Patents

Literature

30 results about "Dioctyl phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Artificial leather with high peel strength and preparation method thereof

ActiveCN103603209ANo smellHigh peel strengthSynthetic resin layered productsLaminationDioctyl phosphatePolymer science

The invention relates to artificial leather with high peel strength and a preparation method thereof. The artificial leather comprises a surface layer, a foamed layer, a bonding layer and a base cloth layer, wherein the foamed layer is formed by drying PVC (Polyvinyl Chloride) foaming slurry; the bonding layer is formed by drying a PVC modified bonding material; the PVC modified bonding material consists of PVC resin, DOP (Dioctyl-Phthalate) and tetraisopropyl di(dioctyl phosphate acyloxy) titanate. The preparation method comprises the following steps of forming the surface layer, the PV foamed layer, the bonding layer and the base cloth layer on release paper in sequence, wherein the bonding layer is formed by drying the PVC modified bonding material, and the PVC modified bonding material is prepared by mixing PVC resin, DOP (Dioctyl-Phthalate) and tetraisopropyl di(dioctyl phosphate acyloxy) titanate; and removing the release paper to obtain the artificial leather. The artificial leather provided by the invention is free from peculiar smell, high in peel strength and low in production cost.

Owner:FUJIAN POLYTECH TECH CO LTD

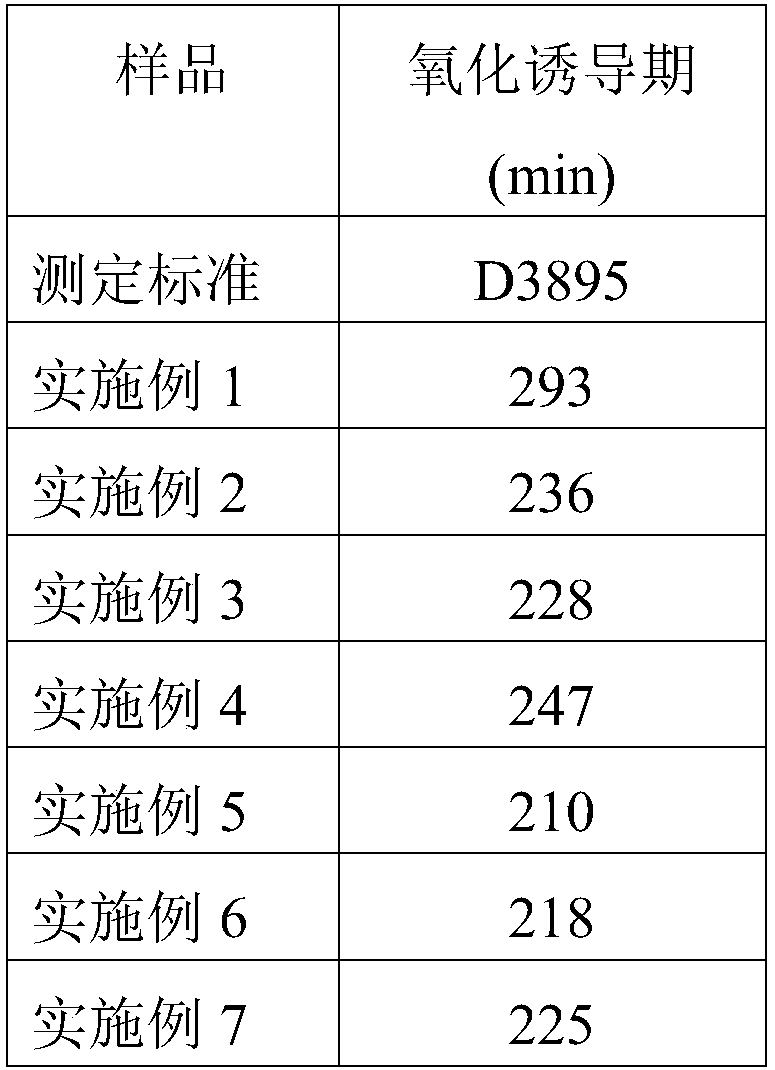

Heatproof and ageing resistant laboratory table top pad

The invention discloses a heatproof and ageing resistant laboratory table top pad, which is prepared from a cis-polybutadiene / epoxy resin composite material. Specifically, the cis-polybutadiene / epoxy resin composite material comprises the following raw materials: cis-polybutadiene, epoxy resin, epoxidized natural rubber, nano-silica, modified graphene, alumina, magnesium oxide, zinc methacrylate, zinc oxide, stearic acid, sulfur, benzoyl peroxide, 2-ethyl-4-methylimidazole, vinyltri(beta-methoxyethoxy)silane, dioctyl phosphate, dibutyl phthalate, an anti-aging agent and an accelerant. The heatproof and ageing resistant laboratory table top pad provided by the invention has high strength, good heat resistance, and excellent aging resistance and corrosion resistance.

