Patents

Literature

97results about How to "Solve easy rust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

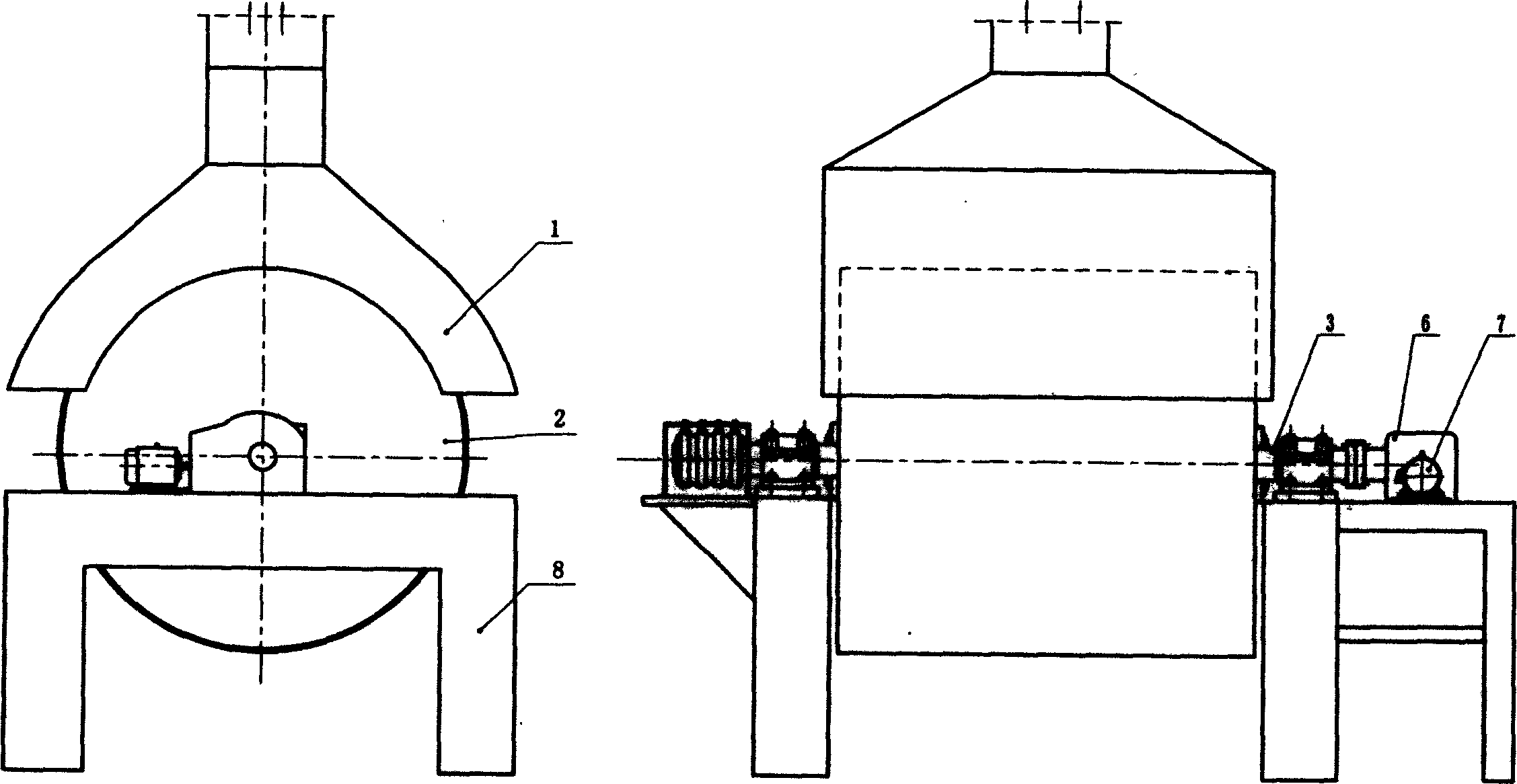

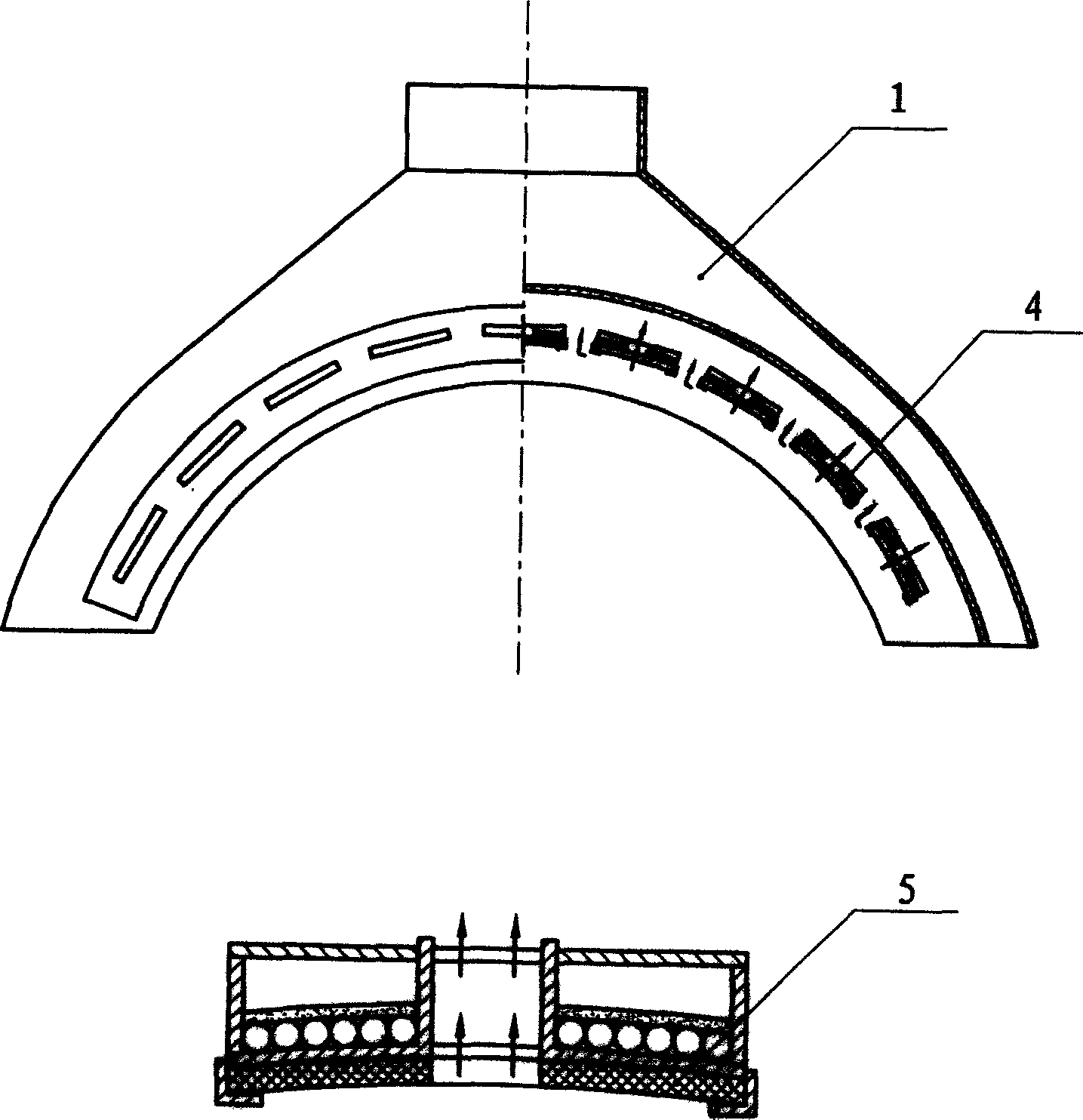

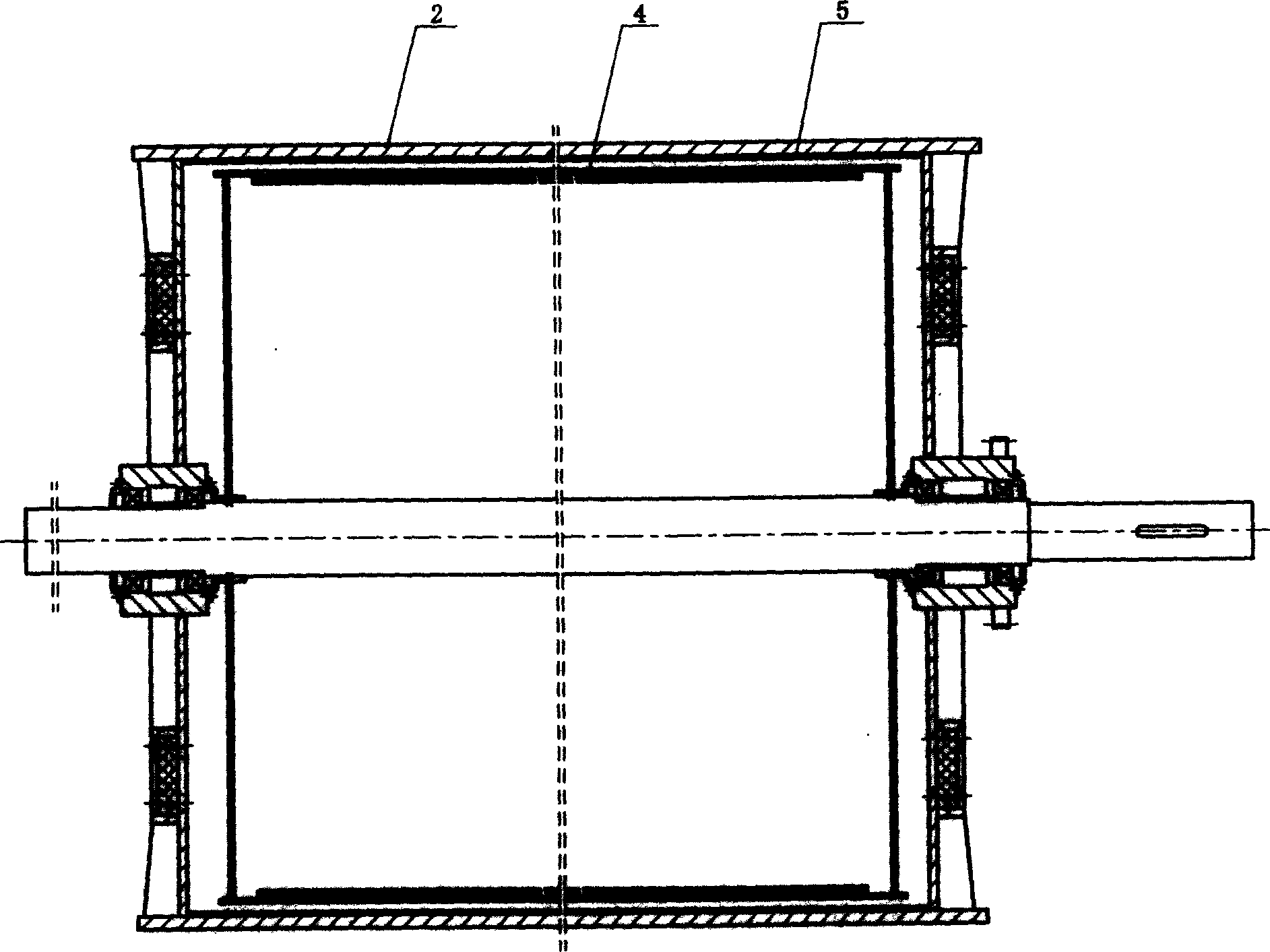

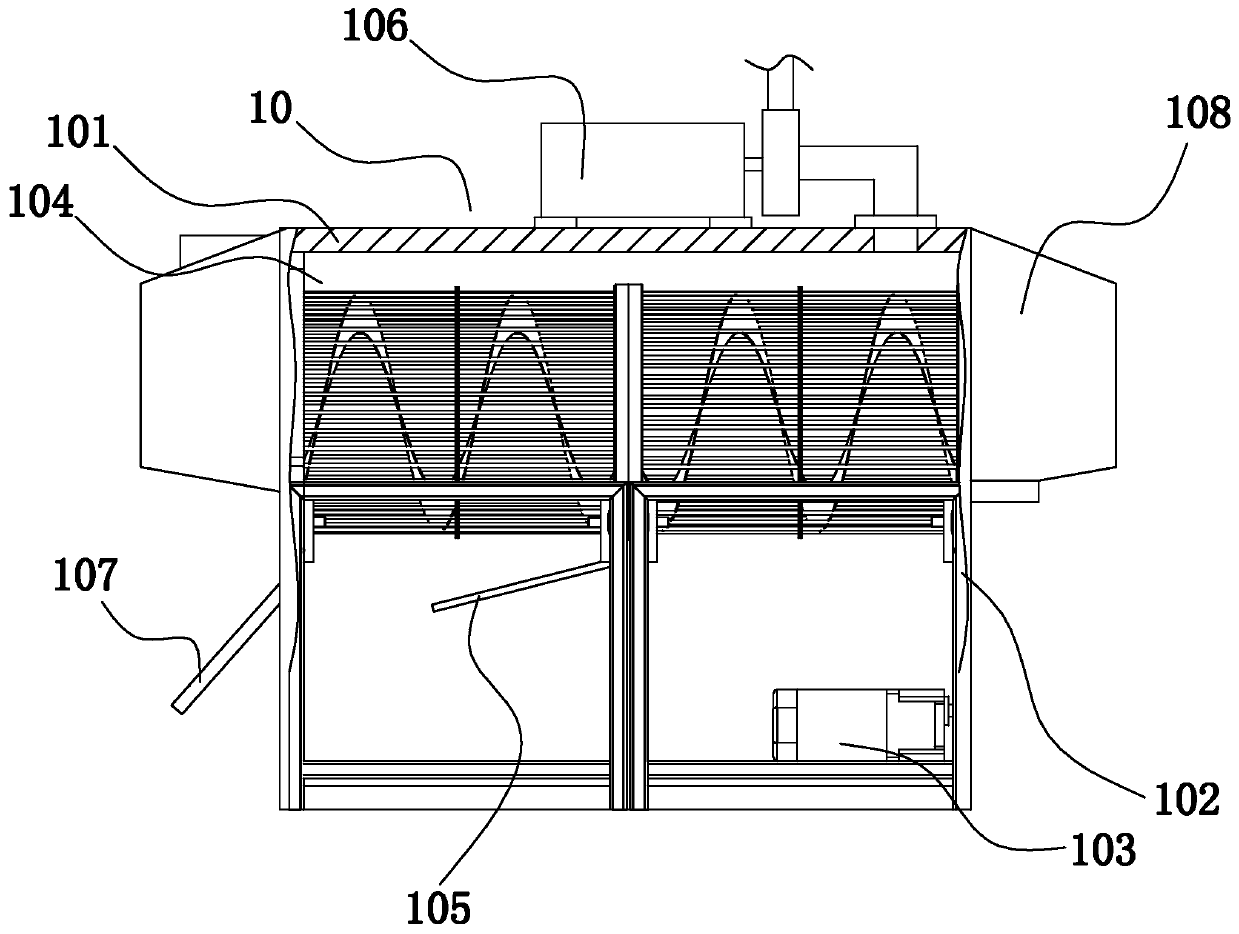

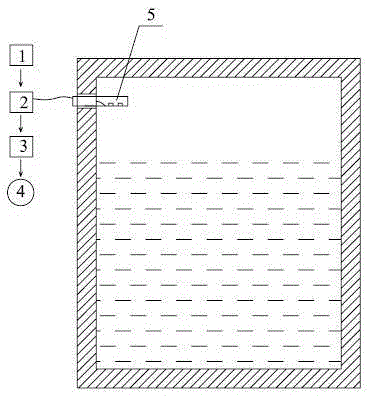

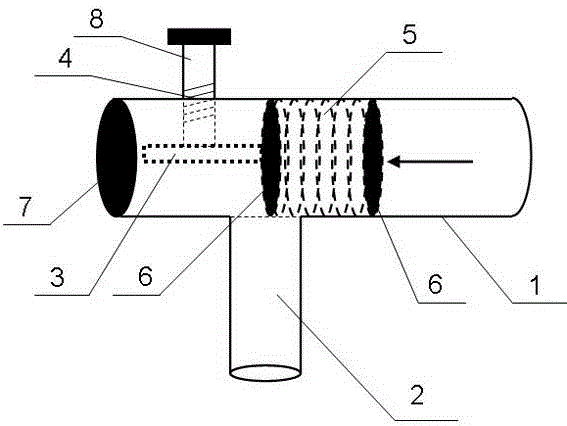

Electromagnetic induction dryer

InactiveCN1560551AChange the heat transfer mode of the heat transfer mediumSimple structureHeating arrangementAutomatic controlHigh frequency power

The invention discloses an electromagnetic induction drying cylinder. It includes a frame, on which there arranges with a gearing spindle, decelerating box, a drying cylinder barrel is arranged on the gearing spindle, a drying cylinder mantle is arranged on the barrel, in the drying mantle there arranges with a electromagnetic induction coil, crystal ceramic glass protection layer, the electromagnetic induction coil is connected to a ring header, a high frequency power and automatic control system. The merits of the invention are: 1)it changes the heat transfer mode of traditional drying cylinder conducting media using the electromagnetic induction heating principle, it needs no steam, oil or other gas as heat conducting media, the structure is simple, high efficient, stable; 2) the efficiency is upgraded, and the cost is reduced; 3) each group of electromagnetic induction coils are allocated with high frequency current, thus the temperature of the working surface of the drier metal is even, at the same time, the device is easy and convenient to be maintained.

