Patents

Literature

78results about How to "Excellent antioxidant stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

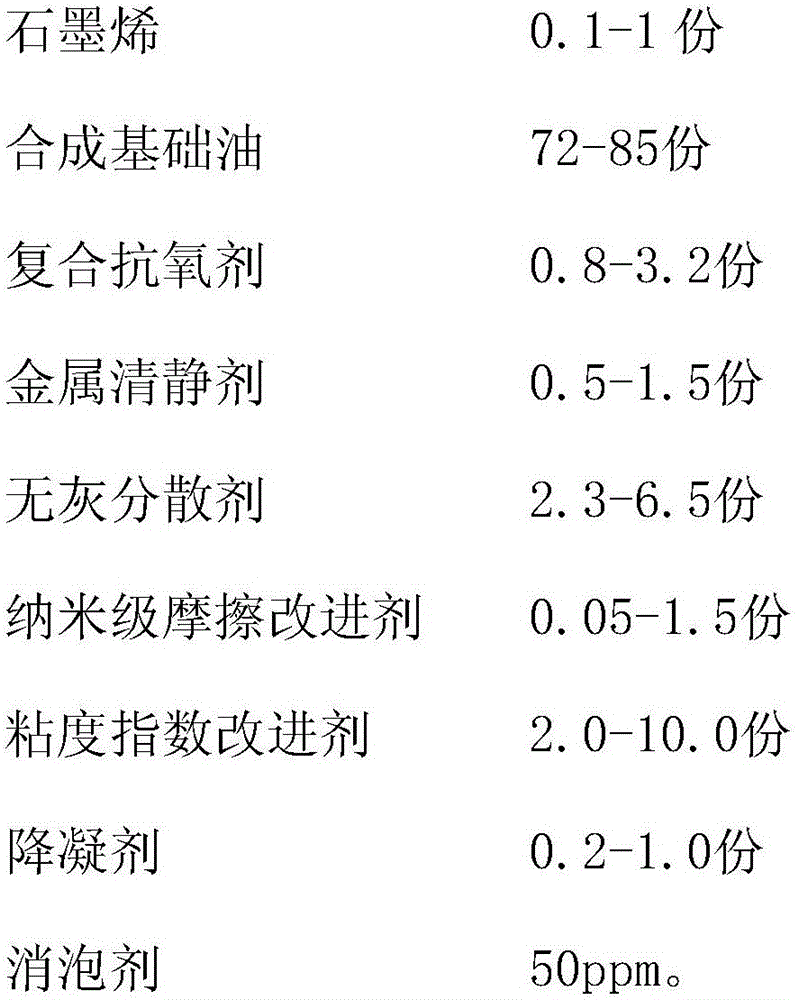

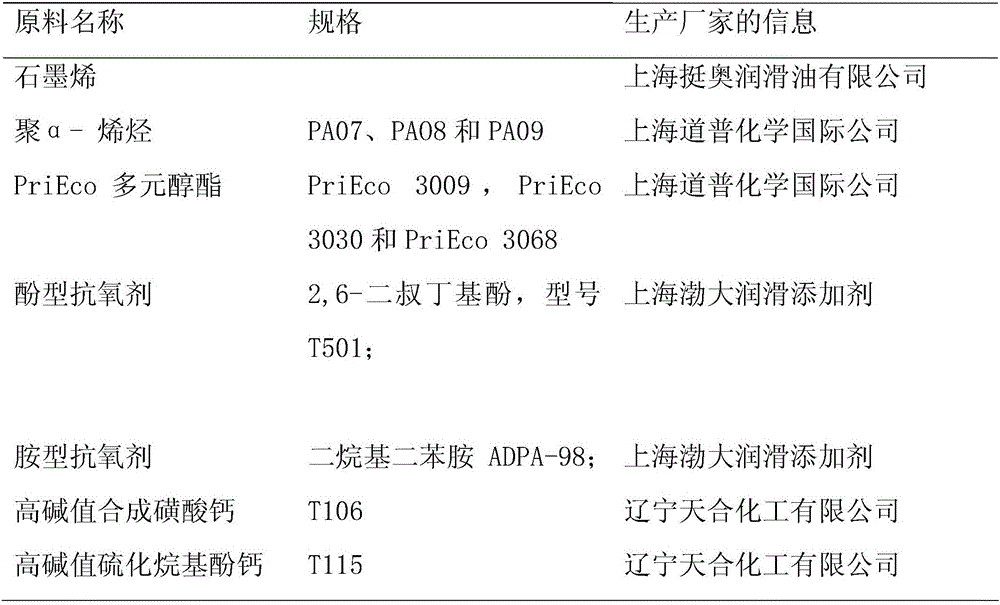

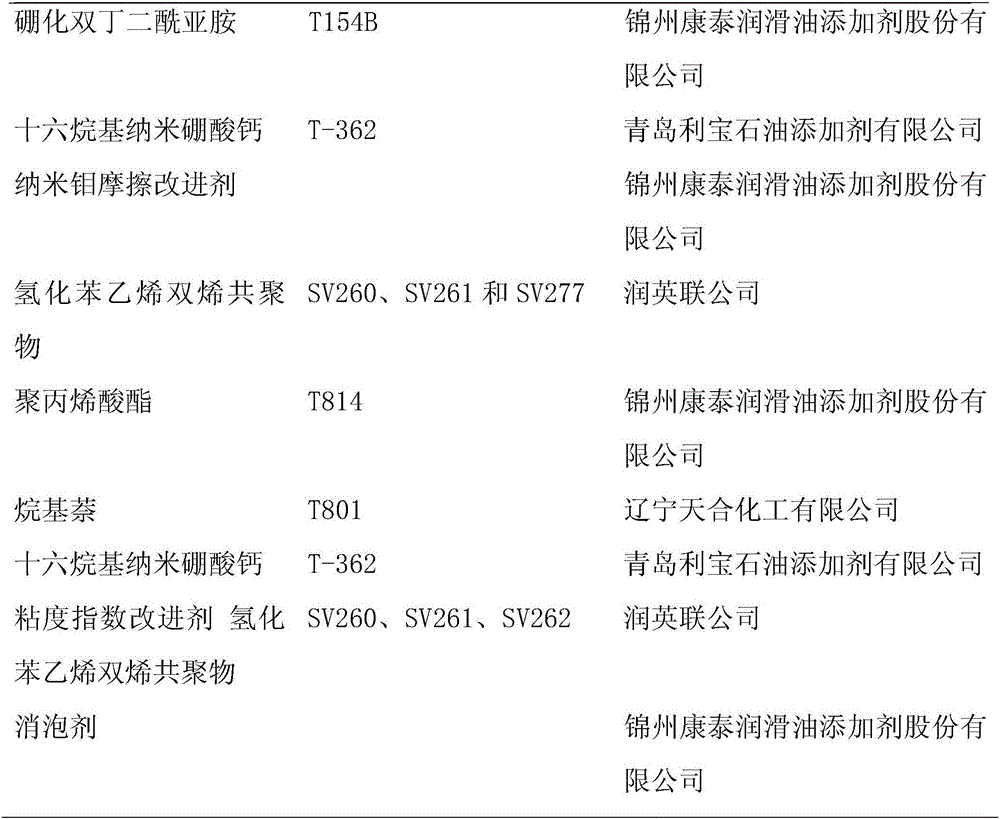

Graphene-containing lubricating oil and preparation method thereof

The invention relates to a graphene-containing lubricating oil and a preparation method thereof. The graphene-containing lubricating oil comprises the following components by weight: 0.1-1 part of graphene, 72-85 parts of synthetic base oil, 0.8-3.2 parts of a composite antioxidant, 0.5-1.5 parts of a metal detergent, 2.3-6.5 parts of an ashless dispersant, 0.05-1.5 parts of a nanoscale friction modifier, 2.0-10.0 parts of a viscosity index improver, 0.2-1.0 part of a pour point reducer, and 50ppm of a defoamer. The preparation method includes: putting the synthetic base oil into a blending kettle, performing stirring, then adding the pour point reducer, the viscosity index improver, the composite antioxidant, the metal detergent, the ashless dispersant, and the nanoscale friction modifier, stirring the substances evenly, adding graphene and the defoamer, maintaining the original temperature, stirring the materials evenly, and performing standing. The graphene-containing lubricating oil provided by the invention solves the problems of corrosion and selectivity in traditional lubricating oil additives, at the same time the process is improved, and the ultrasonic dispersion link of graphene is eliminated.

Owner:SHANGHAI INST OF TECH

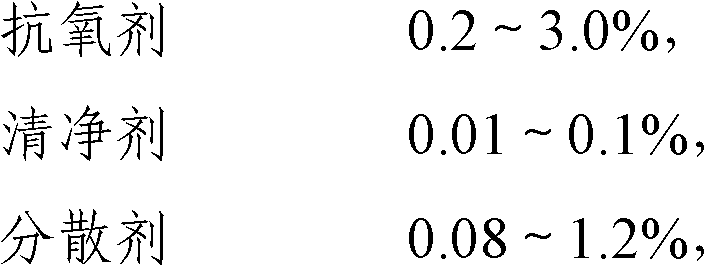

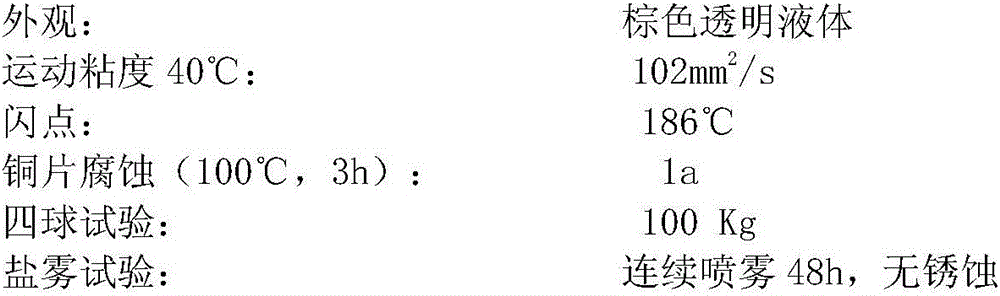

Heat-conductive oil composition having high temperature oxidation resistance

ActiveCN102925256AExcellent high antioxidant stabilityExtended service lifeAdditivesOxidation resistantRust converter