Owner:ANHUI YUAN LAB EQUIP

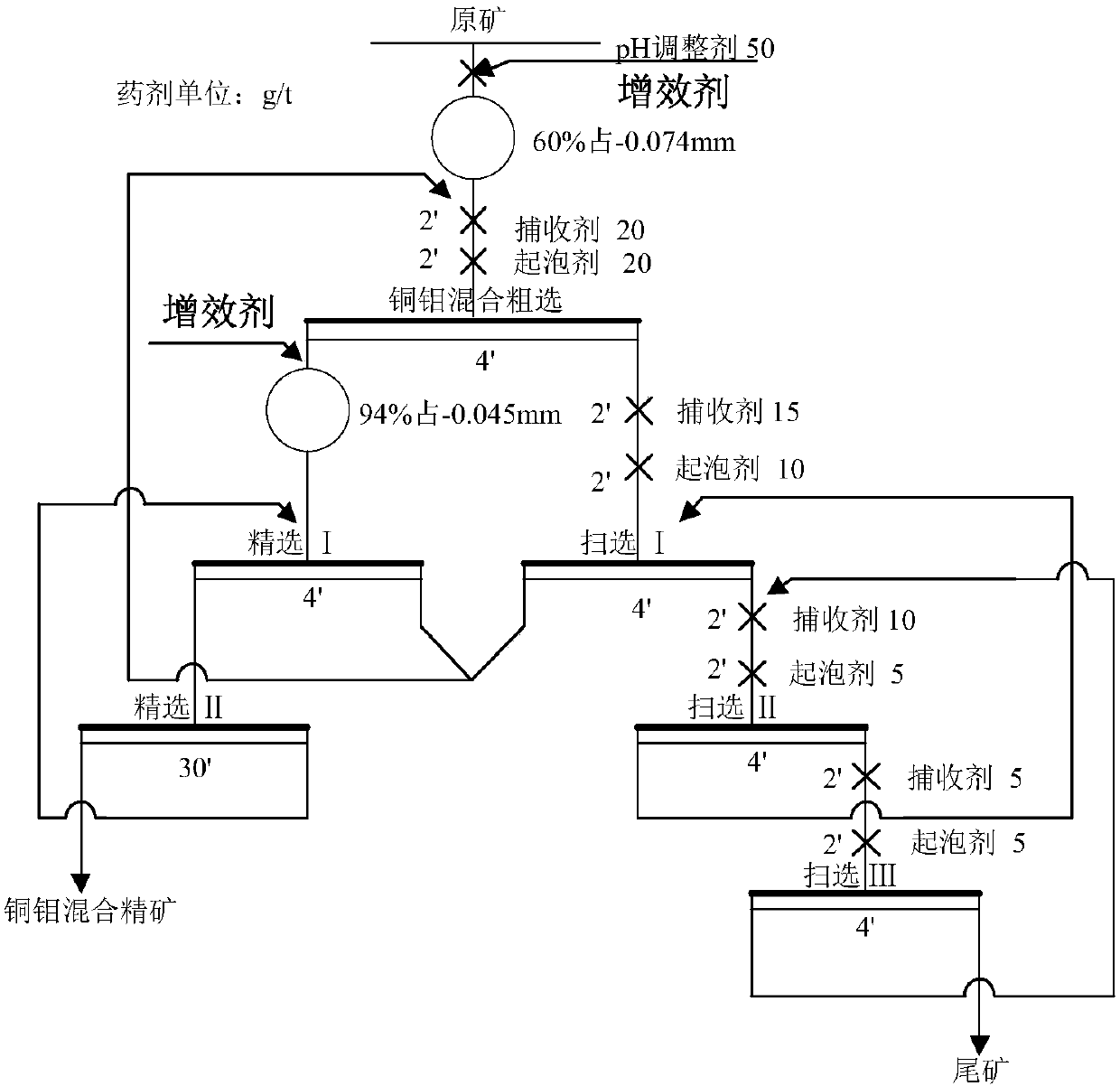

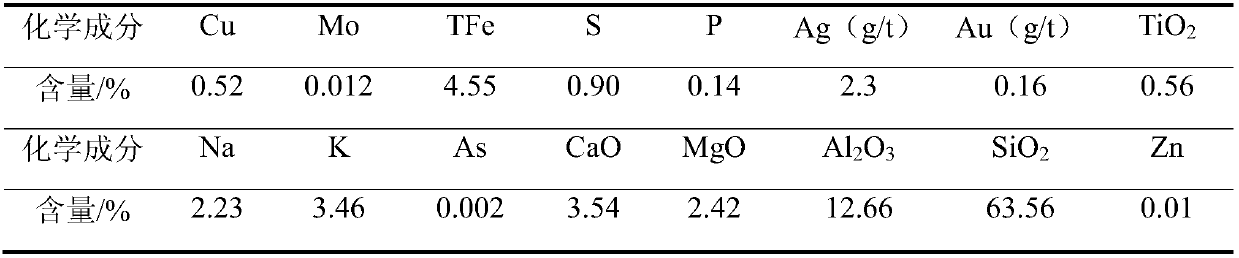

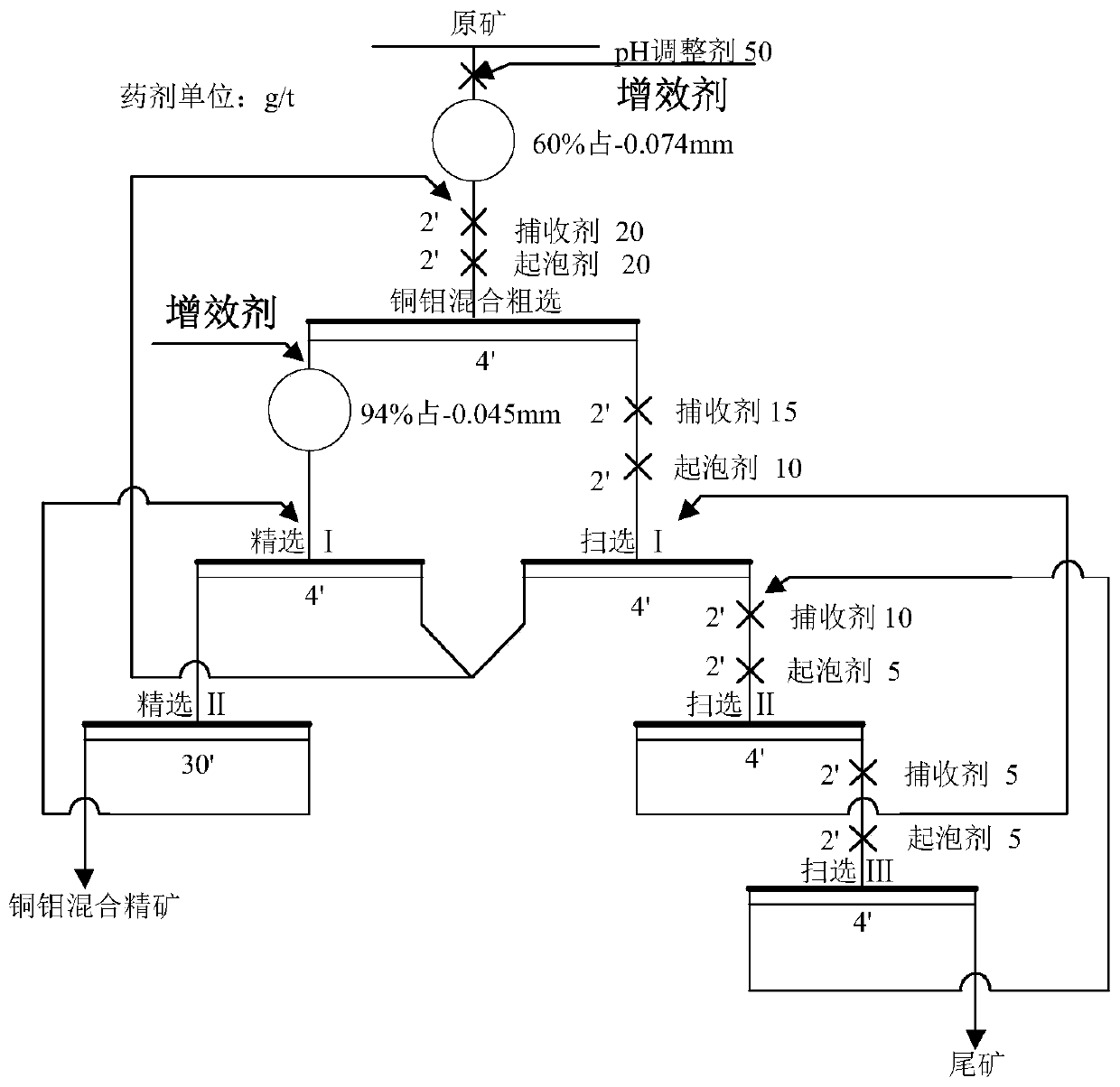

Synergist for refractory copper oxide ore flotation

The invention provides a synergist for refractory copper oxide ore flotation and a preparation method thereof, and belongs to the technical field of flotation. The synergist comprises, by weight, 60 parts of 8-hydroxyquinoline, 45 parts of dioctyl phosphate, 15 parts of ammonium sulfate, 5 parts of kerosene and 5 parts of ethanol. The preparation method comprises the steps of firstly mixing the powdery 8-hydroxyquinoline and ammonium sulfate, then mixing the liquid dioctyl phosphate, kerosene and ethanol, adding the powdery solids into the mixed liquid medicament solution, next adding water soas to prepare the water solution with the volume fraction of 30%-35%, heating to 40-50 DEG C in a microwave field, and stirring for 15-20 min. The prepared synergist can be directly added into the ore grinding operation in the form of a stock solution. The synergist for the refractory copper oxide ore flotation is stable in property, good in solubility, high in activity, less in dosage of the medicament, high in adaptability to ores and capable of effectively improving indexes of the refractory copper oxide ore flotation, and has obvious technical and economic indexes and environmental benefits.

Owner:云南迪庆有色金属有限责任公司 +1

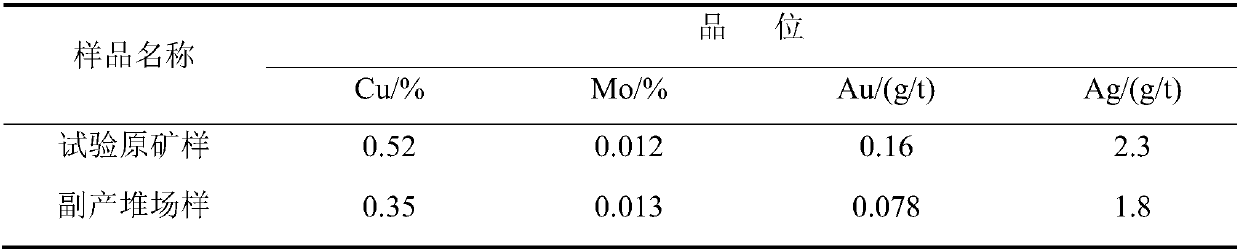

New method of using novel extracting agent to extract scandium oxide from titanium dioxide waste acid

InactiveCN112095026ANot volatileEasy to separateScandium oxides/hydroxidesRare earth metal compounds preparation/treatmentDioctyl phosphateAcid water

The invention discloses a novel method of using a novel extracting agent to extract scandium oxide from titanium dioxide waste acid. The method comprises the following steps of: S1, preparation of rawmaterials: preparing a titanium dioxide waste acid water raw material and a concentrated sulfuric acid raw material; S2, sulfuric acid dissolution: adding water and a concentrated sulfuric acid solution into titanium dioxide waste acid water, stirring and mixing; S3, precipitation: adding a flocculating agent into the mixed solution, performing precipitation, and filtering the after-precipitationsolution; and S4, washing: adding water, sulfuric acid and hydrogen peroxide into the filtered solution, mixing and stirring, adding hydrogen peroxide, and continuously stirring. According to the method, a new extraction method is carried out by adopting dioctyl phosphate and tributyl phosphate to replace a traditional old extracting agent; during extraction, the separation effect is better, therecovery rate is high, the scandium oxide can be further purified, the extraction rate is increased from about 60% to 85%, and the price of the dioctyl phosphate and the tributyl phosphate is low; andfurthermore, the added flocculating agent is cheap and practical, and the flocculating agent is non-toxic and high in flocculating capacity.

