Patents

Literature

49results about How to "High curing reactivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

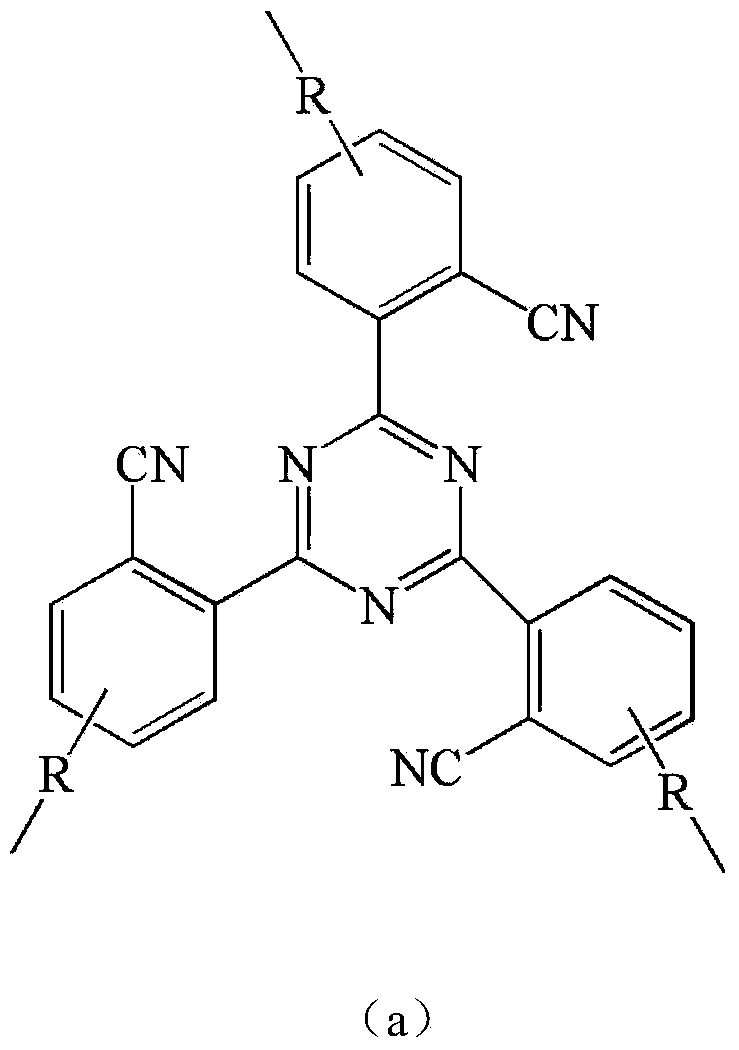

Nitrile resin monomer, nitrile resin polymer and preparation method of nitrile resin monomer and nitrile resin polymer

InactiveCN102976972ALow viscosityReduce liquidityCarboxylic acid nitrile preparationOrganic compound preparationPolymer scienceResin matrix

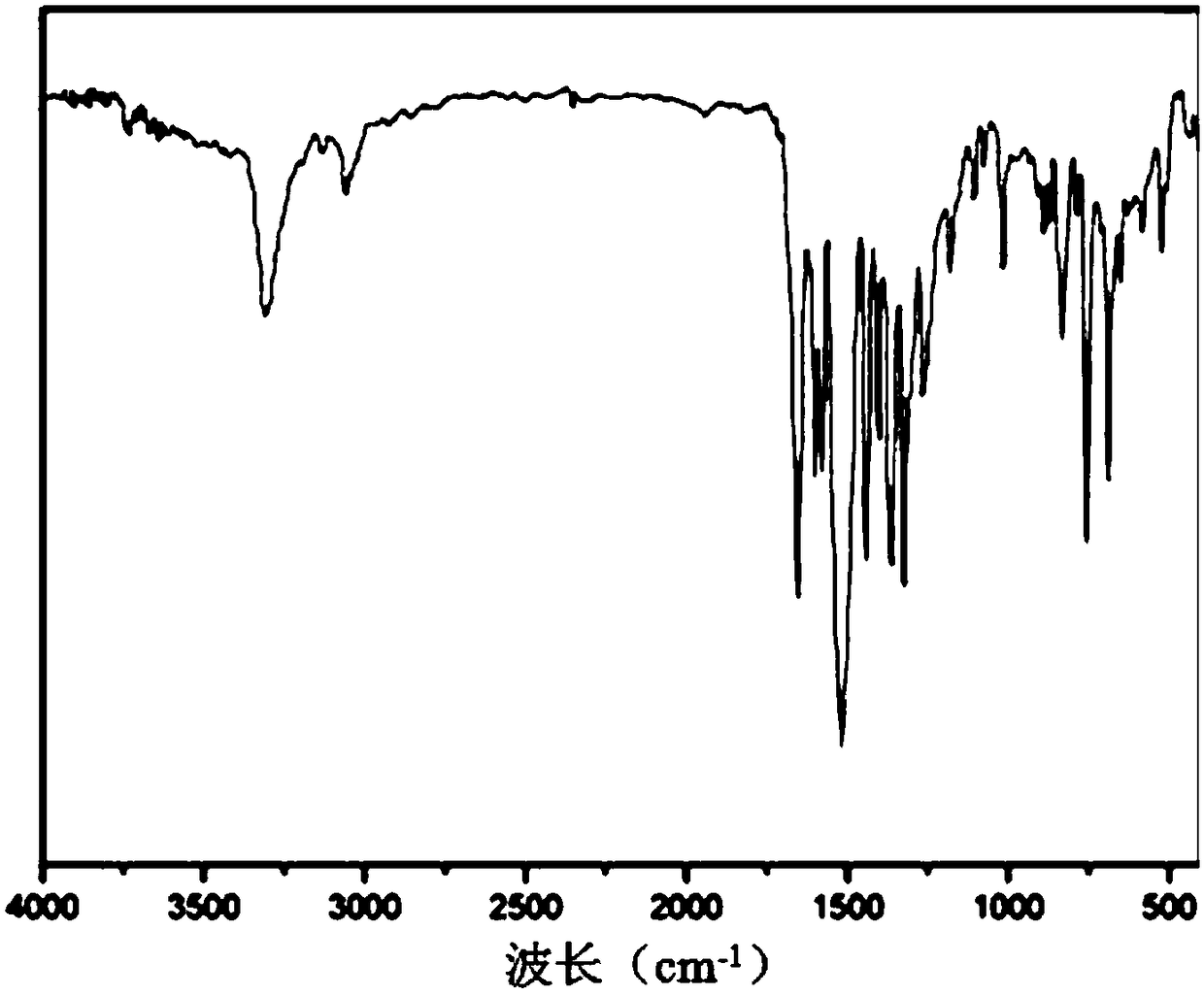

The invention discloses a nitrile resin monomer, a nitrile resin polymer and a preparation method of the nitrile resin monomer and the nitrile resin polymer, belonging to the technical field of organic polymer materials. The nitrile resin monomer is a tetraphthalonitrile resin monomer containing benzoxazine cycle, and the nitrile resin polymer is a product obtained by heating polymerization of the nitrile resin monomer. The nitrile resin monomer has a low viscosity, a good mobility and the processing performances of low-temperature curing and the like at a low temperature. The nitrile resin polymer has the good curing performances of self-flame resistance, adhesion, heat stability and the like. The resin monomer has the good processing performances of benzoxazine resins, and the resin polymer has the high-temperature resistance of nitrile resins, thus reducing the curing processing temperature and being capable of being used in a high-temperature temperature, namely, having the advantages of low temperature processing, medium temperature formation and high temperature use; and the resin monomer and the resin polymer can be used in the fields of coatings, adhesives, electronic packaging materials, aeronautics, astronautics, ships, resin matrix composites and the like. The preparation method is simple and easy to control, low in reaction temperature, energy-saving, and suitable for industrialized production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