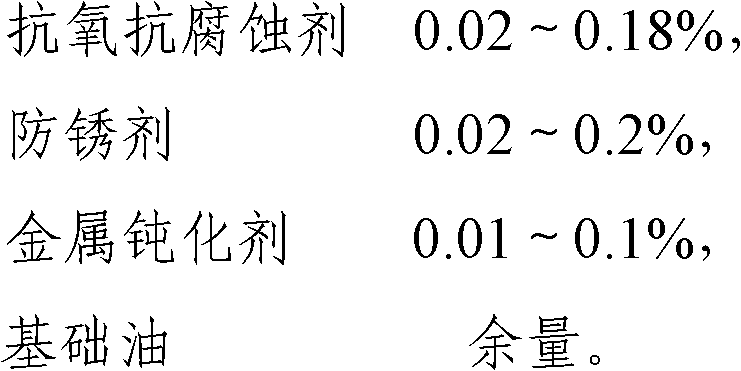

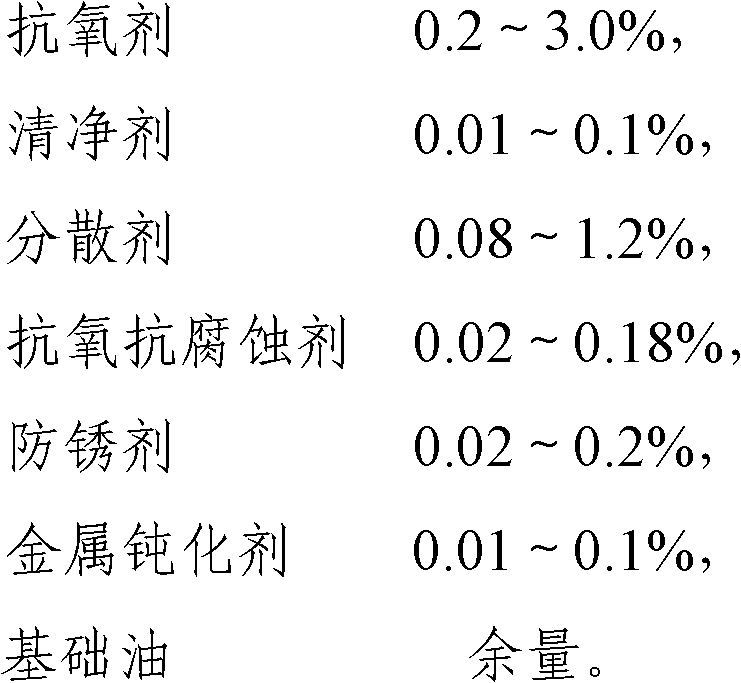

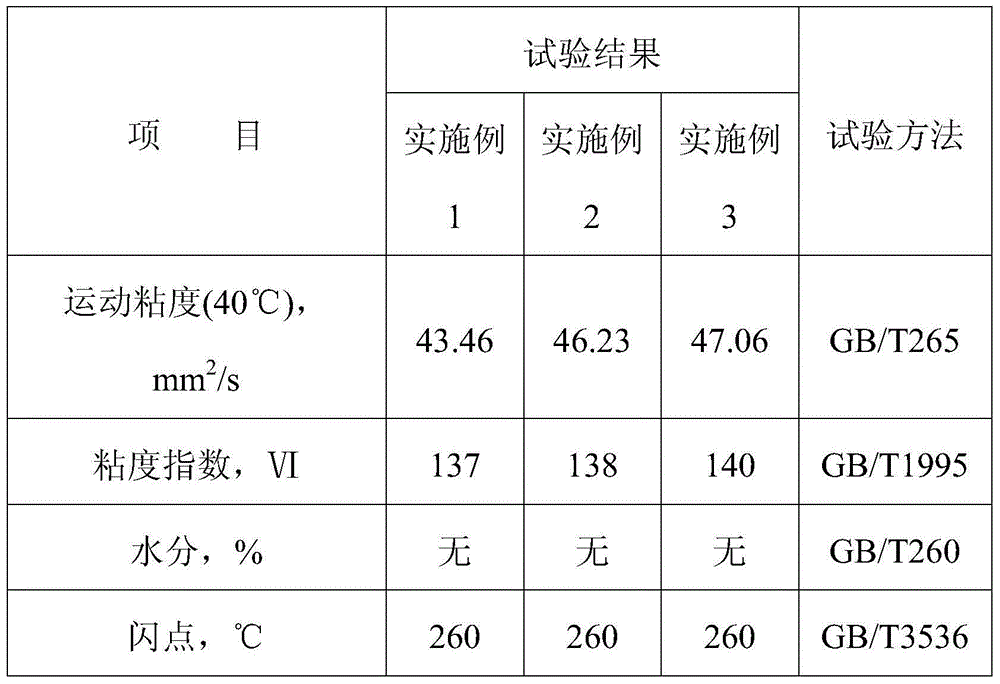

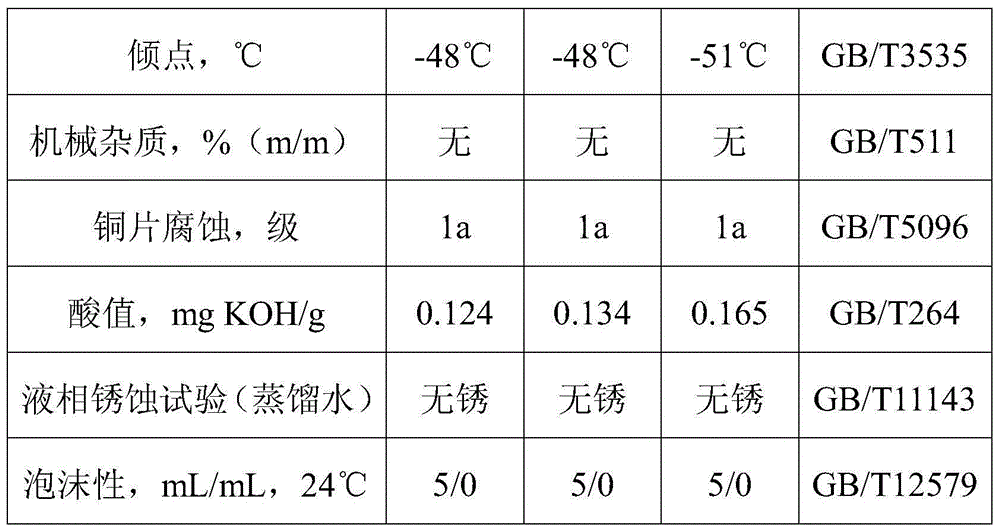

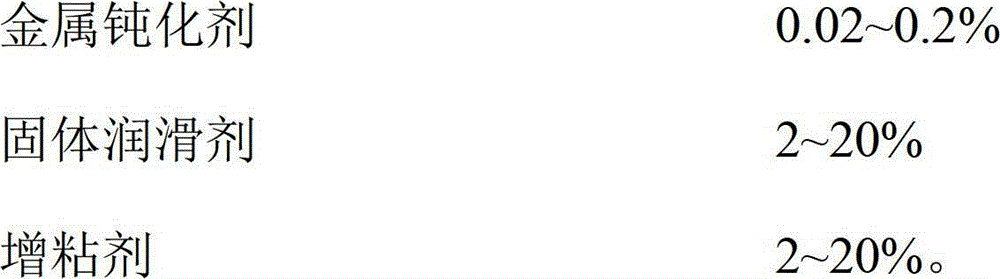

The invention provides a heat-conductive oil composition having a high temperature oxidation resistance. The heat-conductive oil composition comprises 0.2-3.0wt% of an antioxidant, 0.01-0.1wt% of a detergent, 0.08-1.2wt% of a dispersant, 0.02-0.18wt% of an anti-oxidation and anti-corrosion agent, 0.02-0.2wt% of an antirust agent, 0.01-0.1wt% of a metal deactivator, and the balance base oil. The heat-conductive oil composition has high anti-oxidation and stabilization performances, is suitable for the conditions of a plurality of processing technologies, and has the advantages of long service life, reasonable raw material compatibility, simple preparation method, wide application range, and easily available raw materials.

Owner:CHINA PETROLEUM & CHEM CORP

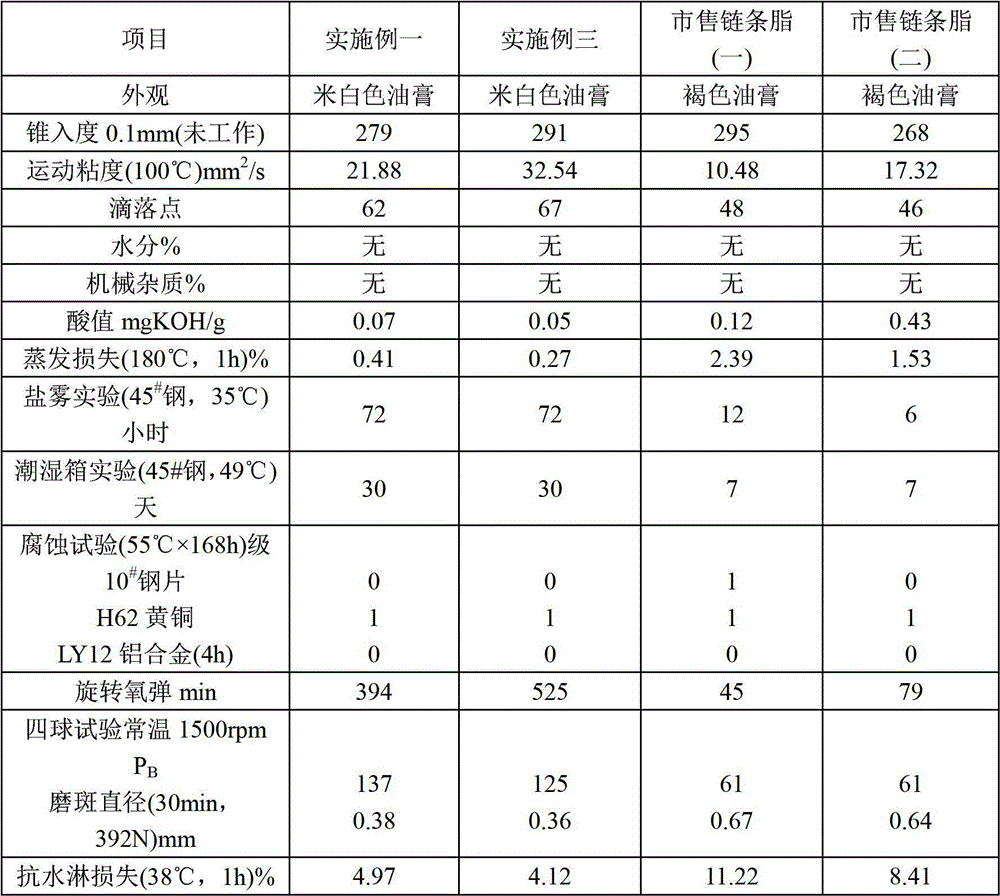

Oil-soluble polyether oil for screw-type air compressor

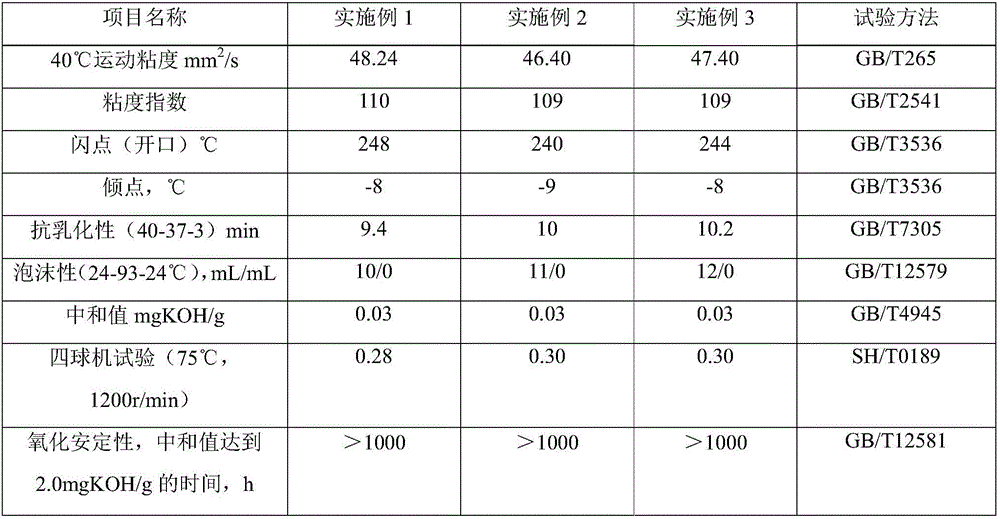

InactiveCN104130842AExcellent antioxidant stabilityGood demulsibilityLubricant compositionPerformance indexMechanical equipment

The invention discloses oil-soluble polyether oil for a screw-type air compressor. The oil-soluble polyether oil is prepared from 20-40 parts or 10-20 parts by mass of oil-soluble polyether base oil, 60-80 parts or 80-90 parts by mass of poly(alpha-olefin), 0.1-1.4 parts by mass of benzenamine, 0.8-2 parts by mass of a borate anti-oxidant, 1.2-2.2 parts by mass of a high-temperature ashless antiwear agent, 0.5-1.8 parts by mass of polyoxyethylene sorbitan fatty acid ester and 0.001-0.05 parts by mass of an acrylate-ether copolymer. The oil-soluble polyether oil for a screw-type air compressor is environmentally friendly, has the advantages of excellent antioxidation stability, emulsification resistance, corrosion and rusting resistance, very good defoaming performance and excellent viscosity-temperature performance, has performance indexes satisfying standards of air compressor oil 46 and can be used for mechanical equipment of an air compressor system.

Owner:张家港市胜宇石油化工制品有限公司

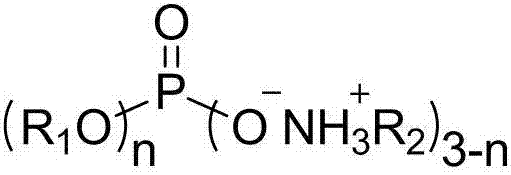

High-base number metal detergent and preparation method thereof

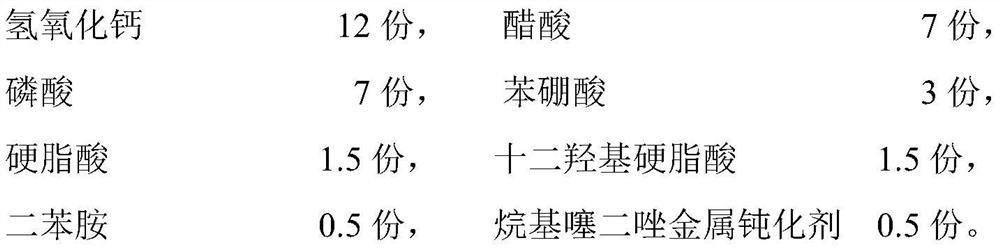

ActiveCN102071085AExcellent antioxidant stabilityWide range of usesAdditivesCalcium hydroxideHydrocarbon solvents

The invention relates to a high-base number metal detergent and a preparation method thereof. The preparation method comprises the following steps of: mixing and performing a neutralization reaction on a hydrocarbon solvent, neutral oil, naphthenic acid, water, alkylphenol and calcium hydroxide and / or calcium oxide; and adding methanol and the calcium hydroxide and / or the calcium oxide; introducing carbon dioxide to perform a carbonation reaction twice; and obtaining a product through an aftertreatment process. The product has an ultra-high base number and better anti-oxidation stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

