Patents

Literature

83results about How to "Solve browning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production process of instant Chinese chestnut kernels and product

The invention relates to a production process of instant Chinese chestnut kernels and a product, which belong to the field of the deep processing of agricultural products. The production process comprises the following main technological processes: taking Chinese chestnuts with high water content, low reducing sugar, low starch and low fruit breaking rate as a raw material, processing instant Chinese chestnut kernels, sieving the raw material, classifying, removing outer peels, blanching, removing inner peels, quick-freezing, unfreezing, saccharifying, steaming, pasting, packaging and sterilizing. The instant Chinese chestnut kernels produced by the method have golden color, low fruit breaking rate and proper sweetness, are fragrant, glutinous and delicious and can be used as leisure foods for eating.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

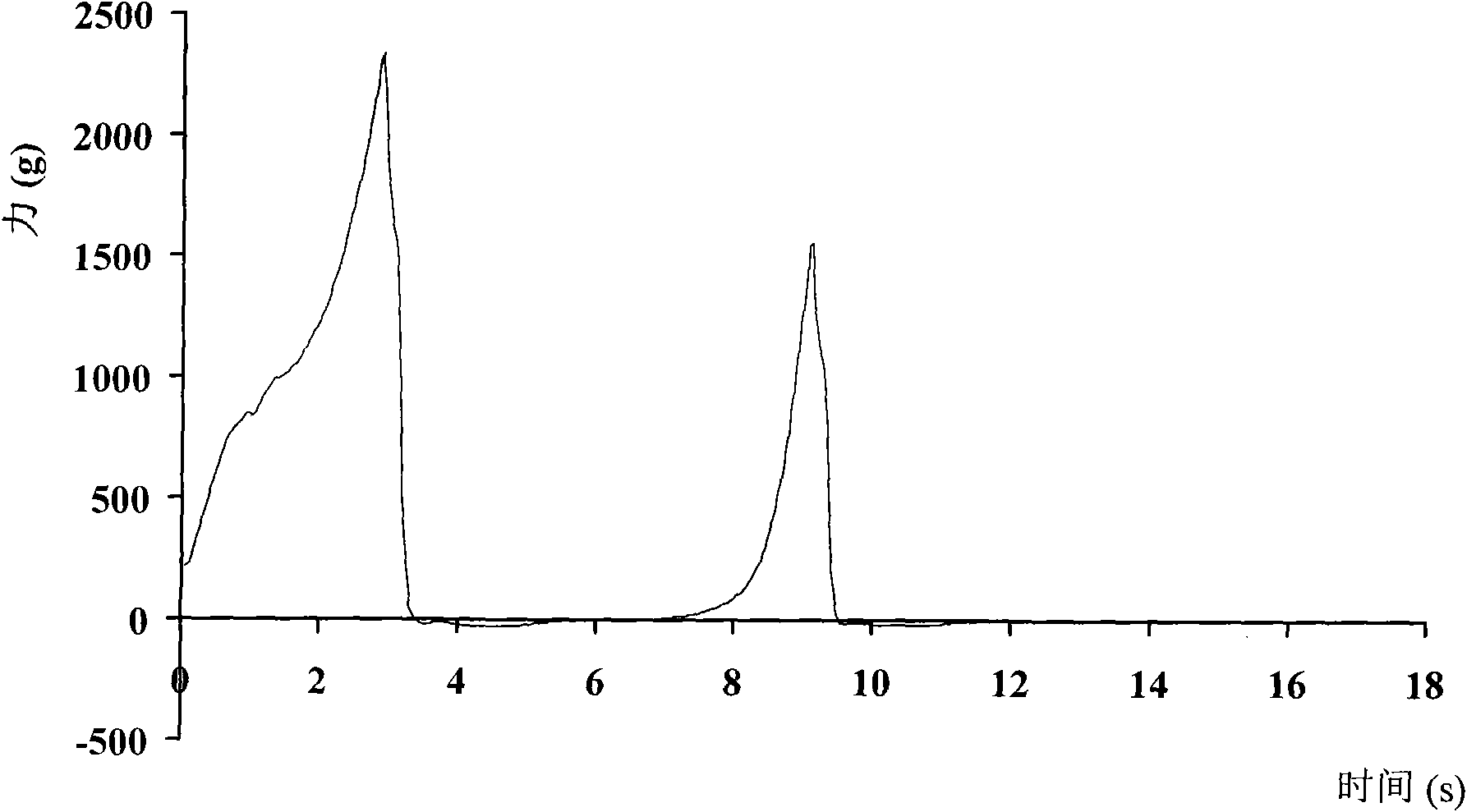

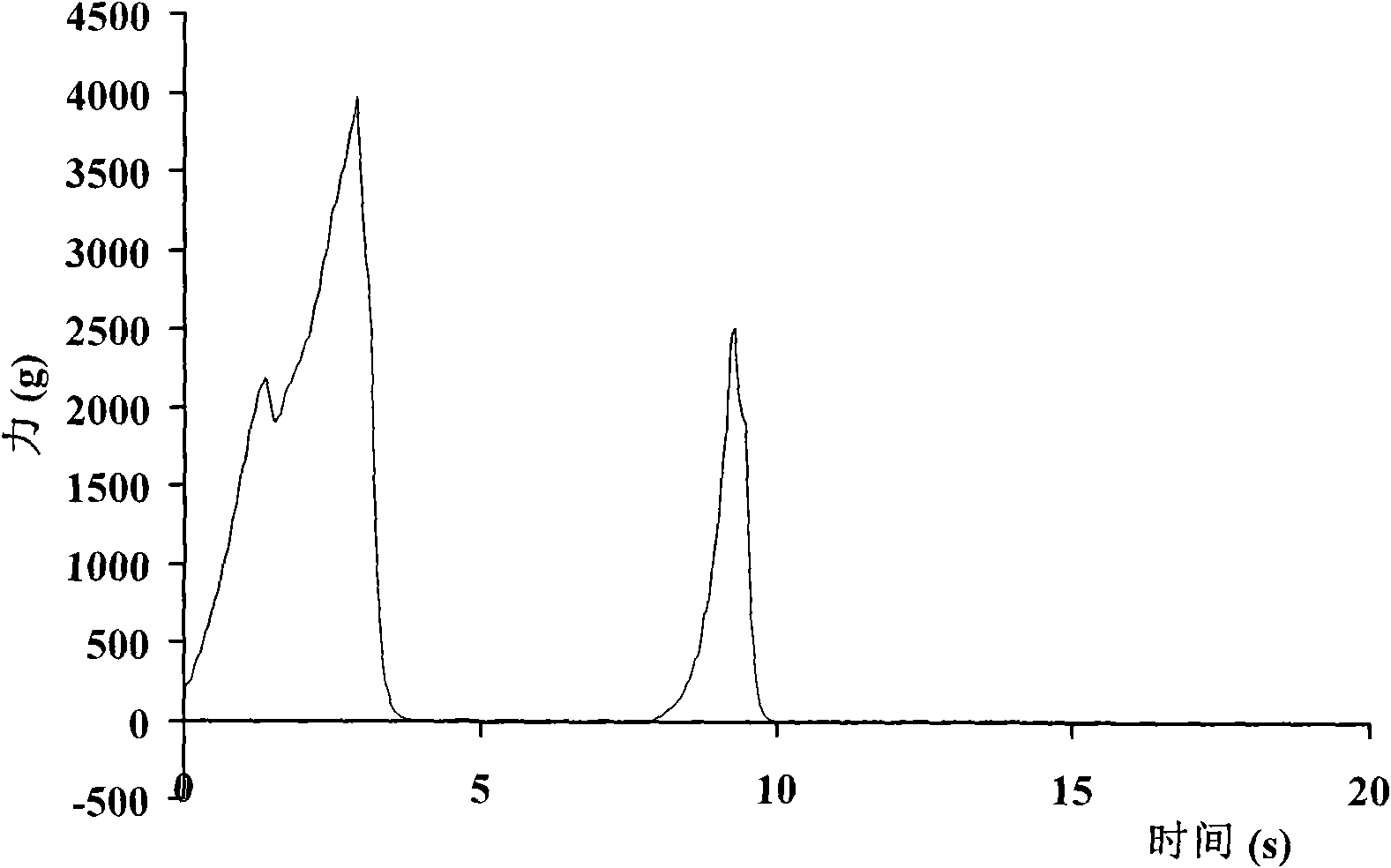

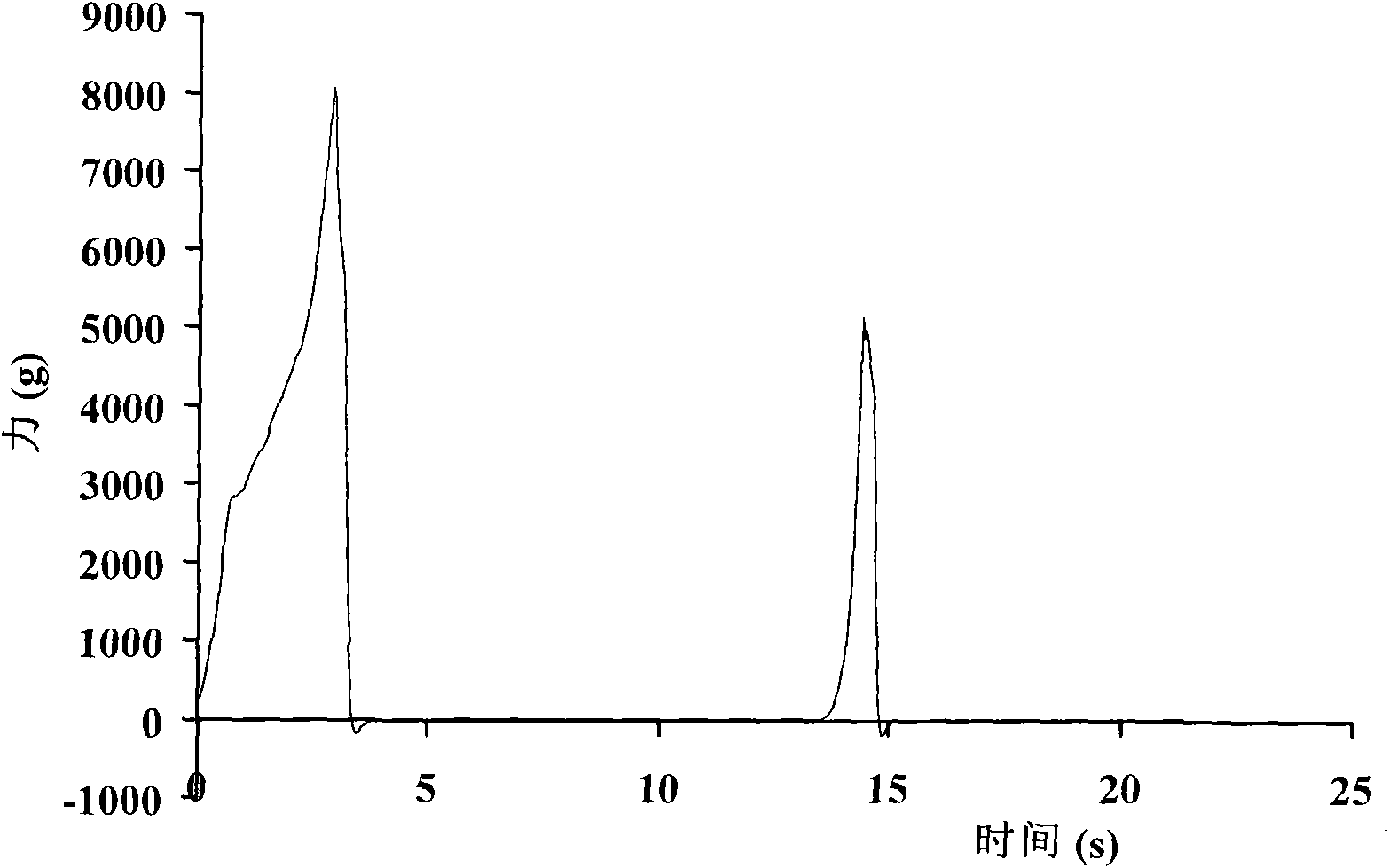

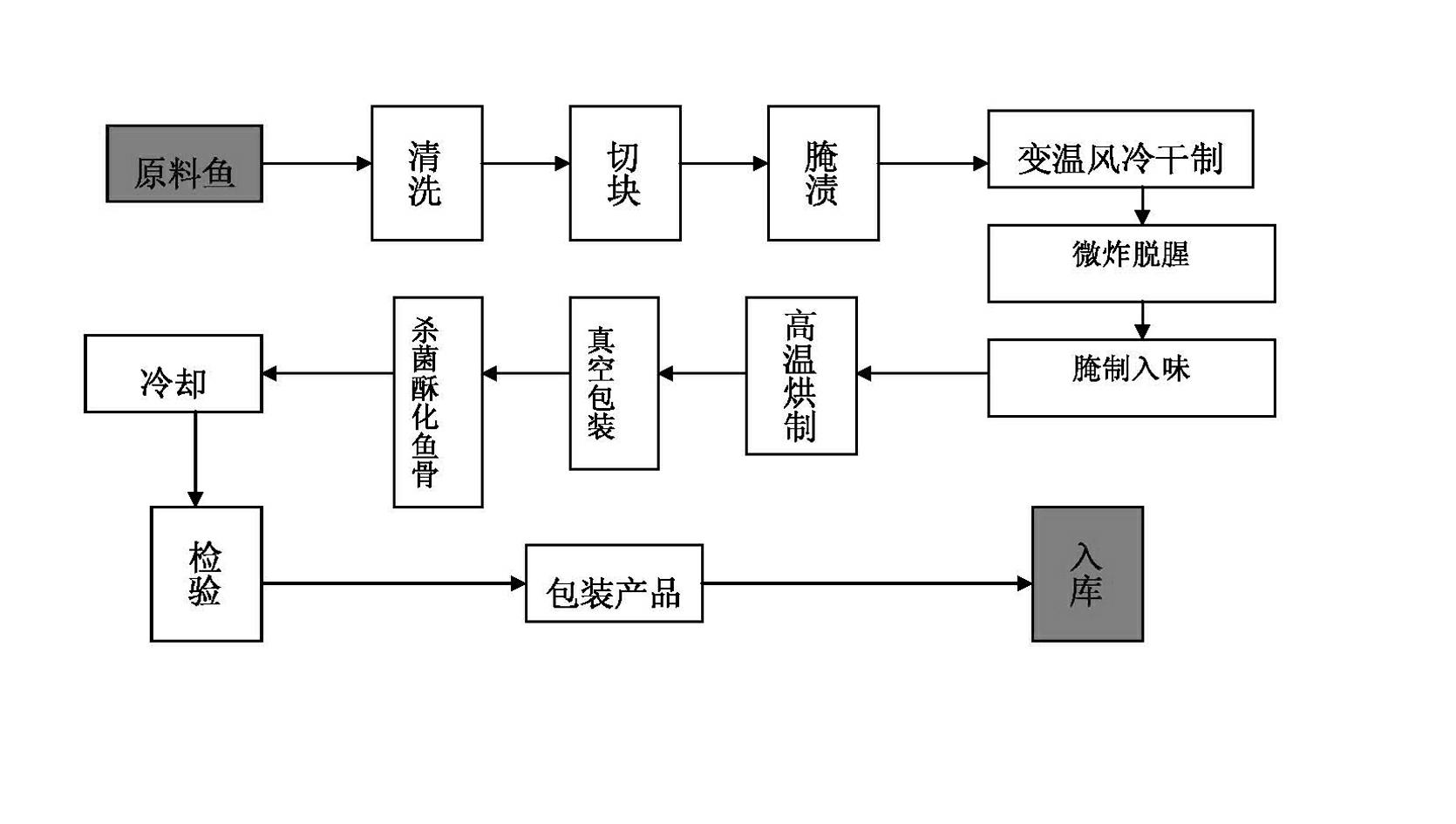

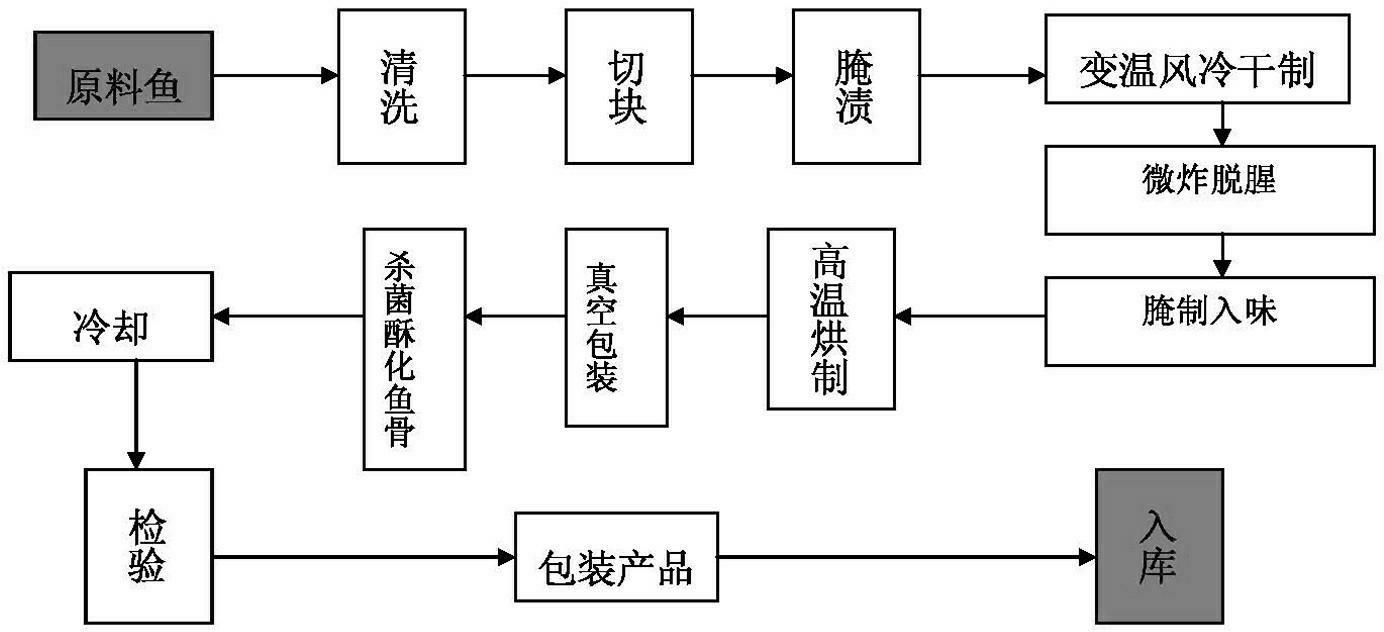

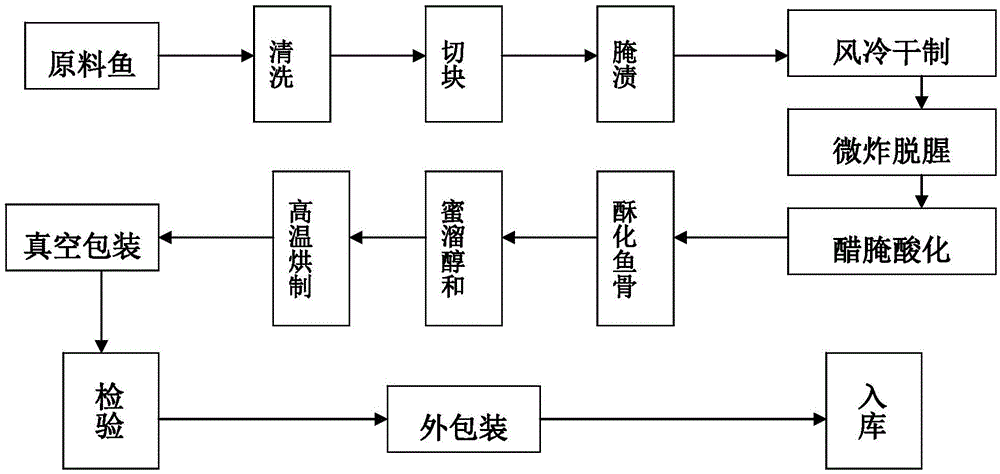

Instant hand-ripped fish and preparation method of instant hand-ripped fish

The invention relates to instant hand-ripped fish and a preparation method of the instant hand-ripped fish. The instant hand-ripped fish is characterized in that a basic production process is completed through raw material fish preparation, pickling, variable-temperature air cooling drying, slight frying deodorization, pickling for taste enhancing, vacuum package, fish bone sterilization and crisping and outer package. The color of the produced instant hand-ripped fish is shallow brown, the