Patents

Literature

244 results about "Aluminum chloride anhydrous" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anhydrous aluminum chloride (aluminum trichloride, AlCl3) is an odorless, white or yellow crystalline solid that reacts violently with water to liberate hydrogen chloride (HCL) gas.

Rechargeable aluminum ion cell and preparation method thereof

InactiveCN104241596AImprove conductivityImprove thermal stabilityCell electrodesElectrolyte accumulators manufactureAluminum IonMetal foil

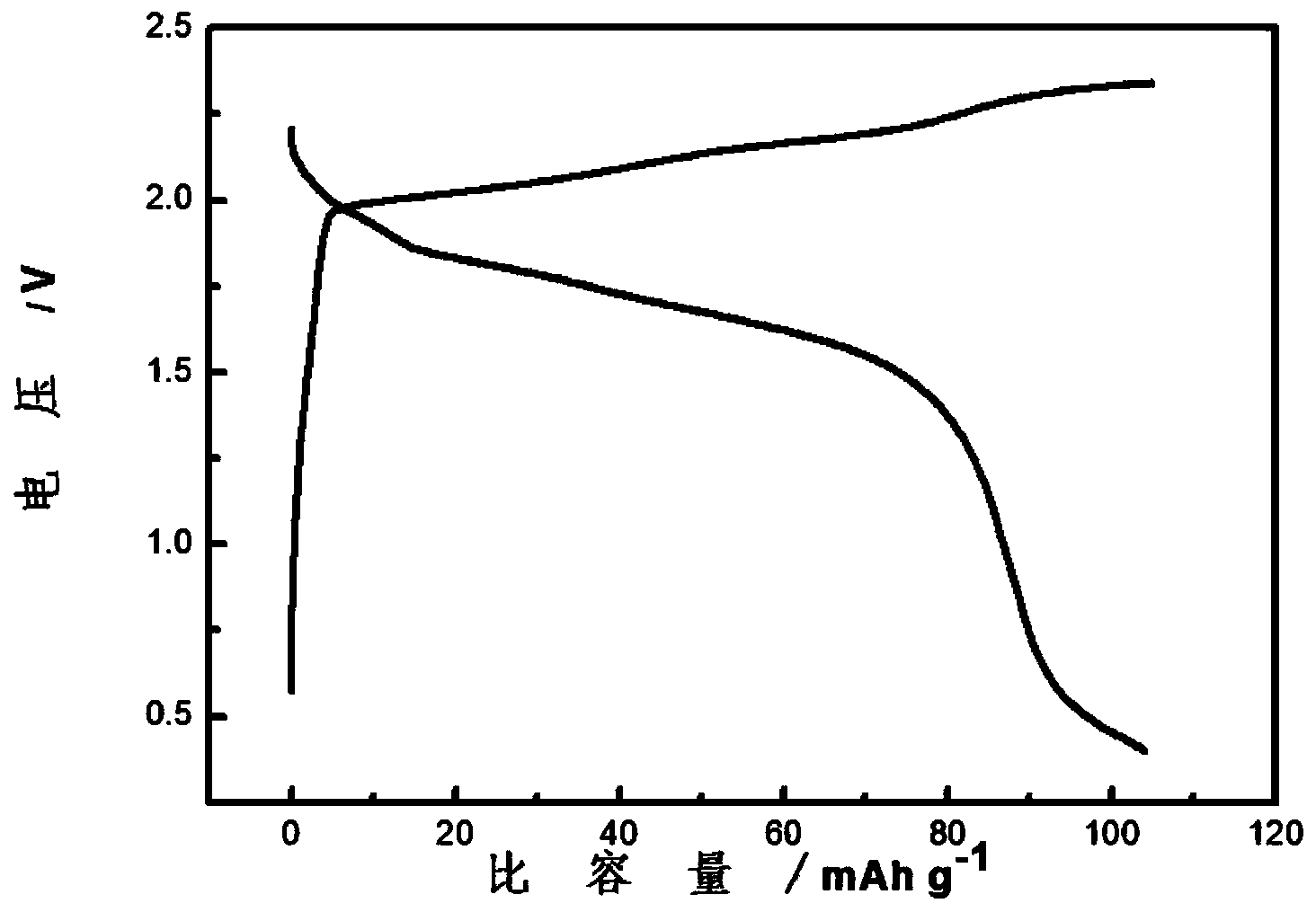

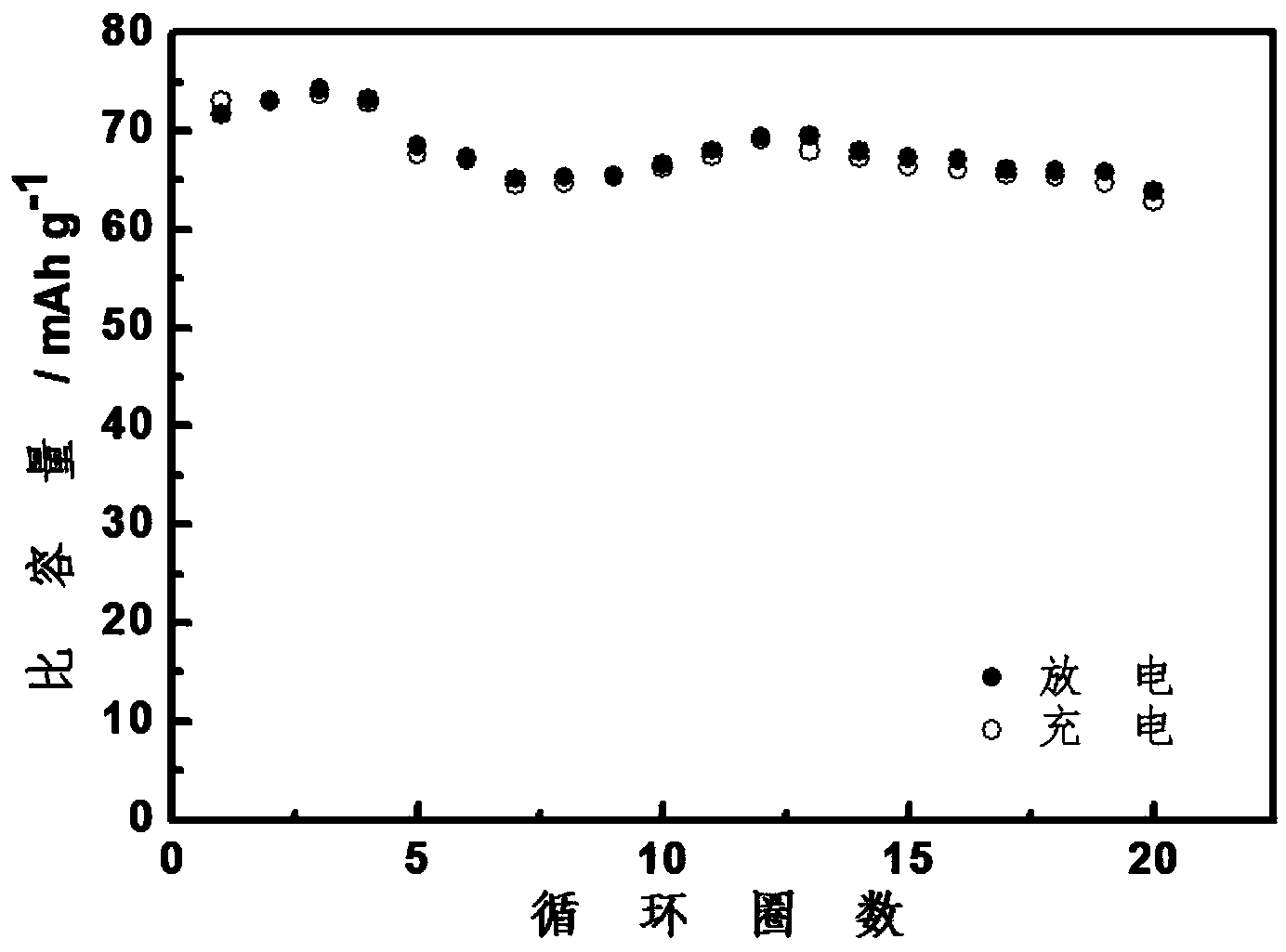

The invention discloses a rechargeable aluminum ion cell and a preparation method thereof and belongs to the field of energy reutilization. The cell comprises an anode, a cathode, a liquefied aluminum ion electrolyte and a diaphragm material, wherein the anode is made of graphite structure carbon material; the cathode is made of highly pure aluminum; the liquefied aluminum ion electrolyte is formed by mixing anhydrous aluminum chloride and 3-methyl imidazole compound; the molar ratio between the anhydrous aluminum chloride and the 3-methyl imidazole compound is from 1.1:1 to 1.6:1. The preparation process of the cell comprises the following steps: processing the graphite structure carbon material into laminar shapes; fixing the anode material with inertial metal foil as a current collector and covering the anode with the diaphragm material; washing highly pure aluminum cutting piece as the cathode; preparing the liquefied aluminum ion electrolyte which contains A13 plus ion capable of freely moving. The anode, the cathode and the liquefied aluminum ion electrolyte are assembled in a glove box to form the cell; the cell has the characteristics of high capacity and good circulating stability and is applicable to multiple fields such as electronic industry, communication industry and electric automobile.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for producing aluminium and aluminium alloy by low temperature electrolysis

InactiveCN1664170ALight in massNon-volatilePhotography auxillary processesProcess efficiency improvementMetallic materialsIonic liquid

The invention relates to a method of making aluminum and aluminum alloy through electrolyzing in low temperature, which belongs to the metal material field, characterized in that it uses the alumina or silicate mineral containing aluminum as raw materials, and gets anhydrous aluminum chloride after chloridization, then prepares AlCl3 ionic liquid with anhydrous aluminum chloride, and uses the AlCl3 ionic liquid as ionogen, the aluminum will be produced in the cathode while the chlorine will be discharged from the anode. When producing the aluminum alloy, preparing the alloy elements chloridate-AlCl3 ionic liquid through adding alloy elements chloridate MeCln to the AlCl3 ionic liquid, Using the direct current to electrolyzing, wherein the voltage is above the higher decomposition voltage of the aluminium chloride and chloridate and below the electrochemistry window of the ionic liquid, and the aluminum will be produced in the cathode while the chlorine will be discharged from the anode.

Owner:UNIV OF SCI & TECH BEIJING

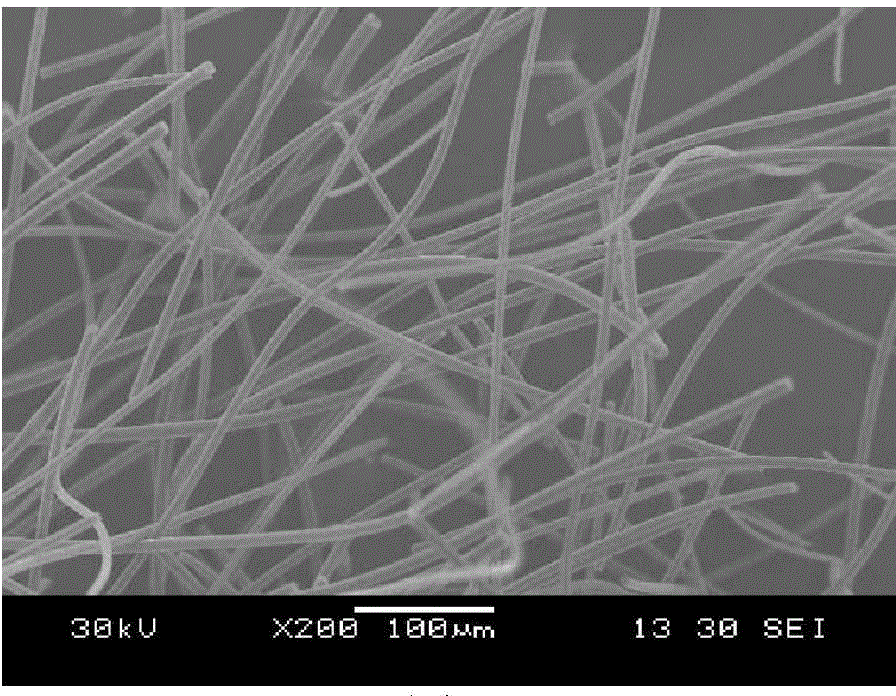

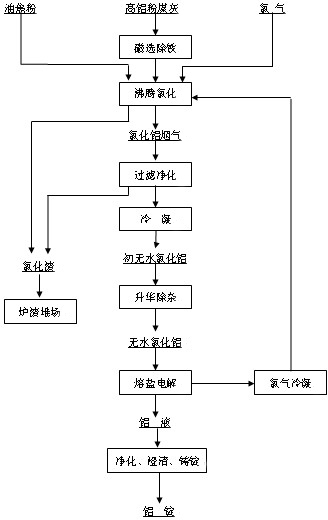

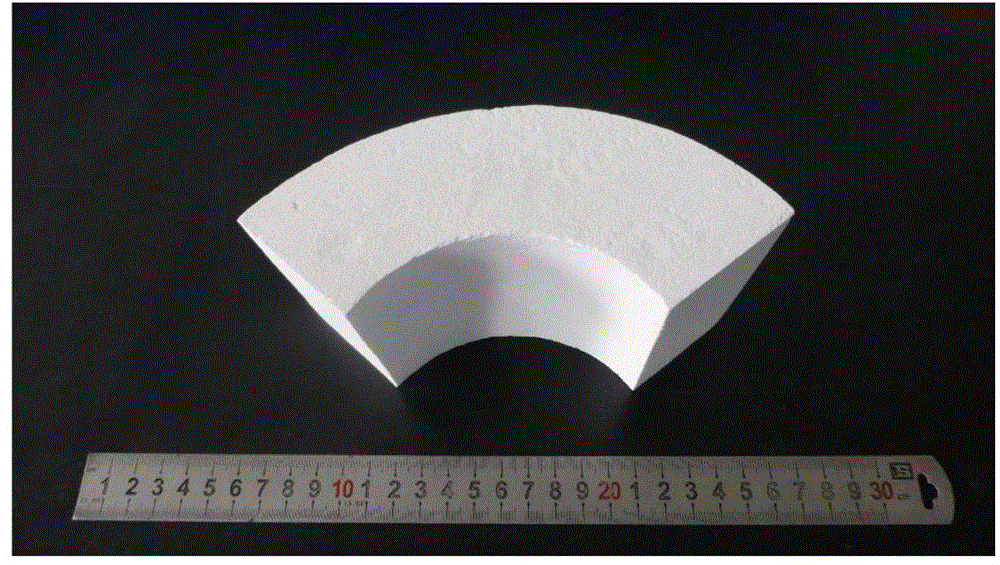

Preparation method of mullite fiber

The invention discloses a preparation method of high-purity continuous mullite fiber. The mullite fiber is prepared by adopting a sol-gel method and a centrifugal spinning technology through taking anhydrous aluminum chloride and aluminum powder as an aluminum source, tetraethylorthosilicate as a silicon source, and glacial acetic acid as a colloid stabilizer and spinning auxiliary. The preparation method comprises the following steps: firstly, preparing a mullite fiber precursor sol according to raw materials, preparing gel fibers through the centrifugal spinning technology, and finally drying and sintering at high temperature to obtain the mullite fiber. In order to improve the room-temperature and high-temperature mechanical performance of mullite, 0-2wt% of oxide second phase is added. Compared with the prior art, the mullite fiber prepared by adopting the method has the advantages that the consumed time is short, raw materials are low in price, and industrial production can be considered; the mullite fiber is higher in high-temperature resistance degree and better in physical and chemical properties compared with aluminum silicate fiber and high-purity alumina fiber; the mullite fiber can also be used as base fibers of mullite fiber felts and fiberboards, and can be further processed.