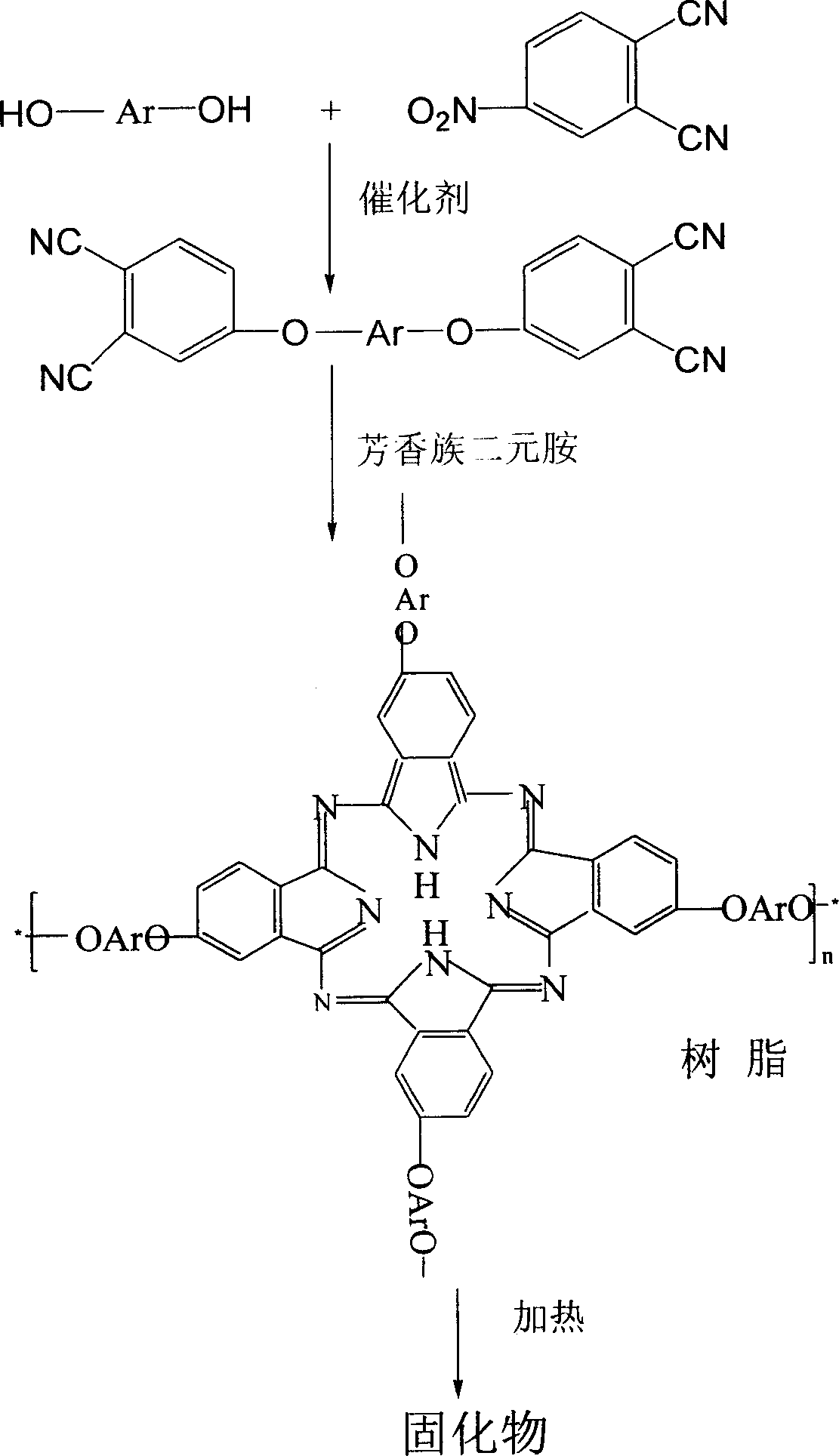

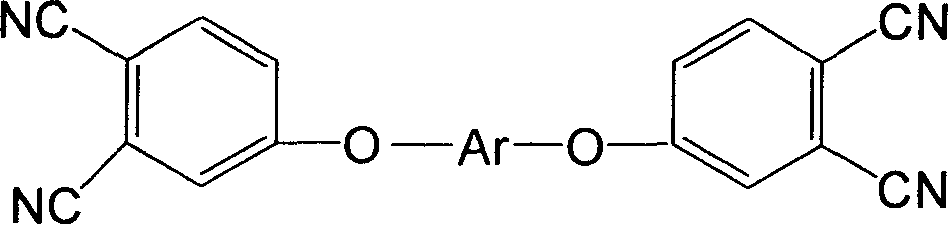

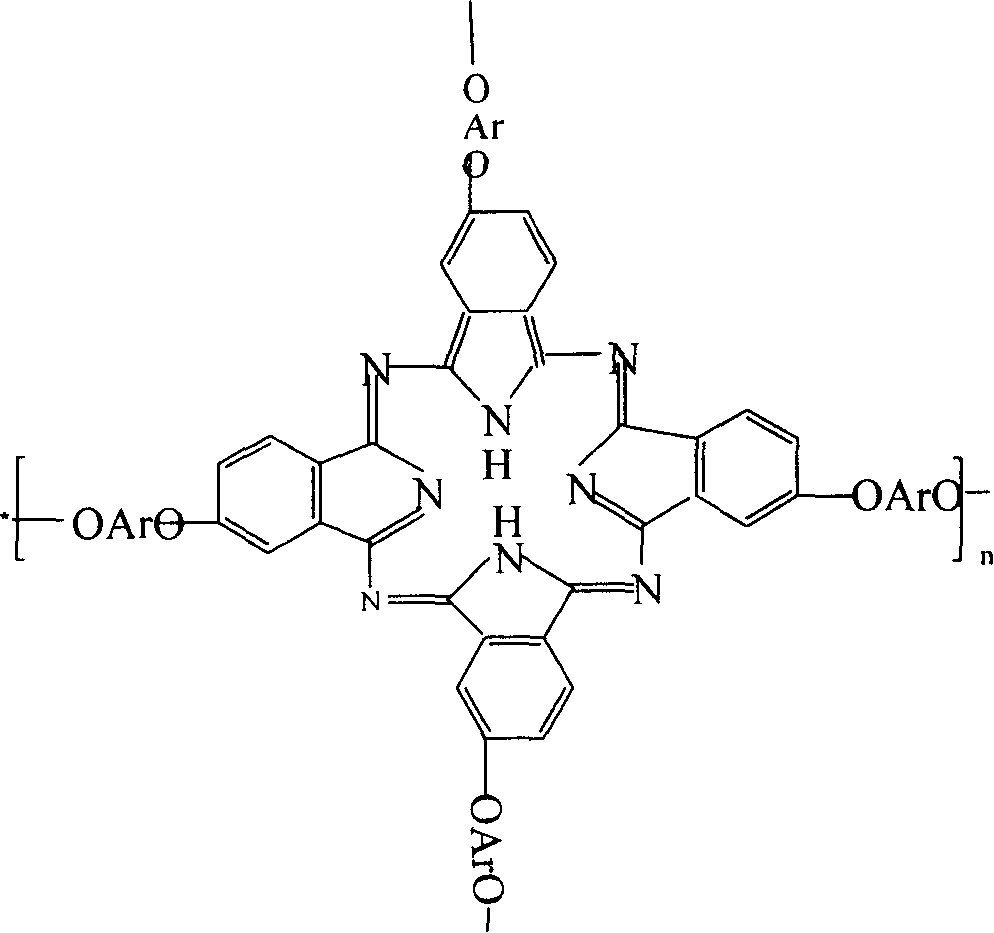

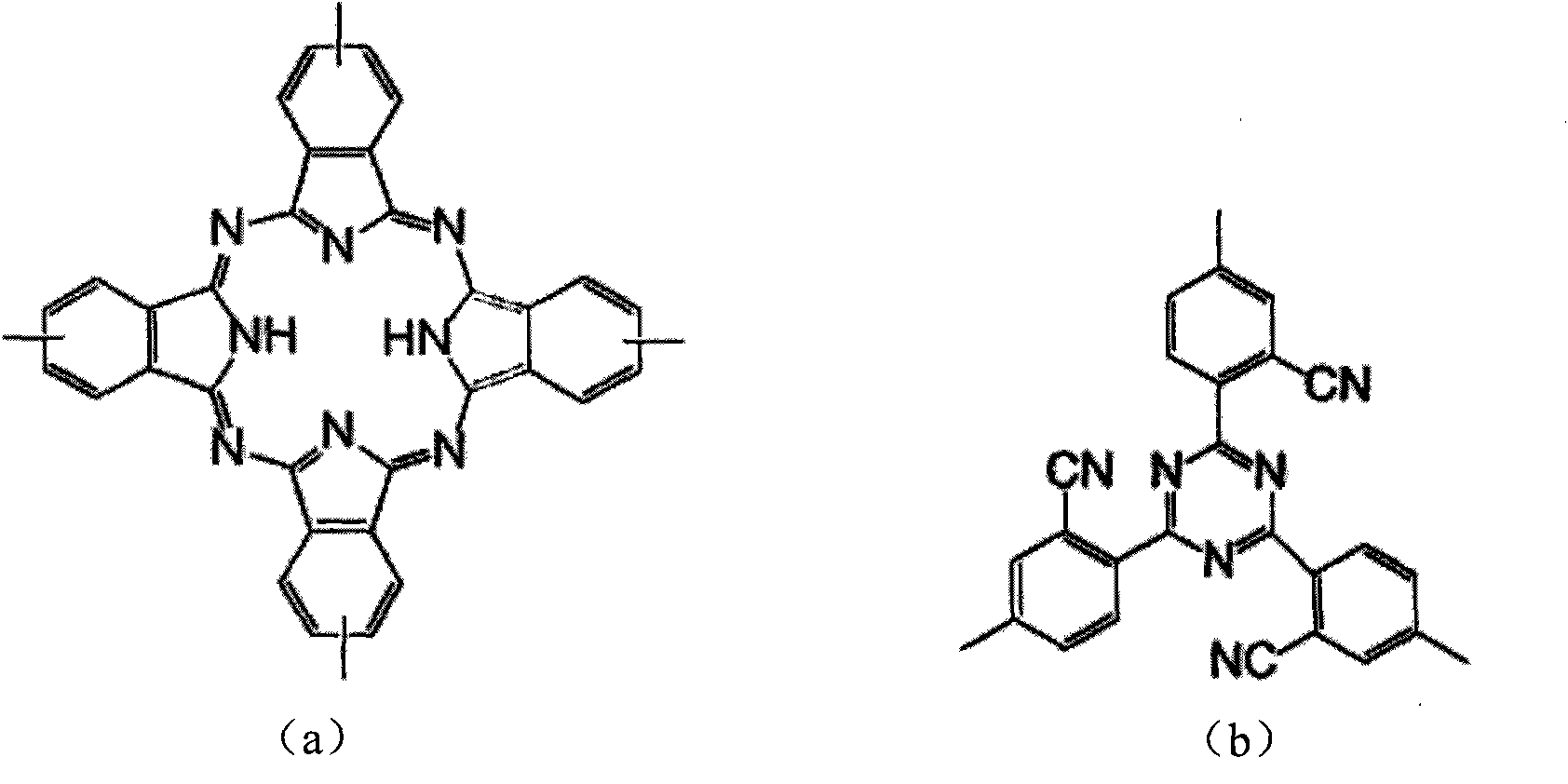

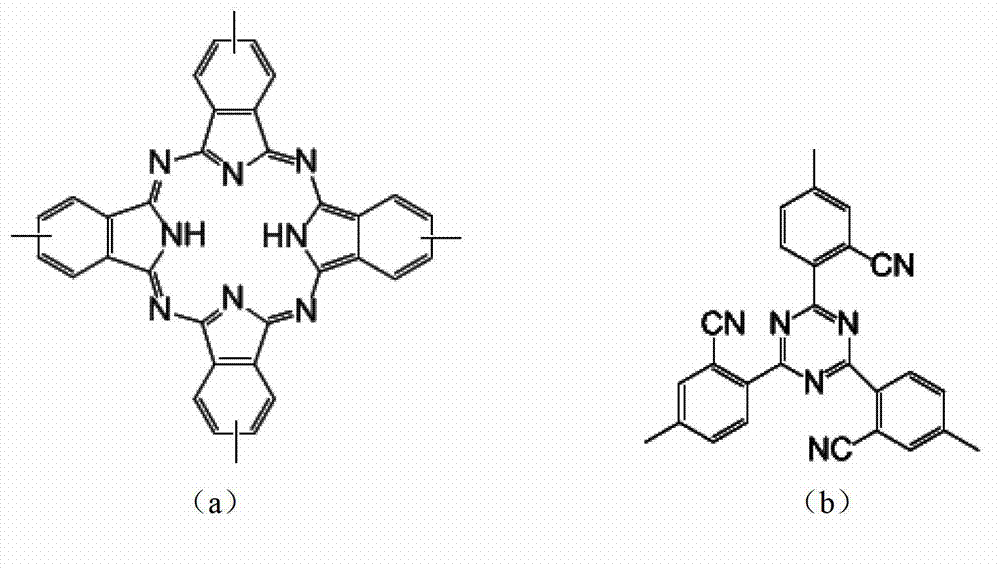

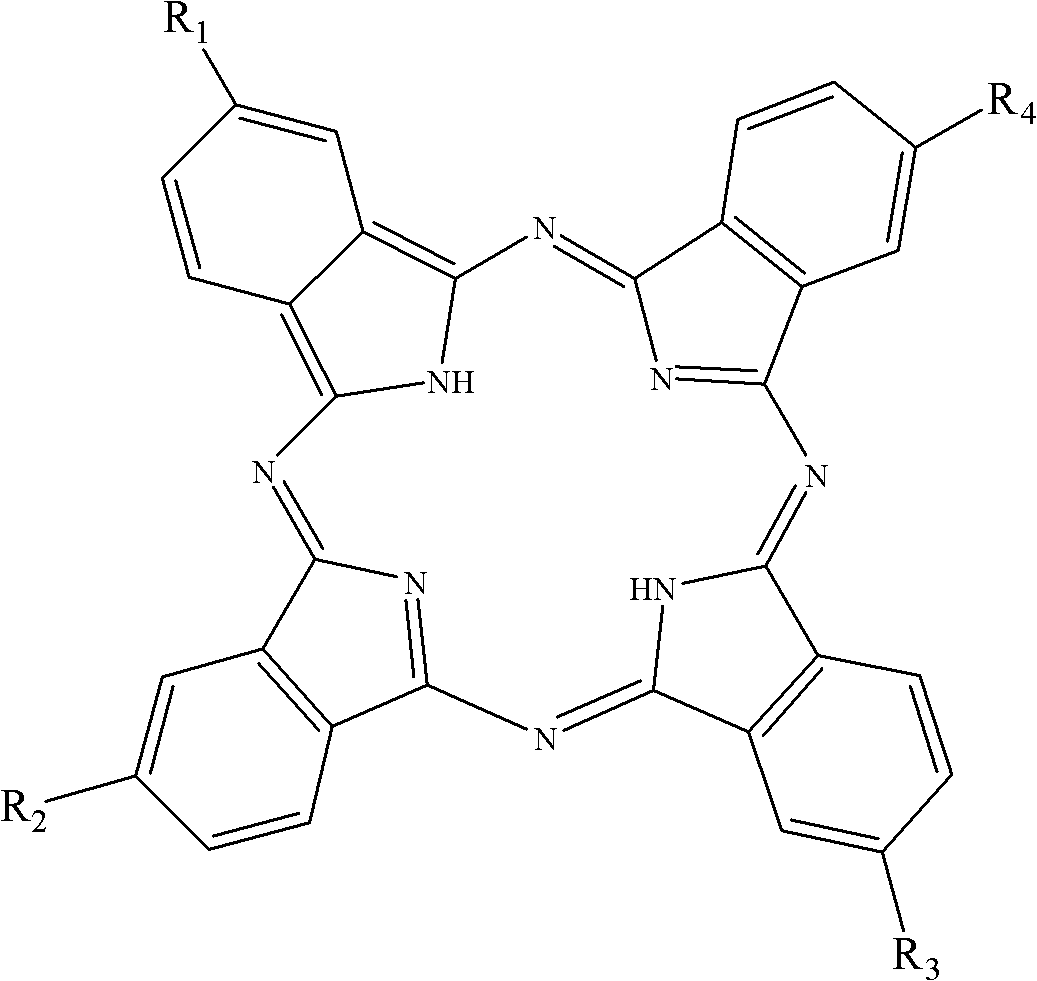

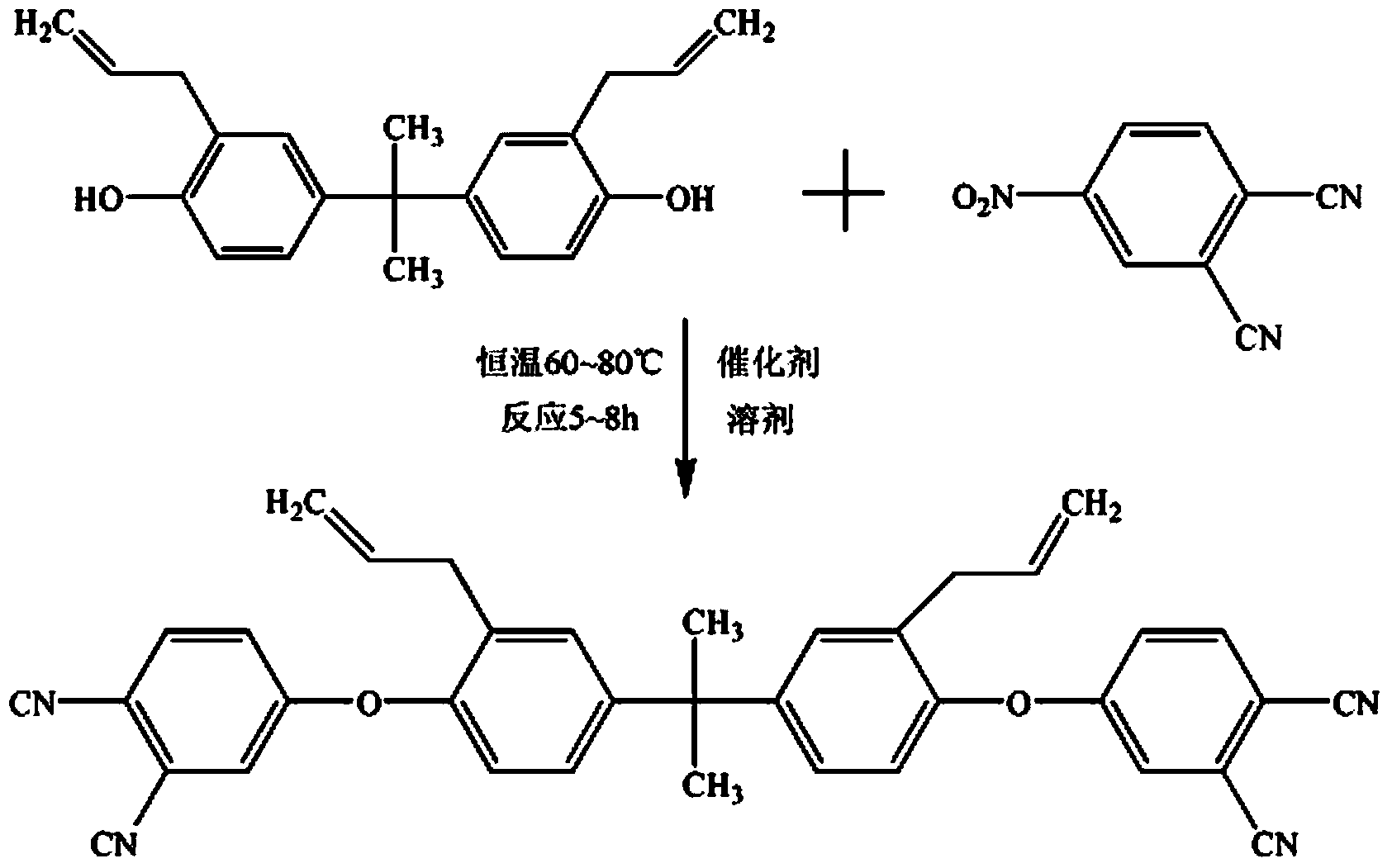

Double end-group phthalonitrile, resin, condensate and its preparation method and uses

ActiveCN1876615ARegulatory and Control StructuresTuning and Controlling PerformanceOrganic chemistryPolymer scienceEnd-group

The invention belongs to the high molecular synthetic material field. The invention relates the double-end phthalonitrile, resin, condensate, which are made by phthalonitrile, and preparing method. The invention uses 4-nitro-o-phthalonitrile and dihydric phenol as reaction integral to get double-end phthalonitrile. The double-end phthalonitrile and diamine are used to react in aromatic amine solution at 140-200Deg.C to get phthalonitrile resin which possesses phthalocyanine ring structure. The resin is cured at 220-280Deg.C, then carried out heat treatment at 320-370Deg.C to get phthalocyanine condensate which possesses high heat stability. The invention has the advantages of good heat stability and fire-retardancy.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

LED photocuring non-solvent type photosensitive transfer printing adhesive for cover plate glass substrate and preparation method thereof

ActiveCN105062405AStrong responsivenessImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesNon solventAdhesive

The invention discloses LED photocuring non-solvent type photosensitive transfer printing adhesive for a cover plate glass substrate. The photosensitive transfer adhesive comprises aliphatic polyurethane acrylate, an acrylate reactive diluent, a photoinitiator, an acrylic auxiliary and a silane coupling agent. The LED photocuring non-solvent type photosensitive transfer printing adhesive for the cover plate glass substrate is free of solvents and environmentally friendly, integrates advantages of the transfer printing technology and advantages of the photosensitive technology, and can be particularly used for development through a pure water neutral developing solution. The LED photocuring non-solvent type photosensitive transfer printing adhesive for the cover plate glass substrate has excellent physical performance, resistant to solvents, resistant to cold and hot impact and good in adhesion with the substrate after being cured. The adhesive force of an adhesive layer and the substrate is larger than 4B and environmental pollution is little especially after a boiling test. The problem that existing UV adhesive is poor in adhesion on cover plate glass and not resistant to boiling or solvents is solved, industrial requirements are met, production cost of enterprises is reduced, and benefits are brought to the enterprises.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

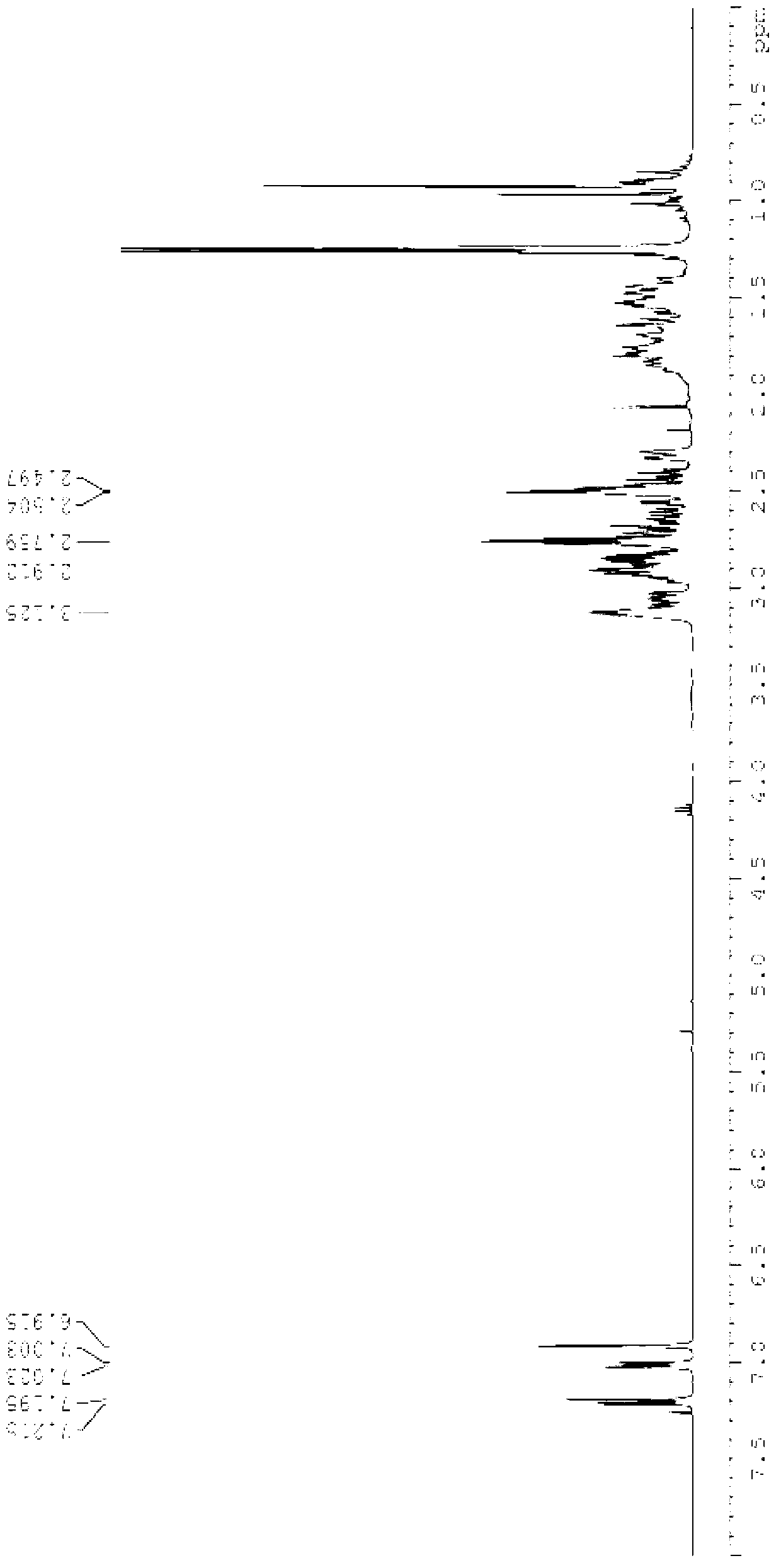

Photopolymerizable monomers having epoxide and unsaturated double bonds and their composition

ActiveUS20090163683A1Superior photopolymerization efficiencyGood curing reactivityOrganic chemistryEpoxideDouble bond

Provided are a novel photopolymerizable monomer having at least one unsaturated double bond and epoxide, and a photocurable composition comprising the photopolymerizable monomer and an initiator, which is polymerizable with good efficiency using light and / or heat, provides reduced shrinkage, and has superior mechanical strength including adhesion and transparency.