fragrance is intense, and the fish is crispy but not mushy and can be directly eaten through being ripped into small blocks by hand. The invention also provides a processing method of the instant hand-ripped fish with the advantages that the eating is safe, no any additives are added, the quality guarantee period can reach more than 180 days, and all of the color, the fragrance and the taste are good.

Owner:佛山六奇食品科技有限公司

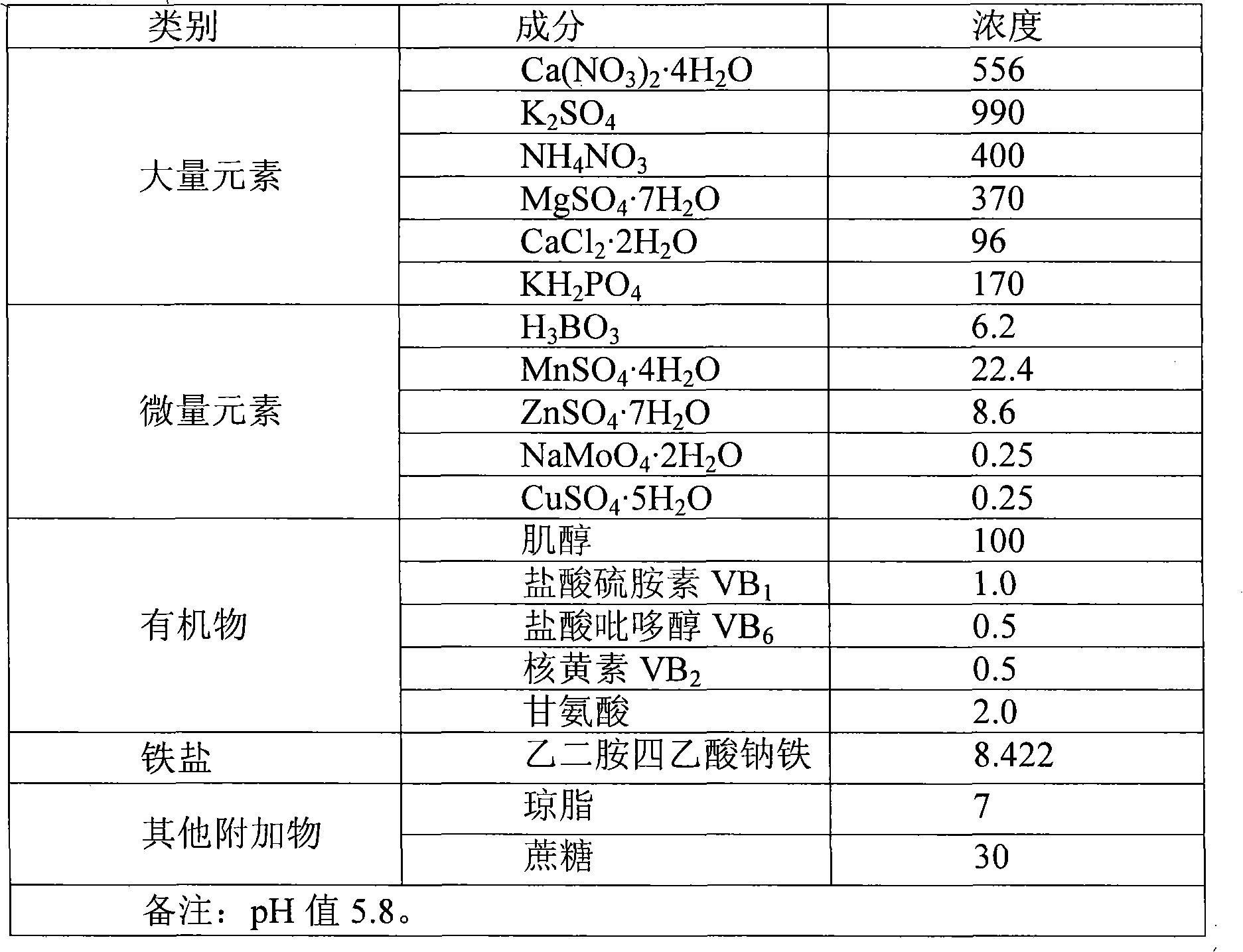

Method for culturing tissue of 'Zhongzhen No.1'

ActiveCN101926287AGuaranteed genetic stabilitySolve pollution and browning problemsHorticulture methodsPlant tissue cultureNutrientPrimary culture

The invention discloses a method for culturing tissue of 'Zhongzhen No.1'. The method comprises the following steps of: performing sterile pre-culture on 'Zhongzhen No.1' seeds to obtain sterile seedlings; and then performing primary culture on stem tips of the sterile seedlings to obtain regenerated seedlings. Experiments show that by performing pre-culture before producing the 'Zhongzhen No.1' regenerated seedlings, the differentiation rate of the stem tip of the pre-cultured seedling reaches 87.77 percent while the differentiation rate of the stem tip of the seedling cultured in nutrient soils is only 21.07 percent. In the method of the invention, the seeds are used as explant materials, and by adopting a mode of preculture of the sterile seedlings, the genetic stability of excellent characters is guaranteed; moreover, the method of the invention has the advantages that: the antiseptic processing method is improved; and the types of suitable anti-browning materials and hormones and the concentrations of the materials are screened out, the pollution and browning problems in present researches are solved, and a 'Zhongzhen No.1' sterile cultivation system is established successfully.

