Patents

Literature

171 results about "Triethylamine hydrochloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

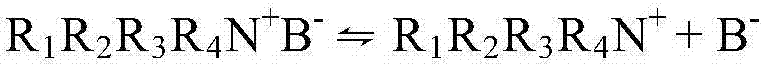

Tertiary salts such as triethylamine hydrochloride produced incomplete hemolysis of dog erythrocytes in vitro, whereas primary salts produced complete hemolysis. The decreased activity was attributed to the increased bulkiness and lipophilicity of successively alkyl-substituted amine cations.

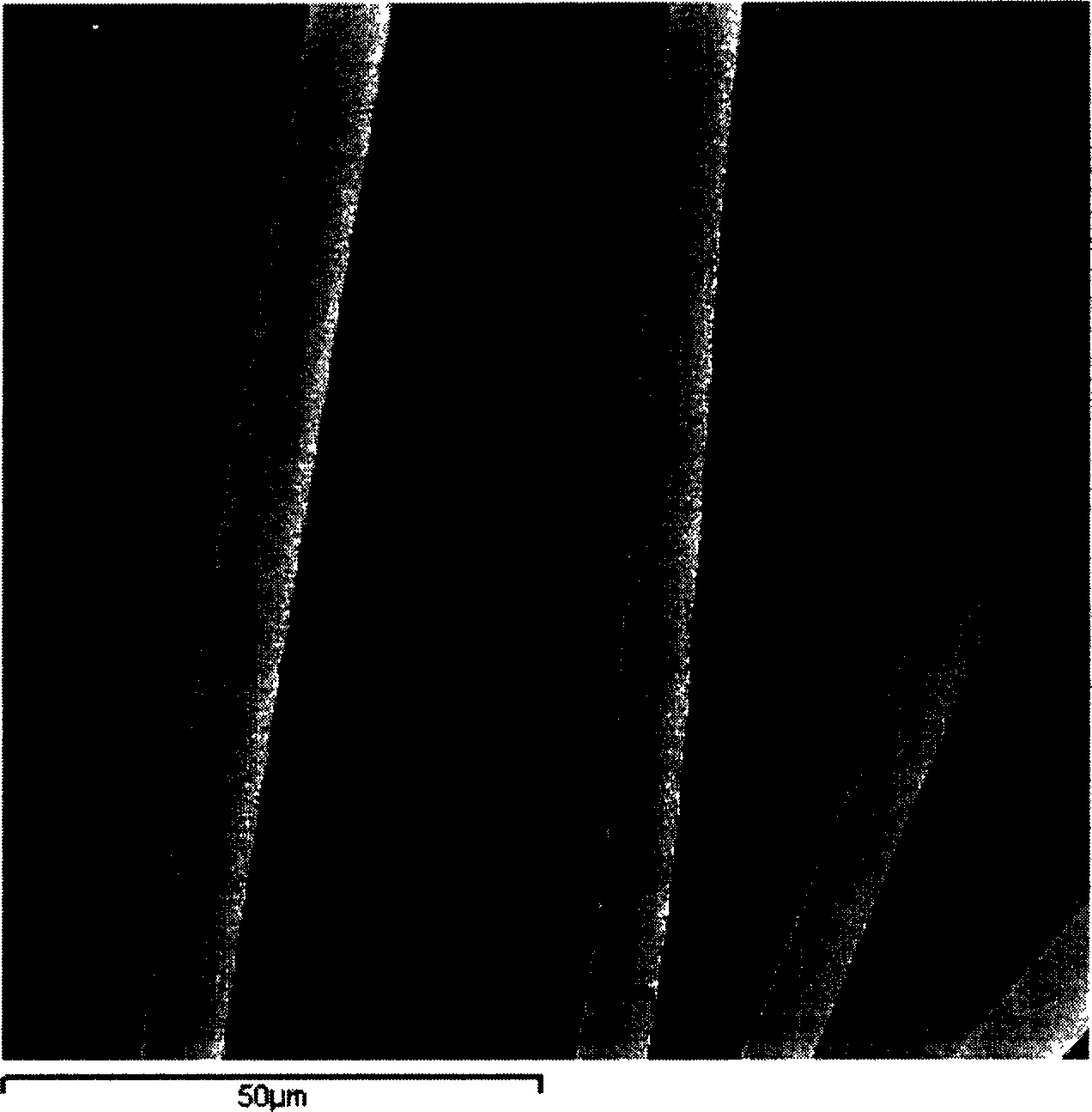

Zirconium oxide fabrics prepared from organic polyzirconium fore spinning solution by silk process

InactiveCN1584155AGood effectRaw materials are cheap and easy to getInorganic material artificial filamentsFuranSolvent

The manufacture method of a kind of zirconia fibre cotton relates to the field of resistance of fire fibre material. We compose van-style acetamide acetone zirconium polymer according to chloridze zirconia, acetamide acetone and three-ethylamine. We use methanol as the dilute impregnant, we mix round them to let hloridize zirconia, acetamide acetone and three-ethylamine react at 40-20 deg.C, and we can receive poly-acetamide acetone zirconium van-substance. Four-hydrogen furan filtrate and remove the outgrowth hydrochloric three-ethylamine. The offspring dissolve in the filature liquid made of methanol. After centrifugal swing, we can receive van-substance fibre. After we do special hear treatment, the zirconia fibre cotton we receive has the characteristic of good filature ability, high content of zirconium, equality andclarity and jarles capability. It can be used as industrial stove, roomage fusion stove, atomic energy reactor and the high temperature heat insulation material used in aviation and military. The material of the invention cost low, the method is easy, the impregnant can be recycled, the preparation of fibre cost low.

Owner:绍兴市圣诺超高温晶体纤维材料有限公司

Preparation of complete stable cubic phase zircite crystal fibre

InactiveCN101498063AGood effectSimple processFibre chemical featuresZirconium oxidesFiberPolymer solution

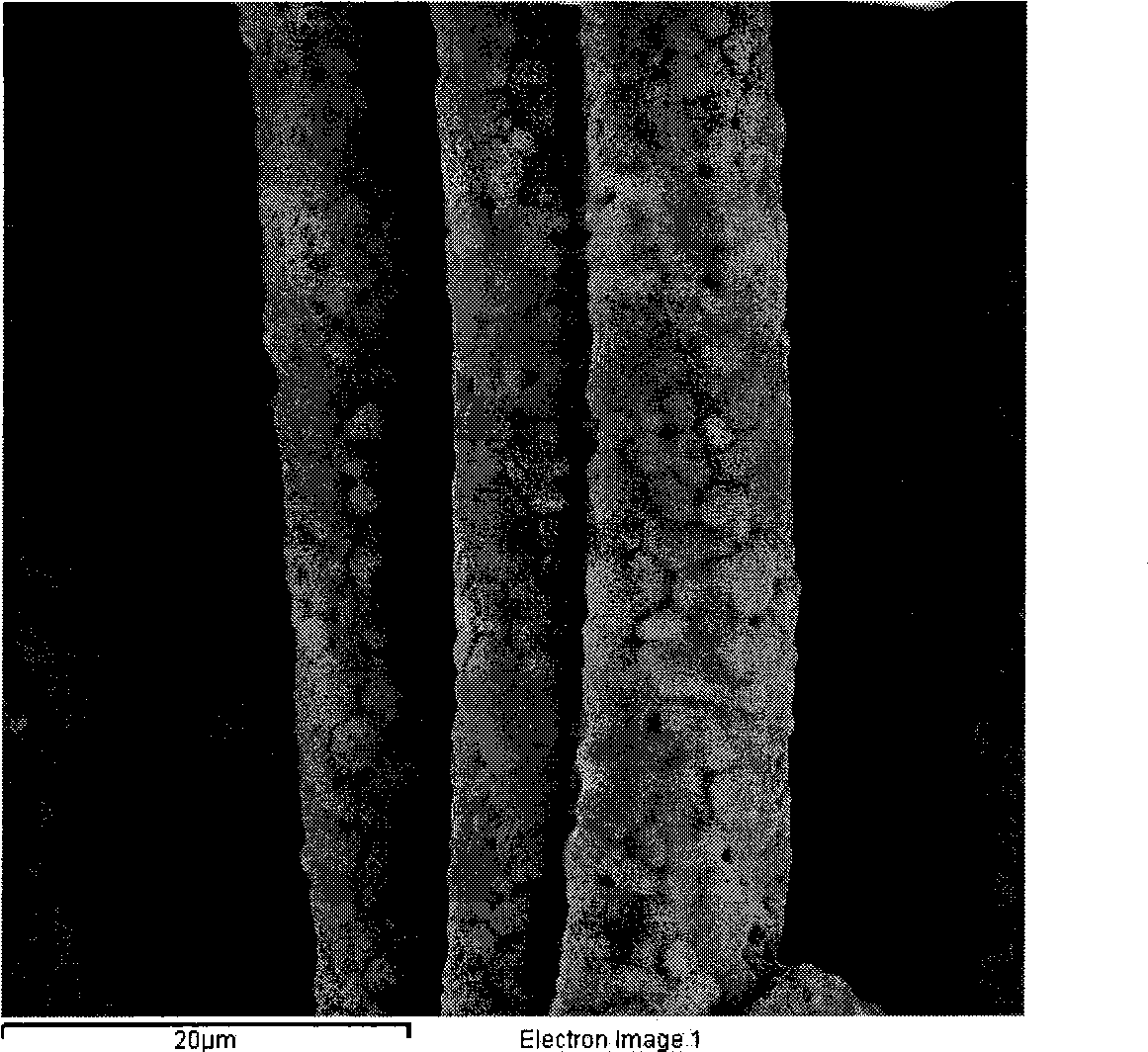

The invention relates to a method of preparing full-stable and cubic-phase zirconia crystal fibers, which mainly comprises the following steps: using zirconium oxychloride, acetylacetone and triethylamine as main raw material and using ethanol as diluent solvent to directly react at a temperature of 0 DEG C to 50 DEG C under a stirring condition so as to generate an organic polymer solution comprising zirconium; evaporating the ethanol and using acetone as solvent to dissolve soluble substances and filter and remove an undissolved substance of triethylamine hydrochloride; recycling the acetone, dissolving the obtained products and yttrium salt to the ethanol to prepare a spinning solution which is centrifugally flung at a high speed to obtain organic polymer fibers comprising zirconium; and carrying out heat treatment in a special atmosphere and ultra-high temperature treatment of the organic polymer fibers comprising zirconium. The invention has simple preparation technology and can recycle the solvent, and the prepared crystal fibers have single ingredients, high purity and stable high-temperature performance and can be used in a range from 1700 DEG C to 2150 DEG C for a long time.

Owner:SHANDONG UNIV +1

Preparing method for titanium dioxide fibre

The producing method of two-oxidation titanium fibre belongs to function fibre material technology scopes. Compose poly-acetamide acetone titanium to be the van-substance. Let chemic dosage of four-chloridize titanium, distilled water, acetamide acetone and three-ethylamine dilute in methanol respectively. Mix them and react when mixing round at 0-25 deg.C. Compose poly-acetyl acet, titanium. Remove hydrochloric three-ethylamine by using four-hydrogen furan. Dissolve poly-acetyl acet, titanium in methanol to make filature liquid. Obtain van-substance short fibre by using acentric swing method. Obtain van-substance long fibre by using dry filature method. And we can obtain two-oxidation titanium fibre by using high pressure or normal pressure vapor heat treatment technique agglomeration. The intension of extend of this invention is 100 MPa-1.2GPa. The diameter is 3um-20um. The one-thread series length is 1 cm-50 cm or higher than 1 m. The crystal diameter is 5 nm-100 nm. The appearance is two-oxide ation short fibre or consecutive fibre with titanium droff-titanium-mine posture or rutile posture or coexistence.

Owner:SHANDONG UNIV

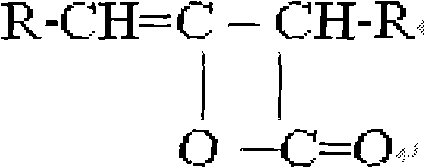

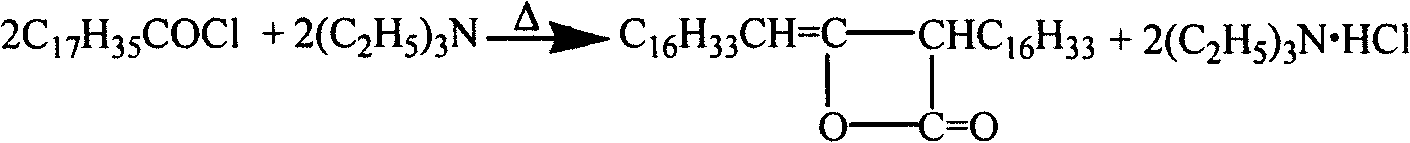

Method for preparing AKD by serialization

The invention provides a method for preparing AKD by serialization. The method includes the following steps: reaction of acyl chloride and tertiary amine is carried out, acyl chloride in formula ratio is divided into two or three parts, each part is 10-90% of the formula ratio, the rest part of acyl chloride is added in times after 30-300 seconds, triethylamine in formula ratio and first part of acyl chloride are simultaneously, respectively and continuously added at the front end of a reactor; material is continuously fed into a hybrid reactor from different feeding holes by virtue of a plurality of metering pumps, the material is subject to hybrid reaction in the hybrid reactor by stirring, cutting and malposition moving, and the temperature of material is controlled; the material is remained in the reactor, discharged from the outlet of the reactor and enters into a continuous extractor, and meanwhile diluted hydrochloric acid is continuously added into the extractor, is dispersed with reaction product to form uniform mixed solution and then enters into a slope precipitator, separation of oil phase and water phase is carried out, the oil phase is discharged from the upper outlet, and the water phase is discharged from the lower outlet; and the oil phase is namely the AKD, and the water phase is triethylamine hydrochloride solution.