Owner:麻红昭

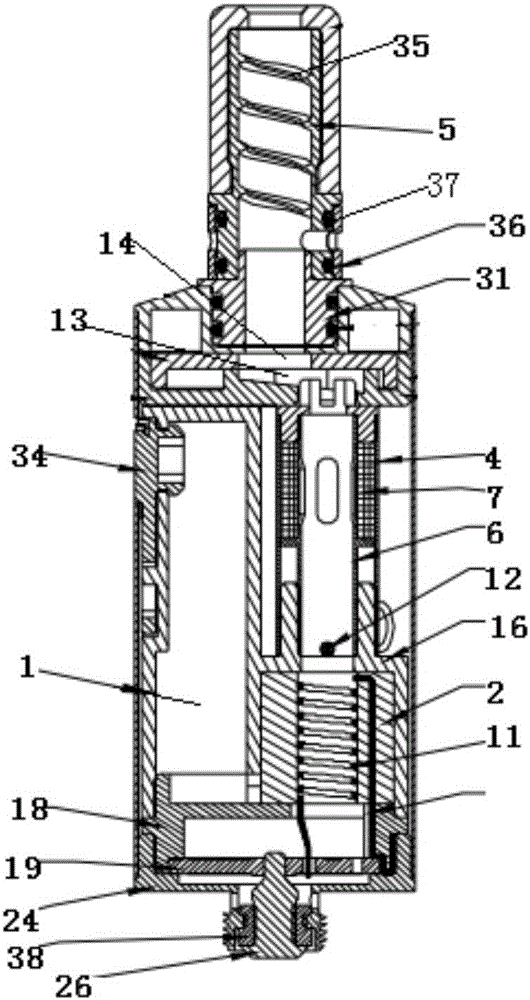

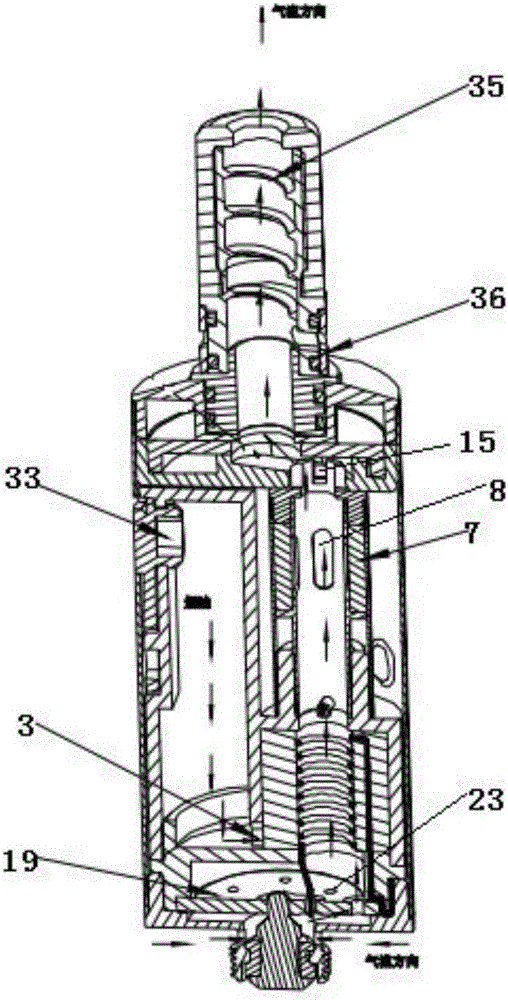

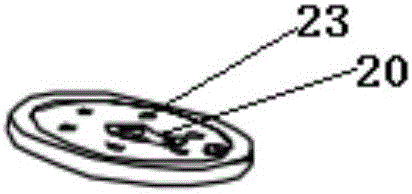

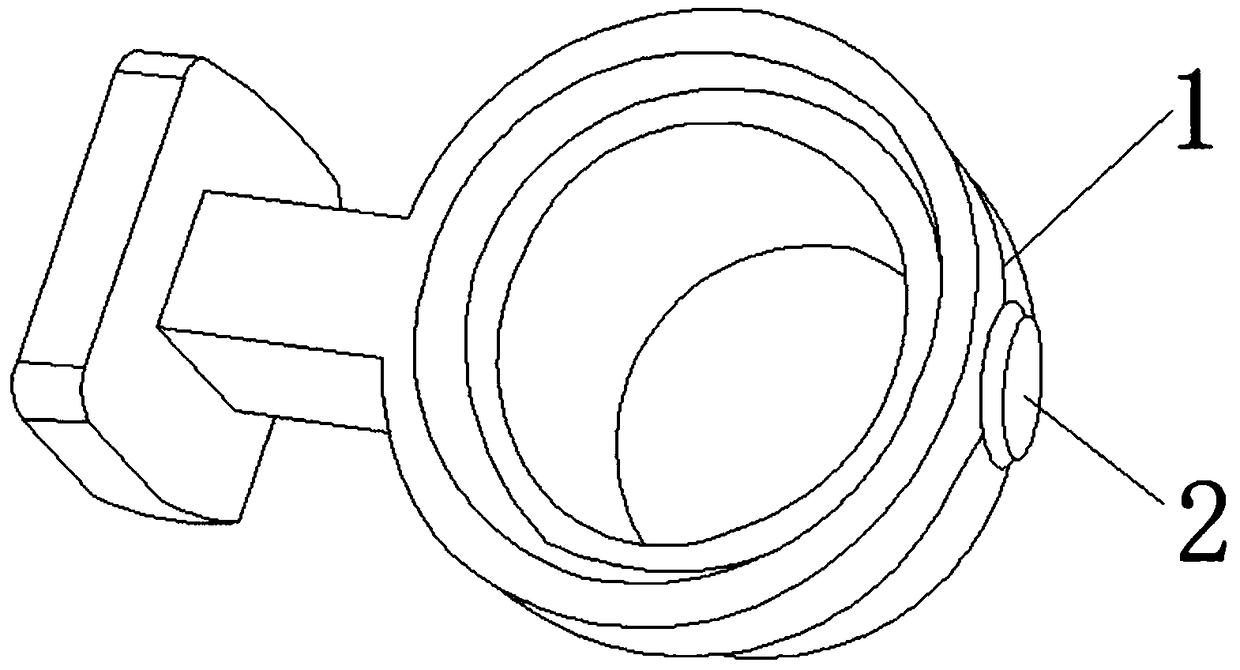

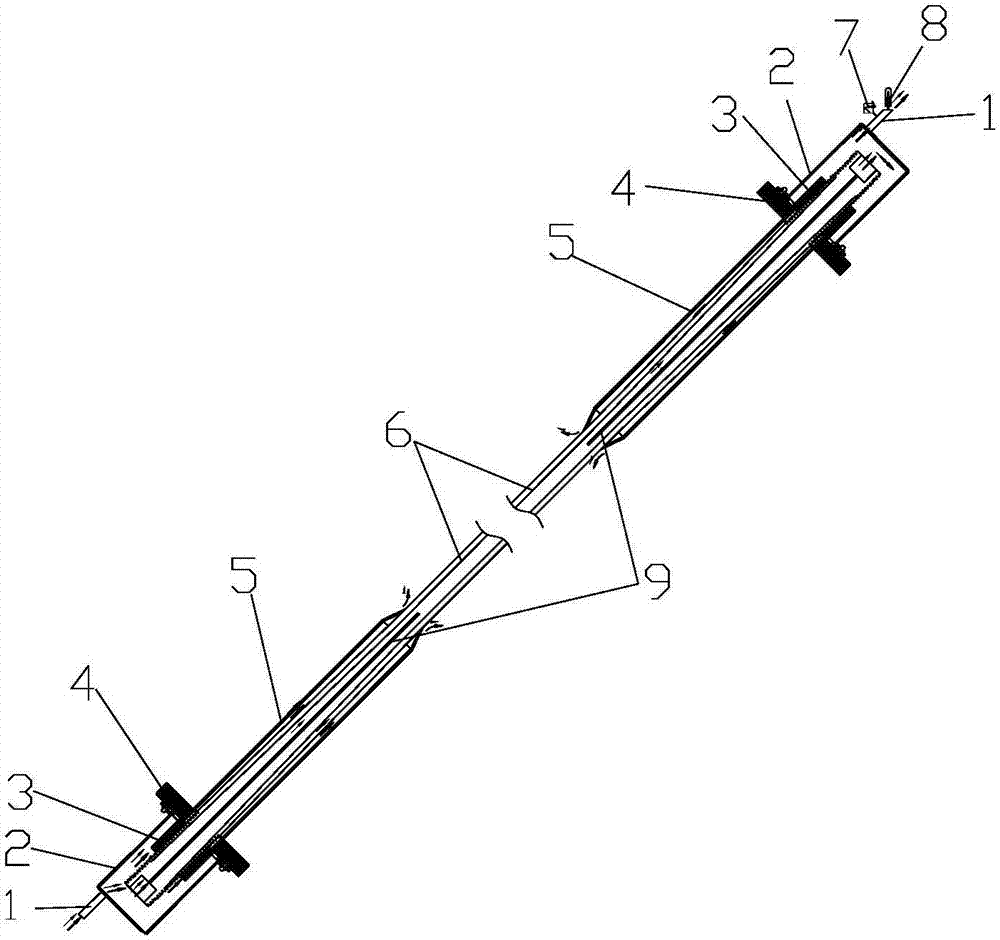

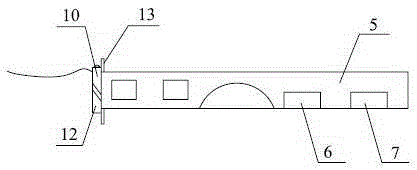

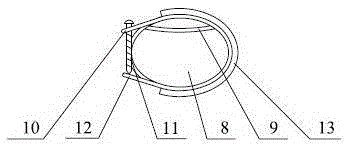

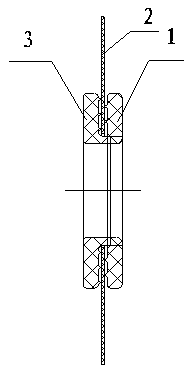

Atomizer

The invention discloses an atomizer. The atomizer comprises a suction nozzle, a liquid storage cavity and an atomization core, wherein the liquid storage cavity and the atomization core are arranged side by side and are communicated via a liquid inlet hole; an air pipe is arranged on the atomization core; the two ends of the air pipe are respectively communicated with the suction nozzle and the atomization core. The atomizer has the beneficial effects that the liquid storage cavity and the atomization core are arranged side by side, thus solving the problems that the surface of the atomization core is easy to rust and oil leakage easily happens to the atomization core and preventing deterioration of tobacco tar from affecting the physical and psychological health of smokers; when being damaged, the atomization core is convenient to change.

Owner:CHINA TOBACCO HUNAN INDAL CORP

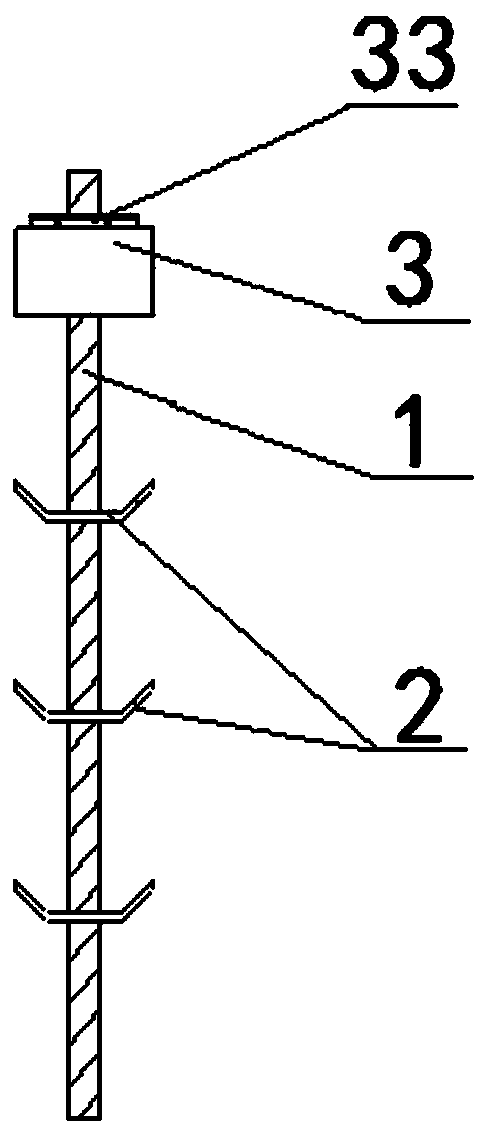

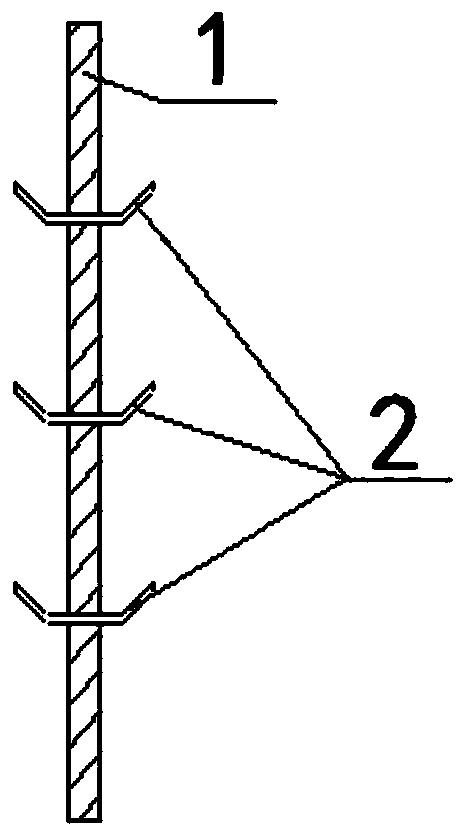

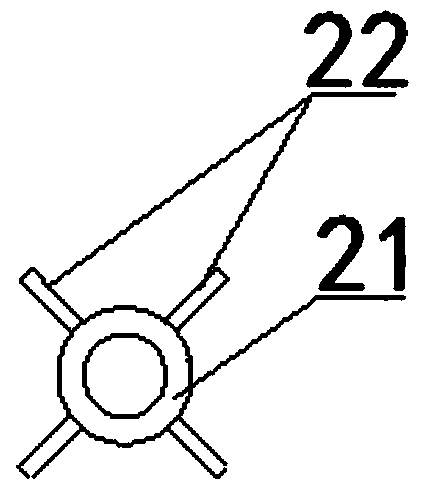

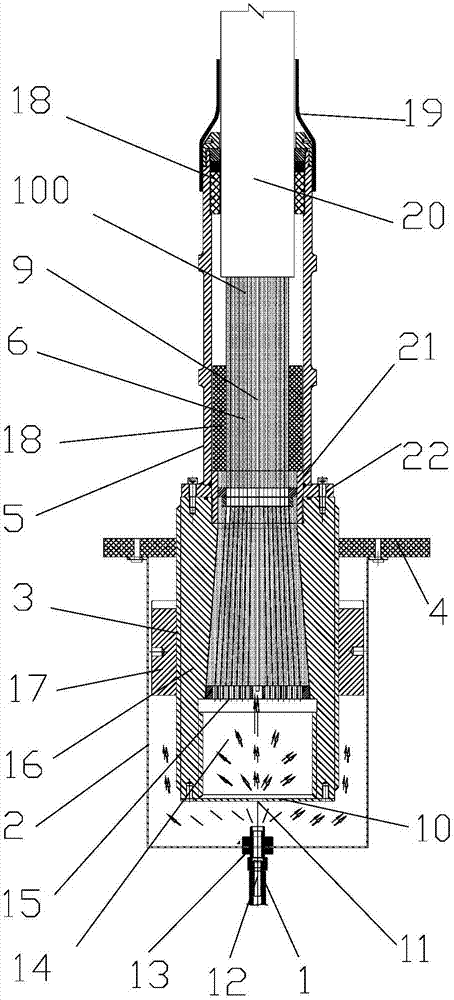

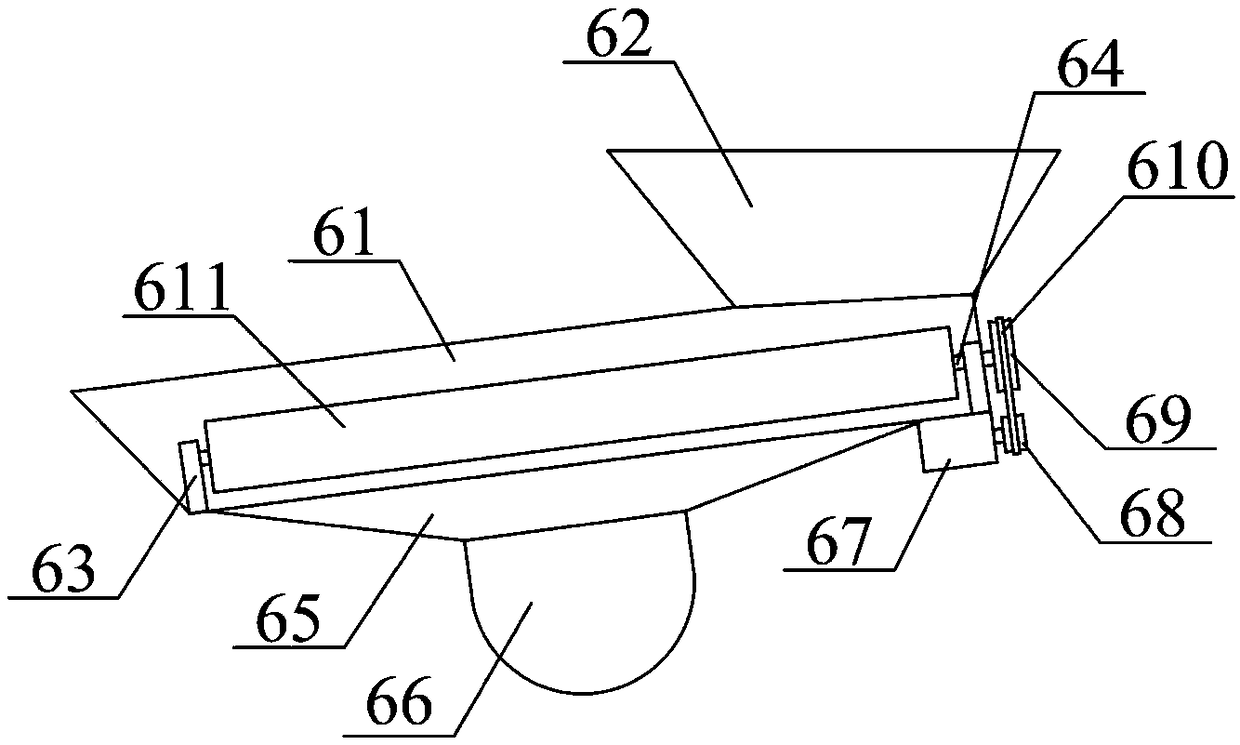

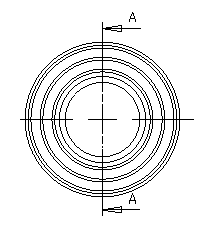

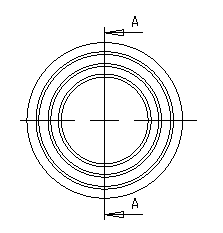

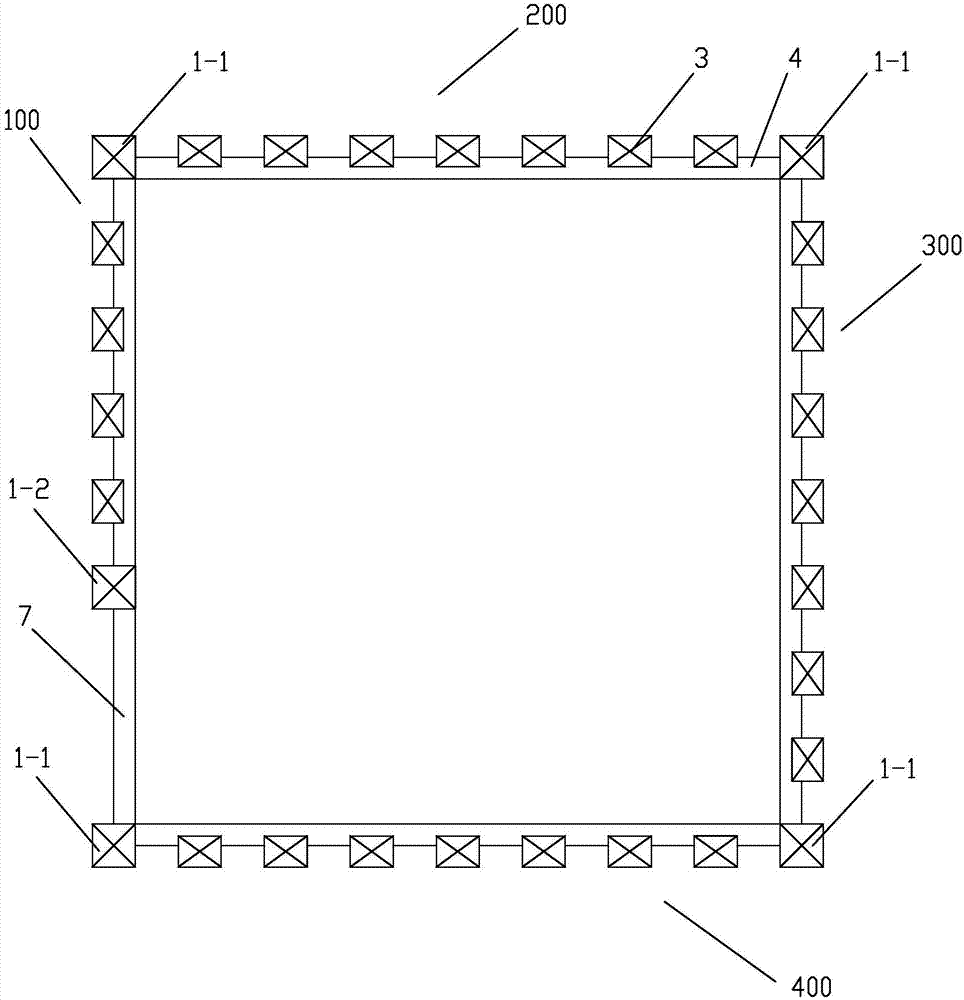

Anchoring system of fishbone-shaped basalt fiber

PendingCN108547291AScientific and reasonable structureEasy to installBulkheads/pilesAnchoring boltsEngineeringBasalt fiber

The invention discloses an anchoring system of a fishbone-shaped basalt fiber. The system comprises a fishbone-shaped basalt fiber anchor rod, an anchorage device is arranged at the top end of the fishbone-shaped basalt fiber anchor rod in a penetrating and inserting mode, and a fishbone-shaped bulge structure sleeves the basalt fiber anchor rod; and the fishbone-shaped bulge structure comprises aplurality of centering supports, each centering support comprises a circular ring base, a plurality of branch structures are arranged on the outer edges of the circular ring bases in the circumferential direction, one ends of the branch structures are fixed on the circular ring bases, and the other ends of the branch structures are obliquely arranged upwards. The fishbone-shaped basalt fiber anchor rod is scientific and reasonable in structure and easy to install, the operation is convenient, the property of light weight and high strength of the basalt fiber material is utilized, the materialbasis is provided for improving the corrosion resistance of the anchor rod, and the operation quality long-term performance of the anchor rod are improved, so that the problem that a traditional anchor rod is prone to rust is fundamentally solved; and meanwhile, the invention provides an anchoring method capable of improving bonding strength of the anchor rod, the operation is convenient, the bonding strength of the anchor rod can be improved, so that the construction quality of the anchoring system is further improved.

