Patents

Literature

576 results about "Zirconium carbide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zirconium carbide (ZrC) is an extremely hard refractory ceramic material, commercially used in tool bits for cutting tools. It is usually processed by sintering.

Preparation method for fiber reinforced carbon-silicon carbide-zirconium carbide-based composite material

The invention discloses a preparation method for a fiber reinforced carbon-silicon carbide-zirconium carbide-based (C / C-SiC-ZrC) composite material. The preparation method comprises the following steps of: (a) evenly dispersing ZrC nanopowder in absolute ethyl alcohol; (b) mixing phenolic resin and ZrC dispersion liquid to form slurry; (c) immersing a two-dimensional carbon fiber sheet into the slurry for dipping and drying, then carrying out continuous superposition paving on the two-dimensional carbon fiber sheet, and carrying out curing and post-curing treatment to prepare a fiber-reinforced sintered body; (d) cracking the fiber-reinforced sintered body to obtain a porous C / C prefabricate; (e) placing silicon powder into a graphite crucible, burying the porous C / C prefabricate into the silicon powder, heating to 1,500-1,650 DEG C, and preserving heat for preset time so as to carry out liquid silicon permeation. The method can be used for improving the high-temperature oxidizing property and ablation property of the carbon fiber reinforced ceramic (C / C-SiC) composite material.

Owner:DALIAN UNIV OF TECH

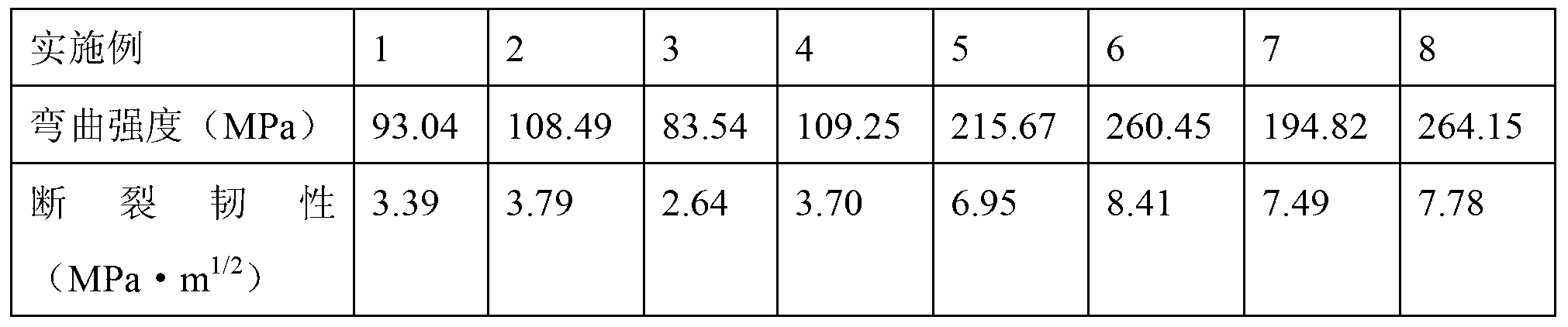

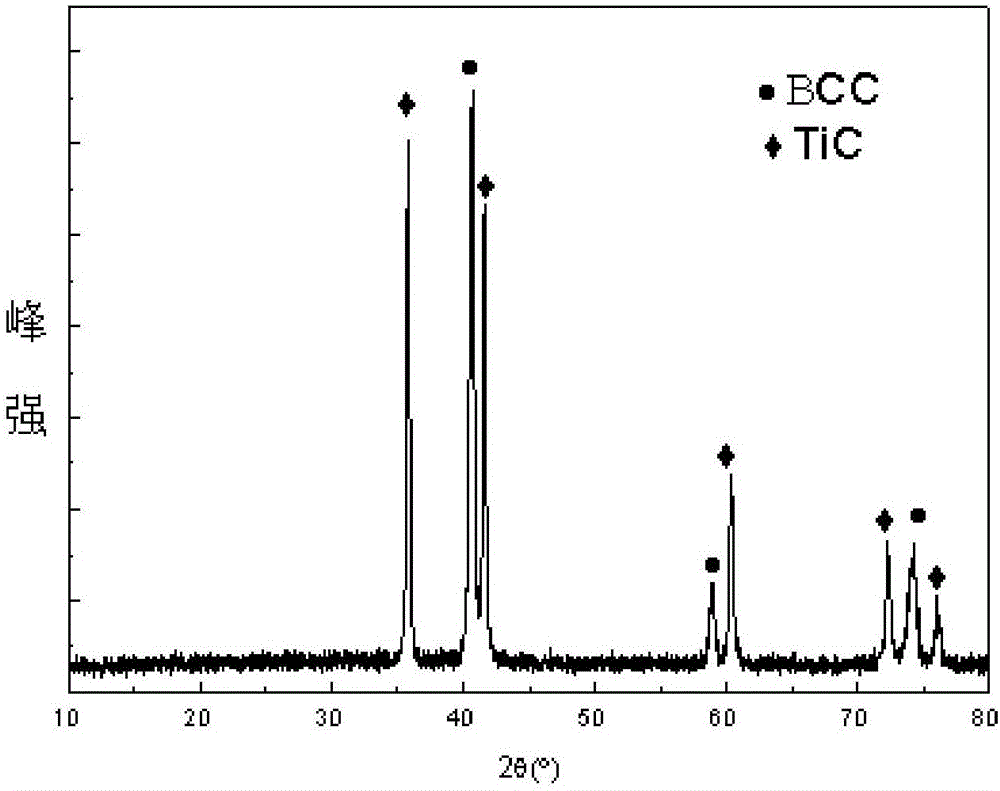

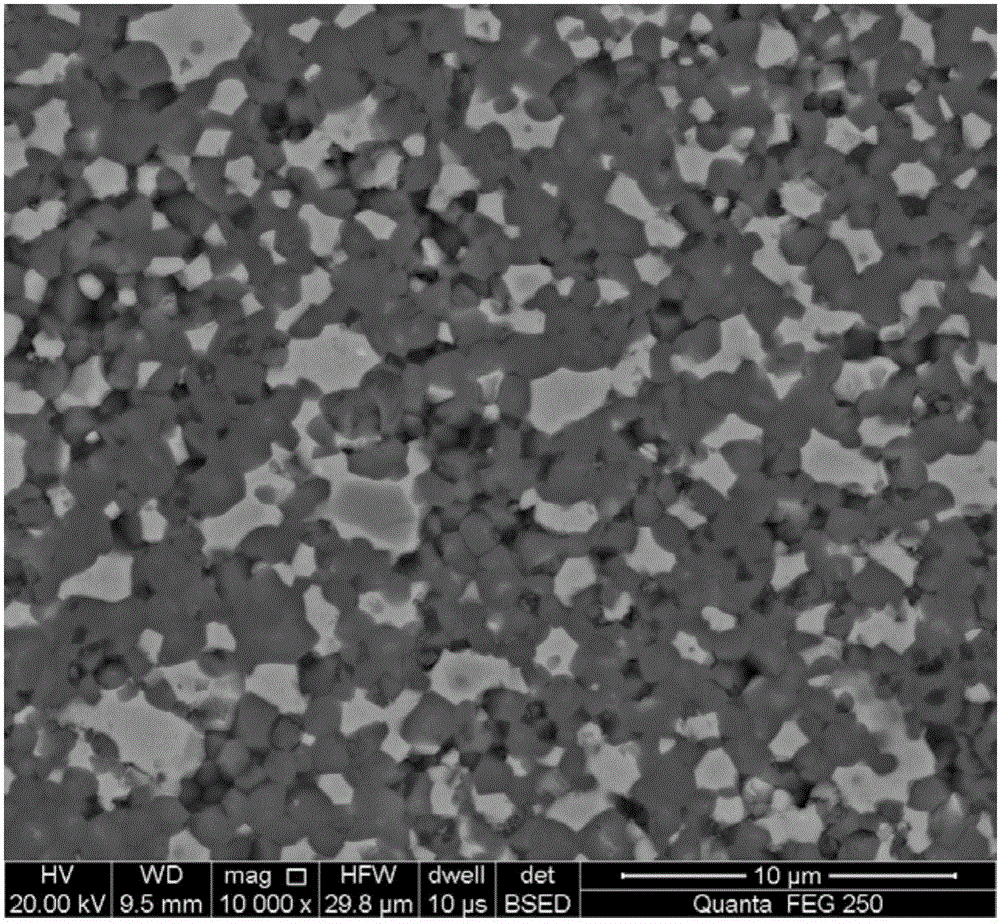

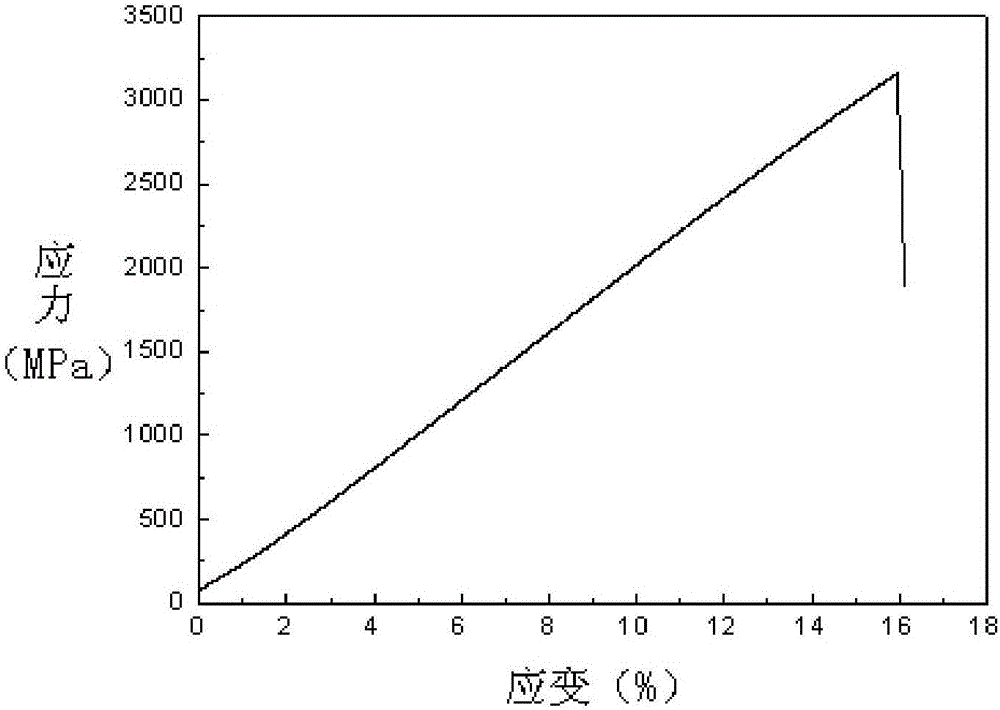

Refractory high-entropy alloy/titanium carbide composite and preparation method thereof

The invention discloses a refractory high-entropy alloy / titanium carbide composite. A refractory high-entropy alloy serves as a matrix phase, and titanium carbide serves as a wild phase; and elements in the refractory high-entropy alloy are selected from at least four kinds of elements of W, Mo, Ta, Nb, V, Ti, Zr, Hf and Cr. A preparation method of the refractory high-entropy alloy / titanium carbide composite comprises the steps that at least four kinds of carbonization metal powder in tungsten carbide, molybdenum carbide, tantalum carbide, niobium carbide, vanadium carbide, the titanium carbide, hafnium carbide, zirconium carbide and chromium carbide are selected and mixed according to the equal molar ratio or the ratio close to the equal molar ratio to form high-entropy matrix powder; and after the high-entropy matrix powder and titanium powder are mixed, alloy mechanization is carried out, then spark plasma sintering or hot-press sintering is carried out, and the refractory high-entropy alloy / titanium carbide composite is obtained. The density and cost of the composite are reduced while the hardness of the composite is improved, excellent high-temperature performance is achieved, and the requirement for manufacturing a high-temperature structural component is met.

