Patents

Literature

81results about How to "Reduce the color number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

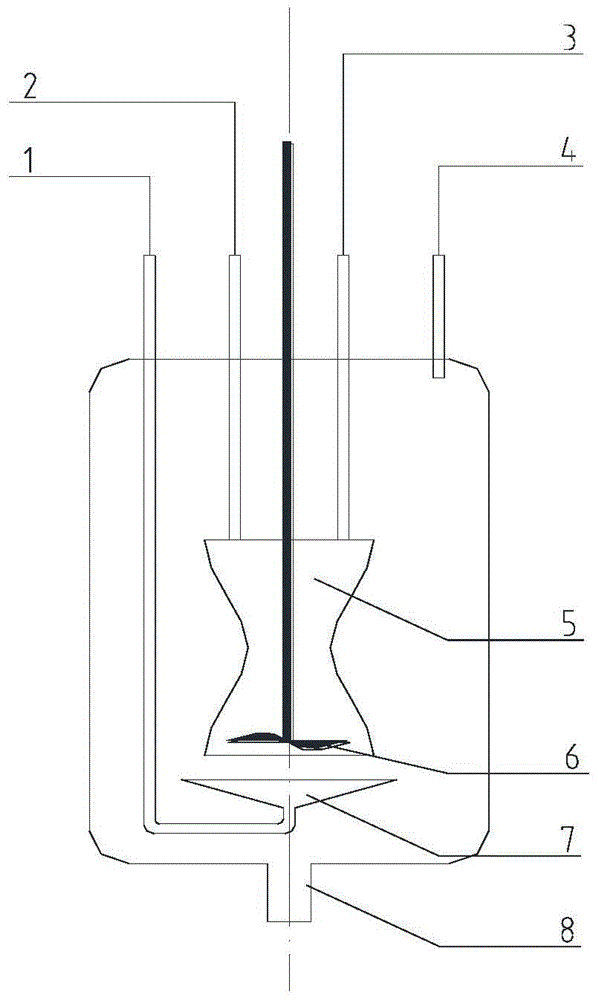

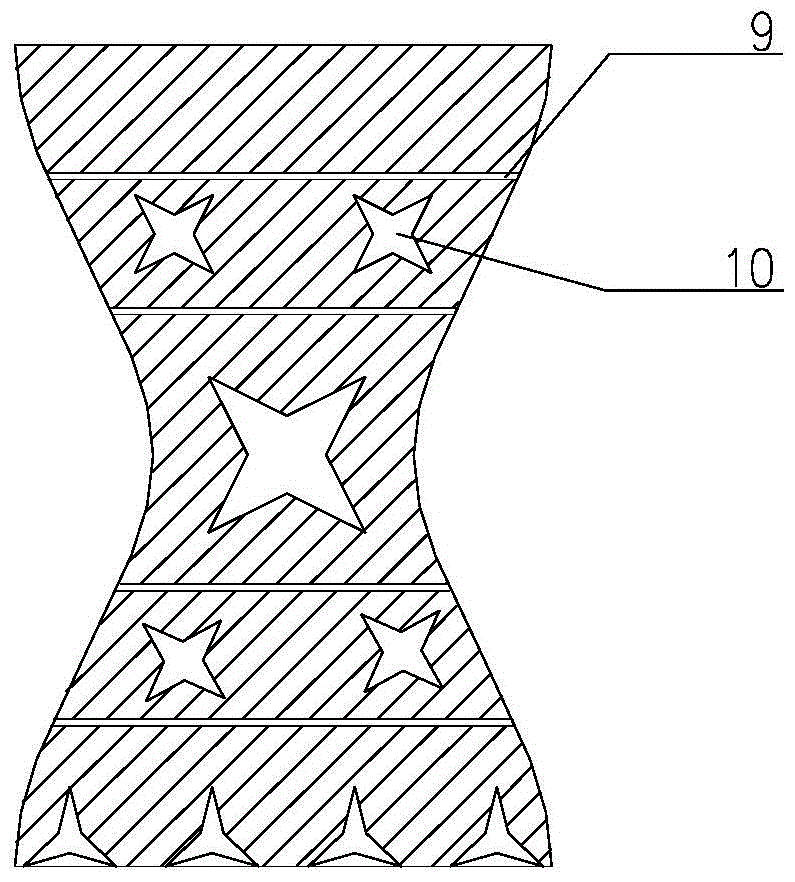

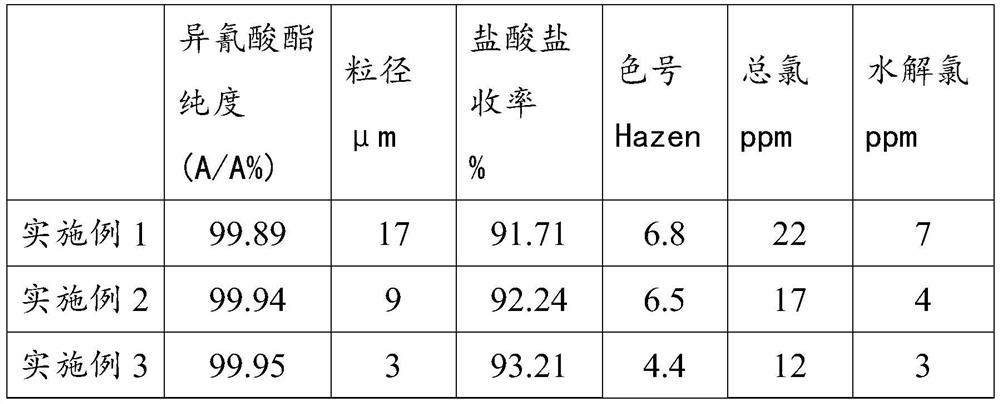

Preparation method of isocyanate

ActiveCN105218422AImprove solubilityImprove uneven distributionOrganic chemistryIsocyanateOrganic solvent

