Patents

Literature

41results about How to "Solve high temperature oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

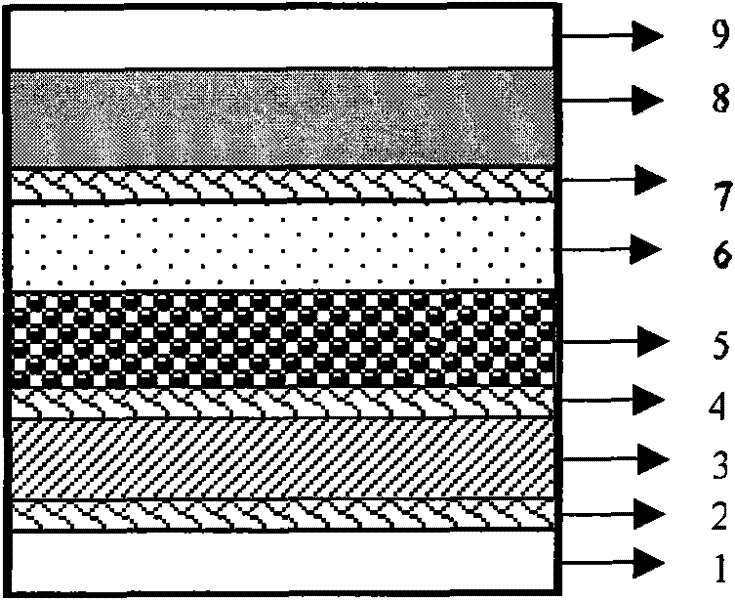

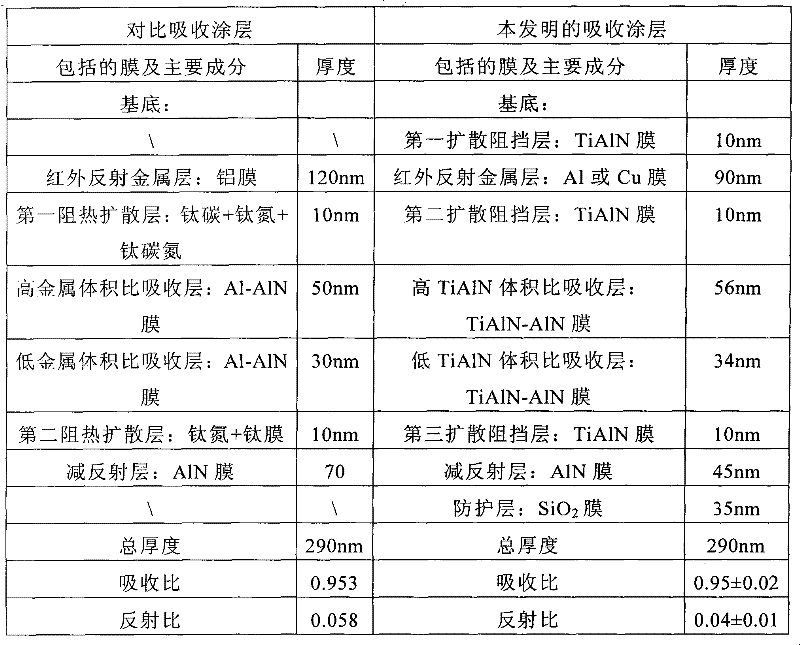

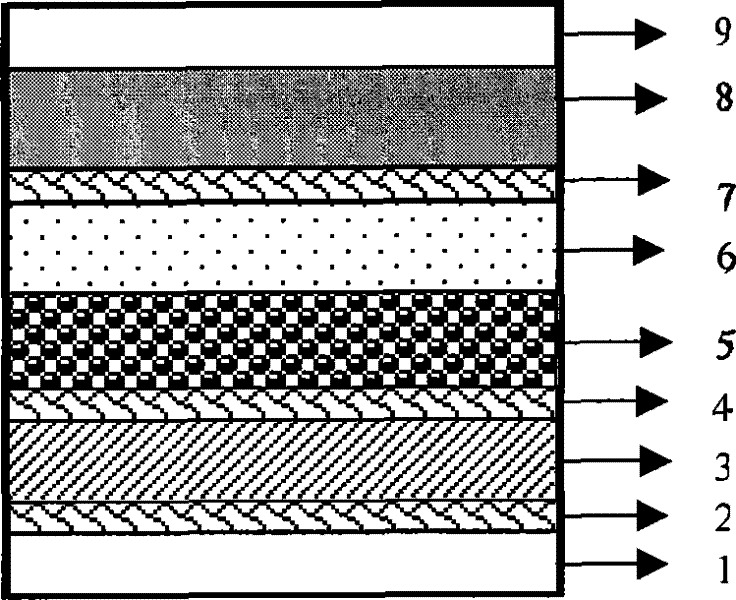

Solar spectrum selective absorbing coating and preparation method thereof

ActiveCN102122006AHigh absorption rate αLow high temperature oxidation resistanceVacuum evaporation coatingSputtering coatingHigh absorptionLow emissivity

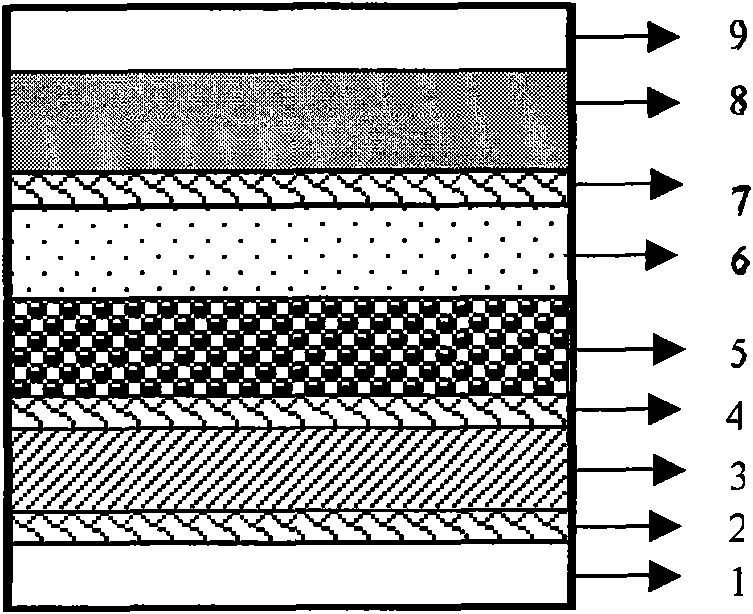

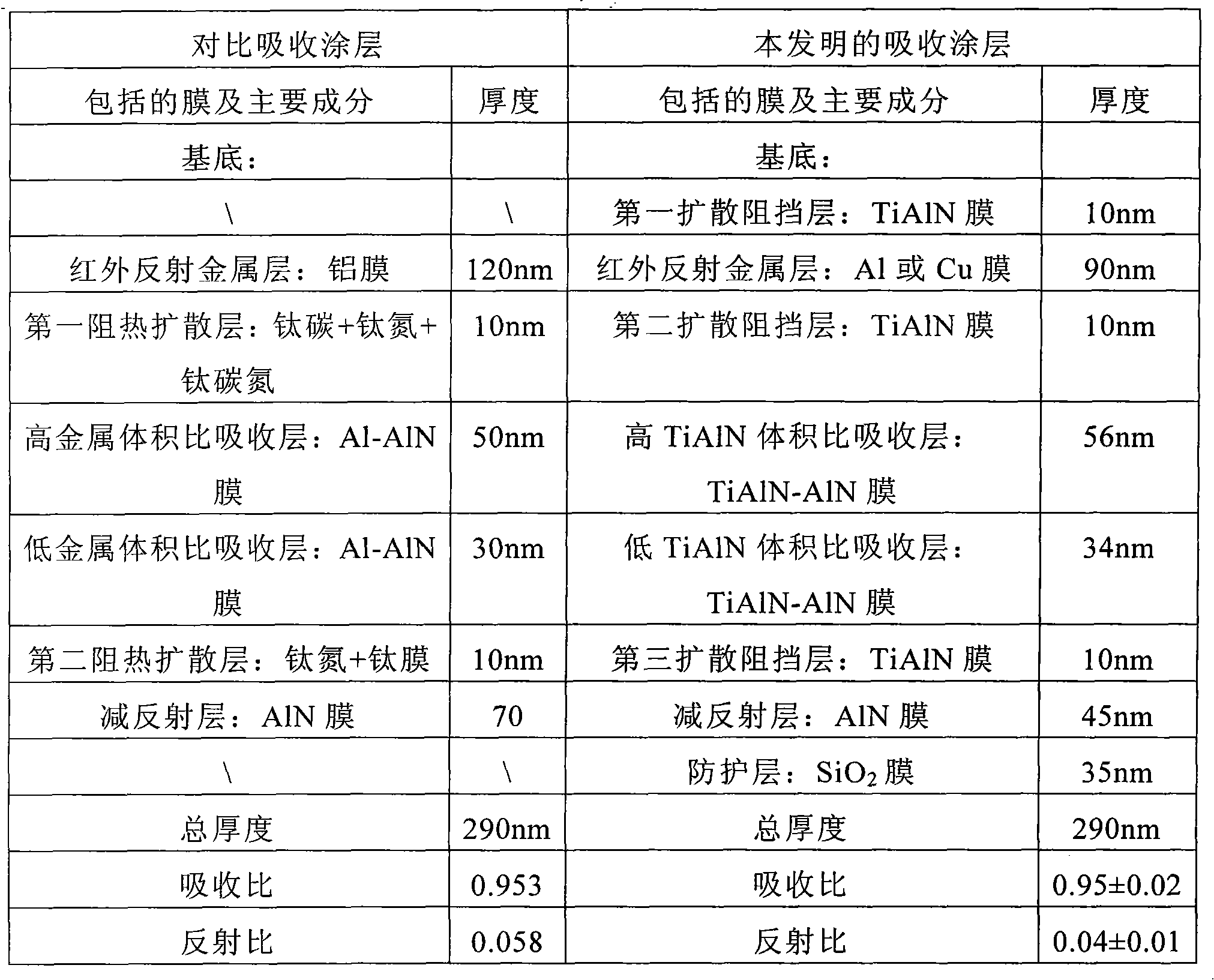

The invention provides a solar spectrum selective absorbing coating and a preparation method thereof, wherein the preparation method comprises the following steps of: (1): selecting copper or stainless steel as substrate material; (2): selecting high-temperature oxidation resisting TiAlN as a diffusion impervious layer, using pure metal Cu or Al as a high infrared reflective layer, wherein an absorbing layer consists of two conductive particle-ceramic (AlN) composite layers with different volume percentages of metal nitride conductive particle (TiAlN), using AlN as an antireflection layer, and using SiO2 as a protective layer; (3): controlling components and contents of different film materials by controlling the gas flow and the sputtering power and the like; (4): before placing the substrate material into a vacuum chamber, carrying ultrasound treatment on the substrate material for 10-30 min, drying, after placing the substrate material into the vacuum chamber, roasting for 10-30 min at 100-120 DEG C, before sputtering, bombarding the surface by argon ions; and (5): obtaining a coating with a multi-layer structure, which has high absorption rate Alpha (0.95 + / - 0.02) in the solar spectral region (0.3-2.5 micrometers), and which has quite low emissivity Epsilon (0.04 + / - 0.01) in an infrared region (2.5-50 micrometers).

Owner:GRIMAT ENG INST CO LTD

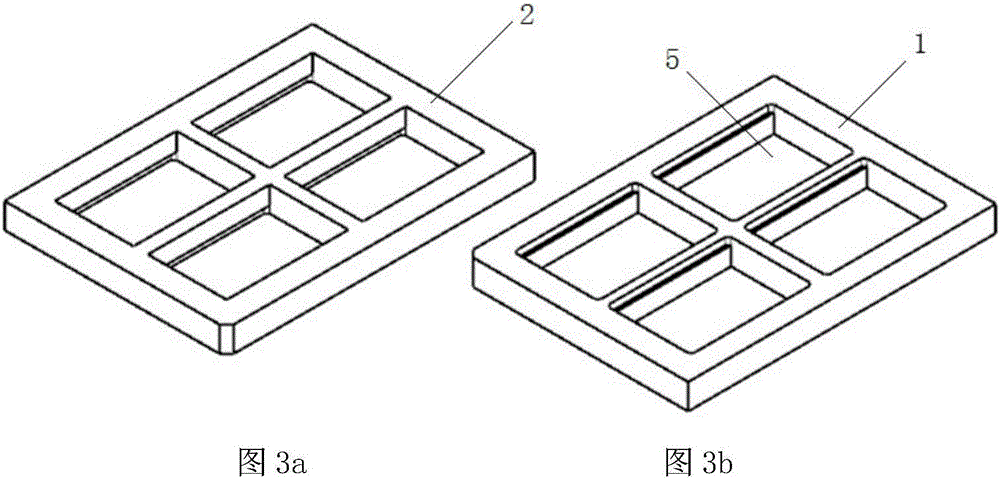

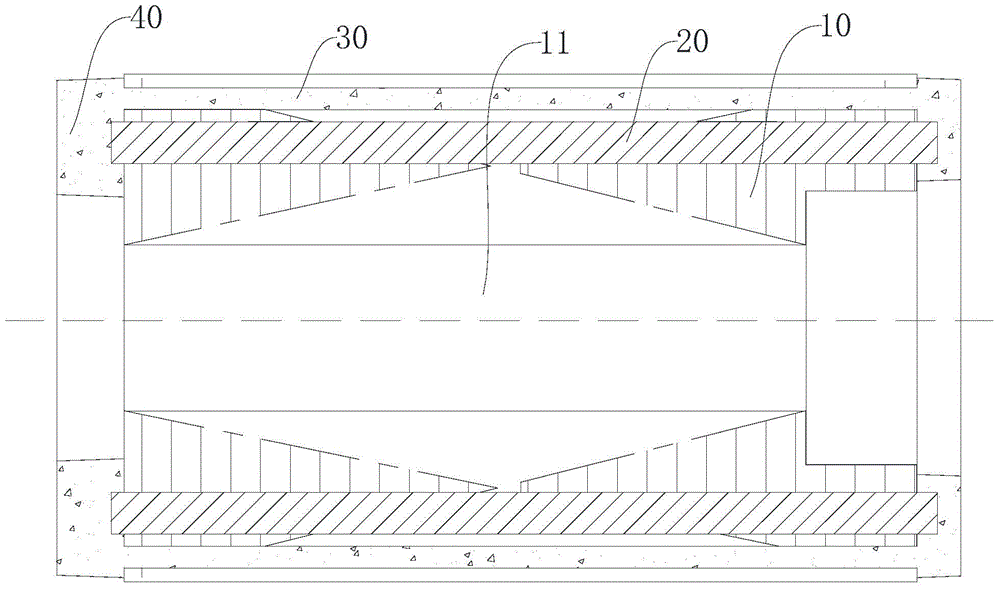

Glass heating graphite mold and production method thereof

ActiveCN106746526AImprove molding qualityGood for mass productionGlass reforming apparatusGlass productionGraphiteMaterials science

The invention discloses a glass heating graphite mold and a production method thereof. The mold comprises a front mold and a rear mold, wherein the front mold comprises a front mold base and a front mold core made of a graphite material; the rear mold comprises a rear mold base and a rear mold core made of the graphite material; a cavity matched with the front mold core is formed in the front mold base; the front mold core is arranged in the cavity of the front mold base; a cavity matched with the rear mold core is formed in the rear mold base; the rear mold core is arranged in the cavity of the rear mold base; intermediate areas of opposite surfaces of the front mold core and the rear mold core are three dimensional curved surfaces suitable for processing to obtain hot bending glass during mold closing; edge areas of the opposite surfaces of the front mold core and the rear mold core are respectively provided with a plurality of supporting insert via holes; supporting inserts are arranged in the supporting insert via holes; when the mold is closed, the supporting inserts, which are oppositely arranged, on the front mold core and the rear mold core, make contact with one another, so that the effects of positioning and supporting the mold cores are realized, and the pressures of the mold cores are borne. According to the glass heating graphite mold disclosed by the invention, large-scale mass production is easily realized while the molding quality of the graphite mold is improved.