Owner:HUNAN CHUANGDA YUTU CHEM CO LTD

Lightweight soundproof heat-insulating material and preparation method thereof

InactiveCN107162492AReduce the disadvantage of easy water absorptionLow costSodium bicarbonatePolyester

The invention discloses a lightweight soundproof heat-insulating material, comprising, by weight, 45-65 parts of Portland cement, 20-25 parts of enveloped perlite, 10-15 parts of glass beads, 5-8 parts of trimethylolpropane, 2-5 parts of rosin, 1-2 parts of sodium bicarbonate, 5-20 parts of ethyl acetate, 1-3 parts of dioctyl phosphate, 1-3 parts of natural fiber, 1-3 parts of acrylamide, 1-3 parts of aluminum silicate fiber, 1-2 parts of polyester polyol, 1-3 parts of sodium formate, 1-3 parts of a composite flame retardant, 1-2 parts of a foaming agent, and 0.5-1.5 parts of dispersible latex powder. The lightweight soundproof heat-insulating material has the advantages that by enveloping the expanded perlite, the fire resistance and thermal insulation in expanded perlite are made full use, and the defect of the expanded perlite absorbing water easily is improved; the natural fiber and the aluminum silicate fiber are used as one of materials for the lightweight soundproof heat-insulating material, giving the features of low heat conductivity coefficient and low density, the materials are easy to obtain, and the cost is low.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

Plant fiber outer wall hanging plate and preparation method thereof

InactiveCN106396571AImprove toughnessHigh strengthLaminationLamination apparatusFiberDioctyl phosphate

The invention discloses a plant fiber outer wall hanging plate, which comprises a bottom material layer, a middle material layer and a surface material layer, wherein the bottom material layer is mainly prepared from the following raw materials including sulphate aluminate cement, flyash, silica fume, sawdust, plant fiber, coke powder and additives; the middle material layer is mainly prepared from the following raw materials including sulphate aluminate cement, flyash, silica fume, sawdust, plant fiber, red brick powder, kieselguhr, quartz sand, silicon carbide, magnesium oxide, quicklime, acrylamide, cassava starch, cinerite, dioctyl phosphate, bauxite and additives; the surface material layer is mainly prepared from the following raw materials including sulphate aluminate cement, flyash, silica fume, sawdust, plant fiber, silica sol and additives. The plant fiber outer wall hanging plate has the advantages that the forming speed is high; the production period is short; the stability is high; a preparation method is simple; the mixing quantity of the plant fiber is not limited by stirring and can be regulated according to requirements; a production process is simple; the mass production can be realized.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

Flaming-retarding and leakage-stopping material for buildings

The invention discloses a flaming-retarding and leakage-stopping material for buildings. The material comprises the following components in parts by weight: 0.2-0.5 part of methylbenzene diphenyl phosphate, 0.5-2 parts of stannous chloride, 0.5-2 parts of dioctyl phosphonate, 5-10 parts of cellulose, 8-12 parts of ammonium persulfate, 3-10 parts of triethanolamine, 30-50 parts of water, 15-20 parts of acrylamide and 15-20 parts of methylene bisacrylamide. The flaming-retarding and leakage-stopping material for buildings has the advantages of low cost, simple process, waterproofness, flame retardancy and good aging resistance.