Owner:CHINA AGRI UNIV

Fresh fruit preservative

ActiveCN103976017ASolve browningLow raw material costFruit and vegetables preservationFlavorAntioxidant

The invention belongs to the field of fresh-cut fruit fresh keeping and particularly relates to a fresh-cut fruit preservative. The preservative mainly comprises the components in parts by weight: 0-5 parts of alkaline preparation and 100 parts of water and further comprises one or more selected from the following components in parts by weight: 0-0.1 part of surfactant, 0-0.1 part of thickening agent, 0-10 parts of humectant and 0-5 parts of antioxidant. The fresh-cut fruit preservative has the advantages of favorably solving the problems of brown stain, discoloration, excessively fast softening, section drying, quality reduction, flavor loss, mildew, pollution and the like of fresh-cut fruits, and prolonging the eating guarantee period of the fresh-cut fruits.

Owner:CHINA AGRI UNIV

Production method of germinated milled rice

InactiveCN101617793AReduce pollutionReduce usageFood preparationMicroorganismGamma-Aminobutyric acid

The invention provides a production method of germinated milled rice, comprising the following steps: adopting milled germ-retaining rice that is produced by a special process as germinating materials, sterilizing the milled germ-retaining rice in water solution with the ozone concentration of 1.0-1.5mg / kg, coating by 1-2 percent of chitosan solution, soaking in clear water or 0.005-0.015 percent of gibberellin for 20-30 hours, culturing in the situation of 20-30 DEG C, and drying at 50-60 DEG C when the length of germs of germinated rice is 0.5-1.0 mm to obtain the germinated milled rice. In the production method, the germination ratio is more than 95 percent, Gamma-aminobutyric acid is more than 60mg every 100g of germinated rice, and the water content is 12-15 percent. The invention has simple process, reduces the microbial contamination in the germinating process and solves the difficult problems of brown stains, cracking, and the like in the drying process; and the germinated milled rice obtained by the method is better than germinated brown rice and milled germ-retaining rice on the taste, and has good colors, rich nutriments and strong heath care function.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Tissue-culture breeding method for high-borneol-content cinnamomum camphora

InactiveCN104365476AEasy accessHigh in essential oilsHorticulture methodsPlant tissue cultureCinnamomum camphoraCinnamomum

The invention discloses a tissue-culture breeding method for high-borneol-content cinnamomum camphora. The tissue-culture breeding method comprises: selecting and culturing a cinnamomum camphora individual with the borneol content of 90% or more from cinnamomum camphora natural variation plant, acquiring a semi-lignification stem segment with annual sprouting as an explant, performing disinfection processing, establishing an aseptic line, and then forming a regenerated plant through bud primary induction, propagation culture, rooting culture and the like. Proper formulas and culture conditions of all links for tissue-culture breeding of high-borneol-content cinnamomum camphor are screened out, and the high-borneol-content cinnamomum camphor regenerated plant is successively obtained. Therefore, the method effectively solves the technical problems that browning and dead seedlings are generated during tissue-culture breeding of cinnamomum camphor with the borneol content of 90% or more, and provides seedling guarantee for construction of an excellent cinnamomum camphor raw material forest base.

Owner:JIANGXI ACAD OF FORESTRY

Processing method of instant salted pork kidney

InactiveCN105166960AImprove processing productivityImprove qualityFood preparationPork KidneyHigh pressure

The invention discloses an instant salted pork kidney and a processing method thereof. A preparation process comprises the following nine steps of preparing a raw material pork kidney, pickling the pork kidney, rapidly cooling by air and drying, slightly frying to remove the odor, pickling the pork kidney to be tasty, salting, packaging in vacuum, sterilizing at high pressure and externally packaging. The produced instant salted pork kidney has light brown color and luster and rich aroma, is crispy and is not broken, and can be torn into suitable small blocks by hands or a cutter to be directly eaten.

Owner:刘富来

Taro crisp slice without oil and the processing method

InactiveCN101040697AReduce oil contentSolve abnormal colorFruits/vegetable preservation by heatingFruits/vegetable preservation by freezing/coolingMicrowaveChemistry

The invention discloses a method for producing non-oil taro crisp sheet, which combines vacuum refrigerating drying and microwave techniques, and uses special composite color protector to produce taro crisp sheet, resolving the problems of traditional technique as high oil content, abnormal color, thin taste, non-uniform taste or the like. The produce does not contain fatty, with stable quality and high safety.

Owner:SOUTH CHINA AGRI UNIV

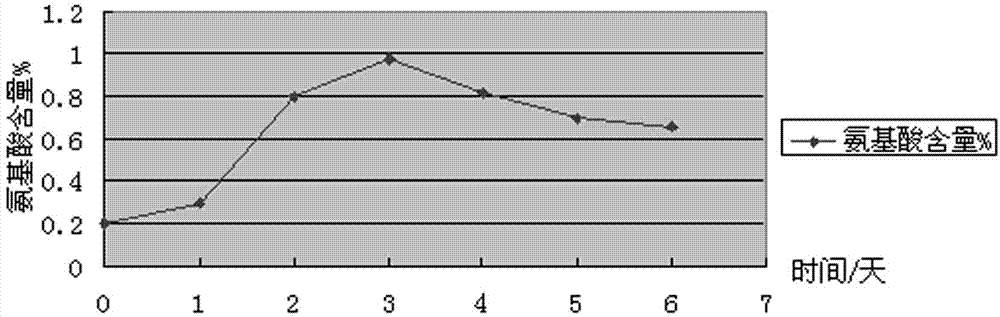

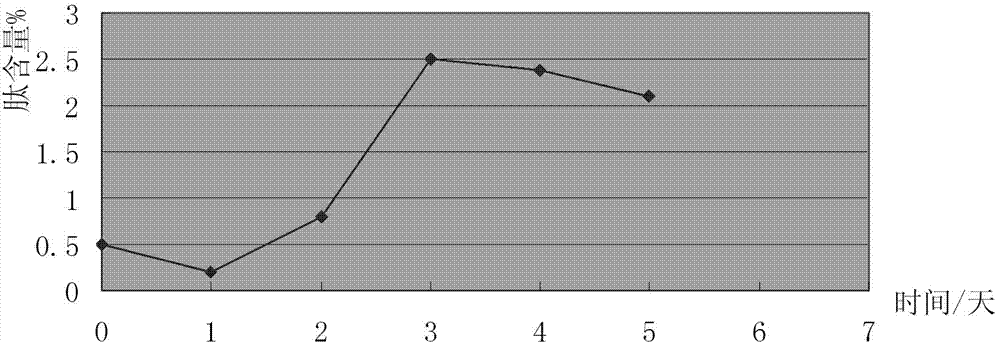

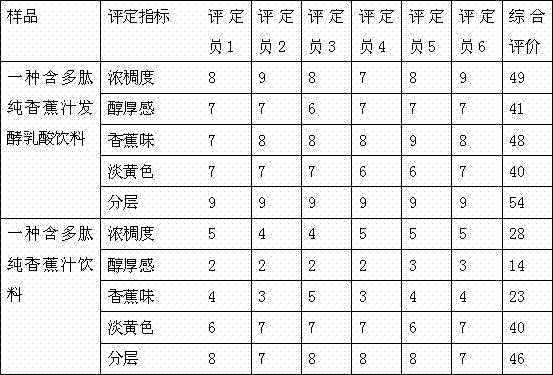

Polypeptide-containing pure banana juice fermented lactic acid beverage

InactiveCN104116108ASolve browningAddressing Nutrient Loss ProblemsFood ingredient functionsFood preparationCarrageenanBeta-Glycan

The invention relates to a polypeptide-containing pure banana juice fermented lactic acid beverage. The polypeptide-containing pure banana juice fermented lactic acid beverage comprises the following components in parts by weight: 5-25 parts of banana pulp, 8-10 parts of white granulated sugar, 0.005-0.015 part of lactic acid bacteria, 0.02-0.12 part of corn peptide, 0.05-0.08 part of yeast beta-glucan, 0.03-0.08 part of sodium carboxymethylcellulose, 0.02-0.08 part of xanthan gum, 0.01-0.05 part of gellan gum, 0.005-0.05 part of carrageenan, 0.05-0.15 part of citric acid, 0.05-0.15 part of sodium citrate, 0.05-0.15 part of banana essence and 14-64 parts of purified water.

Owner:福建康之味食品工业有限公司

Application of L-cysteine, and low sulfur long-term preservation method for fruit blanks

InactiveCN102406156AGood effectLittle change in flavorFood preservationFood preparationChemistryPlastic bag

The present invention discloses an application of L-cysteine, and a low sulfur long-term preservation method for fruit blanks. A purpose of the present invention is to solve the problems of browning, softening, decaying, high use amount of sulfur dioxide of the fruit blanks during the preservation process of the fruit blanks of the preserved fruits. With the present invention, first fruits are hardened by a calcium chloride solution, and are subjected to a impregnation treatment by L-cysteine, sodium metabisulfite, an ascorbic acid composite color protecting preservation solution and salt; the resulting treated material can be preserved in a plastic bag and other sealed containers at a room temperature. The method of the present invention provides the same effects of preservation, color protecting and antisepsis as the effects provided by the 1% sodium metabisulfite and a proper amount of the salt in the prior art, at the same time, the use amount of the sodium metabisulfite can be reduced to 0.08-0.16% of the original use amount so as to improve the hygienic quality of the fruit blanks, reduce the subsequent desulfurization work load, and reduce the over standard risk of the residue sulfur dioxide in the finished product. The low sulfur long-term preservation method for the fruit blanks of the preserved fruits is further applicable for the preservation of the fruit blanks during other fruit processing process.