Owner:IND ACADEMIC COOP FOUNDATION YONSEI UNIV

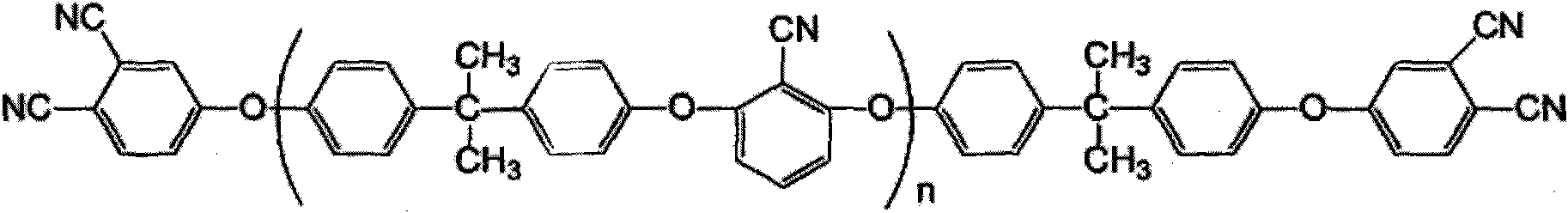

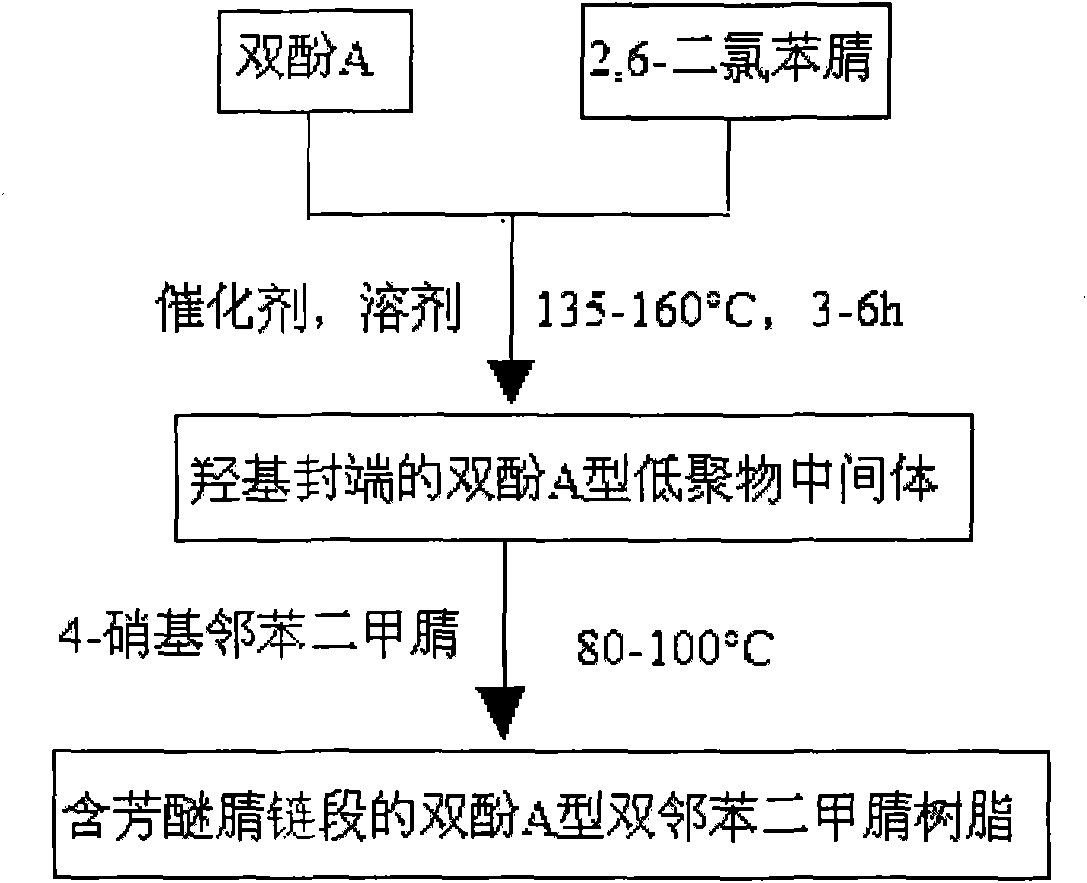

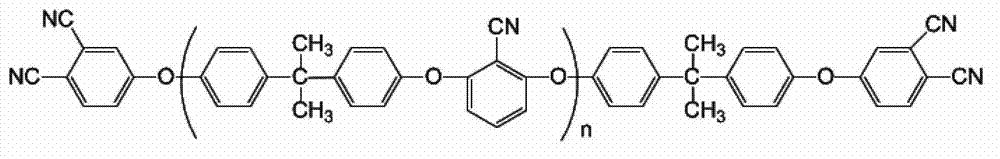

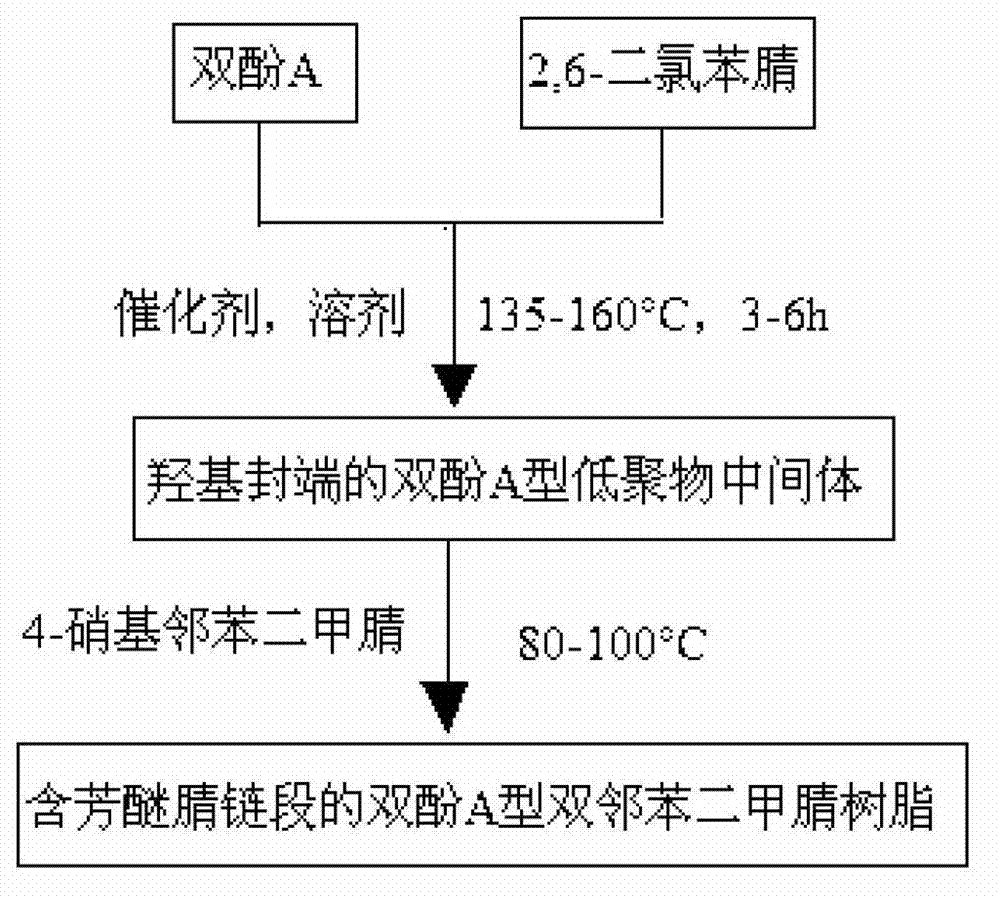

Bisphenol A type bis-phthalonitrile resin with aryl ether nitrile segments, cured product and preparation method thereof

InactiveCN101914038ALow water absorptionImprove curing effectCarboxylic acid nitrile preparationOrganic compound preparationPhthalonitrileSolvent

The invention discloses a bisphenol A type bis-phthalonitrile resin with aryl ether nitrile segments, a cured product and a preparation method thereof and belongs to the field of polymer materials. Raw materials of bisphenol A and 2,6-dichlorobenzonitrile are subjected to nucleophilic substitution reaction, anhydrous potassium carbonate and anhydrous sodium carbonate are used as a catalyst, a hydroxyl-terminated bisphenol A type oligomer intermediate is formed in mixed liquor of a strong polar solvent and toluene, and then hydroxyl groups are substituted by 4-nitrophthalonitrile, thus obtaining the resin. A cure-crosslinking agent, the mass of which is equal to 5 percent of the resin, is added into the resin, and then after pre-curing at 220-240DEG C and heat treatment at 375DEG C at least, the cured product of the resin can be obtained. The bis-phthalonitrile resin provided by the invention has different chain lengths and the aryl ether nitrile segments as well as a low melting point and wider curing process temperature, and the cured product is of a net structure which comprises a phthalocyanine ring and a triazine ring and has excellent heat stability. The manufacturing methods of the resin and the cured product are simple and controllable and are suitable for industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

