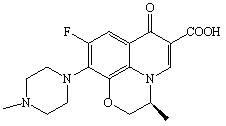

Recovering and applying method of triethylamine in acylation liquid for preparing levofloxacin 1

A technology of levofloxacin and triethylamine, which is applied in the field of recovery and application of triethylamine in levofloxacin acylation solution, can solve the problems of serious pollution, difficult handling of triethylamine, high production cost, etc., achieve good effect, high recovery rate, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The above filter cake triethylamine hydrochloride was adjusted to pH 12 with 10% NaOH, heated to 25°C, and extracted three times with 210g toluene, and the extract was dehydrated with calcium oxide to obtain 234g dry triethylamine / toluene solution. Ethylamine content 12.5wt%, recovery rate 96.5%, the calculation method of recovery rate is the ratio of the amount of triethylamine in the amount of triethylamine in 234g triethylamine / toluene solution and the amount of triethylamine in 41.3g filter cake triethylamine hydrochloride .

Embodiment 2

[0026] The above filter cake triethylamine hydrochloride was adjusted to PH to 12 with 20% NaOH, heated to 25°C, and extracted three times with 300g toluene, and the extract was dehydrated by calcium oxide to obtain 326.1g of dry triethylamine / toluene solution. The content of triethylamine is 9.23wt%, and the recovery rate is 99.3%.

Embodiment 3

[0028] Use 30% NaOH to adjust the pH to 14 with the above filter cake triethylamine hydrochloride, heat it to 25°C, extract it three times with 300g toluene, and dehydrate the extract with calcium oxide to obtain 328g dry triethylamine / toluene solution. The content of ethylamine is 9.15wt%, and the recovery rate is 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com