Owner:SOUTH CHINA AGRI UNIV

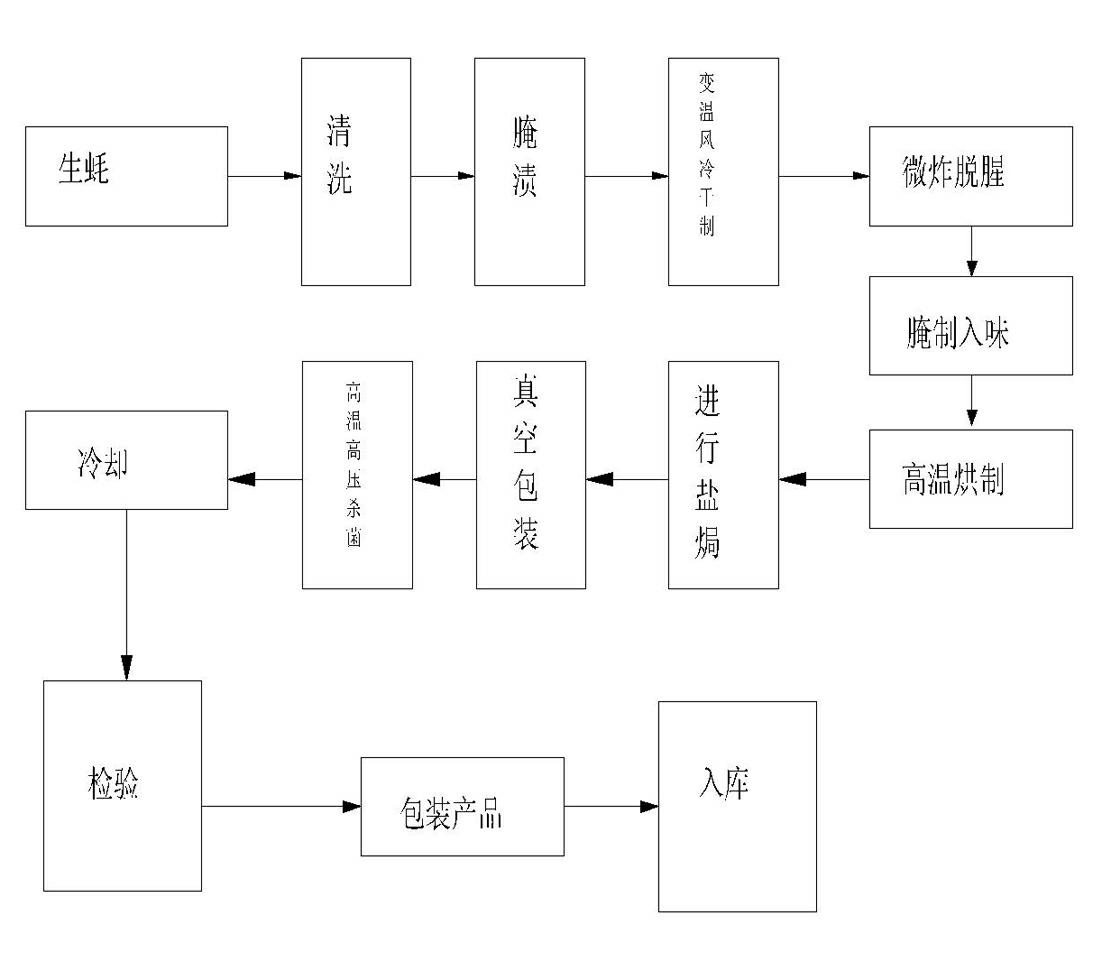

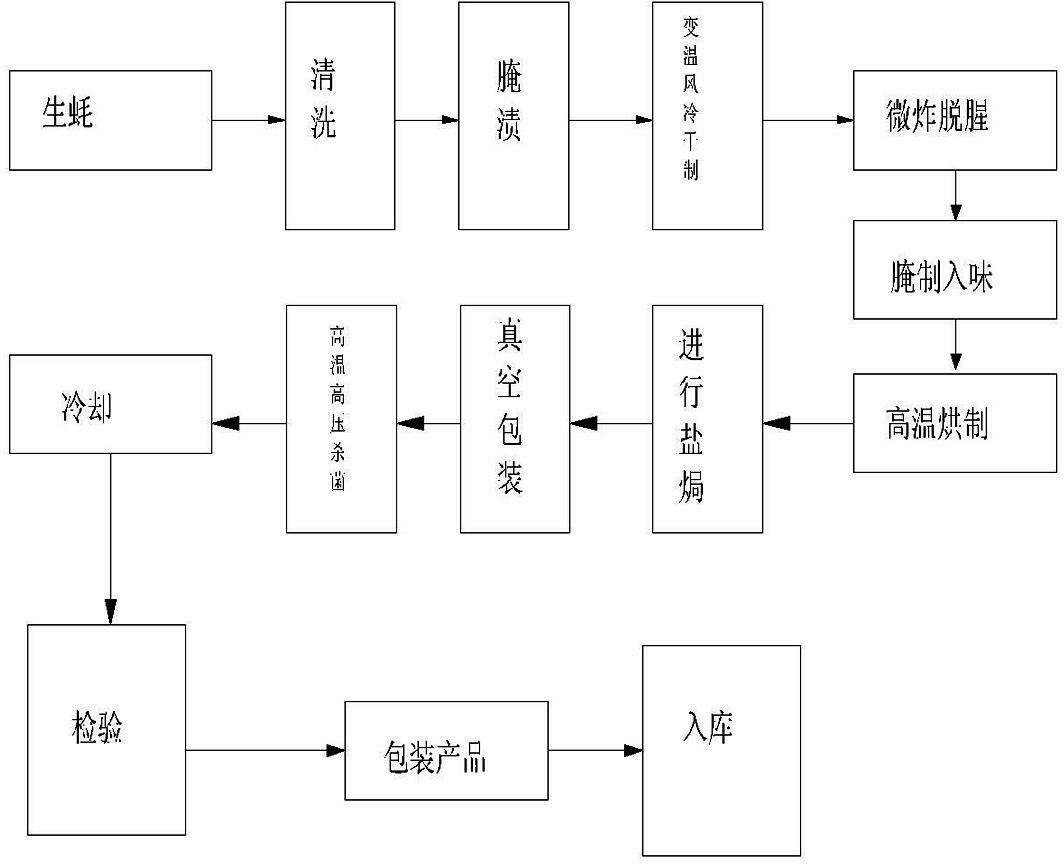

Processing method for instant salt-roasted fresh oyster

The invention discloses a processing method for instant salt-roasted fresh oyster. The processing method is characterized in that a preparation process comprises one or more of the following steps: material preparing, pickling, air-cooling and dry-curing at changing temperature, lightly frying for deodorization, pickling, salt-roasting, vacuum-packaging, high-temperature and high-pressure sterilizing and external packaging. The instant salt-roasted fresh oyster prepared by the processing method is moderate in texture tightness and provided with certain chewiness; a browning phenomenon of oyster meat is effectively restrained in a hot processing process, a drying and dehydrating process, and a sterilizing process to keep the attractive golden colour of the oyster meat, so that the good promotional value is achieved..

Owner:佛山六奇食品科技有限公司

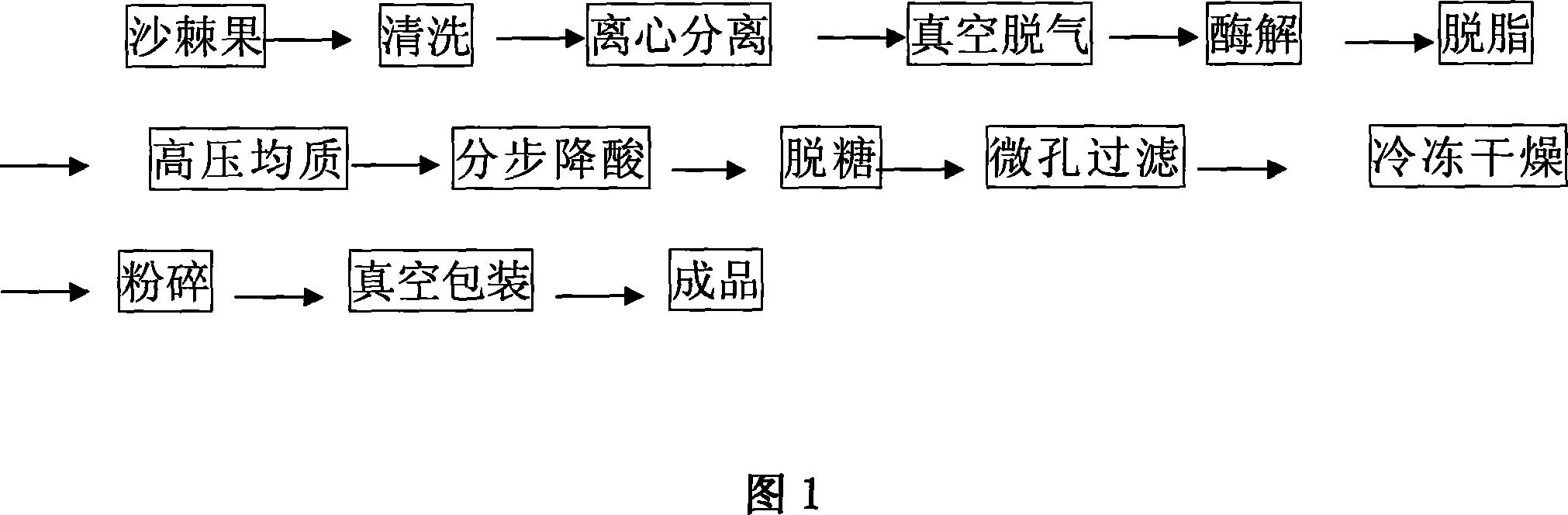

Method for preparing mixture containing natural vitamin P from sea-buckthorn

InactiveCN101084943ASolve high temperature oxidationSolve browningOrganic active ingredientsMetabolism disorderVitamin CFreeze-drying

The invention relates to a method for preparing mixture containing vitamin P from sea buckthorn, and is for the prupose of providing a method for preparing a mixture containing 0.5-50% of vitamin P and 2-30% of vitamin C through extracting juice, degassing, enzyme-hydrolyzing, degreasing, homogenize, reducing acid, desugarizing, millipore filtering, freeze drying and pulverizing. The method is simple; solve the problem of brown stain of highly active substance in sea buckthorn due to high temperature oxidation by adopting biologic-physical method at low temperature, has no requirement of any solvent, no residue, low cost, and high biologically active substance yield. Vitamin P and vitamin C is in coexistence in the product, which promotes absorption.

Owner:QINGHAI TSINGHUA BIOTRY BIO TECH

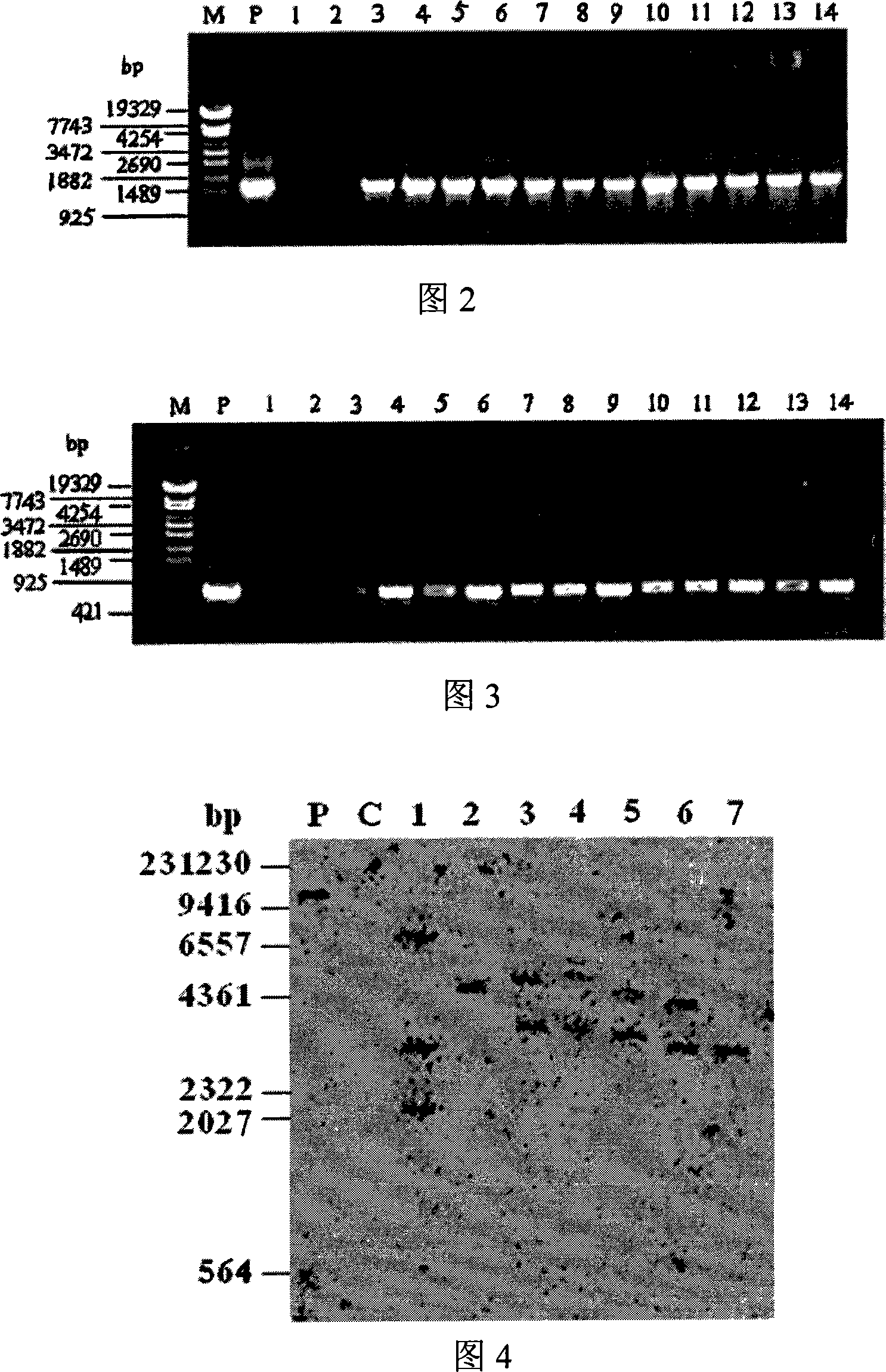

Method for carrying out agrobacterium tumefaciens mediated banana genes by employing liquid co-culture system

The invention discloses a method for converting the meloidogynosis agrobacterium lead banana gene with the fluid co culture system, which comprises the following steps: stewing the banana ECS in the meloidogynosis agrobacterium and the black condition for a spell of time; proceeding with the co culture in the banana ECS liquid culture medium; transferring the banana ECS to the idiosome directly in order to induce and grow; culturing on the selective culture medium; transferring the mature resistant idiosome to the blastema germination culture medium; culturing in the light-black alternative condition until the idiosome is germinated; getting sprout; transferring the sprout to the basis screen selective culture medium; acquiring the whole conversion plant by culturing in the light-black alternative condition. The invention changes the co culture condition, which solves the brown problem of banana ECS in the co culture process, and shortens the cycle of converting the plant.

