Patents

Literature

229results about How to "Free from outside interference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

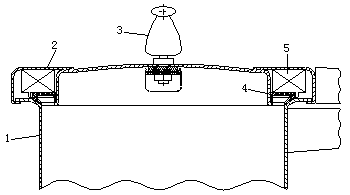

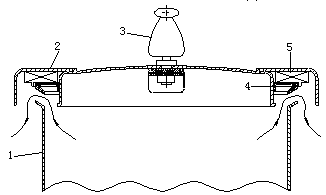

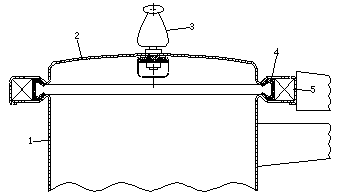

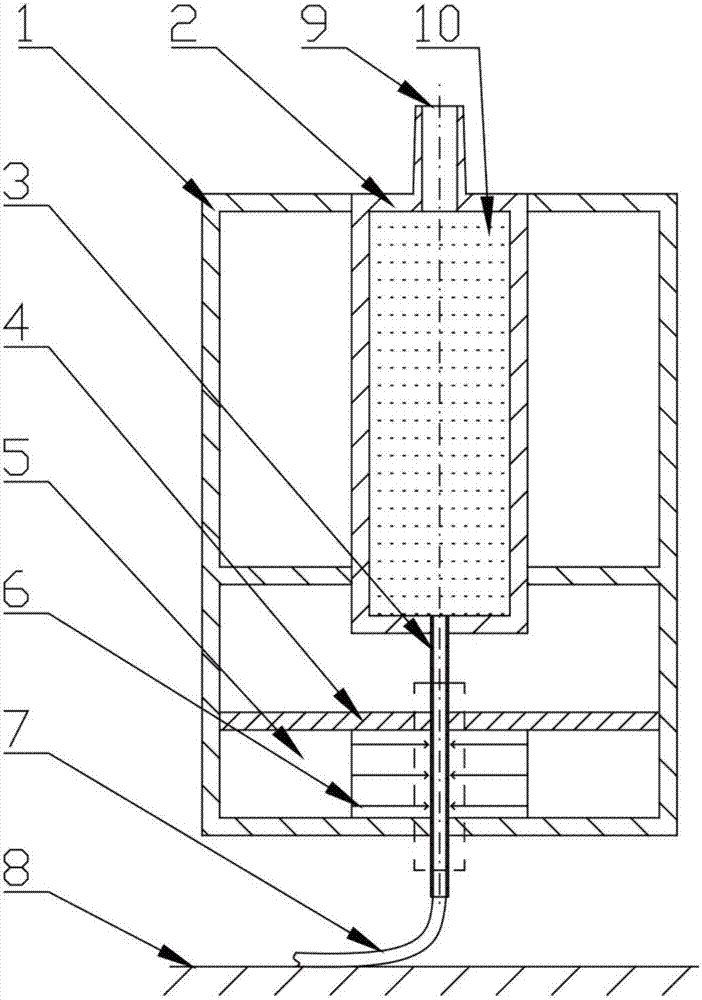

Safety pressure cooker

InactiveCN107836988AEliminate potential safety hazardsSimple structurePressure-cookersVapor pressureEngineering

The invention is a cooking utensil, a safety pressure cooker, and aims to provide a safety pressure cooker with simple and reliable structure and no explosion. The pressure cooker comprises a pot body, a pot cover, a pressure limiting valve and a sealing ring. It is characterized in that the sealing ring is connected with the elastic body, and the sealing ring moves or rotates under the action of the steam pressure in the pot, and its action is controlled by the elastic body. The elastic body is added with a preset force or a preset torque, and its value is equal to the pressure or torque of the steam on the sealing ring when the steam pressure in the pot is a safe pressure. Therefore, when the steam pressure in the pot is lower than the safety pressure, the sealing ring will not move and maintain its sealing effect. But when the steam pressure in the pot exceeds the safety pressure, the pressure or torque of the steam in the pot on the sealing ring is greater than the preset value of the elastomer, so that the sealing ring moves or rotates, and a gap is formed between the sealing ring and the pot body and cover. The steam releases and the steam pressure decreases. The safety device has the advantages of simple structure, stability and reliability, and can effectively eliminate potential safety hazards of the pressure cooker.

Owner:文竞业

Controllable discharge switch of high-energy impulse in three electrodes under vacuum environment

InactiveCN1697107AReduce ablation rateDiffusion fastSpark gaps with auxillary triggeringHigh-tension/heavy-dress switchesElectricityHigh energy

The disclosed discharge switch includes upper and lower electrodes setup inside insulated case. Pressure inside the air locked shell body formed by the insulated case and flanges at two ends of the case is 10 -3 - 10 -4 Pa. At least one of the upper and lower electrodes is a movable electrode. Trigger electrode is inlaid inside the fixed electrode or setup between the upper and lower electrodes. Since being air locked in vacuum environment, the upper and lower electrodes possess tremendous ability of ducting transient current in high energy. Moreover, operation reliability of pulse switch is raised because vacuum environment is not interfered from outside. Features are: raised reliability, very low ablation rate of electrode, and wide range of stable operation voltage.

Owner:XI AN JIAOTONG UNIV

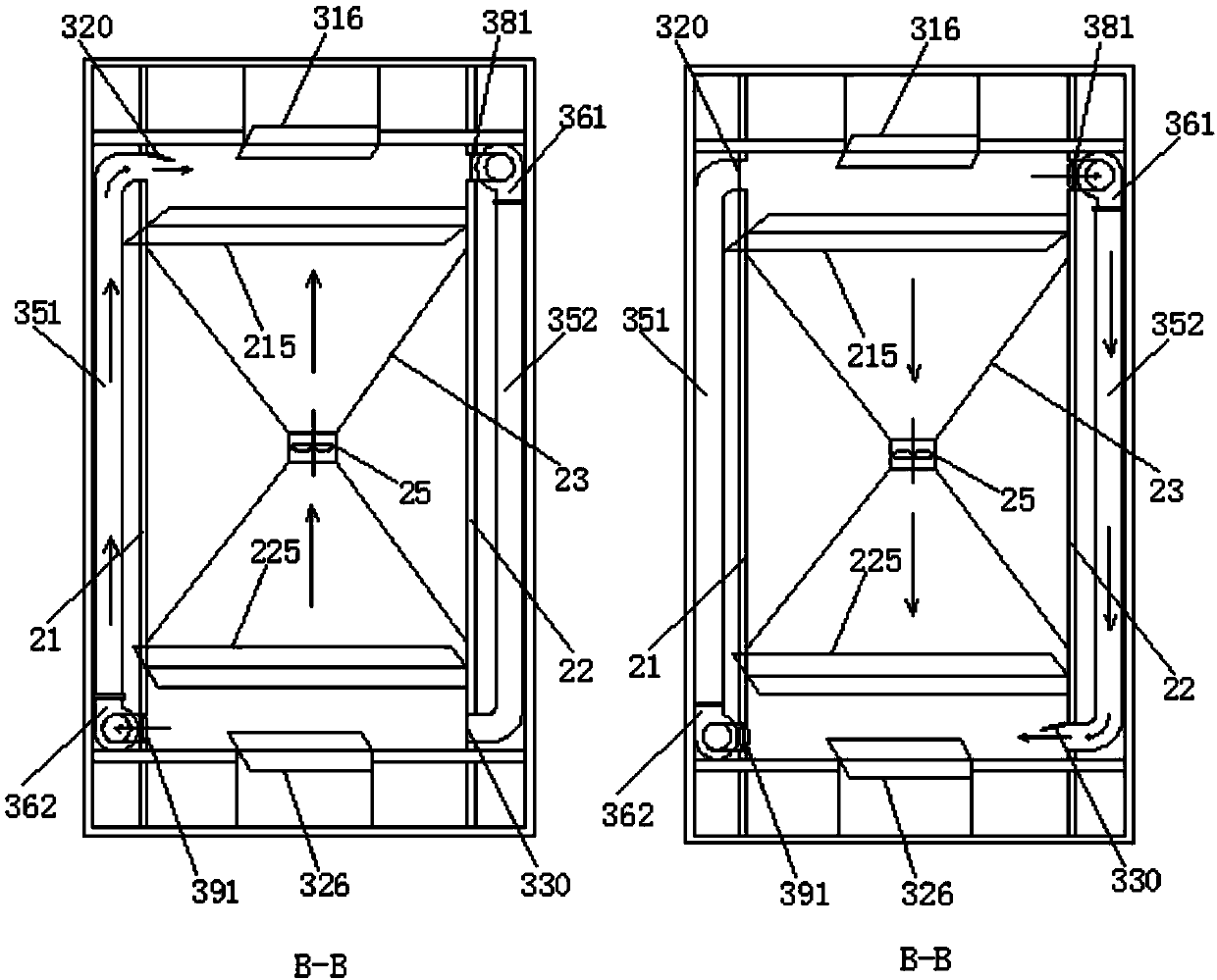

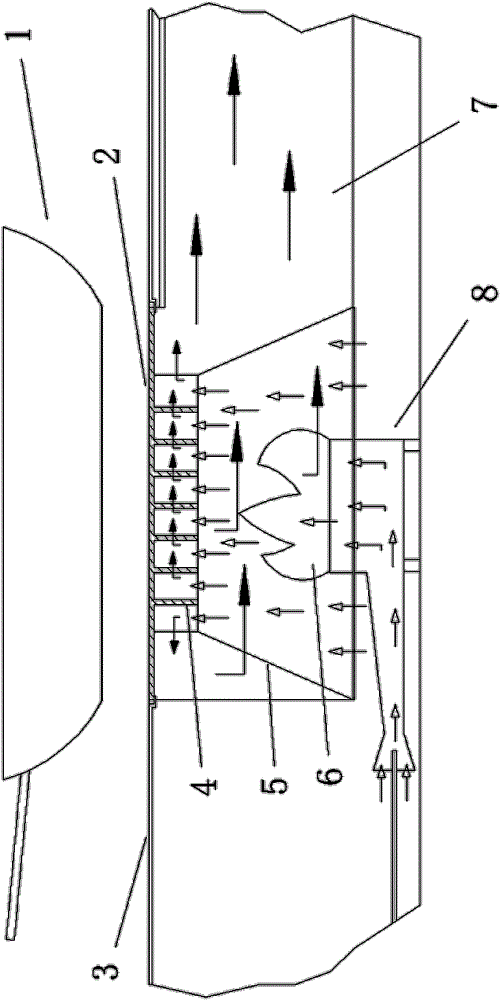

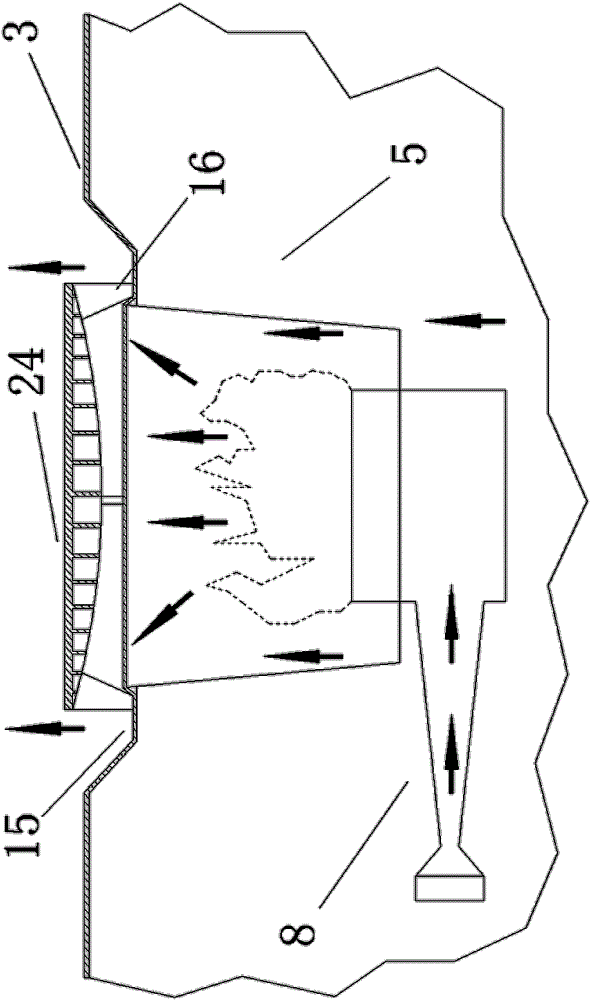

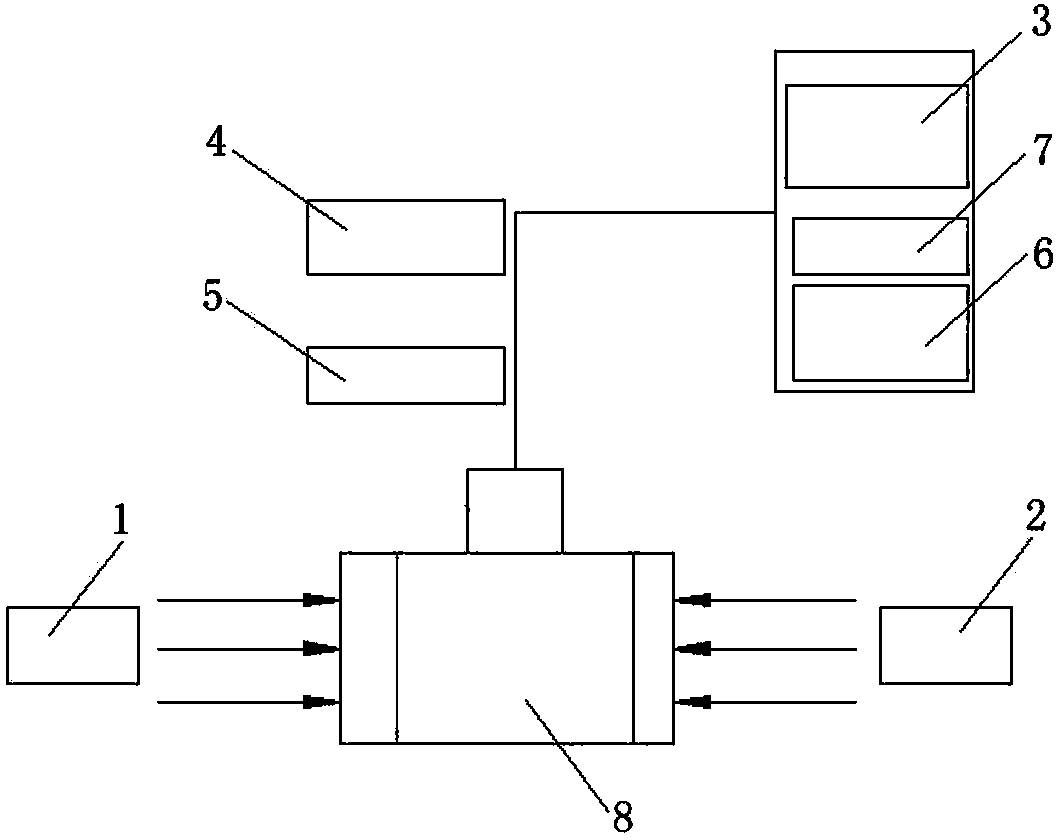

Bidirectional airflow baking device

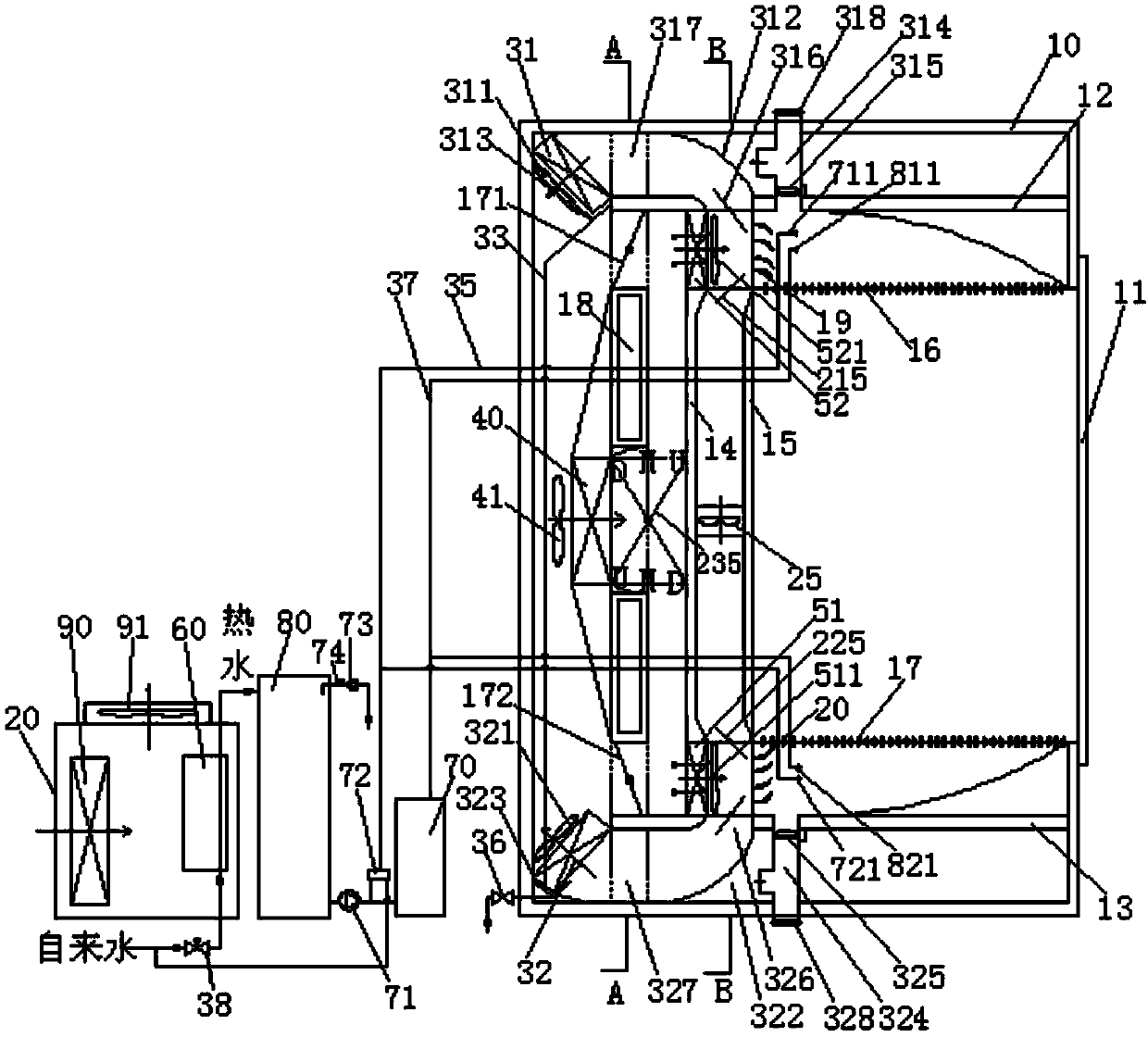

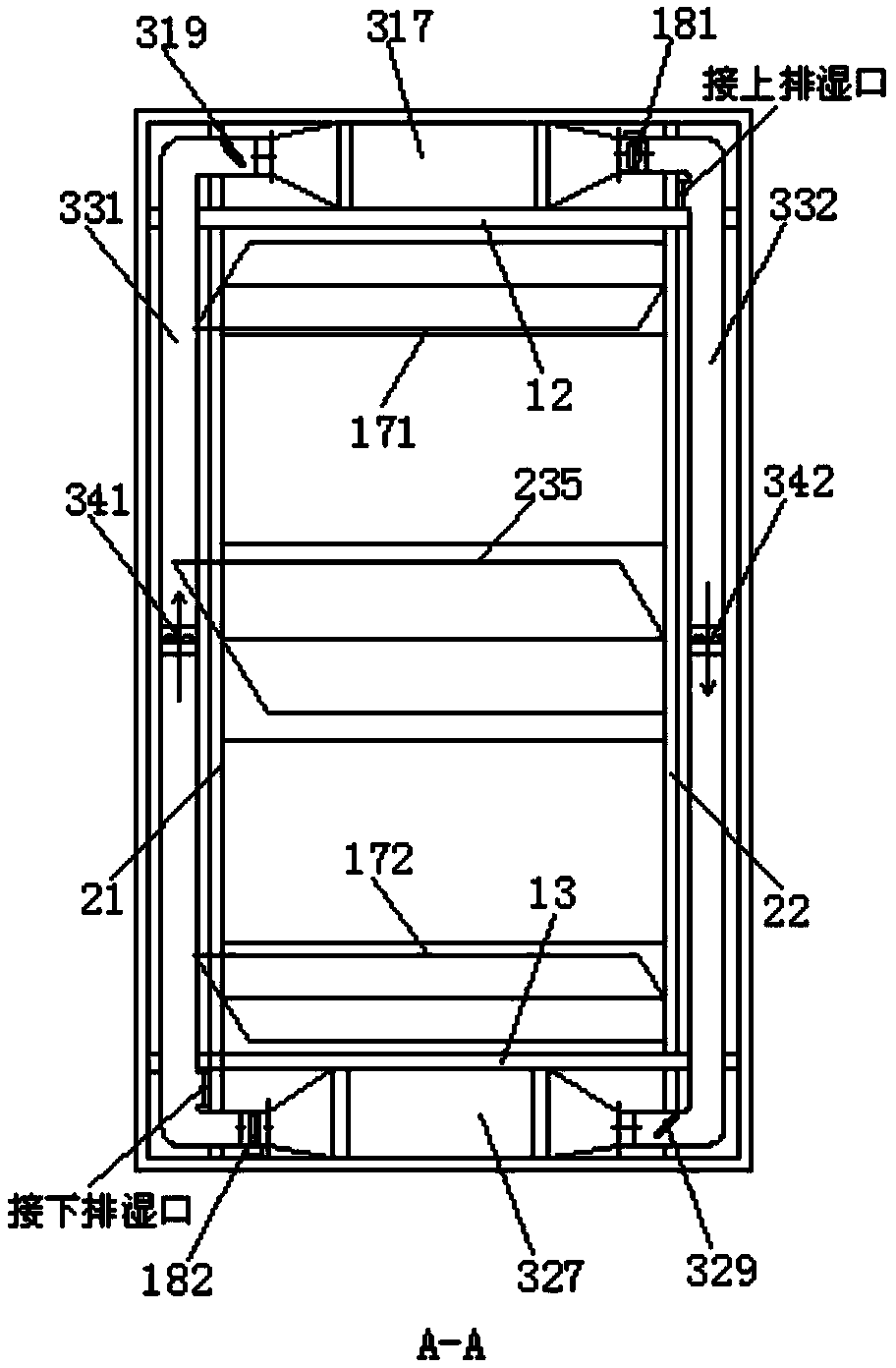

ActiveCN104197652AEliminate temperature dead angleImprove dehumidification efficiencyDrying gas arrangementsDrying machines with local agitationWater pipeEngineering