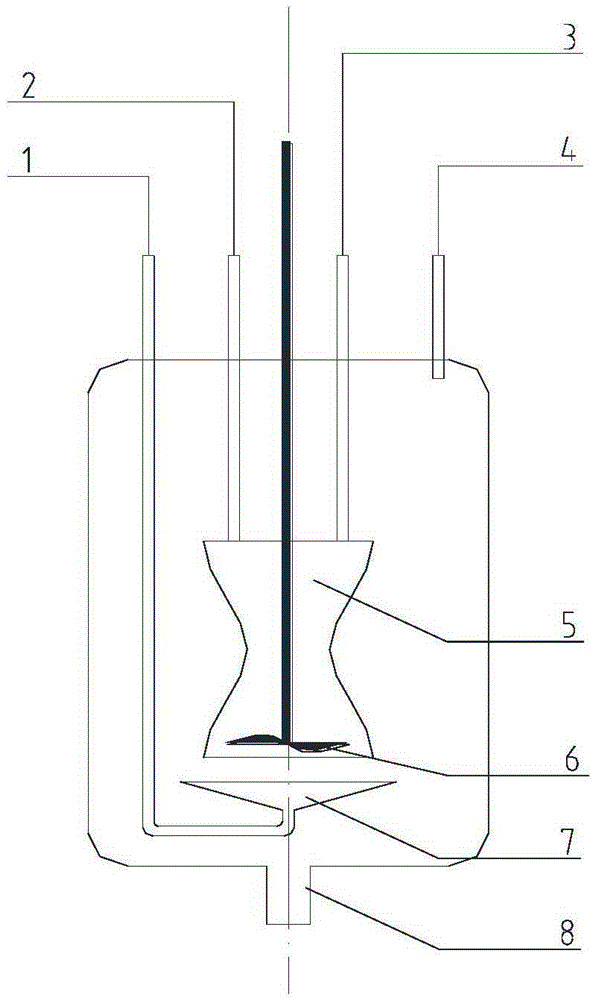

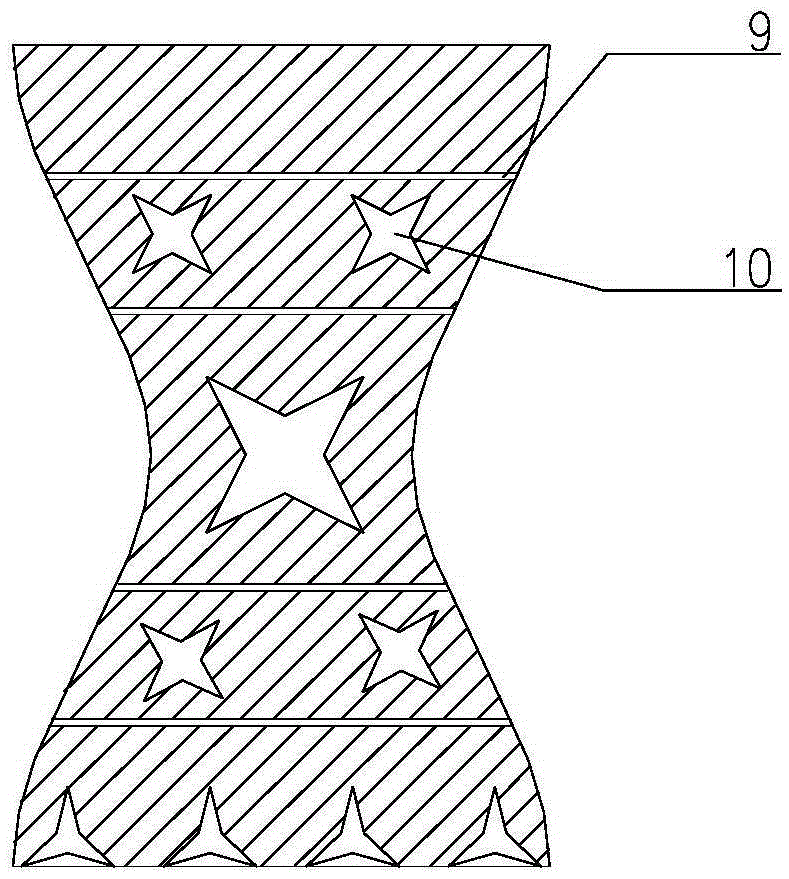

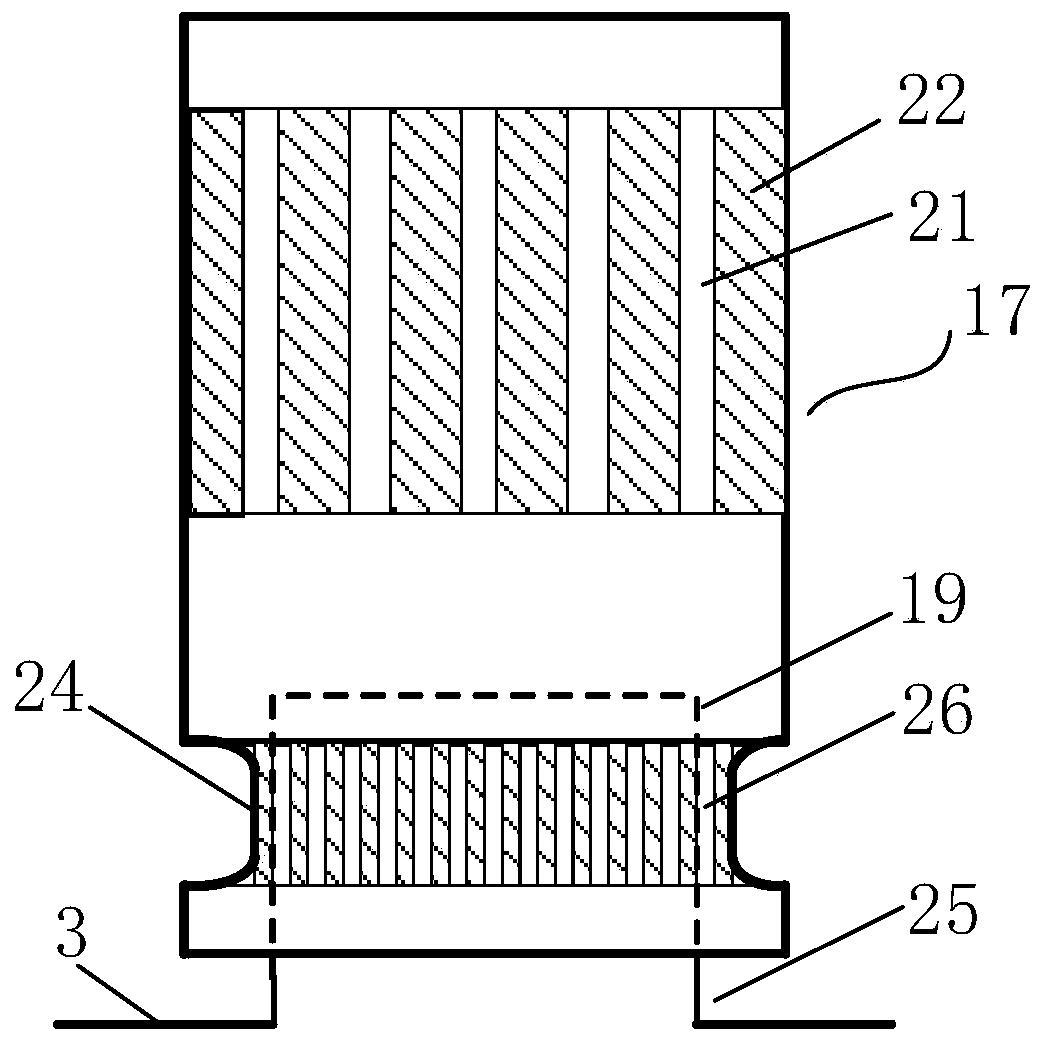

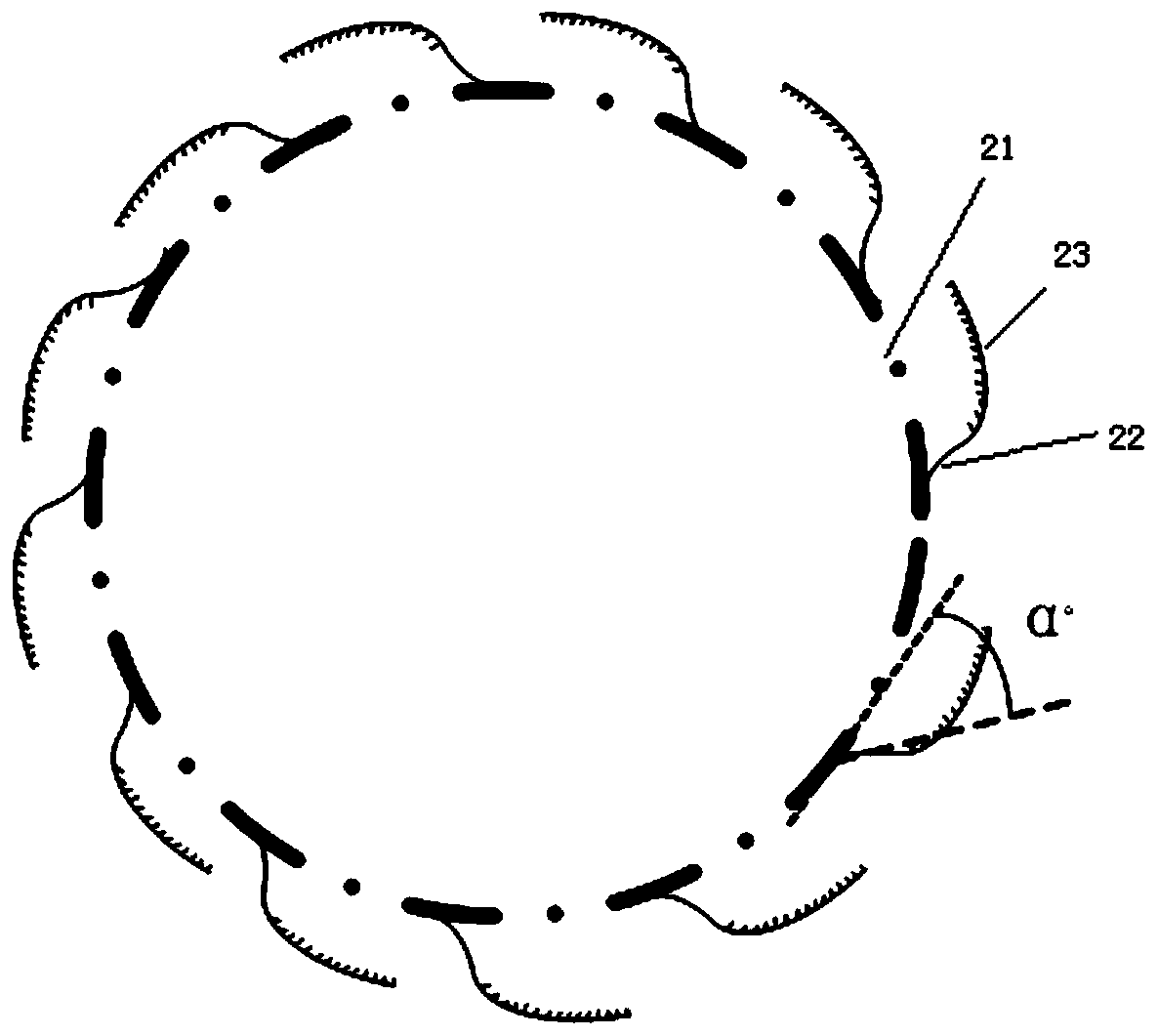

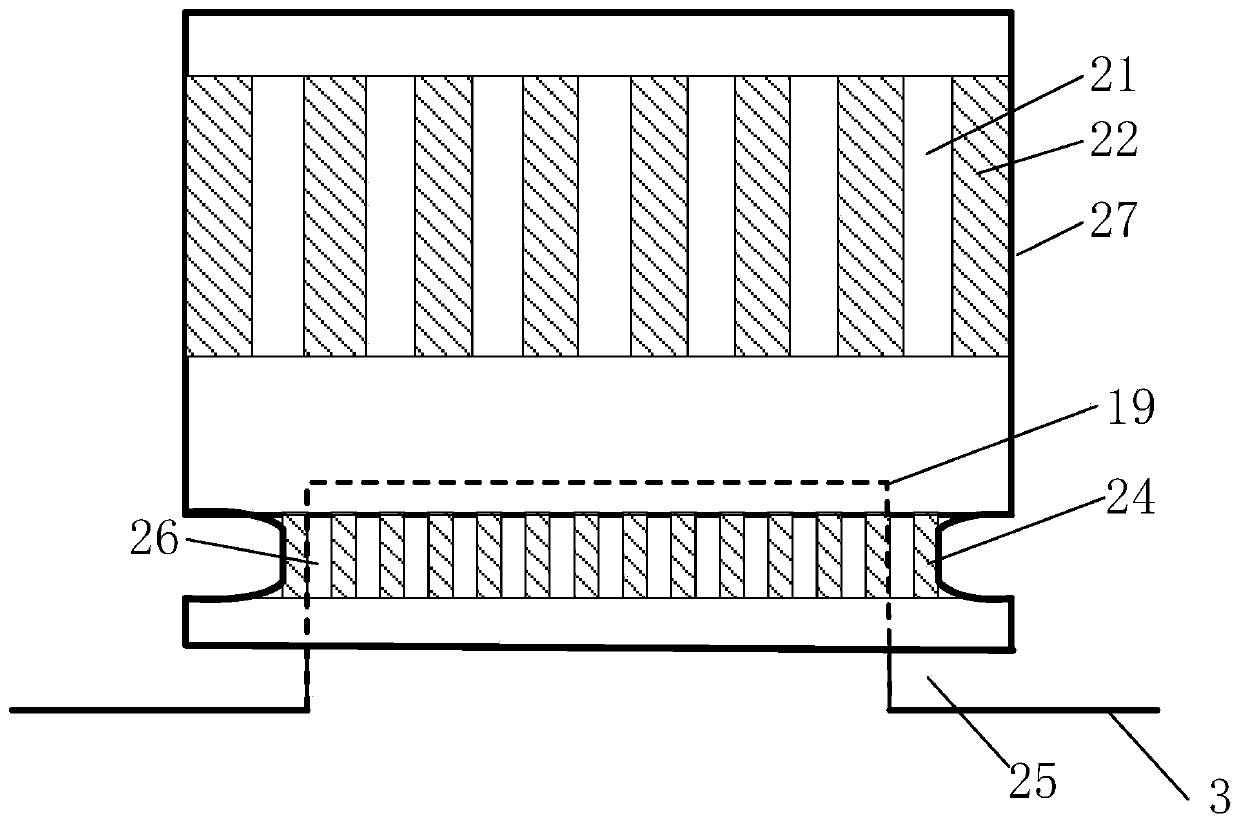

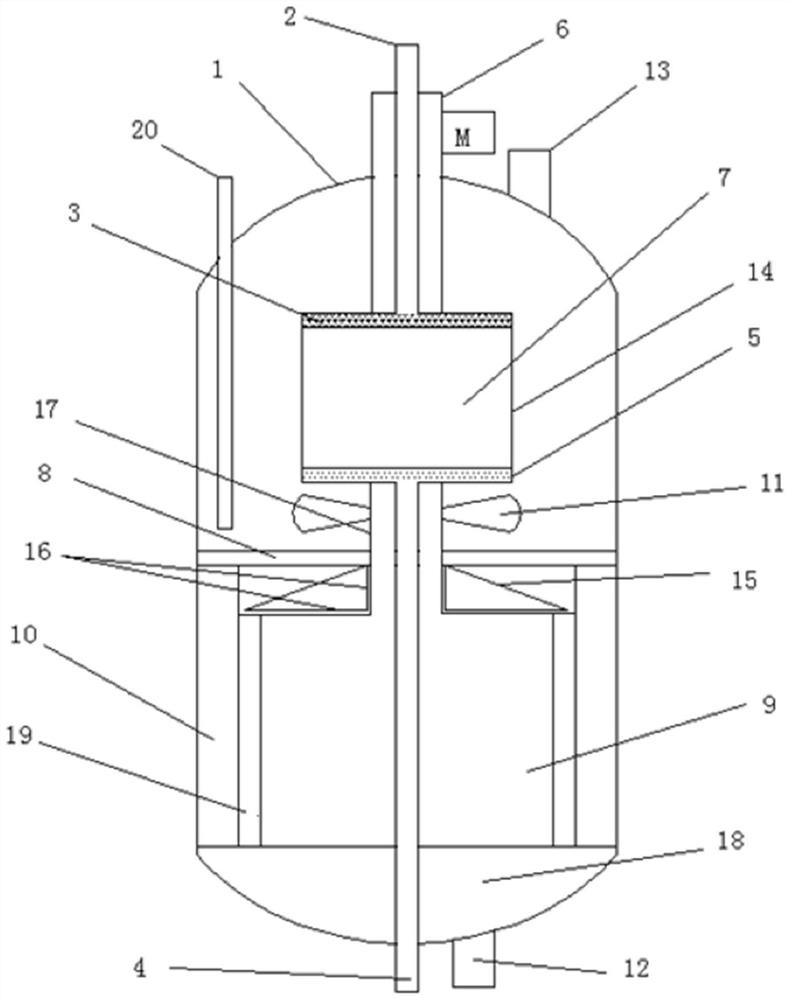

The invention provides a method for preparing isocyanate based on a salifying phosgenation method. A salt forming reaction in the method comprises the following two steps: firstly, performing preliminary salt forming reaction by adopting a conventional reactor; secondly, adding a moderately polar organic solvent with a certain proportion into a reactor provided with an hourglass type liquid slurry disperser to carry out salt forming curing reaction, wherein star-shaped discharge openings are arrayed in a cylinder body of the hourglass type disperser. According to the preparation method, the fact that amino groups in raw materials are converted into amine hydrochlorides with high conversion rate can be ensured through the salt forming curing reaction, and the isocyanate product can be obtained with high yield through a follow-up photochemical reaction.

Owner:WANHUA CHEM GRP

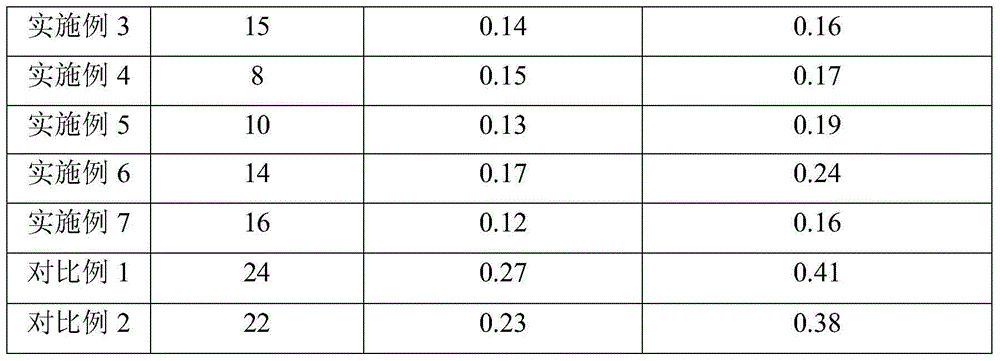

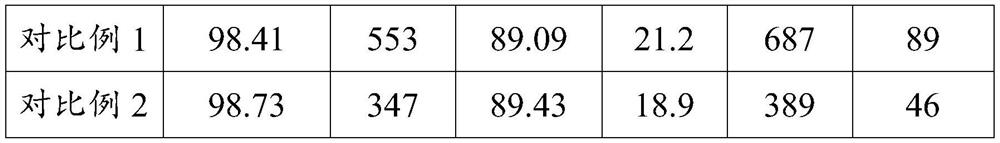

Preparation method for low-color number environment-friendly polyurethane curing agent

ActiveCN103848954ALow viscosityUniform molecular weight distributionChemical industryThermal energyAlcohol

The invention discloses a preparation method for a low-color number environment-friendly polyurethane curing agent. The method comprises the following steps of 1, continuously reacting dihydric alcohol, trimethylolpropane and toluene diisocynate to generate prepolymer reaction liquid by using a continuous reaction device, wherein the trimethylolpropane is fed in a batch addition way; 2, separating the prepolymer reaction liquid by using two stages of film evaporators, pumping evaporation residues obtained by separation into a diluting tank by using a pump, and performing diluting to obtain low-free isocyanate monomer content polyurethane curing agent. The method has the advantages that the whole production process is continuous, the use of a solvent is avoided, reaction heat is maximally utilized, the method is energy-saving and environmentally friendly, the color of a product is improved, and the quality of the curing agent product is improved.

