Nonpolar zirconium carbide liquid-phase ceramic precursor, preparation method therefor and application thereof

A technology of ceramic precursor and zirconium carbide liquid, which is applied in the field of non-polar zirconium carbide liquid phase ceramic precursor and its preparation, can solve the problems of zirconium difficulty and system incompatibility, so as to improve the ceramic production rate and reduce the loss of Zr element , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

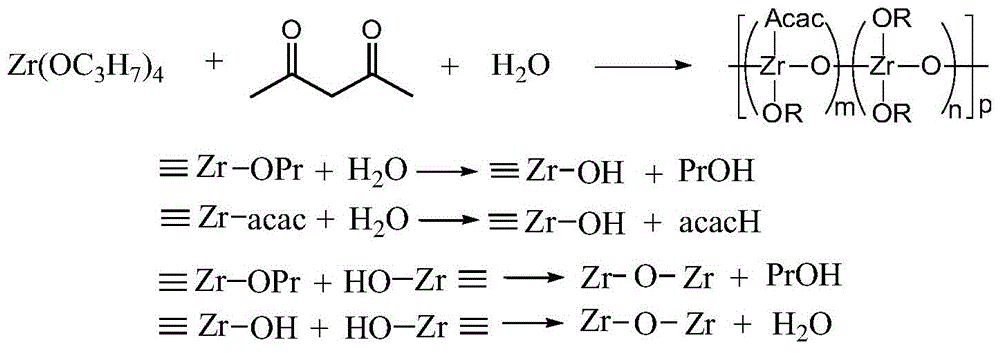

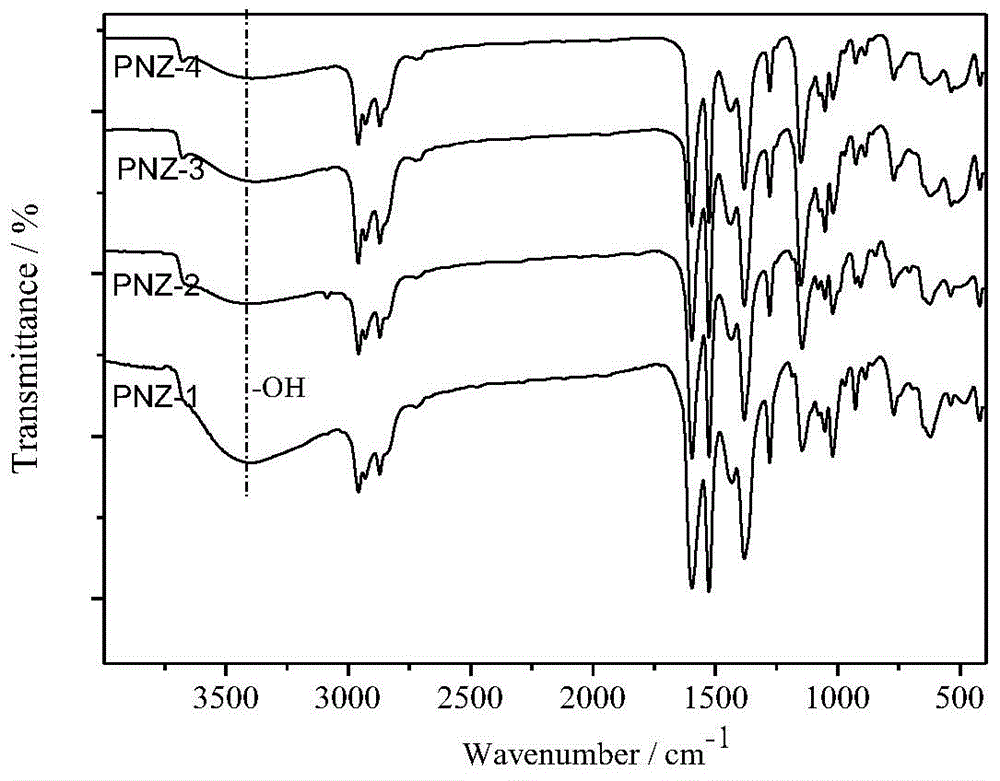

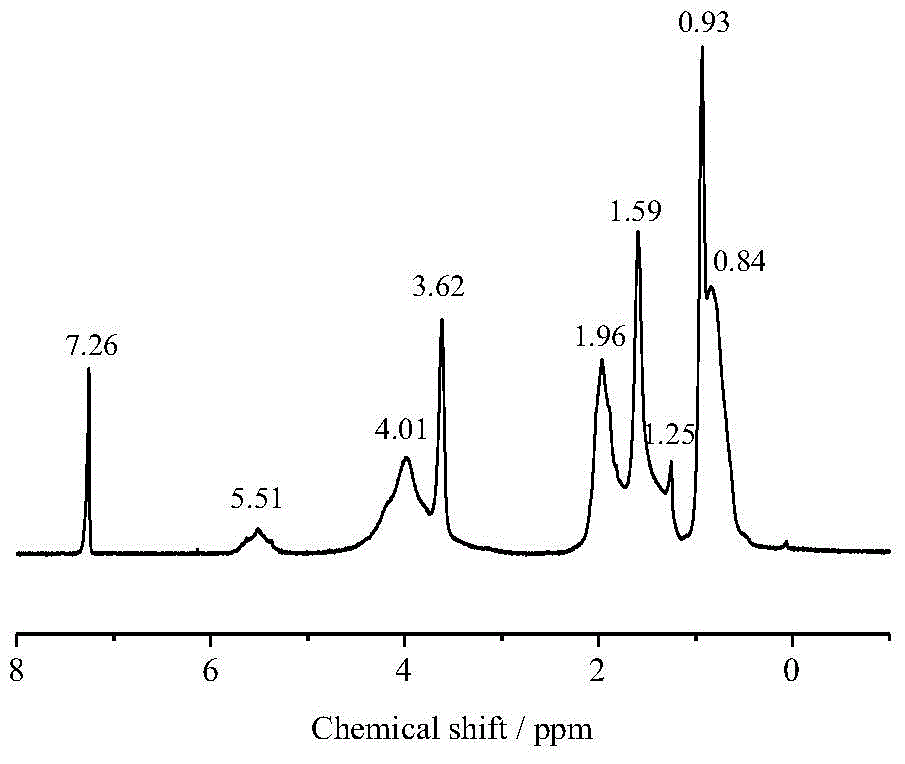

[0062] Heat 227.5g of propyl zirconate in n-propanol (zirconium content 20.05%, concentration 72%, containing 0.5mol propyl zirconate) to 90°C, add 25g (0.25mol) acetylacetone dropwise, and control the rate of addition, 2 After 1 hour of dropwise addition, the mixture was heated to reflux for 1 hour. Keep heating to reflux, continue to slowly add dropwise a mixed solution of 9.9g (0.55mol) of water and 30g of n-propanol, and then heat to reflux for 2 hours after the dropwise addition is completed for 2 hours. The temperature was lowered to room temperature, and most of the solvent was removed by rotary evaporation to obtain a n-propanol solution of polyziroxane (denoted as PNZ-1). Add 54.7g of divinylbenzene and stir to dissolve, continue rotary steaming at 70℃~75℃ for 0.5h to ensure complete removal of n-propanol solvent, and finally add a small amount of xylene to adjust the solution viscosity to 50~500mpa.s to obtain homogeneous and transparent Precursor solution (referred...

Embodiment 2