Owner:SUZHOU TIANMA SPECIALTY CHEM

Method for synthesizing vinylene carbonate

ActiveCN101407508AAvoid the problem of crystallization clogging pipesEasy to separate by filtrationOrganic chemistryFiltrationUltraviolet lights

The invention discloses a method for synthesizing vinylene carbonate, and the method mainly comprises the following steps: (1) chlorine gas is introduced into the raw material of ethylene carbonate in ultraviolet light condition, thus synthesizing chlor-ethylene carbonate; (2) taking mixture of ester, ether and hydrocarbon as the organic solvent, the chlor-ethylene carbonate which is obtained in the step (1) produces elimination reaction with triethylamine, thus eliminating hydrogen chloride and generating the vinylene carbonate; and (3) the mixed product obtained in the step (2) is distilled and purified after filtration. By adopting the mixed solvent of ester, ether and hydrocarbon, the reaction product is easily isolated from triethylamine hydrochloride, thus increasing the yield and the production efficiency; and BHT can be used as a polymerization inhibitor in the reaction process, thus controlling the polymerization of the vinylene carbonate effectively and increasing the yield.

Owner:江苏瀚康新材料有限公司

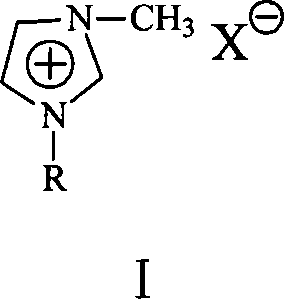

Process for producing cyclohexylbenzene

InactiveCN101219922AEasy to recycleHigh purityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsBenzeneAlkyl transfer

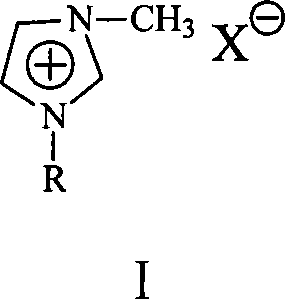

The invention relates to a method for preparing cyclohexylbenzene by benzene and cyclohexene through alkylation reaction, comprising the main step that under the condition with a catalyst, target substance is prepared by the benzene and the cyclohexene through the alkylation reaction; the invention is characterized in that the catalyst is imidazole ionic liquid or triethylamine hydrochloride ionic liquid. The invention overcomes the defects that the catalyst in the prior art can not be repeatedly used or the reaction activity decreases after repeated usage.

Owner:EAST CHINA UNIV OF SCI & TECH

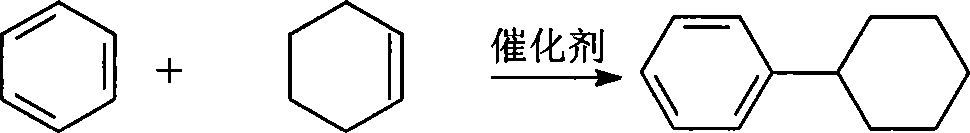

Weathering crust deposit type rare earth ore compound leaching agent

InactiveCN103789561AStrong hydration swelling abilityPrevent landslidesProcess efficiency improvementClay mineralsRare earth

The invention belongs to the field of wet metallurgy and in particular discloses a compound leaching agent for preventing landslide in the process of leaching weathering crust deposit type rare earth ore in situ. The compound leaching agent consists of a mixed aqueous solution of an organic amine salt anti-swelling agent, a leaching agent and a pH regulator, wherein the concentration of the organic amine salt anti-swelling agent is 1-15g / L; the concentration of the leaching agent is 5-30g / L; the pH value of the mixed aqueous solution is regulated to be 4.0-6.0 by using the pH regulator. The compound leaching agent is preferably any one of dimethylamine hydrochloride, di-n-propylamine hydrochloride, diethylamine hydrochloride and triethylamine hydrochloride. Due to the addition of the anti-swelling agent, the compound leaching agent has the capacity of well preventing swelling of clay minerals, the rare earth leaching effect is not influenced, the leaching agent has the functions of leaching and preventing swelling, and landslide is effectively avoided in the process of leaching the weathering crust deposit type rare earth ore in situ.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

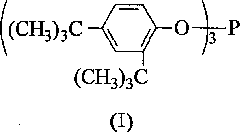

Preparation method of antioxidant product with stable performance

ActiveCN101798325ASimple production processHigh yieldGroup 5/15 element organic compoundsDistillationSolvent

The invention provides a preparation method of antioxidant product with stable performance. 2, 4-di-tert-butylphenol and phosphorus trichloride are taken as raw materials, organic amino compound is taken as catalyst, organic solvent is taken as reaction solvent, esterification is carried out to prepare tri(2,4-ditertrabutyl phenyl) phosphite ester crystal product, namely antioxidant crude product; after reaction is completed, the organic solvent is added into a kettle, so that the antioxidant crystal product is completely dissolved into the organic solvent, an amount of triethylamine is added to react with HCl remained in product mixture, so as to generate triethylamine hydrochloride crystal, filter aid is added to remove solids triethylamine hydrochloride and organic amine catalyst hydrochloride by heat filtering, reduced pressure distillation is carried out to remove the organic solvent, and crystal is washed by low carbon fatty alcohol, thus obtaining the antioxidant product with stable performance. The invention has the advantages of simple production technology, high product yield and good quality; and the obtained product has long time hydrolytic resistance, pyrolysis resistance and good oxidation resistance.

Owner:溧阳常大技术转移中心有限公司

Production method of beta-glucan

ActiveCN105255964AAvoid dark colorsAvoid secretionMicroorganism based processesFermentationMonopotassium phosphateBiological activation

The invention discloses a production method of beta-glucan. The production method comprises the following steps of (1) schizophyllum commune activation; (2) seed activation; (3) fermentation culture; (4) coarse extraction; (5) purification. A colorless liquid culture medium prepared from 25 to 30g / L of glucose, 10 to 15g / L of sorbitol, 0.2 to 0.8g / L of monopotassium phosphate, 3 to 5g / L of epsom salt, 0.5 to 1g / L of ammonium sulphate, 0.1 to 0.5g / L of triethylamine hydrochloride, 1 to 2.2ml / L of trace element mixed solution and water is used as a fermentation culture medium for performing deep layer liquid fermentation culture on strains to obtain the colorless fermentation liquid. No pigment exists in the whole process; a decoloring step is not needed; loss due to adsorption is reduced; the problem of beta-glucan separation purification is overcome; high-purity white beta-glucan is obtained; the production method is suitable for mass industrial production.

Owner:NINGBO XINUOYA MARINE BIOTECH CO LTD

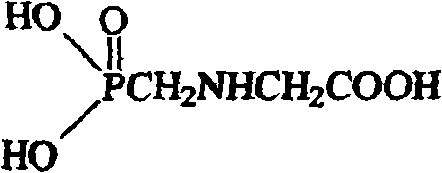

Recovery method of triethylamine in glyphosate mother liquid

ActiveCN101307002AHigh recovery rateSimple processAmino compound purification/separationGroup 5/15 element organic compoundsRecovery methodOrganic solvent

The invention relates to a novel method for reclaiming triethylamine in glyphosate mother liquid produced by a method of dialkyl phosphite. The reclaiming method is realized by the following steps that: (1) in the process for preparing the glyphosate by the method of dialkyl phosphite, liquid caustic soda is added into the crystallized mother liquid to make the triethylamine layered, the lower layer is the glyphosate mother liquid; (2) an extracting agent prepared by an organic solvent and an acid phosphorus oxide extracting agent is added into the glyphosate mother liquid, the mixture is stirred and is kept stand to layer and separate; (3) the glyphosate waste water in the lower layer is concentrated to prepare glyphosate; the organic phase in the upper layer is added with hydrochloric acid to generate triethylamine hydrochloride and is kept stand to layer; a regenerating extracting agent in the upper layer returns to the production process and is used to extract continuously; and the triethylamine hydrochloride in the lower layer is added with liquid caustic soda and is adjusted to be basic so that the triethylamine hydrochloride is converted into the triethylamine which is layered and is used to synthesize after dewatered. The novel method effectively improves the coefficient of reclaiming of the triethylamine and has simple process, easy operation and high economical benefits.

Owner:SHANDONG WEIFANG RAINBOW CHEM

Technique for recycling triethylamine from hydrochloric acid triethylamine water solution

ActiveCN101293840ALow priceReduce dosageAmino compound purification/separationCalcium Chloride HexahydrateChloride

A method for recovering triethylamine from triethylamine hydrochloride aqueous solution comprises allowing calcium oxide and the triethylamine hydrochloride to react, and distilling at 50-150 DEC C to obtain the triethylamine; adding the calcium oxide into the collected triethylamine, refluxing under heating to remove water, and distilling to collect the triethylamine having water content smaller than 0.5%, distilling to obtain the triethylamine, separating solid from a turbid aqueous solution residual in a reaction kettle, adjusting the pH value of the aqueous solution to 7 with hydrochloric acid, and removing water to respectively obtain calcium chloride hexahydrate, calcium chloride dehydrate and anhydrous calcium chloride; and allowing the calcium oxide after drying the triethylamine and the triethylamine hydrochloride to react to obtain the triethylamine. Compared with the prior method for recovering the triethylamine from the triethylamine hydrochloride aqueous solution, the method has the advantages of simple operation, low price, high recovery rate, and no three wastes discharge.

Owner:凯米拉天成万丰化学品(兖州)有限公司

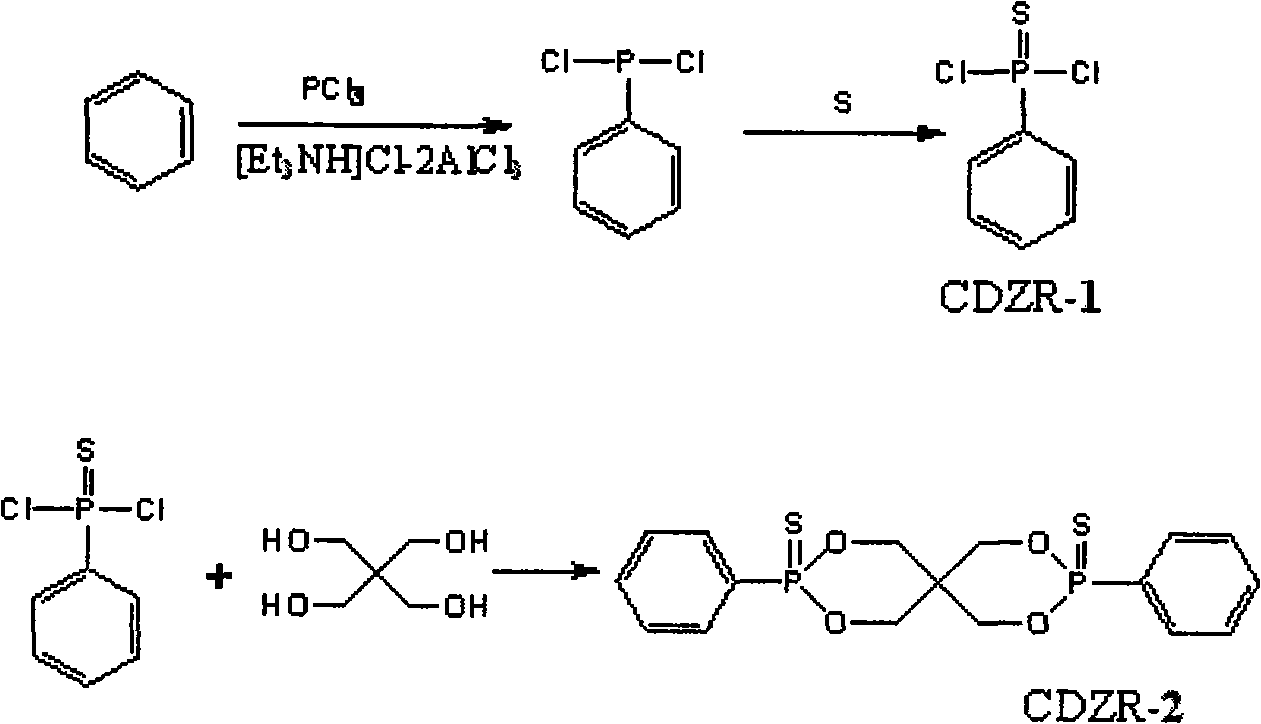

Preparation method of combustion inhibitor containing P-S

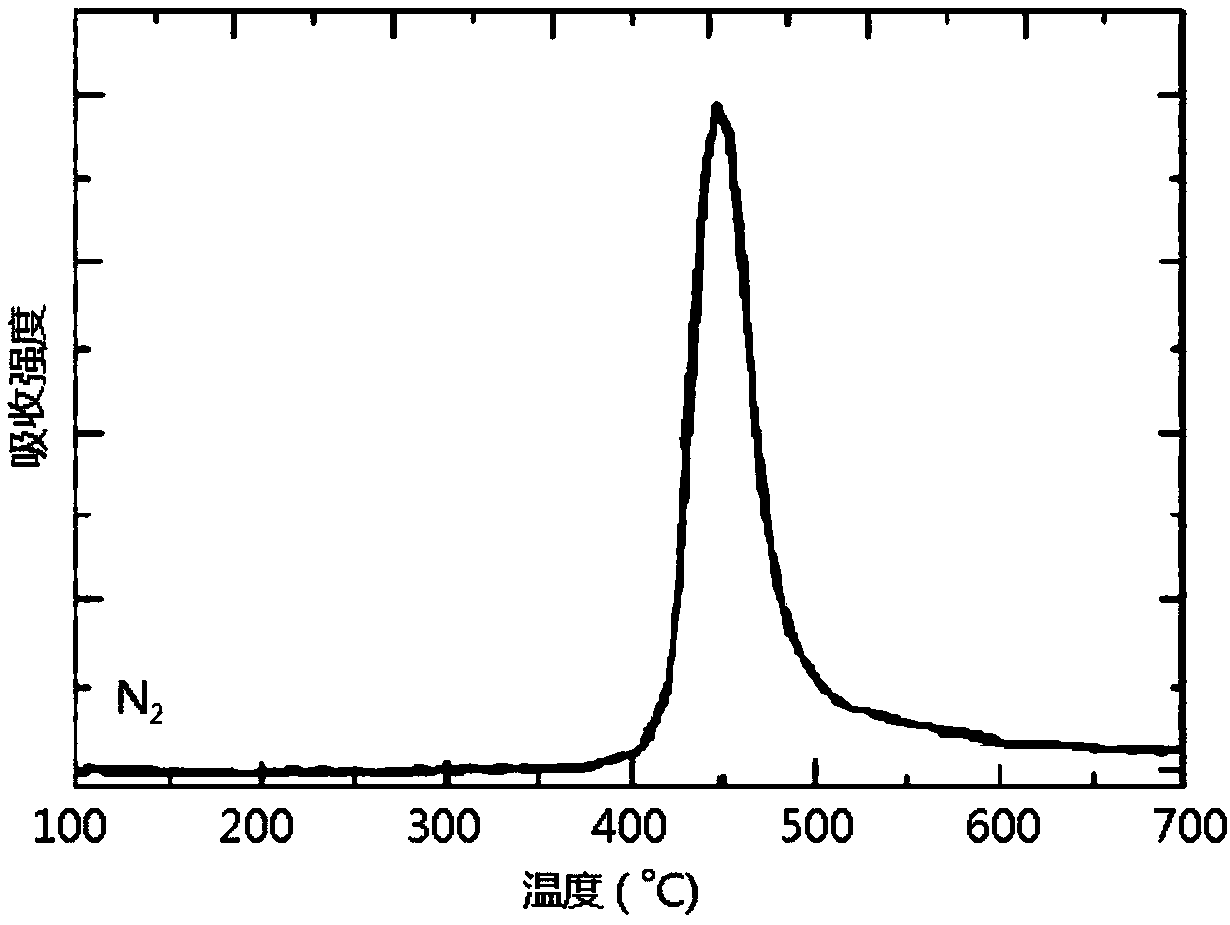

InactiveCN101586032AGood char formationAvoid problems that cannot be removedGroup 5/15 element organic compoundsAluminium chlorideNitrogen gas

The invention relates to a preparation method of combustion inhibitor containing P-S, which includes the steps: (1) under the nitrogen gas atmosphere, adding triethylamine hydrochloride and anhydrous aluminium chloride, mixing; (2) adding benzene into refluxing liquid of PCl3 and [Et3NH]Cl-2AlCl3 for refluxing reaction; vacuum distilling, and then adding sulphur powder in batches for continue reaction; adding petroleum ether and stirring, separating and collecting petroleum ether phase on upper layer, washing, drying; pressure reducing and steaming petroleum ether; collecting distillate; dispersing pentaerythritol and pyridine in carrene, dropping sulfo-phenylphosphono with stirring for refluxing reaction, after the reaction ends, rotary steaming, water washing and recrystallizating. The combustion inhibitor provided the invention has good char formation.