Owner:WANHUA CHEM GRP CO LTD +1

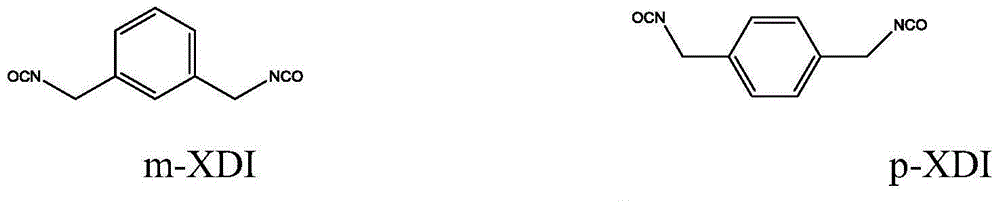

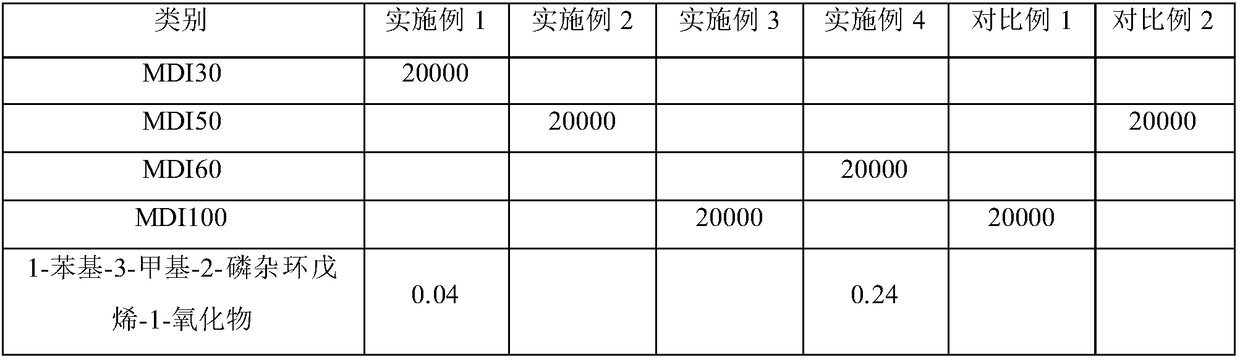

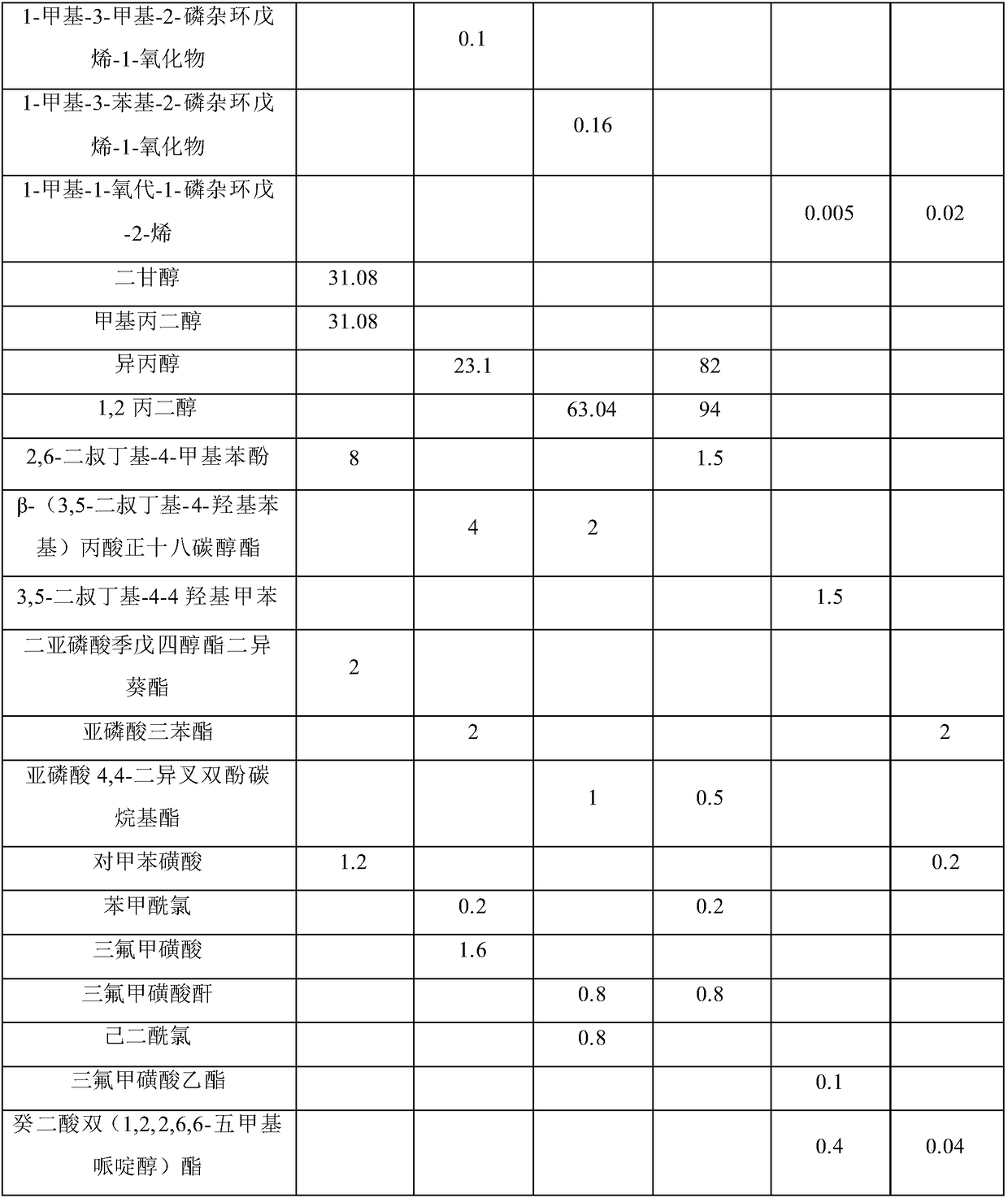

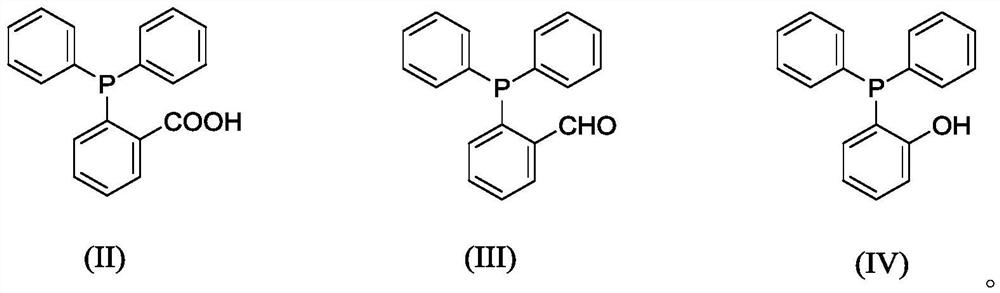

Light color modified isocyanate mixture and preparation method thereof

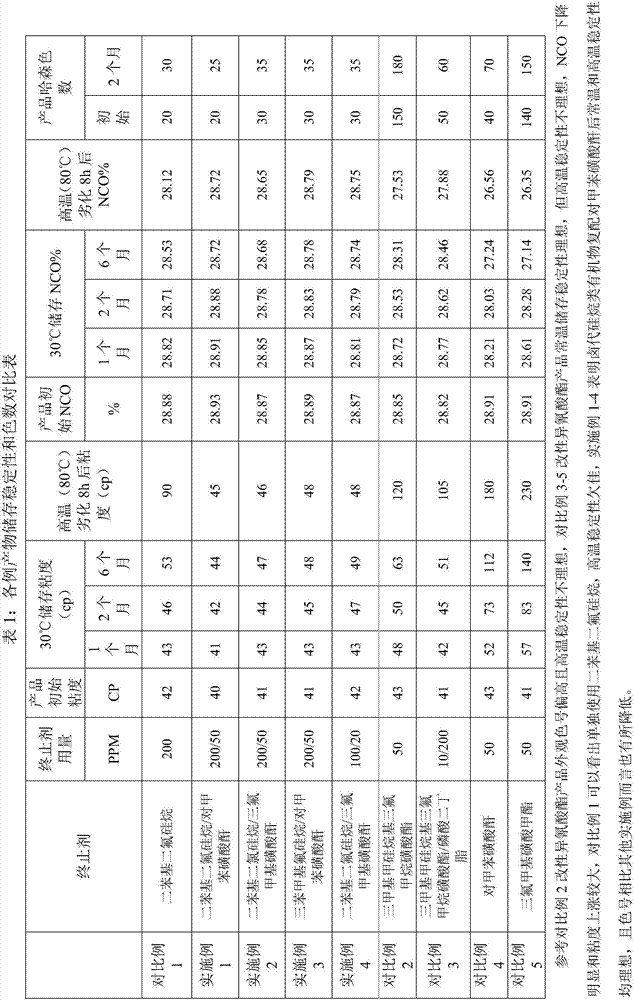

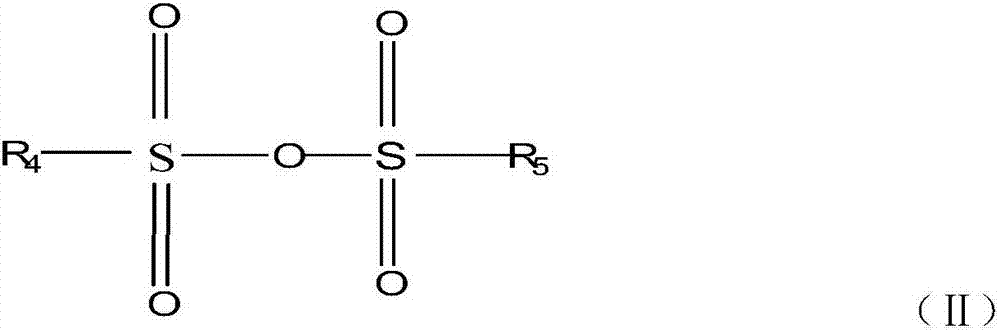

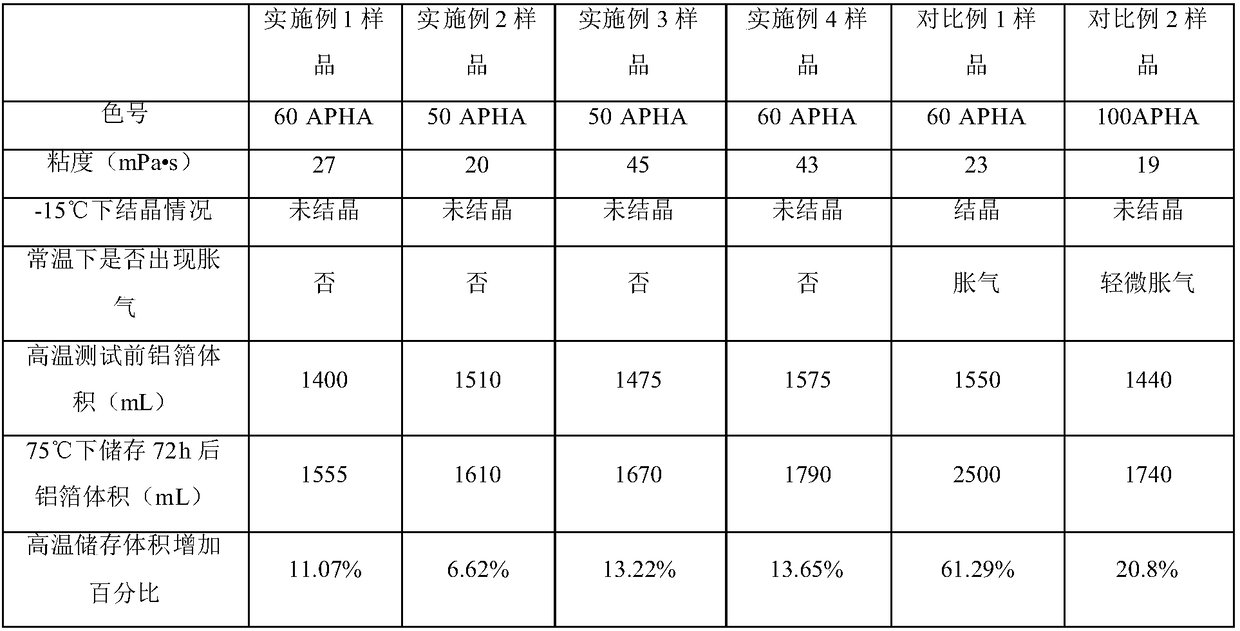

ActiveCN107879951AGood storage stability at room temperatureGroup content decreasedIsocyanic acid derivatives purification/separationHigh temperature storageSilanes

The invention relates to a light color modified isocyanate mixture and a preparation method thereof. The method comprises the following steps: (a) carrying out reaction on isocyanate groups of the rawmaterial isocyanate in the presence of phosphorus-heterocycle catalysts, and finally obtaining a modified isocyanate reaction solution containing carbodiimide and / or uretonimine derivatives; and (b)adding a terminating agent compounded from halogenated silane organic matters and sulfonic anhydrides into the reaction solution obtained in the step a so as to terminate the carbodiimide reaction. The modified isocyanate prepared by the method has the characteristics of normal-temperature liquid and normal temperature and high temperature storage stability and low color number.

Owner:WANHUA CHEM GRP CO LTD

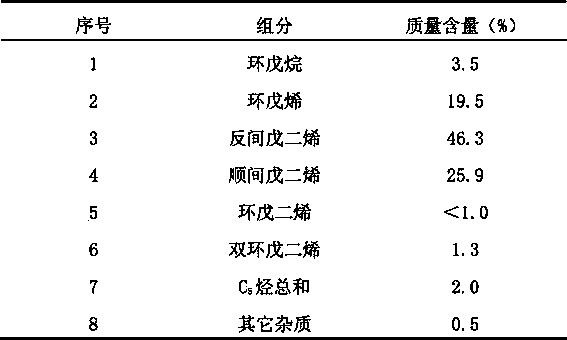

Synthesis method of light chroma C9 petroleum resin

The invention discloses a synthesis method of light chroma C9 petroleum resin. Fine C9 of 80-190 DEG C in distillation range of C9 distillate of the ethane cracking byproduct is taken as raw material;after solvent extraction, settlement separation and washing to be neutral, thermal telomerization is performed for 8-48 hours at the temperature of 210-280 DEG C and the pressure of 0.5-2.0 MPa; then, the product can be obtained after removing un-reacted monomer and oligomer; and the solvent is one of or the mixture of parts of sodium hydroxide, potassium hydroxide, ammonium hydroxide and ethanolamine solution. The invention needs no catalyst, saves the post-treatment processes after removing catalyst, has no waste residues, and has no environment pollution problem caused by discharging alkali waste water containing fluorine. The invention improves resin yield, improves product quality, has lower production energy consumption and material consumption and has wide resin application range.

Owner:广东新华粤石化集团股份公司

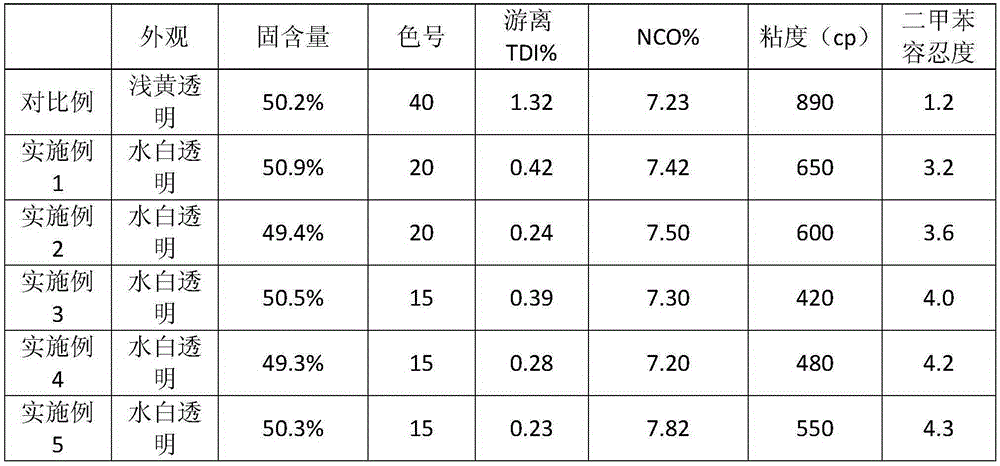

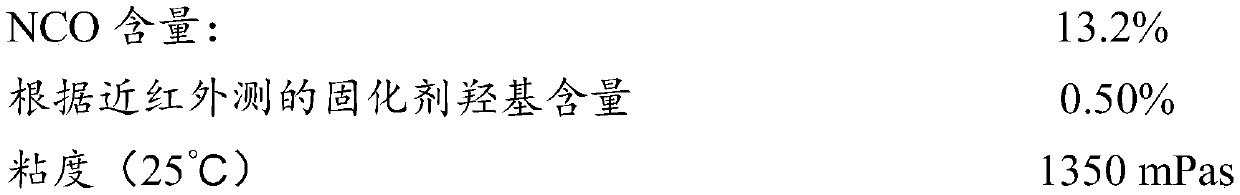

Low-free high-compatibility toluene diisocyanate trimer curing agent and preparation method thereof

ActiveCN105315433AFacilitated DiffusionReduce contentPolyurea/polyurethane coatingsToluene diisocyanateAntioxidant

The invention discloses a low-free high-compatibility toluene diisocyanate trimer curing agent and a preparation method thereof. The preparation method comprises the following steps: under nitrogen protection, putting a toluene diisocyanate monomer, a solvent and an antioxidant into a reaction vessel; controlling the reaction temperature to be 10-50 DEG C at an earlier stage; adding a catalyst in batches when NCO% is 12-14wt% and 10-11wt% and reaction is started; when NCO is 9.3-10wt%, adding the residual catalyst and controlling the temperature to be 50-100 DEG C; when NCO% is 8.0-9.3wt%, adding a polymerization inhibitor, reacting for 0.5-1 h, adding a component A, reacting for 2-4 h, adding a component B, reacting for 1-2 h, stopping reaction, cooling to room temperature and discharging materials so as to obtain the toluene diisocyanate trimer curing agent with free TDI less than 0.5%, xylene tolerance larger than 3, light color, quick drying and stable performance finally.

