Patents

Literature

75results about How to "Reduce ablation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

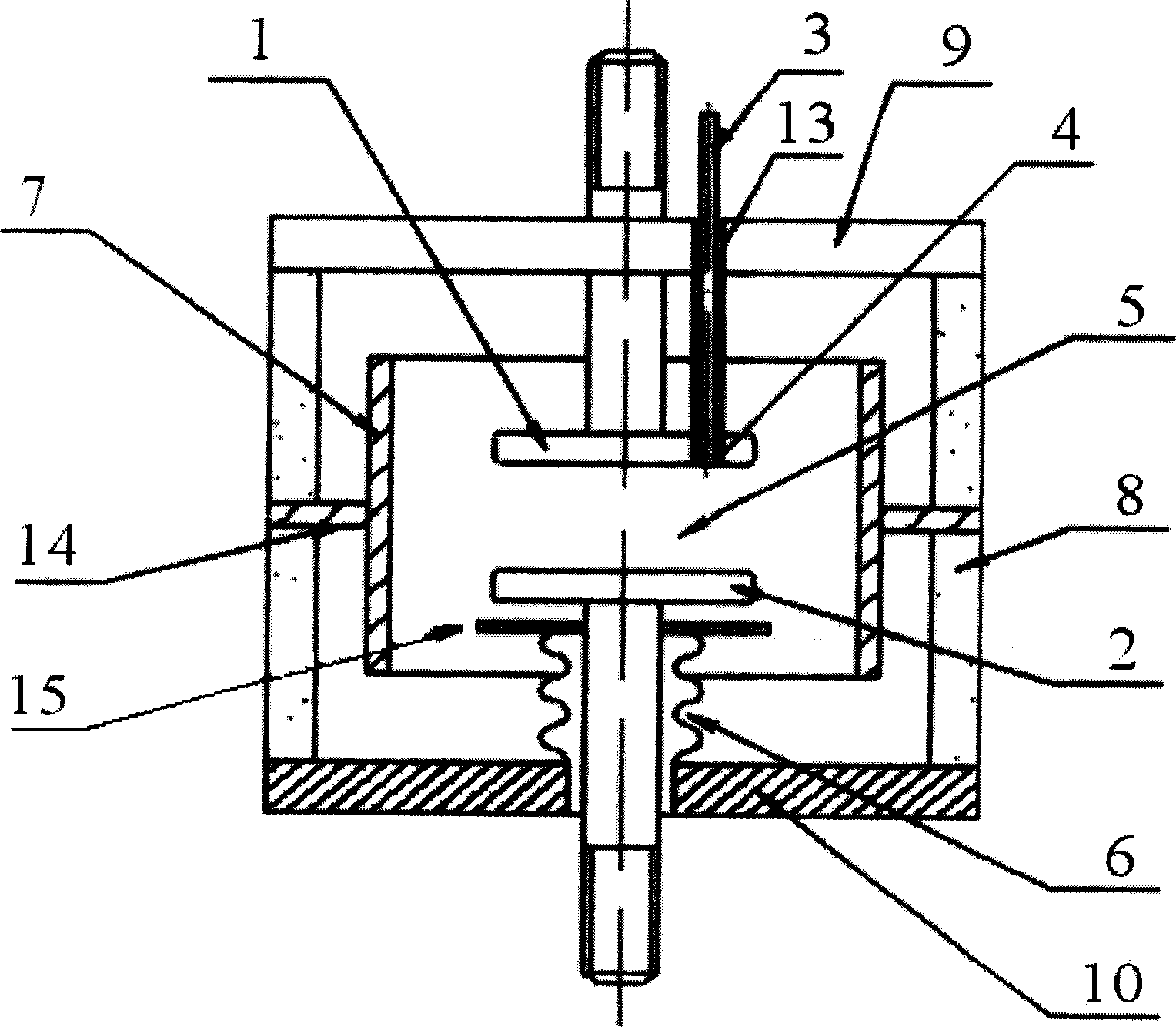

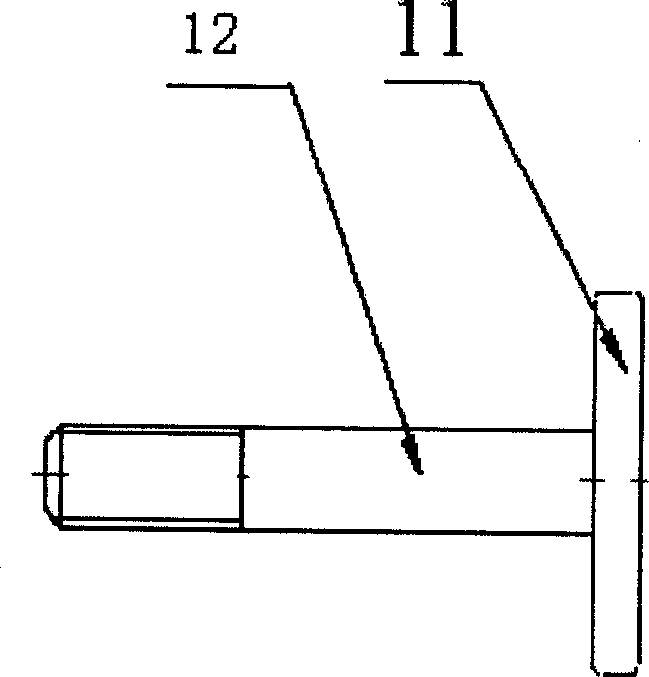

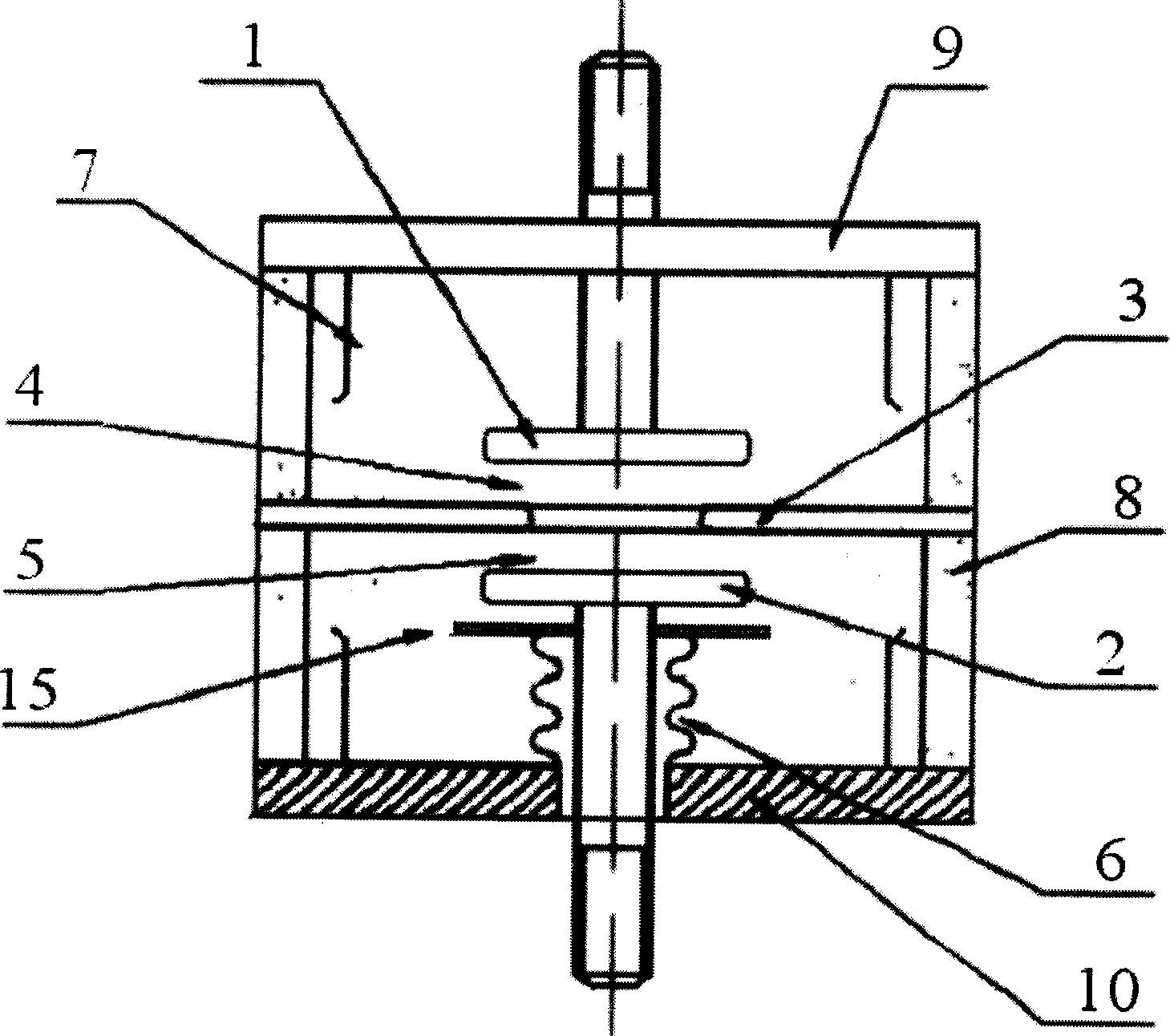

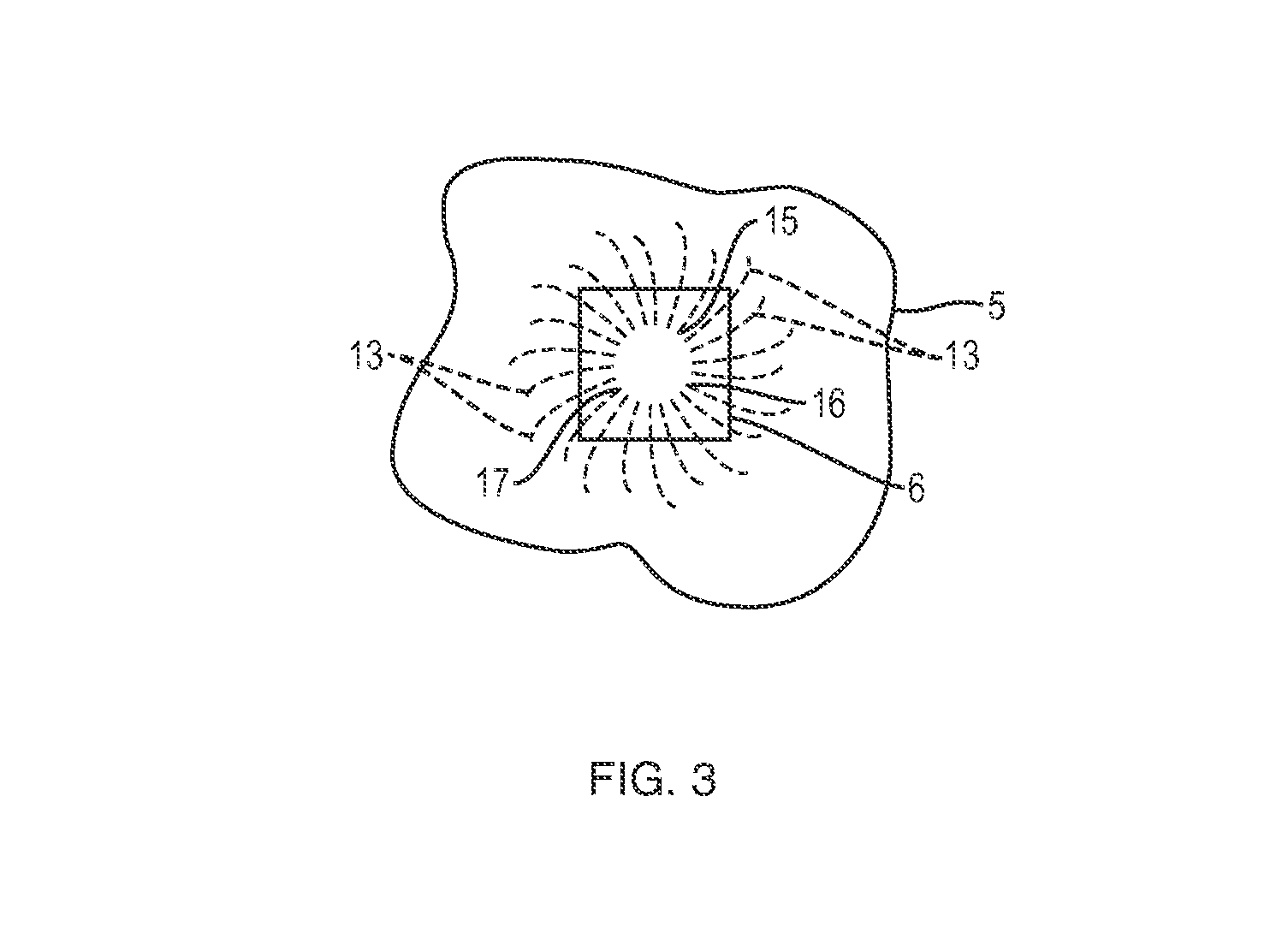

Controllable discharge switch of high-energy impulse in three electrodes under vacuum environment

InactiveCN1697107AReduce ablation rateDiffusion fastSpark gaps with auxillary triggeringHigh-tension/heavy-dress switchesElectricityHigh energy

The disclosed discharge switch includes upper and lower electrodes setup inside insulated case. Pressure inside the air locked shell body formed by the insulated case and flanges at two ends of the case is 10 -3 - 10 -4 Pa. At least one of the upper and lower electrodes is a movable electrode. Trigger electrode is inlaid inside the fixed electrode or setup between the upper and lower electrodes. Since being air locked in vacuum environment, the upper and lower electrodes possess tremendous ability of ducting transient current in high energy. Moreover, operation reliability of pulse switch is raised because vacuum environment is not interfered from outside. Features are: raised reliability, very low ablation rate of electrode, and wide range of stable operation voltage.

Owner:XI AN JIAOTONG UNIV

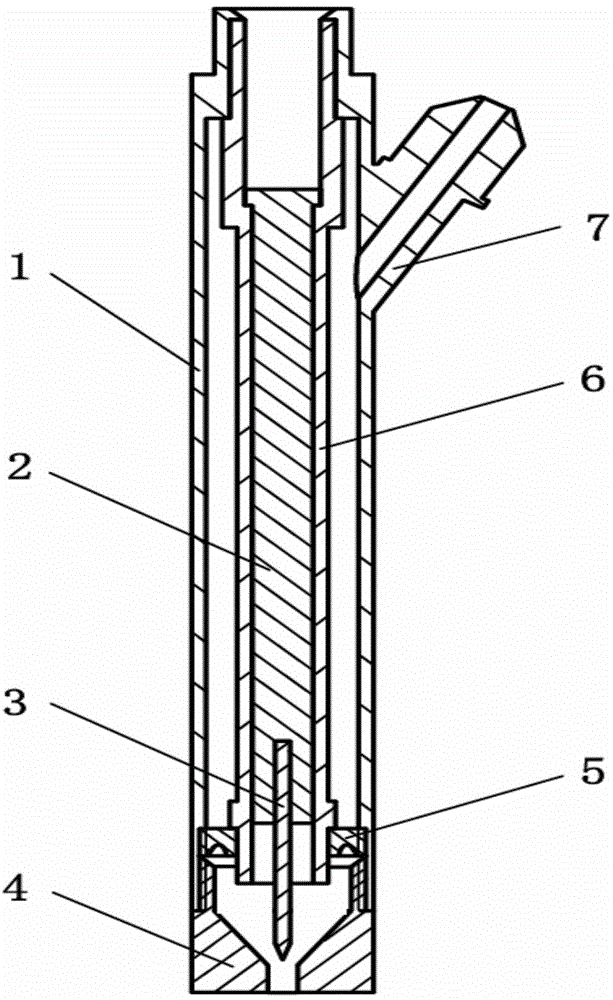

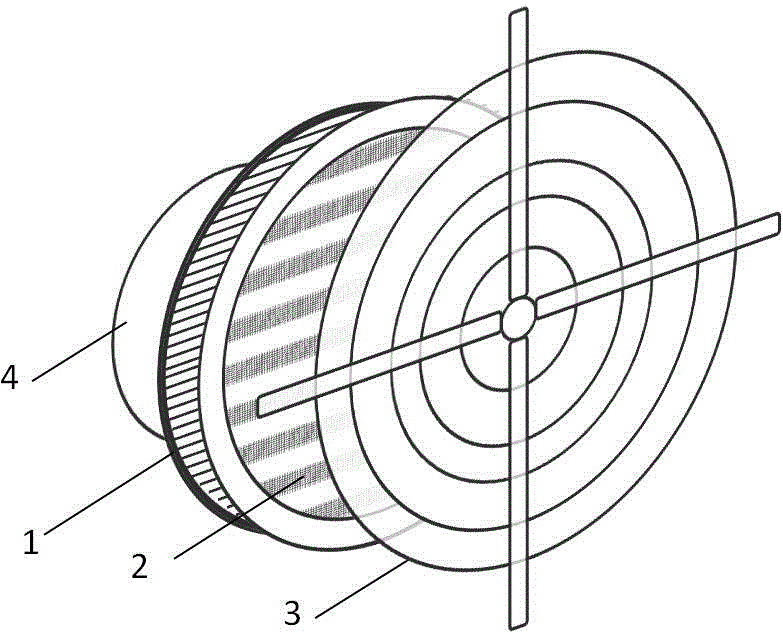

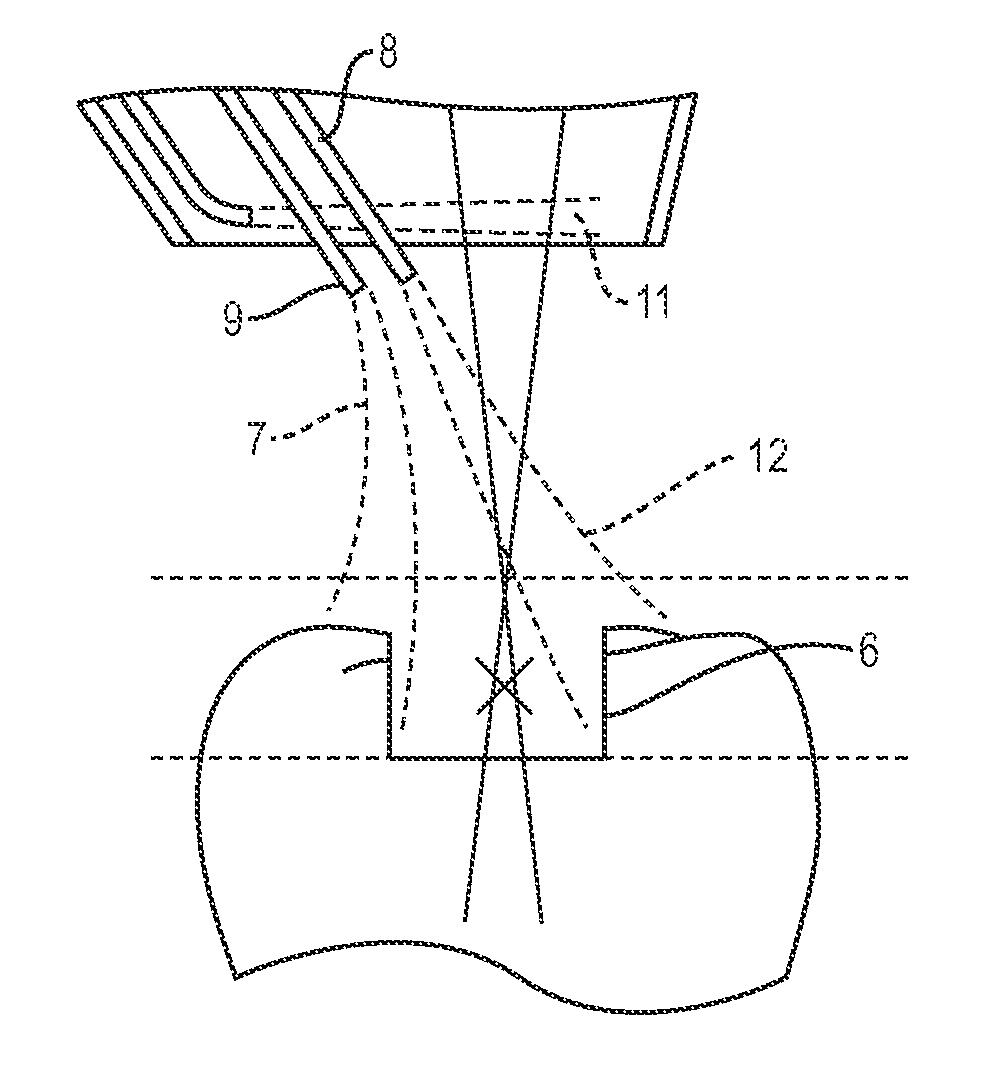

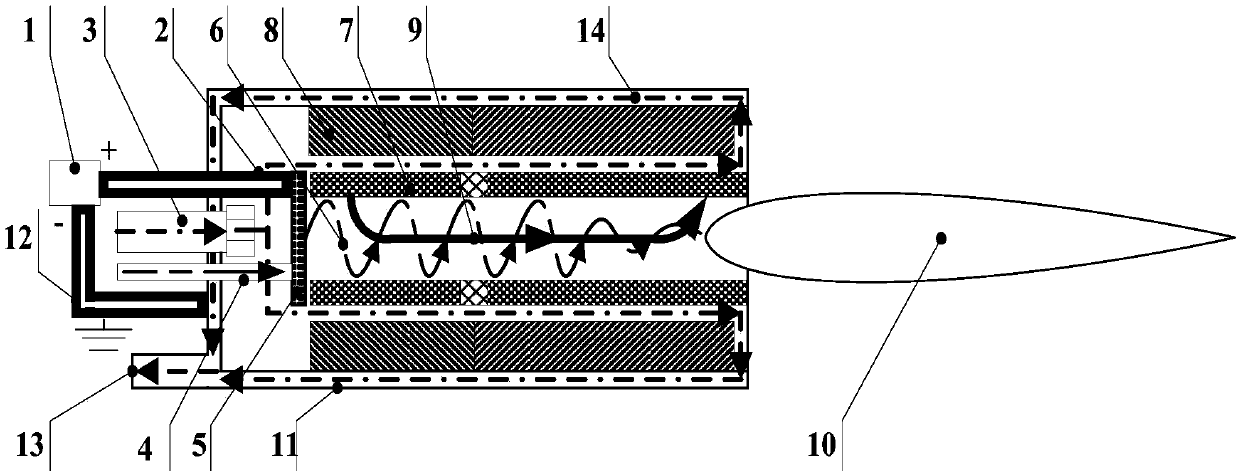

Elongating arc plasma jet ignition device

ActiveCN104454290AIncrease the speed of flame spreadStrong penetrating powerMachines/enginesEngine ignitionPlasma jetFlame spread

Disclosed is an elongating arc plasma jet ignition device. A swirler is fixed to the bottom of an inner cavity of a shell; a positive pole is located in the shell and fixedly connected with the swirler; the lower end of an insulation sleeve is installed in a central hole of the swirler, and an air chamber is formed in the gap between the outer peripheral surface of the middle of the insulation sleeve and the inner surface of the shell. A negative pole is embedded on a negative pole installation base, and the arc end of the negative pole extends out of the lower end of the insulation sleeve to be located in the positive pole. An arcing distance 2-8 mm long is kept between the arc end of the negative pole and a nozzle of the positive pole; an air inlet pipe is located at the upper end of the shell and communicated with the space of the air chamber formed between the insulation sleeve and the shell. The taper angle beta of the arc end of the negative pole is 40 degrees. The taper angle alpha of a contraction section of the positive pole is 60-90 degrees. Eight swirling holes with the spiral angle of 45 degrees are evenly distributed in an end surface of the swirler, and work media passing through the swirler generate swirling flow. The elongating arc plasma jet ignition device has the advantages of being high in flame spreading speed, high in penetrating power and rich in active air plasma.