Owner:陆玉珍

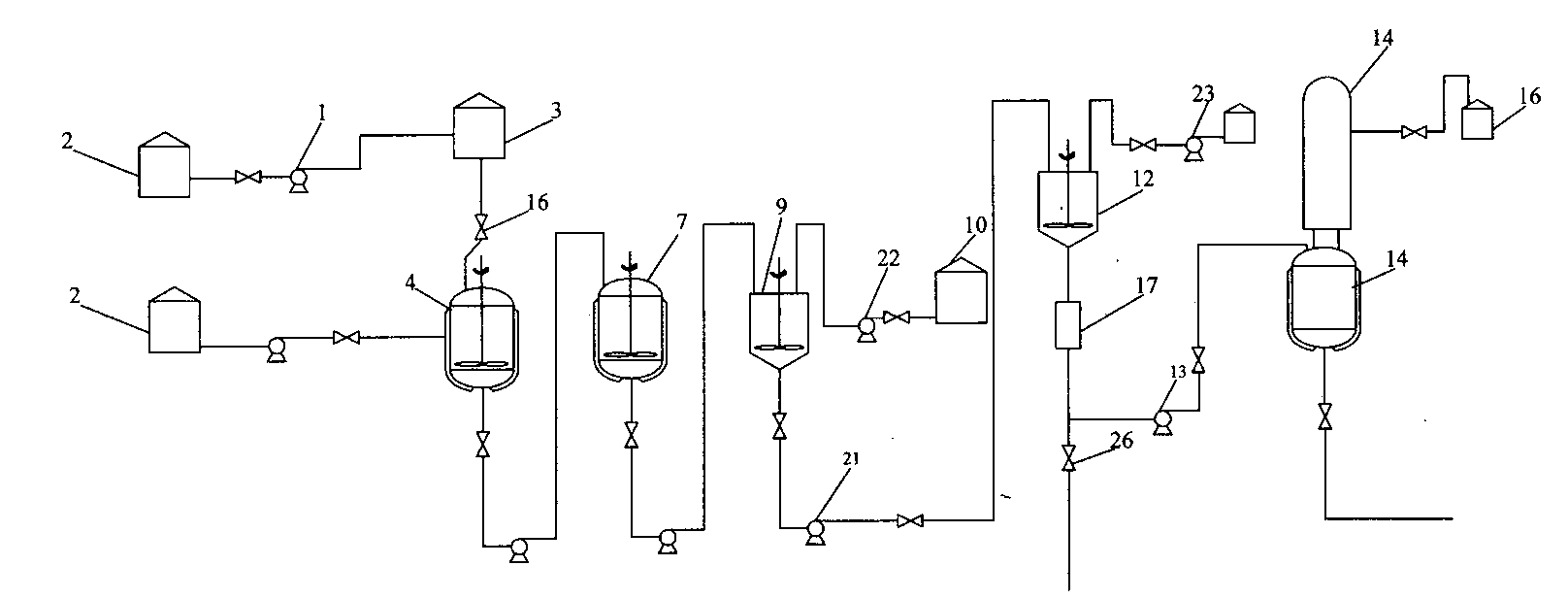

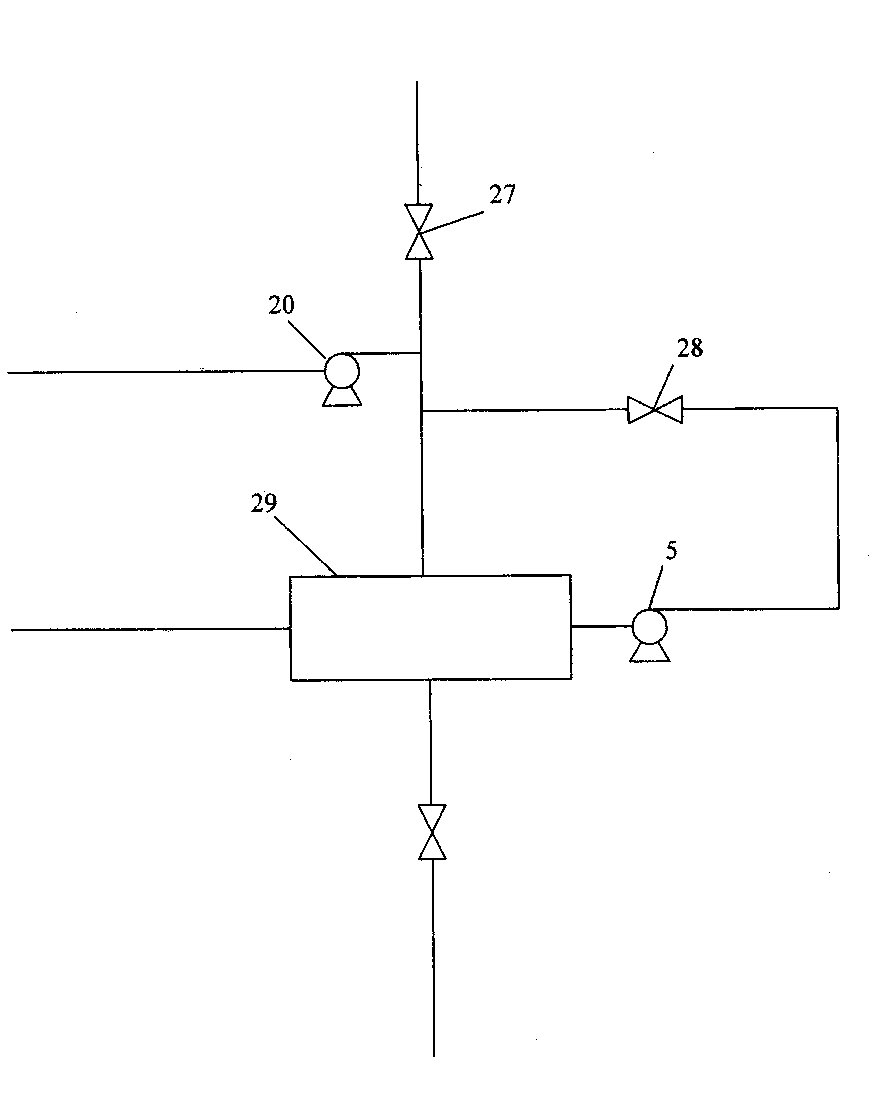

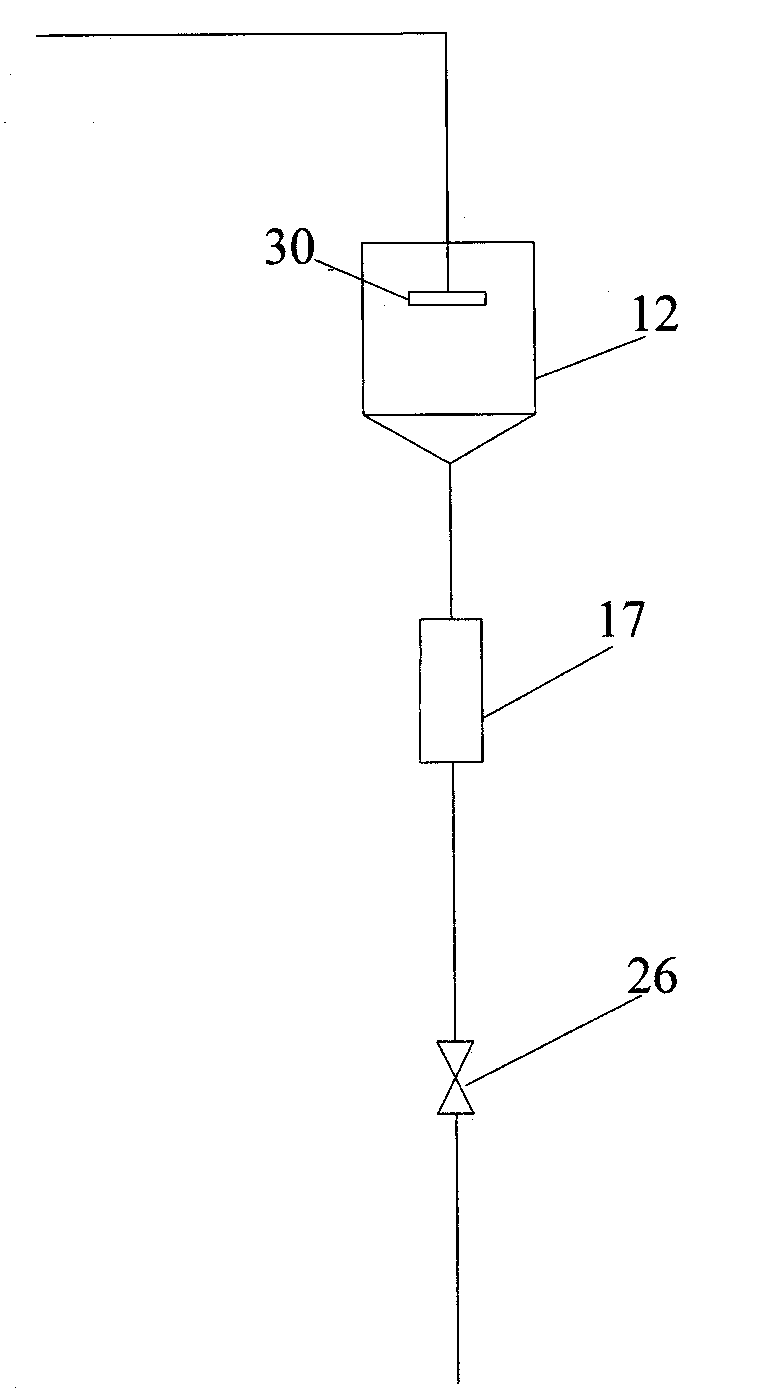

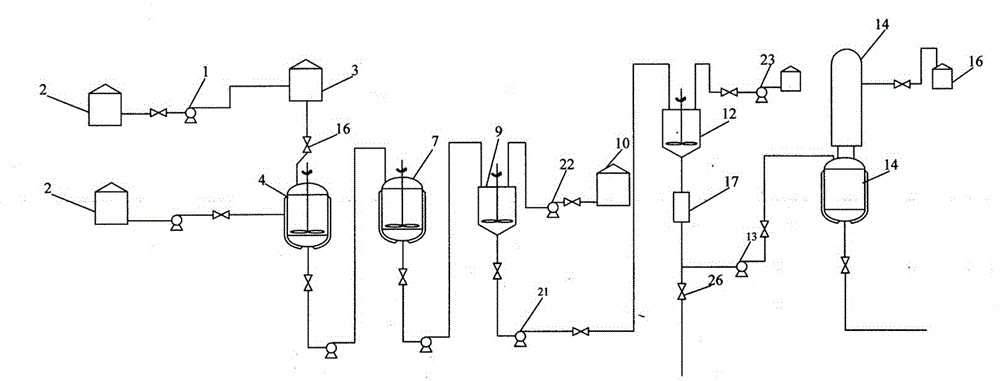

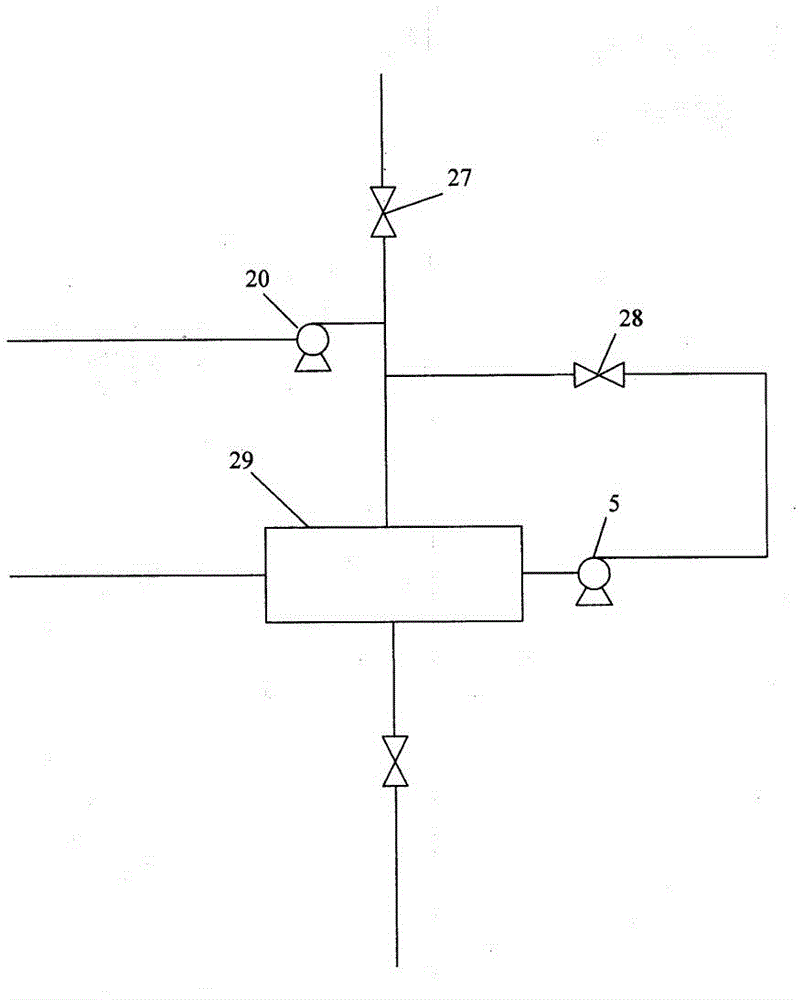

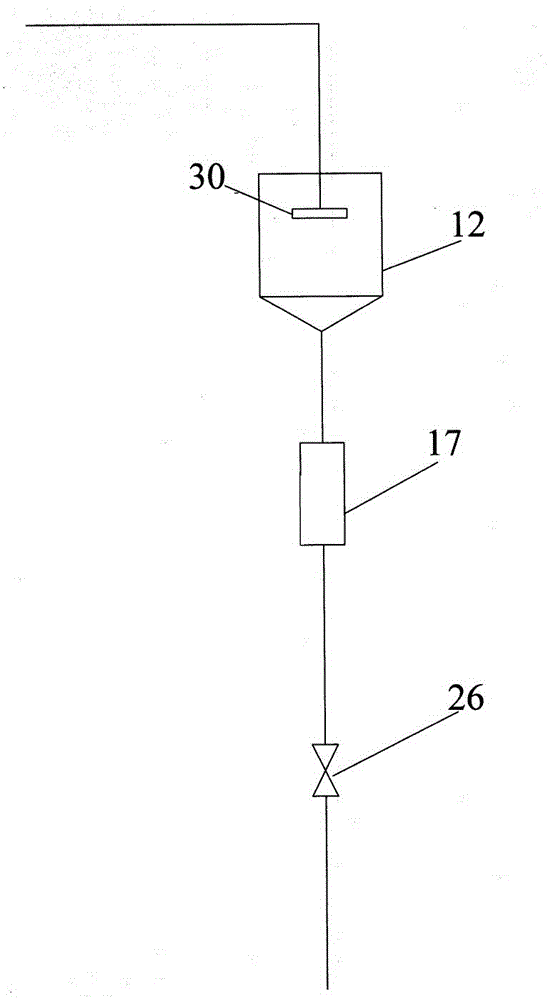

Industrial production method for trioctyl phosphate

ActiveCN103304595AHigh purityLow costGroup 5/15 element organic compoundsPreparation from chloridesDioctyl phosphatePhosphate

The invention relates to an industrial production method for trioctyl phosphate, and in particular relates to an industrial production process for trioctyl phosphate and a byproduct recovering method. Raw materials comprise octanol, phosphorus oxychloride, phosphorus oxychloride and aqueous alkali. The device mainly comprises a centrifugal pump, an octanol storage tank, an octanol metering tank, a mixing kettle, a freezing brine pump, a freezing brine device, an esterification kettle, a steam pipeline, a neutralizing kettle, an alkaline water tank, a hydrogen chloride recovering device, a washing device, a vacuum pump, a dealcoholization pump, a condenser and an alcohol-water separator. According to the method provided by the invention, hydrogen chloride can be recovered and marketed in form of hydrochloric acid product, so that pollution is reduced. The washing device is further arranged to adequately remove impurities such as monooctyl phosphate and dioctyl phosphate. A lens is additionally installed, so that whether washing water is discharged completely or not is easy to judge. A spraying stirring device is adopted to reduce the degree of emulsification during separation. The alcohol-water separator can produce octanol products, so that the product purity of trioctyl phosphate is increased and the production cost is lowered.