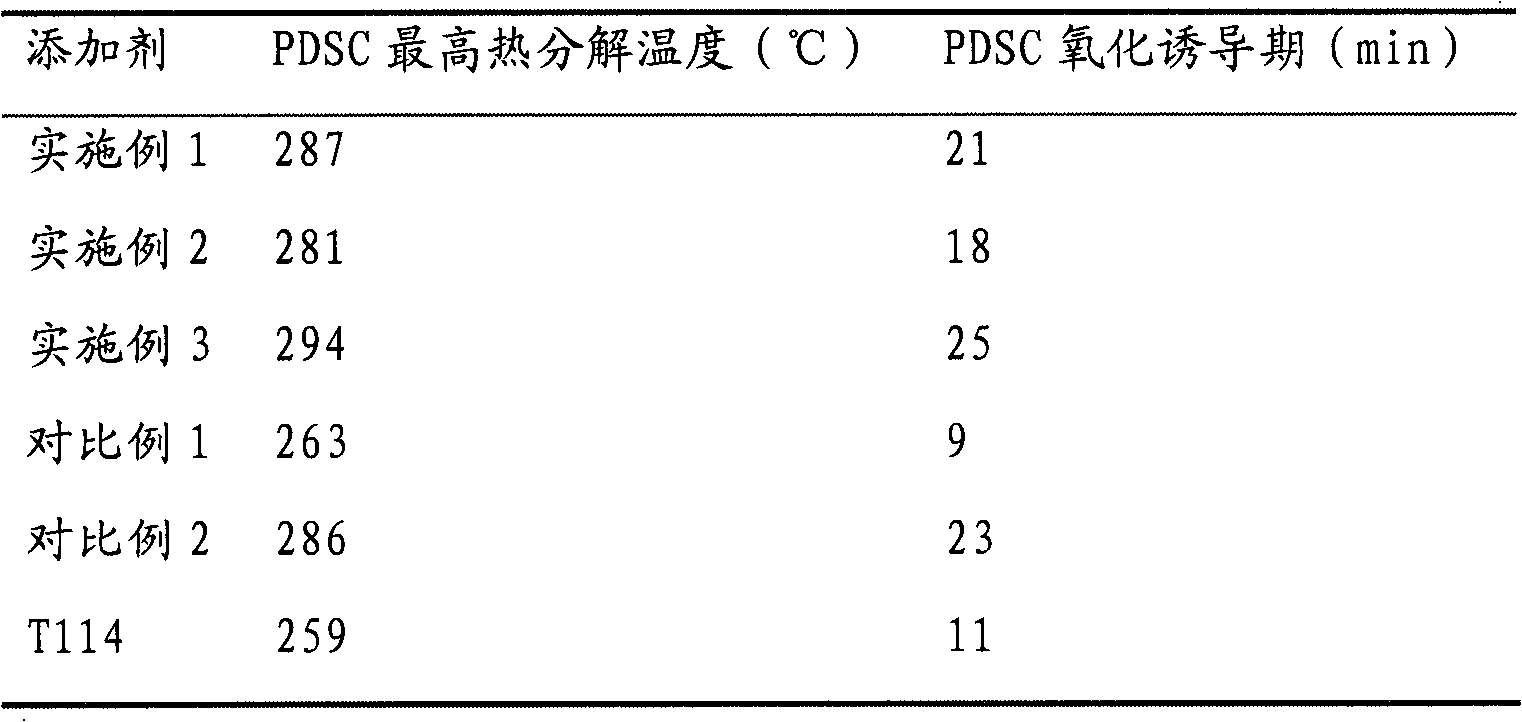

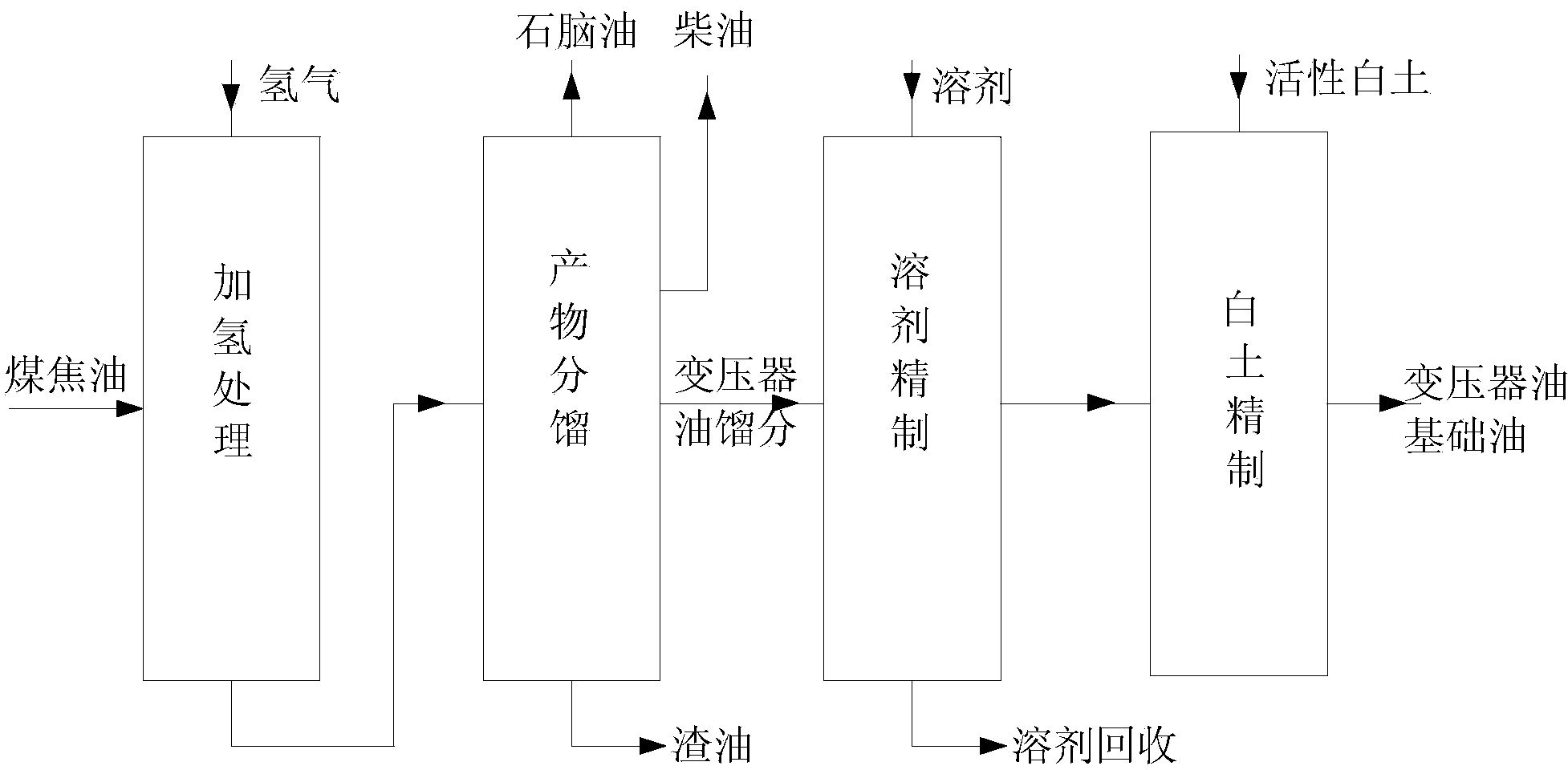

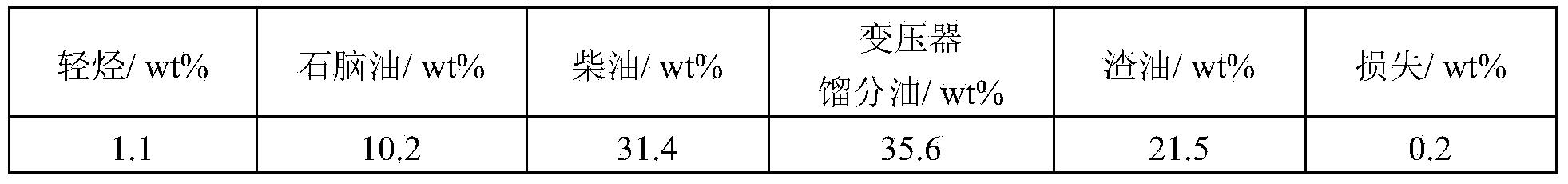

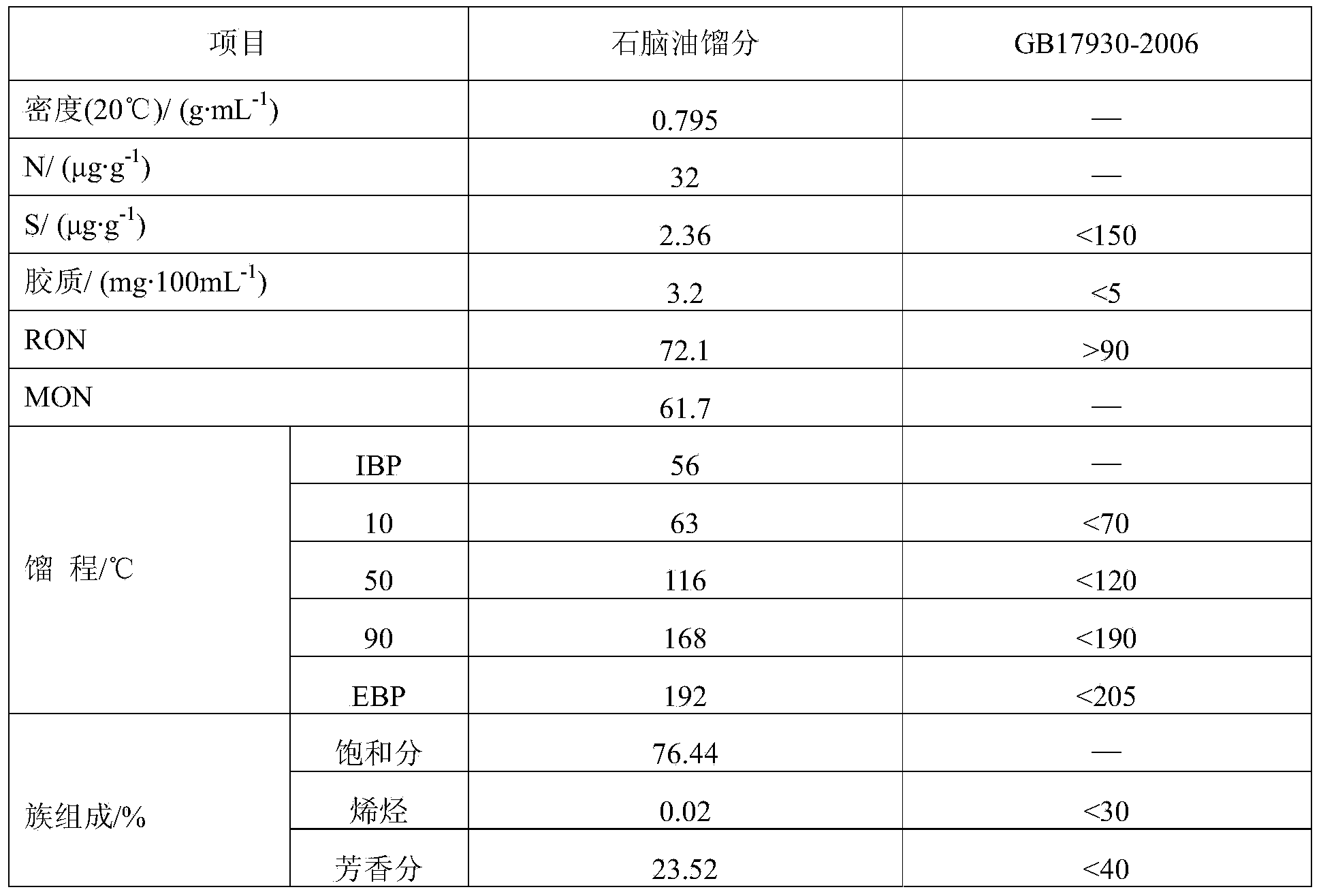

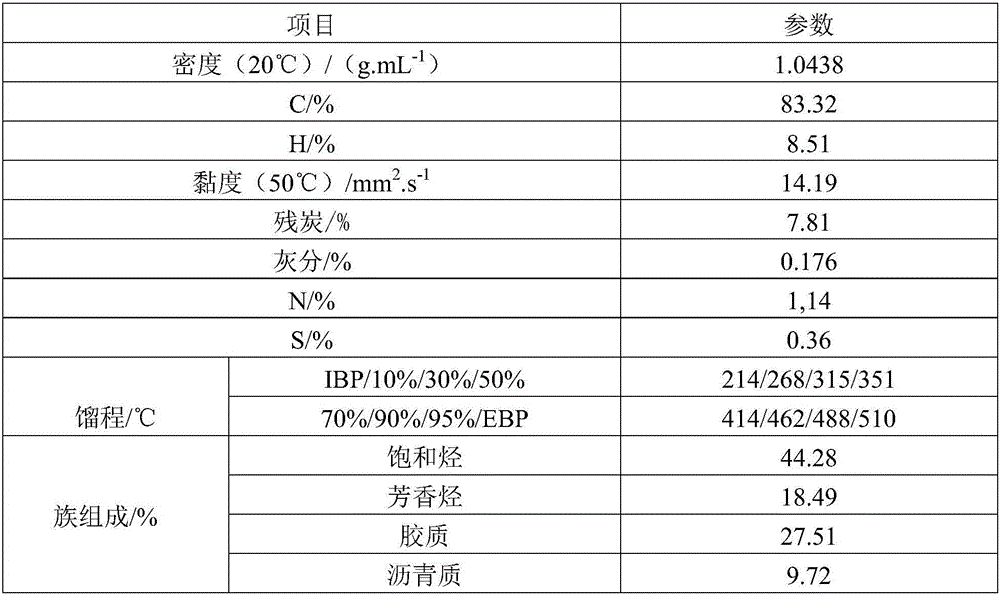

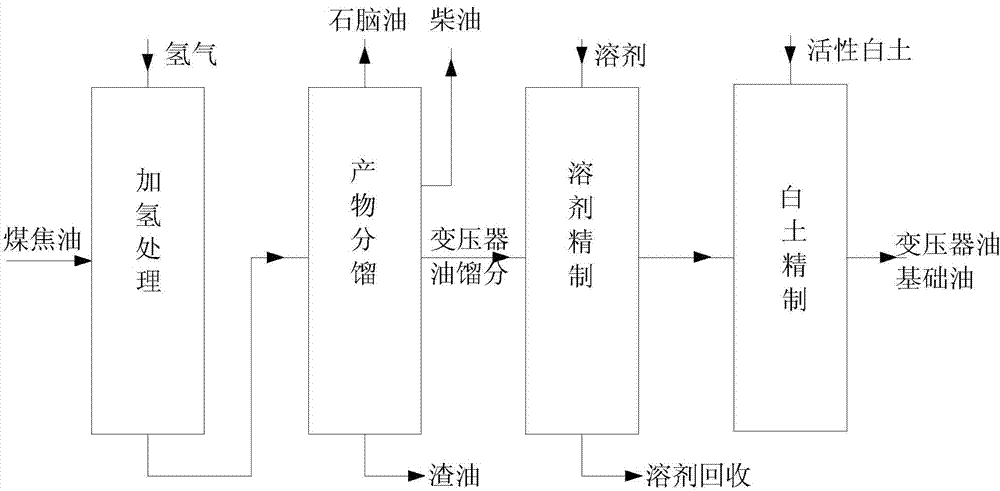

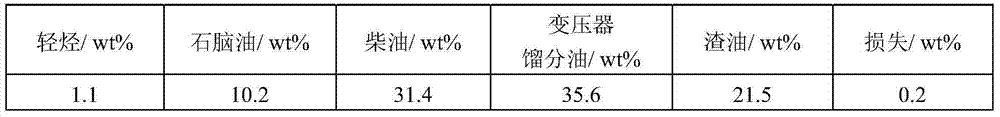

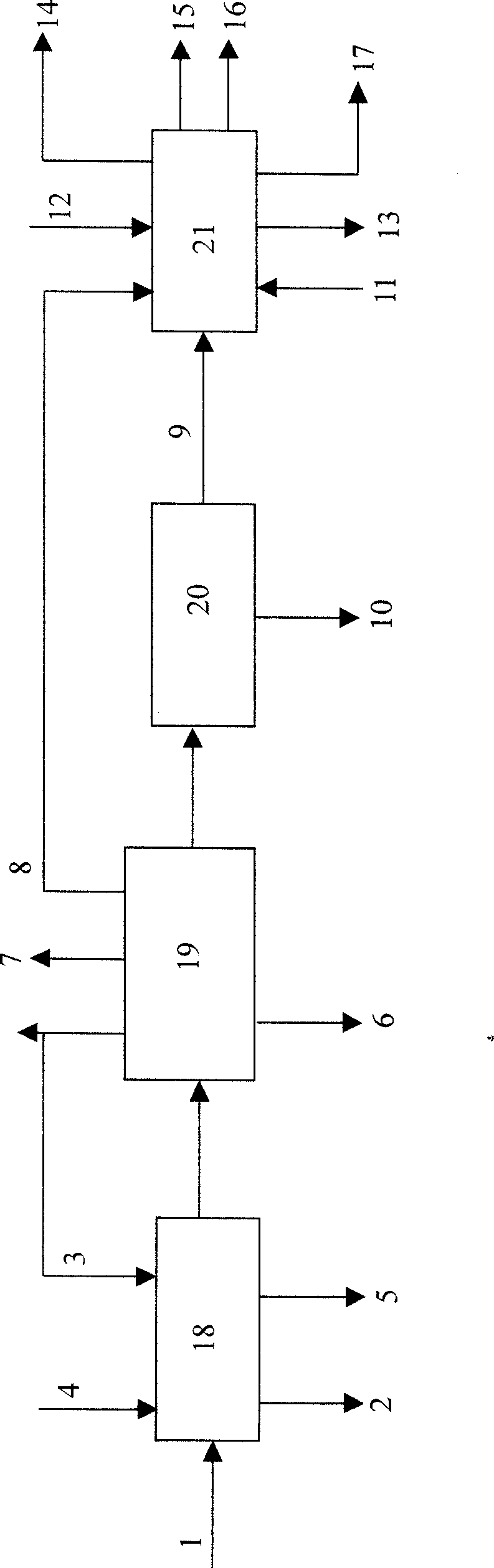

Method for producing naphthenic base transformer oil base oil by using coal tar oil