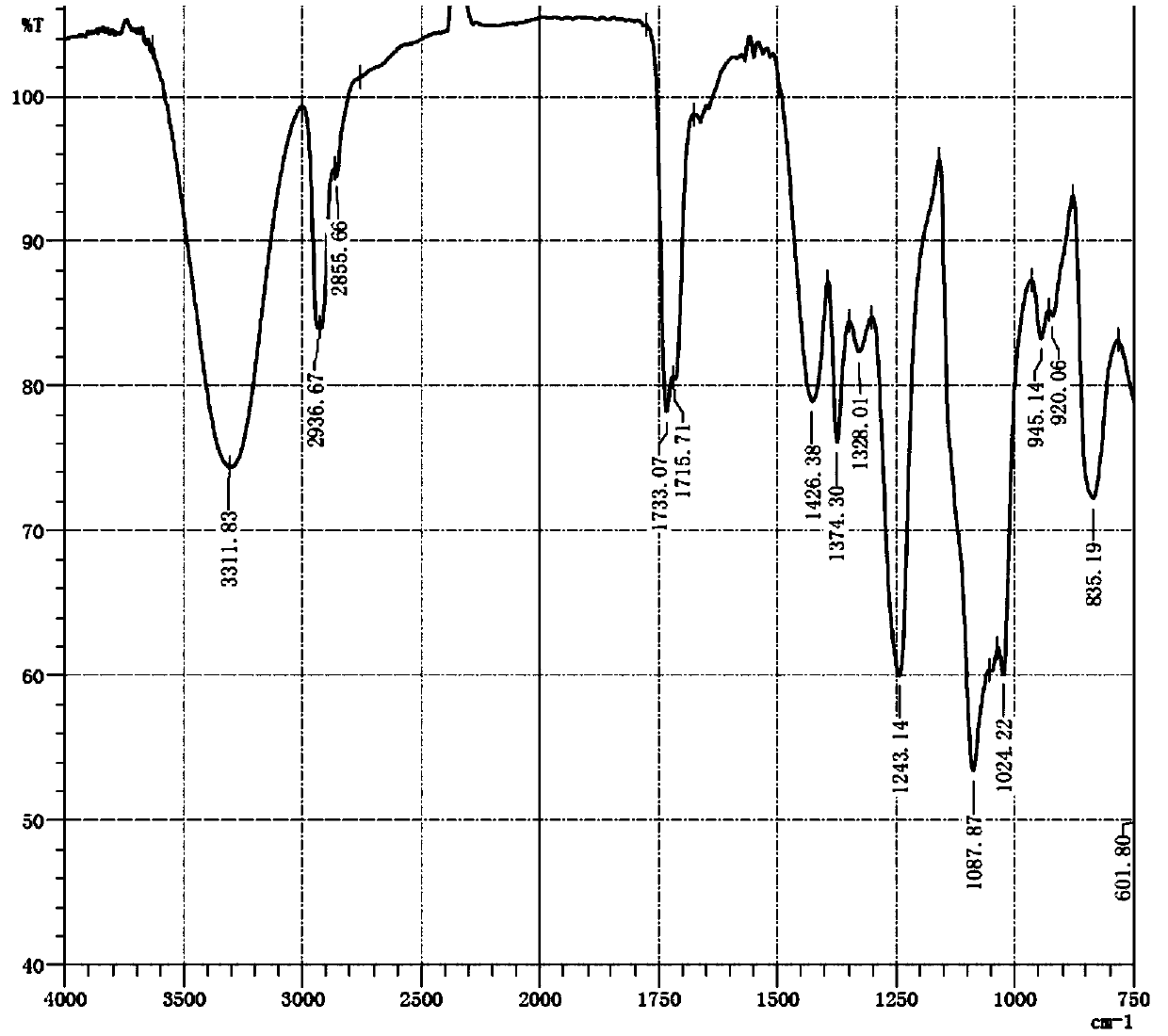

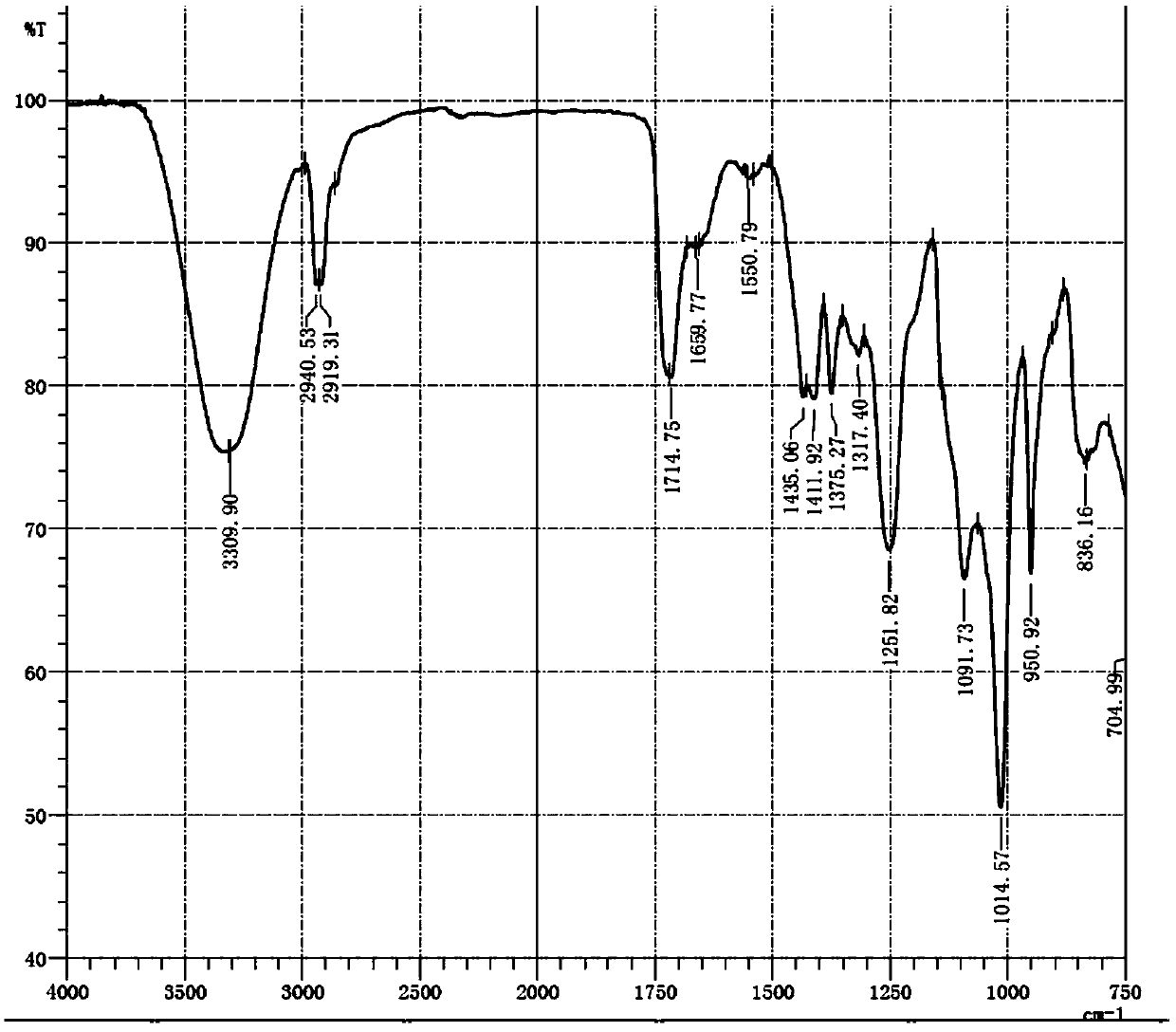

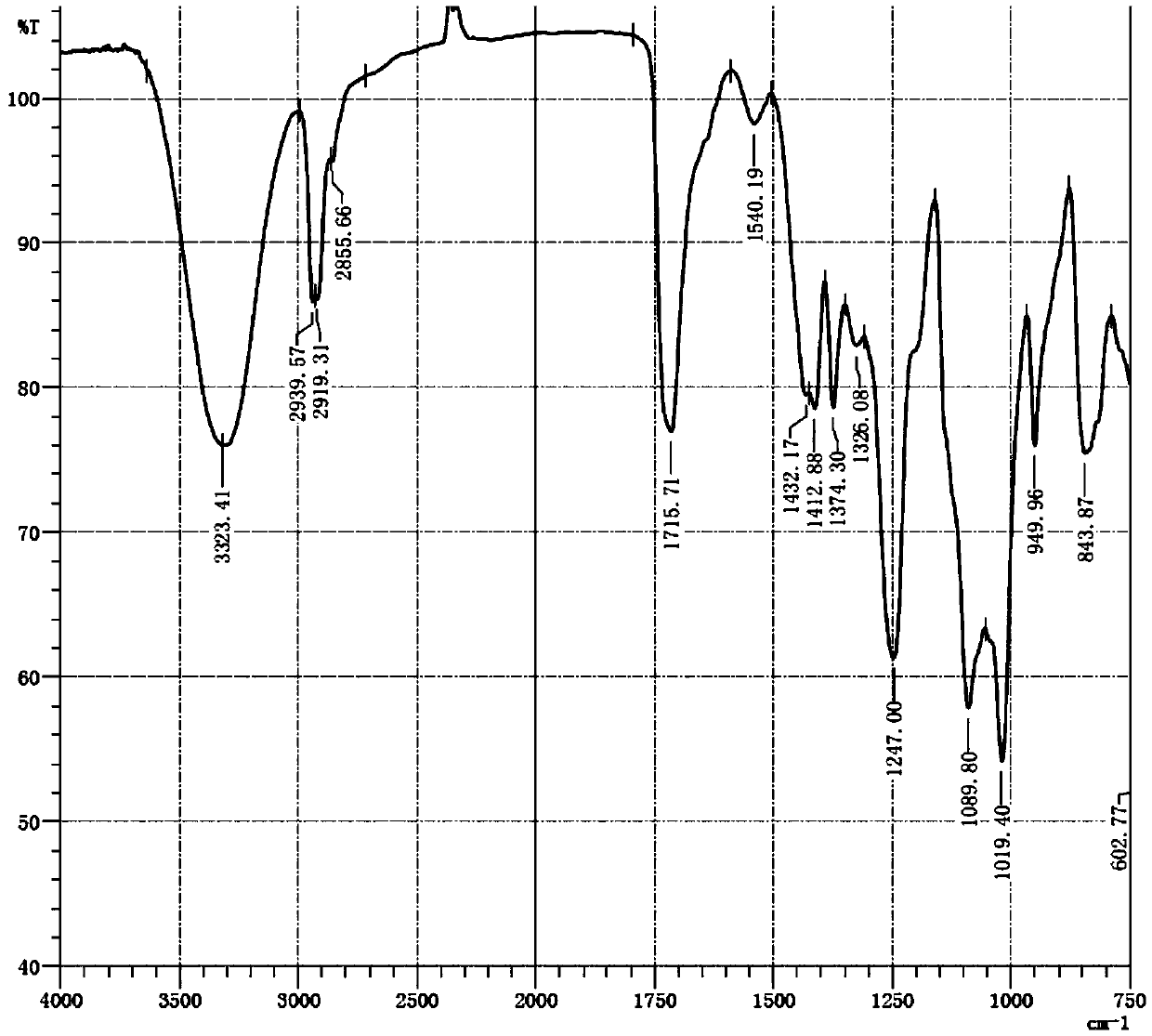

Heat-resistant substrate resin and preparation method thereof

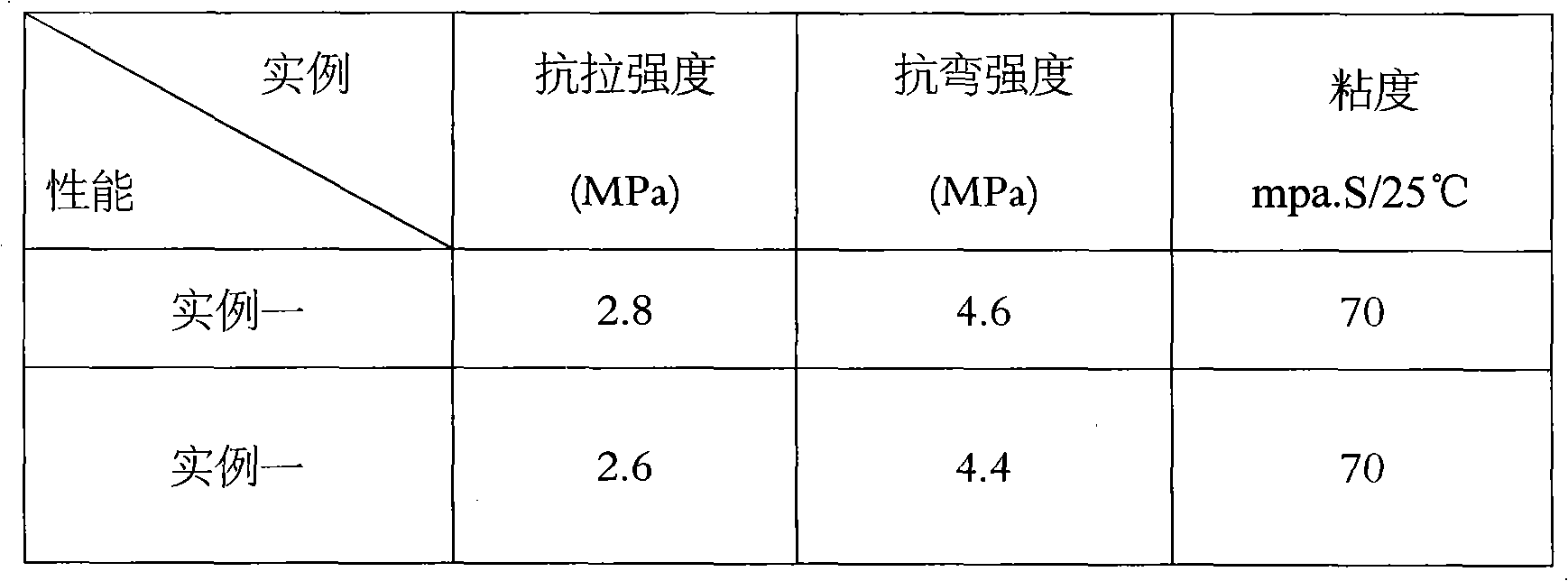

The invention discloses a heat-resisting matrix resin and the preparation method thereof. The heat-resisting matrix resin provided by the invention is prepared after the reaction of PN resin in formula I structure and APMI monomer in formula II structure. The PN resin and the APMI monomer of the invention are characterized in that the PN resin is modified with the APMI monomer to develop a matrix resin (PN-APMI) with good heat resistance and manufacturability used in high temperature resistant compound materials. The PN-APMI resin system of the invention is proved based on a test result to have good solidifying reactivity and excellent heat resistance, simple preparation, easy operation and low cost, thereby being applicable to mass popularization and application.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Hydroxyl-terminated alkaline phenolic resin and preparation thereof

InactiveCN101348549AHigh curing reactivityHigh strengthFoundry mouldsAldehyde/ketone condensation polymer adhesivesPolymer sciencePolyol

The invention relates to a preparation method for an organic macromolecular binder for casting, in particular to a hydroxy terminated alkaline phenolic resin as a binder of resin sand for large-sized castings and a preparation method thereof. The hydroxy terminated alkaline phenolic resin is prepared by phenolic compounds, aldehyde compounds, modifiers, solution of a catalyst, and a coupling agent according to proper weight proportion. The hydroxy terminated alkaline phenolic resin adopts polyols as modifiers and a hydroxy for macromolecular termination. The product can remarkably improve the activity of cure reaction of the phenolic resin, the strength of the resin and the service performance of the resin. Therefore, the organic macromolecular binder is suitable for preparing an organic curing alkaline phenolic resin.

Owner:LIAONING FU-AN HEAVY INDUSTRY CO LTD

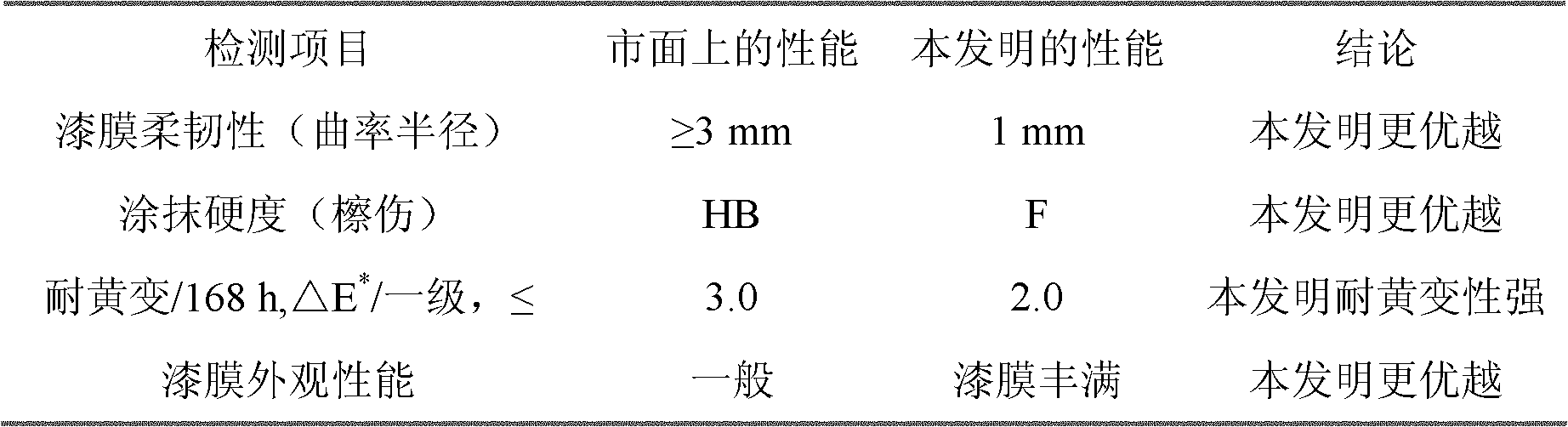

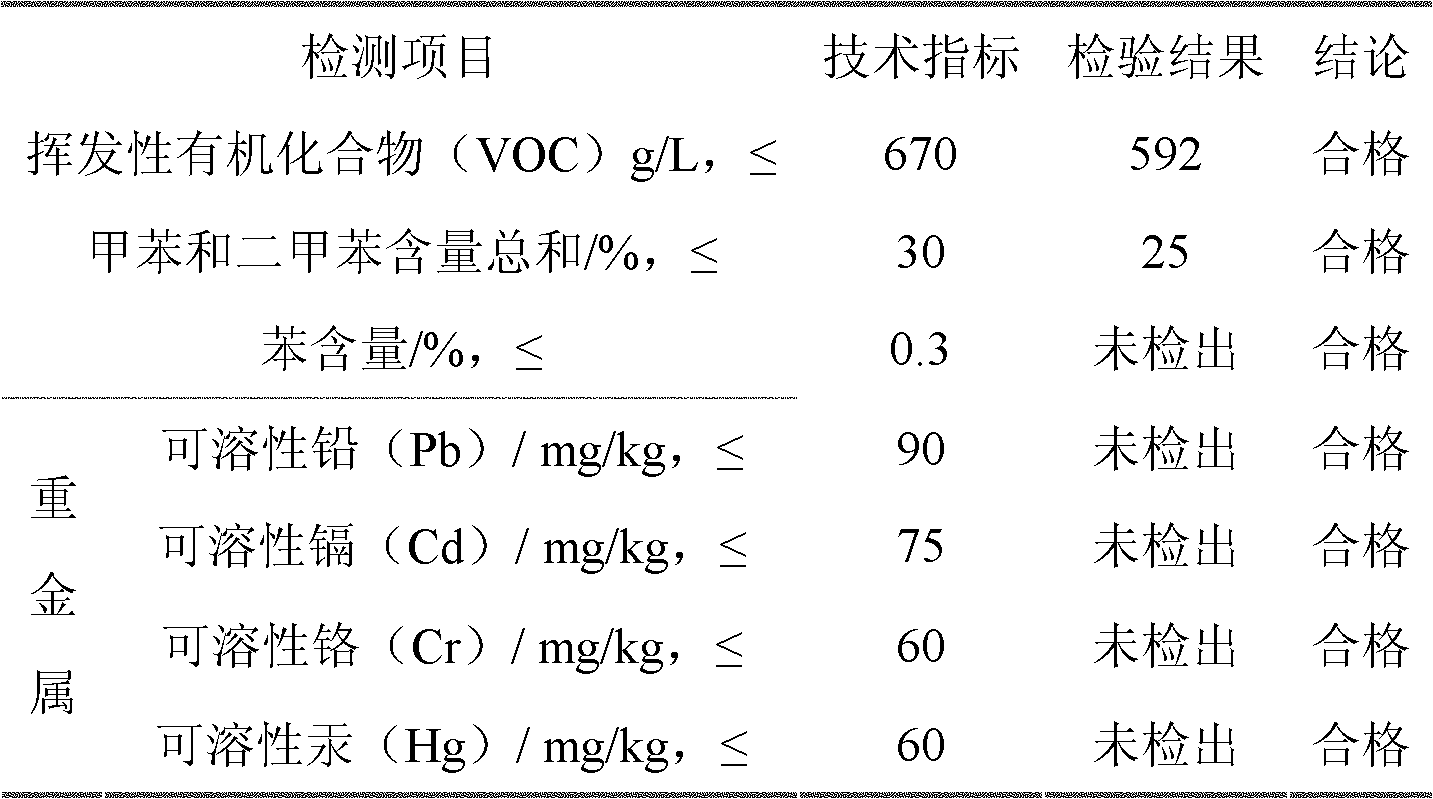

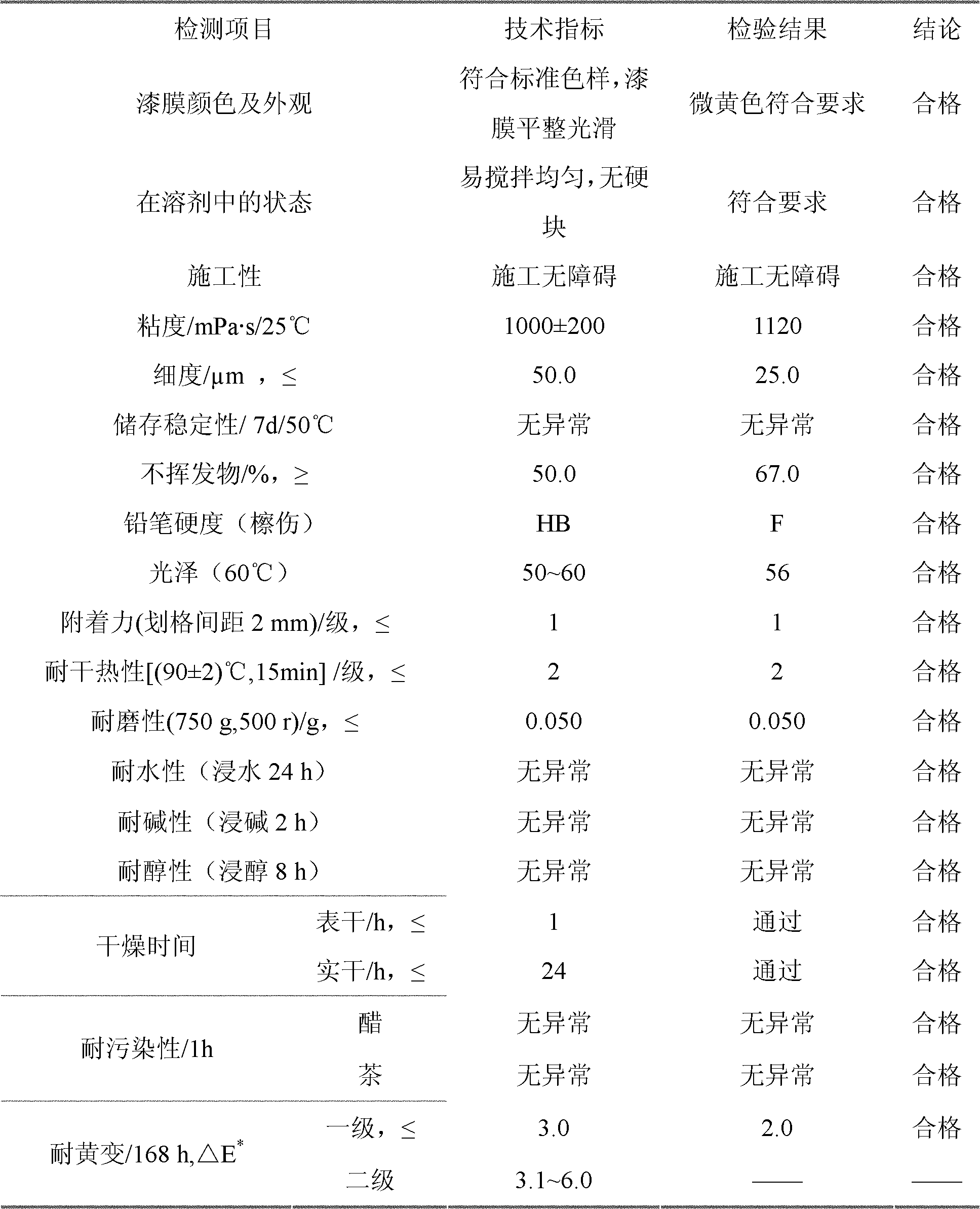

Novel polyurethane semi-matte white finish for woodware protection

InactiveCN101967340AHigh glass transition temperatureSmall steric hindrancePolyurea/polyurethane coatingsWaxDeodorant

The invention discloses novel polyurethane semi-matte white finish for woodware protection. The finish is prepared by mixing the following components: stearic acid modified alkyd resin, polyketone resin solution, an antifoaming agent, an anti-settling agent, a dispersing agent, white slurry, handfeel wax powder, aerosol extinction powder, 20 percent hydroxyl modified vinyl acetate (VAGH) resin, a leveling agent, an anti-yellowing auxiliary agent, a deodorant and butyl ester. A film prepared from the novel polyurethane semi-matte white finish has the advantages of fullness, moderate hardness, high flexibility, high water resistance, yellowing resistance and environmental protection; and the semi-matte white finish has high comprehensive performance.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Bisphenol A bisphthalonitrile resin containing arylethernitrile chain segment, cured resin and preparation method thereof

InactiveCN102887999AWide processing temperature windowEasy to solidify and processPolymer sciencePhthalocyanine

The invention relates to a bisphenol A bisphthalonitrile resin containing an arylethernitrile chain segment, a cured resin and a preparation method thereof, belonging to the field of high polymer materials. The preparation method comprises the following steps: performing nucleophilic substitution reaction on bisphenol A and 2,6-dichlorobenzonitrile used as raw materials in a strongly polar solvent / methylbenzene mixed solution in the presence of anhydrous potassium carbonate or anhydrous sodium carbonate used as a catalyst, thus forming a hydroxyl-terminated bisphenol A low polymer intermediate; then, substituting hydroxyl therein with 4-nitrophthalonitrile, thus obtaining the target resin; and adding curing crosslinking agent of which the mass is equivalent to 5% of that of the resin into the resin, precuring at 220-240 DEG C, and performing heat treatment at a temperature not lower than 375 DEG C to obtain the cured resin. The bisphthalonitrile resin provided by the invention has different chain lengths, contains an arylethernitrile chain segment, and has a low melting point and a wide curing processing temperature; the cured resin is in a network structure comprising phthalocyanine rings and triazine rings, and has excellent heat stability; and the provided preparation method of the resin and the cured resin is simple and controllable, and is suitable for industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

