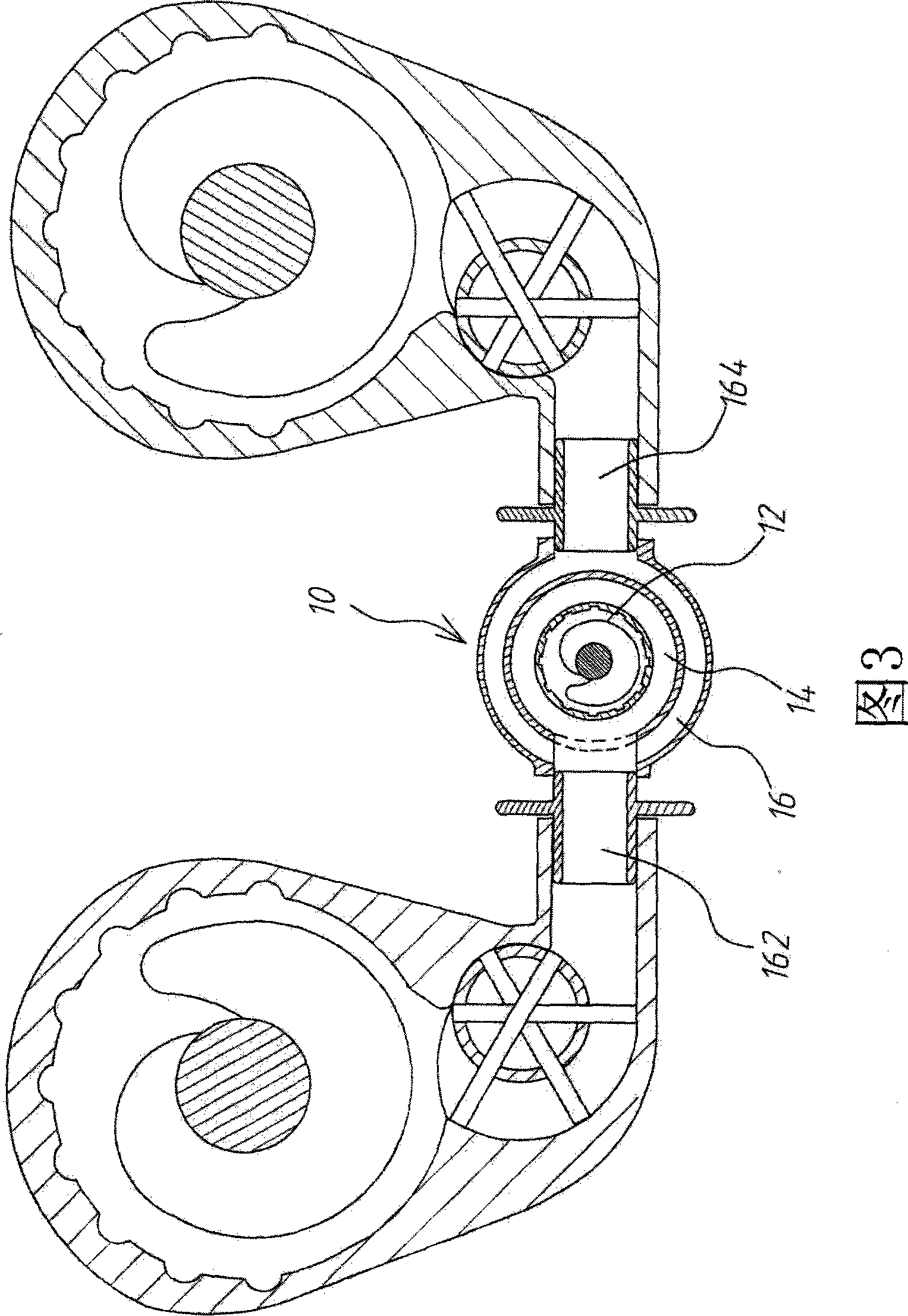

Forming device for producing food with three layers of different stuffing and method

InactiveCN101380032AMuscle strengtheningReduce moisture contentFood coatingFood shapingEngineeringNozzle

The invention relates to a molding device and a molding method thereof for producing food with three different fillings coated inside, which consists of a combined nozzle capable of continuously outputting cylindrical filling composed of three layers of different fillings, a conveyer belt capable of synchronously shifting high glutton flour stripe along a specific direction; and the cylindrical filling falls on the surface of the moving flour stripe and moves forward and shifts with the conveyer belt; an oblique wheel frame is arranged on the conveyer belt in a reversed rotating state; the flour stripe in a moving forward and shifting state is swept into a circular stripe raw food when touching the perimeter of the oblique wheel frame; the circular stripe raw food is input in a cutting and molding device and is cut and molded into spheroidal raw food; the dough cover of the spheroidal raw food has relatively high tendon or thin pastry and fillings with three different favors distributed inside.

Owner:YANG JENQ MACHINERY

Toaster pastry

InactiveUS20050084567A1Quality improvementImprove stabilityConfectionerySweetmeatsAdditive ingredientWheat flour

A dough and a filling for making a toaster pastry and a method for making same. A method of forming the dough for the toaster pastry, comprises forming a blend of ingredients comprising wheat flour of from about 25 to about 44% by weight of ingredients for the dough, wheat farina of from about 13 to about 35% by weight of ingredients for the dough, shortening of from about 1.5 to about 2.5% by weight of ingredients for the dough, and water of from about 25 to about 35% by weight of ingredients for the dough; adding puff pastry shortening in the form of cubes such that the amount of puff pastry shortening is in the range of from about 5 to about 15% by weight of the ingredients for the pastry; and blending the ingredients such that a heterogeneous mixture of the cubes of shortening in the remainder of the ingredients is obtained. In a preferred aspect, the method further comprises forming the dough into a layered structure, the layered structure comprising a single base sheet of the dough covered with a pastry filling, with a single top sheet of the pastry blend of the dough applied thereover.

Owner:BROWN MARY +4

Plain egg-yolk puff pastry and preparation method thereof

The invention discloses a plain egg-yolk puff pastry. The plain egg-yolk puff pastry is prepared from, by weight, 15-50 parts of strong flour, 5-25 parts of cake flour, 10-25 parts of butter, 1-12 parts of white granulated sugar, 20-50 parts of ghee, 50-80 parts of egg yolk, 20-30 parts of mashed purple sweet potatoes, 10-30 parts of dried meat floss, 20-40 parts of red bean paste, 0.01-0.04 part of food additive and 1-10 parts of water. The invention further provides a preparation method of the plain egg-yolk puff pastry. According to the filling of the plain egg-yolk puff pastry, the egg yolk, the mashed purple sweet potatoes, the dried meat floss and the red bean paste are located in sequence from inside to outside, the filling is clear in layering, abundant in nutrition, soft and not overly sweet, and the added mashed purple sweet potatoes further have sweet and sour tastes, can promoting gastrointestinal motility and has cancer-prevention and anticancer effects; the outer wrapper layer of the plain egg-yolk puff pastry is multi-layer flour-made wrappers, compact and crisp; the plain egg-yolk puff pastry is abundant in flavor, reasonable in structural design, novel in style, convenient to eat and easily popular with consumers.