Owner:江西咏泰粉末冶金有限公司

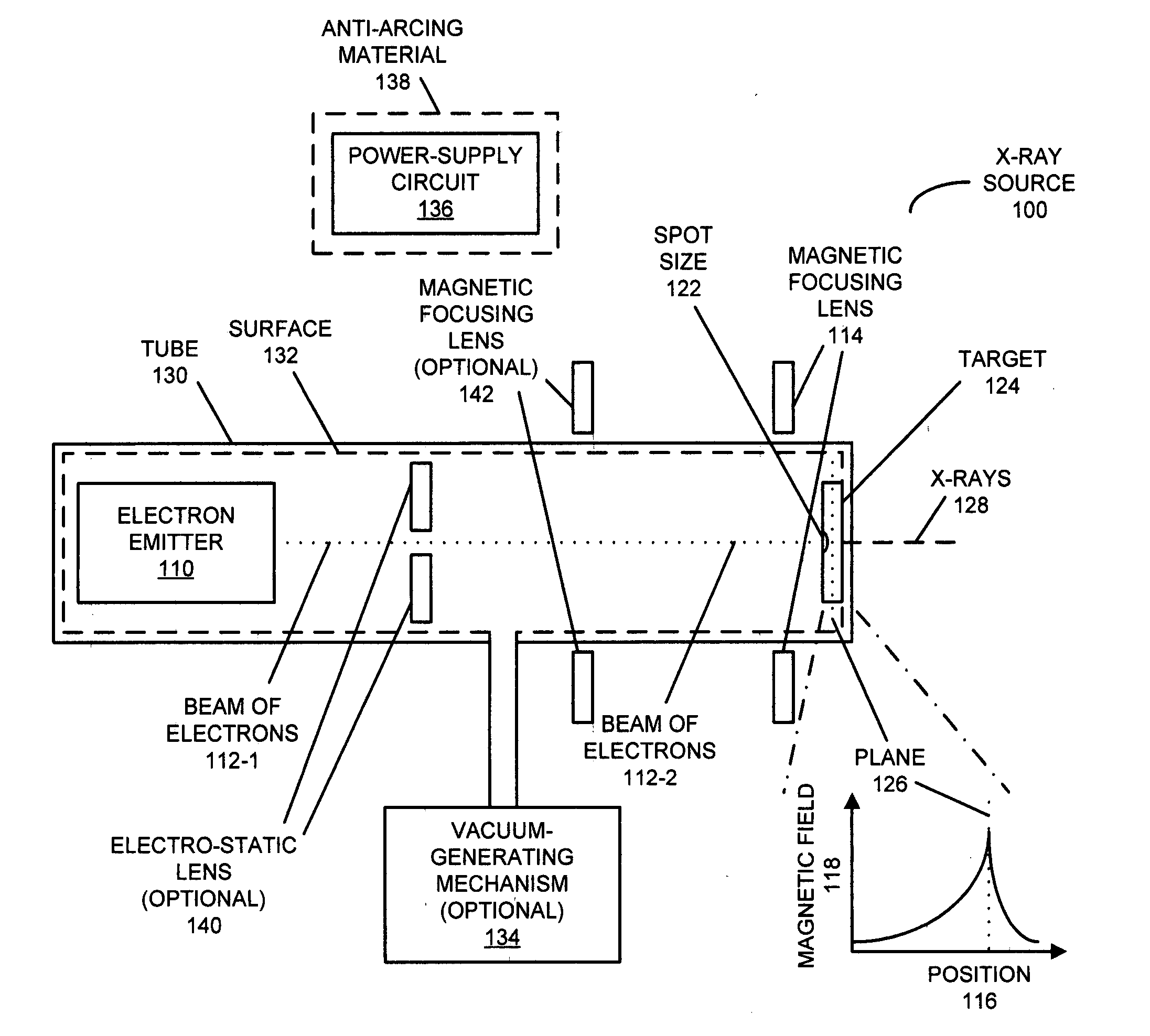

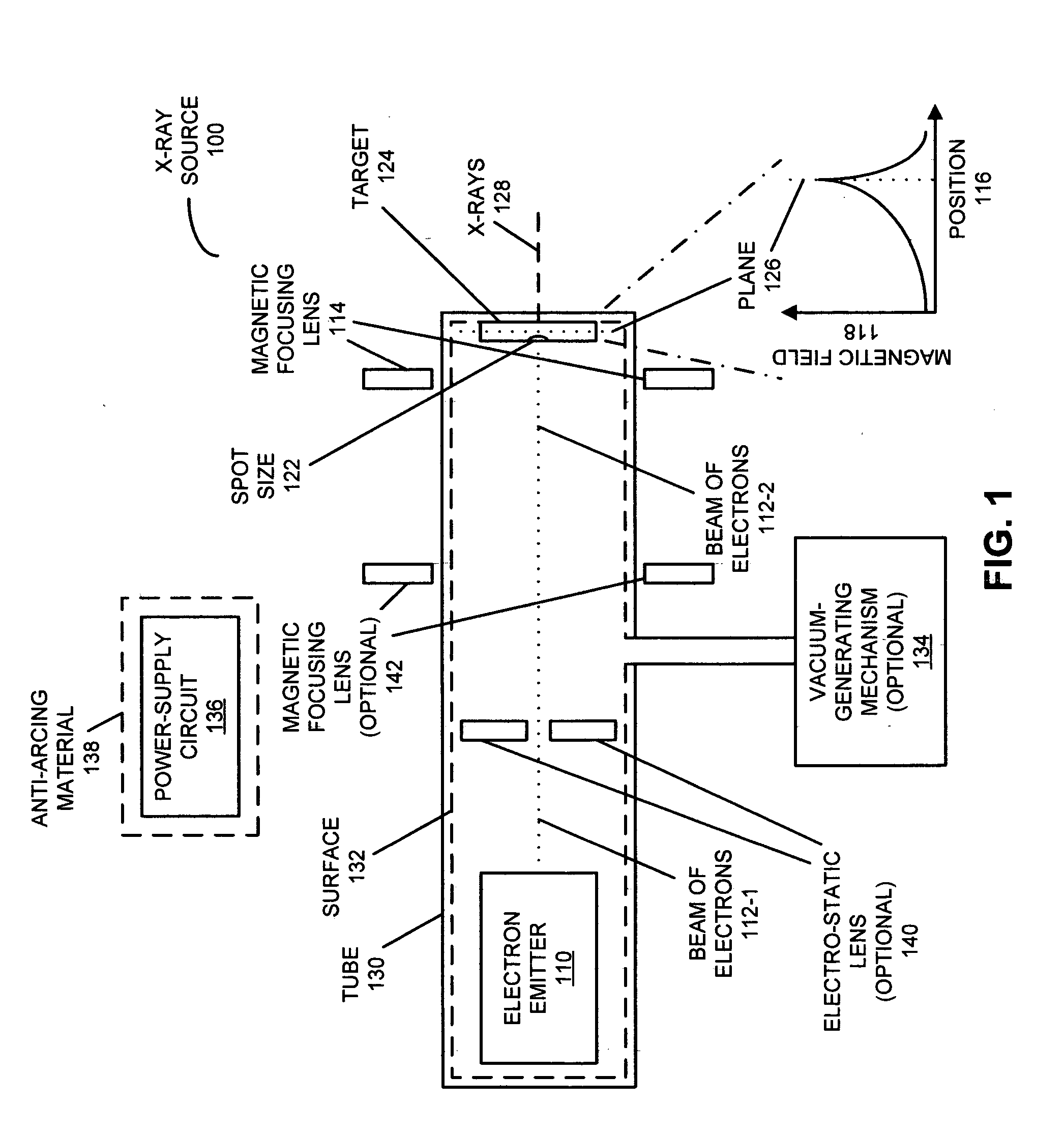

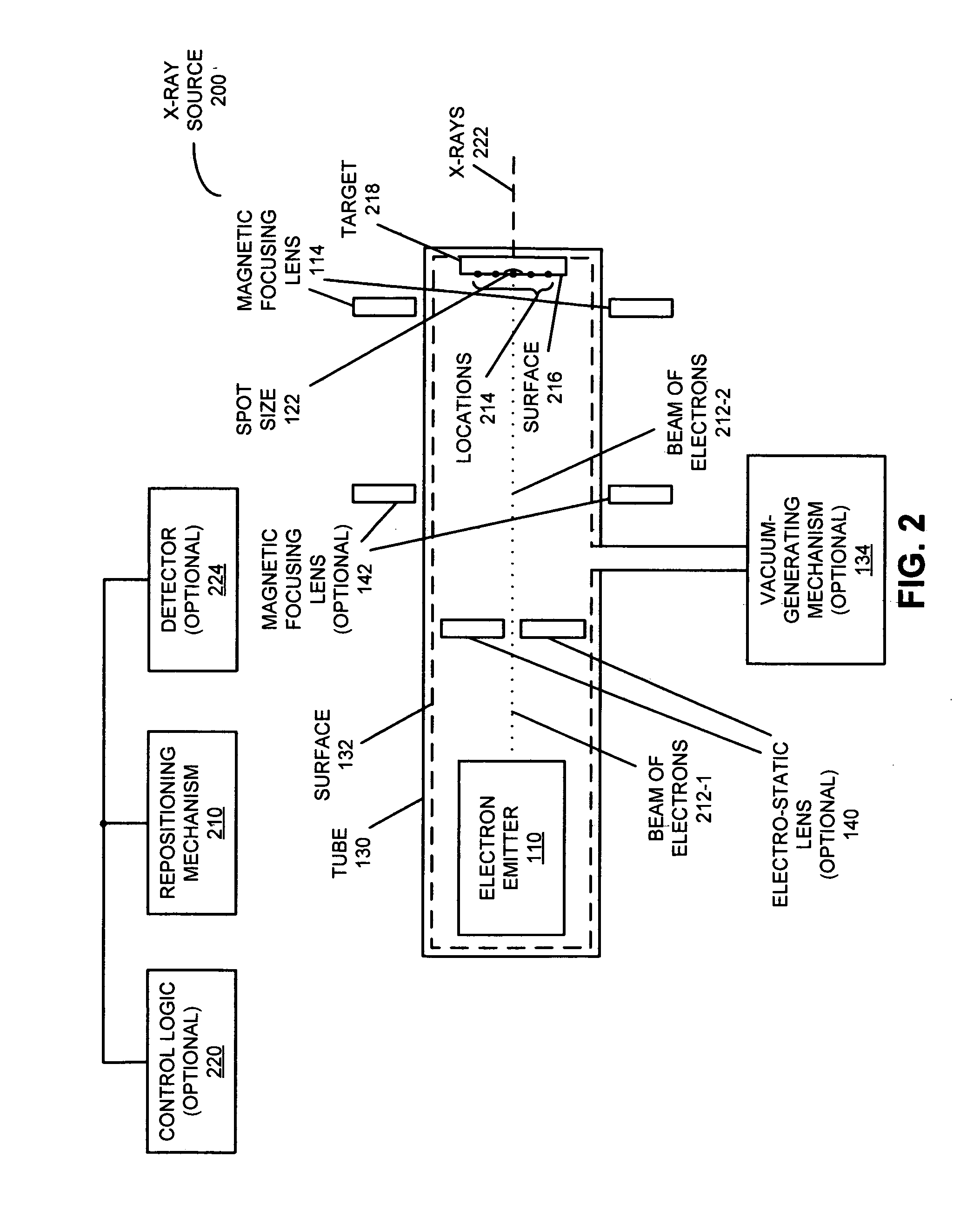

X-ray source with high-temperature electron emitter

InactiveUS20120269326A1X-ray tube electrodesCathode ray concentrating/focusing/directingElectron sourceX-ray

An x-ray source is described. This x-ray source includes an electron source with a refractory binary compound having a melting temperature greater than that of tungsten. For example, the refractory binary compound may include: hafnium carbide, zirconium carbide, tantalum carbide, lanthanum hexaboride and / or compounds that include two or more of these elements.

Owner:ADLER DAVID L +1

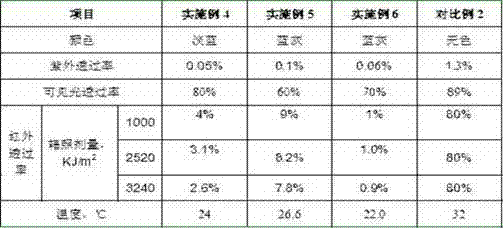

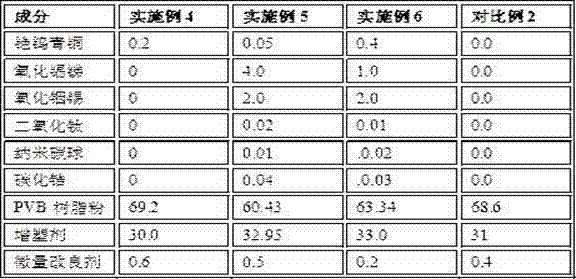

PVB (polyvinyl butyral) film for dynamically rejecting infrared rays and resisting ultraviolet rays and preparation method thereof

ActiveCN104262874AHas the effect of heat insulation and UV protectionPlay the effect of energy saving and environmental protectionPolyvinyl butyralInfrared

The invention discloses a PVB (polyvinyl butyral) film for dynamically rejecting infrared rays and resisting ultraviolet rays and a preparation method thereof. The functional PVB film comprises cesium tungsten bronze, antimony indium oxide, indium tin oxide, titanium dioxide, nano carbon spheres, zirconium carbide, PVB resin powder, a plasticizer, a trace improver and the like. The preparation method comprises the following steps: dispersing the cesium tungsten bronze composite nanoparticles with a solvent, adding the plasticizer, stirring uniformly, adding the PVB resin powder and trace improver, thoroughly mixing, and carrying out film formation on the mixture by running to obtain the heat-insulation ultraviolet-resistant PVB film. The ultraviolet rejection ratio of the PVB film is greater than 99.0%, the visible light transmittance is adjustable within the range of 60-85%, and the infrared rejection ratio is up to 80-99%; and the PVB film can be directly used for producing heat-insulation infrared / ultraviolet-resistant safety laminated glass, can be widely used in architectural curtain walls, doors / windows, zeniths, automobile windshields and the like, and is a novel energy-saving film material.

Owner:SUZHOU POLIMA MACROMOLECULE MATERIAL CO LTD

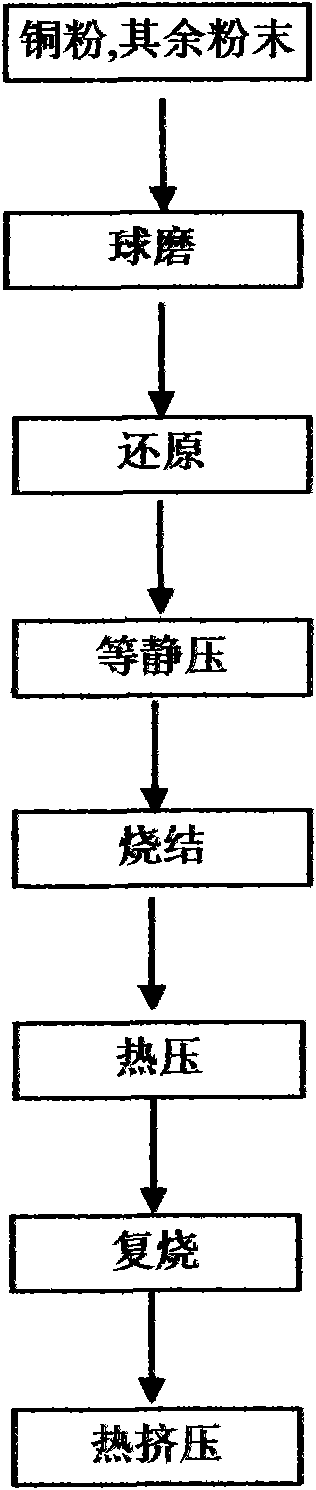

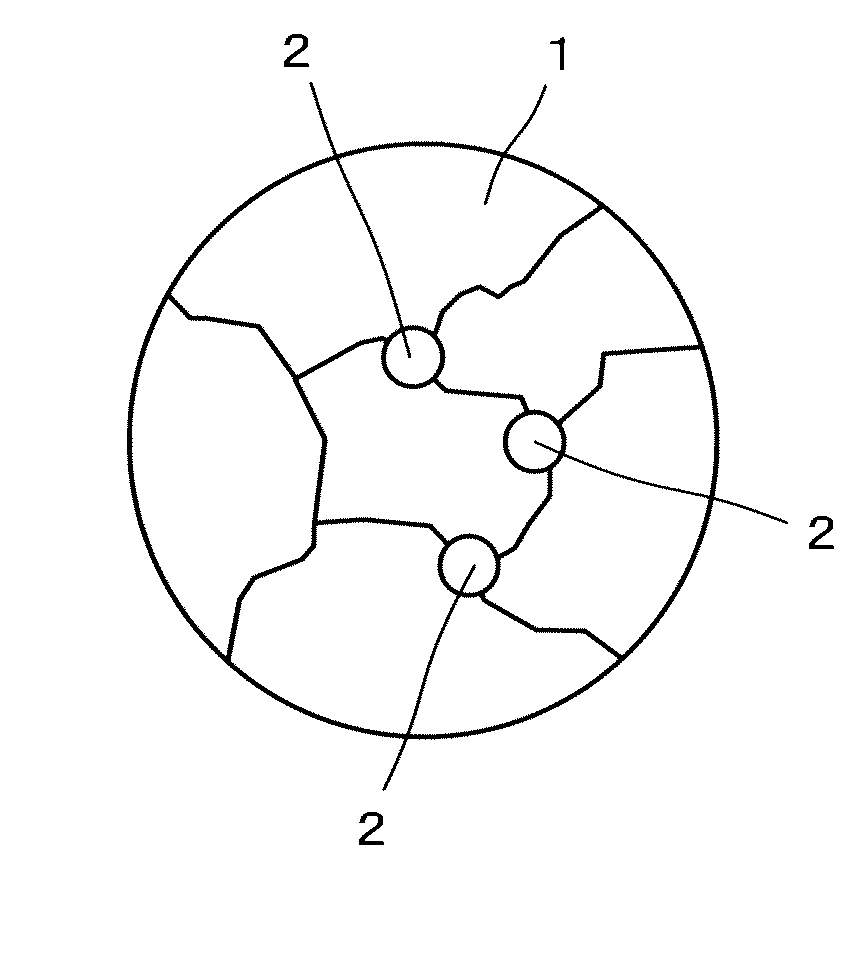

Multiple dispersion strengthening copper-base composite material prepared in situ and preparation method thereof

InactiveCN101613816APromote generationImprove organizational structureTitanium carbideSelf generation

The invention discloses a multiple dispersion strengthening copper-base composite material produced in situ and a preparation method thereof; the reinforced phase comprises at least three of the following substances: titanium carbide, zirconium carbide, alumina, titanium boride, aluminum carbide, chromium oxide, zirconia, graphite and copper; wherein, the contents of titanium carbide, zirconium carbide, alumina, titanium boride, chromium oxide and zirconia are not less than 0.3% and not more than 5%, the content of aluminum carbide is not less than 0.1% and not more than 5%, the content of graphite is not less than 0.1% and not more than 1% and the balance is copper. The particle size of the reinforced phase is between 10nm to 10mu m. The preparation method adopts ball milling; pressing, sintering and squeezing processes and the technological parameters are optimized and controlled properly to obtain the multiple dispersion strengthening copper-base composite material. Because the in situ self-generation technology is adopted and various reinforced phase methods are combined, the material of the invention has higher high-temperature strength and better electroconductibility and anti-creep property compared with the traditional ceramic particle strengthening copper-base composite material.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Probe needle material, probe needle and probe card each using the same, and inspection process

ActiveUS20100194415A1Maintain contact stabilityNot abraded heavilyElectrical measurement instrument detailsElectrical testingProbe cardHafnium

Disclosed is a probe needle material used for producing a probe needle which is used in contact with an inspection object to inspect electrical characteristics of the inspection object, comprising not less than 0.1% by volume but not more than 3.5% by volume of at least one compound selected from the group consisting of titanium boride, zirconium boride, hafnium boride, niobium boride, tantalum boride, chromium boride, titanium carbide, zirconium carbide, hafnium carbide, vanadium carbide, niobium carbide, tantalum carbide, zirconium oxide, hafnium oxide and chromium oxide and the balance of a tungsten alloy mainly consisting of tungsten.

Owner:KK TOSHIBA +1

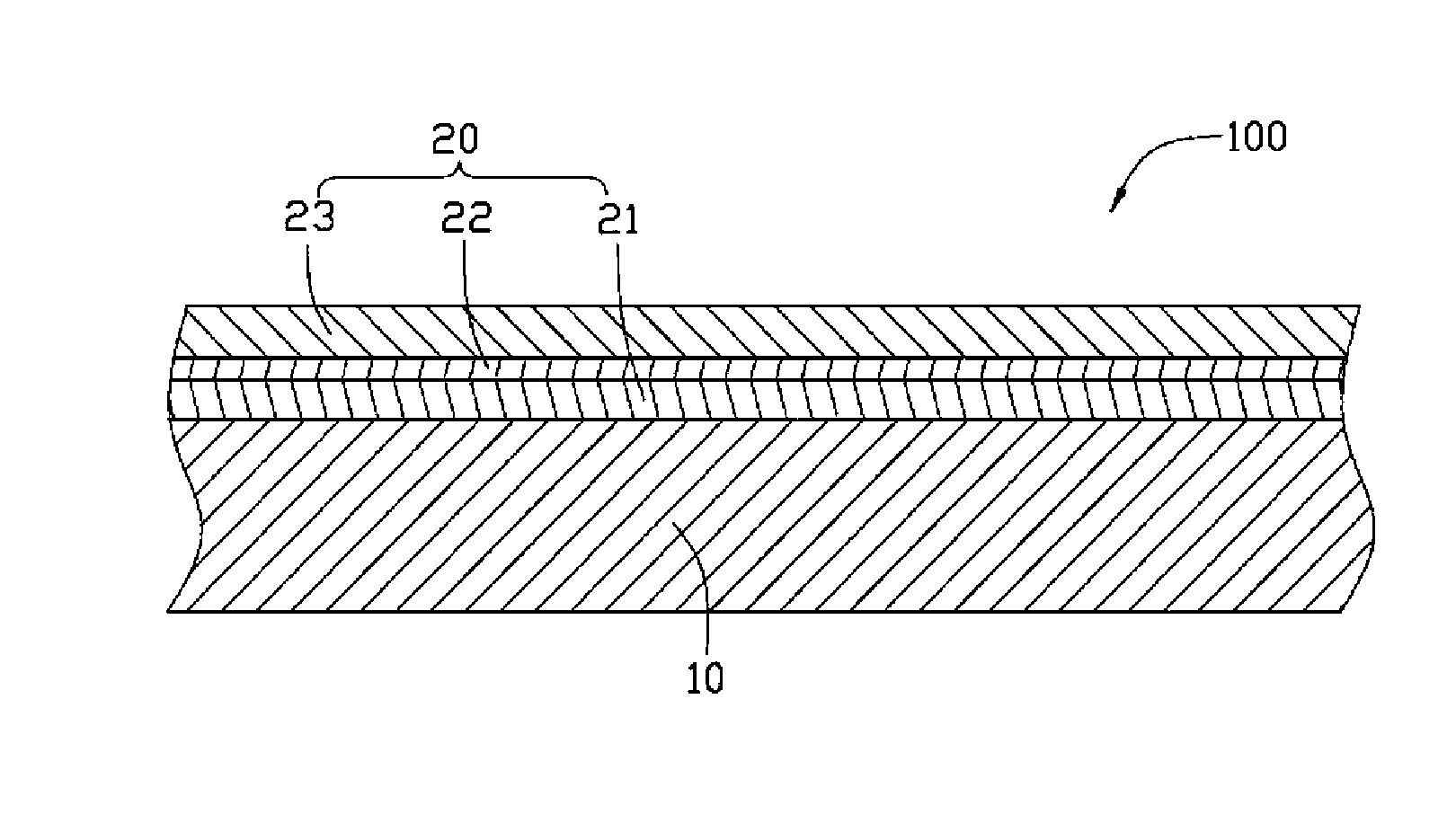

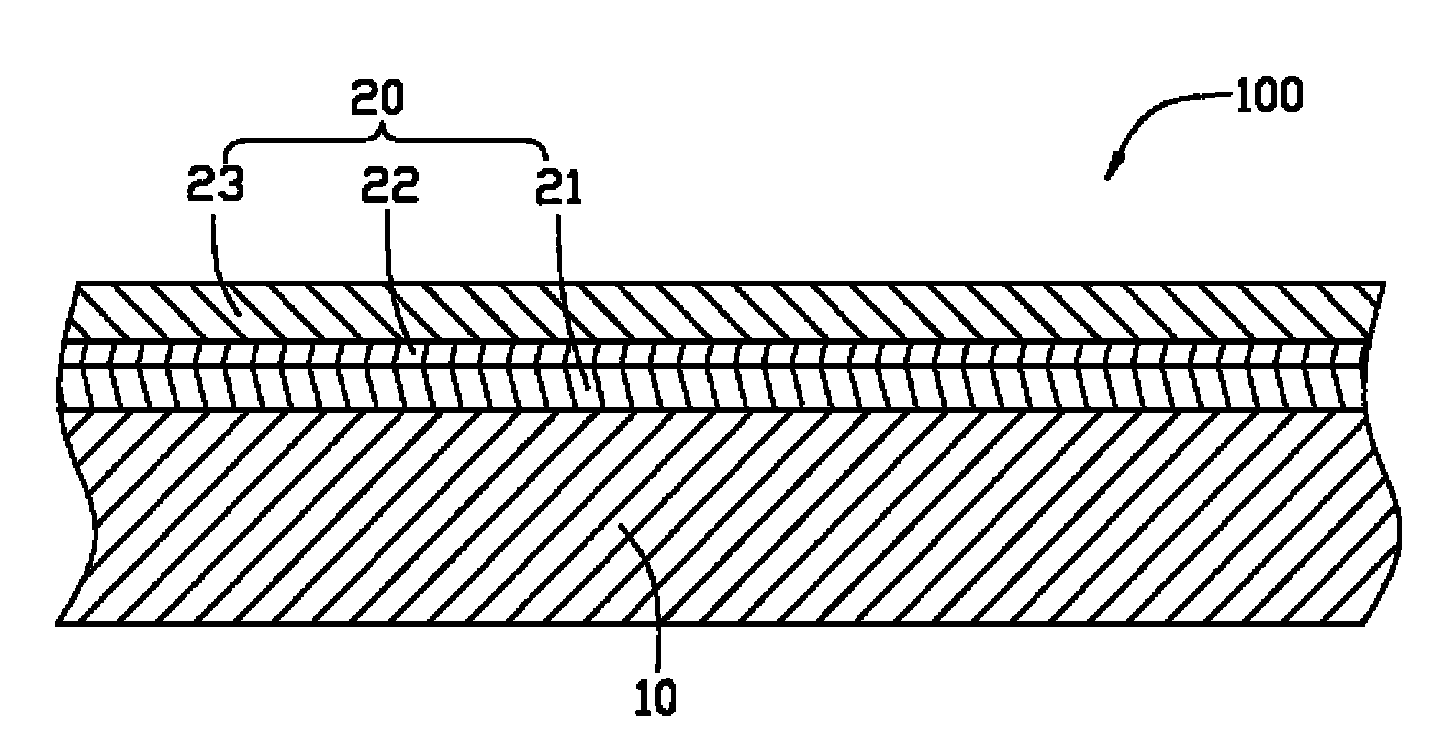

Nuclear fuel cladding with high heat conductivity and method for making same

ActiveUS20110170653A1Optimal transfer of thermal energyEasy transferFuel elementsNuclear energy generationThermal energyFiber