Owner:AIR FORCE UNIV PLA

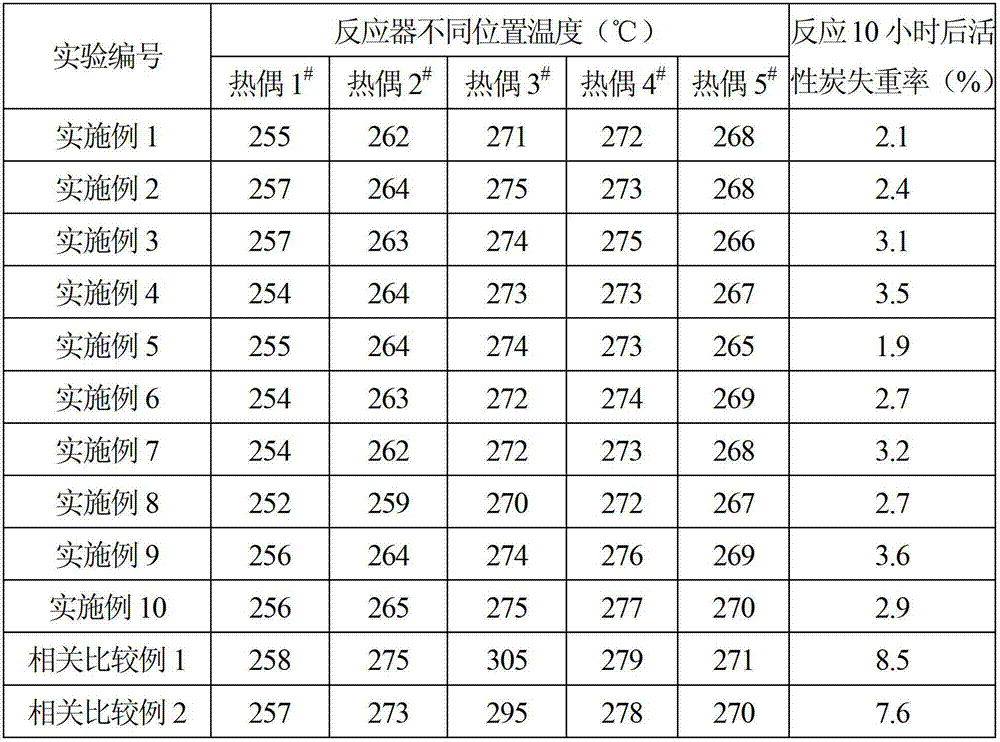

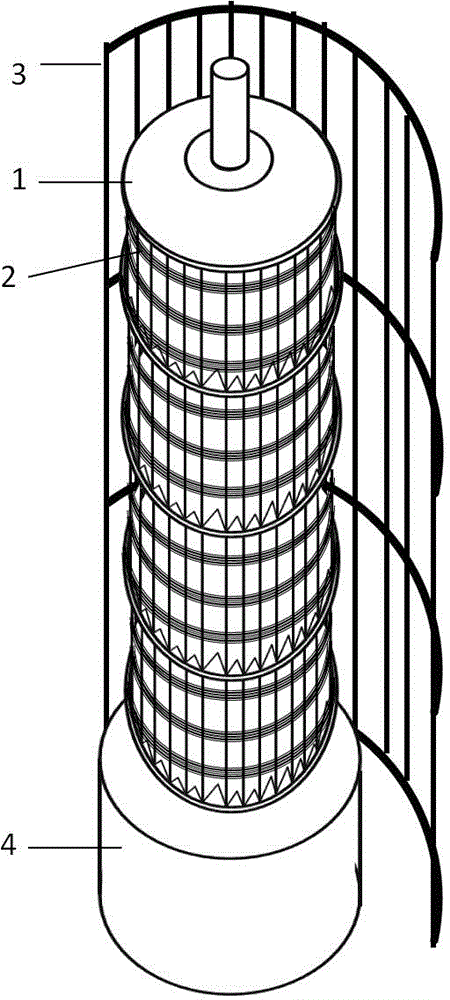

Activated carbon coating/foam silicon carbide structural catalyst and preparation method thereof

ActiveCN102814188AUniform temperature distributionSufficiently chemically inertCatalyst activation/preparationChemical reactionHeat inactivation

The invention relates to the field of structural catalysts, in particular to an activated carbon coating / foam silicon carbide catalyst with a three-dimensional communicated structure and a preparation method for the catalyst. The invention aims to solve the problems that hole opening is discontinuous, the catalyst and reaction products are separated, a heat transfer and mass transfer effect is poor and the like in the prior art. By taking foam silicon carbide as a catalyst carrier, an activated carbon coating covers on the surface of the foam silicon carbide, wherein the activated carbon coating is between 0.1 micron and 500 microns thick, and a metal catalysis active component is loaded on the activated carbon coating. The activated carbon coating is prepared on the surface of the foam silicon carbide with the three-dimensional communicated structure, then, the metal catalysis active component is loaded, and activating treatment is performed on the metal catalysis active component to obtain the catalyst. According to the activated carbon coating / foam silicon carbide catalyst, holes in the catalyst carrier are totally communicated, thus, an enclosure space does not exist, and a heat transfer and mass transfer process of the chemical reaction can be strengthened. The activated carbon coating / foam silicon carbide catalyst has the characteristics that the temperature field distribution of the catalytic reaction is uniform, the heat inactivation rate is low, the pressure drop is low and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

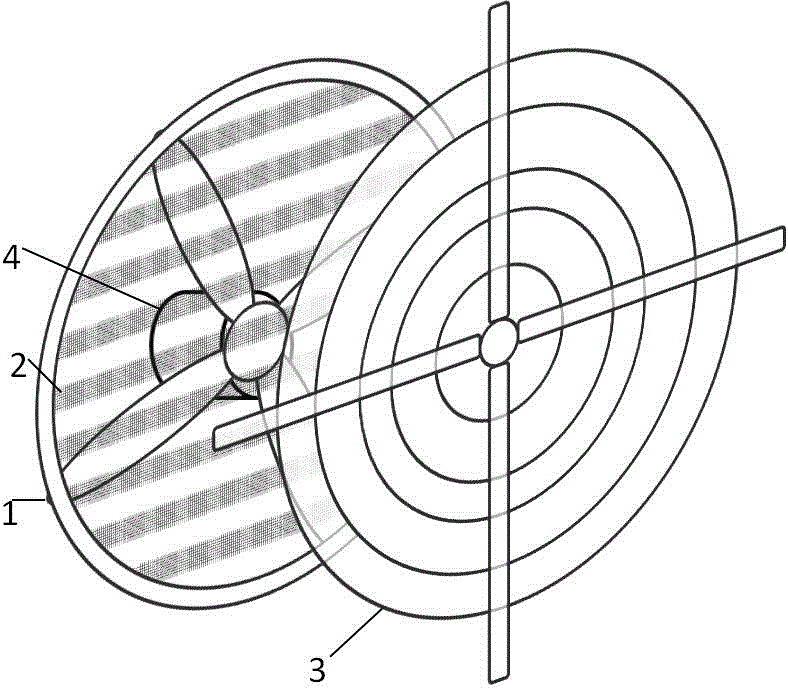

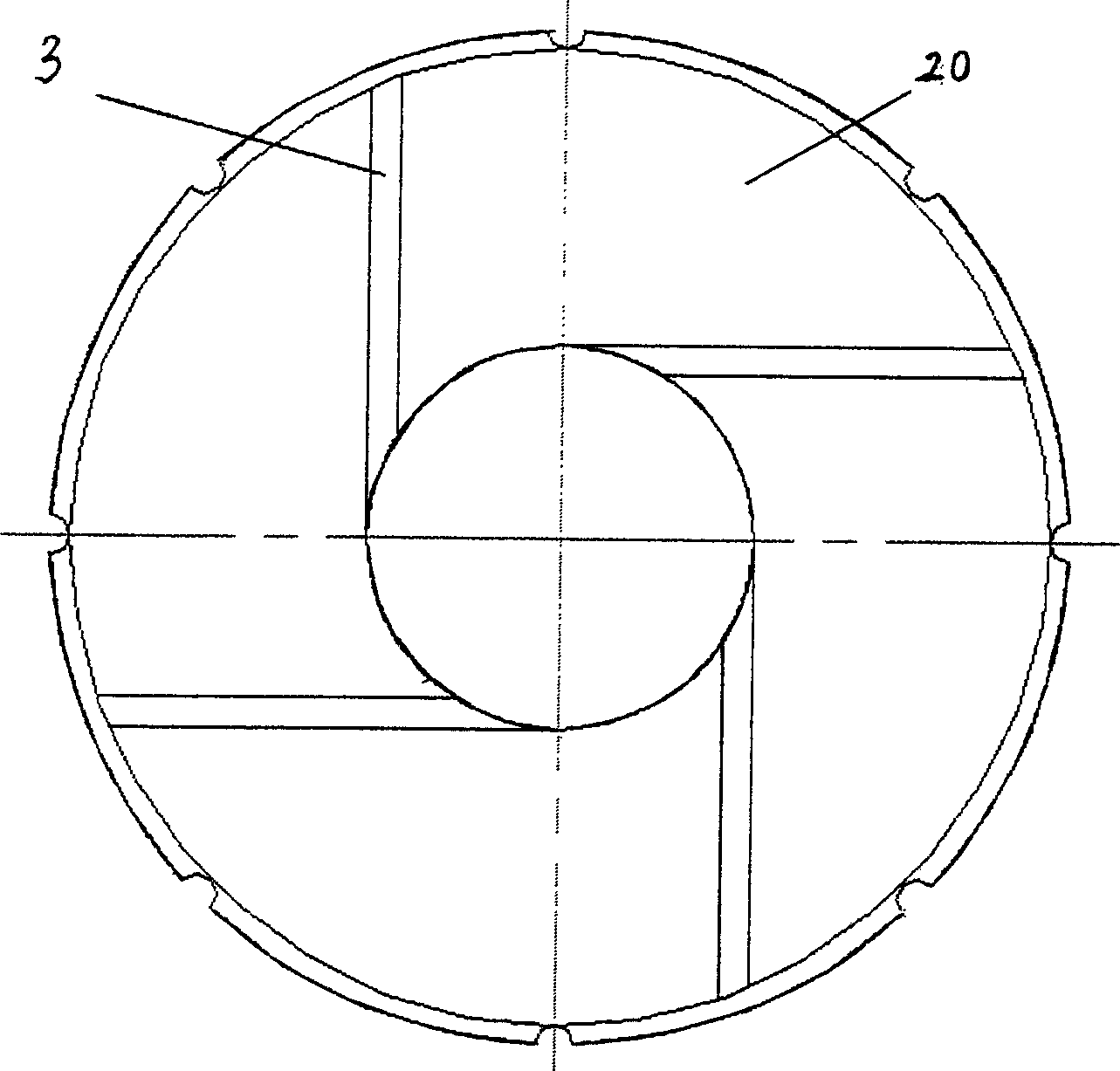

Electric discharging device of rotation electrode

InactiveCN105478240APrevent escapeReduce rapid ablationElectrode constructionsPlasma techniqueImpellerElectric discharge

The invention belongs to the technical field of low-temperature plasma application, and relates to an electric discharging device of a rotation electrode. The device comprises an impeller, a rotation electrode, a fixed electrode, and an electric motor, wherein the rotation electrode is arranged between the electric motor and the fixed electrode, and is fixedly arranged on the impeller or a shaft of the electric motor. The electric motor drives the impeller and the rotation electrode to move. High voltage is applied between the rotation electrode and the fixed electrode, and corona discharging is generated between the two electrodes. Since the electric motor drives the rotation electrode to move, corona rotates with the movement to draw a large-volume plasma area. Plasma is uniformly dispersed in a whole airflow channel between the two electrodes. Therefore, the electric discharging device can be applied to an air purifier and allows no dead corner to be left during purification. Moreover, the rotation electrode can greatly reduce the ozone yield, and prolongs the service life of asymmetric electrodes.

Owner:孙红梅

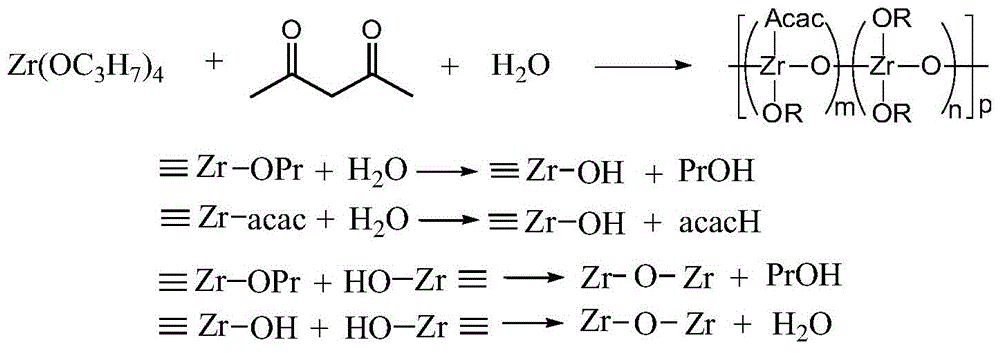

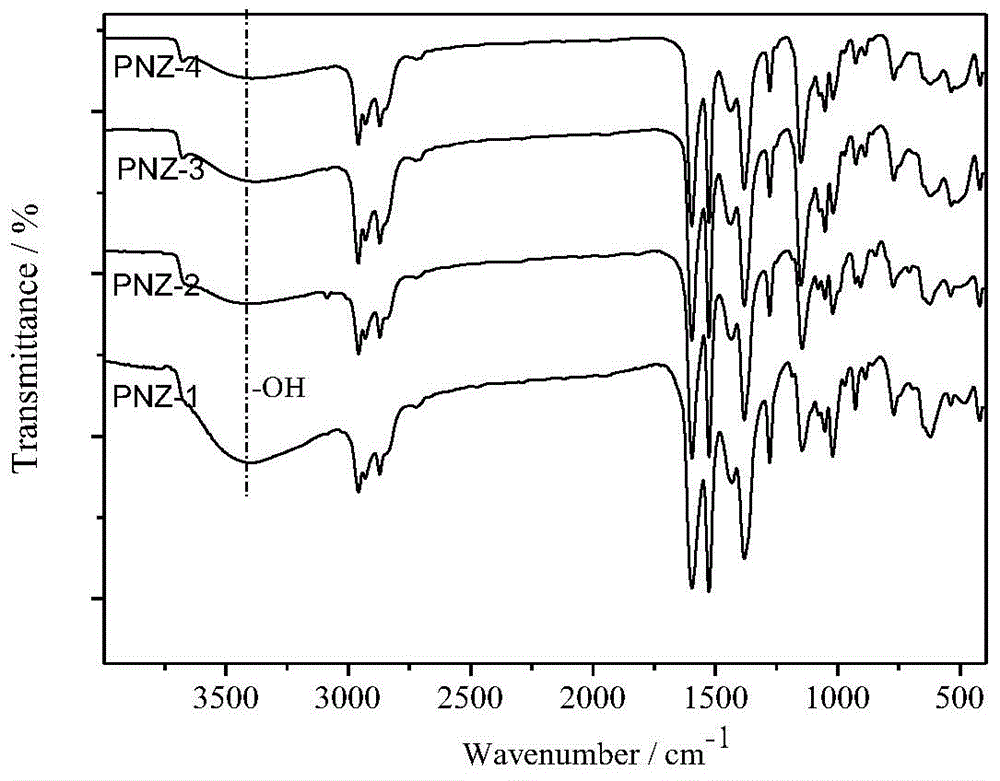

Nonpolar zirconium carbide liquid-phase ceramic precursor, preparation method therefor and application thereof

The invention relates to a nonpolar zirconium carbide liquid-phase ceramic precursor, a preparation method therefor and application thereof. The preparation method comprises: firstly preparing a nonpolar zirconium polymer-polyzircooxane through coordination protection of propyl zirconate and controllable hydrolysis condensation reaction; and by using the polyzircooxane as a zirconium source and divinyl benzene as a carbon source, compounding the components to obtain the nonpolar zirconium carbide liquid-phase ceramic precursor. The liquid-phase precursor prepared by the invention has the characteristics of polymer resin; the viscosity of the precursor can be controlled between 50 mpa.s and 500 mpa.s by adjusting the solid content, and the manufacturability is good. The zirconium carbide liquid-phase ceramic precursor which is cured and thermally treated can be converted into a pure-phase zirconium carbide ceramic at a relatively low temperature ( for example, 1500 DEG C). The liquid-phase ceramic precursor prepared by the invention is expected to be used as impregnating resin for a ceramic-based composite material and an antioxidant C / C and C / Si composite material so as to improve the ultra-high temperature antioxidant performance of the material and reduce the ablativity of the material.

Owner:SUZHOU TUNABLE MATERIALS TECH CO LTD

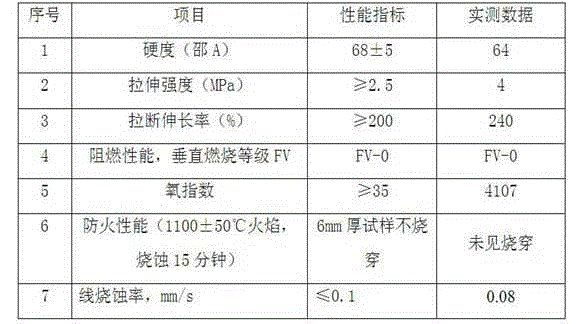

Fireproof heat-insulation silicon rubber and preparation method thereof

The invention discloses a fireproof heat-insulation silicon rubber and a preparation method thereof. The fireproof heat-insulation silicon rubber comprises the following components in percentage by mass: 45-55% of substrate, 10-15% of high-temperature-resistant functional filler, 15-25% of flame retardant, 10-20% of reinforcing agent and 1-5% of other assistants, totaling 100%. The preparation method of the fireproof heat-insulation silicon rubber comprises four steps. The invention provides a silicon rubber material with excellent fireproof and heat-insulation properties, which is prepared by compounding the high-temperature-resistant functional material, flame-retardant material, reinforcing material and other assistants according to the optimized formula. The fireproof heat-insulation silicon rubber is especially suitable for fireproof heat-insulation requirements of rocket engines and potential fire region working condition requirements of airplanes.