Owner:吉林省交通科学研究所 +1

Working fluid used for zinc alloy

ActiveCN107723072ASolve the white spot problem of zinc corrosionSolve rust problemsLubricant compositionWorking fluidZinc alloys

The invention belongs to the technical field of zinc alloy processing, and provides working fluid used for zinc alloy, aiming at solving the technical problem of easy corrosion in the use process of zinc alloy in the prior art. The working fluid comprises the following components by weight percent: 10%-25% of base oil, 3%-10% of fatty acid, 5%-15% of mixed alcohol amine, 4%-8% of boric acid, 1%-5%of non-ferrous metal corrosion inhibitor, 3%-5% of a sulfonate antirust agent, 1%-5% of binary acid, 1%-3% of polyether amine, 3%-8% of an ester lubricant, 0.3%-1.0% of an ester coupling agent, 2%-7%of a nonionic surfactant, 0.5%-2.0% of a hard water resistant stabilizer, 2%-5% of a sterilizing agent, 0.05%-0.15% of a defoaming agent and the balance of deionized water. The working fluid has thecharacteristics of preventing corrosion of zinc alloy, and prolonging the service life of zinc alloy.

Owner:东莞市晶索润滑科技有限公司

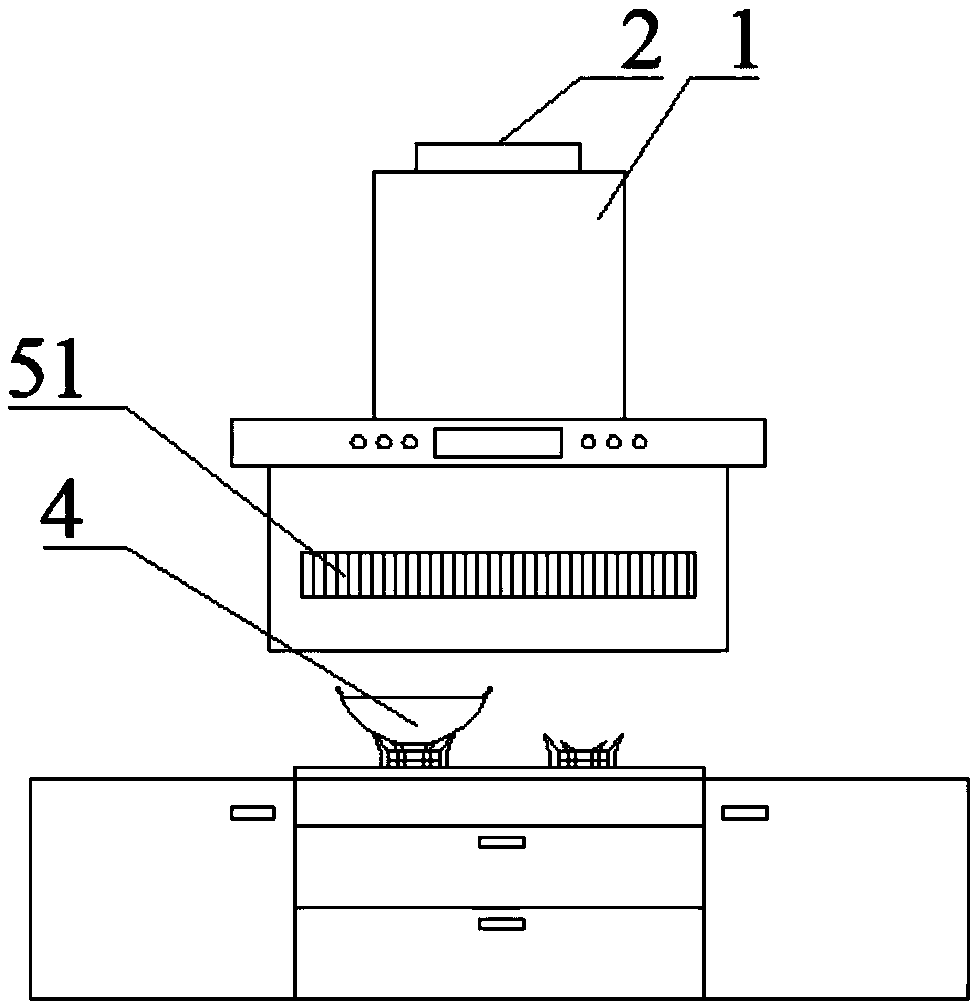

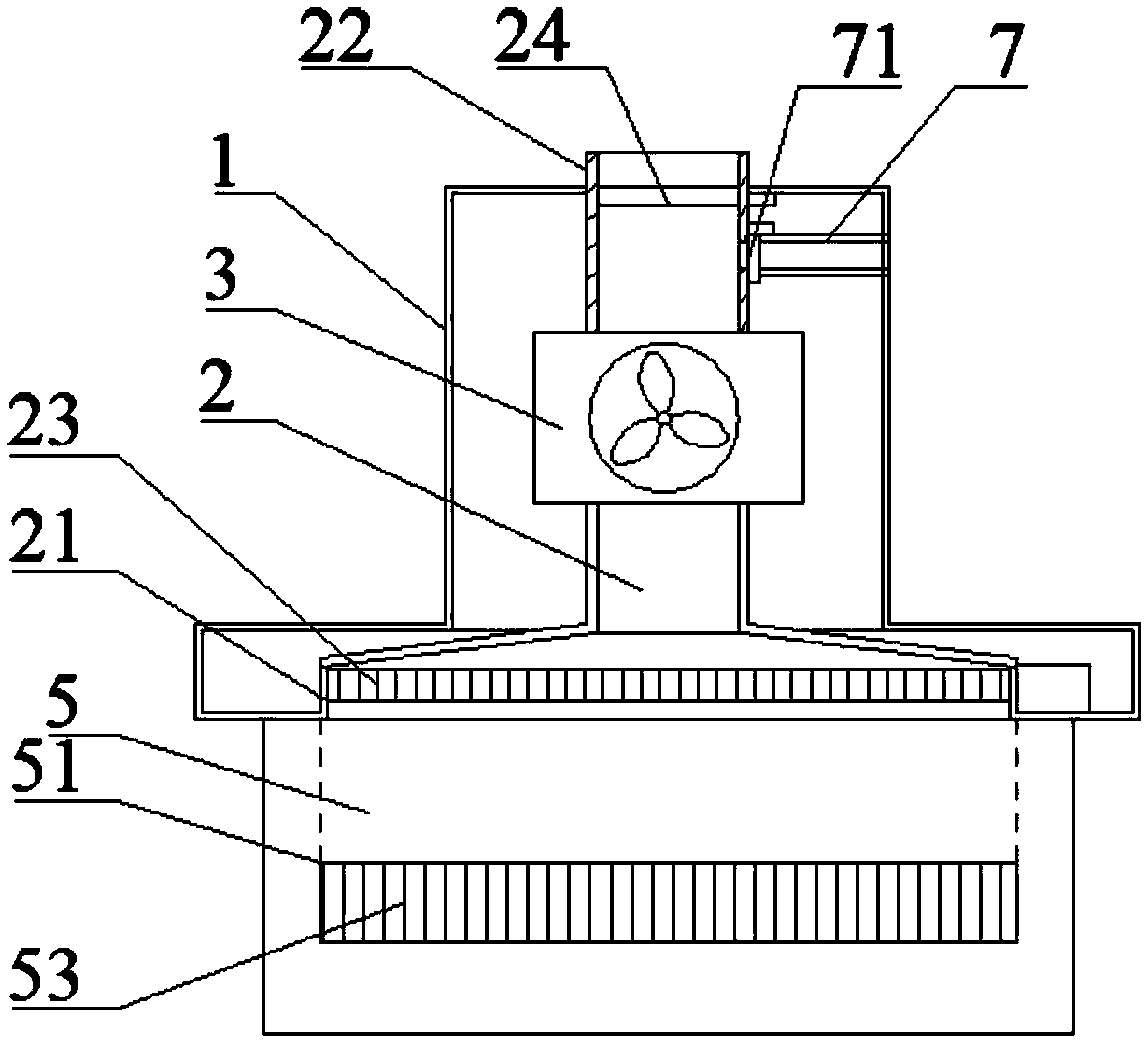

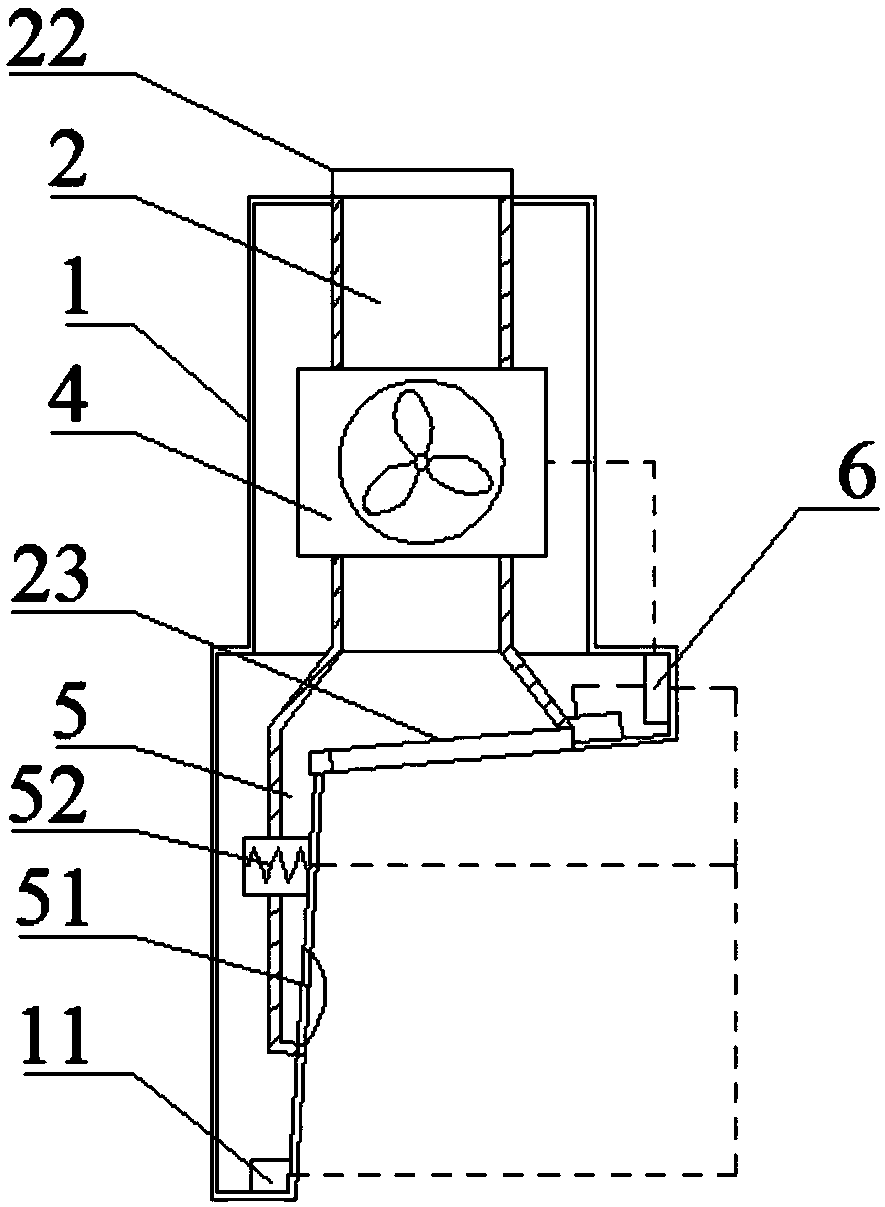

Extractor hood preventing water remaining

ActiveCN109373413ASolve easy rustKeep dryDomestic stoves or rangesLighting and heating apparatusEvaporationControl theory

The invention provides an extractor hood preventing water remaining. A shell, a smoke discharging pipeline, a draught fan, an air blowing pipeline and a controller are included. When cooking is performed, the controller controls the draught fan to rotate forwards, so that air circulation to the outdoor environment is generated in the smoke discharging pipeline, and lampblack generated by cookwareis absorbed. After the cookware is cleaned, the controller firstly controls an electric louver to be closed, and a smoke absorbing opening is blocked. Then the draught fan is controlled to rotate reversely, so that air circulation to the indoor environment is generated in the smoke discharging pipeline, and air passes through the air blowing pipeline, air flow is blown and fed to the cookware froman air blowing opening, and evaporation of remaining water in the cookware is accelerated. According to the extractor hood preventing water remaining, due to the fact that the air blowing pipeline communicating with the smoke discharging pipeline is additionally arranged, and reverse rotating of the draught fan is utilized, the extractor hood can blow and feed airflow to the cookware, the remaining water on the cookware is fast evaporated, the cookware is kept dry, and therefore it is avoided that due to the remaining water, the cookware is rusted, and the problem that after cleaning of traditional cookware, the water remains, and the cookware is likely to be rusted is solved.

Owner:蚌埠金达科技有限公司

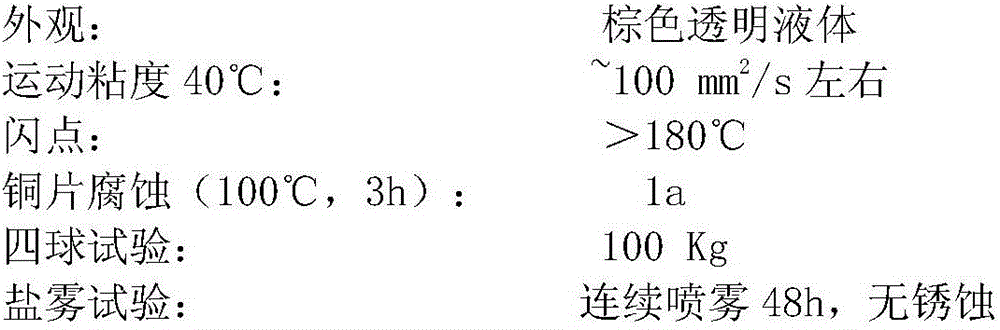

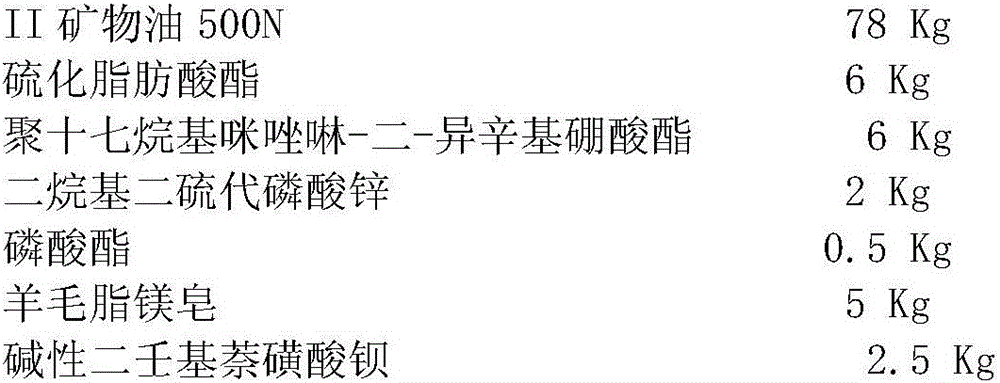

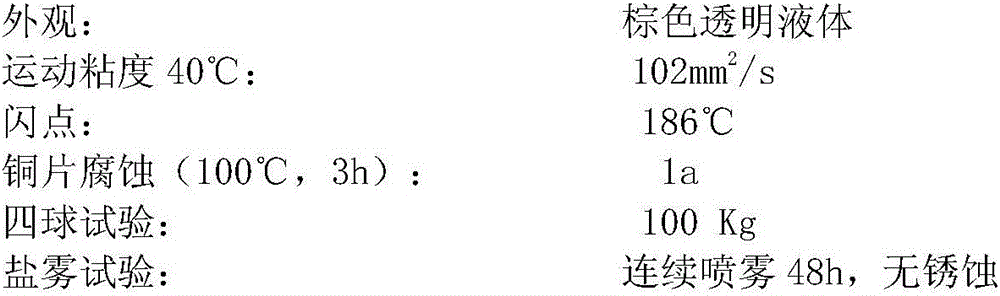

High-performance punching oil used for thick plate

The invention discloses high-performance punching oil used for a thick plate, belongs to the field of metal processing operating fluid, and particularly relates to operating fluid for metal stamping processing. The high-performance punching oil comprises, by mass, 60%-80% of refined mineral oil, 5%-10% of a sulfur-containing extreme pressure agent, 5%-15% of a macromolecule polymerization ester extreme pressure agent, 0.5%-5% of an antiwear agent and 5%-10% of an antirust agent. One of sulfide aliphatic acid ester and over-based sulfosalt or a mixture of the sulfide aliphatic acid ester and the over-based sulfosalt is selected as the sulfur-containing extreme pressure agent. Polyheptadecylimidazoline-di-isooctyl borate is selected as the macromolecule polymerization ester extreme pressure agent. According to the high-performance punching oil, under the synergistic effect of the macromolecule polymerization ester extreme pressure agent and the sulfur-containing extreme pressure agent, excellent lubricating performance and anti-corrosion performance can be given to the punching oil, and the high-performance punching requirements for the thick plate are met. Moreover, the rusting problem of punched products and the ecological environment problem are solved without chlorinated paraffin.