Owner:南京理工宇龙新材料科技股份有限公司 +1

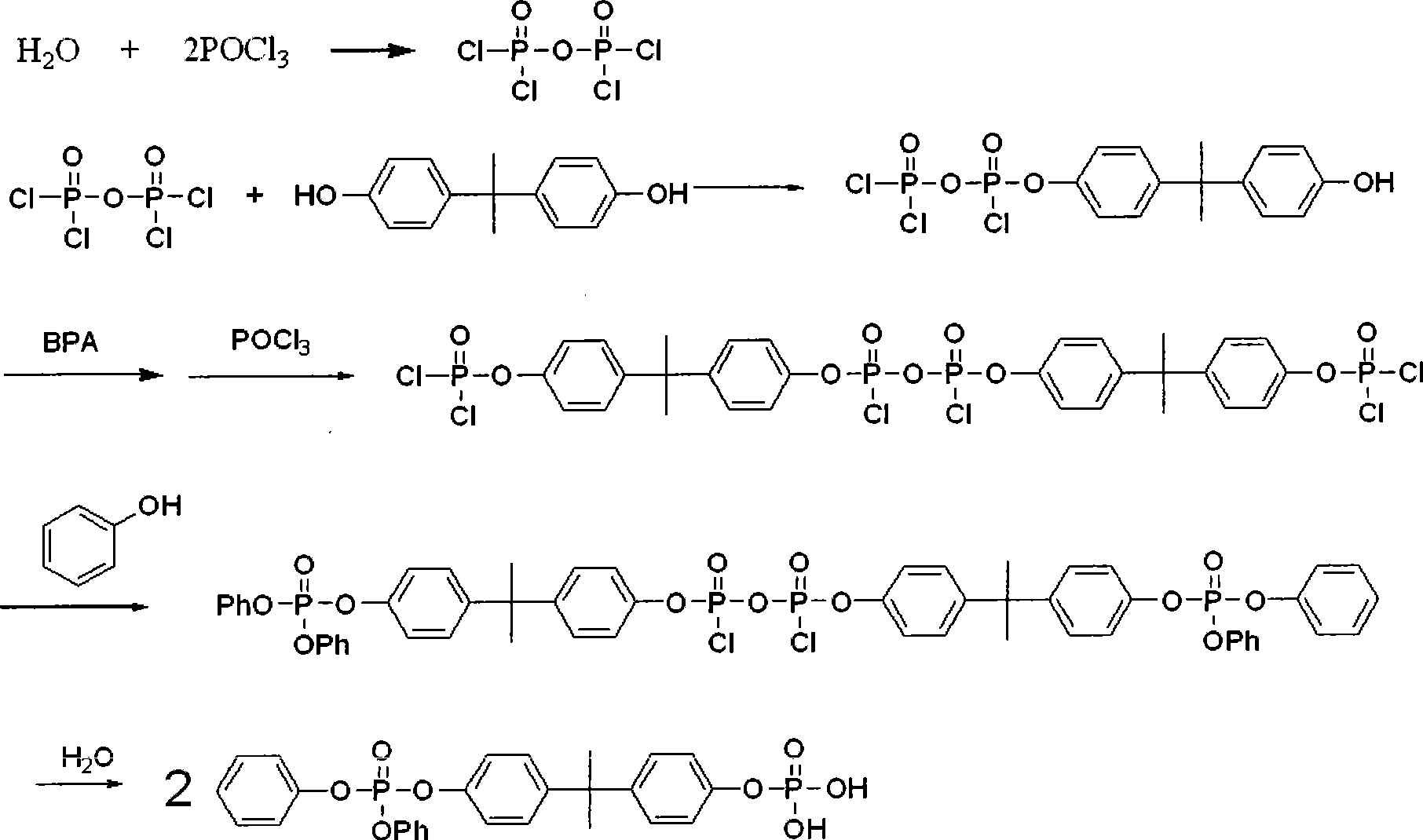

Method for preparing combustion inhibitor bisphenol A bis(diphenyl phosphate)

ActiveCN101456879ASignificant progressSignificant positive effectGroup 5/15 element organic compoundsPhenolBisphenol

The invention relates to a preparation method for flame retardant bisphenol A bi(diphenyl phosphate). The preparation method comprises the following steps: taking phosphorus oxychloride, bisphenol A and phenol as raw materials, adopting anhydrous zinc chloride or anhydrous aluminum chloride as a main catalyst, and adopting anhydrous calcium chloride or calcium phosphate as a promoter; adding the phosphorus oxychloride, the main catalyst and the promoter into a reactor for intensive stirring, when the materials are heated up to 73 to 78 DEG C, continuously adding bisphenol A, after the addition of bisphenol A is completed within 2.5 to 3 hours, heating up to and maintaining the temperature of 110 to 115 DEG C, and continuing the reaction for 1.5 to 2 hours; leaking out excessive phosphorus oxychloride under the normal and reduced pressure; and cooling down the intermediate product to 100 DEG C, continuous dropping phenol into the intermediate product, heating up to 140 DEG C 2 hours later, carrying out the reaction for 3 to 4 hours, monitoring the content of phenol through the liquid chromatography, and complementing phenol till the phenol content in the crude product is less than 0.5 percent. The yield reaches 98 percent; the content of triphenyl phosphate is less than 1.5 percent; and the acid number is 0.03mgKOH / g.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of sodium-free refining agent for aluminum and aluminum alloy and production method thereof

The invention discloses a sodium-free refining agent for aluminum and aluminum alloy, which consists of the following ingredients in percentage by weight: 15 to 25 percent of potassium aluminium fluoride, 5 to 15 percent of calcium fluoride, 10 to 25 percent of potassium carbonate, 10 to 25 percent of potassium sulfate, 5 to 15 percent of barium sulfate, 15 to 30 percent of potassium chloride and3 to 5 percent of anhydrous aluminium chloride. The invention also discloses a production method of the sodium-free refining agent. Because the sodium-free refining agent does not contain sodium salts, compared with sodium-containing refining agents, the sodium-free refining agent effectively solves the problem of antimony modification and phosphor modification influence caused by more or less sodium salt contained in the existing refining agent and overcomes the defects of alloy casting performance influence, melt flowability reduction and sodium brittleness possibly caused by the sodium element in aluminum-magnesium system alloy with the magnesium content being higher than 2 percent. A better use effect can be obtained in the antimony modification and phosphor modification alloys and high-magnesium-aluminum alloy. The invention belongs to the qualitative improvement on the prior art.

Owner:HEBEI SITONG NEW METAL MATERIAL CO LTD

Method for electroplating inorganic molten salt on surface of magnesium and magnesium alloy with aluminum

The invention relates to a method for electroplating inorganic molten salt on surface of magnesium and magnesium alloy with aluminum, which belongs to the technical field of metal surface treatment. The method comprises a step of preplating a zinc layer as a substrate and a step of electroplating inorganic molten salt with aluminum. The step of preplating the zinc layer as the substrate comprises a step of immersion-plating the zinc layer and a step of electroplating the zinc layer. The step of electroplating the zinc layer is performed in an inorganic molten salt system, wherein anhydrous aluminum chloride is main salt, and sodium chloride, potassium chloride or a mixture of the two is a main complexing agent. An aluminum coating obtained by the method is complete, dense, uniform and bright, is firmly combined with a matrix, can be individually used as a protective layer, and can be prepared into a surface functional layer with better corrosion resistance, better wear resistance and high hardness through subsequent treatment. The whole process of the method has the advantages of simple process, cheap equipment, friendliness to environment, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Anhydrous aluminum chloride production method

InactiveCN104773746ASolve the problem that the purity is also very low and it is difficult to meet the industrial requirementsAluminium chloridesAluminium chlorideCalcium Chloride Hexahydrate

The invention relates to an anhydrous aluminum chloride production method. In the prior art, the aluminum chloride product produced by using the hydrochloric acid dissolution method has disadvantages of fine particle, large specific surface area and high impurity content, does not meet metallurgical grade alumina requirements, and is difficultly be subjected to direct use, and the prepared aluminum chloride purity is low and difficultly meets the industrial requirements even the aluminum chloride product is utilized. With the production method of the present invention, the problems in the prior art are solved. The production method comprises: immersing an aluminum production raw material into hydrochloric acid to obtain an aluminum chloride solution; directly carrying out concentration crystallization on the prepared aluminum chloride solution to obtain an aluminum chloride hexahydrate crystal; calcining the aluminum chloride hexahydrate crystal to obtain primary alumina; and mixing the primary alumina and carbon, adding to a chlorination furnace, introducing chlorine gas, heating, carrying out a reaction of the alumina and the chlorine gas to generate gaseous aluminum chloride, and carrying out refining impurity removing to obtain the pure anhydrous aluminum chloride. The production method of the present invention is used for industrial production of the anhydrous aluminum chloride.

Owner:GUIYANG AL-MG DESIGN & RES INST

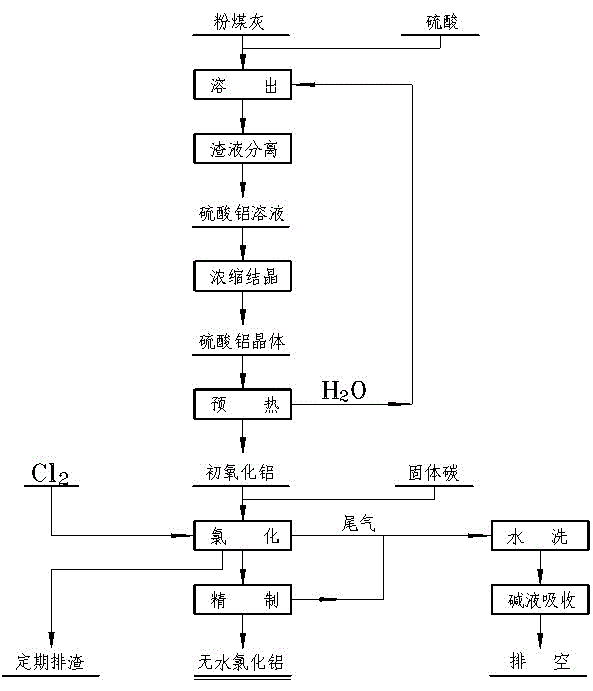

Preparation method of anhydrous aluminum chloride

ActiveCN103936047AReduce consumptionReduce manufacturing costAluminium chloridesSolid carbonElectrolysis

The invention discloses a preparation method of anhydrous aluminum chloride; and the method is as follows: using fly ash or aluminum ore with more than 25% of alumina as a raw material for leaching with sulfuric acid to obtain an aluminum sulfate solution, then concentrating for crystallization to obtain an aluminum sulfate crystal, and preheating at above 80 DEG C for more than 30 minutes to remove crystal water to obtain aluminum sulfate; mixing the aluminum sulfate and solid carbon, then adding into a chlorination furnace with the temperature above 600 DEG C and the pressure of normal pressure or slightly negative pressure, letting in chlorine gas to produce an anhydrous aluminum chloride mixed gas with the mass percent content of more than 30%, and then refining and purifying to obtain the anhydrous aluminum chloride with a purity above 99%. Chlorination tail gas is washed with water, absorbed by use of an alkaline solution, and then discharged. The preparation method has the characteristics cheap and easily-available raw materials, less energy consumption, simple process, easiness in industrial large-scale production and the like. Because of the characteristics, the preparation method is especially suitable for the anhydrous aluminum chloride preparation in the production of metal aluminum by aluminum chloride molten salt electrolysis method.

Owner:GUIYANG AL-MG DESIGN & RES INST

Lithium ion battery electrode material preparation method

ActiveCN106981661AImprove conductivityWide variety of sourcesCell electrodesSecondary cellsChemical reactionHigh energy

The invention relates to a lithium ion battery electrode material preparation method. The method includes: well mixing anhydrous aluminum chloride and sodium chloride, heating and stirring to obtain a fused salt phase; well mixing a fused ring compound with anhydride according to a molar ratio of 1:1, adding into the fused salt phase, well mixing, and calcining; adding products obtained after calcination into hydrochloric acid solution, stirring for acidolysis for 12-48h, and leaching to obtain a crude product; sequentially subjecting the crude product to reflux with deionized water, ethyl alcohol and methyl benzene for one time, and performing vacuum drying to obtain a lithium ion battery electrode material. The method is simple, feasible, low in cost, green and environmental friendly, and completion in fused salt systems such as NaCl-AlCl3 can be realized; by binary or polybasic copolycondensation, flaws are introduced into the material to reduce intermolecular close packing and enhance electrochemical reaction activity of the electrode material; by doping of heteroatoms, electrical conductivity of the material is effectively improved; high energy density, high specific capacity and excellent rate and cycle performances are realized.