Owner:SOUTH CHINA UNIV OF TECH

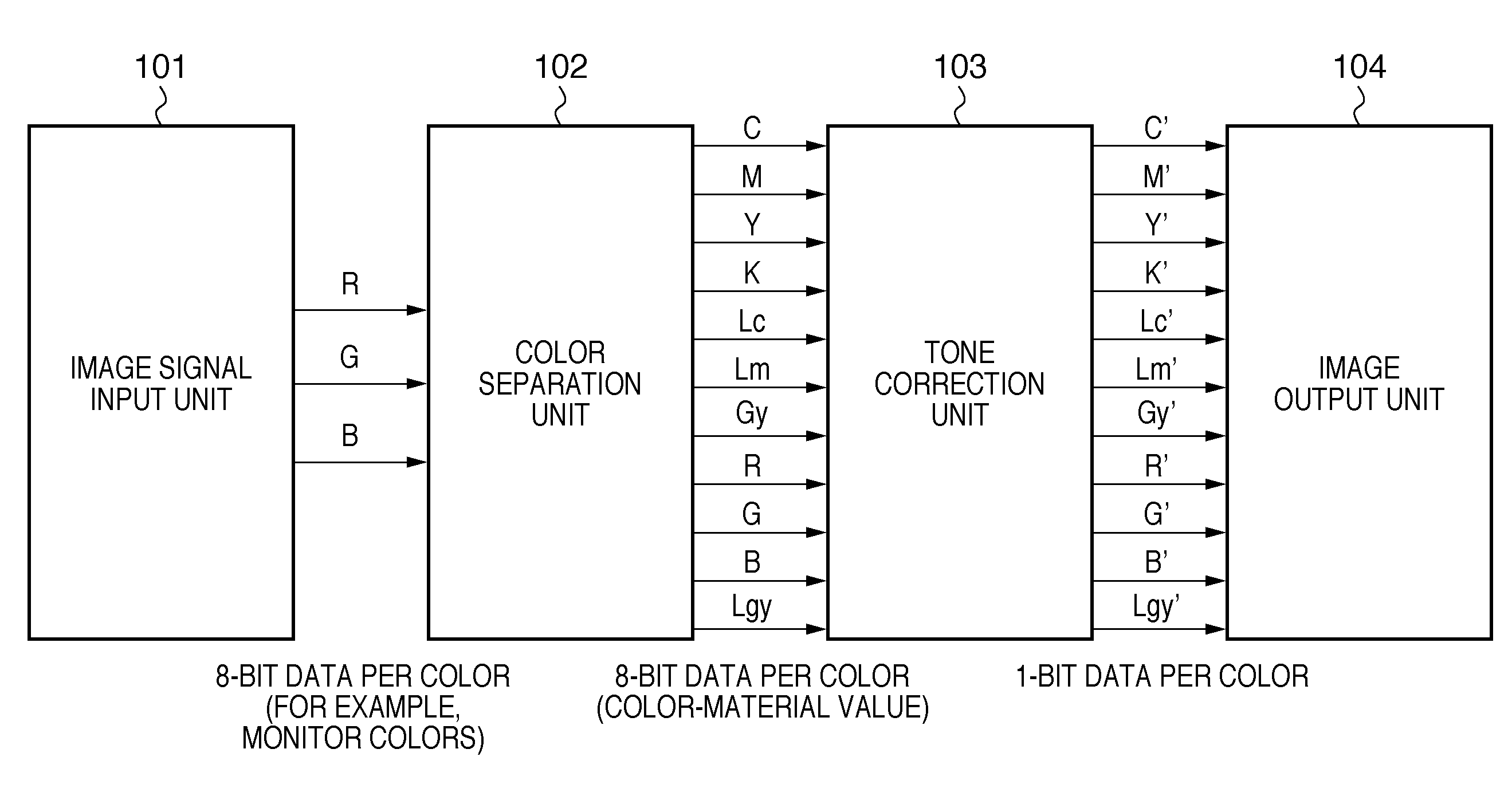

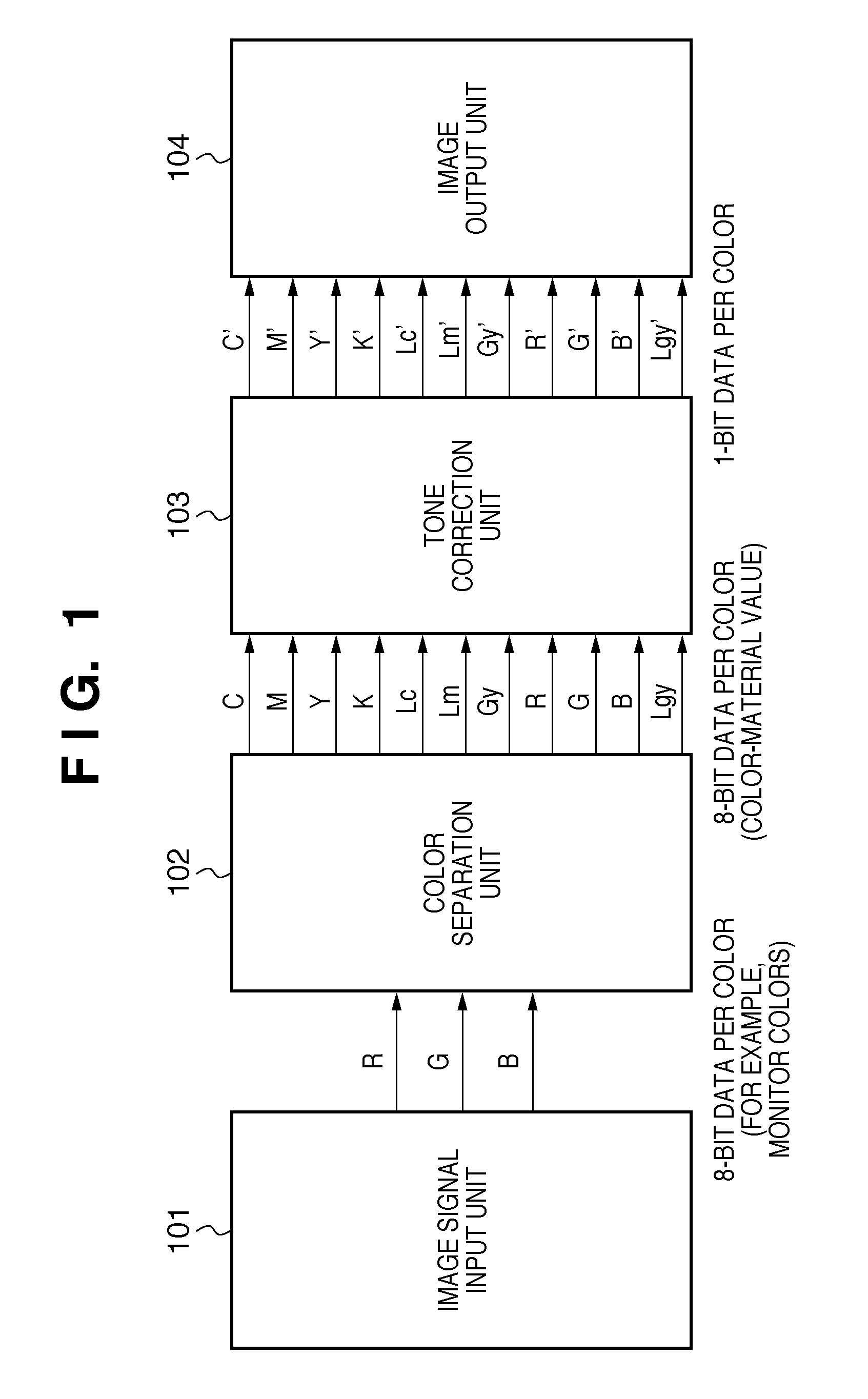

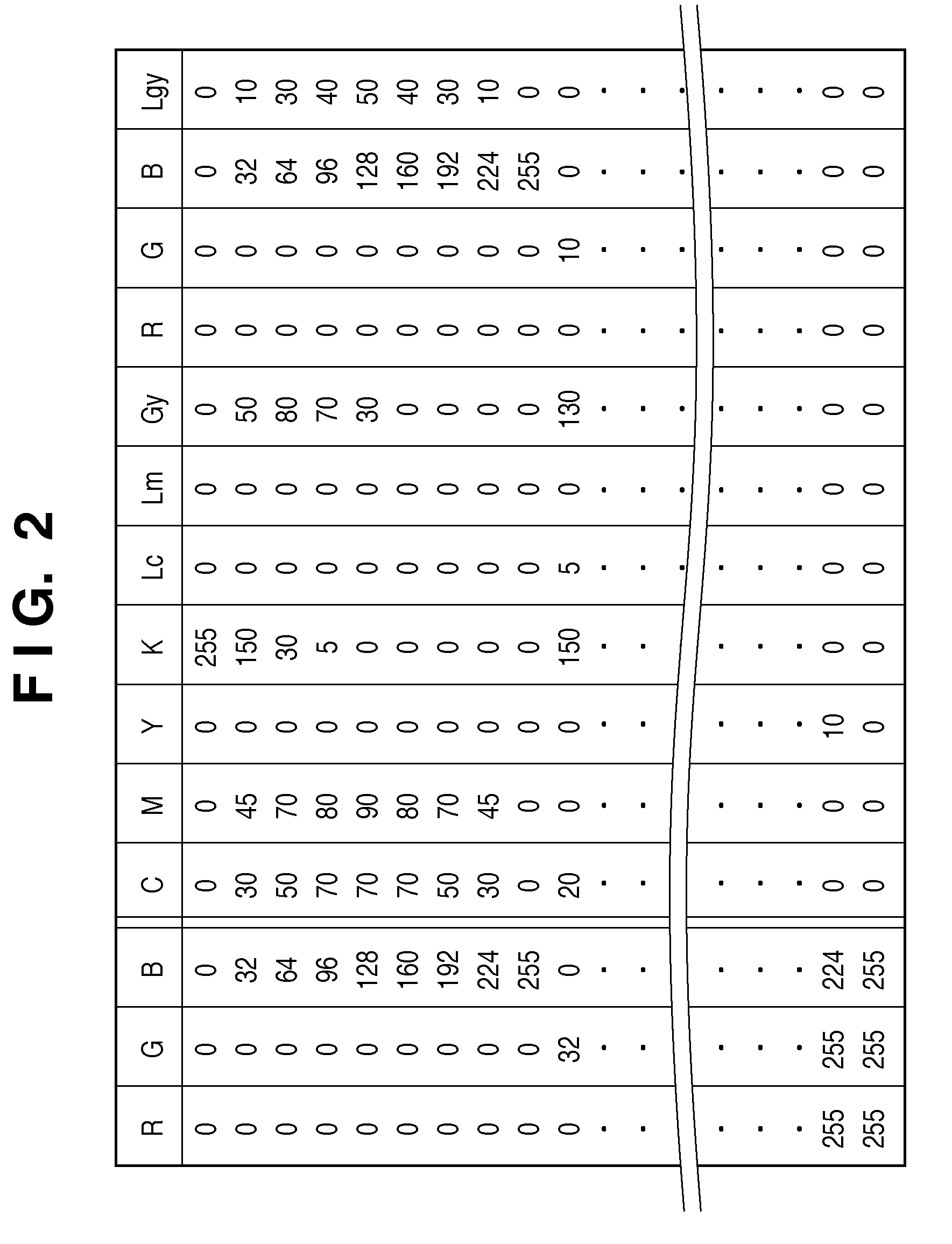

Color processing apparatus and control method thereof

InactiveUS20090168084A1Reduce the color numberColorDigitally marking record carriersDigital computer detailsColor processingPattern recognition

The number of color patches is reduced to attain high-precision color estimation. Hence, the colorimetric values of a plurality of color patches of at least one primary color output by an output device are input. Based on the colorimetric value of first color patches corresponding to a part of the plurality of color patches, colorimetric values corresponding to second color patches other than the first color patches of the plurality of color patches are estimated. Errors between the input colorimetric values of the second color patches and the estimated colorimetric values corresponding to the second color patches are calculated. A plurality of color patches corresponding to the output device is determined based on the calculated errors.

Owner:CANON KK

Modified isocyanate and preparation method thereof

The invention relates to modified isocyanate and a preparation method thereof. The modified isocyanate has excellent storage stability and low color number; the color number is smaller than or equal to 100 APHA, is preferably smaller than or equal to 90APHA, and is more preferably smaller than or equal to 70APHA; the viscosity at 25 DEG C is 5 to 500 mPa*s, and is preferably 20 to 200mPa*s; the storage for more than 100 days without crystallization at -15 DEG C can be realized; the obvious gas expansion cannot occur after the storage for more than 100 days at the normal temperature (20 to 35 DEG C); the obvious gas expansion cannot occur after the storage for 72h at the high temperature of 60 to 80 DEG C. The preparation method is simple; the implementation is easy; the product storage stability can be improved.