Owner:DONGHUA UNIV +1

Method for treating glyphosate mother solution

ActiveCN101985426ASolve processing problemsHigh recovery rateAmino compound purification/separationCalcium/strontium/barium chloridesChemical oxygen demandPhosphate

The invention discloses a method for treating glyphosate mother solution, which comprises the following steps of: adding aqueous solution of calcium hydroxide into the glyphosate mother solution to regulate pH until the solution is alkaline and make triethylamine hydrochloride in the mother solution generate triethylamine simultaneously; adding the treated glyphosate mother solution into a distillation tower for distillation, and collecting 40 to 100 DEG C fractions on the top of the tower; adding a dehydrating agent into the fractions on the top of the tower to obtain the triethylamine; and adding hydrochloric acid into the mother solution at the bottom of the tower to regulate the pH until the solution is neutral, performing solid-liquid separation and treating and discharging separatedwaste water. The process is simple and high-efficiency; the recovery rate of the triethylamine is over 98.5 percent; the chemical oxygen demand (COD) of the discharged waste water is less than 500mg / L, total phosphate (TP) is less than 1mg / L and ammonia nitrogen is less than 15mg / L; the zero emission of the waste water is basically realized; and the method has great environmental benefit and economical benefit.

Owner:SHANDONG WEIFANG RAINBOW CHEM

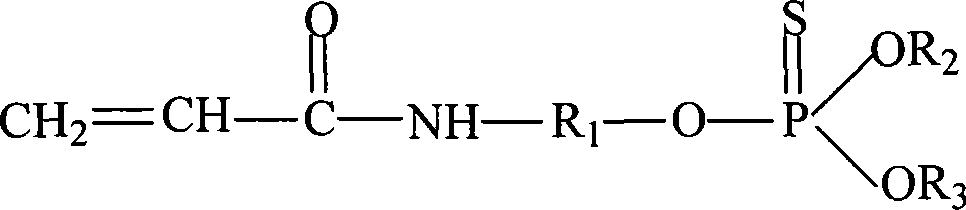

Combustion inhibitor and preparing method and flame-proof acrylic fibre using the same

InactiveCN101113211AImprove flame retardant performanceSimple processFlame-proof filament manufactureDistillationFiltration

The invention relates to a flame retardant, a preparation method and purposes thereof. The flame retardant is called O-alkyl acrylamide dialkyl thiophosphate. The preparation method is that: 1mol new distilled N- hydroxyalkyl acrylamide is dissolved in 500ml dry aether and poured into a 1000ml four-neck reaction flask with a constant pressure funnel, a refluxing condensing tube and a magnetic stirrer, and 1.05mol distilled triethylamine is added, and the reaction temperature is kept at 0-50 DEG C, then 1mol distilled sulfur dialkyl phosphoryl chloride is dripped into the reaction flask through the constant pressure funnel and the time of dripping is controlled for 1-6h; reaction is kept for 10-48 hours under room temperature, then the reaction is stopped and filtration is made to take out triethylamine hydrochloride, the filtrate is washed with 5 percent sodium hydroxide solution, then is washed with distilled water, and distillation is carried out to remove the aether and water, finally drying is carried out with anhydrous magnesium sulfate so as to obtain the O-alkyl acrylamide dialkyl thiophosphate. The flame retardant of the invention is particularly applicable to be used as a comonomer to prepare flame retardant Orlon.

Owner:CHINA PETROLEUM & CHEM CORP +2

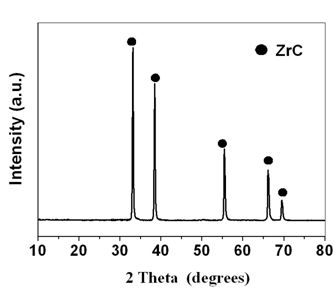

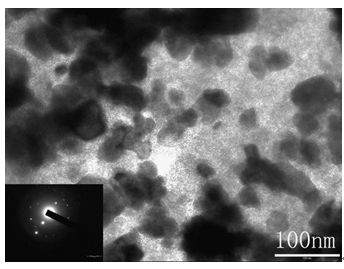

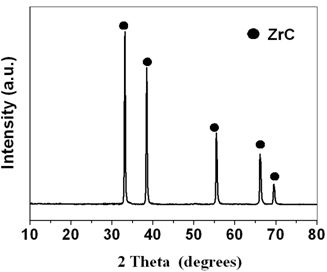

Synthetic method of superhigh temperature resistant zirconium carbide ceramic precursor

A synthetic method of a superhigh temperature resistant zirconium carbide ceramic precursor belongs to preparation methods of ceramic precursors. The synthetic method includes firstly, dissolving 6.44g zirconium oxychloride in 50 mL absolute methanol, stirring the mixture at a room temperature for dissolving, subjecting the mixture to ice bath for cooling, dropwise adding 2.4g-3.47g saligenin, finally dropwise adding 4.24g triethylamine at a dropping speed of 1 droplet per second, and subjecting the mixture to magnetic stirring in the process of the dropping adding; after the dropping adding, removing the ice bath and stirring the mixture at a room temperature for 4 hours; then subjecting the mixture to rotary evaporation for 10 minutes to evaporate solvents, adding 50 mL tetrahydrofuran, stirring the mixture at a room temperature for 2 hours, and performing suction filtration to remove a precipitation of triethylamine hydrochloride; subjecting the mixture to rotary evaporation for 15 minutes to evaporate the solvents of colatuie, adding 100 mL hexyl hydride, stirring the mixture at a room temperature for 12-48 hours, performing filtration to obtain a pale yellow precipitation, and subjecting the pale yellow precipitation to vacuum drying for three hours to obtain the zirconium carbide ceramic precursor. The synthetic method of the superhigh temperature resistant zirconium carbide ceramic precursor has the advantages that the even dispersing of modular zirconium components in precursor reins is achieved, the solidification group saligenin are contained in the ceramic precursor so that crosslinking solidification is facilitated, the synthesis temperature is low, the reaction speed is rapid, and the toxicity of solvents is small.

Owner:CHINA UNIV OF MINING & TECH

Method for recovering glycine acid-binding agent triethylamine employing triethylamine method

InactiveCN103524352AAmino compound purification/separationCalcium/strontium/barium chloridesEvaporationEthylamine

The invention provides a production technology of recovering a glycine acid-binding agent triethylamine employing a triethylamine method. An industrial calcium chloride product can be coproduced. The production technology comprises the following steps: washing a triethylamine hydrochloride crystalline solid by using an aqueous solution to remove impurities; dissolving the washed triethylamine hydrochloride crystal into water; adding calcium hydroxide or calcium oxide, adjusting the PH value to 10-12, so as to obtain a calcium chloride layered solution with a triethylamine layer; separating out a crude product triethylamine, and dewatering and standing to obtain qualified triethylamine; pumping a calcium chloride solution into an evaporation device for evaporation concentration, and recycling condensate containing triethylamine to dissolve washed triethylamine hydrochloride; adjusting the PH value of the residual calcium chloride solution to 7.5-9 with hydrochloric acid, and then feeding to an evaporator to evaporate; cooling and crystallizing, filtering and drying at about 200 DEG C, so as to obtain a calcium chloride dihydrate product; adding concentrated sulfuric acid and urea to a washing solution to process, so as to respectively obtain calcium sulfate, hydrochloric acid and a chemical fertilizer material product.

