Lubricating oil antioxidant composition

A technology of antioxidant and composition, applied in the field of lubrication, can solve problems such as inconsistency, and achieve the effects of prolonging service life, improving induction period, and high-efficiency antioxidant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

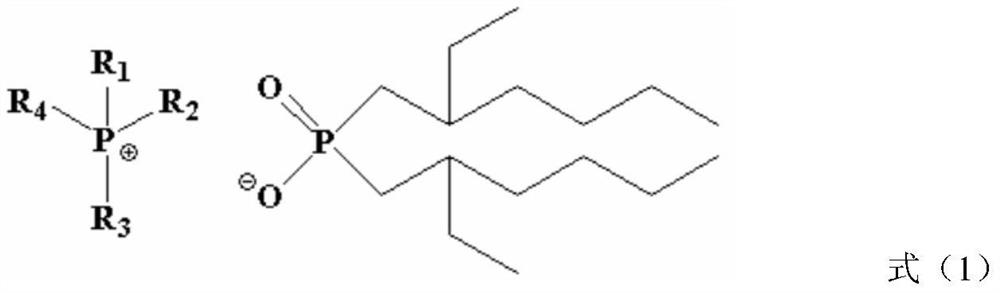

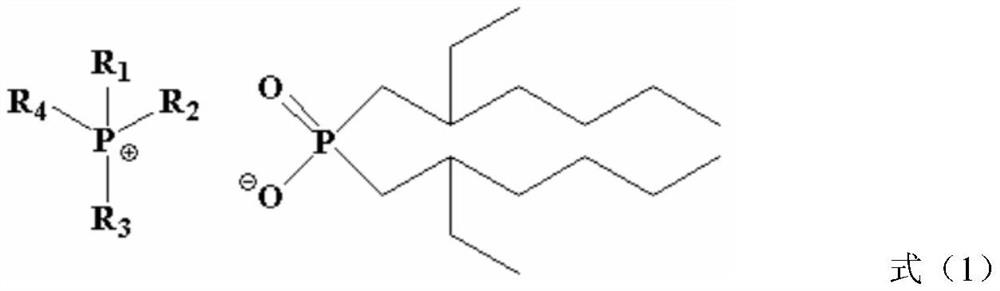

Image

Examples

Embodiment 1

[0021] Using pentaerythritol ester (5750) as the base oil, add 2% L57, 0.2% tetraoctylphosphonium dioctyl phosphate ionic liquid ([P8888][DEHP]) and the combination of the two, and evaluate by the oxidation induction period The antioxidant properties of the oil samples are shown in Table 1.

[0022] Table 1 Example 1 Oil sample oxidation induction period

[0023] oil sample Oxidation induction period, min 5750+2%L57 53.2 5750+0.2%[P8888][DEHP] 0 5750+2%L57+0.2%[P8888][DEHP] 67.2

Embodiment 2

[0025] With pentaerythritol ester (5750) as the base oil, add 1% T531, 1% tributyltetradecylphosphonium dioctyl phosphate ionic liquid ([P44414][DEHP]) and the combination of the two, through oxidation The induction period was used to evaluate the antioxidant properties of the oil samples, and the results are shown in Table 2.

[0026] Table 2 Example 2 Oil sample oxidation induction period

[0027] oil sample Oxidation induction period, min 5750+1%T531 44.3 5750+1%[P44414][DEHP] 0 5750+1%T531+1%[P44414][DEHP] 72.8

Embodiment 3

[0029] Using pentaerythritol ester (5750) as base oil, adding 2% V81, 1% tetraoctylphosphonium dioctyl phosphate ionic liquid ([P8888][DEHP]) and the combination of the two, it is evaluated by the oxidation induction period The antioxidant properties of the oil samples are shown in Table 3.

[0030] Table 3 Example 3 Oil sample oxidation induction period

[0031] oil sample Oxidation induction period, min 5750+2%V81 57.4 5750+1%[P8888][DEHP] 0 5750+2% V81+1%[P8888][DEHP] 105.8

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com