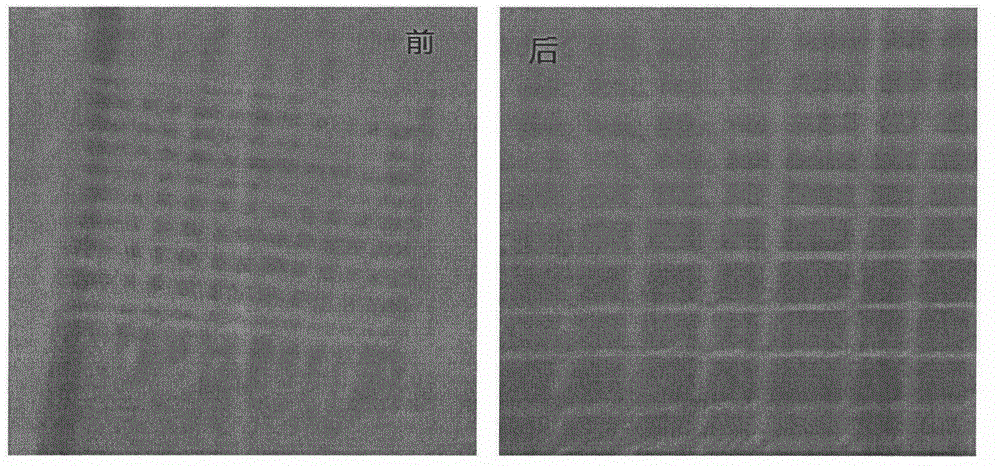

Transfer processing method for glass base material of cover board

ActiveCN105259737AStrong responsivenessImprove adhesionPhotomechanical exposure apparatusMicrolithography exposure apparatusNon solventHigh energy

The invention discloses a transfer processing method for a glass base material of a cover board. The transfer processing method comprises the following steps: coating the surface of the glass base material of the cover board with an LED photo-curable non-solvent photosensitive transfer adhesive; covering a film diaphragm; carrying out a procuring exposure with an LED light source at a low energy of 100-200mJ / cm<2>; removing the film diaphragm, and dissolving an unexposed part adhesive with a developing solution; blowing or drying residual developing solution; and finally carrying out secondary curing on the developed transfer adhesive with the LED light source at a high energy of 1,000-2,000mJ / cm<2>, thereby finishing transfer processing of the glass base material of the cover board. According to the technology disclosed by the invention, the problems that an existing UV adhesive is poor in adhesion to glass of the cover board, poor in boiling resistance and poor in solvent resistance are solved; the industry requirements are met; the production cost of enterprises is reduced; and the benefits of the enterprises are improved.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

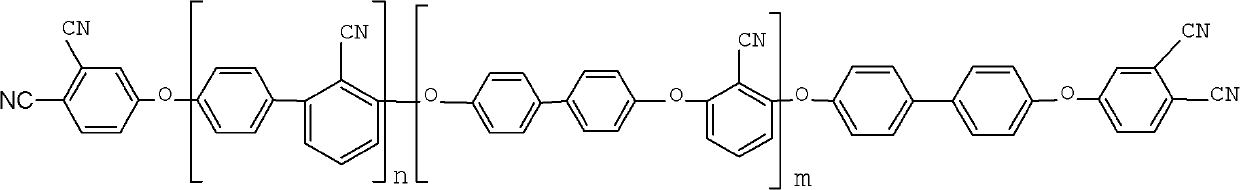

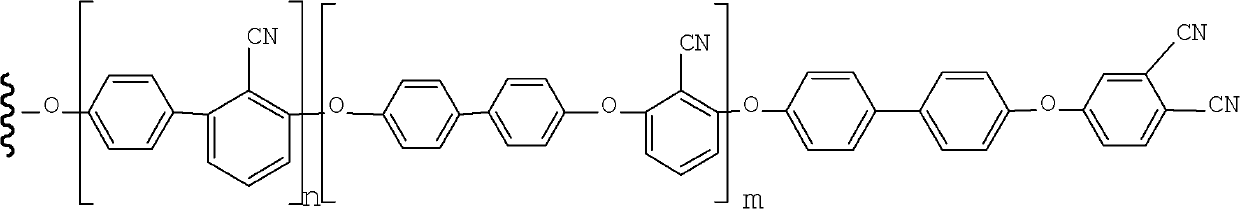

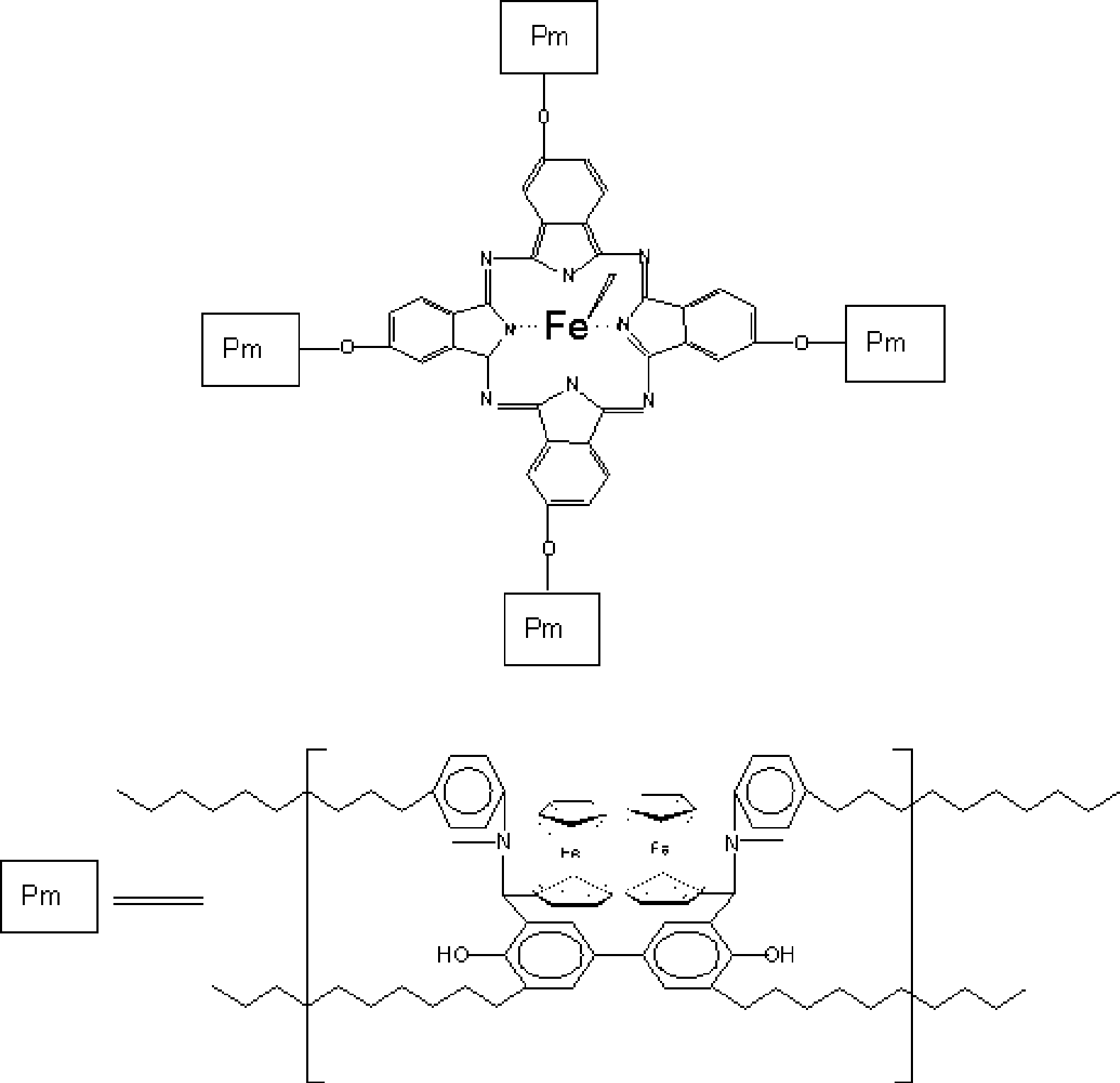

Polyaryl ether nitrile resin, polyaryl ether nitrile film and preparation method thereof

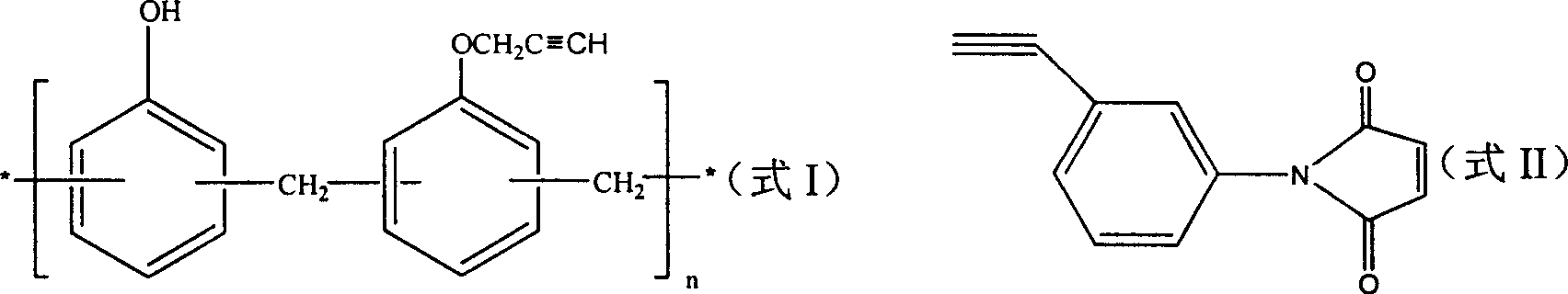

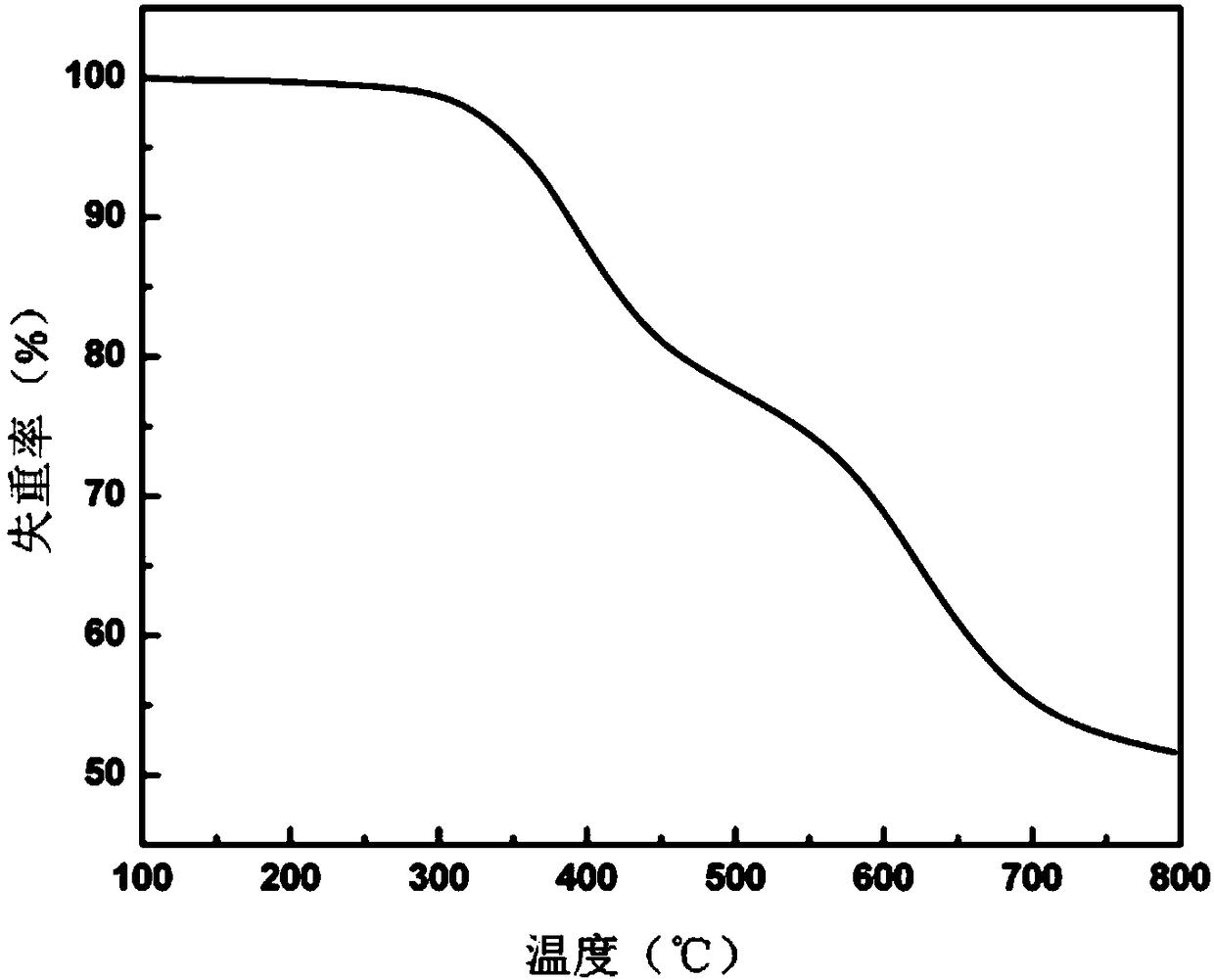

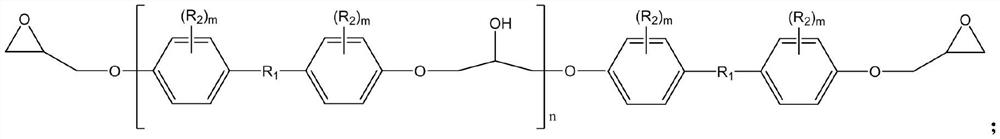

The invention belongs to the field of high polymer materials, and particularly relates to polyaryl ether nitrile resin, a polyaryl ether nitrile film and a preparation method thereof. The structure of the polyaryl ether nitrile resin is represented by formula I: n=40-80, m=10-20. Cross-linking groups are arranged at the chain end of the polyaryl ether nitrile resin, and the polyaryl ether nitrile resin has good curing reaction activity and can be used for preparing a corresponding polyaryl ether nitrile film. The polyaryl ether nitrile film is good in heat-resistant performance, the glass-transition temperature is 200 DEG C to 240 DEG C, the initial decomposition temperature is 560 DEG C to 580 DEG C, and carbon residue rate of thermal decomposition in nitrogen atmosphere at 800 DEG C is more than 69%. The polyaryl ether nitrile film is good in toughness, the elongation at break of the polyaryl ether nitrile film ranges from 8% to 12%, tensile strength is excellent, the tensile strength of the polyaryl ether nitrile film ranges from 80 MPa to 100 MPa.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