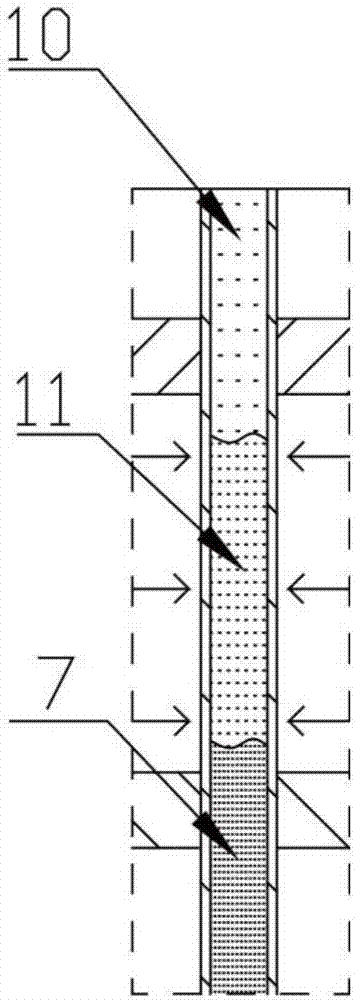

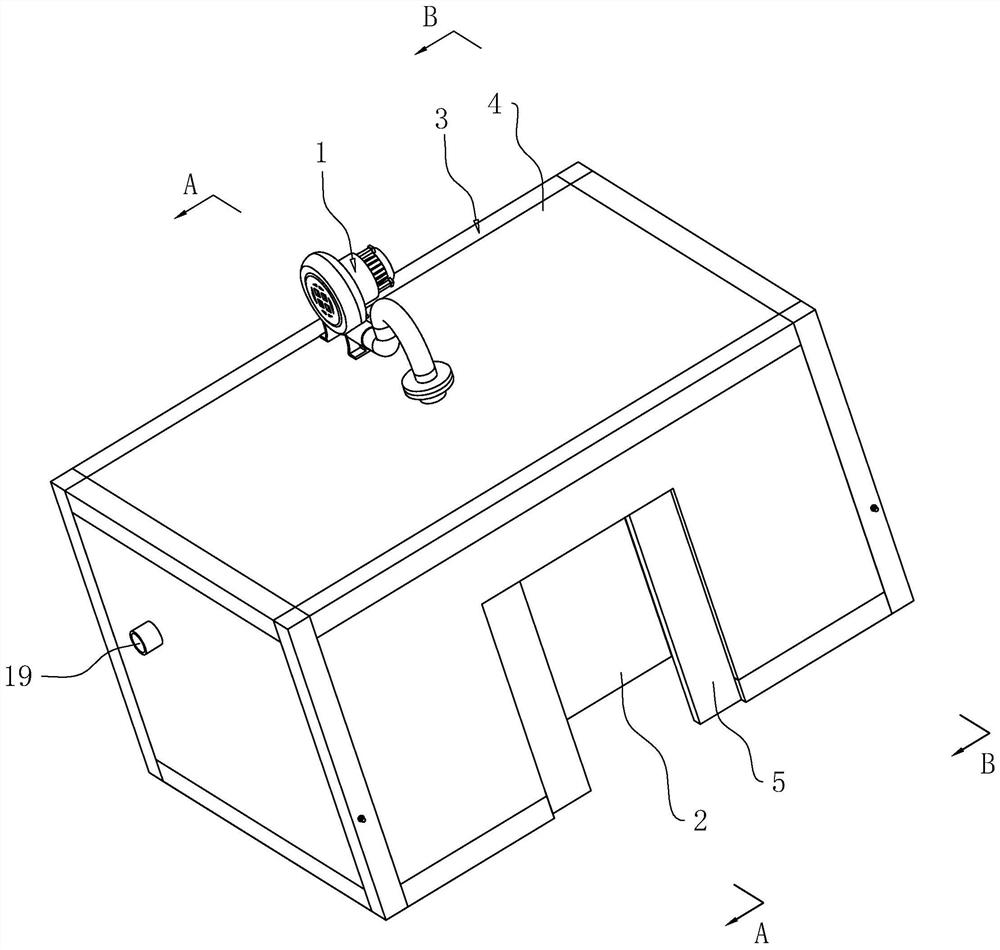

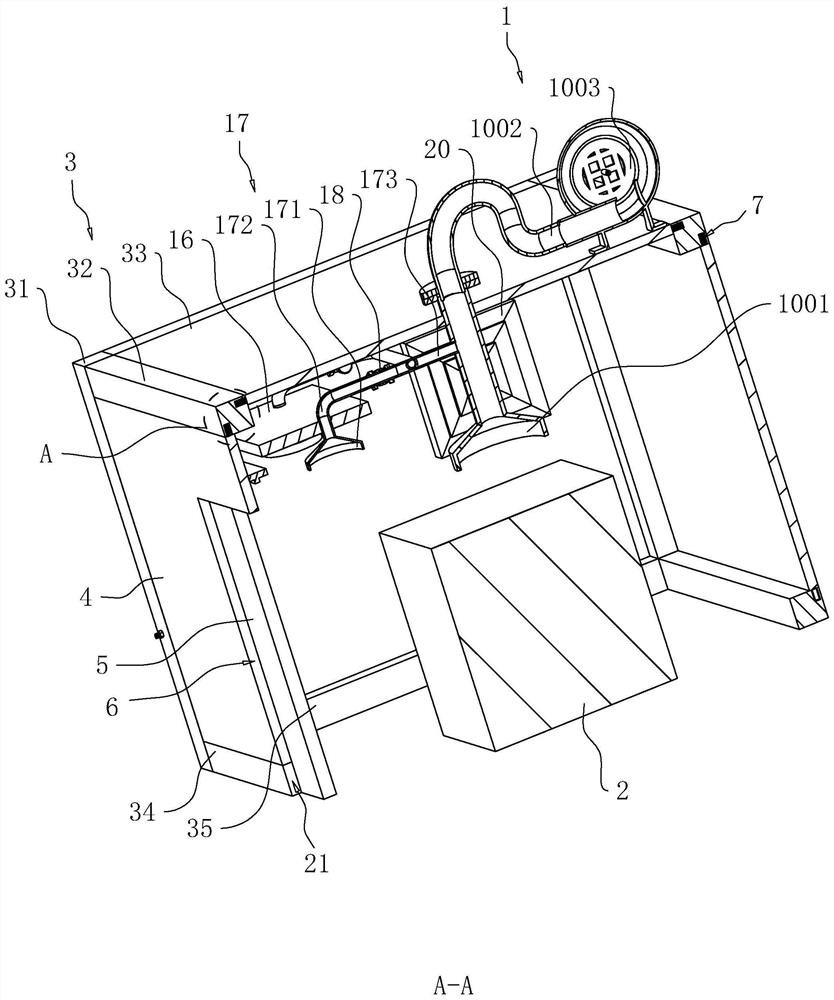

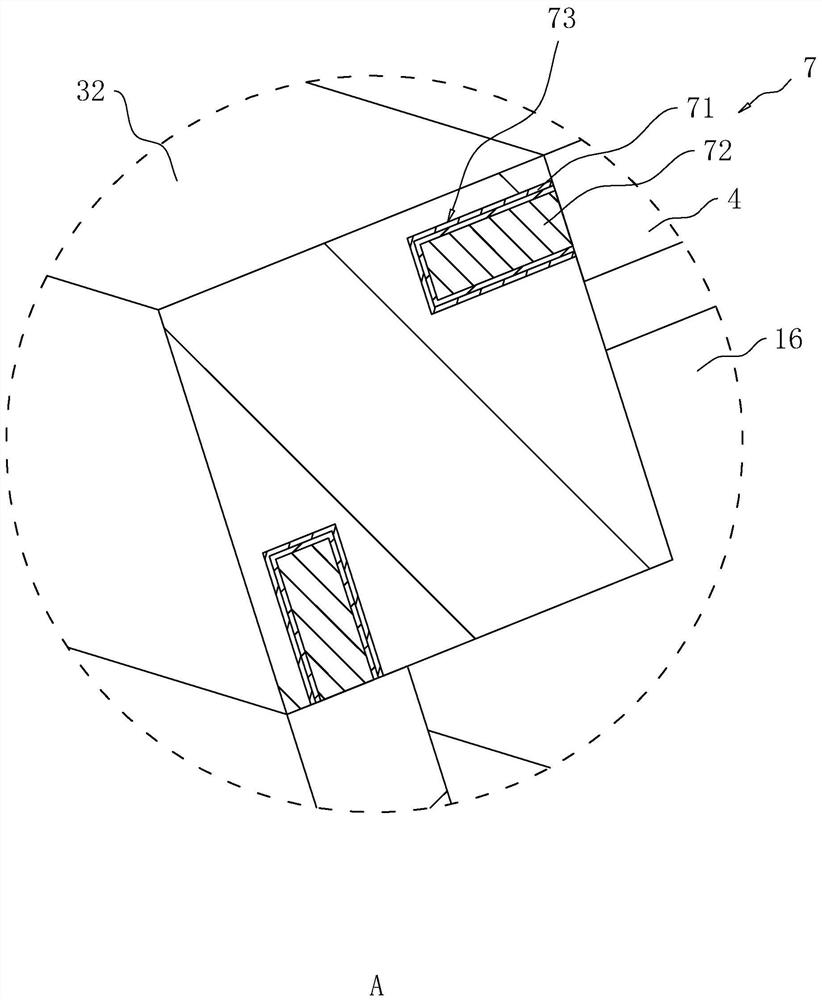

The invention discloses a bidirectional airflow baking device. According to the bidirectional airflow baking device, separation plates parallel to the inner wall of a box are arranged in the box, a separation layer is arranged on the rear portion of the box, a box door is formed on the box, and a heat pump system outer machine is connected with the box through a work medium pipeline; an upper dehumidification evaporator and a lower dehumidification evaporator are communicated through heat preservation pipelines in the separation layer, are obliquely arranged and are oppositely located at the top end and the bottom end of a heat pump air return air channel, airflow is sucked into pipeline fans in the heat preservation pipelines and distributed to the two dehumidification evaporators for dehumidification; a main condenser is arranged in the center of the separation layer and connected with a heat pump system, and the main condenser is used for carrying out heat exchange and temperature rise on the airflow in the airflow circulation process; an upward heater and a downward heater are arranged at the top ends and the bottom ends of the opposite separation plates on the rear portion of the box; a heat storage water tank is connected with a water source pipeline and connected with a box pipeline; a steam generator is connected with a steam pipeline of the box and is connected with a water pipe of the heat storage water tank, water in the heat storage water tank is converted into steam by the steam generator, and the steam is conveyed into the box.

Owner:铜陵三十九度创客公园管理有限公司

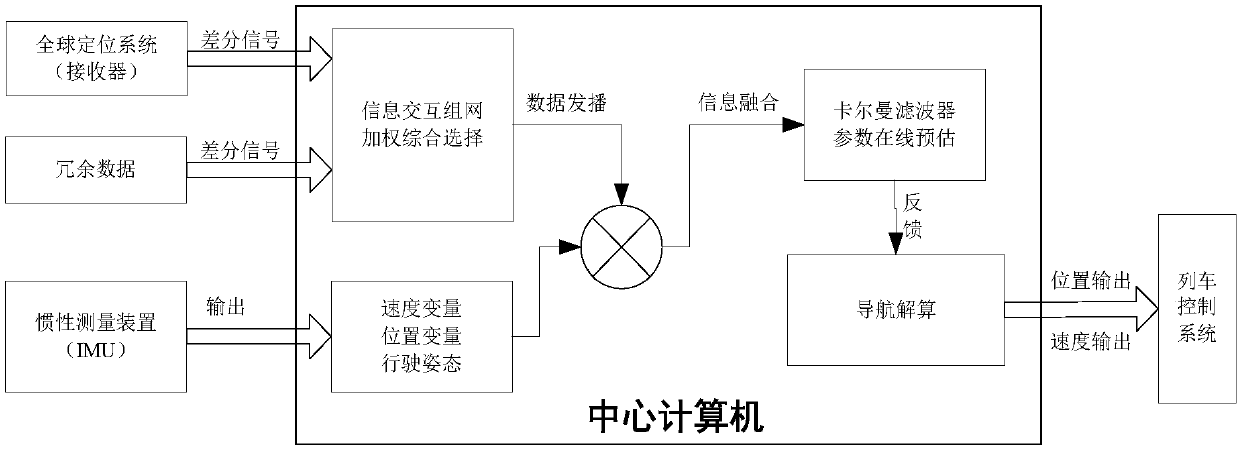

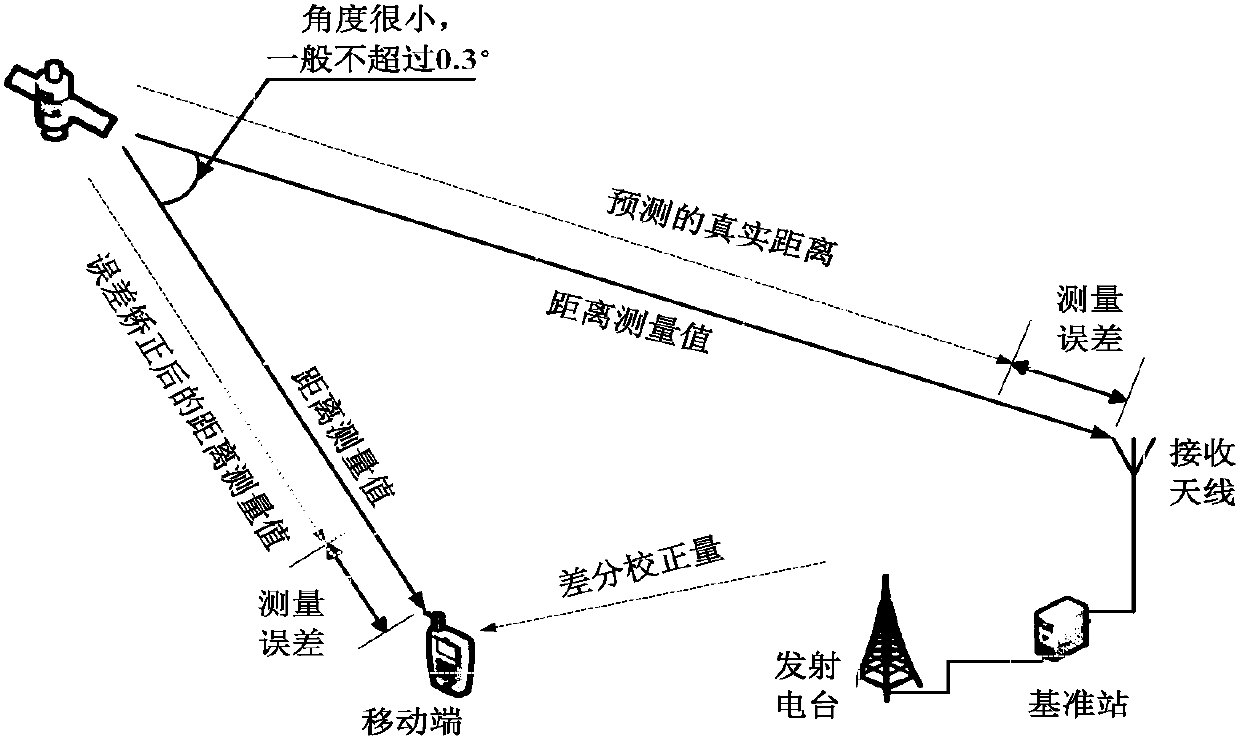

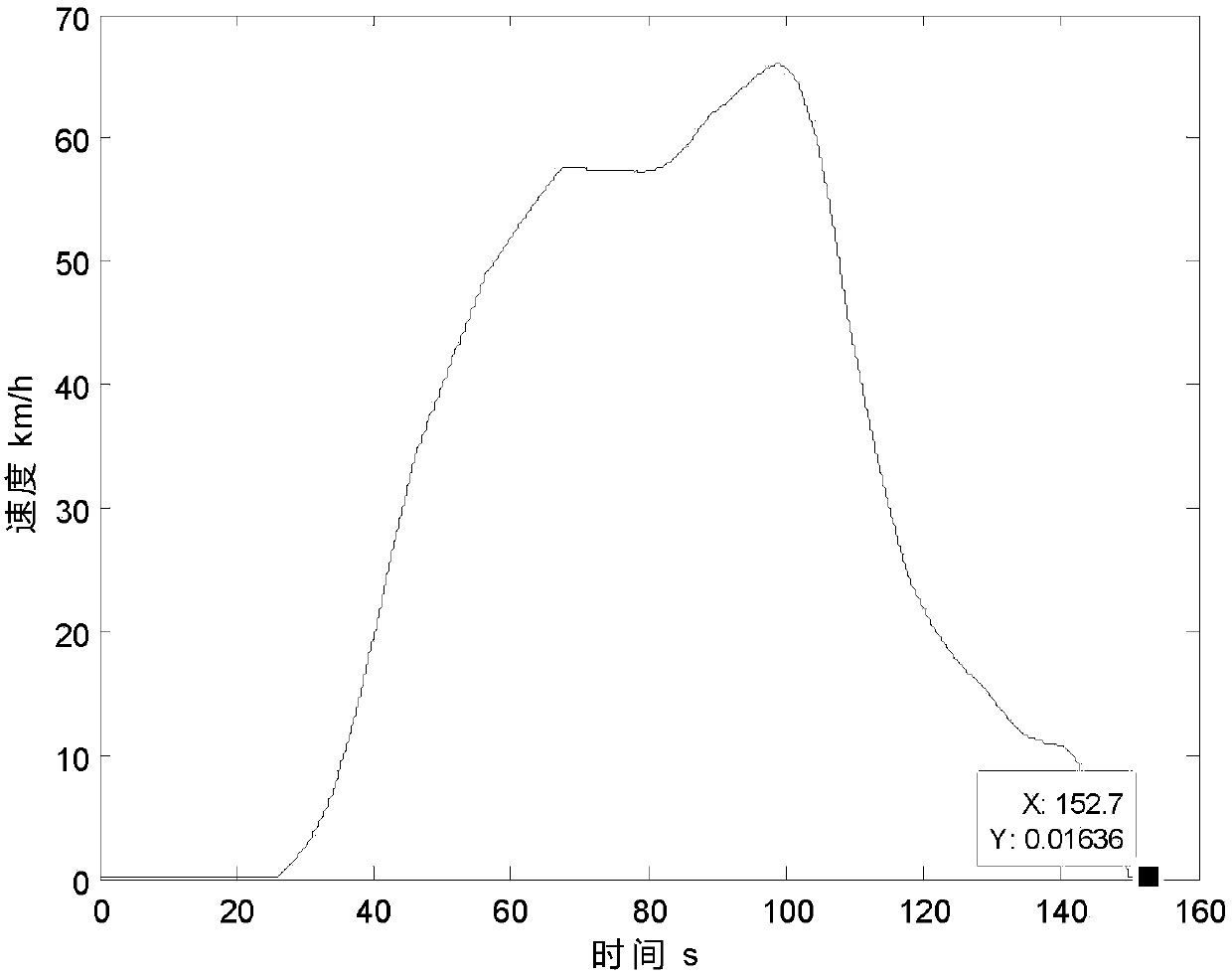

GNSS/SINS combined navigation precise speed measurement and positioning method and system

InactiveCN107894232AImprove long-term accuracyOvercoming long-term low accuracyNavigation by speed/acceleration measurementsSatellite radio beaconingSelf drivingShort terms

The invention discloses a GNSS / SINS combined navigation precise speed measurement and positioning method and system. Navigation data output by SINS and GNSS is fused, the signal tacking process and data fusion are real-time synchronous, the obtained data is the most accurate at any time, and by fully utilizing the advantages that the SINS is high in short-term precision, outside interference doesnot exist, and the GNSS is high in long-term precision, the defects that the SINS is low in long-term precision, and the GNSS is likely to be interfered are overcome; the precision of speed measurement and positioning is improved, and the problem that a solid wheel rail free traditional train adopts a traditional speed measurement method, and then the train speed cannot be measured precisely is solved; strong support is formed for rapid development of the maglev train industry, and meanwhile development of the Beidou satellite application industry is driven, and the method and system can be promoted in rail transportation such as automatic driving or self-driving.

Owner:HUNAN AEROSPACE ELECTROMECHANICAL EQUIP & SPECIAL MATERIAL INST

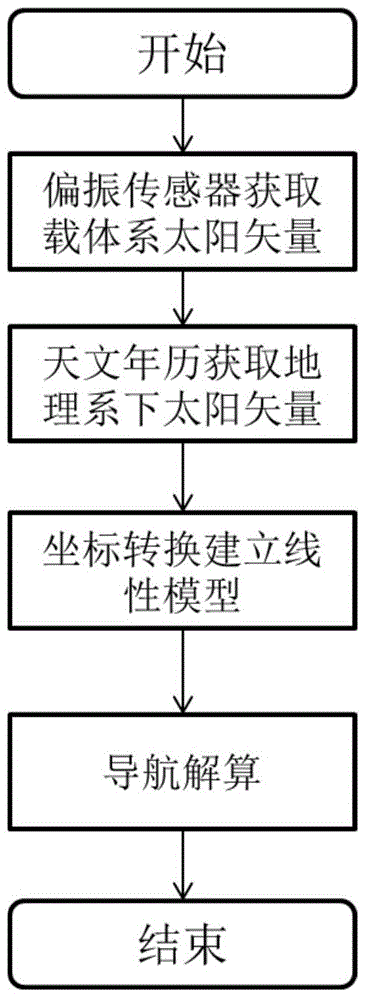

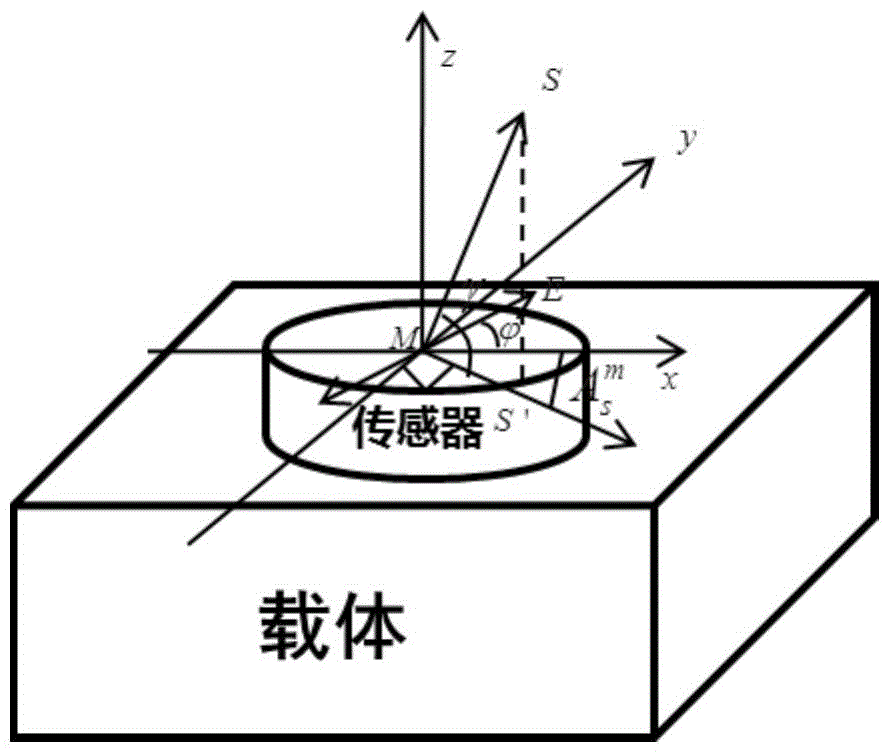

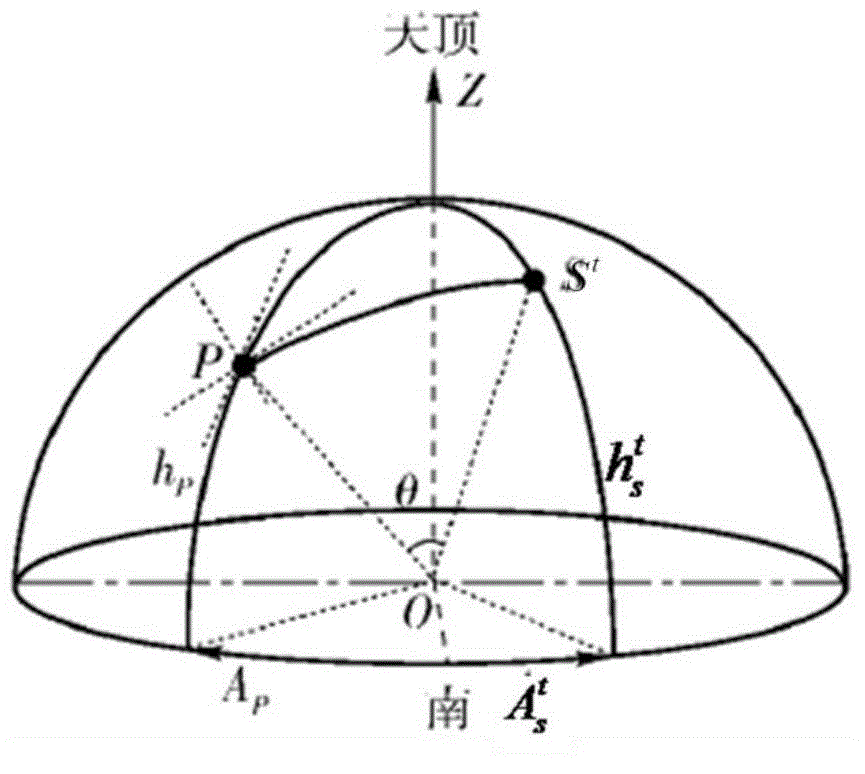

Polarization aided navigation method based on solar vectors

ActiveCN104880191AImplement fixesSuccessful navigation solutionNavigation by speed/acceleration measurementsSensor arrayKaiman filter

The invention relates to a polarization aided navigation method based on solar vectors. The polarization aided navigation method based on the solar vectors comprises the following steps of firstly, obtaining a unit solar vector Sm under a module coordinate system by using a polarization sensor array carried by a carrier; secondly, calculating a unit solar vector St under a geographic coordinate system on the basis of the geographic position and the time information of the carrier according to an astronomical almanac value; and finally, establishing a polarization navigation linear model by using the unit solar vectors under the different coordinate systems and estimating navigation parameters by using a Kalman filter. By the method, the solar vectors are obtained by an atmosphere polarization mode to perform aided navigation, the precision is high, the polarization aided navigation method is not disturbed by other factors of the outside, and passive, non-radiative and full-autonomous navigation can be implemented.