Owner:WANHUA CHEM BEIJING +1

Method for synthesizing trimellitic triesters

ActiveCN106008204AReduce generationReduce cost pressureOrganic compound preparationPreparation by transesterificationEconomic benefits2-Ethylhexanol

The invention discloses a method for synthesizing trimellitic triesters. The method comprises the following steps: carrying out a methyl esterification reaction on trimellitic anhydride light and heavy components and methanol used as raw materials under the catalysis of a catalyst to generate trimethyl trimellitate, rectifying the trimethyl trimellitate to obtain high-purity and low-color number trimethyl trimellitate, and carrying out ester exchange on trimethyl trimellitate and 2-ethylhexanol, and purifying the obtained ester exchange product to obtain a tri(2-ethylhexyl) trimellitate product. The method has the advantages of effective recycling of the trimellitic anhydride light and heavy components, reduction of generation of pollutants, increase of economic benefits, reduction of the product cost and the environmental protection pressure, low requirements of the content and the color number of the raw material trimellitic anhydride, and realization of high content and low color number of obtained trihexyl ester, and allows the quality of the trihexyl ester to be better than the quality of trihexyl ester obtained through direct esterification of trimellitic anhydride and 2-ethylhexanol.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +2

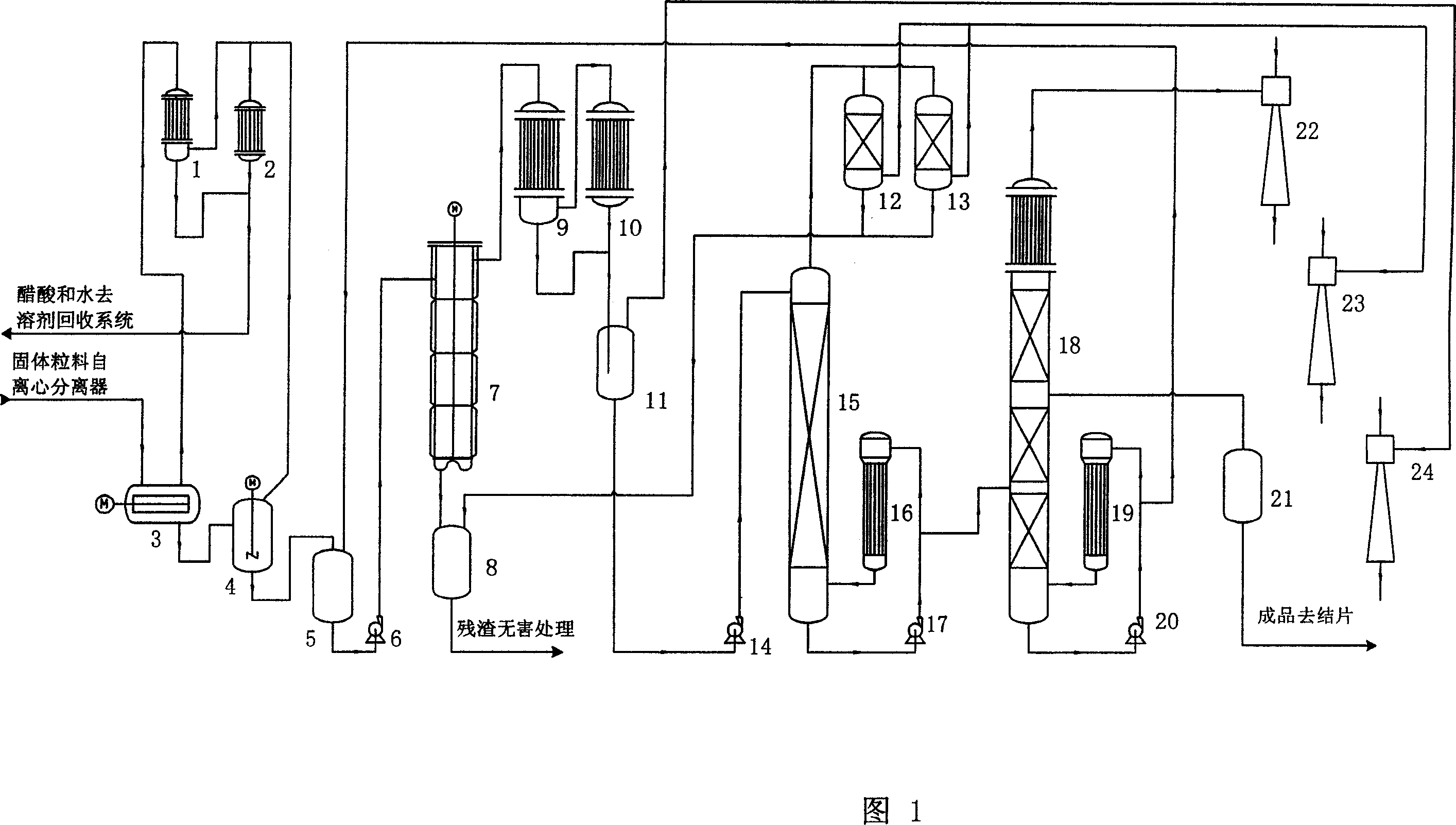

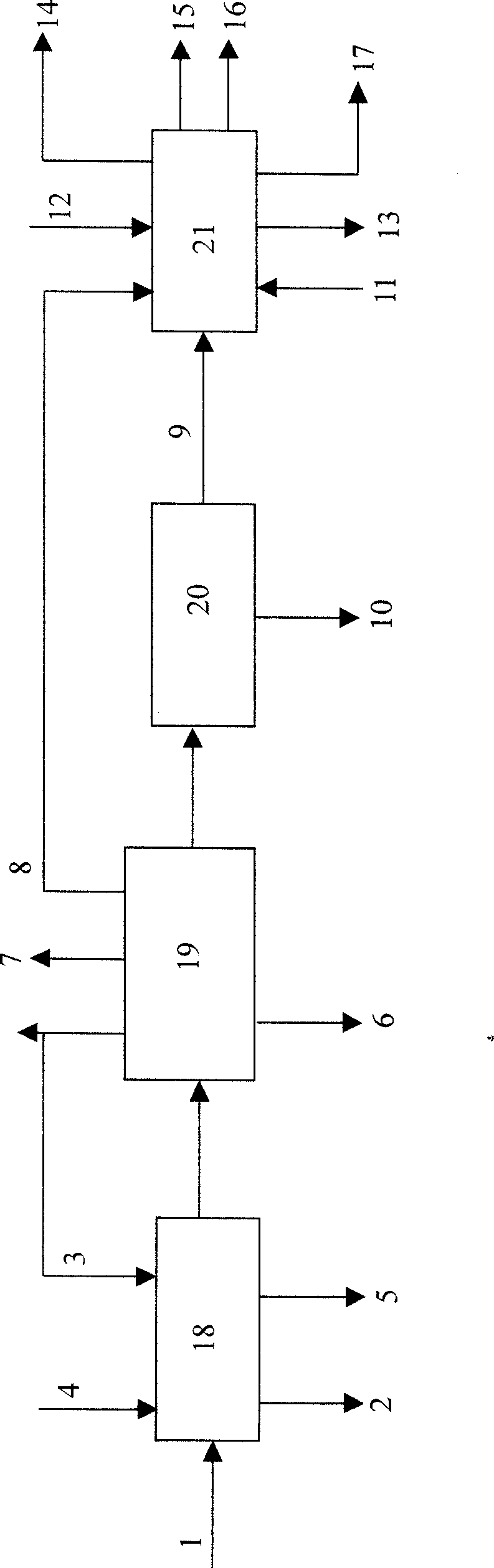

Continuous production process of high purity trimellitic anhydride with trimellitic acid

The continuous production process of high purity trimellitic anhydride with trimellitic acid includes the following steps: smelting trimellitic acid and eliminating acetic acid and water in the first kettle, and eliminating water inside trimellitic acid molecule in the second kettle to form trimellitic anhydride; eliminating heavy components in crude trimellitic anhydride product in one heavy component eliminating evaporator; eliminating light components in the evaporator of one light component eliminating tower; and rectifying through condensing trimellitic anhydride in the condenser on the top of the light component eliminating tower to obtain trimellitic anhydride product fed to the product tank. The present invention has stable product quality, high product purity, high product yield, low power consumption and other advantages.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +1

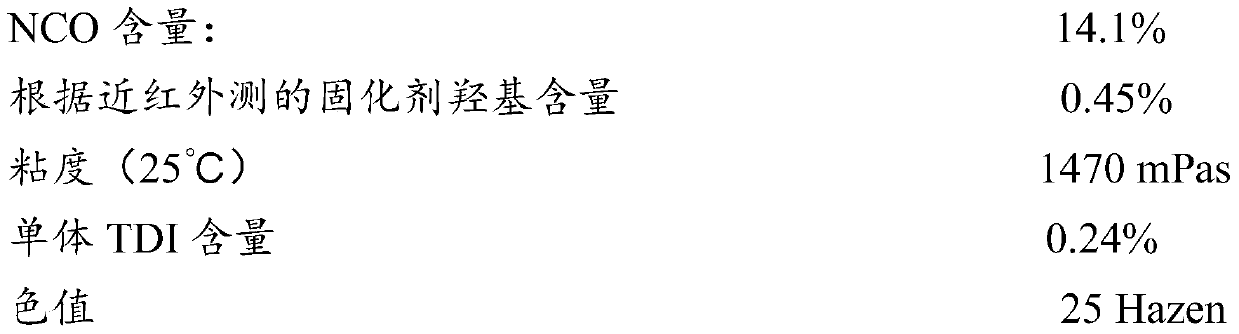

Method for preparing polyisocyanate containing biuret structure with stable storage

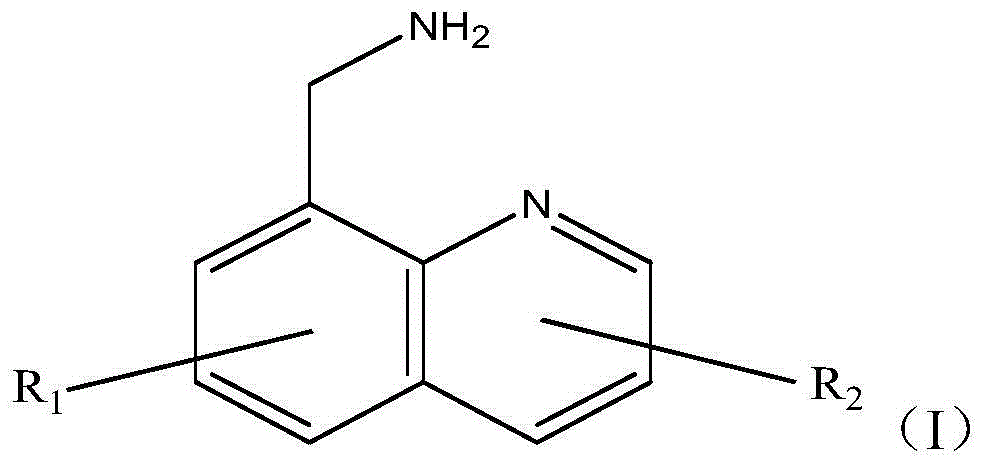

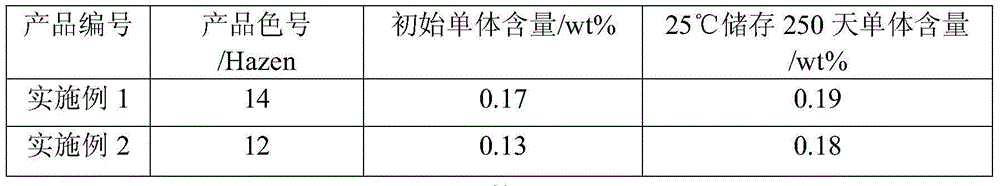

ActiveCN105601565AExcellent long-term storage stabilityDecrease increaseOrganic chemistryQuinolineMonomer

The invention relates to a method for preparing polyisocyanate containing a biuret structure. The method uses a reaction of polyisocyanate and water under existence of a substituted 8-aminomethyl quinoline compound and a hydrazine derivative to prepare biuret-containing polyisocyanate. A color number of the produced product is lower than 20 Hazen, under synergism of the substituted 8-aminomethyl quinoline compound and the hydrazine derivative, product is stored for 6 months, increasing amount of the monomer content is less than 0.1 wt%, and the product has excellent long-term storage stability.

Owner:WANHUA CHEM GRP CO LTD

De-coloring method of benzoic acid heavy by-product benzyl benzoate

ActiveCN107501098AReduce the color numberImprove solubilityOrganic compound preparationCarboxylic acid esters preparationBenzoic acidThermal insulation

The invention discloses a de-coloring method of benzoic acid heavy by-product benzyl benzoate. The de-coloring method comprises the following steps: 1) producing a benzyl benzoate crude product through reduced-pressure distillation of leftovers from production of benzoic acid through methylbenzene liquid phase air oxidation; 2) adding reactive metal and an acidic solution into the benzyl benzoate crude product for thermal insulation reaction; 3) reducing the temperature to a room temperature after the end of reaction, and filtering and removing the unreacted reactive metal; 4) performing layered treatment on a filtrate to obtain an upper oil layer; and 5) performing reduced-pressure distillation and dehydration on the oil layer, wherein an obtained remaining material is a low-color benzyl benzoate finished product. The de-coloring method disclosed by the invention is advanced in process, convenient to operate and high in yield.

Owner:WUHAN YOUJI IND

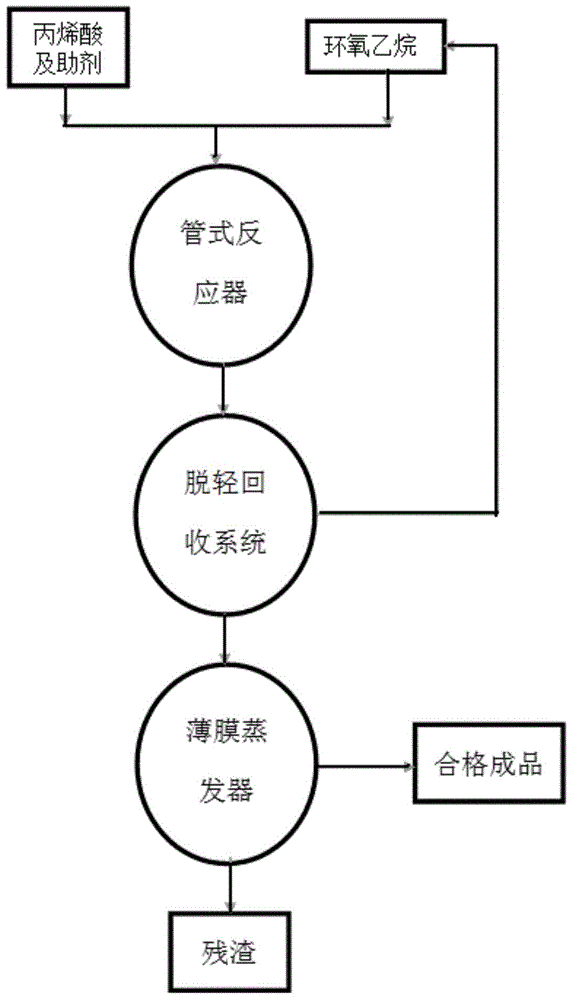

Clean technique for producing acrylate-hydroxy ester by adopting continuous process

InactiveCN104557540ASmall liquid holding capacityImprove controlOrganic compound preparationCarboxylic acid esters preparationNitrogen gasControllability

The invention discloses a clean technique for producing acrylate-hydroxy ester by adopting a continuous process. The clean technique for producing acrylate-hydroxy ester by adopting the continuous process comprises the following steps: 1) dissolving a catalyst and a polymerization inhibitor in acrylic acid, mixing and measuring, and then continuously pumping the obtained mixture into a tubular reactor with ethylene oxide at a certain ratio, wherein the mole ratio of acrylic acid to ethylene oxide is 1:(1.1-1.5); and 2) after reaction is finished, recycling ethylene oxide through low boiling fraction removal, and causing the rest reaction product to continuously enter an evaporator, so that the finished product is obtained. The clean technique for producing the acrylate-hydroxy ester by adopting the continuous process has the beneficial effects that ethylene oxide is excessive, so that the reaction time is short, and less byproducts are produced; reaction polymerization and reaction exotherm controllability is improved, and the production safety is greatly improved; the reaction time is short, the usage amount of the polymerization inhibitor is reduced, colour number can be effectively reduced, and the production cost is reduced; no steam is consumed in a continuous reaction process, and the production energy consumption is reduced; no replacement is required to be carried out after reaction is normally carried out, basically no nitrogen is consumed during production, and the amount of waste gas discharged out is reduced; and ethylene oxide in a degassing process during normal production can be recycled and is not discharged out, so that no pollution is produced to the air and water.