ActiveCN103436289AExtend the industrial chainReasonable useTreatment with hydrotreatment processesSolvent refiningCoal tar

The invention relates to a method for producing naphthenic base transformer oil base oil by using coal tar oil. The method is characterized in that high-additional value products such as naphtha oil, diesel oil and transformer oil base oil are obtained by adopting the steps of hydrotreating of the coal tar oil, the fractional distillation of hydrogenated products, solvent refining of transformer distillate oil and clay refining of the transformer distillate oil. The method has the advantages that the hydrogenation industrial chain of the coal tar oil is extended, the coal tar oil resource is reasonably utilized, the utilization value of the coal tar oil is increased, meanwhile, the density of the coal tar oil hydrogenated diesel oil can be reduced, the cycloparaffin distillate oil (300-360 DEG C) with high content can be obtained, the quality of the transformer oil base oil is ensured, and the obtained transformer oil base oil has high quality and high yield and is in line with the standards on the transformer oil No. 45 in national GB2536-1990 transformer oil.

Owner:SHENMUFUYOU ENERGY TECH

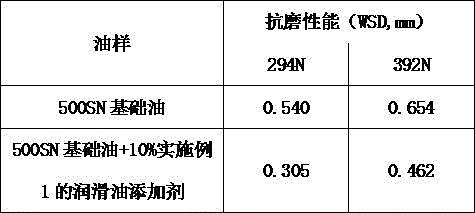

Graphene lubricating oil additive and preparation method thereof

InactiveCN105602654AReduce ultrasonic dispersionSolve corrosiveAdditivesOil additiveMechanical equipment

The invention discloses a graphene lubricating oil additive and a preparation method thereof. The graphene lubricating oil additive is prepared from proper amounts of graphene, a hydrogenated styrene-diolefin copolymer, a borate and an oil-based solvent. The graphene lubricating oil additive disclosed by the invention solves the problem of corrosivity and selectivity in the traditional lubricating oil additive. The nano material additive technique is complex to operate, can discharge waste gas and pollutants, and can pollute the environment. The graphene lubricating oil additive can implement self-repair on the worn part, performs the functions of oil saving, wear resistance, noise reduction, power enhancement and the like, can be well dispersed in many types of lubricating oil base oil, has favorable oxidation stability, can exist stably for a long time, and is suitable for solving the problems of friction, wear and maintenance of different kinds of mechanical equipment under multiple working conditions.

Owner:SICHUAN CARBON WORLD TECH CO LTD

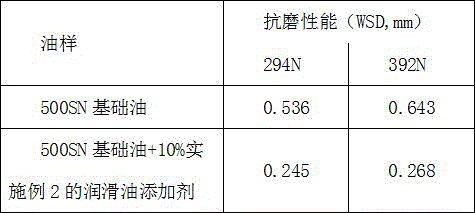

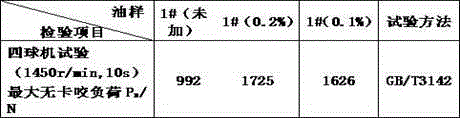

Boron-nitride-type borate lubricating oil additive and preparation method thereof

InactiveCN104017009ASimple production processReduce manufacturing costGroup 3/13 element organic compoundsAdditivesOil additiveBoron nitride

The invention discloses a boron-nitride-type borate lubricating oil additive and a preparation method thereof. The preparation method comprises the following steps: putting tall oil and diethanolamine in a container, and reacting at 100-120 DEG C for 4-5 hours to obtain tall oil acetal amide; mixing salicylaldehyde and n-butylamine, adding ethanol, reacting at 50-60 DEG C in a reflux unit for 2-3 hours, adding the prepared tall oil acetal amide, adding boric acid, and uniformly mixing; reacting at 70-80 DEG C for 1-1.5 hours while keeping the pressure stable at 260-270 mmHg; depressurizing to the stable pressure of 60-70 mmHg, gradually heating to 90-100 DEG C, and reacting for 3-4 hours; and cooling, and filtering to obtain the light yellow liquid. The production method is simple, and has the advantages of low cost, high hydrolysis resistance of the product, high yield and environment friendliness.

Owner:TIANJIN SURENERGY CHEM

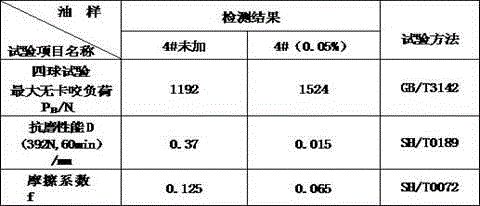

Antiwear energy-saving environment-friendly diesel engine oil

The invention belongs to the technical field of lubricating oil. The antiwear energy-saving environment-friendly diesel engine oil comprises the following components in percentage by weight: 84.5-86% of base oil, 0.5% of antioxidation and anticorrosion agent, 14.0-15.5% of other additive and 0.05-0.2% of microfluorine solid lubricant powder. The preparation method comprises the following steps: adding base oil into a blending kettle, heating to 65 DEG C+ / -5 DEG C, sequentially adding the tackifier, pour-point depressant, antioxidation and anticorrosion agent and complexing agent while continuously stirring, stirring for 30-40 minutes, and standing to settle; and heating the oil to 65 DEG C+ / -5 DEG C, adding a certain amount of polyhexafluoroethylene superfine micropowder while continuously stirring, stirring for 4-5 hours, and standing to settle to obtain the finished product. Compared with the prior art, the wear-resistant lubricating oil with the polyhexafluoroethylene superfine micropowder has the advantages of reasonable component design, favorable antiwear and antifriction properties, favorable use effect and excellent high temperature resistance, and can prevent the machine from overheating in the high-speed operation process due to the favorable thermal conductivity.

Owner:天津市东宝润滑油脂有限公司

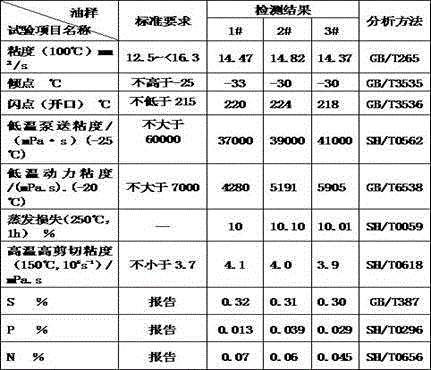

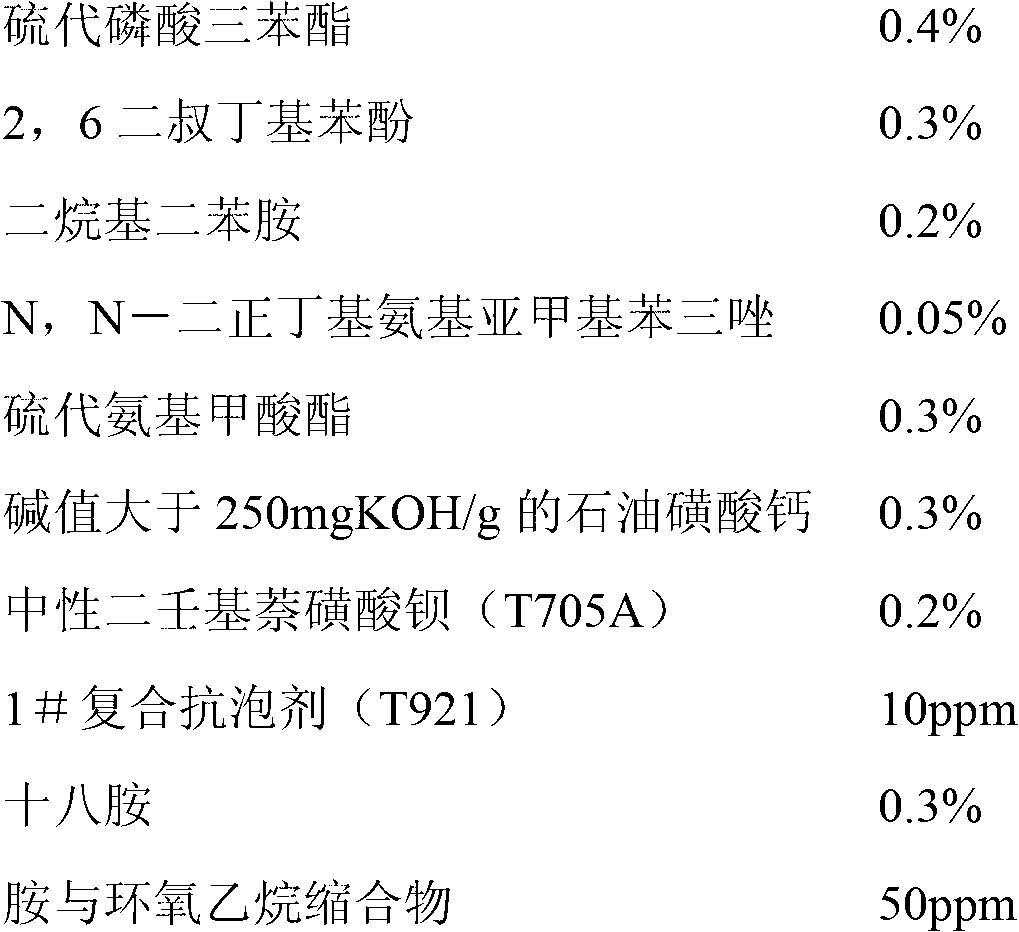

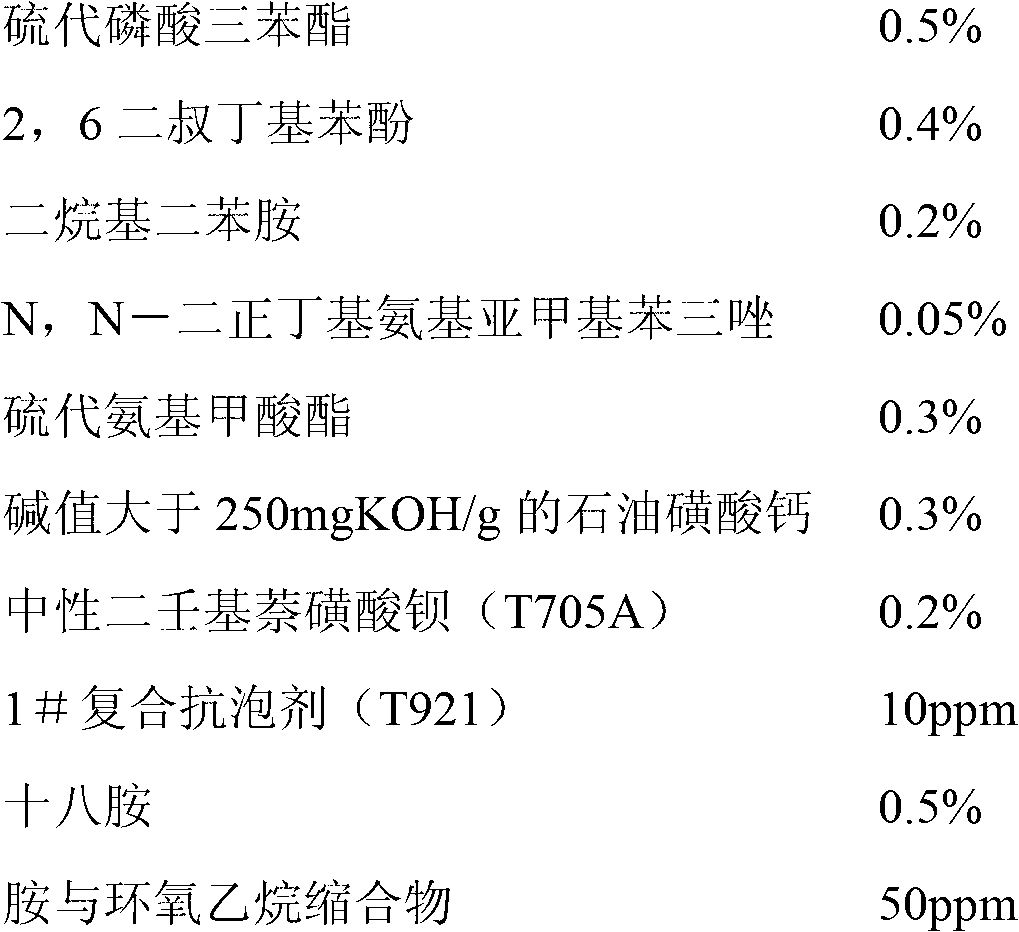

Anti-wear hydraulic oil capable of preventing chromium plated metal from blackening and bluing, as well as preparation method and application thereof

The invention provides anti-wear hydraulic oil capable of preventing chromium plated metal from blackening and bluing, and preparation method thereof. The anti-wear hydraulic oil comprises the following components in weight percent: 0.4%-0.8% of antiwear agent, 0.2%-0.4% of high alkaline petroleum sulfonate, 0.3%-1.2% of antioxygen, 20 ppm-80 ppm of demulsifying agent, 0.2%-0.5% of octadecylamine, 0.1%-0.3% of antirusting agent, 10 ppm-20 ppm of antifoaming agent, and the balance of base oil. The anti-wear hydraulic oil can efficiently avoid the blackening and bluing phenomena frequently occurring during the process that normal anti-wear hydraulic oil is applied onto the piston rod of engineering machinery, and meanwhile has the anti-wear performance; when the anti-wear hydraulic oil is applied, the increase of the acid value along with time is not significant, so that the anti-wear hydraulic oil has excellent antioxidation stability, and can satisfy long-term use by the engineering machinery hydraulic system.