Owner:青岛智融领航科技有限公司

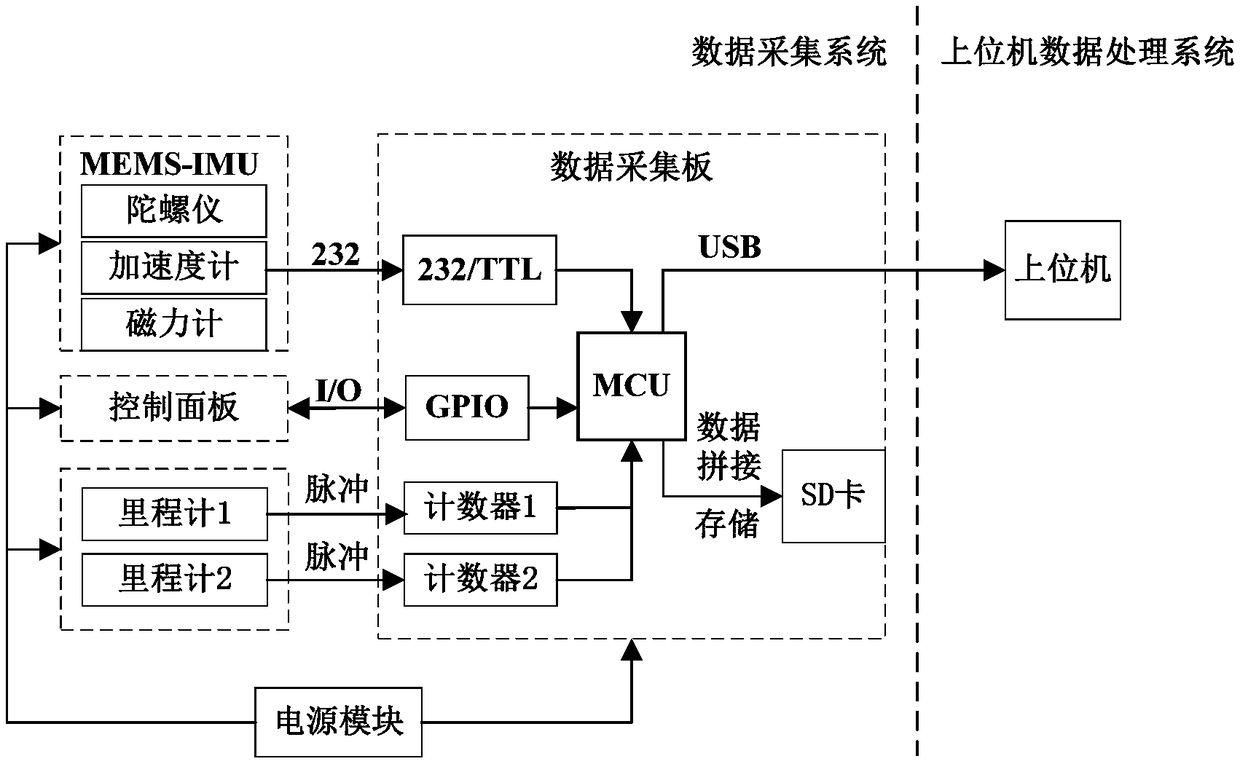

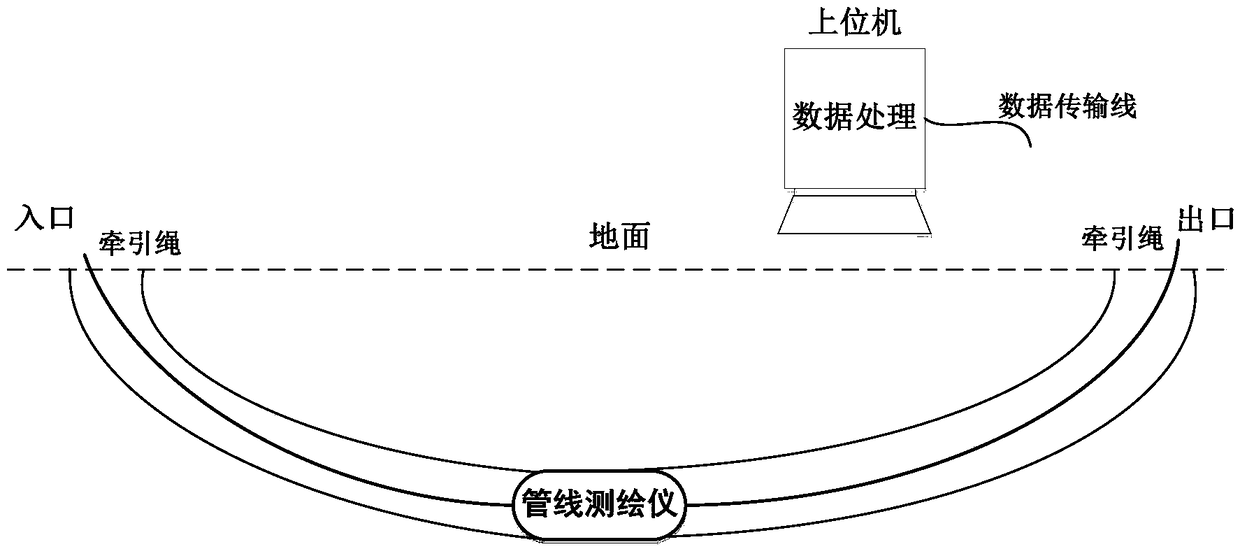

Underground pipeline trajectory detection system and method based on inertia measurement

InactiveCN108955675ADetection accuracy has no effectImprove reliabilityNavigation by speed/acceleration measurementsTime informationSurvey instrument

The invention discloses an underground pipeline trajectory detection system based on inertia measurement. The system is composed of two sub systems. A data acquisition system is loaded in a mechanicalbody to form a pipeline surveying instrument which comprises an MEMS-IMU, a speedometer, a built-in lithium battery and a data acquisition plate. The MEMS-IMU is used for providing a real-time gesture information of the surveying instrument, the speedometer is used for providing real-time journey information of the surveying instrument, the data acquisition plate receives sensor data and stores the data in an SD card, and after measurement, the stored data is uploaded to an upper computer through a USB interface. An upper computer data processing system obtains a real-time gesture angle through inertial navigation calculation and information infusion, carries out dead reckoning by combining the journey information to obtain a walking trajectory of the surveying instrument in the pipeline,and corrects the trajectory by means of the inlet / outlet position of the pipeline to obtain a tested pipeline trajectory. The measuring method is of autonomy, is not affected by external environmentand buried depth of pipelines, and by using non-excavation means, the system does not need ground operations, so that the system is economic, efficient and environment-friendly.