Owner:SUN YAT SEN UNIV

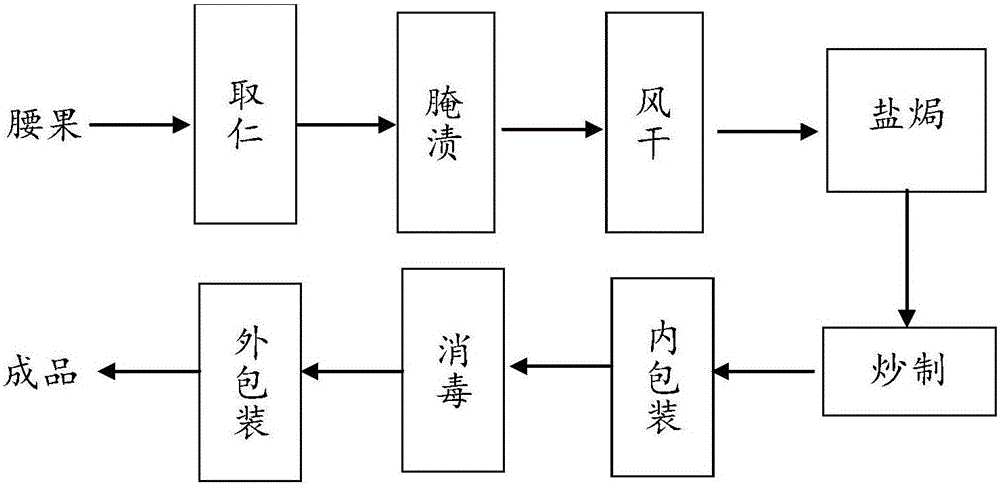

Instant salt baked cashew nuts and preparation method thereof

InactiveCN106136182AGood qualityExtended storage timeFood thermal treatmentFood ingredient as taste affecting agentFlavorCashew nut

The invention provides instant salt baked cashew nuts and a preparation method thereof. The instant salt baked cashew nuts are processed by pre-treating cashew nuts, then taking kernels, pickling, drying by air, baking with salt, frying, internally packaging, sterilizing and externally packaging. The product provided by the invention does not contain any chemical additive and has good quality and long storage time; the cashew nuts are crispy, are crunched when being gently bitten, are convenient to eat and have a delicious taste and a high additional value; the cashew nuts have the features of salt baked foods, have a good flavor, are sanitary, also have a health-care function, can be enjoyed at any time and are convenient to carry; the preparation method provided by the invention is high in production efficiency and can be applied to large-batch industrial production.

Owner:FOSHAN UNIVERSITY

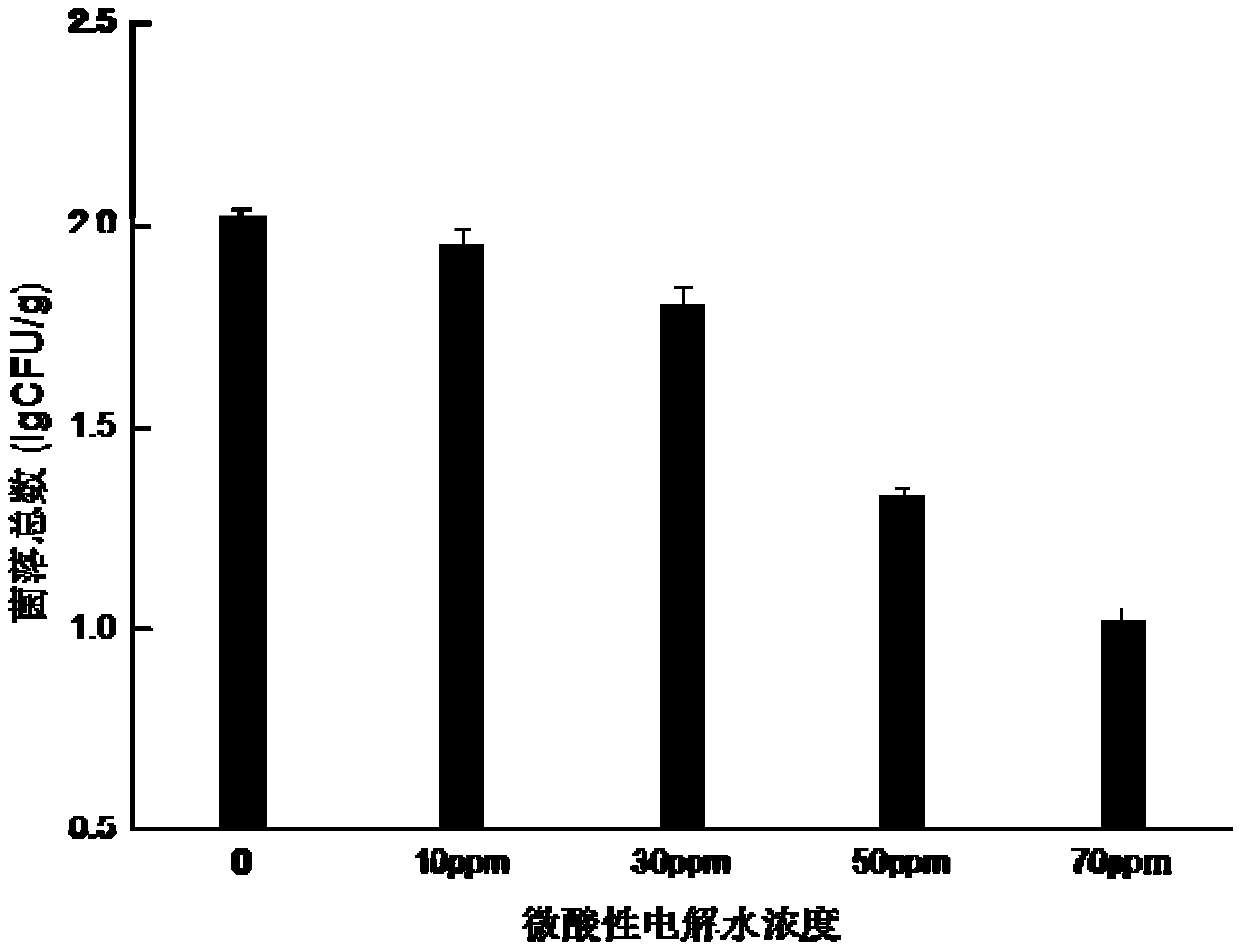

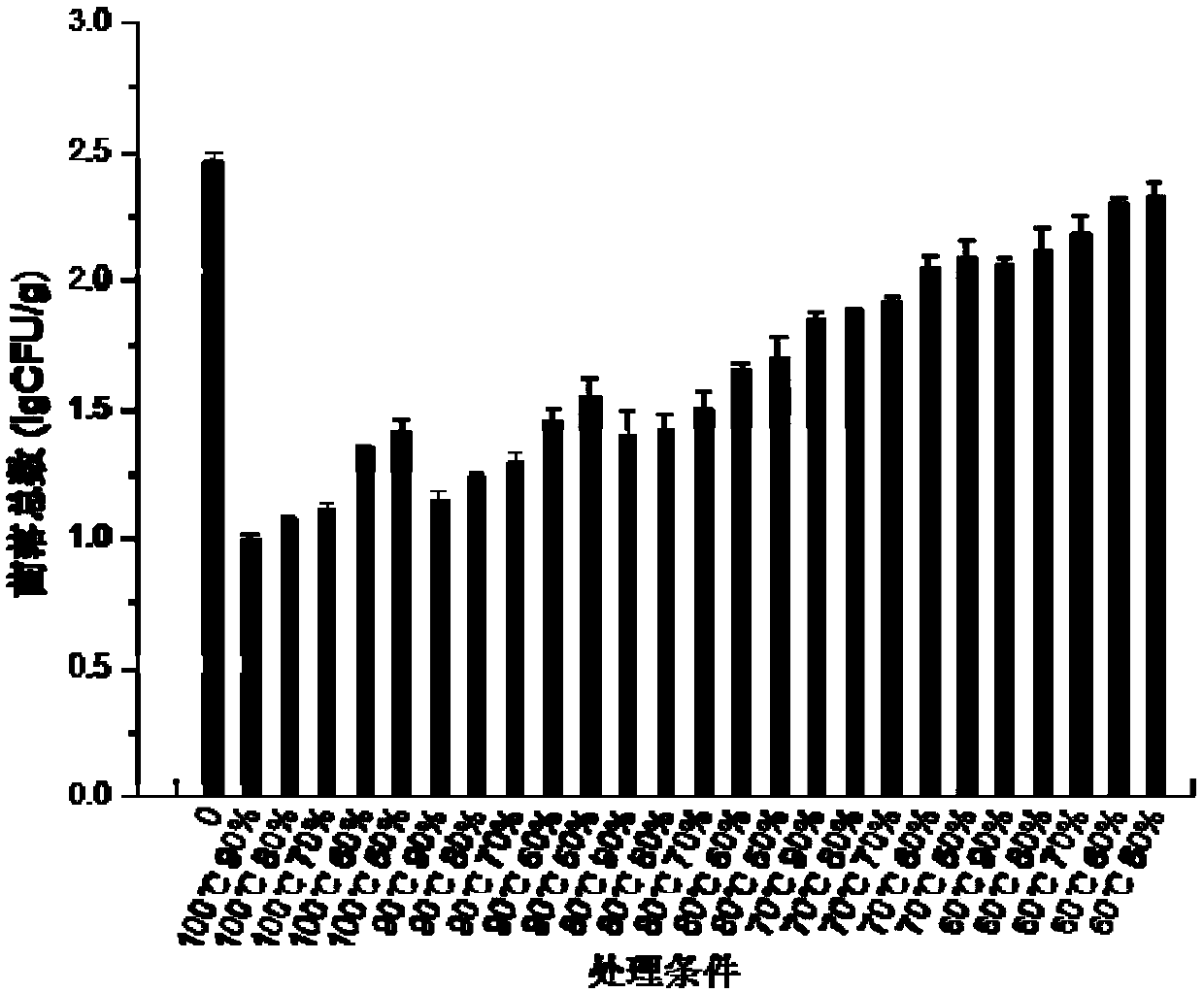

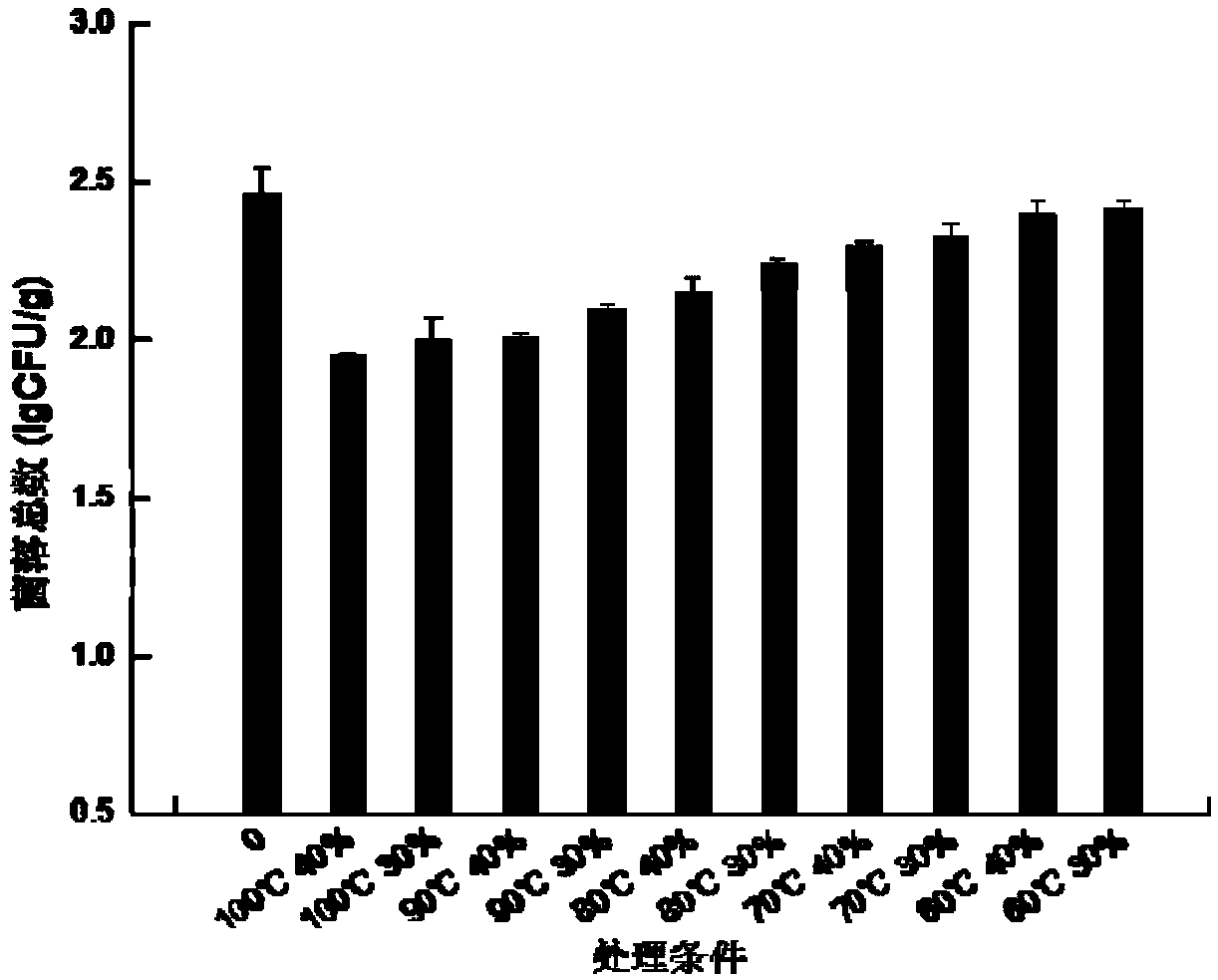

Processing and fresh-keeping method for high-quality wet dough

The invention discloses a processing and fresh-keeping method for high-quality wet dough, and belongs to the field of the industry of processing of flour products. The wet dough is processed by a process of adding much water, 33%-40% of subacid electrolyzed water is utilized, in combination with a high-temperature and high-moisture dewatering process, the initial bacteria quantity of the wet doughis greatly reduced, and good texture property is ensured; and the wet dough is stored under the condition of low temperature (4-10 DEG C), the shelf life of the wet dough can be prolonged effectively, and the wet dough can be stored for 2-3 months at the temperature of 4-10 DEG C.