Owner:岳阳振兴中顺新材料科技股份有限公司

Super-hydrophobic modified hydrogenated butadiene-acrylonitrile rubber magnetic composite material and preparation method thereof

The invention relates to the technical field of super-hydrophobic magnetic rubber materials and discloses a super-hydrophobic modified hydrogenated butadiene-acrylonitrile rubber magnetic composite material and a preparation method thereof. A formula for the material comprises the following raw materials: hydrogenated butadiene-acrylonitrile rubber, graphene oxide, a SiO2 nanocomposite material, amodified ferrite nanocomposite material, a plasticizer, an activating agent, an accelerant, an anti-aging agent, a reinforcing agent--carbon black and a vulcanizing agent--sublimed sulfur. Accordingto the invention, nanometer SiO2 is uniformly loaded into an Al-Fe double-metal hydroxide layered structure, so the agglomeration and caking of the nanometer SiO2 are avoided, and the anti-ageing performance of the rubber material is improved; the ferrite composite material with strong magnetism enhances the damping performance and the magnetic performance of the rubber material; and the tridecafluorooctyltriethoxysilane modified SiO2 and an isopropyldioleoylacyloxy(dioctyl phosphate acyloxy)titanate modified ferrite composite material enhance the hydrophobic performance of the rubber material.

Owner:黄春美

Wear-resistant TNC fabric with excellent waterproof performance

InactiveCN108457091AImprove waterproof performanceImprove wear resistanceCoatingsTextiles and paperDioctyl phosphateFiber

The invention discloses a wear-resistant TNC fabric with excellent waterproof performance. The wear-resistant TNC fabric comprises a TNC fabric layer and a wear-resistant waterproof layer arranged oneach of the upper side and the lower side of the TNC fabric layer; the wear-resistant waterproof layer comprises the following raw materials in part by weight: 1000-1500 parts of isopropyl tris (dioctyl phosphate acyloxy) titanate, 1000-1300 parts of N,N-dimethyl dodecylamine, 1000-1500 parts of nitrocellulose with a particle size of 5-15 mum, 800-1200 parts of polypropylene, 1200-1800 parts of ethyl acrylate, 35-50 parts of high bauxite, 10-20 parts of PVC resin, 50-80 parts of nanometer aluminum trioxide, 60-90 parts of dipentaerythritol and 30-60 parts of isocyanate. The wear-resistant TNCfabric disclosed by the invention has the advantages of being free from by-products, strong in operability, effectively-controllable in production cost and the like; the isopropyl tris (dioctyl phosphate acyloxy) titanate in a formula can improve the wear resistance and the waterproof performance of the TNC fabric, and meanwhile, the brightness and the glossiness of the TNC fabric can be improved.

Owner:SIYANG SHENJIU HOME TEXTILE FABRIC CO LTD

Coupling agent-modified calcium carbonate filled polypropylene plastic

The invention discloses a coupling agent modified calcium carbonate filled polypropylene plastic, which consists of the following components: 100 kg of polypropylene, 15 kg of calcium carbonate, 0.04 kg of γ-chloropropyltriethoxysilane, isopropyl Base tri(dioctyl phosphate acyloxy) titanate 0.12 kilogram and polyethylene glycol trimethoxysilyl propyl ether 0.04 kilogram; Coupling agent is diluted with the solvent xylene of 5 times weight of coupling agent, is dispersed in In the calcium carbonate, the xylene is completely volatilized, and the pulverizer is crushed into fine powder to obtain a modified calcium carbonate; the polypropylene and the modified calcium carbonate are added to the mixer and stirred, and the control speed is 00-400r / min, and the stirring temperature is 70 ‑80°C, stirring time 2‑4 minutes, extrusion granulation, extrusion temperature 180‑200°C, cooling in cold water 10‑40°C for molding. The invention has better various mechanical properties, and has better tensile strength, elongation at break, notched impact strength, thermal deformation temperature and Rockwell hardness.

Owner:青岛九洲千和机械有限公司

Preparing method of biodegradable food packaging material

The invention discloses a preparing method of a biodegradable food packaging material, and belongs to the technical field of preparing packaging materials. Discarded anaerobic cassava distillers' grains are reused, dissolved through a cellulose dissolving system and modified with a lauric acid, bi(dioctyl phosphate) diethylene titanate and polyethylene glycol composite modifying agent, auxiliaries such as specific dispersant, toughener, plasticizer and stabilizer are added, and the biodegradable food packaging material is prepared through extrusion granulation of a double-screw extruder and hot press molding of a press vulcanizer. Tenacity, tensile strength, impact strength and other performance of the biodegradable food packaging material prepared through the preparing method meet the packaging requirement, material cost is greatly reduced, and comprehensive utilization of waste resources is achieved.

Owner:盐城钻梦环保科技有限公司

Solvent system for producing fully acidic hydrogen peroxide working solution by anthraquinone method

InactiveCN110294460AReduce economic costsImprove solubilityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesDioctyl phosphateSolubility

The invention relates to a solvent system, and in particular relates to a solvent system for producing a fully acidic hydrogen peroxide working solution by an anthraquinone method, belonging to the technical field of organic synthesis. The solvent system comprises, by volume, 70-85% of heavy aromatic hydrocarbon (C9-C10), 5-15% of dioctyl phosphate and 10-20% of tetrabutyl urea. The dioctyl phosphate is a colorless transparent oily liquid with a density of 0.969-0.975 g / cm<3>. The solvent system is formed by compounding three-component solvents, so that the solubility of alkyl anthraquinone isimproved, the hydrogenation efficiency is improved, and the economic cost of the solvent is reduced.

Owner:PINGHU PETROCHEM

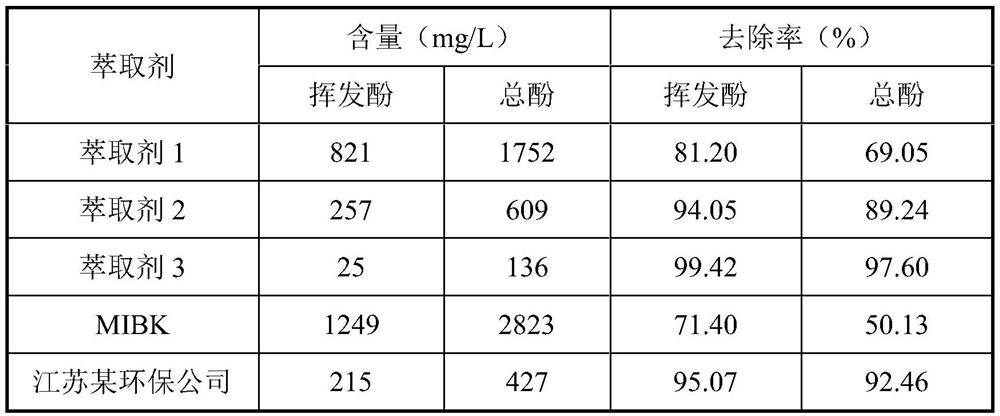

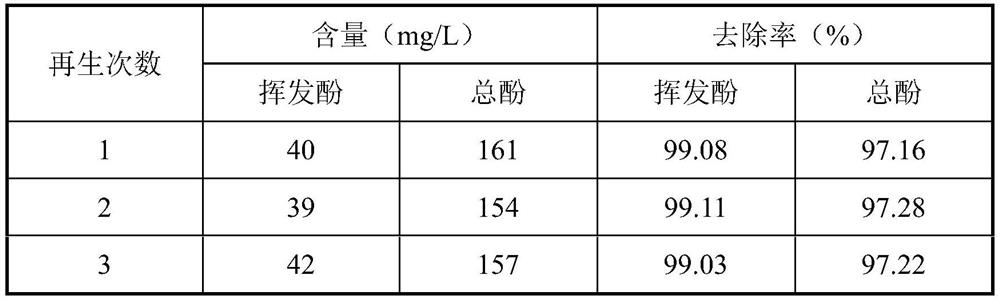

Low-loss high-efficiency dephenolizing extractant for treating low-rank coal quality-divided conversion phenol-containing wastewater

ActiveCN112607812AShort equilibration timeReduce lossesWater contaminantsLiquid solutions solvent extractionDioctyl phosphatePhosphoric acid

