Patents

Literature

642results about How to "Golden color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potato crisp utilizing micro wave processing and its processing method

InactiveCN1891072AEasy to storePreserve nutrientsFood preservationFood preparationChipped potatoesMicrowave

The present invention discloses a kind of potato crisps processed by microwave and its processing method. Said processing method includes the following steps: washing potato flakes, scalding said potato flakes in boiling edible salt water, cooling, draining, freezing, drying, adding palm oil and egg yolk powder, mixing them with potato flakes, uniformly stirring them, roasting them by using microwave and spraying flavouring material so as to obtain the invented product.

Owner:HUNAN AGRICULTURAL UNIV

Phlebopus portentosus cultivation method

ActiveCN101491195ANutrition Facts SimpleFast growthHorticultureFertilizer mixturesSucrosePhlebopus portentosus

The invention relates to a method for culturing a mother spawn, a liquid spawn and a solid spawn of phlebopus portentosus. The method is characterized in that: raw materials such as potato, sucrose, glucose, agar, yeast extract, MgSO4, KH2PO4, rubber wood timber dust or other weed tree dust, grains and water are used to prepare culture media of the mother spawn, the liquid spawn and the solid spawn according to a certain proportion; and according to the culture method from the mother spawn, the liquid spawn to the solid spawn, the phlebopus portentosus mother spawn and liquid spawn are firstly cultured, and then the liquid spawn is inoculated on the solid spawn culture medium so as to culture the solid spawn. The culture mediums are particularly suitable for the culture of the phlebopus portentosus mother spawn, the liquid spawn and the solid spawn. The method can be used to carry out the rapid culture of the phlebopus portentosus spawns from the mother spawn, the liquid spawn to the solid spawn.

Owner:YUNNAN INST OF TROPICAL CROPS

Chromium-free treating liquid for preparing erosion-resisting oxide film on aluminum alloy surface, treating and using method thereof

ActiveCN101054664AImprove corrosion resistanceGolden colorMetallic material coating processesSodium acetateChromium free

The present invention discloses a chromium-free treatment liquid for preparing corrosion resistant oxidation film at aluminium alloy surface as well as the processing and use method thereof, characterized in that said treatment fluid utilizes a cobalt (III) salt as a main salt and a hypermanganate and a nitrate as a composite oxidizing compound to prepare a composite Co-Mn oxidation film having favorable corrosion resistance performances at aluminium alloy surface. The formula for said treatment liquid is that each litre solution contains cobalt salt of 5 g / L(-1)-20 g / L(-1), kalii permangana of 1 g / L(-1)-4 g / L(-1), sodium nitrate of 1 g / L(-1)-4 g / L(-1), promotor (chlorides and fluorides) of 1 g / L(-1)-4 g / L(-1), sodium acetate of 20 g / L(-1)-50 g / L(-1) and wetting agents (sodium dodecylbenzene sulfonate, OP-10) of 0.5 g / L(-1)-1 g / L(-1). Saic processing and use method comprises (1)sanding the aluminium alloy until its surface is smooth and even; (2) pretreating the aluminium alloy surface; (3) performing a conversion processing by using the treatment fluid; (4) cleaning-up using water and atmospheric-drying naturally. Said treatment fluid in accordance with the present invention possesses the advantages of environmental protection due to its hexavalent chromium-free, fast film-forming speed, simple process, uniform rete, strong corrosion resistance, few environment pollution, and the like.

Owner:GUANGYA ALUMINUM

Processing method for papaya fruitcake

The invention discloses a processing method for a papaya fruitcake. The processing method comprises the following steps: (1) preparation of papaya pulp: pouring papaya into 3-5% of salt water, boiling, mashing and grinding; (2) gelatin melting: mixing 15-25% of cane sugar and 1-3% of edible gelatin, and dissolving by hot water; (3) blending and boiling: adding 15-25% of maltodextrin, 10-20% of coconut milk, 0.5-1.5% of citric acid, 0.1-0.5% of sodium citrate and the melted edible gelatin into the papaya pulp to bend, homogenize, boil and stew until the soluble solid reaches 70-80%; (4) forming and drying: placing the papaya pulp material boiled in the step (3) in a forming die to cool, preparing the formed fruitcake body, then alternating temperature, baking, drying and packaging, so that the papaya fruitcake is obtained. The processing method is simple and feasible, the prepared fruitcake is rich in nutrition, and soft and smooth in taste, has unique papaya fragrance and coconut milk fragrance, can be stored for a long time without particles on the papaya fruitcake, and sugar-flowing, and is suitable for people of all ages.

Owner:廖乐隽

Production process of instant Chinese chestnut kernels and product

The invention relates to a production process of instant Chinese chestnut kernels and a product, which belong to the field of the deep processing of agricultural products. The production process comprises the following main technological processes: taking Chinese chestnuts with high water content, low reducing sugar, low starch and low fruit breaking rate as a raw material, processing instant Chinese chestnut kernels, sieving the raw material, classifying, removing outer peels, blanching, removing inner peels, quick-freezing, unfreezing, saccharifying, steaming, pasting, packaging and sterilizing. The instant Chinese chestnut kernels produced by the method have golden color, low fruit breaking rate and proper sweetness, are fragrant, glutinous and delicious and can be used as leisure foods for eating.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Processing method for fumigating eel

InactiveCN101496615ASolve the excessive residue of benzopyreneSolve the problem of poor product flavorMeat/fish preservationFood preparationNational standardCooling down

The invention discloses a bloating processing method for eel. The method is characterized in that: the method comprises the following steps: (1) seasoning and preservation: preparing a salt preserving liquid through edible salt and water, and placing the eel into the salt preserving liquid for seasoning and preservation after cleaning the eel raw material; (2) impregnation smoking: immersing the eel in a smoking liquid for smoking after cleaning the obtained eel through the step (1); (3) drying: drying the obtained eel through the step (2) in the air; (4) spray smoking: carrying out the spray smoking on the obtained eel through the step (3); and (5) cooling: cooling down the eel undergoing the spray smoking. The bloated eel has a good taste and a lower residual quantity of benzopyrene. In addition, the residual quantity of benzopyrene in the smoked eel is lower than 5mu g / k1g , which is lower than the allowable limit of benzopyrene in the smoked eel regulated by Chinese national standard GB7104-94 the Sanitary Standard for the Limited Quantity of Benzopyrene in Food. Therefore, the edibility safety of the smoked eel product is guaranteed.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Aluminum alloy surface rare earth chemical conversion treatment method