Owner:广西朗盛食品科技有限公司

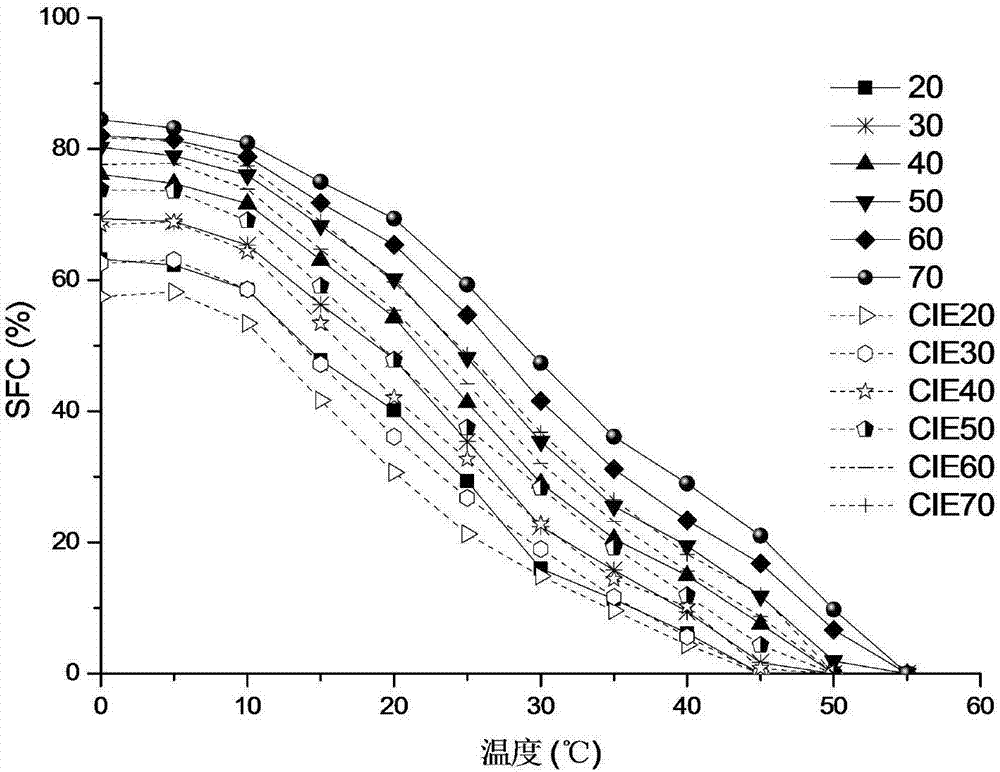

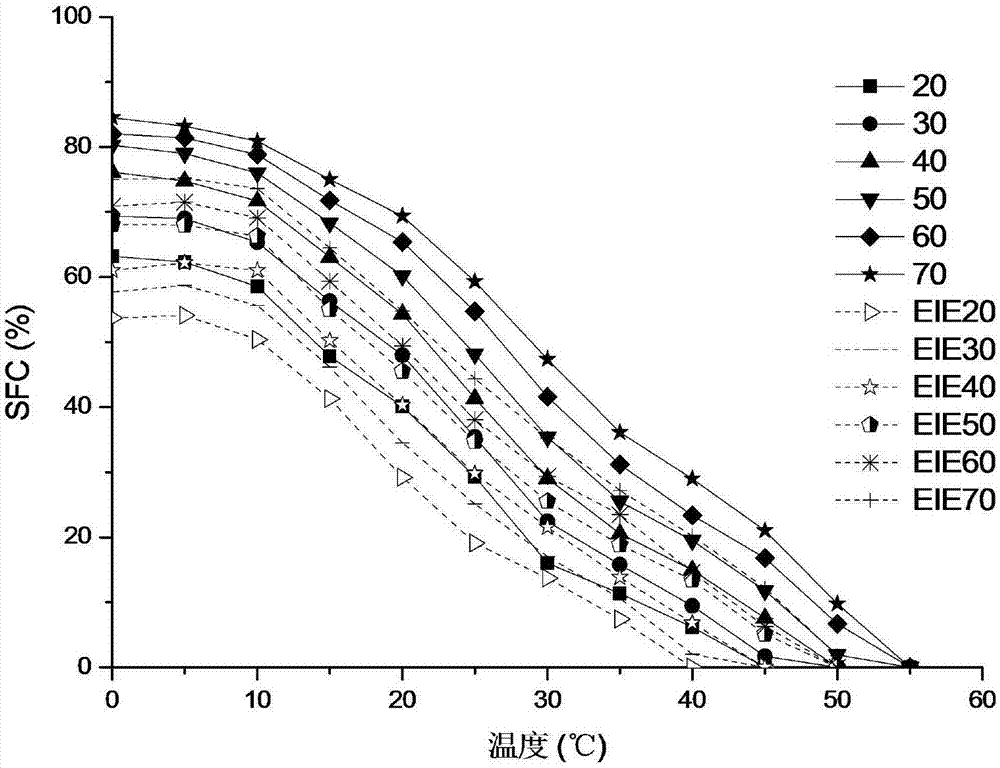

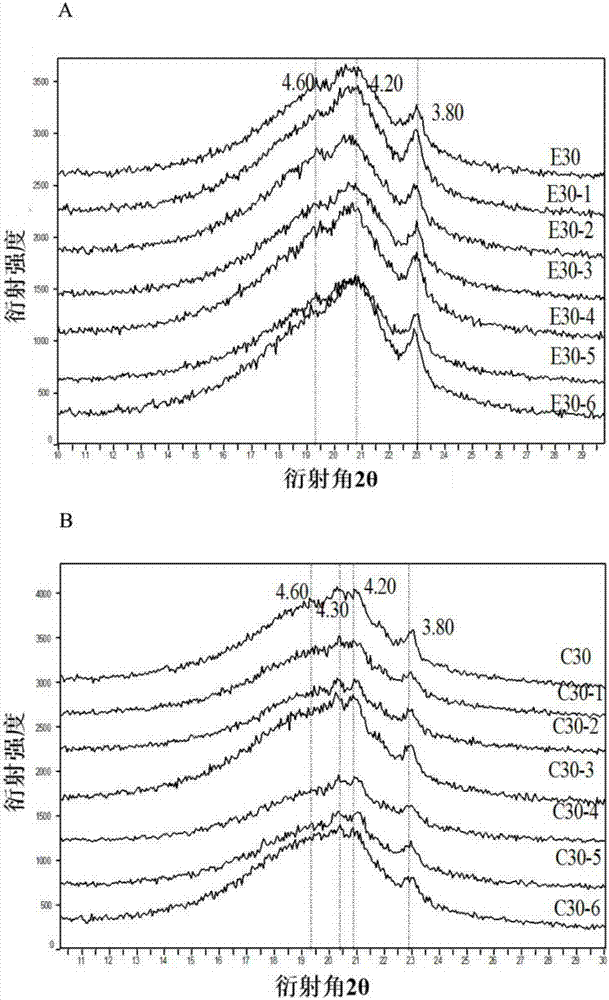

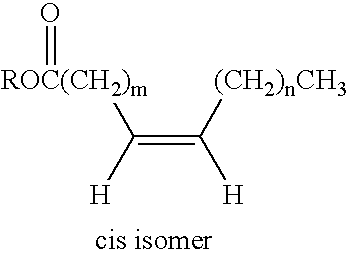

Preparation and application for trans fat-free pastry oil

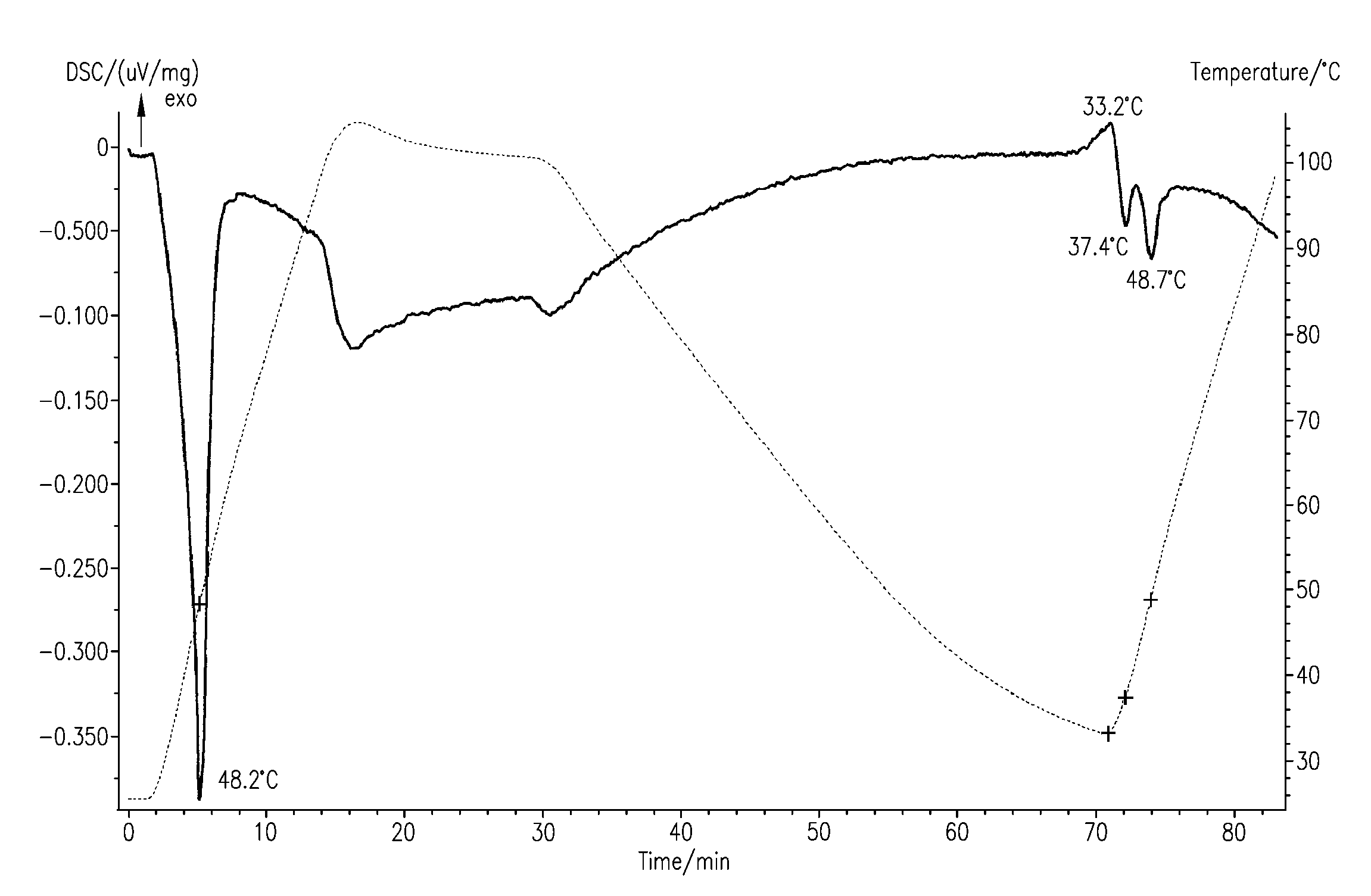

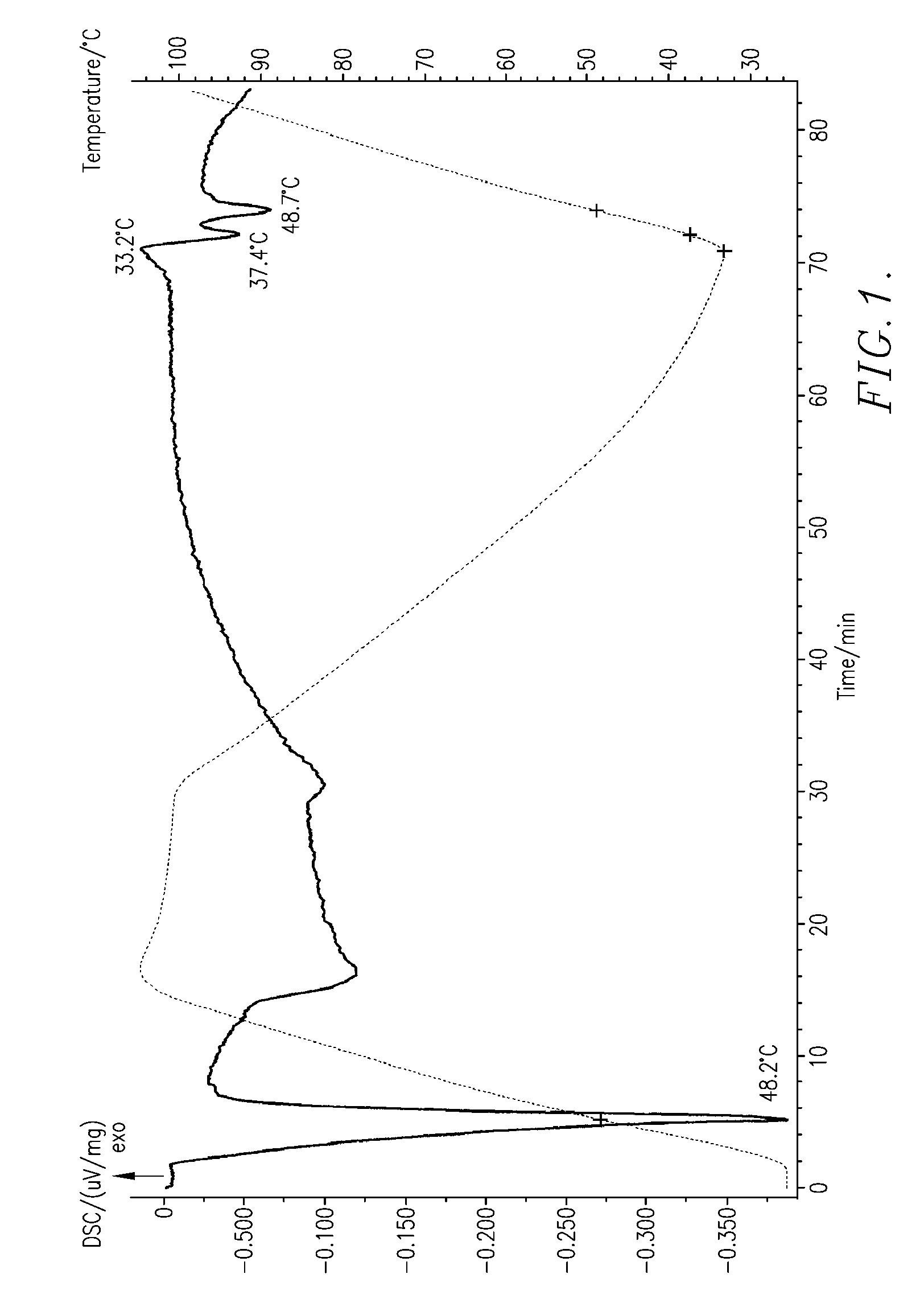

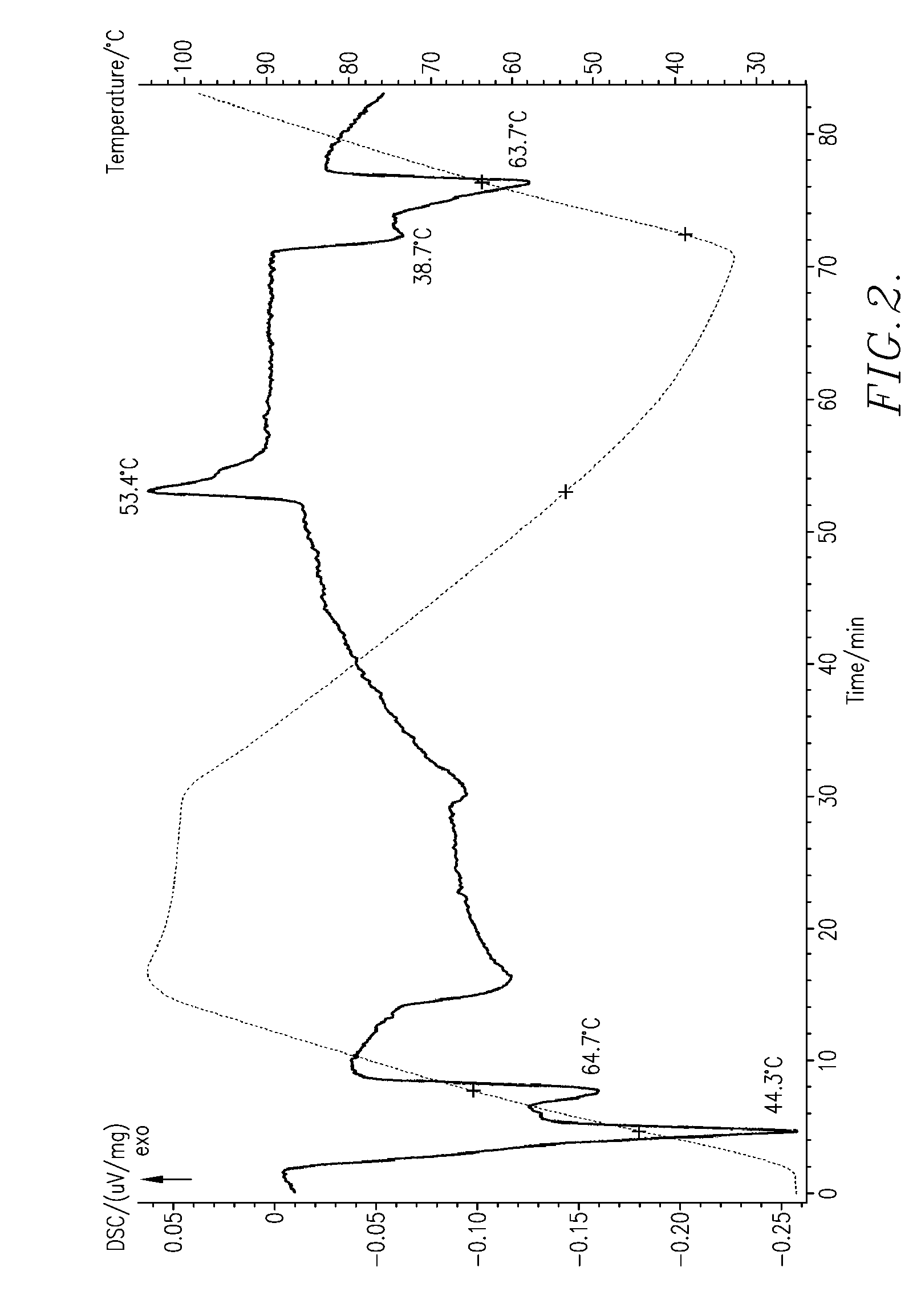

InactiveCN106857882AImprove crystal structureMany β′ crystal formsDough treatmentEdible oils/fatsPalm stearinBeef Tallow

The invention discloses a preparation and an application for trans fat-free pastry oil and belongs to the technical field of cream products. The preparation for the trans fat-free pastry oil provided by the invention comprises the following steps: taking lard oil and palm stearin as raw materials, mixing in corresponding proportion, improving the plasticity scope and crystalline characteristic of compound oil by adopting enzymic ester exchange or chemical ester exchange method, and then researching the change in oil ester crystal form caused by the addition of different emulsifiers. The pastry oil acquired according to the invention is wide in plasticity scope, has fine crystals, contains no trans fat, can be used for locally placing the application of beef tallow in high-class pastry oil, has a potential value in developing the traditional lard oil and is more suitable for industrial operation.

Owner:JIANGNAN UNIV

Red bean paste egg-yolk puff and making method thereof

The invention discloses a red bean paste egg-yolk puff. According to the technical scheme, the red bean paste egg-yolk puff is characterized by comprising wrappers, crusts and stuffing; the wrappers are made of water-oiled crusts, and the water-oiled crusts are made of 995-1005 g of low-gluten flour, 148-152 g of white granulated sugar, 4-6 g of salt, 399-401 g of water and 249-251 g of fermenting butter; the crusts are made of 349-351 g of shortening and 698-702 g of low-gluten flour; the stuffing is made of 400-500 g of red bean paste and 14-16 g of salted egg yolk. The red bean paste egg-yolk puff has the advantages of crispness, rich stuffing and diversified tastes.

Owner:刘希康

Low trans fatty acid shortening compositions

Interesterified or blended shortening compositions having a relatively low proportion of trans fatty acid are described. The shortening compositions are made by blending or interesterifying low-linolenic soybean oil, including from 1 to 3.5 wt. % linolenic fatty acid moieties and from 0 to 2 wt. % trans fatty acid moieties, and a highly saturated fat including from 0 to 2 wt. % of trans fatty acid moieties. The interesterified or blended shortening composition has a trans-fatty acid moiety content of from 0 to 2 wt. %. These interesterified or simple blends are low in trans fatty acid, but are otherwise similar in composition and performance to partially hydrogenated vegetable oils. Products made from the compositions include baked goods, such as short bread cookies, biscuits, pie crusts, or puff pastry shells, or an icing such as cream icing.

Owner:EI DU PONT DE NEMOURS & CO

Passion fruit egg tart and preparation method thereof

The invention discloses a passion fruit egg tart and a preparation method thereof, and belongs to the technical field of manufacture of desserts. The passion fruit egg tart consists of egg tart water and a puff pastry, wherein the egg tart water is prepared from the following raw materials in parts by weight: 200-250 parts of unsalted butter, 100-150 parts of milk, 60-100 parts of granulated sugar, 60-85 parts of egg yolk, 30-60 parts of low-gluten flour, 15-30 parts of butter and 30-60 parts of passion fruit juice; the puff pastry is prepared from the following raw materials in parts by weight: 250-280 parts of low-gluten flour, 30-50 parts of high-gluten flour, 200-300 parts of butter, 10-15 parts of granulated sugar, 1.5-2 parts of salt and 125-150 parts of water. The passion fruit egg tart manufactured according to the preparation method has the characteristics of being special in taste and rich in nutrition.

Owner:高深

Dried meat floss cake and making method

InactiveCN105394129AImprove anti-corrosion performanceReduce perishabilityDough treatmentBakery productsPropolisVegetable oil

The invention discloses a dried meat floss cake and a making method. The dried meat floss cake contains a wrapper material, a pastry material, and filling. Relative to 100 parts of the wrapper material by weight, content of the pastry material is 30-70 parts by weight, and content of the filling is 200-300 parts by weight. At least one of the wrapper material, the pastry material, and the filling contains propolis. The wrapper material contains powders, butter, vegetable oil, sugar, salt, and water. The powders at least contain plain flour. The pastry material contains the plain flour, butter, and vegetable oil. The filling contains green bean paste, dried meat floss, butter, sugar, and salt. Through adding the propolis in the raw materials of the dried meat floss cake, relatively long shelf-life of the dried meat floss cake can be realized without adding food preservatives, thereby greatly improving healthfulness of the dried meat floss cake, and satisfying requirements of people on health.