Owner:DONGGUAN HUAQING OPTICAL TECH

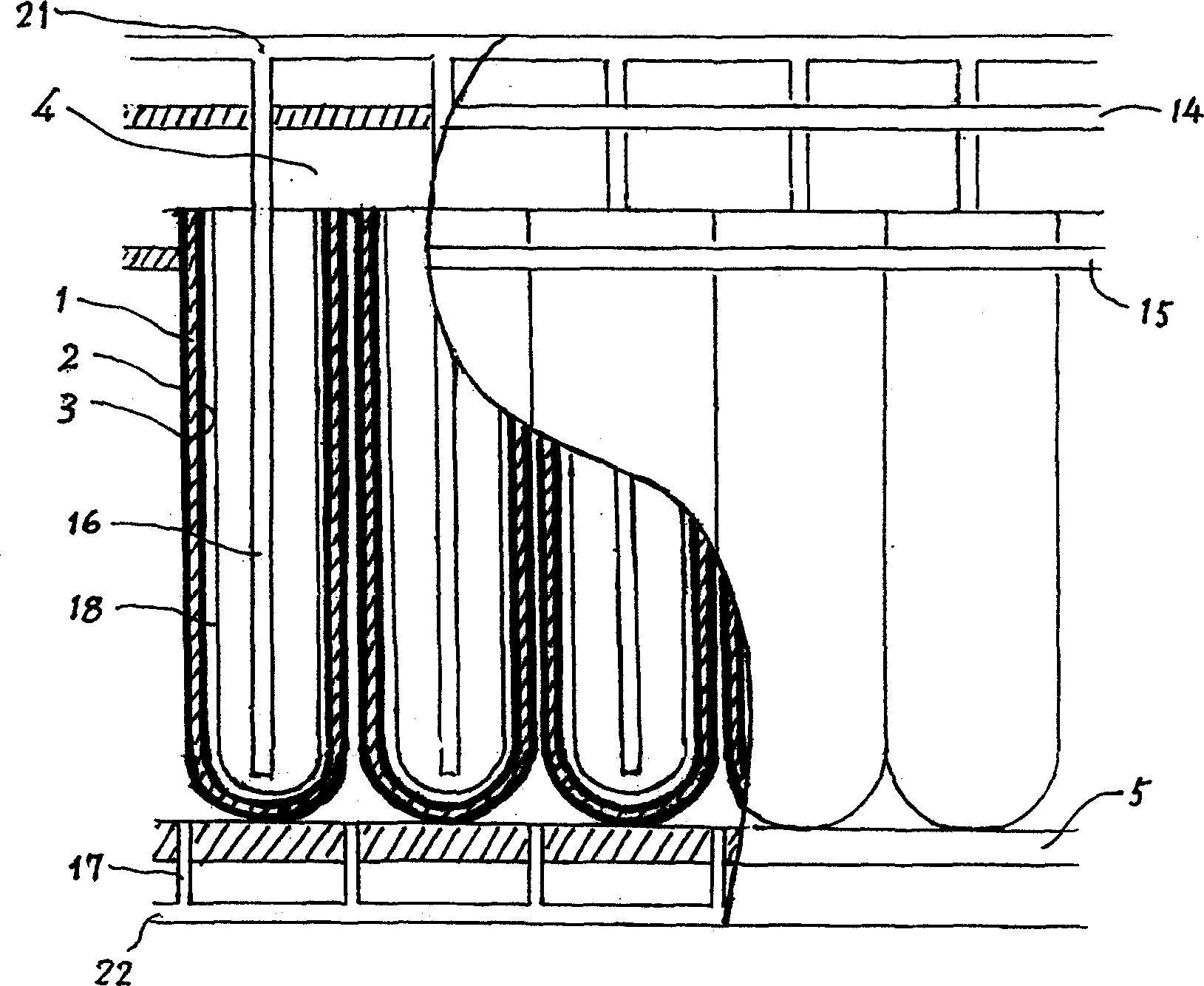

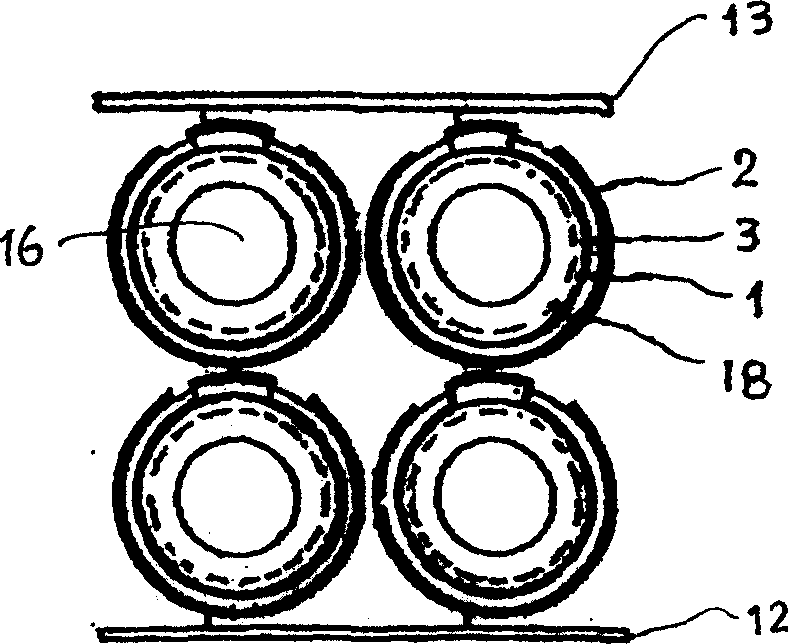

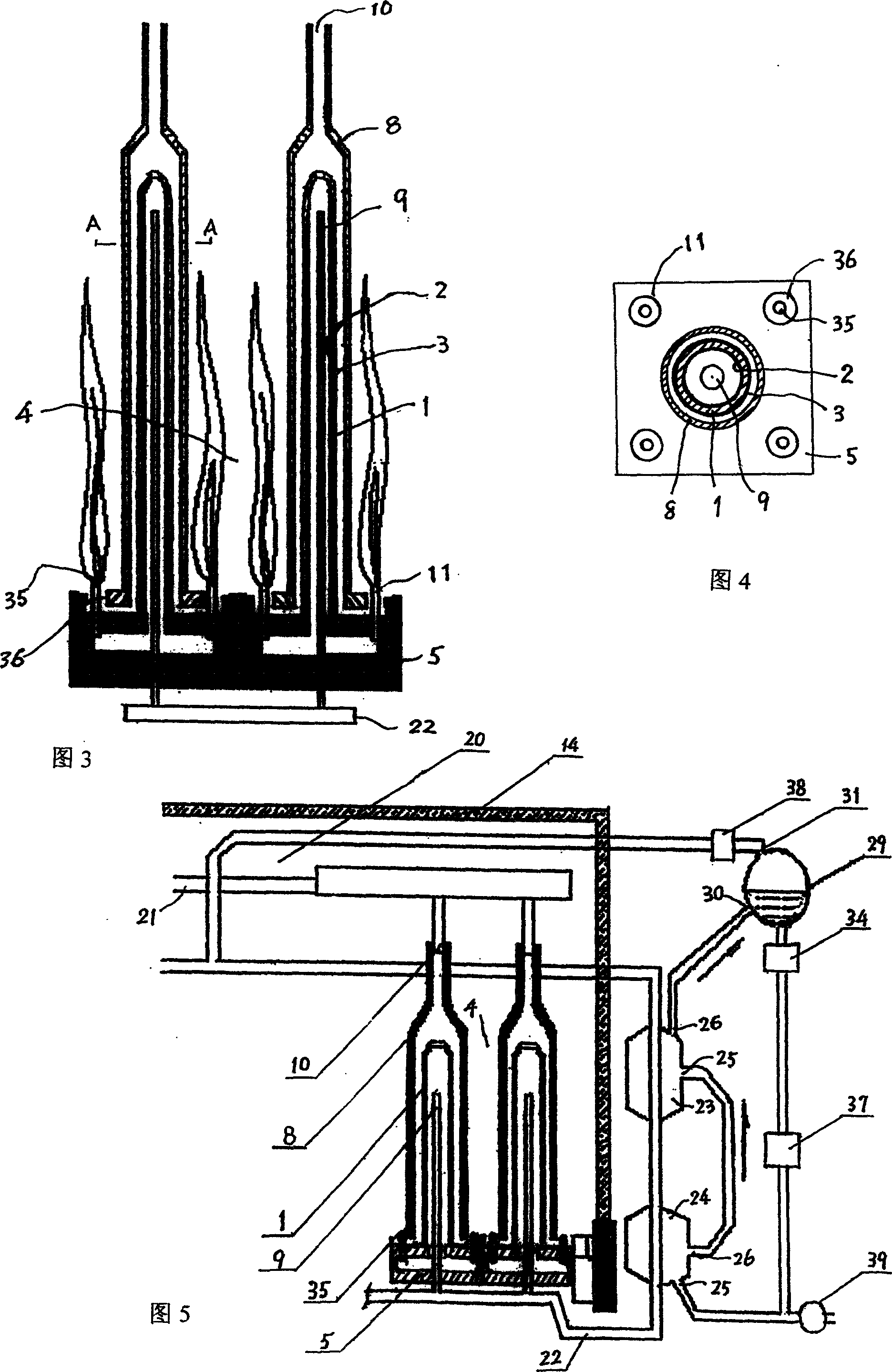

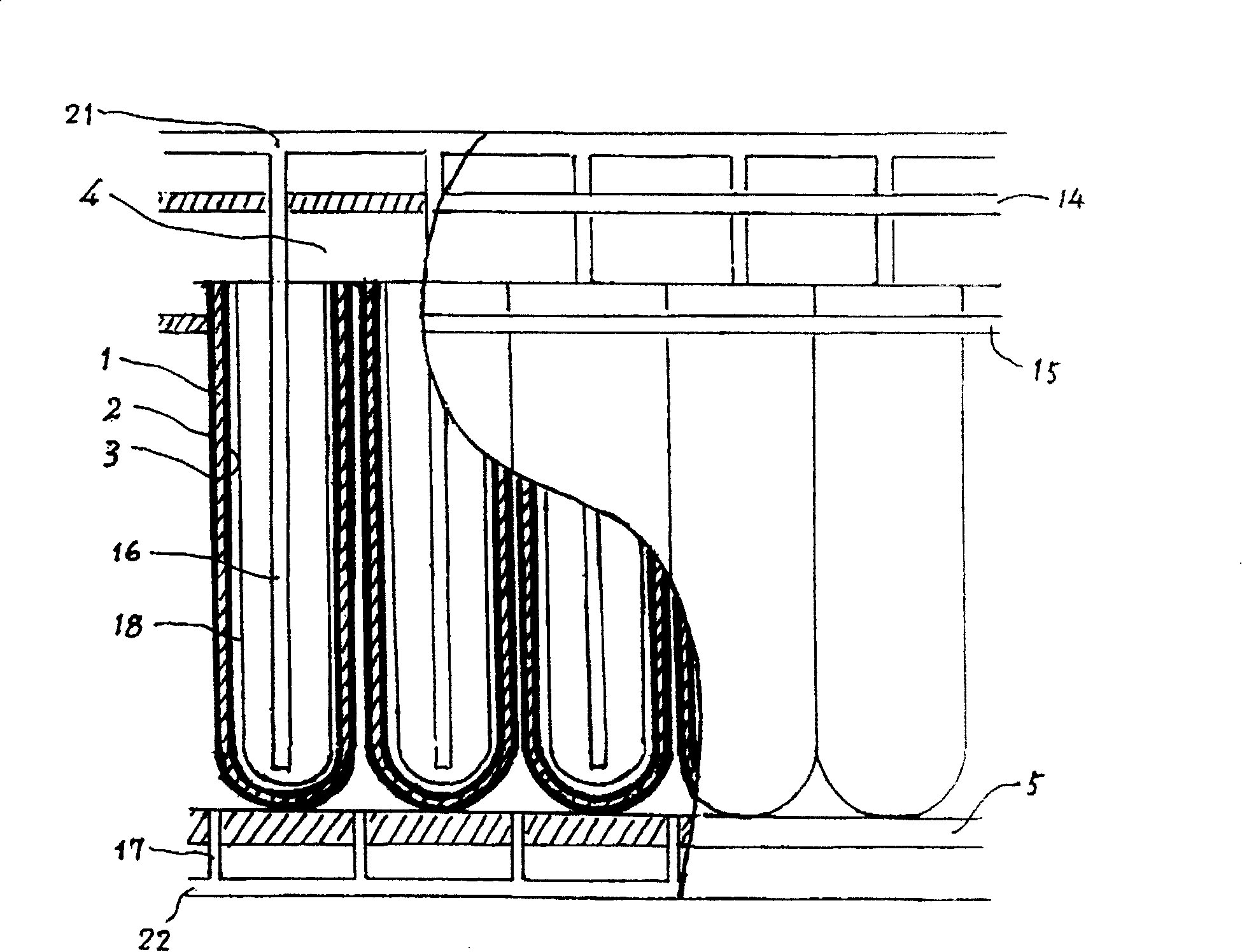

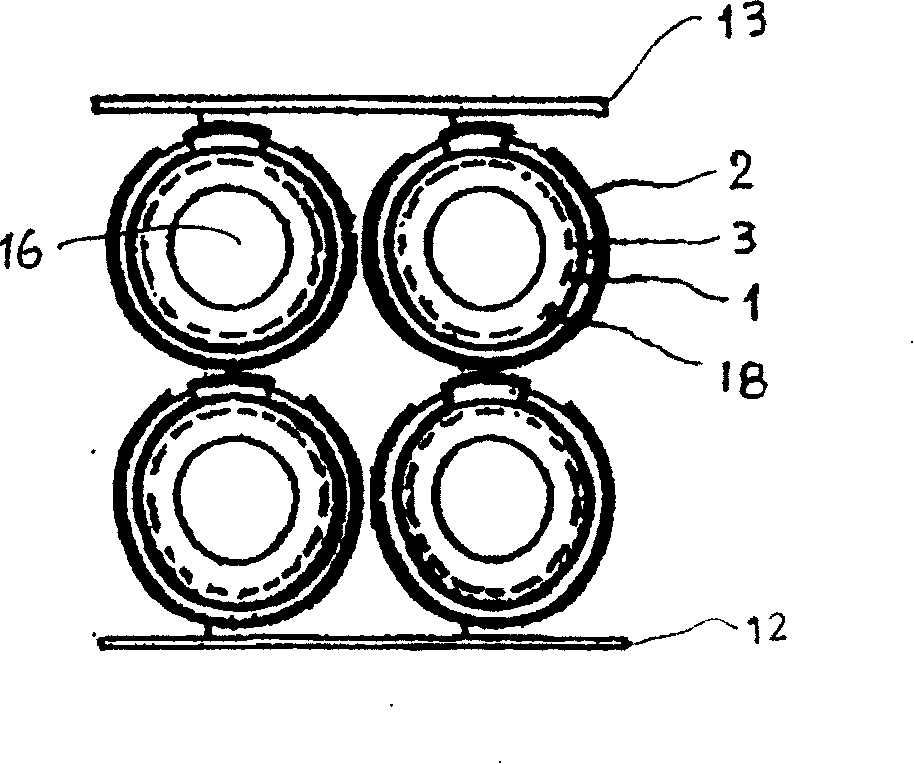

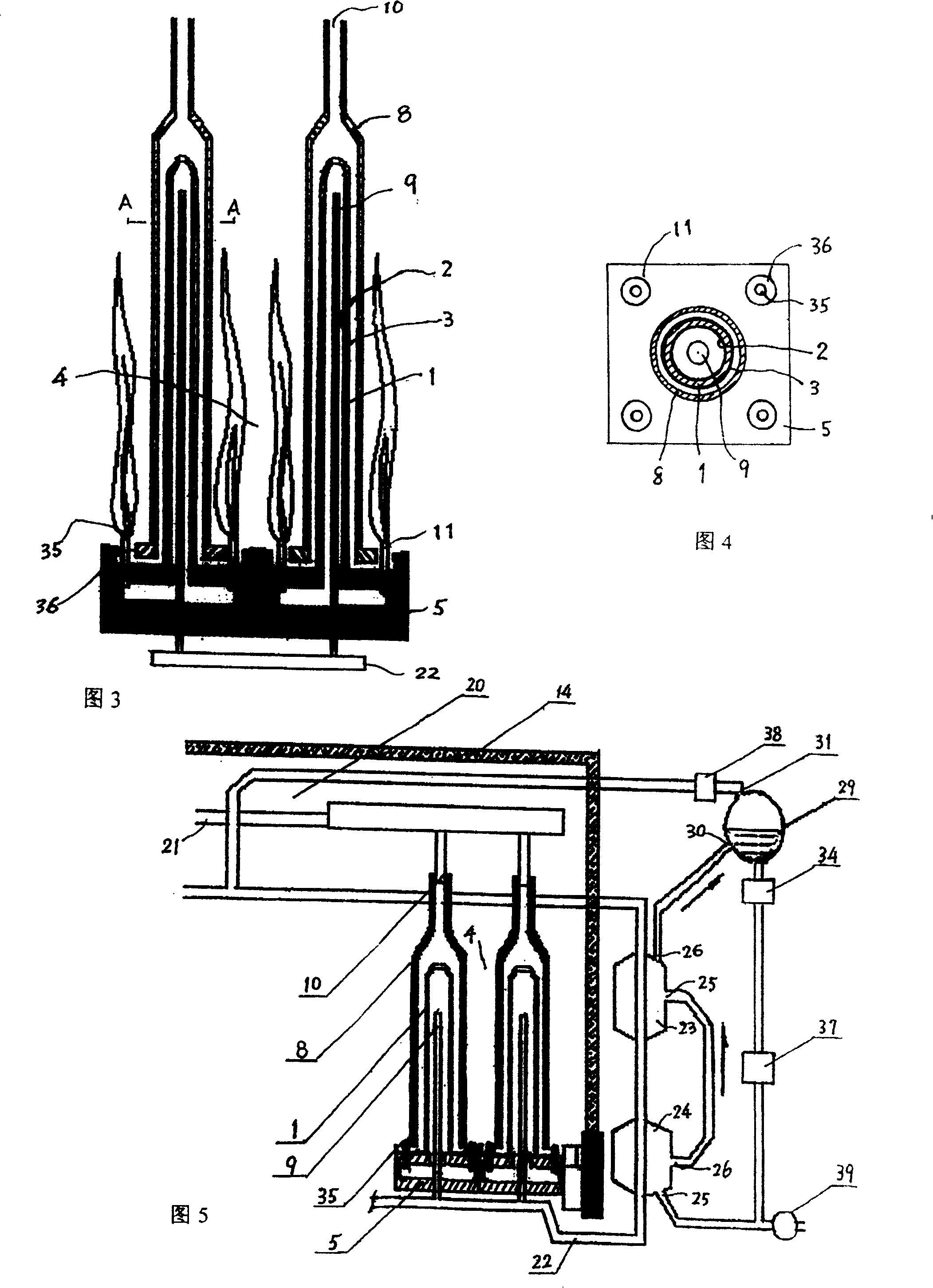

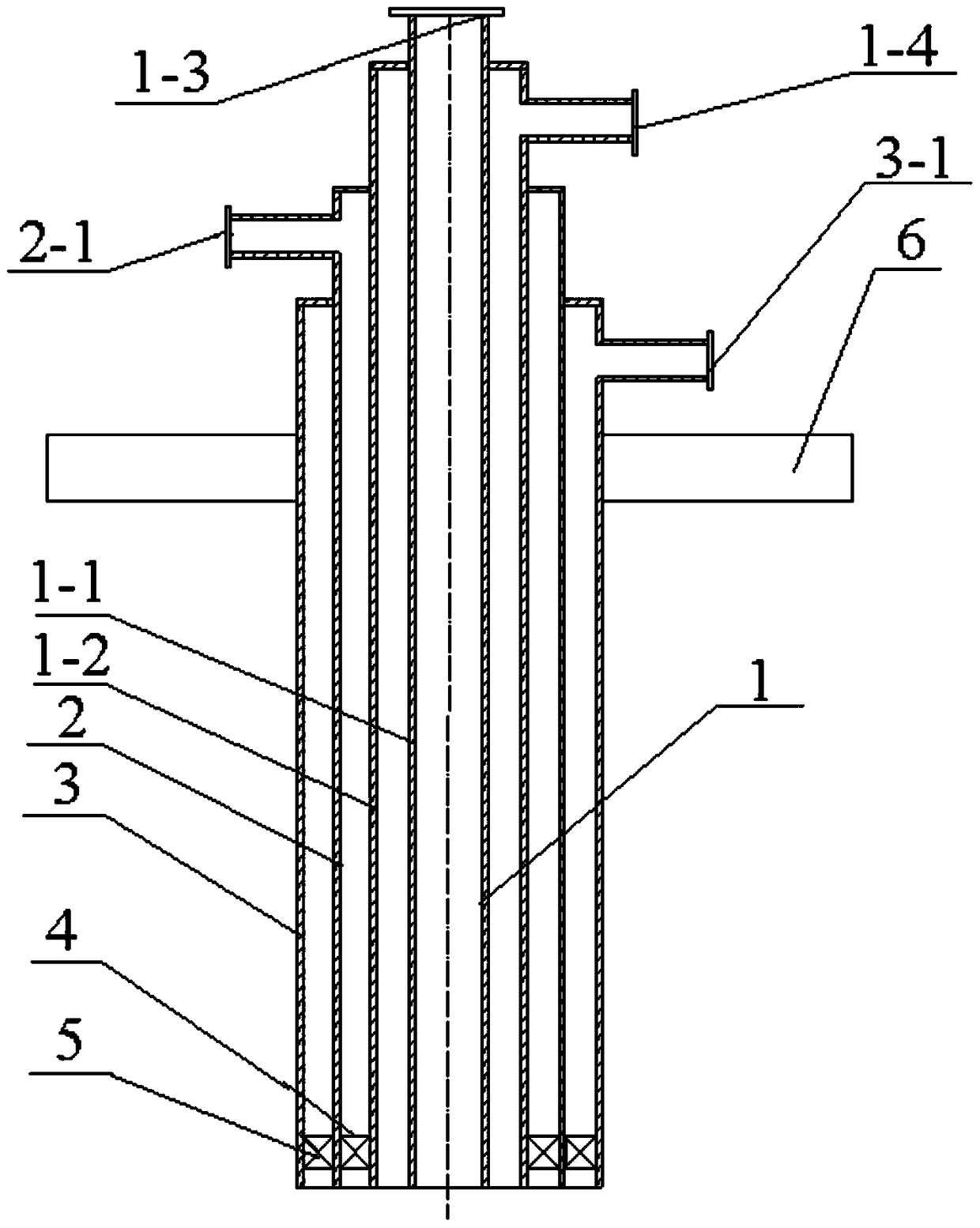

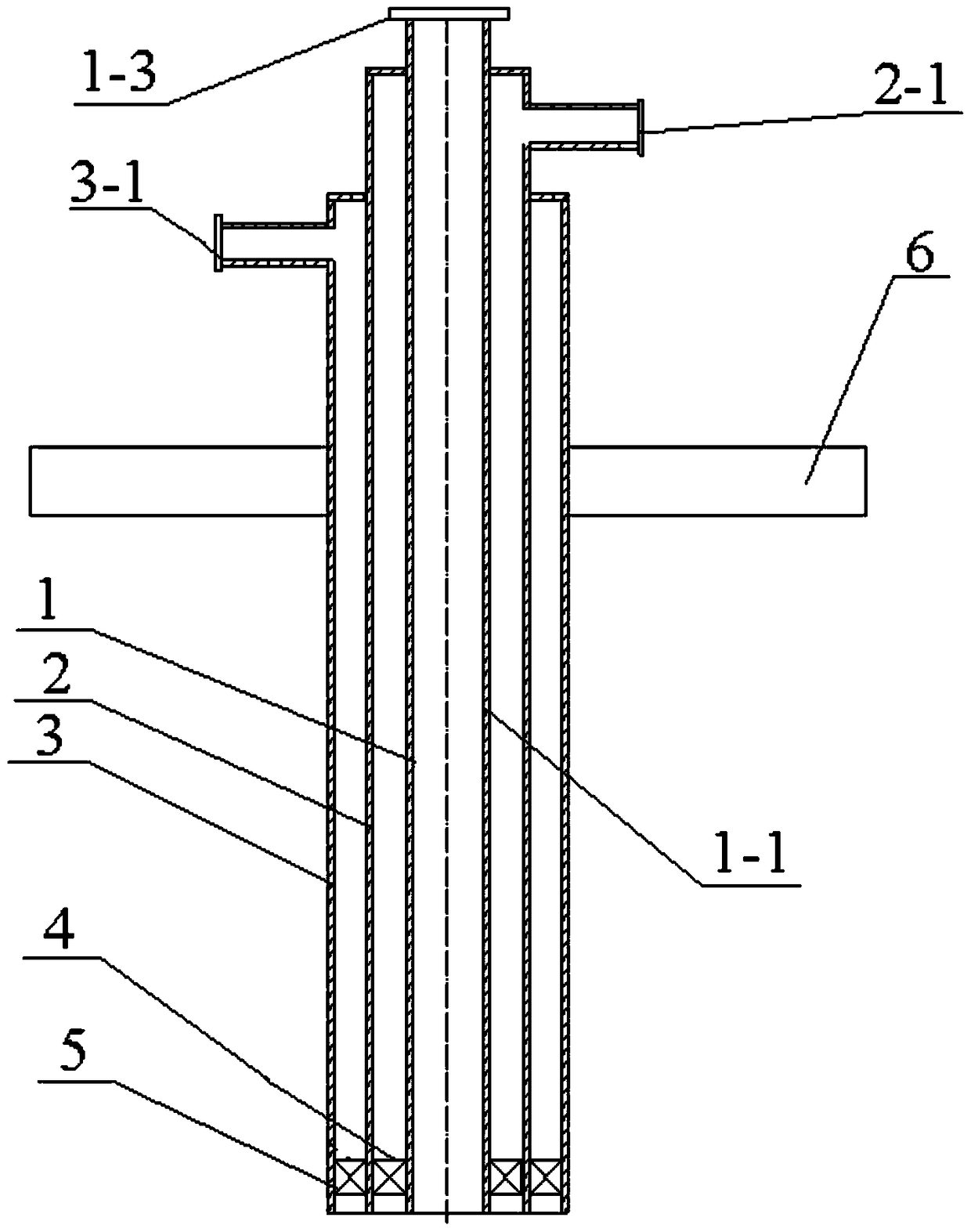

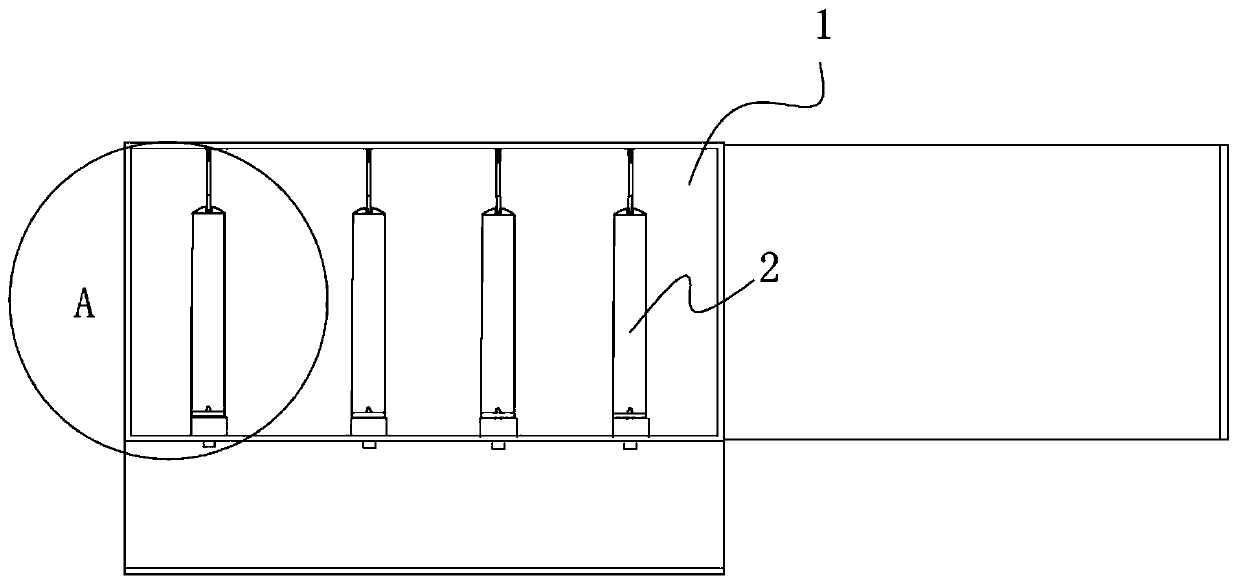

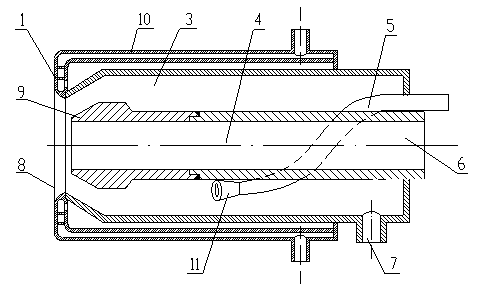

Module type tubular solid oxide fuel cell power generating system

InactiveCN1674344AImprove stabilityImprove battery performanceSolid electrolyte fuel cellsTubular solid oxide fuel cellAutomotive engineering

The present invention relates to a modular tubular solid oxide fuel cell power generation system, belonging to a power generation equipment. Said invention is formed from the following components: single-cell, combustion chamber, base seat, oxidant (air) input tube and fuel input tube. Said invention also provides the concrete structure of the above-mentioned every component. Said invented structure also includes an indirect internal reforming system, so that it can fully utilize hydrogen gas component of fuel, and can raise stability and performance of cell work.