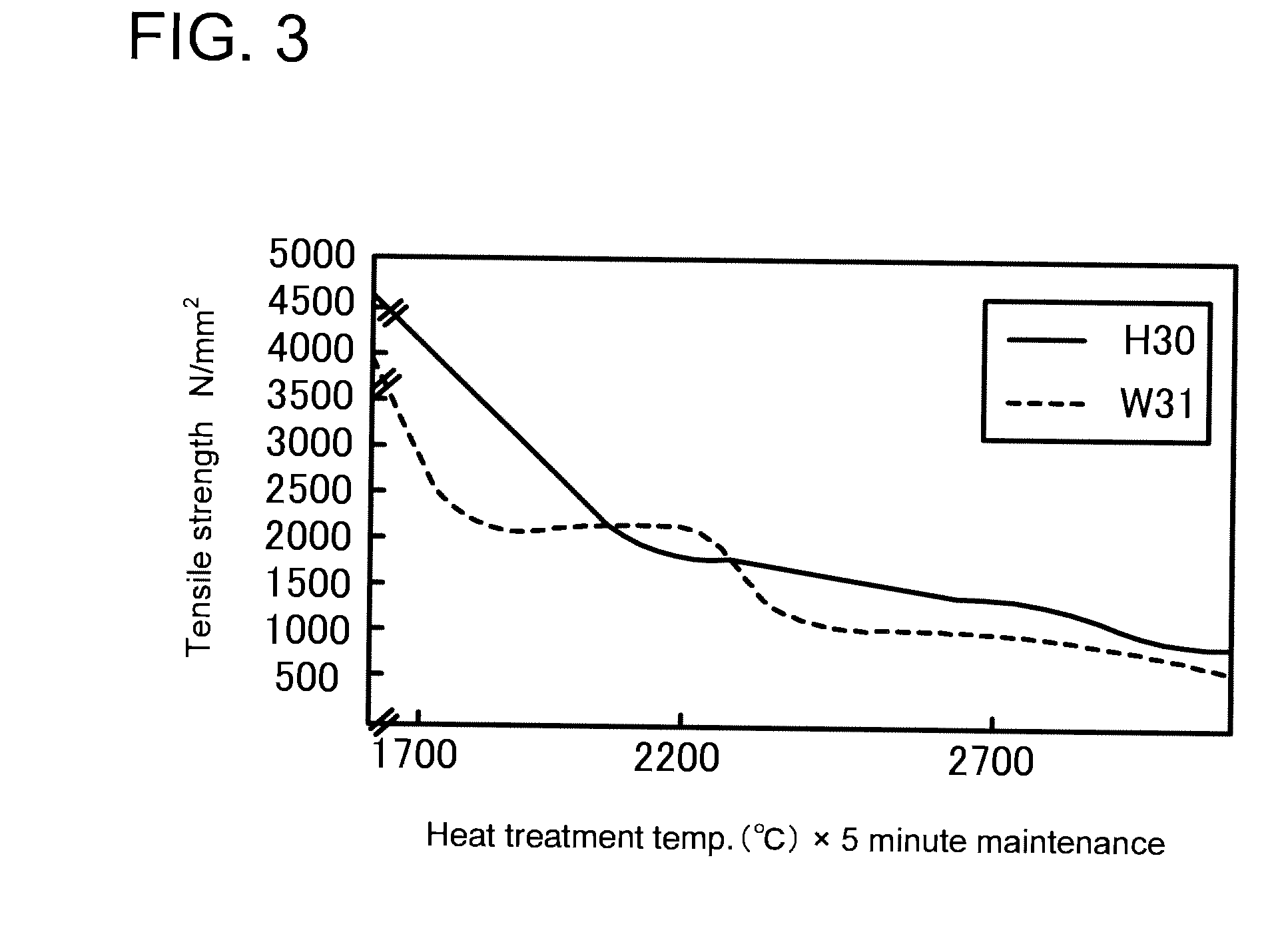

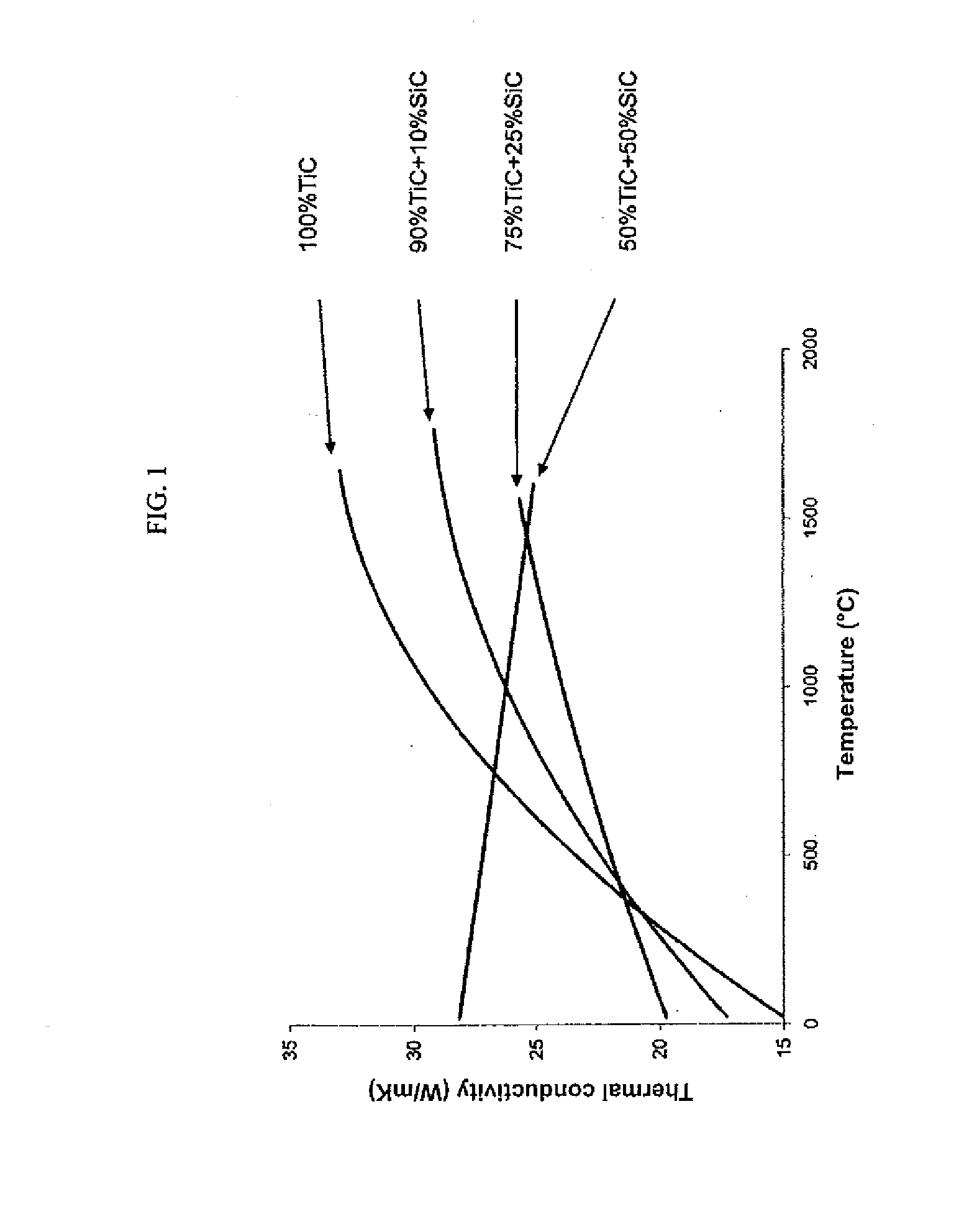

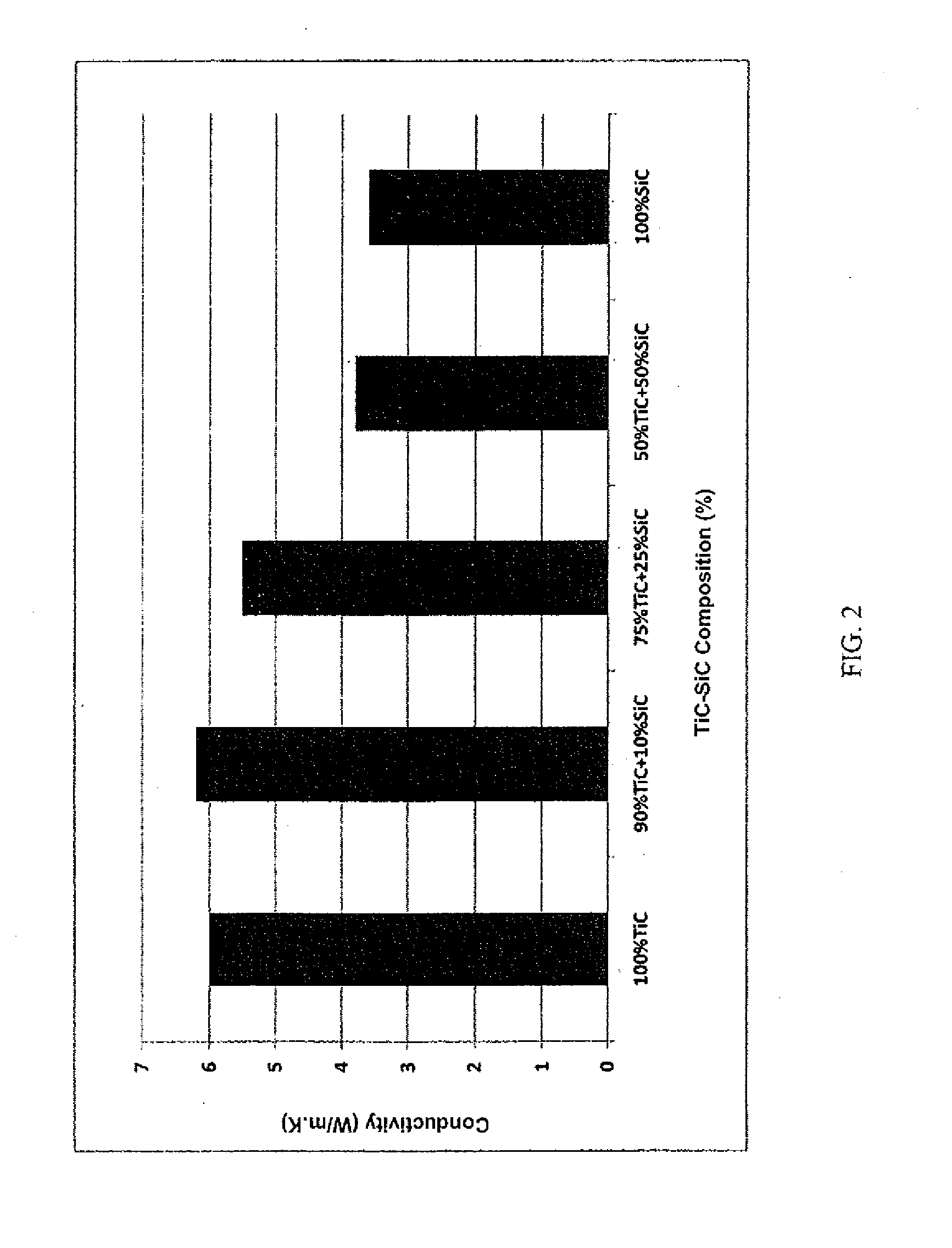

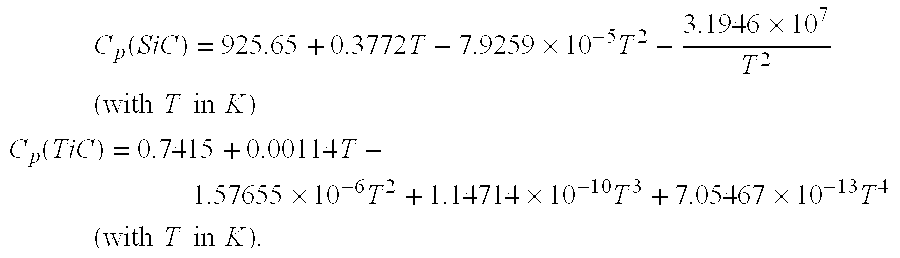

The invention relates to a nuclear fuel cladding totally or partially made of a composite material with a ceramic matrix containing silicon carbide (SiC) fibers as a matrix reinforcement and an interphase layer provided between said matrix and said fibers, the matrix including at least one carbide selected from titanium carbide (TiC), zirconium carbide (ZrC), or ternary titanium silicon carbide (Ti3SiC2).When irradiated and at temperatures of between 800° C. and 1200° C., said cladding can mechanically maintain the nuclear fuel within the cladding while enabling optimal thermal-energy transfer towards the coolant.The invention also relates to a method for making the nuclear fuel cladding.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

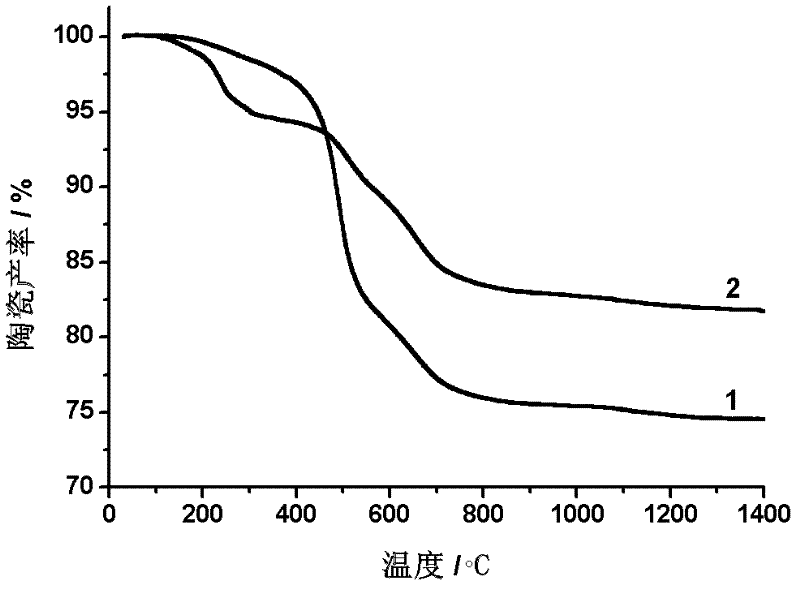

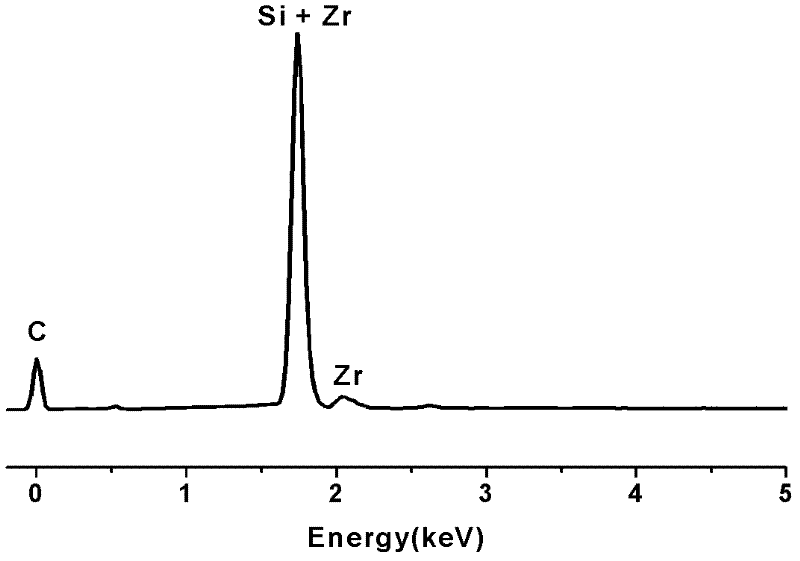

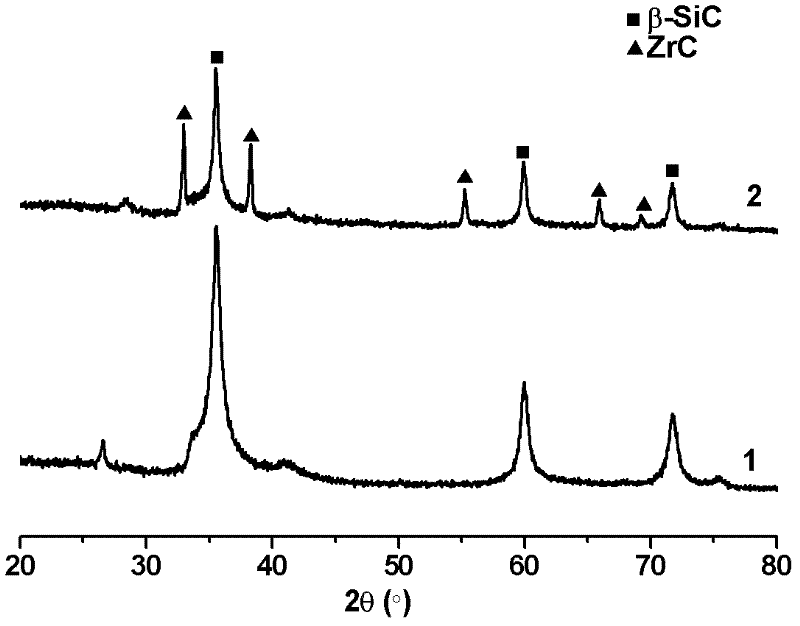

Preparation method of silicon carbide/zirconium carbide composite ceramic

The invention relates to a preparation method of silicon carbide / zirconium carbide composite ceramic, and relates to inorganic nonmetal material composite ceramic. The preparation method comprises the steps of: dissolving bis(cyclopentadienyl) zirconium dichloride with a solvent under the protection of inert atmosphere, and adding liquid hyperbranched polycarbosilane to obtain a mixture A; and distilling the mixture A under reduced pressure under the protection of inert atmosphere to remove the solvent, and carrying out cracking reaction in inert atmosphere to obtain the silicon carbide / zirconium carbide composite ceramic. According to the invention, bis(cyclopentadienyl) zirconium dichloride is used as a zirconium source, and is used for catalyzing the crosslinking reaction of liquid hyperbranched polycarbosilane, so as to increase ceramic yield; zirconium carbide can inhibit the growth of silicon carbide microcrystal grains, and improve high-temperature resistance and oxidation resistance of the composite material; the zirconium content in the composite ceramic can be controlled by controlling the content of bis(cyclopentadienyl) zirconium dichloride in a hybrid precursor; the liquid hyperbranched polycarbosilane / bis(cyclopentadienyl) zirconium dichloride hybrid precursor is free of oxygen, thus the gas escaped in the high-temperature cracking process is reduced; the ceramic has high compactness; and the preparation method is simple to operate, and is easy for engineering.

Owner:XIAMEN UNIV

Ceramic material suitable for repair of a space vehicle component in a microgravity and vacuum environment, method of making same, and method of repairing a space vehicle component

A precursor of a ceramic adhesive suitable for use in a vacuum, thermal, and microgravity environment. The precursor of the ceramic adhesive includes a silicon-based, preceramic polymer and at least one ceramic powder selected from the group consisting of aluminum oxide, aluminum nitride, boron carbide, boron oxide, boron nitride, hafnium boride, hafnium carbide, hafnium oxide, lithium aluminate, molybdenum silicide, niobium carbide, niobium nitride, silicon boride, silicon carbide, silicon oxide, silicon nitride, tin oxide, tantalum boride, tantalum carbide, tantalum oxide, tantalum nitride, titanium boride, titanium carbide, titanium oxide, titanium nitride, yttrium oxide, zirconium, diboride, zirconium carbide, zirconium oxide, and zirconium silicate. Methods of forming the ceramic adhesive and of repairing a substrate in a vacuum and microgravity environment are also disclosed, as is a substrate repaired with the ceramic adhesive.