Owner:NORTHWEST RUBBER & PLASTIC RES & DESIGN INST CO LTD

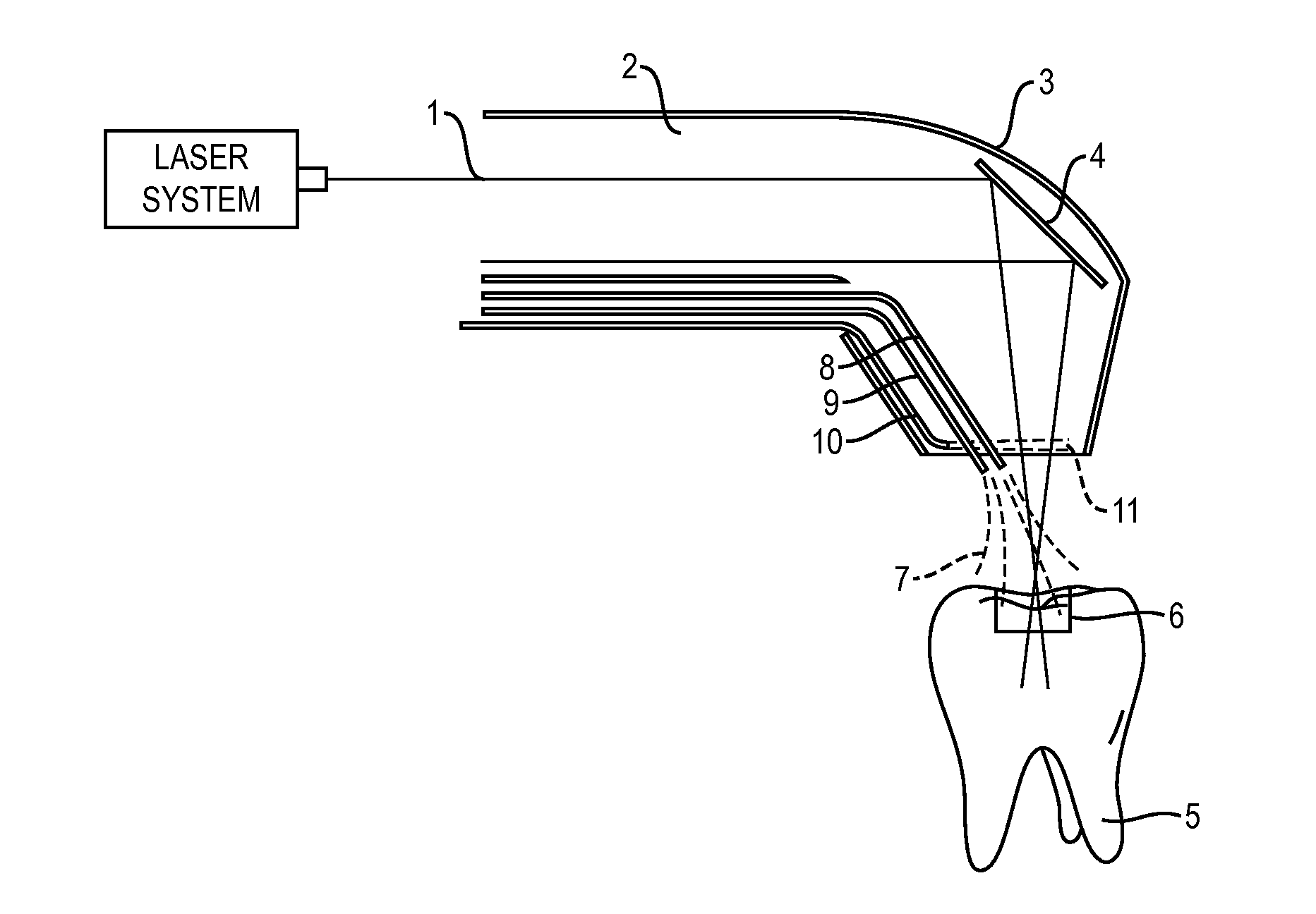

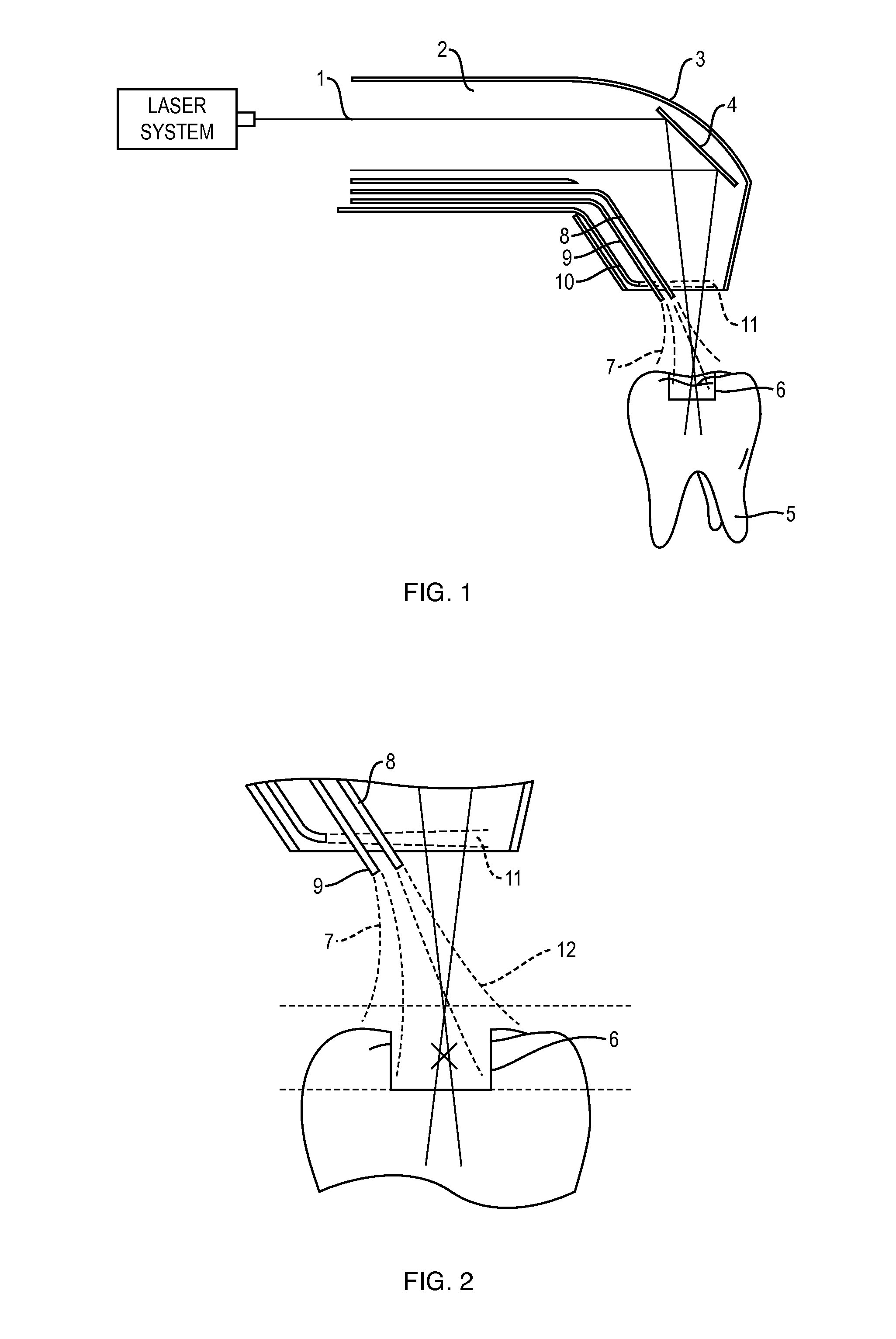

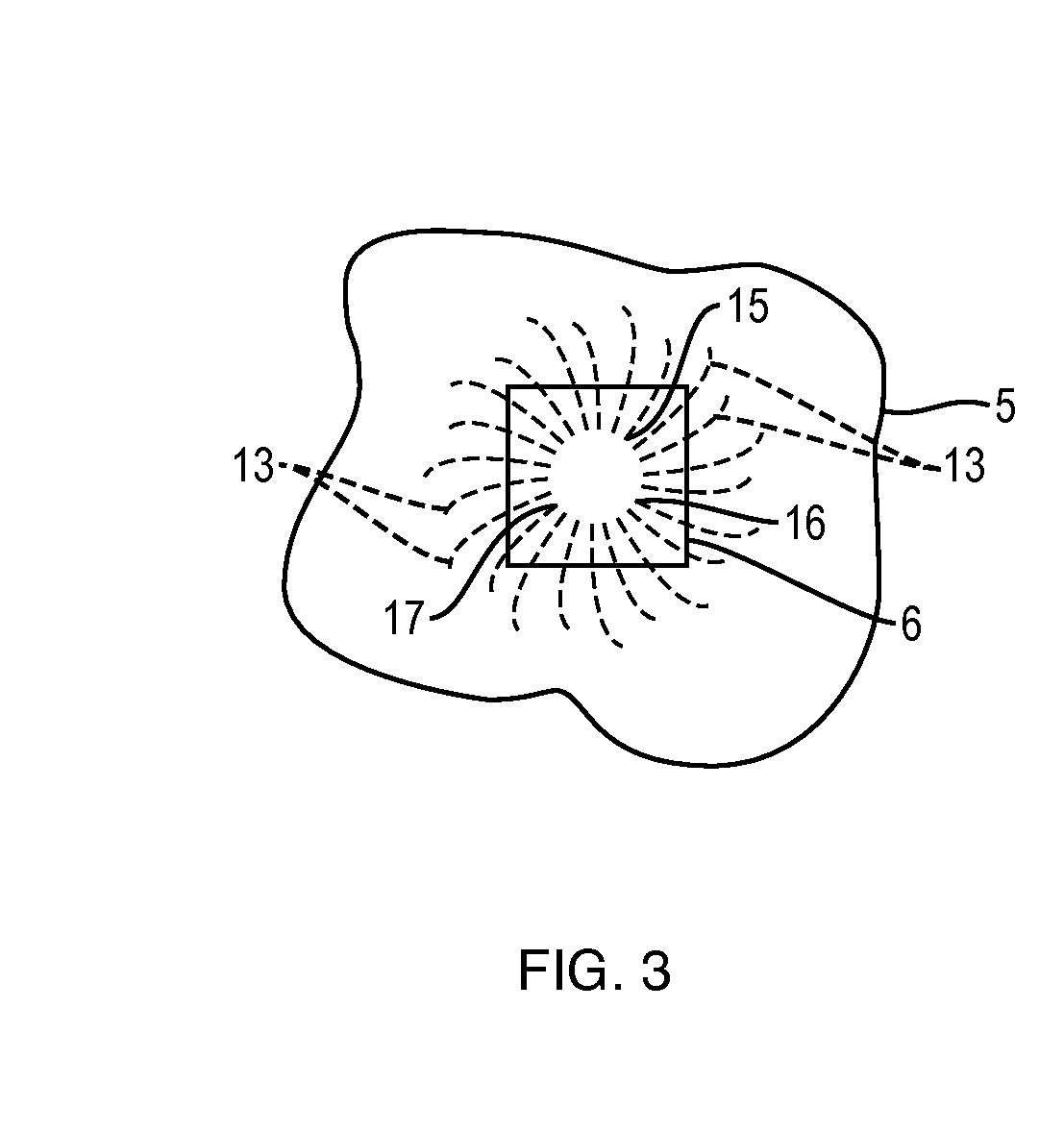

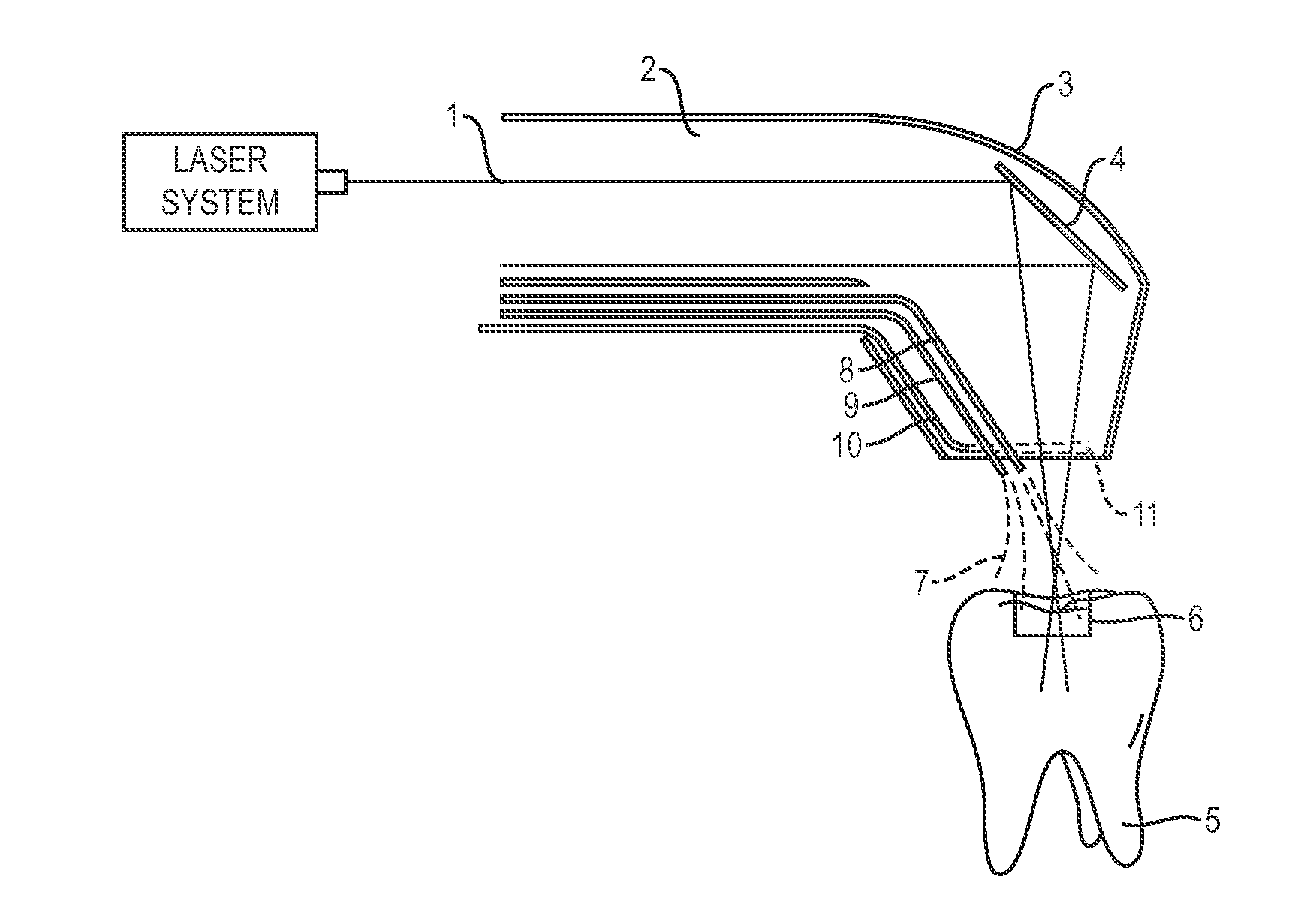

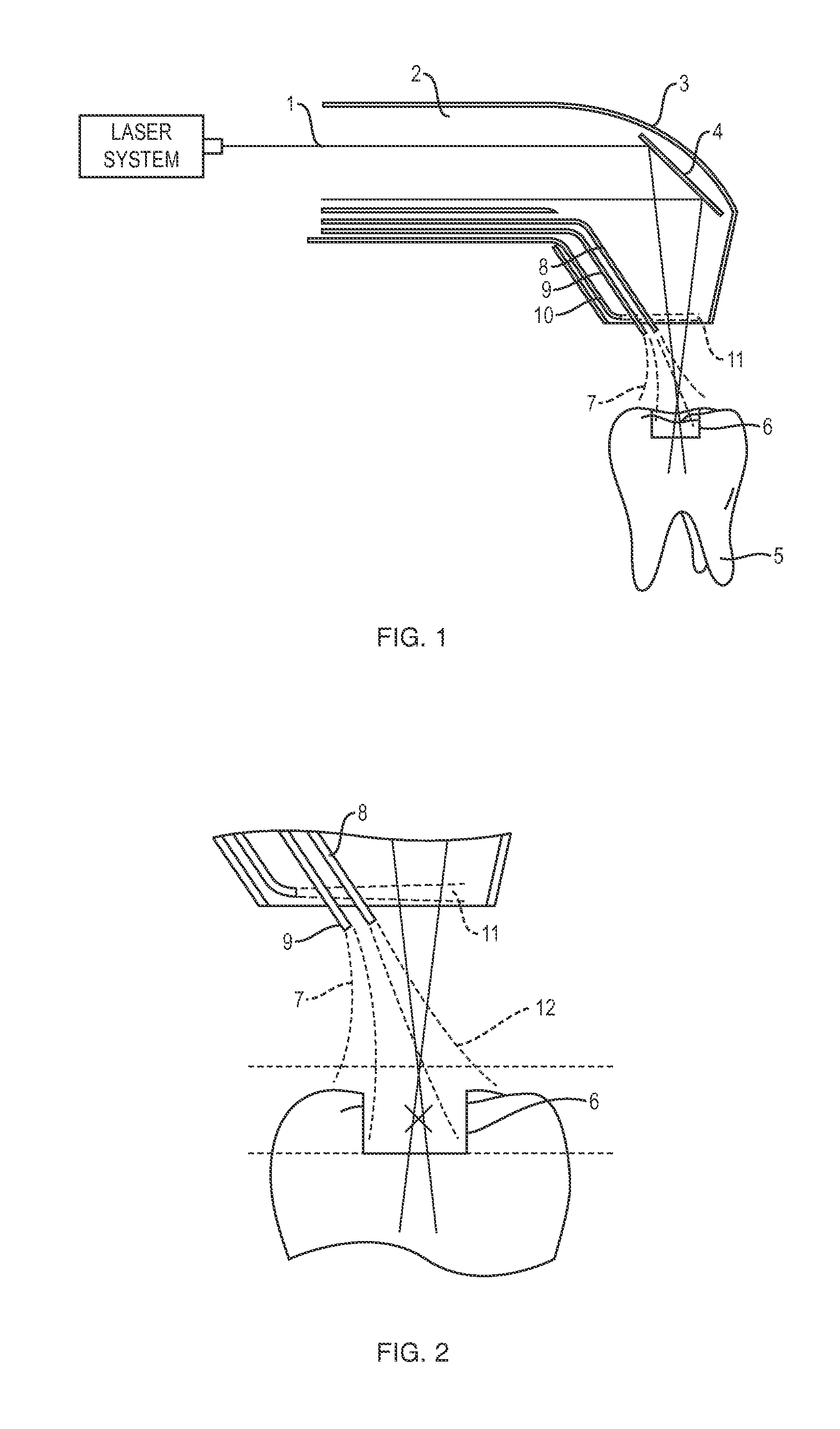

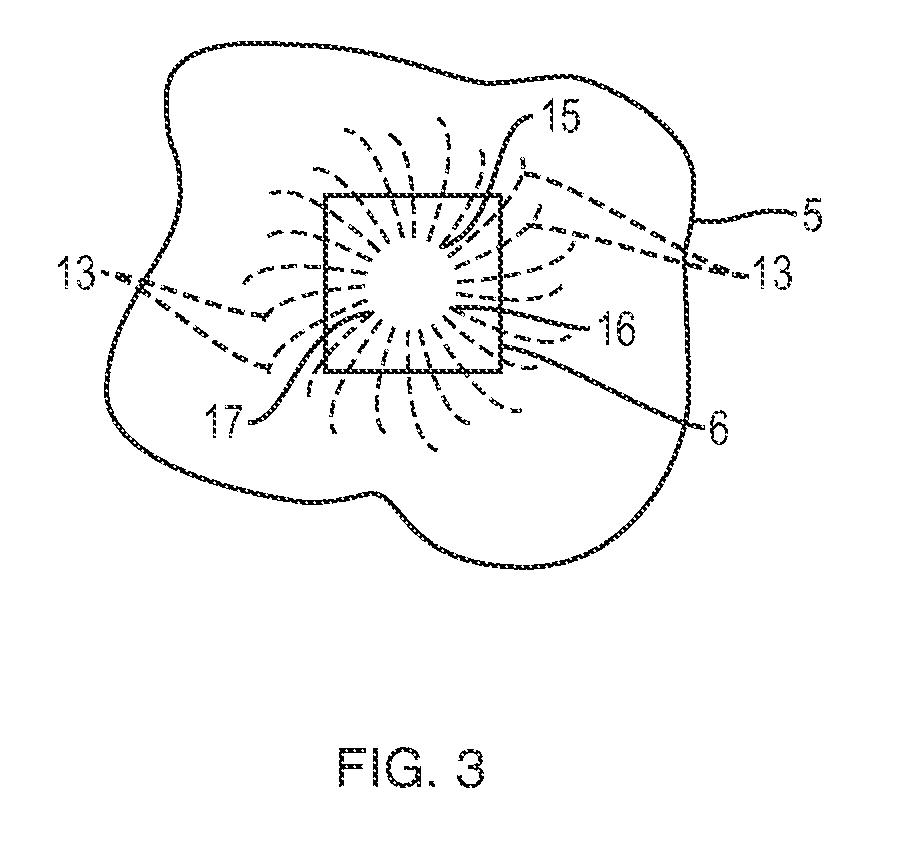

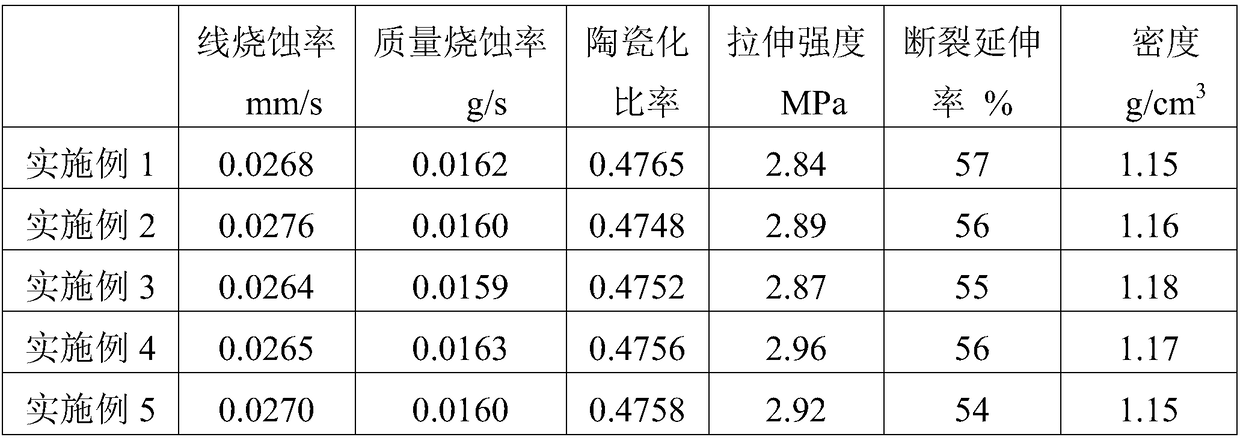

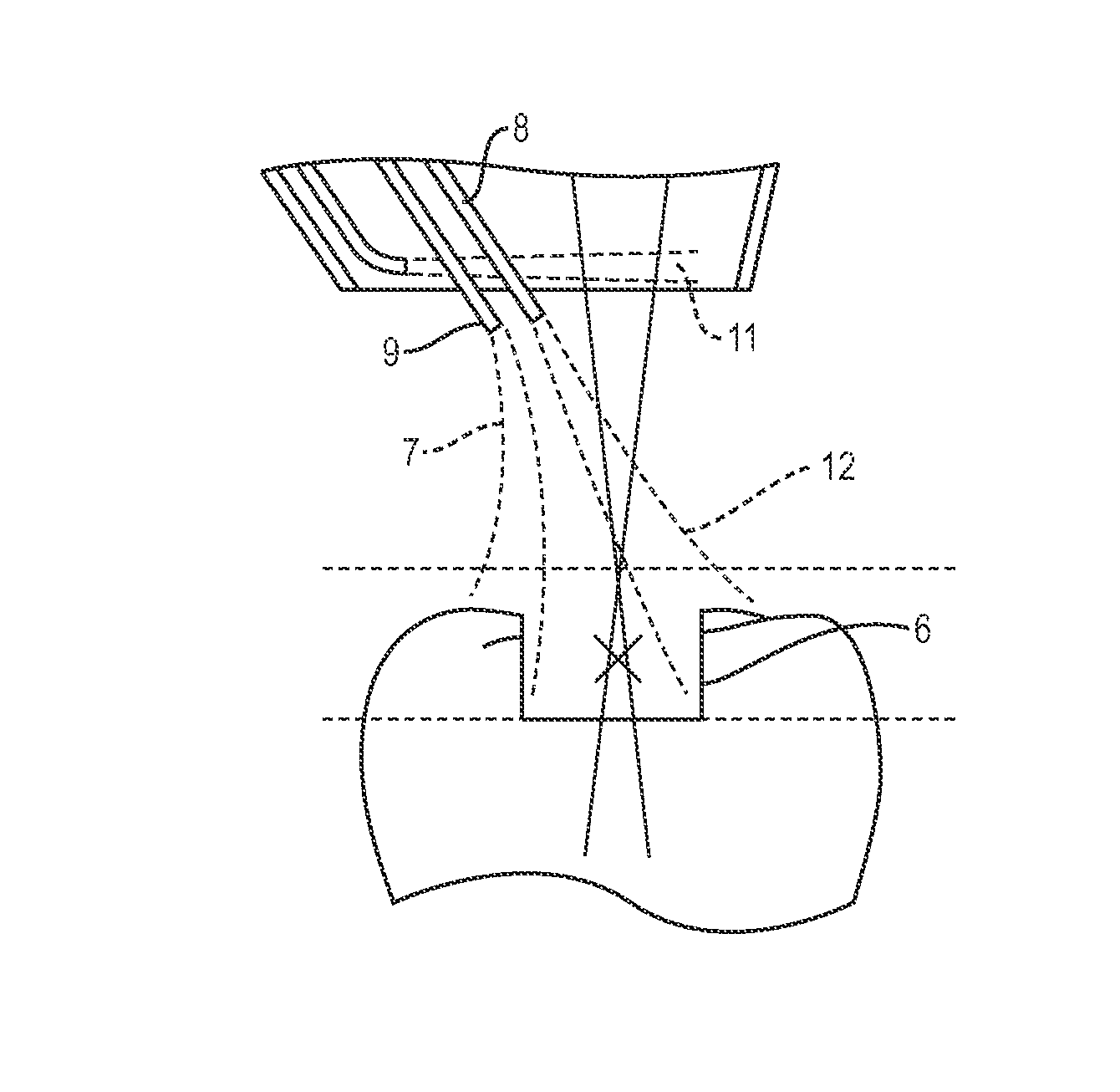

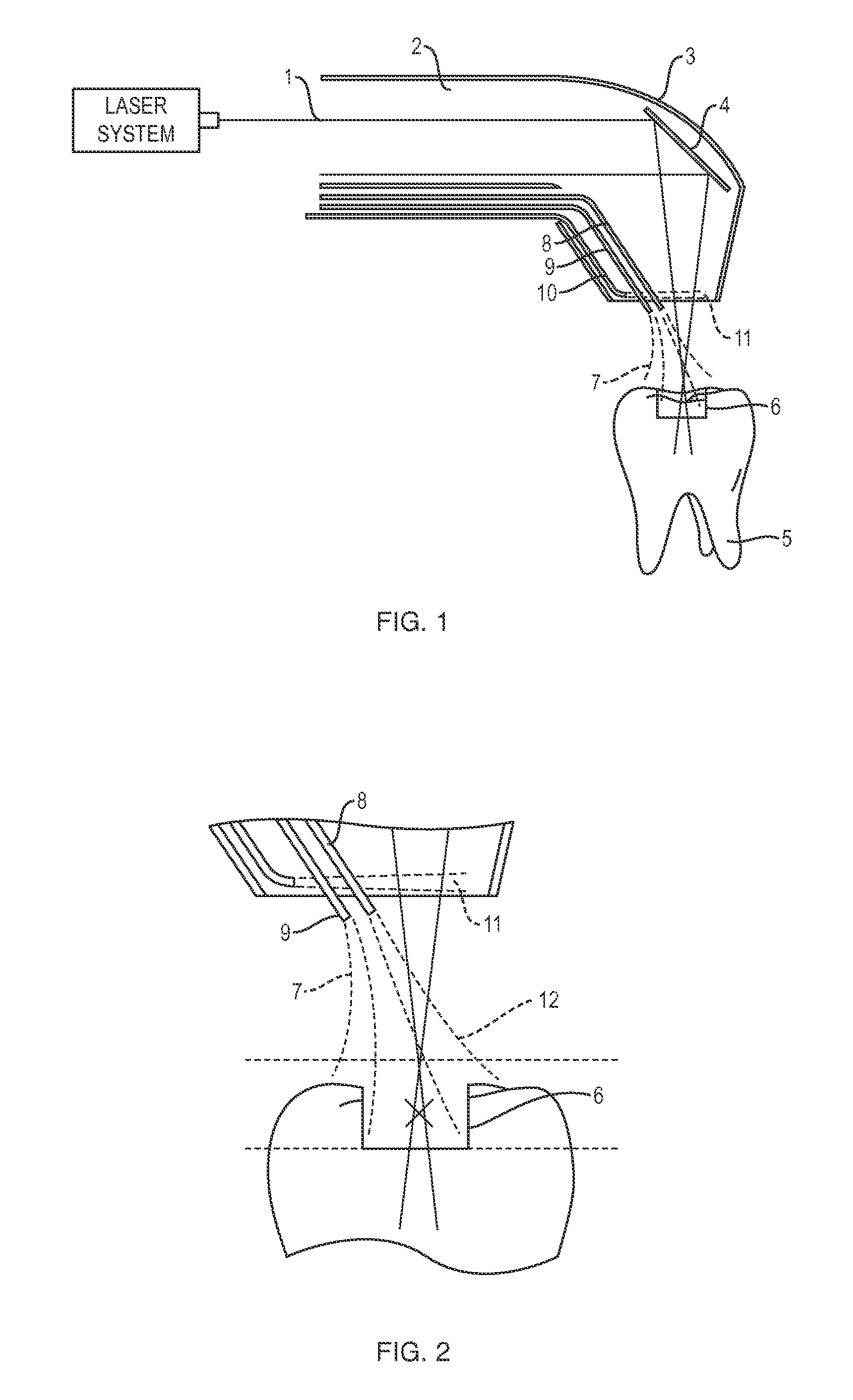

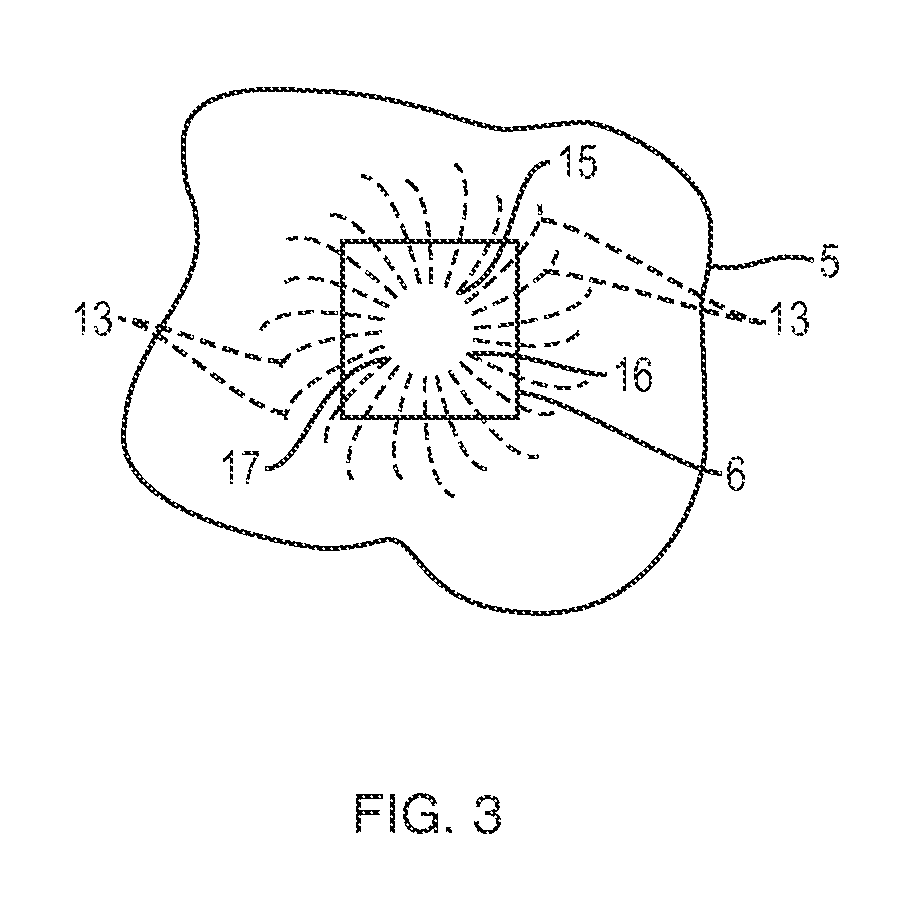

Apparatus and Method for Controlled Fluid Cooling During Laser Based Dental Treatments

ActiveUS20130323672A1Mitigate or eliminate riskMinimize riskTeeth fillingDental toolsUltrasound attenuationTherapeutic Area

A system for dental tissue treatment includes a system for directing a laser beam to an area of dental tissue to be treated, and a fluid-delivery system for directing and controlling a flow of a fluid. The fluid is directed to at least a portion of the area to be treated and the fluid flow is controlled to substantially prevent both a change in laser energy absorption by the dental tissue and attenuation of treatment efficiency due to fluid interference with the laser beam. The fluid present in at least a portion of the area to be treated may prevent or reduce the likelihood of melting of enamel in that area.

Owner:CONVERGENT DENTAL INC

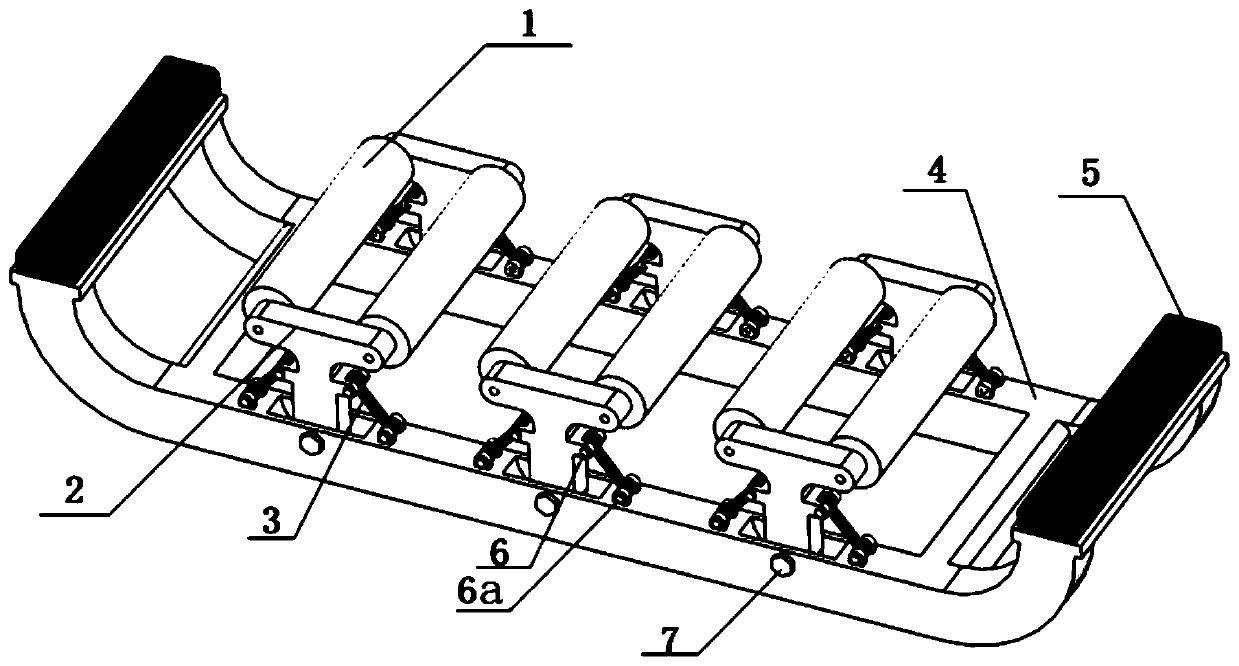

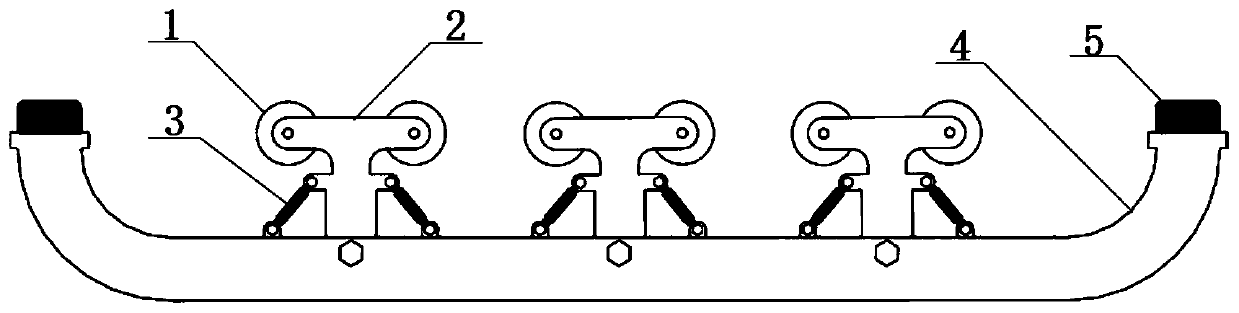

Self-lubricating modular metal roller electric locomotive pantograph head with damping structure

PendingCN110303891AHigh impact and wear resistanceImprove wear resistancePower current collectorsElectricityEngineering

The invention provides a self-lubricating modular metal roller electric locomotive pantograph head with a damping structure. Pure carbon sliding plates are arranged on the two upper end surfaces of aU-shaped insulating base, and more than one group of metal rollers are arranged on the horizontal bottom plate of the base; the setting mode of each group of metal rollers is as follows: the lower parts of every two T-shaped insulating supports extend into grooves of a horizontal bottom plate respectively, and are arranged on fixing bolts which are screwed into the outer side of the horizontal bottom plate through holes in the horizontal bottom plate, spring damping mechanisms are symmetrically arranged on the left side and the right side of each insulating support, and the two metal rollers are arranged between the two supports through fixing shafts; and the structure of the metal rollers are is characterized in that the metal cylinders sleeve the metal shafts through insulating bearings,annular current-receiving electric brushes are fixed on the metal shafts, and the outer surfaces of the annular current-receiving electric brushes are in contact with the inner walls of the metal rollers. The self-lubricating modular metal roller electric locomotive pantograph head has the self-lubricating effect, is in flexible contact with an arch net and forms rolling friction fit, and has thecharacteristics of being capable of adapting to requirements of traction power of a train, being longer in service life and the like.