Owner:SOUTHEAST UNIV

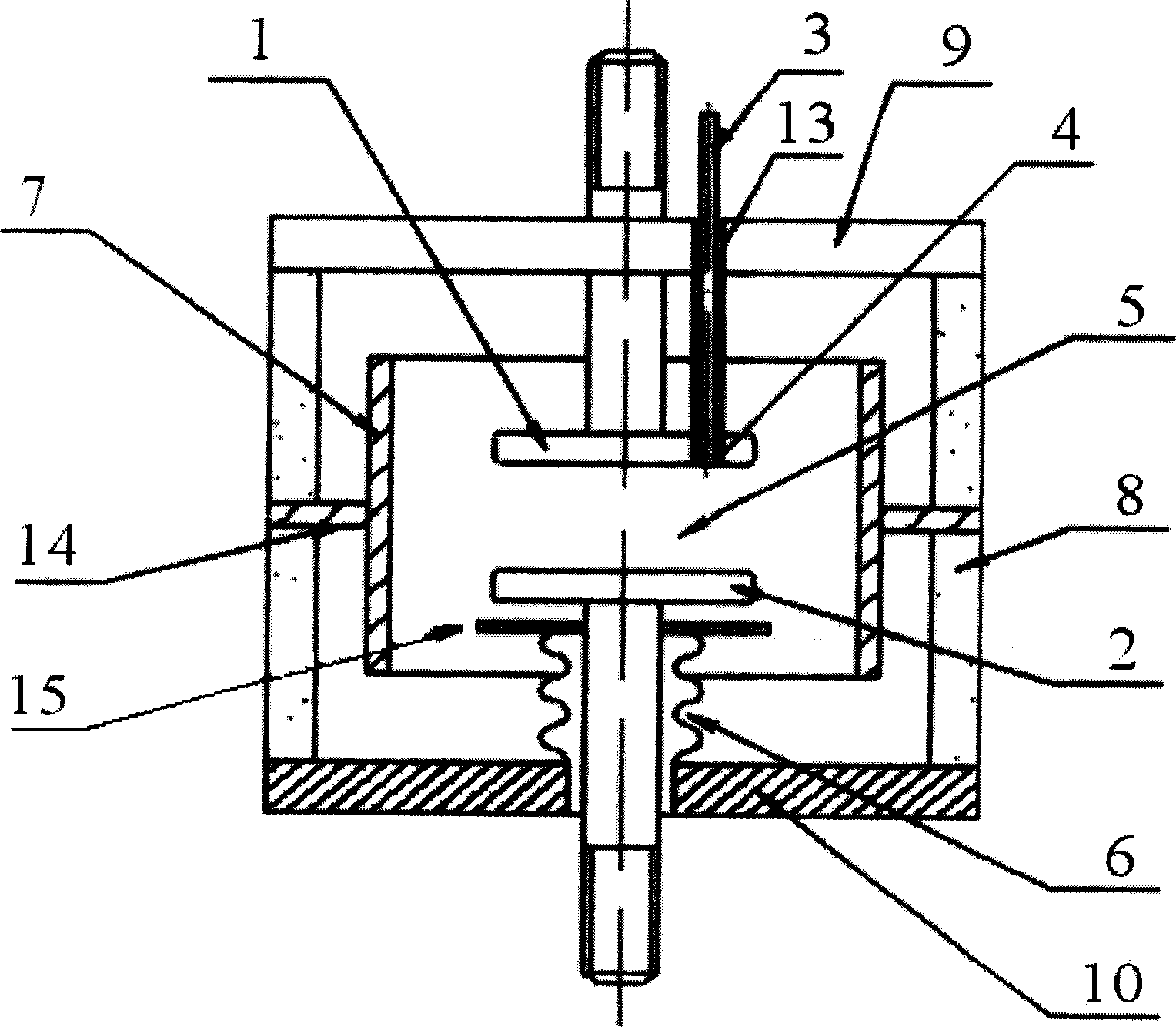

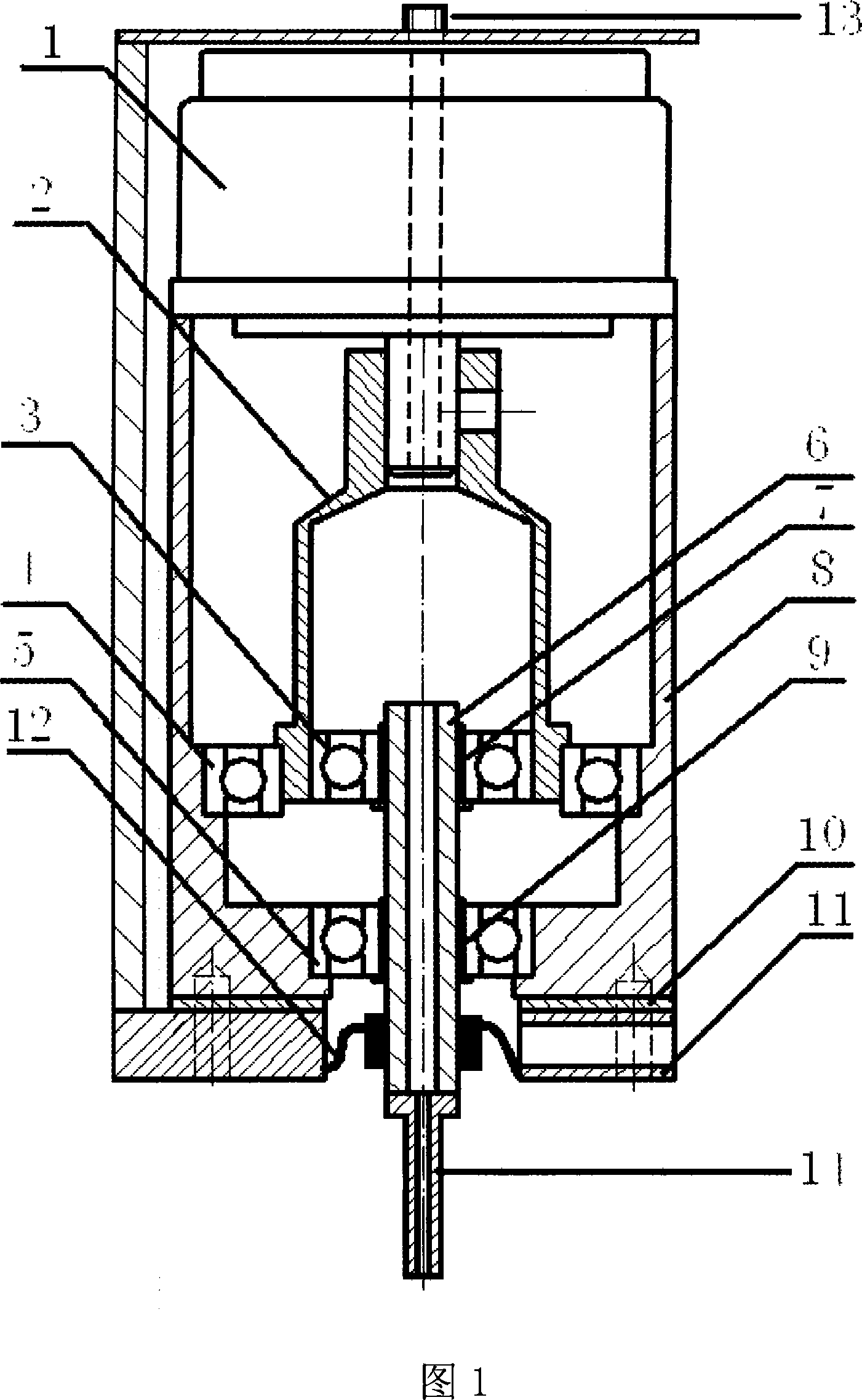

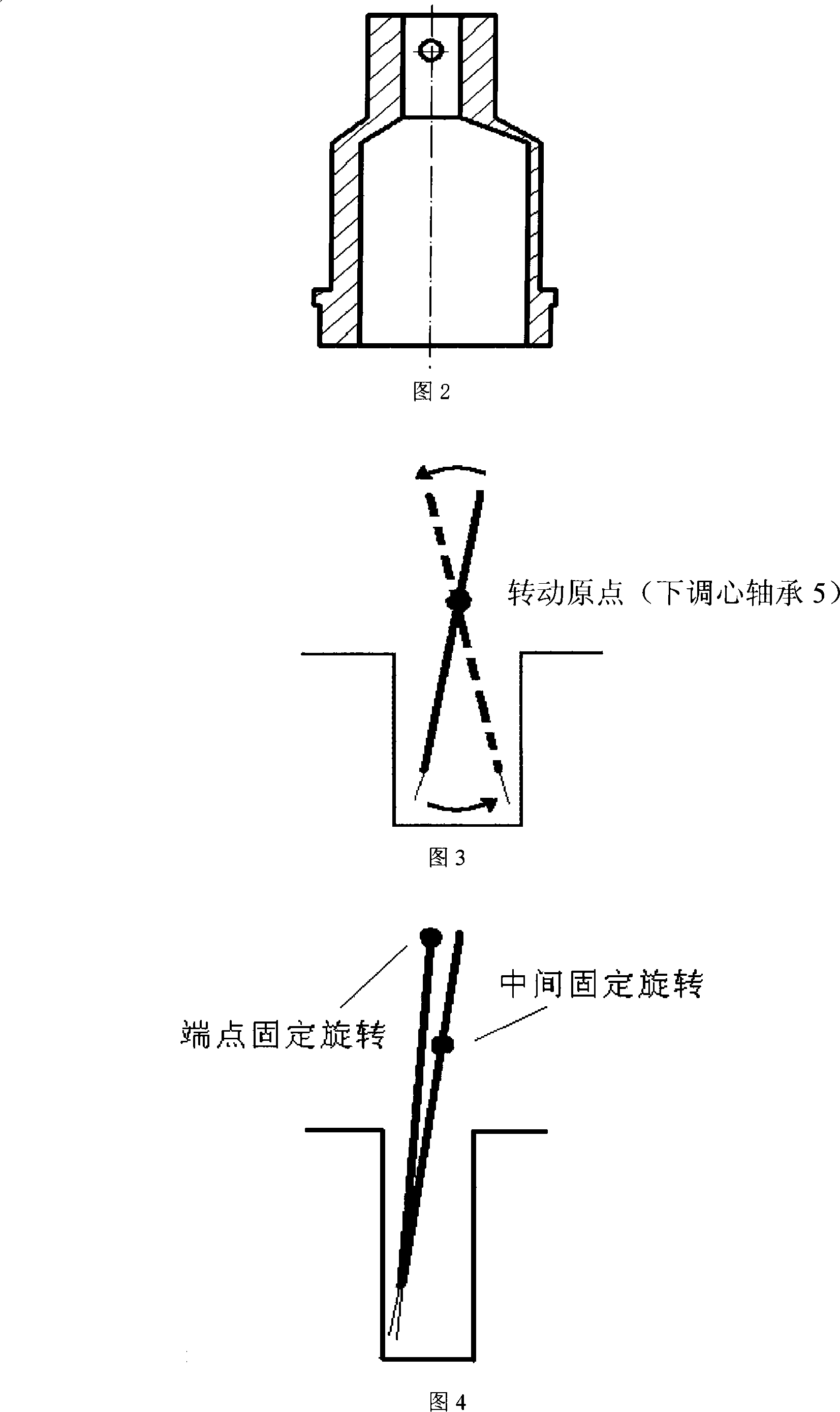

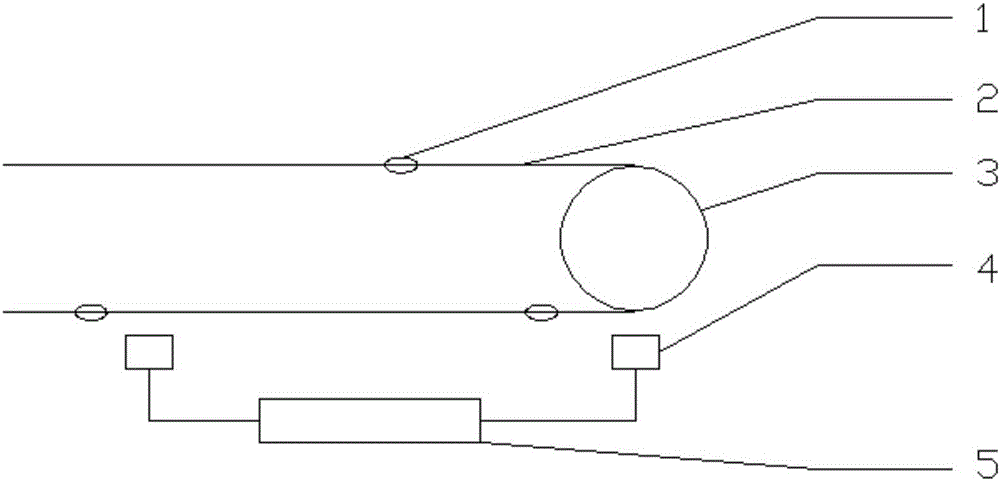

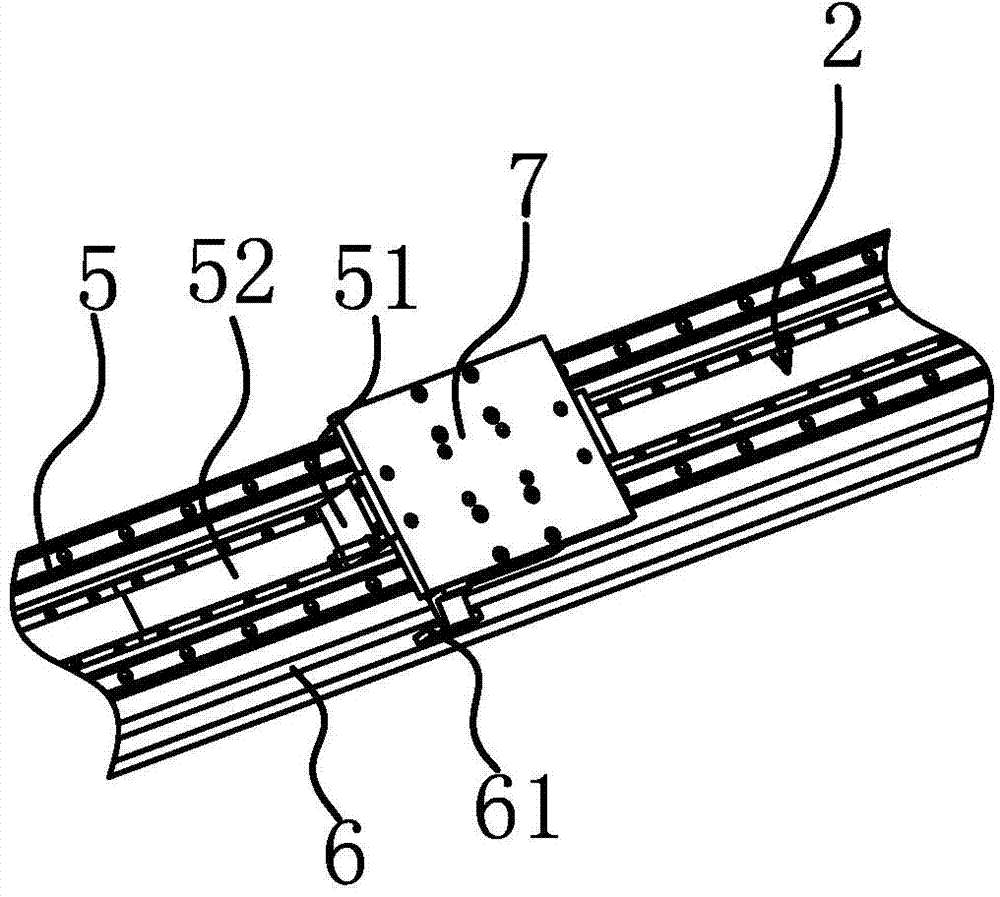

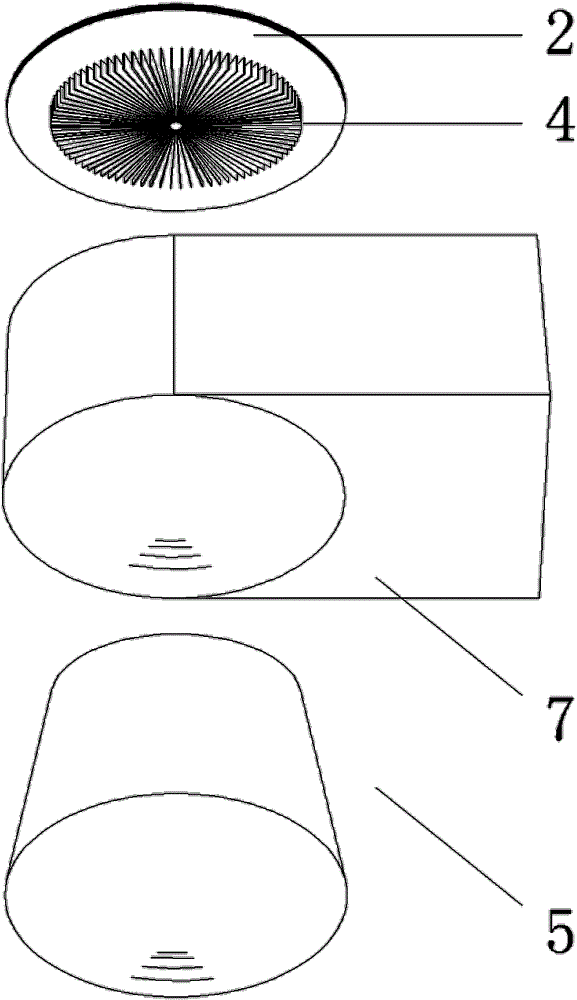

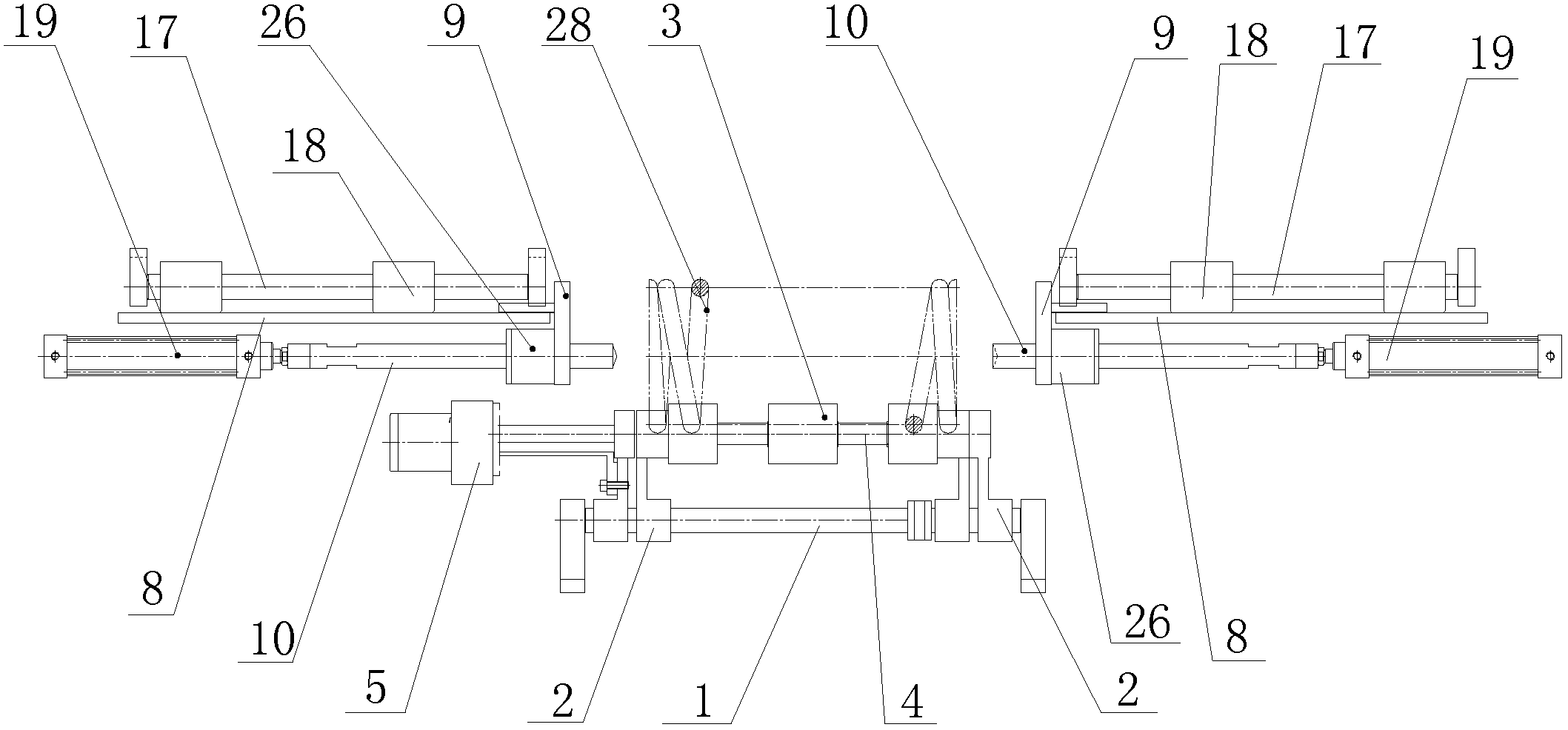

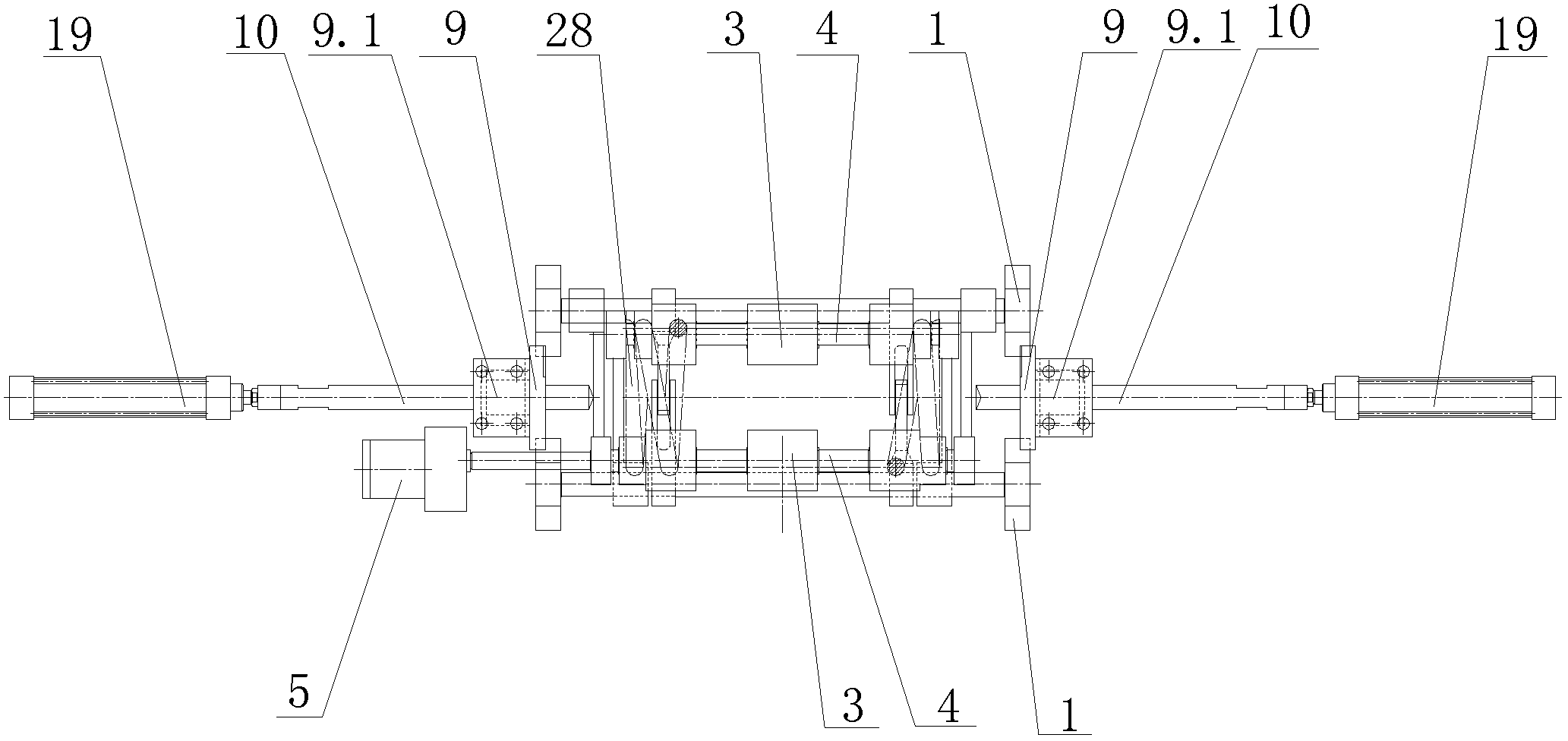

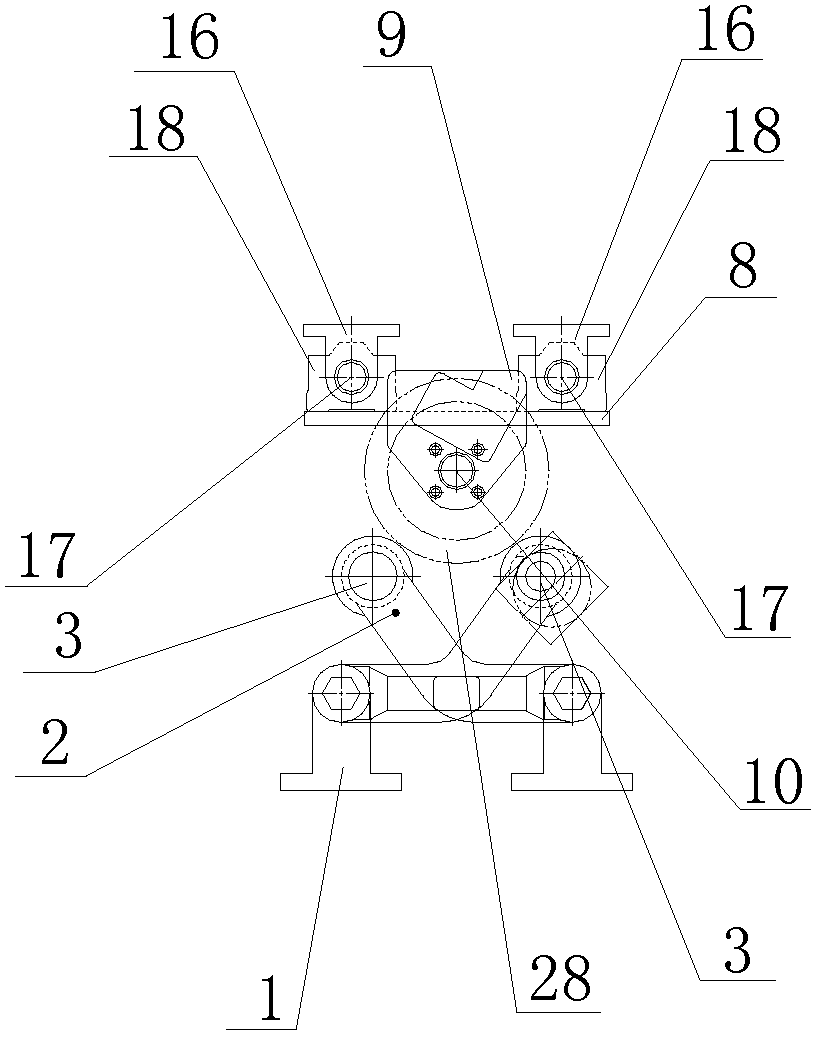

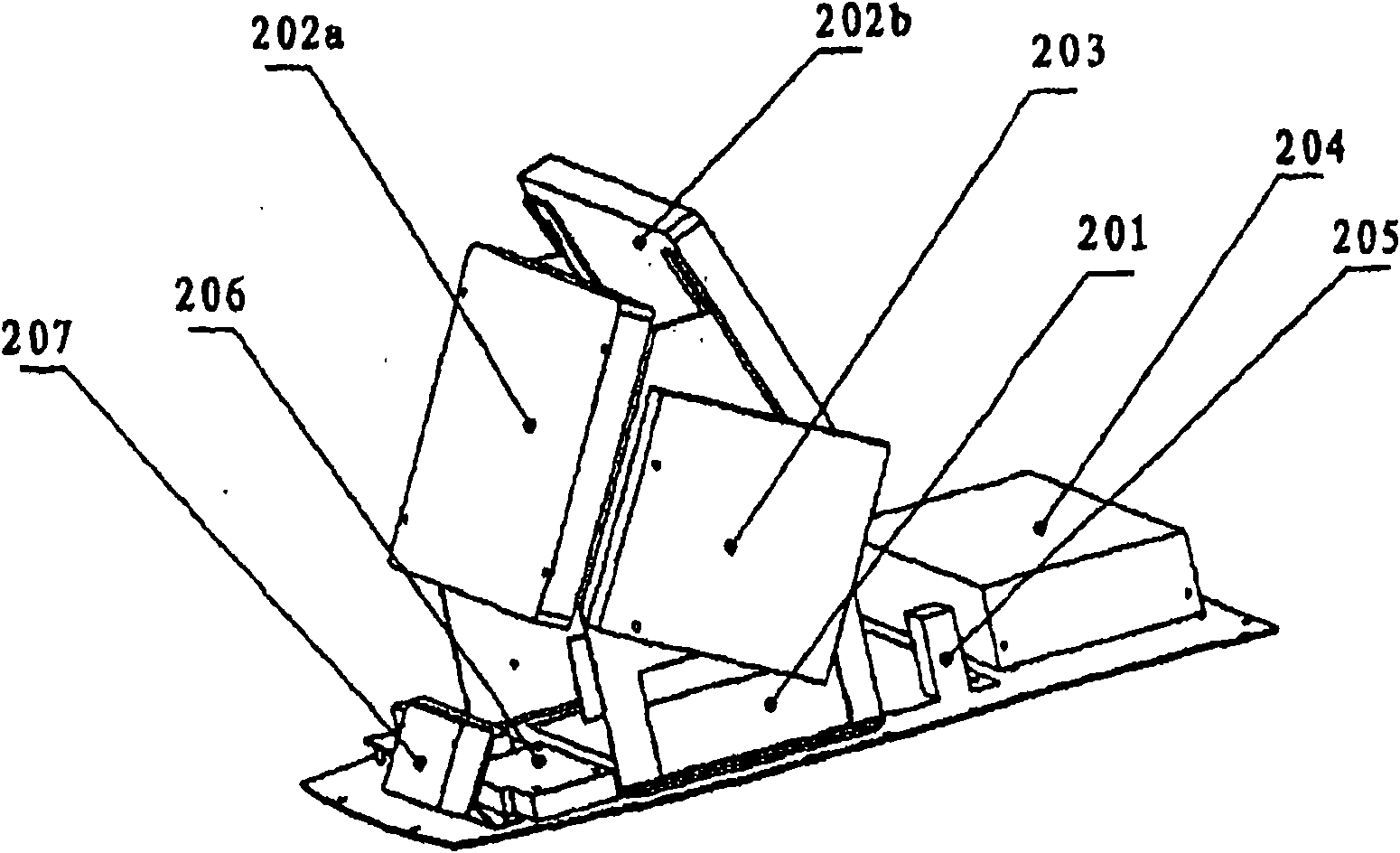

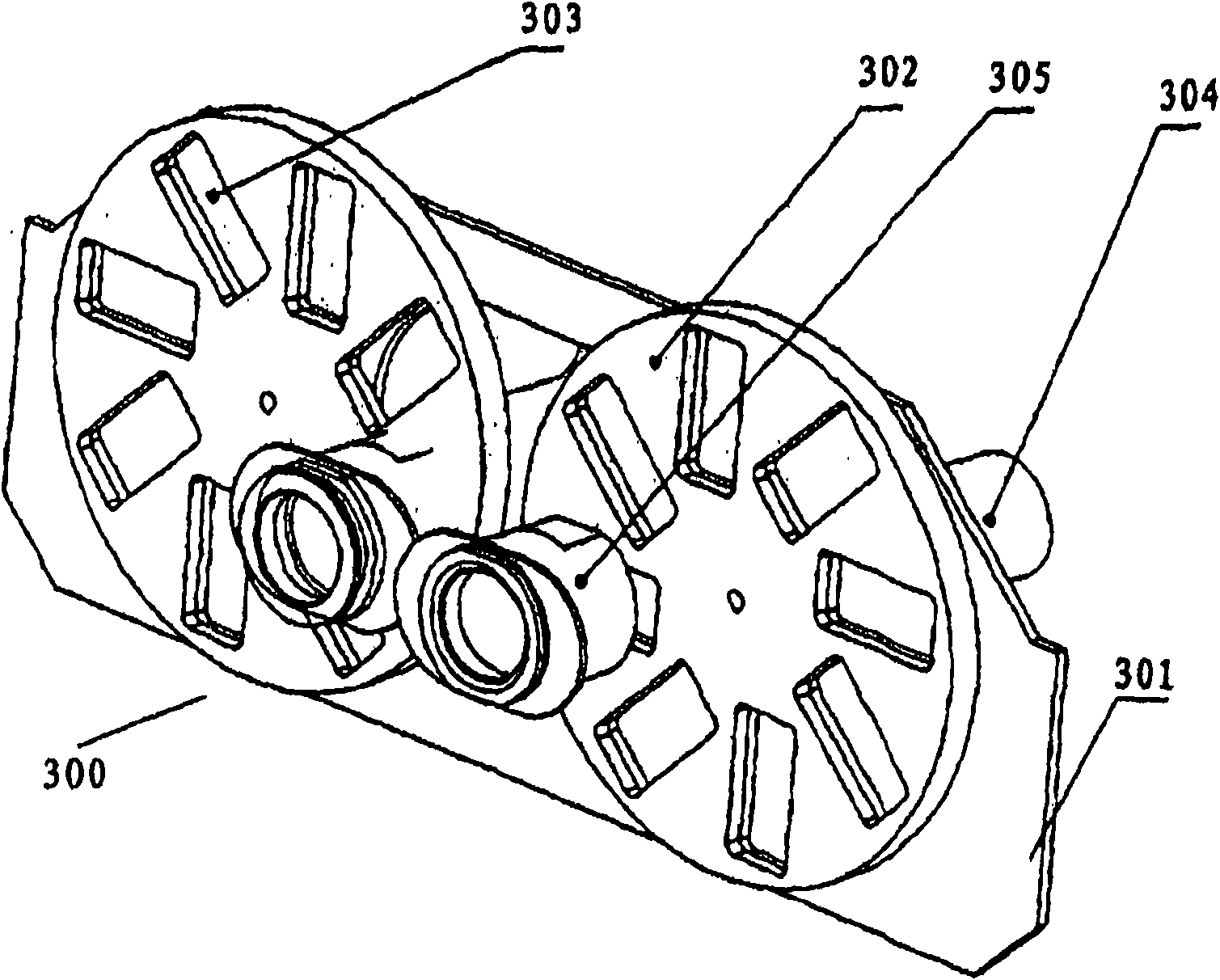

Rotating arc narrow gap welding torque

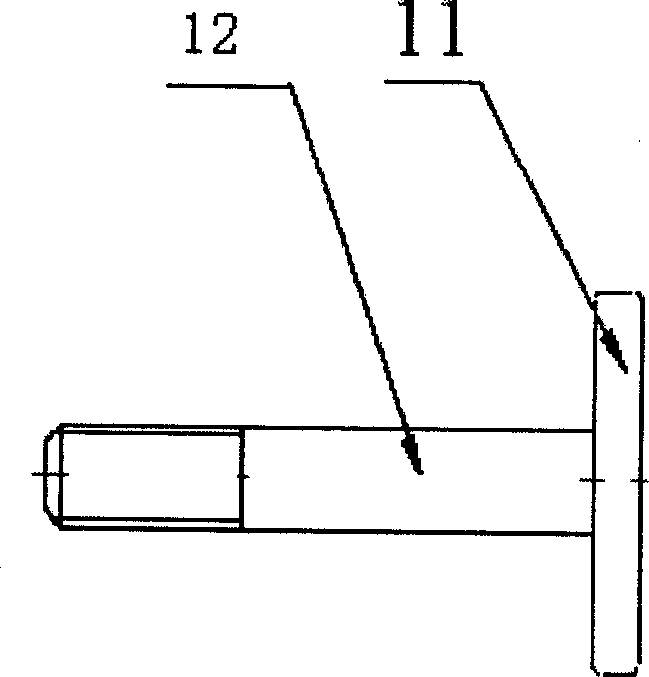

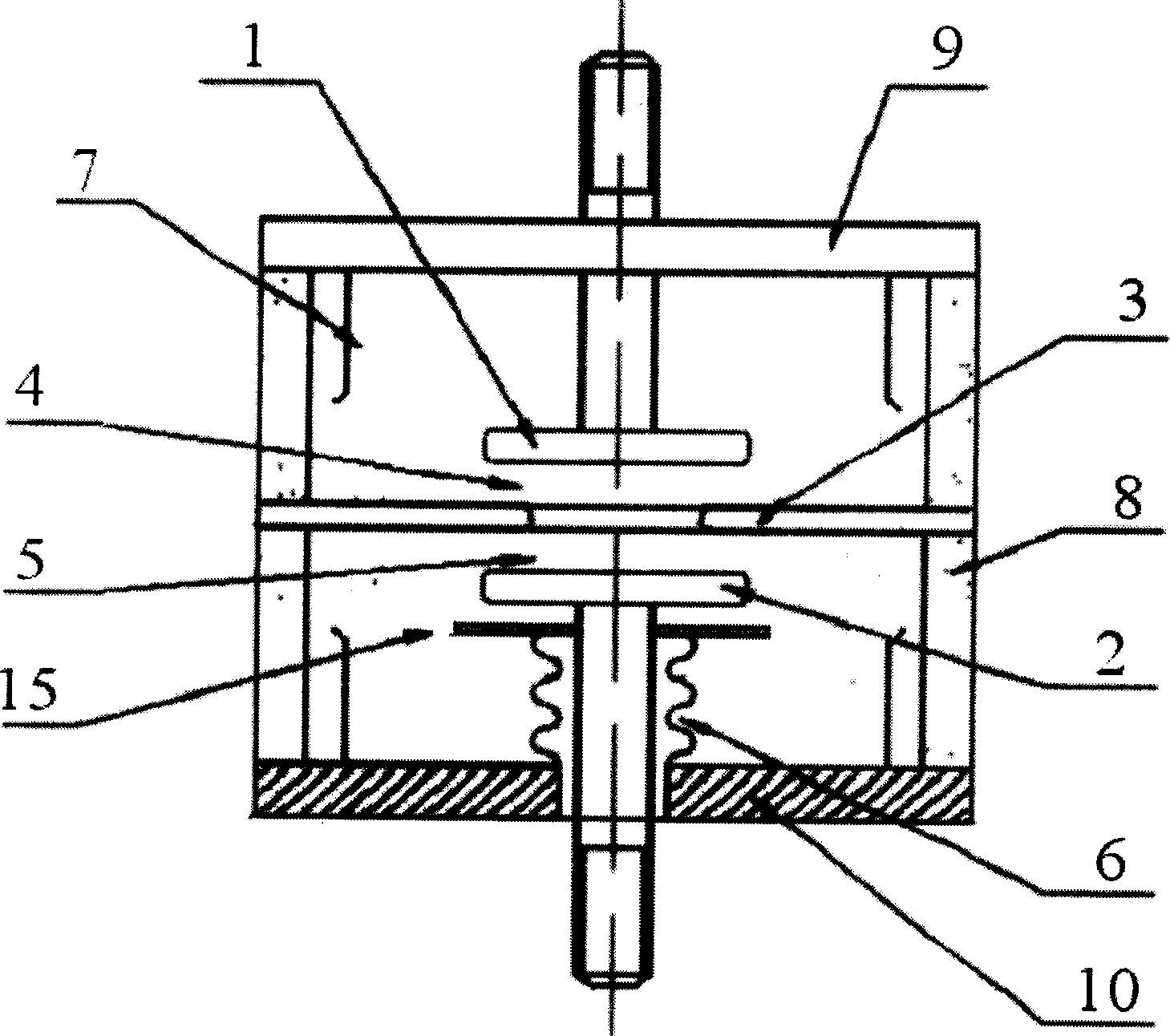

InactiveCN101200018ACompact designNice appearanceElectrode supporting devicesElectrode accessoriesWelding power supplyControl theory