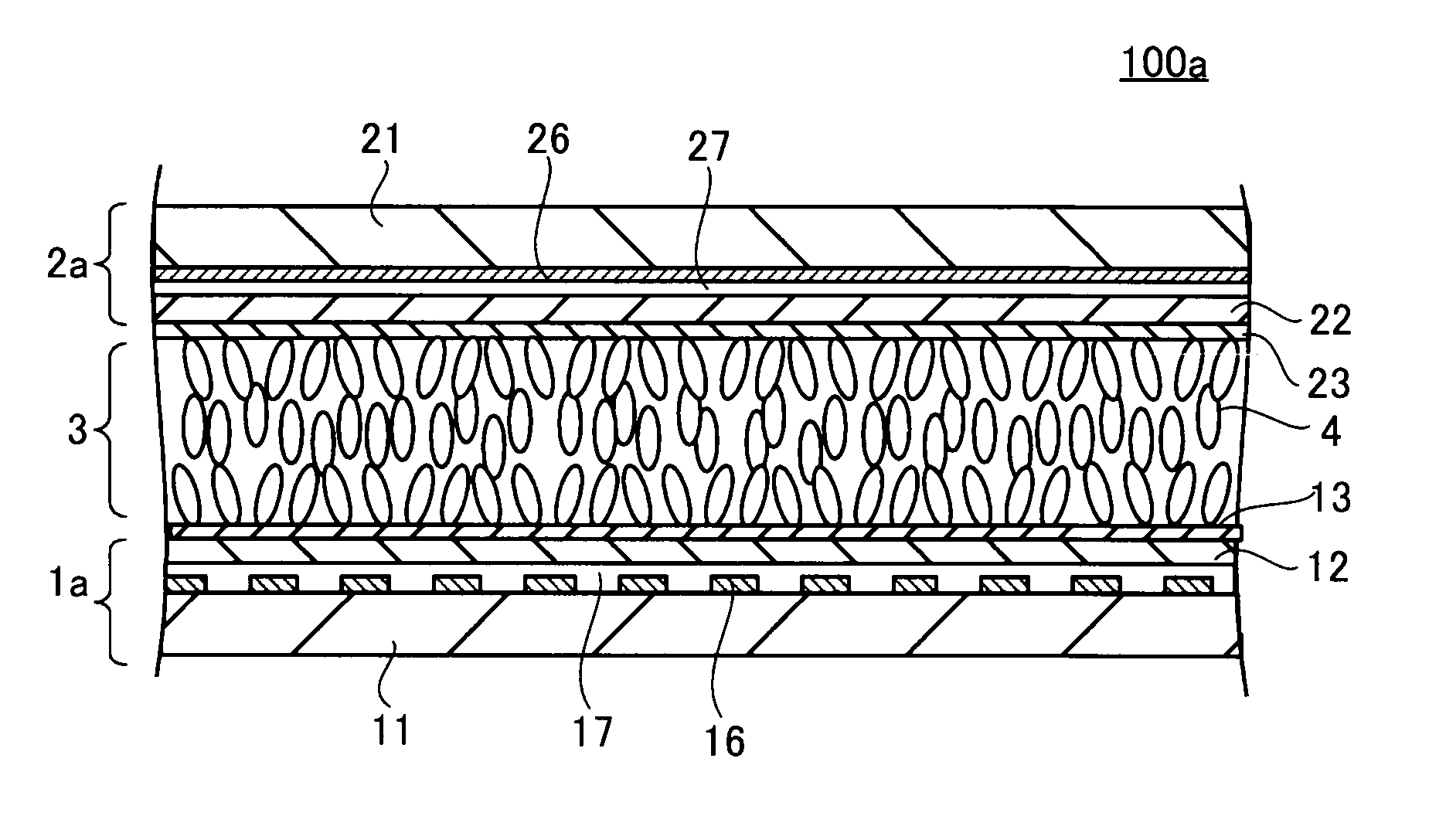

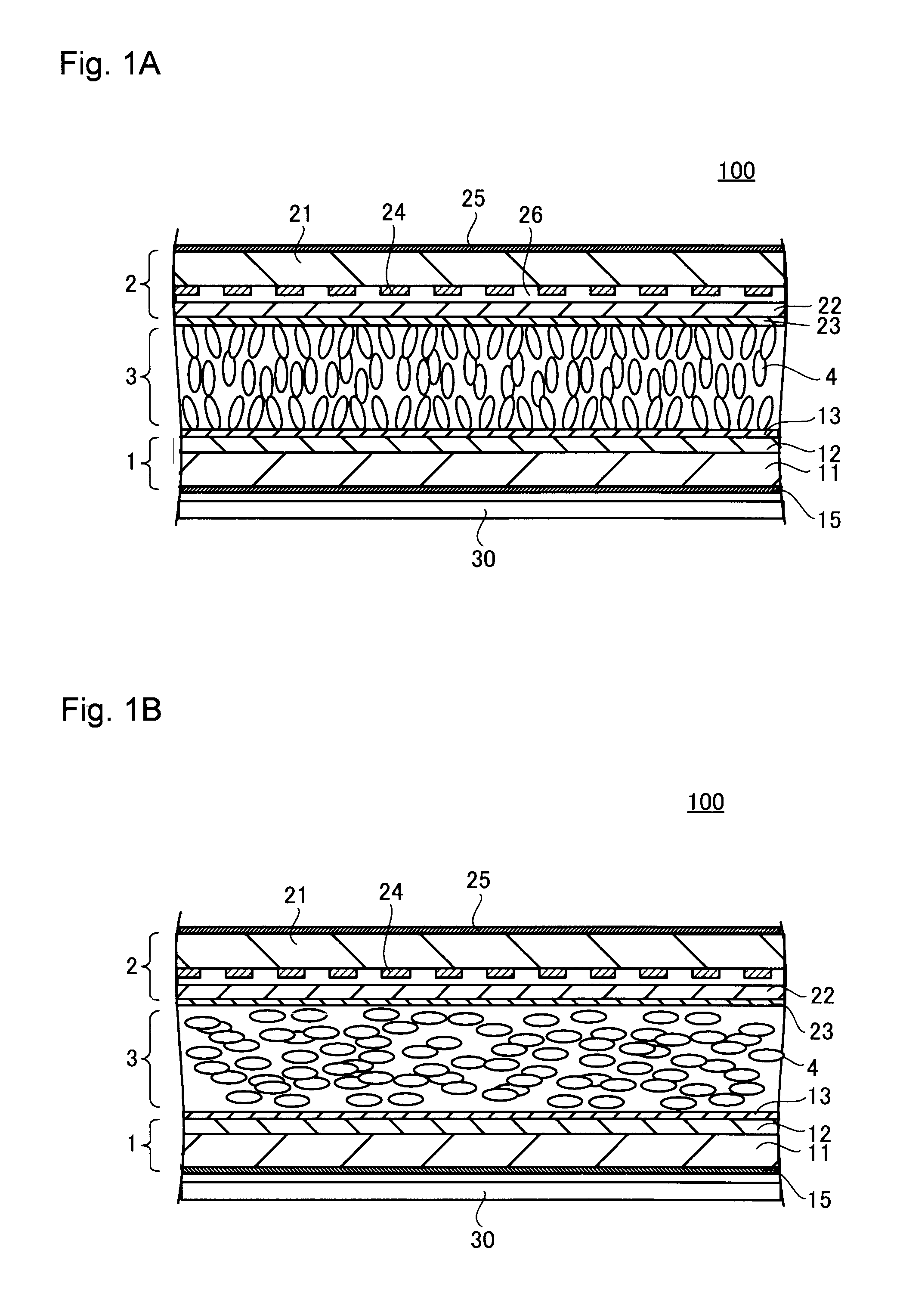

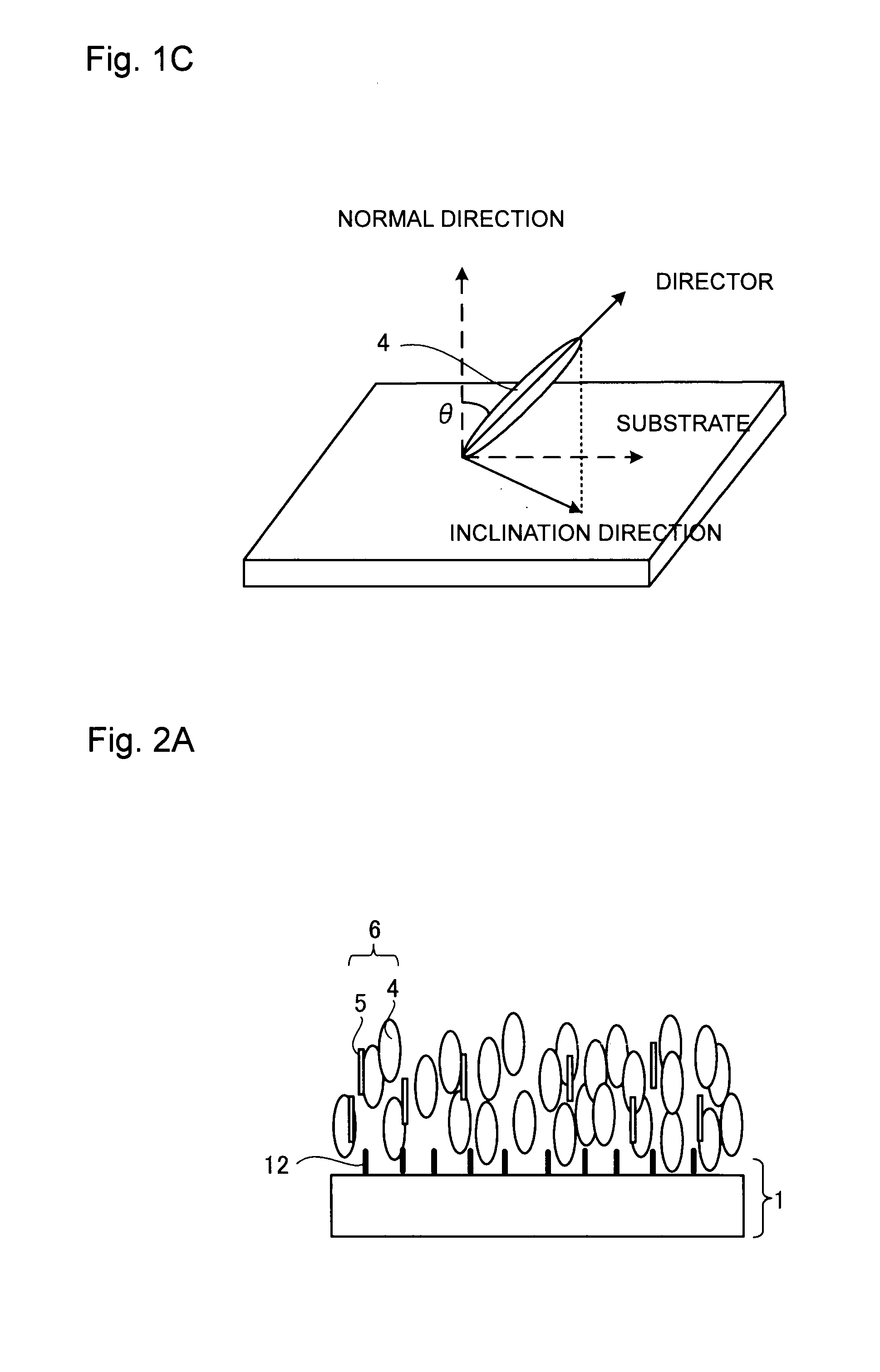

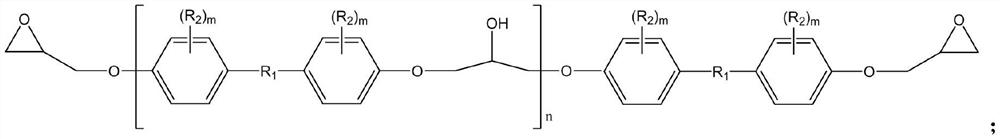

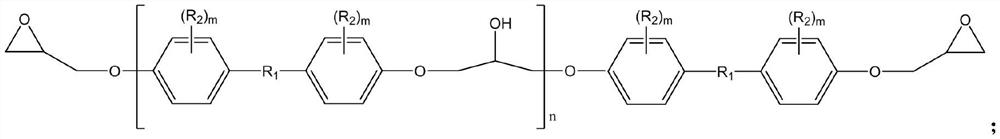

Liquid crystal optical device and its production process

InactiveUS20120268692A1Improve reliabilityProduction processVessels or leading-in conductors manufactureNon-linear opticsCarbon numberCrystallography

A liquid crystal optical device comprising a pair of substrates having an electrode pair formed; a liquid crystal layer sandwiched between the substrates; an alignment layer to align the liquid crystal, provided on each of the facing surfaces of the substrates; and a polymer structure provided on the alignment layer; wherein the polymer structure is formed by curing a curable compound represented by the following formula (1), and when a voltage is not applied, liquid crystal molecules in the vicinity of an interface between the liquid crystal layer and the polymer structure have at least one direction of director different from the alignment direction by the alignment layer:A1-O—R1—O—Z—O—R2—O-A2 Formula (1)wherein each of A1 and A2 is independently a curable functional group to be polymerized by an external energy, each of R1 and R2 is independently selected from a linear alkylene group with carbon number of 2 to 5 which may have a methyl group or an ethyl group as a branched chain, and Z is a bivalent mesogen structure.

Owner:OPTREX CORP +1

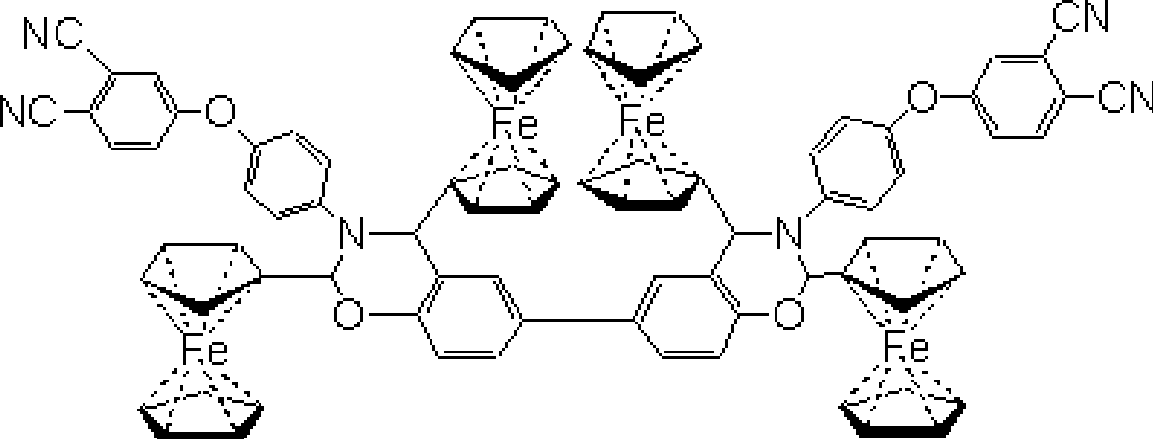

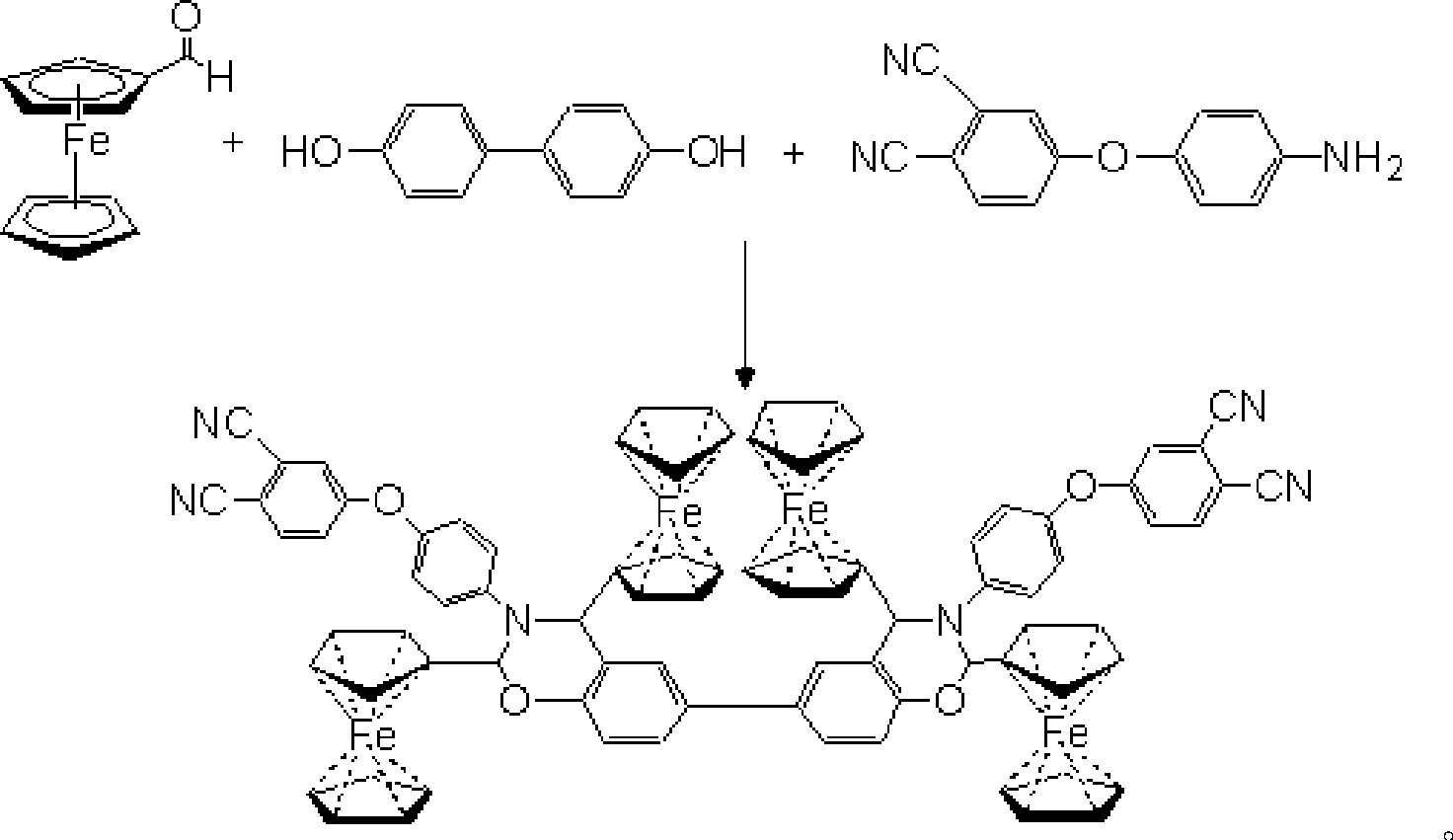

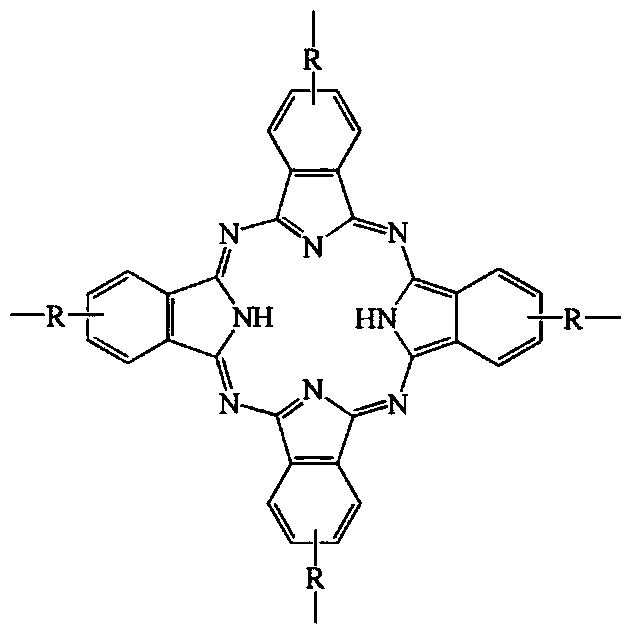

Magnetic ferrocene-double-terminal phthalonitrile resin, condensate and preparation thereof

InactiveCN101463049AImprove thermal stabilityStrong magnetismMetallocenesPolymer scienceMolecular materials