Owner:ANHUI THREE SQUIRRELS ELECTRONICS BUSINESS

Pastry jackfruit pulp mooncake

InactiveCN104255868AHigh nutritional valueRich varietyDough treatmentPre-baking dough treatmentNutritive valuesGluten

The invention discloses a preparation method of pastry jackfruit pulp mooncake. The method is simple, and the mooncake is delicious and high in nutritive value. The pastry jackfruit pulp mooncake comprises, by weight, 200 to 300 parts of low-gluten flour, 200 to 300 parts of plain flour, 50 to 200 parts of butter, 50 to 100 parts of milk, 30 to 60 parts of white sugar, 50 to 100 parts of lard oil, 300 to 400 parts of jackfruit and an appropriate amount of water. The steps of the preparation method of the pastry jackfruit pulp mooncake are simple, operation is convenient, and prepared products are attractive, delicate, delicious and tasty.

Owner:董春年

Mung bean cake and preparation method of mung bean cake

InactiveCN103843858AHeat-clearing and detoxifyingWith blood pressure loweringDough treatmentBakery productsCooking & bakingVegetable oil

The invention discloses mung bean cake and a preparation method of the mung bean cake. The mung bean cake is prepared from the following ingredients in percentage by weight: oil skin comprises the following ingredients in percentage by weight: 40 to 50 percent of low-gluten flour, 20 to 30 percent of water, 10 to 18 percent of vegetable oil and 10 to 20 percent of lotus leaf powder; crust skin comprises the following ingredients in percentage by weight: 50 to 60 percent of low-gluten flour and 30 to 55 percent of vegetable oil; stuffing comprises the following ingredients in percentage by weight: 30 to 40 percent of mung bean, 30 to 40 percent of glucose powder, 1 to 2 percent of water and 25 to 35 percent of butter. The preparation method comprises the steps that the low-gluten flour, the water, the vegetable oil and the lotus leaf powder are taken and are uniformly stirred, the water content is controlled to be 5 to 6 percent, and the oil skin is prepared; the low-gluten flour and the vegetable oil are taken and are uniformly stirred, and the crust skin is prepared; the mung bean is taken and cleaned, the water is added, the mung bean is boiled out, is uniformly stirred and is poured into a pan, the butter and the glucose powder are added, and the mixture is boiled into the stuffing by soft fire; the oil skin and the crust skin are respectively cut into a plurality of identical small blocks, then, the crust skin is placed on the oil skin and is rolled to be longer, and next, the rolling up is carried out; each small block is taken and is flattened by pressing and is rolled into a round shape, the stuffing is taken and wrapped, and the blank is put into a baking oven for to be baked, and the mung bean cake disclosed by the invention is obtained.

Owner:俞华

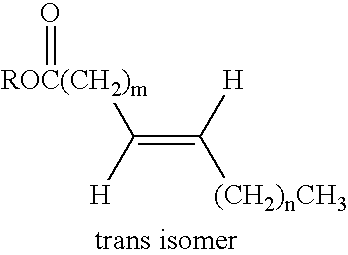

Preparing method of lotus paste puff pastry

The invention relates to a preparing method of a lotus paste puff pastry, mainly providing a manufacturing method of a puff pastry which has attractive color and good smell and taste and is suitable for various consumers. The lotus paste puff pastry is prepared from the following raw materials by the following procedure, wherein the raw materials comprises the following ingredients: 1. major ingredient: pastry wrapper prepared from 10kg of flour, 3.5kg of lard stearin, a proper amount of water; 2. shortening prepared from 5kg of flour, 2.5kg of lard stearin; 3. stuffing prepared from 31.5kg of semi-manufactured products; and the preparing procedure comprises the following steps: 1. stirring the materials: firstly evenly stirring the flour and water of the pastry wrapper , then adding the load stearin and evenly stirring to prepare a dough, and evenly stirring the shortening materials and kneading to make doughs; 2. blanking: wrapping the shortening into the pastry wrapper according to the proportion of 4: 6, calendaring by a small roller, rolling and then folding (three folds) to form a dough, taking 50g of lotus paste stuffing and wrapping into the pastry wrapper, sealing and flat pressing to form a cake, and pressing a lace like a lace cake if a pattern round edge is required; and 3. baking about 20 minutes in the oven at the temperature of 190 DEG C. The prepared puff pastry is full and bright in appearance, soft and free of breakage in pastry wrapper, crispy and sweet in mouthfeel and has no stuffing leaking phenomenon.