InactiveCN101260521AEasy to operateGolden colorMetallic material coating processesCleaning using liquidsCeriumAccelerant

The invention discloses a method for treating the rare earth chemical conversion on the surface of aluminium alloy. The method comprises a pretreatment procedure on the surface of the aluminium alloy, the preparation of rare earth chemical conversion treating liquid and the treatment of rare earth chemical conversion. The rare earth chemical conversion treating liquid consists of 10 to 30g / L cerium salt, 1 to 5g / L oxidant solution, 0 to 5x10<-2> mol / L film forming accelerant and 1 to 3g / L film forming surface morphology truing agent; the PH value of the treating liquid is 1 to 3; the cerium salt is selected form one or two of hydrous cerium chloride and hydrous cerous nitrate; the film forming accelerant is one or a plurality of transitional metal free ions; the film forming process is completed in 5 to 15 minutes. The method for treating a coating by conversion has high combining intensity with a substrate, good protective performance and simple structure; the coating contains no hexavalent chrome or trivalent chromium which is harmful to the environment and human body.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of carbon grilled squid slices

ActiveCN103584188AReasonable processEasy to makeFood ingredient functionsFood preparationLiver and kidneyAngor pectoris

The invention relates to a preparation method of carbon grilled squid slices, which comprises the steps such as preprocessing of raw materials, primary flavoring and pickling, tenderization, injection, secondary flavoring and pickling, carbon grilling, stripping and packaging. The preparation method has the advantages of reasonable procedures, simple preparation and easy realization of scale production; the nutrition and the gold color of squids are retained; the special carbon grilled smell of marine products and the fresh lotus leaf scent are obtained; the meat quality is tender, properly sweet and salty, and delicious; raspberry juice is added in the squid slices for effectively relieving the cardiovascular diseases such as angor pectoris and achieving the effects of tonifying liver and kidney; the raspberry juice is added in flavoring liquid, so that appetites are satisfied after squid products are ate by human bodies, and more nutrition beneficial to the human bodies is absorbed. The squid slices prepared by the invention method are suitable for wide crowds such as children with weak teeth or the aged, and have the advantages of low cost, rich nutrition and long preservation time.