Owner:上海火炬润滑油有限公司

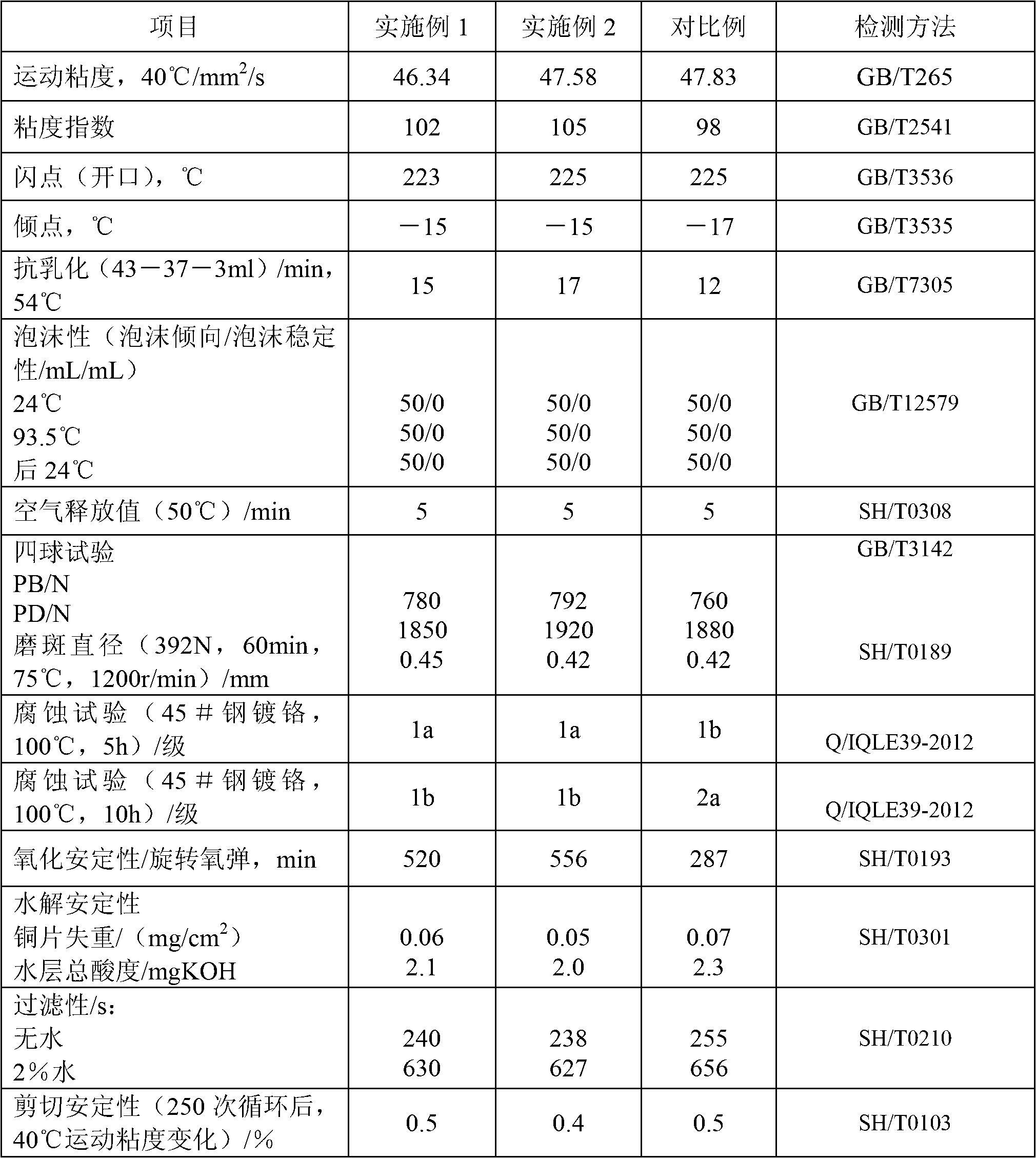

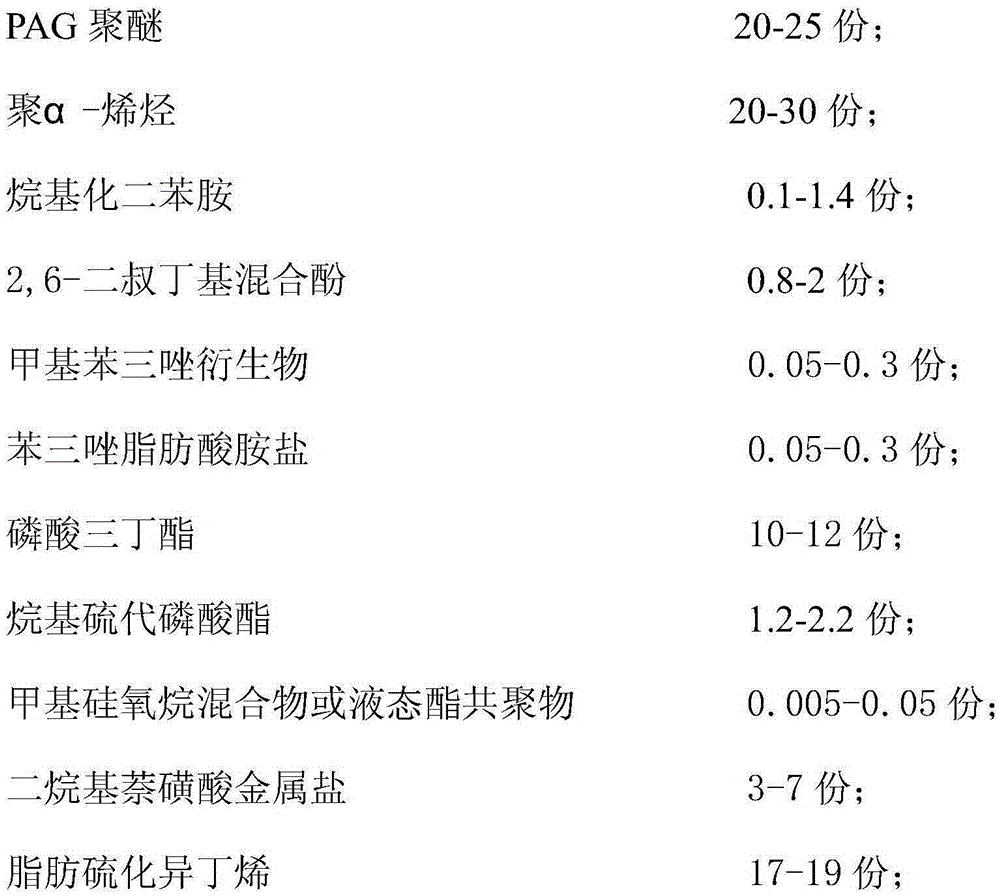

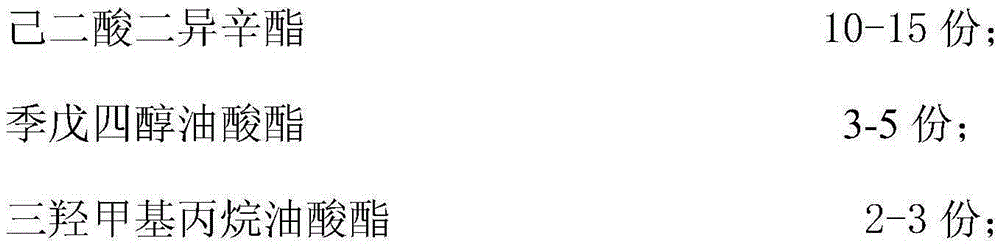

Composite screw type air compressor oil

ActiveCN105296107AEnvironmentally friendlyExcellent antioxidant stabilityLubricant compositionGreek letter alphaPhenols

The invention discloses composite screw type air compressor oil which comprises, by mass, 10-15 parts of raw material synthesis base oil A, 8-12 parts of synthesis base oil B, 20-25 parts of PAG polyether, 20-30 parts of poly-alpha-olefins, 0.1-1.4 parts of alkylated diphenylamine, 0.8-2 parts of 2,6-di-tert-butyl mixed phenols, 0.05-0.3 part of methyl benzene triazole derivative, 0.05-0.3 part of benzene triazole fatty acid amine salt, 10-12 parts of tributyl phosphate, 1.2-2.2 parts of dialkyl dithiophosphate, 0.005-0.05 part of methylsiloxane mixture or liquid ester copolymer, 3-7 parts of dialkyl group naphthalene metal organic sulfonate and 17-19 parts of fat sulphide isobutene. The composite screw type air compressor oil has the advantages of good antioxidation stability, demulsibility and anti-corrosion and anti-rust property, extremely good defoaming performance, excellent viscosity-temperature property and the like. Compared with mineral compressor oil, the energy is saved, oil consumption is lowered, environment pollution is reduced, the service life is prolonged, the performance index reaches the standard of 46# compressor oil, and the compressor oil is used for air compression system mechanical equipment.

Owner:张家港市胜宇石油化工制品有限公司

Emulsified biomass fuel oil and emulsifying method thereof

InactiveCN101906331AEmulsification is cheapSimple methodLiquid carbonaceous fuelsFuel additivesChemistryBiomass

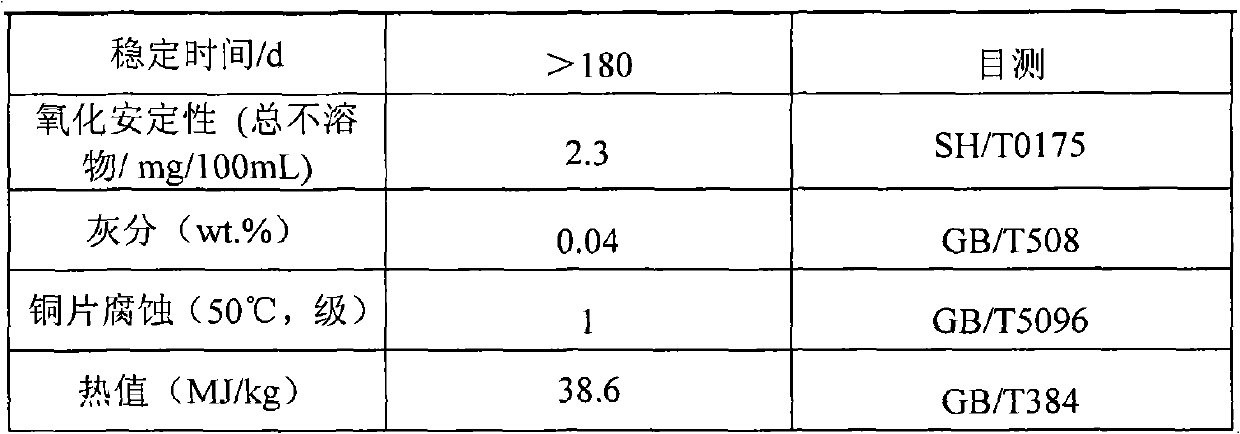

The invention discloses emulsified biomass fuel oil, which comprises the following components in percentage by weight: 1 to 15 percent of biomass crude oil, 75 to 95 percent of diesel oil, 0.45 to 9 percent of emulsifying agent, 0.05 to 0.2 percent of co-surfactant, 0.01 to 0.06 percent of oxidation and corrosion inhibitor and 0.01 to 1 percent of isooctyl nitrate. A preparation method for the emulsified oil comprises the following steps of: filtering the biomass crude oil to remove coarse impurities, and removing heavy components from the biomass crude oil by using a centrifugal machine; and then, adding ester emulsifying agent and ether emulsifying agent into the diesel oil and the biomass crude oil respectively, adding the two kinds of mixed solution into a high-shear homogenizing emulsifier, stirring the mixed solution for 20 to 60 minutes with shearing at the temperature of between 30 and 50 DEG C under 1,500 and 3,000rpm, finally adding the co-surfactant, the oxidation and corrosion inhibitor and an inflame improver into the mixed solution, and uniformly emulsifying the mixed solution to obtain the emulsified biomass crude oil. The emulsified biomass crude oil has long stabilization time which can reach over 6 months; the emulsified biomass crude oil has the advantages of high utilization rate of biomass oil, good anti-oxidation stability, low corrosion, low ash content and high combustion heat value; and the preparation method is simple and feasible, and has low environmental pollution.