Owner:JIANGSU YUANHONG FOOD

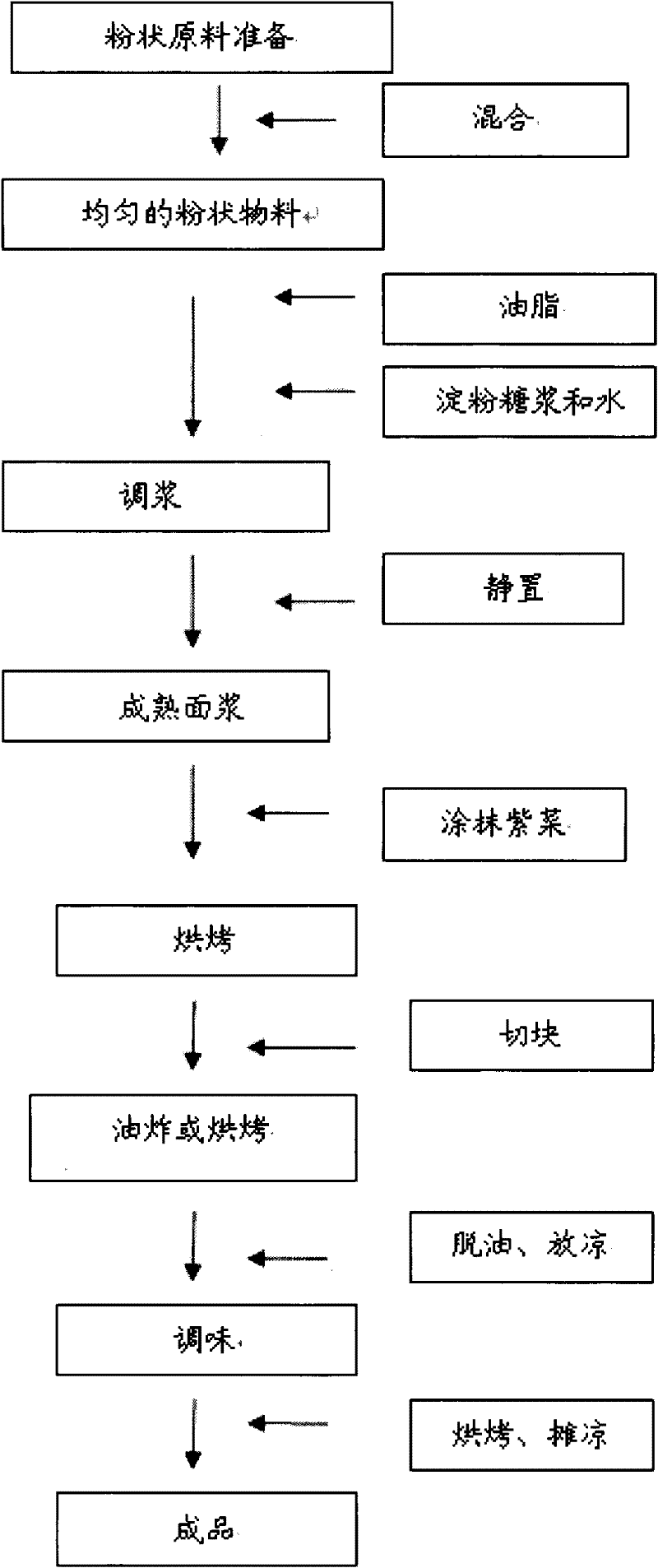

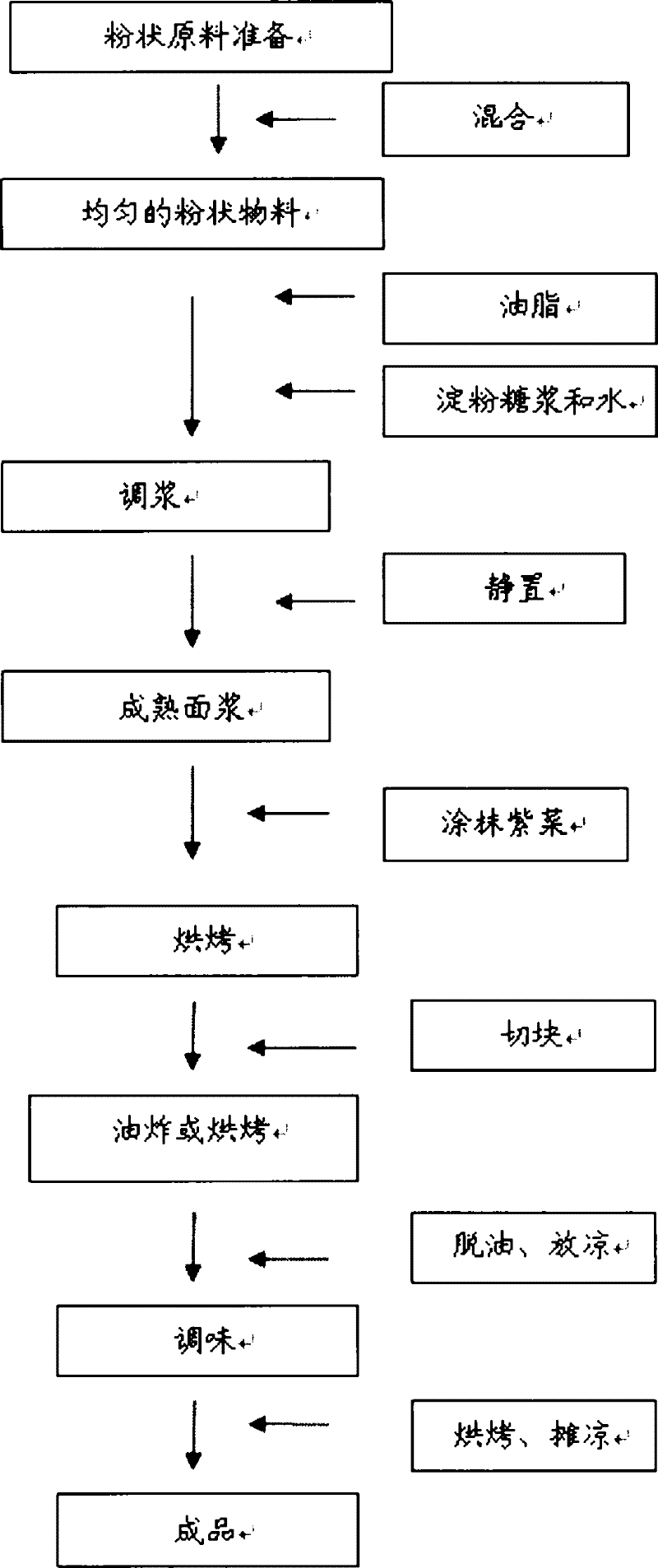

Production process for family laver puff pastry

The invention discloses a production process for a family laver puff pastry, and belongs to the technical field of laver processing. Laver is a treasure in edible alga and has extremely high nutritive value and medicinal value. China is one of the largest countries of breeding the laver; and lianyungang is the largest laver breeding and rough processing base station of China, but most of laver products are sold by export, and the product forms and the marketing channels for products are simple. Since export of enterprises is reduced due to financial crisis of recent years, the overstock of the laver is high. According to the characteristics of the laver, the laver is matched with low-gluten wheat flour, corn starch, potato starch, sugar, salt, plant oil and the like to be fried or roasted and seasoned to be prepared into different flavors; and the production process is suitable for family or large-scale operation.