Owner:JILIN UNIV

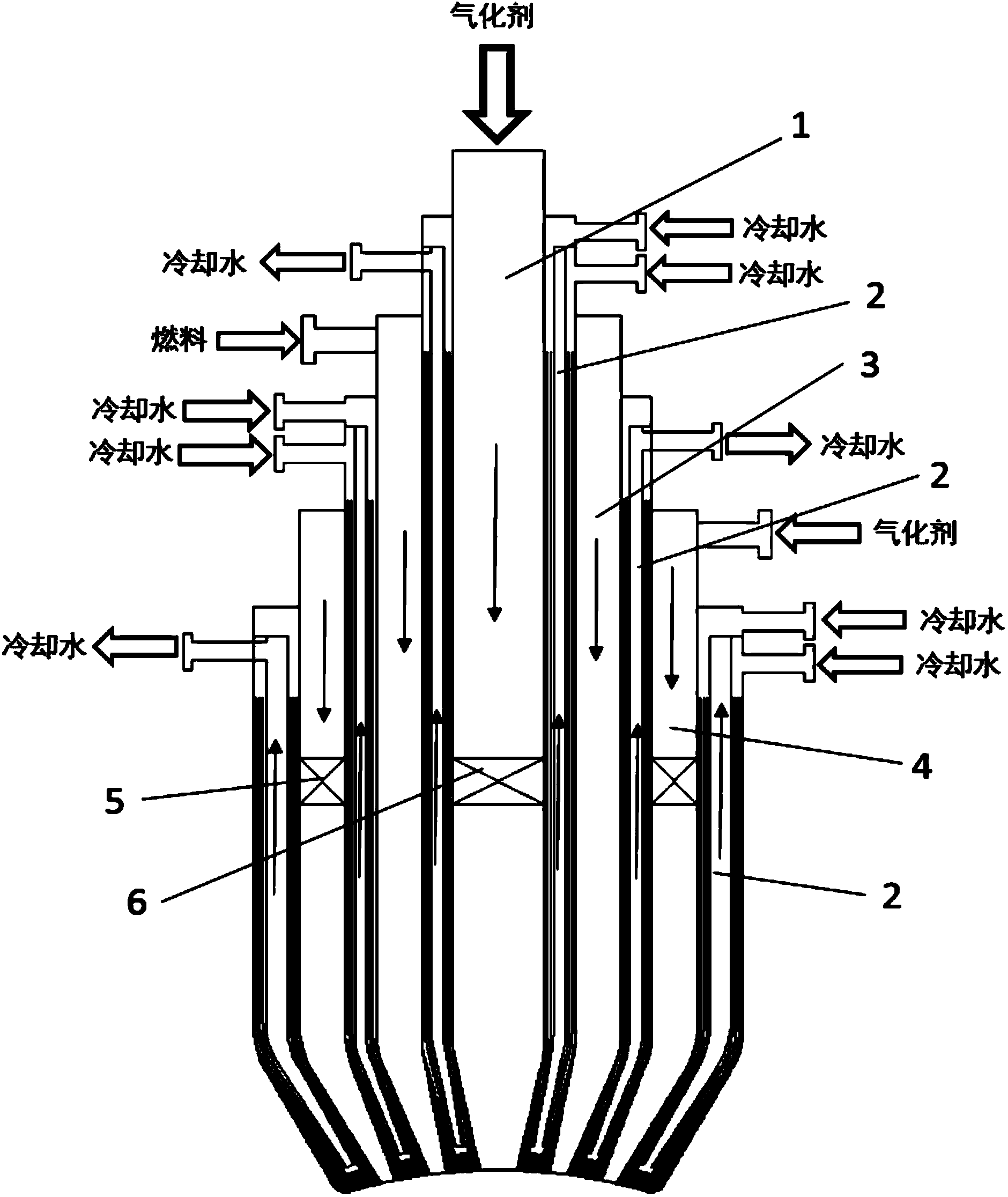

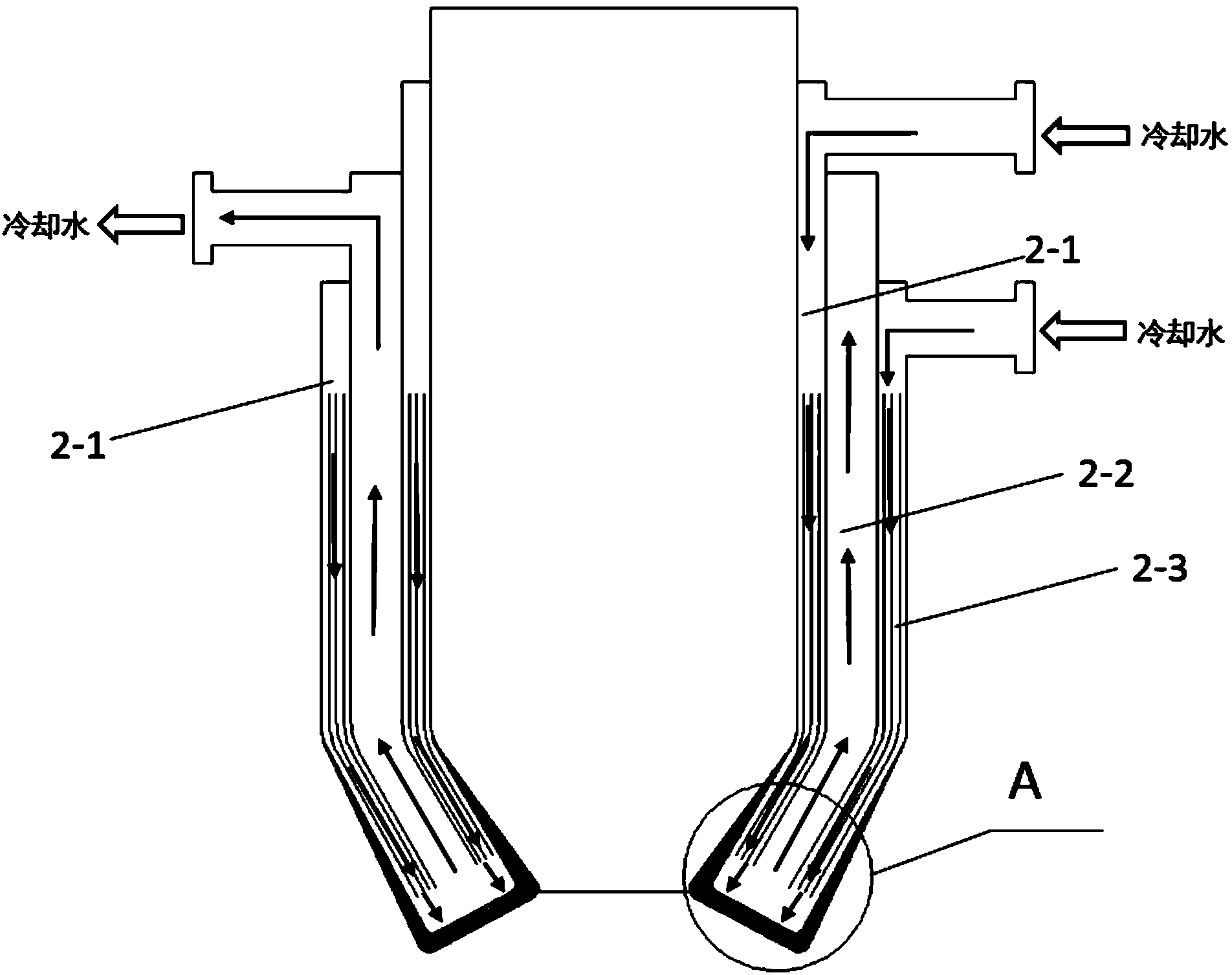

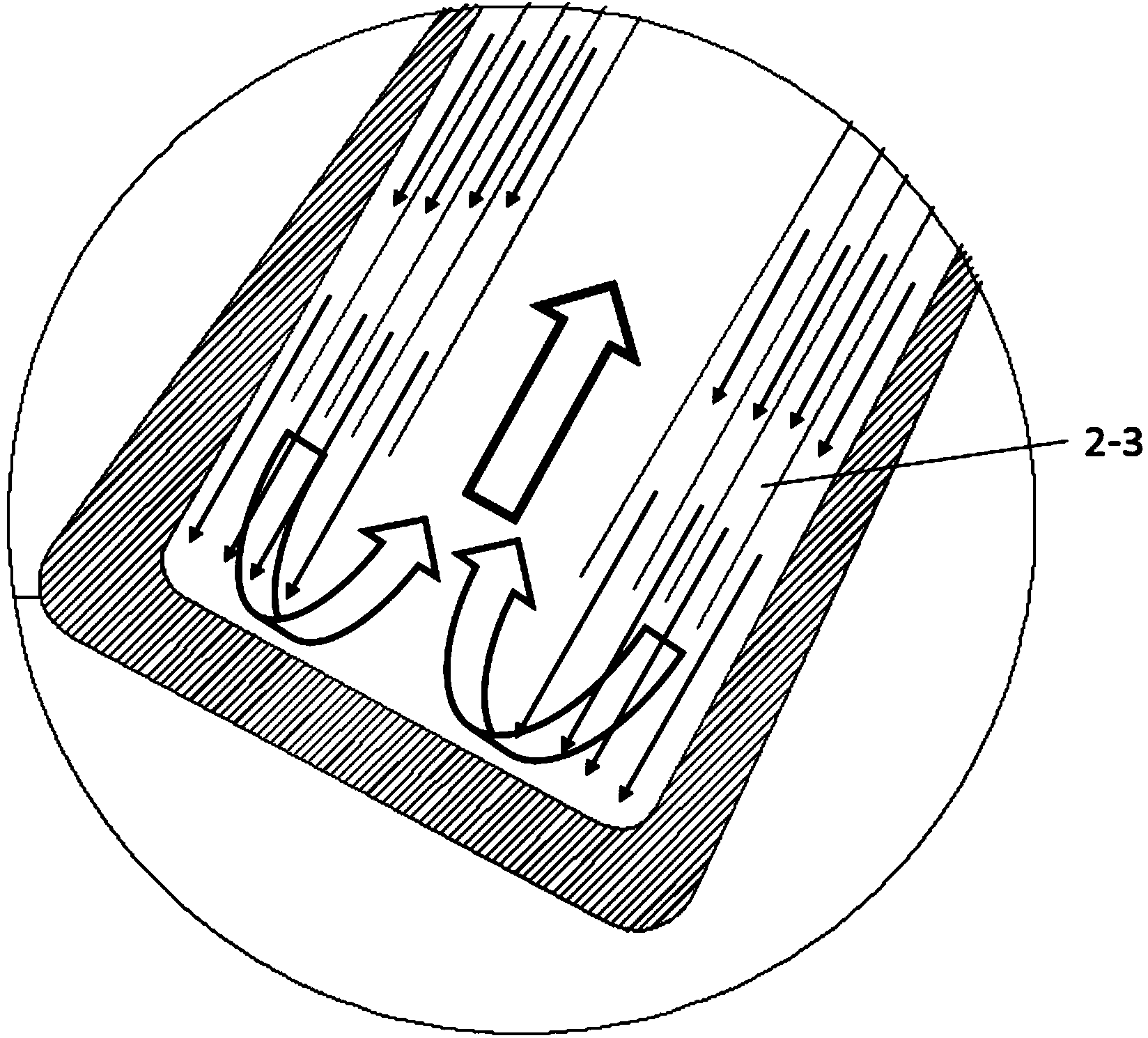

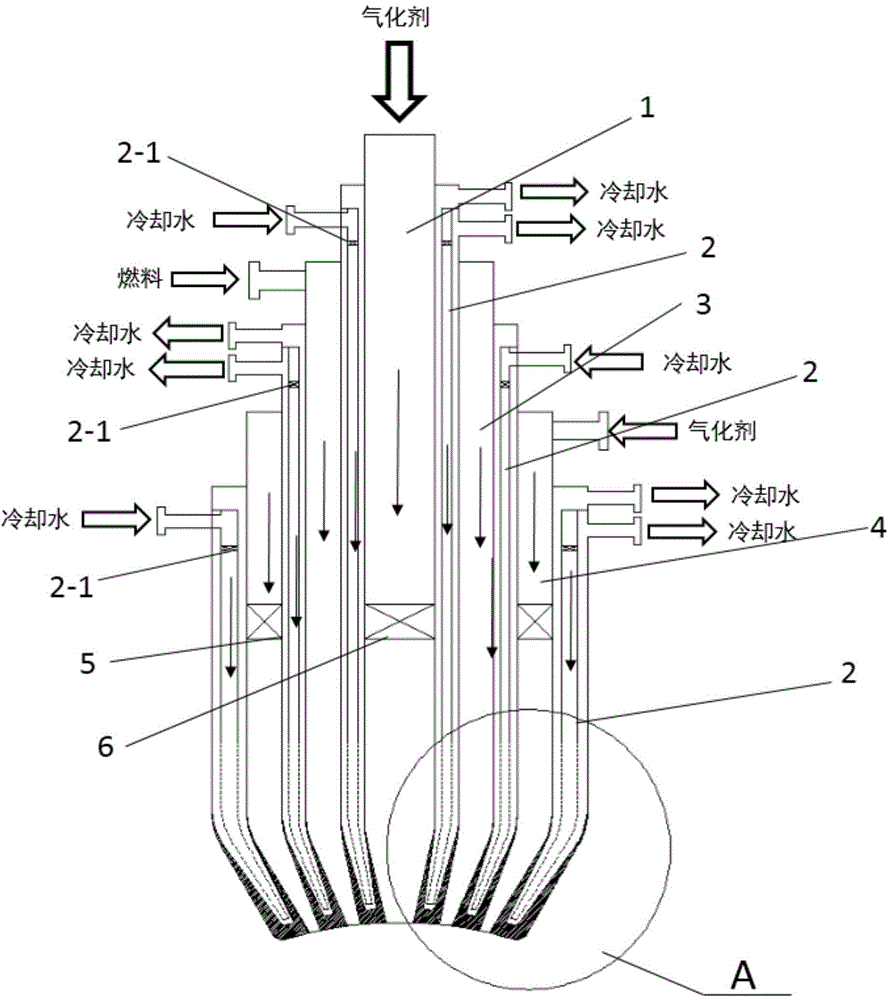

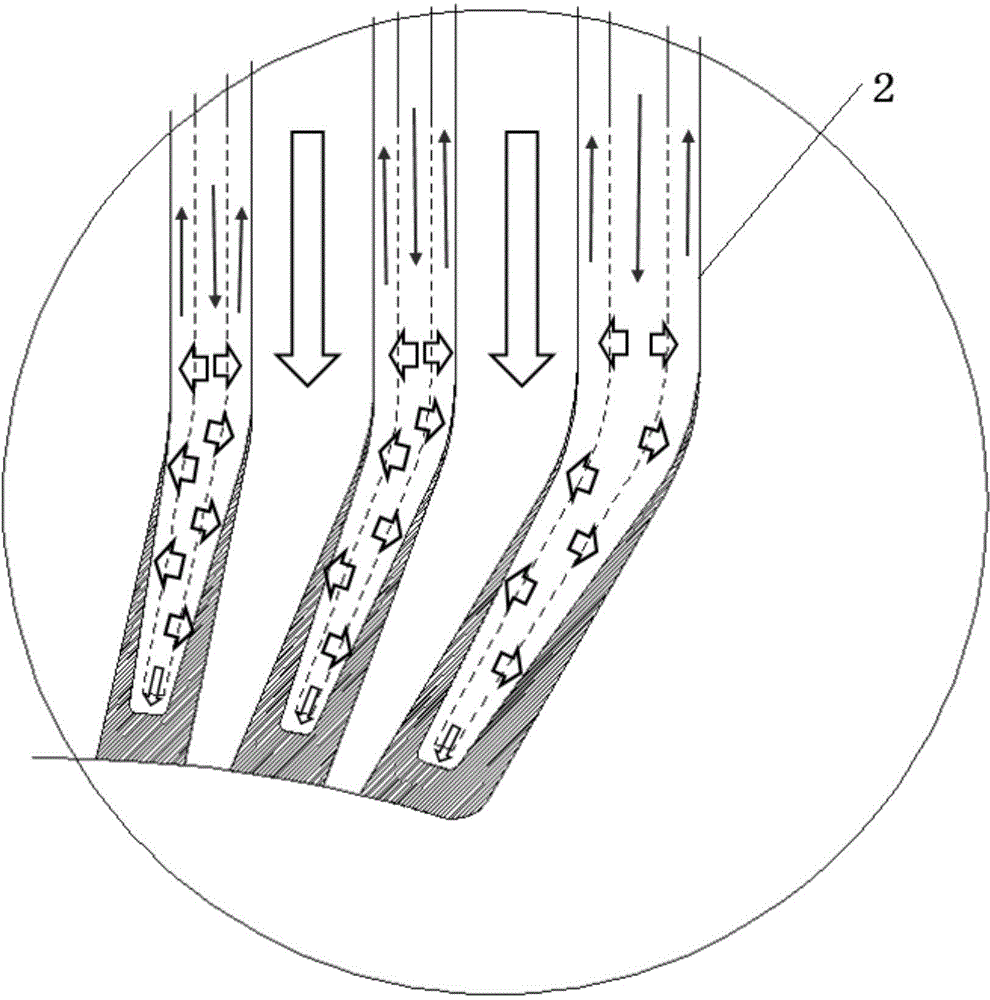

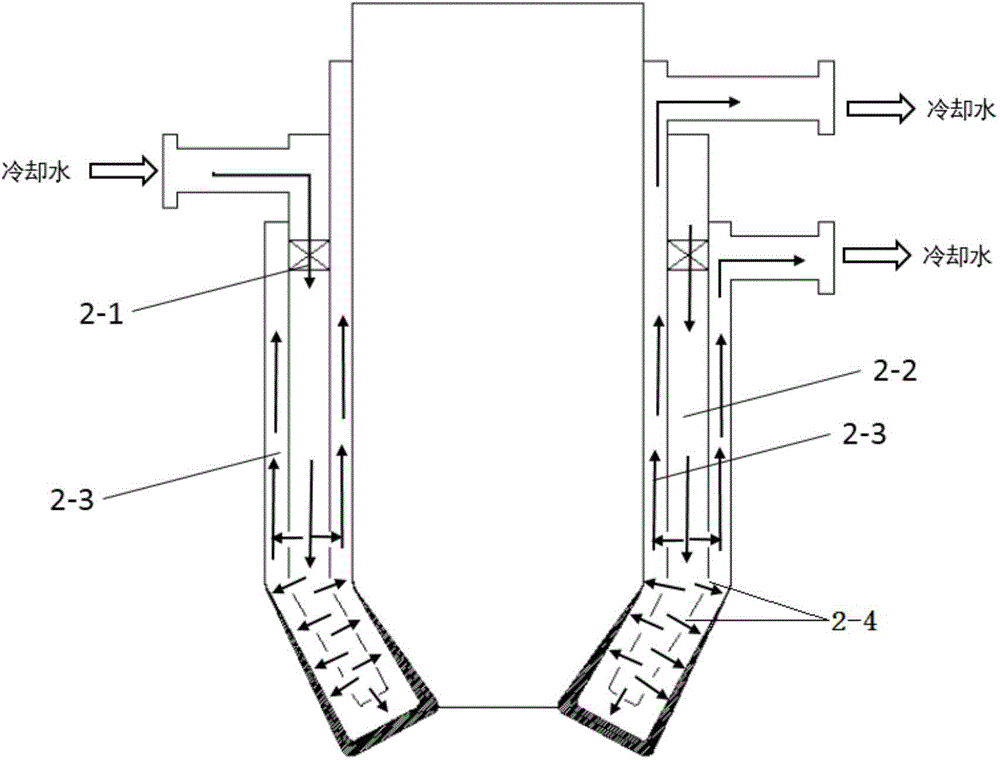

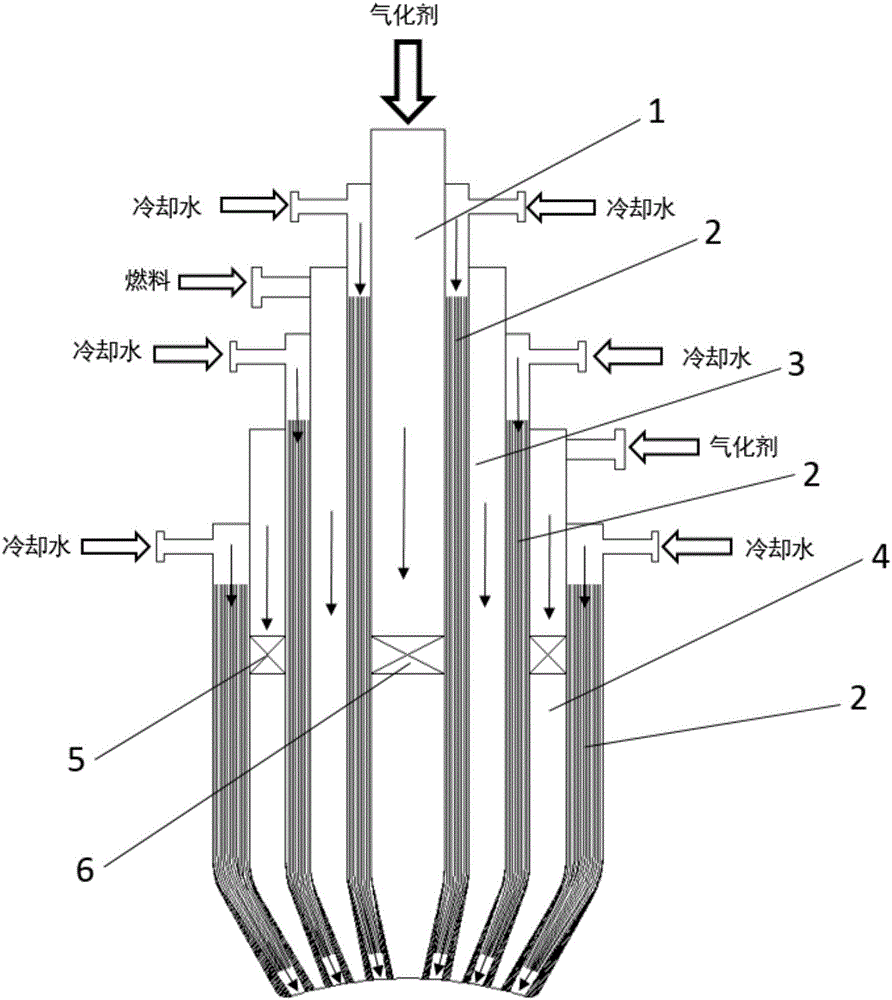

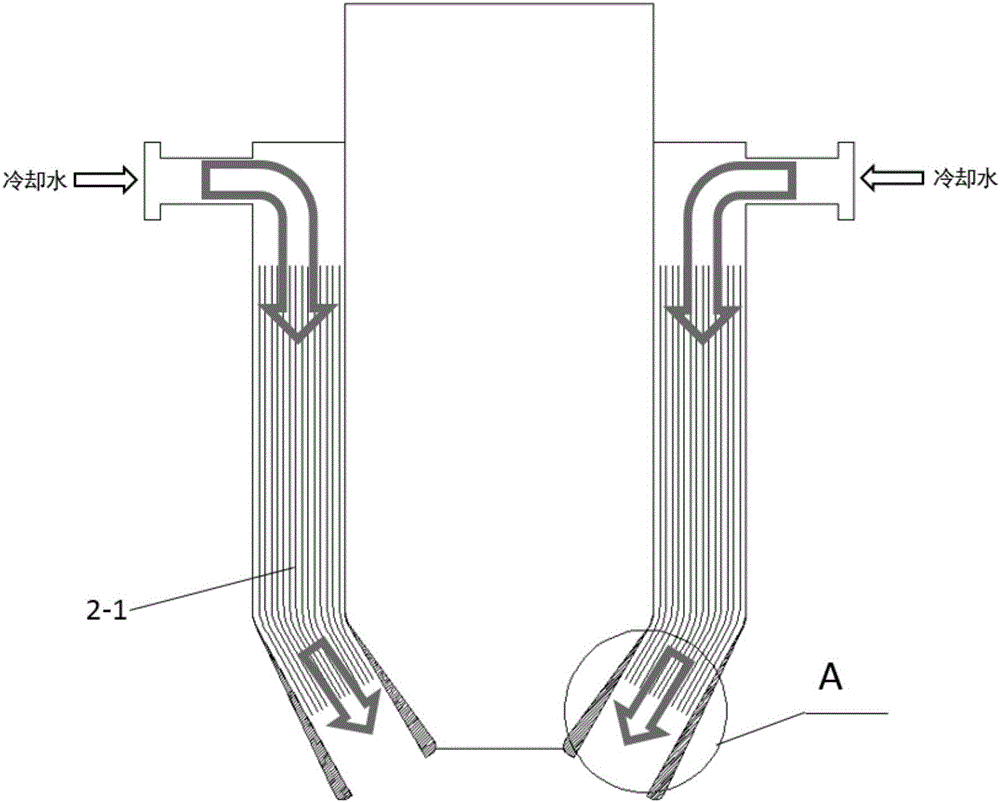

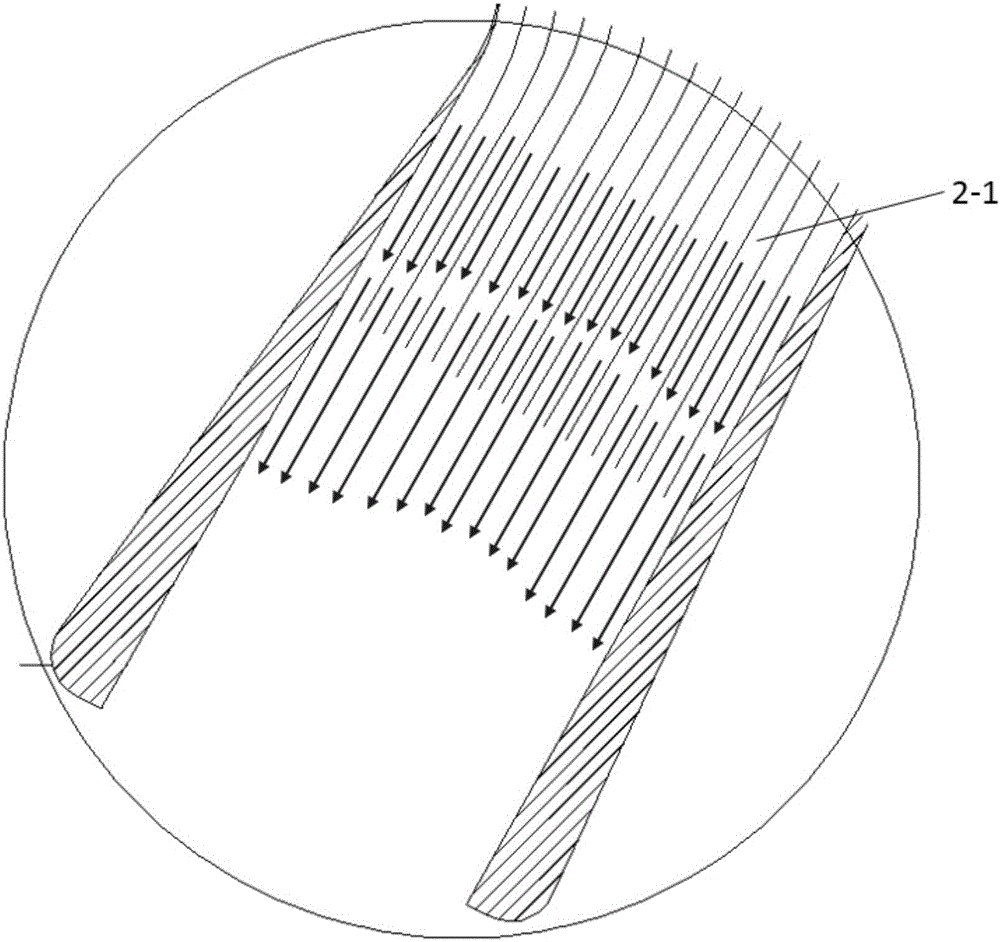

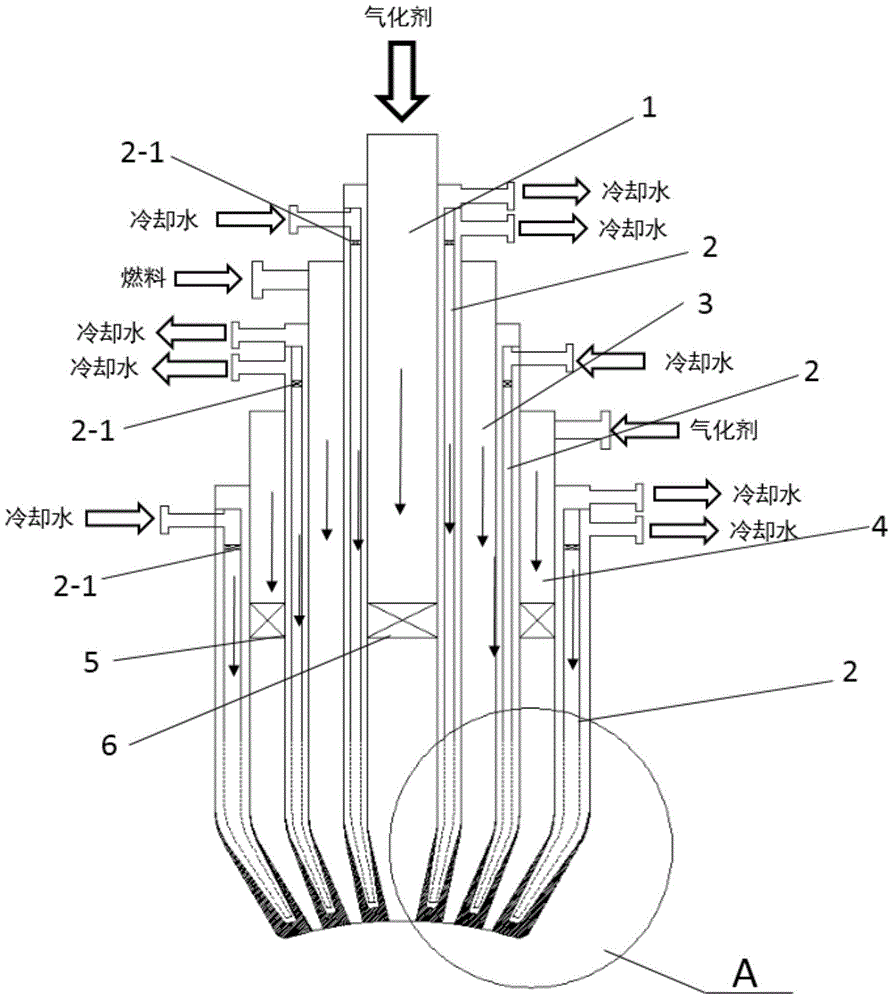

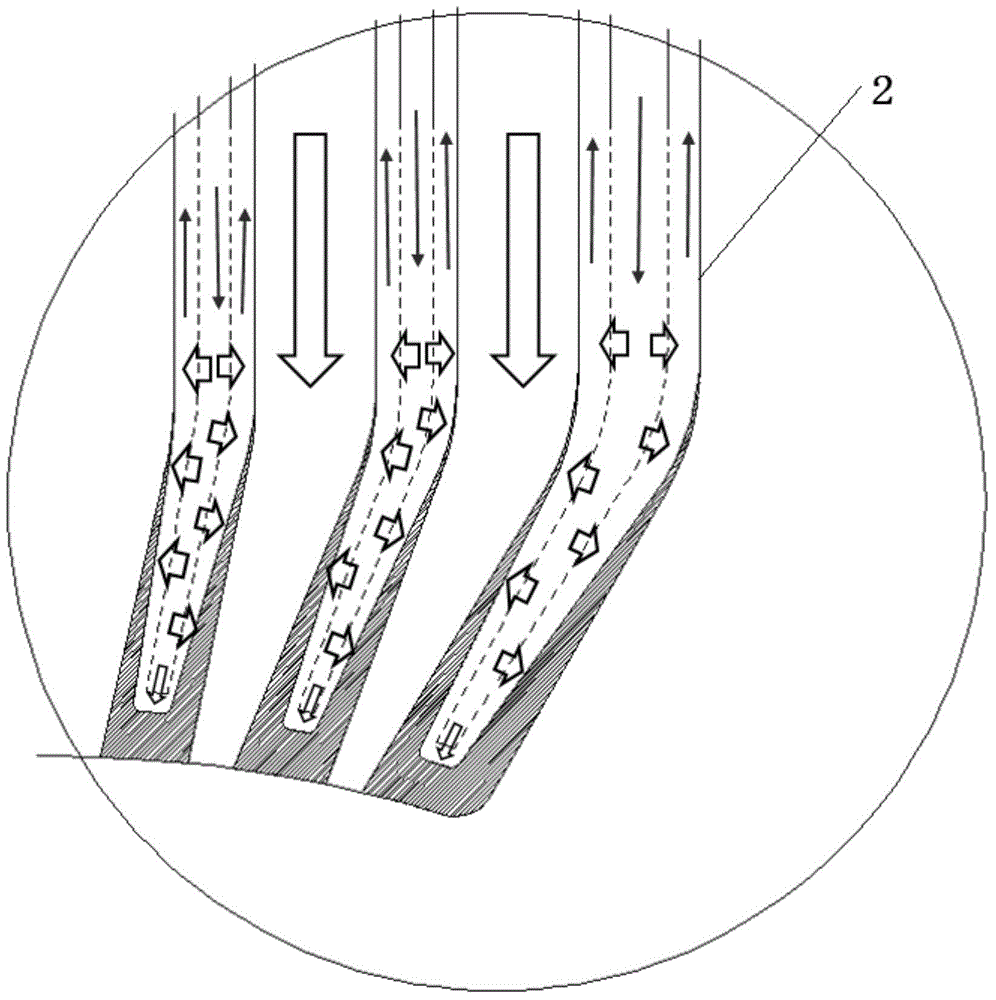

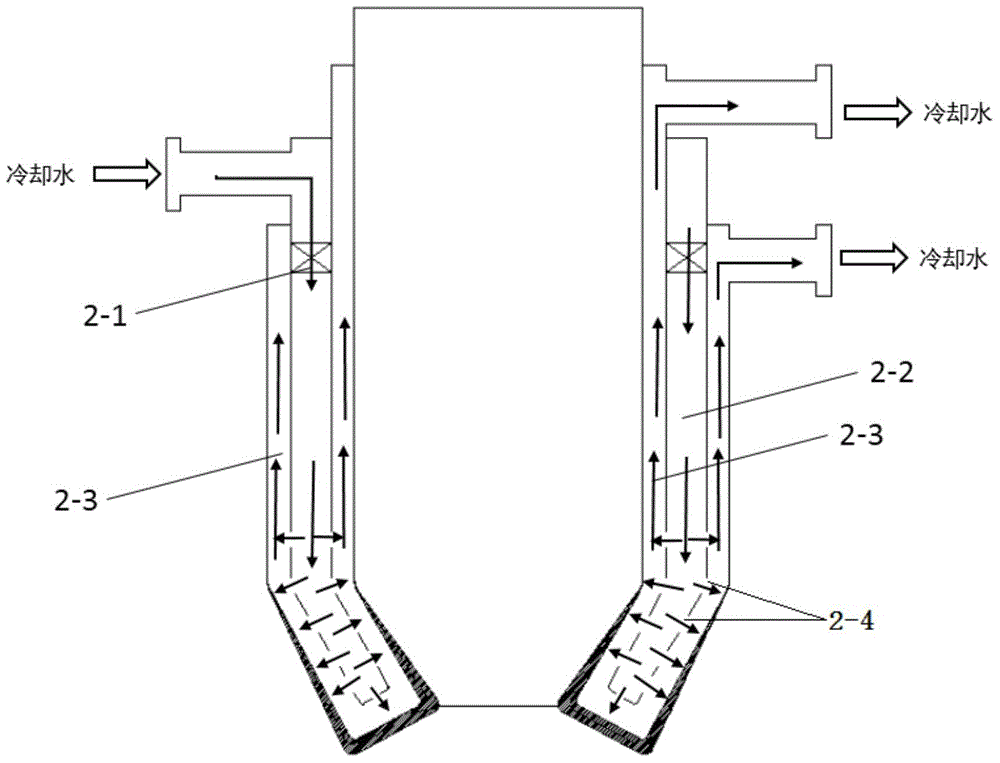

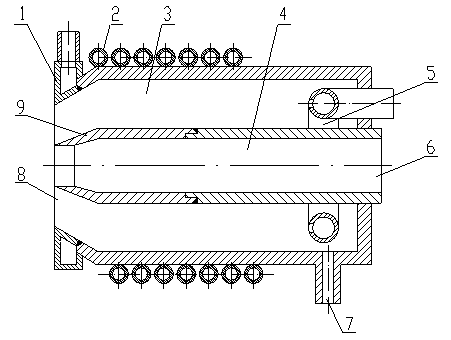

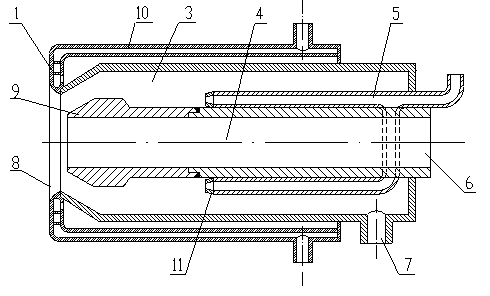

Novel micro-channel circularly cooling gasification process nozzle

ActiveCN103881760AGuaranteed uptimeExtended service lifeGranular/pulverulent flues gasificationWater channelWater flow

The invention provides a novel micro-channel circularly cooling gasification process nozzle. The nozzle comprises a center gasifying agent channel, a fuel channel, an outer gasifying agent channel and cooling water channels which are distributed between the center gasifying agent channel and the fuel channel, between the fuel channel and the outer gasifying agent channel and outside the gasifying agent channel, wherein the fuel channel and the outer gasifying agent are coaxial with and sequentially sleeved on the center gasifying agent channel; the water intake channels of the cooling water channels are composed of a plurality of micro-channels; the flowing speed of high-pressure cooling water increases in the micro-channels, and the center gasifying agent channel, the fuel channel, the outer gasifying agent channel and metal wall surfaces of the cooling water channels are efficiently cooled in heat conduction and forced-convection heat transfer modes; cooling water is sprayed from the micro-channel outlets in a high-speed jet manner, and the bottom metal wall surfaces of the cooling water channels are effectively cooled in a forced impact jet convection heat transfer manner, and