Owner:NANJING UNIV OF TECH

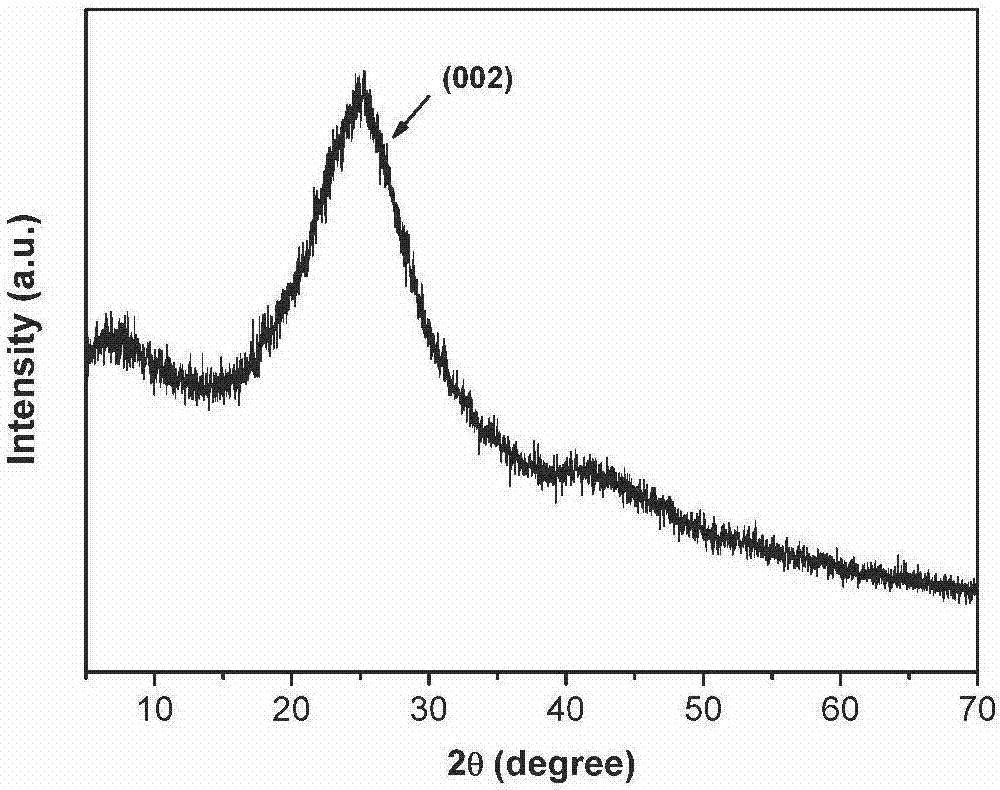

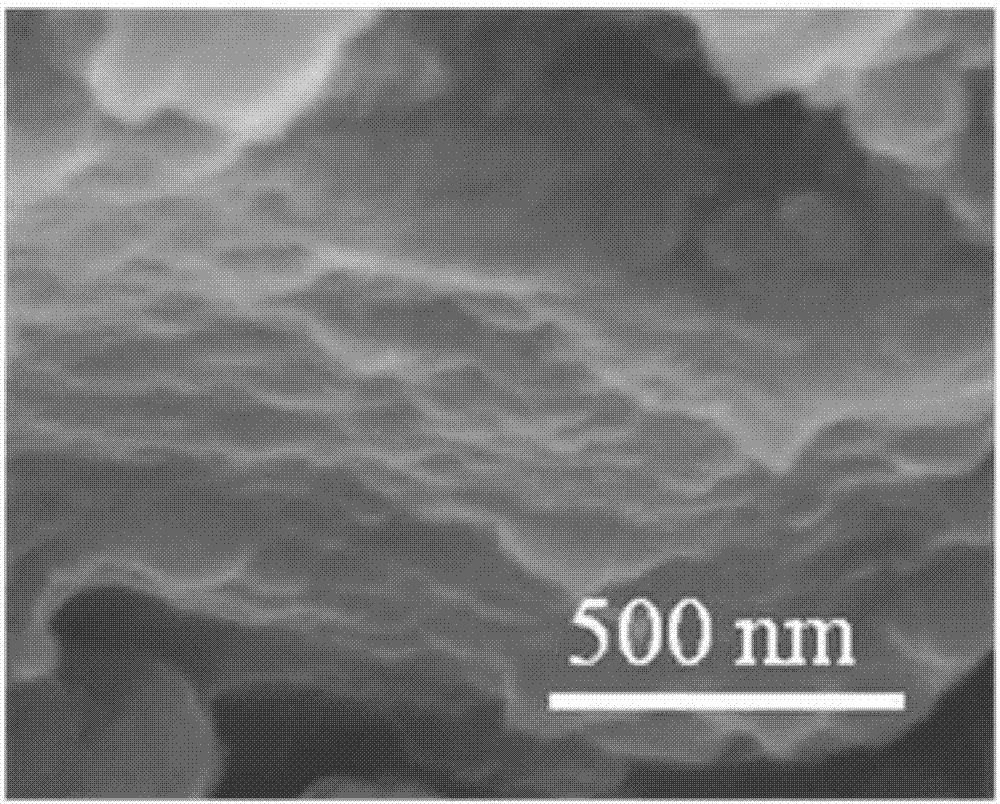

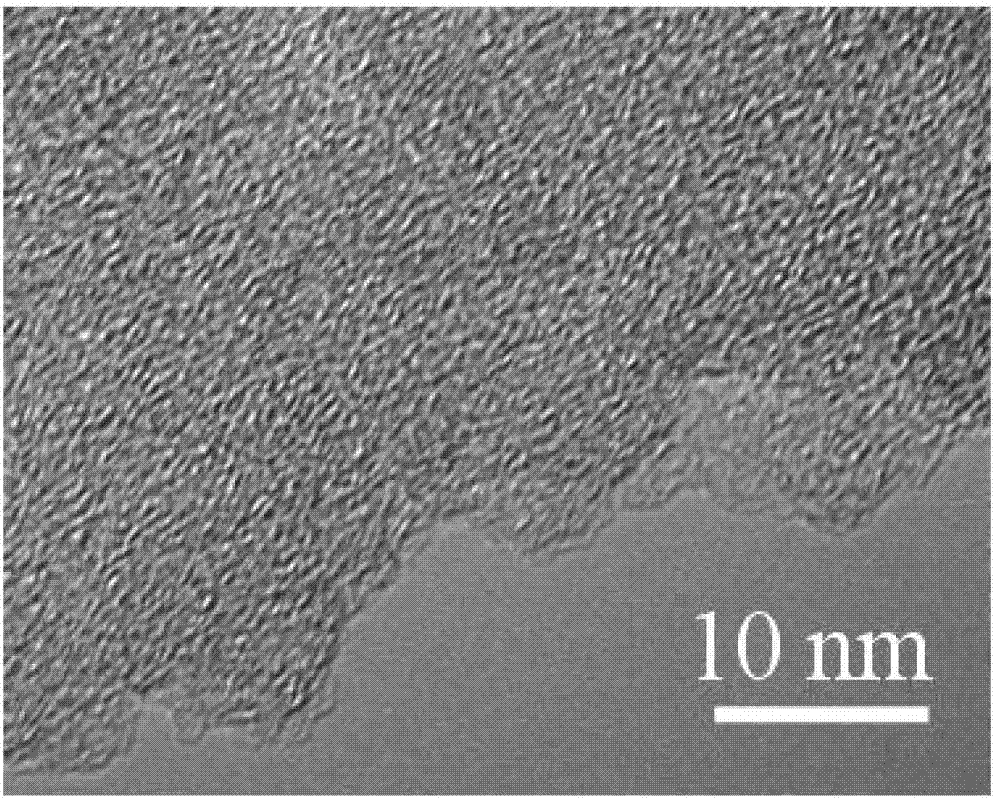

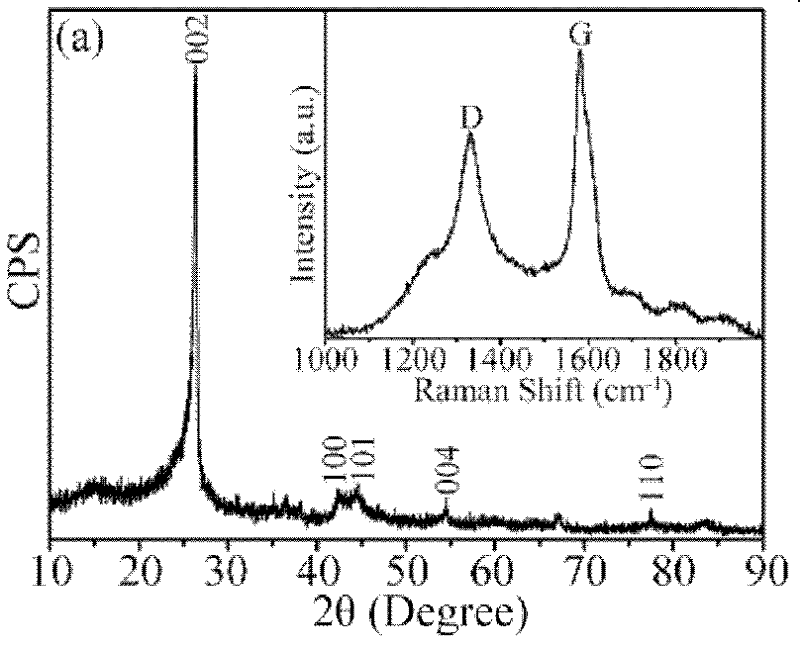

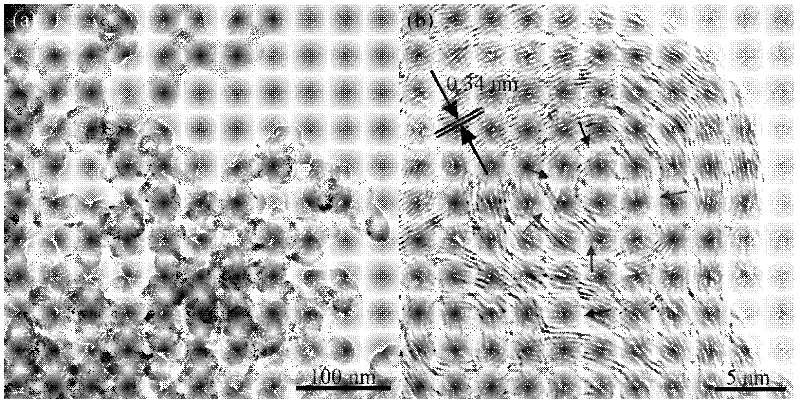

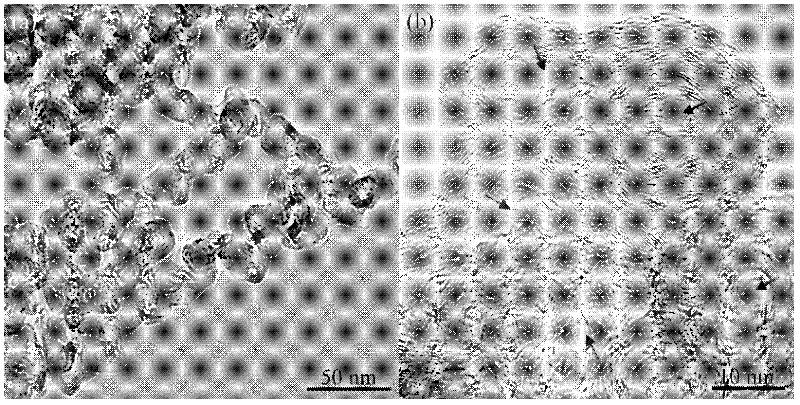

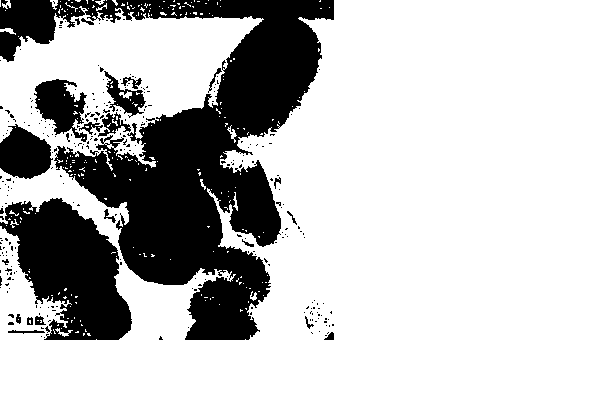

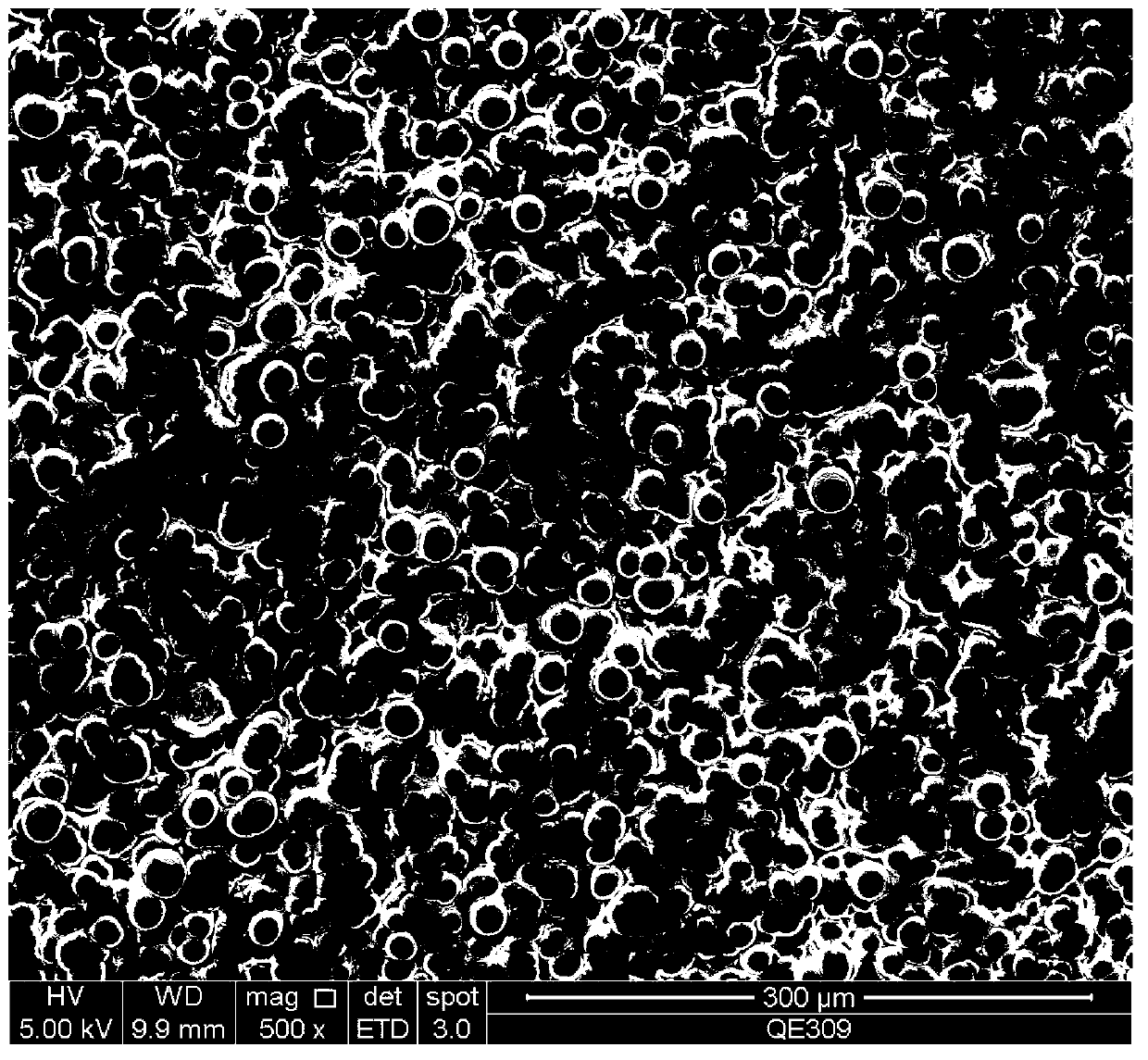

Method for preparing highly-graphitized hollow carbon nanocapsules by using low-temperature reaction

The invention relates to a method for preparing highly-graphitized hollow carbon nanocapsules by using a low-temperature reaction. The method comprises the following steps of: reacting carbon carbide with aluminum chloride hexahydrate for 2-5h at 250-500 DEG C; or reacting the carbon carbide with cobalt chloride hexahydrate for 2-5h at 250-500 DEG C to obtain solid nanocapsules; then mixing the solid nanocapsules with anhydrous aluminum chloride; and heating to 250-500 DEG C, preserving temperature and reacting for 4-5h. The method disclosed by the invention has the advantages of low reactiontemperature, short reaction time and low cost; and the prepared hollow nanocapsules have the advantages of uniform size, high graphitization degree, high purity and high yield.