Owner:刘长飞

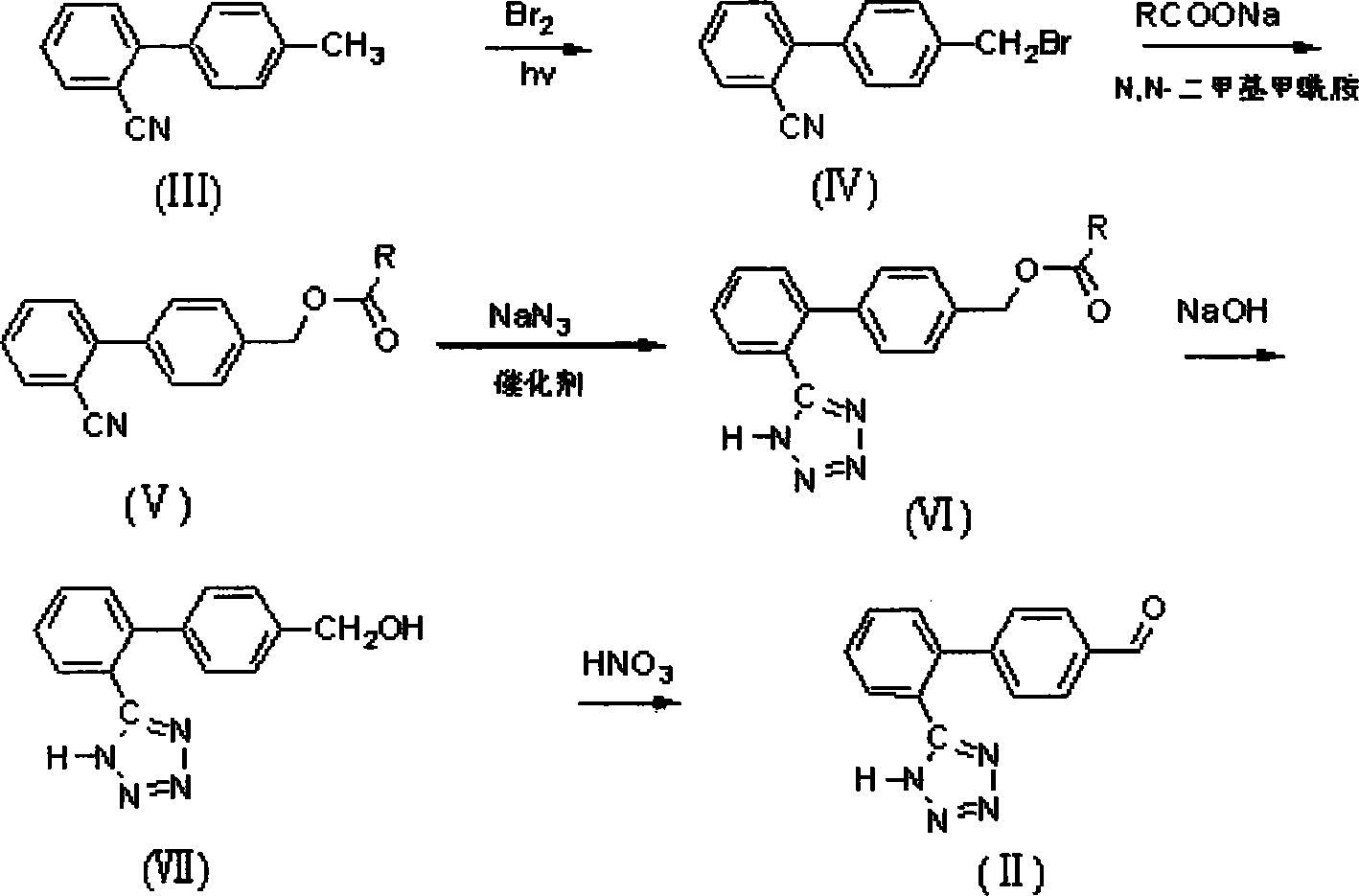

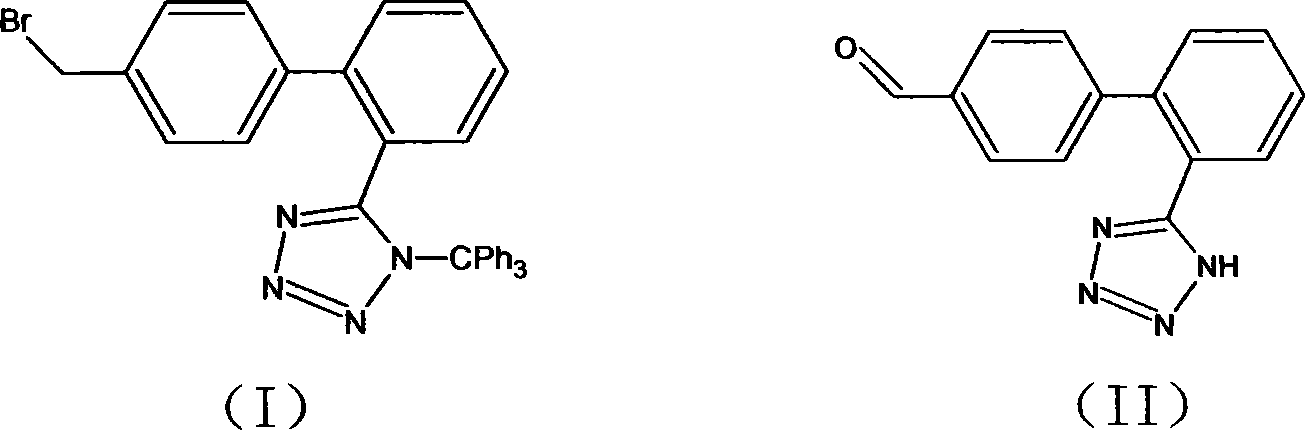

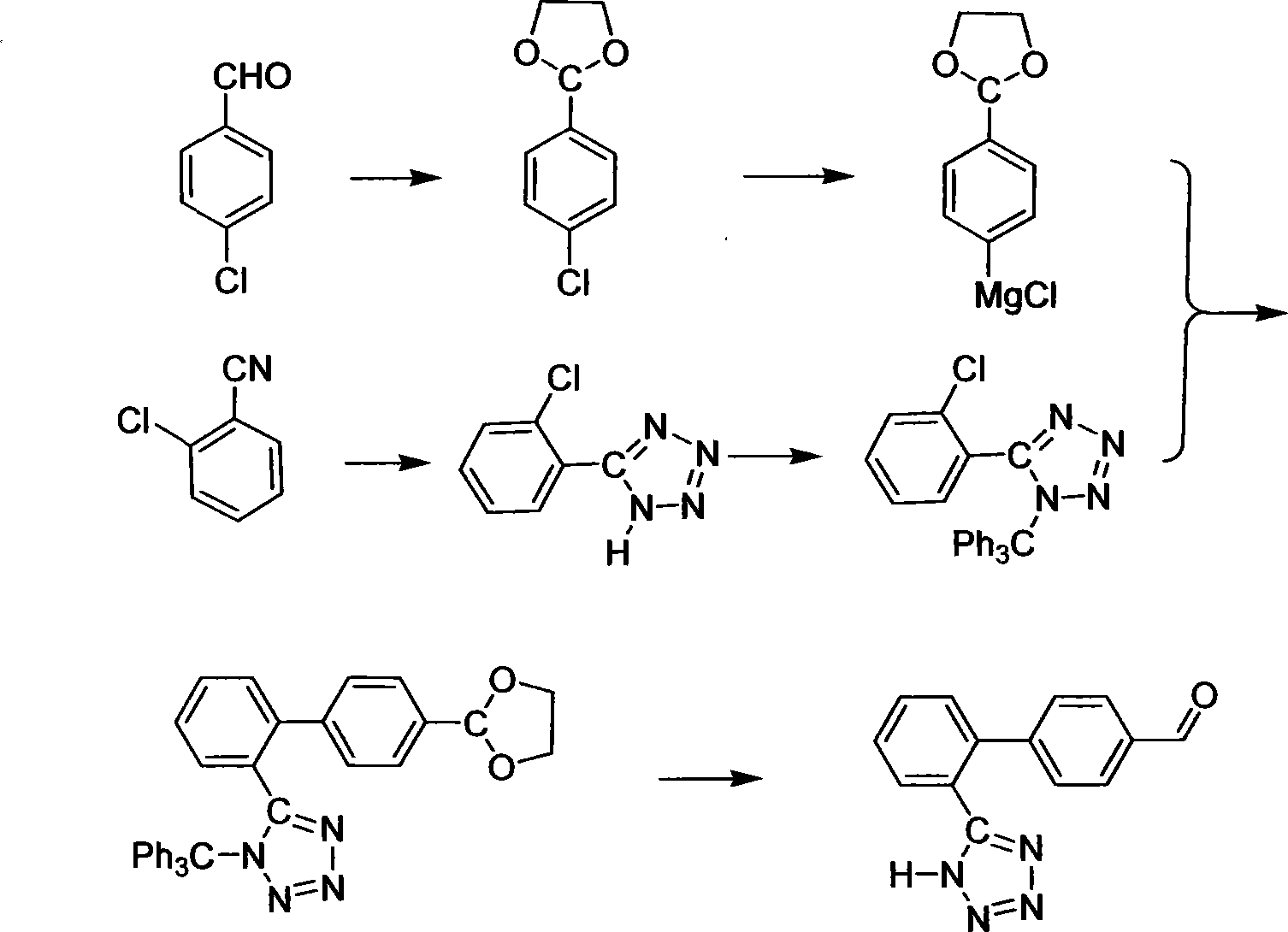

Method for preparing sartan drug main ring 5-(4'-formyl biphenyl-2-group)-1H-tetrazole treating hypertension

The invention belongs to drug synthesis, particularly relates to the main ring of Sartan drug for the treatment of the hypertension i.e. 5-(4'-formyl biphenyl-2-base)-1H-tetrazole. The preparation method comprises the following procedures, bromination, esterification, cyclization, hydrolysis and oxidation. Utilizing the triethylamine hydrochloride to serve as the catalyst, the method of the invention inhibits the side reaction, promotes the purity and the yield of the product, avoids the residue of the poisonous matter in the drug intermediate, reduces the waste discharge, realizes the clean production and protects the environment.

Owner:NANTONG SHIMEIKANG PHARMA CHEM

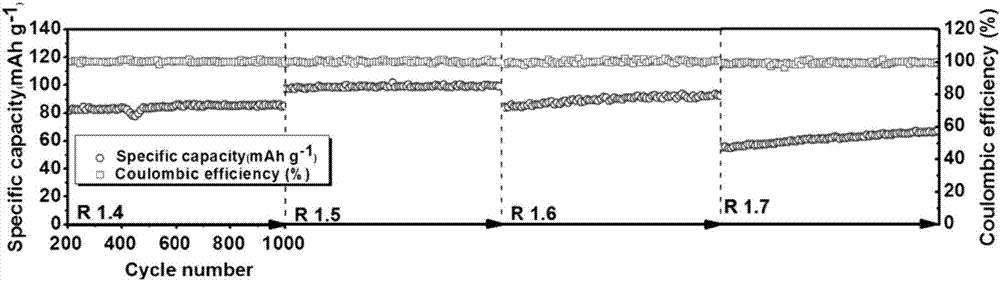

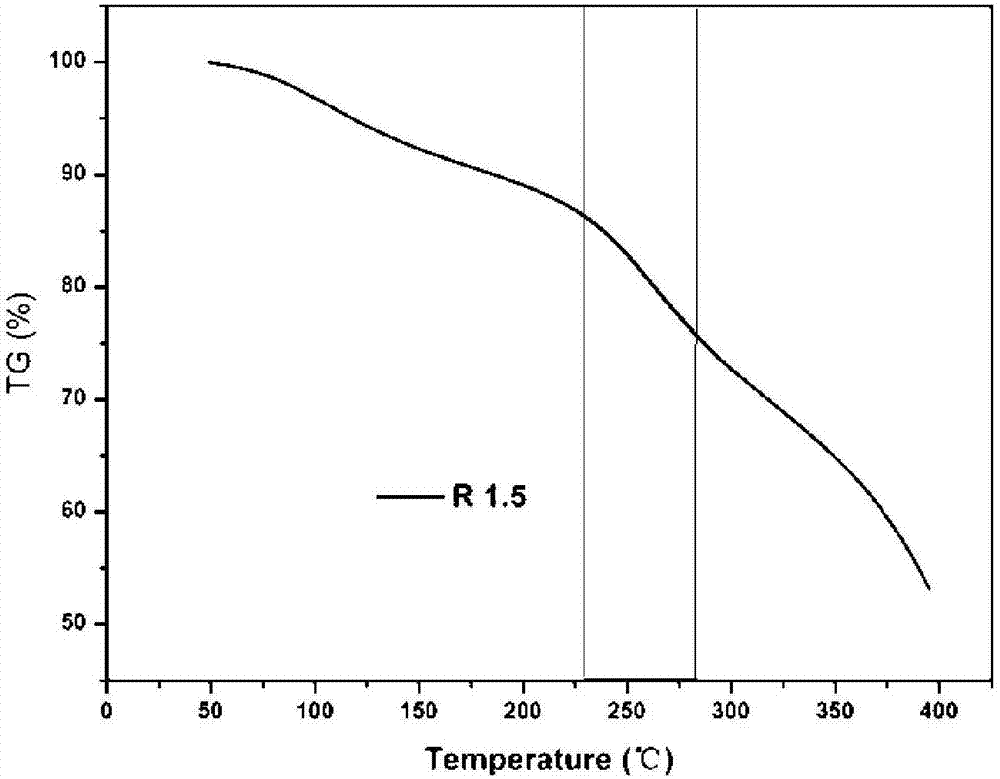

Aluminum ion battery

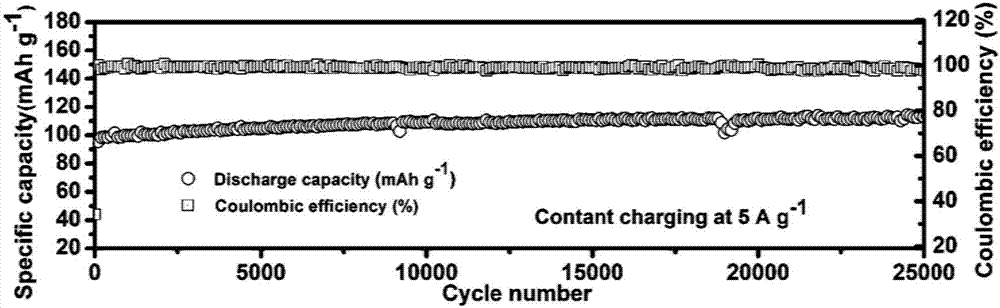

InactiveCN107331889AImprove thermal stabilityImprove Coulombic efficiencyCell electrodesSecondary cellsAluminum IonAluminium chloride

The invention discloses an aluminum ion battery. Electrolyte is ionic liquid composed of triethylamine hydrochloride and aluminum chloride according to the mol ratio of 1 to (1.4 to 1.6); a positive electrode is a graphene foam positive electrode material. According to the aluminum ion battery disclosed by the invention, mostly, triethylamine hydrochloride used in the aluminum ion battery is an industrial waste material, is easy to obtain and low in cost, so that the triethylamine hydrochloride is an environment-friendly and cheap raw material. The power density and energy density of the aluminum ion battery are ensured, and the cut-off voltage and specific capacity of the battery are improved by utilizing the ionic liquid; meanwhile, the efficiency is ensured, so that the safety and energy storage performance of the battery are improved.

Owner:HANGZHOU GAOXI TECH CO LTD

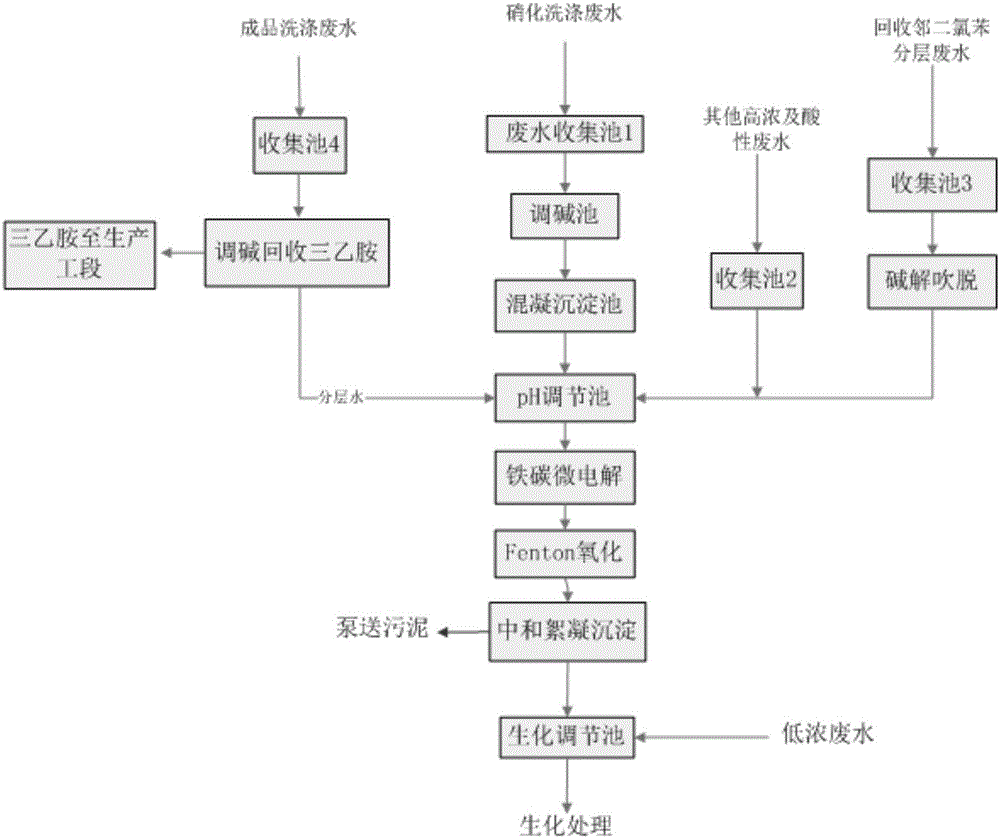

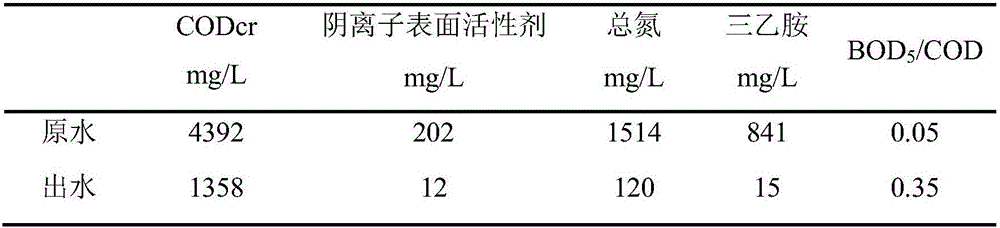

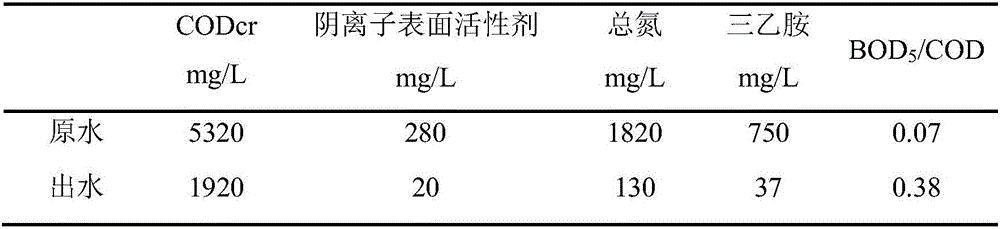

Method for reducing COD (chemical oxygen demand) of permanent violet process wastewater and application of method

ActiveCN106430790AReduce COD concentrationReduce the concentration of ammonia nitrogenWater treatment compoundsWater contaminantsHigh concentrationElectrolysis

The invention discloses a method for reducing COD (chemical oxygen demand) of permanent violet process wastewater and an application of the method and belongs to the technical field of pigment wastewater treatment. The method comprises the following steps: firstly, process wastewater is collected and treated in a classified manner according to specific pollutants of the wastewater: a nekal-bx-containing nitride washing wastewater is subjected to alkali regulating treatment, a flocculating agent is added for coagulating sedimentation, and an anionic surfactant is removed; layered wastewater produced through solvent o-dichlorobenzene recovery is subjected to alkaline hydrolysis and stripping; high-concentration wastewater containing triethylamine hydrochloride at a front section is separated from finished washing wastewater and subjected to alkali regulation and distillation, and triethylamine is recovered; secondly, the three parts of treated wastewater are mixed with other acidic wastewater for iron-carbon micro-electrolysis and Fenton oxidation coupled reinforced treatment. Classified collection and quality-divided treatment are performed according to features of the wastewater pollutants, the treatment process is safe and environment-friendly, wastewater treatment is targeted, refractory organics are removed to a greater extent, and the COD and total nitrogen content of the wastewater are reduced.