Owner:HEFEI UNIV OF TECH

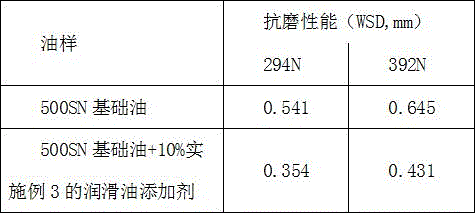

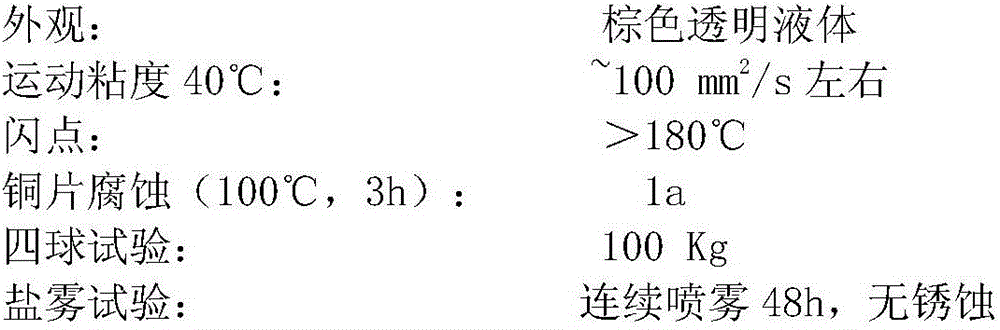

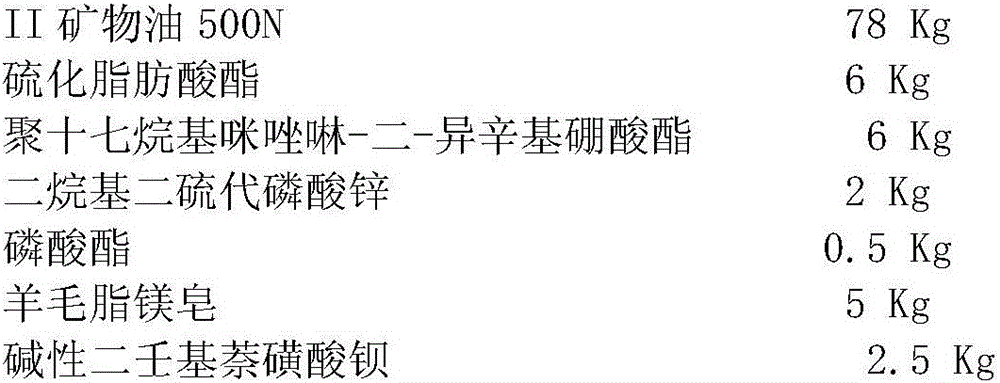

High-performance punching oil used for thick plate

The invention discloses high-performance punching oil used for a thick plate, belongs to the field of metal processing operating fluid, and particularly relates to operating fluid for metal stamping processing. The high-performance punching oil comprises, by mass, 60%-80% of refined mineral oil, 5%-10% of a sulfur-containing extreme pressure agent, 5%-15% of a macromolecule polymerization ester extreme pressure agent, 0.5%-5% of an antiwear agent and 5%-10% of an antirust agent. One of sulfide aliphatic acid ester and over-based sulfosalt or a mixture of the sulfide aliphatic acid ester and the over-based sulfosalt is selected as the sulfur-containing extreme pressure agent. Polyheptadecylimidazoline-di-isooctyl borate is selected as the macromolecule polymerization ester extreme pressure agent. According to the high-performance punching oil, under the synergistic effect of the macromolecule polymerization ester extreme pressure agent and the sulfur-containing extreme pressure agent, excellent lubricating performance and anti-corrosion performance can be given to the punching oil, and the high-performance punching requirements for the thick plate are met. Moreover, the rusting problem of punched products and the ecological environment problem are solved without chlorinated paraffin.

Owner:BOER TECH WUHAN

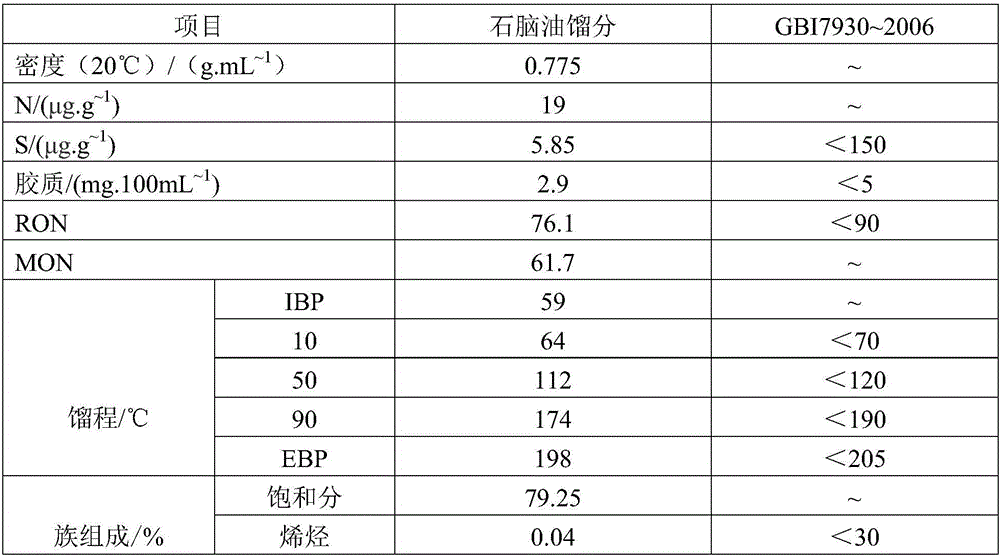

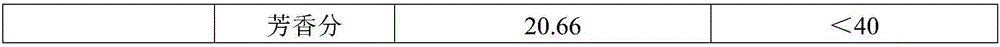

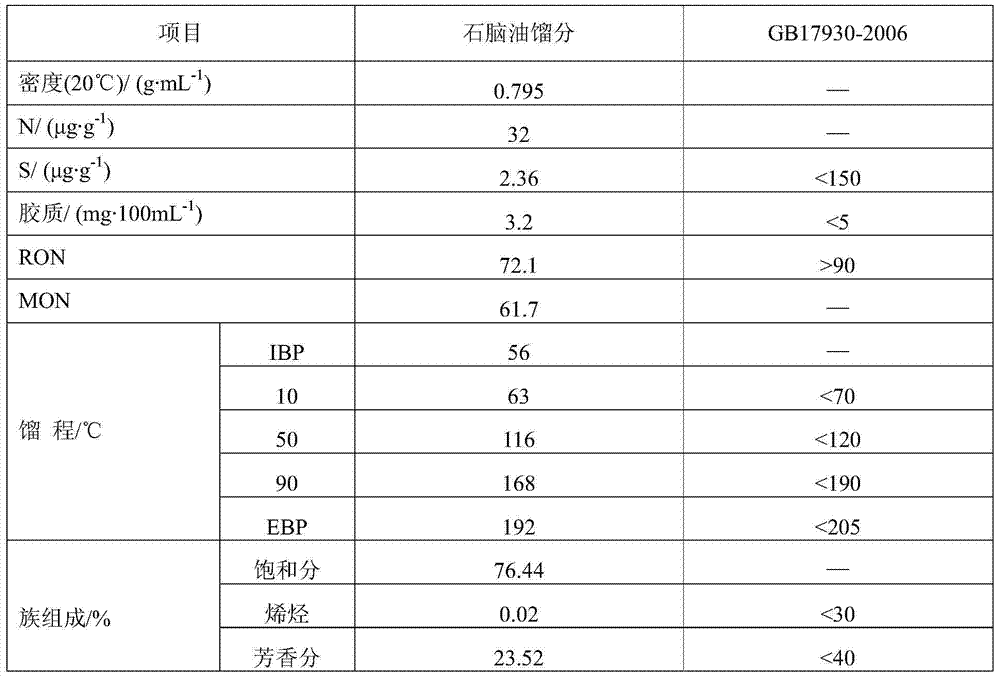

Method for producing high-density jet fuel by virtue of hydrogenation of medium-and-low temperature coal tar

InactiveCN105694970AImprove use valueQuality improvementTreatment with hydrotreatment processesNaphthaHigh density

The invention relates to a method for producing a high-density jet fuel by virtue of hydrogenation of medium-and-low temperature coal tar. The method comprises the following steps of: firstly mixing and heating medium-and-low temperature coal tar and hydrogen; performing hydrogenation reactions sequentially in the presence of a hydrogenation protective catalyst and a hydrorefining catalyst, and performing fractional distillation on hydrogenation products so as to obtain naphtha, a crude jet fuel and tail oil; and performing clay refining on the crude jet fuel, so as to obtain high-density #6 jet fuel with good antioxidation stability, good demulsibility and favorable insulativity. By aiming at the characteristic that hydrogenation products of coal tar have a large amount of naphthenic hydrocarbon and aromatic hydrocarbon, a hydrogenation-clay refining combined process is utilized to process coal tar into high value-added products such as the naphtha and jet fuels under conditions of specific process parameters and specific catalysts; the method can be used for extending the coal tar hydrogenation industry chain, improving the coal tar utilization value, also expanding military fuel sources and better meeting the fuel consumption demand of novel weapons.

Owner:NORTHWEST UNIV(CN)

Heavy-load hydrodynamic drive lubricating oil composition

InactiveCN107474928AExtreme pressure antiwear agent goodGood fluidity at low temperatureLubricant compositionFluid couplingChemical composition

The invention relates to a heavy-load hydrodynamic drive lubricating oil composition, which especially can meet the lubrication demand of hydrodynamic drive equipment (including automatic gearbox, a hydraulic coupler, a hydraulic torque converter) used under extremely low-temperature conditions. The composition also adopts special multifunctional antioxidant and antifriction lubricant, ashless dispersant and anti-wear agent at extreme pressure except for base oil, and is compound together with special clean dispersant and antioxidant, thus giving full play to the synergistic effect among the additives. The lubricating oil composition has good low-temperature fluidity, antiwear property at extreme pressure and anti-oxidization stability, as well as certain anticorrosion and anti-rust properties and anti-emulsion property, thus meeting the lubrication demand of the automatic gearbox, the hydraulic torque converter and the hydraulic couple used under various special environment conditions.

Owner:西安石油大佳润实业有限公司

Process for producing dewatering nano-sheet zinc borate power

The invention relates to a method for preparing hydrophobic nano-plate zinc borate powder, and belongs to the field of inorganic materials. The method is to take boric acid and zinc oxide as raw materials, deionized water as a solvent, and a high-temperature and high-pressure reaction kettle as a reactor, and synthesize the hydrophobic nano-plate zinc borate powder by controlling the reaction temperature, the pressure, the aging time and surface modification. The method has simple process and is suitable for industrialized production, and the product can be used for a lubricating oil additive.

Owner:梁宝忠

Method for producing naphthenic base transformer oil base oil by using coal tar oil

ActiveCN103436289BImprove use valueQuality assuranceTreatment with hydrotreatment processesNaphthaCycloparaffins

The invention relates to a method for producing naphthenic base transformer oil base oil by using coal tar oil. The method is characterized in that high-additional value products such as naphtha oil, diesel oil and transformer oil base oil are obtained by adopting the steps of hydrotreating of the coal tar oil, the fractional distillation of hydrogenated products, solvent refining of transformer distillate oil and clay refining of the transformer distillate oil. The method has the advantages that the hydrogenation industrial chain of the coal tar oil is extended, the coal tar oil resource is reasonably utilized, the utilization value of the coal tar oil is increased, meanwhile, the density of the coal tar oil hydrogenated diesel oil can be reduced, the cycloparaffin distillate oil (300-360 DEG C) with high content can be obtained, the quality of the transformer oil base oil is ensured, and the obtained transformer oil base oil has high quality and high yield and is in line with the standards on the transformer oil No. 45 in national GB2536-1990 transformer oil.

Owner:SHENMUFUYOU ENERGY TECH

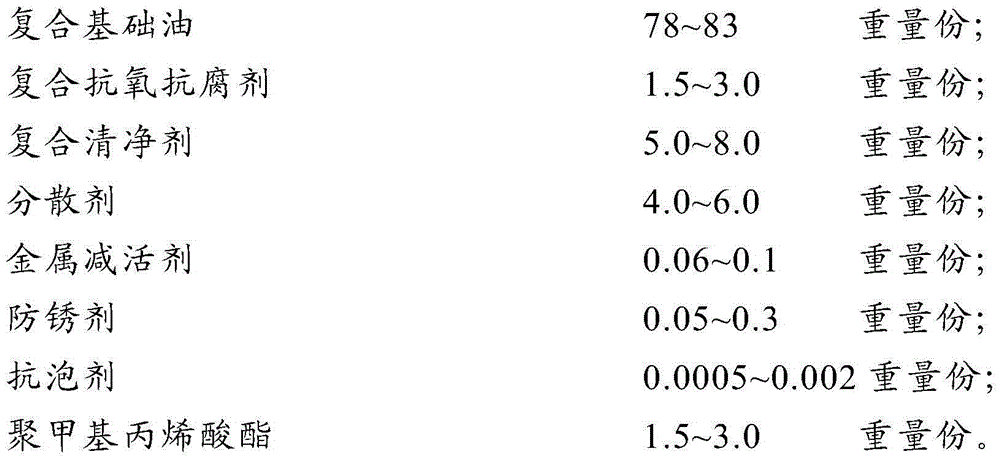

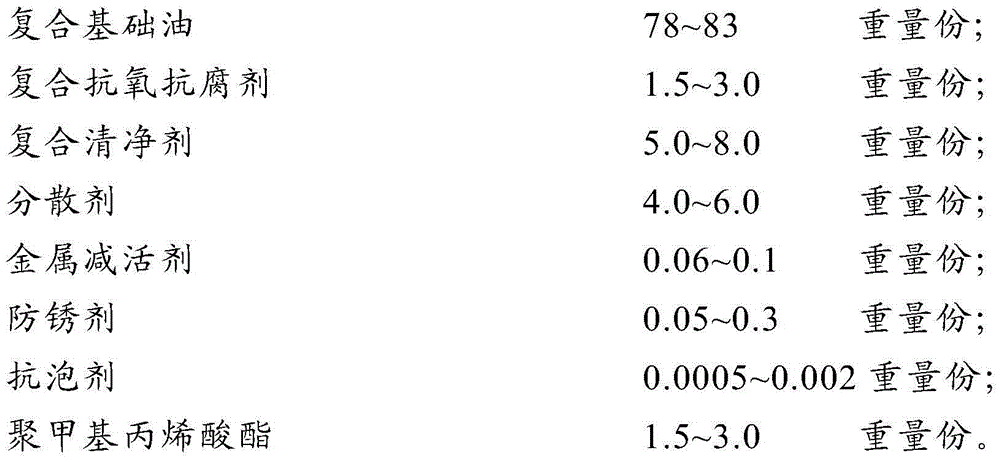

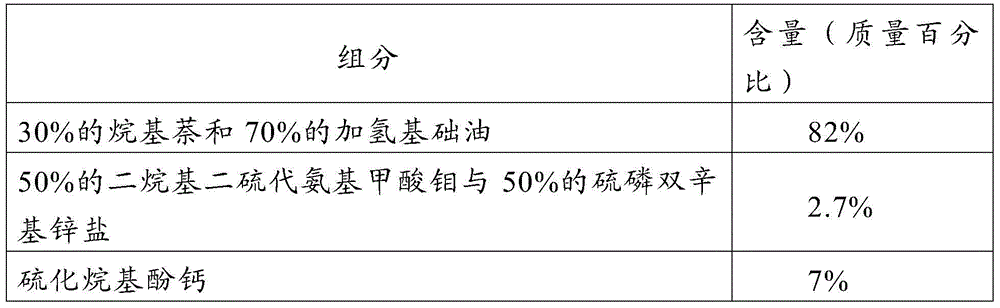

Special lubricating oil for engines and preparation method of special lubricating oil

ActiveCN104946367AExcellent antioxidant stabilityGood compatibilityBase-materialsPoly methacrylateCorrosion inhibitor

The invention provides special lubricating oil for engines and a preparation method of the special lubricating oil. The special lubricating oil comprises the following components by weight: 78-83 parts of compound base oil, 1.5-3.0 parts of one or two compound oxidation and corrosion inhibitors, 5.0-8.0 parts of a compound detergent, 4.0-6.0 parts of a dispersant, 0.06-0.1 part of one or two metal passivators, 0.05-0.3 part of one or two antirust agents, 0.0005-0.002 part of one or two anti-foaming agents and 1.5-3.0 parts of polymethacrylate. The prepared special lubricating oil has the advantages that the oil film thickness can be automatically adjusted, the shearing-resistant property is higher, and the low-temperature fluidity and the low-temperature starting performance are relatively high.