Owner:SHANDONG UNIV

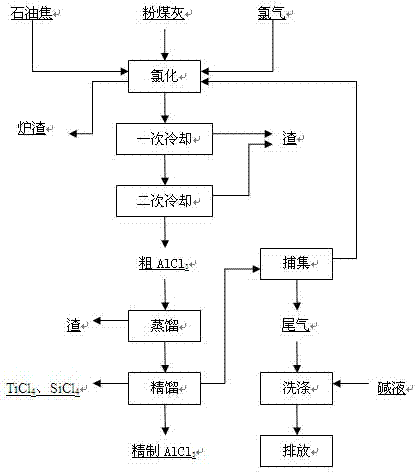

Refining process method for producing anhydrous aluminum chloride through high aluminum fly ash

InactiveCN104773747ARaw materials are cheap and easy to getHigh purityAluminium chloridesDistillationChloride

The present invention discloses a refining process method for producing anhydrous aluminum chloride through high aluminum fly ash, wherein high aluminum fly ash (the alumina content is more than or equal to 25%) is adopted as a raw material, a carbon value reducing agent is matched, chlorine gas is introduced to carry out a chlorination reaction, and the mixed gas discharged from a chlorination furnace is subjected to treatments such as cooling, distillation and rectification to prepare the anhydrous aluminum chloride product meeting the national standard. The method of the present invention has characteristics of cheap and easily available raw material, high product purity, easy large-scale industrial production, and the like.

Owner:GUIYANG AL-MG DESIGN & RES INST

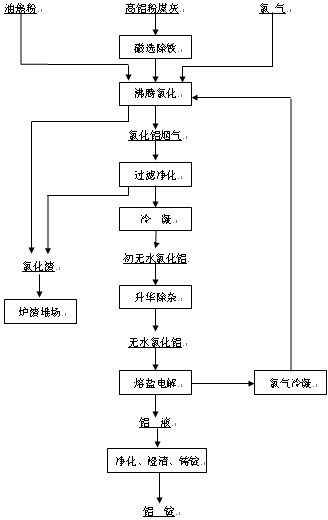

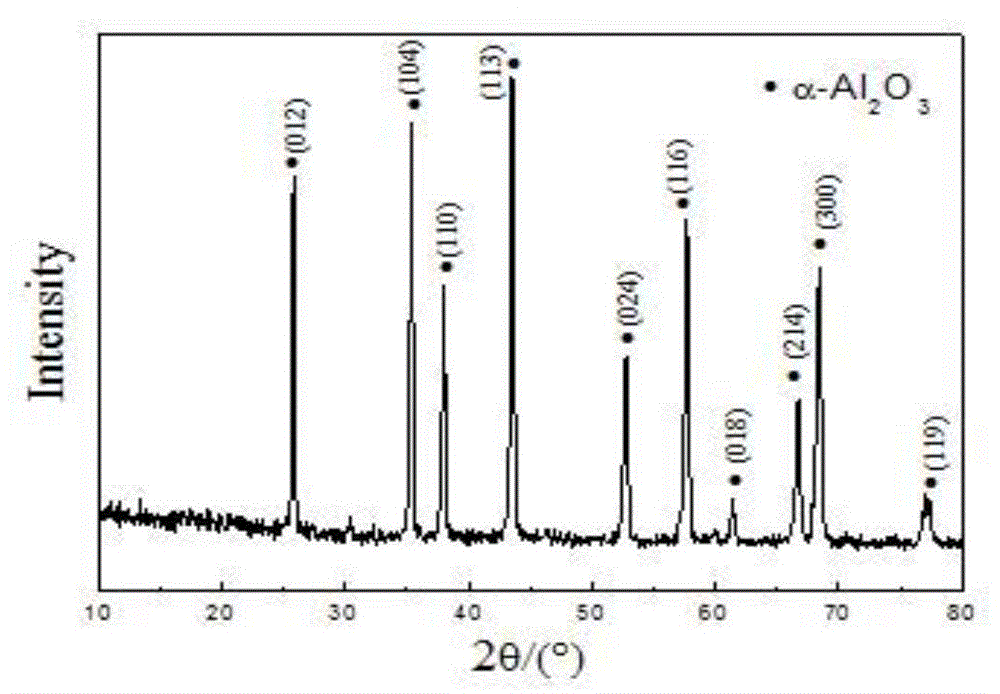

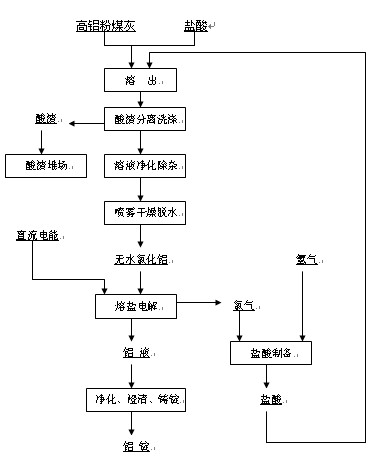

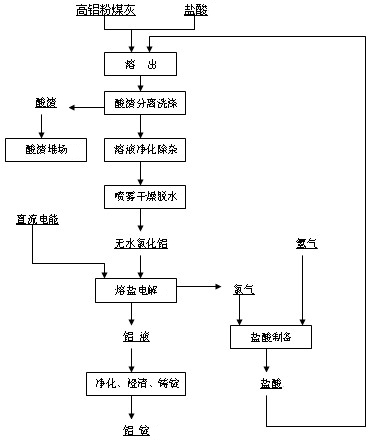

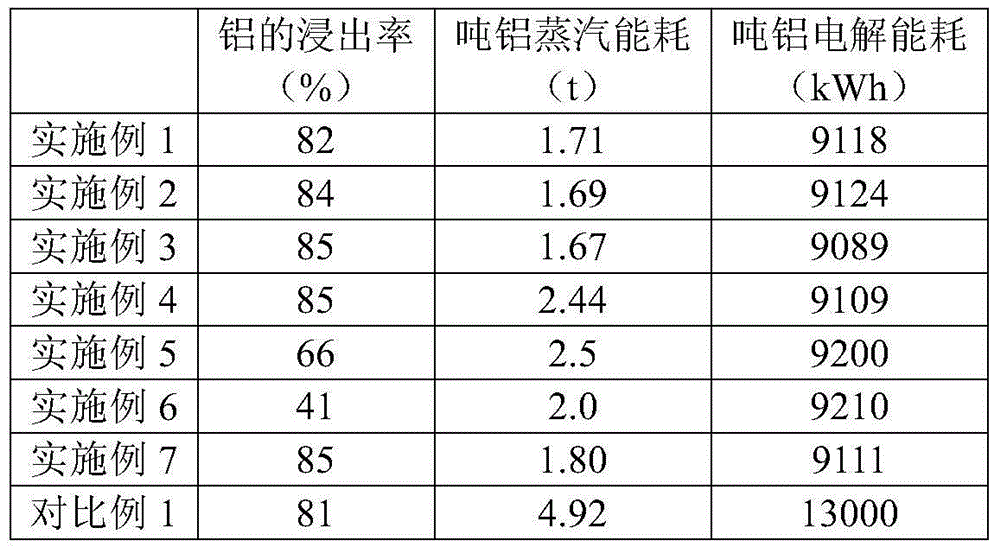

Method for producing metal aluminium by high-alumina fly ash chlorination electrolysis

The invention discloses a method for producing metal aluminium by high-alumina fly ash chlorination electrolysis, which comprises the following process steps: firstly, magnetic separation of fly ash to remove iron; secondly, fluidizing chlorination, that is, mixing high-alumina fly ash and oil coke powder, adding the mixture into a fluidizing chlorination furnace, introducing chlorine into the furnace to allow the alumina in the fly ash to react completely so as to obtain aluminium chloride double molecular flue gas; thirdly, processing and purification of the aluminium chloride flue gas, that is, purifying the aluminium chloride flue gas by a filter, cooling the purified aluminium chloride flue gas in a condenser to condense other chloride impurities, discharging the impurities out of the flow in a form of ash, continuing cooling the flue gas in a trap to obtain raw anhydrous aluminum chloride crystals, performing impurity removal and sublimation purification of the raw anhydrous aluminum chloride crystals by an aluminium chloride sublimation purification furnace; fourthly, molten salt electrolysis, that is, adding the anhydrous aluminum chloride into an aluminium chloride electrolytic tank, performing electrolysis to obtain aluminium liquid, casting the obtained aluminium liquid to prepare aluminum ingots. The process of the invention is used for processing high-alumina fly ash to obtain aluminum ingots, and fly ash is utilized reasonably.

Owner:GUIYANG AL-MG DESIGN & RES INST

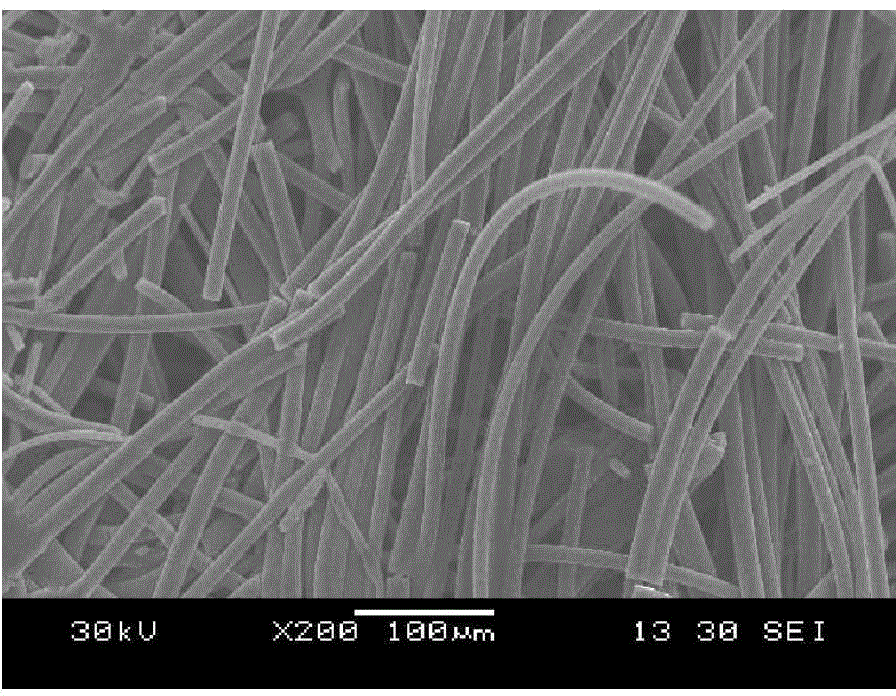

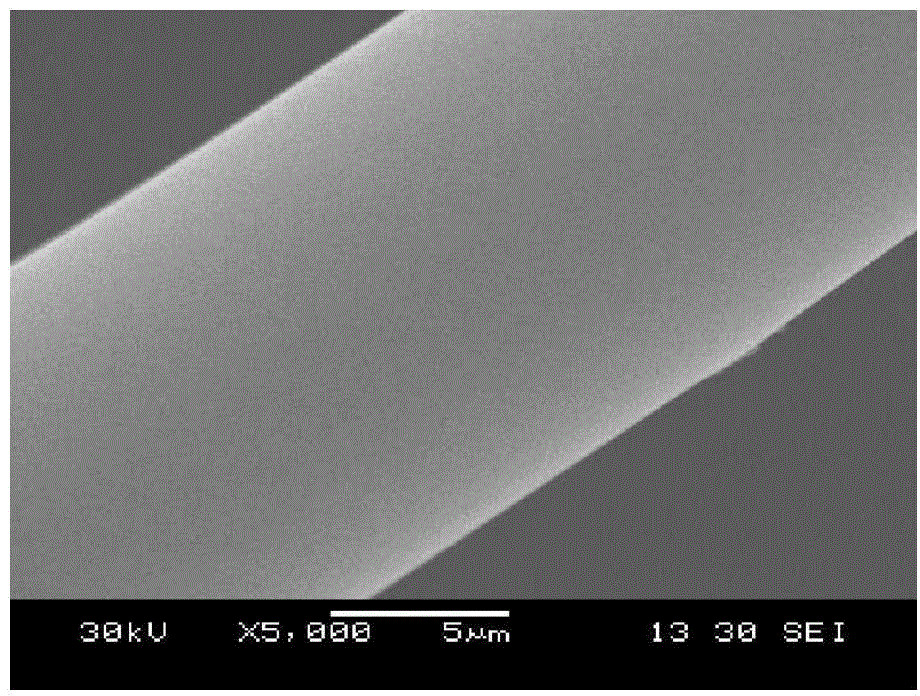

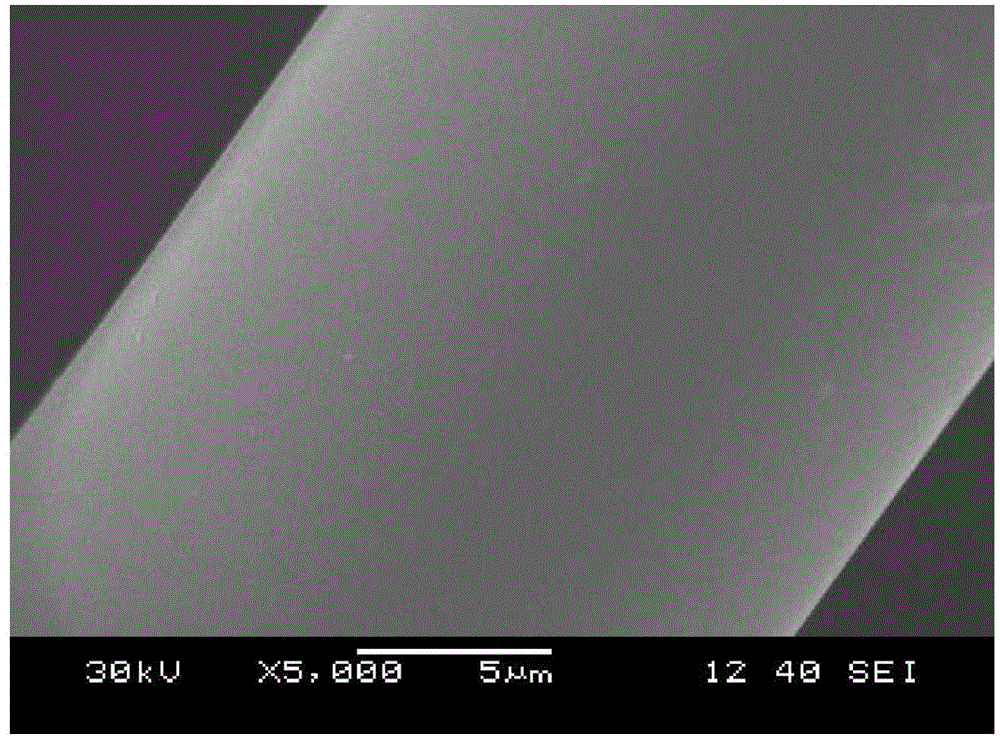

High-purity alumina fiber and preparation method thereof

The invention discloses a preparation method of a high-purity alumina fiber. The alumina fiber takes anhydrous aluminium chloride and aluminium micro powder as raw materials and acetic acid or lactic acid as a stabilizer and a spinning auxiliary and is added with an oxide second phase (MgO, SiO2, Y2O3, ZrO2 and the like) with mass fraction of 0-2%, so that mechanical properties of the alumina fiber at room temperature and high temperature are improved. An alumina fibreboard is composed of alumina fibers, an inorganic binder, an organic binder and an additive in a mass ratio of (30-40) to (55-65) to (0-1) to (4-5). A preparation method of the alumina fibreboard is characterized by comprising the following steps: preparing colloid, carrying out centrifugal spinning, preparing alumina fibers, preparing a wet blank, carrying out high temperature treatment, and machining, so that the alumina fibreboard finished product is obtained. The high-purity alumina fiber product has excellent thermal insulation properties and mechanical properties, and an operating temperature is increased, so that an operating temperature range of a similar product is expanded.