Owner:山东兴鲁生物科技有限公司

A kind of preparation method of isocyanate

The invention provides a method for preparing isocyanate based on a salifying phosgenation method. A salt forming reaction in the method comprises the following two steps: firstly, performing preliminary salt forming reaction by adopting a conventional reactor; secondly, adding a moderately polar organic solvent with a certain proportion into a reactor provided with an hourglass type liquid slurry disperser to carry out salt forming curing reaction, wherein star-shaped discharge openings are arrayed in a cylinder body of the hourglass type disperser. According to the preparation method, the fact that amino groups in raw materials are converted into amine hydrochlorides with high conversion rate can be ensured through the salt forming curing reaction, and the isocyanate product can be obtained with high yield through a follow-up photochemical reaction.

Owner:WANHUA CHEM GRP CO LTD

Plug flow distillation tray and method for preparing IP (isophorone) through liquid-phase condensation of acetone

ActiveCN110038317AEvenly distributedUniform fluidityOrganic compound preparationChemical industryIsophoroneDistillation

The invention provides a plug flow distillation tray and a method for preparing IP (isophorone) through liquid-phase condensation of acetone. The plug flow distillation tray comprises a tray and a plug flow assembly arranged on the tray, wherein the plug flow assembly comprises a downcomer, a grading overflow weir, a light and heavy phase distributing element, a liquid receiving plate I and a flowguide element; the downcomer is connected with the tray, and the grading overflow weir is arranged at an inlet of the downcomer; the light and heavy phase distributing element is arranged in the downcomer and located below the grading overflow weir; the liquid receiving plate I is connected with the tray and located on the side opposite to the side where the downcomer and the tray are connected;the flow guide element is arranged above the connection position of the liquid receiving plate I and the tray and is provided with multiple flow guide channels. A pressurized reaction distillation tower containing the plug flow distillation tray is applied to perform aftertreatment on an easily foaming IP / alkaline solution system, so that a liquid phase is more uniformly distributed and flow, andthe reaction effect is favorably improved.

Owner:WANHUA CHEM GRP CO LTD +1

Salifying reactor and method for preparing isocyanate

ActiveCN113181859AHigh salt concentrationAvoid incomplete responseIsocyanic acid derivatives preparationOrganic compound preparationFluid phaseProcess engineering

The invention discloses a salifying reactor and a method for preparing isocyanate by adopting the same. The reactor comprises a kettle body, a crude salt system, a refined salt system, a disc distributor, a fluid director and a mechanical stirrer; the crude salt system comprises a gas-phase feeding distributor, a liquid-phase feeding distributor and a cylindrical perforated plate, wherein the liquid-phase feeding distributor and the gas-phase feeding distributor are respectively communicated with a gas-phase feeding pipe and a liquid-phase feeding pipe; and the refined salt system comprises a rotary grinding cylinder and a grinding sheet. Through the reactor, the conversion rate of amino salifying can be improved while the salifying efficiency is improved; and the yield and the product quality of isocyanate are effectively improved by reducing the particle size of hydrochloride particles.

Owner:WANHUA CHEM GRP CO LTD

Polyisocyanate curing agent with good storage stability and preparation method thereof

ActiveCN109824865AGood storage stabilityReduce the color numberPolyurea/polyurethane coatingsOrganic acidOrganic solvent

The invention relates to a polyisocyanate curing agent with good storage stability and a preparation method thereof. The preparation method comprises the steps of (1) subjecting excessive toluene diisocynate and a hydroxy compound to reaction to obtain a prepolymer reaction liquid containing a toluene diisocynate monomer; (2) adding an organic acid with pKa value of 1-15 into the prepolymer reaction liquid of the step (1), and separating the non-reacted isocyanate monomer; (3) adding an organic solvent to the reacted liquid of the step (2) with the isocyanate monomer separated, and diluting toobtain the finished polyisocyanate curing agent. The content of hydroxy groups in the polyisocyanate curing agent is controlled by adding the organic acid; the prepared polyisocyanate curing agent has good storage stability and also has the advantages of small color number, low content of free isocyanates and the like.

Owner:WANHUA CHEM GRP CO LTD

Synthetic method of dipropylene glycol dibenzoate

PendingCN106565471AHigh yieldReduce the color numberOrganic compound preparationCarboxylic acid esters preparationBenzoic acidPtru catalyst

A method for preparation of dipropylene glycol dibenzoate is disclosed. According to the method, a synthetic route of esterification-decoloration-washing-dehydration is adopted. benzoic acid and dipropylene glycol are used as raw materials; a stannous oxalate and basic zirconium carbonate binary complex catalyst is used; and an excessive amount of dipropylene glycol and nitrogen are used as a water carrying agent to reasonably control the temperature. Through decoloration, neutralization, washing and dehydration, the finished product dipropylene glycol dibenzoate is prepared. The synthetic method of the invention has advantages of simple process, short production period, high yield of the product, small colour number, etc. By the method, it is easy to realize industrialization.

Owner:HUBEI GREENHOME MATERIALS TECH INC

Method for preparing phenyl glycidyl ether

The invention relates to a synthetic method of phenyl glycidyl ether. The method comprises the following steps: carrying out ring-opening reaction; carrying out ring-closure reaction; washing; refining; and recovering excessive epoxy chloropropane in vacuum from a phenyl glycidyl ether coarse to obtain a phenyl glycidyl ether finished product, wherein the recovered epoxy chloropropane is directly reused in next batch. The method comprises the following steps: by taking phenol and epoxy chloropropane as raw materials, firstly, carrying out ring-opening reaction under the action of a ternary compound catalyst comprising N,N-dimethylethanolamine, tetrabutylammonium hydrogen sulfate and quaternary ammonium salt-7 to prepare an intermediate phenyl chlorhydrin; and then carrying out ring-closure reaction with a sodium hydroxide solution to prepare the phenyl glycidyl ether, wherein the recovered epoxy chloropropane can be directly reused. The method provided by the invention has the advantages of simple process, short production cycle, high final product yield, high epoxide number, small color number and the like and is easily industrialized.

Owner:HUBEI GREENHOME MATERIALS TECH INC

Method for preparing light-color pentadiene petroleum resin

The invention relates to a method for preparing light-color pentadiene petroleum resin. The method comprises the following steps of: adding pentadiene serving as a raw material and trichloro triethyl di-aluminum in an amount which is 0.3 to 3 percent of the mass of the pentadiene into a dried and closed reactor, stirring, heating to the temperature of between 30 and 90 DEG C, and performing polymerization reaction for 3 to 9 hours by taking the trichloro triethyl di-aluminum as a catalyst and methylbenzene, dimethylbenzene or tetrahydrofuran as a solvent to obtain viscous liquid; and washing to remove the catalyst by using 3 to 12 mass percent alkaline liquor, washing by using distilled water until the viscous liquid is neutral, and distilling at the temperature of between 180 and 350 DEG C to remove the solvent to obtain the light-color pentadiene petroleum resin, wherein a mass ratio of the pentadiene to the solvent is 1:(1-3). The prepared pentadiene petroleum resin has the advantages of small color number, moderate softening point, narrow molecular weight distribution and the like, and the preparation process is easy to operate.

Owner:PETROCHINA CO LTD

Regeneration method for waste lubricating oil

InactiveCN100503796CMeet environmental protection requirementsFlexible technology routeLubricant compositionSlagDiluent

The invention discloses a regeneration method of waste lubricating oil. The method is to settle the waste lubricating oil naturally to remove the water and mechanical impurities contained in it. When the content of mechanical impurities in the waste lubricating oil is less than 0.08% by weight or the pentane insoluble matter is less than 0.30% by weight, direct atmospheric and vacuum distillation , otherwise add a diluent accounting for 0 to 3.5 times the total weight of the waste lubricating oil, raise the temperature to 30°C to 95°C, and then carry out atmospheric and vacuum distillation after separation. Refined with lubricating oil to obtain regenerated lubricating oil. Using the method of the invention to regenerate the waste lubricating oil has no acid residue discharge, and by-products can be directly utilized, and the technological process meets the requirements of environmental protection.

Owner:CHINA PETROCHEMICAL CORP +1

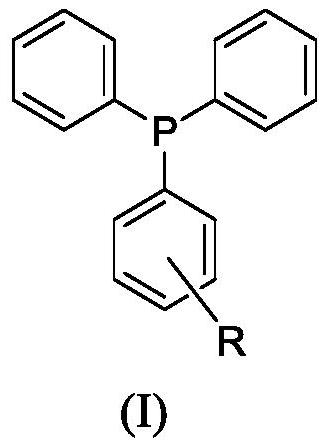

Citral with low color number and preparation method thereof

ActiveCN112574018AReduce the color numberSuitable reducibilityOrganic compound preparationCarbonyl compound separation/purificationArylCarboxyl radical

The invention provides citral with a low color number and a preparation method thereof. The method comprises the following steps: (1) carrying out countercurrent contact on CO2 and a crude citral stream in a gas stripping tower; and (2) conducting rectifying in the presence of a triarylphosphine compound to obtain a citral product with a low color number. The structural formula of the triarylphosphine compound is shown as a formula (I) in the specification. In the formula (I), R is a hydroxyl, carboxyl or aldehyde group, and R is at the ortho-position, meta-position or para-position of a P atom. The citral product treated by using the method provided by the invention has a lower color number and purer smell.

Owner:WANHUA CHEM GRP CO LTD

Andrographolide and extraction method thereof

The invention provides an extraction method of andrographolide. The extraction method is characterized by smashing andrographis paniculate raw leaves, extracting with ethanol, and filtering to obtainan extracting solution; charging nitrogen into the extracting solution, heating, stirring, decoloring, and performing low temperature crystallization to obtain coarse grains; charging nitrogen into the coarse grains, heating, stirring, decoloring, crystallizing, and separating to obtain recrystals; repeating the step for multiple times to obtain andrographolide; and washing, drying, smashing and packaging into finished products. The andrographolide prepared by adopting the method does not contain toxic reagent, and is high in safety, high in purity and high in yield.

Owner:四川文龙药业有限公司

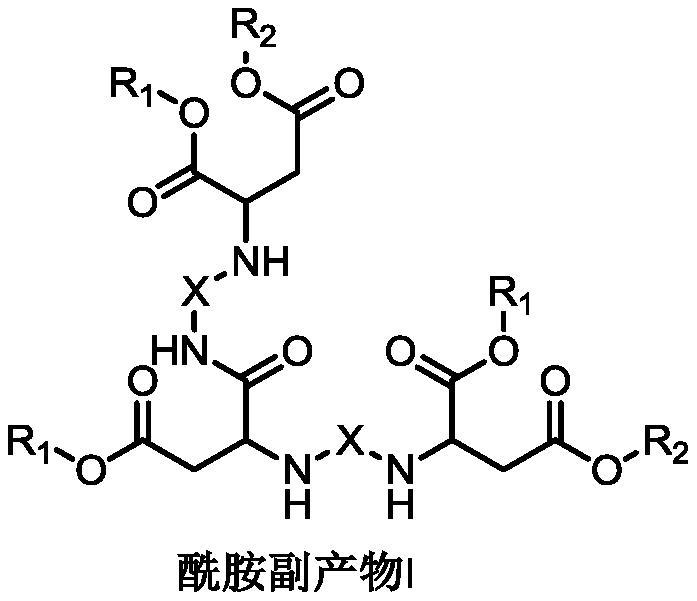

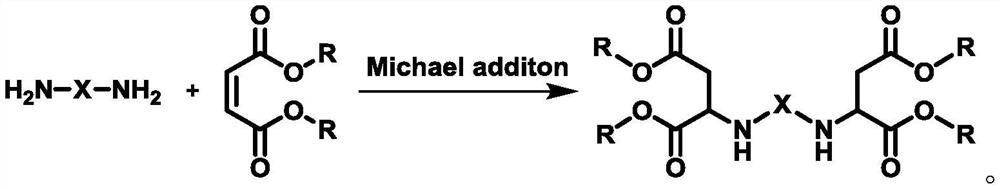

Polyaspartic acid ester composition as well as preparation method and application thereof

ActiveCN112876956AGood storage stabilityReduce the color numberPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolyaspartic acidWeather resistance

The invention provides a high-quality polyaspartic acid ester composition and a preparation method thereof. According to the method, by controlling the process, the ratio of the secondary amine value to the total amine value of the polyaspartic acid ester composition is 95%-99.9%, so that the gelation time of polyurea compounded by the polyaspartic acid ester composition is prolonged, the viscosity is moderate, and the adhesive force, impact resistance and weather resistance of a coated film are excellent.