Owner:HUAIHAI INST OF TECH +2

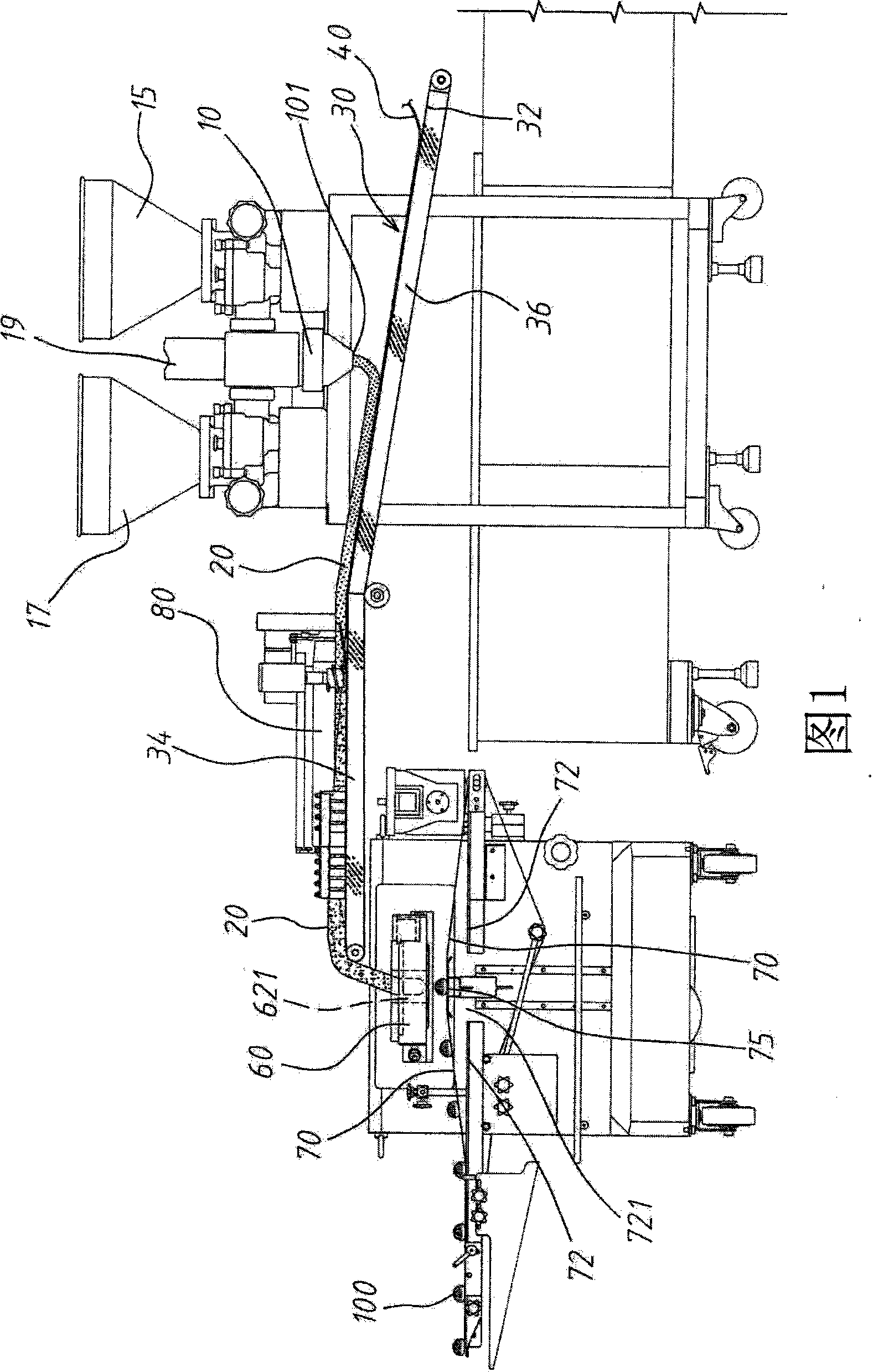

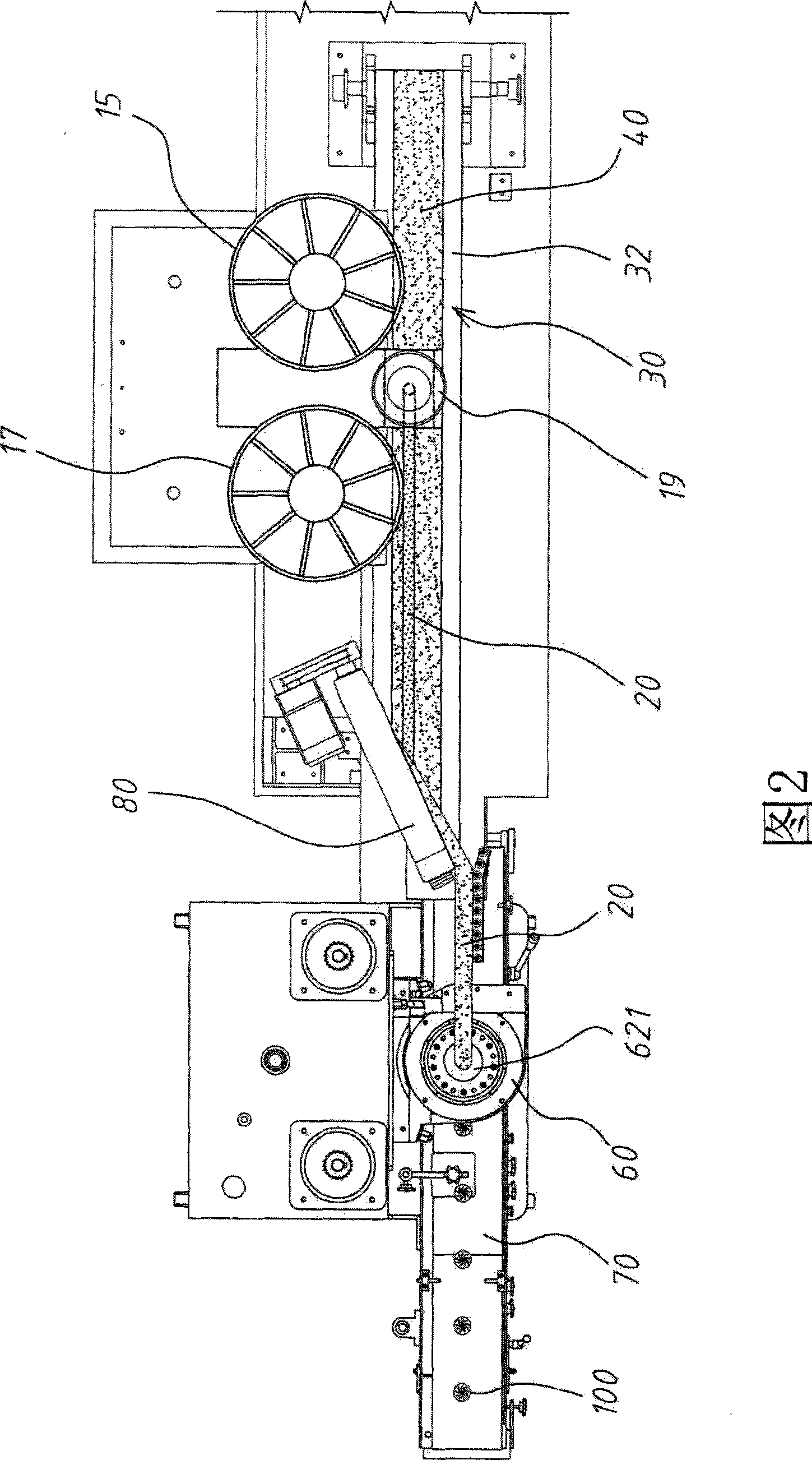

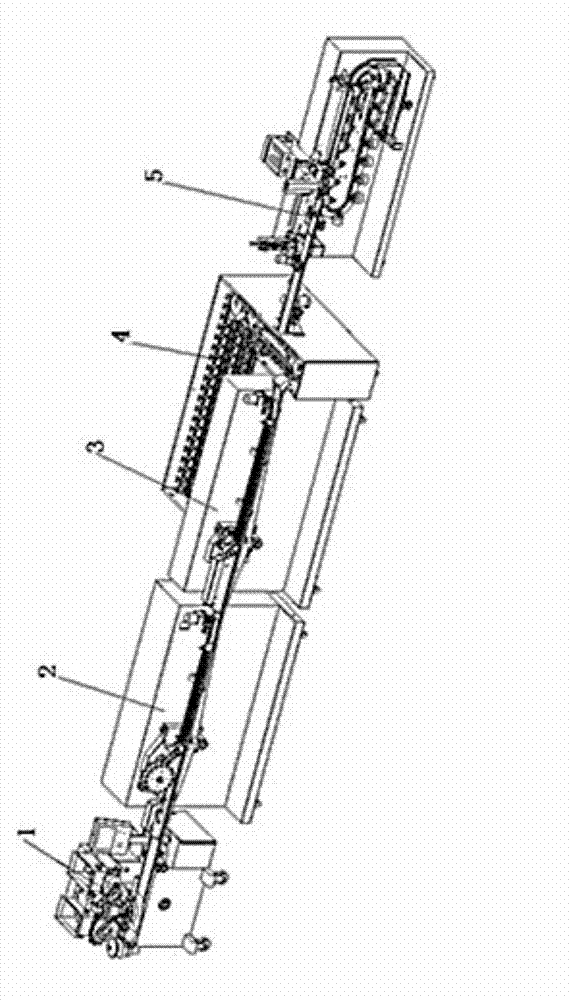

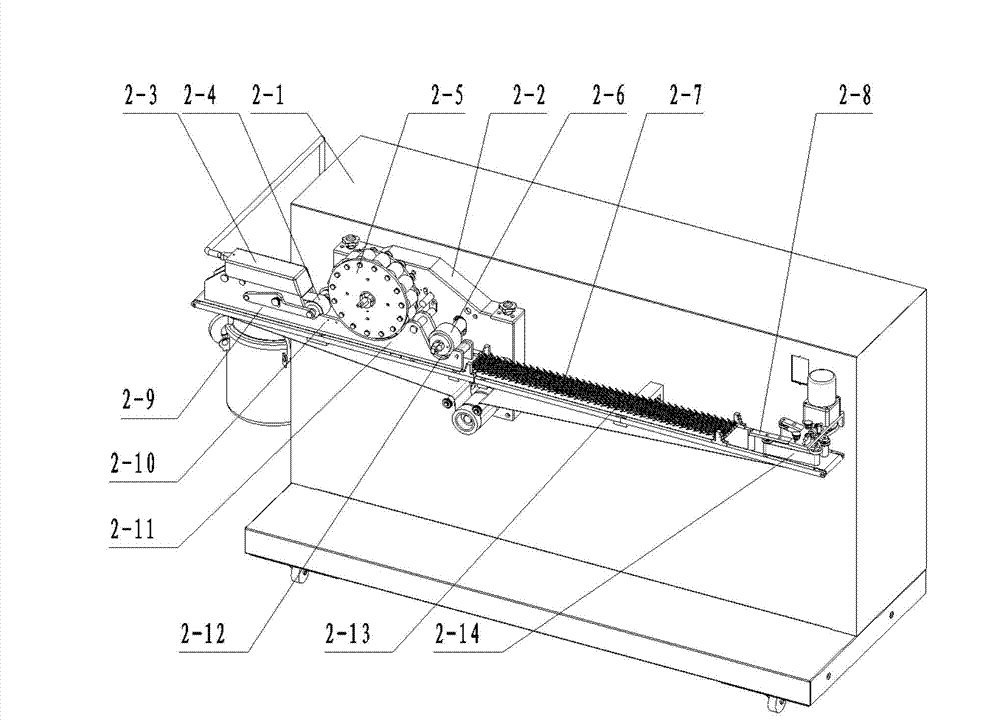

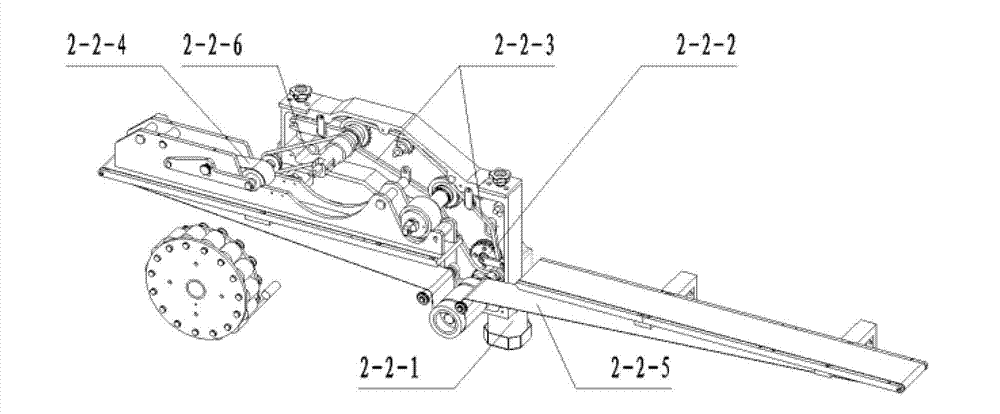

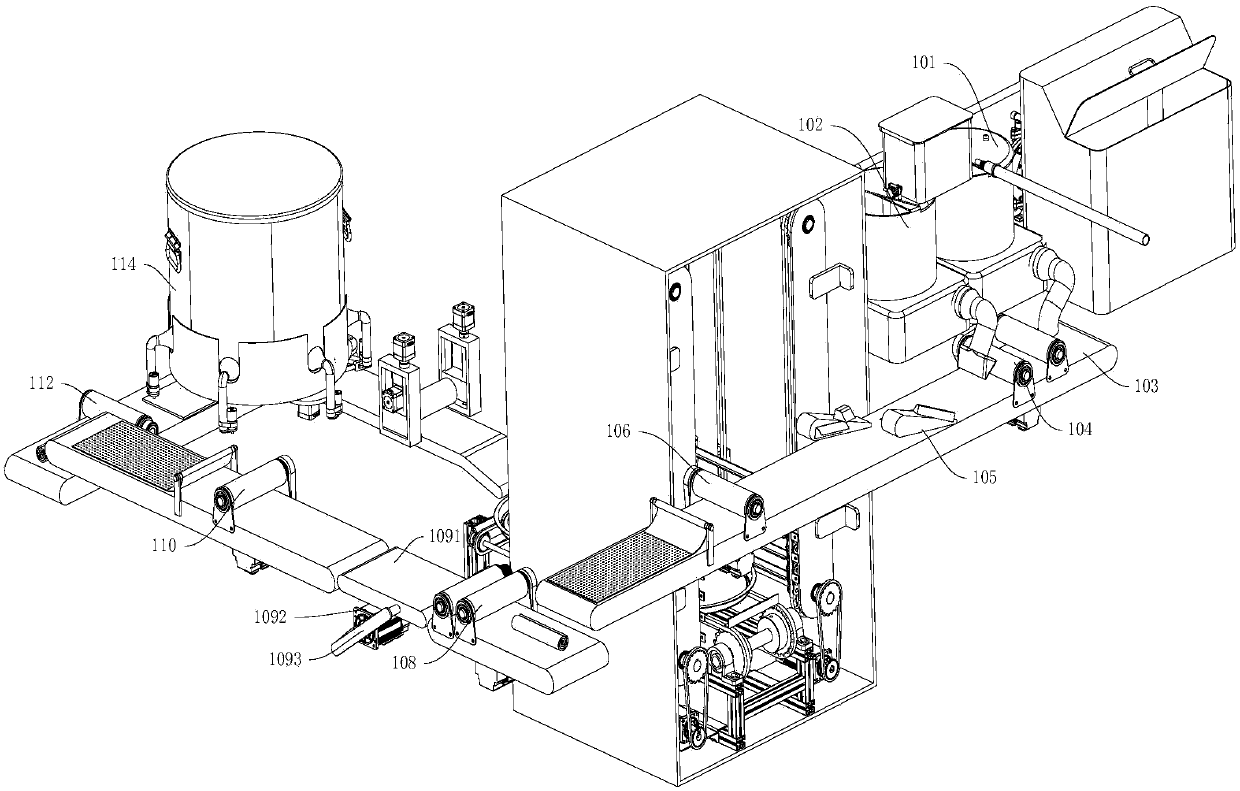

Multi-station automatic forming system device for multilayer crisp stuffed moon cakes

InactiveCN102885100AIncrease productivityAvoid congestionDough sheet coiling machinesDough-sheeters/rolling-machines/rolling-pinsFood flavorMultiple layer

The invention relates to a multi-station automatic forming system device for multilayer crisp stuffed moon cakes. The multi-station automatic forming system device comprises a dough and crisp packing and discharging machine, a first-time flattening and coiling forming machine, a second-time flattening and coiling forming machine, a crisp layer leavening machine and a follow-up stuffing supplying and sealing machine, wherein a programming controller is connected with the dough and crisp packing and discharging machine, the first-time flattening and coiling forming machine, the second-time flattening and coiling forming machine, the crisp layer leavening machine and the follow-up stuffing supplying and sealing machine respectively to control the five machines. The programming controller is connected with the five machines respectively, and sends out commands to control the five machines to execute processes on line. The five machines are connected by transmission devices on the five machines, and blank or multiple layers of cake blanks are transmitted from an inlet of the multiple players of cake blank to an outlet by the transmission devices after the mechanical action is accomplished. The multi-station automatic forming system device can ensure traditional flavor and taste of the crisp dessert, and realizes the output at the speed of 40-60 desserts per minute. The multi-station automatic forming system device opens up a new technical field of producing the multilayer crisp stuffed moon cakes through mechanical automation.

Owner:上海伟隆机械设备股份有限公司

Pasty and preparation method thereof

InactiveCN106259781AAids in fermentationCrispy and softDough treatmentPre-baking dough treatmentSugarBalance water

The invention relates to the technical field of food, in particular to a pasty and a preparation method thereof. The pasty comprises a crust and stuffing, and the crust is prepared from, by weight, 60-66% of flour, 0.7-1.8% of yeast, 3.6-7.8% of sugar, 0.3-0.6% of edible salt, 0.3-0.5% of leavening agent, 0.1-0.3% of bread improver, 4.5-6.5% of shortening and the balance water. The preparation method of the crust of the pasty includes dough preparing, proofing, rolling and shaping. The pasty is low in oil content, not oily, crisp and tough in crust, capable of well keeping both integrity and crisp taste and less prone to crust breaking, cracking and stuffing exposure. The preparation method is simple, convenient, easy to control and suitable for industrialized production.