Owner:COI CERAMICS

Continuous fiber-reinforced zirconium carbide based composite material and preparation method thereof

ActiveCN104909792AHigh structural reliabilityImprove antioxidant capacityRe entryOxidation resistant

The present invention relates to a continuous fiber-reinforced zirconium carbide based composite material and a preparation method thereof, and belongs to the technical field of high temperature thermal protection materials. According to the present invention, the prepared continuous fiber-reinforced zirconium carbide based composite material has excellent performances of lightweight, high performance resistance, anti-oxidation property and the like, the density is 1.9-2.2 g / cm<3>, the tensile strength is 96-150 MPa, the bending / compressive strength is 130-180 MPa, the mass loss under the 2000 DEG C aerobic environment only is 10<-4> g / cm<2>s magnitude, and the composite material shows the good comprehensive performance advantages, and can be applied in novel high hypersonic aircrafts, high-speed re-entry vehicles, reusable orbital maneuvering aircrafts, advanced power systems, and other high temperature thermal protection systems.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Metallic bipolar plates with high electrochemical stability and improved water management

InactiveUS20070117003A1More hydrophilicStable environmentFuel cells groupingFuel cell auxillariesChromium carbideEtching

A flow field plate or bipolar plate for a fuel cell that includes a carbide coating that makes the bipolar plate conductive, hydrophilic and stable in the fuel cell environment. Suitable carbides include, but are not limited to, chromium carbide, titanium carbide, tantalum carbide, niobium carbide and zirconium carbide. The carbide coating is then polished or textured by a suitable process, such as laser or chemical etching, to provide a surface morphology that makes the coating more hydrophilic, and further reduces the contact resistance on its surface.

Owner:GM GLOBAL TECH OPERATIONS LLC

Synthetic fibre with functions of heat storage, warm keeping and health protection and preparation method thereof

InactiveCN102115920AGuaranteed durabilityImprove heat storage and heat preservation effectMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberCoupling

The invention relates to a synthetic fibre with the functions of heat storage, warm keeping and health protection. The fibre consists of a master batch with the functions of heat storage, warm keeping and health protection and a fibre grade resin slice, wherein the master batch comprises the following components in percent by weight: 30-70 percent of carrier resin, 10-40 percent of zirconium carbide powder, 3-8 percent of silane coupling agents, 5-10 percent of solid coupling agents and 15-18 percent of dispersing agents. The method for preparing the fibre comprises the step of preparing the master batch with the functions of heat storage and warm keeping as well as the step of spinning. The invention has the beneficial effects that the zirconium carbide can be used for absorbing visible light and near and far infrared light, the concept of applying the absorption and thermal conversion characteristics of the zirconium carbide to the heat storage and warm keeping fibre is different from the traditional fibre, and the heat storage and warm keeping effects are obviously improved. The method for preparing the fibre has peculiar process for treating the zirconium carbide, thus causing the spinning process to be smoothly carried out and ensuring the fibre quality and the durability of the heat storage function.

Owner:TIANJIN SAIYUAN HEALTH PROD

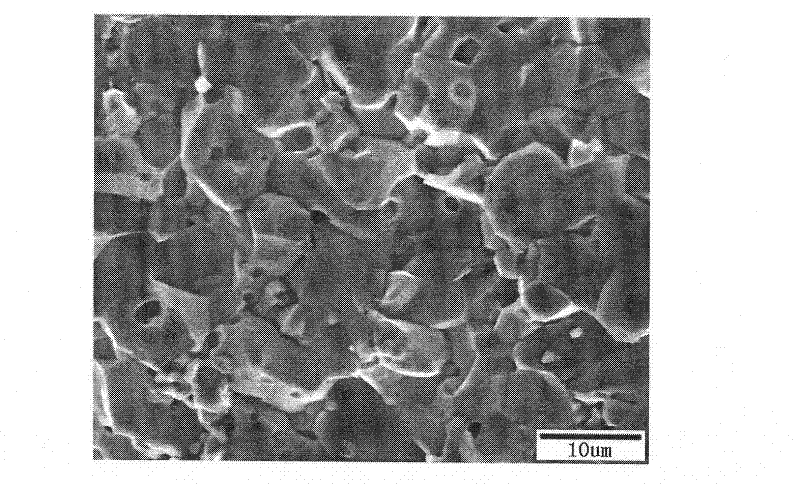

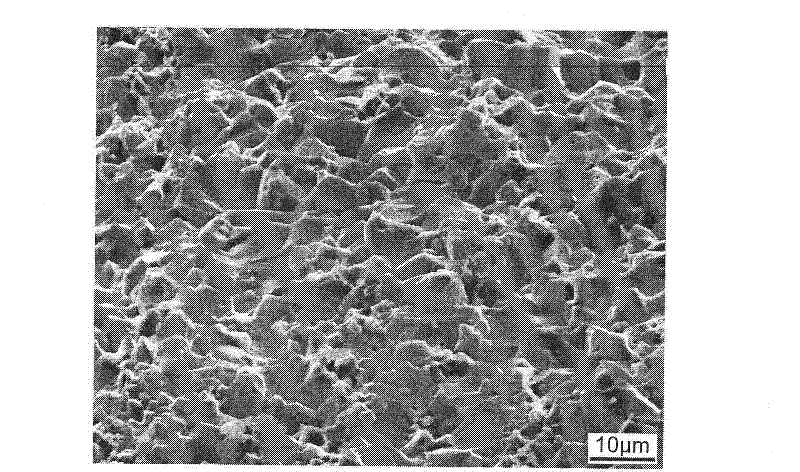

C/ZrC composite material prepared on basis of vapor infiltration reaction, preparation method thereof and equipment for process

The invention discloses a C / ZrC composite material prepared on the basis of vapor infiltration reaction. The C / ZrC composite material adopts zirconium carbide as a matrix and adopts a carbon fiber prefabricated body as an enhanced phase. For the C / ZrC composite material, the density is 1.98-4.25g / cm<3>, the aperture ratio is 6%-18% and the content of metal zirconium is below 0.5wt%. A preparation method comprises the following steps of: in preparation, firstly forming a fiber prefabricated body, then preparing a fiber protective coating and a porous C / C prefabricated body, carrying out high-temperature treatment on the prepared porous C / C prefabricated body in the inert atmosphere, finally putting the metal zirconium at the bottom of a graphite crucible, putting the C / C prefabricated body above the metal zirconium, heating under the vacuum condition, enabling zirconium steam to be volatilized and carry out vapor impregnation reaction with the C / C prefabricated body so as to obtain a product. Self-made vapor impregnation equipment is adopted in preparation. The invention has the advantages that the period is short, the cost is low, the high-temperature resistance of a product is good, the mechanical property is excellent, the residual amount of metal is minimum and the like.

Owner:NAT UNIV OF DEFENSE TECH

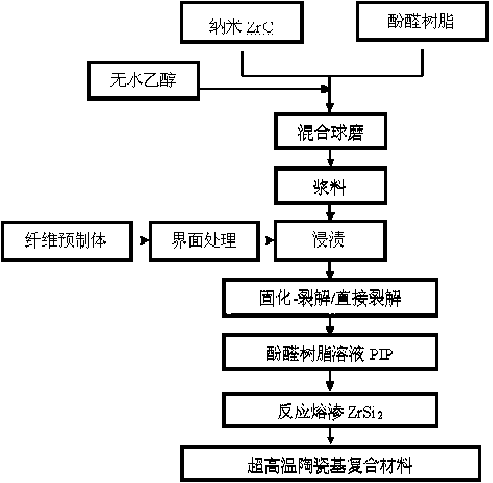

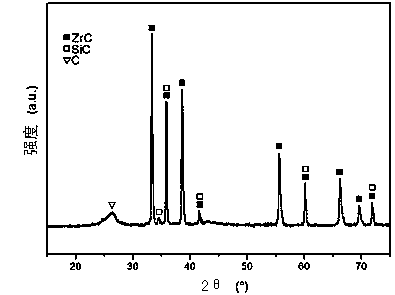

Preparation method for fiber-reinforced superhigh temperature ceramic matrix composite

The invention relates to a preparation method for a fiber-reinforced superhigh temperature ceramic matrix composite. The preparation method comprises the following steps: 1) adopting a slurry infiltration fibrous preform containing nano zirconium carbide and phenolic resin, and obtaining a fibrous tackified preform containing ZrC through curing-splitting or direct splitting; 2) using organic polymer as an organic carbon source precursor to infiltrate the fibrous tackified preform containing the ZrC, and splitting so as to obtain a ZrC-C composite porous intermediate; 3) using zirconium disilicide as a silicon source and a zirconium source to perform infiltration on the porous intermediate at the temperature of 1800-1950 DEG C so as to obtain the fiber-reinforced superhigh temperature ceramic matrix composite.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

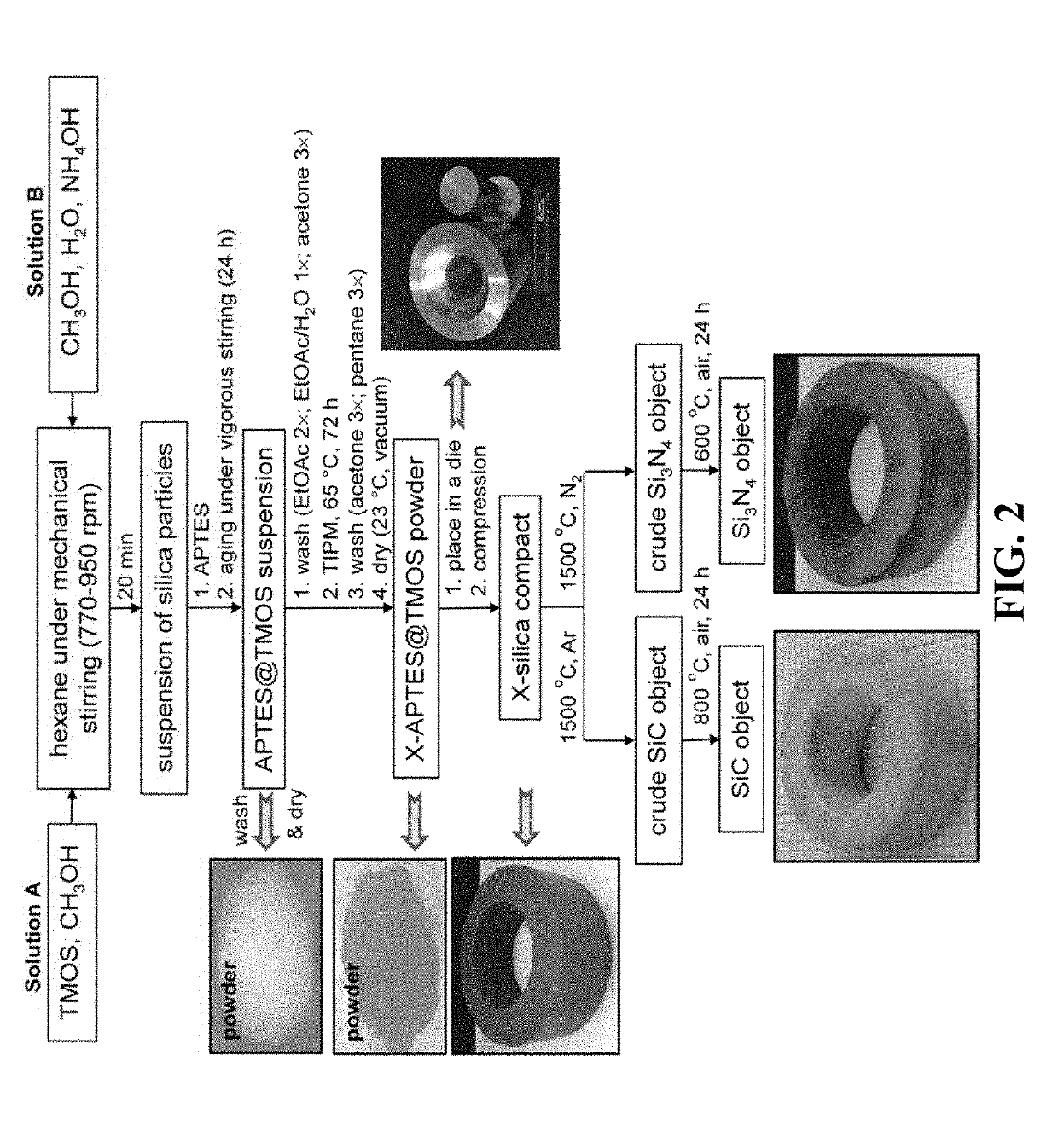

Novel highly porous ceramic and metal aerogels from xerogel powder precursors, and methods for their production and use

ActiveUS20190308912A1Speed up the processReduce lossesTransportation and packagingMetal-working apparatusConvertersBoride

The present invention discloses novel methods for producing highly porous ceramic and / or metal aerogel monolithic objects that are hard, sturdy, and resistant to high temperatures. These methods comprise preparing nanoparticulate oxides of metals and / or metalloids via a step of vigorous stirring to prevent gelation, preparing polymer-modified xerogel powder compositions by reacting said nanoparticulate oxides with one or more polyfunctional monomers, compressing said polymer-modified xerogel powder compositions into shaped compacts, and carbothermal conversion of the shaped xerogel compacts via pyrolysis to provide the highly porous ceramic and / or metal aerogel monolithic objects that have the same shapes as to their corresponding xerogel compact precursors. Representative of the highly porous ceramic and / or metal aerogel monolithic objects of the invention are ceramic and / or metal aerogels of Si, Zr, Hf, Ti, Cr, Fe, Co, Ni, Cu, Ru, Au, and the like. Examples include sturdy, shaped, highly porous silicon carbide (SiC), silicon nitride (Si3N4), zirconium carbide (ZrC), hafnium carbide (HfC), chromium carbide (Cr3C2), titanium carbide (TiC), zirconium boride (ZrB2), hafnium boride (HfB2), and metallic aerogels of iron (Fe), nickel (Ni), cobalt (Co), copper (Cu), ruthenium (Ru), gold (Au), and the like. Said aerogel monolithic objects have utility in various applications such as, illustratively, in abrasives, in cutting tools, as catalyst support materials such as in reformers and converters, as filters such as for molten metals and hot gasses, in bio-medical tissue engineering such as bone replacement materials, in applications requiring strong lightweight materials such as in automotive and aircraft structural components, in ultra-high temperature ceramics, and the like.