The invention discloses a low-loss high-efficiency dephenolizing extractant for treating low-rank coal quality-divided conversion phenol-containing wastewater. The extractant is composed of dioctyl phosphate, kerosene, trialkylamine and isomeric beta-branched chain primary alcohol. The use method of the extractant comprises the following steps: at normal temperature, regulating the pH value of the wastewater generated by low-rank coal quality-divided conversion to 1-6 by using acid, demulsifying to remove emulsified oil and suspended matters, adding the extractant provided by the invention, extracting to obtain an extraction phase (extractant) and a raffinate phase (extracted wastewater), treating the extraction phase by using alkali liquor to obtain a regenerated extractant, and recycling. The product effectively solves the problems of high equipment investment, complex operation, high operation cost and the like caused by complex extraction process, low dephenolization efficiency and large loss of the extractant in the existing extractant.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

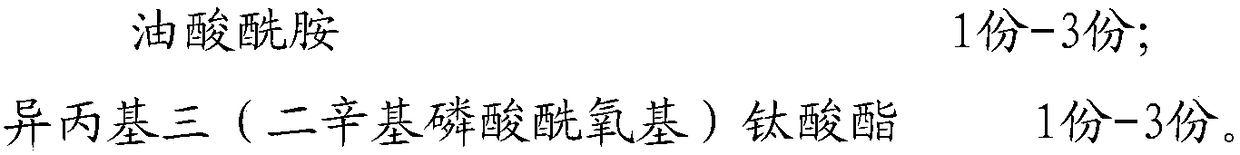

PA66 composite material and preparation method thereof

The invention relates to a PA66 composite material and a preparation method thereof. The PA66 composite material is prepared from the following components in parts by weight: 80-100 parts of PA66, 40-50 parts of functional modified masterbatches and 0.1-0.5 part of an antioxidant. The functional modified masterbatches is prepared from the following componnets in parts by weight: 20-40 parts of MBS, 20-30 parts of wollastonite, 40-60 parts of talcum powder, 1-3 parts of oleamide and 1-3 parts of isopropyl tris(dioctyl phosphate acyl oxide) titanate. By the technical scheme, compared with a packing used directly, the functional modified masterbatches optimizes a production environment, improves the production efficiency, and has quite high promotion value.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

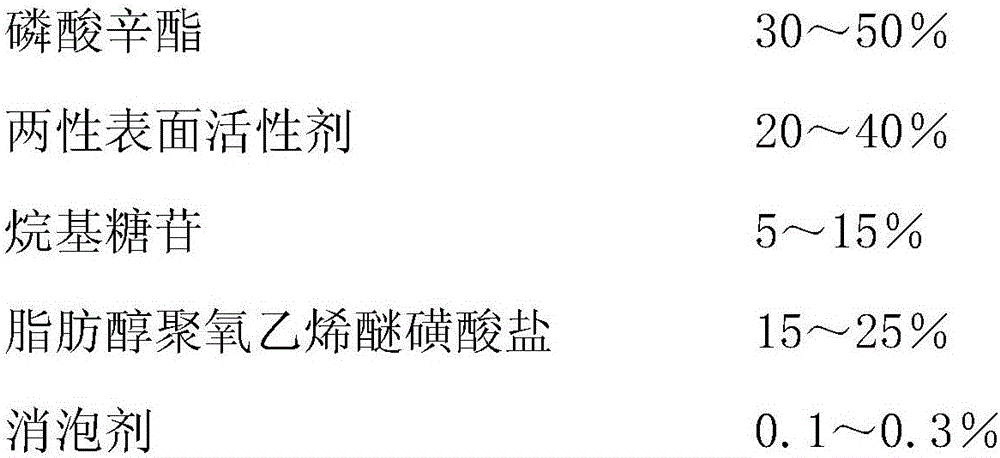

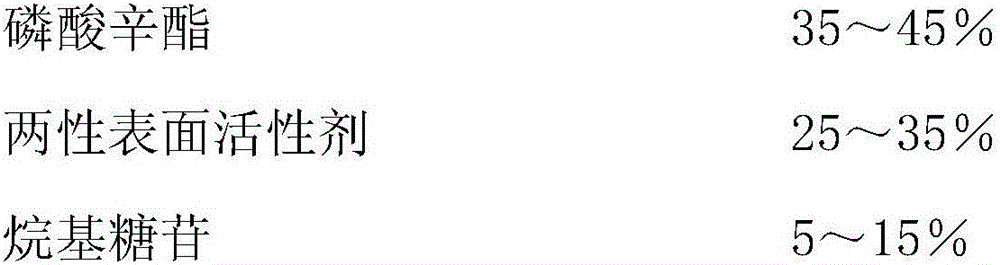

A kind of rapid alkali-resistant penetrating agent and preparation method thereof

The invention discloses a fast alkali-resistant penetrating agent and a preparation method thereof. The fast alkali-resistant penetrating agent comprises the following components by weight percentage: octyl phosphate 10-60%, amphoteric surfactant 10-30%, alkanes 5-20% of sugar anhydride, 10-30% of fatty alcohol polyoxyethylene ether sulfonate, and 0.1-0.5% of defoamer. Add the above-mentioned raw materials into the mixing tank according to the required ratio, stir evenly, add NaOH solution to adjust the pH=7~8, and finally add water to dilute to obtain the rapid alkali-resistant penetrant. The penetrant prepared by the present invention has an alkali resistance of up to 300g / l NaOH, and has good penetration, emulsification, and washing properties under neutral to strong alkaline conditions, and does not contain APEO, is easy to degrade, and is suitable for printing and dyeing. various processes.

Owner:广东灵捷制造化工有限公司

Zinc-rich paint with addition of isopropyl tri (dioctyl phosphate acyloxy) titanate

InactiveCN104987796ASimple preparation processEasy to operateAnti-corrosive paintsDioctyl phosphateZinc

The invention discloses zinc-rich paint with addition of isopropyl tri (dioctyl phosphate acyloxy) titanate and a preparation method thereof. According to the zinc-rich paint with the addition of the isopropyl tri (dioctyl phosphate acyloxy) titanate, through the addition of an isopropyl tri (dioctyl phosphate acyloxy) titanate coupling agent, not only is the adhesive force of the paint improved greatly, but also the effects of preventing sedimentation and improving the mechanical strength of the composite material can be effectively achieved.

Owner:刘星

Heat-proof chemical-resistant pad for laboratory table board

InactiveCN104987608AImprove air tightnessFast vulcanizationPigment treatment with non-polymer organic compoundsDioctyl phosphateMethacrylate

The invention discloses a heat-proof chemical-resistant pad for a laboratory table board. The pad is made of a modified brominated butyl rubber material which comprises the following raw materials: brominated butyl rubber, epoxidized natural rubber, polytetrafluoroethylene, carbon black, modified graphene, aluminum oxide, magnesium oxide, zinc methacrylate, zinc oxide, stearic acid, sulfur, brominated phenolic resin, benzoyl peroxide, rosin, dioctyl phosphate, an antiager and an accelerator. The pad provided by the invention is high in strength and heat resistance, and excellent in chemical resistance and wear resistance.

Owner:ANHUI YUAN LAB EQUIP

Sound insulation and heat insulation material and preparation method thereof

The invention discloses a sound insulation and heat insulation material which comprises, by weight, 100-120 parts of natural ore, 40-60 parts of natural fibers, 30-50 parts of organic fibers, 10-40 parts of aluminum silicate fibers, 60-90 parts of sound insulation particles, 80-100 parts of heat insulation particles, 30-50 parts of glass beads, 20-40 parts of ceramic particles, 30-50 parts of Di(2-ethylhexyl)phosphate, 2-7 parts of polyethylene glycol, 2-6 parts of antioxidants, 4-8 parts of plasticizers, 1-3 parts of high-temperature ceramic glue, 2-5 parts of flame retardants, 1-3 parts of foaming agents and 120-140 parts of water. The sound insulation and heat insulation material has good sound insulation and heat insulation performance, barriers noise pollution and is environmentally friendly and efficient in energy, added glass bead particles have compact shells and hollow interiors, propagation paths of sound waves can be effectively prolonged, loss of the sound waves is increased, and sound insulation effect is further enhanced.

Owner:合肥聪亨新型建材科技有限公司

A kind of trioctyl phosphate industrial production method

ActiveCN103304595BHigh purityLow costGroup 5/15 element organic compoundsPreparation from chloridesDioctyl phosphatePhosphate

The invention relates to an industrial production method for trioctyl phosphate, and in particular relates to an industrial production process for trioctyl phosphate and a byproduct recovering method. Raw materials comprise octanol, phosphorus oxychloride, phosphorus oxychloride and aqueous alkali. The device mainly comprises a centrifugal pump, an octanol storage tank, an octanol metering tank, a mixing kettle, a freezing brine pump, a freezing brine device, an esterification kettle, a steam pipeline, a neutralizing kettle, an alkaline water tank, a hydrogen chloride recovering device, a washing device, a vacuum pump, a dealcoholization pump, a condenser and an alcohol-water separator. According to the method provided by the invention, hydrogen chloride can be recovered and marketed in form of hydrochloric acid product, so that pollution is reduced. The washing device is further arranged to adequately remove impurities such as monooctyl phosphate and dioctyl phosphate. A lens is additionally installed, so that whether washing water is discharged completely or not is easy to judge. A spraying stirring device is adopted to reduce the degree of emulsification during separation. The alcohol-water separator can produce octanol products, so that the product purity of trioctyl phosphate is increased and the production cost is lowered.