Owner:江苏南大华兴环保科技股份公司

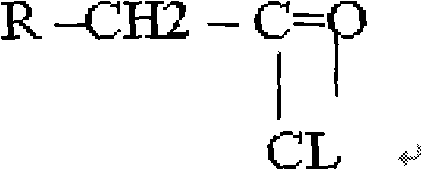

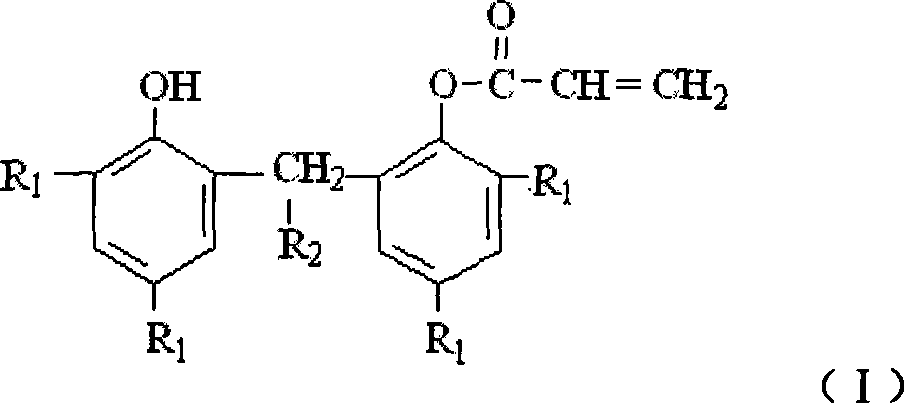

Method for preparing bisphenolmonoacryates compounds antioxidant

InactiveCN101148408AHigh molar yieldImprove product qualityOrganic compound preparationCarboxylic acid esters preparationReaction temperatureSolvent

The present invention is technological process of preparing bisphenol monoacrylate compound as oxidant with bisphenol compound, acrylic acid and phosphorus oxychloride as materials, triethylamine as acid absorbent and aliphatic hydrocarbon as solvent, and through acyl chlorination and esterification in a reactor. The technological conditions include the molar ratio between bisphenol compound and acrylic acid of 1 to 1.05, the molar ratio between acrylic acid and phosphorus oxychloride of 3 to 1.05, the molar ratio between phosphorus oxychloride and triethylamine of 1 to 3.5; reaction temperature of 63-66 deg.c and reaction time of 150-155 min. After reaction, the resultant is filtered to eliminate solid triethylamine hydrochloride, the filtrate is cooled to re-crystallize to produce white crystal product of smelting point 117.5-18.6 deg.c. The present invention is simple, and has high bisphenol monoacrylate compound yield and low material consumption.

Owner:CHANGZHOU UNIV

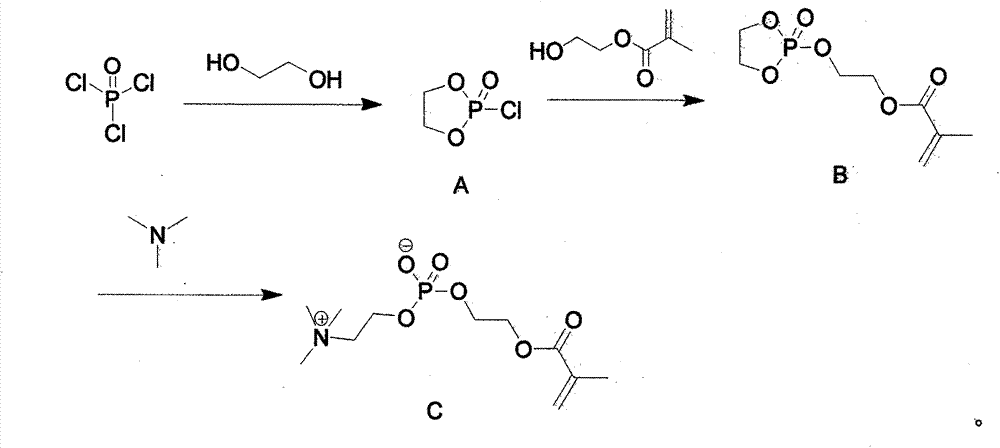

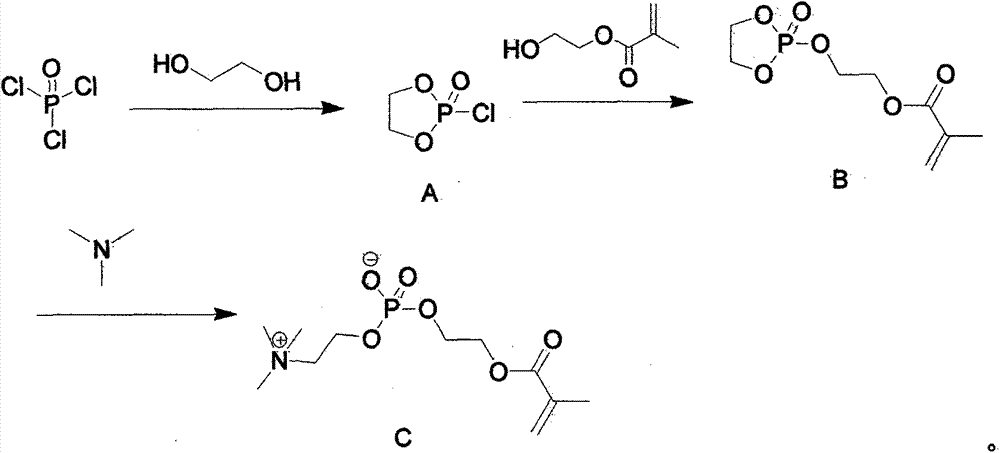

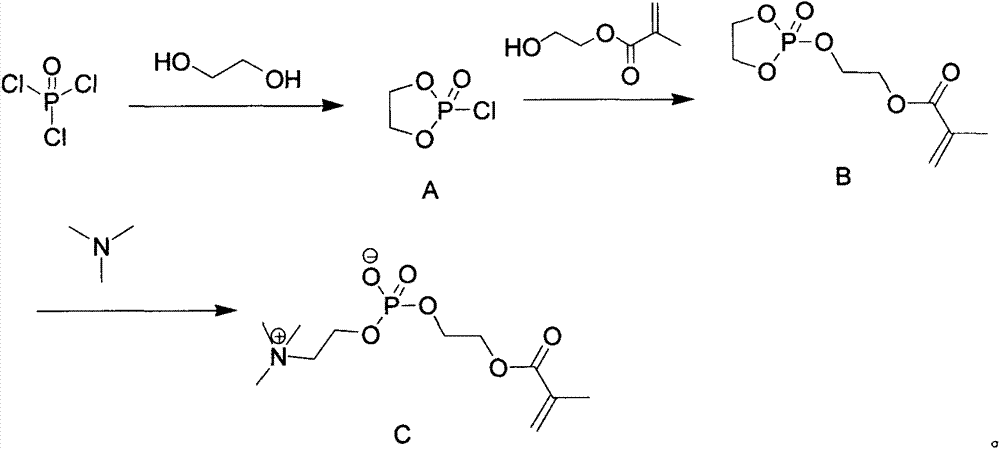

Method for synthesizing MPC using one-pot method

InactiveCN103193819AReduce investmentEasy to operatePhosphorus organic compounds(Hydroxyethyl)methacrylateFiltration

Owner:SUZHOU COSMETIC MATERIALS

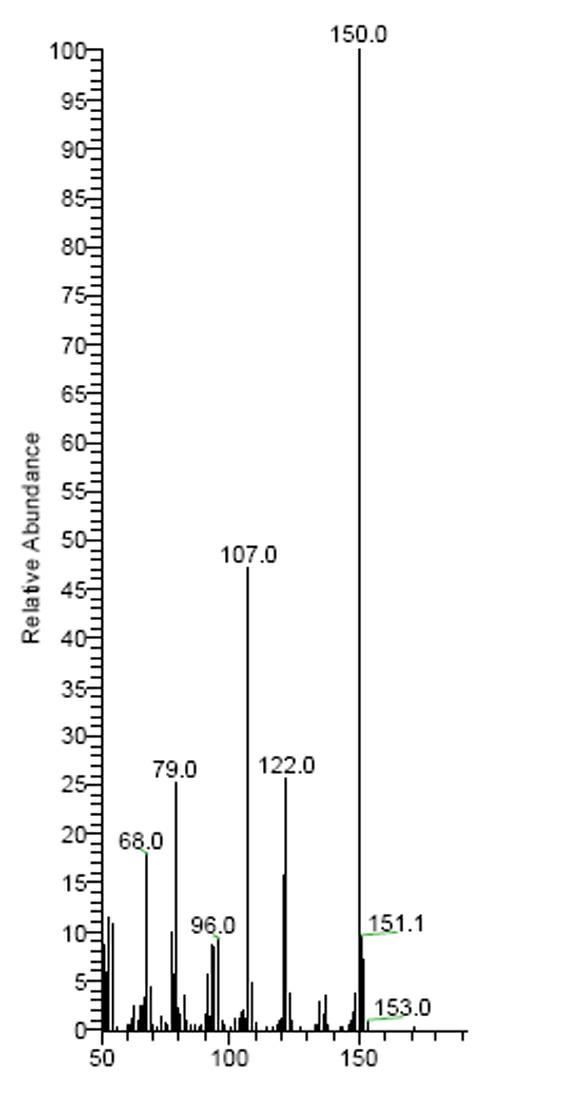

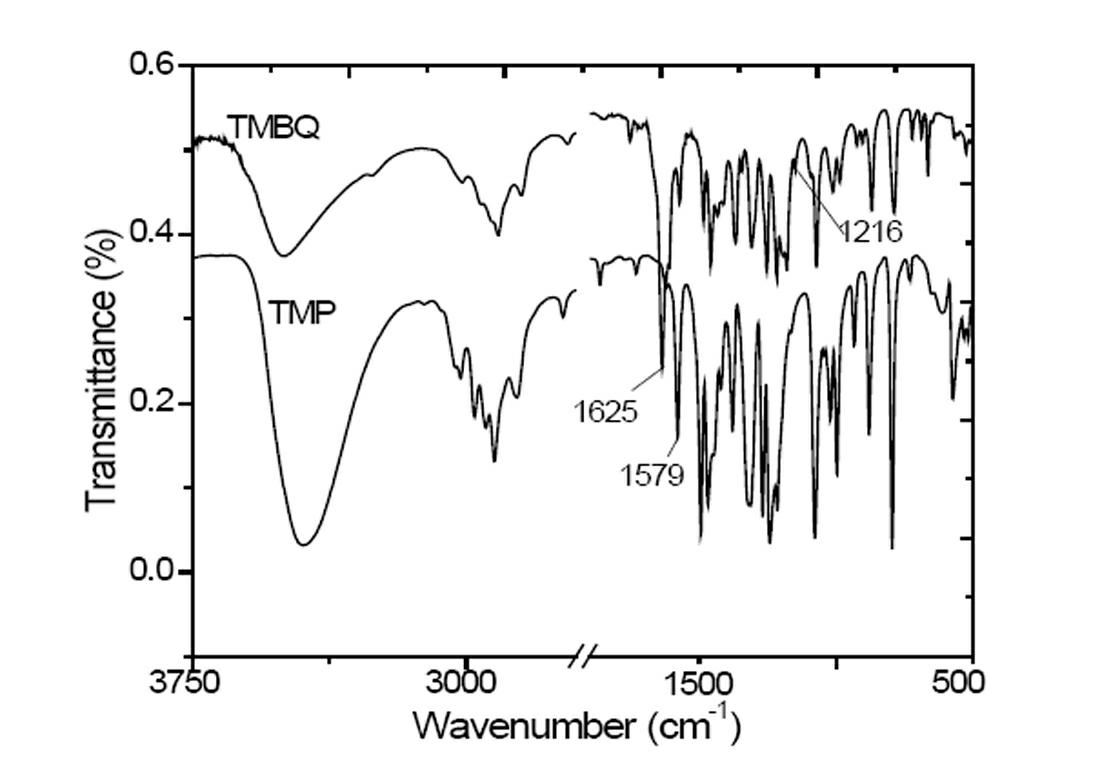

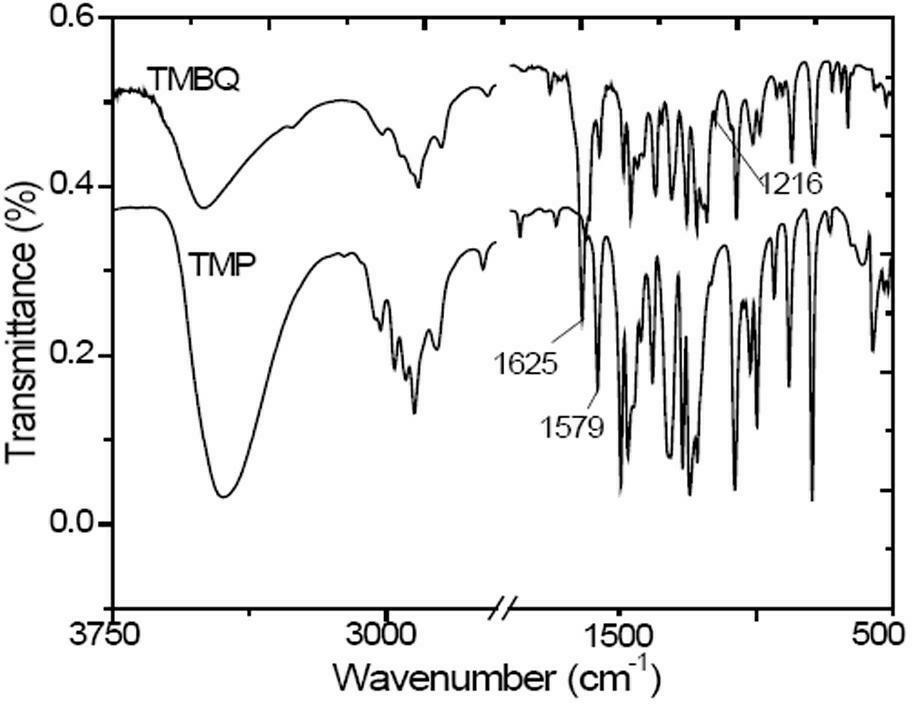

Preparation method of 2, 3, 5-trimethyl benzoquinone (TMBQ)