Owner:BOER TECH WUHAN

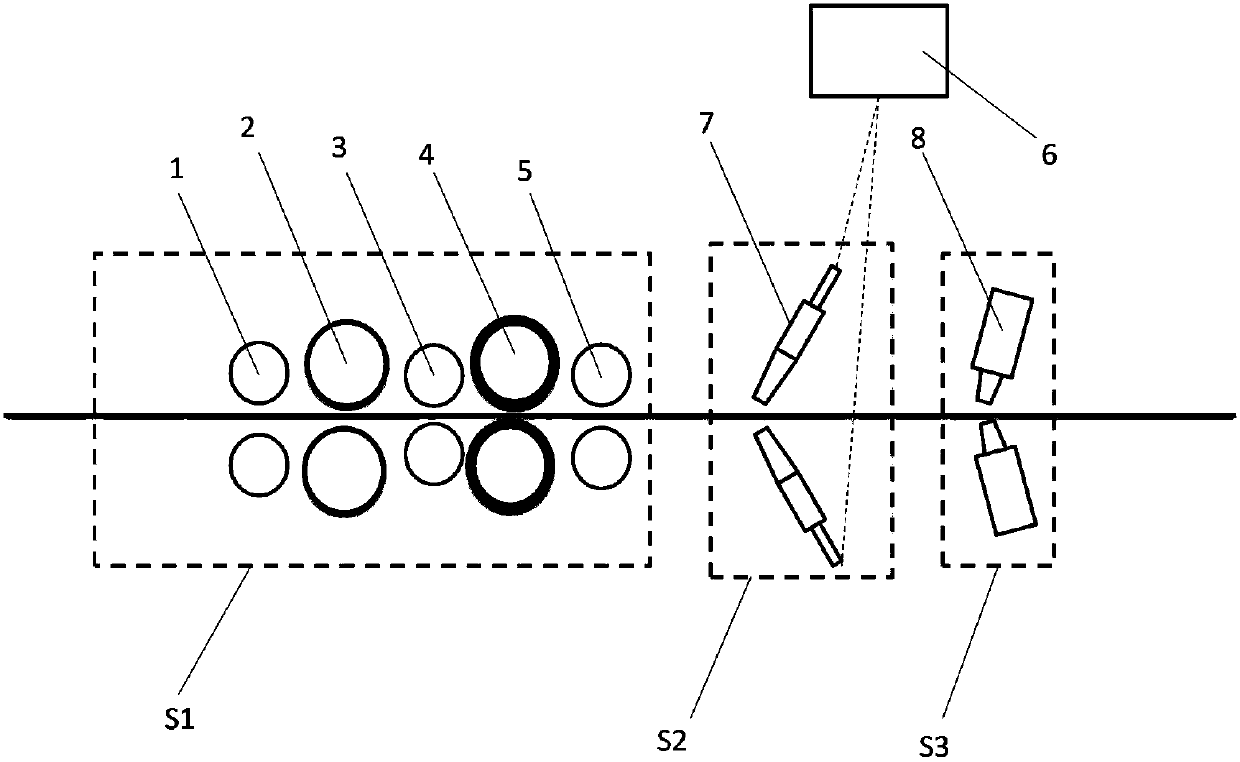

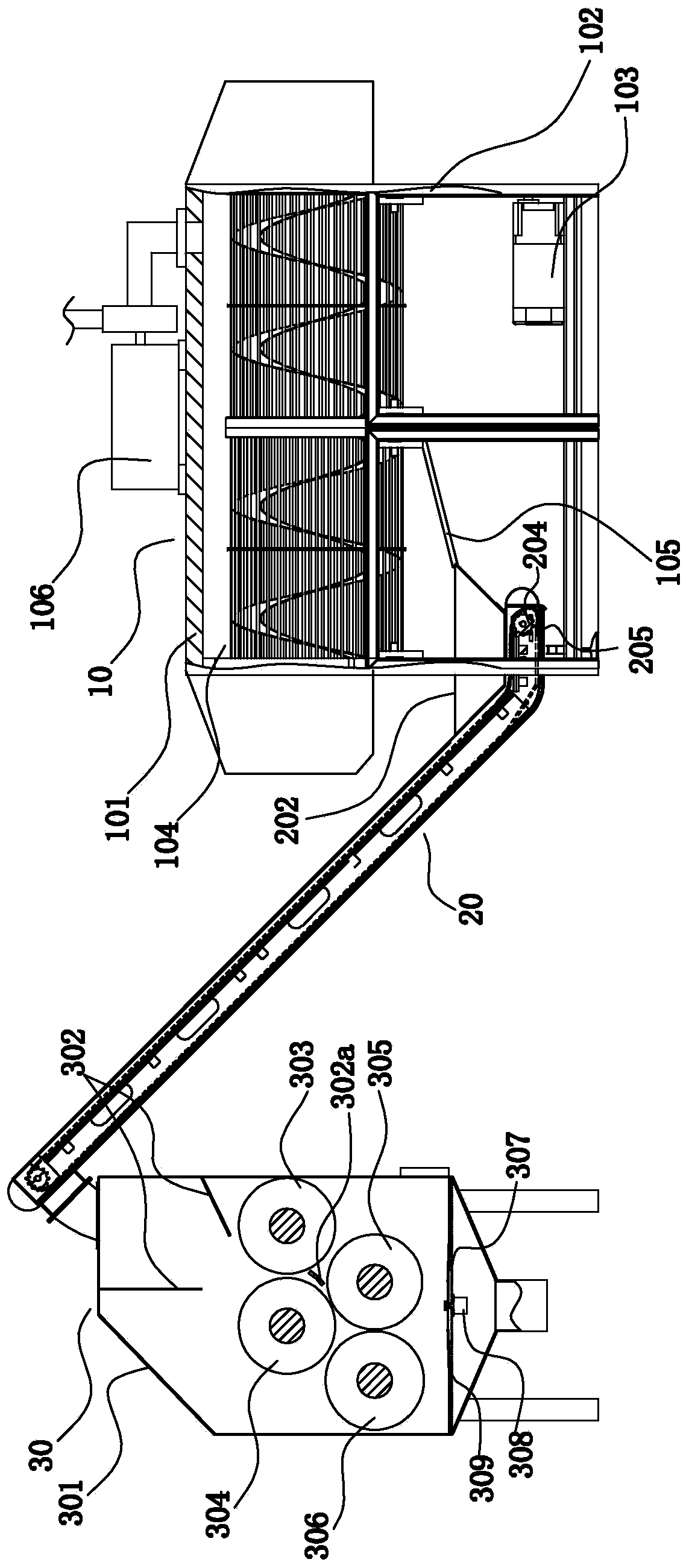

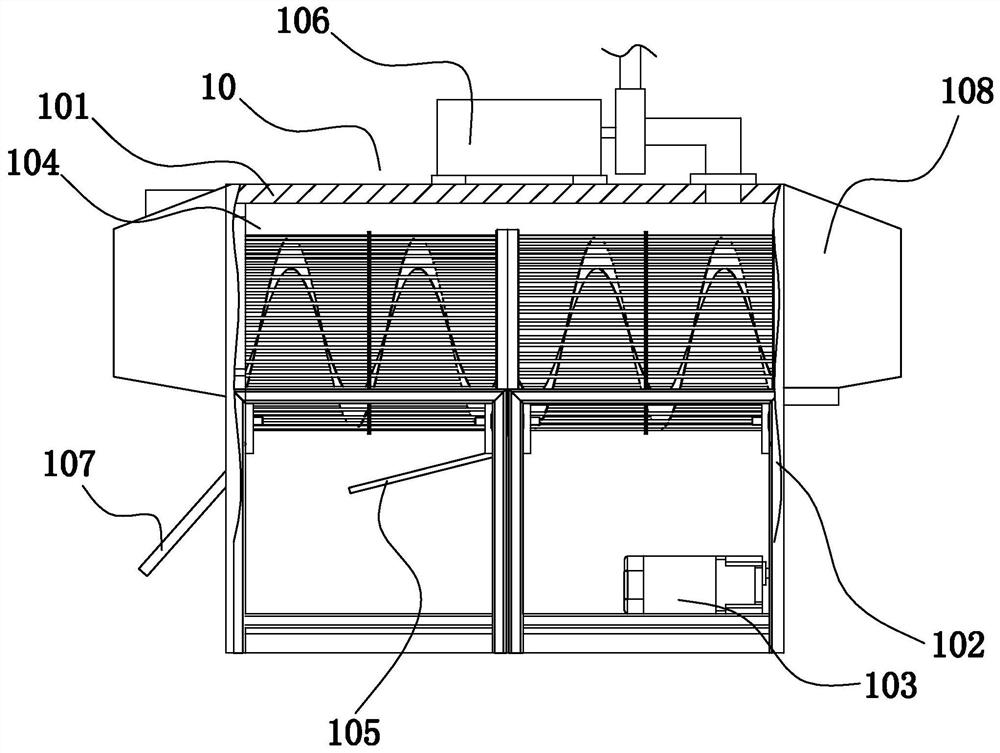

Long-acting anti-rust method and equipment for hot-rolled magnetic yoke steel

InactiveCN109097758AGood mechanical propertiesImprove rust resistanceMetallic material coating processesSocial benefitsLiquid storage tank

The invention provides long-acting anti-rust equipment for hot-rolled magnetic yoke steel. The long-acting anti-rust equipment of the hot-rolled magnetic yoke steel comprises first pinch rollers, up-down rough brushing rollers, second pinch rollers, up-down fine brushing rollers, third pinch rollers, antirust agent nozzles and purging nozzles according to the moving direction of the hot-rolled magnetic yoke steel; and in addition, an anti-rust agent liquid storage tank is further arranged and is connected with the anti-rust agent nozzles. The invention further provides an anti-rust method using the equipment. The rust-proof equipment and the rust-proof method are used, so that the hot-rolled magnetic yoke steel is not rusted for 72 hours under the conditions of the temperature of 49 DEG Cand the relative humidity of 98%, and the anti-rust effect is good. The long-acting anti-rust equipment and method effectively solve the problem that hot-rolled chromium-molybdenum low alloy steel iseasy to rust, and therefore, the long-acting anti-rust equipment and method belong to the environment-friendly production process of steel and iron, and have good social benefit and environmental benefit.

Owner:BAOSHAN IRON & STEEL CO LTD

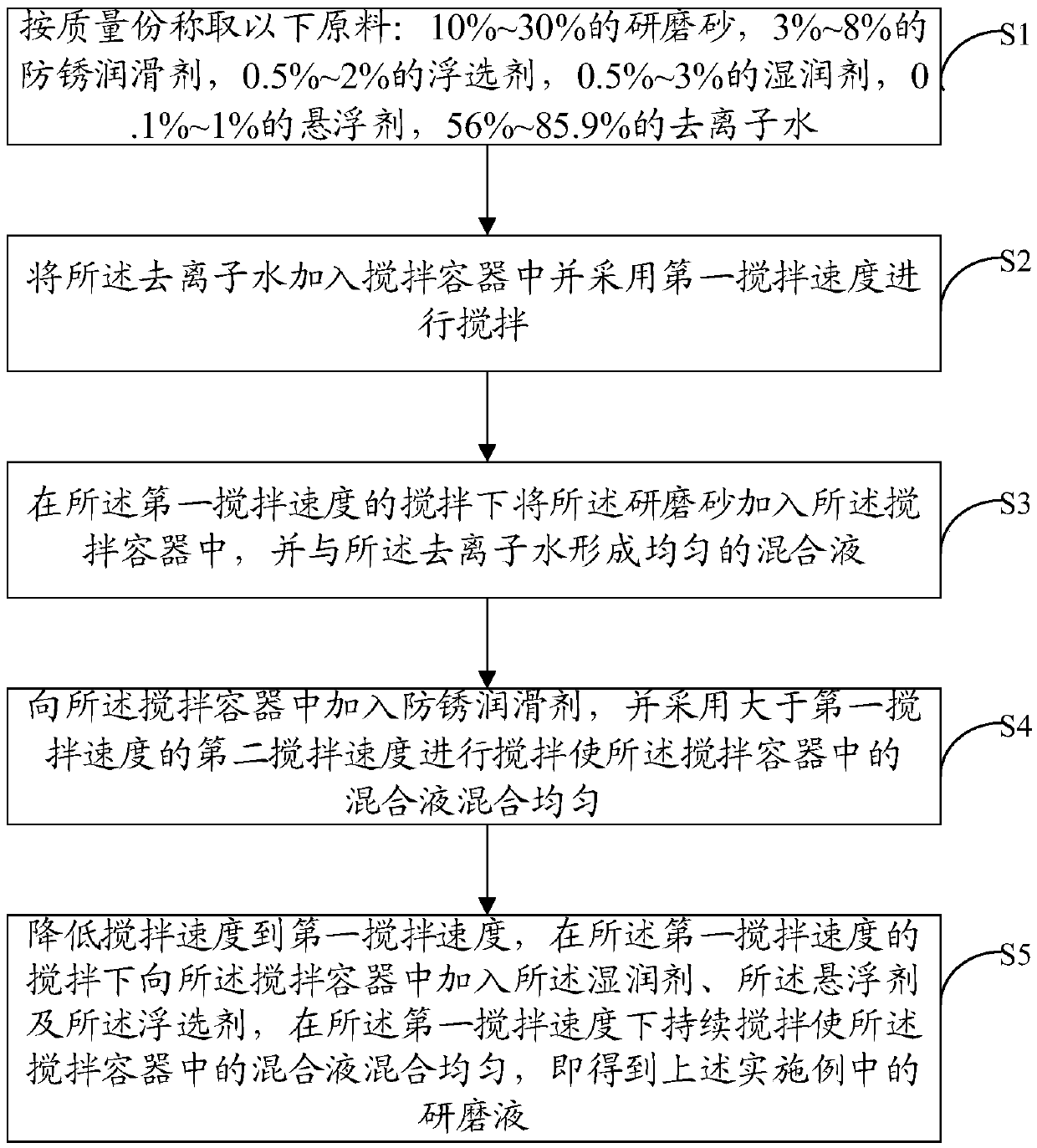

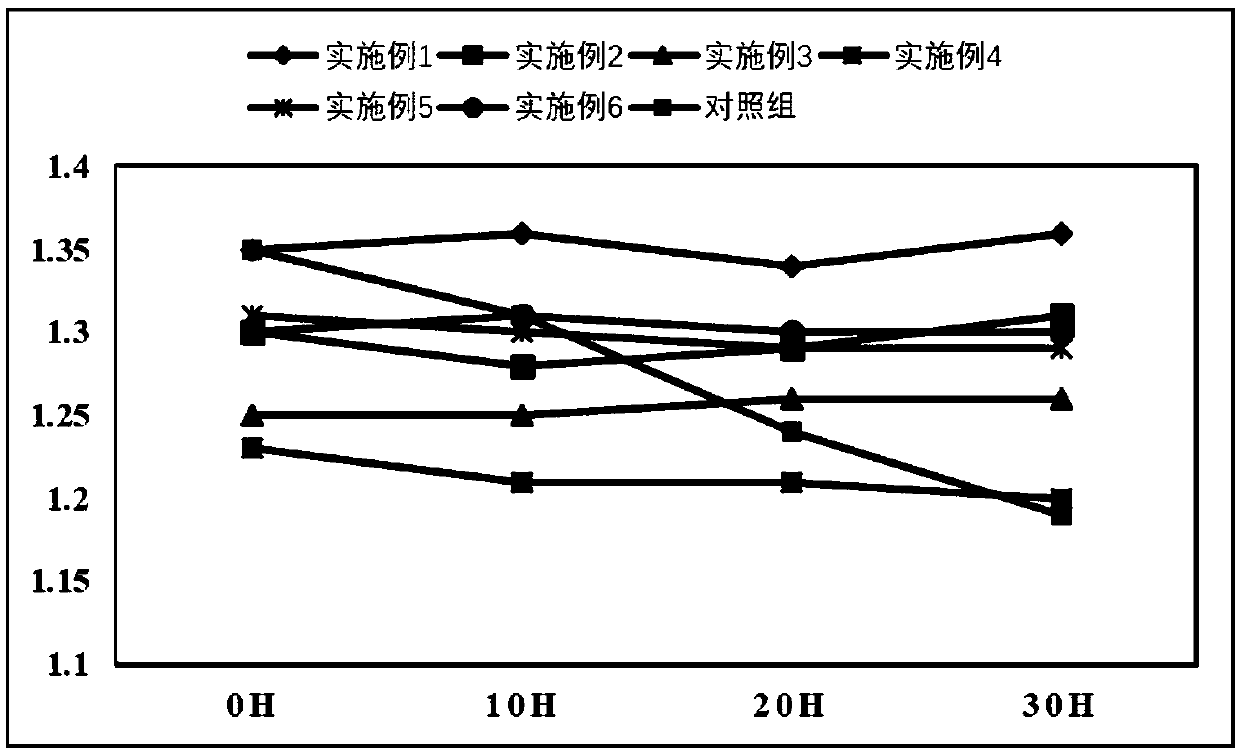

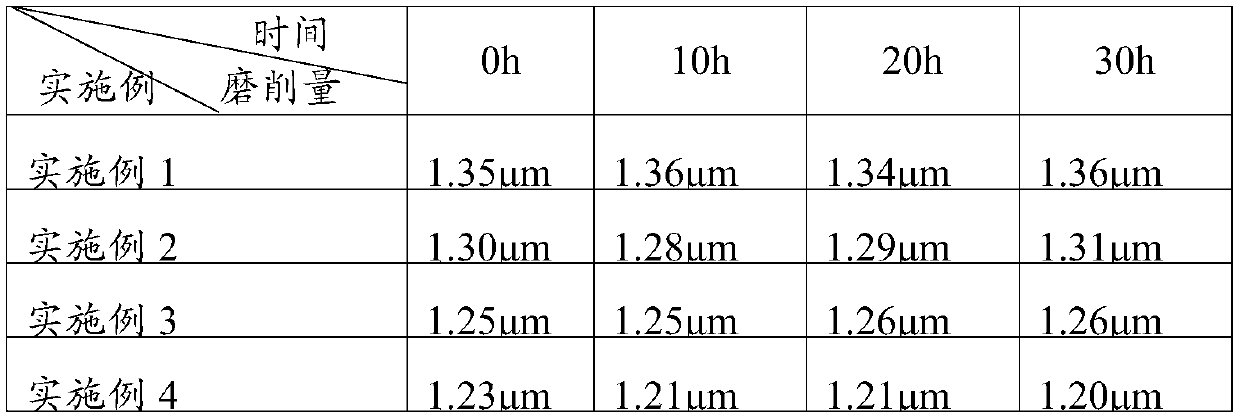

Grinding solution and preparation method thereof

InactiveCN109628064ALow efficiencySolve easy rustOther chemical processesSemiconductor materialsBatch processing

The invention discloses a grinding solution and a preparation method thereof. The grinding liquid is used for batch processing of semi-conductor material chips of novel silicon wafers, silicon chips and the like. The grinding solution comprises, by weight, 10%-30% of grinding sands, 3%-8% of an anti-rusting lubricant, 0.5%-2% of a flotation reagent, 0.5%-3% of a moistening agent, 0.1%-1% of a suspending agent and 56%-85.9% of deionized water. The grinding liquid and the preparation method have the advantages that inorganic alkali is not needed, which is safe and protects the environment, the grinding efficiency is maintained under the condition that the performance of the grinding solution is not reduced, the grinding sands can uniformly act on the surfaces of the silica wafers or the silica chips in the grinding process, and therefore the long-term use of the grinding solution is achieved while the efficiency is not reduced.