Owner:JIANGNAN UNIV +1

Processing method of fruit juice

The invention relates to a food depth processing technology and especially relates to a processing technology for processing fruits into fruit juice. The method comprises steps of: first checking and accepting raw materials, selecting mature fruits as raw materials and removing fruits with insects and diseases and rotted fruits; and preferably selecting 80% mature fruits as raw materials; second, fragmenting cleaned fruits properly and killing enzyme immediately; third, heating fragmented fruits to 100 DEG C rapidly and maintaining for 5 min; fourth, adding the above treated fruit blocks into a juice extractor to squeeze juice; fifth, carrying out coarse filtration on the extracted juice and centrifuging with a rotating speed of 3000 round / min for 5 min to obtain a normal juice; sixth, mixing well the blended fruit juice and homogenizing in a high pressure homogenizer for one time; seventh, introducing a homogenized material liquid into a vacuum degasser, degassing for 5 min and filling; and eighth, maintaining at 95 DEG C for 5 min to sterilize and cooling fully to obtain a finished product. The fruit juice has good mouthfeel and colour preserving and will not influence health of consumers for long-term drinking. The processing technology has high machining efficiency, and according to tests, the fruit juice produced by the method has an average juice yield higher than 75%.

Owner:李忠盘

De-browning method of browned calluses of taxus cuspidata

InactiveCN103563750ASolve browningHigh browning removal ratePlant tissue cultureHorticulture methodsCell cultureBiology

The invention discloses a de-browning method of browned calluses of taxus cuspidate. Namely, young immature stem sections or leaves of the current taxus cuspidate are used as explants to carry out induction on the calluses on a culture medium developed by an inventor, and then, the subculture is carried out on the calluses of the taxus cuspidate according to published documents, wherein a browning phenomenon easily exists in the calluses of the taxus chinensis in the subculture process. De-browned calluses of the taxus cuspidate in a good state can be re-induced on the browned calluses by carrying out culture on a subculture culture medium, developed by the inventor, of the calluses of the taxus cuspidate. The de-browning method disclosed by the invention not only can enable the browned calluses of the taxus cuspidate to be de-browned, but also can provide a technical support for producing taxol by applying a cell culture technology of the taxus cuspidate.

Owner:DALIAN NATIONALITIES UNIVERSITY +1

Preparation method of ferric pyrophosphate applied to infantal foods

InactiveCN110236201ABarrier Catalytic OxidationSolve browningFood coatingFood ingredientsCatalytic oxidationGlycerol

The invention discloses a preparation method of ferric pyrophosphate applied to infantal foods. The preparation method comprises the following steps of (1) preparing a mixed suspension of 80 DEG or above from ferric pyrophosphate which is subjected to superfine grinding, maltodextrin, glyceryl monostearate, glycerol distearates, enzymolysis soybean lecithin and a polysaccharide compound; (2) performing high-speed shearing on the mixed suspension obtained in the step (1), performing homogenizing, and then performing spray drying to obtain entrapping ferric pyrophosphate; and (3) performing treatment on the entrapping ferric pyrophosphate obtained in the step (2) through a coating technology so as to obtain finished products of the ferric pyrophosphate. An emulsified, homogenized and sprayed microcapsule method and a coating method are combined to perform emulsifying and modifying treatment on common ferric pyrophosphate, so that the problem that in the storage process of products, the products generate brown stains is solved, the catalytic oxidation of ferrum to fat is separated, storage stability and eating safety of the products are improved, and the effect is notable.

Owner:NINGBO XINUOYA MARINE BIOTECH CO LTD

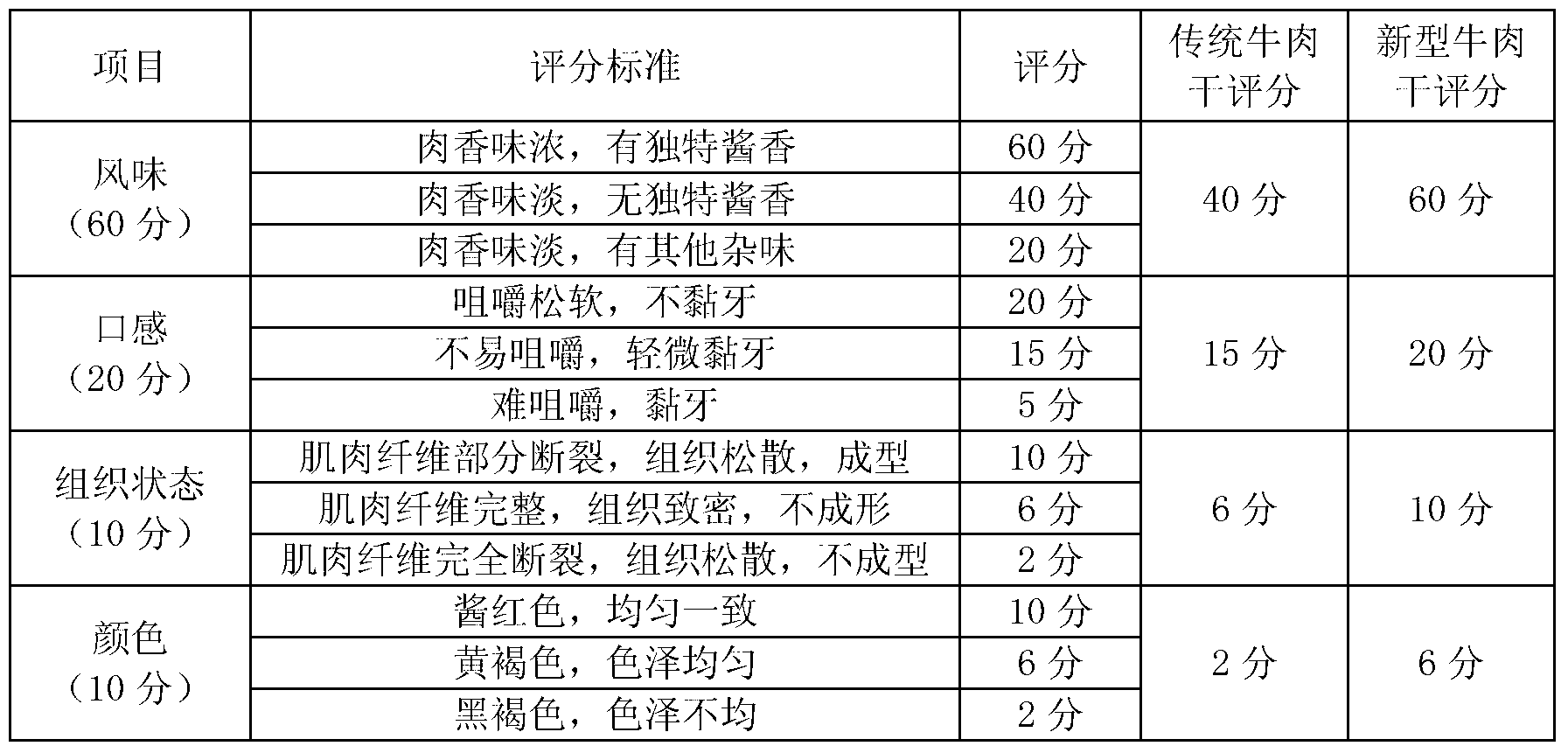

Preparation method of low-sugar type middle-water sliced dried beef

The invention belongs to the field of research and machining of foods and particularly relates to low-sugar type middle-water sliced dried beef and a preparation method thereof. The method comprises the following steps of: discharging acid of fresh beef and cooking; then adding pickling agents to cure, wherein the adding amounts of the pickling agents are as follows based on the weight of the beef: 2-8% of xylitol, 3-9% of sorbitol, 1.5% of table salt, 0.5% of curry powder and 1.0% of soybean sauce; and then carrying out tumbling, pre-boiling, dicing and boiling and marinating and carrying out two-section type drying to obtain the low-sugar type middle-water sliced dried beef. According to the low-sugar type middle-water sliced dried beef and the preparation method thereof, the problems of the traditional sliced dried beef that the mouth feel is rough, the texture is hard and fat can be oxidized and become brown in the storing process are effectively solved.

Owner:YANGZHOU UNIV

Chinese chestnut tissue culture method and special culture medium thereof

InactiveCN101331851AGuaranteed genetic stabilityPerfect sterilization methodPlant tissue cultureHorticulture methodsCulture mediumsHormones regulation

The invention discloses a method for reproducing Chinese chestnuts and a special culture medium thereof. The culture medium of the invention is the culture medium obtained by adding IBA and at least one of the two hormones (KT and TDZ) in WPM culture medium; the final concentration of IBA is 0.1-1.0mg / l, and the final concentration of KT or TDZ is 0.5-1.0mg / l. The culture medium of the invention screens out the type of hormone, the type of antibiotic, the anti-browning substances, and the like, which are applicable for the growth of Chinese chestnuts, solves the problems of pollution and browning existing in the cultivation of Chinese chestnuts at present, and successfully establishes the asepsis cultivation system of the bearing trees of Chinese chestnuts. The method by using the culture medium of the invention for cultivating Chinese chestnuts has the advantages of simple operation and low cost, which is applicable for promotion and application.

Owner:CHINA AGRI UNIV

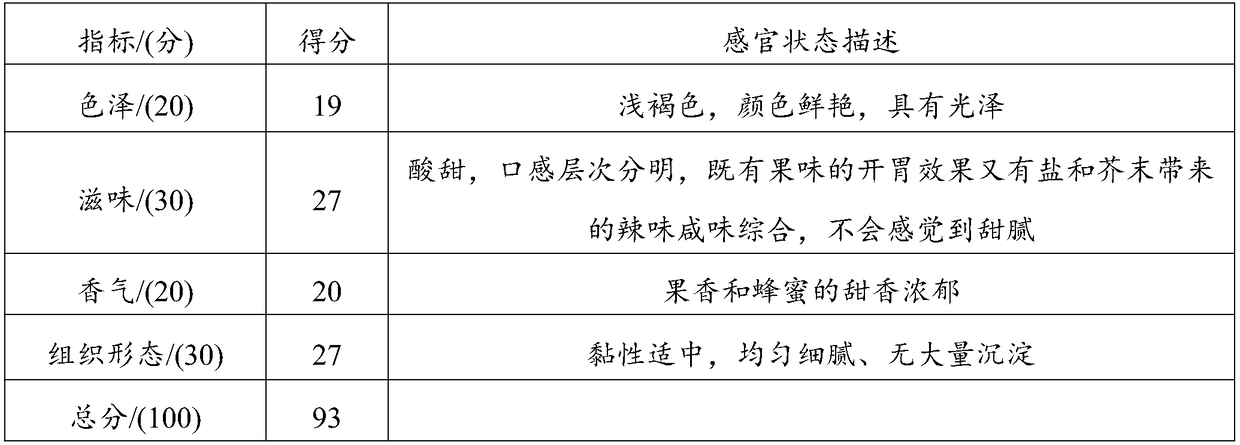

Green plum salad seasoning sauce and preparation method thereof

ActiveCN108185387AFull of nutritionIncrease available avenuesFood ingredient as antioxidantFood extractionChemistryFood science

The invention provides a green plum salad seasoning sauce and a preparation method thereof. The sauce is prepared from the following raw materials in parts by mass: 40 to 100 parts of green plums, 20to 50 parts of olive oil, 20 to 50 parts of brewed vinegar, 5 to 10 parts of a water-soluble sugar-type compound, 5 to 10 parts of salt, 5 to 10 parts of mustard and 3 to 10 parts of honey. The greenplums are rich in phenolic substances, and are manufactured into the antioxidant health-care salad seasoning sauce which is smooth and delicate in mouth feel and has a rich plum fragrance and rich nutrients. The method increases the available approaches of the green plums, broads the market of the green plums, and also increases the color of the seasoning sauce.