then the cooling water flows back to the water outlets of the cooling water channels from a return channel. The novel micro-channel circularly cooling gasification process nozzle can be used for overcoming the defect of the gasified nozzle technology in the prior artthe nozzle is poor in cooling effect and has a short service life.

Owner:XI AN JIAOTONG UNIV

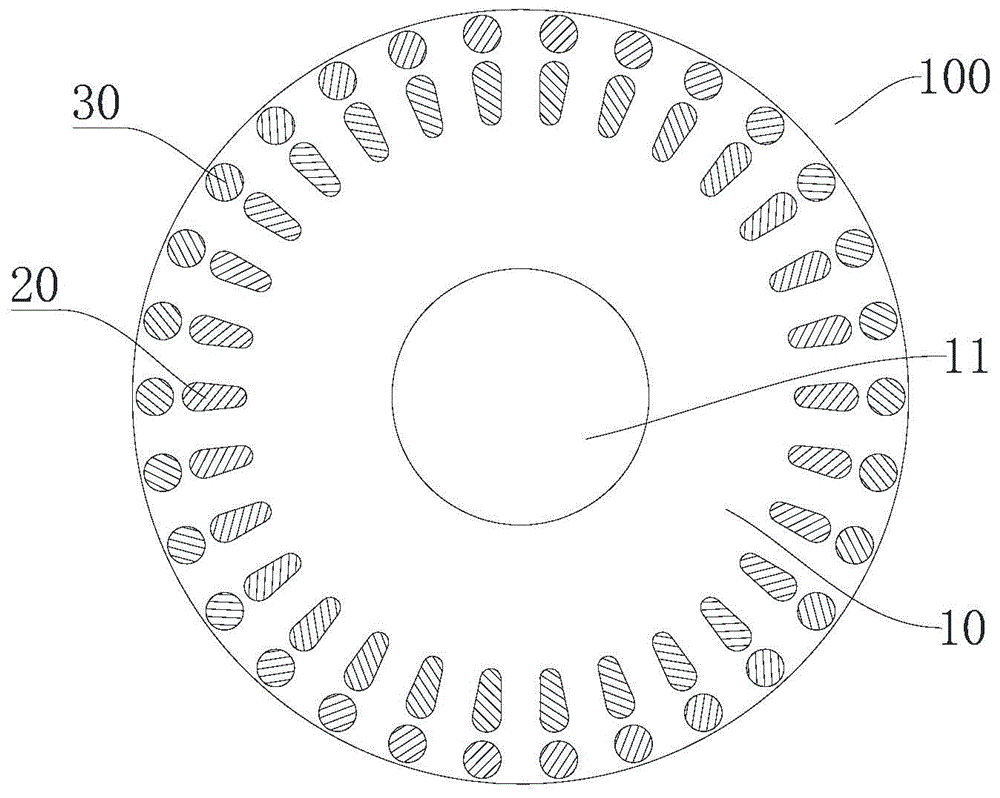

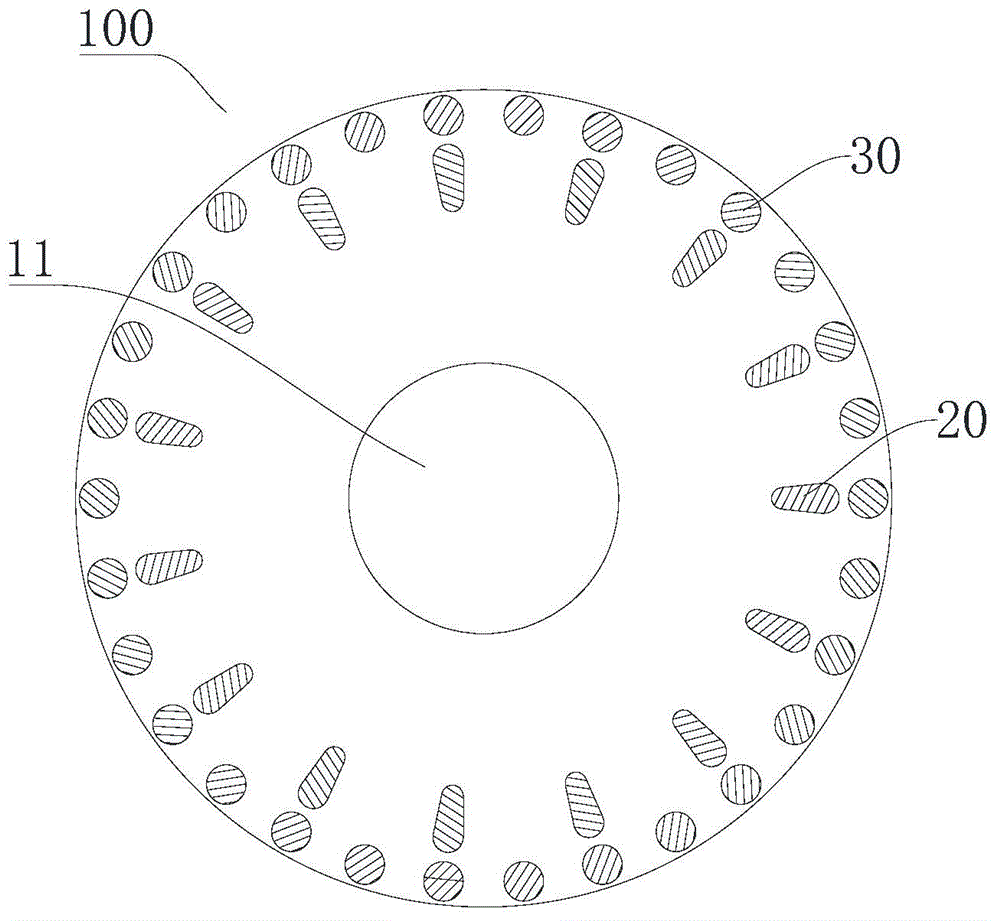

Motor rotor

InactiveCN104600932AImprove boot performanceImprove operational efficiencyMagnetic circuit rotating partsAsynchronous induction motorsEngineeringForming processes

The invention discloses a motor rotor. The motor rotor comprises a rotor core in which an axle hole is arranged, wherein the periphery of the axle hole is provided with multiple inner rotor slots and multiple outer rotor slots all which are spaced along the radial direction of the rotor core and along the circumferential direction of the rotor core, and each inner rotor slot is arranged inside the outer rotor slot along the radial direction of the rotor core; the motor rotor further comprises multiple inner conductive strips, multiple outer conductive strips and an end short-connection ring; said multiple inner conductive strips are respectively inserted in said multiple rotor slots, said multiple outer conductive strips are respectively inserted in said multiple outer rotor slots, and the electrical conductivity of each outer conductive strip is different from that of the inner conductive strip; the end short-connection ring is arranged on both ends of the rotor core, and said inner conductive strips and said outer conductive strips are respectively connected through the end short-connection ring. According to the motor rotor, the motor is better in start ability, and higher in operation efficiency, meanwhile high-temperature oxidation can be effectively avoided in a formation process, and the process can be simply and conveniently realized.

