Regeneration method for waste lubricating oil

A technology for waste lubricating oil and lubricating oil, applied in the direction of lubricating composition, etc., can solve the problems of high investment of waste lubricating oil regeneration device and insufficient technology, and achieve good oxidation stability, flexible process technology route and small color number. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

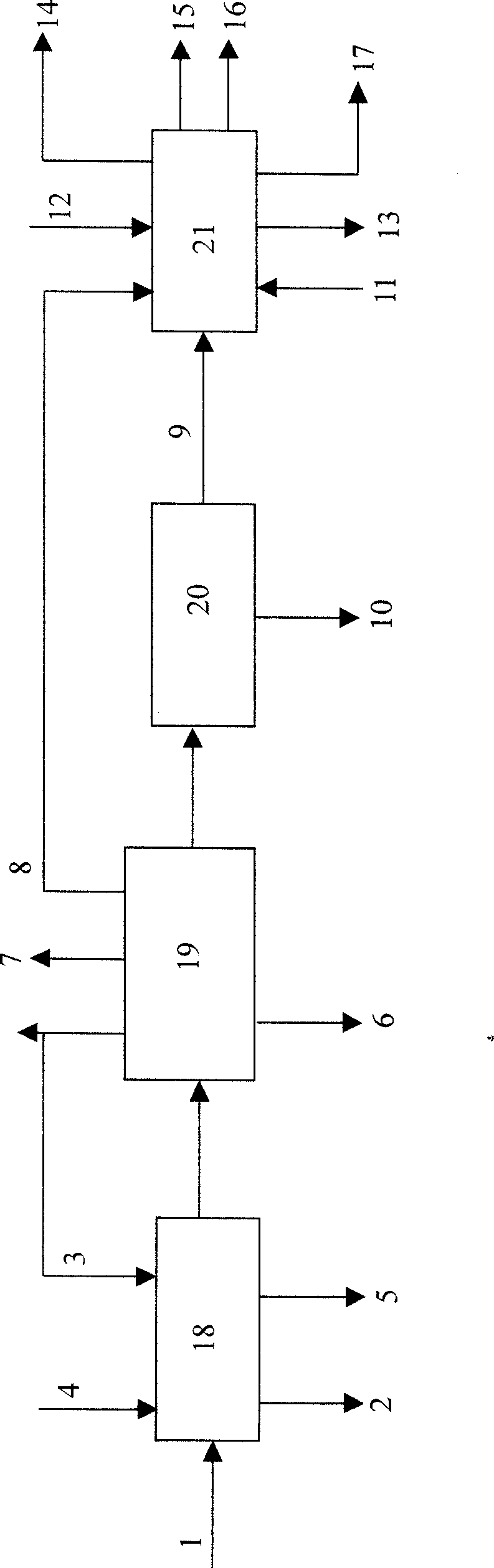

Image

Examples

Embodiment 1

[0041] The properties of waste lubricating oil A are shown in Table 1. 100 parts of the waste lubricating oil were naturally settled, and then 150 parts of No. 120 solvent oil were added, and the uniformly diluted mixed oil sample was heated to 50° C. and centrifuged to further separate mechanical impurities in the oil.

[0042] The mixed oil sample from which mechanical impurities have been separated is heated to 230°C under normal pressure distillation to distill the gasoline fraction (including diluent) at 200°C is heated and distilled under the condition of residual pressure of 650Pa 200℃~300℃ distillate (as light fuel oil), 300℃~370℃ distillate (as spindle oil production raw material oil) and 370℃~450℃ distillate (as 100SN production raw material oil); >450℃ distillate heating After one-stage short-path distillation (falling film) at 280°C, the 450°C-520°C fraction is cut under the condition of a residual pressure of 40Pa (as the raw material oil for 350SN); Distillation...

Embodiment 2

[0053] The properties of waste lubricating oil B are shown in Table 4. 100 parts of waste lubricating oil B were naturally settled, then 200 parts of No. 200 solvent oil were added, and 1.5 parts of organic flocculant polyether was added at the same time, the mixed oil sample was heated to 70 ° C, stirred for 30 minutes, settled for 1 hour, and further separated by centrifugation Mechanical impurities in oil.

[0054] The mixed oil sample from which mechanical impurities have been separated is heated to 230°C under normal pressure to distill the gasoline fraction (including diluent) at 200°C is heated at a residual pressure of 5KPa to reduce A proper amount of water vapor is blown into the bottom of the pressure tower to distill out fractions at 200°C to 370°C (as light fuel oil); fractions >370°C are heated to 235°C and undergo one-stage short-path distillation (falling film). Cut out 370℃~440℃ fraction under the condition (as raw material oil for 100SN production); >440℃ fr...

Embodiment 3

[0061] The properties of waste lubricating oil C are shown in Table 6. The waste lubricating oil C is naturally settled to separate mechanical impurities, and then heated to 230°C under normal pressure to distill the gasoline fraction 200°C is heated to a residual pressure of 4Kpa and decompressed Under the condition of blowing an appropriate amount of water vapor into the bottom of the tower, the 200℃~370℃ fraction (as light fuel oil) and the 370℃~450℃ fraction (as the production raw material oil of 100SN) are distilled out; the >450℃ fraction is heated to 268℃ After one-stage short-path distillation (falling film), under the condition of residual pressure of 50Pa, cut out 450℃~500℃ fraction (as the production raw material oil of 150SN); Membrane), under the condition of residual pressure of 8Pa, cut out 500 ℃ ~ 540 ℃ fraction (as 350SN production raw material oil), > 540 ℃ residual oil as heavy fuel oil.

[0062] 370℃~450℃ distillate, 450℃~500℃ distillate and 500℃~540℃ dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com