[0071] Heat 227.5g of propyl zirconate in n-propanol (zirconium content 20.05%, concentration 72%, containing 0.5mol propyl zirconate) to 90°C, add 50g (0.5mol) acetylacetone dropwise, and control the dropping rate, 2 After 1 hour of dropwise addition, the mixture was heated to reflux for 1 hour. Keep heating to reflux, continue to slowly add dropwise a mixed solution of 8.1 g (0.45 mol) of water and 30 g of n-propanol, and then heat to reflux for 2 hours after the dropwise addition is completed. The temperature was lowered to room temperature, and most of the solvent was removed by rotary evaporation to obtain a n-propanol solution of polyziroxane (referred to as PNZ-2). Add 52.5g of divinylbenzene, stir evenly, further rotary steam at 70℃~75℃ for 0.5h to ensure that the n-propanol solvent is completely removed, and finally add a small amount of xylene to adjust the viscosity of the solution to prepare a homogeneous and transparent precursor solution (denoted as PZC-2). At ...

Embodiment 3

[0078] Heat 227.5g of propyl zirconate in n-propanol (zirconium content 20.05%, concentration 72%, containing 0.5mol propyl zirconate) to 85°C, add 75g (0.75mol) acetylacetone dropwise, and control the rate of addition, 2 After 1 hour of dropwise addition, the mixture was heated to reflux for 1 hour. Keep heating to reflux, continue to slowly add dropwise a mixed solution of 7.2g (0.4mol) of water and 30g of n-propanol, and then heat to reflux for 2 hours after the dropwise addition is completed for 2 hours. The temperature was lowered to room temperature, and most of the solvent was removed by rotary evaporation to obtain a n-propanol solution of polyziroxane (referred to as PNZ-3). Add 50.2 g of divinylbenzene and stir to dissolve, and further rotate steam at 70°C to 75°C for 0.5h to ensure that the n-propanol solvent is completely removed, and finally add a small amount of xylene to adjust the viscosity of the solution to prepare a homogeneous and transparent precursor solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com