Preparation method of combustion inhibitor containing P-S

A flame retardant, P-S technology, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., to achieve the effect of good carbon formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

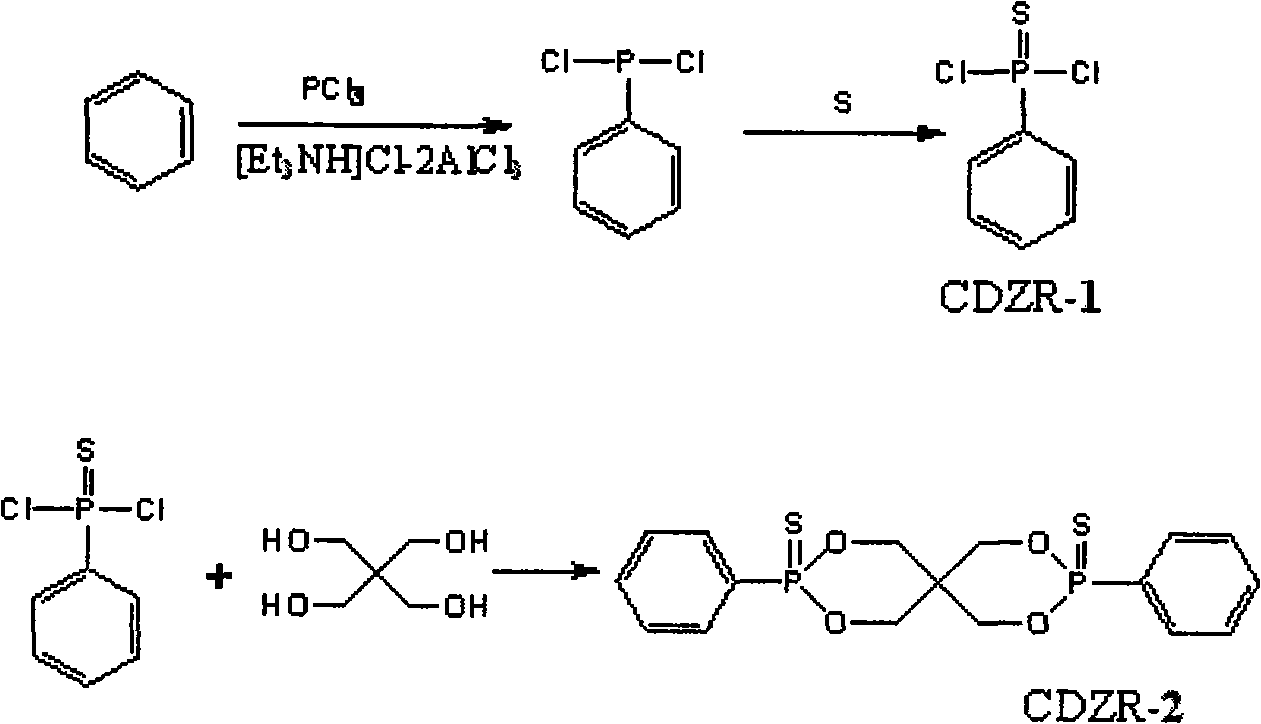

[0023] Synthesis of CDZR-1;

[0024] To PCl 3 (34.4g, 0.25mol) and [Et 3 NH]Cl-2AlCl 3 (6.3g, 0.0810mol) benzene was added dropwise to the reflux liquid of (2.84g, 7.0mmol), and the reflux reaction was continued at 78-80°C for 3.5h after the addition was completed for 1h. The mixture was cooled to room temperature and allowed to stand for 30 min. The excess PCl was then distilled off under reduced pressure at 40°C 3 . The residual liquid was cooled to 30°C, and sulfur powder (27.2 g, 0.0850 mol) was added in batches to ensure that the reaction temperature was around 80°C. After the addition was complete, the reaction was continued at 80°C for 1.5h. After cooling the reactant, petroleum ether was added and stirred for 30 min. After the stirring was stopped, the solution was separated into layers, the upper layer was the petroleum ether phase, and the lower layer was the ionic liquid phase. Separate and collect the petroleum ether phase, wash with cold water to remove un...

Embodiment 2

[0028] Synthesis of CDZR-1;

[0029] To PCl 3 (37.84g, 0.275mol) and [Et 3 NH]Cl-2AlCl 3 Add (6.5g, 0.0833mol) benzene dropwise to the reflux liquid of (3.08g, 7.6mmol), and continue the reflux reaction at 78-80°C for 4h after the addition is completed for 1h. The mixture was cooled to room temperature and allowed to stand for 30 min. The excess PCl was then distilled off under reduced pressure at 40°C 3 . The residual liquid was cooled to 30°C, and sulfur powder (28.4g, 0.0887mol) was added in batches to ensure that the reaction temperature was around 80°C. After the addition was complete, the reaction was continued at 80°C for 1.5h. After cooling the reactant, petroleum ether was added and stirred for 30 min. After the stirring was stopped, the solution was separated into layers, the upper layer was the petroleum ether phase, and the lower layer was the ionic liquid phase. Separate and collect the petroleum ether phase, wash with cold water to remove unreacted phenyl...

Embodiment 3

[0033] Synthesis of CDZR-1;

[0034] To PCl 3 (41.28g, 0.30mol) and [Et 3 NH]Cl-2AlCl 3 Add (6.68g, 0.0856mol) benzene dropwise to the reflux liquid of (3.24g, 8.0mmol), and continue the reflux reaction at 78-80°C for 4h after the addition is completed for 1h. The mixture was cooled to room temperature and allowed to stand for 30 min. The excess PCl was then distilled off under reduced pressure at 40°C 3 . The residual liquid was cooled to 30°C, and sulfur powder (29.0 g, 0.0906 mol) was added in batches to ensure that the reaction temperature was around 80°C. After the addition was complete, the reaction was continued at 80°C for 1.5h. After cooling the reactant, petroleum ether was added and stirred for 30 min. After the stirring was stopped, the solution was separated into layers, the upper layer was the petroleum ether phase, and the lower layer was the ionic liquid phase. Separate and collect the petroleum ether phase, wash with cold water to remove unreacted phen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com