The invention provides a rotating arc welding torch with narrow clearance, comprising a hollow axle high speed servo motor 1, an eccentric sleeve 2, a center-up-adjusted bearing 3, a sealed bearing4, a center-down-adjusted bearing 5, a conducting pole 6, a welding torch shell 8 and a conducting nozzle 14, etc. The invention is characterized in that the hollow axle high speed servo motor 1 and the eccentric sleeve2 which are connected together drive the conducting pole 6 and the conducting nozzle 14 to make an eccentric revolution around the axes of the welding torch; the revolution original point is close to the middle part of the conducting pole 6 which runs through the fixed center-down-adjusted bearing 5 and is fixed with the center-down-adjusted bearing 5; the revolving range is regulated jointly by the eccentric magnitude of the eccentric sleeve 2 and the position where the center-down-adjusted bearing 5 of the revolution original point exists on the conducting pole 6. The welding wire produces the rotating arc along with the revolution of the conducting pole 6 and the conducting nozzle 14. A soft wire cable 12 is connected with the loading welding power supply of the soft wire cable. The wearing components of the invention are all standard parts; thereby the implementation cost is low and the welding torch has long service life; using the soft conducting wire connection is convenient and reliable; when in operation, the welding torch can not be affected by the external disturbances.

Owner:HARBIN INST OF TECH

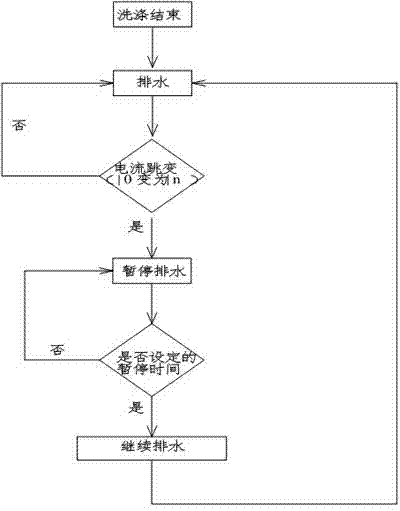

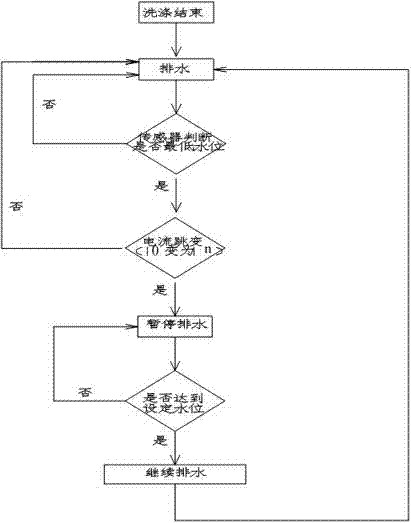

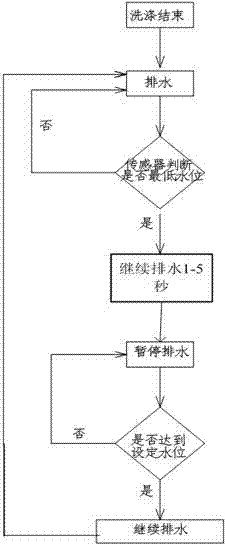

Washing machine control method and washing machine

ActiveCN102260984AAccurate load judgmentFree from outside interferenceOther washing machinesControl devices for washing apparatusEffective solutionWork period

A washing machine control method, the washing machine includes a housing, an outer tub, a drum for holding clothes, a drain pump for draining water, and a water level detection device for detecting water volume, the control method includes a washing program, a rinsing program, and a dehydration process. program, wherein the dehydration program is divided into a drainage process and a dehydration process. During the drainage process, the load detection of the drainage pump is carried out and the detection and control process of controlling the switching action of the drainage pump is performed according to the detection results. When the current of the drainage pump jumps and the difference reaches the set value △I, stop the working time of the drainage pump, stop the time T or detect that the water level exceeds the minimum set value, continue to drain and detect, and complete the dehydration program in this cycle. The invention also relates to a washing machine using the method. By improving the control program and circuit, the invention has simple structure, low cost, easy implementation, effectively solves the problem of high noise of the washing machine, meets user needs, and is more humanized.

Owner:FOSHAN SHUNDE HAIER ELECTRIC APPLIANCES CO LTD

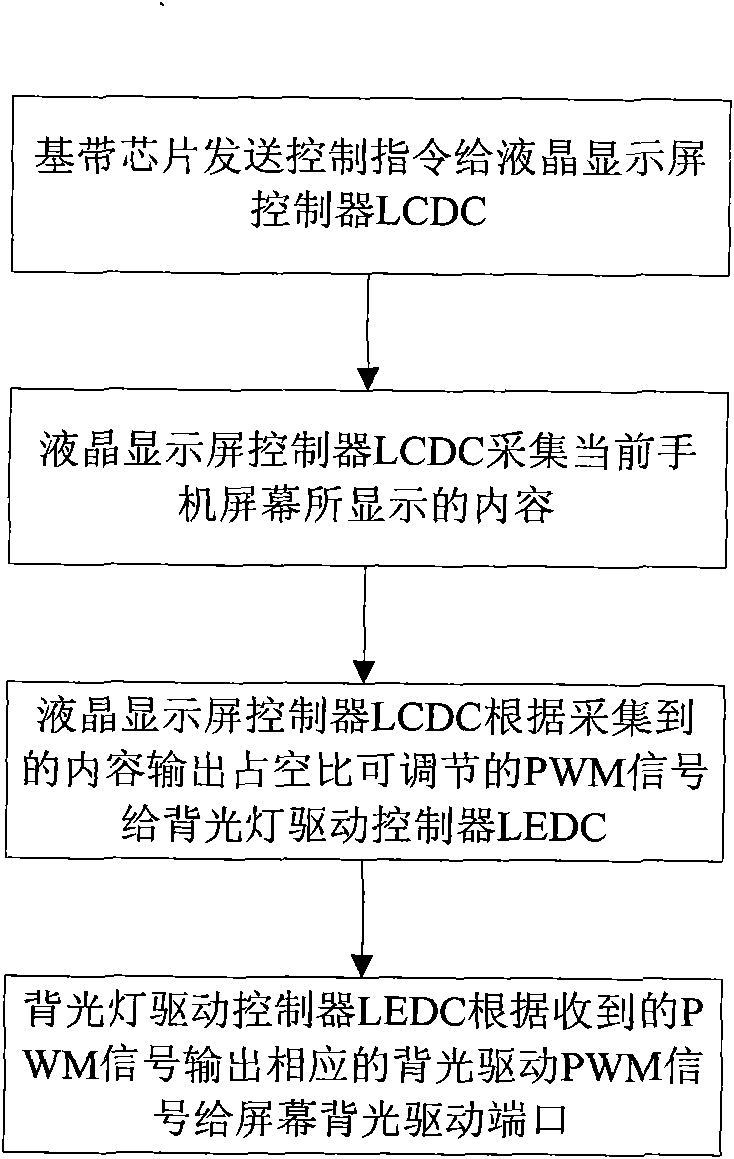

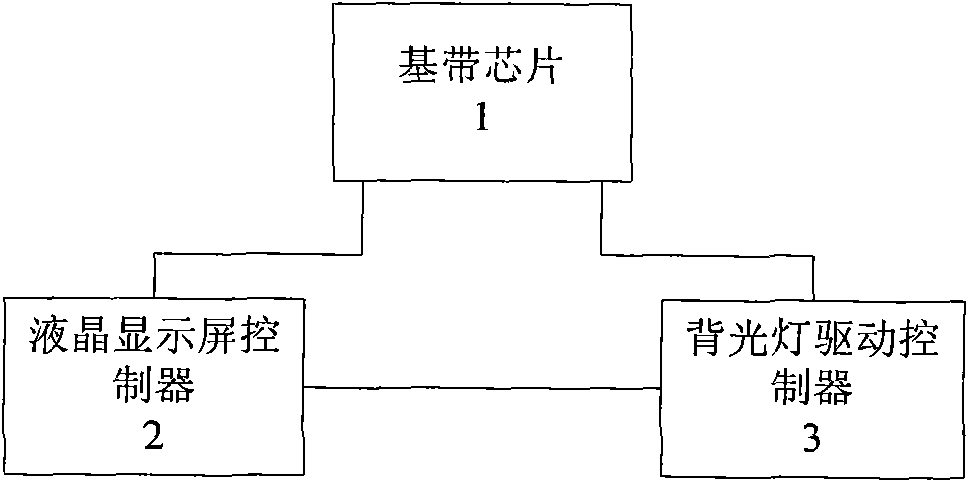

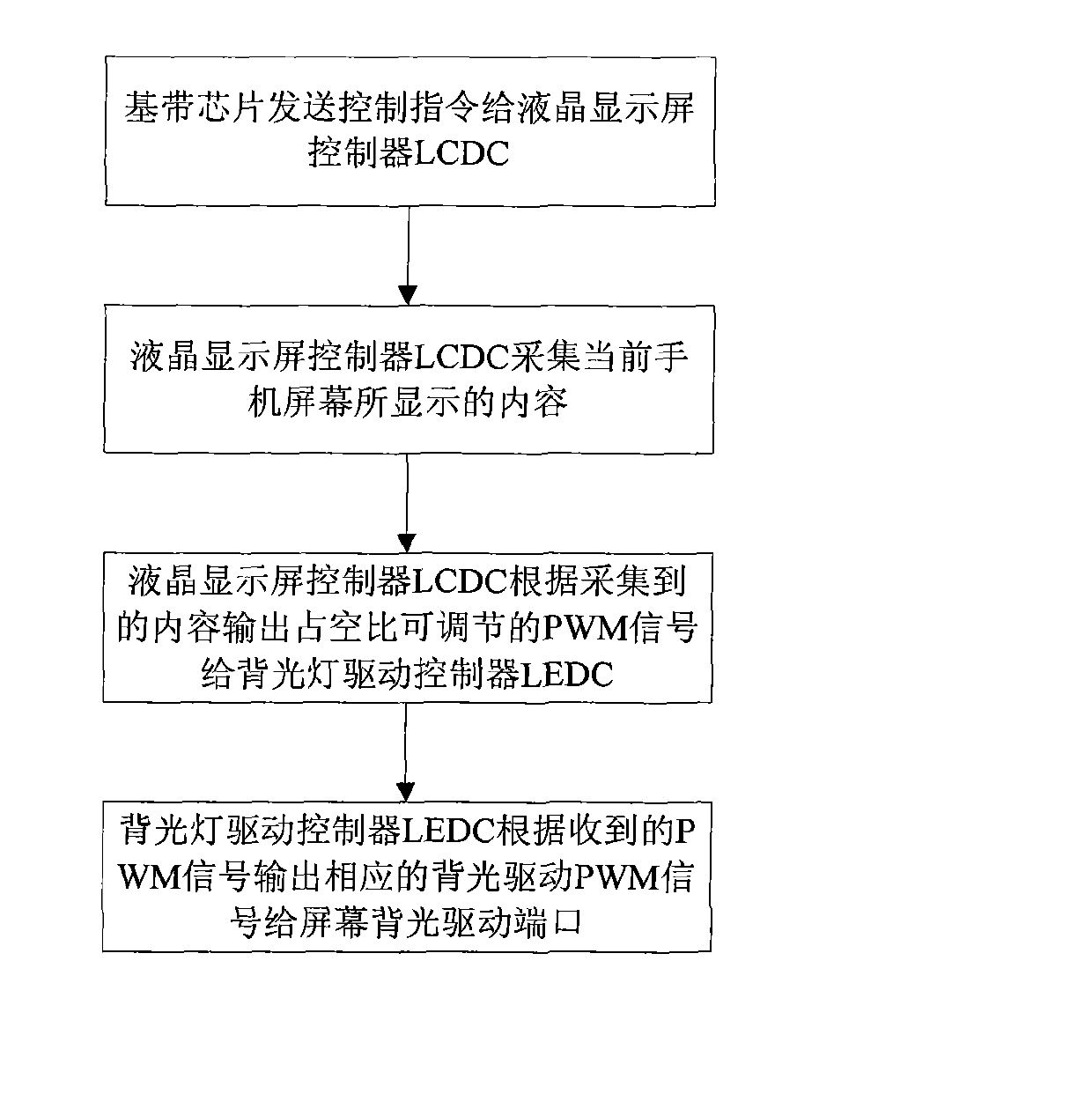

Method for dynamically controlling backlight according to contents of mobile phone screen

InactiveCN102088500ADisplays bright and vibrant colorsReduce current consumptionStatic indicating devicesTelephone set constructionsEmbedded systemLiquid-crystal display

The present invention relates to a method for dynamically controlling a backlight according to contents of a mobile phone screen, the method comprises the steps as follows: A. a baseband chip sends a control instruction to a LCDC (Liquid Crystal Display Controller); B. the LCDC acquires the contents displayed by the mobile phone screen at present; C. the LCDC outputs a PWM (Pulse-Width Modulation) signal with an adjustable duty ratio to a LEDC (Light Emitting Driving Controller) according to the contents acquired; and D. the LEDC outputs a corresponding backlight driving PWM signal to a screen backlight driving port according to the PWM signal received. Compared with the prior art, the method in the present invention can dynamically control the backlight according to the different contents displayed by the screen without any extraneous interference, so that current consumption of the backlight is reduced, color of the screen display is bright and brilliant, and users can feel comfortable when watching the screen of the mobile phone.

Owner:SHANGHAI SIMCOM LTD

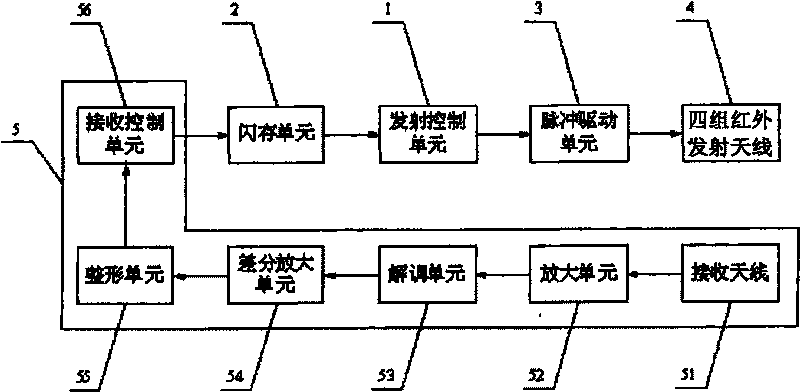

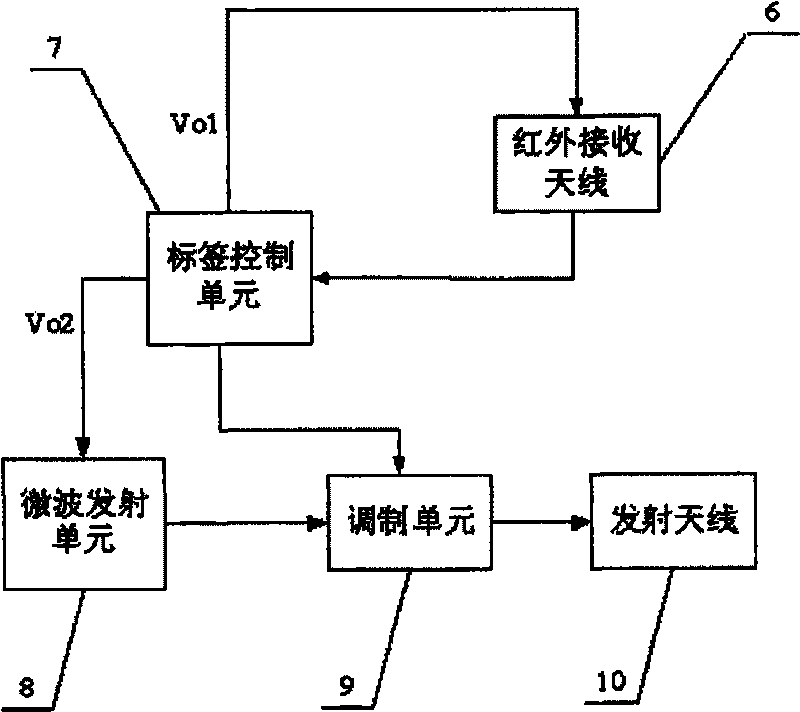

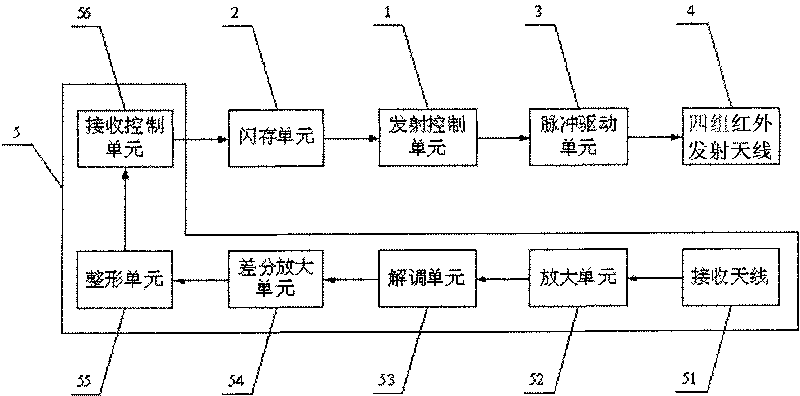

Electronic tag infrared positioning system

InactiveCN101714207AExtended service lifeFree from outside interferenceRecord carriers used with machinesSensing by electromagnetic radiationEngineeringApplication areas

The invention relates to an electronic tag infrared positioning system, and belongs to the field of RFID technical application. The electronic tag infrared positioning system solves the problems that the conventional infrared positioning technology is influenced by external environment greatly, tag signals received by a reader-writer are not unique and a battery and a high-power infrared pipe are short in service life. A flash memory unit of the reader-writer is connected with a transmitting control unit which is connected with a pulse driving unit; the pulse driving unit is connected with an infrared transmitting antenna; a microwave receiving and demodulating unit is connected with a reader-writer control unit; an infrared receiving antenna of an electronic tag is connected with a tag control unit; two control ends of the tag control unit are respectively connected with the infrared receiving antenna and a microwave transmitting unit; the microwave transmitting unit is connected with a modulation unit; the modulation unit is connected with the tag control unit; and the modulation unit is connected with the transmitting antenna. The infrared positioning technology of the invention is not interfered by the external environment, the service life of the battery and the infrared pipe are prolonged, and simultaneously, the infrared positioning technology can provide the unique signal for the tag received by the reader-writer.