Owner:SOUTHWEST JIAOTONG UNIV

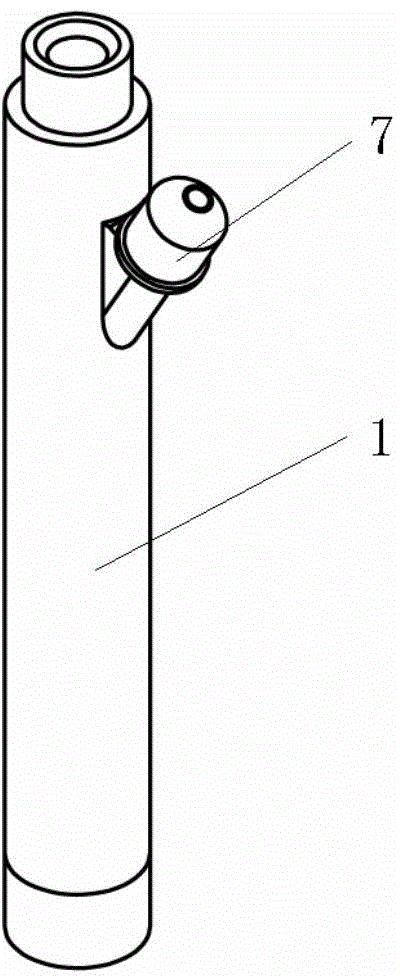

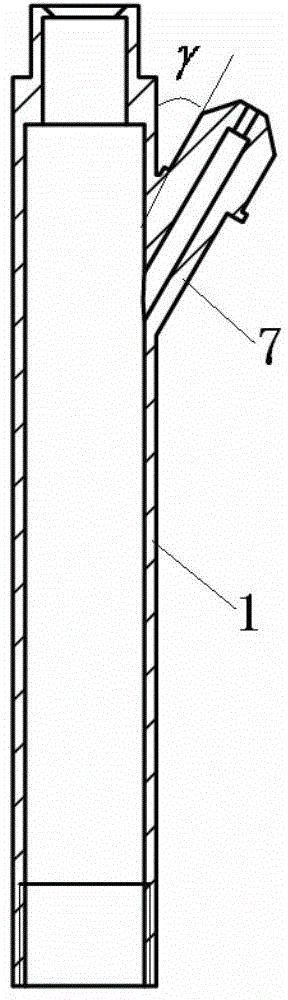

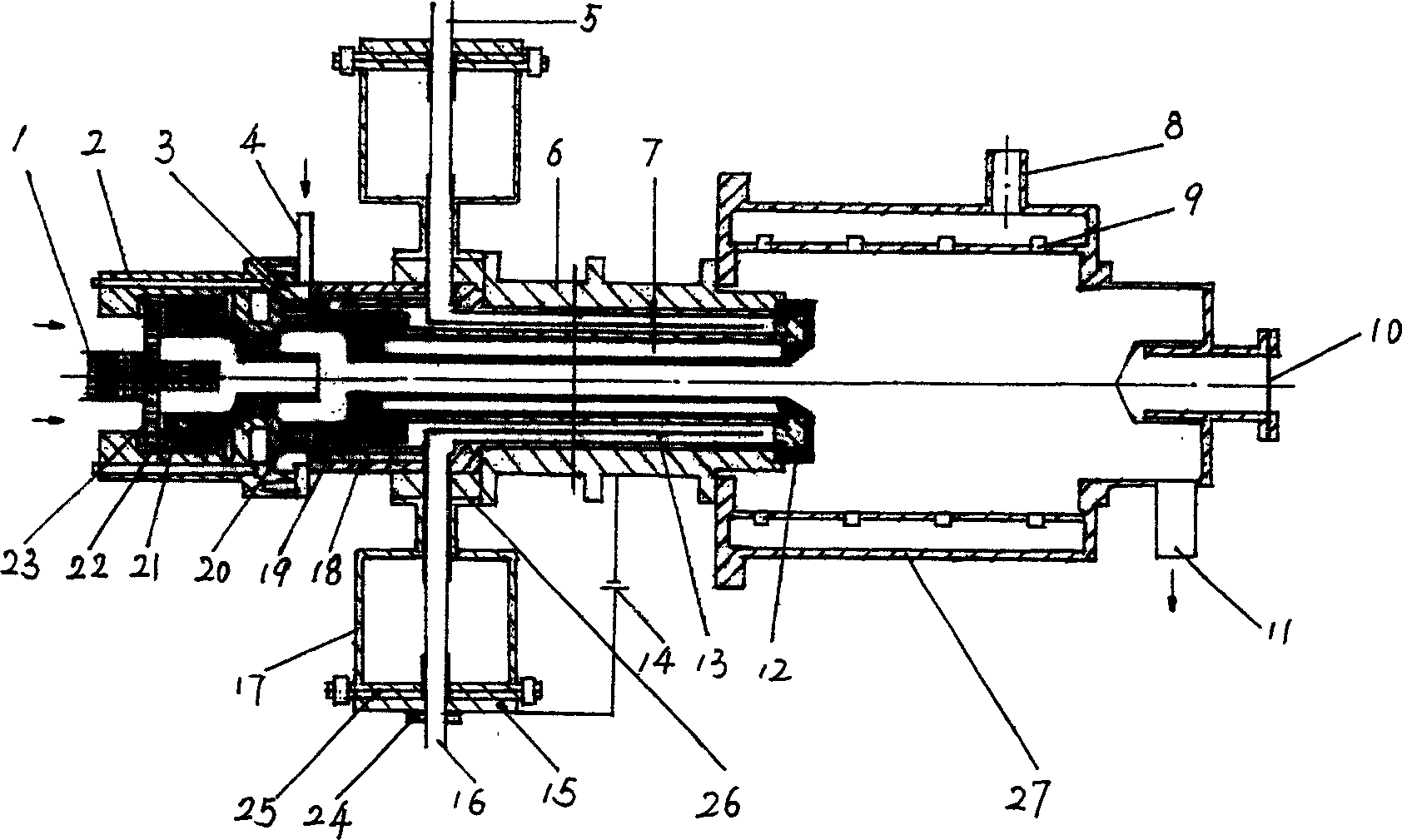

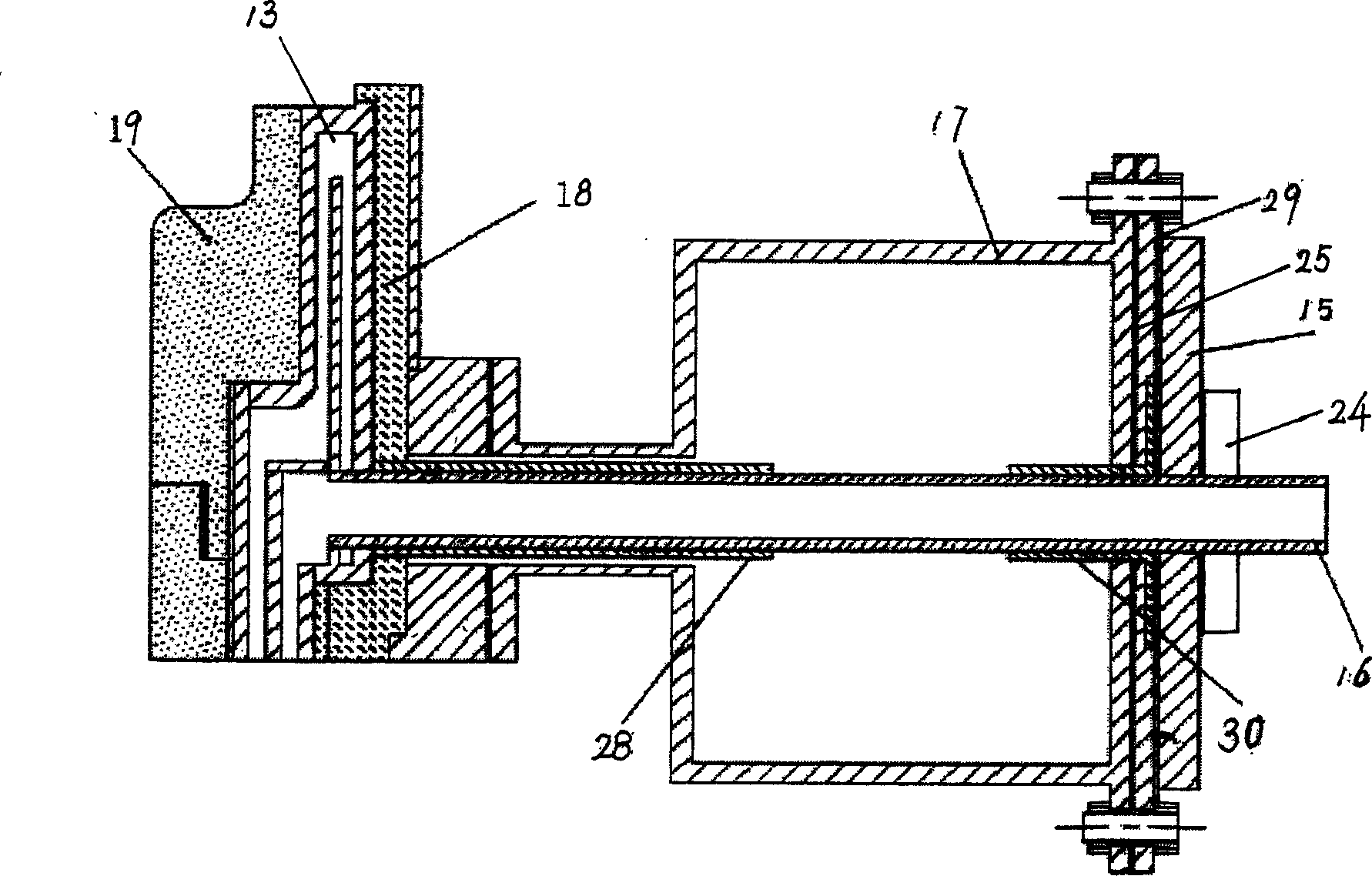

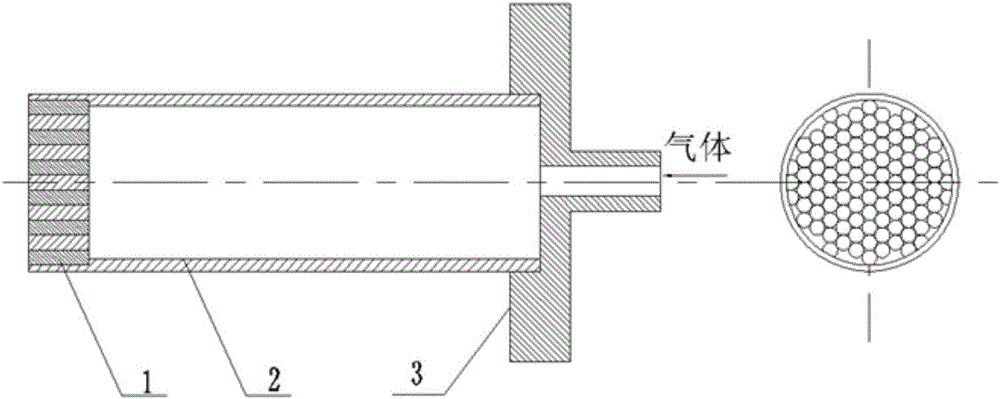

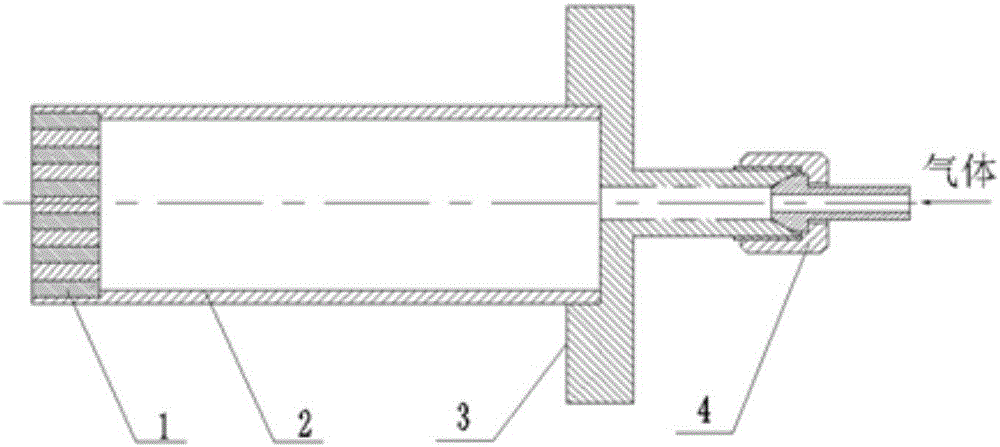

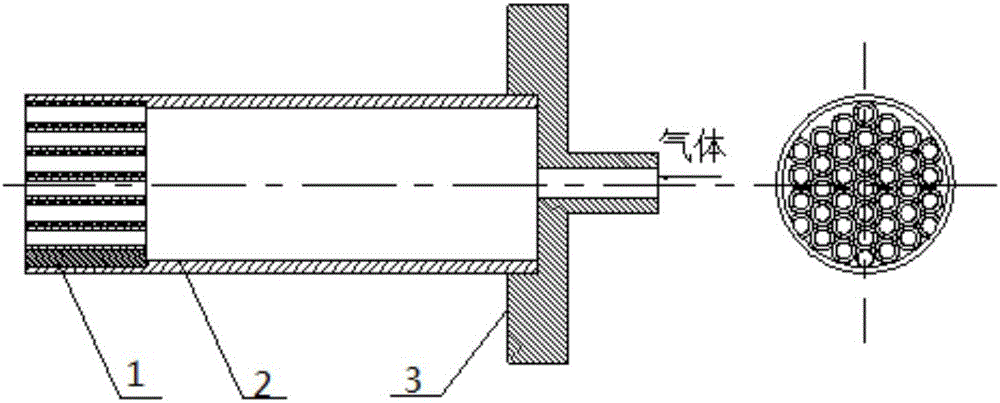

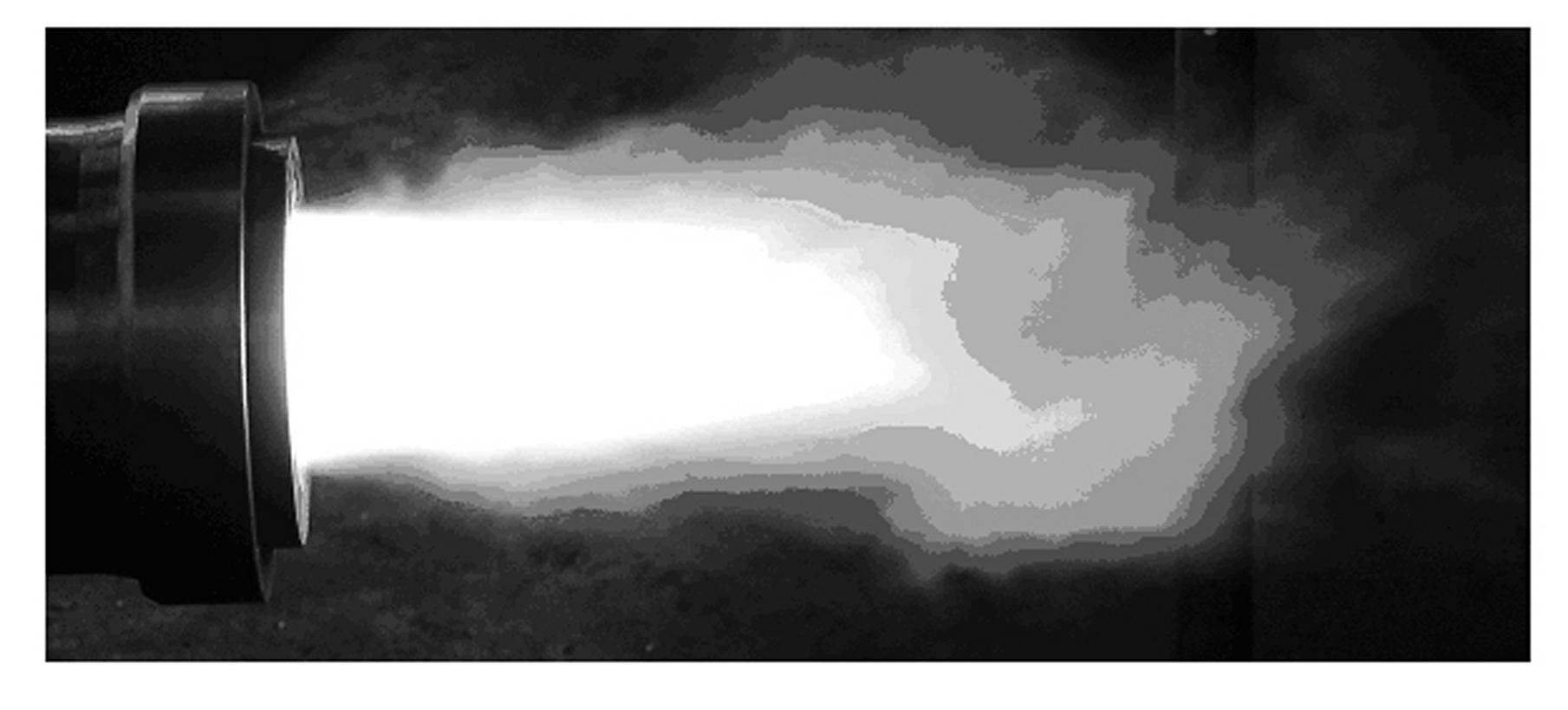

Apparatus and process for producing acetylene by low-temperature plasmochemical pyrolysis of natural gas

InactiveCN1613838AReduce ablationReduced localized point ablationHydrocarbon by hydrocarbon crackingElectrical conductorEngineering

A low-temperature plasma chemical reactor for producing ethyne by cracking natural gas and its process are disclosed. The reactor consists of microwave plasma torch and DC plasma exciting mechanism. The external conductor of the microwave plasma torch is of hollow structure, of which outlet forms a nozzle, the DC plasma exciting mechanism consists of external conductor, conductive pipe corresponding to the external conductor nozzle, the cavity of the conductive pipe as reacting chamber , the external conductor as cathode, the conductive pipe as anode, with the conductive pipe connected with DC electric source by choking structure. The process is carried out by: microwave plasma entering into DC plasma exciting mechanism; 2) microwave plasma forming normal DC plasma under the action of the DC electric source, and natural gas cracking to obtain ethyne. It achieves long life and high efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Apparatus and method for controlled fluid cooling during laser based dental treatments

ActiveUS20130323684A1Impacting efficiencyMinimize risk of meltingTeeth fillingTooth rinsingUltrasound attenuationTherapeutic Area

A system for dental tissue treatment includes a system for directing a laser beam to an area of dental tissue to be treated, and a fluid-delivery system for directing and controlling a flow of a fluid. The fluid is directed to at least a portion of the area to be treated and the fluid flow is controlled to substantially prevent both a change in laser energy absorption by the dental tissue and attenuation of treatment efficiency due to fluid interference with the laser beam. The fluid present in at least a portion of the area to be treated may prevent or reduce the likelihood of melting of enamel in that area.

