A kind of rapid alkali-resistant penetrating agent and preparation method thereof

An alkali-resistant penetrating agent, fast technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of application limitations, low alkali resistance, etc., and achieve the effect of low cost and improved alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

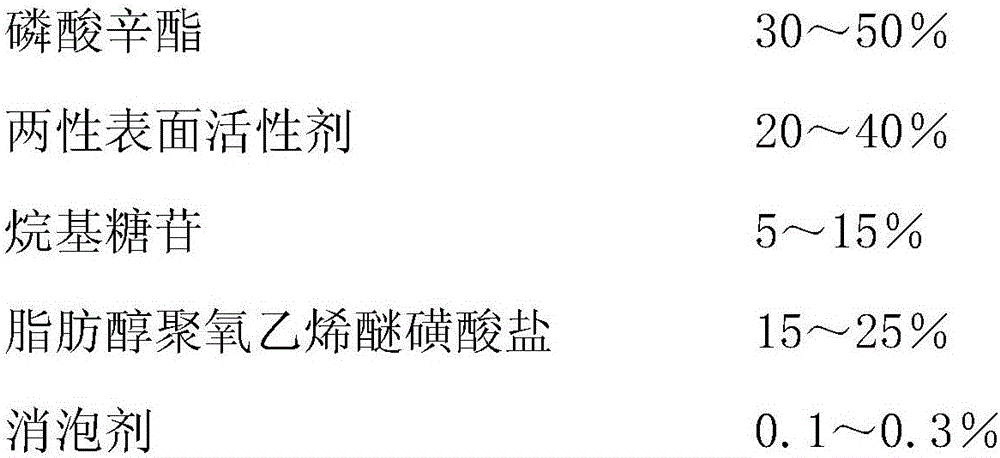

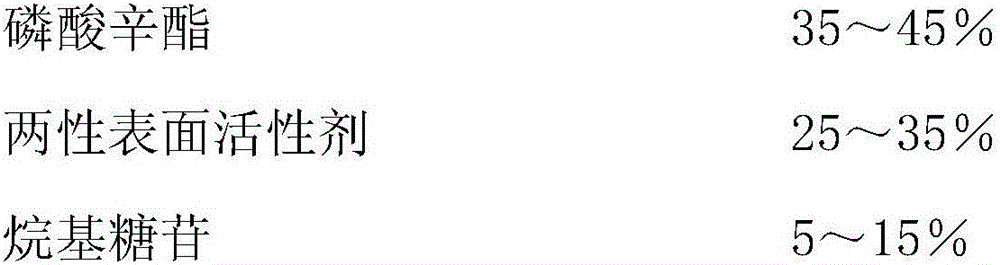

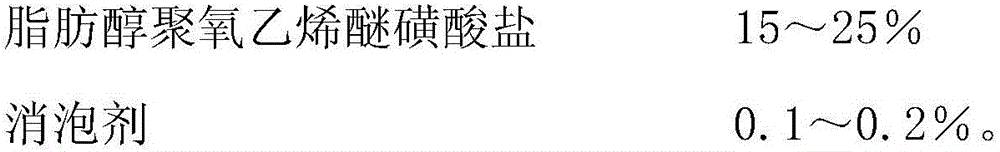

Method used

Image

Examples

Embodiment 1

[0034] In percent by weight, weighed according to the following proportions: octyl phosphate 40%, dodecyl dihydroxyethyl betaine 30%, alkyl glycoside 10%, AES 20%, defoamer 0.1%; the above raw materials Add it into the mixing tank, stir at room temperature for 30-60 minutes, until all raw materials are completely mixed, then add 30% NaOH solution, adjust pH = 7-8, and finally add softened tap water to dilute to an aqueous solution with a solid content of 50% , that is, the rapid alkali-resistant penetrating agent Ⅰ is obtained, its appearance is a colorless transparent liquid, and its alkali resistance can reach 150g NaOH / l.

Embodiment 2

[0036] In percent by weight, weighed according to the following proportions: octyl phosphate 40%, lauryl amidopropyl betaine 30%, alkyl glycoside 10%, AES 20%, defoamer 0.1%; put the above raw materials into the mixing kettle , stirred at room temperature for 30-60 minutes, until all raw materials are completely mixed evenly, then add 30% NaOH solution, adjust pH = 7-8, and finally add softened tap water to dilute into an aqueous solution with a solid content of 50%, which is obtained Rapid alkali-resistant penetrating agent II, its appearance is colorless transparent liquid, and its alkali resistance can reach 180g NaOH / l.

Embodiment 3

[0038] In terms of weight percent, it is weighed according to the following ratio: octyl phosphate 40%, dodecyl dimethyl-2-hydroxypropyl sulfobetaine 30%, alkyl glycoside 10%, AES 20%, defoaming Add the above raw materials into the mixing tank, stir at room temperature for 30-60 minutes, until the raw materials are completely mixed, then add 30% NaOH solution, adjust the pH = 7-8, and finally add softened tap water to dilute into An aqueous solution with a solid content of 50% can be used to prepare rapid alkali-resistant penetrating agent III. Its appearance is a transparent colorless liquid, and its alkali resistance can reach 200g NaOH / l.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com