High-performance punching oil used for thick plate

A high-performance, stamping oil technology, applied in the field of metal stamping working fluid and high-performance stamping oil, can solve the instability of vegetable oil and polyol ester, can not meet the requirements of thick plate stamping lubrication, affect the rust prevention effect of products, etc. problem, to achieve high anti-oxidative stability, good extreme pressure lubrication effect, the effect of preventing direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] According to above-mentioned composition formula, prepare a kind of high-performance stamping oil 100Kg that is used for thick plate of the present invention,

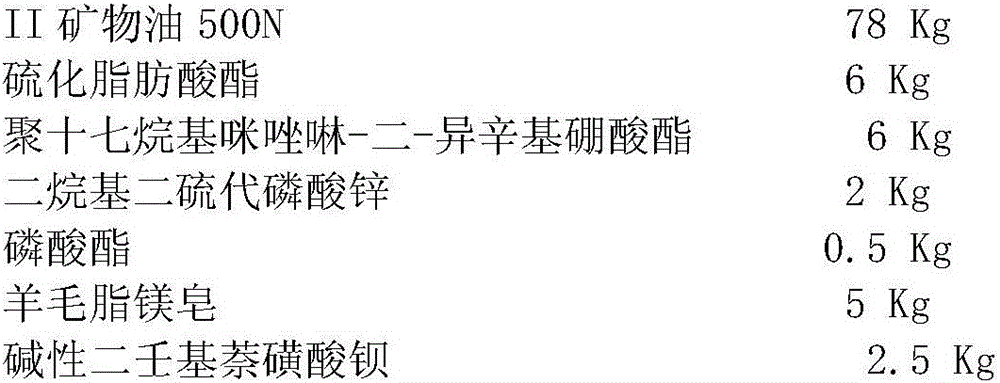

[0036] in:

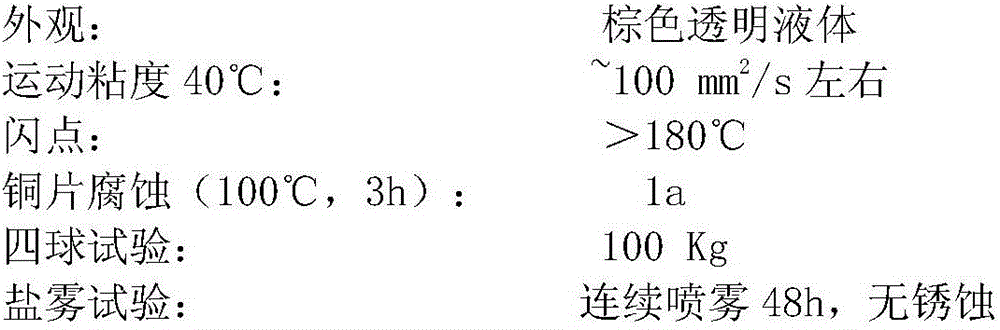

[0037]

[0038] First add 78Kg II mineral oil 500N into the reaction kettle, heat up to 50-60°C, according to the above formula, add 6Kg sulfurized fatty acid ester, 6Kg polyheptadecyl imidazoline-di-isooctyl borate, 2Kg Dialkyl dithiophosphate zinc, 0.5Kg phosphoric acid ester, 5Kg lanolin magnesium soap, 2.5Kg basic barium dinonylnaphthalene sulfonate, stir until transparent, and obtain 100Kg thick plate stamping oil.

[0039]

[0040] Application of this product: Using the stamping oil of the above invention, on a 630-ton FEINTOOL fine blanking machine, the front end cover plate of 6.4mm thick C45E steel is stamped and formed. The surface accuracy of the workpiece meets the requirements, and there is no tear or burn on the processed surface. The workpiece is placed for one month. There was n...

Embodiment 2

[0042] According to above-mentioned composition formula, prepare a kind of high-performance stamping oil 100Kg that is used for thick plate of the present invention

[0043] in:

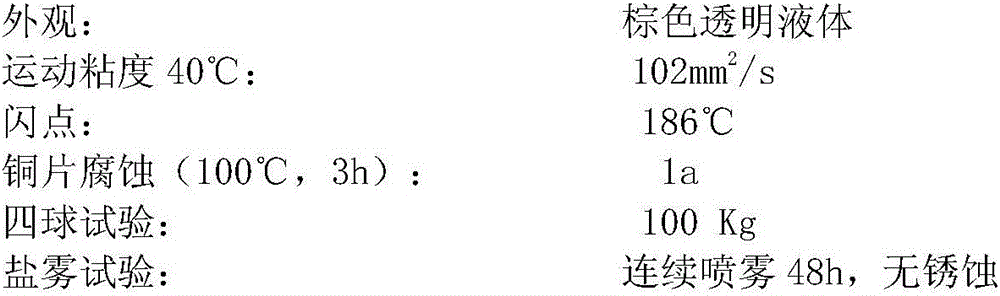

[0044]

[0045] Add 74Kg II to the reactor first + Mineral oil 500N, heat up to 50-60°C, according to the above formula, add 8Kg high alkali value calcium sulfonate petroleum, 10Kg polyheptadecyl imidazoline-di-isooctyl borate, 2Kg dialkyl disulfide Substitute zinc phosphate, 1Kg phosphoric acid ester, 5Kg dodecenyl succinic acid, stir until transparent, obtain 100Kg thick plate stamping oil of the present invention.

[0046]

[0047] Application of this product: Using the stamping oil of the above invention, 30CrMo steel parts with a thickness of 8mm are stamped on a 700-ton FEINTOOL fine blanking machine. The surface accuracy of the workpiece meets the requirements, and there is no tear or burn on the processed surface. Rust phenomenon.

Embodiment 3

[0049] According to above-mentioned composition formula, prepare a kind of high-performance stamping oil 100Kg that is used for thick plate of the present invention

[0050] in:

[0051]

[0052] First add 66Kg II mineral oil 500N into the reaction kettle, heat up to 50-60°C, according to the above formula, add 5Kg sulfurized fatty acid ester, 5Kg high alkali value sodium petroleum sulfonate, 15Kg polyheptadecyl imidazoline-di - Isooctyl borate, 2Kg zinc dialkyl dithiophosphate, 0.5Kg phosphoric acid ester, 5Kg dodecenyl succinic acid, 1.5Kg lanolin magnesium soap, stir until transparent to obtain 100Kg thick plate stamping oil .

[0053]

[0054] Application of this product: Using the stamping oil of the above invention, 16MnCr5 steel parts with a thickness of 10mm are stamped and formed on a 700-ton FEINTOOL fine blanking machine. The surface accuracy of the workpiece meets the requirements, and there is no tear or burn on the processed surface. Rust phenomenon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com