Owner:SANQUAN FOOD

Chinese chestnut pastry and manufacturing method thereof

The invention discloses a Chinese chestnut pastry and a manufacturing method thereof. Chinese chestnut pastry stuffing of the Chinese chestnut pastry is made of chestnut kernels roasted with sugar, sliced chestnut kernels, white kidney bean paste, malt syrup, white granulated sugar, peanut oil, sucrose fatty acid ester, monostearin, sodium dehydroacetate, vanilla extract and gardenia yellow. Chinese chestnut pastry skin of the Chinese chestnut pastry is made of self-raising flour, plain flour, Chinese chestnut flour, butter, white granulated sugar, dehydrated butter, egg yolk, milk powder and salt. Not only is the Chinese chestnut pastry attractive in color, crisp in taste, sweet, delicious and agreeable in sweetness, but also the fragrance of Chinese chestnut is given to the product by adding the Chinese chestnut powder, the nutrition is richer, and the Chinese chestnut pastry is suitable for all ages and better meets people's requirements for nutritional healthy foods.

Owner:SHANDONG HUIFA FOODS

Dried orange peel pastry or crispy and method for manufacturing pastry or crispy

InactiveCN101690561AThe taste is fragrant and mellowCrisp and deliciousFood preparationFilling materialsBody fluid

The invention discloses a dried orange peel pastry or a crispy and a method for manufacturing the pastry or the crispy. The dried orange peel pastry or the crispy consists of a puff pastry and a filling material, wherein the filling material comprises dried orange peel. The method for manufacturing the pastry or the crispy adds a proper amount of dried orange peel into the pastry or the crispy, makes full use of the flavour of the dried orange peel to mix the flavours of other materials mutually so as to form unique local flavour, and plays roles in enhancing aroma, odorizing, increasing freshness, releasing greasiness and promoting the production of body fluid. The prepared dried orange peel pastry or crispy not only keeps original local flavour and mouthfeel characteristics of the variety, but also has faint, mellow, crispy and delicious mouthfeel, promotes the tongue to produce the body fluid, has no greasy feeling, cannot cause excessive internal heat even if people eat too much, has rich nutrition, and is suitable to be produced and sold all the year round.