Owner:CONVERGENT DENTAL INC

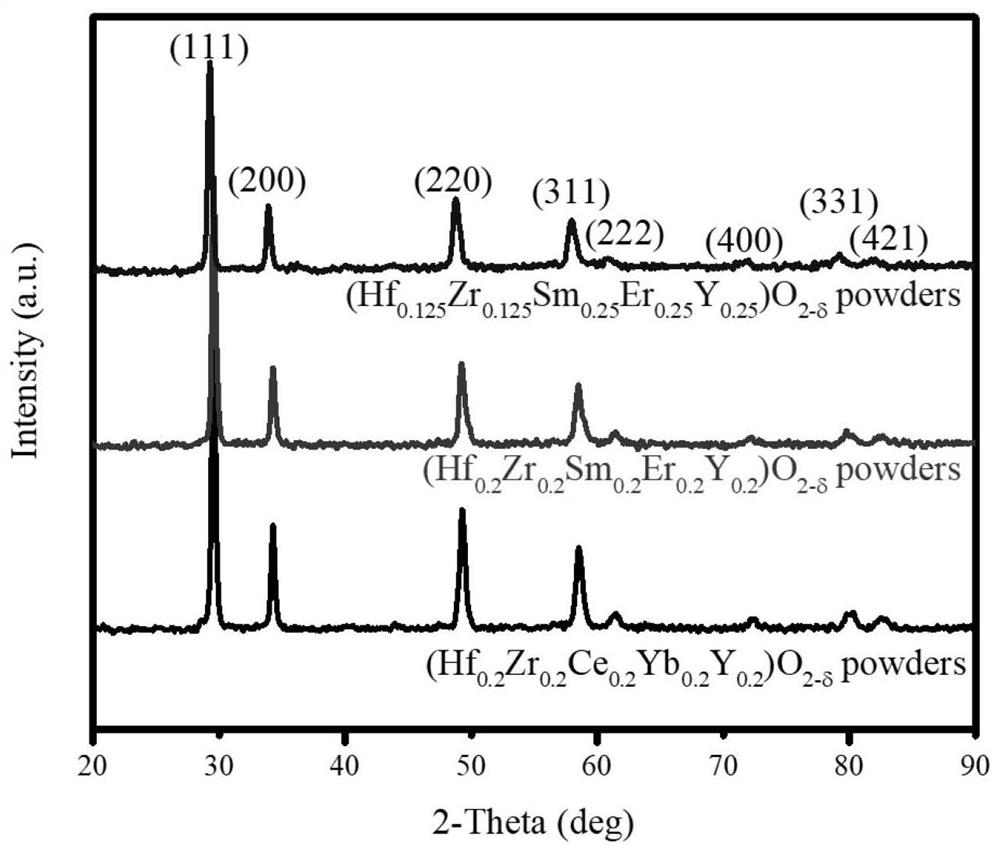

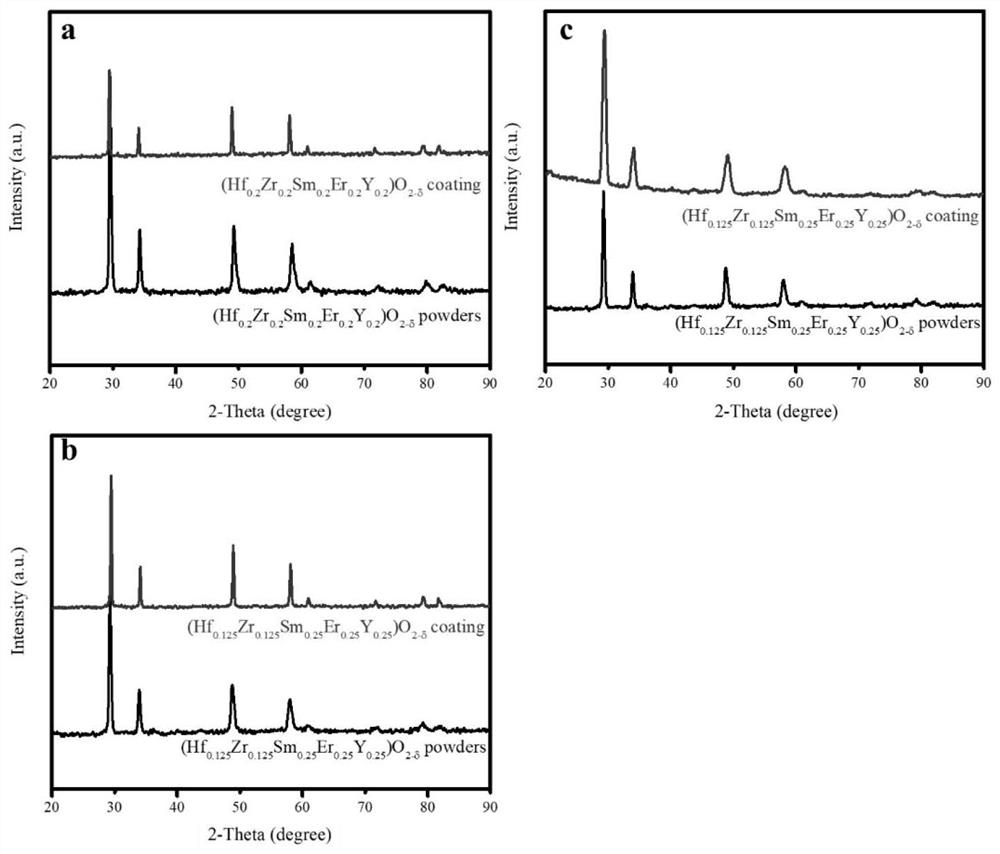

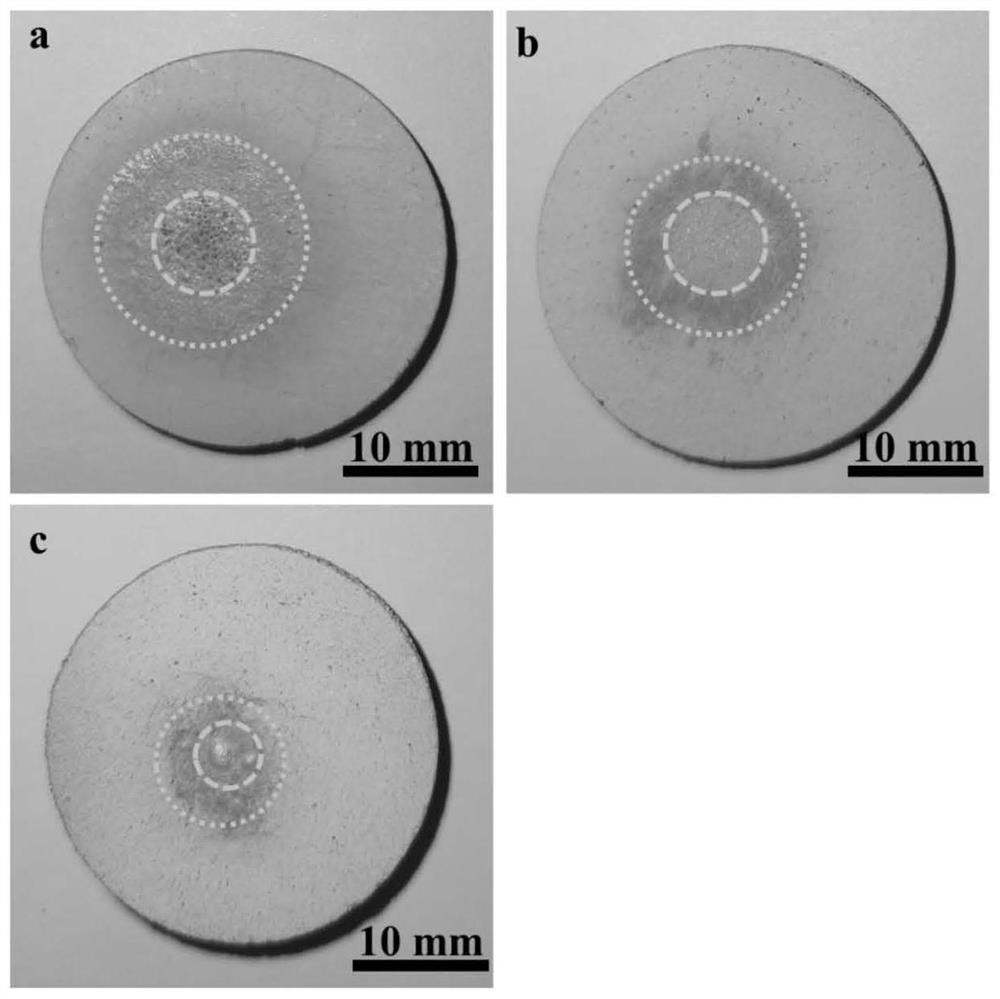

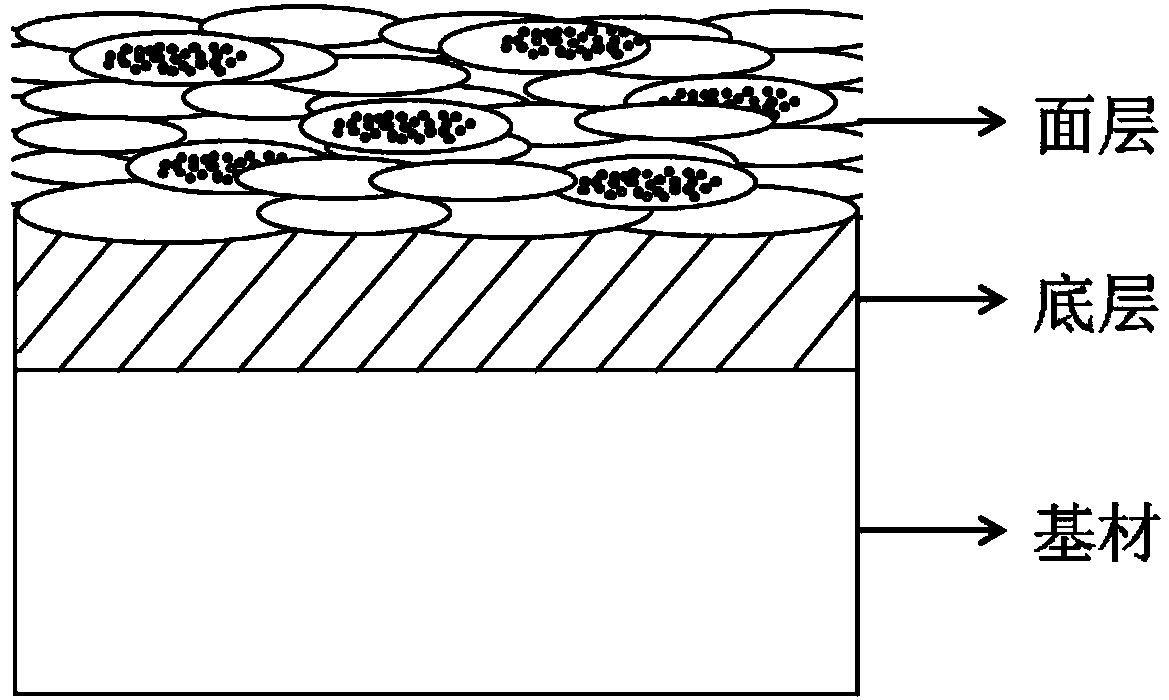

Oxide high-entropy ceramic with defective fluorite structure and preparation method of anti-ablation coating of oxide high-entropy ceramic

ActiveCN113683430AImprove stabilityImprove anti-ablation performanceEfficient propulsion technologiesCoated surfaceCeramic coating

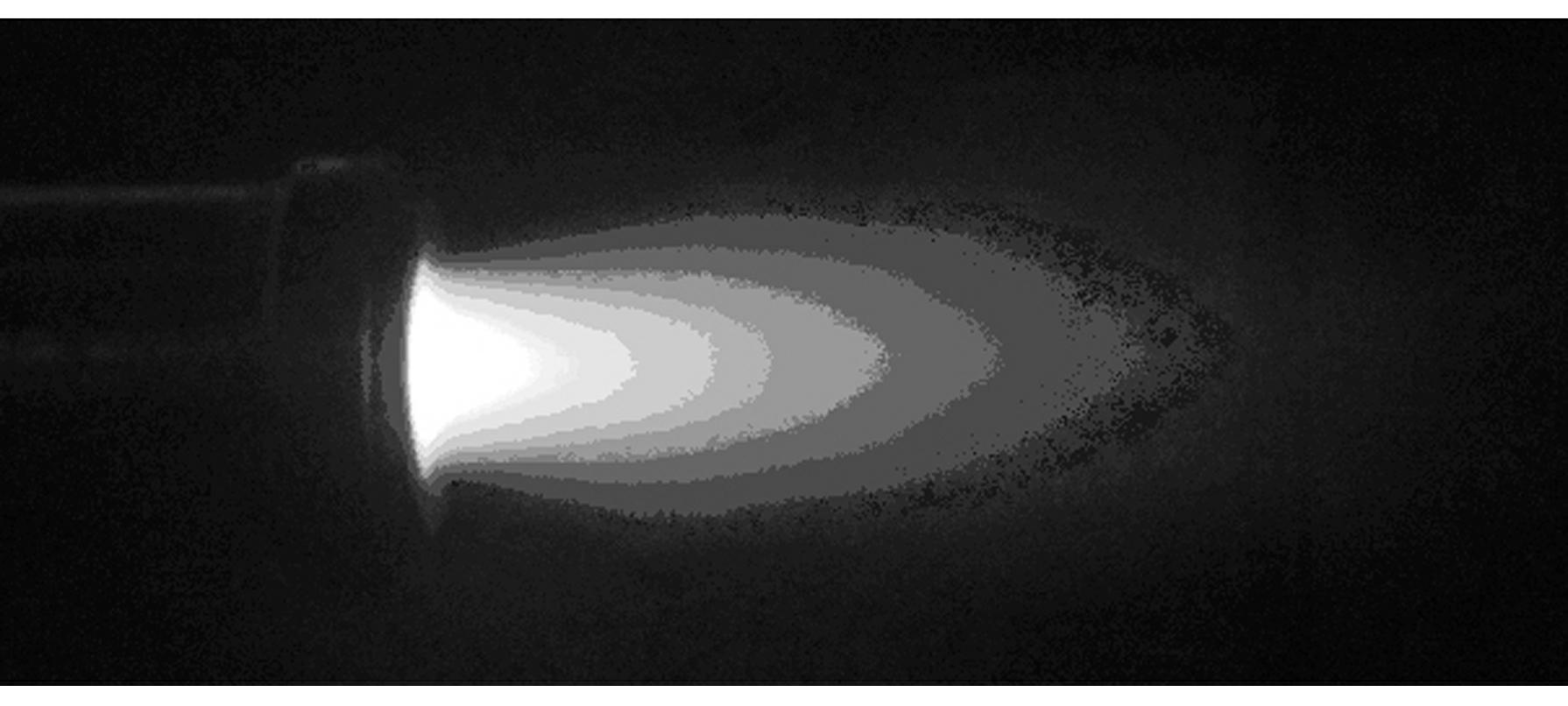

The invention relates to oxide high-entropy ceramic with a defective fluorite structure and a preparation method of an anti-ablation coating of the oxide high-entropy ceramic. The preparation method comprises the following steps of: firstly, preparing high-entropy ceramic powder by adopting a high-temperature solid-phase reaction method; and then, by using a supersonic plasma spraying technology, preparing a high-entropy ceramic coating with corresponding components on the surface of a base material by using the high-entropy ceramic powder having been subjected to spray drying treatment. The high-entropy ceramic coating (HfZr(3RE))O2-delta (wherein RE is selected from Sm, Er, Ce, Y, Yb) provided by the invention has excellent phase stability and ablation resistance. In a supersonic plasma spraying process, the high-entropy ceramic is free of phase change and phase decomposition, and the prepared high-entropy ceramic coating still keeps the phase structure of the original high-entropy ceramic powder. The high-entropy ceramic coating is ablated and examined in oxyacetylene flames with heat flux density of 2.38 MW / m<2>, the highest temperature of the surface of the coating in the ablating process reaches 1900-2100 DEG C, the ablated coating does not have the phenomena of stripping, peeling and the like, an ablating rate is low, and excellent anti-ablating performance is shown.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Multi-component complex phase nano boride, corresponding ultra-high temperature oxidation-resistant coating and preparation method thereof

The invention discloses a multi-component complex phase nano boride, a corresponding ultra-high temperature oxidation-resistant coating and a preparation method, and belongs to the technical field ofultra-high temperature thermal protective coatings. The multi-component complex phase nano boride and the corresponding ultra-high temperature oxidation-resistant coating are composed of 3-20wt% of TiB2, 10-40wt% of SiC and the balance HfB2. A nano structure inside the nano HfB2-SiC-TiB2 coating can control the stress at the grain boundary so as to obtain a high-strength interface, inhibit dislocation movement in a fracture process, hinder crack growth and effectively improve the fracture toughness of the coating; a third phase of TiB2 is added for modification, and TiO2 with a low melting point generated in a service process of the coating can enhance the self-healing ability of an oxide film; and the coating can resist a temperature of more than 1800 DEG C and is more stable in performance, which can effectively solve the problems of poor fracture toughness and insufficient stability of the existing ultra-high temperature oxidation-resistant coating for an aircraft in a service environment.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

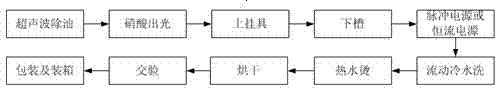

Hard anode oxidation method for aluminum and aluminum alloy

InactiveCN102899700AHigh hardnessReduce ablation rateSurface reaction electrolytic coatingAnthraceneHardness

The present invention discloses a hard anode oxidation method for aluminum and an aluminum alloy. According to the method, lactic acid, citric acid and an anthracene-containing self-made ??additive are adopted as an electrolyte, or only an anthracene-containing self-made ??additive is adopted as an electrolyte; installation suspension manners of the aluminum part and the aluminum alloy part during an electrolysis process are improved, and different installation suspension manners are adopted for the parts with different shapes; and the number of power feeding during the electrolysis process is increased. The oxidation film obtained by using the method has characteristics of uniform appearance and color range from gray black to black, provides advantages of high hardness, good wear resistance and good corrosion resistance compared with the ordinary sulfuric acid anode oxidation film, and further has a good technical effect.

Owner:河南平原光电有限公司

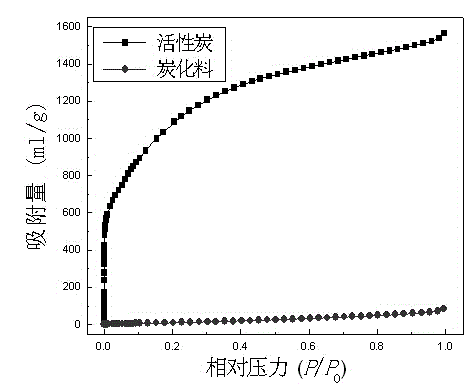

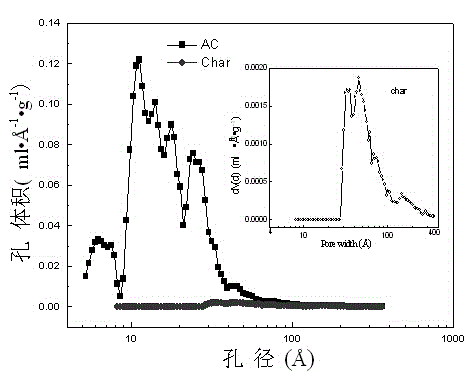

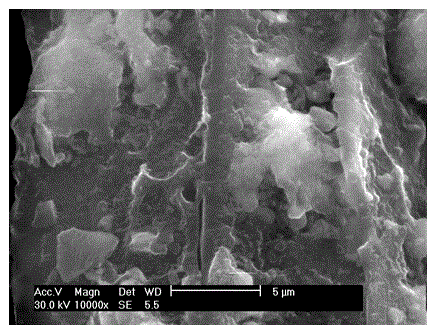

Preparation method of Ageratina-adenophora-base high-specific-area activated carbon

The invention relates to a preparation method of Ageratina-adenophora-base high-specific-area activated carbon, belonging to the field of environmental protection. The method comprises the following steps: uniformly mixing KOH and an Ageratina adenophora carbonization material in a solid-phase state, filling into a ceramic crucible, and putting into a microwave high-temperature reactor; introducing nitrogen to evacuate air in the furnace, heating under microwaves to the last fewer minutes, quickly blowing CO2 into a guide tube communicated with the bottom of the ceramic crucible, and meanwhile, starting an ultrasonic generator; after finishing heating, washing the activated material with water, and recovering the residual KOH activator; and sequentially carrying out acid washing, water washing and drying to obtain the high-specific-area activated carbon. By using the Ageratina adenophora as the raw material, the method uses the CO2 bottom blowing mode to enhance the activation effect of the carbonization material, thereby lowering the production cost of the activated carbon, relieving the environmental pollution, changing harmful substances and waste into valuable substances and implementing comprehensive utilization of natural resources. The high-specific-area activated carbon can be effectively used in the fields of adsorptive collection of gasoline and other organic substances in automobile exhaust emissions and fuel system volatile substances, solvent recovery and the like.

Owner:KUNMING UNIV OF SCI & TECH

High-current multi-channel metal cathode

ActiveCN106531591AReduce ablation rateExtend your lifeDischarge tube electron gunsElectron currentEmission channeling

The invention discloses a high-current multi-channel metal hollow cathode, which comprises a cathode tube, multiple metal emitters and an air circuit interface, wherein the cathode tube is a thin refractory metal tube, the multiple refractory metal emitters are arranged at one end of the cathode tube in parallel, the surfaces between the metal emitters and between the metal emitters and the inner wall of the cathode tube are tangent and the other end of the cathode tube is hermetically welded with the air circuit interface. According to the high-current multi-channel metal cathode, multiple emission channels are formed by adopting multiple metal bars or tubes with low work functions and high electron emission ability, the emission area is increased under the condition of a finite size, the emission current capacity is improved, an external heater is not needed, a certain flow of gas working medium is introduced to the inside, certain high voltage is applied to the outside and electron current of 100-500A can be emitted through direct ignition; and the emission current density of unit area does not exceed 10A / cm<2>, thereby greatly reducing the surface temperatures of the emitters and the material ablation rate and prolonging the service life of the hollow cathode and a thruster.