Owner:UNIVERSITY OF MISSOURI

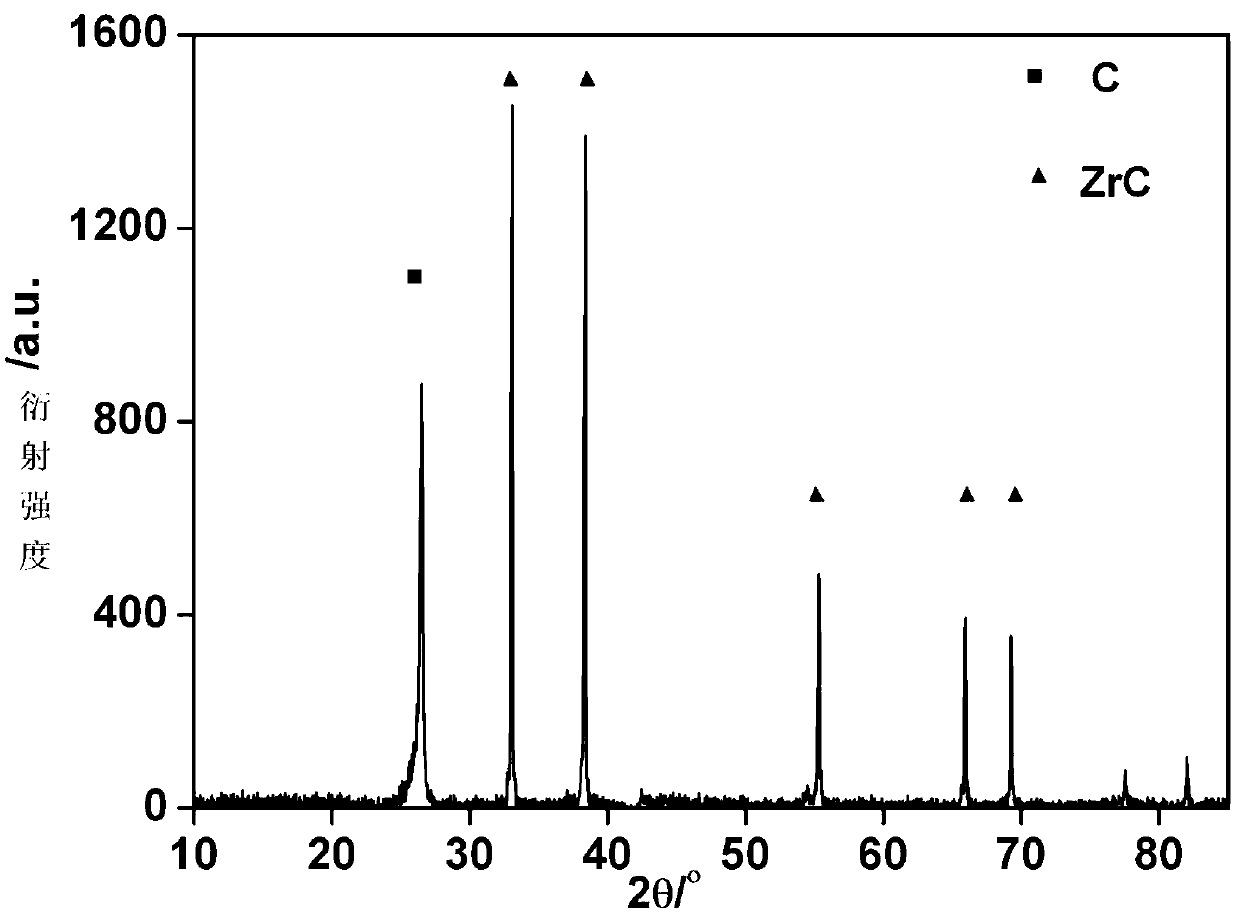

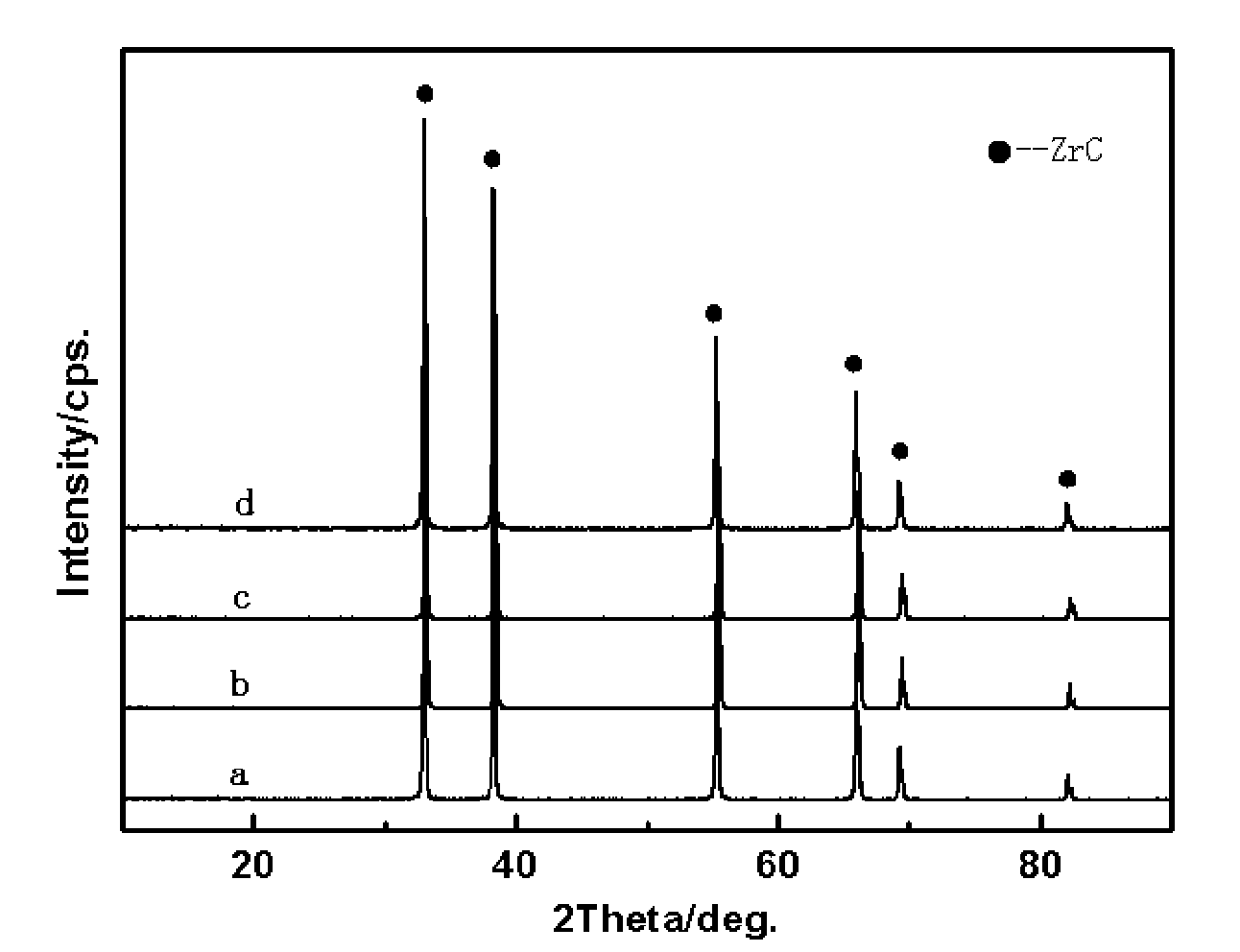

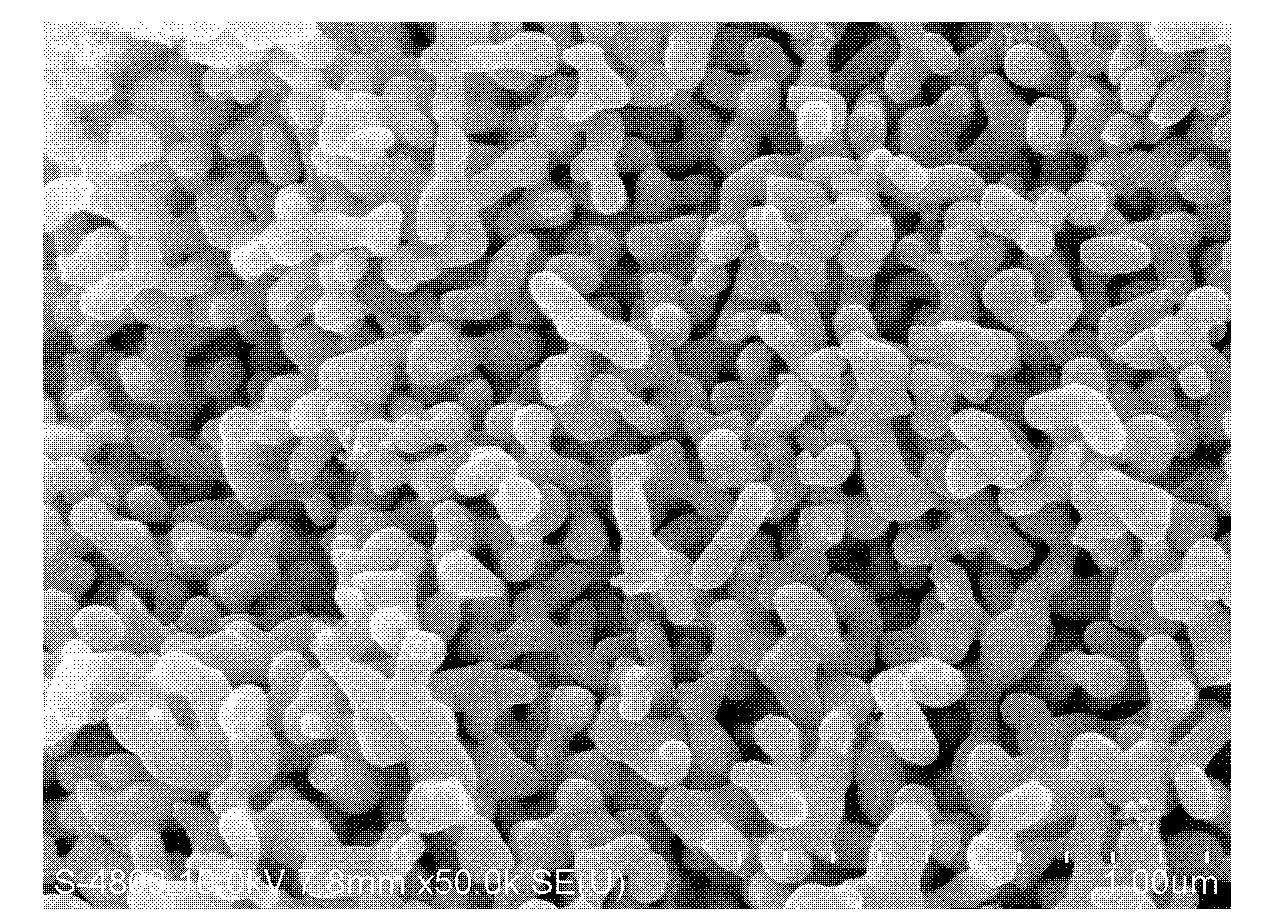

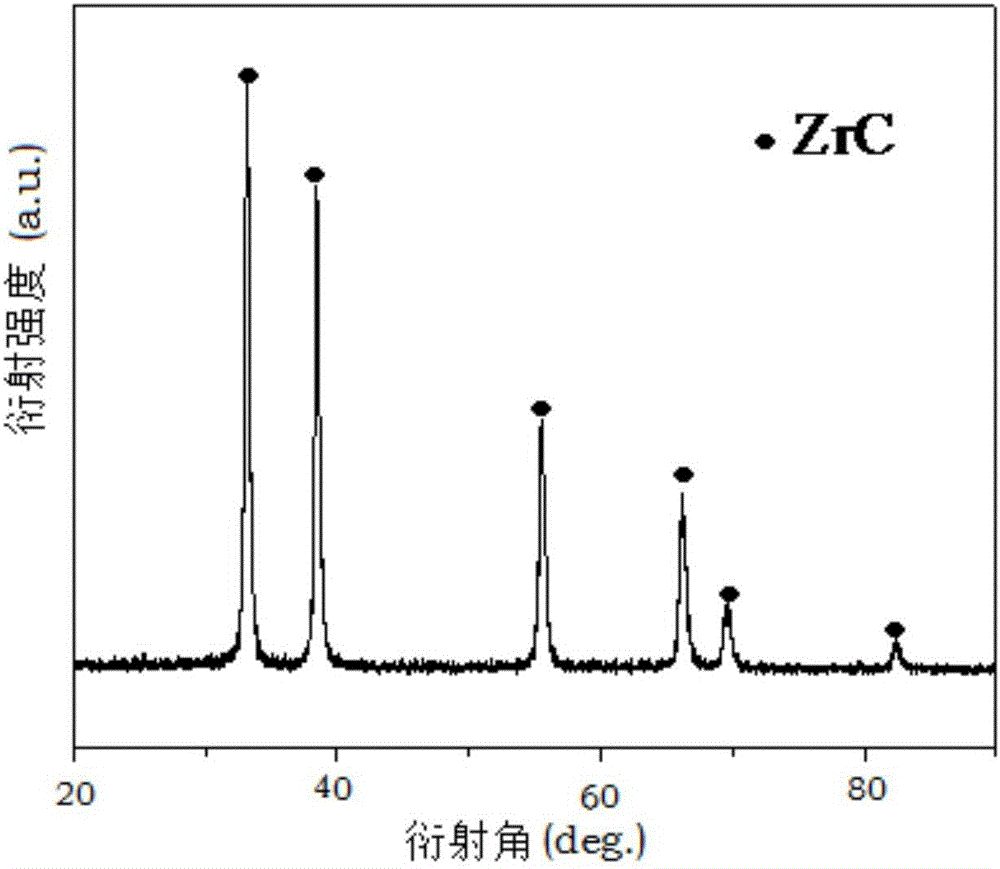

Method for rapidly preparing zirconium carbide ceramics powder

The invention relates to a preparation method of zirconium carbide ceramics powder; the method for rapidly preparing zirconium carbide ceramics powder is characterized in that: the method comprises the following steps: 1) raw material selection: the raw materials are selected according to 12:4-12:5 of mass ratio of zirconium propoxide solution and sugar and 8:32:1:1-8:64:2:4 of volume ratio of zirconium propoxide solution, normal propyl alcohol, chelant-acetic acid and water; the solvent acetic acid is selected according to (7-8)g:50ml of proportion of the sugar and the solvent acetic acid; 2) the preparation of dried gel power; 3) preparation of precursor powder; 4) heat treatment of the precursor powder; carbothermal reduction reaction is carried out under the conditions of high heating rate and short temperature preservation time, the synthesizing process of the zirconium carbide powder is shortened into dozens of minutes even several minutes, so as to obtain high-purity and refined zirconium carbide ceramics powder with good sintering character; single zirconium carbide phase can be analyzed by X-ray diffraction, the oxygen content in the product is 0.5-3 percent, and the free carbon content is from 0.2 to 2 percent; the crystal particles are uniform and tiny, and the mean grain size is less than 500nm.