Owner:周必友

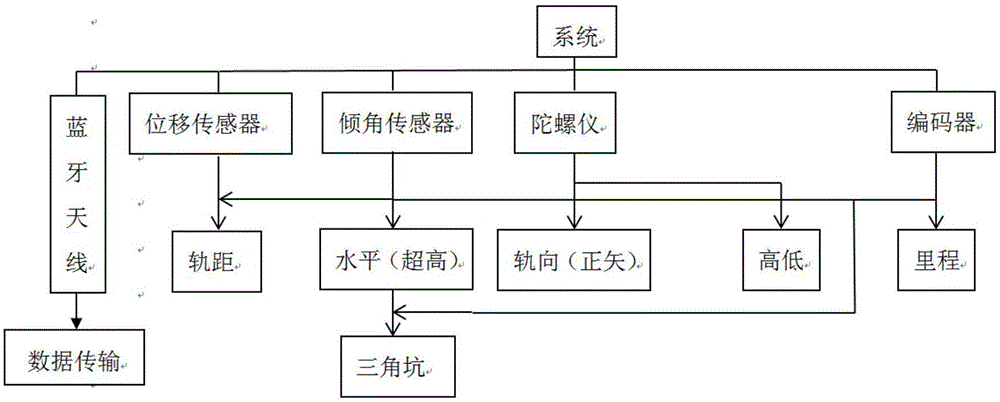

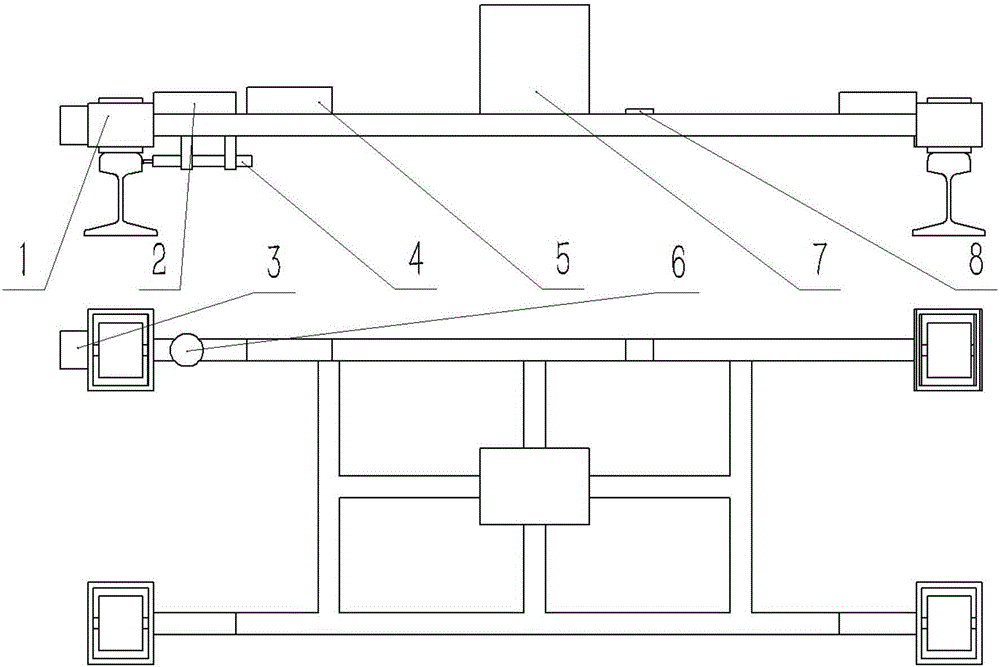

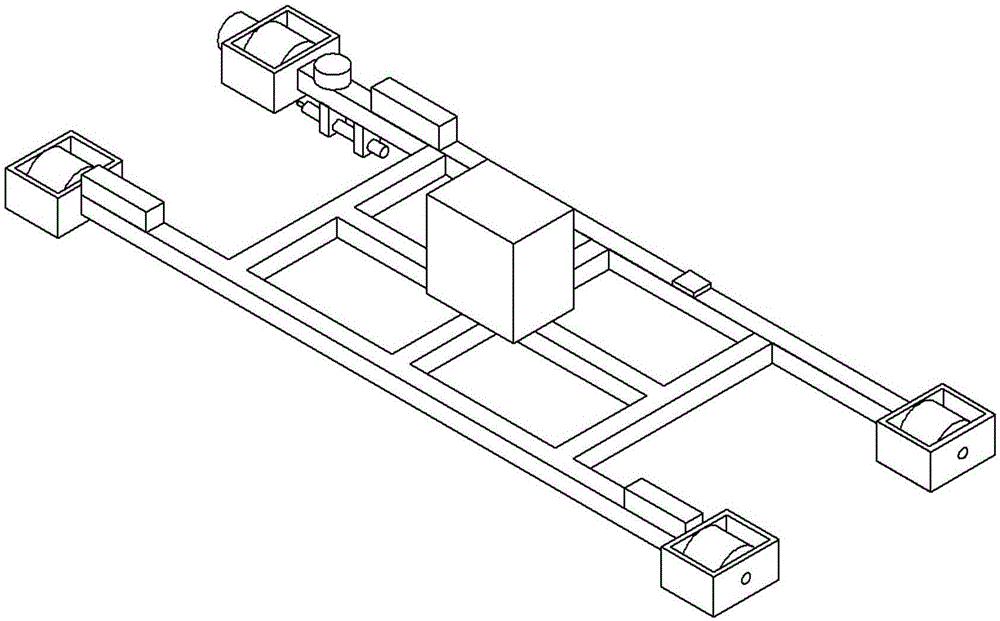

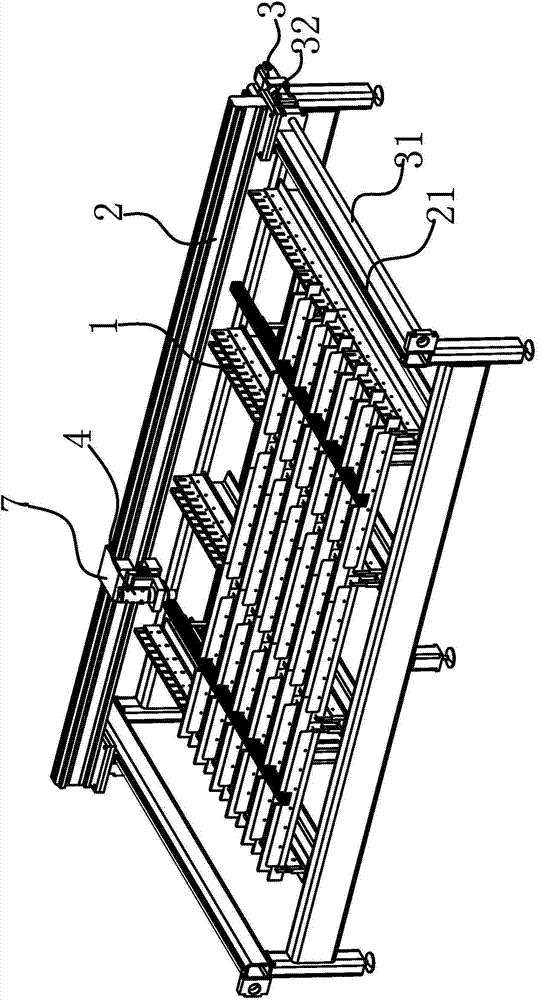

Track detection device and method

ActiveCN106274981AReduce labor intensitySolve the detection speed is slowTransmission systemsRailway auxillary equipmentIn vehicleEngineering

The invention discloses a track detection device. The track detection device comprises a vehicle body, encoders, displacement sensors, tilt angle sensors I and tilt angle sensors II, wherein the vehicle body comprises two cross beams perpendicular to the track direction and a rack which is arranged between the two cross beams and is of a grid framework structure; the encoders are arranged at the tail of at least one end of at least one cross beam and used for measuring the traveling distance in vehicle body detection; the displacement sensors are arranged on the tip of at least one end of at least one cross beam, arranged on the lower surfaces of the ends of the cross beams and used for measuring a track gauge change component in the traveling process of the vehicle body; the tilt angle sensors I are arranged on at least one cross beam, located on the upper surfaces of the ends of the cross beams and used for measuring the vehicle body tilt angle change in the traveling process, and thus a vehicle body level value can be calculated; and the tilt angle sensors II are arranged on at least one cross beam, located on the upper surfaces of the ends of the cross beams and used for measuring angle changes of the course angle and the rolling angle in the traveling process of the vehicle body, and thus the track direction and height value can be calculated according to the principles of attitude measurement and control and trajectory measurement.

Owner:XIANGYANG HONGWEI AIRCRAFT

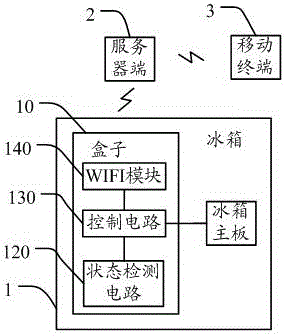

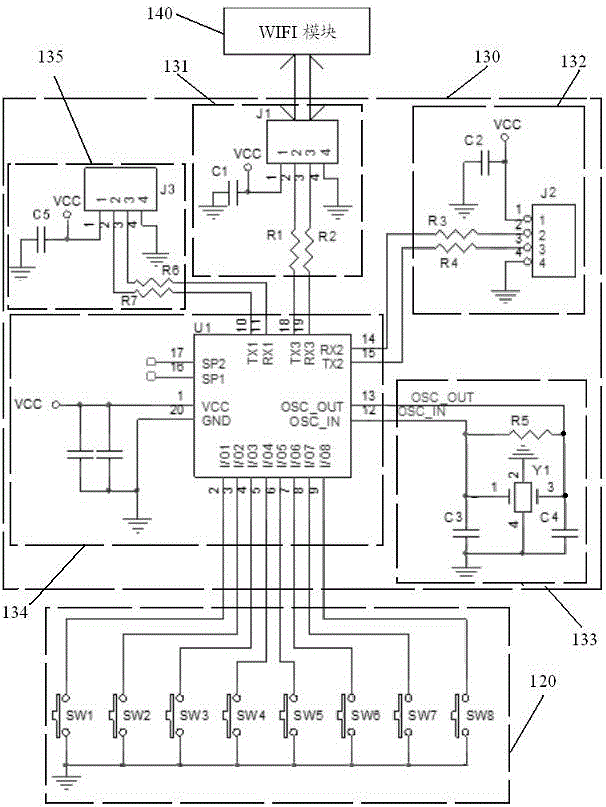

Food management device and method and refrigerator

ActiveCN105043001AImprove practicalityLow costLighting and heating apparatusSupportFood managementEngineering

The invention discloses a food management device and method and a refrigerator. The food management device comprises an attachment piece and a box. The attachment piece is placed in the refrigerator together with food while the food is placed in the refrigerator, and the attachment piece is taken out together with the food while the food is taken out of the refrigerator to be placed in the box. The box detects the take-out and place-back state information of the attachment piece when a refrigerator door is closed and sends the obtained take-out and place-back state information to a server or the refrigerator. The take-out and place-back state of the attachment piece can be accurately recognized. Outside interference is avoided, practicability is higher, and the cost is lower.

Owner:TCL CORPORATION

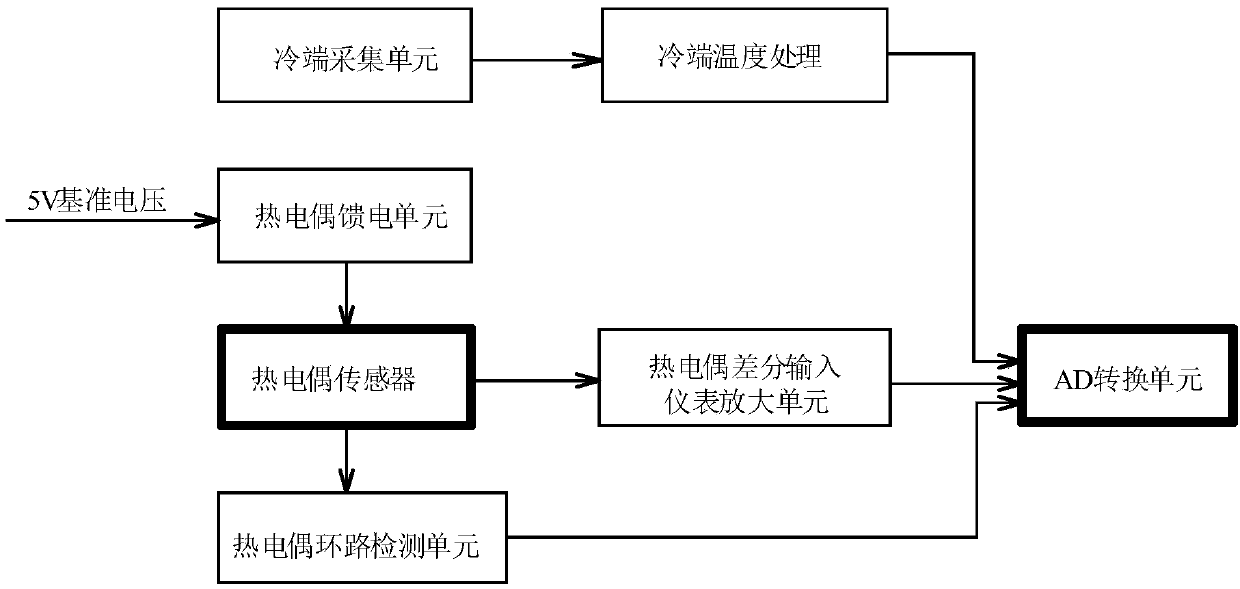

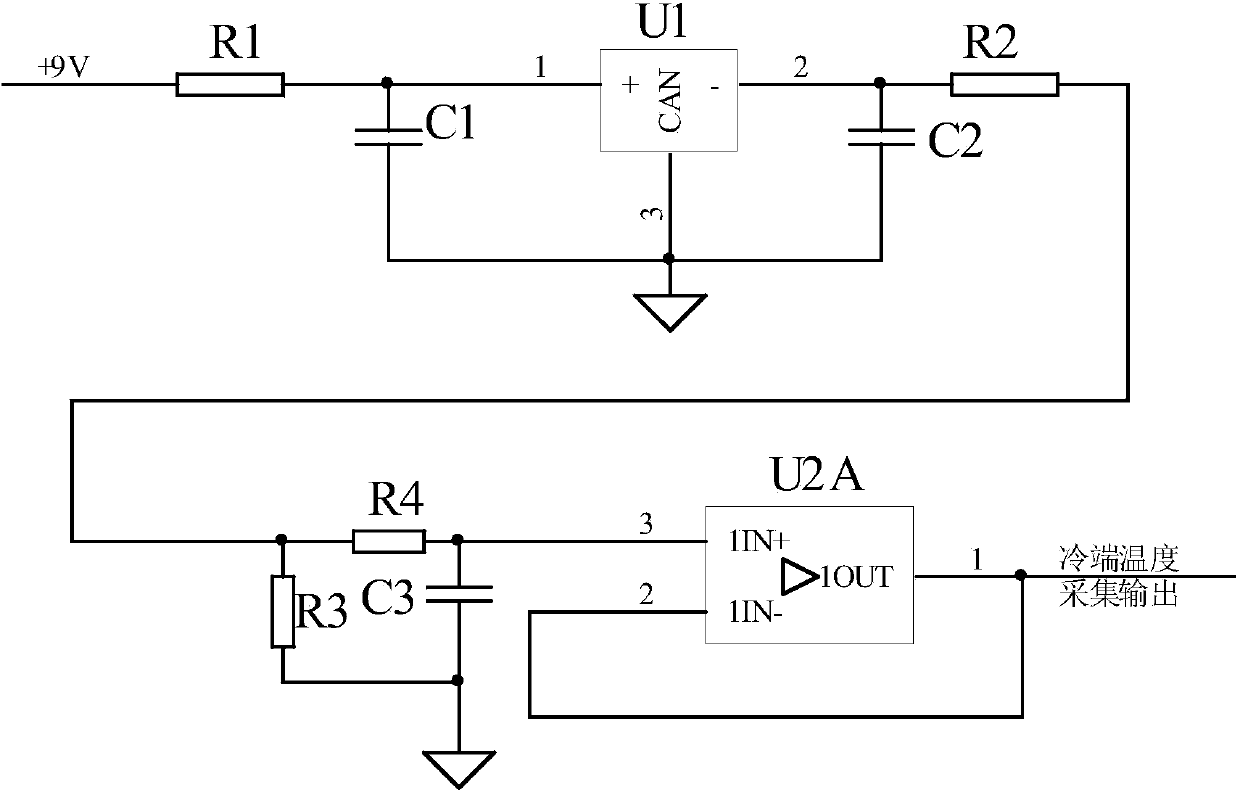

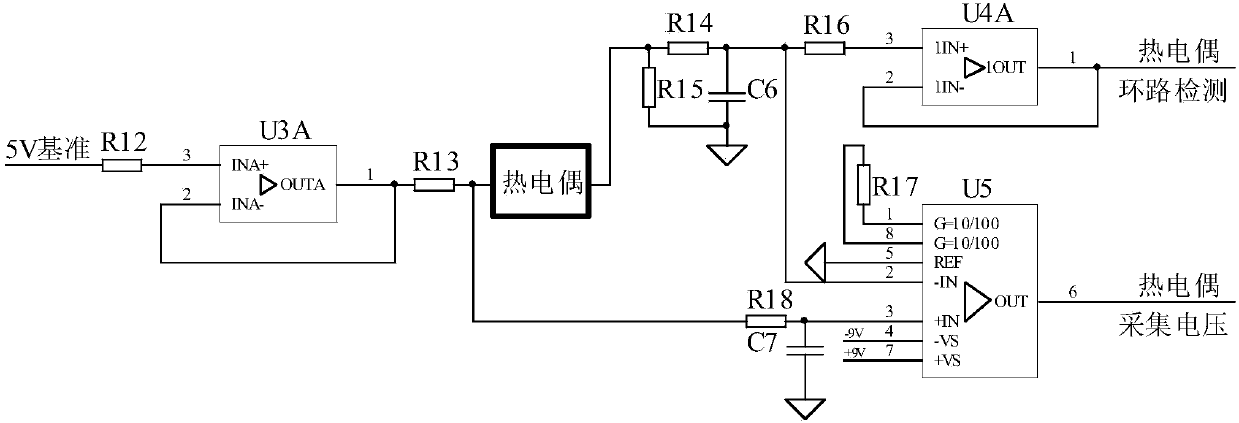

Engine exhaust temperature thermocouple detection circuit

InactiveCN104006902AImprove securitySmall rippleThermometer testing/calibrationTemperature measurement of flowing materialsElectricityEngineering

The invention provides an engine exhaust temperature thermocouple detection circuit, and relates to an engine exhaust temperature detection circuit which is high in test reliability and small in feed circuit ripple. The engine exhaust temperature thermocouple detection circuit is implemented through the following technical scheme, a thermocouple differential input instrument amplification unit and a thermocouple loop detection unit are electrically connected with an AD conversion unit through the positive end and the negative end of a thermocouple sensor to form a thermocouple loop detection circuit, and the output voltage of a thermocouple cold-end collection unit is fed into the AD conversion unit through a cold-end temperature processing unit and calculated through a CPU so that the cold-end temperature can be obtained. A thermocouple feed unit divides the reference voltage into two paths through an external T45 temperature sensor, and the thermocouple sensor negative-end voltage is fed to the AD conversion unit by one path of the reference voltage through the thermocouple loop detection unit; the other path of the reference voltage is input into the thermocouple differential input instrument amplification unit through feeding of the thermocouple sensor, and after a voltage difference signal is differentially amplified, the differentially amplified voltage difference signal is collected by an AD converter, and is fed into the CPU so that a thermocouple fault can be judged.

Owner:SICHUAN YAMEI POWER TECH

Porous composite aerogel material as well as preparation method and application thereof

The invention discloses a preparation method and application of a porous composite aerogel material. The method comprises the following steps of: prefabricating reinforcement, placing the reinforcement in a reaction container, sealing and vacuumizing, sucking prefabricated sodium silicate liquor until the reinforcement is submerged; pumping an acidic gas in, heating up, then standing to form a wet gel reinforcement composite; pumping in surfactant aqueous liquor for immersion reaction, rotating the wet gel reinforcement composite so that liquid liquor in the composite is thrown out; stopping rotation, pumping in mixed liquor of an organic solvent and the surfactant, discharging overflowed liquor after reaction; heating up, evaporating the organic solvent, carrying out vacuum treatment, and releasing pressure to obtain the porous composite aerogel material. The preparation method related in the invention can be used for obtaining the porous composite aerogel material which has the advantages of low heat conduction efficiency, good hydrophobic performance and high hydrophobic performance and low cost and is simple to operate.