Owner:WANHUA CHEM GRP CO LTD

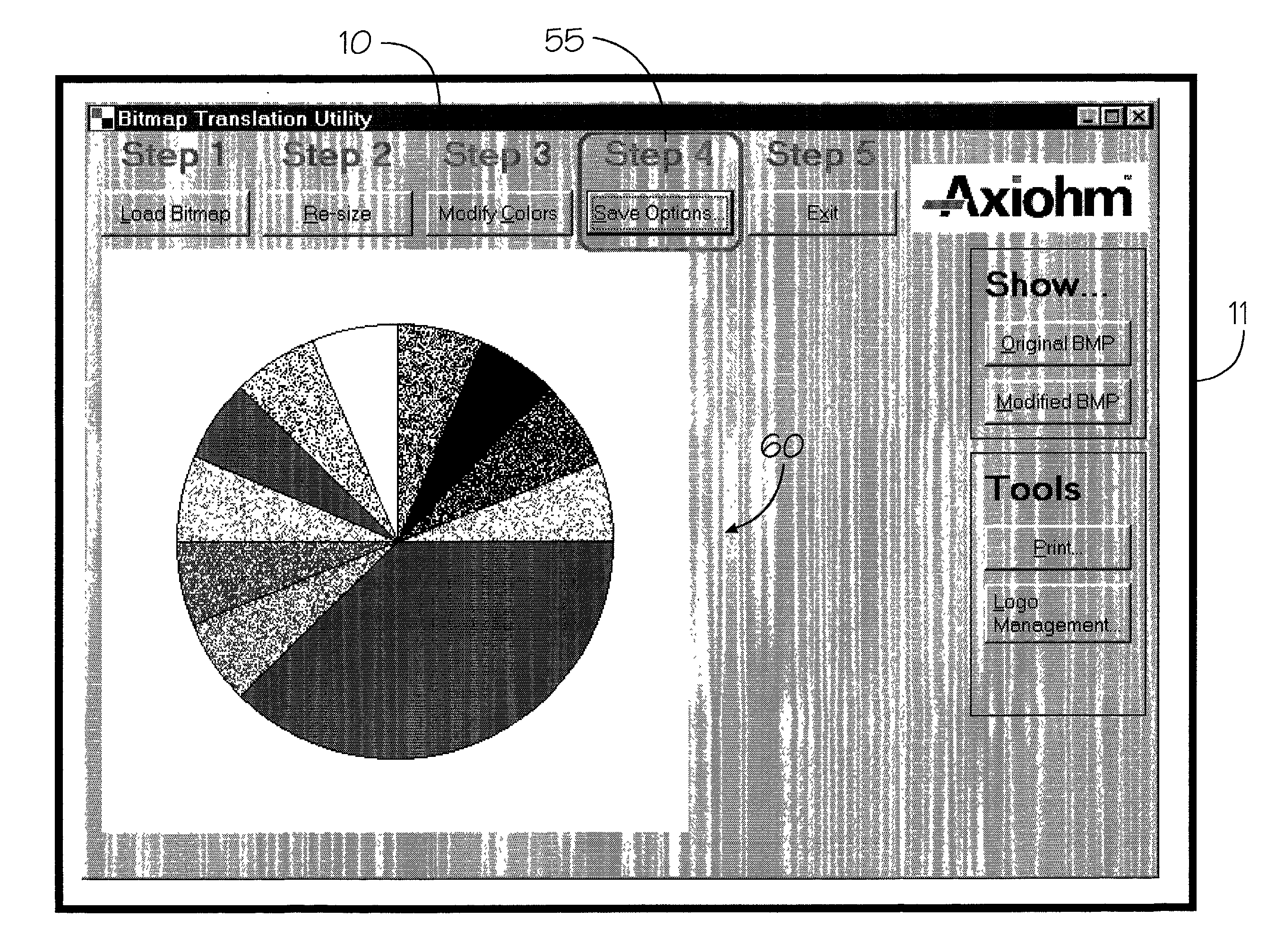

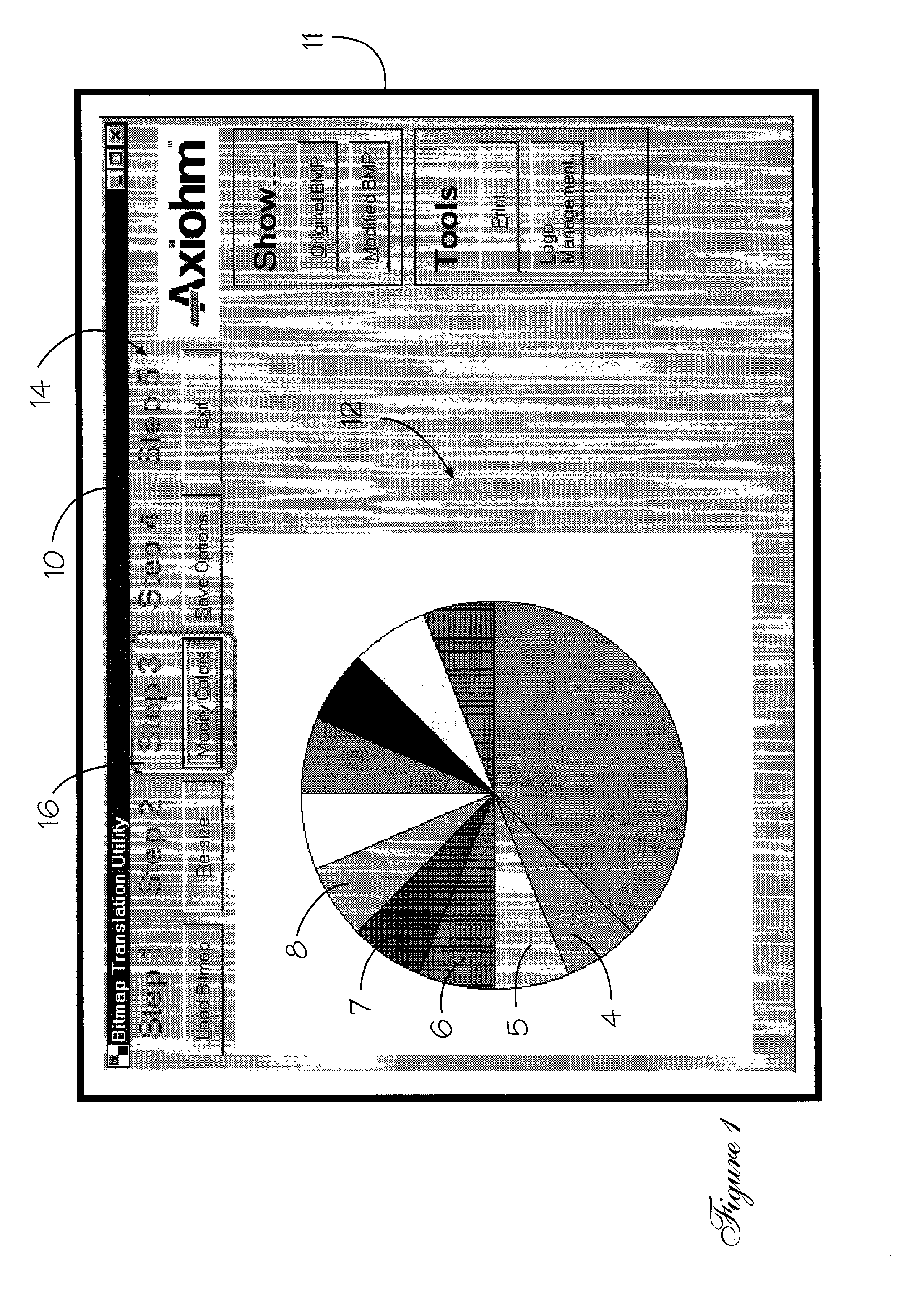

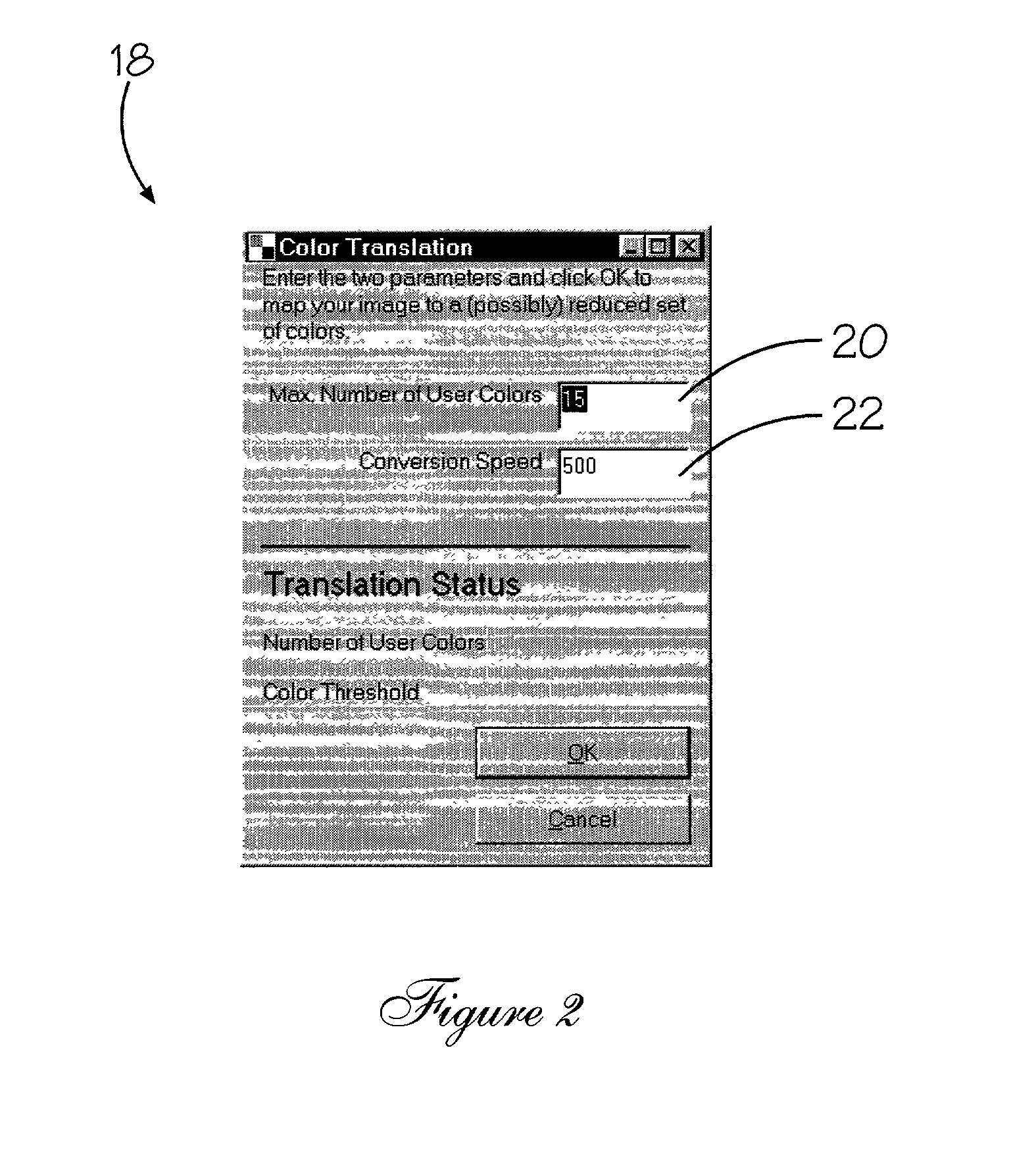

Color adjusted printing

ActiveUS6995867B2Reduce the color numberLower capability requirementsDigitally marking record carriersVisual presentation using printersGraphicsVisual perception

A program method of converting a multiple color file to a two-color, or limited color file, so that an image contained therein can be printed upon a receipt, Point Of Sale, or two-color printer. Most multiple color files that contain logos and graphics cannot be successfully reduced in color by automatic or computer generated methods. The programmatic method of this invention contains a second-stage routine that requests viewer participation and input. The resulting printed or displayed image is visually acceptable by reason of this viewer input.

Owner:COGNITIVETPG

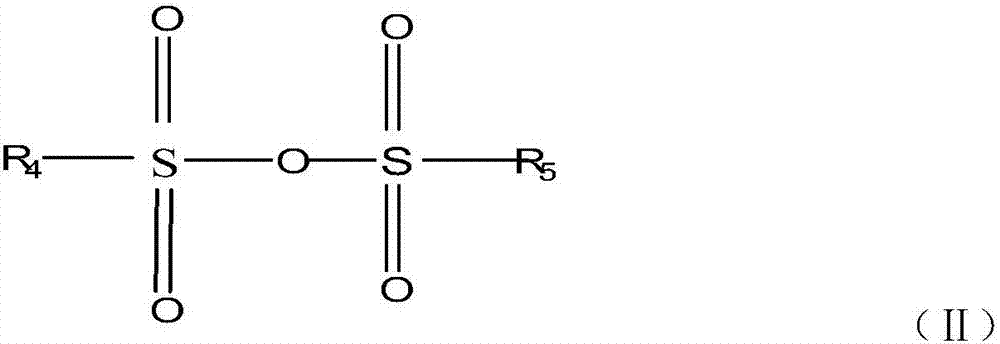

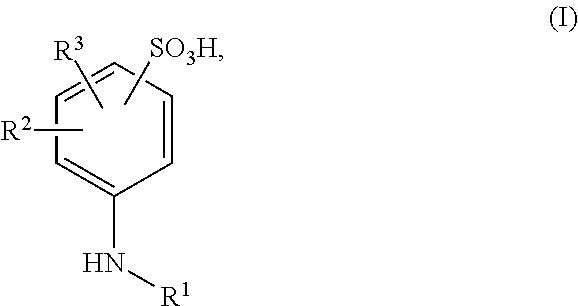

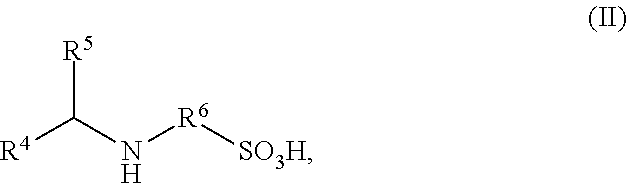

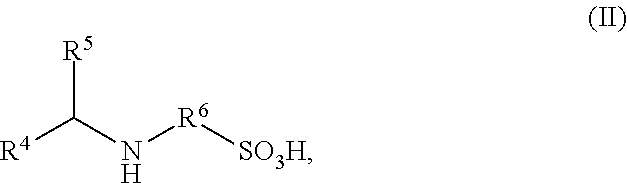

Ionically hydrophilized polyisocyanates and antioxidants

PendingUS20190330409A1Reduce the color numberLow viscosityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAntioxidantCoating

The invention relates to a process for producing polyisocyanates containing sulfonate groups, the products obtainable by said process and also to the use thereof as starting component for producing polyurethane plastics. The invention further relates to coating compositions comprising polyisocyanates containing sulfonate groups and also to the substrates coated with said coating compositions.