Owner:SHANGHAI INST OF SPACE PROPULSION

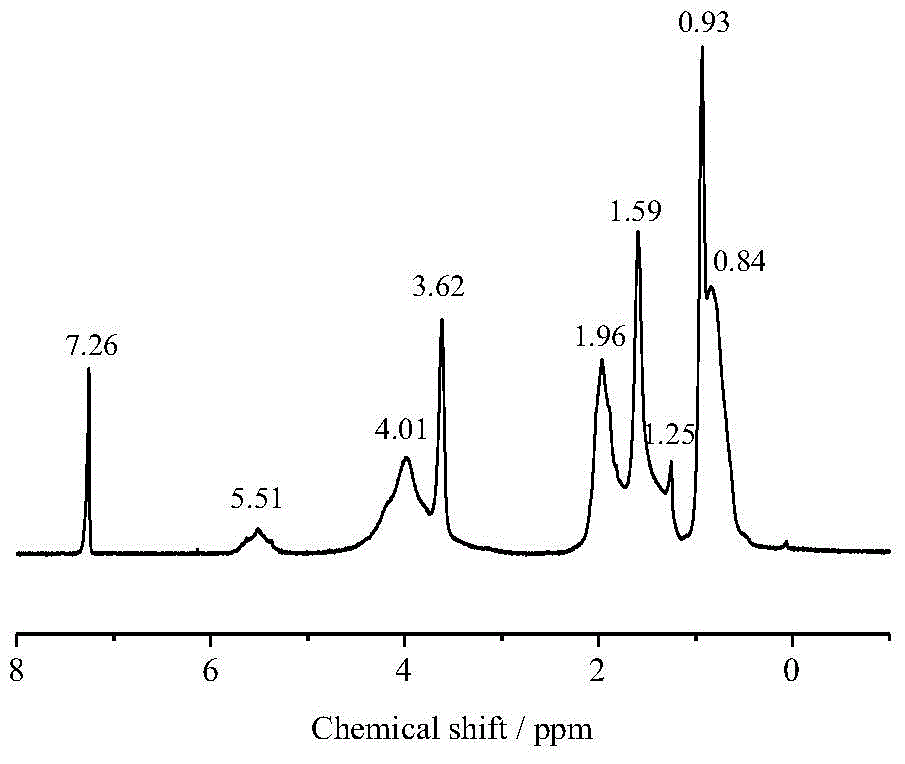

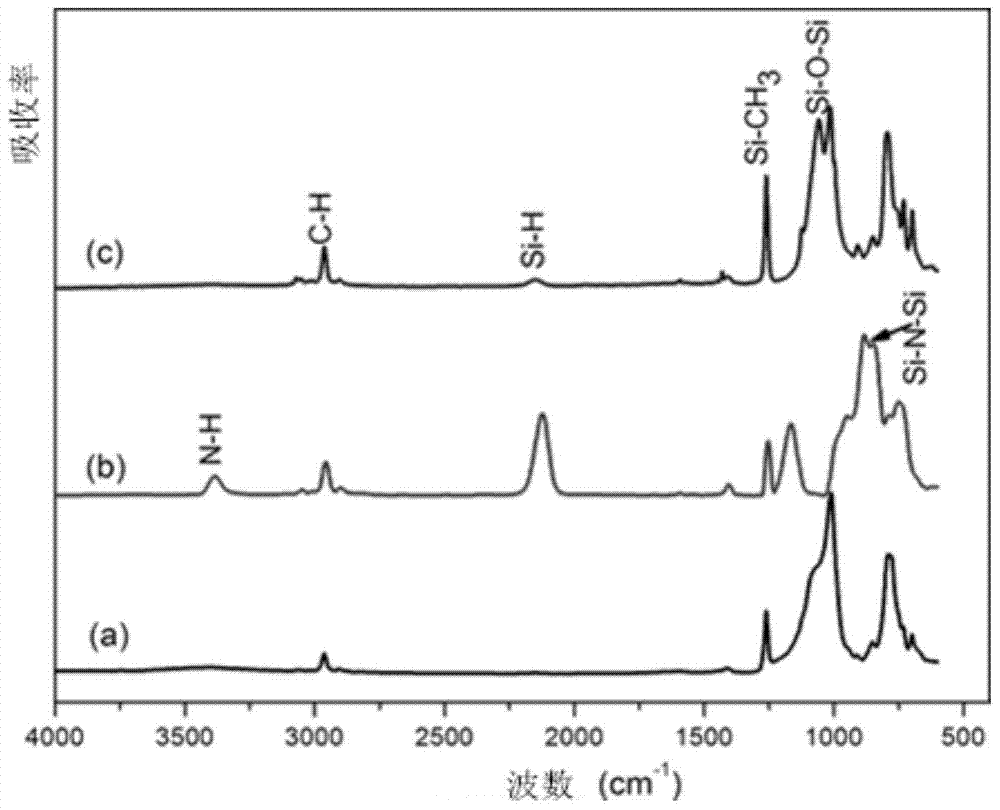

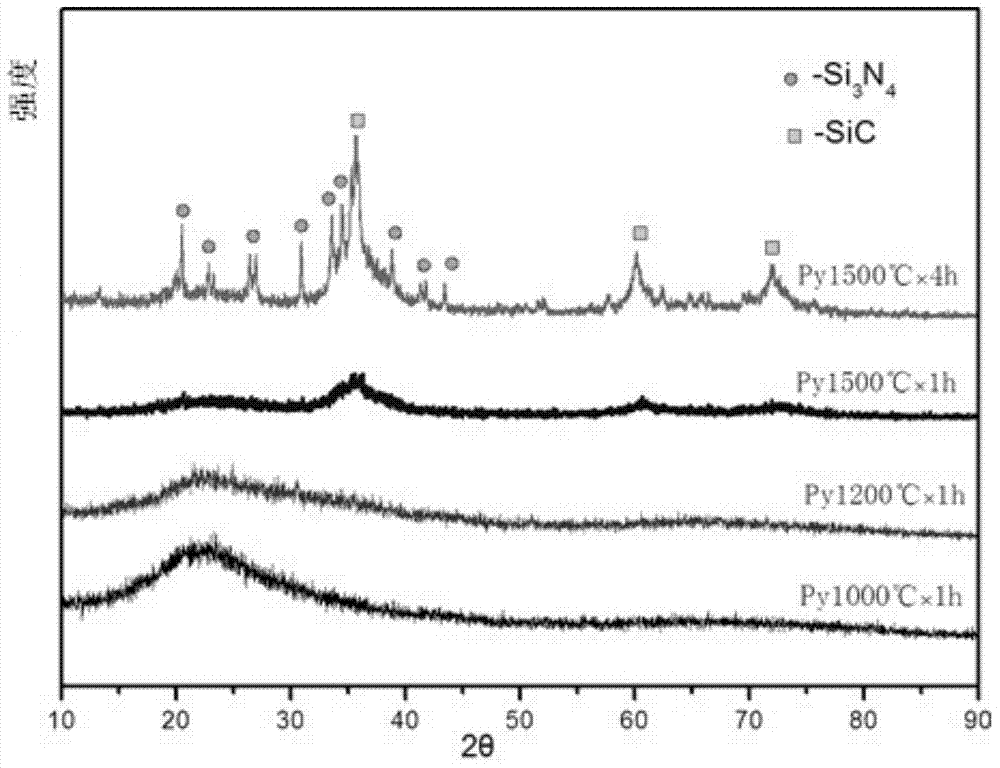

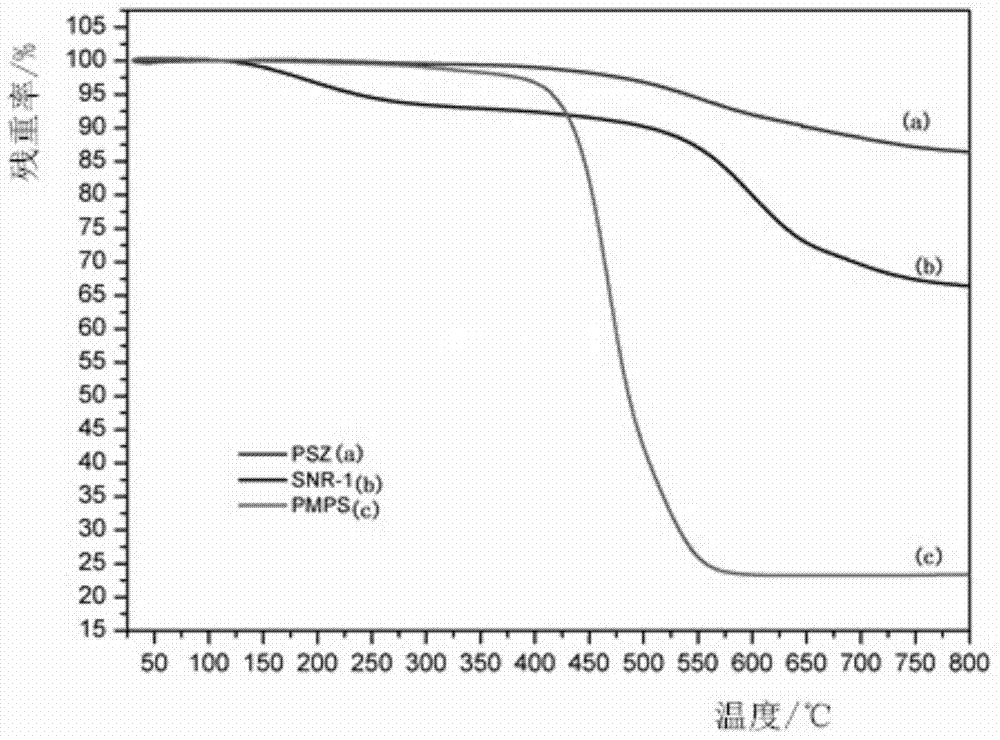

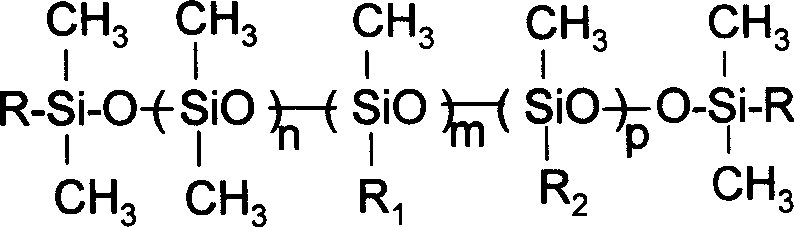

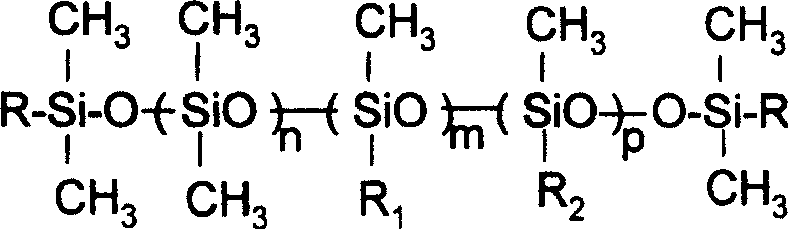

Ablation-resistant organosilicon composite, and preparation method and application thereof

ActiveCN104725879AIncrease elasticityImproves ablation resistanceInsulated cablesInsulated conductorsHydrogenVulcanization

The invention discloses an ablation-resistant organosilicon composite, and a preparation method and application thereof. The composite is a co-cured system of vinyl polymethylphenylsiloxane and silicic hydrovinyl polysilazane, and a silicic hydrogen addition or peroxide vulcanization system is adopted for vulcanization to obtain vulcanized rubber. The invention also discloses a preparation method and application of the composite. The ablation-resistant organosilicon composite has the characteristics of high high-temperature ceramic yield and favorable ablation resistance, and can be used for preparing heat insulating layers and fire-resisting cables of engines and the like.

Owner:SHANDONG UNIV

Activated carbon and preparation method thereof

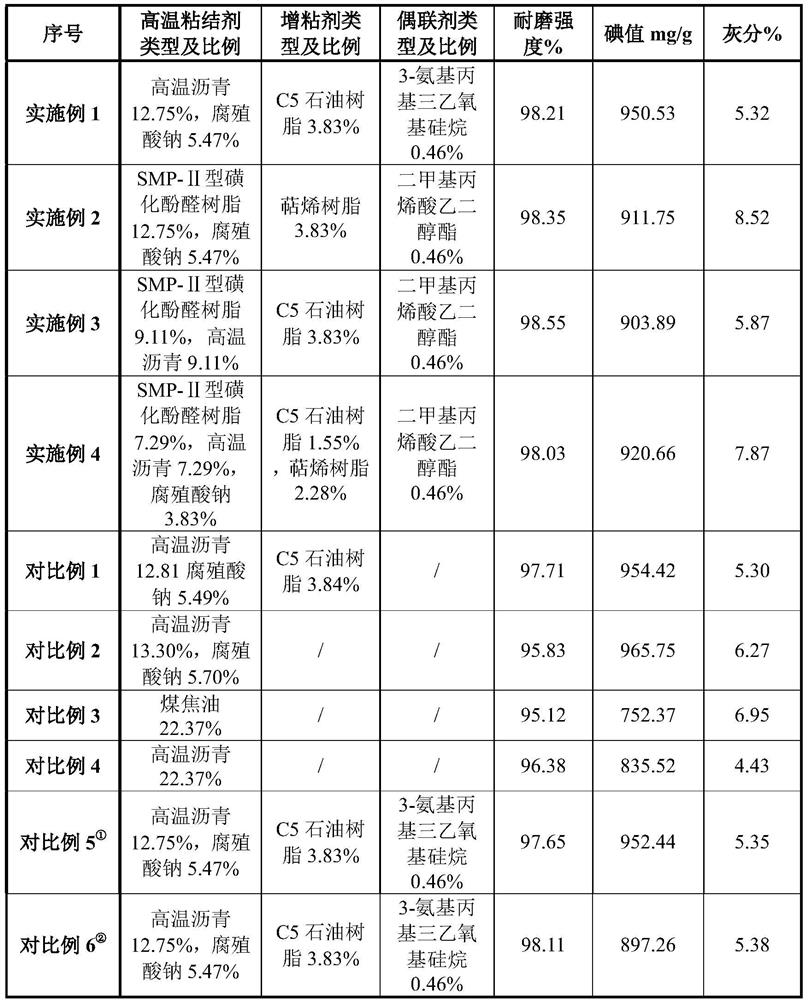

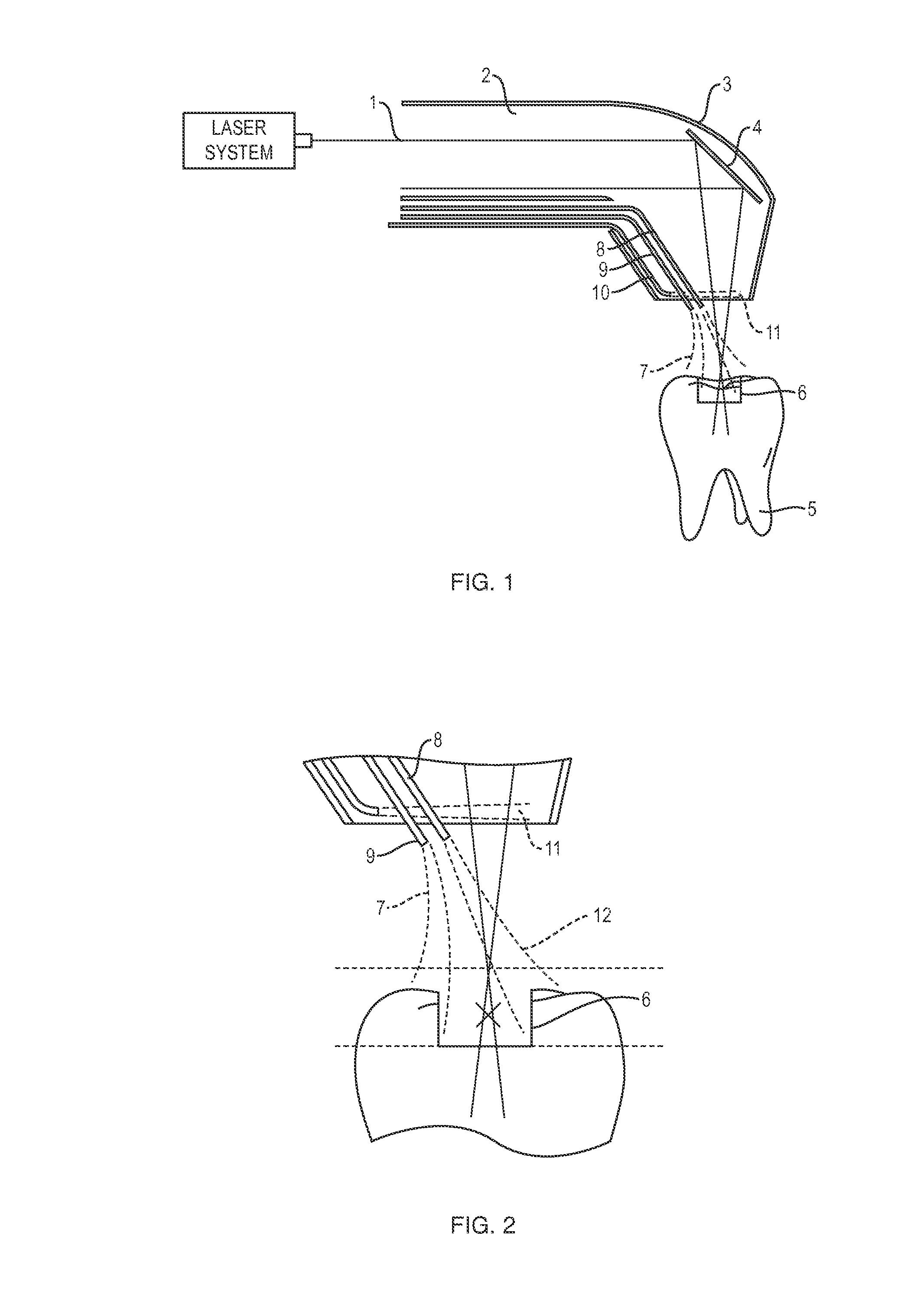

The invention relates to activated carbon. The activated carbon is prepared from the following raw materials in parts by mass: 70-80 parts of wood charcoal powder, 1-6 parts of a normal-temperature binder, 15-20 parts of a high-temperature binder, 3-5 parts of a tackifier, 0.5-1 part of an extrusion aid, 0.1-0.5 part of a coupling agent and water accounting for 35-45% of the total mass of the components. The invention also relates to a preparation method of the activated carbon. The preparation method comprises the following steps of: pulverizing, screening, proportioning, mixing, kneading, aging, carrying out extrusion molding, drying, carbonizing and activating at the same time. High-temperature asphalt, sodium humate and sulfonated phenolic resin are used for replacing dangerous chemical coal tar to serve as adhesives, VOCs gas emission in the preparation process is reduced, environmental pollution is reduced, the adhesion effect of the adhesives is improved through a tackifier anda coupling agent, the abrasion resistance and the adsorption capacity of the activated carbon are improved, the abrasion resistance of the activated carbon reaches 98%, the iodine value of the activated carbon can reach 900 mg / g, the ash content of theactivated carbon is smaller than 10%. The method can be used for some application scenes with high requirements for the abrasion resistance and theadsorption capacity of the activated carbon, such as desulfurization and denitrification catalysts and gold extraction.

Owner:北京中科恩吉科科技发展有限公司

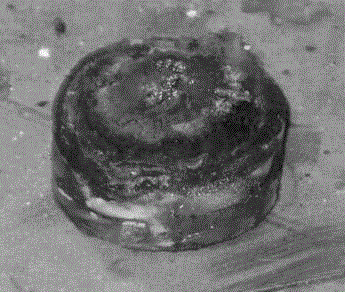

Elastomeric insulating composition for a solid propellant rocket motor

ActiveUS6953823B2Reduced specific gravityLow smoke densitySpecial tyresGreenhouse cultivationFiberEPDM rubber

Non-asbestos elastomeric insulating materials for solid propellant rocket motors are disclosed. The insulating materials are composed of EPDM rubber, polyaramide fiber, liquid EPDM rubber, magnesium hydroxide or aluminum hydroxide, silicon dioxide, chlorinated flame retardant compound and zinc hydroxystannate. The char forming organic fiber is used to substitute asbestos in traditional insulating materials that are believed to cause serious environmental problems. These fillers in the formulation, which when combined, have a synergistic effect that reduces the ablation rate significantly. Also, use of zinc hydroxystannate to substitute Sb2O3, may further reduce density of the insulator and smoke density and smoke toxicity of exhausted gas from the rocket motor.

Owner:NAT CHUNG SHAN INST SCI & TECH

Modified carbon fiber reinforced silicone rubber thermal-insulation material and preparation method thereof

The invention discloses a modified carbon fiber reinforced silicone rubber thermal-insulation material and a preparation method thereof, belonging to the technical field of thermal-insulation materials. The modified carbon fiber reinforced silicone rubber thermal-insulation material is prepared from the following raw materials in parts by weight: 40-60 parts of methyl vinyl silicone rubber, 40-60parts of methyl vinyl phenyl silicone rubber, 20-30 parts of white carbon black, 3-10 parts of graphene, 10-15 parts of modified carbon fibers and 0.5-1.5 parts of a vulcanizing agent. After carbon fibers are processed by virtue of concentrated nitric acid, the surface roughness of the carbon fibers is increased, and oxygen-containing functional groups are increased; after the carbon fibers are soaked in PEG6000 and alpha-aminopropyl triethoxysilane, the surfaces of the carbon fibers contain organic functional groups of N and Si. The tensile strength of the silicone rubber added with the modified carbon fibers reaches 2.96MPa, and the elongation at break reaches 57%; and compared with silicone rubber added with unmodified carbon fibers, the tensile strength and the elongation at break aregreatly increased, and the line ablation rate and the quality ablation rate are greatly decreased.

Owner:芜湖市颂晖商贸有限公司

Apparatus and method for controlled fluid cooling during laser based dental treatments

ActiveUS9011416B2Impacting efficiencyMinimize risk of meltingDental toolsSurgical instrument detailsUltrasound attenuationEnergy absorption

A system for dental tissue treatment includes a system for directing a laser beam to an area of dental tissue to be treated, and a fluid-delivery system for directing and controlling a flow of a fluid. The fluid is directed to at least a portion of the area to be treated and the fluid flow is controlled to substantially prevent both a change in laser energy absorption by the dental tissue and attenuation of treatment efficiency due to fluid interference with the laser beam. The fluid present in at least a portion of the area to be treated may prevent or reduce the likelihood of melting of enamel in that area.

Owner:CONVERGENT DENTAL INC

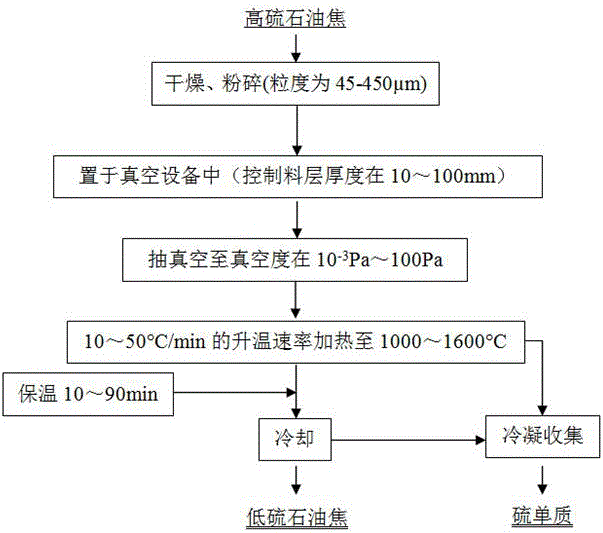

Method for vacuum reinforced desulfurization of high sulfur petroleum coke

InactiveCN106336928AReduce ablation rateAvoid emissionsSolid fuelsCarbon preparation/purificationSulfurGranularity

The invention relates to a method for vacuum reinforced desulfurization of high sulfur petroleum coke and belongs to the technical field of vacuum metallurgy. First petroleum coke is ground and screened to the granularity of 45-450 [mu]m, and the thickness is controlled to be 10-100 mm; under the vacuum degree of 10<-3>Pa to 100 Pa, the temperature rises to 1000-1600 DEG C at a heating rate of 10-50 DEG C and preserving heat for 10-90 min, the petroleum coke desulfurization efficiency reaches 70% or above, and elemental sulfur with a purity of 90% or above is collected in a condensation device at the top. According to the method, a low ash content of the petroleum coke is guaranteed without adding of an additive while a high desulfurization rate is achieved, it is also guaranteed that the petroleum coke has a high recovery rate after being desulfurized, the elemental sulfur can further be obtained in the process, and the problem that plenty of harmful SO2 gas unfavorable for collection is generated according to most of petroleum coke desulfurization methods is solved.