Owner:GUANGDONG MEIZHI COMPRESSOR

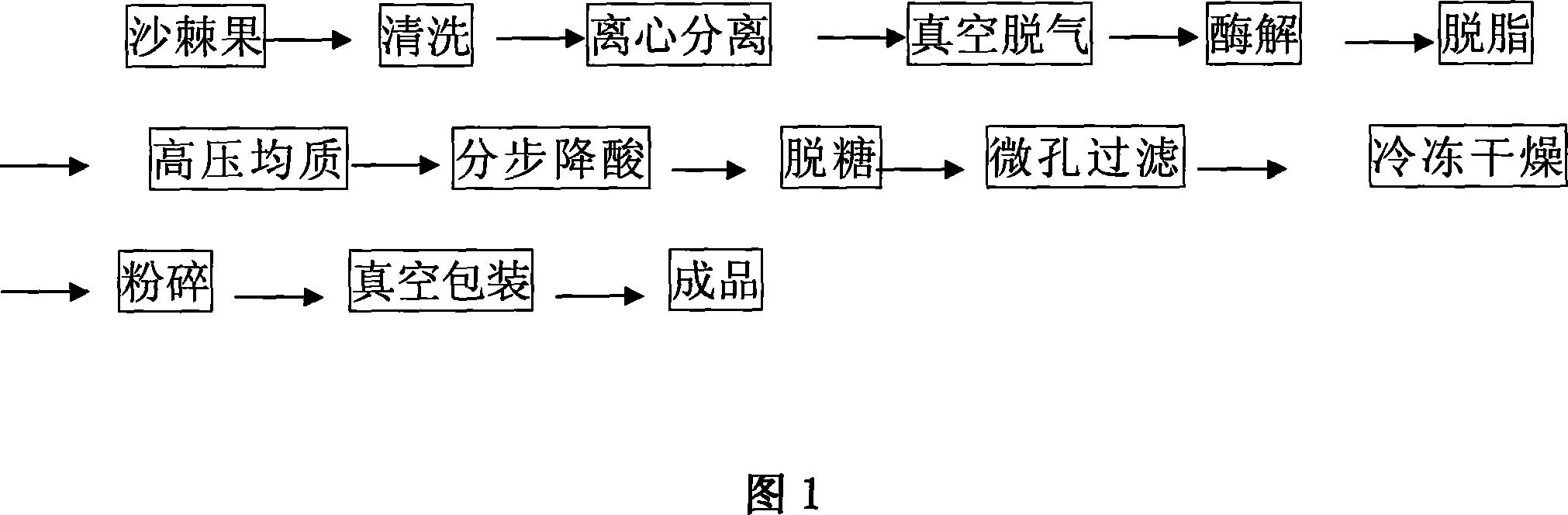

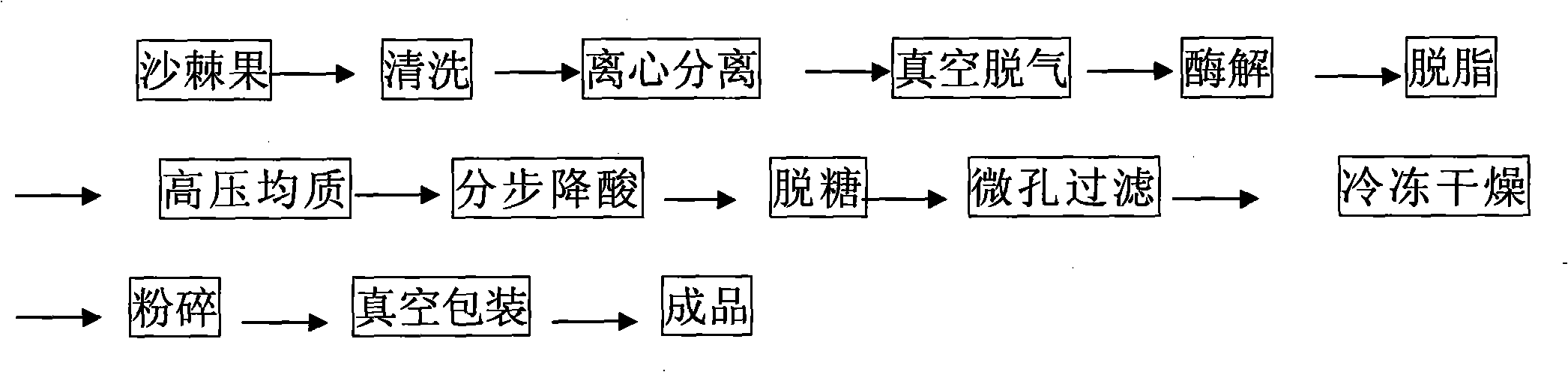

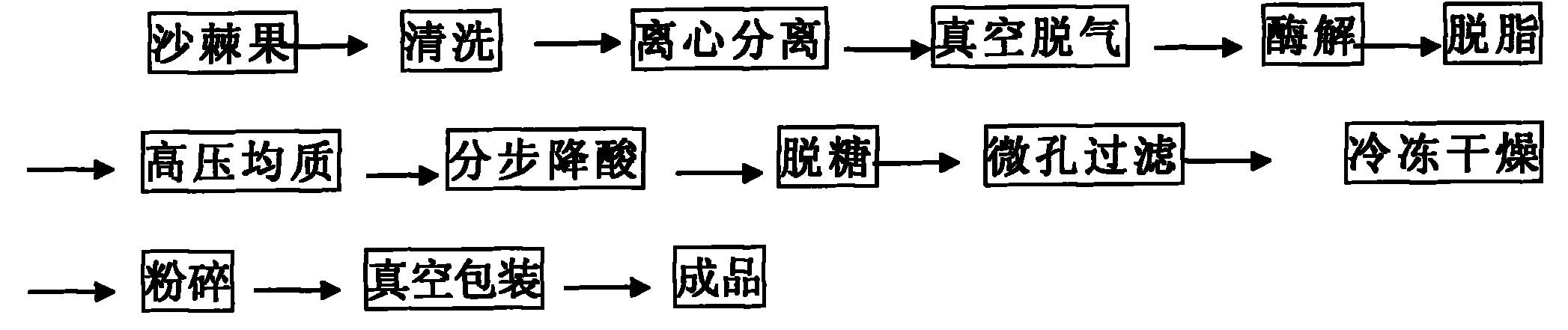

Method for preparing mixture containing natural vitamin P from sea-buckthorn

InactiveCN101084943ASolve high temperature oxidationSolve browningOrganic active ingredientsMetabolism disorderVitamin CFreeze-drying

The invention relates to a method for preparing mixture containing vitamin P from sea buckthorn, and is for the prupose of providing a method for preparing a mixture containing 0.5-50% of vitamin P and 2-30% of vitamin C through extracting juice, degassing, enzyme-hydrolyzing, degreasing, homogenize, reducing acid, desugarizing, millipore filtering, freeze drying and pulverizing. The method is simple; solve the problem of brown stain of highly active substance in sea buckthorn due to high temperature oxidation by adopting biologic-physical method at low temperature, has no requirement of any solvent, no residue, low cost, and high biologically active substance yield. Vitamin P and vitamin C is in coexistence in the product, which promotes absorption.

Owner:QINGHAI TSINGHUA BIOTRY BIO TECH

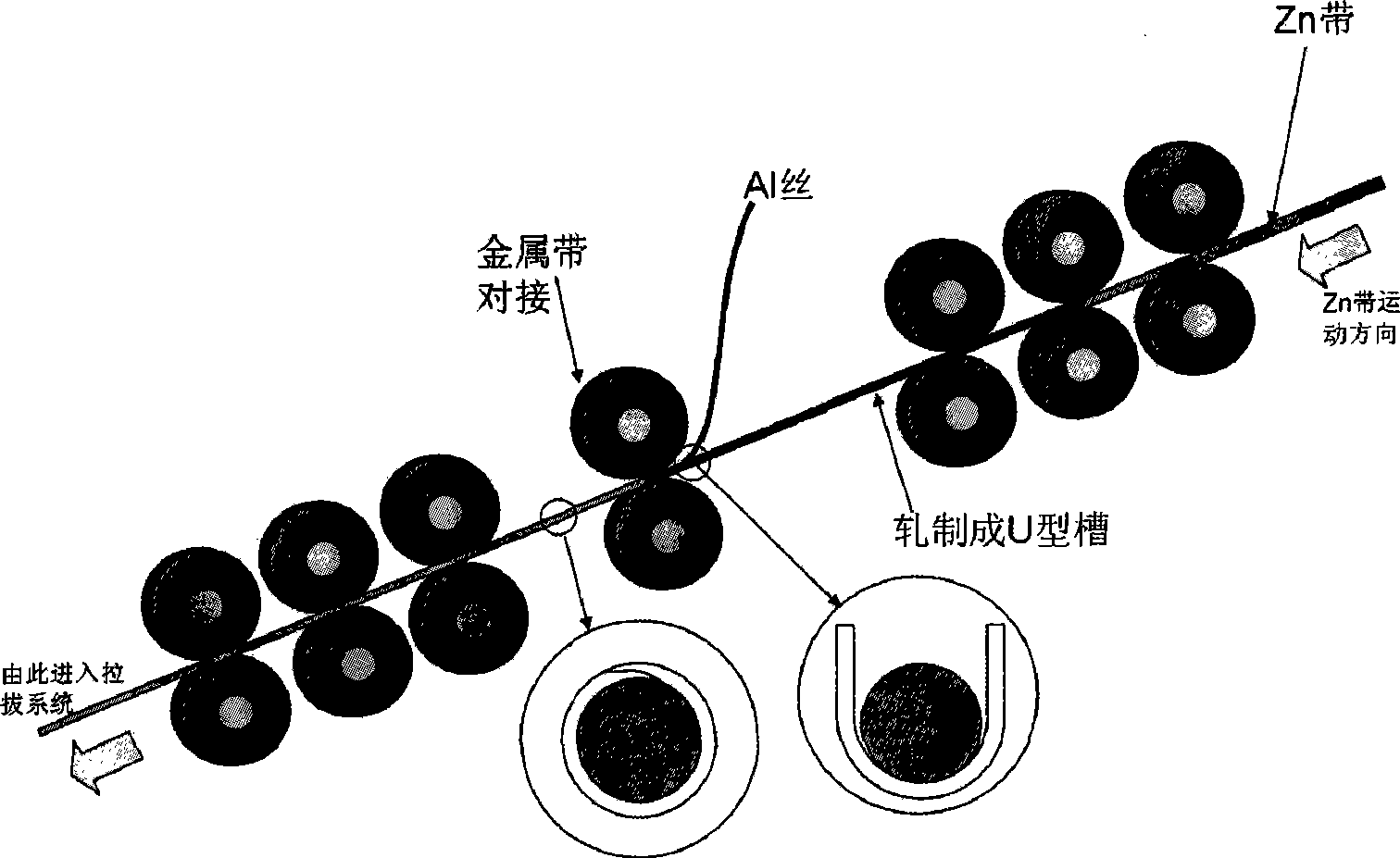

Method for producing Ni-Al bimetal composite material solid core wire material

InactiveCN101413096AEasy to prepareImprove production efficiencyMolten spray coatingThermal sprayingSteel frame

The invention relates to a method for preparing a solid core wire material of a Ni-Al bimetal composite material and belongs to the field of hot spraying in the material processing project; and the method is used for spraying and priming. The finished product is mainly applied to anticorrosion, wearing resistance and the like of pipe wall and four pipelines of a boiler in a power plant. The method can improve the spraying quality of other spraying coats for protection and the application effect of the coats. The preparation method is applied to prepare the wire material and has simple technical process and high production efficiency; and the prepared solid core wire material has excellent quality and good spraying effect. The invention is the method for preparing the solid core wire material of the Ni-Al bimetal composite material and is characterized in that the powdery core comprises the following compositions in mass percentage: 5 to 20 percent of Al and the balance being Ni. The prepared material is mainly applied to an anticorrosive material of the pipeline maintenance of the boiler in a thermal power generating field, ship manufacturing, ocean engineering and other large-scale steel-frame structures.

Owner:北京赛亿表面工程技术有限公司

System for testing high-temperature spectral emissivity of materials based on effective radiation

ActiveCN103196840ASolve high temperature oxidationReduce the cross-sectional areaColor/spectral properties measurementsEmissivityTest sample

The invention relates to the technical field of thermophysical parameter test on materials, and particularly relates to a system for testing the high-temperature spectral emissivity of materials based on effective radiation. The system comprises a water-cooling vacuum chamber, a vacuum radiation heating unit, an effective radiation cavity and a radiation measurement and calibration unit, the test on the spectral emissivity of materials is performed through the combination of the water-cooling vacuum chamber, the vacuum radiation heating unit, the effective radiation cavity and the radiation measurement and calibration unit, in the process of testing, a blackbody origin is not required to be referenced, and the temperature of materials is not required to be known precisely, thereby reducing the testing difficulty and improving the testing precision; and through placing test samples in the water-cooling vacuum chamber, the high-temperature oxidation problem of test samples is avoided.

Owner:TSINGHUA UNIV

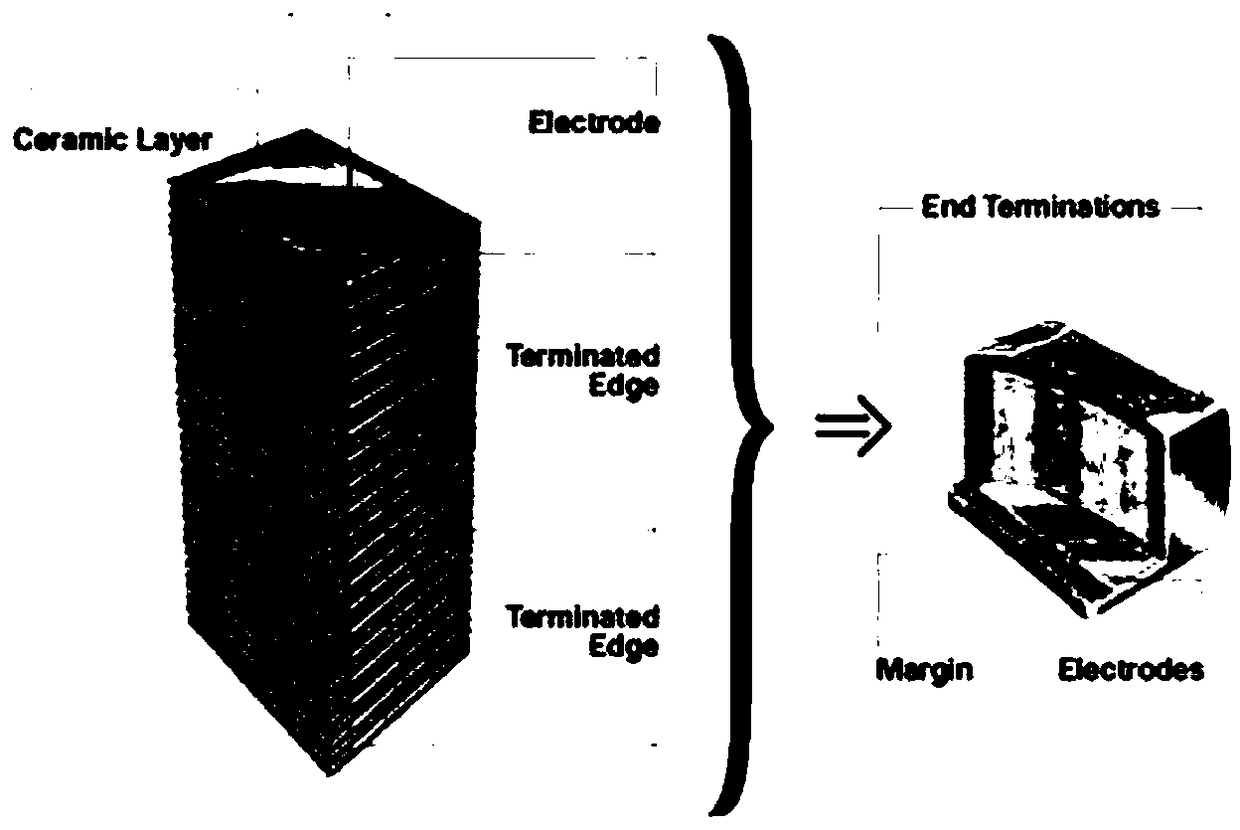

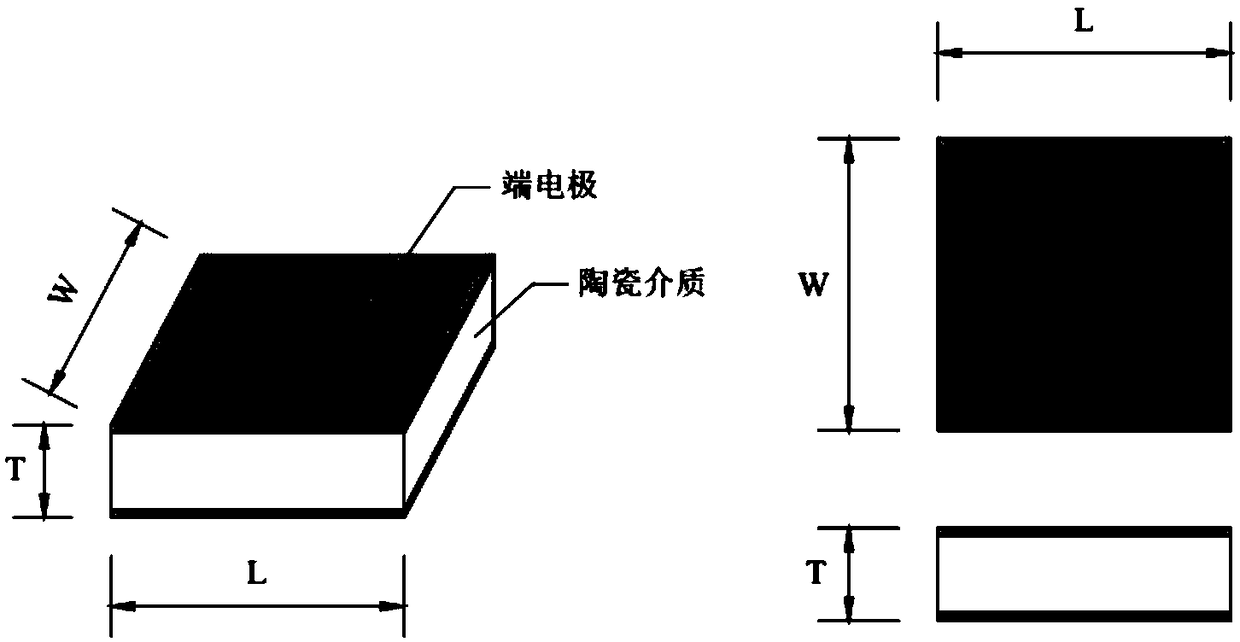

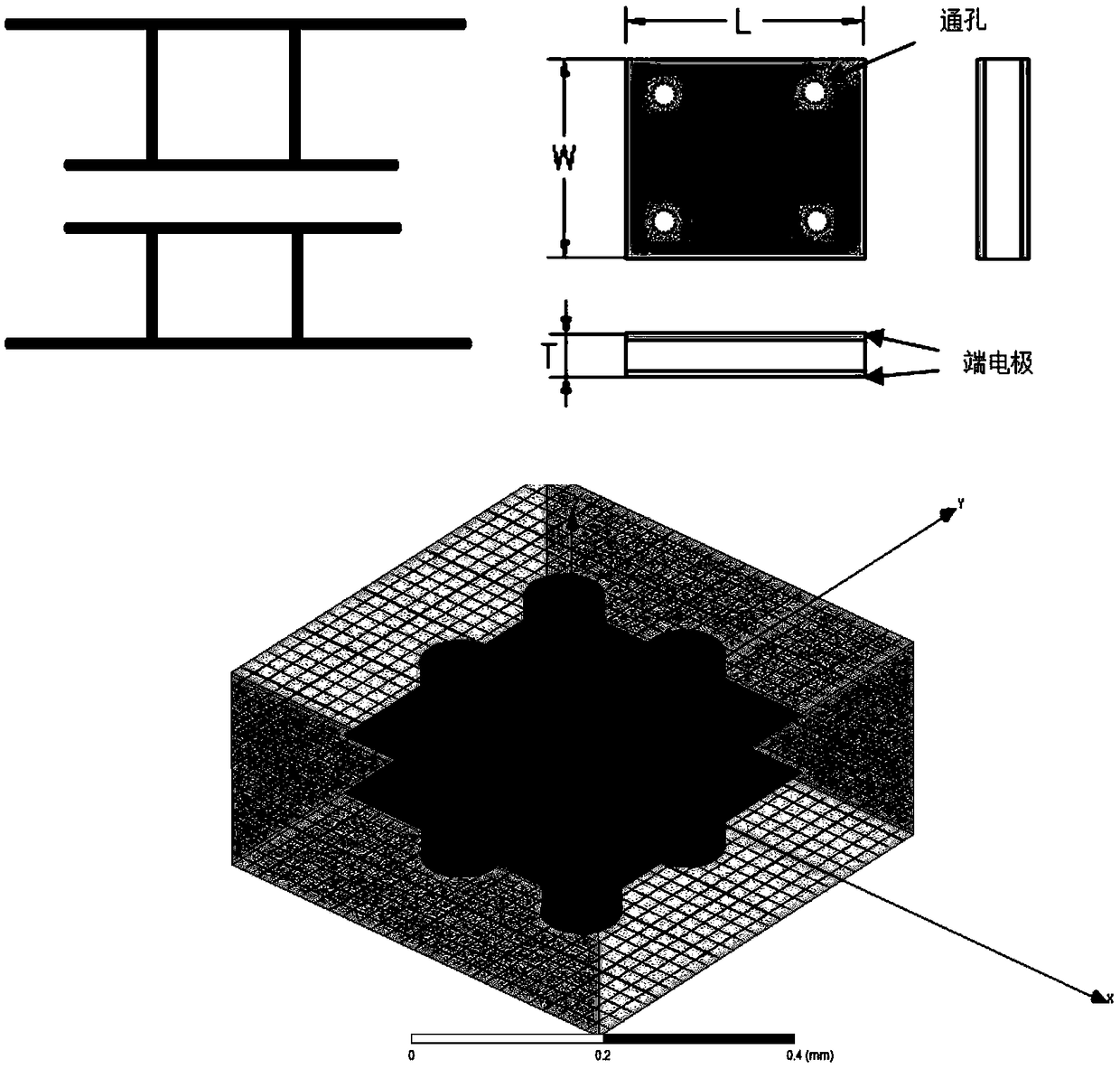

Chip-type through-hole gold electrode chip capacitor and preparation method thereof