Owner:南京理工宇龙新材料科技股份有限公司

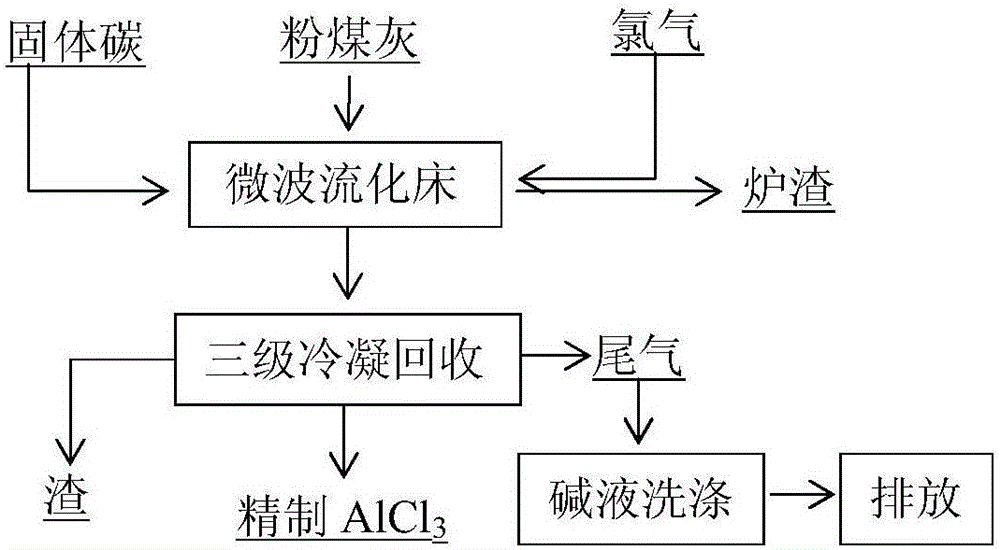

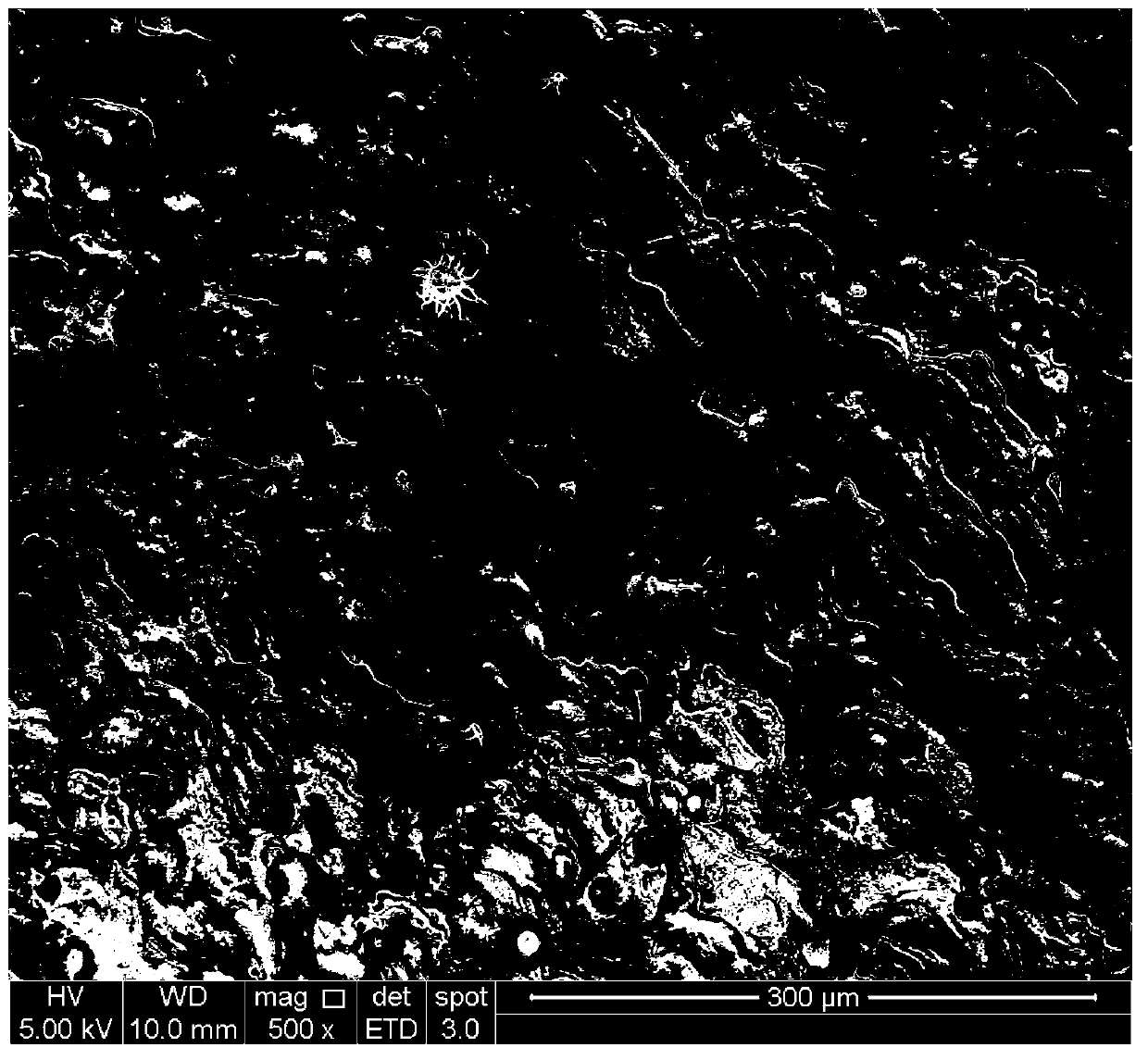

Method for preparing anhydrous aluminum chloride by microwave chlorination of fly ash

InactiveCN106006692AFast heatingRapid responseAluminium chloridesEnergy based chemical/physical/physico-chemical processesAluminium chlorideSolid carbon

The invention relates to a method for preparing anhydrous aluminum chloride by microwave chlorination of fly ash and belongs to the technical field of aluminum chloride production. The method comprises a step 1 of causing high-alumina fly ash to undergo microwave heating chlorination decomposition: adding the high-alumina fly ash into solid carbon, performing mixing evenly, leading chlorine into the mixture, adopting a microwave fluidized bed with a microwave frequency of 2.3-2.5 GHz to perform heating for 5-60 min to reach 300-1200 DEG C, maintaining the constant temperature for 10-60 min, fully decomposing the high-alumina fly ash, and obtaining various chlorinated mixed gases containing aluminum chloride; a step 2 of performing separation and purification: causing the various chlorinated mixed gases containing aluminum chloride to undergo impurity removal and refining through a three-level condensation recycling device, and obtaining the anhydrous aluminum chloride product with a purity of larger than 99%. According to the method, the fly ash is adopted as a raw material to directly produce anhydrous aluminum chloride, the additional value of the product is improved, and the shortcomings of complexity in operation, high energy consumption and high production cost in the prior art are overcome through the method.

Owner:NORTHEASTERN UNIV

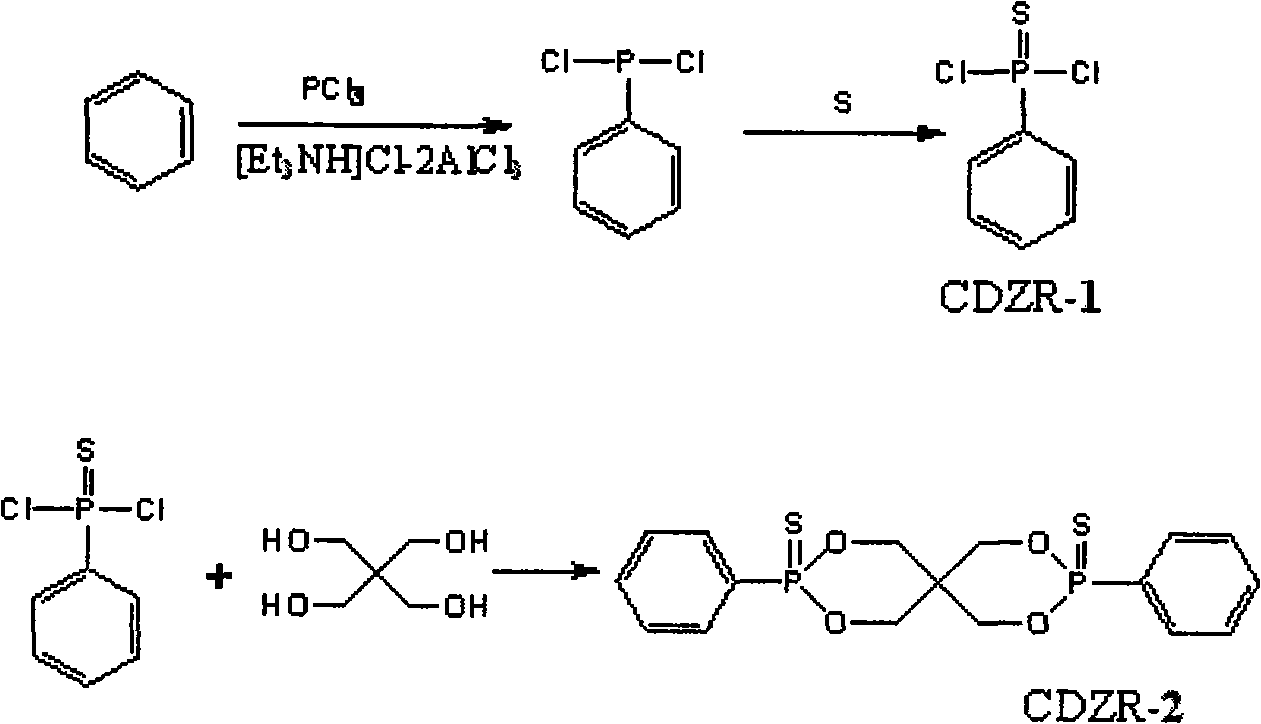

Preparation method of combustion inhibitor containing P-S

InactiveCN101586032AGood char formationAvoid problems that cannot be removedGroup 5/15 element organic compoundsAluminium chlorideNitrogen gas

The invention relates to a preparation method of combustion inhibitor containing P-S, which includes the steps: (1) under the nitrogen gas atmosphere, adding triethylamine hydrochloride and anhydrous aluminium chloride, mixing; (2) adding benzene into refluxing liquid of PCl3 and [Et3NH]Cl-2AlCl3 for refluxing reaction; vacuum distilling, and then adding sulphur powder in batches for continue reaction; adding petroleum ether and stirring, separating and collecting petroleum ether phase on upper layer, washing, drying; pressure reducing and steaming petroleum ether; collecting distillate; dispersing pentaerythritol and pyridine in carrene, dropping sulfo-phenylphosphono with stirring for refluxing reaction, after the reaction ends, rotary steaming, water washing and recrystallizating. The combustion inhibitor provided the invention has good char formation.

Owner:DONGHUA UNIV +1

Preparation method of polyamino phosphoric acid functional-born polyether sulfone functional separating membrane

ActiveCN106823824AEfficient removalEasy to operateMembranesSemi-permeable membranesPhosphorous acidPhosphorylation

The invention relates to a preparation method of polyamino phosphoric acid functional-born polyether sulfone functional separating membrane. The preparation method mainly comprises the following steps: by taking trichloromethane, chloroacetyl chloride and anhydrous aluminum chloride as main reagents, performing chloracetylation to the polyether sulfone at room temperature; then by taking N,N-dimethylacetylamide as a solvent and tetraethylenepentamine as an amination reagent, performing amination to the polyether sulfone, subjected to chloracetylation, at the temperature of 80-85DEG C, and preparing chloroacetyl chloride-tetraethylenepentamine- polyether sulfone anion-exchange membrane; then in methanol and triethylamine solution, by taking paraformaldehyde and phosphorous acid as reagents, performing phosphorylation graft modification to the chloroacetyl chloride-tetraethylenepentamine- polyether sulfone anion-exchange membrane, to prepare the polyamino phosphoric acid functional-born polyether sulfone functional separating membrane. The preparation method has good technological stability, the chelated functional groups of the prepared polyether sulfone functional separating membrane are difficult to lose, and the heavy metal pollutants in water environment can be effectively removed.

Owner:YANSHAN UNIV

Method for electroplating aluminum in ionic liquid

InactiveCN102839403ALower operating temperatureReduce energy consumptionAluminum coatingIonic liquid

The invention provides a method for electroplating aluminum in ionic liquid. The method solves problems that the conventional electroplating aluminum technology has the advantages that energy is consumed, cost is high, a plating liquid environment is rigorous, and the obtained aluminum coating has poor brightness and is easy to be dropped and the like. The method comprises the following steps of: uniformly mixing the liquid which is obtained by heating and mixing urea, halons and amide with aluminum chloride anhydrous so as to obtain the ionic liquid served as the electroplating liquid; controlling an electroplating temperature, current density and electroplating time so as to carry out electroplating; and then glaring through nitric acid solution; and passivating via potassium permanganate solution. The method has lower cost of electroplating, and is stable in electroplating technology, and environment-friendly; and the obtained aluminum coating surface is dense and uniform, and has good brightness, and can be combined with a base body greatly; and the method is suitable for protecting and decorating a surface of a common material.

Owner:TAIYUAN UNIV OF TECH

Process method for producing metal aluminium by high-alumina fly ash

ActiveCN102642857AReasonable useSolve the pollution problemAluminium chloridesProcess efficiency improvementAluminium chlorideElectrolysis

The invention discloses a process method for producing metal aluminium by high-alumina fly ash, which comprises the following process steps: firstly, dissolving fly ash out, that is, mixing high-alumina fly ash containing not less than 38% of Al2O3 with hydrochloric acid with a concentration of 20-30% to prepare raw pulp, dissolving out alumina in the fly ash at a high temperature through a continuous dissolving mode of heat insulation dissolution by a preheater and an autoclave; secondly, separating and washing acid sludge, and purifying an aluminium chloride solution for impurity removal; thirdly, performing spray drying and dehydration to obtain anhydrous aluminium chloride crystal particles; fourthly, electrolyzing the molten salts, that is, adding the anhydrous aluminium chloride into an aluminium chloride electrolytic tank, dissolving the anhydrous aluminium chloride in a molten electrolyte, wherein the temperature in the electrolytic tank is 670-700 DEG C, performing electrolyzation to obtain aluminium liquid, delivering the aluminium liquid to a casting procedure, performing purification and clarification, then preparing aluminum ingots, delivering the chlorine generated at an anode of the electrolytic tank to a hydrochloric acid preparation procedure; fifthly, preparing hydrochloric acid. The process of the invention obtains aluminum ingots by treating high-alumina fly ash, which make reasonable use of fly ash.