Owner:ZHEJIANG OCEAN UNIV

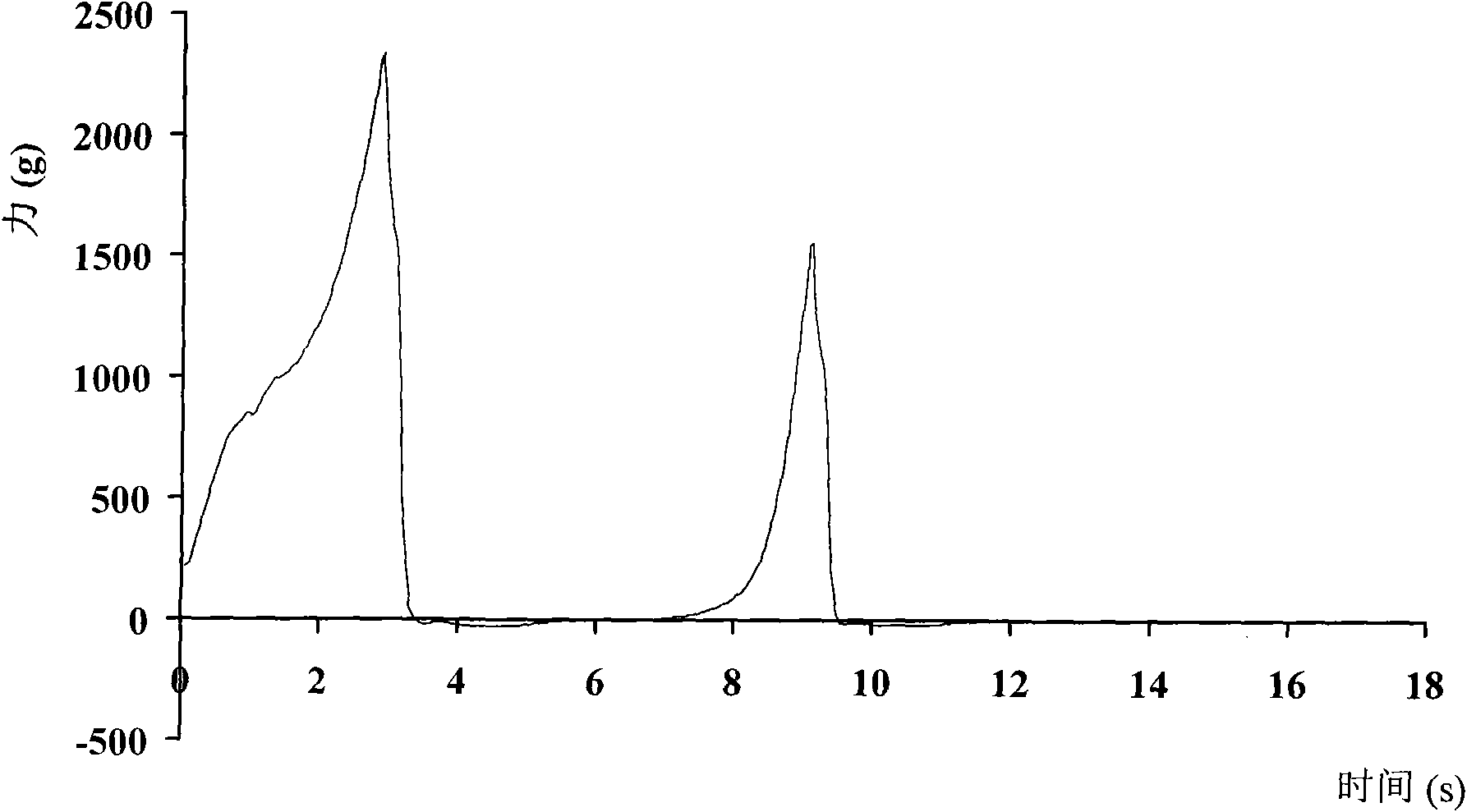

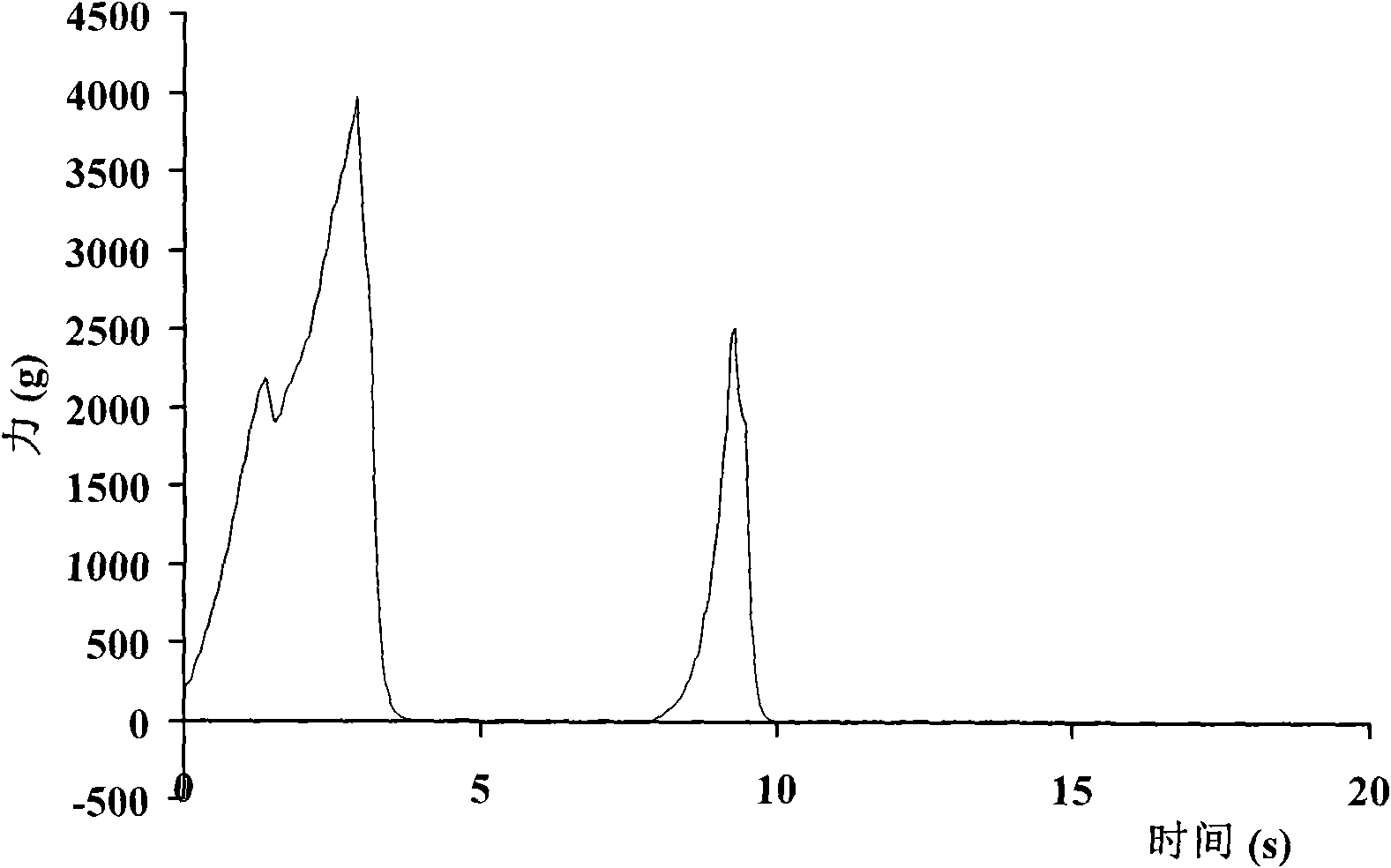

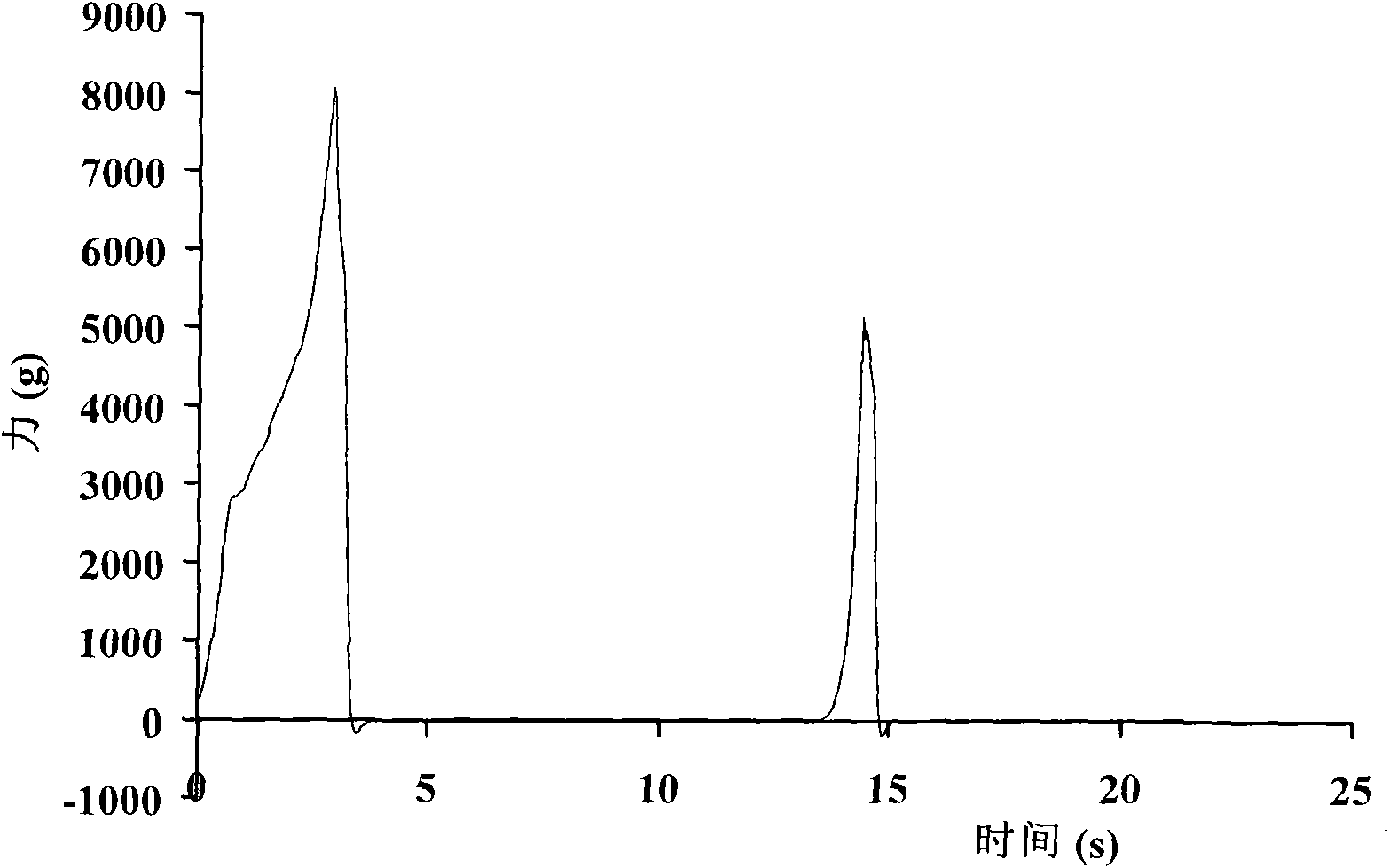

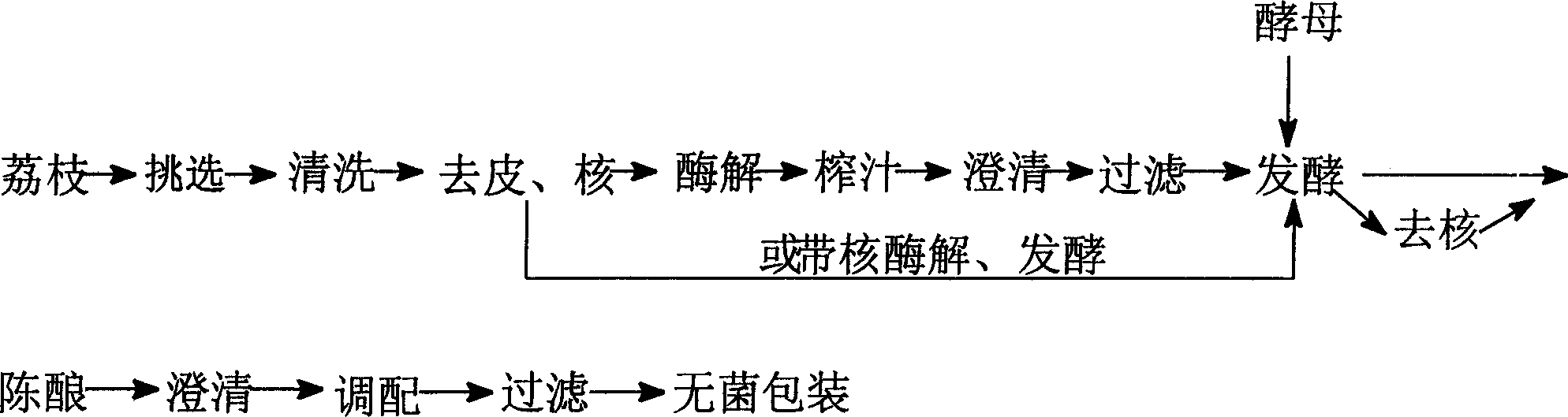

Method for making litchi full-fermented wine

The present invention relates to wine brewing, and is the full fermentation process of making lichi wine. Liche material is produced into fermented lichi wine through sorting, washing, peeling, stoning, enzymolysis, squeezing, clarifying, filtering, fermentation with domesticated yeast, ageing, compounding, filtering and other brewing steps. The lichi wine has the special flavor of lichi and high quality.

Owner:SOUTH CHINA AGRI UNIV

Processing method of Moringa Oleifera leaf tea

The invention discloses a processing method of Moringa Oleifera leaf tea. The processing method sequentially includes steps of delicious picking, withering, fine manipulation of green tea leaves, removing water in the green tea leaves, rolling, drying, flavoring and warehousing. The Moringa Oleifera leaf tea made by adopting the technical scheme maintains dark green without green taste, and tea soup is golden yellow and rich in nutrition.

Owner:FUJIAN INST OF TROPICAL CROPS

Novel mushroom biscuit

InactiveCN101288467AGolden colorCrispy tasteDough treatmentBakery productsSodium bicarbonateMonosodium glutamate

The invention discloses a novel black mushroom biscuit, which is prepared by kneading black mushroom and flour together. The novel black mushroom biscuit is characterized in that: every 926.35g of the biscuit contains the following ingredients: 160g of powdered sugar, 40g of vegetable oil, 0.25g of salt, 5g of monosodium glutamate, 125g of black mushroom