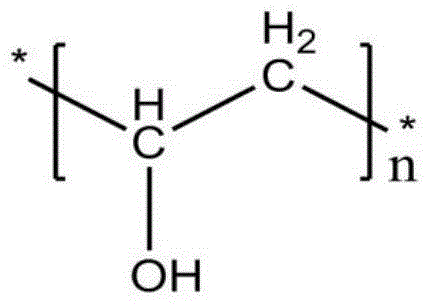

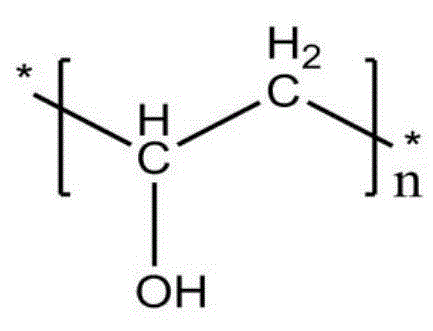

Polyvinyl alcohol spongy material and production method thereof

A polyvinyl alcohol sponge and polyvinyl alcohol technology, applied in the field of sponge materials, can solve the problems of high process requirements, sensitive to changes in foaming conditions, etc., and achieve high application value, large water absorption capacity, and the effect of promoting deepening cross-linking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] A preparation method of polyvinyl alcohol sponge material, comprising the steps of:

[0080] (1) Preparation of polyvinyl alcohol aqueous solution: 10 kg of polyvinyl alcohol was stirred in 200 kg of water at a temperature of 60° C., and dissolved for 10 min at a rotational speed of 500 r / min to obtain a polyvinyl alcohol aqueous solution.

[0081] (2) Preparation of foaming solution: Take 100kg of the above-mentioned polyvinyl alcohol aqueous solution and heat it to 40°C. At a stirring speed of 600r / min, add 0.5kg of azodicarbonamide (AC) foaming agent, stir for 8min, and then add 1kg of sodium lauryl sulfate dispersant was stirred for 5 minutes to obtain a foaming solution.

[0082] (3) Acetalization: at a stirring speed of 1200r / min, add 10kg of hydrochloric acid, stir for 10min, add 12kg of formaldehyde, reduce the stirring speed to 400r / min, stir for 10min, add 0.3kg of foam stabilizer dodecyl di Methyl amine oxide, and gradually reduce the stirring speed until th...

Embodiment 2

[0085] Pour 100g of the slurry obtained in Example 1 into a sealed mold, raise the temperature to 50°C, keep it warm for 10 minutes, then raise the temperature to 150°C, keep it warm for 30s, then lower the temperature to 50°C, and keep it for 2 hours to solidify the molding process After the completion, the temperature of the system is lowered to room temperature, and the foaming material is removed from the mold for multiple washing and drying processes, and processed to obtain a polyvinyl alcohol sponge material.

[0086] The performance test results of the sponge material are that the average pore diameter is 2.4nm, the opening rate is 80%, the water absorption rate is 1500%, and the apparent density is 0.06g / cm 3 .

Embodiment 3

[0088] Pour 100g of the slurry obtained in Example 1 into a sealed mold, raise the temperature to 60°C, keep it warm for 30 minutes, then raise the temperature to 130°C, keep it warm for 60s, then lower the temperature to 60°C, and keep it for 2 hours to solidify the molding process After the completion, the temperature of the system is lowered to room temperature, and the foaming material is removed from the mold for multiple washing and drying processes, and processed to obtain a polyvinyl alcohol sponge material.

[0089] The performance test results of the sponge material are that the average pore diameter is 2.6nm, the opening rate is 85%, the water absorption rate is 2000%, and the apparent density is 0.05g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com