The invention belongs to the high molecular material field, in particular to magnetic ferrocene-double terminal phthalonitrile resin, a cured product and a preparation method thereof. The structure of the magnetic ferrocene-double terminal phthalonitrile resin is as shown in formula I. The magnetic ferrocene-double terminal phthalonitrile resin and ferric iron salt react in an anhydrous and highly polar solvent at the temperature of 150-170 DEG C, then are washed and dehydrated to obtain a prepolymer, and the prepolymer is heated to 190-210 DEG C for precuring for 2-4h, and then heated to 340-360 DEG C for heat treatment for 4-6h to obtain the cured product of the resin. The resin prepared by the method has a wider processing temperature window, simple reaction process and easy operation; and the cured product has abundant crosslinking structures, better thermostability and magnetism, and can be widely applied to high temperature resistant magnetic functional composite materials.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Ultraviolet curing transfer adhesive for glass substrate

ActiveCN106281198AAvoid overall performance degradationReasonable compositionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSolventChemistry

The invention discloses an ultraviolet curing transfer adhesive for a glass substrate. The ultraviolet curing transfer adhesive comprises aliphatic polyurethane acrylate, an acrylate active diluent, a photoinitiator, an acrylate aid and a silane coupling agent. The ultraviolet curing transfer adhesive for a glass substrate, disclosed by the invention, has good mechanical property, wear resistance, solvent resistance and cold / hot impact resistance while the adhesion between the adhesive layer and the substrate is good; and particularly, after water boiling test, the adhesion between the adhesive layer and the substrate is still greater than 4B, and little environmental pollution is caused. The problems that existing ultraviolet curing transfer adhesive has low adhesion and is not resistant to water boiling and solvent are solved; and the ultraviolet curing transfer adhesive disclosed by the invention meets the industry requirements, reduces the production cost of an enterprise and brings profit to the enterprise.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

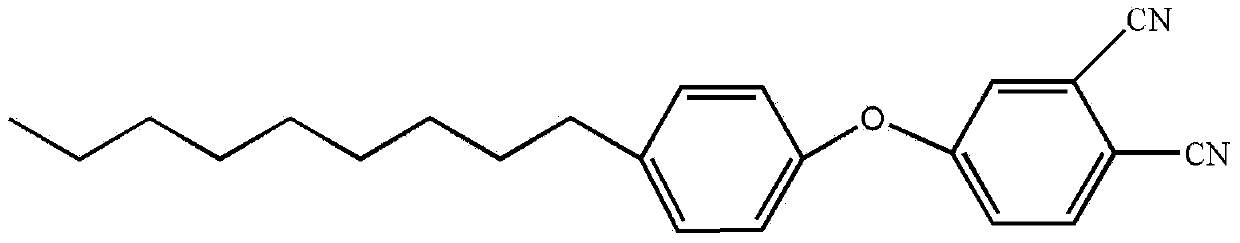

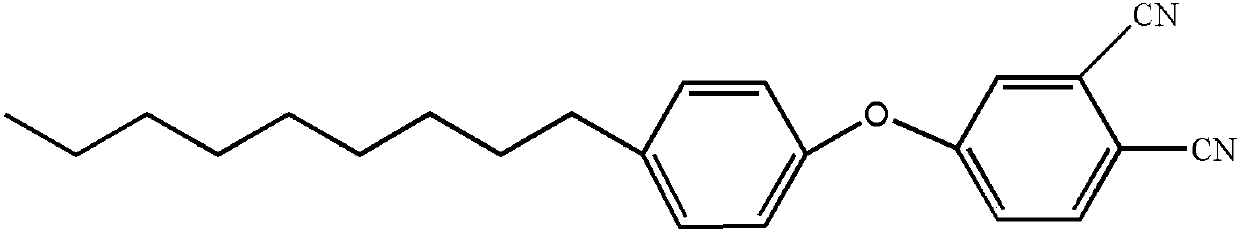

Low-viscosity nitrile resin monomer, copolymer, cured material and preparation method thereof

InactiveCN103739519AEasy to processImprove curing effectCarboxylic acid nitrile preparationOrganic compound preparationReaction temperatureResin-Based Composite

A low-viscosity nitrile resin monomer, a polymer and a preparation method thereof belong to the technical field of organic polymer materials. The low-viscosity nitrile resin monomer is a 4-nonyl phenoxyl-1,2-phthalonitrile resin monomer, and the nitrile resin cured material is a product obtained by heating polymerization of the nitrile resin monomer and benzoxazine-containing nitrile resin monomers. The nitrile resin monomer has good fluidity at low temperature, and is applicable to viscosity modification of general thermosetting resin. Melt blending of the nitrile resin monomer and the benzoxazine-containing nitrile resin is performed to prepare 4-nonyl phenoxyl-1,2-phthalonitrile / benzoxazine-containing nitrile resin copolymer and cured materials. The obtained 4-nonyl phenoxyl-1,2-phthalonitrile / benzoxazine-containing nitrile resin copolymer has low melting viscosity and processing temperature, and is well applicable to composite material preparation by RTM technology. The 4-nonyl phenoxyl-1,2-phthalonitrile / benzoxazine-containing nitrile resin cured material has good curing performance such as self-flame resistance, adhesion performance, heat stability, and the like, and is applicable to fields of paint, bonding agents, electronic packaging materials, aviation, aerospace, ships and resin-based composite materials. The preparation method is simple, easy to control, low in reaction temperature, energy-saving, and suitable for industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

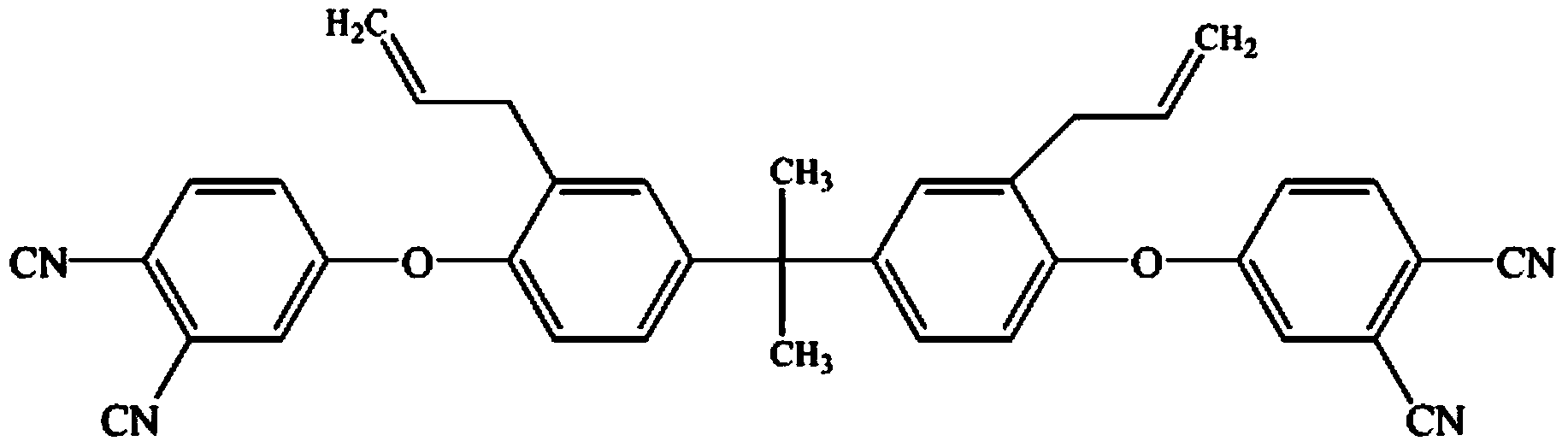

Autocatalytic nitrile resin monomer, polymer and preparation method of polymer

ActiveCN103664699ALow curing temperatureImprove mechanical propertiesCarboxylic acid nitrile preparationOrganic compound preparationPolymer scienceAdhesive

The invention provides an autocatalytic nitrile resin monomer, a polymer and a preparation method of the polymer, belonging to the technical field of organic polymer materials. The autocatalytic nitrile resin monomer is a bisphenol A bisphthalonitrile monomer containing allyl. The nitrile resin polymer is a product obtained by heating and polymerizing the nitrile resin monomer. The nitrile resin monomer has lower curing temperature and wider process window, so that the resin monomer has better processability. The nitrile resin polymer has good curing properties such as self-flame retardance, adhesion, thermal stability and the like. The nitrile resin monomer has low-temperature curing properties of the carbon-carbon double bond. The nitrile resin polymer maintains the high temperature resistance of the nitrile resin and can be widely applied to the fields of coatings, adhesives, electronic packaging materials, aeronautics and astronautics, ships, resin matrix composites and the like. The preparation method is simple and easy to control, is relatively low in reaction temperature and relatively short in reaction time, and is suitable for industrial production.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Photosensitive developed special line transfer glue for sapphire glass base material and preparation method thereof

InactiveCN108517196AImprove performanceGood synergyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPhosphate

The invention discloses photosensitive developed special line transfer glue for a sapphire glass base material and a preparation method thereof. The photosensitive developed special line transfer glueis prepared from an acrylic ester active monomer, a photoinitiator, an acrylic acid phosphate assistant, a silane coupling agent, polyester acrylate, and urethane acrylate. The transfer glue does notcontain an organic solvent, and is environmentally friendly. A transfer technology is used as the foundation, and the advantages of a photosensitive developing technology are organically fused, the advantages are adopted and the defects are avoided. Especially, a product of the transfer glue not only can use the organic solvent for developing, but also can use pure water for developing, and is environmentally friendly, non-inflammable and non-explosible, and is a future tendency. The transfer glue has the excellent properties of solvent corrosion resistance, cold and thermal shock resistanceand the like after curing, and an adhesive force of a glue layer and the sapphire glass base material is excellent, especially, the adhesive force of the glue layer and the sapphire glass base material is greater than or equal to 4B after a water boiling test. The transfer glue is capable of solving problems of current UV glue that the adhesive force on the sapphire glass base material is poor, the water boiling is not resistant, and the solvent is not resistant.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD +1

Radiation child-mother plate cured colloid and child plate forming method thereof

PendingCN111171778AIncrease crosslink densityGood construction performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesElectron beam irradiationPolymer chemistry

The invention relates to a radiation child-mother plate cured colloid and a child plate forming method thereof. The child plate forming method comprises the steps that (1) carving a needed pattern ona metal roller with a metal chrome plating layer and high surface smoothness through lasers, and forming pattern textures used for follow-up transfer printing on the surface of the roller so as to obtain a mother plate; (2) coating the radiation child-mother plate cured colloid on a base material; forming a transfer printing adhesive layer, drying and baking the transfer printing adhesive layer under reduced pressure, controlling the peel strength between the base material and the transfer printing adhesive layer to be more than two times of the peel strength between the transfer printing adhesive layer and the mother plate, pressing the transfer printing adhesive layer by adopting the mother plate, and transferring pattern textures on the mother plate onto the adhesive layer; and (3) carrying out electron beam irradiation on the transfer printing adhesive layer coated on the base material and printed with the pattern texture to cure the transfer printing adhesive layer to obtain the child plate convenient to strip. The radiation child-mother plate cured colloid obtained by the method can well keep the uneven feeling corresponding to the concave-convex shape of the required pattern, is good in impressing, has no defects in a line / space, can achieve excellent gloss and high-quality feeling in appearance, and can meet the sticker requirements of various high-grade articles.

Owner:CHUZHOU JINQIAO TEXAS NEW MATERIALS CO LTD

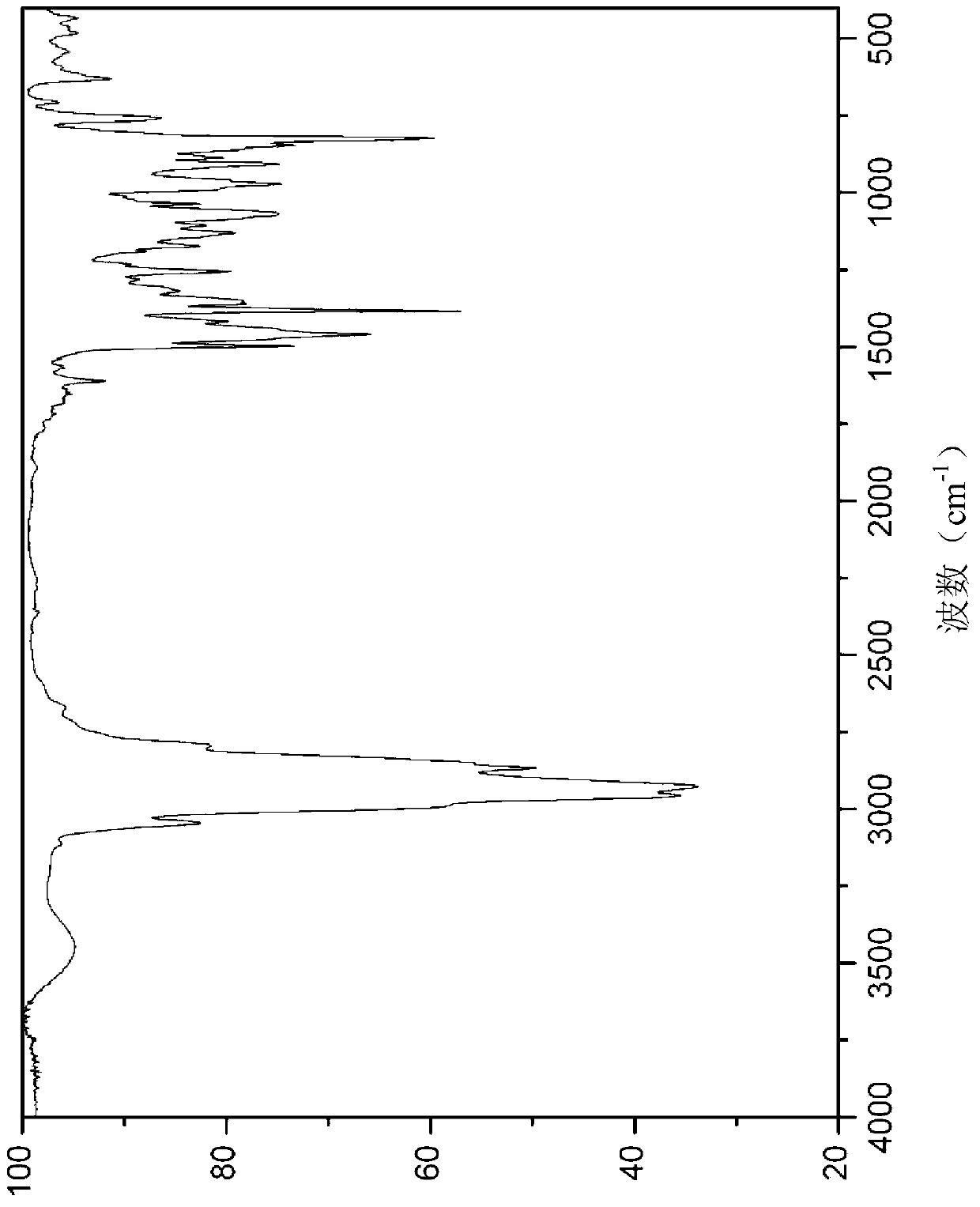

Imidazole dinitrile resin based on acid-base co-melting and preparation method thereof

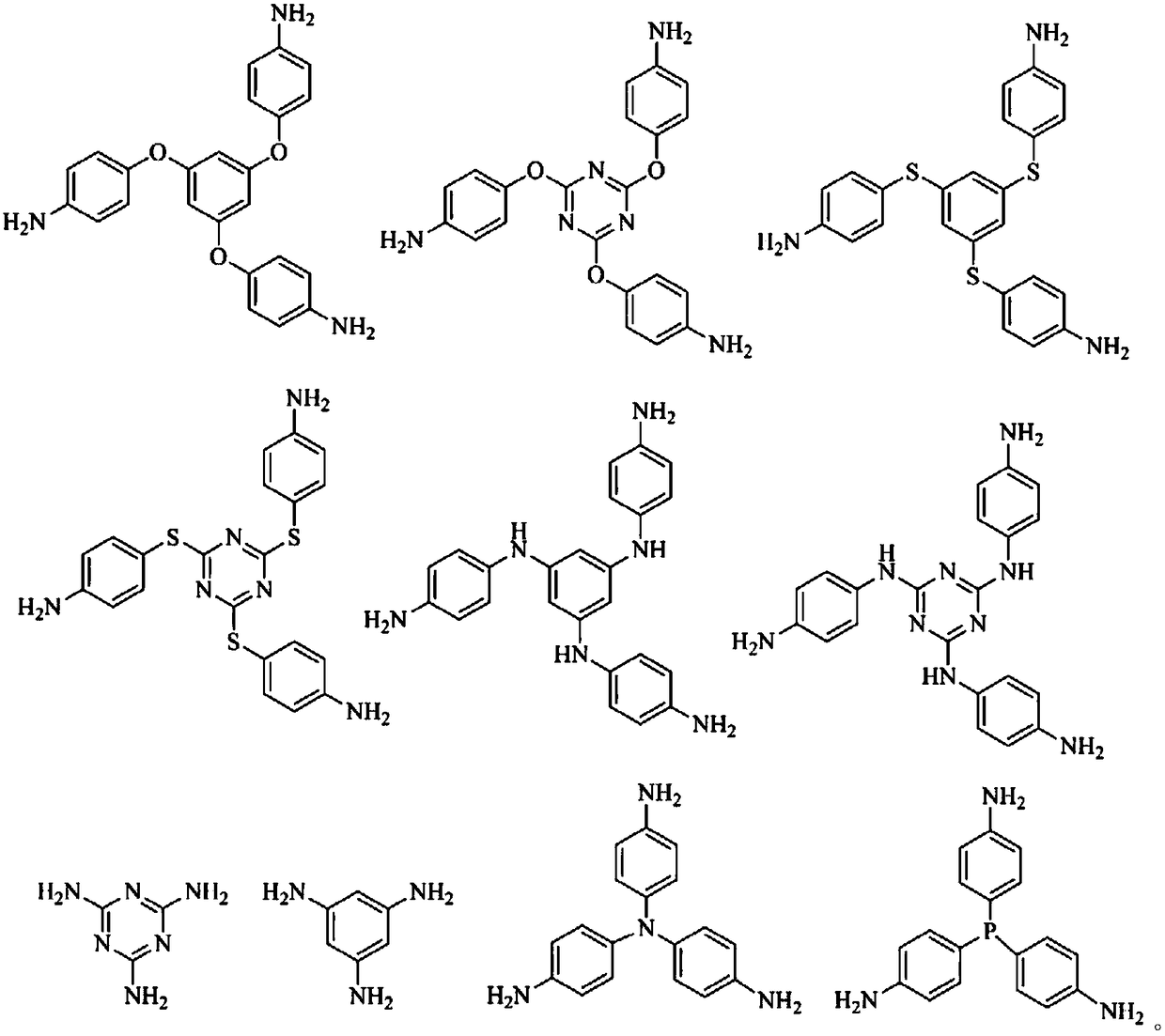

The invention discloses imidazole dinitrile resin based on acid-base co-melting and a preparation method thereof, and the imidazole dinitrile resin is obtained by co-melting and curing at least one imidazole dinitrile compound and at least one organic base as raw materials, and the molar ratio of an N-H structure in the imidazole dinitrile compound to a basic group in the organic base is (3: 1)-(1: 3). Through construction of the imidazole dinitrile and organic alkali ion co-melt, the melting point of the acid-base co-melt is effectively reduced, and the curing temperature of the acid-base co-melt is reduced.