powder, 500g of wheat flour, 3.5g of sodium bicarbonate, 2.5g of ammonium acid carbonate, 0.1g of antioxidant BHT, 35g of lard oil, 30g of eggs and 25g of milk powder. The black mushroom with relatively low calorie is taken as the raw material to prepare the biscuit, thus the calorie of the finished product of the biscuit is lowered, and the proportion of the nutrient content of the product is relatively enhanced; therefore, people can ingest nutrient substances while enjoying a delicious food, and the novel black mushroom biscuit brings health to the people.

Owner:SHANGHAI FISHERIES UNIV

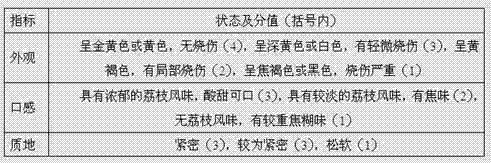

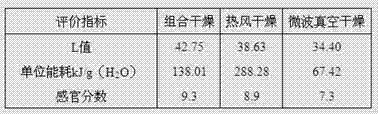

Processing method for drying litchi pulp and longan pulp

The invention discloses a processing method for drying litchi pulp and longan pulp. The method comprises the following steps of: selecting litchi or longan fruits as a raw material, performing blanching and color protecting treatment on the shelled and denucleated pulp, drying the treated pulp by using hot air to obtain a semi-dry product, and performing microwave vacuum drying till the water content of the product is 10 to 15 percent. The product is golden, thick in flavor, sweet and sour and attractive in appearance; the nutritional components are kept well; and the quality of the product is obviously superior to that of the traditional dehydrated litchi pulp or longan pulp product. The processing method has the characteristics of health, environmental friendliness, short production period, low operating cost and high energy utilization rate, and is favorable for improving the market competitiveness of the dried litchi and longan products.