Owner:WUHAN UNIV OF TECH

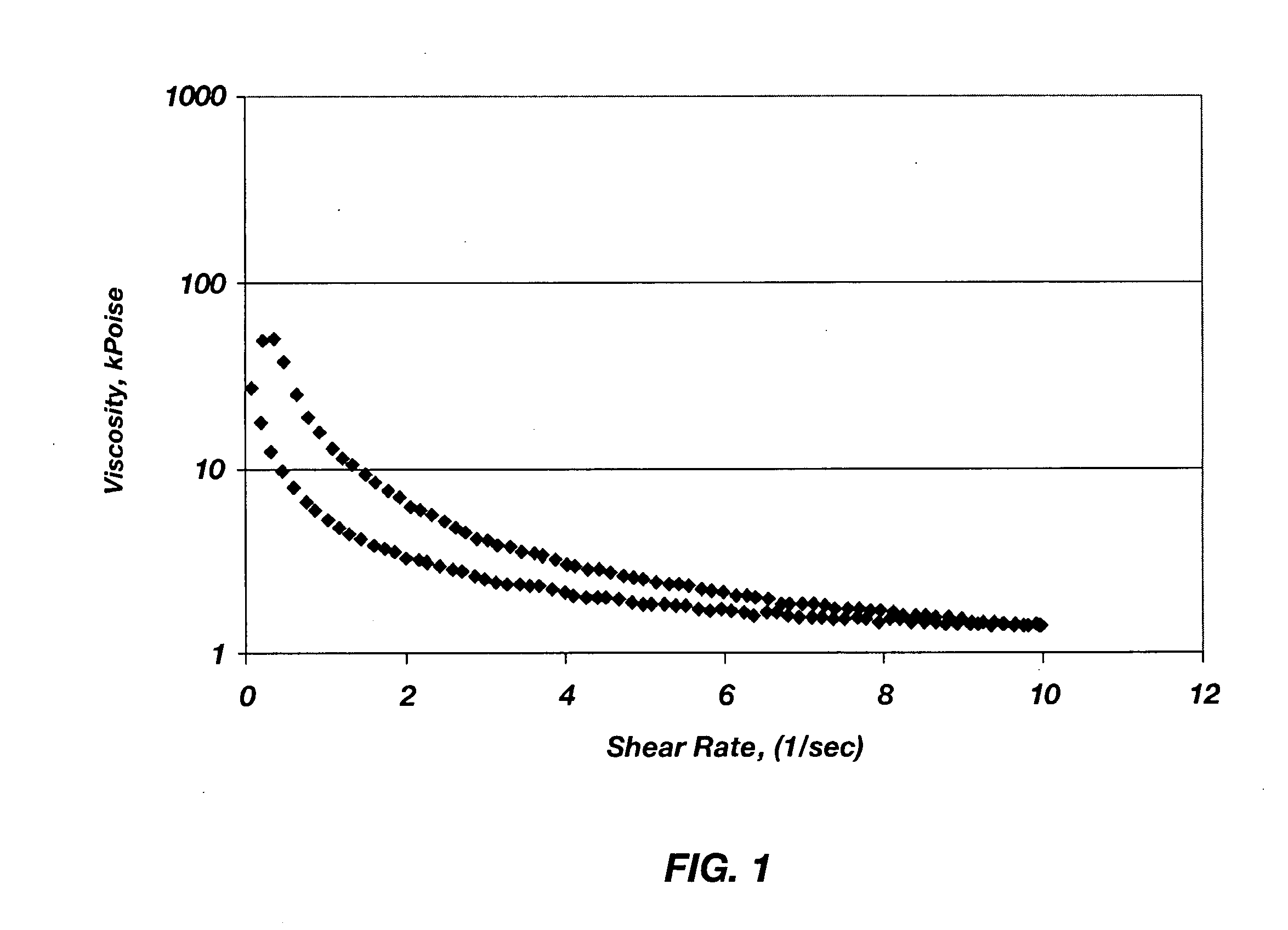

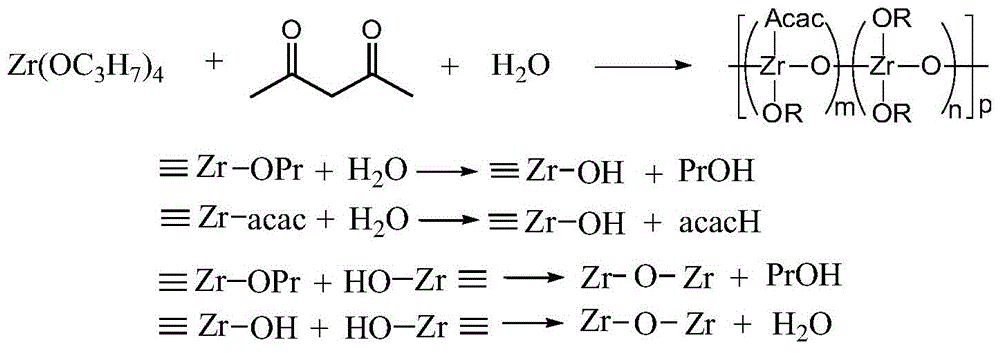

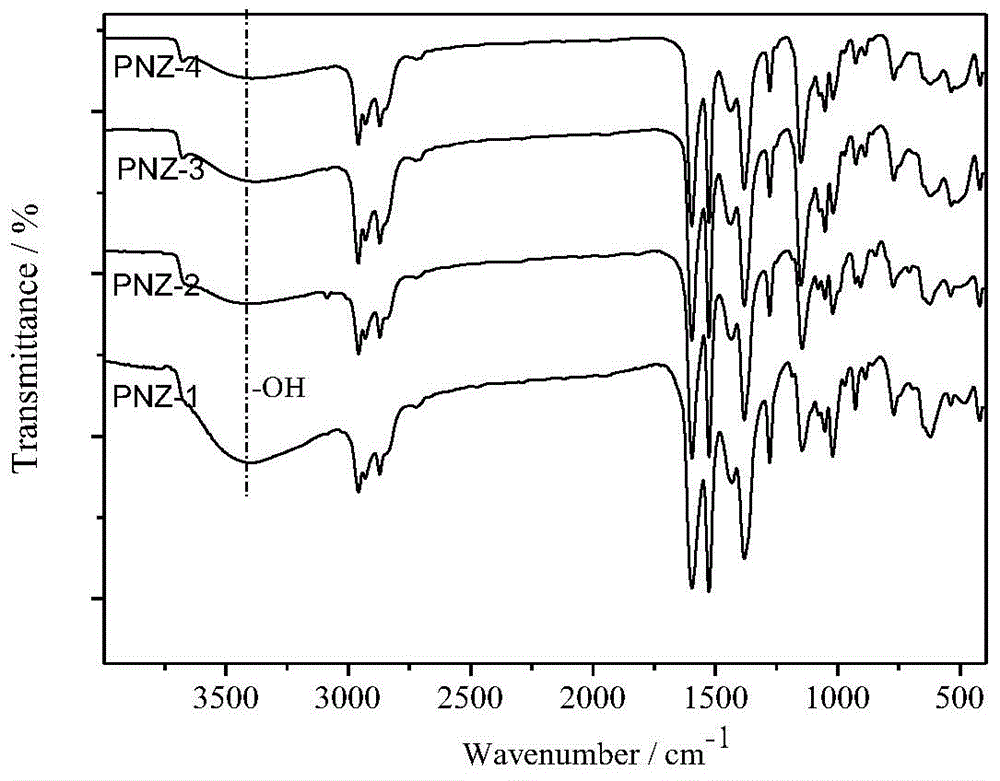

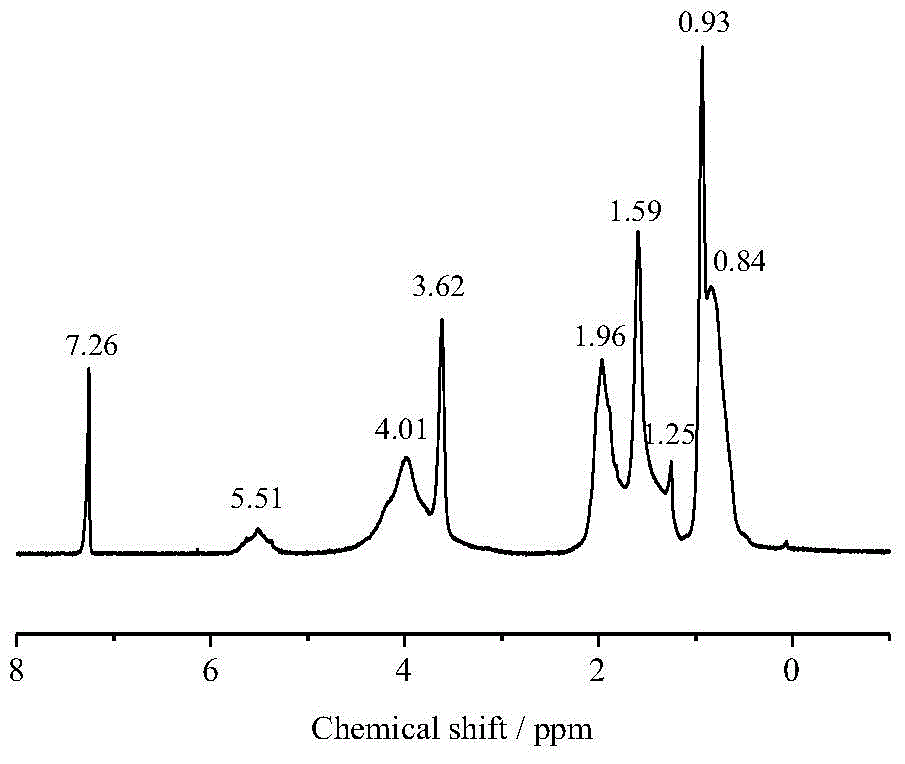

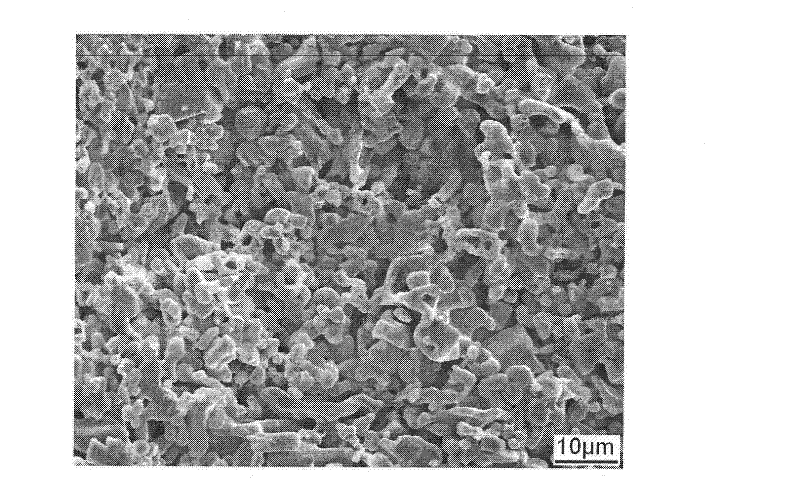

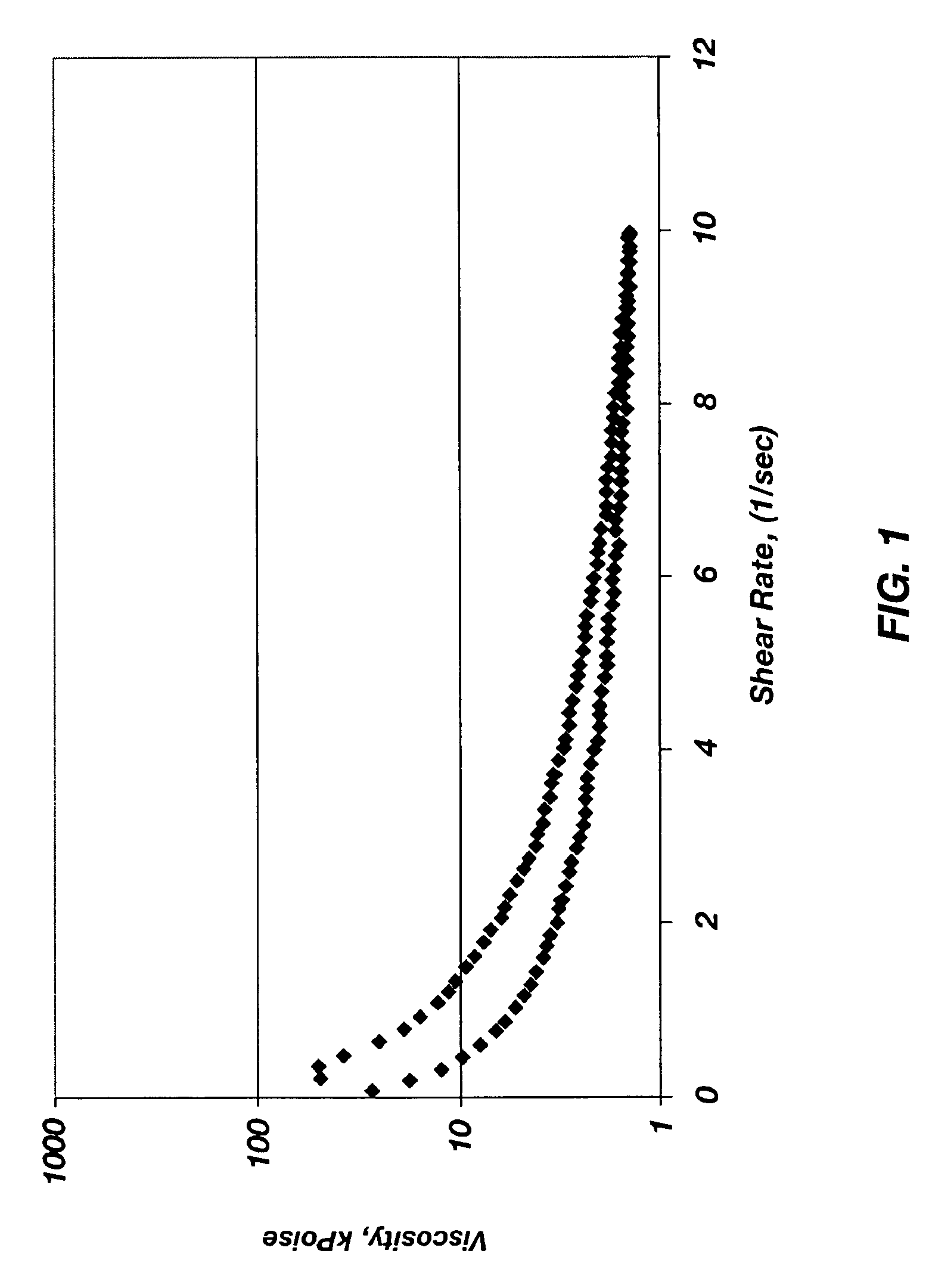

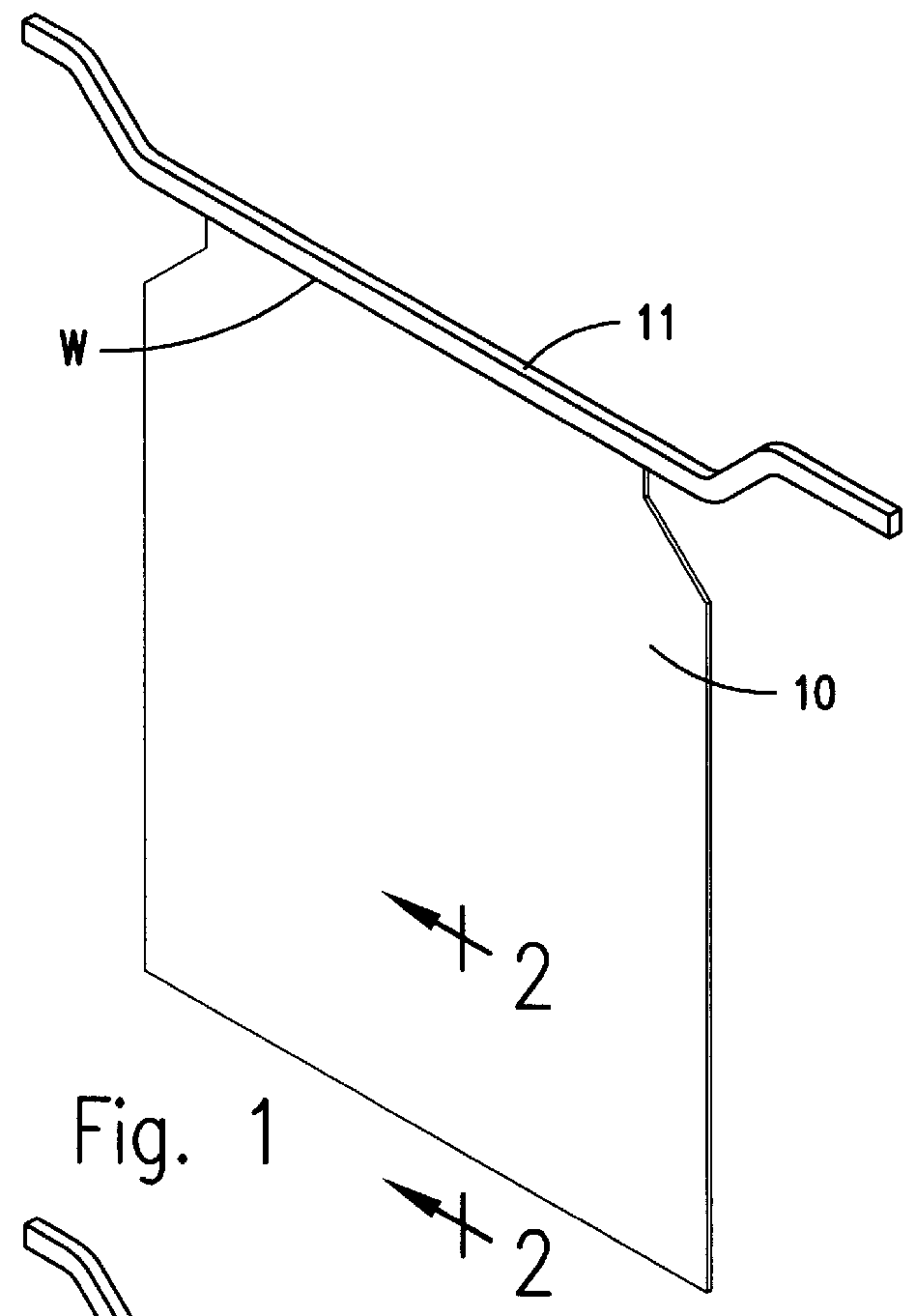

Nonpolar zirconium carbide liquid-phase ceramic precursor, preparation method therefor and application thereof

The invention relates to a nonpolar zirconium carbide liquid-phase ceramic precursor, a preparation method therefor and application thereof. The preparation method comprises: firstly preparing a nonpolar zirconium polymer-polyzircooxane through coordination protection of propyl zirconate and controllable hydrolysis condensation reaction; and by using the polyzircooxane as a zirconium source and divinyl benzene as a carbon source, compounding the components to obtain the nonpolar zirconium carbide liquid-phase ceramic precursor. The liquid-phase precursor prepared by the invention has the characteristics of polymer resin; the viscosity of the precursor can be controlled between 50 mpa.s and 500 mpa.s by adjusting the solid content, and the manufacturability is good. The zirconium carbide liquid-phase ceramic precursor which is cured and thermally treated can be converted into a pure-phase zirconium carbide ceramic at a relatively low temperature ( for example, 1500 DEG C). The liquid-phase ceramic precursor prepared by the invention is expected to be used as impregnating resin for a ceramic-based composite material and an antioxidant C / C and C / Si composite material so as to improve the ultra-high temperature antioxidant performance of the material and reduce the ablativity of the material.

Owner:SUZHOU TUNABLE MATERIALS TECH CO LTD

Preparation method for promoting to sinter zirconium boride or zirconium carbide ceramics by using reaction aids

The invention provides a preparation method for promoting to sinter zirconium boride or zirconium carbide ceramics by using reaction aids. Two-phase sintering aids capable of being reacted, namely Zr powder and C powder, or Zr powder and B4C powder, are added, and a material is promoted to be compact and crystals of a matrix are inhibited from growing by zirconium carbide / zirconium boride second phase particles with higher sintering activity, which are generated through in-situ reaction between the sintering aids. The ZrB2 or ZrC-based bulk material prepared by the method has the relative density of over 97 percent, the room temperature bending strength of 500-800MPa, the fracture toughness of 3.5-6.5MPa.ml / 2, and the hardness of 14-20GPa. The second phase generated through the in-situ reaction has the same melting point as the matrix, and the sintering acids cannot bring adverse effect to the high temperature mechanical properties of the material.

Owner:江苏先进无机材料研究院

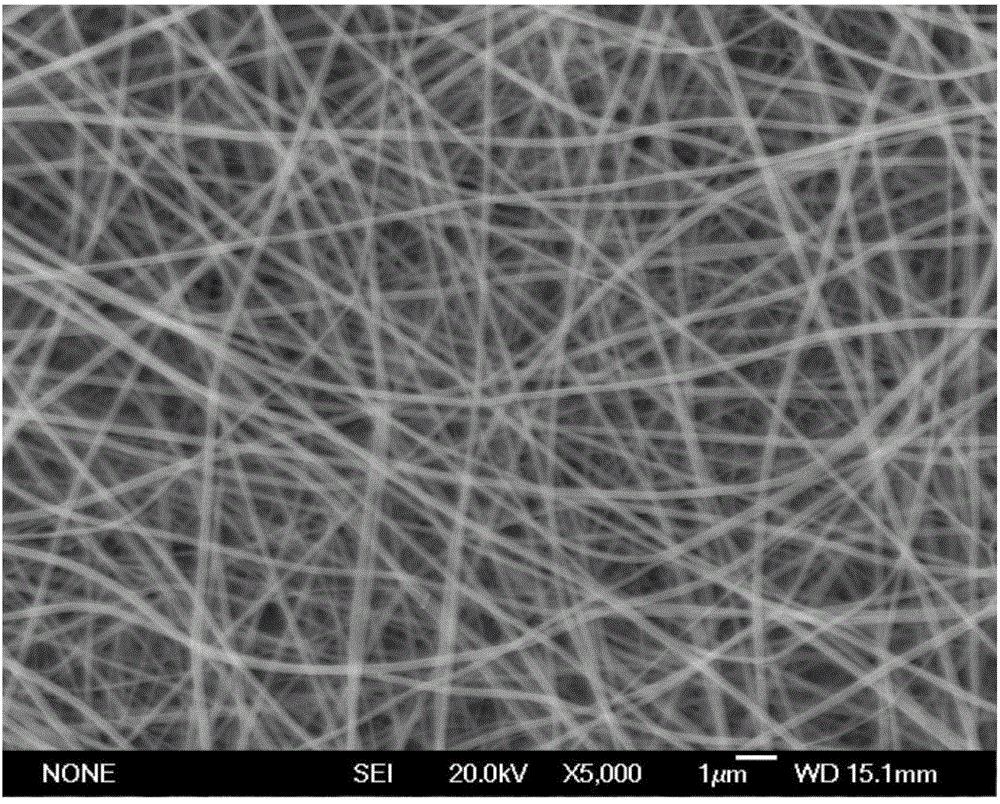

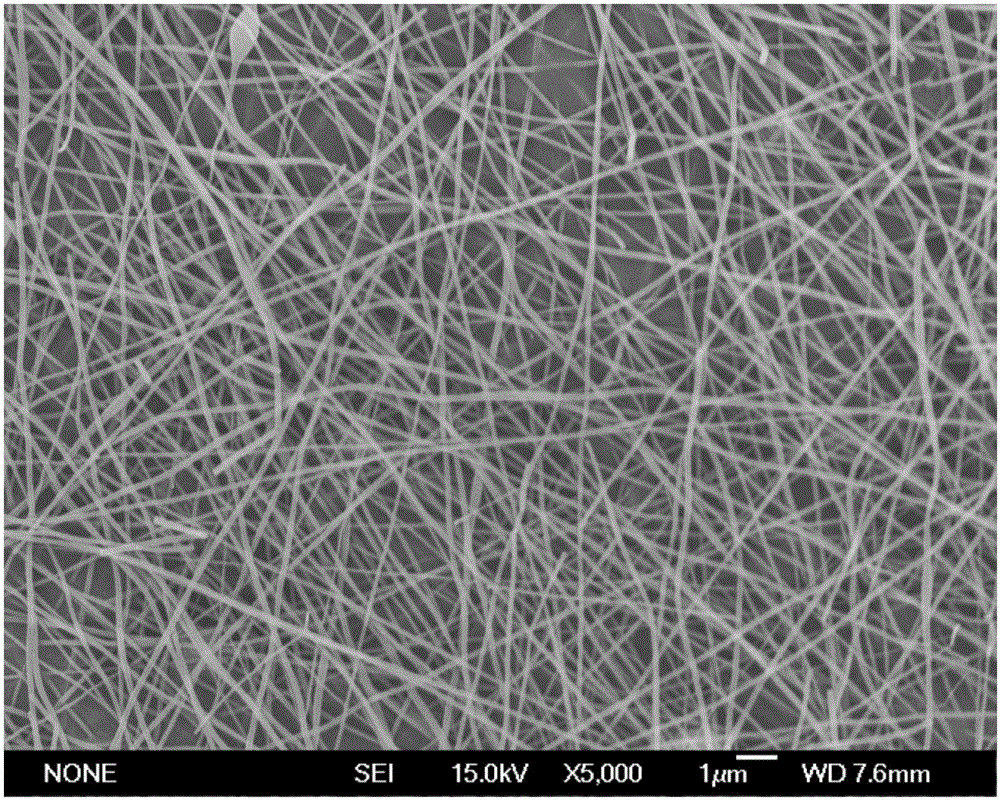

Preparation method of zirconium carbide micro-nanofibers

ActiveCN104988604ASolve complexityResolution cycleFilament/thread formingArtificial filament heat treatmentFiberMaterials preparation

The invention discloses a preparation method of zirconium carbide micro-nanofibers. The method comprises the steps that raw materials are selected and prepared into spinning solutions, precursor fibers are obtained through electrostatic spinning, and the zirconium carbide micro-nanofibers are obtained through heat treatment at last. According to the preparation method of the zirconium carbide micro-nanofibers, the defects that for an existing zirconium carbide ceramic material preparation method, the steps are complex, the preparation period is long, and prepared products are powder are overcome. According to the preparation method of the zirconium carbide micro-nanofibers, the zirconium carbide micro-nanofibers are prepared through an electrostatic spinning method, the zirconium carbide micro-nanofibers with different forms can be obtained by controlling spinning parameters and the sintering temperature, the raw materials are easy to obtain, the cost is low, the preparation technology is simple, and the preparation method of the zirconium carbide micro-nanofibers has wide application prospect in the fields of textiles, electronics, coatings, heat preservation and thermal insulation, aerospace and the like.

Owner:安徽恒硕纺织品有限公司

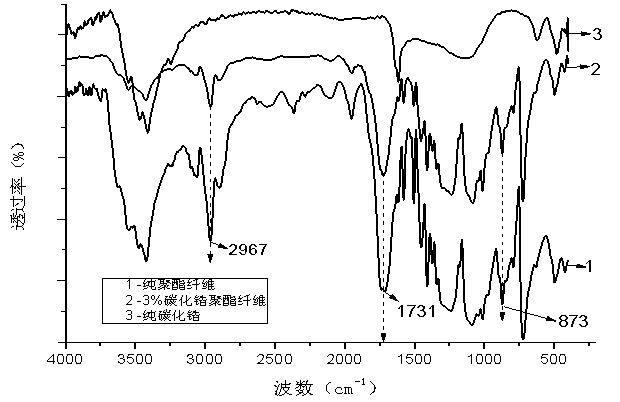

Nano zirconium carbide induction type heat-storage heat-preservation polyester fiber and preparation method thereof

InactiveCN103132177AAdjust and control the effect of induction thermal storage insulationEasy to carryFilament forming substance formingArtificial thread manufacturing machinesFiberPolyester

The invention relates to a nano zirconium carbide induction heat-storage heat-preservation polyester fiber and a preparation method thereof. The preparation method comprises the steps of: adding 1.0-8.0% of nano zirconium carbide using as an additive in an online manner to evenly blend and fuse together with a polyester chip in a screw rod, extruding blend melt from a spinneret micro-hole, winding the extruded blend melt at the winding speed of 3000-3200m / min to prepare a POY (polyester pre-oriented yarn) silk tube by using the processes of cooling, curing, oiling and bundling by a nozzle, stretching to deform after balancing, so as to prepare the nano zirconium carbide induction heat-storage heat-preservation polyester fiber. The nano zirconium carbide induction heat-storage heat-preservation polyester fiber has the functions of efficiently and selectively absorbing visible light and a near infrared ray in a solar radiation ray, and reflecting the heat radiation of a human body, so as to have the functions of two-way temperature induction adjustment and heat preservation, changes the heat-storage mode of cold protective clothing, and has the characteristics of being high in additional value, good in quality and significant in cost performance.

Owner:SUZHOU UNIV

Ceramic material suitable for repair of a space vehicle component in a microgravity and vacuum environment, method of making same, and method of repairing a space vehicle component

A precursor of a ceramic adhesive suitable for use in a vacuum, thermal, and microgravity environment. The precursor of the ceramic adhesive includes a silicon-based, preceramic polymer and at least one ceramic powder selected from the group consisting of aluminum oxide, aluminum nitride, boron carbide, boron oxide, boron nitride, hafnium boride, hafnium carbide, hafnium oxide, lithium aluminate, molybdenum silicide, niobium carbide, niobium nitride, silicon boride, silicon carbide, silicon oxide, silicon nitride, tin oxide, tantalum boride, tantalum carbide, tantalum oxide, tantalum nitride, titanium boride, titanium carbide, titanium oxide, titanium nitride, yttrium oxide, zirconium diboride, zirconium carbide, zirconium oxide, and zirconium silicate. Methods of forming the ceramic adhesive and of repairing a substrate in a vacuum and microgravity environment are also disclosed, as is a substrate repaired with the ceramic adhesive.