InactiveCN102633614AFacilitate and control the rate of decomposition and oxygen productionCatalytic oxidation achievedQuinone preparation by oxidationOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic oxidationSolvent

The invention discloses a preparation method of 2, 3, 5-trimethyl benzoquinone (TMBQ), which comprises the following steps of: (1) mixing CuCl2 and / or CoCl2, ferric chloride and triethylamine hydrochloride, evenly stirring and preparing a composite catalyst; (2) dissolving trimethylolpropane (TMP) in an organic solvent and preparing a TMP organic solvent solution; and (3) adding the prepared composite catalyst into the TMP organic solvent solution, stirring, evenly mixing, heating until backflow, dropwise adding a hydrogen peroxide aqueous solution and then carrying out reaction for 2-8hours at the temperature of 20-80 DEG C, and cooling the reaction solution to room temperature; and finally obtaining the TMBQ product after separating and purifying. The preparation method of the 2, 3, 5- TMBQ adopts TMP catalytic oxidation for one-step synthesis of TMBQ, and is a green technology, the oxidizing agent and solvent which are adopted by the preparation method have the advantages of being low in toxicity and harmless, the composite catalyst has high activity, and the transformation rates of the TMP and the selectivity of the TMBQ are high.

Owner:HENAN UNIVERSITY

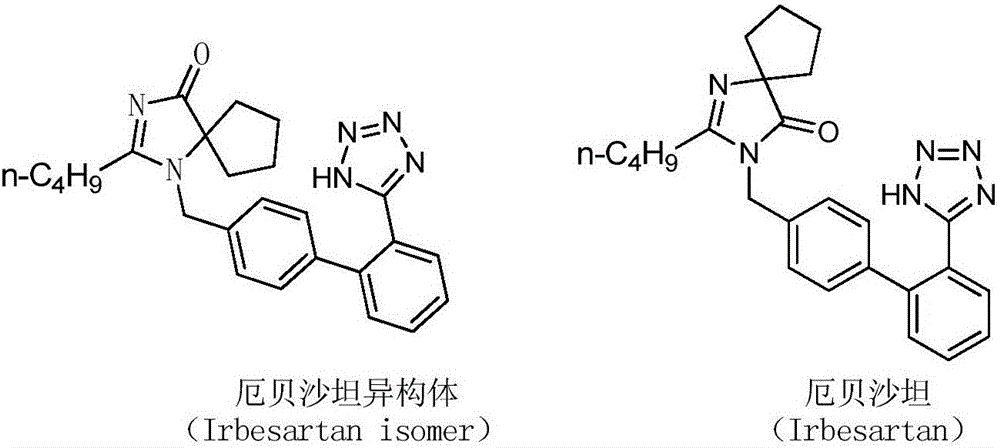

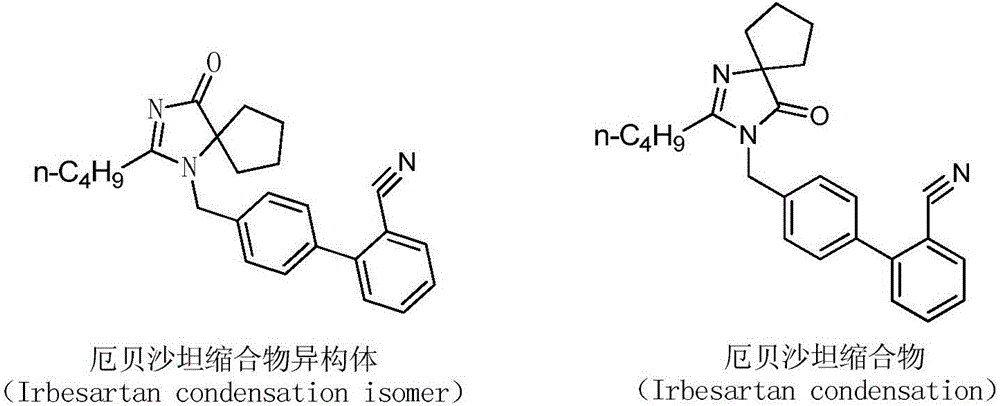

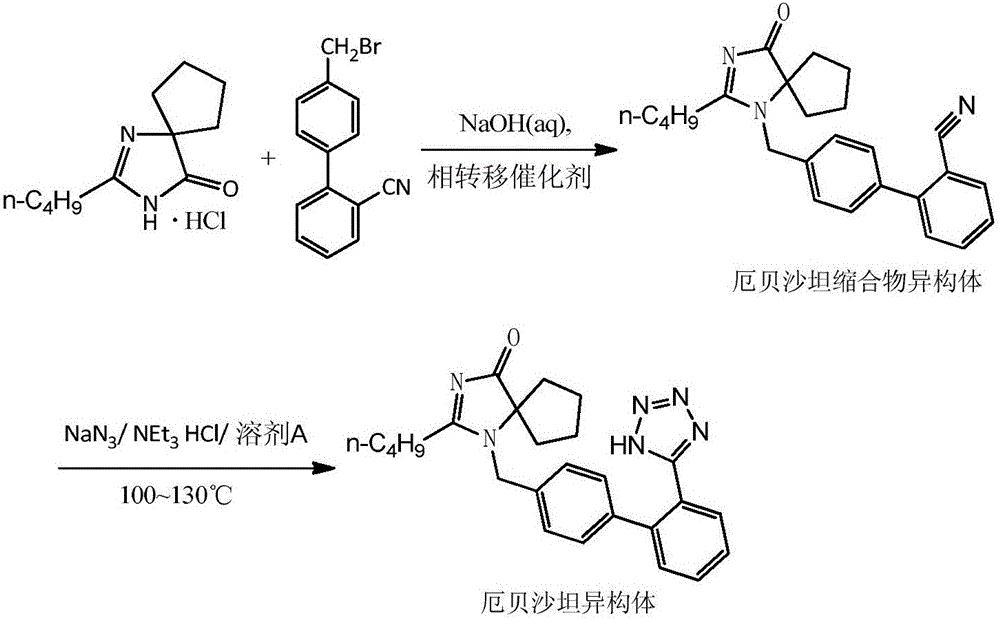

Preparation method of irbesartan isomer and irbesartan intermediate

InactiveCN106083826AHigh purityReduce energy consumptionOrganic chemistryChromatographic separationOrganic layer

The invention relates to a preparation method of an irbesartan isomer and an irbesartan condensation compound isomer as an irbesartan intermediate. The method comprises the following steps: 1) a phase transfer catalyst and an organic solvent are added to an irbesartan ring compound hydrochloride and biphenyl bromide, a sodium hydroxide solution is added, a reaction liquid is filtered after sufficient reaction of the raw materials, a filter cake is subjected to column chromatographic separation, and the irbesartan condensation compound isomer is obtained; 2) triethylamine hydrochloride, sodium azide and an organic solvent A are added to the irbesartan condensation compound isomer, the materials are heated to 100-130 DEG C and reacted, the sodium hydroxide solution and an organic solvent B are added, the mixture is stirred, left to stand and subjected to organic layer removal, hydrochloric acid is added to an aqueous-layer solution to regulate pH to 3.5-6.0, the solution is stirred and filtered, a filter cake is subjected to recrystallization with an organic solvent C or subjected to column chromatographic separation, and the irbesartan isomer is obtained. The irbesartan isomer impurity and the irbesartan intermediate prepared with the method have higher purity and lower energy consumption and cost. Meanwhile, the preparation method is simple to operate and environment-friendly and has important value in irbesartan production and research.

Owner:ZHEJIANG HUAHAI PHARMACEUTICAL CO LTD

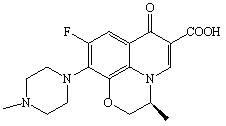

Recovering and applying method of triethylamine in acylation liquid for preparing levofloxacin 1

ActiveCN102153479AEasy to operateNo distillationOrganic compound preparationAmino compound preparationAlkalinityOrganic solvent

The invention relates to a recovering and applying method of triethylamine in an acylation liquid for preparing levofloxacin 1 by a 2,3,4,5-tetrachloro benzoyl chloride acxylation method, belonging to the technical field of fine chemicals. The method is realized by the following steps: 1) filtering the acylation liquid in the process of preparing the levofloxacin by using the 2,3,4,5-tetrachloro benzoyl chloride acxylation method, so as to separate out the triethylamine, wherein the filtrate is an acylated mother liquid, and a filter cake is triethylamine hydrochloride; and 2) adding liquid alkaline to regulate the filter cake triethylamine hydrochloride to alkalinity, so that the triethylamine hydrochloride is converted into the triethylamine hydrochloride to be separated out, extractingwith an organic solvent, dehydrating and converting for synthesis. The triethylamine recovering method is simple to operate, rectification is not needed, and the recovery rate is high and reaches above 93% which is equivalent to the fact that about 35 kg of triethylamine is just added in production of 1 ton of levofloxacin 1, and for expensive triethylamine, production cost is greatly reduced.

Owner:ZHEJIANG LANGHUA PHARMA

Phenyl phosphine diamide derivative as well as synthesis method and application thereof

InactiveCN108659040AFair priceLow boiling pointGroup 5/15 element organic compoundsEpoxySynthesis methods

The invention provides a phenyl phosphine diamide derivative as well as a synthesis method and application thereof. The synthesis method comprises the following steps: by taking phenyl phosphine oxalyl chloride and primary amine as reaction raw materials, tetrahydrofuran or diethyl ether as reaction solvents, and triethylamine as a reaction catalyst, dissolving the primary amine into ethyl ether or tetrahydrofuran, and by taking triethylamine as an equal mass as a substrate, slowly dropping a phenyl phosphine oxalyl chloride containing ethyl ether or tetrahydrofuran solution while stirring ata uniform speed, wherein the dropping time is longer than 2 hours; controlling a reaction temperature to be below 5 DEG C, and continuously stirring for more than 5 hours at the room temperature afterdropping is completed; filtering a product to remove triethylamine hydrochloride, carrying out vacuum distillation, and washing an obtained product with deionized water, so as to obtain a crude product. The product can be applied to flame-retardant modification on an epoxy resin. The product provided by the invention can be used as a flame-retardant modifier, meanwhile is low in synthesis raw material price, simple and gentle in synthesis process and low in solvent melting point in a reaction process and can be recycled and repeatedly used, and energy consumption is correspondingly reduced.

Owner:FUJIAN CONSTR ENG GRP BUILDING MATERIAL SCI & TECH DEV

Treatment process for glyphosate mother liquid

InactiveCN101508700AHigh yieldReduce consumptionGroup 5/15 element organic compoundsWater/sewage treatmentPhosphateAqueous solution

The invention discloses a treatment process of glyphosate mother solution. The glyphosate mother solution is the remaining mother solution obtained after separating glyphosate bulk drug from a system when an acidolysis reaction is over during a process of producing the glyphosate bulk drug by a dialkyl phosphate method. The treatment process of the glyphosate mother solution comprises the following steps: containing the glyphosate mother solution in a concentration device; separating to eliminate most of water under a depressurization condition to separate the glyphosate bulk drug dissolved in the mother solution; standing for layering, wherein, an upper layer is triethylamine hydrochloride and a lower layer is aqueous solution containing the glyphosate; combining the solution of the lower layer with the glyphosate for the concentration treatment process of next batch; neutralizing the triethylamine hydrochloride of the upper layer with alkali to adjust pH value to 8-13; rectifying the triethylamine of the upper layer and returning to a glyphosate synthesis procedure for recycle. The solution of the lower layer is distilled to recover a small amount of the triethylamine hydrochloride, and then discharged after biochemical treatment or used for preparing 10% glyphosate solution. The treatment process is suitable for treatment of the glyphosate mother solution.