Owner:XIHUA UNIV

Brewing process of sweet sparkling apple wine

InactiveCN110819496AImprove easy oxidation and browningImprove qualityMicroorganism based processesAlcoholic beverage preparationReducing sugarChemistry

The invention relates to a brewing process of sweet sparkling apple wine. The process comprises the following steps: (1) soft-pressing juice taking by an extrusion method; (2) juice clarification; (3)low-temperature concentration and separation; (4) temperature-controlled fermentation; (5) pressure-maintaining low-temperature fermentation; (6) sugar-maintaining termination fermentation; and (7) clarification filtering treatment. The physicochemical indexes are as follows: the alcoholic strength is 11.5-12.0 (v / v)%, the reducing sugar content is greater than or equal to 95.0 g / L, the total acidity is 8.0-9.0 g / L, the free SO2 content is less than or equal to 50mg / L, the total SO2 content is less than or equal to 150mg / L, the volatile acid content is less than or equal to 0.8 g / L, and the pressure is 0.25-0.35 MPa. The process has the advantages that the juice is extracted through soft pressing, so that the influence of bitter substances on the aroma, taste and quality of the juice is reduced; the aroma and sugar of the fruit juice are concentrated through a low-temperature concentration technology; and through low-temperature pressure-maintaining fermentation and sugar-maintainingtermination fermentation, the finished wine is beautiful and light golden yellow. The finished wine is clear and transparent, bubbles are lasting and fine, and the finished wine has typical apple aroma and nectar aroma, strong fruity aroma, elegant and pure wine aroma, mellow and mellow taste, fullness, coordination, complexity, balance, and fragrant, fresh and lasting aftertaste.

Owner:TIANJIN AGRICULTURE COLLEGE

Treatment method for restoring and protecting color of herbarium

InactiveCN112602705ARealize restoration and color preservation treatmentHigh practical valueDead plant preservationSodium bicarbonatePlant specimen

The invention discloses a treatment method for restoring and protecting color of a herbarium. The treatment method comprises the steps of restoring and protecting color of red and pink flowers of the herbarium and restoring and protecting color of green leaves of the herbarium. According to the step of reducing and color-retaining of the red and pink flower-series herbarium flowers, tartaric acid, citric acid and water are prepared into a reducing and color-retaining agent according to the proportion of 1-2:1-2:6-8, the reducing and color-retaining agent is made to act on the red and pink flower-series herbarium flowers in a medium-temperature iron pressing mode, and then the herbarium is pressed again. Restoring and protecting color of green leaves of the herbarium comprises the steps as shown in the description. After green leaves of the specimens are treated with a sodium bicarbonate solution and under the action of a green fixing solution, flowers of red and pink flower-series plant specimens are used for reduction and color retention. The method is easy and convenient to operate and low in cost, the color restoration rate of flowers and green leaves of the plant specimen is 50% or above, the practical value, artistic value and ornamental value of the plant specimen are increased, and theoretical and practical bases are provided for restoration and color protection of the plant specimen.

Owner:西藏藏草生态科技有限公司 +1

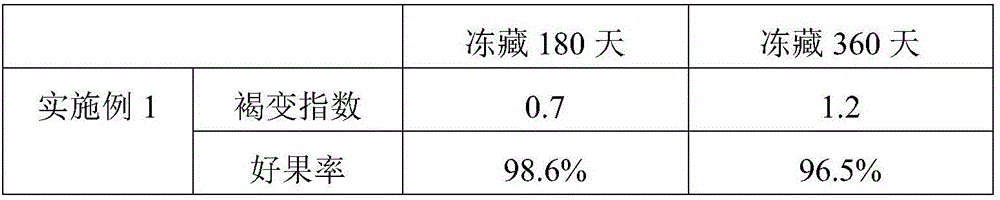

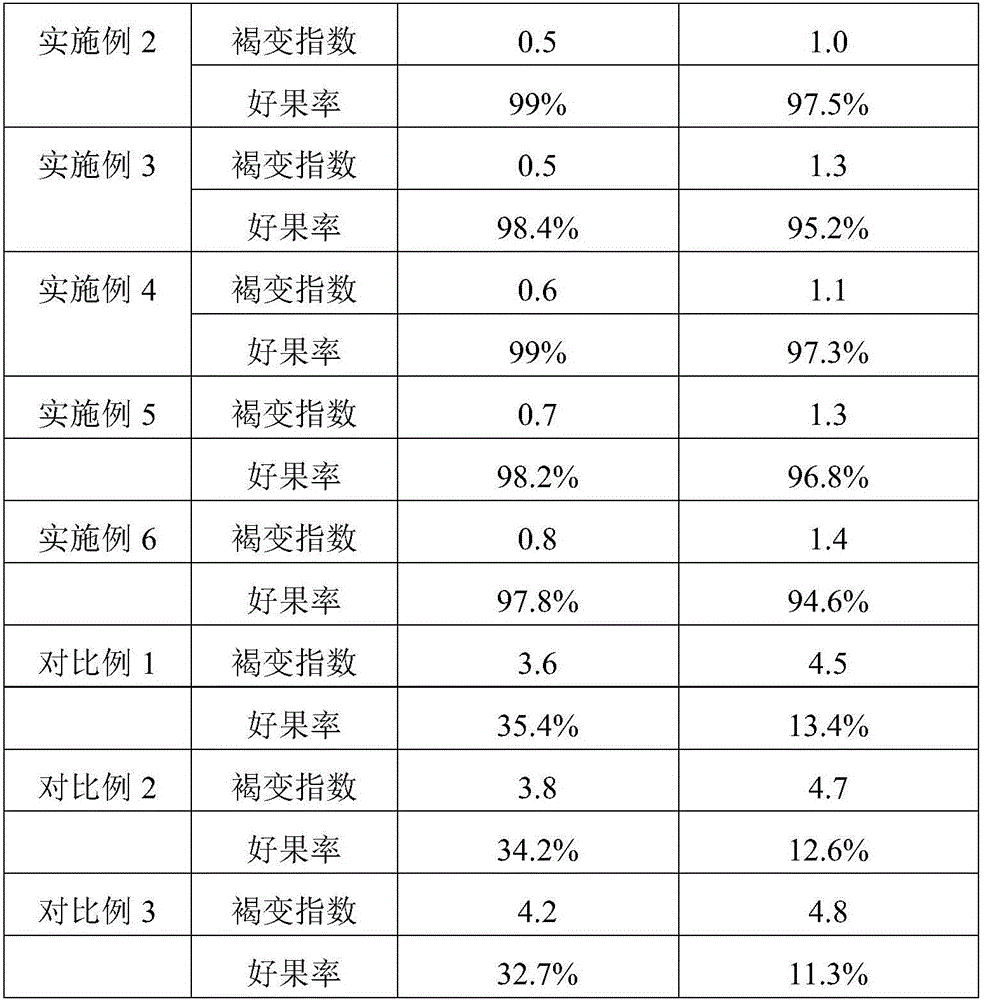

Industrialization preservation method of longans

InactiveCN107173427AExtended shelf lifeImprove protectionFood freezingFood ingredient for microbe protectionFlavorIce water

The present invention relates to the technical field of food low temperature storage and more particularly relates to an industrialization preservation method of longans. The industrialization preservation method of the longans specifically comprises the following steps: S1, ice water precooling and washing; S2, packaging; S3, cooling and liquid nitrogen quick freezing; and S4, sealedly packaging and freezing storing. The method is low in freezing temperatures and rapid in speed, basically clears and inhibits spoilage microorganisms, enables tissue structures to be well preserved, maintains original nutrition and flavor, and effectively solves problems of spoilage and browning of the longan fruits after harvesting, enables the freezing processed longan fruits to have a shelf life up to one year or more, significantly extends a preservation period of the longan fruits, and realizes an industrial preservation of the longans.

Owner:台富科技(深圳)有限公司

Preparation method of honey-vinegar fish

The invention discloses a preparation method of honey-vinegar fish. The preparation method of honey-vinegar fish comprises the following steps: preparing raw-material fishes, pickling the fishes so that the fishes are flavored, air-cooling and drying the pickled fishes, slightly frying the dried fishes to remove the fishy smell, pickling the slightly fried fishes by vinegar so as to carry out acidification, making the fish bones crispy, and carrying out honey-frying, alcohol neutralizing and vacuum packing, so that the instant honey-vinegar fishes are prepared. The prepared instant honey-vinegar fishes are bright in color, heavy in fragrance, mellow in sour-sweet taste, and capable of being directly eaten when the bag is opened. The honey-vinegar fishes are also high in production efficiency, good in quality, long in storage life, crispy in fish bones, convenient to be eaten and delicious in meat, so that the preparation method is a processing method of an attractive sour-sweet food which can be produced by industrialized mass production, and the honey-vinegar fishes also have healthcare functions. The instant honey-vinegar fish pieces of unique flavor are prepared by the honey-vinegar frying food processing technology, and the problem of browning of the dried fishes during the production process is solved by the air-cooling and drying technology, so that the prepared honey-vinegar fish food has a unique flavor.

Owner:FOSHAN UNIVERSITY

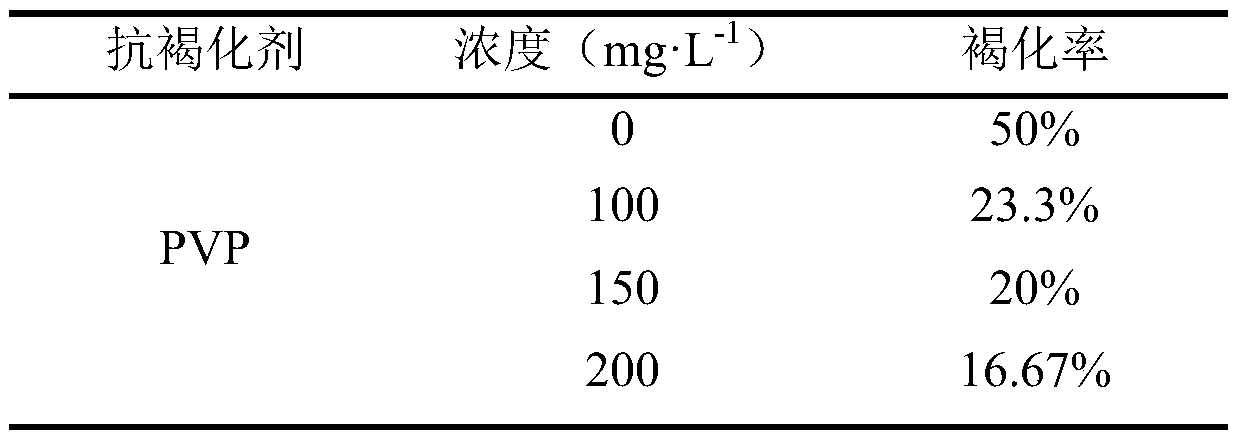

Callus induction and subculture medium for cyclocarya paliurus, and culture method thereof

ActiveCN109997692ALow pollution rateNot easy to pollutePlant tissue cultureHorticulture methodsTriterpeneSecondary metabolite

The invention discloses a callus induction and subculture medium for cyclocarya paliurus, and also discloses a culture method based on the callus induction and subculture medium for the cyclocarya paliurus. The culture method includes explant selection, explant sterilization, establishment of a sterile anti-browning system, and proliferation culture. The callus induction and subculture medium andthe culture method have the advantages that the anti-browning abilities of calluses of the cyclocarya paliurus can be effectively improved, a large quantity of non-browning calluses with high growth speeds can be obtained in a short time, the problem of resource shortage of the cyclocarya paliurus can be solved through biotechnological measures, and accordingly, the foundation is laid for industrial extraction of secondary metabolites of the cyclocarya paliurus, such as triterpenes, flavonoids and polysaccharides, in later period.

Owner:NANJING FORESTRY UNIV

Preparation method of grease-containing seabuckthorn turbid juice

ActiveCN109315645AThe preparation method is simple and feasibleStabilizer significantlyFood scienceFruit juiceHigh pressure

The invention discloses a preparation method of grease-containing seabuckthorn turbid juice, belonging to the technical field of deep processing of agricultural and sideline products. Specific to theproblems of loss of a large quantity of nutrient substances and the like caused by basically selecting a fruit juice complete degreasing method to realize the uniformity of fruit juice appearance in order to solve the problems of fat floating and fruit juice lamination in the prior art, the invention aims at providing the preparation method of the grease-containing seabuckthorn turbid juice specific to the problems mentioned above, a part of fat in seabuckthorn is effectively retained by utilizing a partial degreasing and two-stage high-pressure homogeneous method, not only are the flavor substances and nutrient substances of the seabuckthorn turbid juice effectively retained, but also the problems of fat floating and lamination are effectively solved, so that the seabuckthorn turbid juice, which has high stability and a relatively long shelf life, is obtained, final products have a uniform emulsion state, various kinds of physiological active substances are maintained to the maximum extent, meanwhile, the manufacture cost is significantly reduced, and the seabuckthorn turbid juice can be widely applied to industrial production.

