Novel polyurethane semi-matte white finish for woodware protection

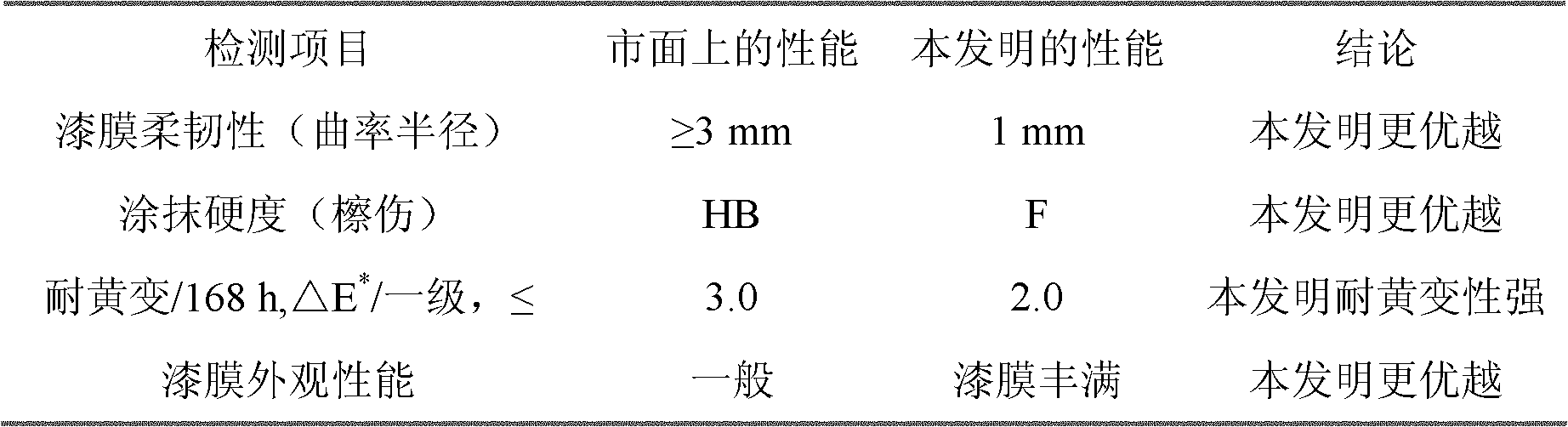

A polyurethane and white topcoat technology, applied in the field of semi-matte white topcoat, can solve the problems of poor yellowing resistance of the paint film, affect the quality of decoration, and have a great impact, achieve full paint film, speed up drying and film formation, space Low steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] 1. Preparation of stearic acid modified short oil alkyd resin I

[0054] 596.05kg of refined oleic acid, 357.63kg of 1081 stearic acid, 157.36kg of benzoic acid, 298.03kg of diethylene glycol, 59.06kg of TMP, 298.03kg of glycerin (95.0%), and 576.44kg of pentaerythritol were put into the reactor, and then 1788.15kg of phthalic anhydride was added. Afterwards, when the temperature is lower than 80°C, add 5.96kg antioxidant, reflux with 119.21kg xylene, heat up, and pass carbon dioxide (when the temperature rises to 170°C, stop ventilation), when the temperature rises to 120°C, start stirring At the same time turn on the return cooling water. Control the voltage so that it takes 2.0 hours to rise to 170°C and keep it warm for 1.0 hours. Continue to raise the temperature so that it takes 2.5 hours to rise to 200°C, then rise to 210°C, and reflux at a constant temperature. After the reaction until the acid value is less than or equal to 12mgKOH / g, lower the temperature. ...

