High-strength anti-scouring ablation-resistant heatproof coating material and preparation method thereof

A heat-resistant coating and anti-scouring technology, applied in coatings, epoxy resin coatings, etc., can solve problems such as light weight and high strength, prevent heat transfer to the substrate, reduce cost, energy consumption, heat The effect of low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

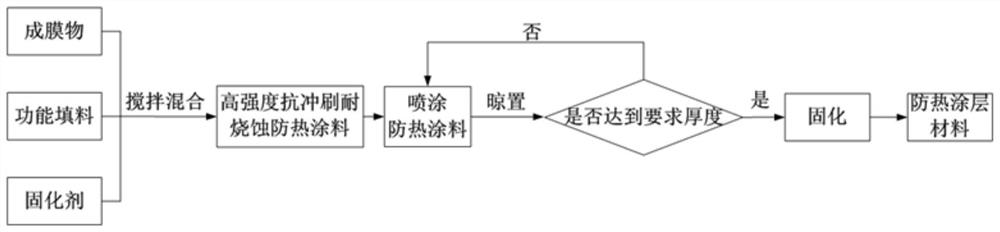

[0042] Such as figure 1As shown, according to the calculation of 100 parts of paint quality, 32 parts of epoxy resin (E-44, Nantong Xingchen), 22 parts of high temperature resistant silicone resin (REN50, Wacker, Germany) and modified silicone resin (MH-30 , Senfeida Chemical) 11 parts are mixed to make a film-forming material, 8 parts of hollow microspheres, 1 part of wollastonite and 8 parts of mica powder are mixed to make a functional filler, and the film-forming material and functional filler are mixed and stirred evenly, and added 15 parts of modified amine curing agent (LS-8801, Jinan Yuyi Chemical), and add 1 part of ethyl acetate and 2 parts of silicone thinner as a solvent, mix and stir evenly, and let it air for 30 minutes at room temperature to make a high-strength anti-scour Ablation-resistant and heat-resistant coating.

[0043] Use a pneumatic spray gun to evenly spray the heat-resistant coating on the clean workpiece surface, control the spraying pressure to 0...

Embodiment 2

[0045] Such as figure 1 As shown, according to the calculation of 100 parts of paint quality, 11 parts of epoxy resin (E-51, Phoenix brand), 26 parts of high temperature resistant silicone resin (3074, Dow Corning) and modified silicone resin (MH-30, Sen Feida Chemical) 5 parts are mixed to make a film-forming material, 8 parts of hollow microspheres, 0.7 parts of wollastonite, 9 parts of mica powder and 0.3 parts of iron oxide red are mixed to make a functional filler, and the film-forming material and functional filler are mixed Stir well, add 15 parts of modified amine curing agent (LS-8801, Jinan Yuyi Chemical), and add 1 part of ethyl acetate and 4 parts of silicone diluent as solvent, mix and stir evenly, and let it air for 30 minutes at room temperature to prepare High-strength, scour-resistant, ablation-resistant, heat-resistant coating.

[0046] Use a pneumatic spray gun to evenly spray the heat-resistant coating on the clean workpiece surface, control the spraying p...

Embodiment 3

[0048] Such as figure 1 As shown, according to the calculation of 100 parts of paint quality, 15 parts of epoxy resin (E-44, Nantong Xingchen), 45 parts of high temperature resistant silicone resin (REN50, Wacker, Germany) and modified silicone resin (MH-30 , Senfeida Chemical) 8 parts are mixed to make a film-forming material, 6.2 parts of hollow microspheres, 6.2 parts of mica powder and 0.6 parts of iron oxide red are mixed to make a functional filler, and the film-forming material and functional filler are mixed and stirred evenly, and added 15 parts of modified amine curing agent (H113, Tianjin Taida Chemical), and add 2 parts of ethyl acetate and 2 parts of silicone diluent as solvent, mix and stir evenly, and let it air for 30 minutes at room temperature to make high-strength anti-erosion and ablation resistance Heat-resistant paint.

[0049] Use a pneumatic spray gun to evenly spray the heat-resistant coating on the clean workpiece surface, control the spraying pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com