Owner:东莞市希尔金属材料有限公司

Application of inner chill in investment casting process

InactiveCN109500359AReduce in quantityReduce volumeFoundry mouldsFoundry coresTinningInvestment casting

The invention discloses an application of an inner chill in an investment casting process, and relates to the technical field of the casting processing application. The application comprises the stepsof hot spot holing, inner chill preparing, inner chill surface oil stain treatment, inner chill surface rust removal treatment, inner chill mounting, and mold shell roasting and steel casting. The application has the beneficial effects that small holes are machined in an independent hot spot of a product, a mode of prefabricating the chill is adopted, the purpose of sequential solidification of acasting is achieved so that the problems of shrinkage cavity, shrinkage porosity, depression and the like of the hot spot of the casting can be effectively solved, the number and the volume of riserscan be reduced, and the yield of the process product can be improved; water glass is adopted for carrying out the rust removal treatment on the inner chill, so that the problems of high difficulty and high cost of tinning and bluing processes of the inner chill are solved; and in addition, the problem that the inner chill cannot be immediately cast after taken out from a drying chamber due to theinfluence of objective conditions so that the inner chill is prone to rust when the inner chill stays in the air for a long time can be effectively solved.

Owner:JIASHAN SINHAI PRECISION CASTING

Low self-noise stainless steel wire

The invention discloses a low self-noise stainless steel wire. The diameter of the low self-noise stainless steel wire is 5.9-6.1 mm. The low self-noise stainless steel wire comprises, by mass percentage, 0.01-0.03% of carbon, 13-17% of chromium, 4-8% of nickel, 0.1-0.12 % of copper, 0.4-0.5 % of magnesium, 1-1.2% of manganese, and the balance iron. The prepared low self-noise stainless steel wire greatly improves the abrasion resistance and corrosion resistance performance, is easy to machine and form, has certain vibration reducing performance, is low in self-noise, better solves the problems that steel wires are likely to be corroded, rusted and abraded and large in noise, and prolongs the service life.

Owner:唐山智新科技有限公司

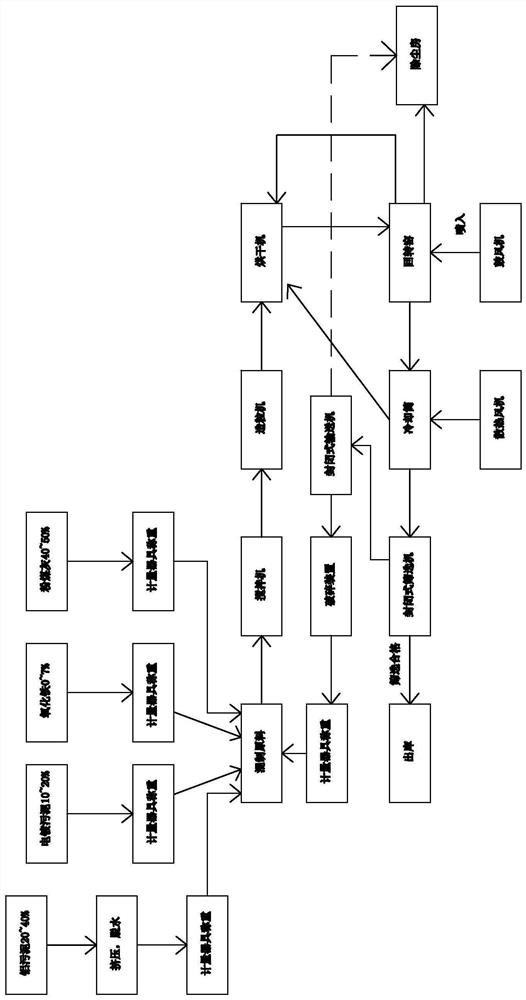

Preparation method of aluminum sludge ceramsite

The invention relates to the technical field of sludge waste utilization, and particularly relates to a preparation method of aluminum sludge ceramsite. The aluminum sludge ceramsite comprises following raw materials: electroplating sludge, aluminum sludge, iron oxide and fly ash. The preparation method comprises following steps: stirring raw materials by a stirrer, conveying the mixture into a granulator; then conveying the mixture into a dryer, conveying the ceramsite raw material into a rotary kiln for roasting; grading and screening by a closed screening machine; conveying waste materialsand ceramsite with a size smaller than the standard size to a crushing device by a closed conveyor; forcibly crushing the ceramsite by a crushing device, screening, conveying the powder to a mixed rawmaterial storage tank, weighing the powder by a gauge, and mixing the powder with the mixed raw materials. The wastes are reproduced and utilized, and the prepared ceramsite can be applied to roadbed materials, concrete aggregates and the like, and is wide in application range. The mixed material is formed and made into blocks; after the ceramic manufacturing, the broken ceramsite is crushed, conveyed and recycled by utilizing a crushing device, through advanced processing, the recycling rate of waste materials is increased, and the production benefit is further improved.

Owner:FUJIAN MINFA ALUMINUM

Novel stay cable

ActiveCN106958198APrevent corrosionReduce maintenance replacementBridge structural detailsEngineering

Owner:WETKING CO LTD +2

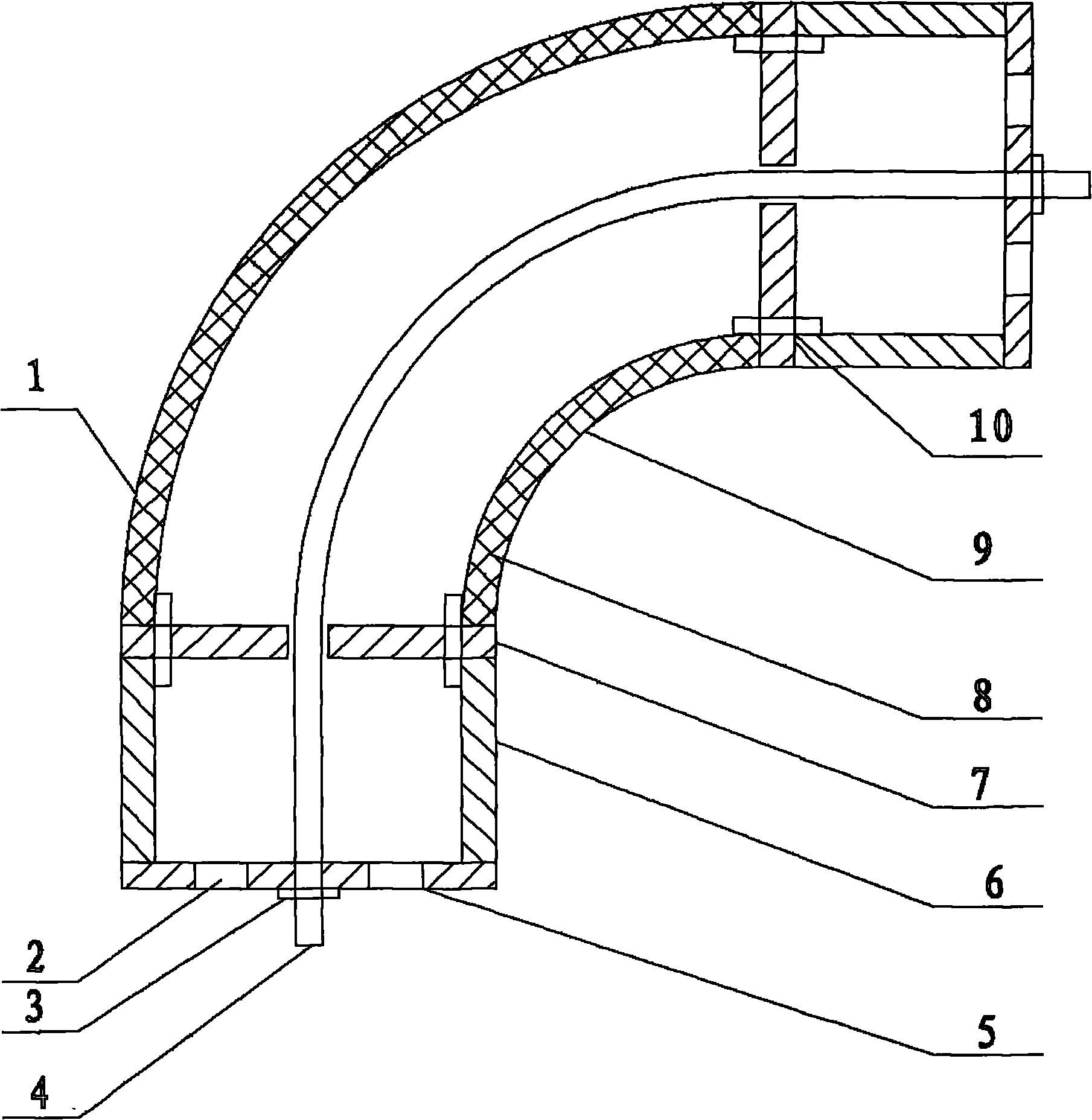

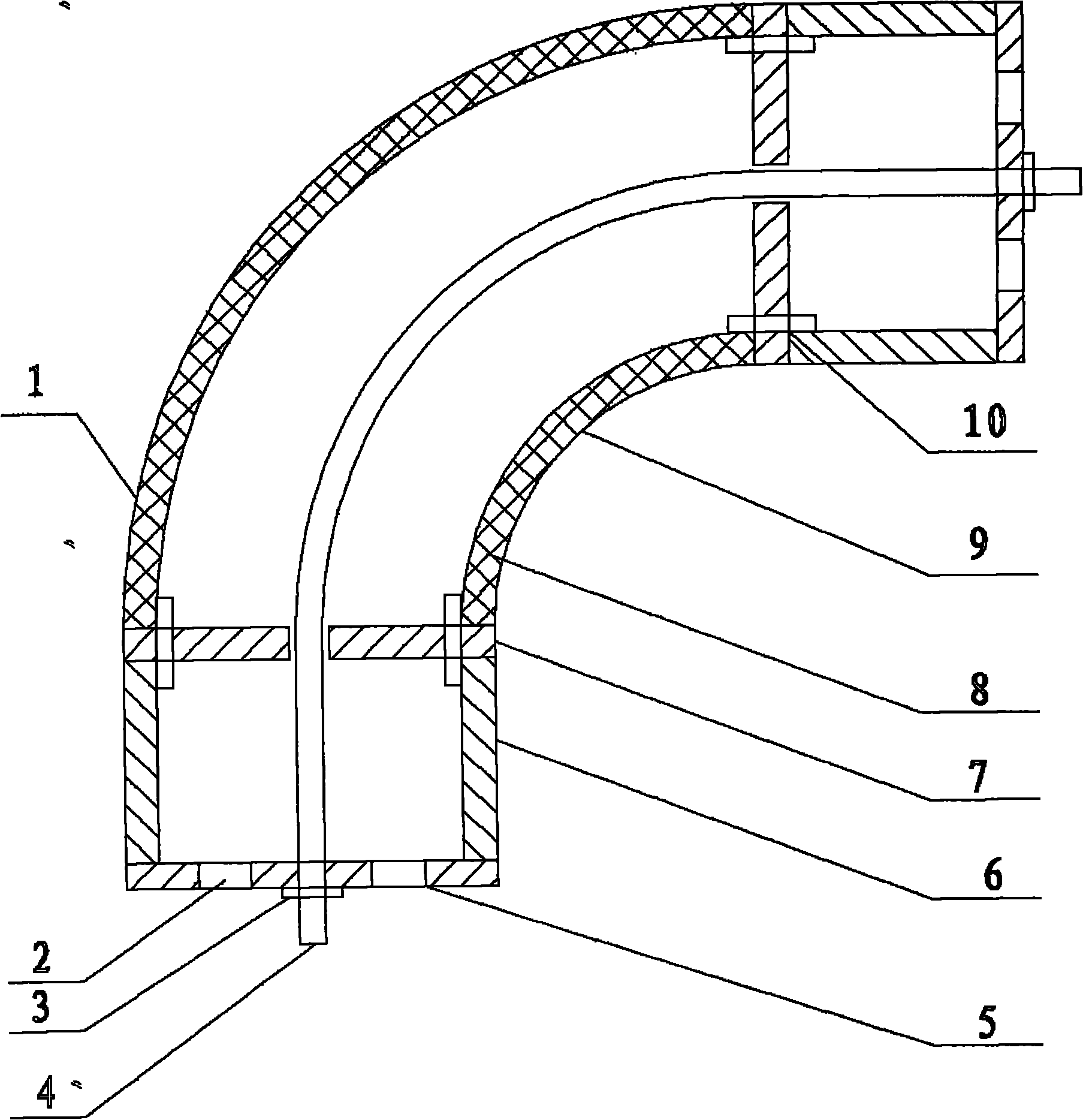

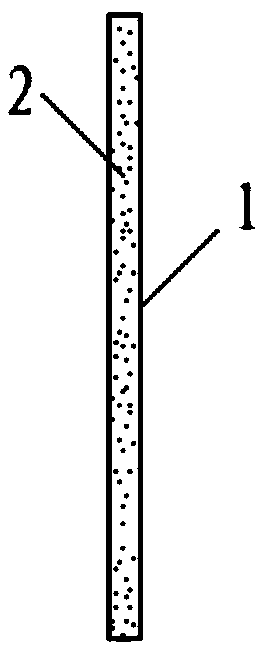

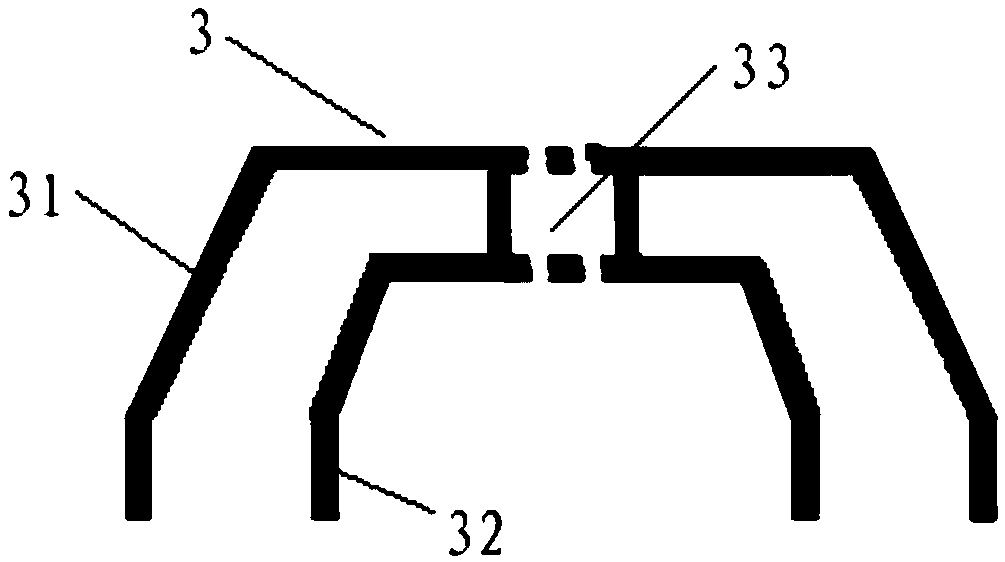

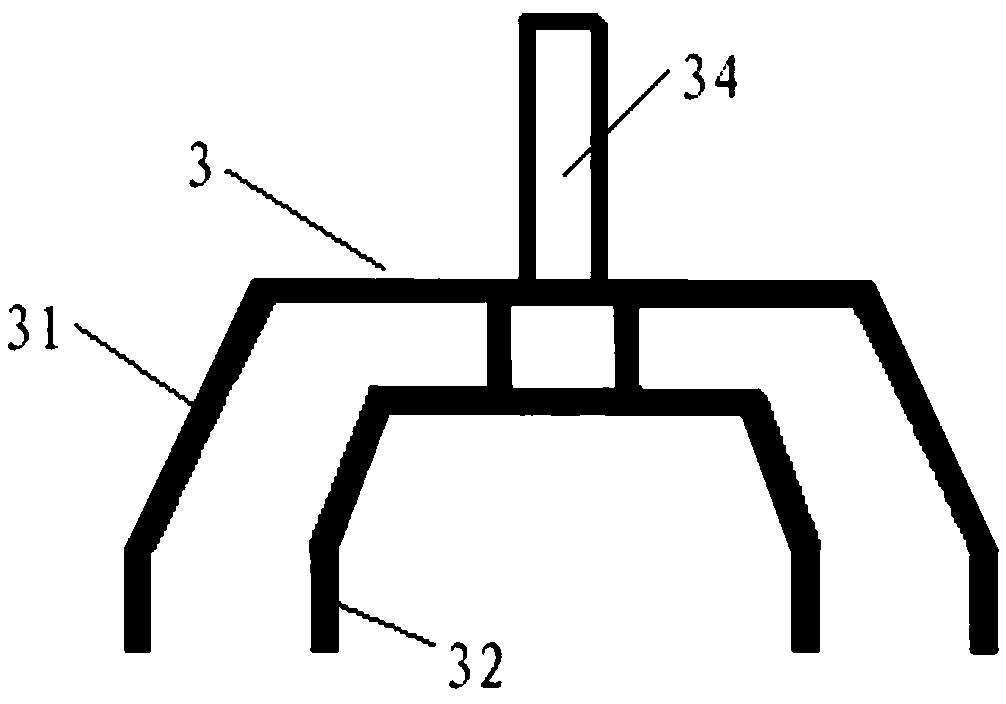

Glass reinforced plastic elbow die and manufacturing method thereof

InactiveCN102145519ASave materialMeet the requirements of hand lay-up processDomestic articlesProduction ratePlastic materials

The invention relates to a glass reinforced plastic elbow die and a manufacturing method thereof. The die comprises an end cover, a connection section die, an elbow die body, an intermediate plate and a pull rod. The elbow die body consists of an elbow inner template and an elbow outer template which are made of glass reinforced plastic material. The lengths of arc seams at both sides, which are butted in a matching mode, are at least 10mm. The connection section die is one of a straight tube connection section die, a butting connection section die, a socket connection section die and a lap joint flange connection section die. The manufacturing method of the elbow die body comprises the following steps of: 1, making a scraper; 2, making a cement die; 3, duplicating a glass reinforced plastic die; 4, carrying out machining; and 5, carrying out surface polishing treatment. The glass reinforced plastic elbow die and the manufacturing method solve the problem that the steel is easy to rust, are easy to repair, have the advantages of simple structure, high precision, high quality, high productivity and low manufacturing cost and are easy to demould. A product produced by the elbow die has a smooth inner wall, good seepage prevention performance and attractive appearance. The materials are saved. Due to the adoption of the elbow die, not only can the requirement of a hand lay-up process be met, but also the requirements of a mechanical winding process can be met.

Owner:奉玉贞

Preparation method for low-self-noise stainless steel wire

The invention discloses a preparation method for a low-self-noise stainless steel wire. The diameter of the low-self-noise stainless steel wire is 5.9-6.1 mm. The low-self-noise stainless steel wire comprises, by mass, 0.01%-0.03% of carbon, 13%-17% of chrome, 4%-8% of nickel, 0.1%-0.12% of copper, 0.4%-0.5% of magnesium, 1%-1.2% of manganese and the balance iron. According to the low-self-noise stainless steel wire prepared through the preparation method, the abrasion resistance and the corrosion resistance of the stainless steel wire are greatly improved; machining and forming are easy; a certain damping performance is achieved; the self noise is low; the problems that a steel wire is prone to being corroded, rusted and abraded and large in noise are well solved; and the service life of the low-self-noise stainless steel wire is prolonged.

Owner:唐山智新科技有限公司

Stainless steel surface grinding head and grinding tool

InactiveCN109623638AChange shapeImprove corrosion resistanceGrinding machine componentsSurface grindingMaterials science

The invention relates to the field of stainless steel surface grinding, and provides a stainless steel surface grinding head and a grinding tool. The stainless steel surface grinding head comprises anon-metal grinding material wire and a base for fixing the non-metal grinding material wire. The non-metal grinding wire comprises a grinding material wire basal body and grinding grains dispersed inthe grinding material wire basal body according to a set proportion. The roughness and the residual stress of the stainless steel ground surface can be reduced, the shape of the ground surface can bechanged, and the anti-corrosion performance of the ground surface can be improved.