Owner:GUIYANG AL-MG DESIGN & RES INST

Cleaning catalyst for automobile exhaust and preparation method of cleaning catalyst carrier

ActiveCN103007955ALow costHigh activityCatalyst carriersDispersed particle separationCerium nitratePolyethylene glycol

The invention provides a cleaning catalyst for automobile exhaust and a preparation method of a cleaning catalyst carrier. The catalyst comprises a carrier, an aid coating coated on the carrier, and an active ingredient loaded on the carrier coating, wherein the active ingredient is a mixed metallic oxide of yttrium, lanthanum, cerium, zirconium, manganese, copper and nickel; the carrier contains alumina and rare-earth lanthanum cerium oxide; and the aid coating is one or several oxides containing lanthanum, cerium, yttrium and zirconium. The preparation method of the carrier comprises the following steps of: hydrolyzing anhydrous aluminum chloride to prepare high-purity alumina, and preparing a saturated solution of lanthanum and cerium nitrate; adding the saturated solution into alumina, stirring, drying, grinding, mixing with graphite and polyethylene glycol, performing mold pressing and roasting. The catalyst has the characteristics that platinum, rhodium and other precious metals are not used, the cost is low, the activity is high, the heat, ageing and oxidization resistance capabilities are high, and the preparation process is simple.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Dissolution method of aluminum from fly ash

The invention discloses a dissolution method of aluminum from fly ash. The method comprises the following steps of: S1, pretreating the fly ash; S2, adding a hydrochloric acid alcohol solution into the pretreated fly ash to carry out an acid dissolution treatment so as to obtain acid soluble products; S3, carrying out solid-liquid separation on the acid soluble products to obtain an alcohol solution of aluminum chloride; S4, evaporating the alcohol solution of aluminum chloride and carrying out solid electrolysis on obtained anhydrous aluminum chloride to obtain primary aluminum. The acid dissolution treatment and the solid-liquid separation are carried out on fluidized bed fly ash with higher reactivity by using the hydrochloric acid alcohol solution, then the alcohol solution of aluminum chloride can be obtained, the alcohol solution of aluminum chloride is evaporated to obtain the anhydrous aluminum chloride, and the anhydrous aluminum chloride is electrolyzed to obtain the primary aluminum. According to dissolution method disclosed by the invention, steps of hydrochloric acid aqueous solution evaporative crystallization and high temperature sintering are eliminated and technological process is simplified. The energy consumed for evaporating the alcohol solution is further lower than that consumed for evaporating a hydrochloric acid aqueous solution, so that the energy is saved and the cost is greatly reduced.

Owner:CHINA SHENHUA ENERGY CO LTD +1

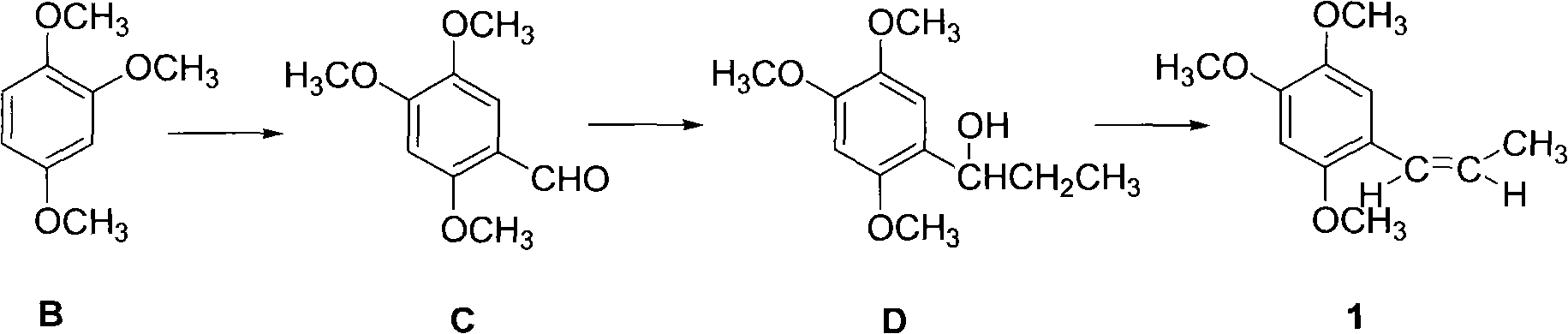

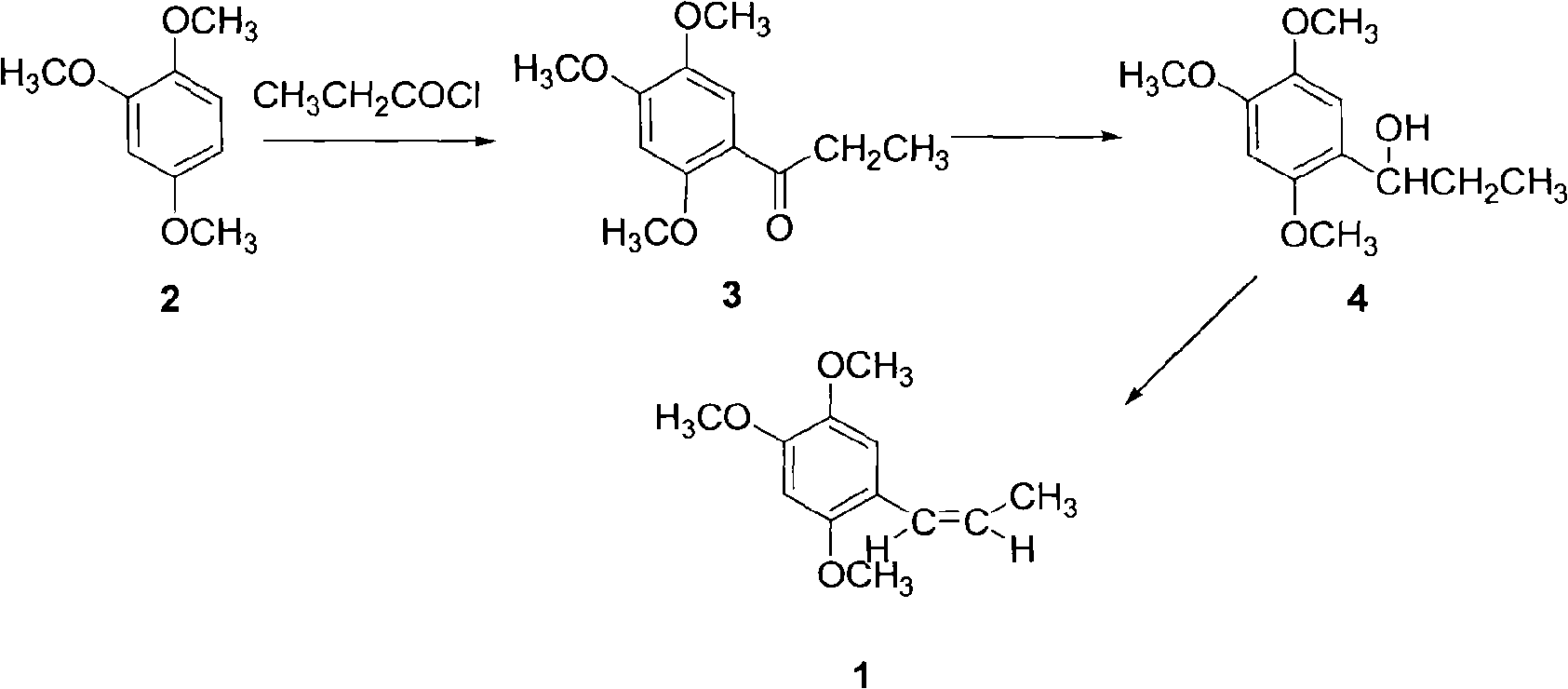

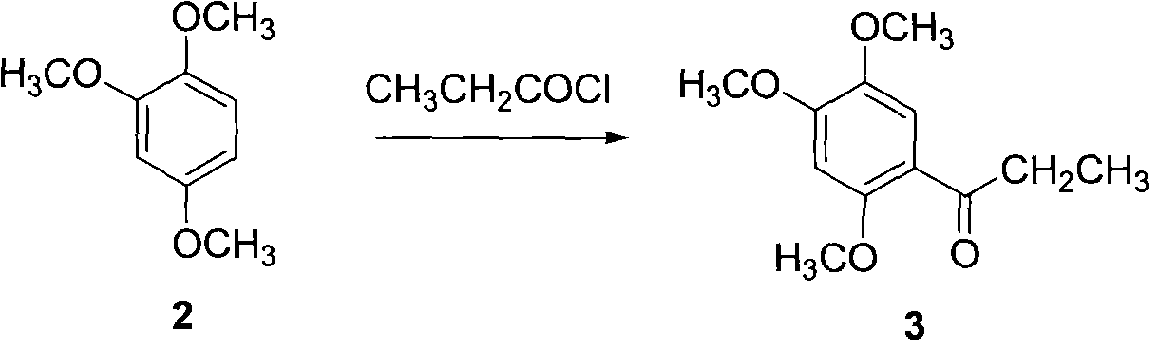

Process for producing asarin

InactiveCN101492351ALow priceReduce manufacturing costOrganic chemistryOrganic compound preparationPropionyl chloridePropionic anhydride

As during the process of preparing asarin from 1, 2, 4-trimethoxybenzene, the raw materials of propionic anhydride, propionyl chloride, anhydrous aluminum chloride, anhydrous zinc chloride, dichloromethane, sodium borohydride, sodium propionate and the like with low prices are used, the production cost is lowered greatly. At the same time, the post treatment of the invention is convenient; products of each step are all solids which are convenient for detecting; the reaction yield of each step is high; and the production process generates few three wastes. In conclusion, in the invention, the 1, 2, 4-trimethoxybenzene which is obtained easily in China is used as a raw material to prepare the asarin by the reactions such as acidylation and the like; the invention has low cost, safe and simple operation, high reaction yield and less environmental pollution; and compared with the existing reported method, the invention is fit for the industrialized production better.

Owner:亚邦化工集团有限公司

Method for preparing polydiallyl itaconate and dimer acid

ActiveCN101293829AReduce dosageEasy to removeOrganic compound preparationCarboxylic acid esters preparationCatalytic methodDecomposition

The invention relates to a method for preparing dimeric acid methyl ester and dimer acid thereof. The method comprises the following steps: performing dimerization reaction of mixed fatty acid methyl ester having high unsaturated fatty acid methyl ester content or mixed fatty acid in the presence of concentrated sulfuric acid as co-catalyst and anhydrous aluminum chloride or anhydrous zinc chloride as catalyst using two step catalytic method; and solving with weak alkali diluted solution (the pH value is 7-8), washing for removing the catalyst to obtain coarse dimmer (yield of more than 80%), and further performing molecular distillation of coarse dimeric fatty acid methyl ester or coarse dimeric fatty acid in certain condition for removing monomer to reach dimmer content of greater than 90%. The method is carried out at normal pressure with less catalyst which can be removed easily. The coarse product is separated using an advanced molecular distillation device to avoid dimmer decomposition and occurrence of other byproducts at high temperature, and improve product purity. The method has simple process, easy operation, reduced energy source and reduced cost.