InactiveCN108922779AAvoid interdiffusion problems that degrade performance metricsSmall sizeFixed capacitor dielectricStacked capacitorsMicron scaleAdhesive

The invention discloses a chip-type through-hole gold electrode chip capacitor and a preparation method thereof. The preparation method comprises the following steps of taking a low-sintered X7R ceramic material of a barium titanate system as a main base material, enabling an oxidant and a glass sintering aid to be grinded and mixed according to a proportion, and then drying the mixture to obtaina dry mixture; performing pre-burning on the dried mixture, and carrying out drying, crushing and refining to obtain multi-layer low-temperature sintered capacitor ceramic powder; enabling the multi-layer low-temperature sintered capacitor ceramic powder, absolute ethyl alcohol and a dispersing agent, a defoaming agent and an adhesive to be mixed and ball-milled to obtain slurry, enabling the slurry to be poured on a PET carrier film of an injection port of a casting machine, wherein a stable and tough micron-scale thickness ceramic membrane strip is formed after the mixture passes through a scraper and a heating region; and equivalently, a capacitive element which integrates the advantages of an MLCC and an SLC can be prepared by simulation design of the product structure parameters, development of the low-sintered ceramic dielectric material, application of filling hole gold slurry and inner electrode gold slurry, an end surface electrode forming mode and other process technologies.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

Novel jet impingement cooling gasification technology burner

ActiveCN103937553AGuaranteed uptimeExtended service lifeGranular/pulverulent flues gasificationJet flowInlet channel

The invention discloses a novel jet impingement cooling gasification technology burner. The novel jet impingement cooling gasification technology burner comprises a central gasifying agent channel, fuel channels, outer gasifying agent channels, and cooling water channels; the central gasifying agent channel is coaxially sieved by the fuel channels and the outer gasifying agent channels successively; the cooling water channels are arranged between the central gasifying agent channel and the fuel channels, between the fuel channels and the outer gasifying agent channels, and on the outsides of the outer gasifying agent channels; the cooling water channels are composed of water inlet channels and water return channels; cooling water uniform distribution devices are arranged in the water inlet channels; the water inlet channels and the water return channels are communicated via a plurality of circular holes which are closely arranged on the lower channel parts of the water inlet channels; high pressure cooling water is delivered into the water inlet channels, and then the walls of the water return channels are impinged by the high pressure cooling water through the plurality of circular holes which are closely arranged on the lower channel parts of the water inlet channels in a jet flow manner, so that high efficient cooling of the walls of the water return channels is realized; and then the high pressure cooling water is delivered to water outlets of the cooling water channels via the water return channels. The novel jet impingement cooling gasification technology burner is capable of solving problems of existing gasification technology burners that cooling effect is poor, and service life is relatively short.

Owner:XI AN JIAOTONG UNIV

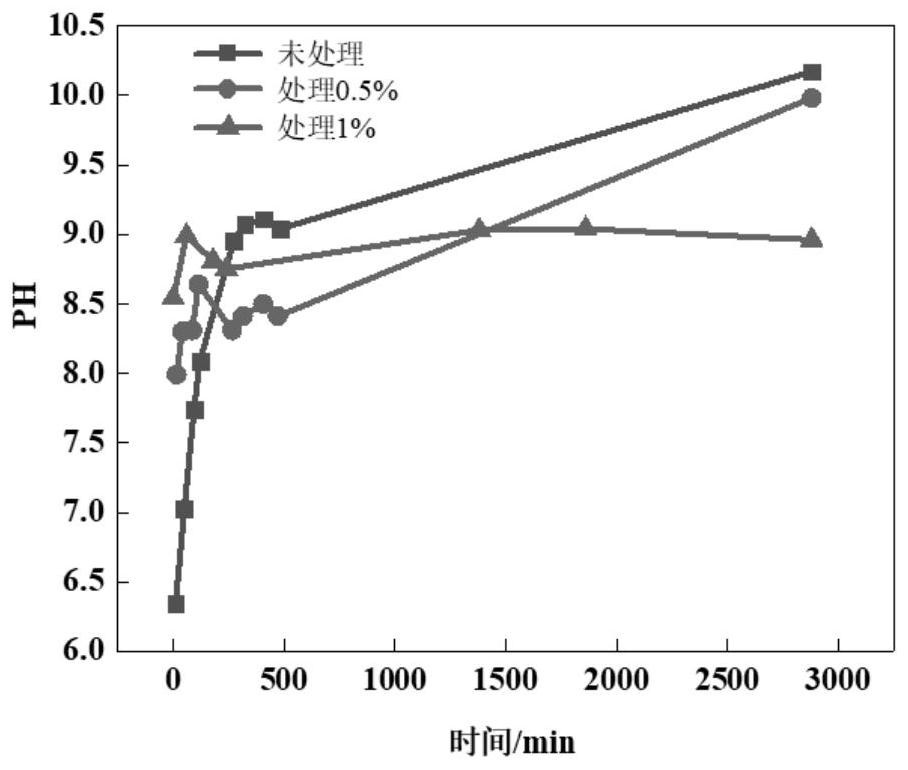

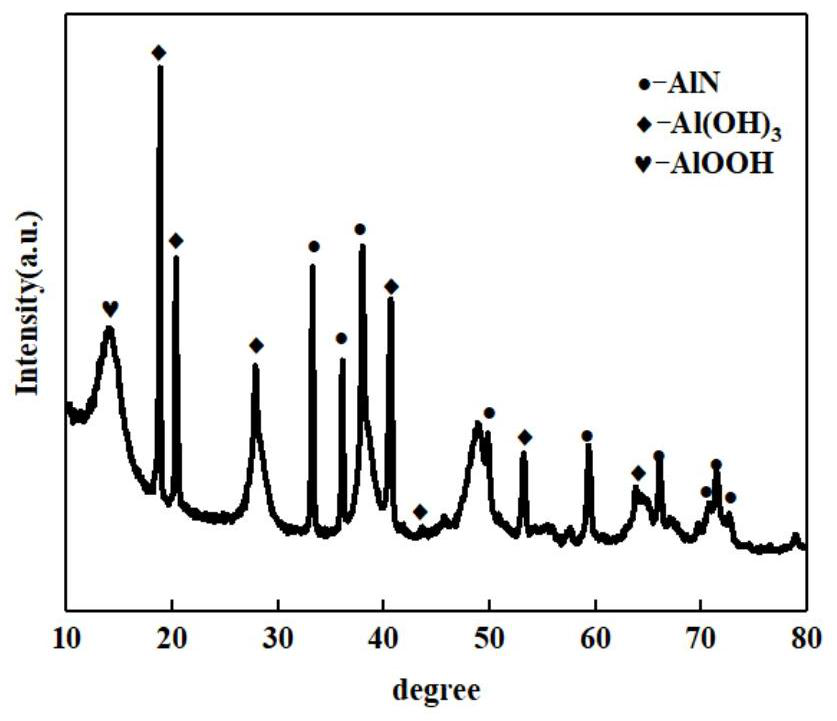

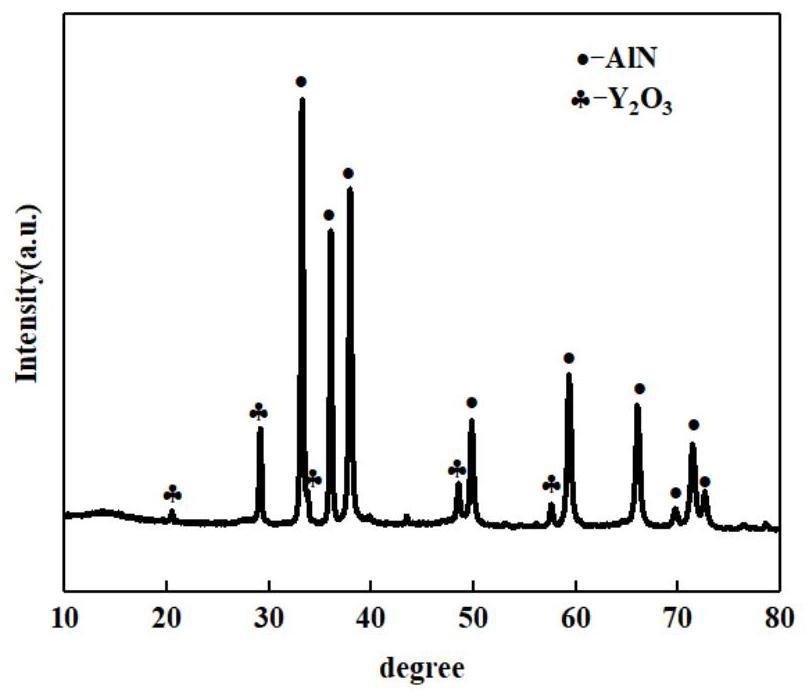

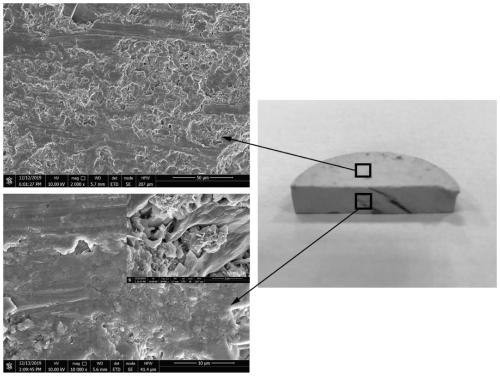

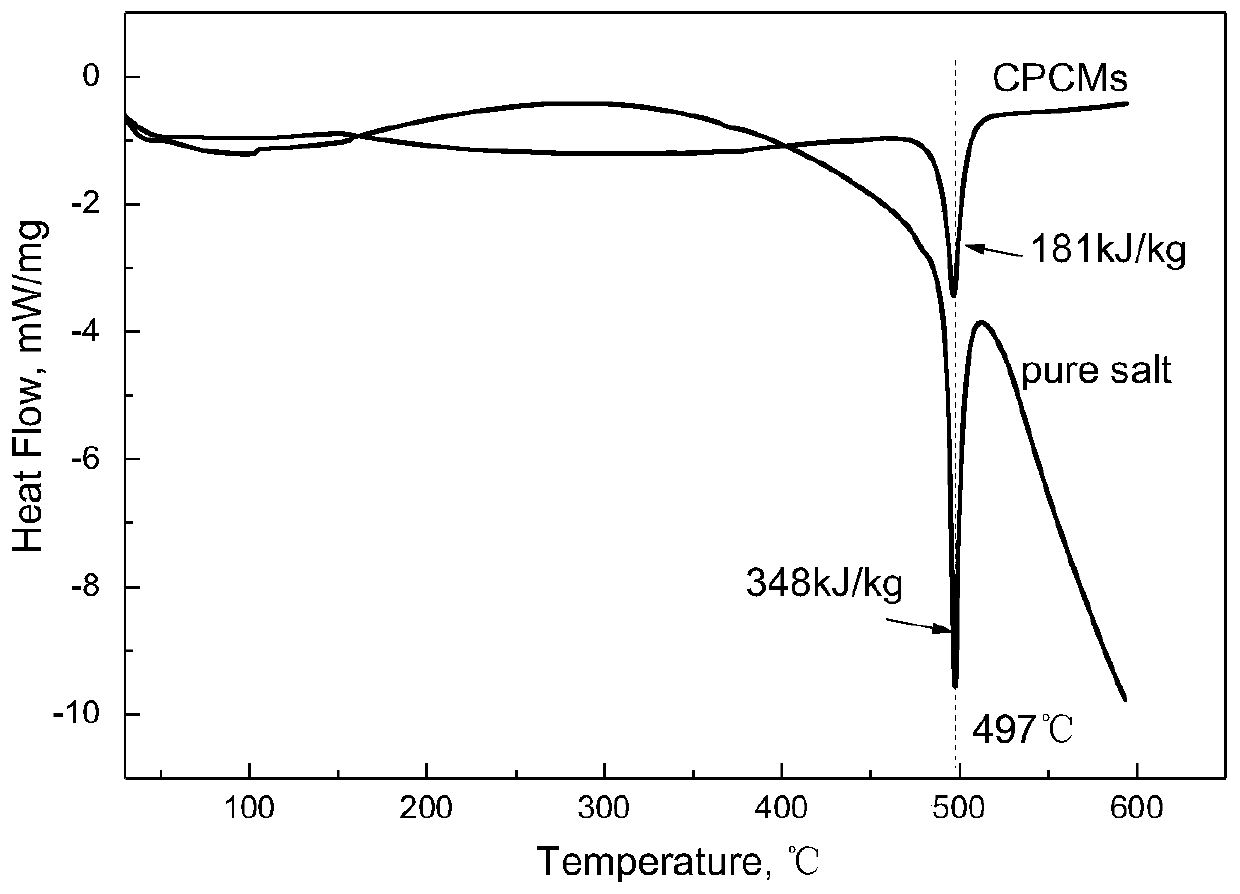

Bone-like hierarchical pore ceramic-based photo-thermal storage material and preparation method thereof

ActiveCN112521158AAvoid corrosionSolve high temperature oxidationHeat-exchange elementsCeramicwareInorganic saltsTitanium nitride

The invention discloses a bone-like hierarchical pore ceramic-based photo-thermal storage material and a preparation method thereof. An aluminum nitride hierarchical pore structure is prepared by adopting a foaming method by imitating a human bone structure, a layer of titanium nitride is loaded on the aluminum nitride framework, and finally, inorganic salt is soaked into the aluminum nitride-titanium nitride framework by a vacuum soaking method to prepare the hierarchical pore aluminum nitride ceramic-based photo-thermal storage material. The aluminum nitride grade pore structure in the composite material forms a continuous heat conduction channel, so that the overall heat conductivity is greatly improved and can reach 27W / m.K, and the problem of low heat storage / release rate caused by low heat conductivity of the phase change material is greatly improved. The loaded titanium nitride enables the composite material to directly take the sun as a heat source, the aluminum nitride framework conducts heat quickly, inorganic salt stores heat, and the composite material is a novel composite photo-thermal storage material integrating absorption, transmission and heat storage.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

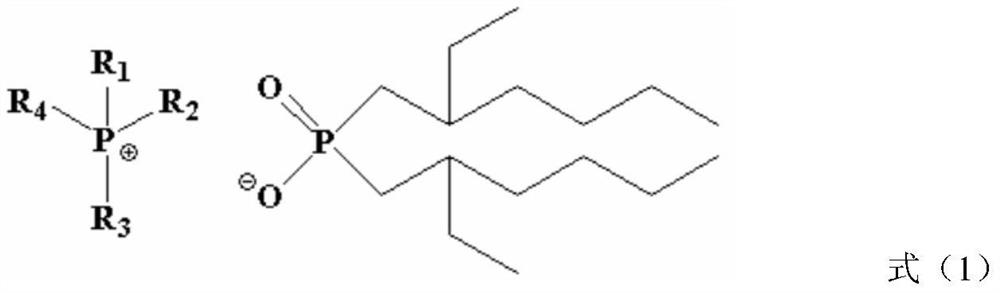

Lubricating oil antioxidant composition

ActiveCN111778084AGood antioxidant propertiesOxidation Induced Lifetime ImprovementAdditivesChemistryProcess engineering

The invention discloses a lubricating oil antioxidant composition. The composition is prepared from an amine antioxidant and tetraalkyl phosphonium phosphate ionic liquid in a ratio of 1: 100-100:1. The lubricating oil antioxidant composition has excellent oxidation resistance in synthetic ester base oil, can remarkably prolong the oxidation induction period of the base oil and prolong the servicelife of lubricating oil, and is particularly suitable for lubricating working conditions with strict high-temperature requirements.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

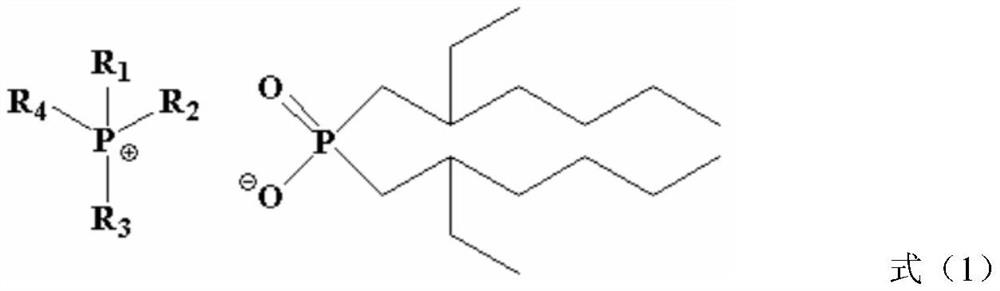

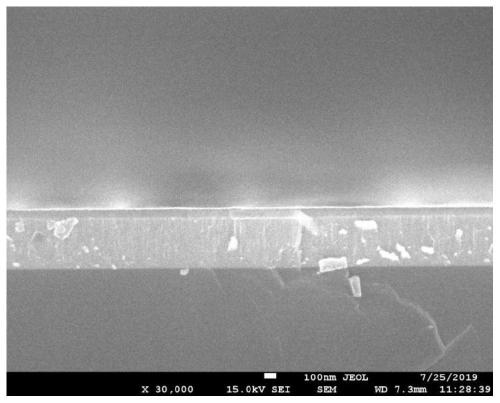

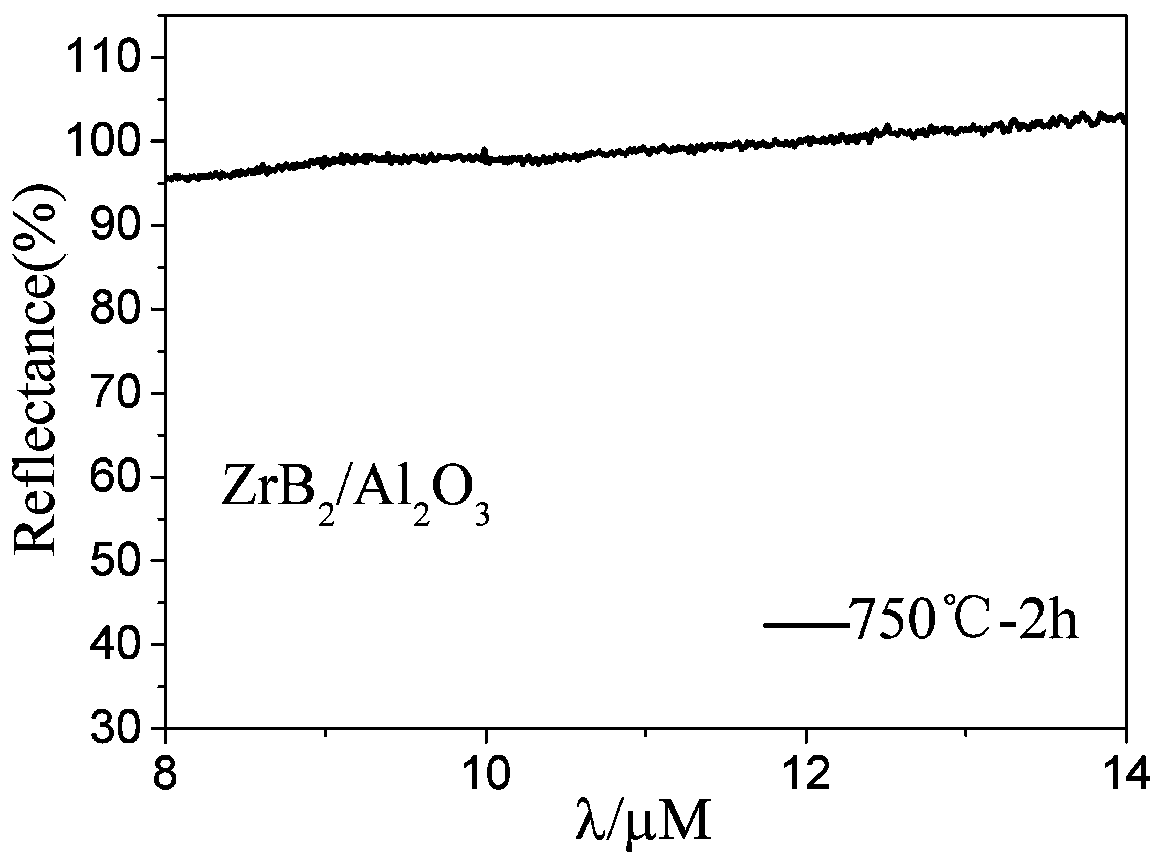

High-temperature-resistance and antioxidant infrared low-emissivity composite film and preparation method thereof

PendingCN111321382AEasy to makeLow costVacuum evaporation coatingSputtering coatingComposite filmLow emissivity

The invention belongs to the technical field of infrared stealth, and particularly relates to a high-temperature-resistance and antioxidant infrared low-emissivity composite film and a preparation method thereof. The high-temperature-resistance and antioxidant infrared low-emissivity composite film is of a double functional layer superposition structure and sequentially comprises a low-emissivityfunctional layer and an oxidation isolation layer from bottom to top; and during using, the lowest layer of the high-temperature-resistance and antioxidant infrared low-emissivity composite film covers the surface of a target object, the low-emissivity functional layer is a high-temperature conductive ceramic film continuously formed, and the oxidation isolation layer is an Al2O3 film. According to the high-temperature-resistance and antioxidant infrared low-emissivity composite film, the emissivity at 8-14 [mu]m is less than 0.1 after being used in 750 DEG C high temperature and aerobic environment for 2 h, the emissivity and high temperature stability are excellent, and the preparation method of the high-temperature-resistance and antioxidant infrared low-emissivity composite film is simple and easy to operate and low in cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Module type tubular solid oxide fuel cell power generating system

InactiveCN100401571CImprove stabilityImprove battery performanceSolid electrolyte fuel cellsCombustion chamberFuel cells

The present invention relates to a modular tubular solid oxide fuel cell power generation system, belonging to a power generation equipment. Said invention is formed from the following components: single-cell, combustion chamber, base seat, oxidant (air) input tube and fuel input tube. Said invention also provides the concrete structure of the above-mentioned every component. Said invented structure also includes an indirect internal reforming system, so that it can fully utilize hydrogen gas component of fuel, and can raise stability and performance of cell work.