Owner:岳阳振兴中顺新材料科技股份有限公司

Solubilizing modified anti-corrosion paint added with sodium dodecyl benzene sulfonate

InactiveCN106189616ASimple preparation processEasy to operateAnti-corrosive paintsDioctyl phosphateMetasilicate

The invention discloses solubilizing modified anti-corrosion paint added with sodium dodecyl benzene sulfonate and a preparation method thereof. The method comprises the following steps that firstly, a certain amount of potassium metasilicate solution and a certain amount of sodium silicate solution are respectively poured into a container to be mixed and heated; silica sol is added; then, a certain amount of dioctyl phosphate acyloxy titanate and sodium dodecyl benzene sulfonate are added; high-speed uniform stirring is performed; finally, silicon-acrylate emulsion and 700-mesh zinc powder are sequentially added; solubilizing modified zinc-rich anti-corrosion paint is obtained after the continuous uniform stirring.

Owner:严应倩

A kind of preparation method of biodegradable food packaging material

The invention discloses a preparing method of a biodegradable food packaging material, and belongs to the technical field of preparing packaging materials. Discarded anaerobic cassava distillers' grains are reused, dissolved through a cellulose dissolving system and modified with a lauric acid, bi(dioctyl phosphate) diethylene titanate and polyethylene glycol composite modifying agent, auxiliaries such as specific dispersant, toughener, plasticizer and stabilizer are added, and the biodegradable food packaging material is prepared through extrusion granulation of a double-screw extruder and hot press molding of a press vulcanizer. Tenacity, tensile strength, impact strength and other performance of the biodegradable food packaging material prepared through the preparing method meet the packaging requirement, material cost is greatly reduced, and comprehensive utilization of waste resources is achieved.

Owner:盐城钻梦环保科技有限公司

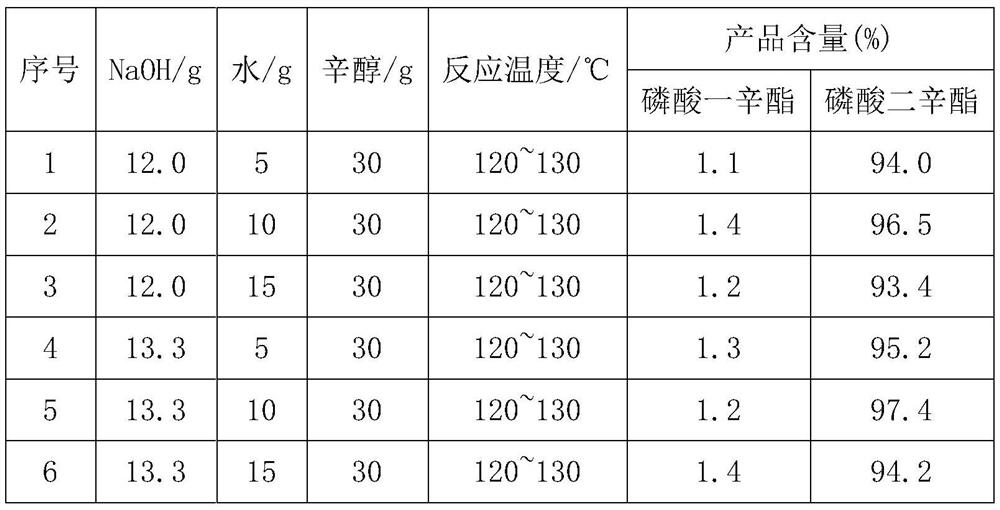

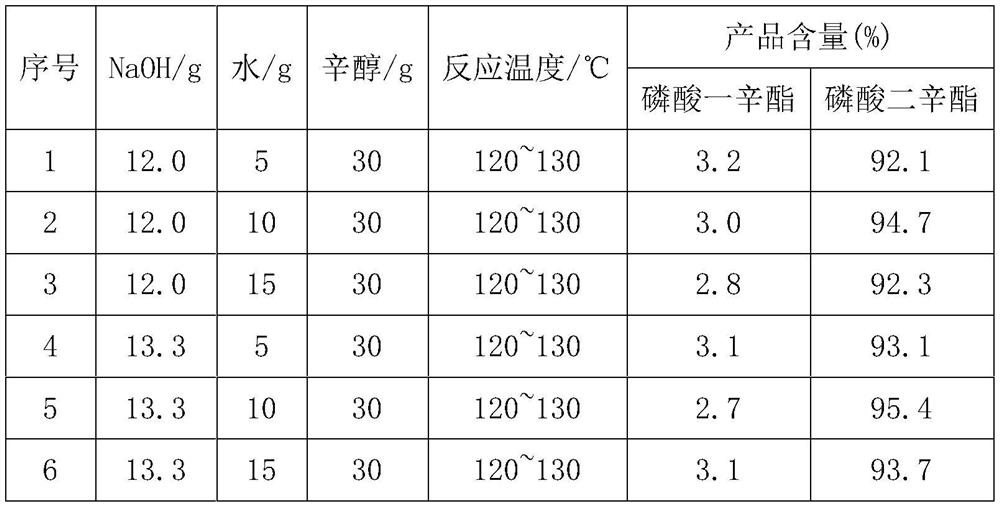

Preparation method of high-purity dioctyl phosphate

PendingCN113717222AReduce dosageIncrease contentGroup 5/15 element organic compoundsDioctyl phosphateO-Phosphoric Acid

The invention provides a preparation method of high-purity dioctyl phosphate, which comprises the following steps: taking octanol and water as solvents, adding phosphoric acid mixed octyl ester and solid alkali which is 1.1-1.35 times of theoretical quantity required by alkaline hydrolysis of the phosphoric acid mixed octyl ester, performing high-temperature alkaline hydrolysis, and performing acidification reaction twice to obtain the high-content and high-purity dioctyl phosphate. According to the method, the dosage of the solid alkali is reduced, a phase transfer catalyst does not need to be added, the steps are simple, the reaction conditions are mild, the energy consumption is low, the reaction period is short, the content of the obtained dioctyl phosphate is larger than 93%, and the purity is high.

Owner:HANGZHOU QIANYANG TECH

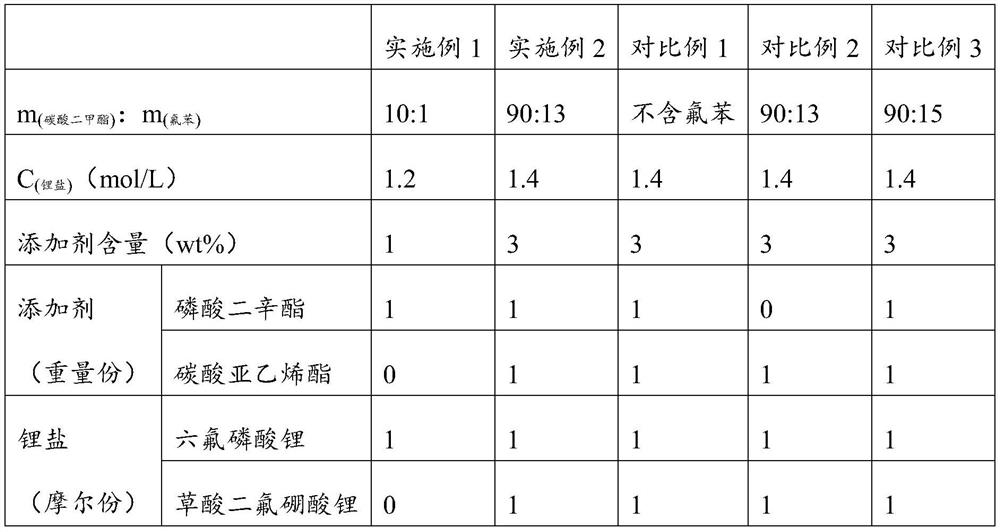

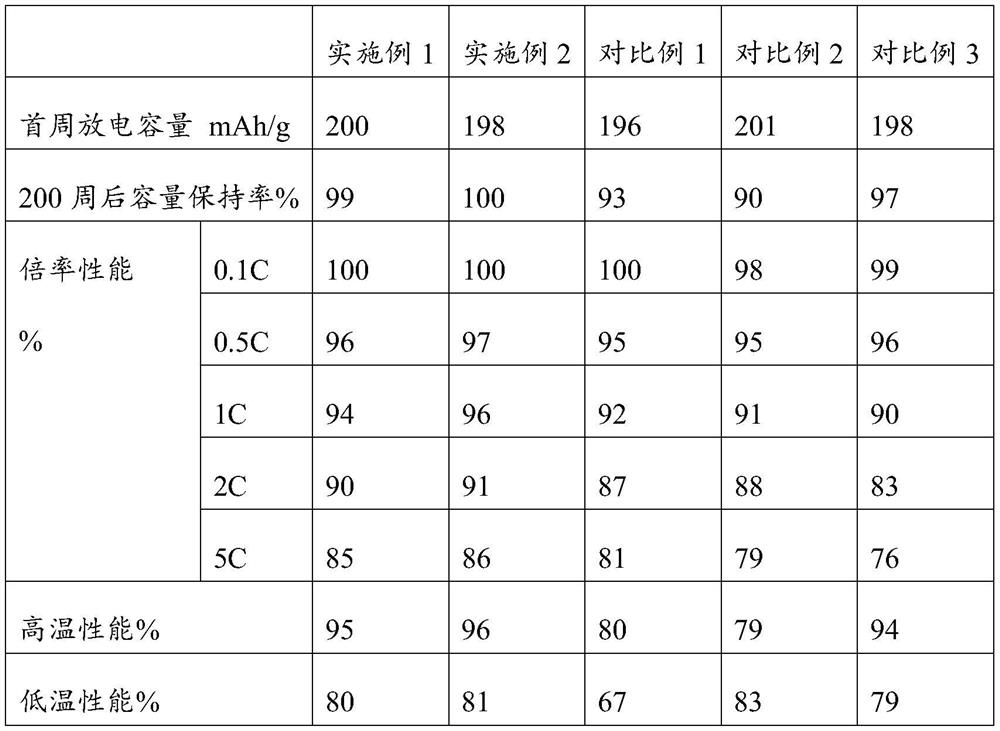

Electrolyte for lithium secondary battery as well as preparation method and application of electrolyte