Owner:ZHONGBEI UNIV

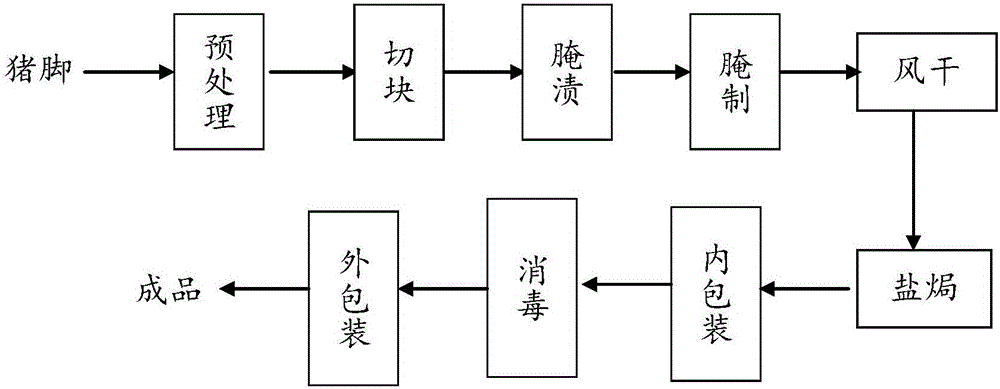

Instant salt roasted pig trotter and preparation method thereof

The invention provides an instant salt roasted pig trotter and a preparation method thereof. The pig trotter is pretreated and then is cut, cured, pickled, dried, salt-roasted, internally packaged, disinfected and externally packaged and processed, so that the instant salt roasted pig trotter is formed. The instant salt roasted pig trotter provided by the invention contains no any chemical additive, is high in quality, can be stored for a long time, has golden yellow appearance, tastes glutinous, soft and chewy and can melt after nibbling; the greasy problem of the pig trotter is solved; the contents of fat, heat and cholesterol are all lower; the nutrition is richer; the instant salt roasted pig trotter has the features of salt roasted food, good flavor, hygiene and healthcare function, can be enjoyed at any time and is portable; and according to the preparation method provided by the invention, the production efficiency is high and the industrial batch production can be realized.

Owner:FOSHAN UNIVERSITY

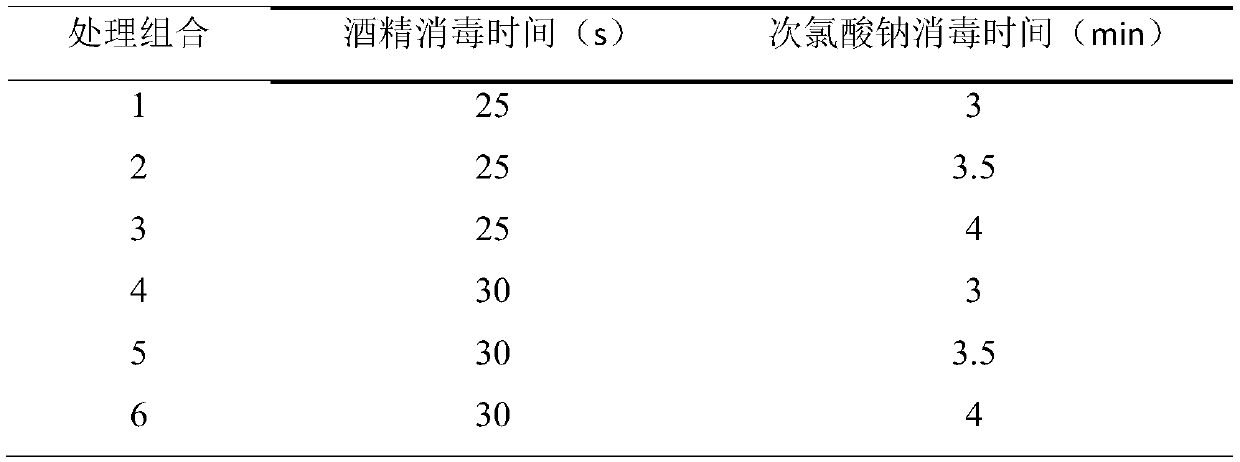

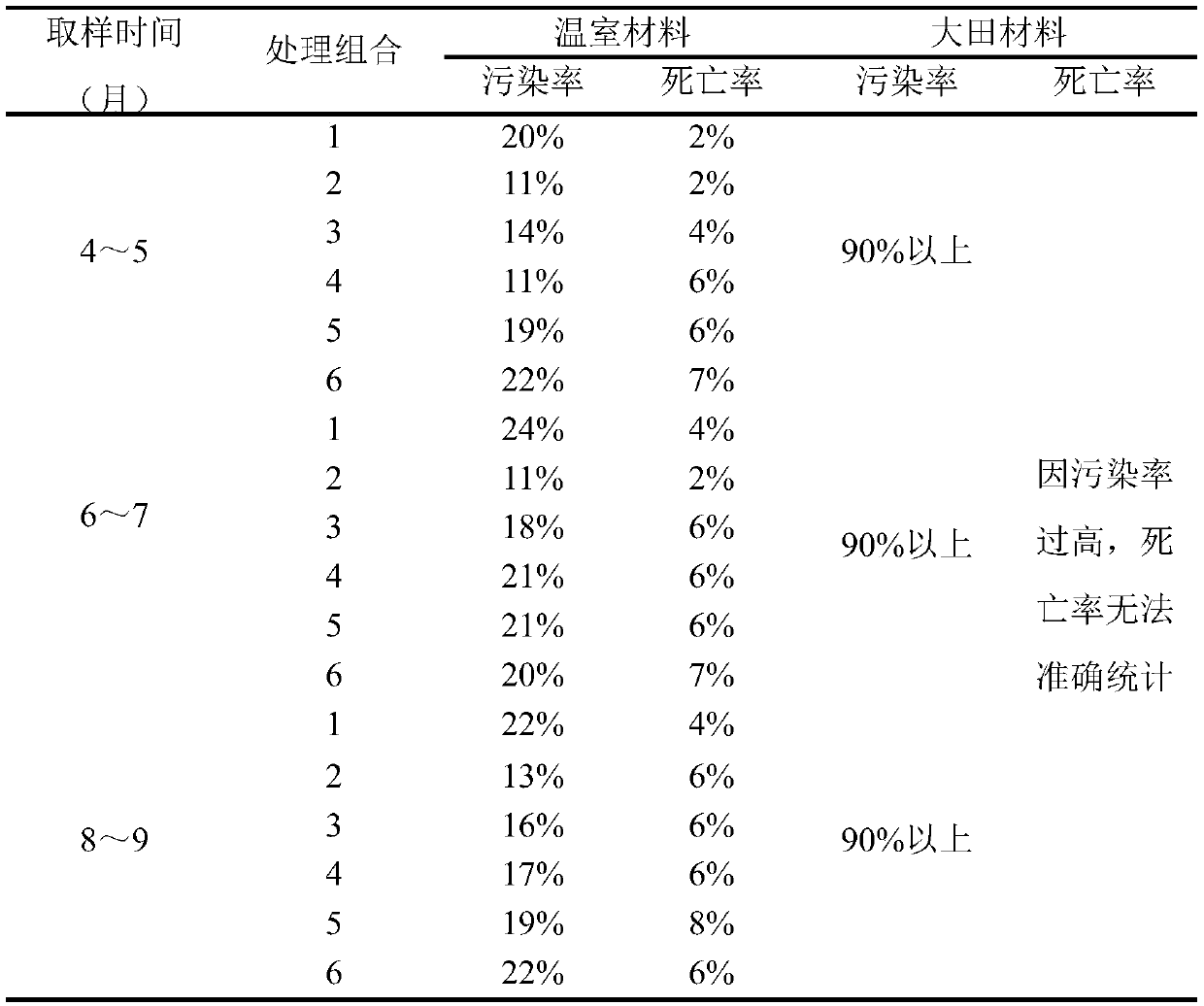

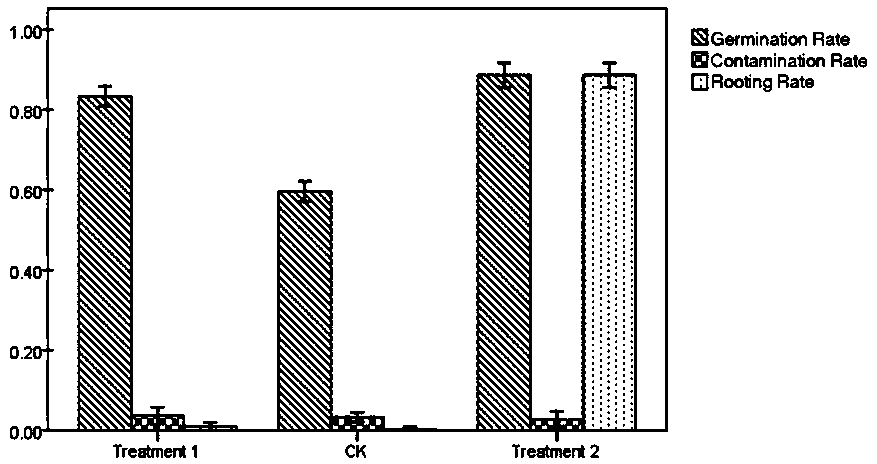

Method of establishing aseptic culture system for mature seed embryos of oil-use paeonia ostia 'feng dan'

ActiveCN110476807AShorten dormancyImprove germination rateHorticulture methodsPlant tissue cultureContamination rateEmbryo

The invention relates to a method of establishing an aseptic culture system for mature seed embryos of oil-use paeonia ostia 'feng dan', and belongs to the field of plant tissue culture. The method includes the following steps of (1) selecting seeds; (2) removing outer seed coats; (3) washing and soaking the seeds after coat removal; (4) conducting disinfecting treatment; (5) removing endosperms;(6) conducting inoculation and culture. According to the method, the mature seed embryos of the paeonia ostia 'feng dan' are selected and used, and after strict selection, coat removal, soaking, disinfection, inoculation and culture, four weeks after the start of the constructed high-efficiency aseptic culture system, the germination rate is >=80%, the contamination rate is <=5%, and no browning occurs. The problem of browning in the establishment of the aseptic culture system of a peony tissue culture technology using scale buds or soil buds as explants is thoroughly solved, the pollution rate during the establishment of the system is greatly reduced, and the application efficiency of the peony tissue culture technology in the establishment of the aseptic culture system in production andpractice is improved.

Owner:HENAN UNIV OF SCI & TECH

Brewing process of mixed fragrance type sparkling sweet apple wine

InactiveCN110938512AImprove easy oxidationPromote browningMicroorganism based processesAlcoholic beverage preparationBiotechnologyBrowning

The invention relates to a brewing process of mixed fragrance type sparkling sweet apple wine. The brewing process comprises the following steps: step 1, carrying out soft-pressing to take juice; steptwo, adjusting the acidity of lemon juice; step three, carrying out clarification of fruit juice; step four, carrying out concentration and separation at a low temperature; step five, carrying out temperature-controlled fermentation; step six, carrying out clarification and filtering; step seven, carrying out pressure-maintaining secondary fermentation; step eight, carrying out incomplete fermentation termination; step nine, carrying out low-temperature ageing; and step ten, carrying out clarification and filtration treatment under the conditions of setting physical and chemical indexes as follows: 11.5 to 12.0 (v / v) percent of the alcoholic strength, reducing sugar being greater than or equal to 95.0 g / L, total acidity of 8.0 to 9.0 g / L, free SO2 being less than or equal to 50mg / L, totalSO2 being less than or equal to 150mg / L, volatile acid being less than or equal to 0.8g / L, and the pressure of0.25 to 0.35 MPa. The brewing process has the following advantages: after the process operation, the influence of easy oxidation and browning of the apples after juicing on the aroma, taste and quality of the juice is reduced; the acidity of the apple juice is adjusted by lemon juice, sothat the complexity of the fragrance and the taste of the apple juice are increased; the oxidation resistance of the apple juice is improved; with the low-temperature concentration technology, the pressure-maintaining secondary fermentation technology, the incomplete fermentation termination technology and the low-temperature ageing technology with yeast paste, the yeast fragrance is enhanced while the wine fragrance contains the fine apple fragrance and elegant lemon fragrance, so that the aroma richness is improved, the taste is more mellow and complex, and the sweetness is pure and clean without sweet greasy feeling.

Owner:TIANJIN AGRICULTURE COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com