Owner:JILIN UNIV

A Gasification Process Burner with Narrow Channel Jet Cooling

ActiveCN103881758BGuaranteed uptimeExtended service lifeGranular/pulverulent flues gasificationCooling effectHigh pressure

The invention relates to a novel gasifying process nozzle with a function of spray cooling through narrow channels. The nozzle comprises a central gasifying agent channel, a fuel channel and an external gasifying agent channel which are coaxially and sequentially sleeved outside the central gasifying agent channel, and cooling water channels which are arranged between the central gasifying agent channel and the fuel channel, between the fuel channel of the external gasifying agent channel and outside the external gasifying agent channel, wherein each cooling water channel consists of a plurality of narrow channels. High pressure cooling water is increased in the narrow channels at a flow rate to enhance the cooling effect on the central gasifying agent channel, the fuel channel, the external gasifying agent channel and the metal wall of the water cooling channel by way of heat conduction and forced-convection heat transfer. High pressure cooling water is sprayed from the outlets of the narrow channels in form of high speed impact jet to spray and cool the outlets of the nozzle so as to effectively cool the outlets of the nozzle by way of forced-convection heat transfer and phase-change heat transfer. The nozzle provided by the invention overcomes the defect that a nozzle in the gasifying nozzle technology in the prior art is poor in cooling effect and short in service life.

Owner:XI AN JIAOTONG UNIV

Ceramic-based high-thermal-conductivity composite phase-change heat storage material and preparation method thereof

ActiveCN111548167AEvenly distributedHigh thermal conductivityHeat-exchange elementsThermal conductivityComposite phase change material

The invention discloses a ceramic-based high-thermal-conductivity composite phase-change heat storage material and a preparation method thereof. The ceramic-based high-thermal-conductivity composite phase-change heat storage material is prepared from the following raw materials in percentage by mass: 50 to 70 percent of inorganic salt, 20 to 50 percent of aluminum nitride and 5 to 15 percent of water. The preparation method comprises the following steps: weighing inorganic salt and aluminum nitride according to a formula ratio, uniformly stirring the components, adding water, mixing the components, and molding the mixture to prepare a composite phase change heat storage material precursor; then sealing and packaging the precursor, and placing in a blast drying oven for low-temperature reaction to prepare a green body; and finally, heating and sintering the green body to obtain the ceramic-based high-thermal-conductivity composite phase change heat storage material. The heat-conductingceramic-based framework is prepared in one step through an in-situ reaction method, the heat conductivity of the composite phase-change material is greatly enhanced while eutectic phase-change salt ispackaged, and the heat conductivity can reach 4 W / m.K or above; due to the adoption of micron-sized raw materials, the production cost can be remarkably reduced, and the potential of industrial production is achieved.

Owner:NARI TECH CO LTD

Preparation method of grease-containing seabuckthorn turbid juice

ActiveCN109315645AThe preparation method is simple and feasibleStabilizer significantlyFood scienceFruit juiceHigh pressure

The invention discloses a preparation method of grease-containing seabuckthorn turbid juice, belonging to the technical field of deep processing of agricultural and sideline products. Specific to theproblems of loss of a large quantity of nutrient substances and the like caused by basically selecting a fruit juice complete degreasing method to realize the uniformity of fruit juice appearance in order to solve the problems of fat floating and fruit juice lamination in the prior art, the invention aims at providing the preparation method of the grease-containing seabuckthorn turbid juice specific to the problems mentioned above, a part of fat in seabuckthorn is effectively retained by utilizing a partial degreasing and two-stage high-pressure homogeneous method, not only are the flavor substances and nutrient substances of the seabuckthorn turbid juice effectively retained, but also the problems of fat floating and lamination are effectively solved, so that the seabuckthorn turbid juice, which has high stability and a relatively long shelf life, is obtained, final products have a uniform emulsion state, various kinds of physiological active substances are maintained to the maximum extent, meanwhile, the manufacture cost is significantly reduced, and the seabuckthorn turbid juice can be widely applied to industrial production.

Owner:ZHONGBEI UNIV

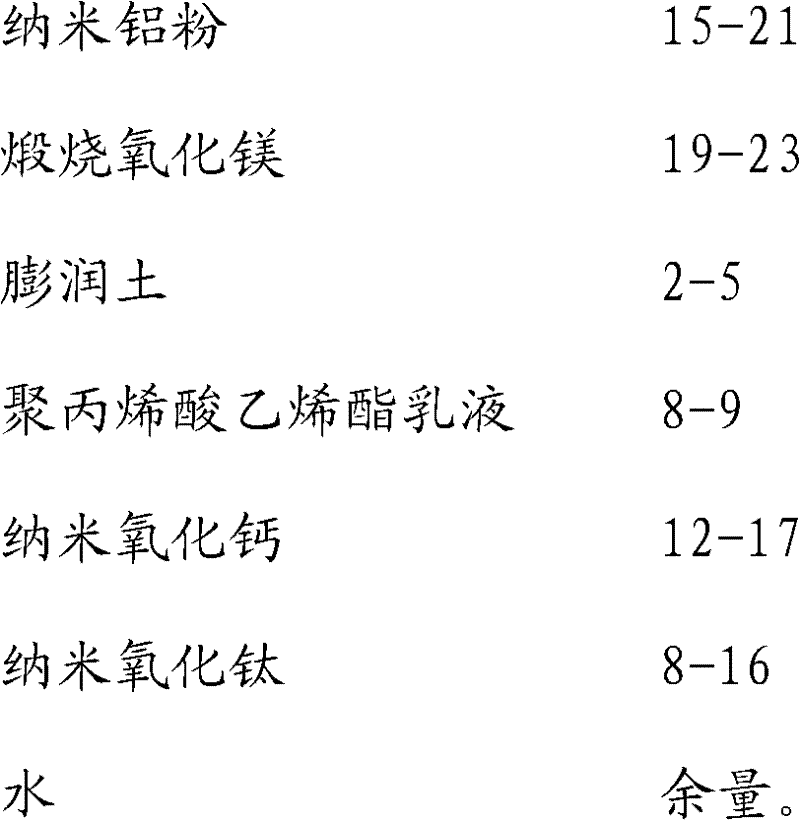

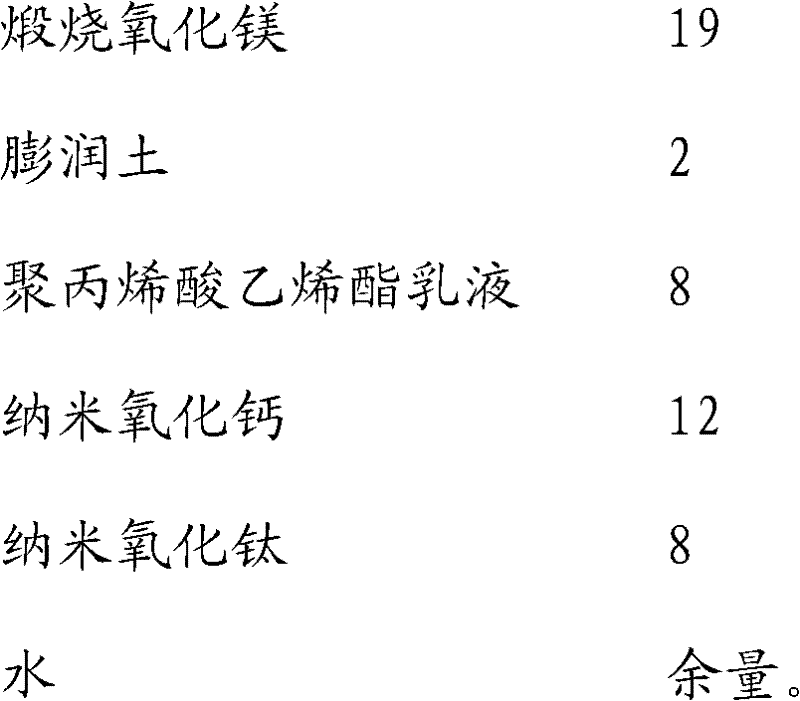

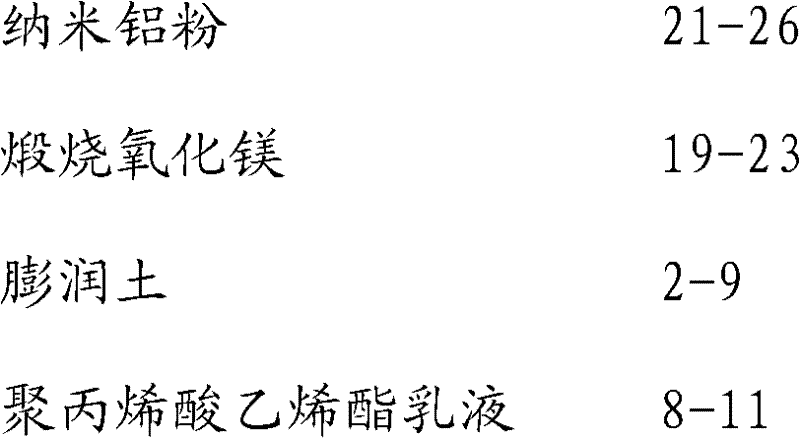

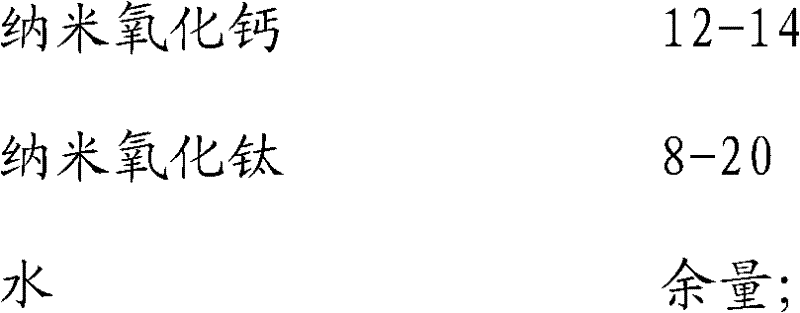

Coating composition

InactiveCN102329532AProtectionchemical resistanceSolve high temperature oxidationAnti-corrosive paintsEmulsionTitanium oxide

The invention discloses a coating composition. The composition comprises the following components, by weight, 21 parts of nanometer aluminum powder, 19 parts of calcined magnesia, 2 parts of bentonite, 8 parts of an aqueous epoxy resin emulsion, 12 parts of nanometer calcium oxide, 8 parts of nanometer titanium oxide, and the balance water. The composition which has a wide application has the advantages of anticorrosion and certain temperature resistance.

Owner:ANHUI MEIJIA NEW MATERIAL

Preparation method of coating composition

InactiveCN102329547AProtectionchemical resistanceSolve high temperature oxidationAnti-corrosive paintsEpoxyMicrowave

The invention discloses a preparation method of a coating composition. A coating consists of the following components in parts by weight: 21 parts of nano aluminum powder, 19 parts of calcined magnesia, 2 parts of bentonite, 8 parts of water borne epoxy resin emulsion, 12 parts of nano-calcium oxide, 8 parts of nano-titanium oxide and the balance of water. In the assistance of ultrasonic waves and microwave heating, the overall performance of the coating can be enhanced; and the prepared coating has wide application, is corrosion-resistant and erosion-resistant, and can be used at certain temperature.