Owner:刘碧华

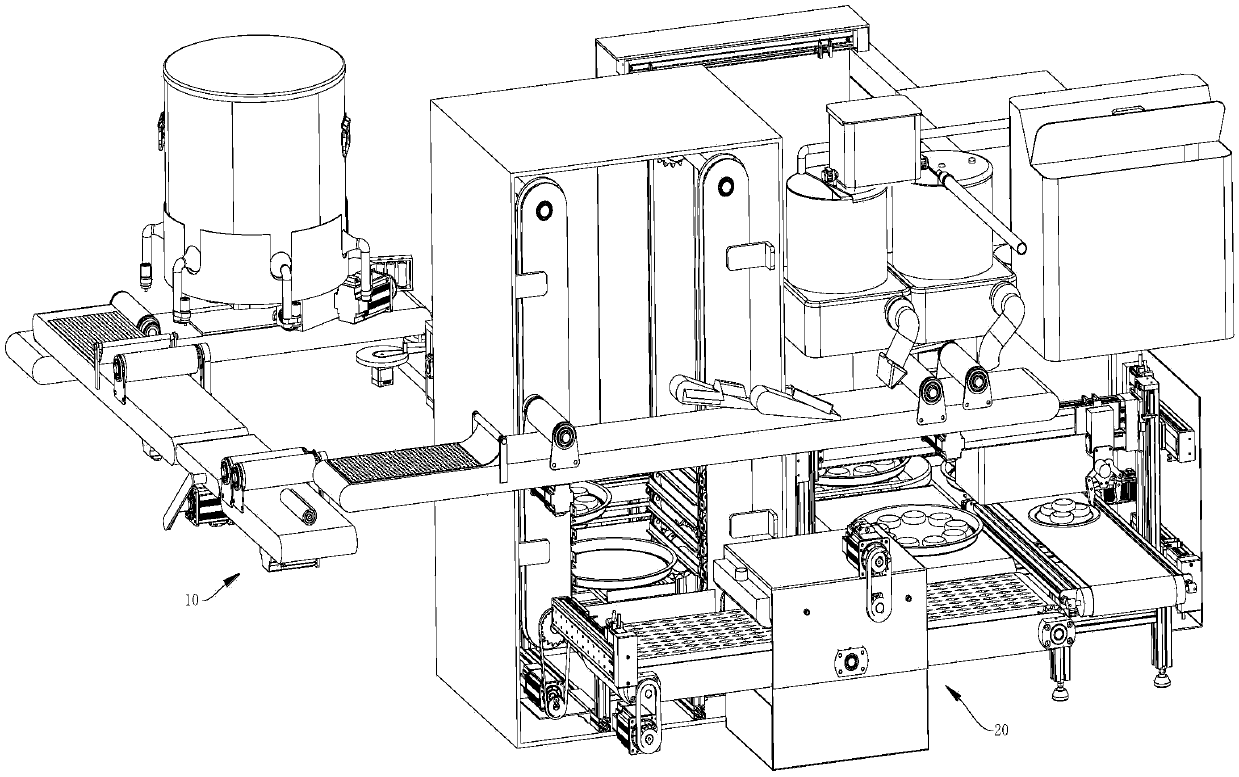

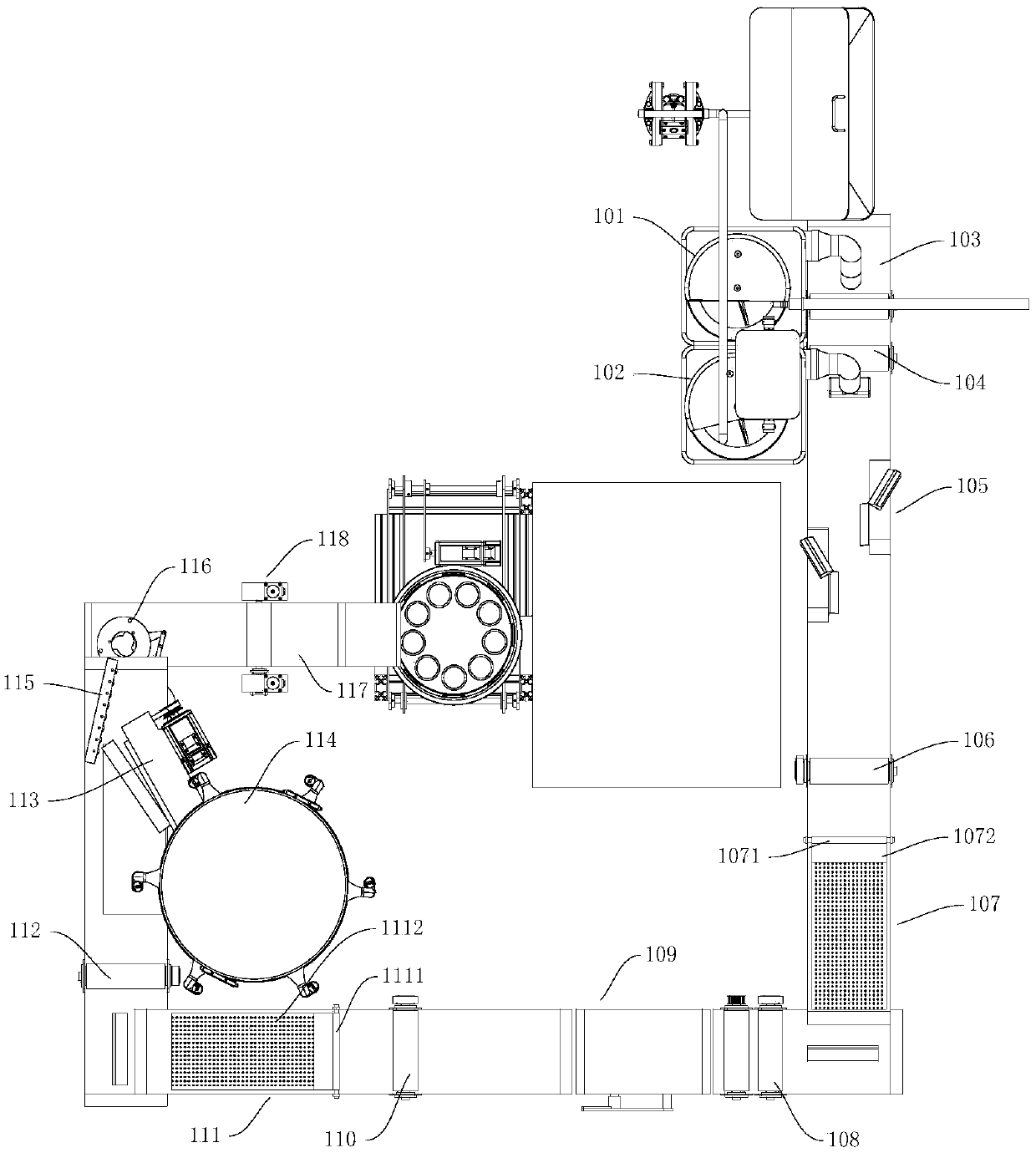

Fully automatic flaky pastry machine

The invention discloses a fully automatic flaky pastry machine. The fully automatic flaky pastry machine comprises a flaky pastry shaping device and a baking device, wherein the flaky pastry shaping device comprises a pastry shaping assembly, a pastry folding assembly and a folded pastry rolling and pressing assembly; when the pastry folding assembly is in a first state, the pastry shaped by the pastry shaping assembly is carried; when the pastry folding assembly is in a second state, the pastry folding assembly folds the pastry; the folded pastry rolling and pressing assembly rolls and presses the folded pastry formed by being folded by the pastry folding assembly; the baking device comprises a baking tray delivery mechanism, a pushing mechanism and a baking oven; the baking device has atray loading station; the baking tray delivery mechanism is used for supplying baking trays to the tray loading station one by one; the pushing mechanism moves between the tray loading station and aninlet and outlet opening of the baking oven or moves between the inlet and outlet opening of the baking oven and an outlet opening of the baking device. The fully automatic flaky pastry machine can achieve the goal of folding the pastry, automatically delivering baking trays, automatically pushing the baking trays into the baking oven or automatically pulling out the baking trays in the baking oven.

