Sandstone veneer stone and manufacturing method thereof

A production method and technology of veneer stone, applied in the direction of chemical instruments and methods, lamination, coating, etc., can solve the problems of short color duration, unfavorable ecology of natural stone, environmental protection, transportation and difficult construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

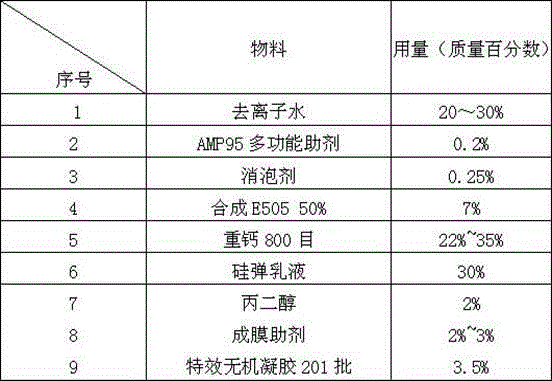

[0034] Preparation steps of sandstone paint:

[0035] Preparation of sandstone slurry: 25.5% deionized water, 0.2% multifunctional additive, 0.25% defoamer, and 7% synthetic E505 were added to the dispersion tank in sequence with a mass percentage of 25.5% of the overall sandstone paint. Centrifugal dispersion at 800r / min for 20min, then add 30% silicone emulsion, 2% propylene glycol, 3% film-forming aid, 3.5% inorganic gel, and slowly increase the speed to 1000-1500r / min, continue for 10min, to obtain sandstone slurry, and add 70% natural colored sand to the obtained sandstone slurry to obtain sandstone paint;

[0036] Preparation steps of sandstone veneer stone:

[0037] (1) Fully clean, flatten and dry the base material with polyester fiber as the main material. When cleaning, use a detergent with PH=8, keep the ambient temperature: T=5℃, and then use high-quality anti-crack sealing primer Brush evenly on one side of the substrate, and let it dry. The amount of high-quali...

Embodiment 2

[0048] Table 5 is each component of embodiment 2 sandstone paint and preparation steps and conditions.

[0049]

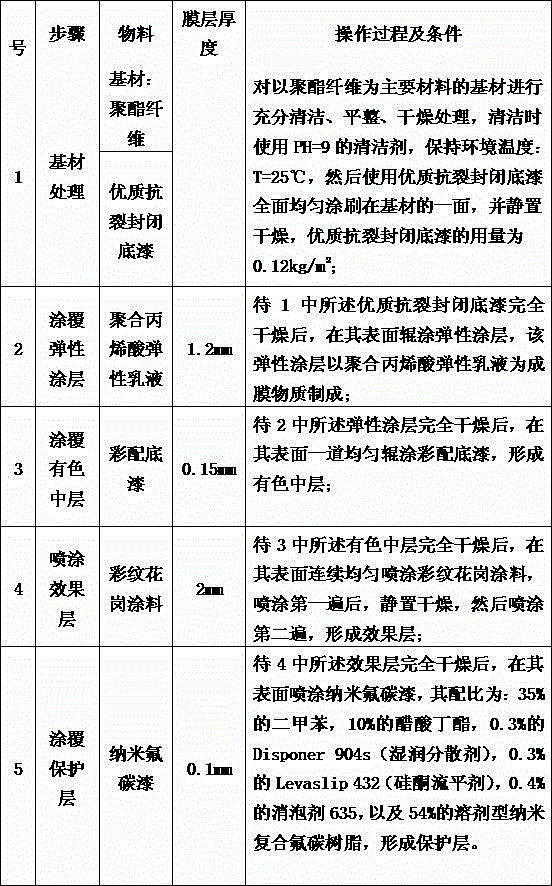

[0050] Table 6 shows the preparation steps and conditions of the sandstone veneer stone in Example 2.

[0051]

Embodiment 3

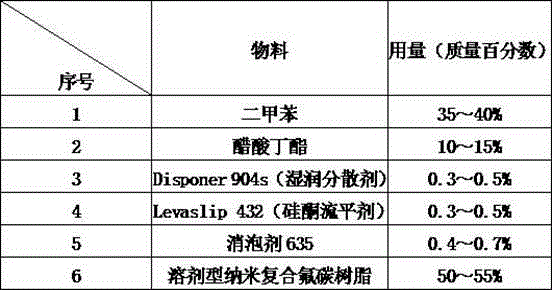

[0053] Table 7 is each component of embodiment 3 sandstone coatings and preparation steps and conditions.

[0054]

[0055] Table 10 shows the preparation steps and conditions of the sandstone veneer stone in Example 3.

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com