Owner:FUJIAN AGRI & FORESTRY UNIV

Process for preparing rose shrimp meat cake

The invention provides a processing method of rose-shrimp meat pie. The processing method comprises the following steps: washing fresh water chestnuts, removing peels and pedicels, cutting into pieces and placing in a dish for later use; washing shrimp meat and pork, mincing, flavoring with cooking wine, refined salt, monosodium glutamate, shallot and ginger juice, adding water chestnut pieces and dry starch, stirring thoroughly, adding egg white and stirring thoroughly for later use; beating egg yolk, slowly pouring to an oiled cooker, steaming in a steamer until well-cooked, naturally cooling, and dicing; mincing ham for later use; squeezing minced meat to obtain meat balls, coating with diced yolk, pressing in pie shape, placing in a dish, placing minced ham in the middle part of each pie, steaming over moderate fire for about 5 to 7 minutes, and removing from the fire and ready for serving. The rose-shrimp meat pie has gold color, good appearance, tender, soft and crisp taste and rich nutrition; is easy to be absorbed and ingested; and is particularly suitable for the elderly and infants.

Owner:董善品

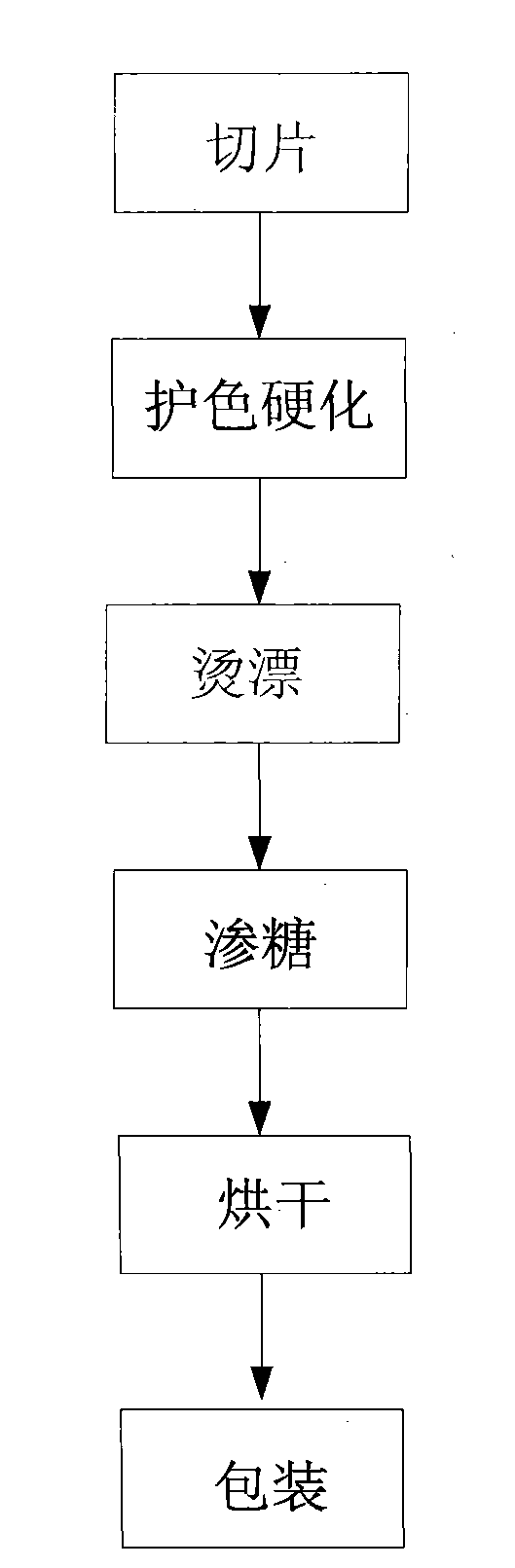

Candied mango and preparation method thereof

The invention discloses a preparation method of candied mangos. The preparation method comprises the following steps of: slicing, color protection, hardening, blanching, sugar infusion, drying and packaging. The preparation method of the candied mangos is simple, few food additives are needed, not only is the nutritive value of mangos realized, but also the color and the fruity flavor of the produced candied mangos can be guaranteed, and a novel way is developed for the further processing of the mangos. The invention also provides a candied mango prepared through using the preparation method.

Owner:李友志

Producing method for bread freshwater lobster cake

The patent provides a preparation method of bread freshwater lobster cake and relates to a food processing method, specifically which is bread cake making method with freshwater lobster as material, wherein the procedure for making break includes, conventional blank-making, quick freezing, enveloping slurry, enwrapping breadcrumb, pre-frying, pre-cooling, packaging and warehousing. Bread freshwater lobster cake made with the method of invention has following advantages including, golden yellow appearance, testing crisp and tender, special flavor, which can be eaten by simple frying, portable and suitable to people of all ages. The present invention provides a making method of bread freshwater lobster cake to accord with common dietary of east and west people, which increases variety of freshwater lobster production, thus contributes to expand domestic and foreign markets of freshwater lobster production.

Owner:JIANGSU BAOLONG GROUP

Tartary buckwheat flavor pecan and tartary buckwheat leach liquor processing method

InactiveCN105011053AEvenly steamedRich aroma of wheatFood ingredient as flavour affecting agentFood preparationPolygonum fagopyrumDigestion

The invention discloses a tartary buckwheat flavor pecan and tartary buckwheat leach liquor processing method. The tartary buckwheat leach liquor processing technology includes the procedures of tartary buckwheat obtaining, impurity removal, fine selection, cleaning, soaking, steaming, drying, frying, cooling, soaking and leach liquor combining. The tartary buckwheat flavor pecan processing technology includes the procedures of pecan obtaining, grading, cleaning, samming, opening, de-enzyming, taste adding (material liquid), taste oozing, drying, baking, cooling and packaging. Pecans obtained through the technology are bright in color, kernels are crisp, and a special flavor of tartary buckwheat is obtained. The pecans are pure and natural in fragrance, and physical properties in the tartary buckwheat are integrated in the pecans. The pecans have the functions of helping digestion and reducing blood fat, and leisure nut food which is natural, fragrant and beneficial to health and shows a whole new concept is provided for customers.

Owner:ANHUI TIANMEI FOOD

Processing method of Tujia dried bean curd

ActiveCN103315070APromotes Nutritional BalanceGuaranteed qualityCheese manufactureFood scienceFlavorReady to eat

A processing method of Tujia dried bean curd belongs to the technical field of bean product processing, and comprises the technological steps of immersing, pulp refining, pulp filtering, pulp boiling, solidifying, shaping, squeezing, cutting, marinating, blow drying, seasoning, and packaging sterilizing. The method is in favor of the food nutrition balance because of the six-tank continuous boiling of the obtained soybean pulp, guarantees the dried bean curd raw material quality because of the filtration before and after the pulp boiling, can realize the golden color, crisp and tender mouthfeel, fresh, delicious taste, ready-to-eat, easy carrying and easy preservation by commonly utilizing the seasoning and quality guarantee of a Tujia perfume and the seasoning and color adjustment of a golden sauce, maintains the traditional fresh, fragrant, crisp and tender mouthfeel of Tujia dried bean curd, substantially improves the production efficiency and the product quality and solves the easy acetification and difficult preservation problems of dried bean curd by utilizing a modern technology, and is suitable for the popularization.