Owner:GUANGZHOU FUGANG WANJIA INTELLIGENT TECH CO LTD

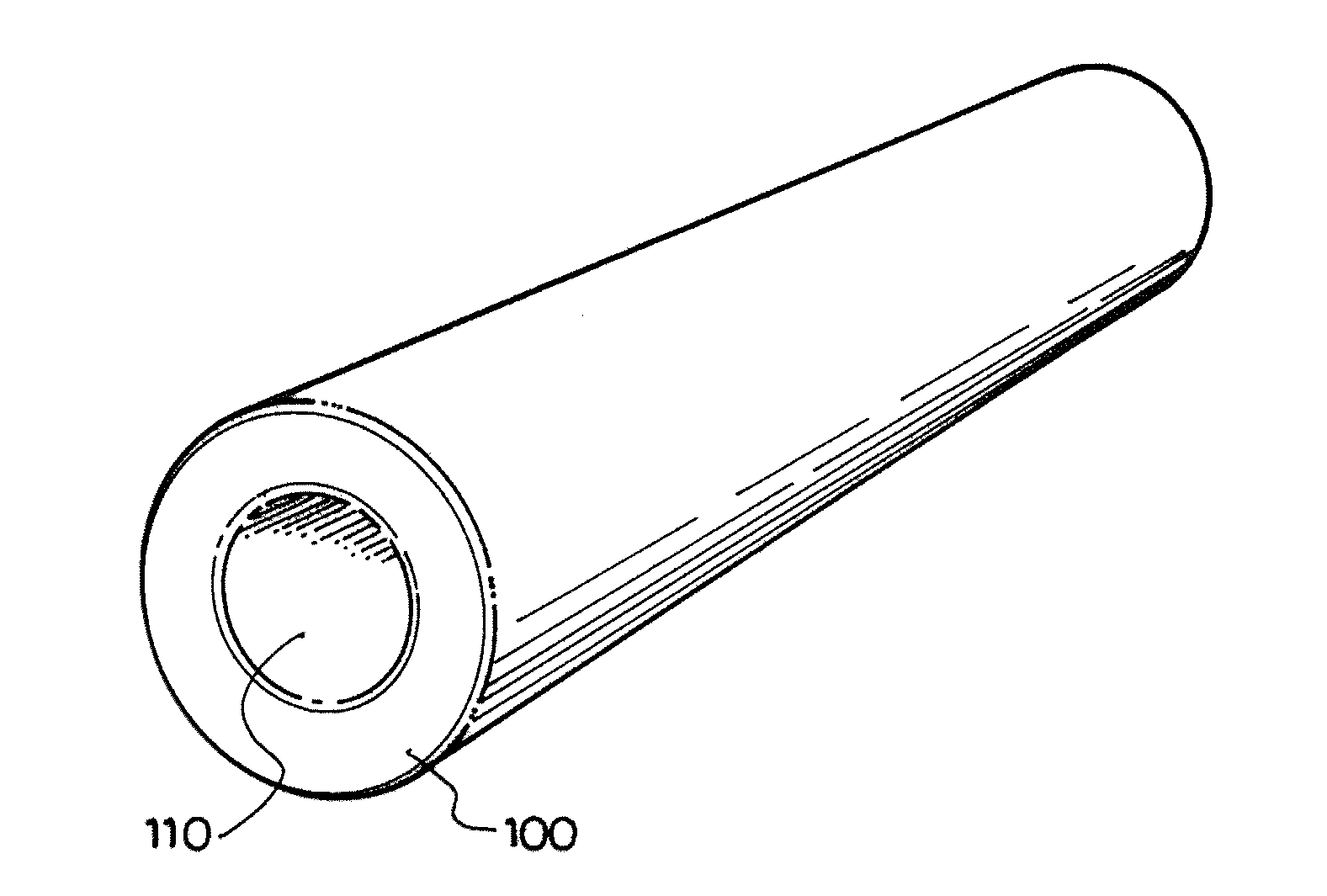

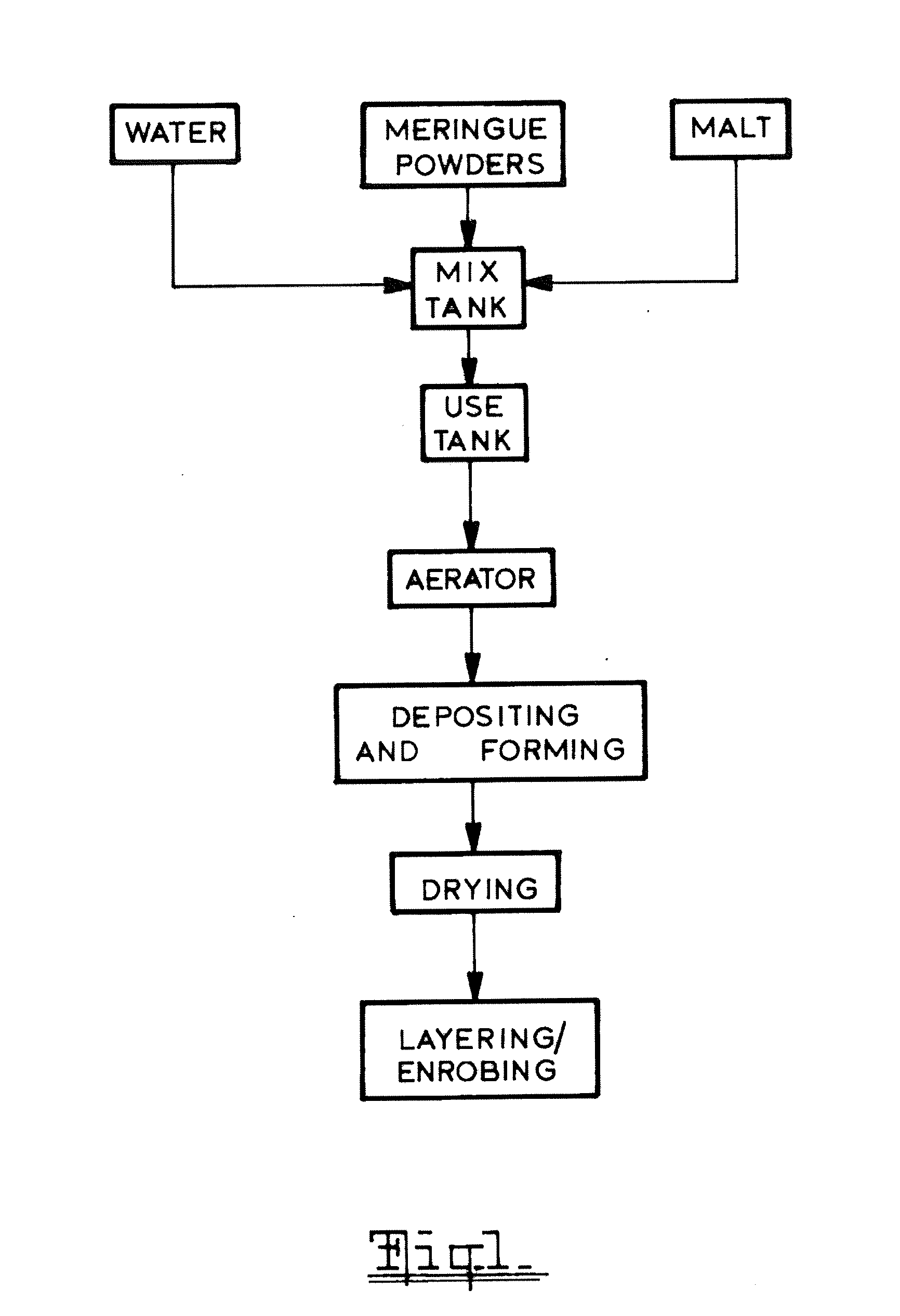

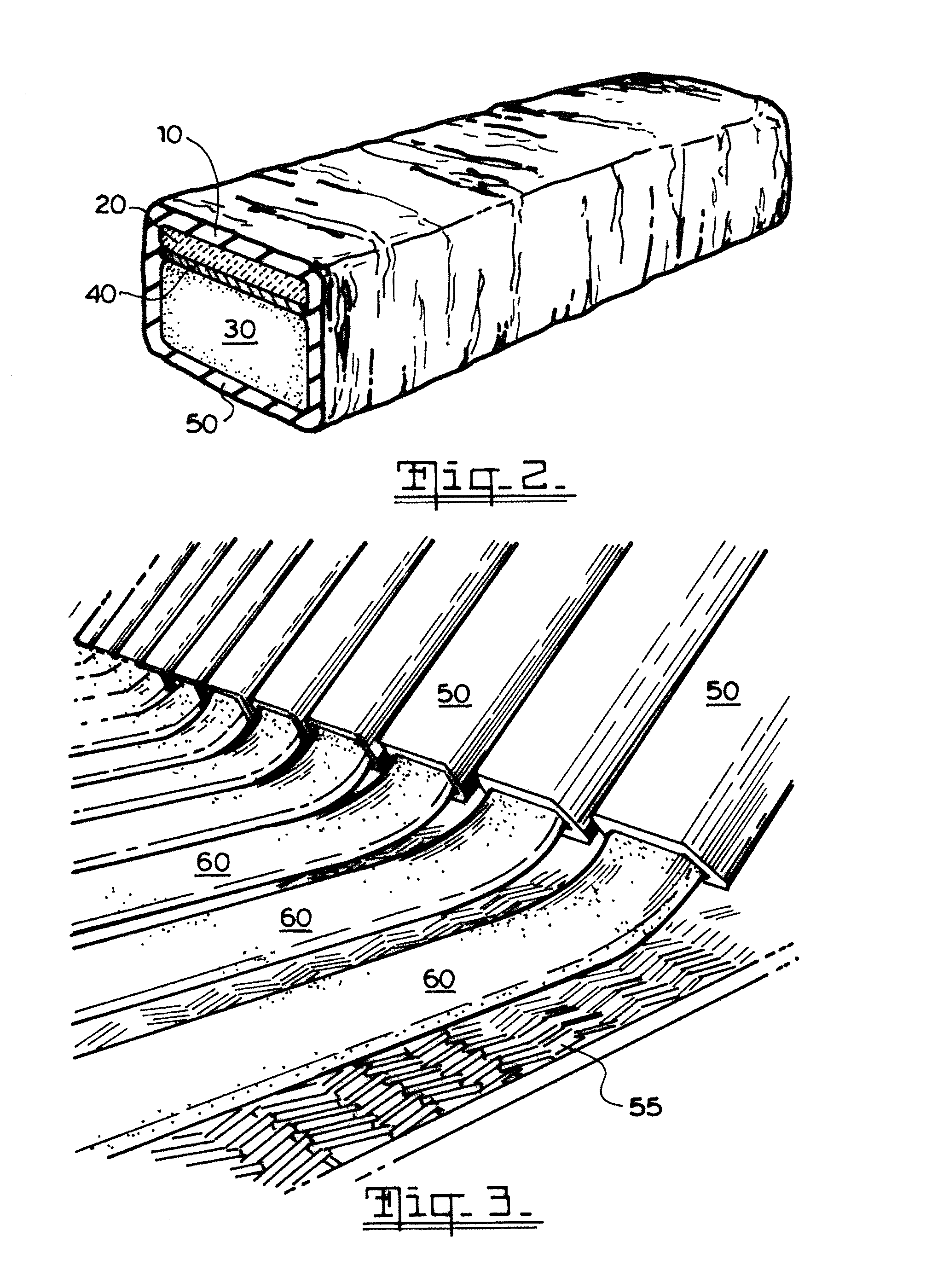

Confectionery meringue

A dried confectionery meringue formed from a meringue mixture having a pre-drying moisture level of between about 18% and about 30%, said mixture including a protein foaming agent, sucrose and at least one monosaccharide.

Owner:MARS INC

Making method of puff pastry sesame seed cakes

InactiveCN107361107AThin meringueGolden colorDough treatmentPre-baking dough treatmentFermentationSesame seed

The invention discloses a making method of puff pastry sesame seed cakes. The making method comprises the thirteen steps of making fillings, performing dough mixing for the first time, performing dough recovery, performing dough mixing for the second time, performing the process of making crusts through coating oil-mixed dough with water-oiled dough, performing shortening, wrapping the fillings, performing rolling, performing splitting, brushing a baking pan with oil, performing brushing with syrup, performing roasting for the first time and performing roasting for the second time. Through the thirteen steps in the making method disclosed by the invention, the bottlenecks that conventional sesame seed cakes are difficult to store, and the fermentation process is greatly influenced by weather are broken through by the produced sesame seed cakes; besides, the products made through the steps are different from conventional circular sesame seed cakes in appearance and are rectangular; openings are formed in two sides of each sesame seed cake; and the puff pastry sesame seed cakes are thin in crusts, golden in color, loose and layered, crisp like scales, free from greasy taste, short in roasting time, crisp in mouth feel, good in storage stability, golden in color, loose and layered, and crisp like scales, and are deeply loved by vast consumers.

Owner:汪卫清

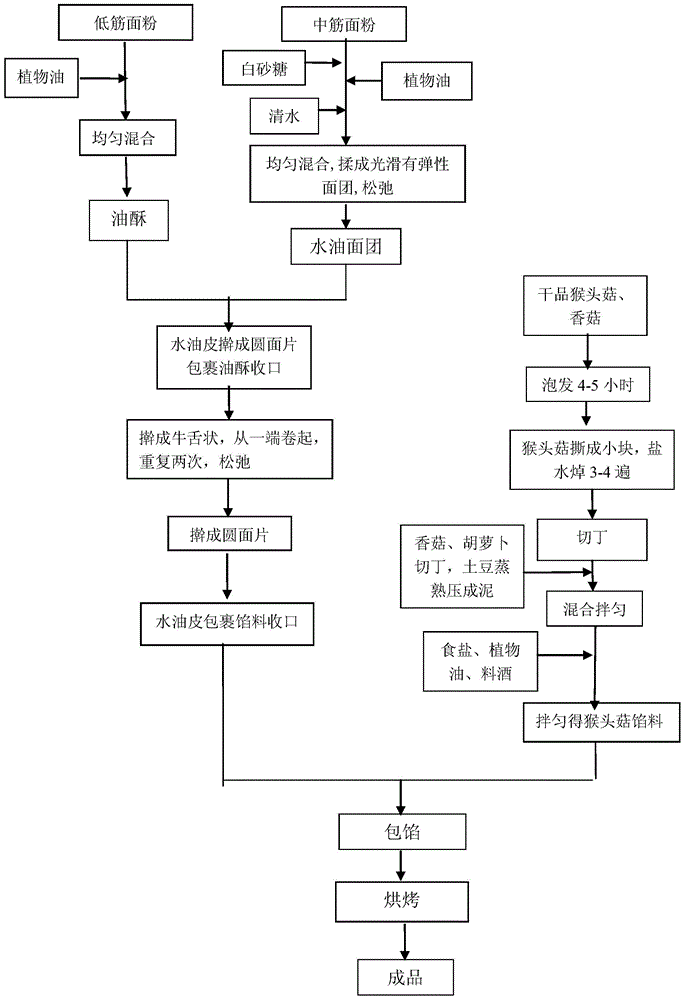

Vegetarian moon cake of hericium erinaceus and production method thereof

InactiveCN104872257AFull of nutritionNutritional balanceDough treatmentBakery productsNutritive valuesBearded tooth

The invention discloses a production method of a vegetarian moon cake of hericium erinaceus. The production method comprises the step of producing stuffing and cake crust. The raw materials of the stuffing comprise, by weight, 75 to 90 parts of dried hericium erinaceus, 12 to 15 parts of dried mushroom, 6 to 7.5 parts of carrot, 12 to 15 parts of potato, 10 to 12 parts of salt, 15 to 20 parts of vegetable oil A and 8 to 12 parts of cooking wine. The cake crust comprises a water-oil crust and a crisp crust. The raw materials of the water-oil crust comprise, by weight, 100 to 120 parts of plain flour, 25 to 35 parts of vegetarian oil B, 10 to 15 parts of white granulated sugar and 25 to 30 parts of water. The raw materials of the crisp crust comprise, by weight, 85 to 100 parts of low-gluten flour and 40 to 55 parts of vegetarian oil C. The production method comprises the steps of crust producing, stuffing preparing, encrusting and baking. According to the vegetarian moon cake of the hericium erinaceus and the production method thereof, the traditional animal oil is replaced by pure vegetable oil to improve the content of unsaturated fatty acid and lower the heat of the moon cake; the crust producing craft is optimized to improve the feature that the vegetarian oil is hard to be crisp; at the same time, the hericium erinaceus serves as the main raw material, partial bitter taste contained in the hericium erinaceus is removed by the processing craft, the inner stuffing of the moon cake with a similar taste to meat is produced supplemented by pure vegetarian accessories, the nutritive value of the hericium erinaceus is reserved better, and a new vegetarian moon cake of the hericium erinaceus is provided.

Owner:唐山市西禾米唐食品有限公司

Fermented hard-shell crispy sesame-seed cake

InactiveCN103349047AImprove plasticityImprove crispnessDough treatmentPre-baking dough treatmentFlavorSesame seed

The invention discloses a fermented hard-shell crispy sesame-seed cake, wherein flour is mixed with boiling water so that the moldability and the crispy property of dough can be enhanced; and by a yeast fermentation method, many micropores can be formed in the wrapper dough, the crispy effect can be realized by using little oil and the product is endowed with the special flavor and nutrition of the fermented products. Due to addition of table salt, the flexibility and the elasticity of the wrapper dough can be enhanced and the taste of the product is enriched. All the existing pastries are broken easily and the skin is likely to fall. The fermented hard-shell crispy sesame-seed cake has the advantages that a hard shell is formed outside the cake blank by virtue of the technology of watering and adhering dough and sesame seeds after the cake blank is shaped, and therefore the integrity of the product can be kept better, and the taste of the product is enriched. Such cake has the characteristics that sesame seeds are fully attached to the outside hard shell, the crispy skin is crisp, the stuffing core is soft and glutinous, and the cake is layered well and rich in tastes. The cake is fragrant, fragile and crisp and therefore is very unique.

Owner:李江

Technology for processing crispy chestnut cakes

InactiveCN104186625AEasy to storeDelicate tasteDough treatmentBakery productsCooking & bakingEdible oil

The invention discloses a technology for processing crispy chestnut cakes. The technology includes steps of manufacturing fillings of chestnut cakes; manufacturing puff pastry; shaping the chestnut cakes. The step for shaping the chestnut cakes includes 1), primarily baking the chestnut cakes, to be more specific, placing the to-be-shaped chestnut cakes in molds into baking ovens, regulating the temperatures of the baking ovens until the temperatures of the baking ovens reach 180-200 DEG C, baking the chestnut cakes for 8-10 minutes, taking the chestnut cakes out of the baking ovens and uniformly sprinkling edible oil on the surfaces of the chestnut cakes; 2), secondarily baking the chestnut cakes, to be more specific, reducing the temperatures of the baking ovens until the temperatures of the baking ovens reach 150-160 DEG C, and baking the chestnut cakes for 10-12 minutes until the surfaces of the chestnut cakes are golden; 3), baking the chestnut cakes for the third time, to be more specific, increasing the temperatures of the baking ovens until the temperatures of the baking ovens reach 220-230 DEG C, and baking the chestnut cakes in the baking ovens again for 5-7 minutes. The technology has the advantages that the crispy chestnut cakes which are baked by the aid of a unique three-times baking technique are crispy on the outside and soft on the inside, have uniform layers, taste fine and smooth, can melt in the mouth and are cool and refreshing, excessive internal heat can be prevented from eaters.

Owner:NANPING TONGLIJIA FOOD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com