Owner:重庆现代石油股份有限公司

Regeneration method for waste lubricating oil

InactiveCN100503796CMeet environmental protection requirementsFlexible technology routeLubricant compositionSlagDiluent

The invention discloses a regeneration method of waste lubricating oil. The method is to settle the waste lubricating oil naturally to remove the water and mechanical impurities contained in it. When the content of mechanical impurities in the waste lubricating oil is less than 0.08% by weight or the pentane insoluble matter is less than 0.30% by weight, direct atmospheric and vacuum distillation , otherwise add a diluent accounting for 0 to 3.5 times the total weight of the waste lubricating oil, raise the temperature to 30°C to 95°C, and then carry out atmospheric and vacuum distillation after separation. Refined with lubricating oil to obtain regenerated lubricating oil. Using the method of the invention to regenerate the waste lubricating oil has no acid residue discharge, and by-products can be directly utilized, and the technological process meets the requirements of environmental protection.

Owner:CHINA PETROCHEMICAL CORP +1

Automobile anti-wear lubricating oil

InactiveCN104371805AExcellent high temperature detergencyExcellent antioxidant stabilityAdditivesPhosphateSalicylic acid

The invention discloses an automobile anti-wear lubricating oil, comprising the following raw materials in percentage by weight: 2%-3% of alkyl salicylic acid, 0.2%-2.0% of zinc dialkyl dithiophosphate, 0.6%-5% of borate, 1.0%-2.5% of polyvinyl-N-butylether, 0.05%-0.40% of benzotriazole, 0.1%-1.0% of alkyl naphthalene, 1%-3% of methyl silicone oil, 1%-3% of anitimony diisopropyl dithio phosphate, 1%-3% of butyl stearate and the balance of base oil. Compared with the prior art, the automobile anti-wear lubricating oil has the beneficial effects of excellent high temperature detergency, antioxidation stability, anti-friction and anti-wear properties and base number retentivity, and low average fuel consumption; the noise of an engine is lowered; the vibration of the engine is reduced; the operation is relatively stable; and the driving control performance is obviously improved.

Owner:江苏金润润滑油科技股份有限公司

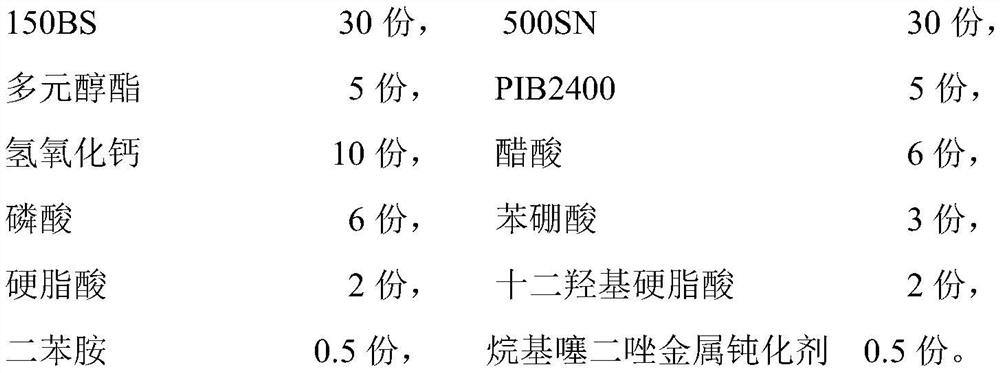

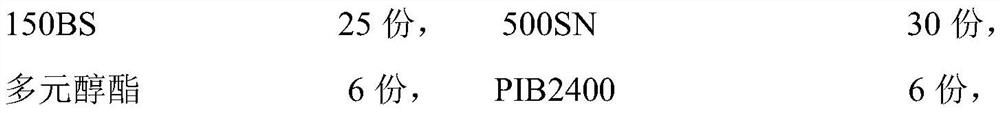

Composite calcium-based lubricating grease and preparation method thereof

ActiveCN111718778AImprove anti-friction and anti-wear effectGood extreme pressure and anti-wear propertiesLubricant compositionCalcium biphosphateCalcium pidolate

The invention relates to novel composite calcium-based lubricating grease and a preparation method thereof. The novel composite calcium-based lubricating grease is prepared from, by weight, 50-80% ofa base liquid, 20-40% of a novel composite calcium-based composite calcium soap thickening agent and 0.1-5% of a function improvement additive. The novel composite calcium-based lubricating grease ischaracterized in that the novel composite calcium-based thickening agent is adopted, a calcium phenylborate-calcium phosphate component is introduced to improve the friction and wear resistance and the antioxidant stability of the composite calcium-based thickening agent and improve the storage hardening problem of the composite calcium-based lubricating grease, and meanwhile, the characteristicsof excellent extreme pressure wear resistance, mechanical stability, water resistance and the like of the composite calcium-based thickening agent are fully utilized, so that the prepared novel composite calcium-based lubricating grease can meet the use requirements of high temperature, high speed, high reliability and long service life of the hub bearing of the heavy-duty vehicle.

Owner:长沙众城石油化工股份有限公司

Carrier-based aircraft tractor hydraulic oil

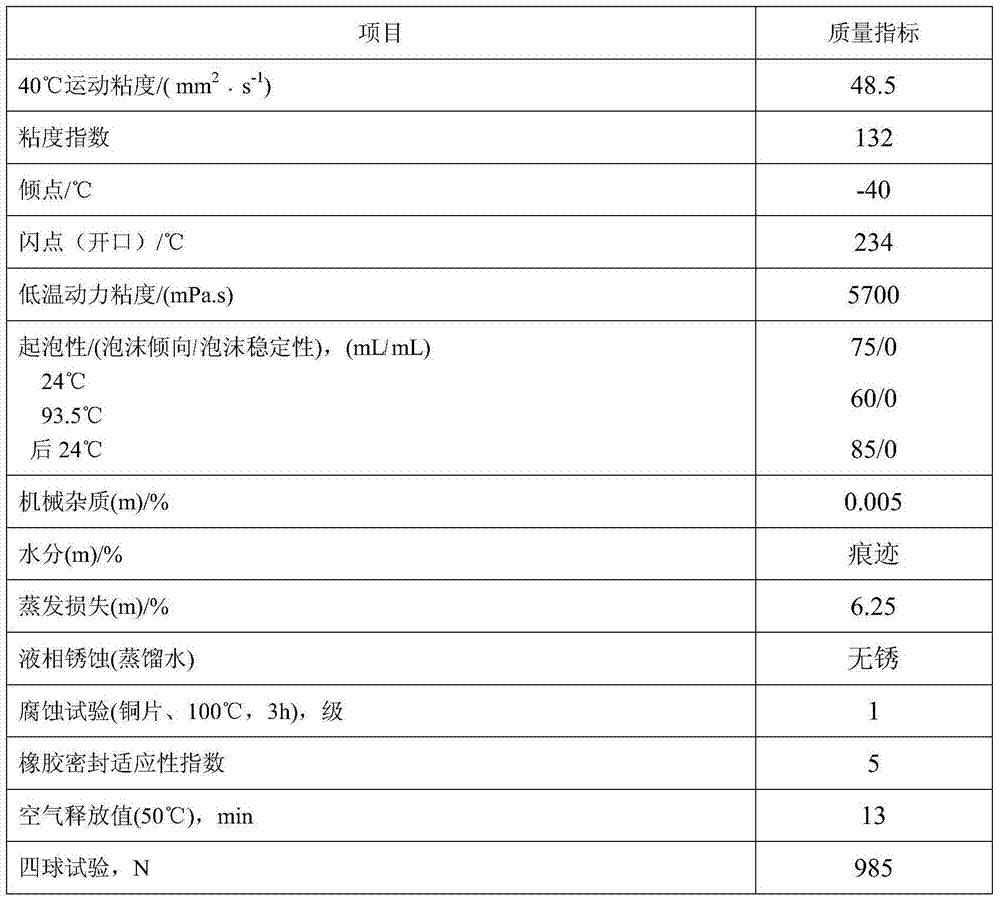

ActiveCN103695096AExcellent antioxidant stabilityImprove wear resistanceBase-materialsFoaming agentWear resistance

The invention discloses carrier-based aircraft tractor hydraulic oil. The carrier-based aircraft tractor hydraulic oil is characterized in that a dioctyl sebacate compound prepared from polyalphaolefin and castor oil is used as base oil; dioctyl sebacate is compounded with a plurality of composite additives comprising an anti-oxidant, an antiwear agent, a friction improver, a metal passivator, an antirust agent, an anti-foaming agent, a demulsification agent and an anticorrosion assistant. The carrier-based aircraft tractor hydraulic oil has excellent antioxidation stability, wear resistance and rust resistance, can resist sea severe condition influences, can protect a hydraulic member, can ensure power transmission accuracy, can realizes displacement in a predetermined path, has outstanding air release properties, emulsification resistance and foam resistance, has stable composition, does not corrode equipment, has no toxicity and an excitant smell, and is suitable for a carrier-based aircraft tractor hydraulic system.

Owner:GUANGXI UNIV

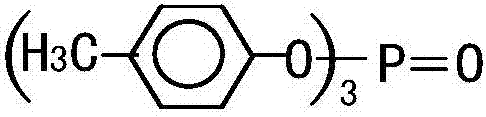

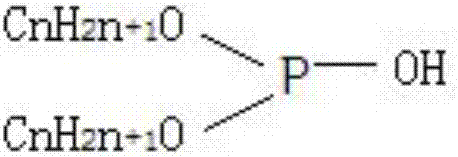

Anti-wear hydraulic oil and preparation method thereof

InactiveCN106398826AQuality improvementImpurities are removed thoroughlyAdditivesChemistryTritolyl Phosphates

The invention discloses anti-wear hydraulic oil and a preparation method thereof. The anti-wear hydraulic oil comprises the following raw materials, by weight part, 90-100 parts of base oil, 2-4 parts of tritolyl phosphate, 6-8 parts of zinc dialkyl dithiophosphate, 0.5-1 part of a thiadiazole derivative, 5-7 parts of polymethacrylate, 2-4 parts of barium dinonylnaphthalene sulfonate, and 3-5 parts of an adsorbent, wherein the base oil is I-kind base oil, and the adsorbent is a mixture of bentonite and halloysite, wherein the mass ratio of bentonite to halloysite is 1:0.4-0.6. According to the method, pre-treated bentonite and halloysite are taken as an adsorbent, and since the bentonite and halloysite have certain preference selection for adsorbing impurities in base oil, according to the matching ratio provided in the invention, impurities in base oil can be fast removed, thereby greatly improving the quality of base oil in the hydraulic oil. Since the impurities are completely removed, the hydraulic oil has better antioxidant stability and corrosion resistance than anti-wear hydraulic oil prepared in the prior art.

Owner:湖南宏旺环保科技有限公司

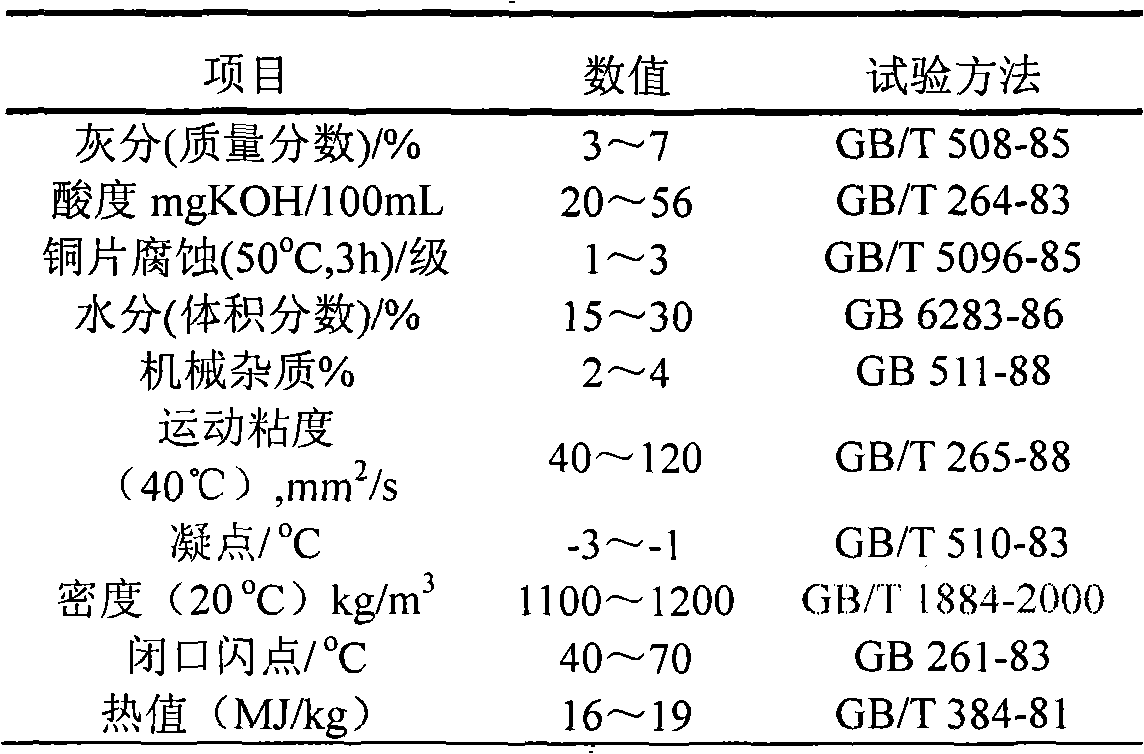

Microemulsion biomass fuel oil and preparation method thereof

InactiveCN106590786AThe preparation method is simple and reliableLow costLiquid carbonaceous fuelsSolventBiomass

The invention discloses microemulsion biomass fuel oil and a preparation method thereof. The microemulsion biomass fuel oil is prepared from, by mass, 40-50 parts of biomass fuel oil, 4-6 parts of cosurfactant, 15-25 parts of diesel oil, 12-16 parts of petroleum, 1-2 parts of an oxidation and corrosion inhibitor, 12-16 parts of glycerinum, 1-3 parts of cosolvent, 11-13 parts of rhamnolipid, 2-4 parts of water-splitting microemulsion and 1-3 parts of emulgator. The microemulsion biomass fuel oil is good in anti-oxidation stability, low in corrosivity, low in ash content and high in combustion heat value; the preparation method is simple, reliable and low in cost, and has the important application value in the fields of biomass energy, automobiles, environmental friendliness and the like.