PendingCN113871717ASecondary cells servicing/maintenanceOrganic electrolytesDioctyl phosphateElectrolytic agent

The invention discloses an electrolyte for a lithium secondary battery as well as a preparation method and application of the electrolyte. The electrolyte for the lithium secondary battery comprises the following preparation raw materials: a solvent, which comprises dimethyl carbonate and fluorobenzene; an additive, wherein the additive comprises dioctyl phosphate; and a lithium salt. According to the electrolyte for the lithium secondary battery provided by the invention, the performance reduction of the secondary battery caused by dissolution of positive electrode material metal can be remarkably inhibited through the matching of the preparation raw materials.

Owner:湖南法恩莱特新能源科技有限公司

Biodegradable plastic master batch

InactiveCN108559155AReduce manufacturing costSimple preparation processLow-density polyethyleneEpoxy

The invention discloses a biodegradable plastic master batch. The biodegradable plastic master batch is prepared from, by weight, 20-40 parts of low-density polyethylene, 20-40 parts of bentonite, 5-15 parts of chlorinated paraffin, 1-3 parts of butyl epoxy stearate, 0.1-1 part of tetraisopropyl (dioctyl phosphate) titanate, 0.1-1 part of dispersing agent and 1-2 parts of antioxidant. The providedbiodegradable plastic master batch has the advantages that the production cost is low, the preparation process is simple, the degradation property is good, the biodegradable plastic master batch hasa good mechanical property, fire resistance and a antibacterial property, and the degradation property accords with environment-friendly requirements.

Owner:韩其洋

Manufacturing method of anti-static filtering material and anti-static filtering material

InactiveCN114159888APrevent electrostatic hazardsImprove spinnabilityFiltration separationDioctyl phosphateFluoride

The invention provides a manufacturing method of an anti-static filtering material and the anti-static filtering material. PTFE micro powder, isopropyl tri (dioctyl phosphate acyloxy) titanic acid, tourmaline and vinylidene fluoride are blended and extruded into a rod-shaped object according to a certain proportion, and multi-component improved PTFE fibers are prepared through rolling film forming and film cracking. The composite fibers are subjected to opening, mixing, fine opening, carding, lapping and needling to form the improved fiber filter material. The modified PTFE fiber has the advantages that due to the existence of tourmaline, the antistatic performance of PTFE can be effectively improved, the performance of the PTFE fiber is not influenced, and the prepared modified fiber has better antistatic performance than common PTFE fiber and better strength than the common PTFE fiber. The filter material is small in static electricity in the production process, has good acid and alkali resistance stability, and can be used under the working conditions that static electricity is easily generated and the acid and alkali concentration of smoke gas is high.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

A synergist for refractory copper oxide ore flotation

ActiveCN107899755BRealize heating and fusionHigh reactivityFlotationDioctyl phosphateMining engineering

The invention provides a synergist for refractory copper oxide ore flotation and a preparation method thereof, and belongs to the technical field of flotation. The synergist comprises, by weight, 60 parts of 8-hydroxyquinoline, 45 parts of dioctyl phosphate, 15 parts of ammonium sulfate, 5 parts of kerosene and 5 parts of ethanol. The preparation method comprises the steps of firstly mixing the powdery 8-hydroxyquinoline and ammonium sulfate, then mixing the liquid dioctyl phosphate, kerosene and ethanol, adding the powdery solids into the mixed liquid medicament solution, next adding water soas to prepare the water solution with the volume fraction of 30%-35%, heating to 40-50 DEG C in a microwave field, and stirring for 15-20 min. The prepared synergist can be directly added into the ore grinding operation in the form of a stock solution. The synergist for the refractory copper oxide ore flotation is stable in property, good in solubility, high in activity, less in dosage of the medicament, high in adaptability to ores and capable of effectively improving indexes of the refractory copper oxide ore flotation, and has obvious technical and economic indexes and environmental benefits.

Owner:云南迪庆有色金属有限责任公司 +1

UV-cured conductive silver paste and preparation method thereof

PendingCN114864178AImprove dispersionClose contactApparatus for heat treatmentNon-conductive material with dispersed conductive materialDioctyl phosphatePhosphorous acid

The invention relates to the technical field of new material preparation, in particular to UV curing conductive silver paste and a preparation method thereof. The preparation method of the UV-cured conductive silver paste comprises the following steps: step 1, dissolving a photoinitiator in a reactive diluent under a heating condition, and cooling to obtain a photo-initiation curing liquid; step 2, adding a prepolymer, a conductive additive and conductive powder into the photo-initiation curing liquid in the step 1, and grinding to obtain a conductive adhesive; wherein the conductive auxiliary agent is prepared from at least one of tetra-neo-alkoxy bis (didecyl phosphorous acid acyloxy) titanate, isopropoxy dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate and isopropoxy trioleic acid acyloxy titanate. The conductive auxiliary agent is prepared from at least one of the following components: tetrakis (neo-alkoxy) bis (didecyl phosphorous acid acyloxy) titanate, isopropoxy dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate and isopropoxy trioleic acid acyloxy titanate. According to the invention, the titanate coupling agent with a special structure is innovatively introduced as a conductive auxiliary agent, so that the use amount of silver powder can be effectively reduced, the conductivity of the silver paste can be improved, the flexibility of the cured silver paste can be enhanced, and the bending resistance can be improved.

Owner:SHENZHEN TONGTAIYING ELECTRONICS TECH CO LTD

Anti-aging PE water supply pipe

InactiveCN112625325AImprove anti-aging propertiesImprove mechanical propertiesRigid pipesPipe protection against damage/wearDioctyl phosphateLow-density polyethylene

The invention discloses an anti-aging PE water supply pipe, and particularly relates to the field of pipes, the anti-aging PE water supply pipe comprises the following raw materials by weight: 90-100 parts of low density polyethylene, 6-8 parts of bentonite, 0.1-0.3 part of tribasic lead sulfate, 2-4 parts of stearamide, 2-4 parts of sodium polyacrylate, 0.1-0.3 part of isopropyl dioleoyl (dioctyl phosphate) titanate, 0.1-0.3 part ofN-isopropyl-N'-phenyl p-phenylenediamine 0.1-0.3 part of 2-mercaptobenzimidazole, 1-3 parts of glycerol triacetate, 10-15 parts of filler and 3-5 parts of a modifying aid, the filler is one selected from glass fiber, diatomite, asbestos and carbon black, and the modifying aid is one selected from a silane coupling agent, a titanate coupling agent or an aluminate coupling agent. According to the PE water supply pipe, the ageing resistance of the PE water supply pipe can be effectively improved, meanwhile, the mechanical property of the PE water supply pipe is improved through the wear-resistant material in the filler, and therefore the service life of the PE water supply pipe can be effectively prolonged.

Owner:JIANGXI LIDA PLASTIC PIPE IND CO LTD

A kind of thermosetting heat-conducting and heat-dissipating coating and preparation method thereof

InactiveCN103351807BAging resistantImprove adhesionAntifouling/underwater paintsPaints with biocidesDioctyl phosphateXylylene

A heat-curing heat-conducting and heat-dissipating coating and a preparation method thereof, characterized in that it is made of the following raw materials in parts by weight: silicone resin 32-35, melamine formaldehyde resin 12-14, xylene 21-23, ethyl acetate 24-26 , butanol 8-10, aluminum nitride powder 26-28, diaminodiphenylmethane 2-3, diisopropylethanolamine 4-5, benzoin 1-2, di-n-octyl-4-isothiazoline- 3-ketone 1-2, mica powder 12-15, itaconate 4-6, isopropyl dioleate acyloxy (dioctyl phosphate acyloxy) titanate 3-5, vinyl tri( β-methoxyethoxyl) silane 2-3, film-forming agent 4-5; The present invention adopts di-n-octyl-4-isothiazolin-3-ketone, which has increased the anti-mold performance of coating, long-term storage, Will not deteriorate and produce odor.

Owner:TIANCHANG CHICHENG ELECTRIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com