Owner:COI CERAMICS

Insoluble titanium-lead anode for sulfate electrolytes

InactiveUS6287433B1Easy to useHigh mechanical strengthMachining electrodesSolid state diffusion coatingSulfateTitanium carbide

An insoluble anode for sulfate electrolytes composed of, generally, from 1 to 99 wt % titanium or titanium alloy and the remainder lead or lead alloy, comprising a titanium-lead active layer, or a titanium-lead active layer covering and a core being made from titanium or lead. The anode is produced by infiltration of porous titanium with lead, either by consolidation of the mixture of titanium and lead powders. The anode formed of the active layer, or of the active layer covering and a sheet core is fabricated in the shape of a plate. The anode formed of the active layer covering and a rod or tube core is fabricated in the shape of a lattice. Advantageously, the titanium-lead active layer is dispersion-strengthened by zirconium carbide or titanium carbide particles, and it's surface is released of a portion of lead.

Owner:SAPOZHNIKOVA ALLA

Preparation method of silicon carbide ceramic body for rubber mold

The invention relates to a method for preparing zirconium carbide ceramic body by using a rubber mold, which belongs to the field of ceramic-plastic molding. The invention is characterized in that the SiC ceramic body is prepared by utilizing the rubber mold. The water-soluble epoxy resin is taken as a gel system of SiC gel casting molding to prepare the SiC sizing agent which is fit for the gel casting molding, and then a fine and complex structure of molding substance can be reproduced directly by using the rubber mold. The method has the outstanding advantages that: the water-soluble epoxy resin gel system will not be inhibited by the mold material; the preparative body has a high strength and smooth surface without crack and surface shedding phenomena; the fine and complex Sic body can be prepared by using the soft and stretchy rubber mold, thereby the production cost and processing difficulty for the mold can be lowered.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Insoluble titanium-lead anode for sulfate electrolytes

An insoluble anode for use in electrowinning metals and electrolytic manganese dioxide production wherein the anodes are composed of, generally, titanium or lead (including titanium or lead alloys). The anode includes a titanium-lead active layer, or a titanium-lead active layer covering and a core being made from titanium and lead and is produced by infiltration of porous titanium with lead, either by consolidation of the mixture of titanium and lead powders. The anode formed of the active layer, or of the active layer covering and a sheet core is fabricated in the shape of a plate. The anode formed of the active layer covering and a rod or tube core is fabricated in the shape of a lattice, wherein the covering is made from a plurality of bushings, which are strung on the core. The titanium-lead active layer is optionally dispersion-strengthened by zirconium carbide or titanium carbide particles, and the active layer surface is released of a portion of lead. A hanger bar is attached to the anode by welding or mechanical joint.

Owner:FERDMAN ALLA

Shell with colored film layer

The invention discloses a shell with a colored film layer, and the shell provided by the invention comprises a substrate and a composite film layer plated on the substrate, wherein the composite film layer comprises a colored layer, a middle layer and a protective layer, the colored layer is combined with the substrate, the middle layer is coated on the colored layer, and the protective layer is coated on the middle layer; the composition of the colored layer is selected from a mixture of aluminum oxides and chromic oxides, titanium nitride, aluminium-titanium nitride, zirconium nitride, titanium carbide nitride, zirconium carbide nitride or aluminium nitride; and the colored layer is used for displaying colors, the middle layer is used for increasing the color saturation of the colored layer, and the protective layer is made of a transparent wear-resisting material and used for protecting the colored layer and the middle layer. The composite film layer not only can display bright colors, but also has the advantages of good adhesiveness and good abrasive resistance.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

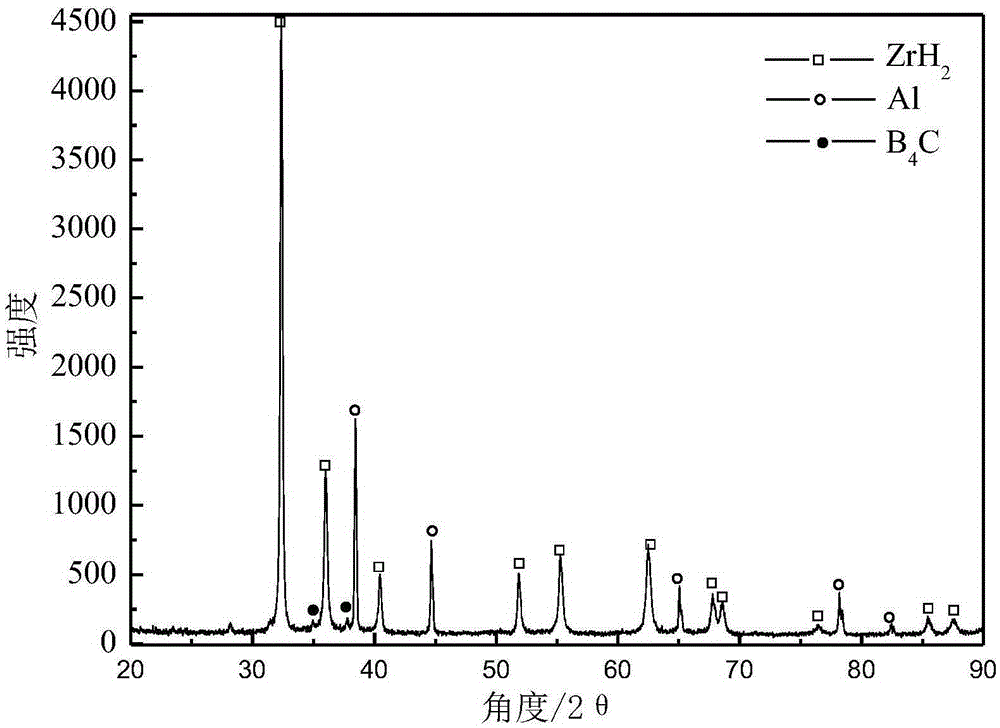

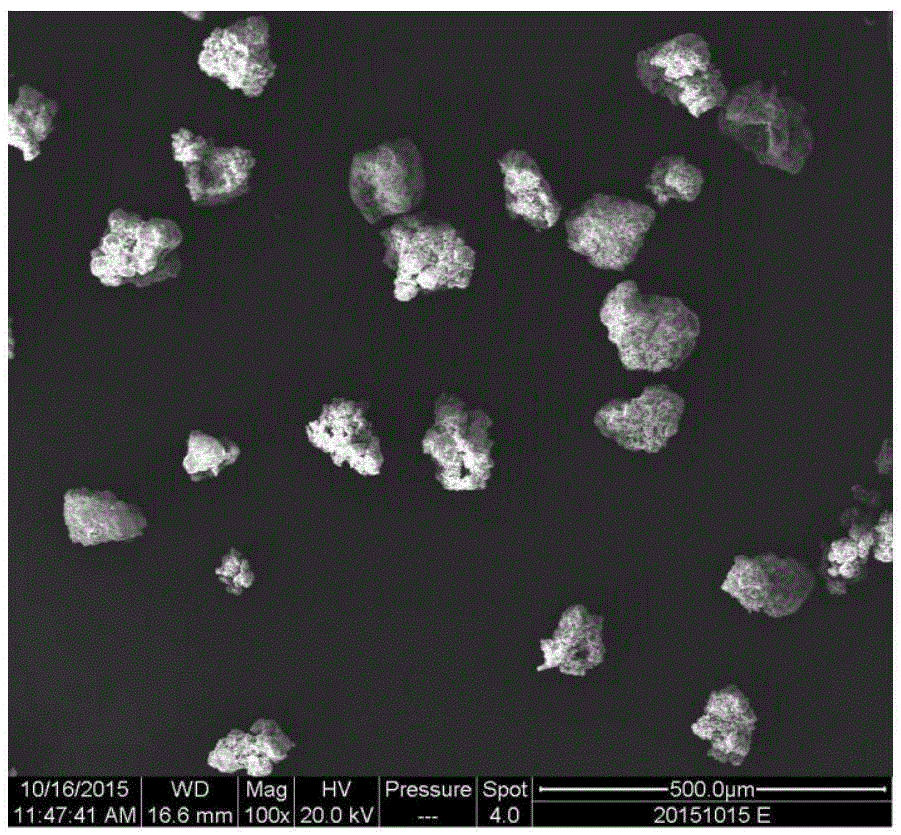

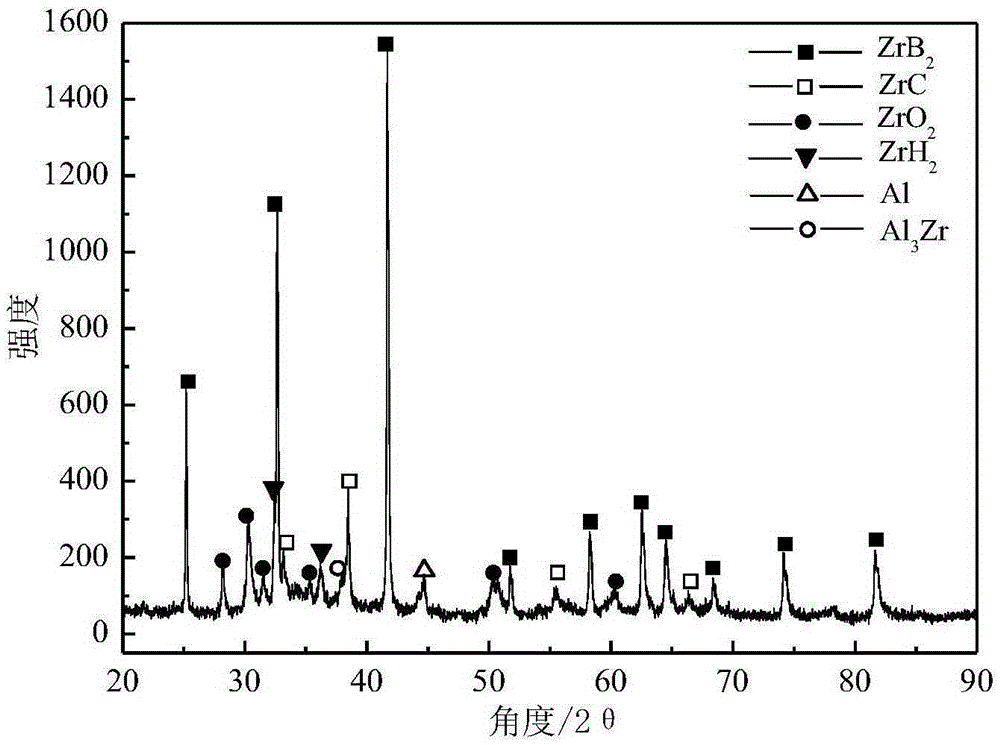

Spraying powder, hot-sprayed in-situ synthesized zirconium boride-zirconium carbide base ceramic coating and preparation method thereof

The invention provides spraying powder. The spraying powder comprises aluminum powder, zirconium hydride powder and boron carbide powder. Compared with the prior art, the spraying powder contains zirconium hydride, the zirconium hydride can replace metal zirconium so as to lower the spontaneous combustion risk of powder manufacturing and can be resolved to generate active zirconium and hydrogen gas in the spraying process, and the generated hydrogen gas can be ionized or combusted so as to further increase the temperature of a heat source and improve the reducing atmosphere; the spraying powder is good in liquidity and self-propagating reaction characteristic and can make a prepared ceramic base coating compact in structure and low in porosity. According to the invention, the compositions of the spraying powder are reasonably designed, the ceramic base coating mainly comprising zirconium boride and zirconium carbide can be synthesized in situ, and there is no need to spray zirconium boride powder and zirconium carbide powder independently for obtaining the ceramic base coating containing the zirconium boride and the zirconium carbide. The invention further provides the hot-sprayed in-situ synthesized zirconium boride-zirconium carbide base ceramic coating and a preparation method thereof.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

High temperature resistant antioxidative metal ceramic composite coating and preparation method thereof

InactiveCN103540936AFast deposition rateGood high temperature oxidation resistanceVacuum evaporation coatingSputtering coatingComposite filmOxidation resistant

The invention relates to high temperature resistant antioxidative coating materials, and particularly provides a high temperature resistant antioxidative metal ceramic composite coating and a preparation method thereof. The composite thin film is characterized in that the coating consists of refractory metal, refractory carbide and an intermetallic compound. The coating is 10-50 mu m thick. The refractory metal is one or more of molybdenum, tantalum, zirconium and hafnium, the refractory carbide consists of silicon carbide as well as one or more of tantalum carbide, zirconium carbide and hafnium carbide, and the intermetallic compound consists of one or more of molybdenum silicide, tantalum silicide, zirconium silicide, hafnium silicide, tantalum silicon carbide, zirconium silicon carbide and hafnium silicon carbide. The crystal structure of the coating consists of amorphous and / or polycrystal nanoparticles.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