Owner:COVESTRO DEUTSCHLAND AG

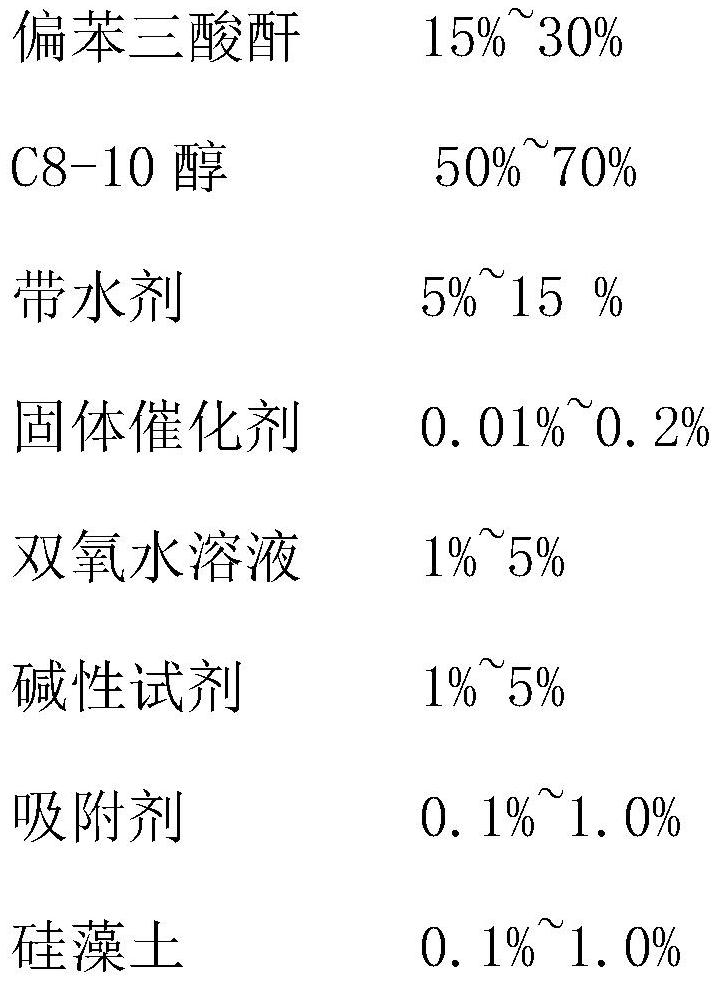

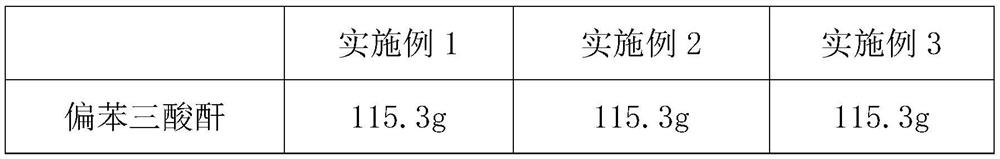

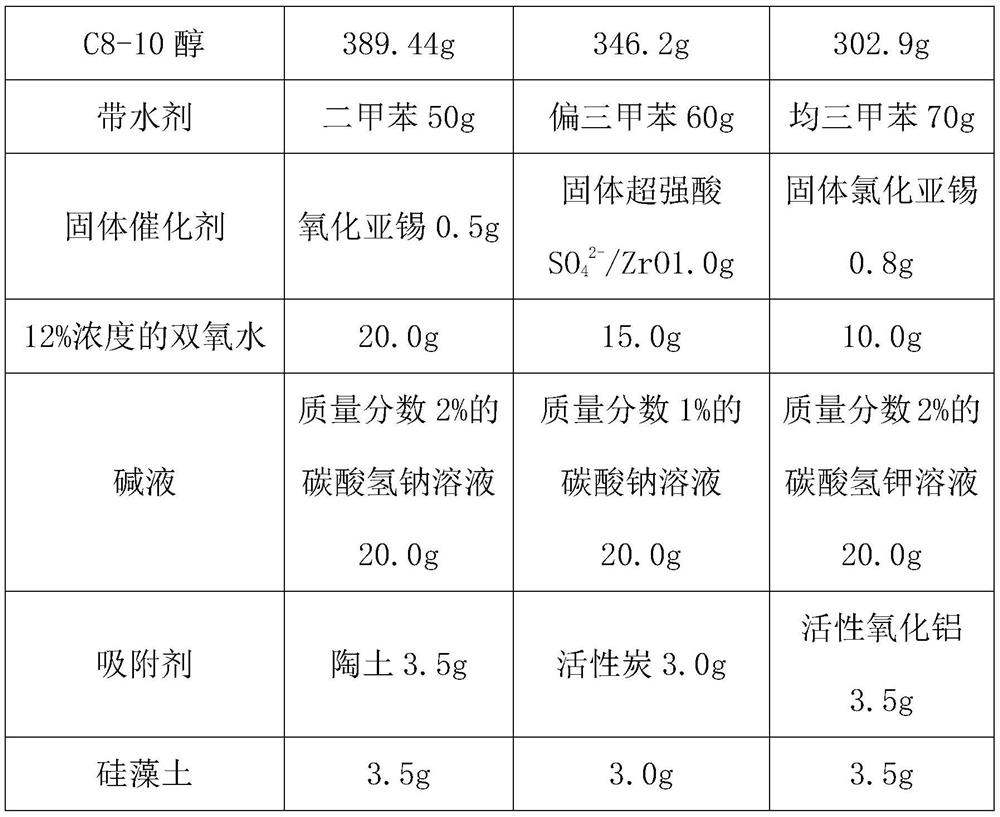

Preparation method of low-color-number tri(C8-10 alcohol) trimellitate

PendingCN112552170AReduce generationLess side effectsOrganic compound preparationCarboxylic acid esters separation/purificationPtru catalystAlcohol

The invention discloses a preparation method of low-color-number tri(C8-10 alcohol) trimellitate, belonging to the technical field of organic chemical production. The method comprises the following steps: esterification: putting raw materials into a reaction kettle, and adding a water-carrying agent and a solid catalyst for a reaction; dealcoholization: starting vacuum, and pumping out most of excessive C8-10 alcohol; filtering: filtering a reaction product in the previous step while the reaction product is still hot to recover the solid catalyst; oxidation: adding hydrogen peroxide; alkali washing: adding an alkaline reagent solution, conducting standing for layering, and removing a water phase; dealcoholization: pumping out residual moisture and C8-10 alcohol; adsorption: adding an adsorbent and a filter aid, namely diatomite; and filtering: filtering a decolorized solution while the decolorized solution is still hot to obtain a filtrate, namely the finished product tri(C8-10 alcohol) trimellitate. The method has the advantages that the solid catalyst is adopted, a dehydrating agent is added, and an oxidizing agent is added, so the high-quality product with a low color number, alow acid value and high volume resistivity can be obtained, less wastewater is generated, the catalyst can be recycled, and the purposes of environmental protection and clean production are achieved.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +1

Method for reducing pentadiene petroleum resin color number

ActiveCN103665266AConcentration controllableThe generation is easy to controlPetroleum resinDesiccant

The invention relates to a method for reducing pentadiene petroleum resin color number. The method is characterized in that C5 olefin fraction obtained by a C5 separation device is used as a raw material, the weight of pentadiene concentrate is 60-75 percent; silicon tetrachloride is used as a drying agent, solvents and aluminum chloride anhydrous serving as a catalyst are added to control the dropwise adding speed, and the dropwise adding temperature is less than 30 DEG C, the reaction temperature is 0-80 DEG C and the reaction time is 0.5-10h, so that pentadiene petroleum is prepared. According to the method, the using amount of the synthetic pentadiene petroleum resin catalyst and the resin color number are successfully reduced, and the problem that the color needs to be deepened when high-grade pentadiene petroleum resin is produced is solved, so that the quality of the pentadiene petroleum resin is stable, the process is controlled, and multi-grade requirement of clients is met, and the economic benefit is improved.

Owner:PETROCHINA CO LTD

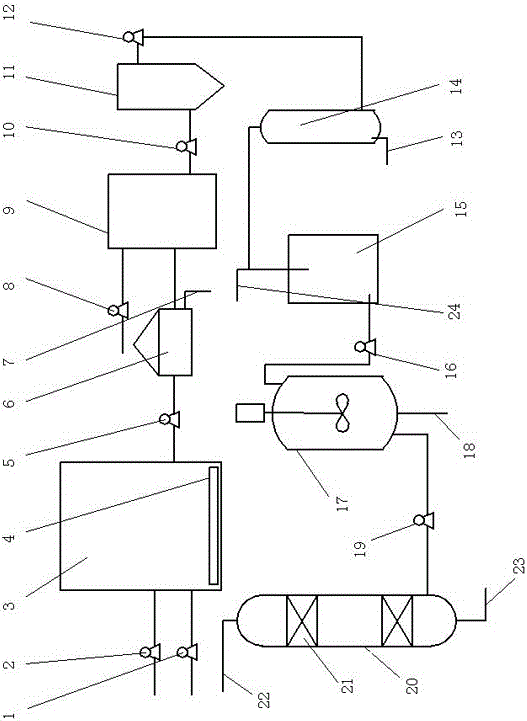

Production equipment and process of high-quality low-sulfur biodiesel

ActiveCN105694999BLow sulfur content in fats and oilsReduce the color numberBiofuelsLiquid carbonaceous fuelsBiodieselWater source

Disclosed is high-quality low-sulfur-content biodiesel production equipment.An aeration reaction pool is connected with a salt solution supply source and a raw oil supply source through pipelines respectively.The aeration reaction pool is connected with a butterfly type centrifugal machine through a pipeline.The butterfly type centrifugal machine is connected with an ultrasonic box through a pipeline.The ultrasonic box is connected with an oil-water separation tank through a pipeline.The ultrasonic box is further connected with a clean water source through a pipeline.The oil-water separation tank is connected with an atmospheric distillation tower through a pipeline.The atmospheric distillation tower is connected with a raw material storage tank through a pipeline.The raw material storage tank is connected with an esterification reactor through a pipeline and connected with the upper portion of the atmospheric distillation tower through a pipeline to form a low-boiling point material outlet.The esterification reactor is connected with a vacuum distillation tower through a pipeline.

Owner:TANGSHAN JINLIHAI BIODIESEL

Production technology for further purifying tripentaerythritol

The invention relates to a production technology for further purifying tripentaerythritol. The production technology comprises the following steps: step I: adding a tripentaerythritol crude product into a solvent kettle, step II: adding an organic solvent into the solvent kettle to dissolve the tripentaerythritol crude product, step III: separating acetal, alcohol and methylate, and step IV: performing drying, crushing and packaging. According to the production technology, produced high color number and high ash tripentaerythritol is added into the organic solvent and dissolved in the organicsolvent; acetal, alcohol and methylate are not dissolved; tripentaerythritol is extracted using different solubility of tripentaerythritol, acetal, alcohol and methylate; the purity of a product is improved; an ash content and a color number of the product are reduced; overall improvement of quality of tripentaerythritol is achieved.

Owner:PUYANG YONGAN CHEM IND

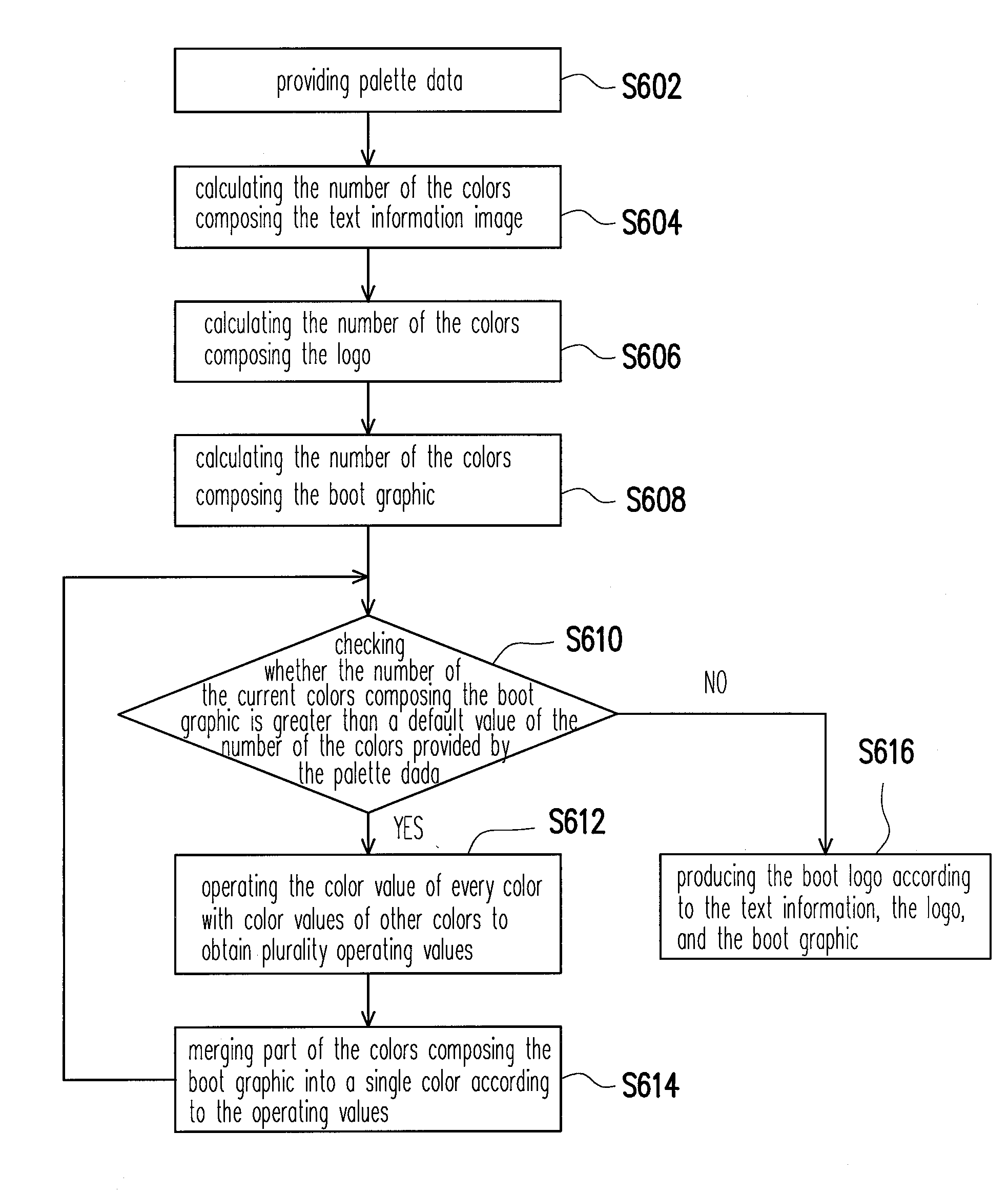

Booting method of computer system and boot logo processing method thereof

ActiveUS20090219297A1Reduce in quantityReduce the color numberDigital computer detailsCharacter and pattern recognitionGraphicsComputer hardware

A boot logo processing method includes the following steps. Palette data and a boot graphic including plurality colors are provided, and the colors include corresponding color values respectively in color gamut of the boot graphic. A boot graphic is provided, and it may be composed of plurality colors. When the number of the colors composing the boot graphic is greater than a default value of the number of the colors provided by the palette data, color value of every color is operated with color values of other colors to obtain plurality operating values. Thereby, in the processing method of the invention, part of the colors in the color gamut of the boot graphic are merged into a single color according to the operating values to decrease the number of the colors composing the boot graphic, and produce the boot logo at least according to the latest boot graphic.

Owner:ASUSTEK COMPUTER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com