Owner:CRRC QINGDAO SIFANG CO LTD

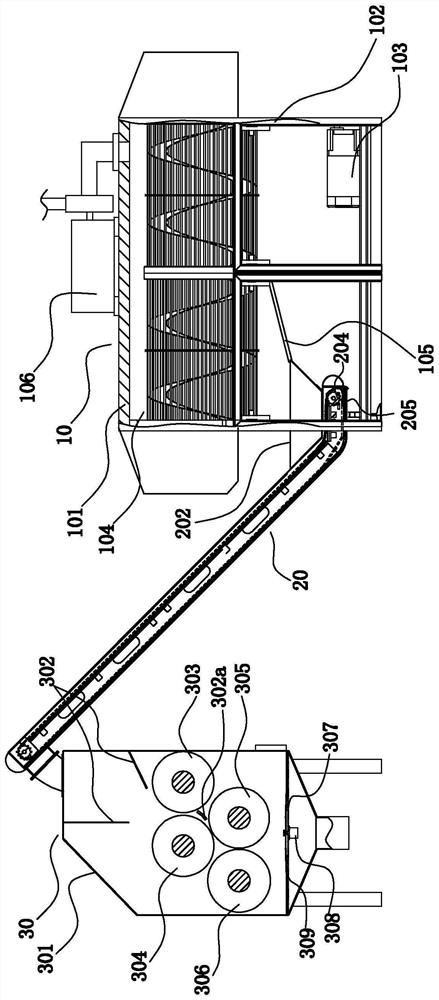

Circular belt cleaning system

The invention relates to the field of cleaning of coal slime attached on a belt of a conveyor, in particular to a circular belt cleaning system. The circular belt cleaning system comprises a a frame with a top positioned between upper and lower two layers of belts, and a first coal remover, a second coal remover, a sprayer, a slime scraping brush roller, a third coal remover, a water scraping brush roller and an air heater lifted below the top of the frame in sequence in the operation direction of the lower layer of belts and matched with working surfaces of the lower layer of belts; the sprayer, the slime scraping brush roller, the third coal remover and the water scraping brush roller are supported with filter pools with filter plates through stone tables; one sides of the filter pools are communicated with settling pools; the setting pools lead upper layer of clear water inside into a clear water pool; a water pump is mounted below the frame; a water inlet of the water pump is deeply inserted into the clear water pool; and a water outlet of the water pump is connected to a water inlet of the sprayer through a pipe. The circular belt cleaning system solves the problem of easy rusting of a support roller caused by erosion of water coal slime, and achieves a protection effect on service life of a rubber belt and the support roller of a belt machine.

Owner:DATONG COAL MINE GRP

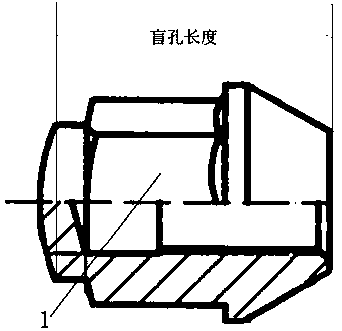

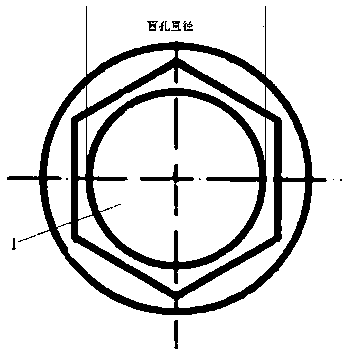

Tire nut deep blind hole plating and coating process

InactiveCN109537009ASolve easy rustPrevent rustMetallic material coating processesDehydrogenationStain

The invention discloses a tire nut deep blind hole plating and coating process. The process comprises the steps that firstly, the parts are sequentially subjected to pretreatment including thermokalite oil removing, thermokalite oil removing, electrolytic oil removing, acid pickling, electrolytic oil removing, excitation, pre-electroplating, stripping and electroplating; the two passes of thermokalite oil removing ensure that oil stain inside blind holes is cleaned away; stripping is conducted after pre-electroplating, and oxide skin inside the blind holes is stripped; additives are added intoelectroplating liquid medicine during electroplating; residual water in the blind holes of the electroplated parts is thrown away through rotation of a production line roller and a discharging centrifugal drier; then dehydrogenation baking is conducted, and residual water inside the blind holes is evaporated through high-temperature baking; and finally, passivation and closing are conducted. Theproblems that the covering power of zinc-nickel alloys is not sufficient, and consequently no clad layer exists in the blind holes and the blind holes rust easily are solved, and the process has the beneficial effects that oil stain and oxide layers in the blind holes are effectively removed, uniform zinc-nickel clad layers are plated, the interiors of the blind holes are prevented from rusting, and the first pass yield of products is improved to be 95% or above.

Owner:鹰普航空科技(南通)有限公司

Copper supporting piece, preparation method thereof and electrical assembly

The invention provides a copper supporting piece and a preparation method thereof and an electrical component, the copper supporting piece comprises a first metal layer, a second metal layer and a middle metal layer, the first metal layer and the second metal layer are made of pure copper, copper alloy or composite copper, the middle metal layer is made of iron or low-carbon steel, and the three layers are compounded into a whole to form a layered composite material strip. The thickness of the first metal layer is larger than that of the second metal layer, and the first metal layer wraps the side edge of the layered composite material belt, so that the middle metal layer is not exposed in the air; the first metal layer serves as a welding surface, the middle metal layer serves as a non-welding surface, and the welding surface is provided with a through hole penetrating through the thickness direction of the layered composite material belt. According to the invention, the problems of mechanism clamping, easy tilting of an arc striking angle, welding creeping points and poor deslagging and exhausting caused by rusting of the electrical component are effectively solved, so that the temperature rise of an electrical product is reduced, the electrical life of the electrical product is prolonged, the welding process is shortened, the quality of the electrical component is greatly improved, the use amount of high-valence copper is reduced, and the method is suitable for batch production.

Owner:温州宏丰特种材料有限公司

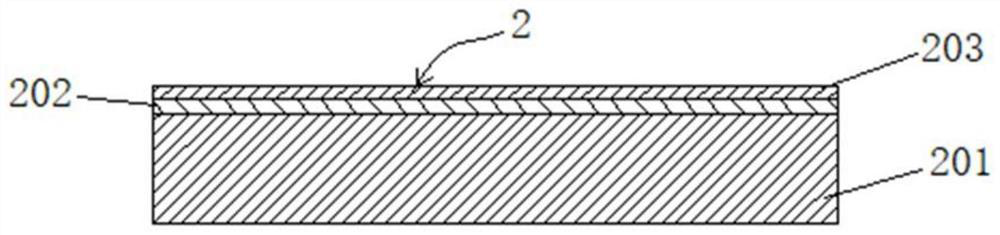

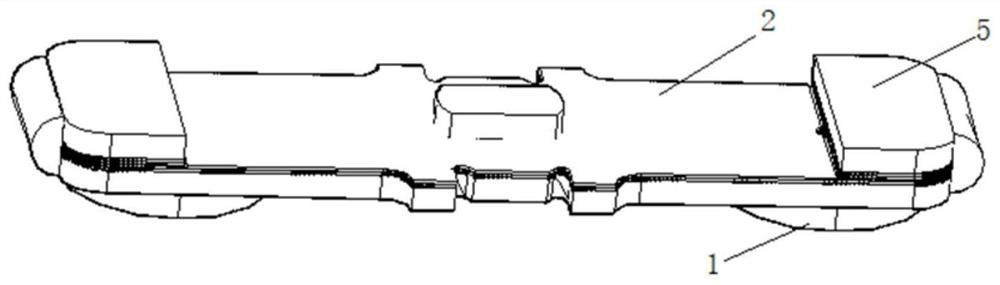

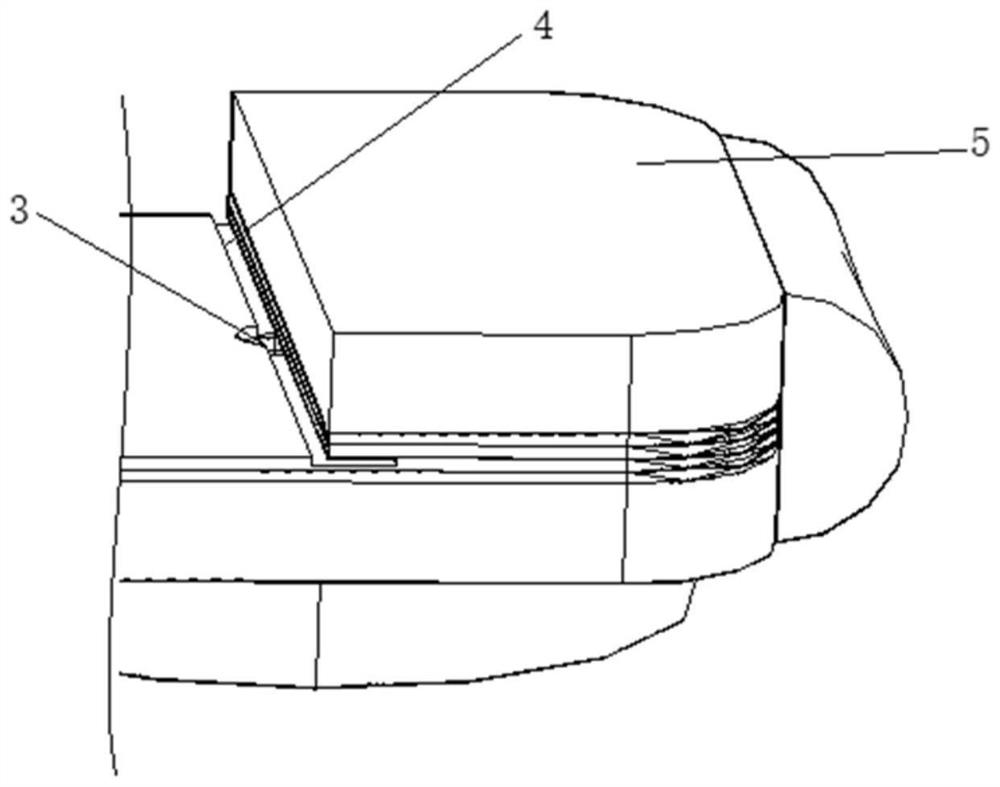

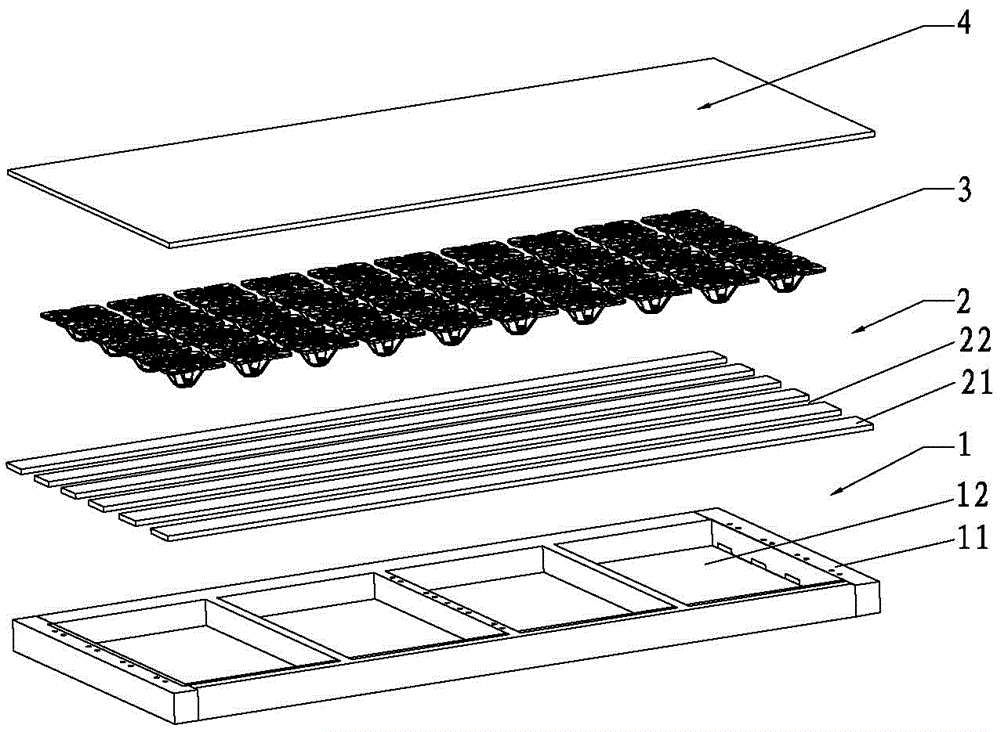

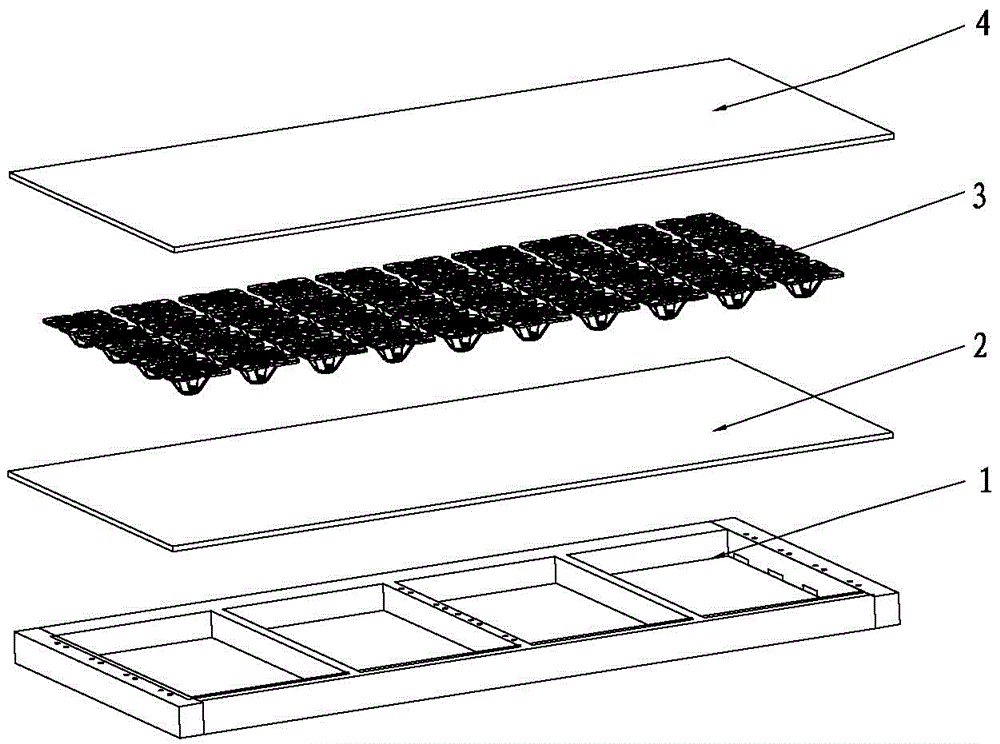

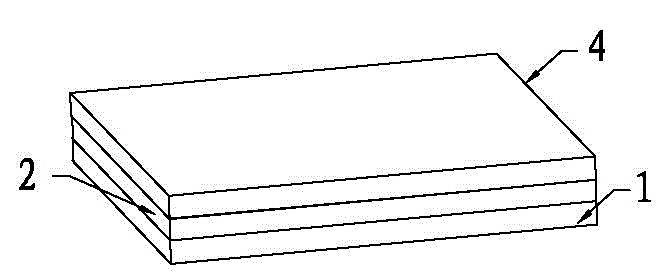

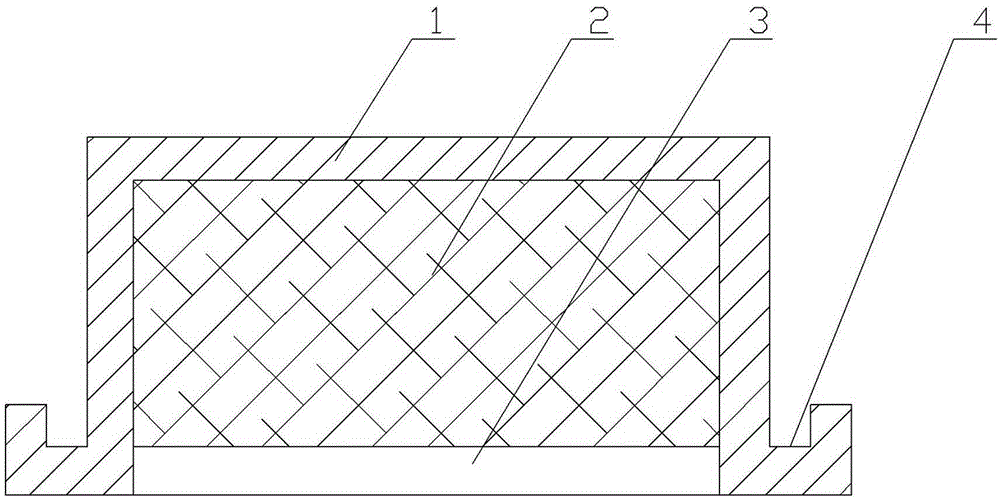

Mattress with nonmetal elastic members

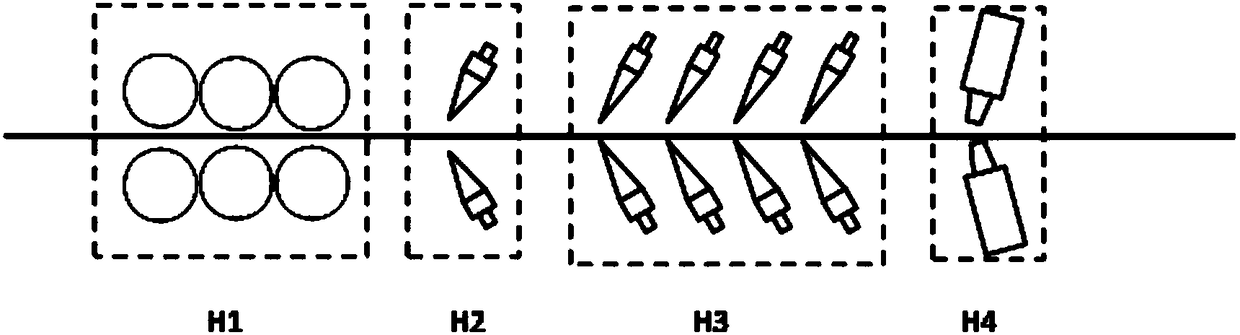

The invention relates to a mattress with nonmetal elastic members. The mattress is used for replacing a structure of springs inside the mattress, and on the premise of no influence to the appearance and the integral effect of the original mattress, the problems that the service life is shortened and generated electromagnetic waves and heavy metals endanger the health of a human body due to rusting and deforming the springs inside the mattress can be avoided; and meanwhile, the comfort of the mattress is improved to ensure that the fatigue is effectively relieved. The mattress with the nonmetal elastic member comprises a base, an elastic member fixing piece embedded in the base, and an elastic layer formed by a plurality of nonmetal elastic members fixed by the elastic member fixing piece, wherein a pressure partitioning sheet which is adjustable in hardness and is used for decomposing and buffering the pressure from the upside is arranged at the top of each nonmetal elastic member; and the base is composed of a frame with a plurality of concave holding cavities, and is used for regulating the integral heights of the nonmetal elastic members.