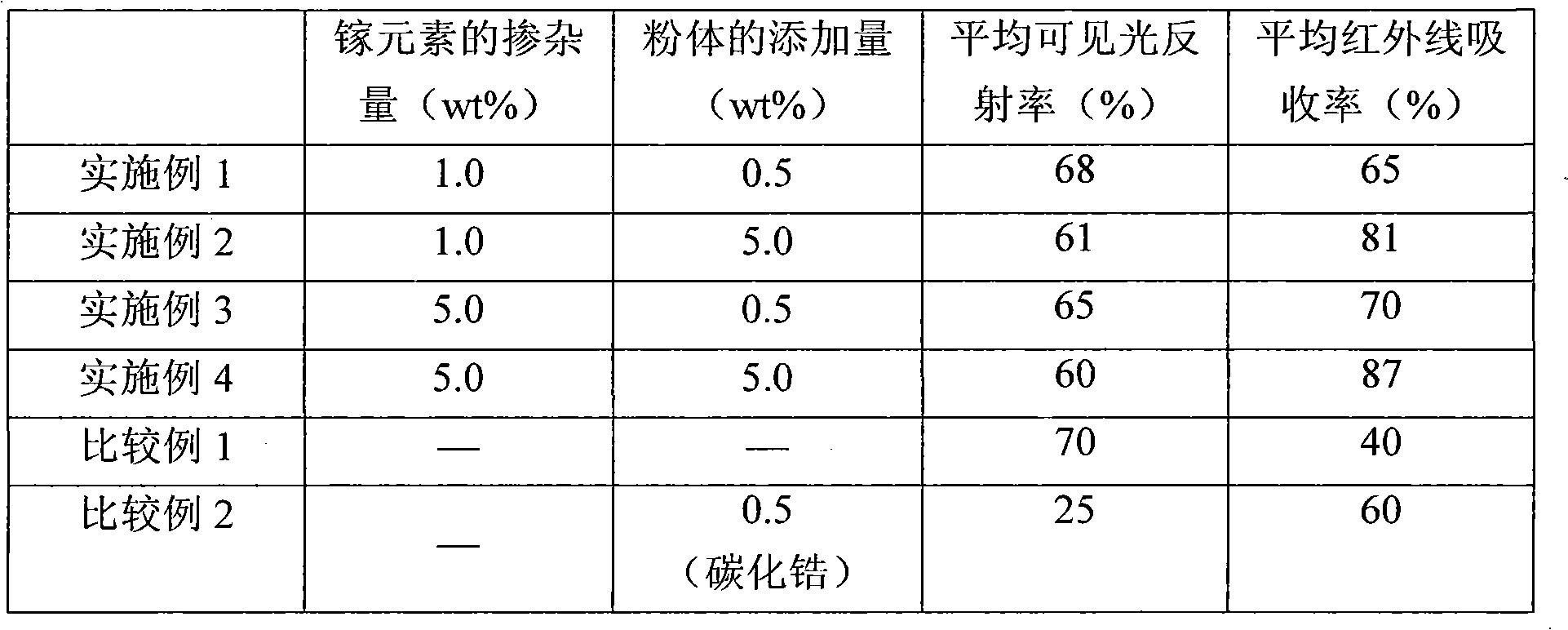

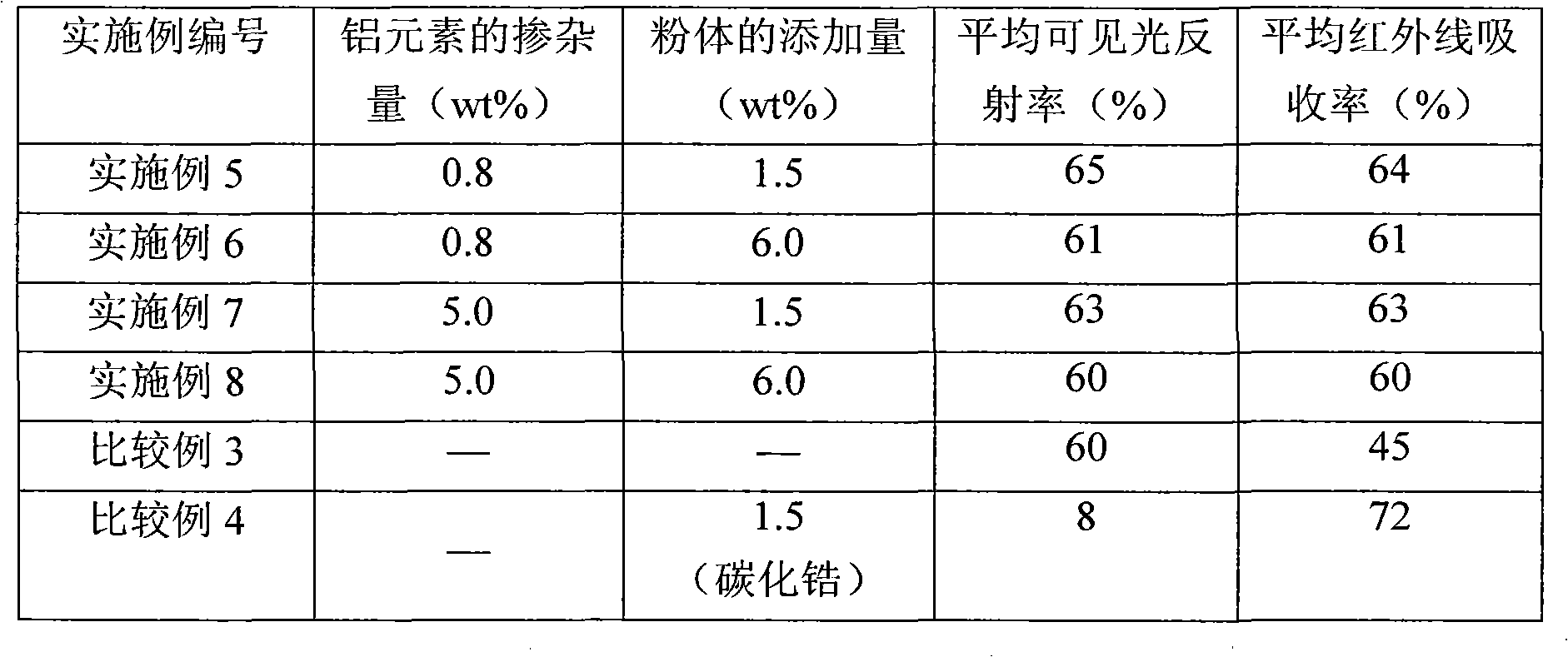

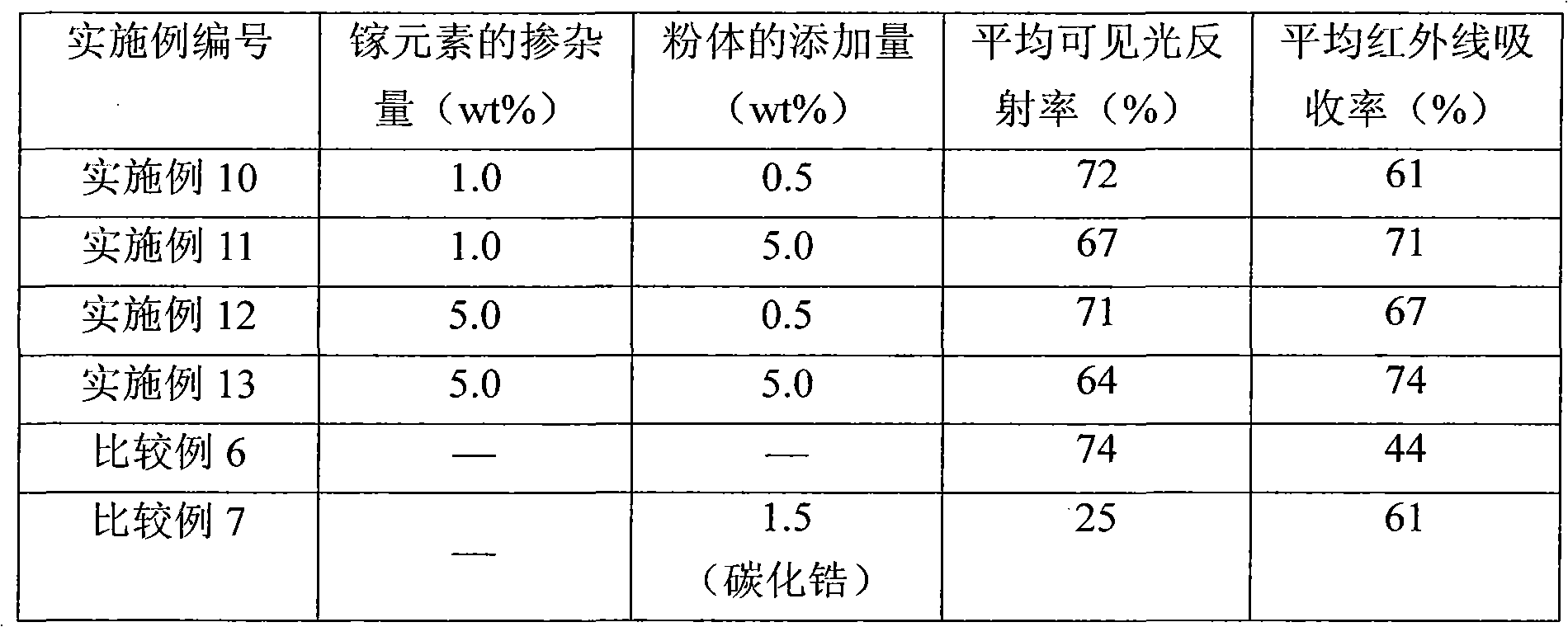

Fiber with function of infrared ray absorption, and its preparation method and textile

InactiveCN102337603AHas the function of absorbing infrared raysColor change excellentMonocomponent polyolefin artificial filamentMonocomponent polyesters artificial filamentInfraredFiber

The invention relates to a fiber with a function of infrared ray absorption, and its preparation method and textile. The fiber with a function of infrared ray absorption comprises a fiber main body and powder which has infrared ray absorption functions and is added and dispersed in the fiber main body. The preparation method comprises the following steps that the powder with infrared ray absorption functions and at least one monomer are mixed and undergo polymerization to form a polymer; or the powder with infrared ray absorption functions is mixed directly with at least one polymer; and the polymer composite material mixed with the powder with infrared ray absorption functions is subjected to spinning possessing to form the fiber with a function of infrared ray absorption. The fiber with a function of infrared ray absorption can be prepared into a textile with a function of infrared ray absorption. Compared with a textile without the powder with a function of infrared ray absorption, based on color change, the textile added with the powder with a function of infrared ray absorption has a good property that an average difference of visible light reflectivity is only 2%. The property of the textile added with the powder with a function of infrared ray absorption is far better than that of a textile which is added with zirconium carbide powder and has a function of infrared ray absorption. Color change of the textile added with the powder with a function of infrared ray absorption is very obvious and an average difference of visible light reflectivity can reach above 40%.

Owner:IND TECH RES INST

Preparation method of zirconium carbide ceramic powder

A preparation method of zirconium carbide ceramic powder belongs to the preparation field of ceramic powder. By improving a raw material mixing method and enabling subparticles with smaller particle size to be directly contacted and reacted, reaction activity of precursors is improved, thereby helping to enable the precursors to be compounded to high-purity fine-grained ceramic powder at a low temperature. A zirconium source is zirconium nitrate or zirconium oxychloride, a carbon source is glucose, and additives are carbamide, ammonium nitrate and hydrogen nitrate. Molar ratio of the zirconium source to the carbon source (Zr: C) is 1: 5-18. Molar ratio of +5 valence of nitrogen and -3 valence of nitrogen is N +5: N-3 = 1: 0.1-10. The particle size of the zirconium source and the carbon source in the precursors is small, mixing is even, reaction activity is good, carbothermic reduction reaction temperature can be lowered, reaction rate can be improved, and nano-level zirconium carbide ceramic powder with good dispersibility can be prepared. In addition, a variety of raw material sources are available, price is low, production cost is low, and prepared zirconium carbide nano-powder is stable in property, simple in production process and capable of achieving mass production.

Owner:UNIV OF SCI & TECH BEIJING

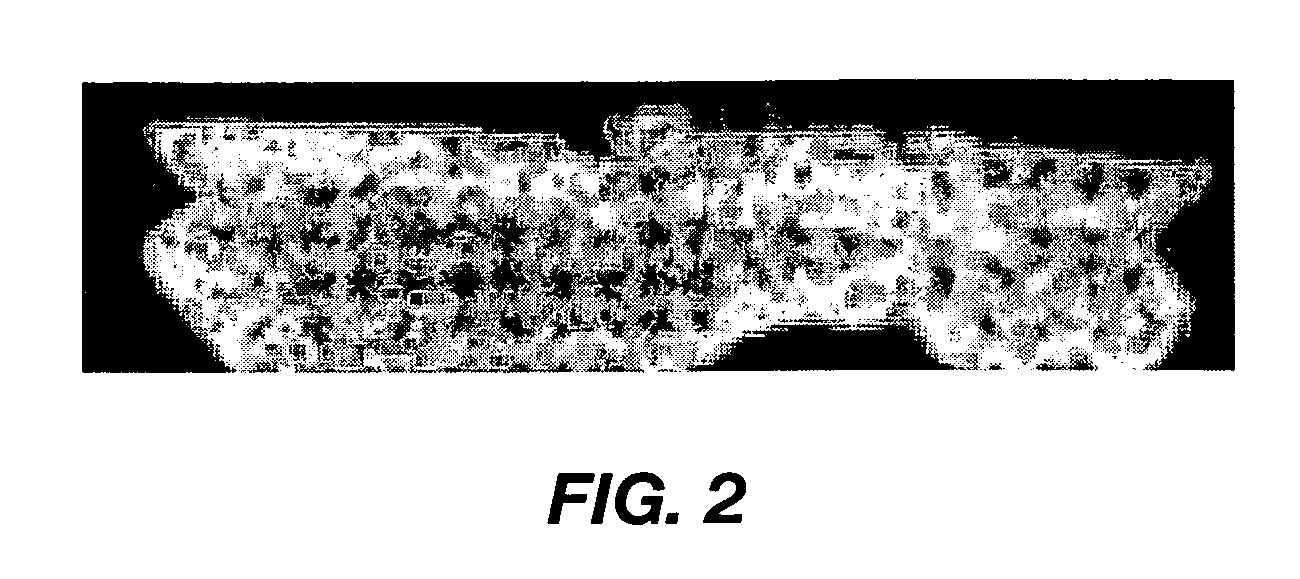

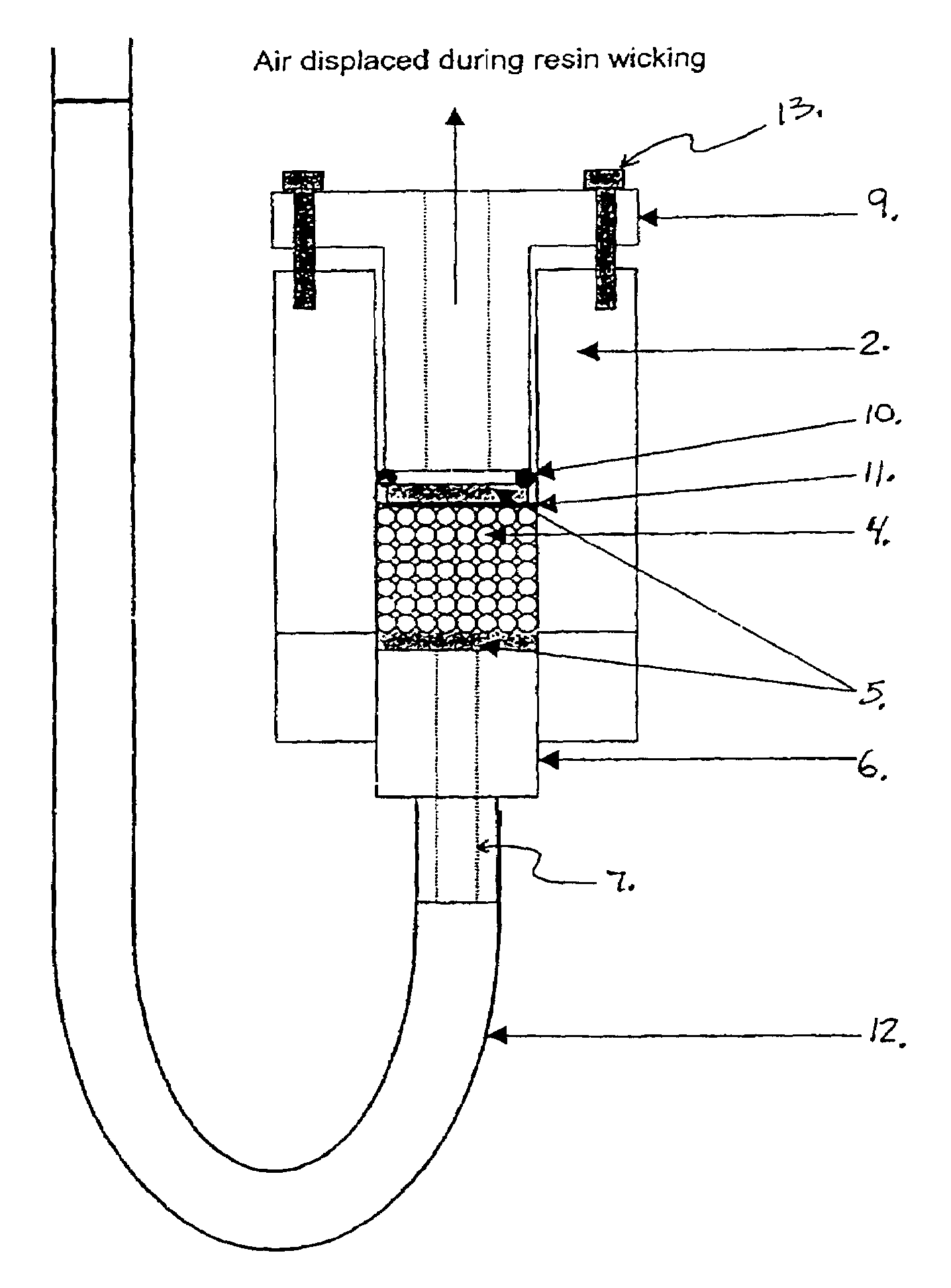

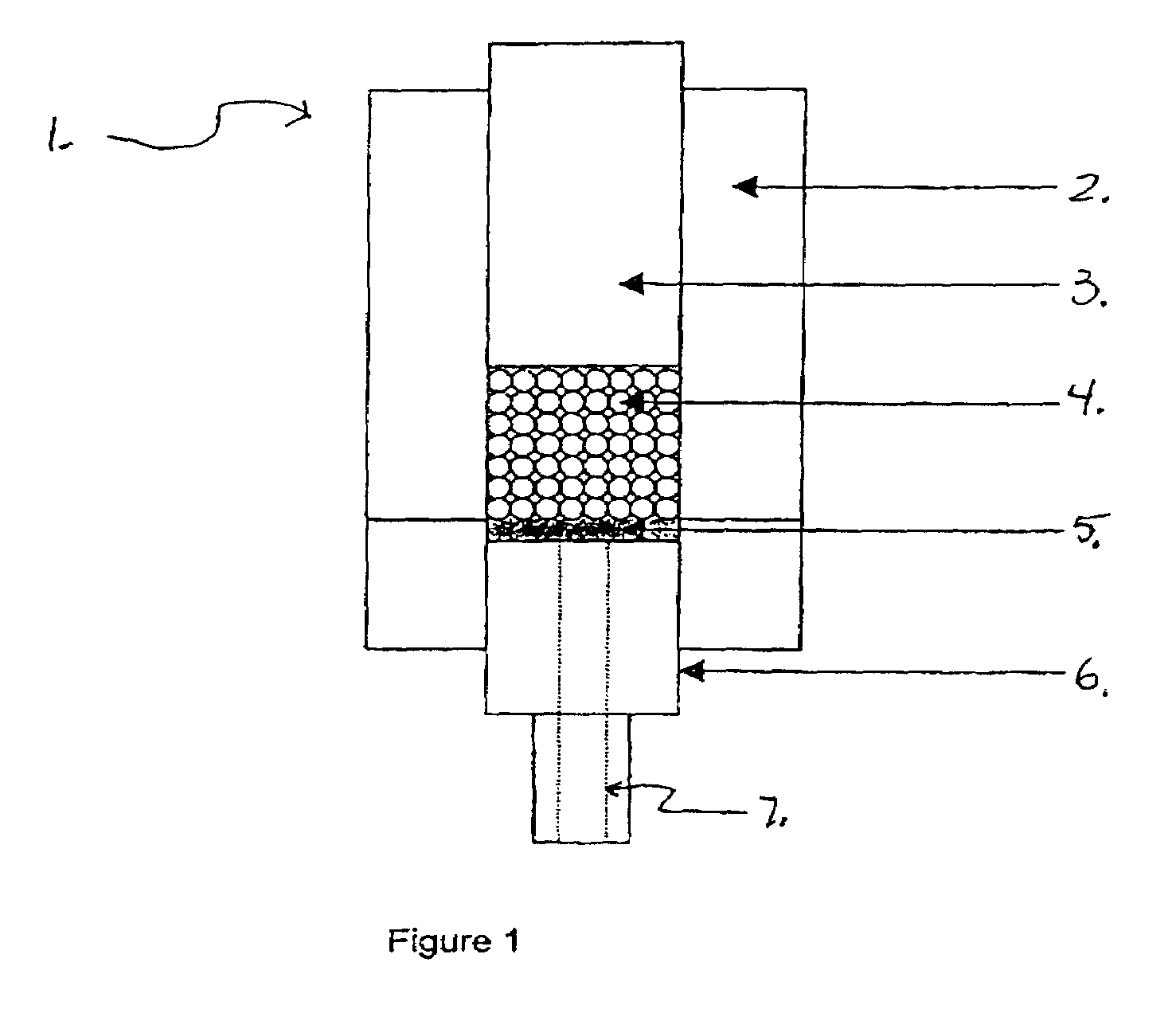

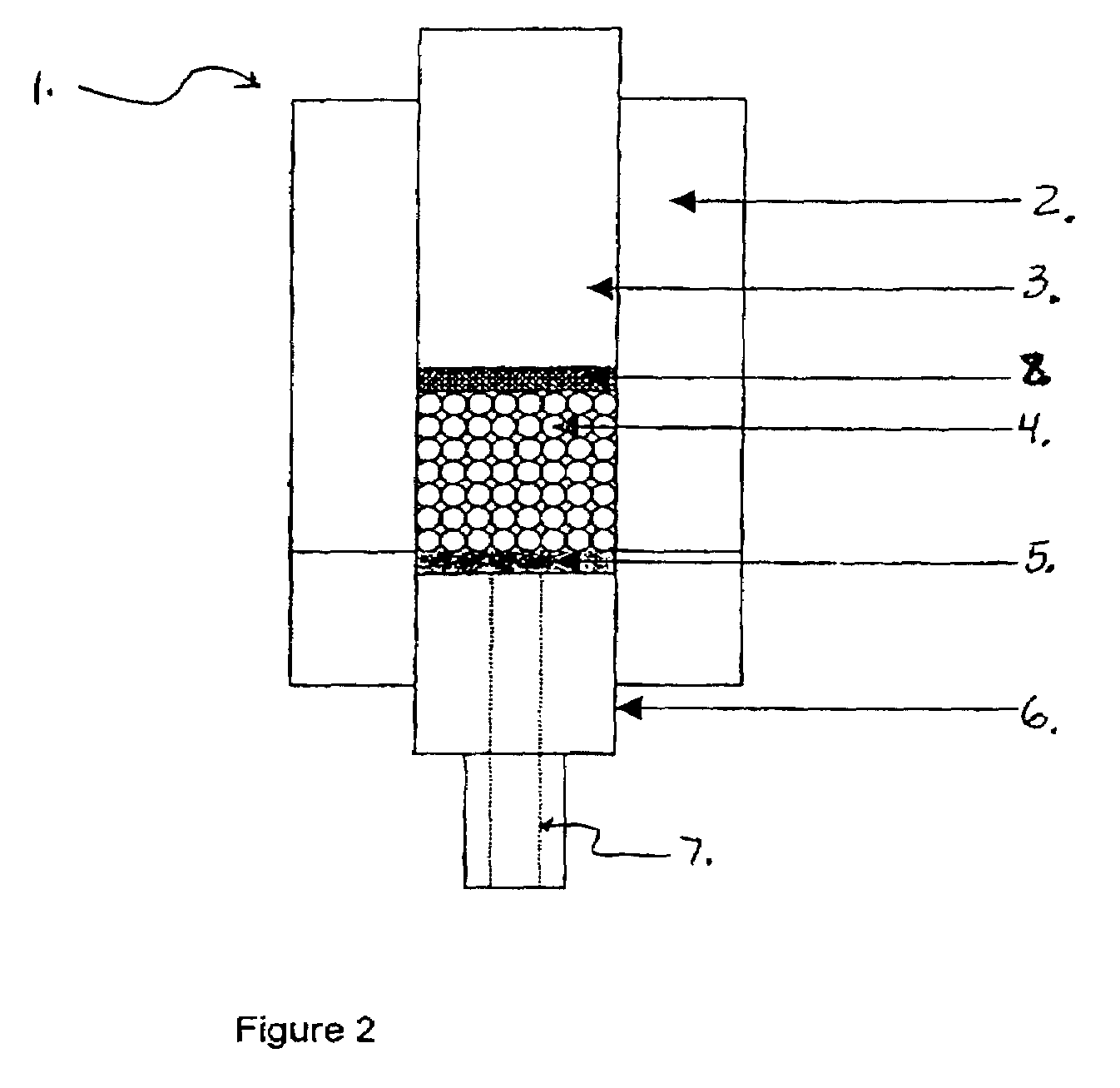

Resin infiltration transfer technique

InactiveUS7628942B1Desired loading levelQuality improvementLaminationWood working apparatusCeramic compositeCrack free

A process has been developed for fabricating composite structures using either reaction forming or polymer infiltration and pyrolysis techniques to densify the composite matrix. The matrix and reinforcement materials of choice can include, but are not limited to, silicon carbide (SiC) and zirconium carbide (ZrC). The novel process can be used to fabricate complex, net-shape or near-net shape, high-quality ceramic composites with a crack-free matrix.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com