Owner:GUANGDONG ALISON HI TECH

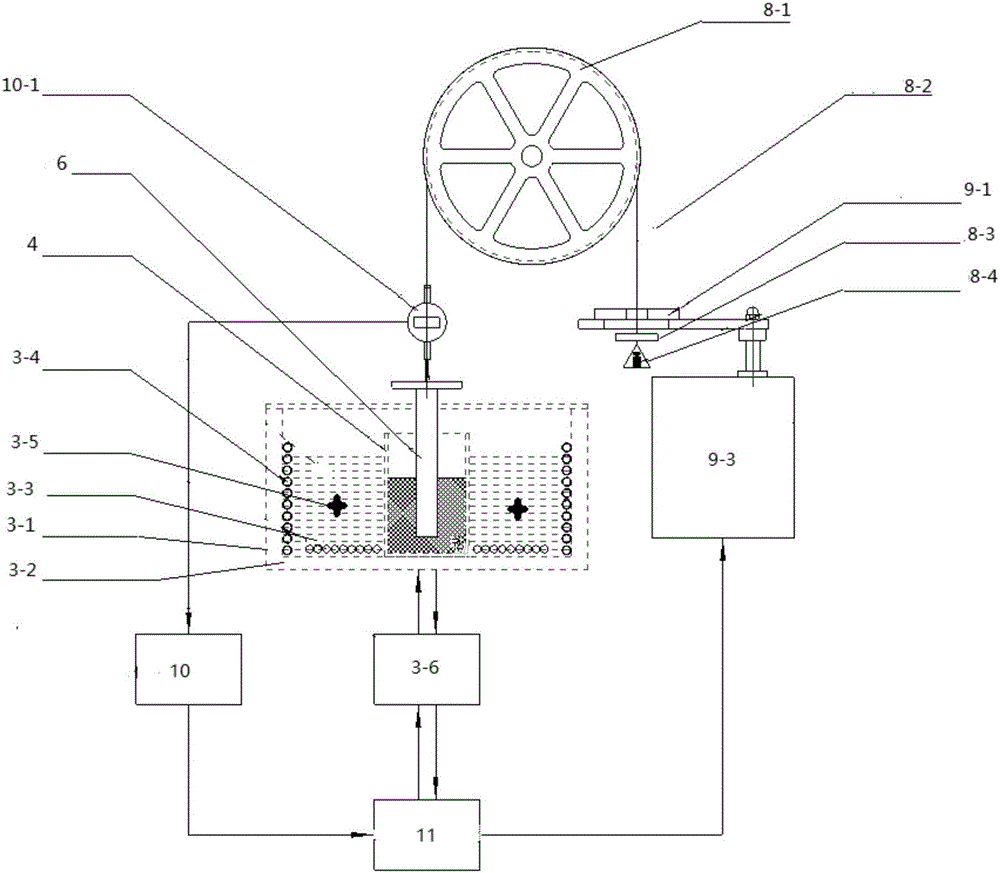

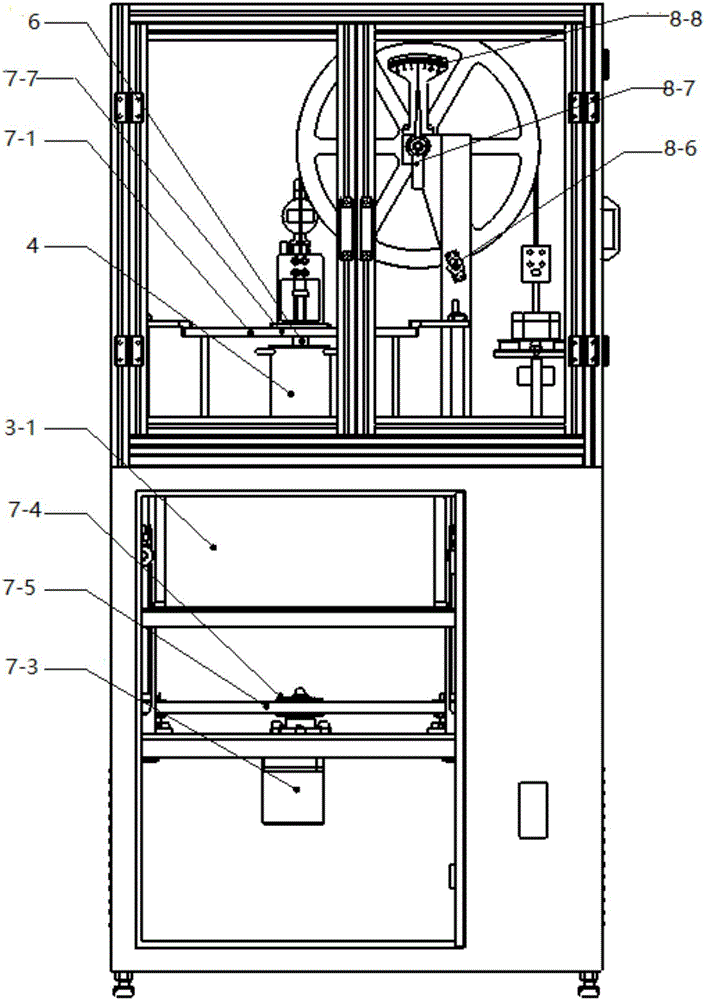

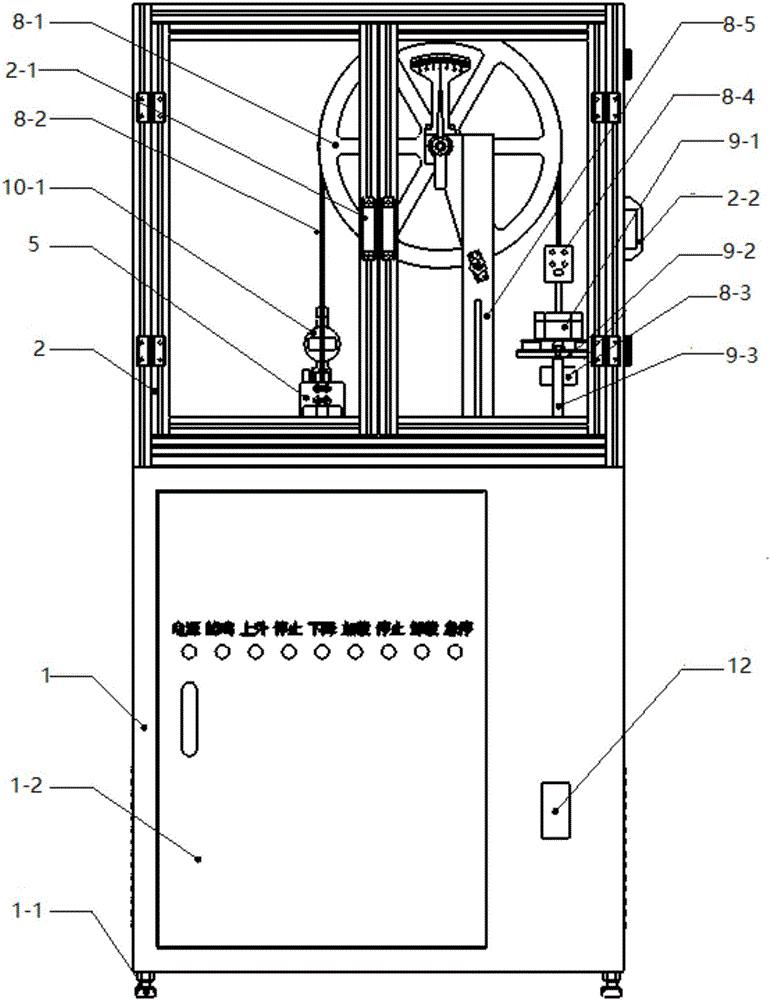

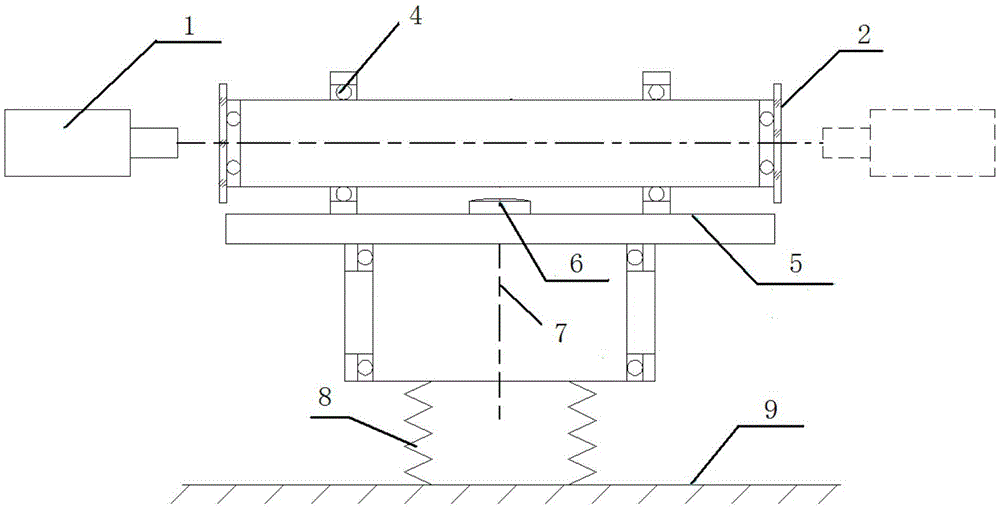

Rheological measurement equipment for materials and using method thereof

ActiveCN106596333AFree from outside interferenceAccurate dataFlow propertiesMaterial strength using tensile/compressive forcesTemperature controlMeasurement device

The invention belongs to the research field of liquid-state and semi-solid state materials rheological features and provides rheological measurement equipment for materials and a using method thereof. In the prior art, when the rheological features of materials are measured, a spring scale is manually pulled upwards for loading, and loading intensity, loading temperature and displacement collecting stability is quite poor. The rheological measurement equipment comprises a temperature-control oil bath device, a weight automatic loading device, a balance device, a displacement measurement device, a sample holder lifting device, a slice clamp, a slice, a sample box, a machine frame and a protective cover, wherein the temperature-control oil bath device, the sample holder lifting device, the balance device, the weight automatic loading device and the protective cover are installed on the machine frame, the displacement measurement device and the sample box are installed on the sample holder lifting device, the slice clamp is connected to the balance device, and the slice is installed on the slice clamp. By the adoption of the rheological measurement equipment, during measurement, loading intensity, loading temperature and displacement collecting are kept well stable.

Owner:MTS IND SYST CHINA

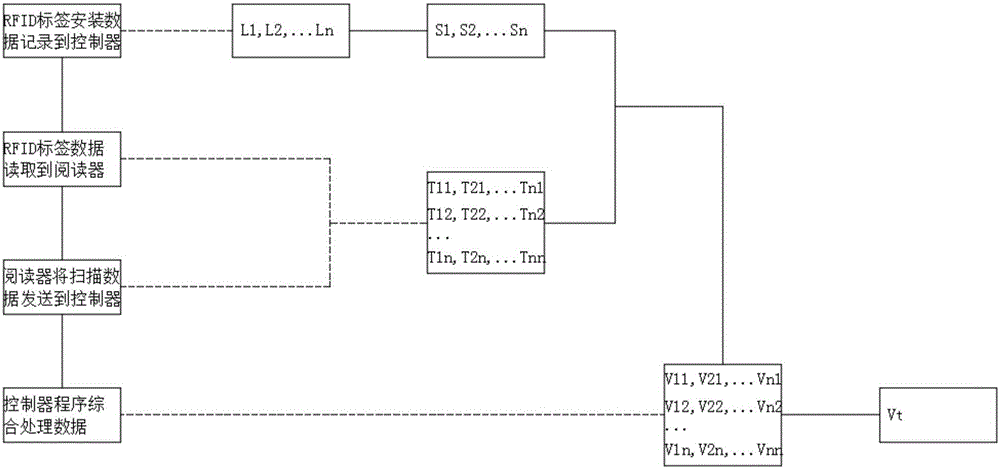

Belt conveyor speed detecting system based on radio-frequency identification

InactiveCN105775664ALabel scanning is fast and accurateFree from outside interferenceConveyorsControl devices for conveyorsEngineeringRadio frequency

The invention discloses a belt conveyor speed detecting system based on radio-frequency identification. The belt conveyor speed detecting system comprises two or more radio-frequency identifying labels, a belt, two or more readers and a controller; the radio-frequency identifying labels are embedded on the belt; the belt moves along with a drum; the distance between every two readers is fixed; the readers identify the radio-frequency identifying labels, and send signals to the controller; and the controller calculates the operation speed of a belt conveyor according to identified label signals. The belt conveyor speed detecting system has the multiple beneficial effects of: fast label scanning speed; capability of penetrating through dust to read under bad field environments without being interfered by external; incapability of causing such mechanical damage as collision and wear under strong vibration environment; and incapability of influencing the label characteristics and the monitoring accuracy.

Owner:INSTALLATION ENG CO LTD OF CCCC FIRST HARBOR ENG

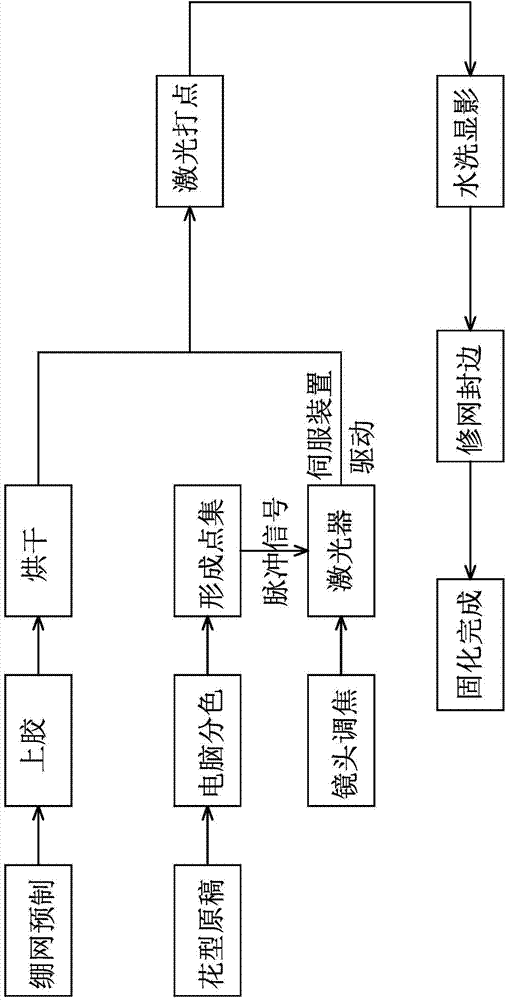

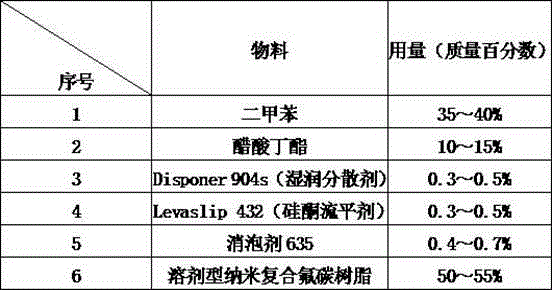

Screen making method of digital printing imitating flat screen

The invention relates to a screen making method of a digital printing imitating flat screen, and belongs to the technical of laser screen making, aiming at solving the problem of poor precision of laser screen making in the prior art. The screen making method of the digital printing imitating flat screen comprises the following steps: (1) carrying out color separating by virtue of a computer; (2) converting an image formed by color separating into a pixelated dot matrix set, wherein the dot matrix set is formed by combining a plurality of strip-shaped dot matrix sets which are fixed in width; (3) converting the processed dot matrix set image into a pulse signal, and conveying the pulse signal to a driver, wherein the driver can drive the opening and closing of a laser solid matter in a laser device; (4) stretching and prefabricating, and regulating the lens focus length of the laser so as to focus laser light on the flat screen; (5) starting a servo device on the stand, and driving the laser device to carry out laser dotting according to a preset dot set position; (6) developing and washing the flat screen obtained from laser screen making; and (7) trimming and banding the screen, and completing curing. The screen making method of the digital printing imitating flat screen disclosed by the invention has the advantages of high precision and high definition.

Owner:绍兴光线数码科技有限公司

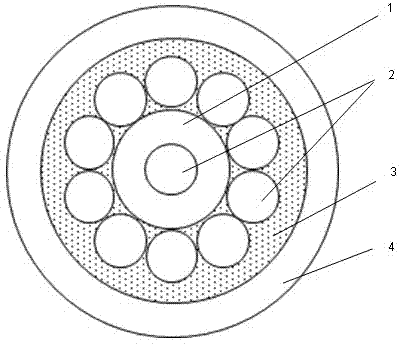

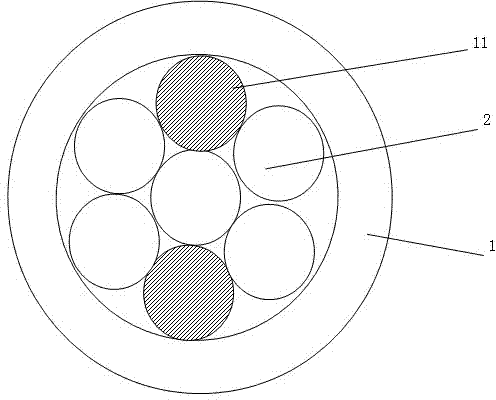

Optical fiber unit with communication and sensing functions and manufacturing method thereof

ActiveCN103487878AMaintain sensitivityFree from outside interferenceCladded optical fibreOptical waveguide light guideFiberLow speed

The invention discloses an optical fiber unit with communication and sensing functions. The optical fiber unit comprises a tightly-wrapped optical fiber sensing unit, a plurality of precoated optical fibers and an optical fiber unit protective tube arranged on the outer portion in a loose mode, wherein the precoated fibers are reversely twisted on the tightly-wrapped optical fiber sensing unit and used for communication. The invention further discloses a manufacturing method of the optical fiber unit with the communication and sensing functions. The tightly-wrapped optical fiber sensing unit passes through a center hole of a wire distribution rotating disk driven by a reversible low speed motor, the precoated optical fibers penetrate through distributing holes in the wire distribution rotating disk to wind on the tightly-wrapped optical sensing unit to form optical fiber bundles, the optical fiber bundles are led into an optical fiber convergence device, an optical twisting device and optical fiber unit protective tube forming equipment are started, and the precoated optical fibers are twisted on the tightly-wrapped optical fiber sensing unit at a certain angle and in periodic reversing. The optical fiber unit enables communication transmission to be free of external interference while sensing sensitivities on the changes of external physical fields are also maintained, and the same optical fiber unit acquires the sensing and communication functions.

Owner:JIANGSU TONGGUANG OPTICAL FIBER CABLE CO LTD

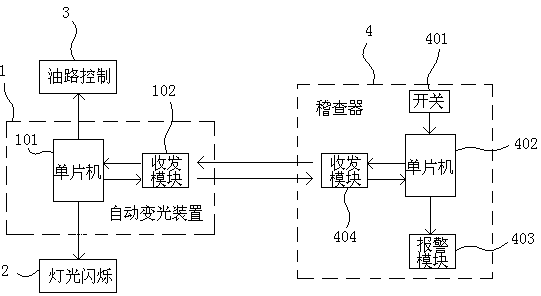

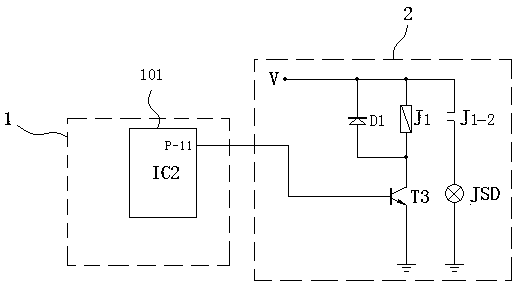

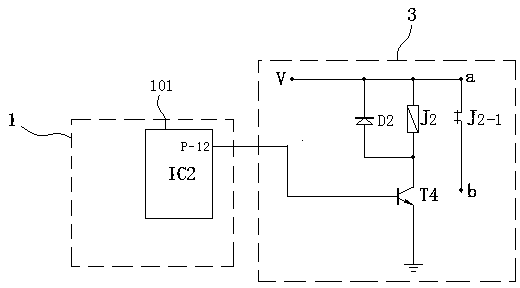

Intelligent light-alternating inspection system of motor vehicle

ActiveCN103640516AFree from outside interferenceEasy to useRoad vehicles traffic controlOptical signallingMicrocontrollerMicrocomputer

The invention discloses an intelligent light-alternating inspection system of a motor vehicle. The intelligent light-alternating inspection system comprises an automatic light-alternating device and an inspection device, wherein the automatic light-alternating device comprises a first single-chip microcomputer circuit, as well as a first transceiver module, a lamplight flashing circuit and an oil line control circuit which are connected with the first single-chip microcomputer circuit, and the oil line control circuit is connected with an oil pump control circuit of the motor vehicle; the inspection device comprises a second single-chip microcomputer circuit as well as a switching circuit, a second transceiver module and an alarming module which are connected with the second single-chip microcomputer circuit; and the inspection device is wirelessly connected with the first transceiver module of the automatic light-alternating device through the second transceiver module. The system has the advantages of rejection of outside interference, convenience in use, multiple functions, accurate inspection recognition, high efficiency and the like.

Owner:长沙硕铠电子科技有限公司

Closed gas stove

InactiveCN105091040AImprove efficiencyConducive to intelligenceDomestic stoves or rangesLighting and heating apparatusProcess engineeringCombustion chamber

A closed gas stove comprises a burner, a stove face, a stove shell, a heat conductor, a combustor, a flue gas channel and the like, wherein the burner and the combustor are arranged in a hearth; the combustor is of a semi-closed or fully-closed structure; and the gas stove is provided with the heat conductor composed of heat conductive blocks and fins, the heat conductive blocks are exposed and are connected with or make contact with the fins, and the fins are used for enhancing the flame or flue gas heat energy absorbing or transferring capacity of the heat conductive blocks. The closed gas stove has the beneficial effects that the heat efficiency is higher than that of a common gas stove, appearance is more elegant, and dirt is avoided.

Owner:彭萍芳

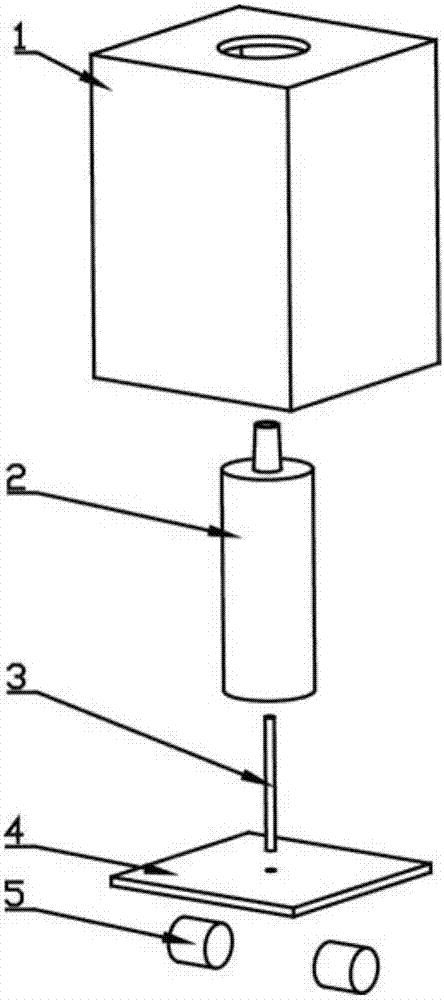

In-situ light curing extrusion nozzle

InactiveCN107127971AExpanded size rangeImprove printing accuracy3D object support structuresApplying layer meansLiquid stateUltraviolet lights

The invention discloses an in-situ light curing extrusion nozzle. The in-situ light curing extrusion nozzle comprises a shell, a liquid chamber, a transparent / semitransparent slim tube, a light source and a light shading plate, wherein the liquid chamber, the transparent / semitransparent slim tube, the light source and the light shading plate are arranged in the shell. The transparent / semitransparent slim tube communicates with the liquid chamber. The light source perpendicularly irradiates on the transparent / semitransparent slim tube, and is arranged in the circumferential direction of the transparent / semitransparent slim tube and used for perpendicularly irradiating on the transparent / semitransparent slim tube. The light shading plate is arranged between the light source and the liquid chamber. When the in-situ light curing extrusion nozzle works, the liquid chamber is internally provided with a liquid light curing material, and the liquid light curing material passes the transparent / semitransparent slim tube and is cured to form a solid filament to be extruded after being irradiated by ultraviolet light emitted from the light source. In-situ light curing refers to that light curing reaction is conducted in the nozzle, thus, the liquid light curing material can be input, and the solid filament can be directly printed out. The size range of the printed filament is greatly expanded through the transparent / semitransparent slim tube with the set size, and the size precision of the extruded filament is ensured.

Owner:XI AN JIAOTONG UNIV

Independent negative-pressure exhaust gas dust removal device

InactiveCN111992563AConstant wind speedAvoid wastingDirt cleaningDust controlEnvironmental engineering

The invention discloses an independent negative-pressure exhaust gas dust removal device, and relates to the technical field of indoor exhaust gas dust removal. The device comprises an equipment body,a supporting steel frame, a plurality of dust baffles arranged on the side wall of the supporting steel frame and a sealing door arranged on the side wall of one dust baffle in a sliding mode. An access hole is formed in the side wall, located on the sealing door, of the corresponding dust baffle. Connecting assemblies which are used for fixing the dust baffles are arranged the supporting steel frame, the supporting steel frame and the multiple dust baffles are combined to form a dust cover which is used for covering the equipment body, and a dust pumping mechanism which is used for pumping out dust and the harmful gas inside the dust cover is arranged on the dust cover. According to the independent negative-pressure exhaust gas dust removal device, the nearby region of the equipment bodyis defined to form an independent space, and therefore the dust and the harmful gas generated by the equipment body can be independently pumped, the energy is effectively saved, and the dust removalefficiency is high.

Owner:天津市卫印印刷有限责任公司

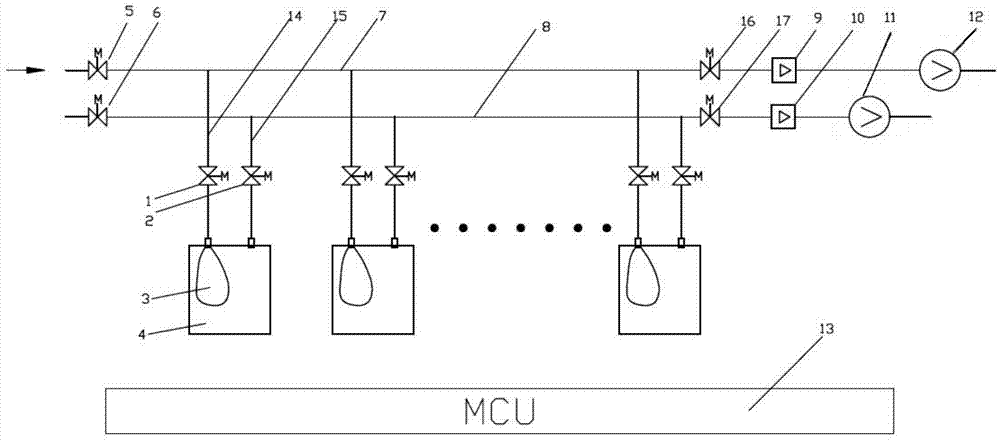

Non-contact type full-automatic gas sample retention device

ActiveCN104764632AImprove accuracyIncrease productivityWithdrawing sample devicesControl engineeringAir pump

The invention discloses a non-contact type full-automatic gas sample retention device. The non-contact type full-automatic gas sample retention device comprises a sampling pipe which is sequentially provided with a sample gas valve, an evacuation flowmeter and an air pumping pump, wherein a plurality of gas bags are connected to the sampling pipe between the sample gas valve and the evacuation flowmeter via sample gas branch pipes, and a communicating valve is arranged on each sample gas branch pipe; the non-contact type full-automatic gas sample retention device further comprises an air pipeline which is sequentially provided with an air valve, a sampling flowmeter and a sampling gas pump, a plurality of vacuum boxes which are in one-to-one correspondence with the gas bags are connected to the air pipeline between the air valve and the sampling flowmeter via evacuation branch pipes, each gas bag is hermetically arranged in the corresponding vacuum box, and a bleeder valve is arranged on each evacuation branch pipe; and the non-contact type full-automatic gas sample retention device further comprises a controller which is electrically connected with the various flowmeters, the valves and the gas pumps. The device can be used for not only realizing automatic precise sample retention of gas, improving the production efficiency and saving the labor cost, but also isolating artificial contact by the design of the non-contact type gas bags, facilitating the installation of a gas heating device and simultaneously improving the production safety; and furthermore, the device can ensure that gas has no pollution and no loss during the whole process.