Owner:周升忠

Hot-rolled chrome molybdenum low-alloy steel antirust production method

A hot-rolled chrome molybdenum low-alloy steel antirust production method comprises the steps that in the roller brush technology section, an annealed hot-rolled chrome molybdenum low-alloy steel plate enters the roller brush technology section; the surface cleaning technology section is conducted; the antirust agent spraying technology section is conducted, and then the steel plate enters the antirust agent spraying technology section, antirust agent spraying liquid is pure water containing 3-8 g / L of poly-diethanol amine, 6-9g / L of polyvinylamine and 30-50 mg / L of polyaspartic acid; and finally, the heating purging technology section is conducted, finally, the hot-rolled chrome molybdenum low-alloy steel enters the purging technology section, purging gas in the heating purging technologysection is compressed air, the temperature of the compressed air ranges from 65 DEG C to 80 DEG C, and the spraying pressure is 0.2-5 MPa. According to the hot-rolled chrome molybdenum low-alloy steel antirust production method, the hot-rolled chrome molybdenum low-alloy steel does not rust for 72 h under the conditions that the temperature is 49 DEG C and the relative humidity is 98%; and the problem that hot-rolled chrome molybdenum low-alloy steel is prone to rusting is effectively solved.

Owner:BAOSHAN IRON & STEEL CO LTD

Novel wallboard

ActiveCN104446300AWide variety of sourcesLow costSolid waste managementArchitectural engineeringWater flow

The invention belongs to the field of building materials and discloses a novel wallboard. The novel wallboard comprises a gypsum core material layer, wherein a facing layer is arranged on the lower face of the gypsum core material layer; metal lamellar layers with anti-static pant and metal thread layers cover the upper face and two side faces of the gypsum core material layer; and a water flowing channel in which rainwater can conveniently flow is formed on the lower face of the side metal plate layer on each side. According to the novel wallboard disclosed by the invention, gypsum has the anti-static and anti-radiation ability, and the novel wallboard is good in waterproof and moisture proof effects.

Owner:广东基业长青建筑科技有限公司

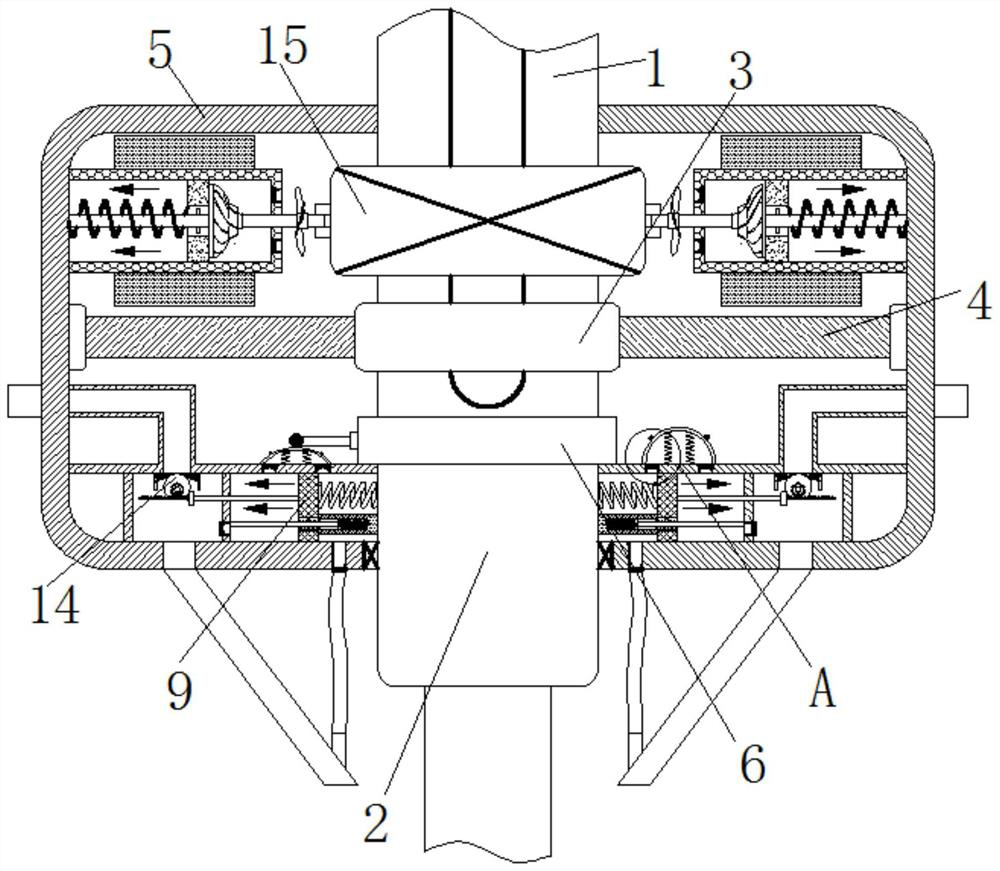

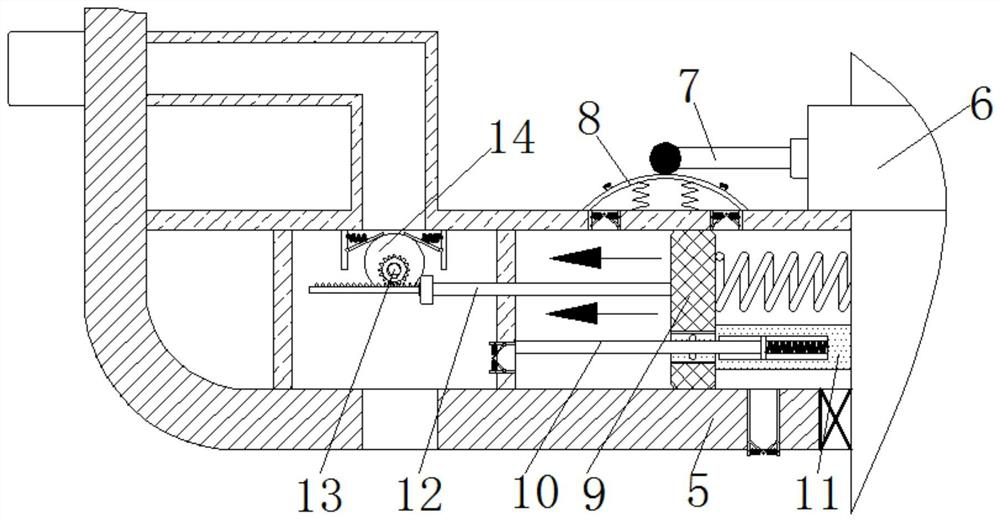

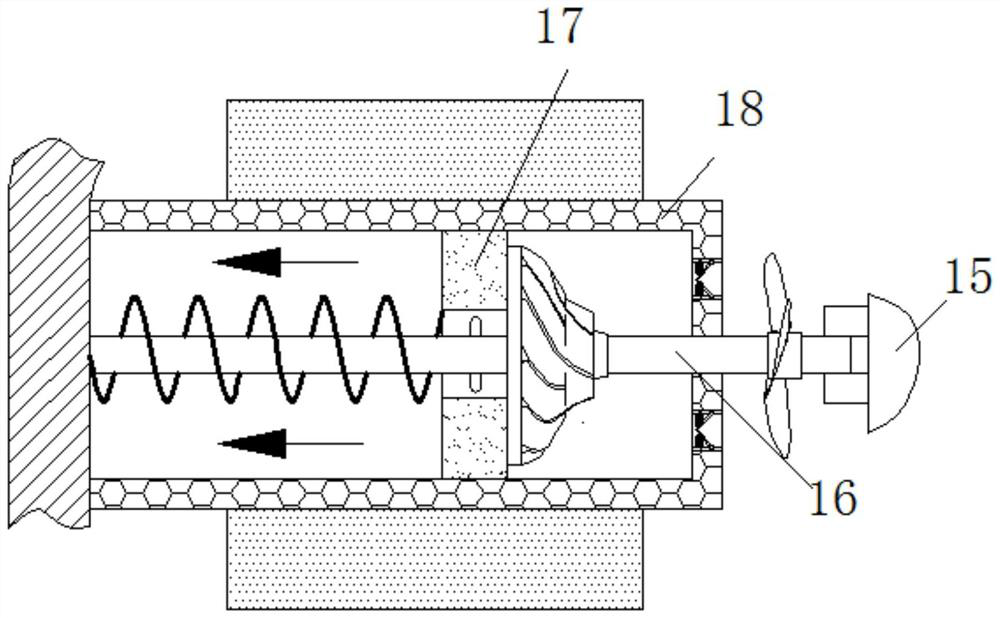

Abrasion-preventing centrifugal protection device for main shaft of vertical machining center

PendingCN113601199AAvoid wear and tearAvoid enteringLarge fixed membersMaintainance and safety accessoriesMetal swarfCentrifugal force

The invention relates to the technical field of vertical machining center equipment, and discloses an abrasion-preventing centrifugal protection device for a main shaft of a vertical machining center. The device comprises a first connecting shaft, a shaft key is fixedly connected to the outer side of the first connecting shaft, a first connecting block is clamped in the middle of the shaft key, a first connecting rod is fixedly connected to the outer side of the first connecting block, one end of the first connecting rod is fixedly connected with a first shell, and the bottom end of the first connecting shaft is rotationally connected with a second connecting block. According to the abrasion-preventing centrifugal protection device for the main shaft of the vertical machining center, through connection of the first connecting shaft and the second connecting block, the problem that a bearing in a main shaft in the prior art is prone to rusting is solved, centrifugal force is utilized, the flow speed of cooling liquid can be controlled, the cost is reduced, meanwhile, metal cuttings, dust and the like can be prevented from entering the main shaft, the purpose of prolonging the service life is achieved, the dead weight of the equipment is effectively reduced, and the reliability is greatly improved.

Owner:蒋涛

Corrosion resistant iron picture

InactiveCN106626942ASolve easy rustMeet needsSpecial ornamental structuresMartensitic stainless steelCorrosion resistant

The invention relates to a corrosion resistant iron picture applied to a traditional craft art product and a derivative product of the traditional craft art product and belongs to the field of craft arts. To overcome the defect of the product, the adopted technical scheme comprises the step that a material used for iron picture forging is put forward and innovated, and the problem that the iron picture is easily corroded is solved. The corrosion resistant iron picture is characterized in that the iron picture is made of stainless steel materials through iron picture forging techniques such as forging, welding, drilling, filing and chiseling, and further characterized in that the stainless steel is any kind of materials of ferrite stainless steel, austenite stainless steel, martensite stainless steel and austenite / ferrite diphase stainless steel.

Owner:马洪斌

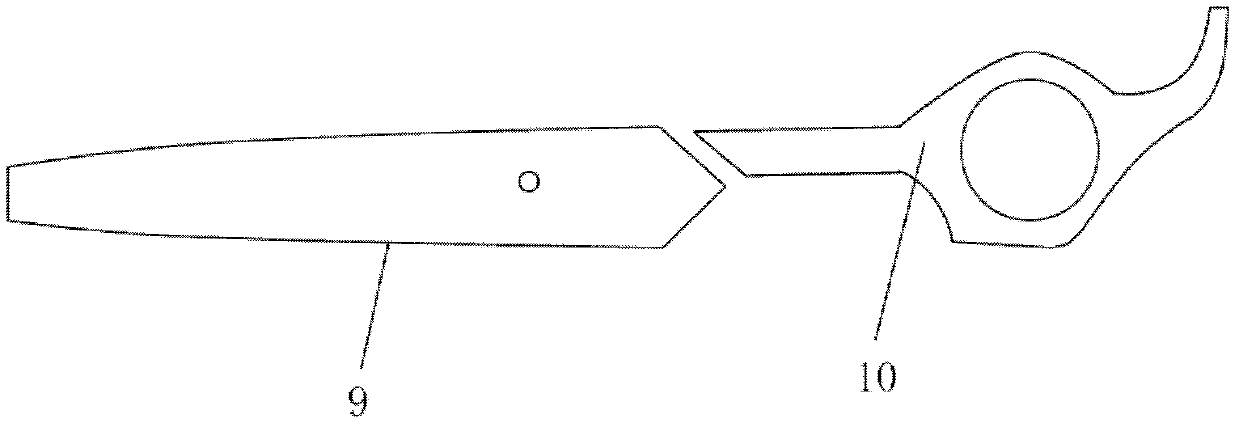

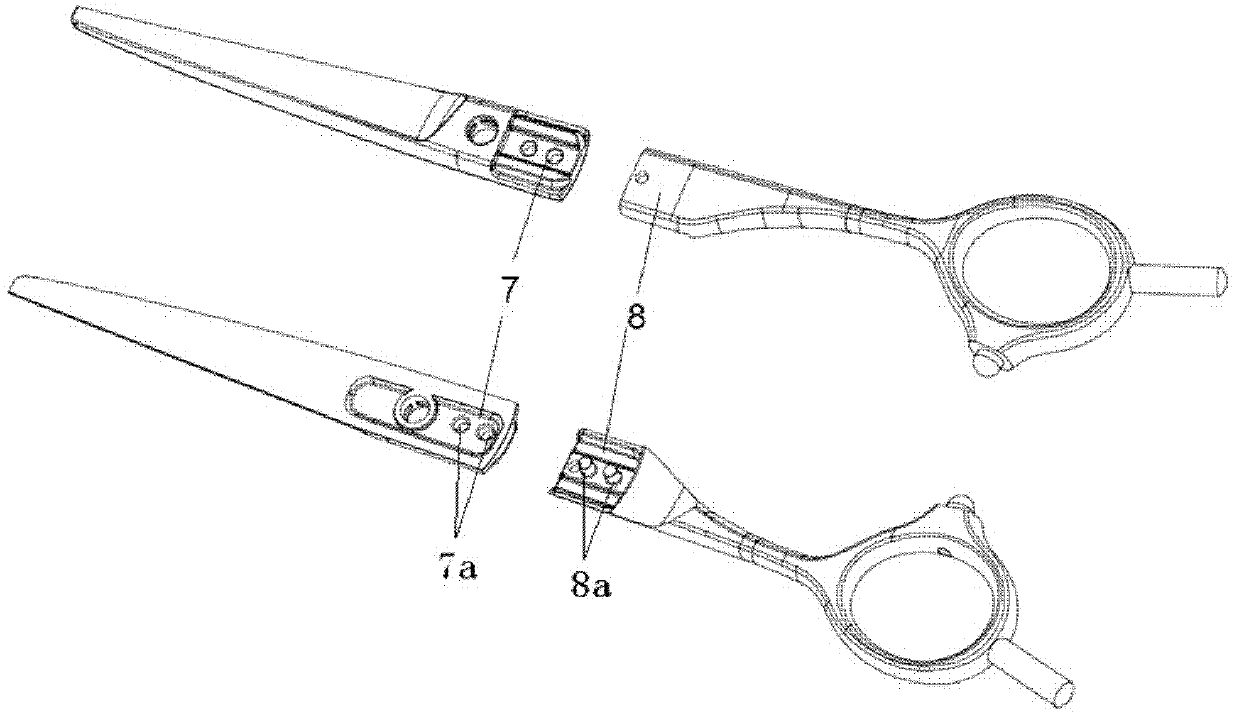

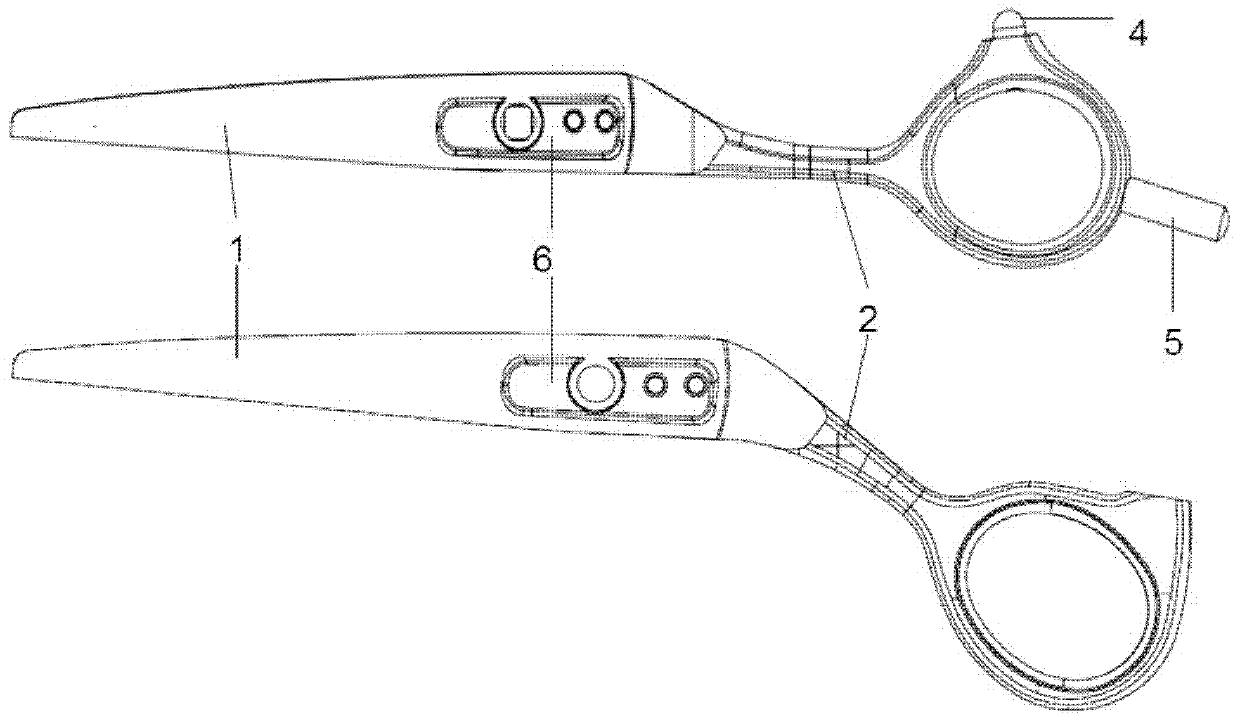

Hair clipper

InactiveCN103317532AHigh hardnessImprove high temperature resistanceMetal working apparatusEngineeringKnife blades

The invention relates to a hair clipper applied to the hairdressing industry, aims to provide a hair clipper adopting a special method to connect haircut blades with haircut tool holders so as to enable the haircut blades and the haircut tool holders to be more firm in connection and more higher in connection strength, and allows that the hair clipper is polished and girdled in advance before the blades and the tool holders are connected, without again polishing processing, thereby reducing manufacturing cost and improving the production efficiency. The hair clipper comprises a pair of cutter bodies, wherein each cutter body comprises a scissor blade and a scissor tool holder; the two cutter bodies are connected by a pivot, and the hair clipper is characterized in that first bosses are arranged at the end parts of the scissor blades, and are provided with through-holes; second bosses are arranged at the end parts of the scissor tool holders, and are provided with vertical rivets; the first bosses are mutually overlapped with the second bosses, and the vertical rivets penetrate the through-holes to be in fixedly riveted with the scissor tool holders.