Owner:重庆市蓬江食品有限公司

Method for preparing industrial fermentation pickled vegetable

ActiveCN101697751AAdd beneficial ingredientsGood antibacterial effectFruits/vegetable preservation using acidsSaline waterIndustrial fermentation

A method for preparing industrial fermentation pickled vegetable relates to a method for preparing fermentation pickled vegetable, solving the problems that pickled vegetable produced by the current large-scale factory is still prepared by traditional technique depending on natural fermentation and the cabbage in the fermentation jar can be easily damaged by other bacteria and be easily rotten and goes bad. The method comprises the following steps: 1, palletizing cabbages; 2, adding pickled vegetable fermentation engineering bacteria; 3, fully injecting brine to the fermentation jar; 4, carrying out fermentation to obtain the product of pickled vegetable. The method uses controllable industrial technique to ferment the pickled vegetable; the added components are known and controllable; thus, the method avoids the pollution of the cabbage by other bacteria, rot and metamorphism.

Owner:HEILONGJIANG UNIV

Processing method for fumigating ready-to-eat tilapia mossambica

The invention discloses a processing method for fumigating ready-to-eat tilapia mossambica, comprising the following steps: killing live tilapia mossambica; sequentially cutting and extracting meat; removing skins; picking out tilapia mossambica bones; chopping and reshaping; washing; fumigating and pickling by fluctuation pressure; drying to dehydrate; immersing by oil; vacuum packaging; and then curing and sterilizing to obtain the ready-to-eat tilapia mossambica. The processing method for fumigating the ready-to-eat tilapia mossambica has the advantages that condiments and a smoke solutionare mixed and added to the tilapia mossambica meat, then the pickling and the fumigating are synchronously completed in a rotating sealing container by using a fluctuation pressure technology, the flavor of the ready-to-eat tilapia mossambica is improved due to added condiment oil, the curing and sterilizing steps are simultaneously carried out; the production process is simple, short in cycle, convenient to product automatically and easy to control; the ready-to-eat tilapia mossambica is ready-to-eat as soon as a bag is opened, is free of tilapia mossambica bones and has unique flavor.

Owner:GUANGXI UNIV

Aromatic sunflower oil

the invention discloses a super fine sunflower seed oil in the edible oil manufacturing technological domain, which comprises the following steps: toasting; dewatering; hulling; rolling the model; evaporating the model; cooking the model; squeezing through large-size squeezer; removing phosphine wax; reserving; packing.

Owner:SHANDONG LUHUA GROUP

Navel orange peel jam and processing method thereof

InactiveCN102524617AImprove use valueImprove economyFood preparationSaline solutionsNational standard

The invention belongs to the field of deep processing of agricultural products and discloses navel orange peel jam and a processing method thereof. The processing method comprises the following steps of: soaking navel orange peel into water for 1 to 2 days; draining; placing into saline solution and cooking for 10 to 20 minutes; draining; rinsing and draining; crushing into navel orange peel pulp; placing navel orange flesh into water at the temperature of 90 to 95 DEG C; blanching for 2 to 10 minutes; crushing into fruit pulp; mixing the navel orange peel pulp and the fruit pulp; adding citric acid; heating to 90 to 100 DEG C; preserving heat for 5 to 10 minutes; adding white granulated sugar and pectin; and boiling on a soft fire at the temperature of 80 to 90 DEG C for 30 to 40 minutes to obtain the navel orange peel jam. In the navel orange peel jam, the soluble solid matter content is more than or equal to 35 percent, the total sugar content is less than or equal to 65 percent, the total arsenic content is less than or equal to 0.5, the lead is less than or equal to 1.0 and the microbiological index accords with the national standard. In addition, the navel orange peel jam is golden yellow, sour and sweet and delicious, maintains fragrance of the navel orange peel and the mouthfeel of the fruit flesh, is uniform and exquisite and has high flowability.

Owner:SOUTH CHINA UNIV OF TECH

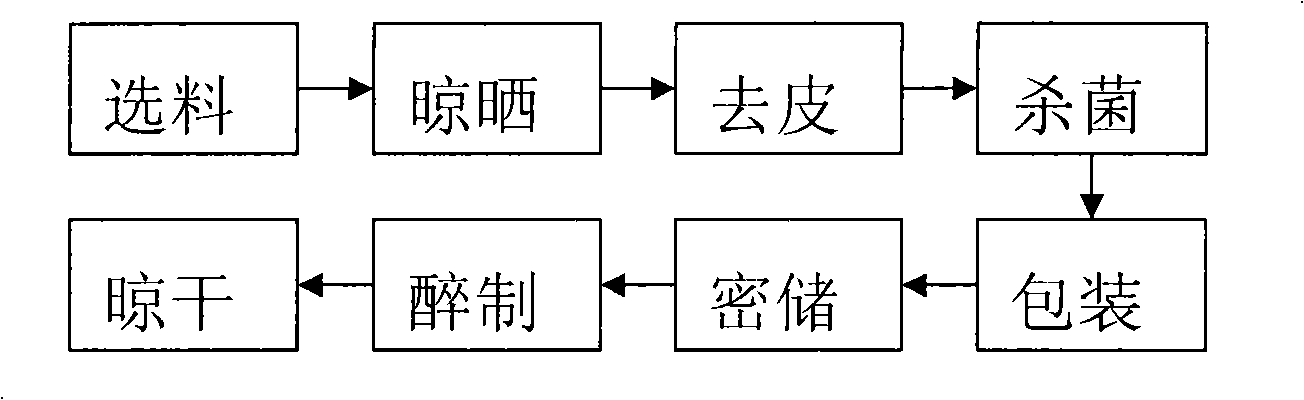

Liquor-saturated chestnut process technique

The invention relates to a technique for deeply processing chestnuts, in particular to a technique for processing drunken chestnuts, which comprises the following steps: selecting materials: selecting the chestnuts which have even size and no worm-eaten and rotten; sunning: sunning the selected chestnuts under normal temperature for 48 hours; peeling: peeling the dried chestnuts to obtain the chestnut kernels; sterilizing: cleaning and sterilizing the chestnut kernels by aseptic steam; air drying: drying the chestnut kernels cleaned and sterilized by aseptic steam in breeze; liquor-saturating: putting the chestnut kernels in the container, soaking the kernels in the liquor with higher than 45 percent of alcohol concentration for 40 minutes and adding white sugar, honey, mature vinegar according to the mass ratio of 2:1:1 and keeping the kernel liquor-saturated for a week; sealed storage: storing the liquor-saturated kernels in a sealed manner for ten days; package: packing the kernels in separated bags in a vacuum condition after 10-day sealed storage. The invention puts forth a new path for deeply processing chestnuts; the chestnuts liquor-saturated by the technique of the invention has golden yellow in color and sweet in taste; the technique completely preserves the original contents of chestnuts and prolongs the shelf life.

