Cotton fabric and scattered fiber mercerization instrument for teaching and manufacturing method thereof

A technique of using cotton fabrics and production methods, applied in the field of light chemical industry, can solve the problems of poor mercerizing effect and accuracy, inability to apply tension to fabrics or yarns, and inability to save fabric or yarn consumption, so as to ensure durability, The effect of saving the cost of use and reducing the cost of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

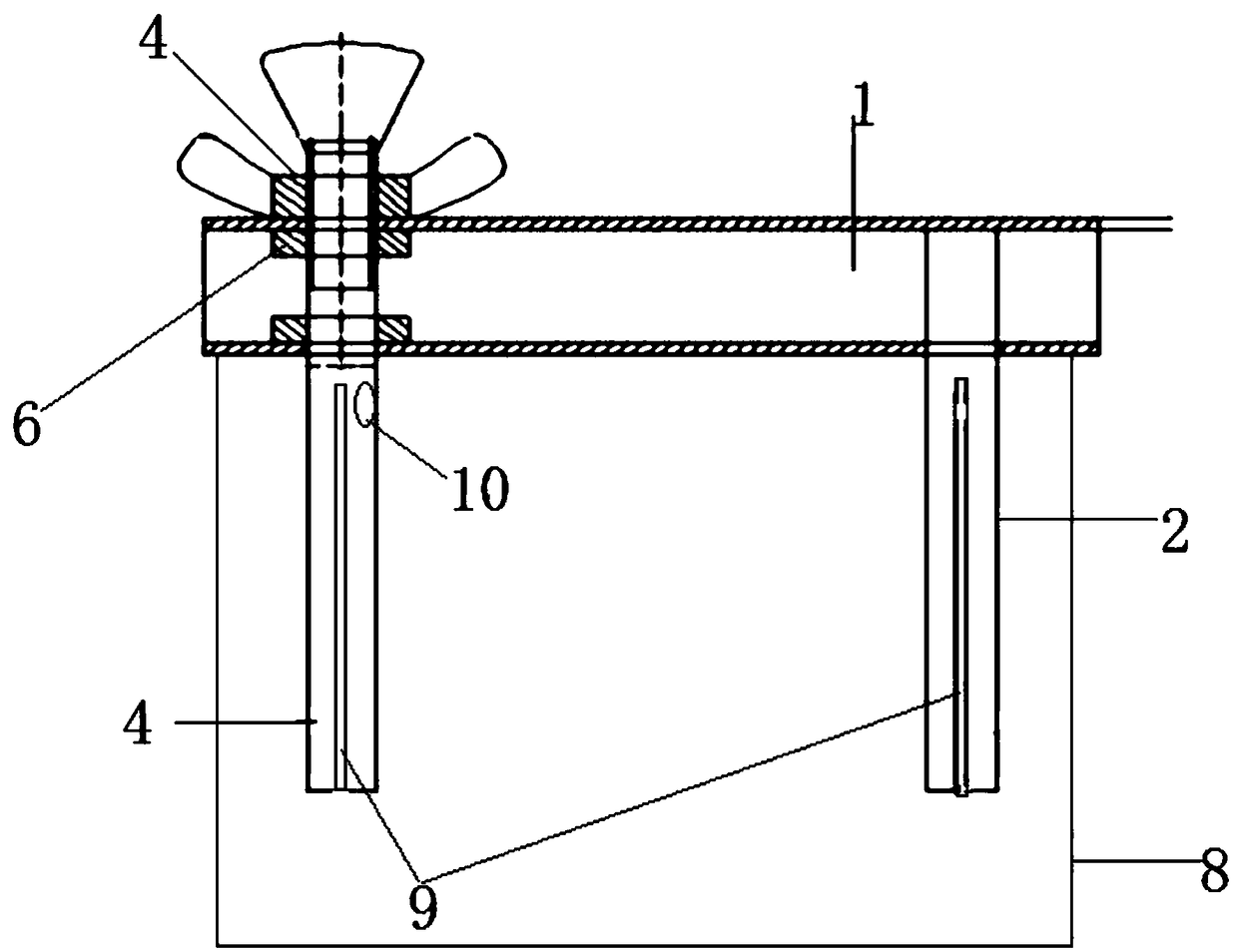

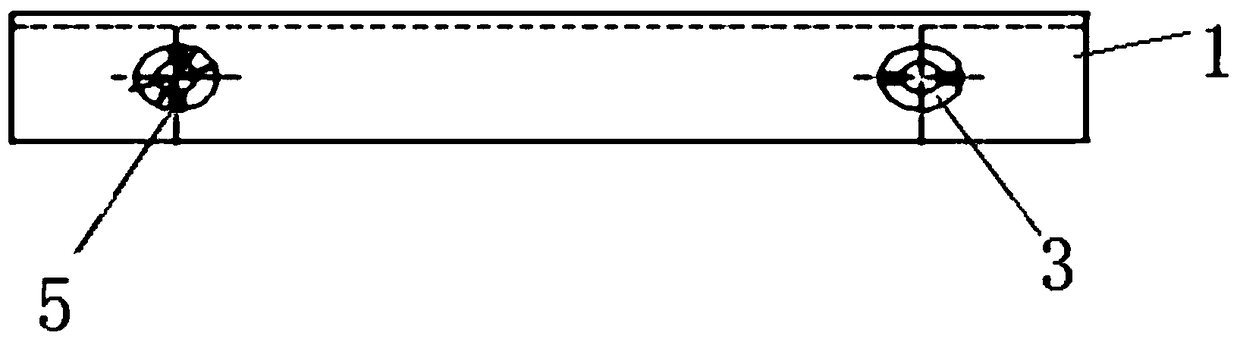

[0041] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0042] The design and manufacture method of the cotton fabric for teaching and the loose fiber mercerizing instrument provided by the embodiment of the present invention includes:

[0043] Choose highly alkali-resistant PP plastic to make mercerized alkali tank;

[0044] The inner size of the mercerized alkali tank produced: length (150-180mm) × width (105-135mm) × height (85-105mm);

[0045] Use 304 or 316L stainless steel to make the mercerized frame;

[0046] The movable steel pipe is screwed on the mercerized frame to adjust the tension of the mercerized fabric or yarn, and the tension applied to the fabric or yarn is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com