Owner:ANHUI MEIJIA NEW MATERIAL

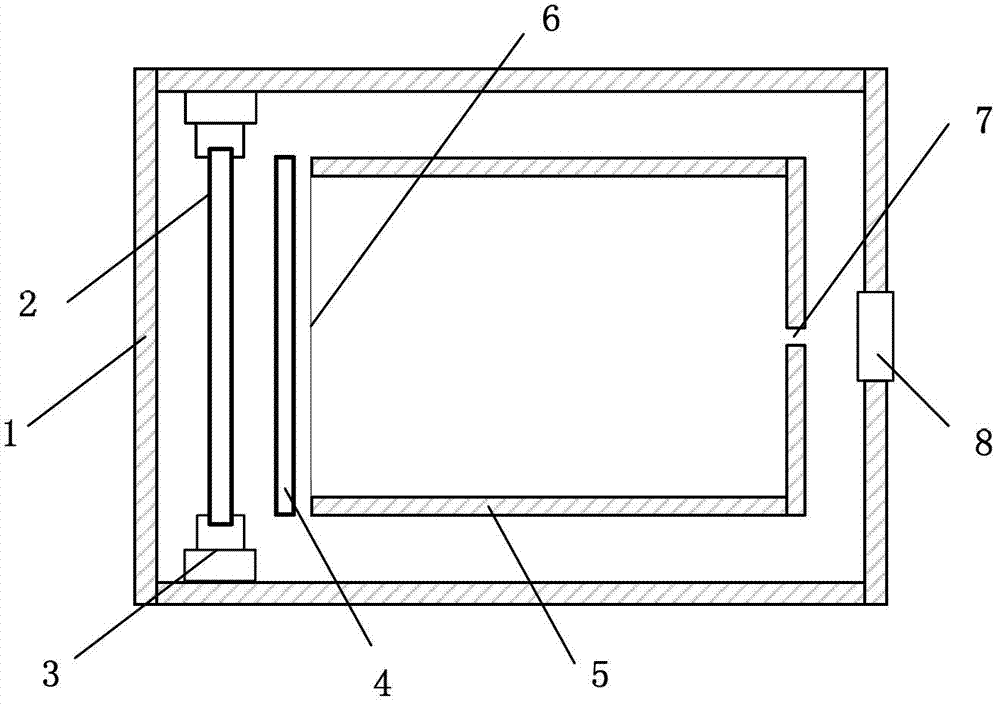

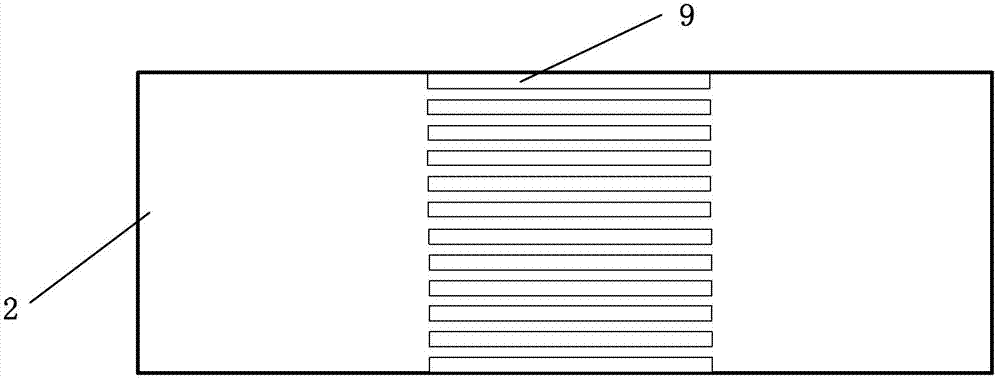

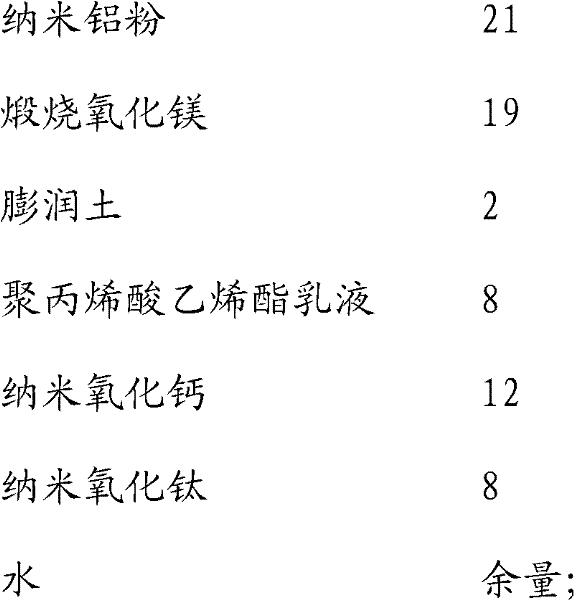

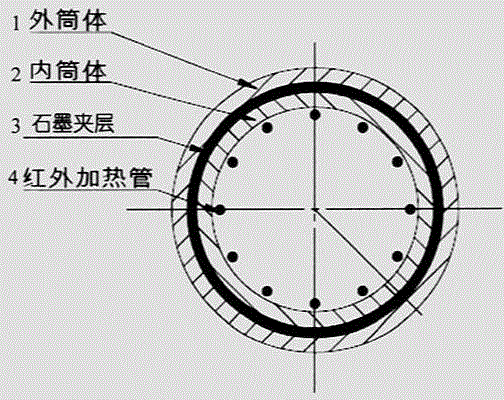

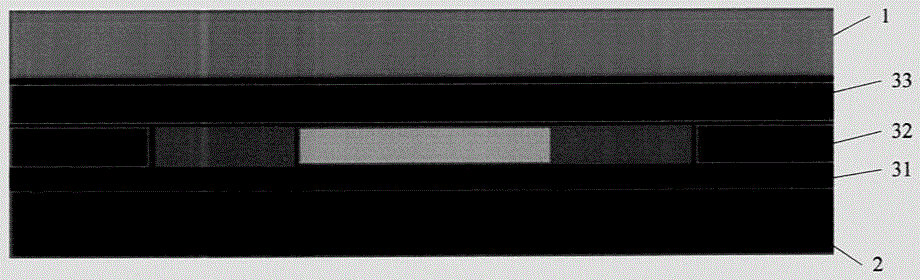

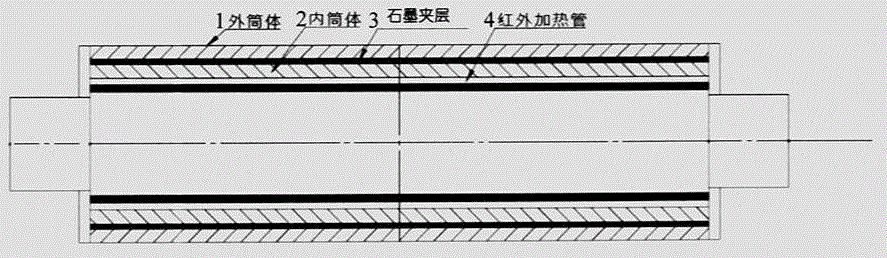

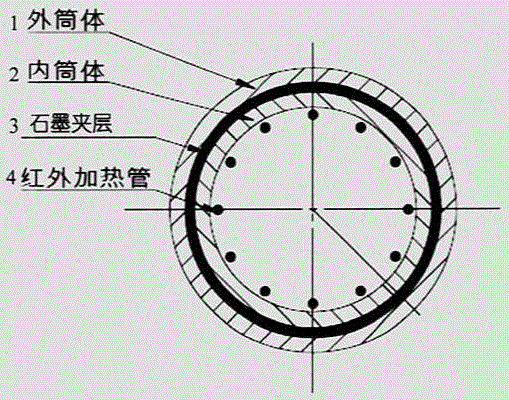

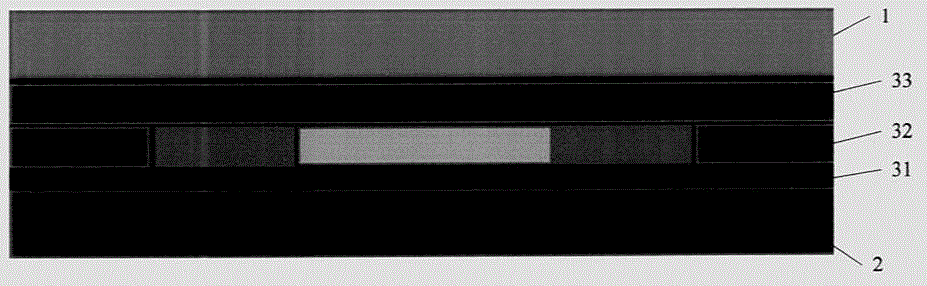

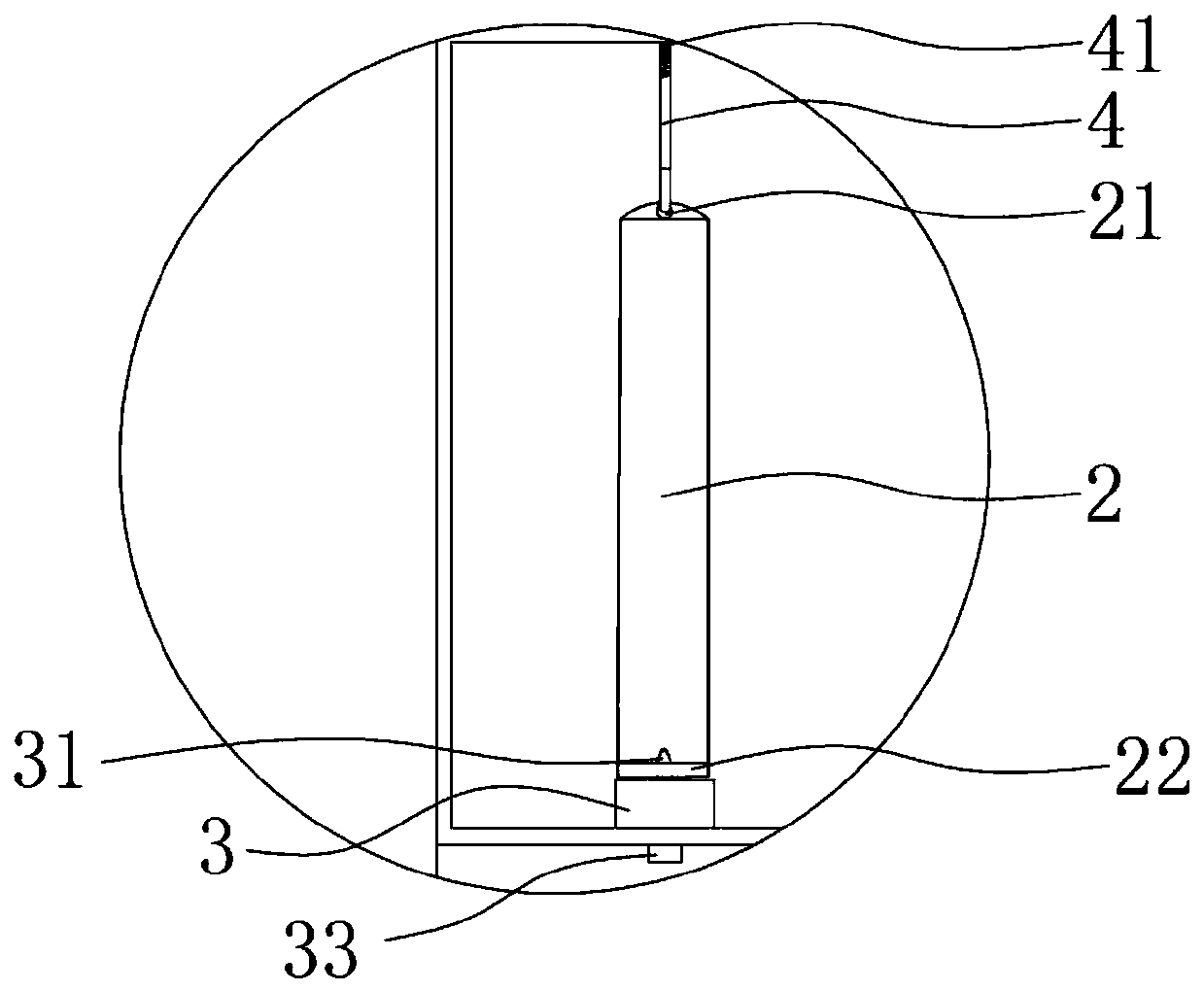

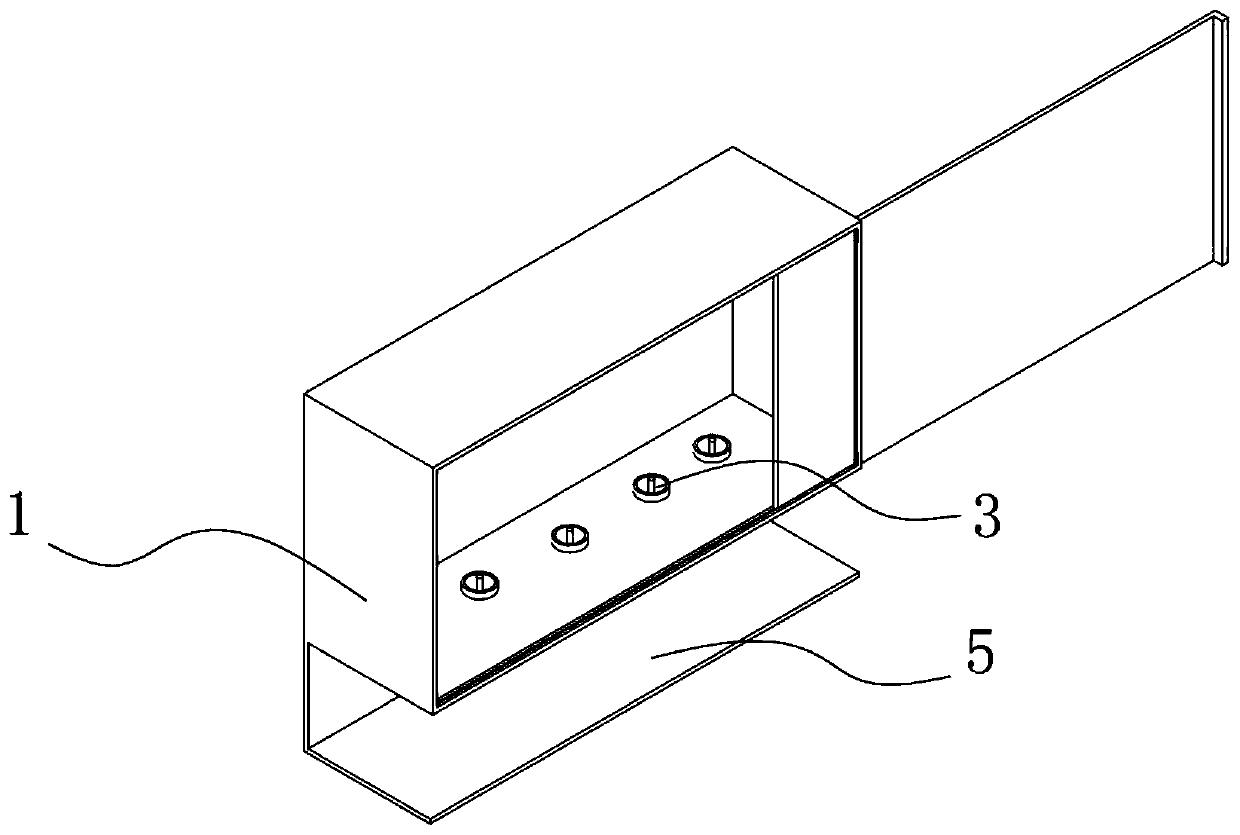

Heat transmission roller with graphite interlayer and heat transmission method of heat transmission roller

ActiveCN104691027AImprove temperature uniformitySimple structureLamination ancillary operationsLaminationInter layerHeat transmission

The invention discloses a heat transmission roller with a graphite interlayer and a heat transmission method of the heat transmission roller. The heat transmission roller comprises an external roller body 1, an internal roller 2, the graphite interlayer 3 and an infrared heating pipe 4. The graphite interlayer 3 is clamped between the internal roller body 2 and the external roller body 1 of the heat transmission roller. The internal roller body 2 and the external roller body 1 are both metal layers. According to the invention, the temperature transmission efficiency along the surface of the heat transmission roller is improved by utilizing the characteristic that the plane thermal conductivity of graphite is rather high, the graphite interlayer is arranged in the heat transmission roller device, and the temperature uniformity of the heat transmission roller is greatly improved.

Owner:史春彦 +1

Burner for pulverized coal gasifier

ActiveCN105132037BAvoid burnsSolve high temperature oxidationGranular/pulverulent flues gasificationCoal pipelineEngineering

A burner for a pulverized coal gasifier. The present invention relates to a burner. The present invention solves the problem of complex manufacturing process, high manufacturing cost, inconvenient disassembly and maintenance, and The problem of short service life, which includes at least one layer of shielding gas pipeline, gasification agent pipeline, pulverized coal pipeline, first swirl blade, second swirl blade and flange; gasification agent pipeline is sleeved on at least one layer of protection Outside the gas pipeline, the pulverized coal pipeline is sleeved outside the gasification agent pipeline, the flange is sleeved on the outer wall of the pulverized coal pipeline, and the first swirl vane is set on at least one layer of the outer wall of the protective gas pipeline and the inner side of the gasification agent pipeline Between the walls, the second swirl vane is set between the outer wall of the gasification agent pipeline and the inner wall of the pulverized coal pipeline, and the top of the pulverized coal pipeline is provided with a pulverized coal airflow inlet, and the top of the gasification agent pipeline is provided with a gas flow inlet. The inlet of the protective gas is provided at the top of at least one layer of the protective gas pipeline. The invention is used in a coal gasification device.

Owner:HARBIN INST OF TECH

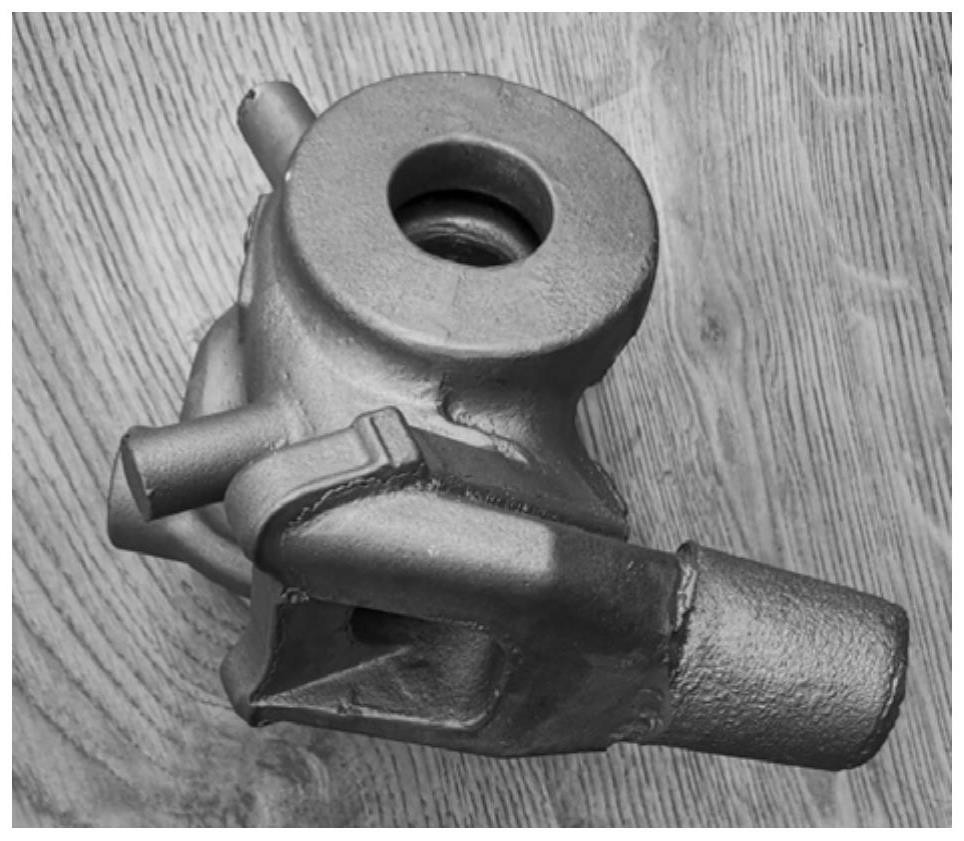

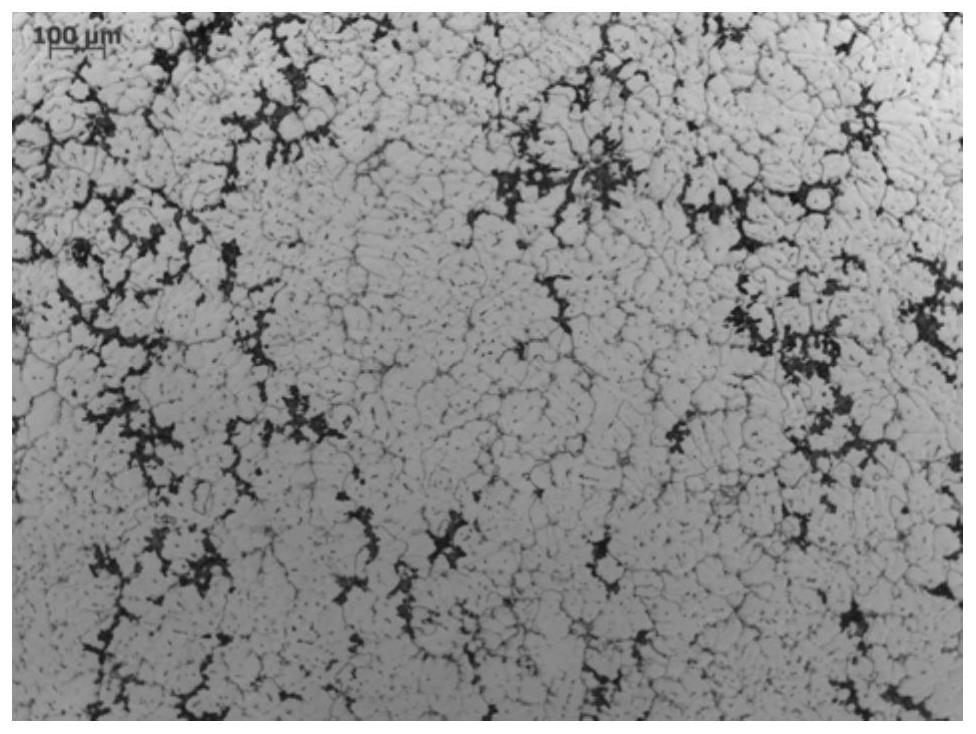

Anti-oxidation and anti-fatigue CREE rare earth heat-resistant steel for turbocharger shell and preparation method of CREE rare earth heat-resistant steel

PendingCN114107804AImprove antioxidant capacityImprove thermal fatigue resistanceFoundry mouldsFoundry coresThermal fatigueTurbocharger

The invention relates to the field of automobile parts, in particular to anti-oxidation and anti-fatigue CREE rare earth heat-resistant steel for a turbocharger shell and a preparation method of the anti-oxidation and anti-fatigue CREE rare earth heat-resistant steel. The alloy comprises the following components in percentage by weight: 0.1 to 0.5 percent of C, 1.0 to 3.0 percent of Si, 5.0 to 10.0 percent of Mn, 15.0 to 25.0 percent of Cr, 1.0 to 6.0 percent of Ni, 0.05 to 0.50 percent of V, 0.05 to 0.50 percent of Nb, 0.2 to 0.7 percent of N, 0.005 to 0.5 percent of RE and the balance of Fe. According to the anti-oxidation and anti-fatigue CREE rare earth heat-resistant steel for the automobile turbocharger shell, by controlling the C / N atom proportion, a film-shaped second phase is formed at the grain boundary, intragranular oxidation is inhibited, and the high-temperature oxidation resistance is improved; by means of the inhibition effect of rare earth elements on second phase growth, the high-temperature structure stability is improved, and thus the thermal fatigue resistance is improved. The intermediate frequency furnace high-nitrogen alloying, high-purity rare earth treatment and sand casting technologies are adopted, a turbocharger shell casting which is uniform in component, compact in structure and excellent in performance is obtained, and the technical problems of high-temperature oxidation, fatigue cracking and the like of a furnace turbocharger can be effectively solved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A new gasification process burner with jet impingement cooling

ActiveCN103937553BGuaranteed uptimeExtended service lifeGranular/pulverulent flues gasificationJet flowInlet channel

The invention discloses a novel jet impingement cooling gasification technology burner. The novel jet impingement cooling gasification technology burner comprises a central gasifying agent channel, fuel channels, outer gasifying agent channels, and cooling water channels; the central gasifying agent channel is coaxially sieved by the fuel channels and the outer gasifying agent channels successively; the cooling water channels are arranged between the central gasifying agent channel and the fuel channels, between the fuel channels and the outer gasifying agent channels, and on the outsides of the outer gasifying agent channels; the cooling water channels are composed of water inlet channels and water return channels; cooling water uniform distribution devices are arranged in the water inlet channels; the water inlet channels and the water return channels are communicated via a plurality of circular holes which are closely arranged on the lower channel parts of the water inlet channels; high pressure cooling water is delivered into the water inlet channels, and then the walls of the water return channels are impinged by the high pressure cooling water through the plurality of circular holes which are closely arranged on the lower channel parts of the water inlet channels in a jet flow manner, so that high efficient cooling of the walls of the water return channels is realized; and then the high pressure cooling water is delivered to water outlets of the cooling water channels via the water return channels. The novel jet impingement cooling gasification technology burner is capable of solving problems of existing gasification technology burners that cooling effect is poor, and service life is relatively short.

Owner:XI AN JIAOTONG UNIV

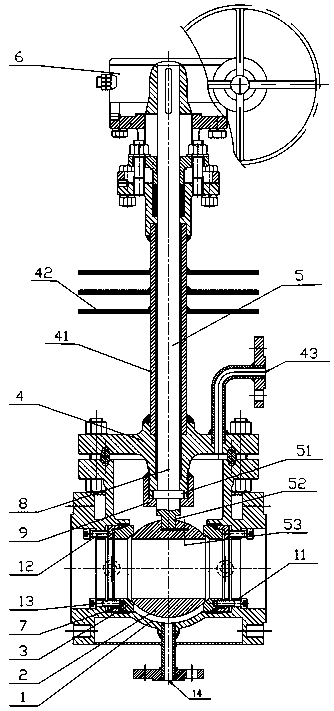

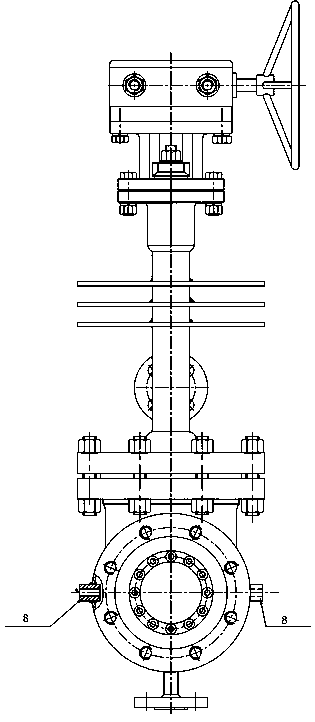

Upper ultra-high-temperature ball valve

PendingCN109681662ASolve high temperature oxidationImprove securityPlug valvesOperating means/releasing devices for valvesBall valveEngineering

The invention discloses an upper ultra-high-temperature ball valve. Graphite sealing is replaced by the unique valve seat and valve body sealing structure, the problem of high-temperature oxidation ofgraphite sealing is solved, and meanwhile, the problem about common springs in the ultra-high-temperature state is solved; a boss is designed ingeniously, a valve seat is fixed and pre-tightened, andthe specific pressure for sealing pre-tightening is reached; by the aid of a limiting cap designed ingeniously, the problems that a bonnet is lengthened at the high temperature and a ball is stuck due to expansion of a valve rod are solved; the problem of jamming of particles and powder is solved through purging in the closed and totally-open states of the valve; by the aid of the water cooling design of a jacket, the problem about the strength of the valve body when the temperature increases to 1,000 DEG C abnormally is solved, the safety guarantee is enhanced, and the problem of jamming dueto thermal expansion of the valve is solved.

Owner:XUANDA IND GRP +1

A heat transfer roller with graphite interlayer and heat transfer method thereof

ActiveCN104691027BImprove temperature uniformitySimple structureLamination ancillary operationsLaminationInter layerGraphite

The invention discloses a heat transfer roller with a graphite interlayer and a heat transfer method thereof. The heat transfer roller includes: an outer cylinder 1 , an inner cylinder 2 , a graphite interlayer 3 , and an infrared heating tube 4 . The graphite interlayer 3 is sandwiched between the inner cylinder 2 and the outer cylinder 1 of the heat transfer roller. Both the inner cylinder body 2 and the outer cylinder body 1 are metal layers. The invention utilizes the very high thermal conductivity of the graphite plane to improve the temperature transfer efficiency along the heat transfer roller surface, and an intermediate layer of graphite material is arranged in the heat transfer roller device to greatly improve the temperature uniformity of the heat transfer roller.

Owner:史春彦 +1

Method for preparing mixture containing natural vitamin P from sea-buckthorn

InactiveCN101084943BSolve high temperature oxidationSolve browningOrganic active ingredientsMetabolism disorderVitamin CFreeze-drying

The invention relates to a method for preparing mixture containing vitamin P from sea buckthorn, and is for the prupose of providing a method for preparing a mixture containing 0.5-50% of vitamin P and 2-30% of vitamin C through extracting juice, degassing, enzyme-hydrolyzing, degreasing, homogenize, reducing acid, desugarizing, millipore filtering, freeze drying and pulverizing. The method is simple; solve the problem of brown stain of highly active substance in sea buckthorn due to high temperature oxidation by adopting biologic-physical method at low temperature, has no requirement of any solvent, no residue, low cost, and high biologically active substance yield. Vitamin P and vitamin C is in coexistence in the product, which promotes absorption.

Owner:QINGHAI TSINGHUA BIOTRY BIO TECH

Solar spectrum selective absorbing coating and preparation method thereof

ActiveCN102122006BSolve high temperature oxidationChange colorVacuum evaporation coatingSputtering coatingHigh absorptionLow emissivity

Owner:GRIMAT ENG INST CO LTD

Preparation method of heat-resisting solid solution blue and white porcelain

The invention discloses a preparation method of heat-resisting solid solution blue and white porcelain, which mainly comprises the steps of raising temperature, drying, sintering, keeping warm, cooling, taking out from a kiln, and the like. The heat-resisting solid solution blue and white porcelain comprises the following components in percentage by weight: 20-65 percent of silicon dioxide, 0.01-1 percent of hydroquinone, 0.01-1 percent of zinc oxide, 0.05-2 percent of ammonium heptamolybdate, 0.01-2 percent of ethyl acetate, 15-35 percent of aluminium oxide, 0.1-3 percent of ferric oxide, 0.04-1.50 percent of trifluoroacetylacetone holmium, 5 to 10 percent of calcium oxide, 5-10 percent of magnesium oxide, 3-6 percent of potassium oxide, 1-5 percent of sodium oxide, 1-10 percent of lithium oxide, 0.01-2 percent of rutile type titanium dioxide, 0.06-2 percent of 1-bromine-3-methyl-2-butene and 0.01-1.55 percent of 3-ethyoxyl-4- carboxyl benzyl. According to the invention, the problem of high temperature oxidization during a firing process can be avoided in a better manner; a finished product is high in heat-resistant performance, and piezoelectric behavior can be shown; zero pollution can be caused, and the cost is low.

Owner:ANHUI QINGHUAFANG FINE BONE PORCELAIN

Bag type edible oil filling machine

PendingCN110171590AAvoid oxidation reactionsGuaranteed refrigeration temperatureLiquid materialEdible oilSelf weight

The invention discloses a bag type edible oil filling machine. The bag type edible oil filling machine is characterized by comprising self-deformed soft bags used for containing edible oil and an oilfilling machine body used for receiving and fixing the soft bags, wherein the oil filling machine is mounted in kitchen or other fixtures; oil discharging mechanisms are arranged in the oil filling machine body; each oil discharging mechanism comprises an oil inlet connected with each soft bag, a valve body and an oil outlet extending out of the oil filling machine body. According to the bag typeedible oil filling machine, after the soft bags are connected with oil inlets in the oil filling machine body, flow valves are capable of quantitatively supplying edible oil; meanwhile, the oil in thesoft bags enters the oil discharging mechanisms according to the self weight; and the bag bodies can automatically generate deformation according to the remaining oil amount so as to prevent the airfrom entering the bag bodies and generating oxidation reaction.

Owner:合肥启功科技有限公司

Burner used for gasifier

ActiveCN102399593BAvoid the problem of being easily burned by high temperatureAvoid heat damageLiquid spraying apparatusGranular/pulverulent flues gasificationProcess engineeringWater jacket

Belonging to the field of gasification equipment, the invention discloses a burner used for a gasifier. The burner comprises: a cooling water jacket or a cooling water coil disposed on a front housing of the burner, a burner front face jacket positioned at the top of the burner, and at least one fuel channel and a gasifying agent channel that is coaxial and directly sleeved with the fuel channel. The burner is characterized in that: at least one cooling pipe is arranged inside the gasifying agent channel, and a coolant inlet of the cooling pipe is located outside the gasifying agent channel, and a coolant outlet of the cooling pipe is positioned inside the gasifying agent channel, the cooling pipe introduces a coolant into the gasifying agent channel from the outside, and the coolant is directly sprayed to the burner head for cooling and finally ejected from an air nozzle. The burner of the invention can effectively prevent high temperature heat radiation and a thermal current from causing high temperature burning loss to the burner head, realize stable burner operation and have effectively extended service life.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com