Owner:苏州聚阳环保科技股份有限公司

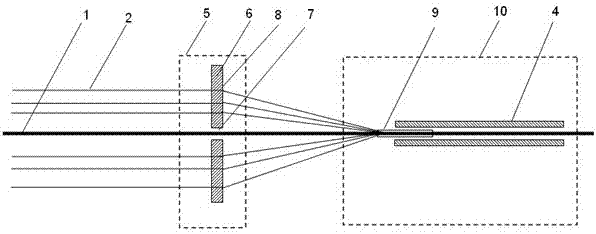

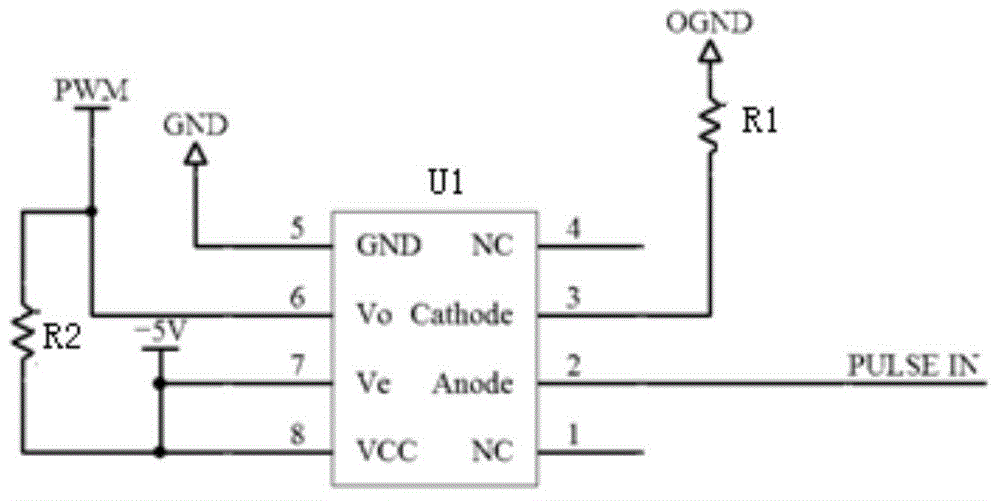

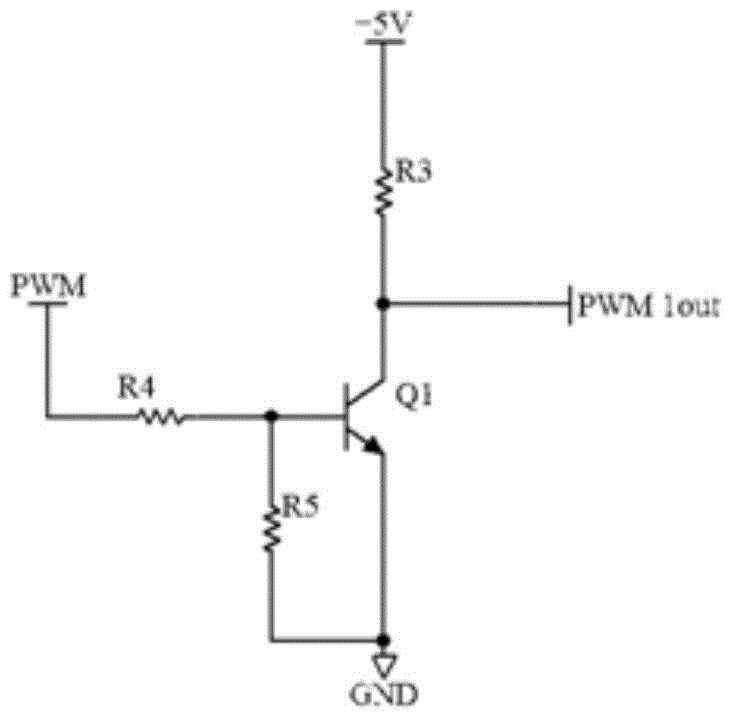

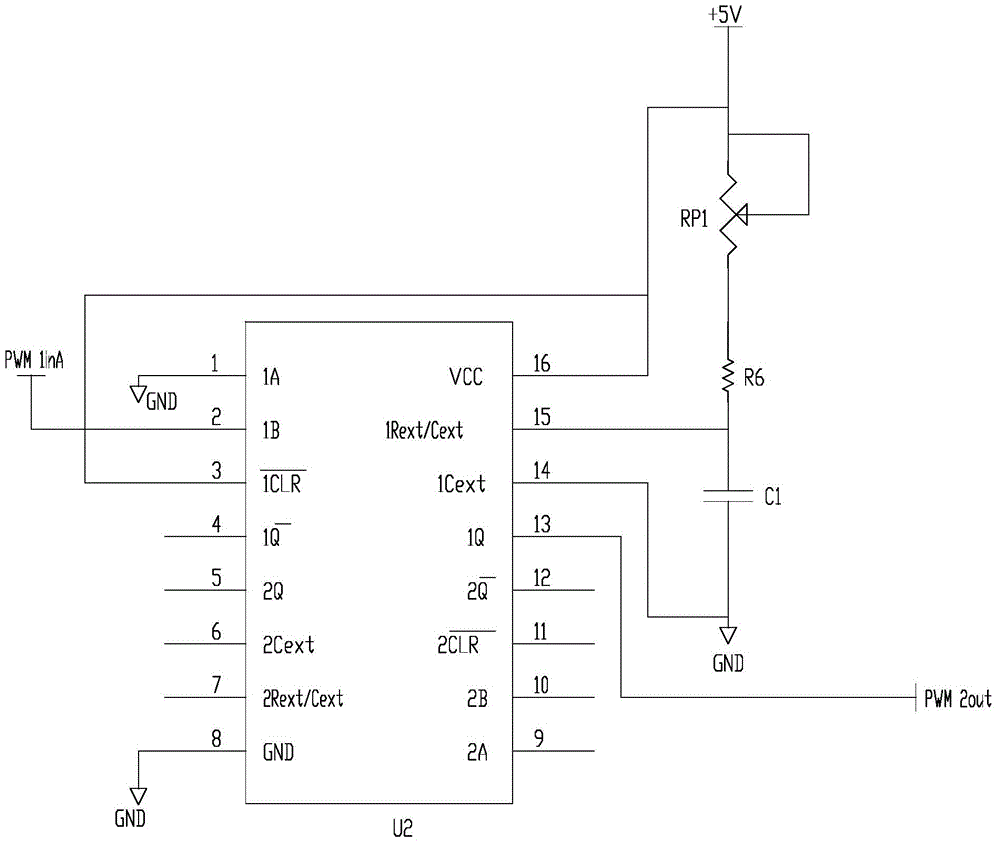

Pulse modulation drive circuit of semiconductor laser unit

ActiveCN103986060AImprove general performanceSimple structureLaser detailsSemiconductor lasersNanosecondAmpere

The invention discloses a pulse modulation drive circuit of a semiconductor laser unit. The pulse modulation drive circuit of the semiconductor laser unit comprises an isolation input circuit, a phase inverter circuit, a pulse width limiting circuit, a pulse signal amplification circuit, a pulse current control circuit and a laser unit interface matching circuit. The pulse modulation drive circuit of the semiconductor laser unit has the advantages that the universality is high, the structure is simple, and performance is reliable; pulse response is fast, and the nanosecond response speed requirement is met; the pulse output power is large, and the maximum output pulse current can reach up to ten amperes; the anti-interference capacity is high, external disturbance is avoided in practical application, and the electromagnetic radiation environment of the system cannot be affected.

Owner:WUXI LUMISOURCE TECH

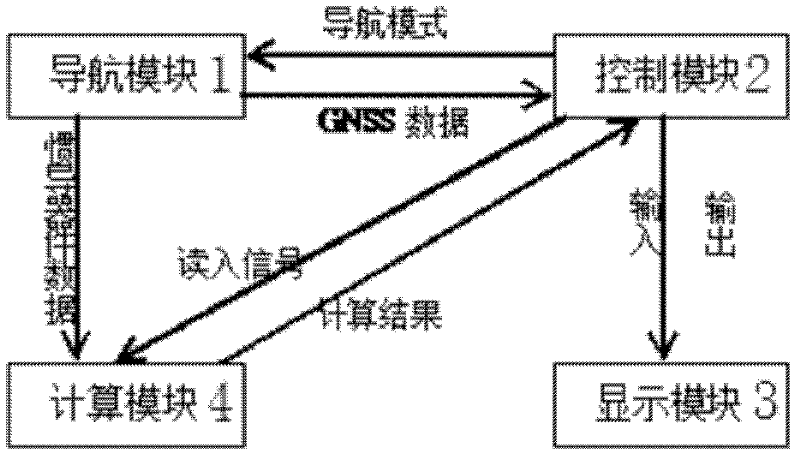

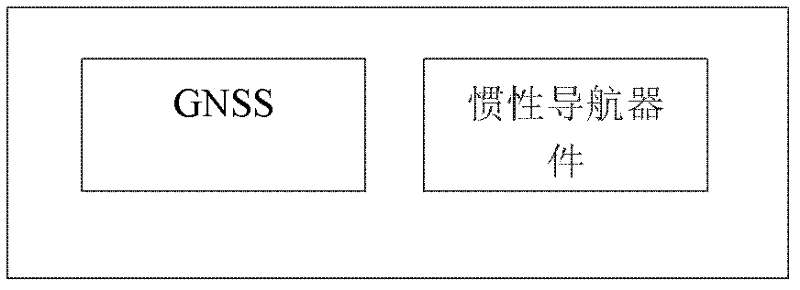

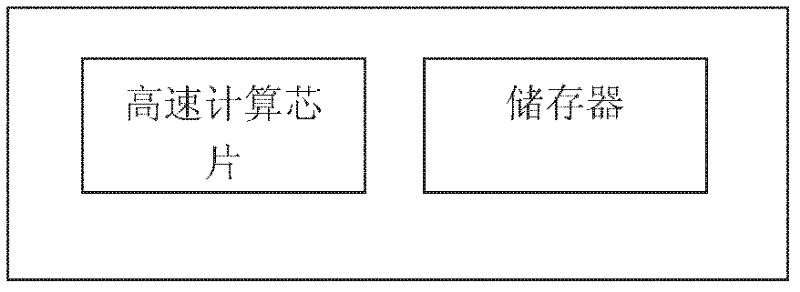

Energy optimization navigation unit based on combined navigation

InactiveCN102645667AEliminate cumulative errorsControl cumulative errorSatellite radio beaconingInterference resistanceMarine navigation

The invention discloses an energy optimization navigation unit based on combined navigation, which comprises a navigation module, a computation module, a control module and a display module. The navigation module, the computation module and the display module are connected with the control module, and the navigation module is further connected with the computation module. The energy optimization navigation unit is a handheld energy optimization GNSS (global navigation satellite system) receiver based on an inertial navigation device, and the handheld energy optimization GNSS receiver integrates advantages, including high precision, low power consumption, high independency and external interference resistance, of the inertial navigation device and a common GNSS receiver. On the premise of guaranteeing the navigation precision and sensitivity, the power consumption can be reduced to be 21% of the original power consumption. In addition, compared with the pure inertial navigation device, the energy optimization navigation unit can effectively control accumulated errors on the premise of keeping low power consumption and low dependency on external environments.

Owner:SHANGHAI JIAO TONG UNIV

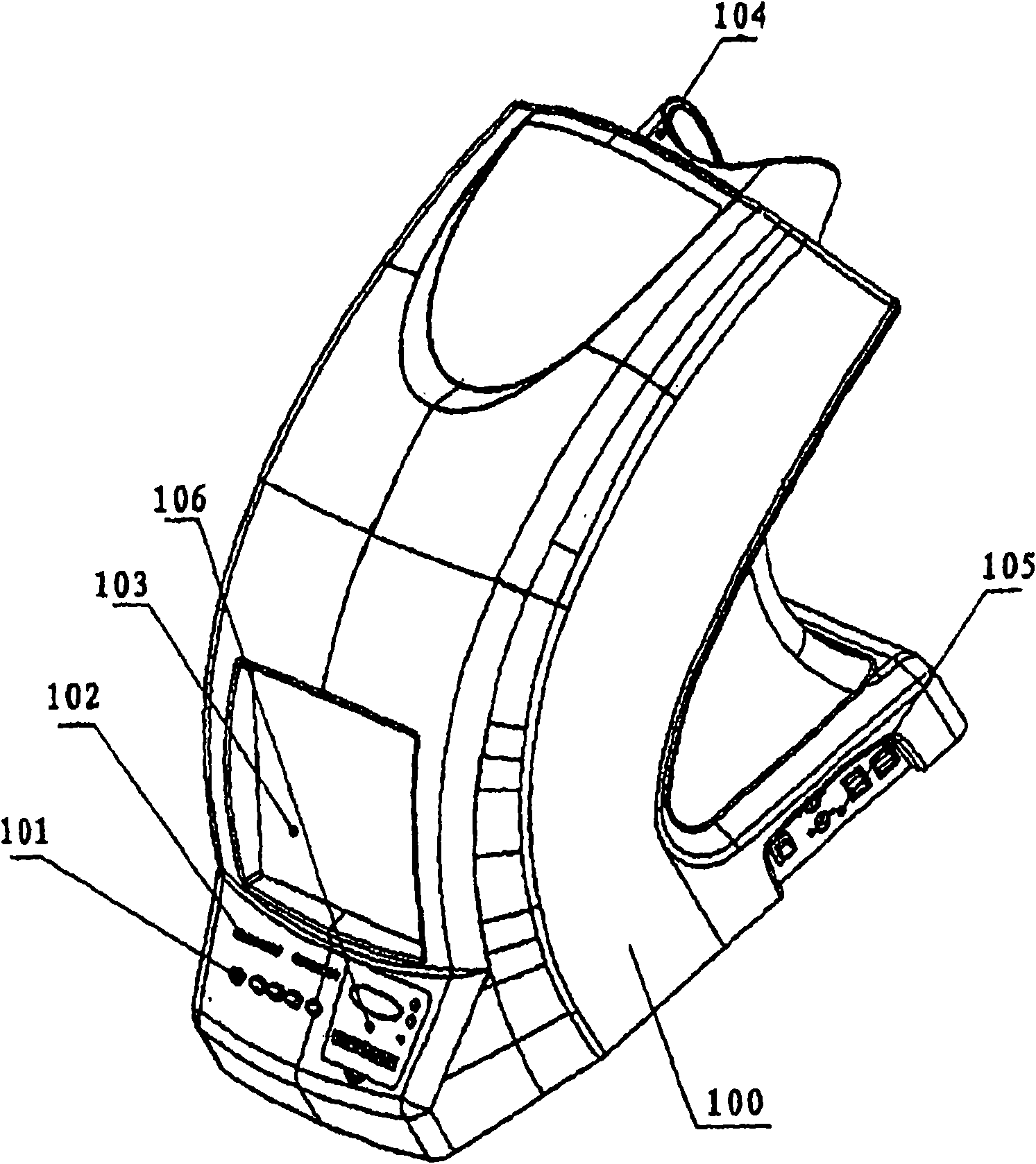

Flaw detection device of buffer spring

ActiveCN103018322AGuaranteed to work properlyFree from outside interferenceMaterial magnetic variablesEngineeringUltimate tensile strength

The invention discloses a flaw detection device of a buffer spring. The flaw detection device of the buffer spring comprises a fixing seat, a rotary support, a roller, a connecting shaft and a rotary motor, wherein support seats are arranged at two ends of the fixing seat; transversely arranged fixing plates are arranged on the support seats; a piston of a first cylinder on each fixing plate is connected with a movable plate; a clamping electrode plate is arranged at one end of the movable plate; circumferential magnetic threading bars inserted into the buffer spring are arranged near the movable plate; the circumferential magnetic threading bars are oppositely arranged and respectively insulated with the movable plate and the clamping electrode plate; the clamping electrode plate and the two circumferential magnetic threading bars are connected with two poles of an external power supply; a convex arc surface is arranged at the end part of one circumferential magnetic threading bar; and a concave arc surface is arranged at the end corresponding to the other circumferential magnetic threading bar, and the convex arc surface is matched with the concave arc surface. By adopting the flaw detection device, the magnetization intensity and the magnetic field distribution of the circumferential magnetic threading bars can be improved; a magnetization effect of the buffer spring for flaw detection is ensured; and interference in a magnetic circuit is avoided, and the flaw detection device can be widely applied to the fields of manufacturing and overhauling of railway vehicles.

Owner:CRRC YANGTZE CO LTD

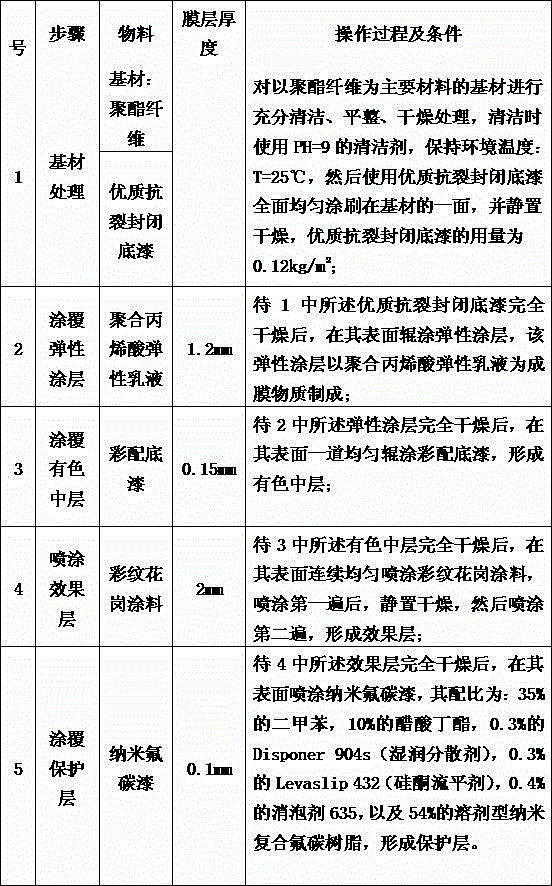

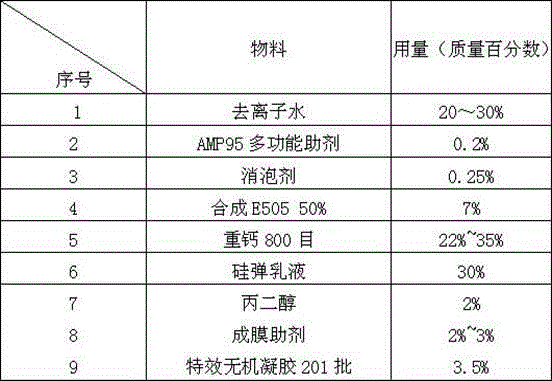

Sandstone veneer stone and manufacturing method thereof

The invention discloses a sandstone veneer stone. The sandstone veneer stone comprises a base material, an elastic coating arranged on the base material in a coating mode, a colored middle layer arranged on the elastic coating in a coating and rolled mode, an effect layer formed by spraying the sandstone on the colored middle layer, and a protection layer arranged on the effect layer in a coating mode. The protection layer is nanometer fluorocarbon paint. The sandstone paint comprises 30% sandstone paste and 70% natural color sand. The sandstone paste comprises, by weight, 25%-30% of deionized water, 0.2% of multifunctional assistant, 0.25% of defoamer, 70% of synthesis E505, 22%-35% of 800-mesh coarse whiting, 30% of silicon elastic emulsion, 2% of propylene glycol, 2%-3% of coalescing agent and 3.5% of inorganic gel. The sandstone veneer has the advantages of being convenient to transport and construct, stable in variety, smooth in hand feeling and delicate.

Owner:浙江泰基涂料有限公司

Differential pressure type high sensitivity liquid level flow measuring device

InactiveCN103438960AReduce measurement impactReduce maintenance costsVolume/mass flow by differential pressureLevel indicators by pressure measurementMeasuring instrumentDifferential pressure

The invention belongs to the technical field of liquid level flow on-line monitoring devices, and particularly relates to a differential pressure type high sensitivity liquid level flow measuring device. The problems that an existing mechanical liquid level flow speed measuring instrument cannot adapt to the special environment where a field monitoring device is placed and cannot work for a long time are solved. The differential pressure type high sensitivity liquid level flow measuring device comprises a pressure probe immersed under the liquid level, and further comprises a reference pressure compensation module, a flow speed conversion module and a signal amplifying processing module, wherein the reference pressure compensation module is far away from the liquid level, and the pressure probe is internally provided with a total pressure measuring module and a static pressure module. The static pressure measuring module is connected with the signal amplifying processing module through the reference pressure compensation module, and the reference pressure compensation module is provided with an air guiding device which transmits the barometric pressure to the static pressure measuring module. By means of the differential pressure type high sensitivity liquid level flow measuring device, full-automatic and real-time monitoring is achieved, people are free from heavy work of monitoring the liquid level regularly, and hidden dangers are removed in advance through warning information.

Owner:SINOGREEN ENVIRONMENTAL PROTECTION SCI & TECH

Optical axis horizon reference and method for establishing optical axis horizon reference

ActiveCN105573344AHigh transfer accuracySimple structurePosition/direction controlHorizonOptical axis

The invention discloses an optical axis horizon reference and a method for establishing the optical axis horizon reference. The optical axis horizon reference comprises a vertical shaft system, a horizontal shaft system, optical flats and a pitching adjusting tool. The vertical shaft system comprises a table. The horizontal shaft system is arranged on the table. The optical flats are arranged on two ends of the horizontal shaft system through the pitching adjusting tool. Monitoring surfaces of the optical flats are perpendicular to the horizontal shaft system. According to the invention, the transmission precision is high, the horizon precision of an adjusted optical axis is at the level of seconds of arc, and the repeating precision is high.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Color vision detector

InactiveCN101601578ARapid diagnosisAccurate diagnosisEye diagnosticsDisplay deviceMedical prescription

The invention discloses a color vision detector comprising a casing, a display and a control device, wherein the display is arranged in the casing; and the control device is arranged in the casing, coupled to the display, used for controlling the display to display a color vision check chart which corresponds to different color blindness varieties and is identified by a person to be checked to determine the color blindness variety of the person, and also used for controlling the display to quantificationally change the tricolor ratio of the color vision check chart to be identified by the person to be checked to determine the color blindness grade of the person. According to the invention, the color vision colors of human beings are digitized; pseudo color blindness, total color blindness, two kinds of color blindness of Ar, Ag and Ab with lower primary colors, one kind of color blindness of Br, Bg and Bb with lower primary colors and the grade thereof are rapidly checked according to the digitizing definitions of the color blindness variety and the grade, the color blindness rectification effect can be verified, and a check result and a rectification recipe also can be printed.

Owner:陈晓光 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com