Owner:陈桢铭 +1

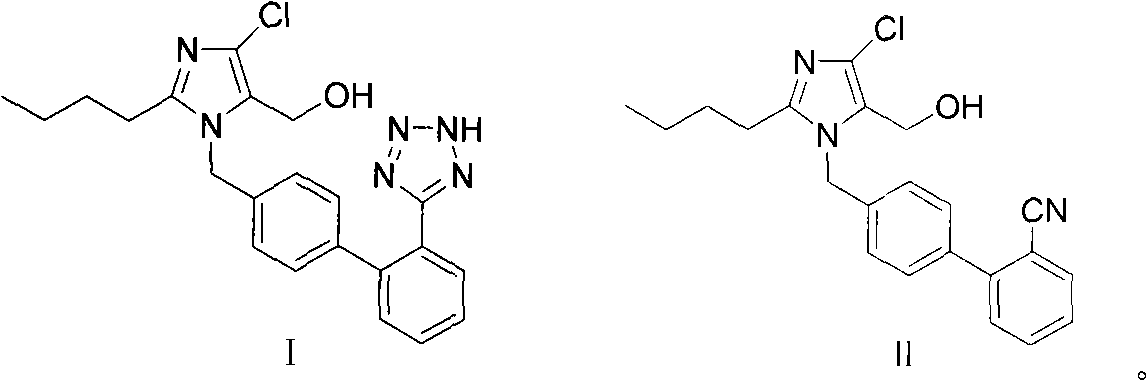

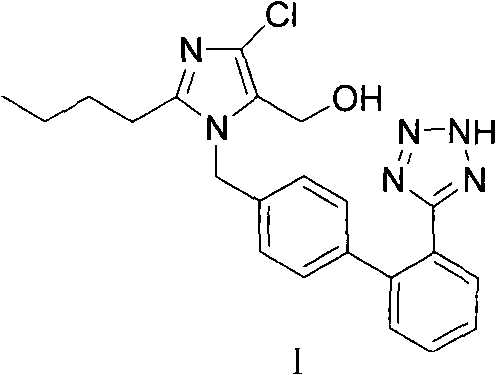

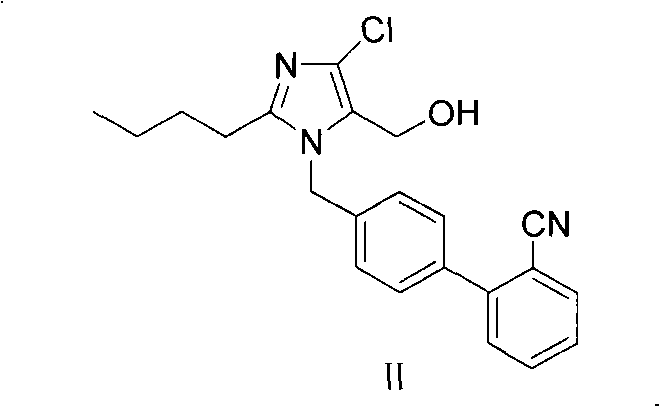

Preparation of losartan

The invention provides a method for preparing losartan shown in a formula (I). The method comprises the following steps: reacting 2-butyl-4-chlorine-5-(hydroxymethyl)-1-{[(2'- cyano-group) xenyl-4-group]methyl} imidazole and natrium azide and triethylamine hydrochloride shown in a formula (II) in toluol; regulating the obtained reaction liquid by alkali to separate organic layers; adding a reducing agent into the collected liquid; regulating the obtained reaction liquid by acid to obtain losartan solid; and if required, refining the losartan solid by isopropyl alcohol. The method has the advantages of high yield, high purity of the losartan, low cost, little environmental pollution and suitability for industrialized production.

Owner:ZHEJIANG MENOVO PHARMA

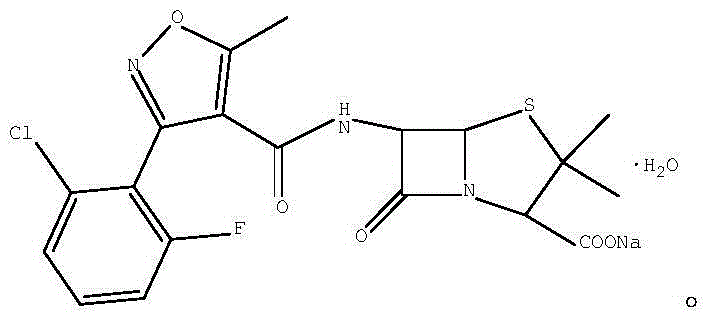

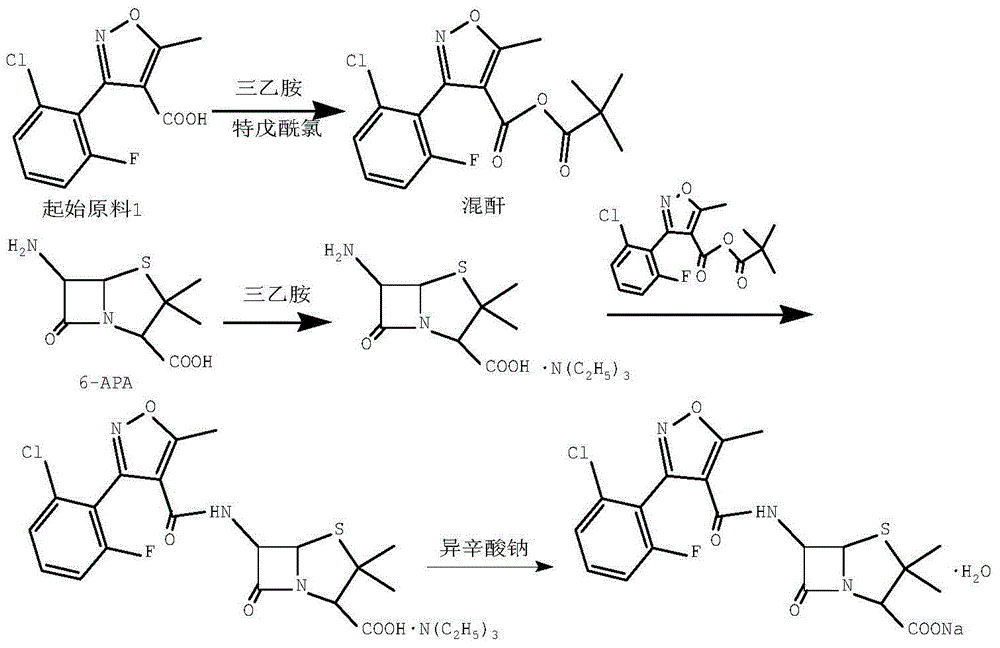

Preparation method for flucloxacillin sodium

The invention discloses a preparation method for flucloxacillin sodium. The method comprises: (1) adding an initial raw material 1 into dichloromethane, dropwise adding triethylamine, and then dropwise adding pivaloyl chloride for reaction, so as to obtain a mixed anhydride; (2) adding 6-APA into dichloromethane, then adding triethylamine, reacting until the material solution is clear, so as to obtain a 6-APA triethylamine salt solution; dropwise adding the mixed anhydride into the 6-APA triethylamine salt solution for reaction, then distilling at a reduced pressure to remove dichloromethane, so as to obtain an oily substance, then adding acetone into the oily substance, stirring, and filtering off triethylamine hydrochloride, so as to obtain an acetone solution of flucloxacillin triethylamine salt; and (4) adding water and an ethyl acetate solution of sodium 2-ethylhexanoate into the acetone solution of flucloxacillin triethylamine salt, controlling the temperature to be 0-40 DEG C after adding is finished, and crystallizing, so as to obtain flucloxacillin sodium monohydrate. The preparation method has the advantages of mild reaction conditions, high yield, good purity, simple operation, friendliness to environment, and the like.

Owner:山东安信制药有限公司

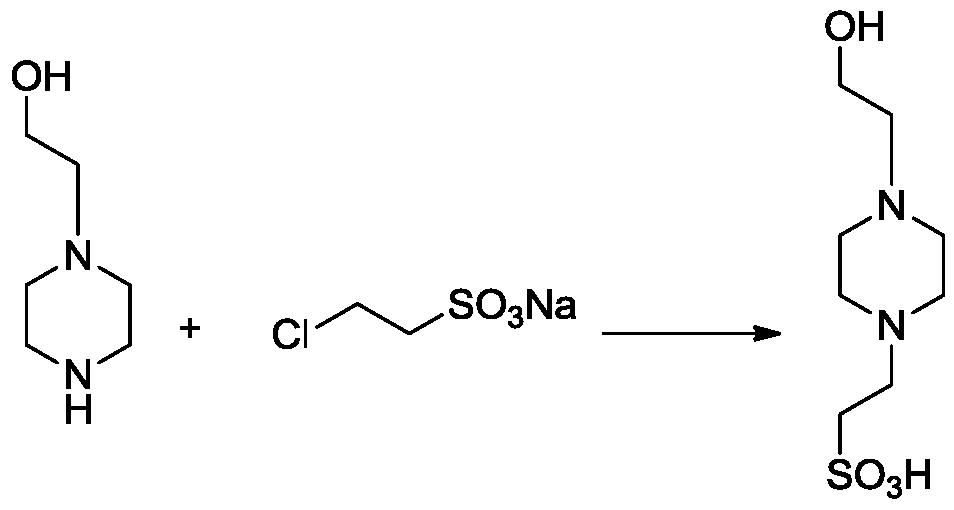

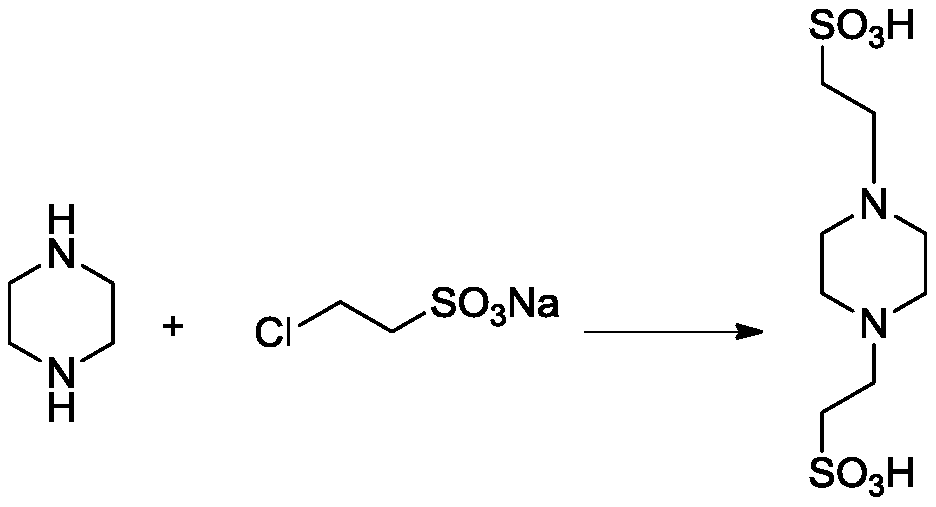

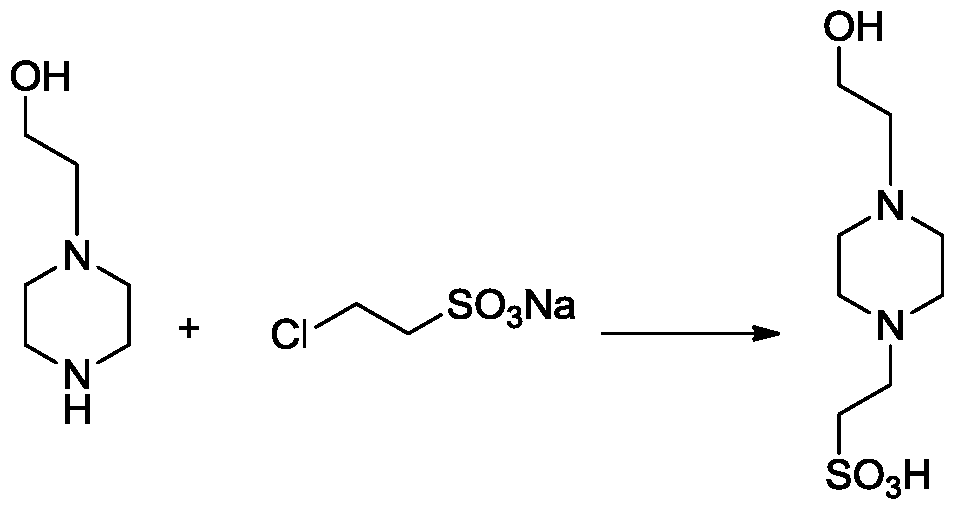

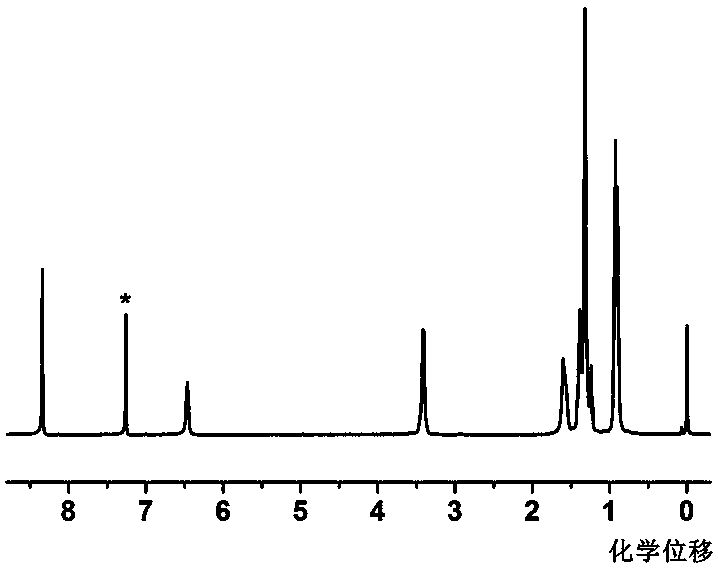

Preparation method of piperazine ethane sulfonic acid derivatives

The invention discloses two preparation methods of piperazine ethane sulfonic acid derivatives. In the early stage of feeding, the reaction is initiated by pre-heating, and heating is carried out after the system is self-heated to a certain degree by reaction, so as to effectively control side reaction of 2-hydroxyethyl piperazine and 2-chloroethane sulfonic acid sodium salt, so that the reactioncan be carried out relatively thoroughly. By reducing the way of adding NaOH solution, the generation of NaCl in the reaction system is reduced, and then triethylamine hydrochloride soluble in water and ethanol is formed by forming salt with triethylamine, which can be directly removed from the system, thus reducing the way of desalting using ion exchange resin; by directly adding the mixed solution of ethanol to the water of the original reaction system for recrystallization, and further using ethanol-water mixed solution in the amount of water added, recrystallization is performed, so as toeffectively reduce the residue of inorganic salts, and the final product has relatively high purity.

