Technique for recycling triethylamine from hydrochloric acid triethylamine water solution

A technology of triethylamine hydrochloride and triethylamine, which is applied in the direction of amino compound purification/separation, organic chemistry, etc., can solve the problems of difficult disposal of three wastes, high price, low recovery rate, etc., and achieves low price, low cost, and easy processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

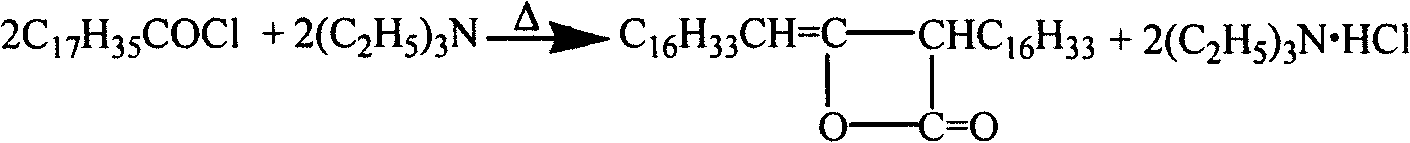

Method used

Image

Examples

Embodiment 1

[0020] (1) produce triethylamine from triethylamine hydrochloride aqueous solution with calcium oxide

[0021] Add 1200Kg of 48% (w / w) triethylamine hydrochloride aqueous solution into the reaction kettle, add 240Kg of powdered calcium oxide with a purity of 80% under stirring, distill the triethylamine at 50-150°C, and drain the aqueous solution into the storage tank for later use. deal with.

[0022] (2) Remove moisture in triethylamine with calcium oxide

[0023] Add 240Kg of powdered calcium oxide with a purity of 80% to the steamed triethylamine. After heating to remove water, what is collected by distillation is colorless and transparent triethylamine with a water content of less than 0.5%. The recovery rate of triethylamine is 96%. .

[0024] (4) Treatment of calcium chloride aqueous solution

[0025] After the aqueous solution discharged in the storage tank is cooled to room temperature, the solid matter is separated and adjusted to neutrality with 30% hydrochloric ...

Embodiment 2

[0027] (1) produce triethylamine from triethylamine hydrochloride aqueous solution with calcium oxide

[0028] Add 1200Kg of 48% (w / w) triethylamine hydrochloride aqueous solution into the reaction kettle, add 200Kg of powdered calcium oxide with a purity of 90% under stirring, distill the triethylamine at 50-150°C, and drain the aqueous solution into the storage tank for later use. deal with.

[0029] (2) Remove moisture in triethylamine with calcium oxide

[0030] Add 200Kg of powdered calcium oxide with a purity of 90% to the steamed triethylamine. After heating to remove water, what is collected by distillation is colorless and transparent triethylamine with a water content of less than 0.5%. The recovery rate of triethylamine is 98%. .

[0031] (4) Treatment of calcium chloride aqueous solution

[0032] After the aqueous solution discharged in the storage tank is cooled to room temperature, the solid matter is separated and adjusted to neutrality with 30% hydrochloric ...

Embodiment 3

[0034] (1) produce triethylamine from triethylamine hydrochloride aqueous solution with calcium oxide

[0035] Add 1200Kg of 48% (w / w) triethylamine hydrochloride aqueous solution into the reaction kettle, add 160Kg of powdered calcium oxide with a purity of 95% under stirring, distill the triethylamine at 50-150°C, and drain the aqueous solution into the storage tank for later use. deal with.

[0036] (2) Remove moisture in triethylamine with calcium oxide

[0037] Add 160Kg of powdered calcium oxide with a purity of 95% to the steamed triethylamine. After heating to remove water, what is collected by distillation is colorless and transparent triethylamine with a water content of less than 0.5%. The recovery rate of triethylamine is 99%. .

[0038] (4) Treatment of calcium chloride aqueous solution

[0039] After the aqueous solution discharged in the storage tank is cooled to room temperature, the solid matter is separated and adjusted to neutrality with 30% hydrochloric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com