Owner:溧阳常大技术转移中心有限公司

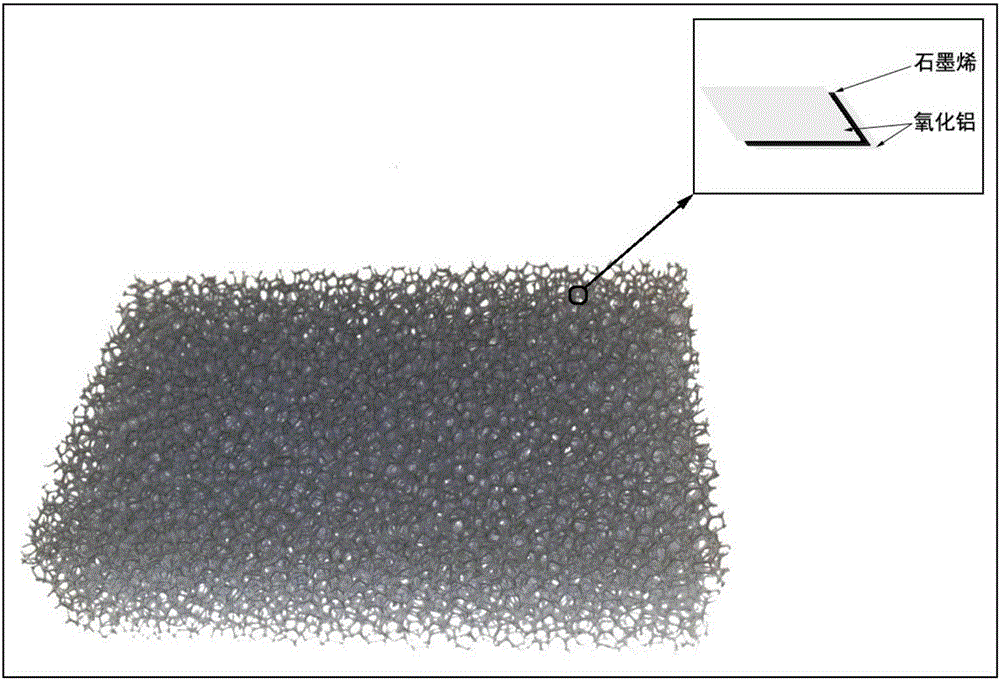

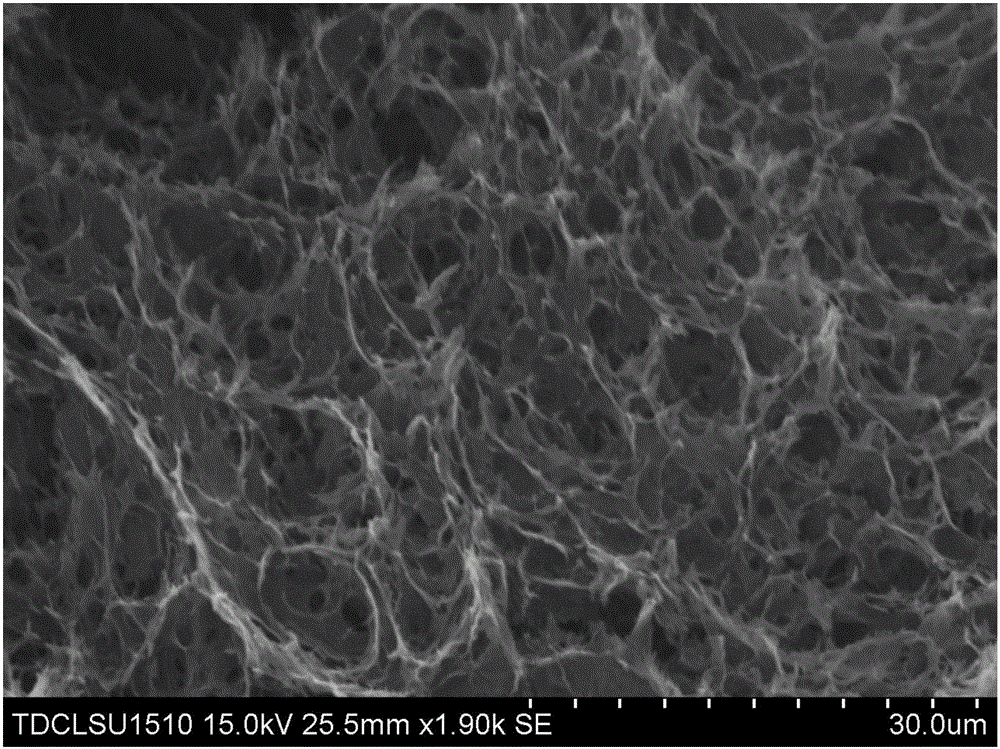

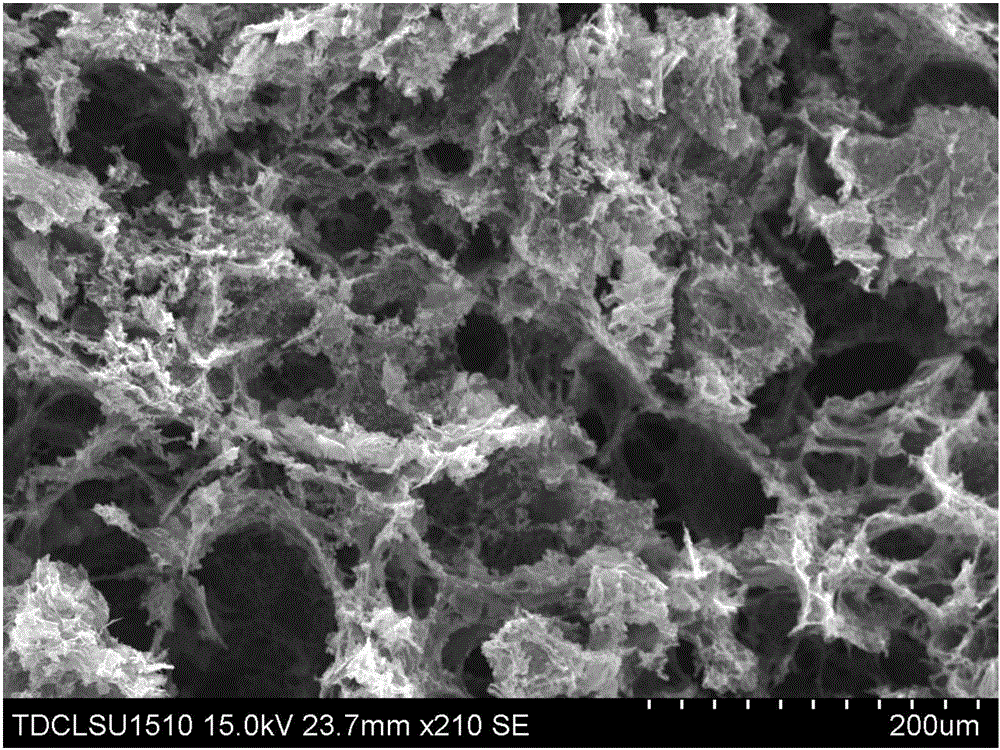

Preparation method of high-temperature and oxidation resisting heat conduction alumina/graphene foam composite material

ActiveCN105923641AAchieve compositeThermally conductiveAluminium oxide/hydroxide preparationOxidation resistantUltrasonic dispersion

The invention relates to a preparation method of a high-temperature and oxidation resisting heat conduction alumina / graphene foam composite material. The preparation method comprises the following steps: placing an aqueous solution of graphene oxide in a hydrothermal reaction kettle, heating the aqueous solution to 170-200DEG C, keeping the temperature for 10-14h, cooling the heated aqueous solution to obtain graphene hydrogel, adding pure graphene aerogel obtained after lyophilization and anhydrous aluminum chloride powder to a solvent, and carrying out ultrasonic dispersion; adding the above prepared mixed suspension to the hydrothermal reaction kettle, heating the mixed suspension to 180-300DEG C, and keeping the temperature for 10-22h; displacing the solvent of the above prepared graphene / aluminum hydroxide mixed sol with deionized water, lyophilizing the obtained sol, and calcining the lyophilized graphene / aluminum hydroxide mixed aerogel at 950-1300DEG C for 10-20h to obtain the alumina / graphene foam composite material. The thermal weight loss of the composite material is lower than 60% after the composite material is ablated at 800DEG C for 5h, and the heat conductivity of the composite material is higher than 9W / m.K.

Owner:TIANJIN UNIV

Preparation method of aluminum oxide powder

InactiveCN103351012AControl reaction temperatureControl stirring speedAluminium oxides/hydroxidesReaction temperatureTwo temperature

The invention relates to a preparation method of aluminum oxide powder and particularly relates to a preparation method of high-purity aluminum oxide powder. The preparation method is characterized in that according to the preparation process, anhydrous aluminum chloride and ammonia water are taken as raw materials, sublimation, desublimation and purification are firstly performed on the anhydrous aluminum chloride, then a solution is prepared, the solution is neutralized with the ammonia water under stirring to obtain aluminum hydroxide powder, and drying and high-temperature calcination are further performed to obtain the aluminum oxide powder. According to the preparation method of the aluminum oxide powder, the anhydrous aluminum chloride is taken as the raw material, a two-temperature region is used for sublimation, desublimation and purification, chemical neutralization reaction is further performed with the ammonia water, reaction temperature, stirring speed and feeding speed are further controlled to obtain the aluminum hydroxide powder with high purity and good filtering property, and drying and high-temperature calcination are performed to obtain the high-purity aluminum oxide powder with the purity being not lower than 99.95%. The preparation method has the advantages of simple process, low production cost, two-step purification, high purity of the obtained aluminum oxide and no production of colloids during neutralization reaction.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Modified polyethylene resin and preparation method thereof

InactiveCN102924796AFlexibleImprove flame retardant performanceLow-density polyethyleneAluminium chloride

The invention discloses modified polyethylene resin and a preparation method thereof. The preparation method comprises the following steps of: firstly mixing materials into a high-speed mixer by using linear low-density polyethylene (LLDPE), low-density high-pressure polyethylene (LDPE), polyvinyl chloride resin (PVC), polystyrene resin or a polyvinyl benzene monomer as raw materials and adding epoxidized soybean oil, stearic acid, anhydrous aluminium chloride, magnesium oxide, polyvinyl alcohol and sodium silicate at the temperature of below 60 DEG C; continuously mixing the materials into the high-speed mixer; cooling the materials to 40-45 DEG C when the temperature of the materials reaches 90-120 DEG C; adding the cooled materials into a double-screw pelletizer to pelletize under a high temperature condition; and cooling and slicing the materials to obtain a finished product. Compared with polyethylene (PE) resin, the flame retardancy of the modified polyethylene resin is improved by twice, and the melting oxygen index is improved from 13 to over 27; and moreover, compared with the common resin materials, the modified polyethylene resin has better mechanical property and is wider in using range.

Owner:WENAN COUNTY XINGYUAN PLASTIC IND CO LTD

Method of preparing anhydrous aluminium chloride

The present invention is one method of preparing anhydride aluminum chloride with simple technological process, no waste gas exhaust and high purity product. The aluminum chloride hexahydrate material is first compounded into water solution, C1-C4 alcohol is then added into the water solution for separating crystal, and the separated crystal as anhydride aluminum chloride product is finally separated from the solid-liquid mixture. The liquid after solid-liquid separation has main component alcohol and may be reused. The said process can eliminate impurity from aluminum chloride hexahydrateto obtain high purity anhydride aluminum chloride.

Owner:章浩龙

Preparation method of Al-Mn alloy prevention plating layer on surface of metallic matrix

InactiveCN103103588ASolving difficult-to-plate problemsAvoid corrosionMetallic materialsRoom temperature

The invention provides a preparation method of an Al-Mn alloy prevention plating layer on the surface of a metallic matrix. Specifically, the invention provides a preparation method of an Al-Mn alloy prevention plating layer on the surface of the metallic matrix by utilizing an ion liquid through electro-depositing. The Al-Mn alloy prevention plating layer can be obtained from electro-deposition in a room temperature ion liquid system. An electroplating liquid is formed by preparing R1R2IC, AlCl3 and MnCl2. Compared with originally electro-depositing a metallic prevention plating layer in a water solution, the prevention plating layer is more compact and smoother, and is better combined with the matrix, the corrosion resistance property is obviously improved, and the properties are superior to those of the ion liquid-electro-deposited pure aluminum prevention plating layer. In addition, the ion liquid is not burnt and evaporated, can be repeatedly used, is incapable of producing electroplating waste water, and is green and environment-friendly.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

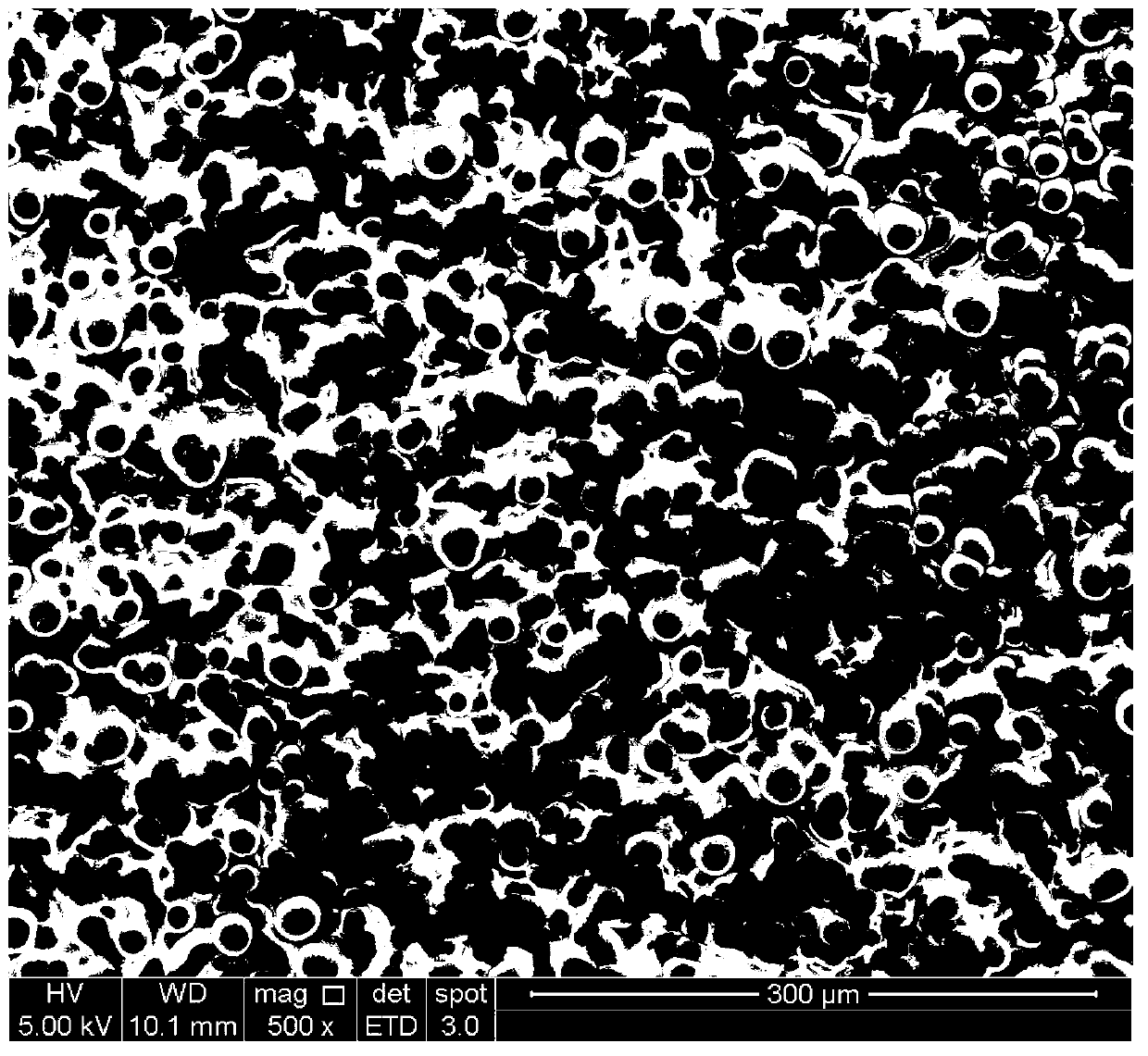

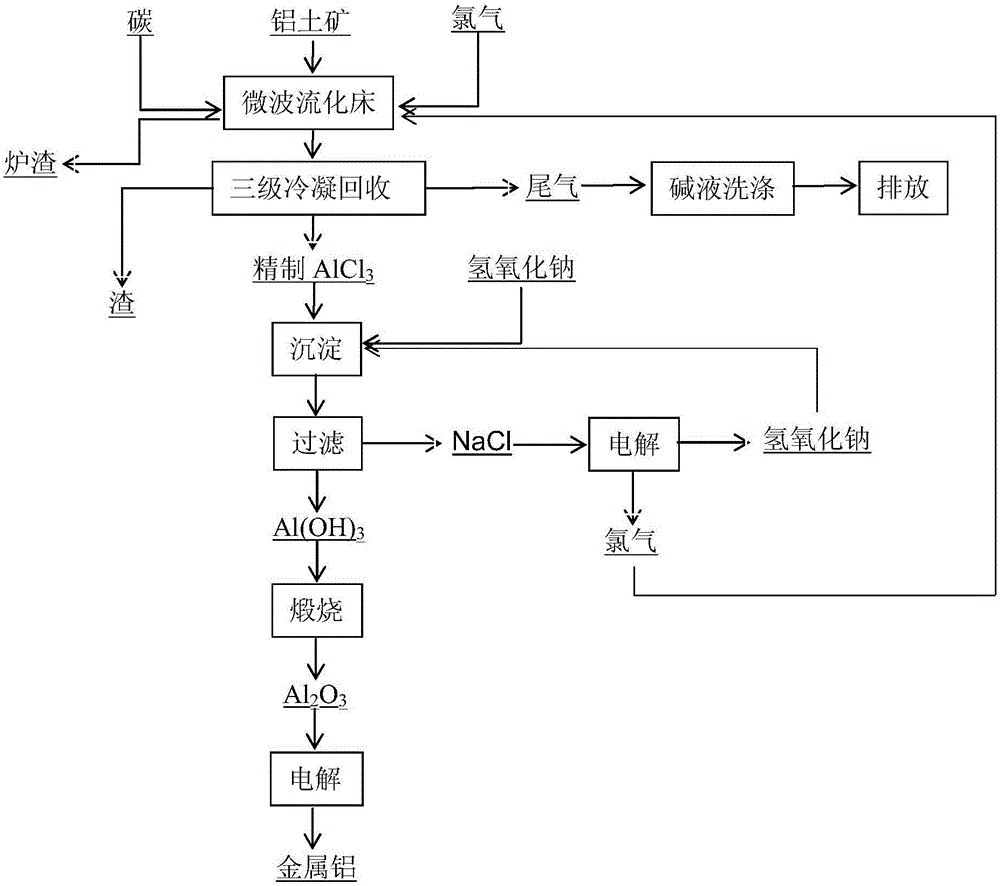

Method for preparing metal aluminum from bauxite through microwave chlorination

ActiveCN106011498AFast heatingRapid responseElectrolysis componentsAluminium chloridesElectrolysisFiltration

A method for preparing metal aluminum from bauxite through microwave chlorination specifically includes the following steps that carbon is added in the bauxite to be evenly mixed, chlorine is pumped in, heating is conducted through a microwave fluidized bed for 5 min to 50 min, the temperature ranging from 300 DEG C to 900 DEG C is achieved, the temperature keeps constant for 10 min to 60 min, the bauxite is sufficiently decomposed, various types of chlorination mixed gas containing aluminum chloride is obtained, and then anhydrous aluminum chloride with the purity larger than 99% is prepared through impurity removal and purification; a sodium hydroxide solution is added in the anhydrous aluminum chloride, an intermediate product is prepared, and aluminum hydroxide precipitate and a sodium chloride solution are obtained through precipitation, filtration and solid-liquid separation; the aluminum hydroxide precipitate is calcined at a temperature ranging from 800 DEG C to 1200 DEG C and decomposed to generate aluminum oxide; and the aluminum oxide is subjected to electrolysis to obtain the metal aluminum. The method is a clean process which is simple in technological process and low in energy consumption, all chlorine gas and sodium hydroxide which are generated by the system are used in a cyclic manner, all elements can be effectively separated and utilized, the whole system is free of emission of waste water, waste acid and waste alkali liquid, and zero emission of 'three wastes' is basically achieved.