Owner:张书秘

Production method of sliced pork food

A technology for preparing the sliced pork food includes such steps as choosing the lean pork, slicing, preserving, baking, stewing, roasting, brushing oil and vacuum packing. Its advantage is good color, fragrance and taste.

Owner:刘德均

Environmental protection flower-pot capable of natural degrading and preparation method thereof

The invention relates to a flowerpot and a manufacturing method thereof, in particular to a degradable environmental-friendly flowerpot and a manufacturing method thereof. Components of the flowerpot comprise: plant fiber powder and a cementing compound, weight percentage of the plant fiber powder is 50 percent to 70 percent and that of the cementing compound is 30 percent to 50 percent; the plant fiber powder comprises rice hull powder, bamboo powder and soybean powder, and the weight percentage of the plant fiber powder is: 40 percent to 70 percent the rice hull powder, 10 percent to 40 percent the bamboo powder and 20 percent to 30 percent the soybean powder. Main processing technique is: mixing, dehydration, pressing, grinding and packaging. The environment-friendly flowerpot manufactured by the invention has the advantages of natural degradation, good stiffness, high strength and being uneasy to deform.

Owner:姚维生 +1

Crisp cake having filling

A stuffed short cake is prepared through proportionally mixing wheat flour, plant oil and water, kneading to obtain dough A, proportionally mixing wheat flour with plant oil, kneading to obtain dough B, overlaying dough A and B, rolling, cutting to become small blocks, stuffing, flattening and roasting at 250 deg.C.

Owner:尹成波

Cherry brandy and preparation technique thereof

InactiveCN102115703APure tasteRefreshing tasteMicroorganism based processesAlcoholic beverage preparationAlcohol contentChemistry

The invention discloses a cherry brandy and a preparation technique thereof, belonging to the technical field of processing of alcoholic beverages. The preparation technique comprises the following steps: crushing cherries used as main raw materials, regulating the components, carrying out inoculation fermentation, squeezing, distilling, aging, blending, bottling and the like to obtain the cherry brandy. The brandy prepared by the technique has the advantages of pure mouthfeel, good taste, strong fruit scent, golden color, transparent precipitate in brandy liquor, high sugar content, low alcohol content and wide applicability, and satisfies the market demand.