Owner:孙根岳

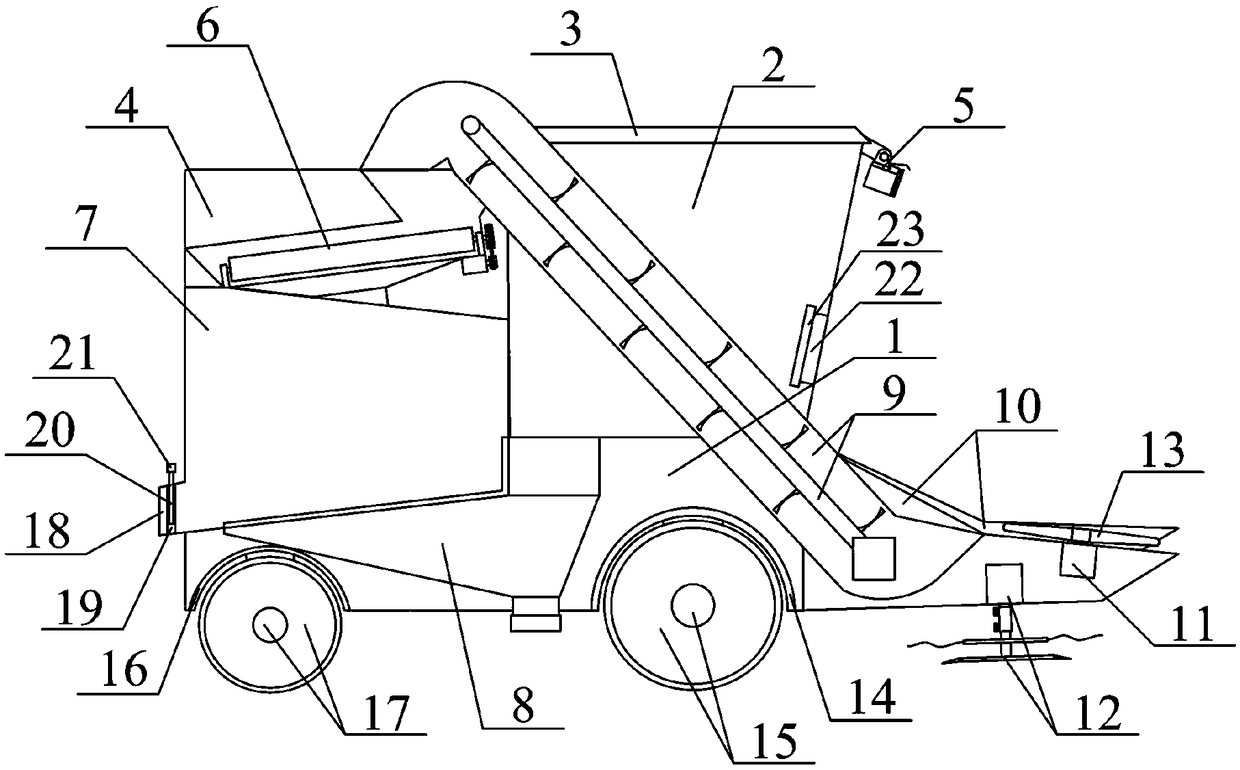

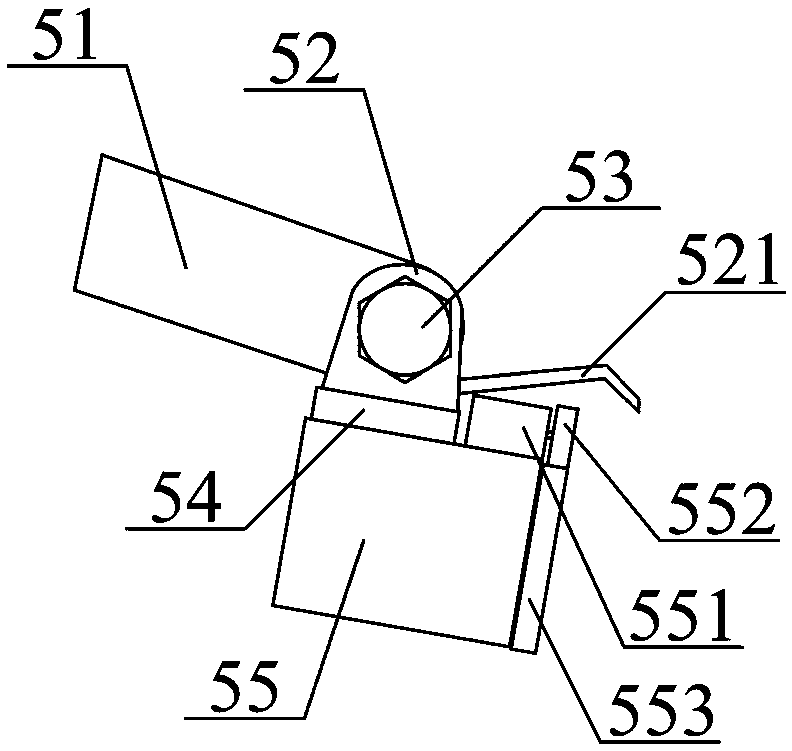

Multifunctional corn harvester

The invention provides a multifunctional corn harvester. The multifunctional corn harvester comprises a frame, an operating room, a rain cover, a storage box, an adjustable monitoring device, a rotaryhusk stripping device, a collecting box, a corn kernel collecting and ventilating device, a conveying, heating and drying device, a front fork, a drive motor, a weed smashing and removing device, a breaking-off frame, right side wheel frames, right side bottom wheels, left side wheel frames, left side bottom wheels, a discharging pipe, a longitudinal inserting groove, a longitudinal inserting plate, a handle, a controller and a touch screen, and the operating room is installed on the right side of the upper portion of the frame through bolts; the rain cover is installed on the upper portion of the operating room through bolts. By arranging a rotating motor, a rotating frame and a slight-wiping roll on a camera, a right side lens of the camera is easily and conveniently wiped to be clean during usage, and accordingly the lens of the camera is prevented from adsorbing dust and affecting shooting; by arranging a fixed rotary disc and a cutting blade on a drive shaft, weeds on the land are easily and conveniently cut during usage.

Owner:QINYANG TAILI MACHINERY MFG

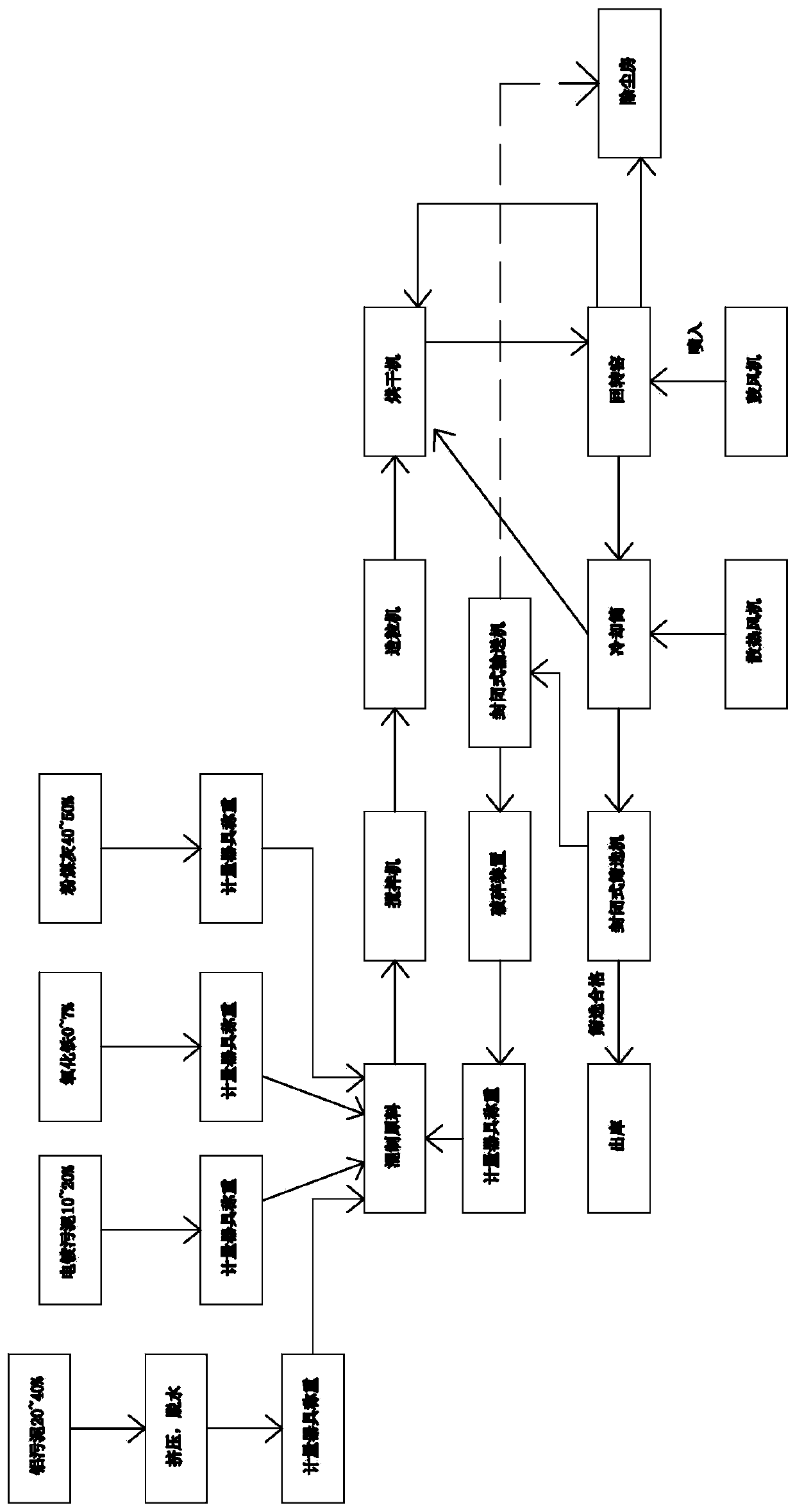

A kind of preparation method of aluminum sludge ceramsite

The invention relates to the technical field of sludge waste utilization, in particular to a method for preparing aluminum sludge ceramsite. , and then transported to the dryer, and then transported the ceramsite raw meal to the rotary kiln for roasting. After being classified and screened by the closed screening machine, the waste and the ceramsite smaller than the standard size were transported to the crushing device through the closed conveyor. , use the crushing device to crush and sieve and then transport it to the storage tank of the mixed raw materials, and then weigh and mix the mixed raw materials with the measuring instrument, and recycle the waste materials. The produced ceramsite can be used in roadbed materials, concrete aggregates, etc. It is widely used; the mixed materials are formed into agglomerates. After the sludge is processed, the ceramsite fragments are crushed, transported and recycled by the crushing device. Through further processing, the recycling rate of waste can be enhanced and the production efficiency can be further improved.

Owner:FUJIAN MINFA ALUMINUM

Filtration cloth bag for pressure filtration machine filtration, and molding method

ActiveCN103252134ASolve the phenomenon of easy disengagementSolve easy rustDomestic articlesGravity filtersFiltrationAcid corrosion

The present invention relates to a filtration cloth bag installation buckle, a filtration cloth bag for pressure filtration machine filtration, and a molding method, wherein a service life of a filtration cloth bag for pressure filtration machine filtration can be effectively prolonged and an effective use period of every set of the filtration cloth bags can be increased in the case of material, manufacture and connection fixation process change with the filtration cloth bag installation buckle, the filtration cloth bag is provided with a plastic buckle along a hanging-on-pile buckle, filtration cloth is arranged between the upper buckle and the lower buckle of the plastic buckle, and the upper buckle, the filtration cloth and the lower buckle are subjected to hot melting adhesion to form the integration. According to the present invention, the phenomenon that the filtration cloth bag hanging-on-pile buckle is easily disengaged from the filtration cloth due to external force impact in the background technology is solved, the problem of easy rusting of the metal hanging-on-pile buckle in an acid corrosion environment and an alkaline corrosion environment is solved, and the problems of tedious installation, high work intensity (including the filtration cloth bag line tying structure), low work efficiency, and the like of on-site filtration cloth bag replacement are solved.

Owner:HANGZHOU XINGYUAN FILTER TECH

Adjustable drain port for heating plate

InactiveCN104697037AIngenious designSimple structureLighting and heating apparatusSpace heating and ventilation detailsTransverse planeWater flow

The invention relates to a heating plate fitting, in particular to an adjustable drain port for a heating plate. The adjustable drain port comprises a main water pipeline, a downward water flow steel pipe, a square baffle plate, a screwing shaft and a strong spring, and is characterized in that the downward water flow steel pipe is connected to the bottom surface of the main water pipeline; water-stop plates are arranged at the two ends of the strong spring; the strong spring is arranged in the main water pipeline; the square baffle plate is connected together with the screwing shaft; the lower end of the screwing shaft and the baffle plate are arranged in the main water pipeline; the end, close to the mounting position of the screwing shaft, of the main water pipeline is sealed by a large-sized water-stop plate; the screwing shaft and the square baffle plate are arranged between the large-sized water-stop plate and the strong spring; when the square baffle plate is at a transverse water-stop position, the strong spring is right at the position, where a pipe orifice of the downward water flow steel pipe can be blocked, of the bottom end of the square baffle plate; a thread is formed on the screwing shaft.

Owner:SHANDONG WANXIN THERMAL TECH

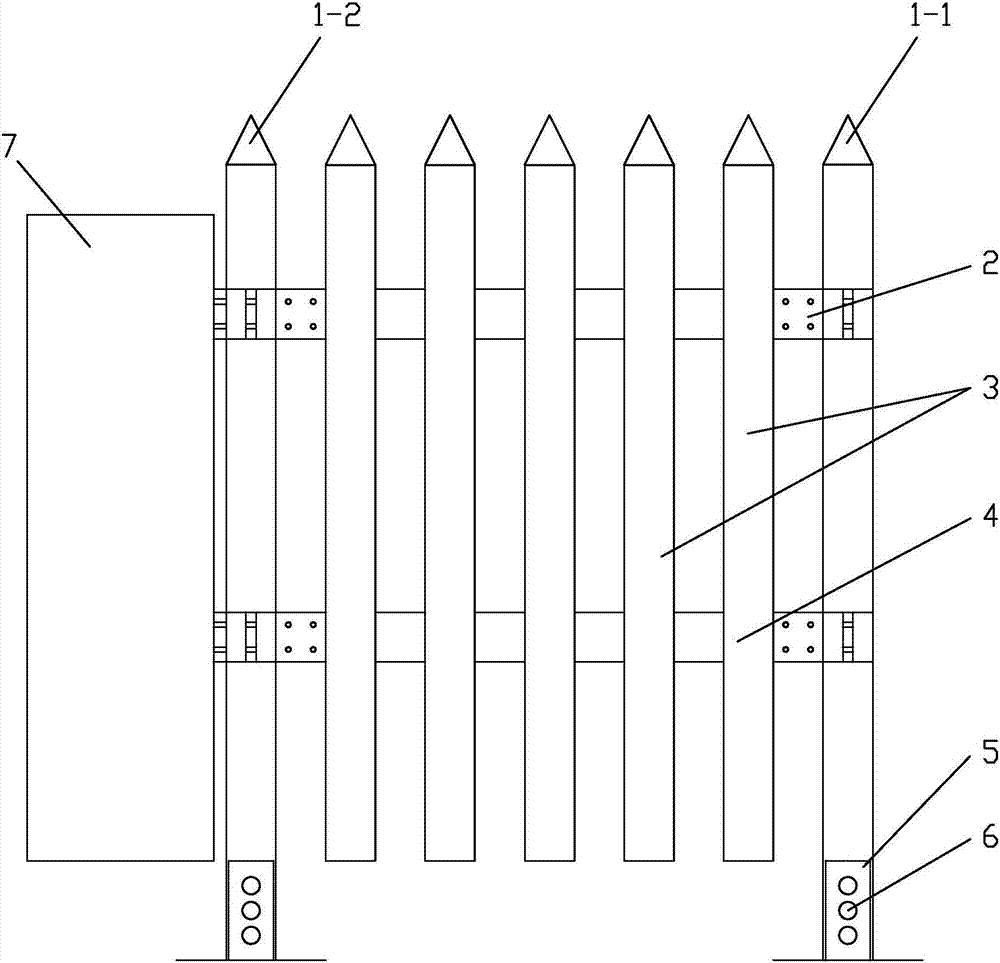

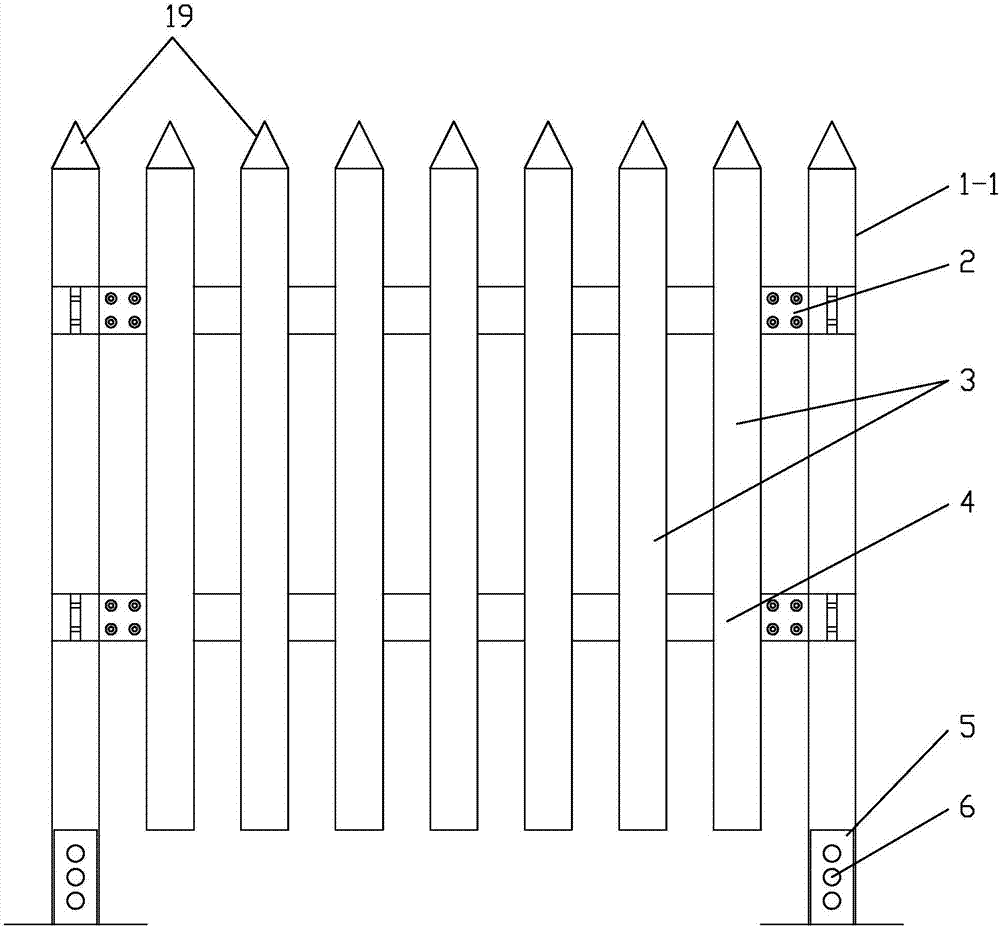

Electric power safety warning fence for power distribution construction power transformer protection

The invention discloses an electric power safety warning fence for power distribution construction power transformer protection. The electric power safety warning fence comprises stainless steel vertical columns, plastic rods and a connecting frame. The electric power safety warning fence is characterized in that the vertical columns are arranged on the connecting frame at intervals, and the bottoms of the vertical columns are arranged on a foundation support; the foundation support is fixed to the ground; multiple grooves are formed in the side face of the connecting frame, and the plastic rods are embedded into the grooves in a one-to-one correspondence mode. The electric power safety warning fence has the advantages that the weight is low, storage, transportation and assembly are convenient, the installing time is saved, the installing efficiency is improved, the use and maintenance cost is low, and energy saving and environmental protection are achieved.

Owner:吴乐洋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com