Owner:QINZHOU UNIV

Antioxidant lubricating oil for automobile

ActiveCN104388156AExcellent high temperature detergencyExcellent antioxidant stabilityAdditivesPolyolefinAlpha-olefin

The invention discloses antioxidant lubricating oil for an automobile. The antioxidant lubricating oil for the automobile comprises the following raw materials by weight percentage: 1-5% of dialkenyl succinimide, 0.2-2.0% of alkylated diphenylamine, 1-3% of lead naphthenate, 0.5-2.0% of polymethacrylate, 3-15% of petroleum barium borate, 1-3% of poly alpha olefin, 1-3% of methylsilicone oil, 1-3% of anitimony diisopropyl dithio phosphate, 1-3% of glyceryl monooleate and the balance of base oil. Compared with the prior art, the antioxidant lubricating oil for the automobile has the advantages that the high-temperature cleanliness, the anti-oxidation stability, the antifriction and abrasive resistance, and the base value retainability are excellent, the average oil consumption is low, the engine noise and engine vibration are reduced, the automobile runs more stably, and the driving control performance is remarkably improved.

Owner:GUANGZHOU LEARNBER SCI & TECH DEV

A kind of automobile anti-wear lubricating oil

InactiveCN104371805BExcellent high temperature detergencyExcellent antioxidant stabilityAdditivesSalicylic acidStearic acid

Owner:江苏金润润滑油科技股份有限公司

High-viscosity high-pressure antiwear hydraulic oil

InactiveCN104673443AImprove shear stabilityStrong demulsification abilityLubricant compositionAntioxidantHigh pressure

The invention discloses a high-viscosity high-pressure antiwear hydraulic oil which is prepared from the following raw materials in parts by weight: 30-50 parts of base oil, 8-16 parts of diisodecyl sebacate, 4-8 parts of polymethacrylate (PMA), 3-9 parts of dustless dithiophosphate, 2-14 parts of thiadiazole derivative, 3-6 parts of arylamine antioxidant, 1-6 parts of sulfonate, 2-4 parts of high-base-number sulfurized calcium alkyl phenate, 6-12 parts of vulcanized isobutylene, 2-8 parts of pentaerythritol ester, 7-10 parts of vulcanized isobutylene, 2-4 parts of di-n-butyl phosphite and 1-6 parts of di-tert-butyl-para-cresol. The high-viscosity high-pressure antiwear hydraulic oil has the advantages of favorable demulsibility, favorable hydrolytic stability, favorable heat stability, favorable filterability, outstanding wear resistance and obvious energy-saving effect.

Owner:QINGDAO KERUN PLASTIC MACHINERY

A kind of high-speed chain lubricating grease and preparation method thereof

ActiveCN102965178BExcellent anti-wear extreme pressure agentGood high and low temperature performanceLubricant compositionAntioxidantBase oil

Owner:武汉博达特种润滑技术有限公司

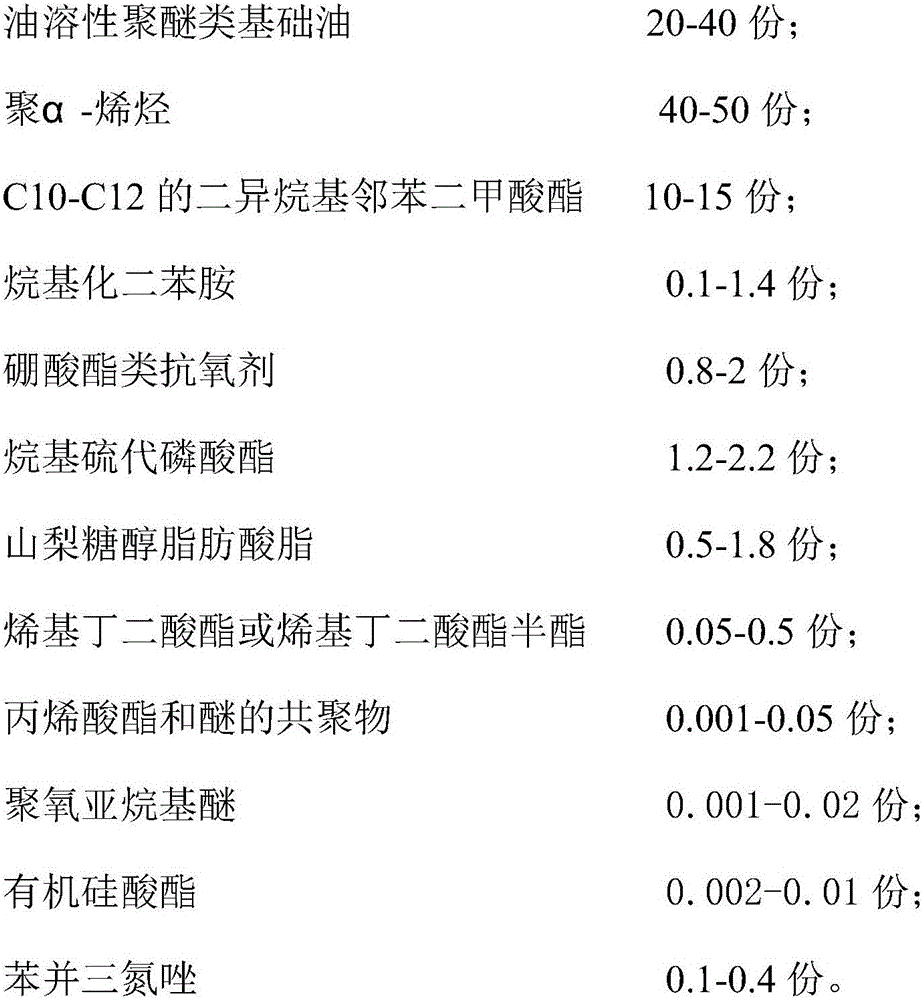

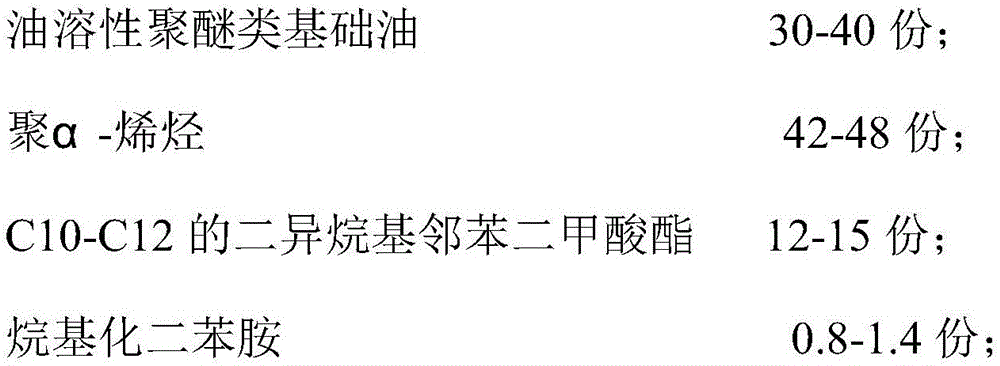

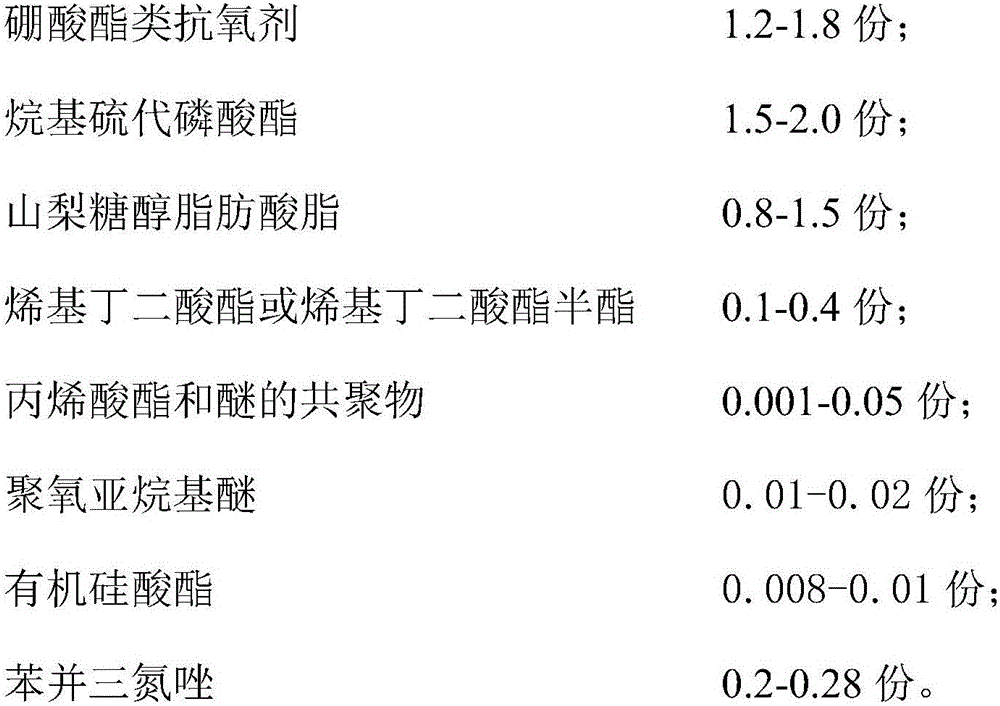

Air compressor oil composition and preparation method thereof

InactiveCN106398829AExcellent antioxidant stabilityExcellent abrasion resistanceLubricant compositionMechanical equipmentAlpha-olefin

The invention discloses an air compressor oil composition prepared from the following raw materials in parts by mass: 20-40 parts of oil soluble polyether based oil, 40-50 parts of poly(alpha-olefin), 10-15 parts of C10-C12 diisoalkyl phthalic acid ester, 0.1-1.4 parts of alkylated diphenylamine, 0.8-2 parts of a boric acid ester type antioxidant, 1.2-2.2 parts of alkyl thiophosphate, 0.5-1.8 parts of sorbitol fatty acid ester, 0.05-0.5 part of alkenyl succinate or alkenyl succinate semi-ester, 0.001-0.05 part of an acrylate and ether copolymer, 0.001-0.02 part of polyethylene alkyl ether, 0.002-0.01 part of organic silicate ester, and 0.1-0.4 part of benzotriazole. The obtained air compressor oil composition is environmentally friendly, has the advantages of excellent antioxidation stability, abrasive resistance, emulsifying resistance, corrosion and rust resistance, extremely good defoaming properties, excellent viscosity temperature properties and the like, has the performance indicators reaching No.46 air compressor oil standards, and is used for air compression system mechanical equipment and the like.

Owner:张家港市胜宇石油化工制品有限公司

Composite graphene-based wind power bearing lubricating oil and preparation method thereof

InactiveCN112175693AMeet high and low temperature changesCorrosion resistanceLubricant compositionSulfonateSilica gel

The invention relates to the technical field of lubricating oil and a preparation method thereof, in particular to composite graphene-based wind power bearing lubricating oil and a preparation methodthereof. The composite graphene-based wind power bearing lubricating oil is prepared from the following raw materials in parts by weight: 75-80 parts of base oil, 8-12 parts of a thickening agent, 2-3parts of a graphene silica gel compound, 0.5-0.8 part of poly(quaternary methanol isobutylene succinate), 0.3-0.5 part of zinc dialkyl dithiophosphate, 0.5-1 part of dithiocarbamate, 0.3-0.5 part ofcopper salt calcium sulfonate, 0.2-0.5 part of an antioxidant and 1-2 parts of tungsten-molybdenum alloy powder. The lubricating oil disclosed by the invention meets the comprehensive performance requirements of high and low temperature change resistance, oxidation resistance, wear resistance, corrosion resistance, oil leakage prevention and the like of the wind power bearing.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Polyester spinning oil agent

The invention discloses a polyester spinning oil agent. The polyester spinning oil agent comprises the following components in parts by mass: 89-94 parts of naphthenic base mineral oil, 3.5-5 parts offatty alcohol polyoxyethylene ether, 0.5-2.5 parts of polyisobutylene, 0.5-1 part of isotridecanol phosphate and 1.5-3 parts of polyethylene glycol monooleate. Elastic fibers provided by the invention have the excellent elasticity, and the lag loss rate of the elastic fibers is greatly smaller than that of polyurethane elastic fibers; and the polyester spinning oil agent can adjust the stress according to the content of a polyester rigid structure body, namely, the polyester spinning oil agent can be used as a sanitary article with the relatively low stress requirement and can be used for theworking condition with the high stress requirement and the like, so that the polyester spinning oil agent the extremely wide market prospect.

Owner:JIANGSU SHUANGJIANG ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com