Owner:NORTHEASTERN UNIV

Preparations of 4-formyl biphenyl, 4-hydroxymethyl biphenyl and 4-chloromethyl biphenyl

ActiveCN101434527AHigh recovery rateThe reaction steps are simplePreparation by carbon monoxide reactionChlorideReaction step

The invention relates to preparation methods of 4-formoxyl biphenyl, 4-hydroxymethyl biphenyl and 4-chloromethyl biphenyl, in particular to preparation methods which adopt biphenyl as substrate, anhydrous aluminum chloride and cuprous chloride as catalysts for preparing the 4-formoxyl biphenyl, and then use the 4-formoxyl biphenyl for preparing the 4-hydroxymethyl biphenyl and the 4-chloromethyl biphenyl. The methods have technical superiorities of high recovery ratio, simple reaction steps, easy-control conditions, applicability to industrialized production, low costs of raw materials, etc.

Owner:BEIJING ODYSSEY CHEM

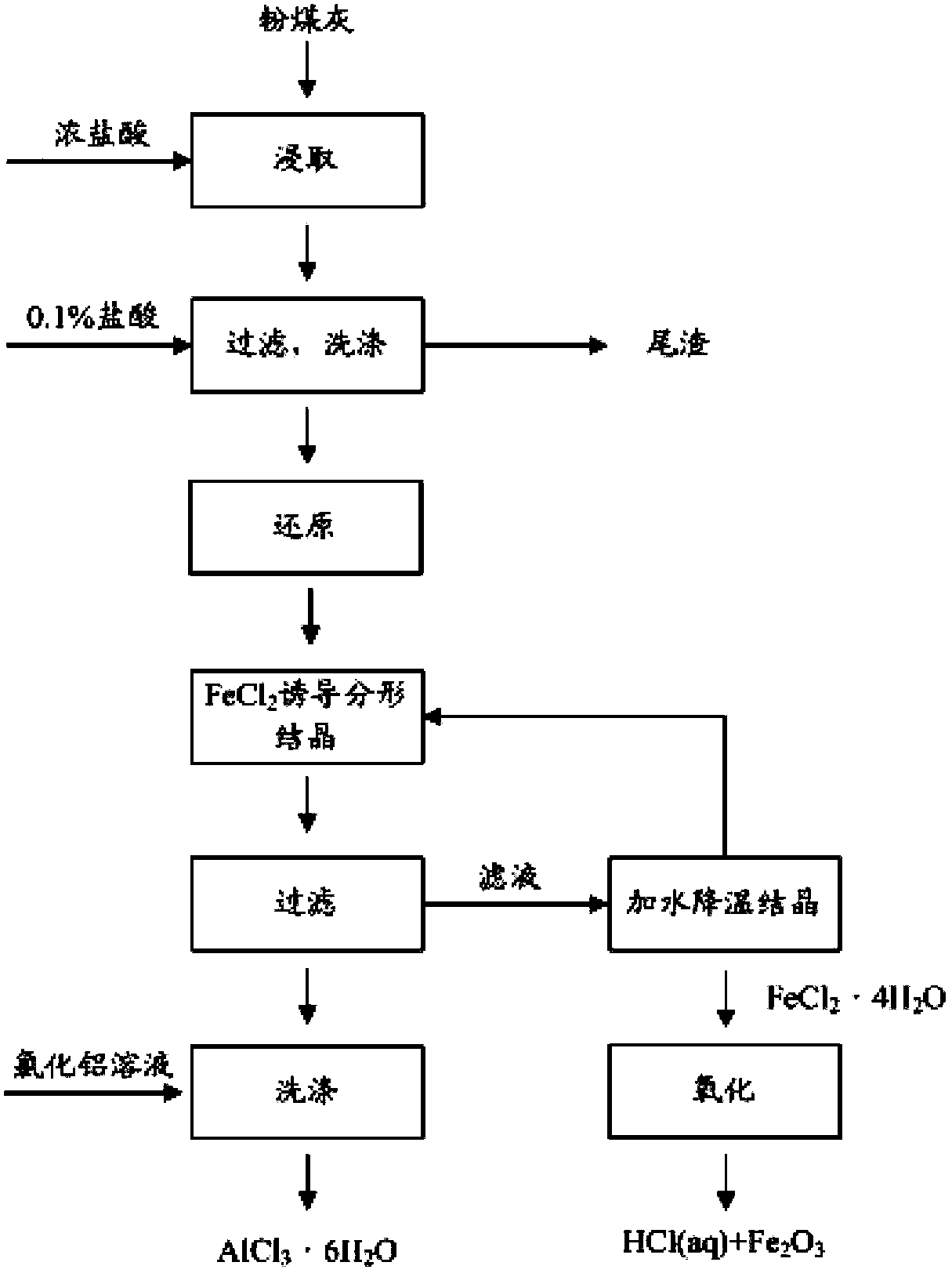

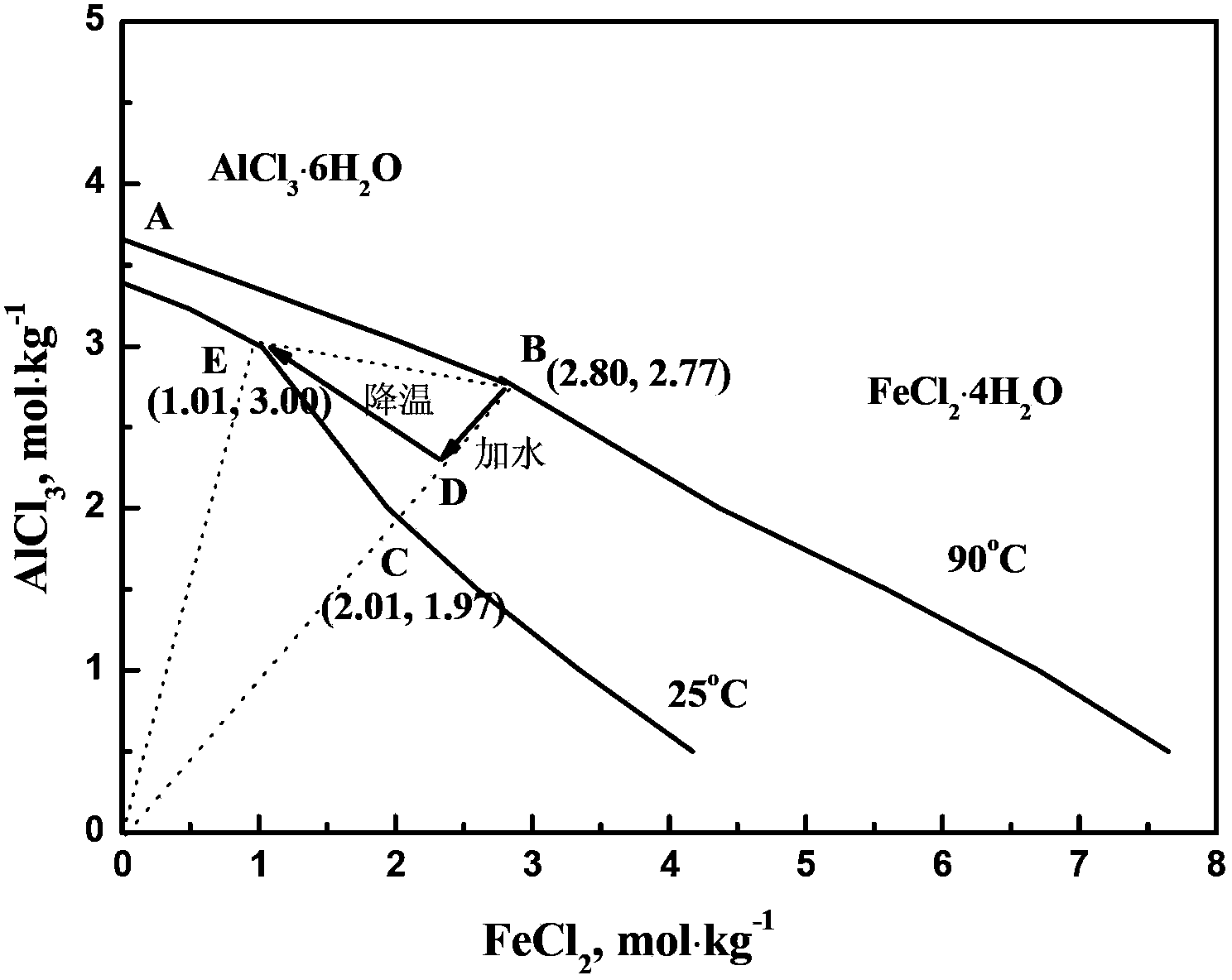

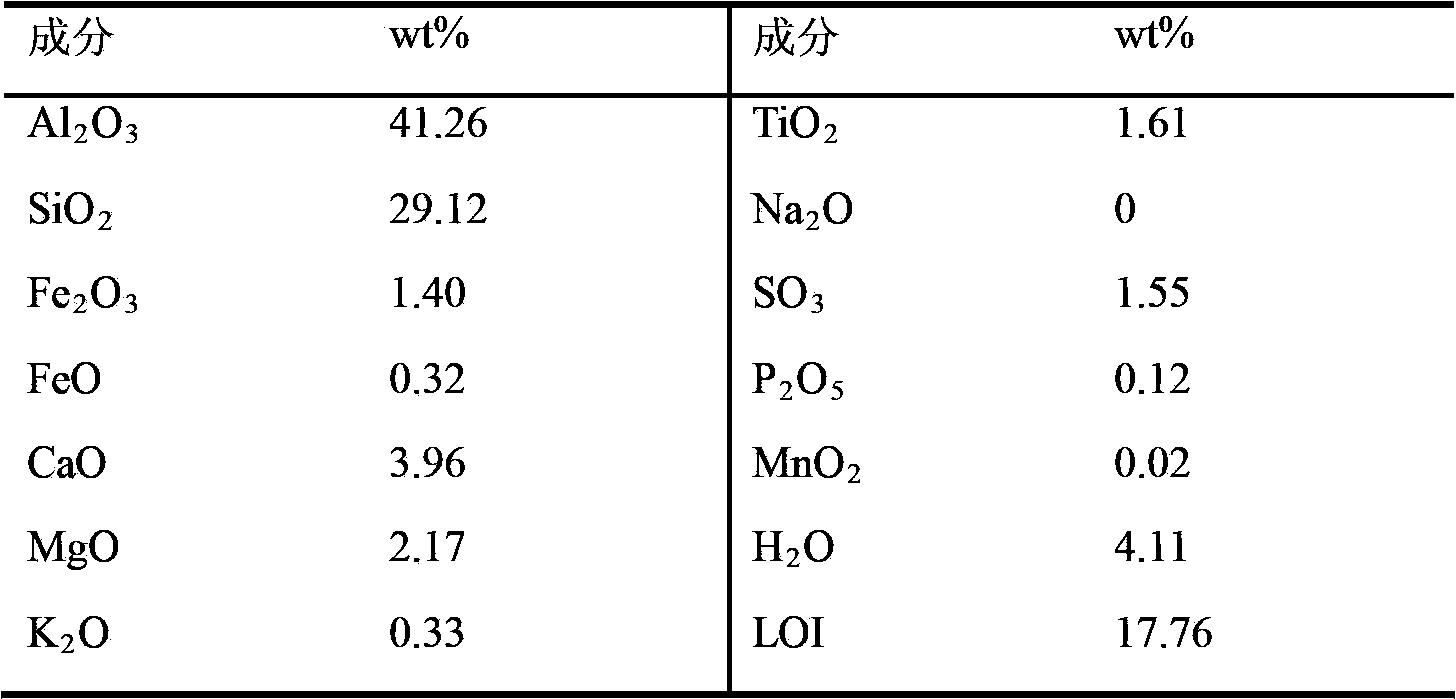

Method for preparing aluminum chloride hexahydrate by using pulverized fuel ash as raw material through ferrous chloride induced crystallization

InactiveCN103539182ARealize high-value utilizationThe process is green and environmentally friendlyAluminium chloridesChemical industryElectromotive force

The invention provides a method for preparing aluminum chloride hexahydrate by using pulverized fuel ash as a raw material through ferrous chloride induced crystallization. The method comprises the following steps: (1) batching the pulverized fuel ash and hydrochloric acid in proportions, and reacting for 1-4 hours at the temperature of 80-120 DEG C; (2) filtering leach liquor and solids, and washing more than three times by using diluted hydrochloric acid; (3) adding a reducing agent to a solution till the electromotive force of the solution is about 770mV, so that all Fe<3+> in the solution is reduced to Fe<2+>, and meanwhile, intrinsic Fe<2+> in the solution generates ferric oxide; (4) adding ferrous chloride, carrying out induction fractal crystallization at the temperature of 80-120 DEG C, filtering to obtain aluminum chloride hexahydrate crystals with relatively good crystalline form, or recrystallizing the obtained crystals, then washing by using a high-concentration aluminium chloride solution, and drying to obtain an aluminum chloride hexahydrate product; (5) adding water, cooling and crystallizing so as to respectively remove calcium, magnesium, potassium, sodium and the like in the solution, and separating out ferrous chloride tetrahydrate (FeC12.4H2O); and (6) carrying out a hydrothermal reaction for 4-12 hours at the temperature of 120-200 DEG C by using obtained the ferrous chloride tetrahydrate, and reacting so as to generate ferric oxide and an HCI solution. The method is easy to operate, pollution-free to environments and in line with the requirements of green chemical industries on clean production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com