Owner:周传银

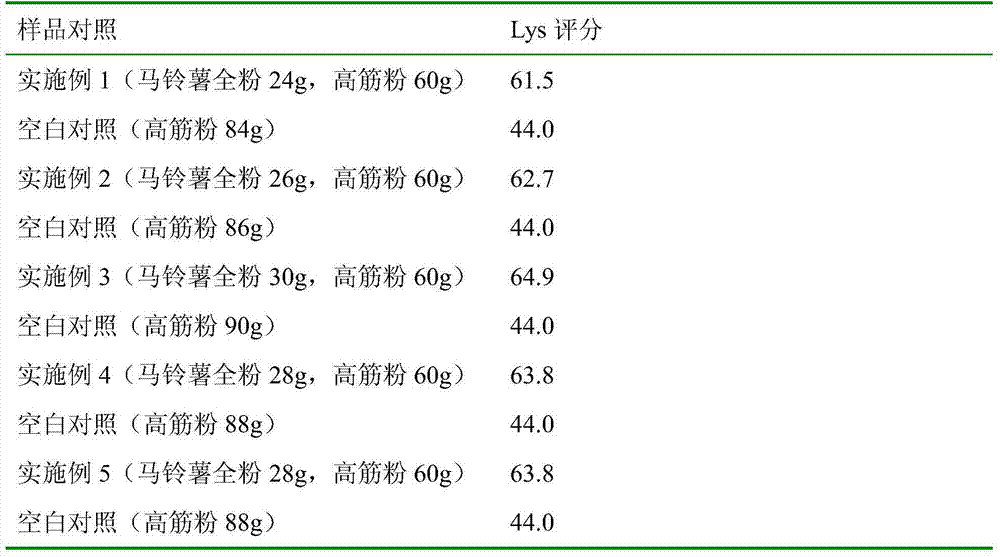

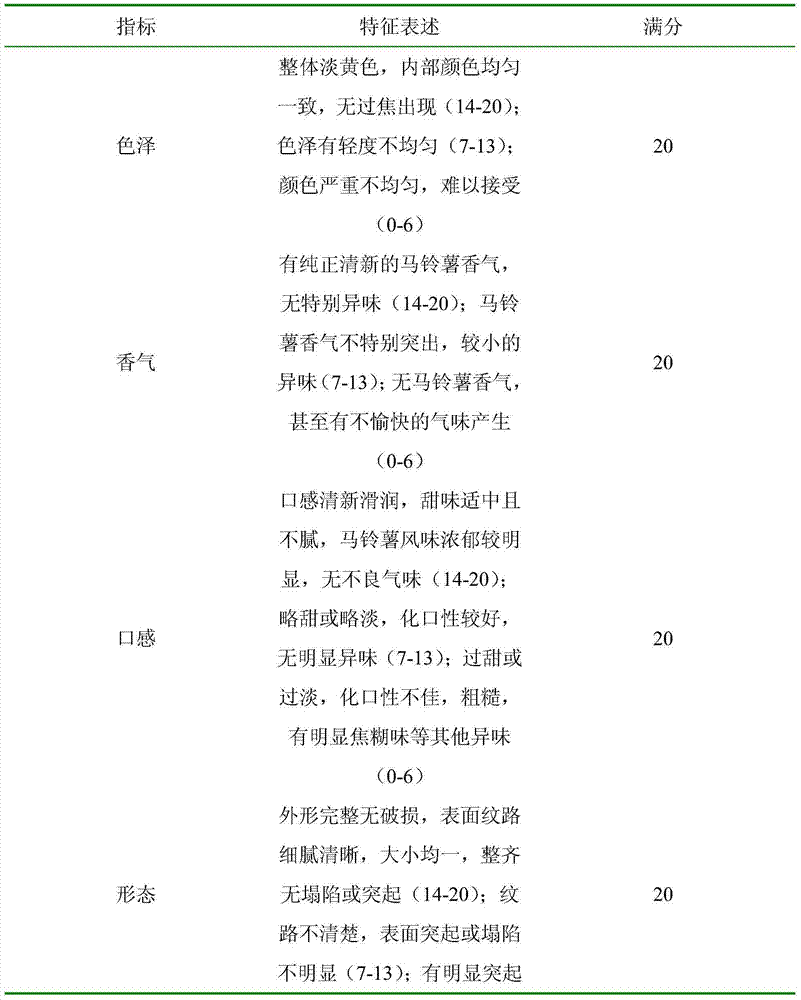

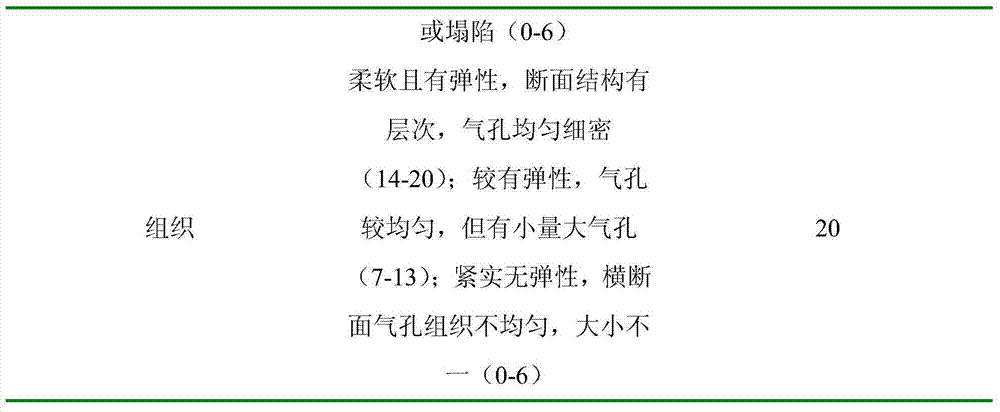

Potato staple food cake and making method thereof

InactiveCN104770452AIncrease contentRich in nutrientsDough treatmentBakery productsPhosphatePhosphoric acid

The invention provides potato staple food cake and a making method thereof. The potato staple food cake comprises, by weight, 20-50 parts of potato flour, 30-80 parts of high gluten flour, 80-240 parts of eggs, 0.1-1.5 parts of baking powder, 0.1-1.8 parts of edible slat; 80-135 parts of white sugar, 1-12 parts of milk powder, 3-10 parts of compound cake emulgator, 10-60 parts of edible oil, 5-35 parts of water, 10-40 parts of dried meat floss and 5-35 parts of watermelon seeds. According to the potato staple food cake, the potato four and whet flour are used cooperatively, compared with cake made of ordinary low-gluten wheat flour, the protein efficiency ratio can be improved, and the content of dietary fiber, vitamins and mineral substances is increased; because the potato flour contains natural phosphate groups, the water absorbing performance and the oil absorbing performance are good, after rehydration, rich natural fragrance is generated, and a smooth taste like bean paste is achieved; in this way, the staple food cake containing the potato flour has the light potato fragrance, compared with the cake made of the ordinary low-gluten wheat flour, the sensory quality is better, and the potato staple food cake is suitable for wide popularization.

Owner:天津桂发祥十八街麻花食品股份有限公司

Technique for producing waxberry brandy

InactiveCN101033440AUnique richUnique alcohol and styleAlcoholic beverage preparationDistillationBottle

This invention relates to a production technology of waxberry aquavit including: selecting and cleaning fresh waxberries, squeezing the fruits to juice, controlling the temperature for biology ferment, rough distillation, fine distillation, storage and aged brewing, preparing it, filtering and freezing and filling them into bottles and checking.

Owner:韩昌盛

Preparation method of sauce-grind eggplant

The invention relates to a food processing method, in particular to a preparation method of a sauce rubbed eggplant, aiming at providing a making method of the sauce rubbed eggplant and sufficiently showing the nutritional value and the deliciousness of the sauce rubbed eggplant. In a technical scheme adopted by the invention for achieving the aim, the preparation method of the sauce rubbed eggplant comprises the following steps of: (1) selecting materials: selecting tender eggplants; (2) removing stalks and husks: removing the eggplant stalks, and then rubbing the husks away; (3) stewing andcooling: placing the eggplants into a pot, closely covering, completely stewing by using fire, and taking out for complete cooling; (4) soaking: placing into sauce for soaking; (5) draining sauce: fishing out after the soaking, and draining the sauce; and (6) pickling: placing the eggplants into sweet sauce, and pickling for one month to obtain a finished product. The preparation method disclosedby the invention has the beneficial effects of sufficiently retaining the nutrient components and ensuring the golden color, the full sauce and the mellow mouthfeel of the sauce rubbed eggplant through the saucing processes of sauce soaking and sweet sauce pickling; in addition, a saucing process has the advantages of easiness for operation and cost saving property.

Owner:山东武定府酿造有限公司

Method for preparing oil from high-quality rapeseeds with high content of oil under low-temperature and low-moisture conditions

InactiveCN104450164AClear colorGolden color and transparentFatty-oils/fats refiningFatty-oils/fats productionRapeseedEnvironmental engineering

The invention discloses a method for preparing oil from high-quality rapeseeds with high content of oil under low-temperature and low-moisture conditions. The method comprises the following steps: selecting raw materials, cleaning and carefully choosing the raw materials, drying and conditioning at a low temperature, conditioning, peeling the rapeseeds, separating peels from kernels, conditioning at a low temperature, squeezing at a low temperature and carrying out pure physical filtration and fine filtration. High-quality natural high-grade and high-end oil is obtained from the high-quality rapeseeds with high content of oil under low-temperature and low-moisture pure physical process technical conditions, compared with commercially available leaching oil and hot-pressed oil, the rapeseed oil is natural, clear and transparent, has golden color and is rich in natural vitamin E and phytosterols; the content of protein in the cakes is increased and the biological activity of protein in rapeseed meals is ensured; the method has the advantages of low energy consumption, low cost and no pollutants.

Owner:贵州禾睦福生态农业有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com