Owner:KUNMING UNIV OF SCI & TECH

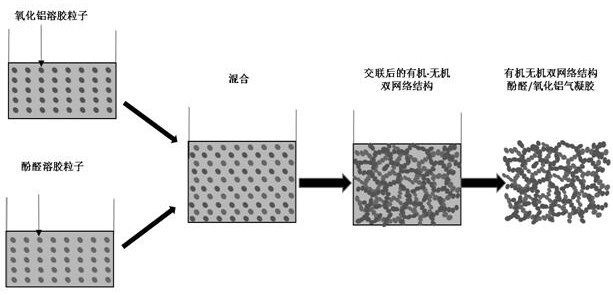

An organic-inorganic double network structure phenolic/alumina airgel composite material and its preparation method

ActiveCN109200955BImprove mechanical propertiesReduce decompositionAerogel preparationColloidal chemistry detailsFiberAluminium chloride

The invention discloses a phenolic / alumina airgel composite material with an organic-inorganic double network structure, which is made of resorcinol, formaldehyde and crystalline aluminum chloride as raw materials, and grown into an organic-inorganic double network in situ through hydrolysis and polycondensation reactions Structured composite gel; then use the chemical liquid phase method to deposit aluminum oxide atomic layer on the double network structure composite gel; finally obtain the organic-inorganic double network structure phenolic / alumina airgel composite material through aging and drying. The composite material of the present invention may be added with functionally modified fillers such as inorganic reinforcing fibers and infrared shielding particles to further improve its mechanical properties and heat insulation performance. The obtained composite material has low density, low thermal conductivity, high mechanical strength, low linear The characteristics of the ablation rate are suitable for lightweight anti- / insulation materials for the thermal protection system of aerospace vehicles, and have great application value.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Industrial regeneration process of waste powdered activated carbon

PendingCN111604040AAvoid inhibitionImpurities addedOther chemical processesCarbon compoundsActivated carbonCarbonization

The invention relates to the field of comprehensive utilization of environment-friendly and hazardous solid waste resources, and particularly provides an industrial regeneration process of waste powdered activated carbon. By adopting a mode of firstly granulating and then carbonizing and activating in a rotary kiln, the influence of flying dust of powdered carbon is avoided, and the ablation rateis greatly reduced; the granulated activated carbon is wetted before feeding, so that the inhibition effect of introducing water vapor into the rotary kiln on flaming of a fuel machine is avoided, pore forming in the activation process is facilitated, and the activation effect is effectively achieved; the binder adopts an organic carbon source material with few impurities, no new impurity is added, the binder is used as a new carbon source, the activation raw material is increased, the operability is strong, and the method is suitable for industrialization.

Owner:山东清博生态材料综合利用有限公司

Apparatus and method for controlled fluid cooling during laser based dental treatments

ActiveUS9011417B2Impacting efficiencyMinimize risk of meltingTeeth fillingSurgical instrument detailsUltrasound attenuationEnergy absorption

Owner:CONVERGENT DENTAL INC

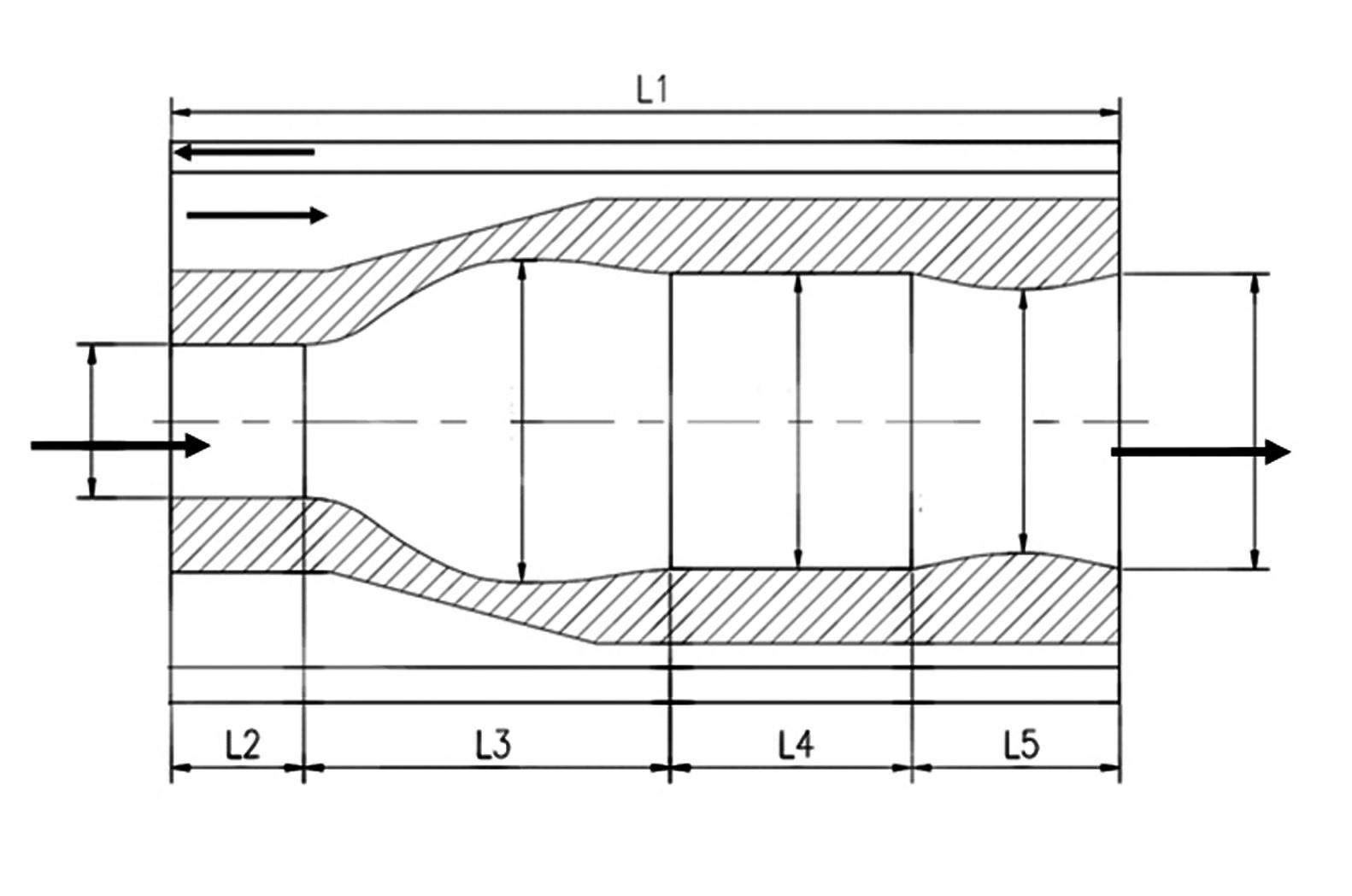

Multi-cavity plasma generator anode

The invention provides a multi-cavity plasma generator anode, which comprises a compression cavity, a stable combustion cavity, a conduction flow cavity and an accelerating cavity, which are connected in succession; the compression cavity is used to compress plasmas generated by a cathode; the stable combustion cavity can meet the requirement of plasma expansion; the conduction flow cavity provides a good electrically conductive path for conduction electrons; the accelerating cavity is a double-parabola structure formed by an upper-open parabola and a lower-open parabola; and the compression section is used to compress plasmas and improve plasma density, and the accelerating section is used to reduce the resistance of plasmas jetting form the leading end of the anode and increase plasma jetting velocity. The multi-cavity plasma generator anode provided by the invention is different from the traditional plasma generator anode, which adopts a first-compression-and-then-expansion type nozzle. In the invention, a unique multi-cavity anode construction is designed according to the expansion property of plasmas, and therefore the shortcoming of the traditional anode that the anode life is shortened due to too fast ablation rate resulting from the overlap of a conducting zone and an electric arc combustion zone is overcome.

Owner:WUHAN TIANHE TECH

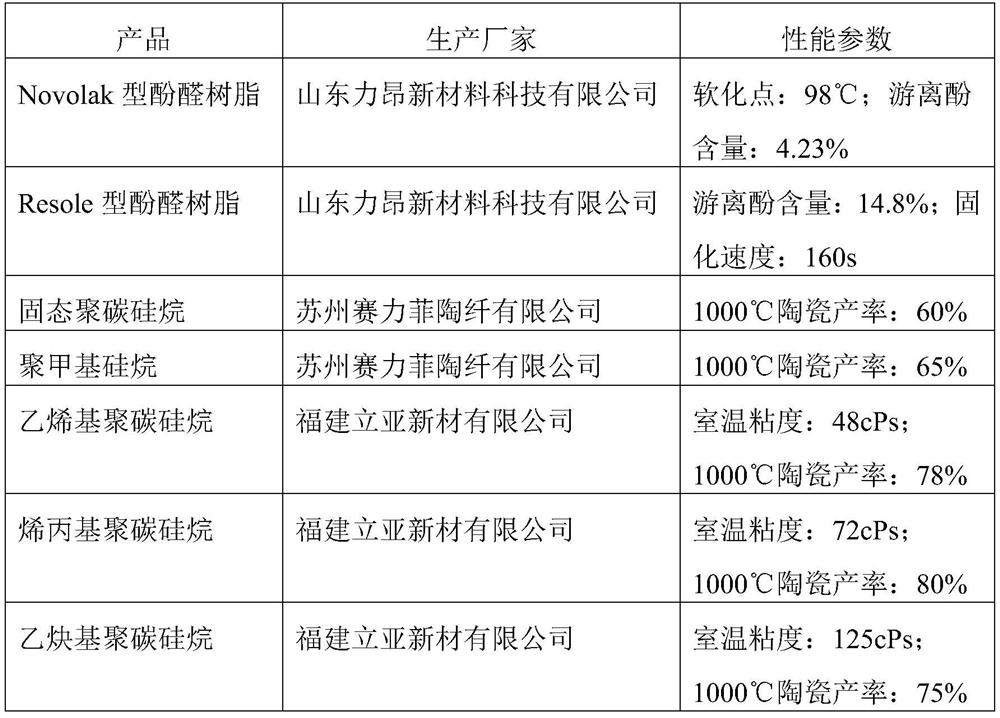

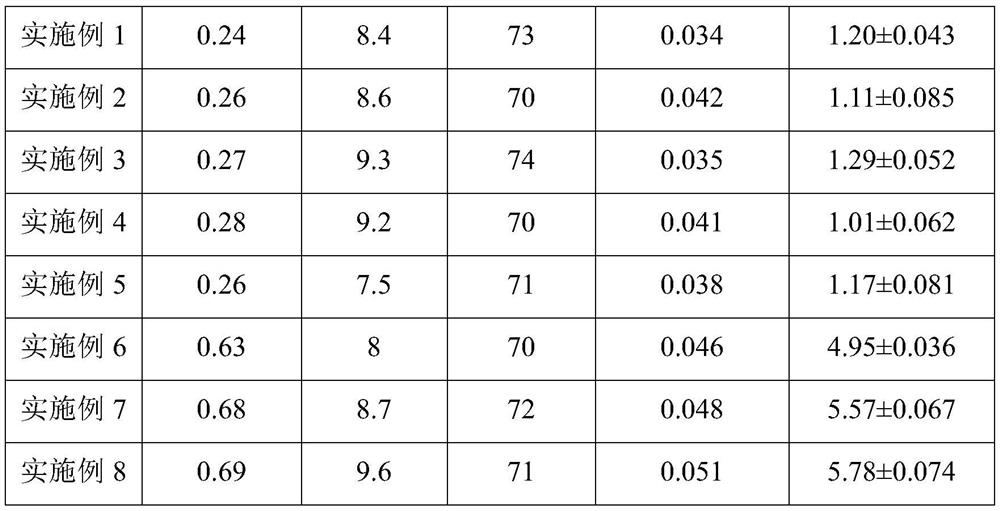

Polycarbosilane/phenolic aldehyde double-system network structure aerogel as well as composite material and preparation method thereof

The invention relates to polycarbosilane / phenolic aldehyde double-system network structure aerogel as well as a composite material and a preparation method thereof. The method comprises the steps of taking phenolic resin and polycarbosilane as reaction raw materials, dissolving, mixing, carrying out sol-gel reaction under a heating condition to obtain wet gel, and drying to obtain the polycarbosilane / phenolic aldehyde double-system network structure aerogel. The composite material can be compounded with a fiber product in situ according to needs to further improve the mechanical property of the composite material. The invention also relates to the phenolic aerogel prepared by the method or the composite material thereof. The phenolic aerogel or the composite material thereof has the characteristics of low density, good heat resistance, low heat conductivity coefficient, good mechanical property, low linear ablation rate, good anti-scouring performance and the like, can be used as a low-density thermal insulation material of a thermal protection system of an aerospace craft, and has important application value.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

High-power long-life plasma torch based on permanent magnet constraint

The invention relates to a high-power long-life plasma torch based on permanent magnet constraint, comprising a cooling structure, a gas distributor, an integrated electrode, a permanent magnet lens and a plasma torch shell; the integrated electrode, the permanent magnet lens and the plasma torch shell are sequentially sleeved from inside to outside; the gas distributor is arranged at the head part of the plasma torch shell, and the external ionized medium gas generates spiral airflow after passing through the gas distributor; an arc is generated between the anode and the cathode of the integrated electrode, and the arc breaks down the spiral airflow to form an arc plasma jet. The plasma torch in the invention has the advantages of being high in temperature, high in enthalpy, centralized in energy height, high in energy conversion efficiency and long in service life, can generate a high-temperature environment, and is widely applied to fields of preparation and treatment of spaceflight, aviation, metallurgy, spray coating, high-temperature-resistant ceramic materials, nano-material preparation, material surface treatment, fuel conversion and combustion-supporting, harmful garbage treatment and the like.

Owner:XIAN AEROSPACE PROPULSION INST

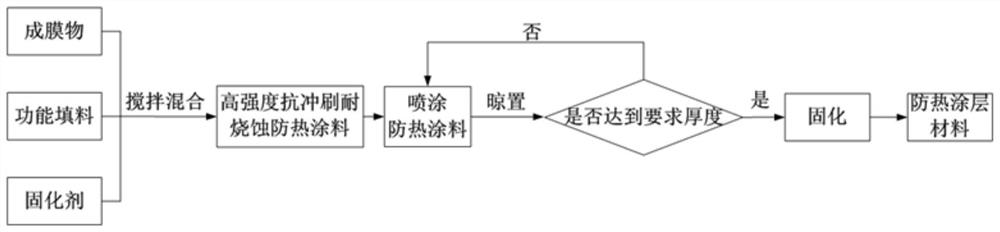

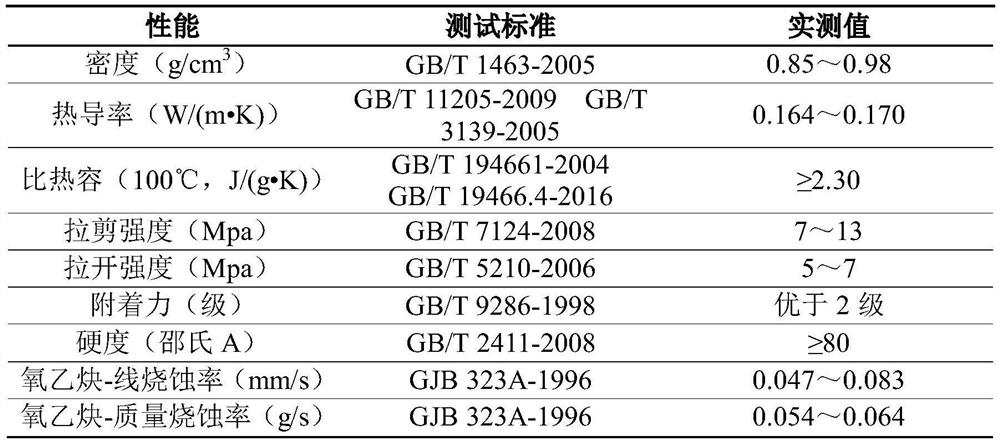

High-strength anti-scouring ablation-resistant heatproof coating material and preparation method thereof

InactiveCN112480789AHigh bonding strengthHigh hardnessEpoxy resin coatingsOrganic solventThermal insulation

The invention provides a high-strength anti-scouring ablation-resistant heatproof coating material and a preparation method thereof. The high-strength anti-scouring ablation-resistant heatproof coating material comprises a film forming matter, a curing agent and functional filler, the film forming matter, the curing agent, the functional filler and an organic solvent are mixed and stirred evenly to prepare heatproof paint, and the heatproof paint is sprayed to the surface of a base material through an air spraying technology; and curing is conducted to obtain the high-strength anti-scouring ablation-resistant heatproof coating. The material is good in thermal insulation performance, low in ablation rate, light in weight, high in strength and excellent in process performance, can be widelyapplied to surface heat protection of aircrafts such as various rocket boats and ships, and can also be popularized and applied to other civil fields.

Owner:西安长峰机电研究所

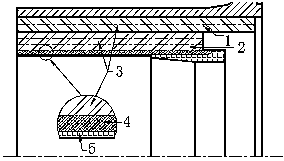

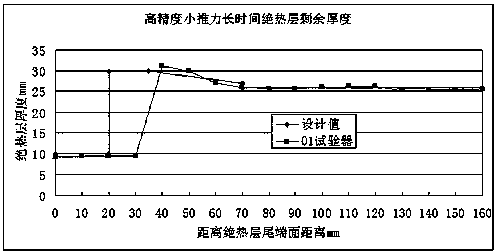

Composite heat insulation structure resistant to long-time ablation overload

ActiveCN109707535AReduce ablation rateReduce thicknessLayered productsRocket engine plantsAdhesiveCorneal ablation

The invention relates to a composite heat insulation structure resistant to long-time ablation overload. According to the composite heat insulation structure, a structure with a composite heat insulating layer is adopted. The composite heat insulating layer is structurally composed of two layers, namely an outer heat insulating layer and an inner heat insulating layer. The outer heat insulating layer is made of a GZ46-2 material, and the inner heat insulating layer is made of a GZ46-3 material. The thickness of the GZ46-3 material is 4 mm, the thickness of the GZ46-2 material is 6 mm, and in other words, the thickness ratio of the GZ46-2 material to the GZ46-3 material is 3: 2. After the outer heat insulating layer and the inner heat insulating layer are molded through die pressing, the inner heat insulating layer is bonded to the inner side surface of the outer heat insulating layer through adhesive. According to the composite heat insulation structure, the ablation rate is decreasedby about two magnitude orders compared with the maximum ablation rate of a common EPDM material heat insulating layer; and under the same working conditions, the thickness of the heat insulation structure can be effectively reduced, and the performance of a solid rocket engine is improved.

Owner:内蒙动力机械研究所

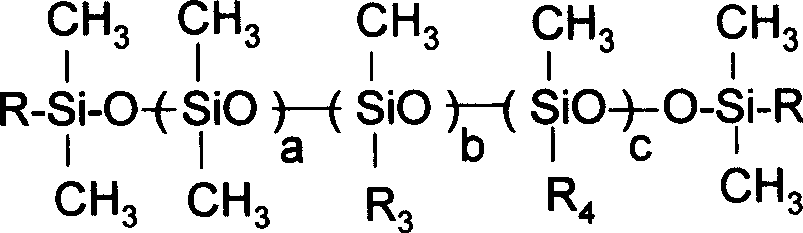

Multifunctional ablation-resistant adhesive for thermal protection and method for preparing same

InactiveCN100460477CSolve problems such as complex construction techniquesAdhesive fitAdhesivesEpoxyPolymer science

The present invention discloses one kind multifunctional protecting ablation resisting adhesive. The adhesive consists of polysiloxane 50-130 (in weight portions, the same below), polysiloxane-II 50-70, epoxy resin 0-10, No. 105 resin 0-5, white carbon black 10-20, carbon powder 5-15, chromium oxide 2-8, zinc oxide 3-10, adhesion promoter 1-3, stabilizer 0-5, crosslinking agent 2-5, and catalyst 0.5-3. The adhesive of the present invention has small density, low ablation rate, excellent adhesion to several kinds of matrix, simple preparation process, low cost and other advantages.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com