Owner:SUZHOU YACOO SCI CO LTD

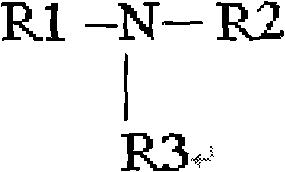

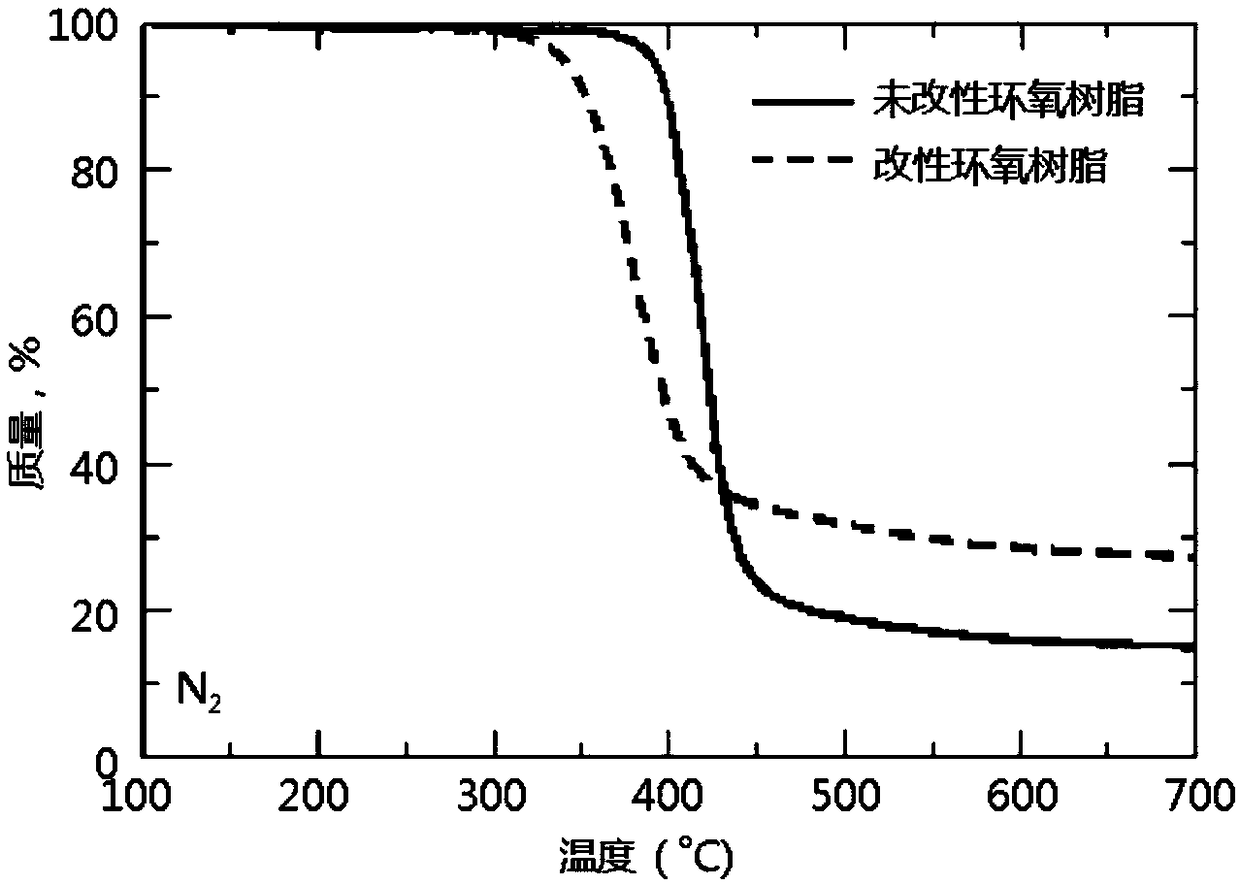

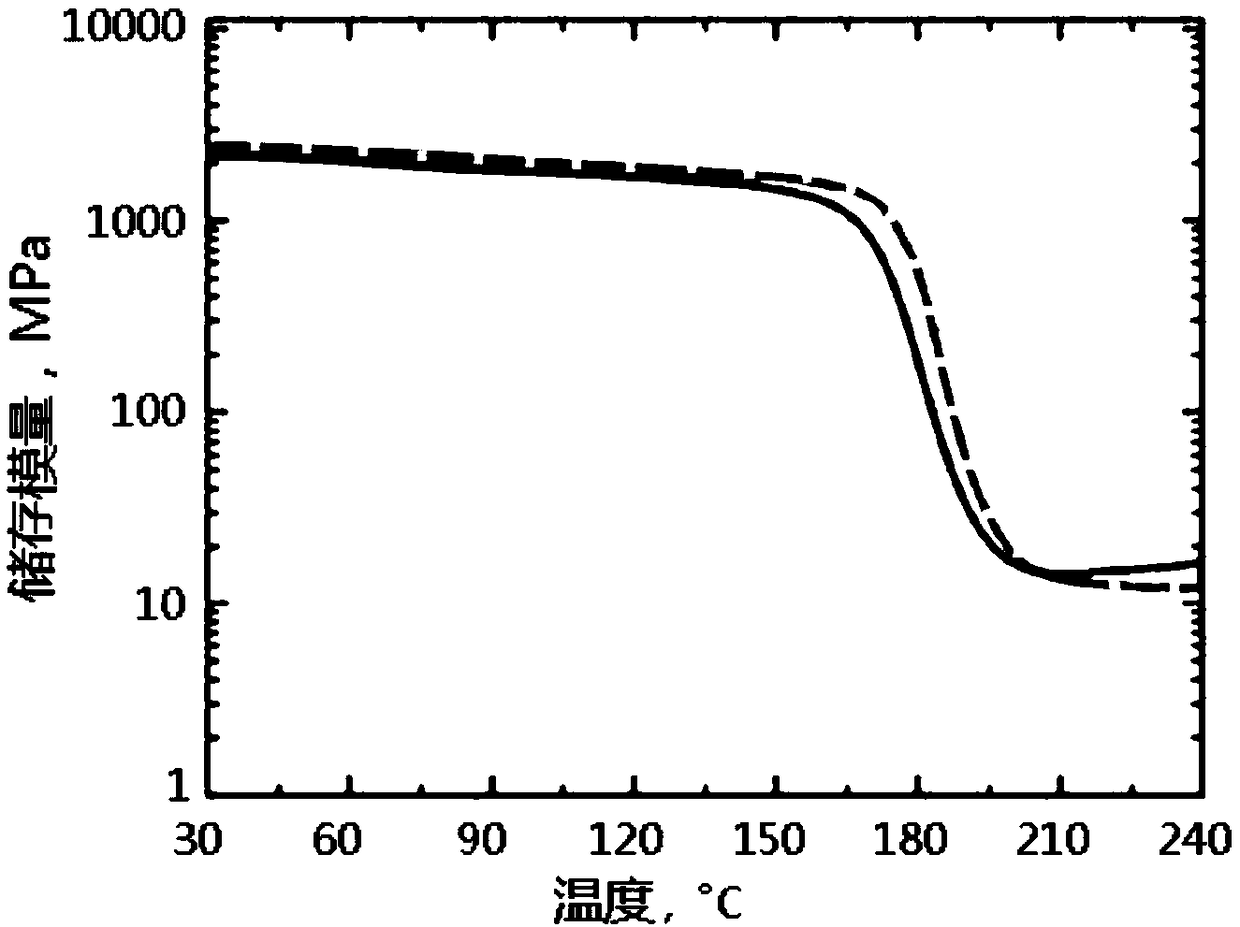

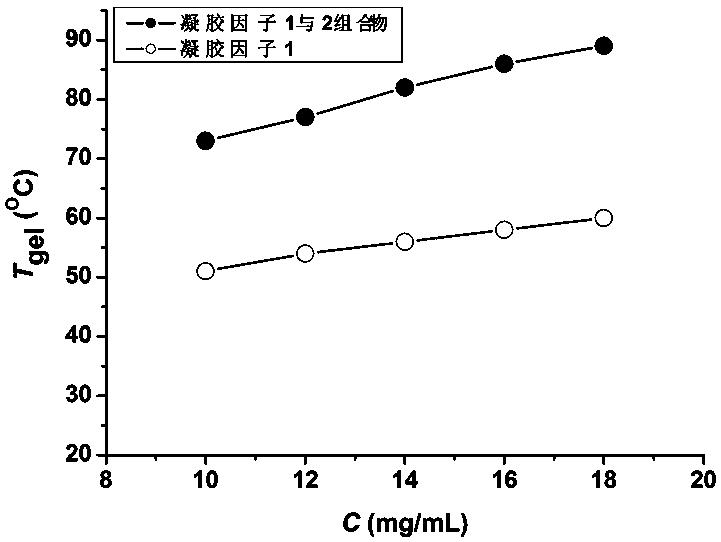

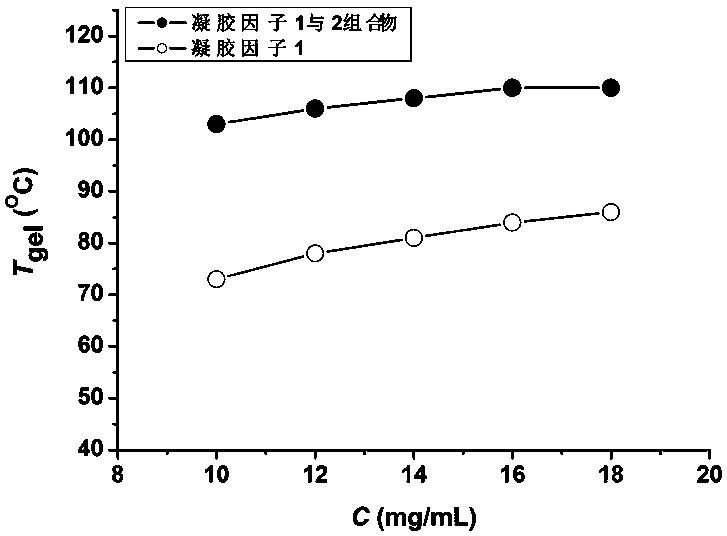

High-thermal stability two-component organic gel and preparation method thereof

ActiveCN107551962AImprove thermal stabilityHigh gel-solution phase transition temperatureColloidal chemistry detailsOrganic solventThermal stability

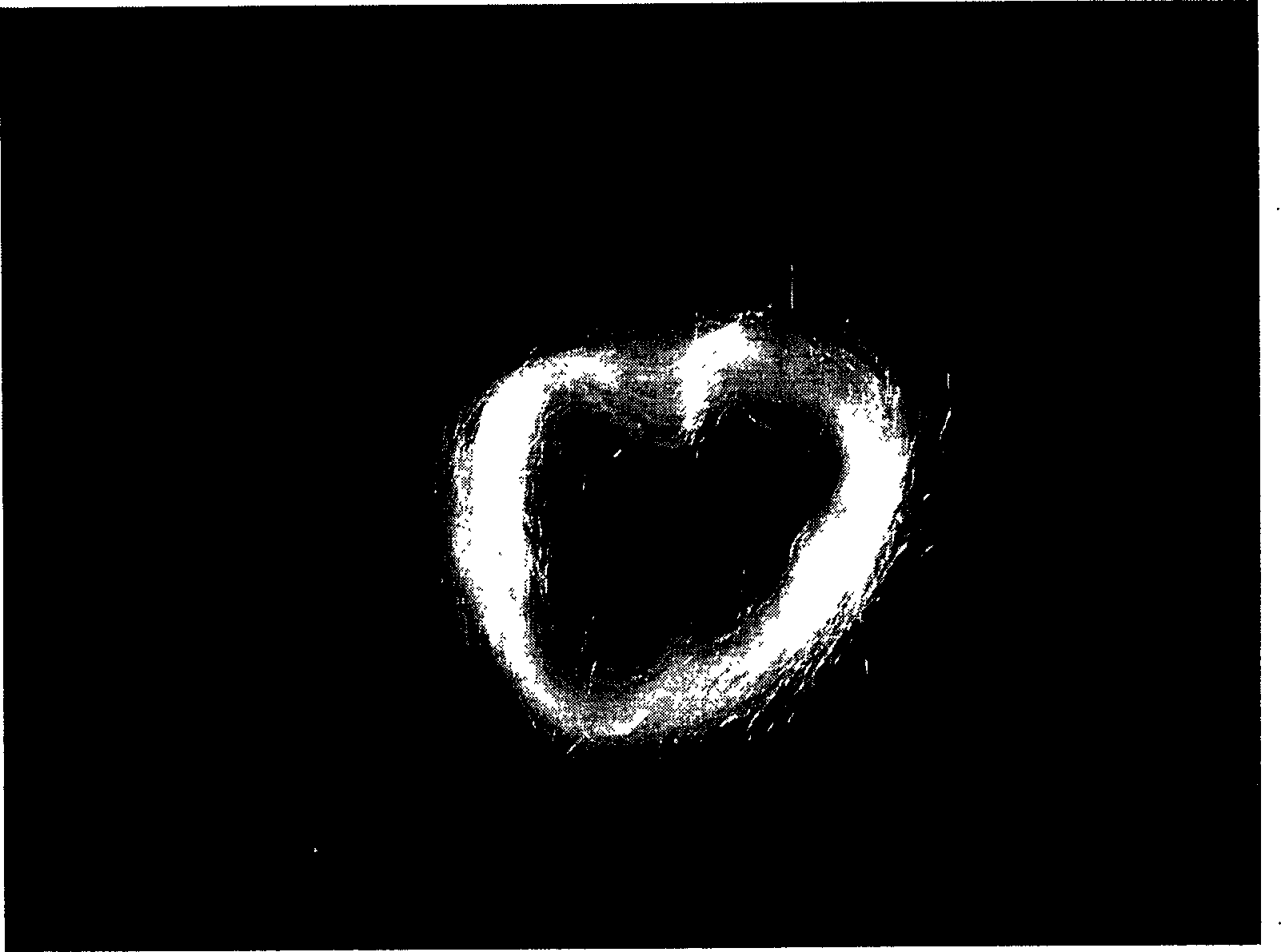

The invention discloses a high-thermal stability two-component organic gel. The high-thermal stability two-component organic gel is a mixed system which is prepared from N<1>,N<3>,N<5>-tris(2-ethylhexyl)phenyl-1,3,5-triformamide serving as a first gel factor, triethylamine hydrochloride serving as a second gel factor and a low-polarity organic solvent. According to the two-component organic gel disclosed by the invention, a porous three-dimensional reticular super-molecular structure is constructed through a synergistic effect between the first gel factor and the second gel factor; the formedorganic gel has high thermal stability, namely, gel-solution phase transition.

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com