Embodiment 1

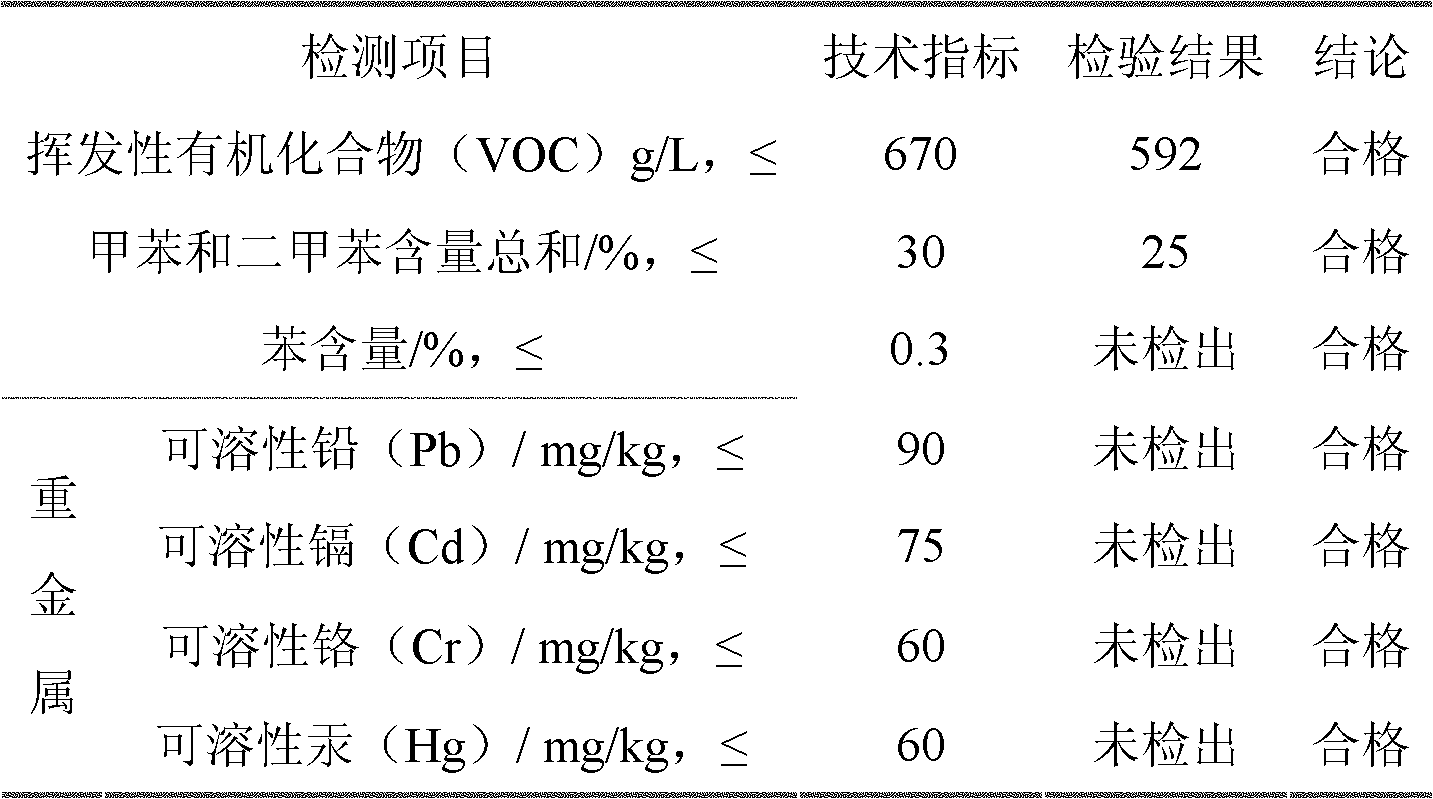

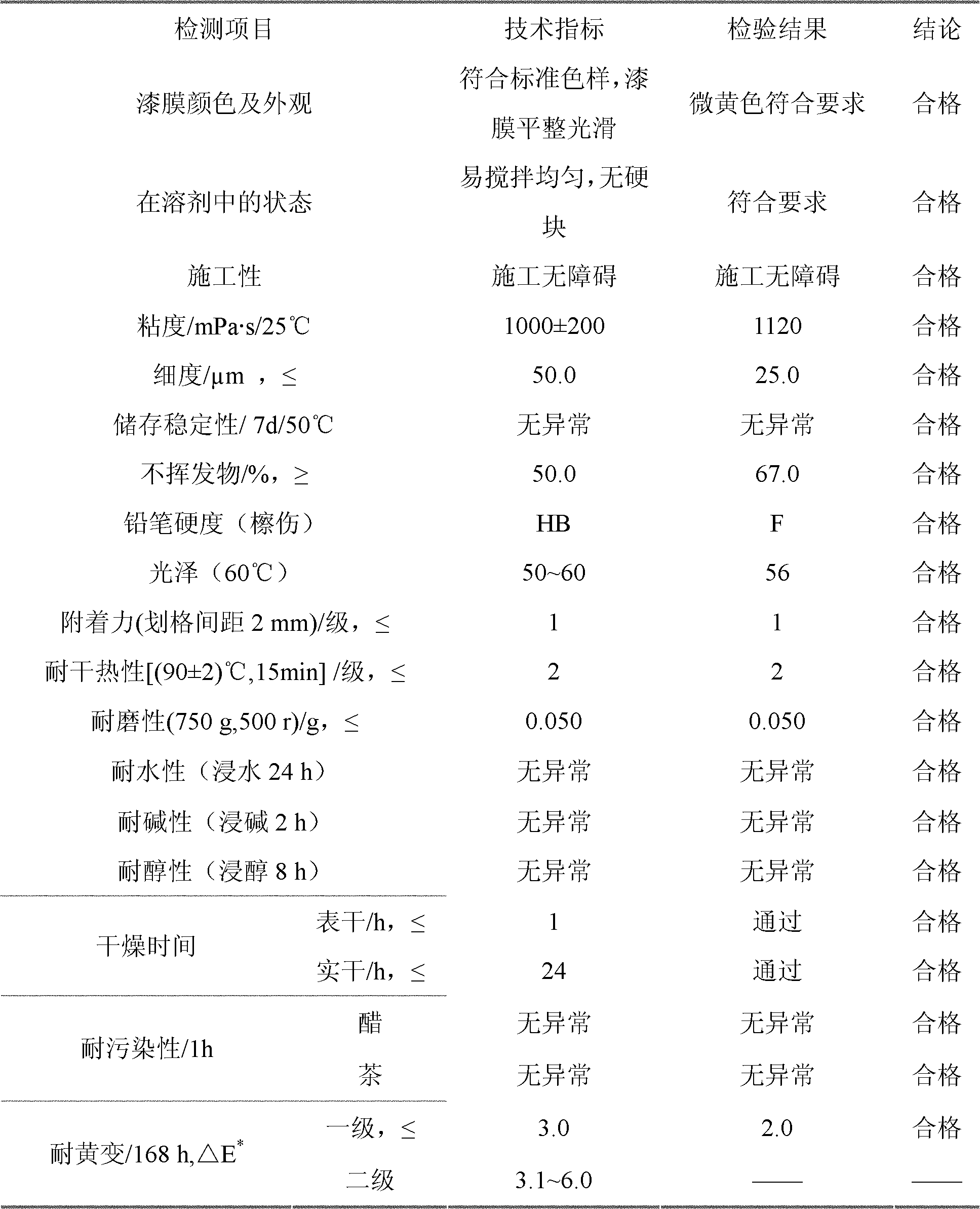

[0062] With 387.39kg stearic acid modified alkyd resin I, 108.95kg polyketone resin solution (concentration 50%), 1.21kg defoamer SS-220, 1.21kg defoamer 5300, 12.11kg anti-settling agent 50% 6900, Add 2.42kg dispersant AF4010, 472.13kg411 white flour paste into the reaction tank, and disperse at a speed of 500-800r / min for 5-10min; Disperse at 1000~1200r / min until the material fineness is ≤25μm; after adding 145.27kg 20% VAGH vinyl chloride resin, 3.63kg leveling agent BYK306, 6.05kg anti-yellowing additive KH-18, 2.42kg deodorant, Disperse at 500~800r / min for 5~10min; finally adjust the viscosity with 32.69kg butyl ester, adjust the viscosity of the material to 1000±200mPa·s / 25℃, and sieve the material with a 200-mesh sieve without sieve residue, it is qualified, qualified After packing in cans for later use, the developed semi-dull white topcoat can be obtained upon arrival, and its appearance is a white milky liquid.

Embodiment 2

[0064] 402.76kg stearic acid modified alkyd resin II, 130.09kg polyketone resin solution (concentration 45%), 2.30kg defoamer SS-220, 13.81kg anti-settling agent 50% 6900, 5.75kg dispersant AF4010, 402.76 Add kg411 white flour paste into the reaction tank and disperse at a speed of 500-800r / min for 5-10 minutes; then add 17.26kg of hand wax powder 1400SF and 57.54kg of new air-soluble matting powder TSS-110, and disperse at a speed of 1000-1200r / min until the material fineness is ≤25μm; add 92.06kg 20% VAGH vinyl chloride resin, 2.30kg leveling agent BYK306, 9.21kg anti-yellowing additive KH-18, 1.15kg deodorant, and disperse at a speed of 500-800r / min 5-10 minutes; finally adjust the viscosity with 5.75kg butyl ester, adjust the viscosity of the material to 1000±200mPa·s / 25℃, use a 200-mesh sieve to sieve the material without sieve residue, it is qualified. The developed semi-dull white finish was obtained, which was a white milky liquid in appearance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com