Owner:SICHUAN UNIV

Modified resin for water-based material and preparation method thereof

The invention relates to the technical field of materials, in particular to modified resin for a water-based material and a preparation method thereof, the modified resin comprises matrix resin and aside chain group graft on the matrix resin; the matrix resin comprises at least one of polyvinyl alcohol resin and polyvinyl acetate resin with hydroxyl; each of the side chain group grafts comprisesat least one isocyanate group and at least one vinyl group. The modified resin for the water-based material provided by the invention can be used as an active emulsifier of various water-based materials, e.g., water-based ink, water-based paint, water-based photo-sensitive adhesive, water-based adhesive, photoresist, 3D printing materials and the like. The water-based photo-curing resin is especially suitable for water-based photo-curing ink, water-based photo-curing paint, water-based photo-curing photo-sensitive adhesive, water-based photoresist and water-based photo-curing 3D printing materials, and has excellent curing reaction activity, water resistance, acid and alkali resistance, solvent resistance, wear resistance, cohesiveness and strength.

Owner:赵锦程

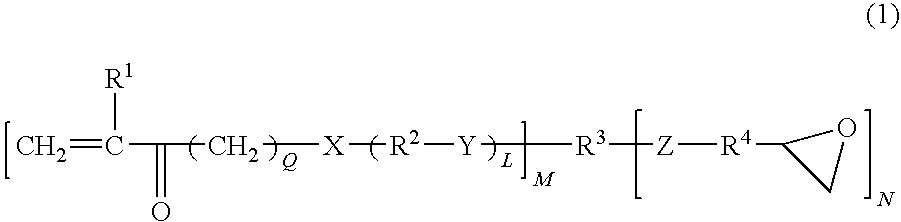

Unsaturated group-containing ester compound, polymer, thermosetting resin composition, and cured film

ActiveUS20190284385A1High curing reactivityExcellent low temperature curingOrganic chemistryCoatingsChemical structureHydrogen

It is an object of the present invention to provide an unsaturated group-containing ester compound which can be used as a raw material of a curable composition using transesterification reaction and which is inexpensive and has a good curability, and a polymer, a thermosetting resin composition, and a curable composition which containing the unsaturated group-containing ester compound, respectively.An unsaturated group-containing ester compound having a chemical structure represented by the following general formula (1):n1: 1 to 10(in the formula, R1, R2, and R3 are the same or different and each is a hydrogen, an alkyl group, a carboxyl group, an alkyl ester group or a structure represented by R4-[COOR5]n1;R4 is an aliphatic, an alicyclic or an aromatic alkylene group with a number of atoms of 50 or less in the main chain, which may have one or more functional groups selected from the group consisting of an ester group, an ether group, an amide group, and a urethane and may have a side chain;R5 is an alkyl group having 50 or less carbon atoms; and in the compound represented by the general formula (1), the R4-[COOR5] group may be a lactone structure represented by the following general formula (1-1).)(Rx is a hydrocarbon group having 2 to 10 carbon atoms which may have a branched chain.)

Owner:KYOEISHA CHEM CO LTD

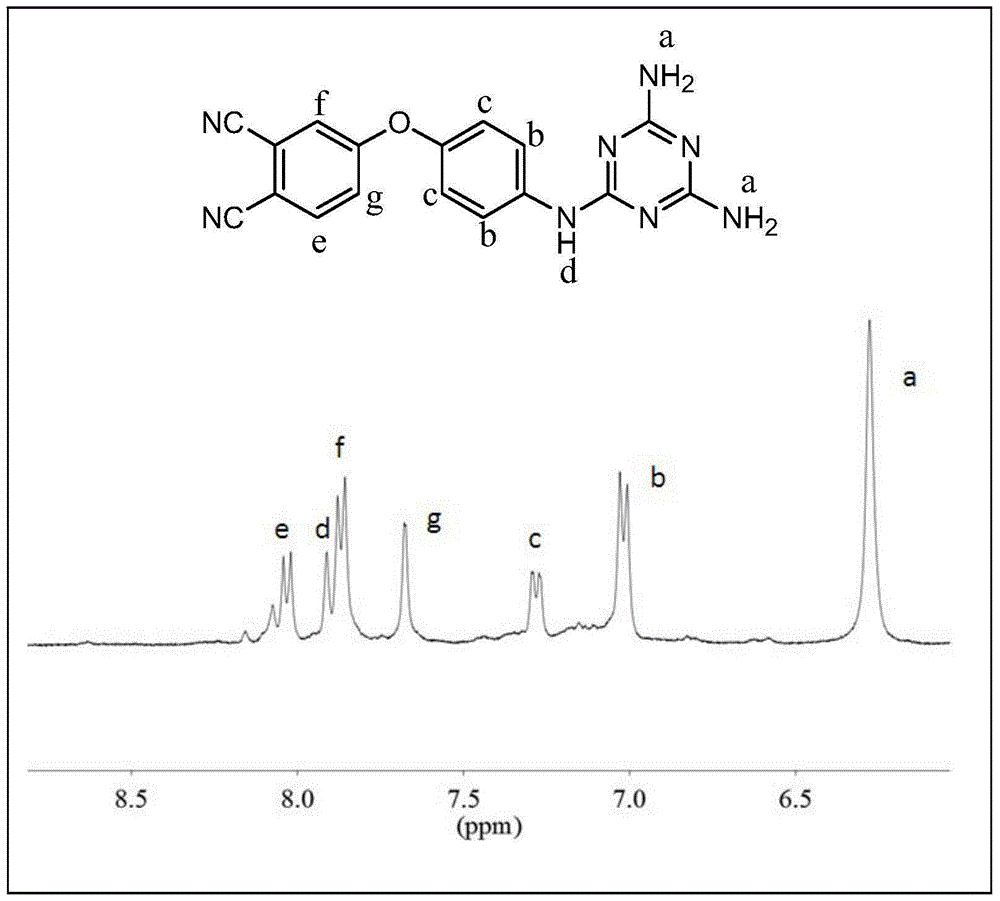

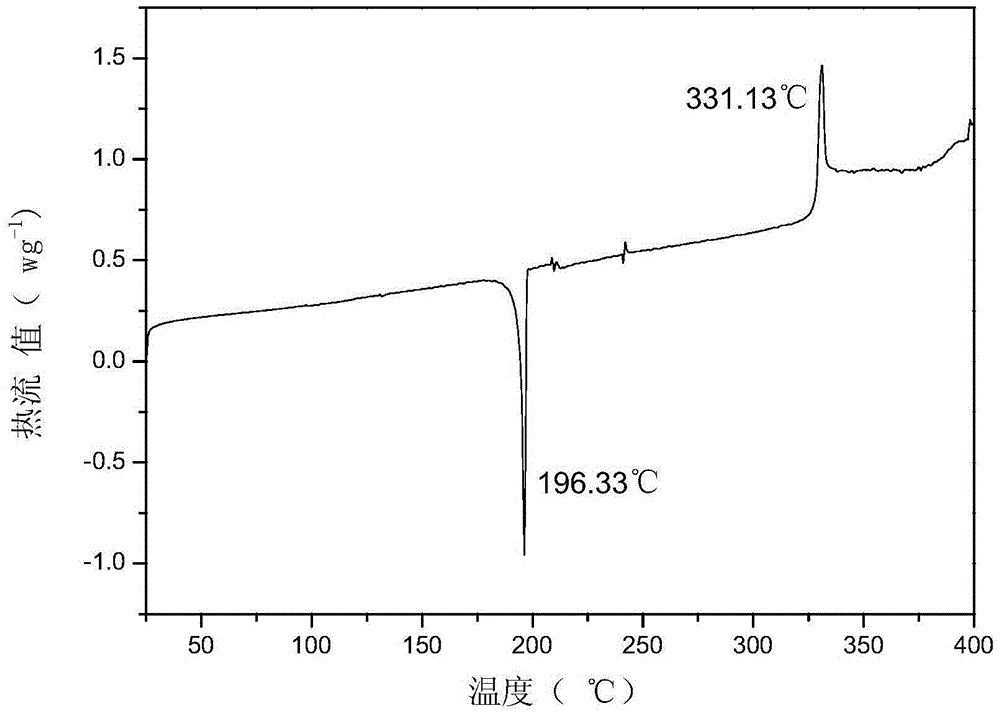

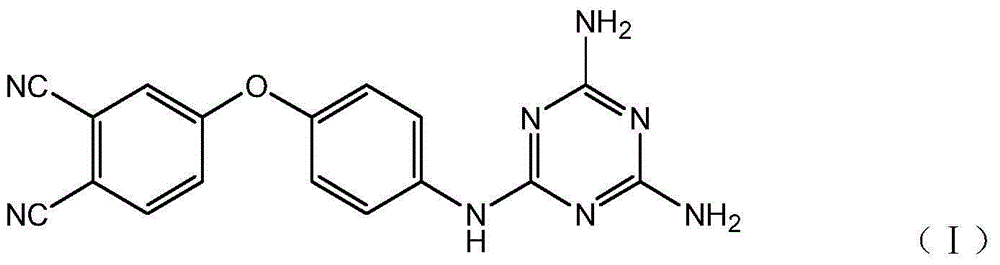

Self-catalyzed resin monomer and synthesis method thereof

InactiveCN105218471AImprove thermal stabilityReduce processing temperatureOrganic chemistrySynthesis methodsP-Aminophenol

The invention discloses a self-catalyzed resin monomer and a synthesis method thereof. The molecular structural formula of the self-catalyzed resin monomer is shown in the specification. The synthesis method includes the steps that 1, with p-aminophenol and 4-nitrophthalonitrile as main raw materials, 4-p-amino-phenoxyphthalonitrile is prepared; 2, with 2,4-diamido-6-chloro-1,3,5-triazine and 4-p-amino-phenoxyphthalonitrile as main raw materials, a reaction is conducted at 80-150 DEG C, and then the self-catalyzed resin monomer is obtained. The self-catalyzed resin monomer has excellent heat stability and curing performance and a low processing temperature. The synthesis method is simple and easy to control, the reaction temperature is low, the reaction time is short, and the synthesis method is suitable for industrial production.

Owner:NAT UNIV OF DEFENSE TECH

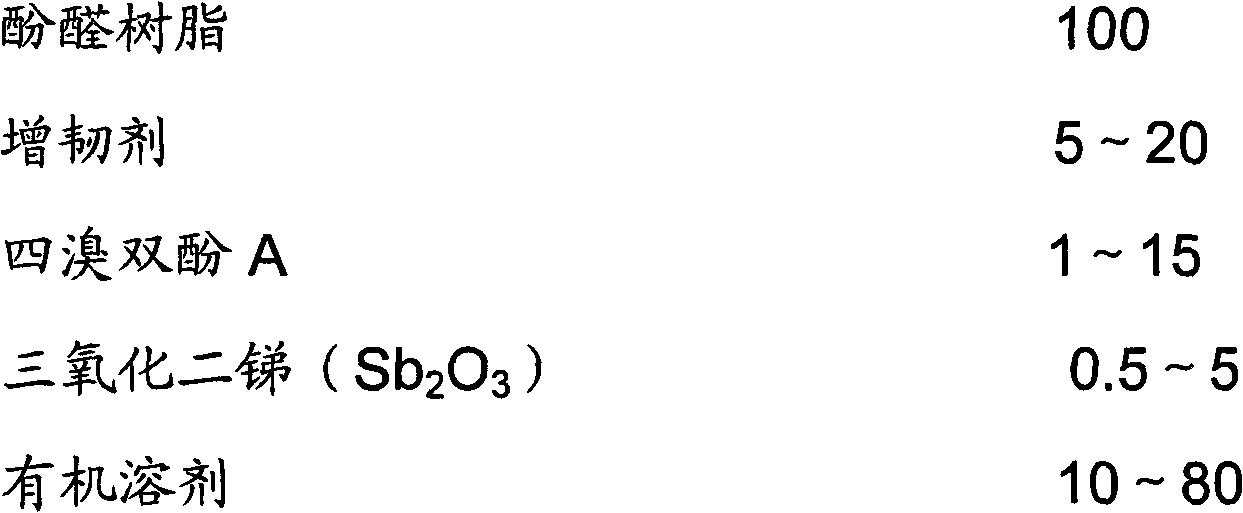

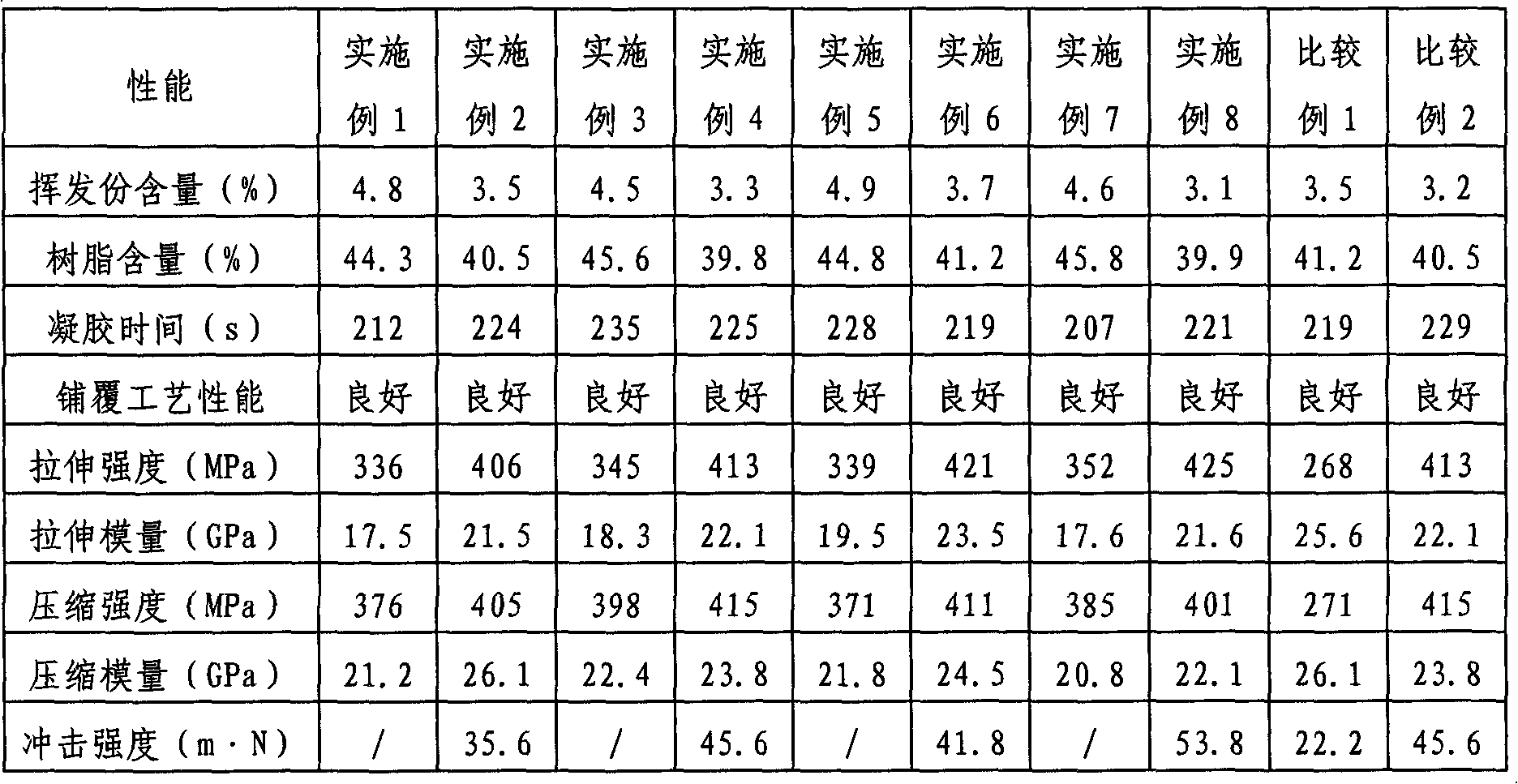

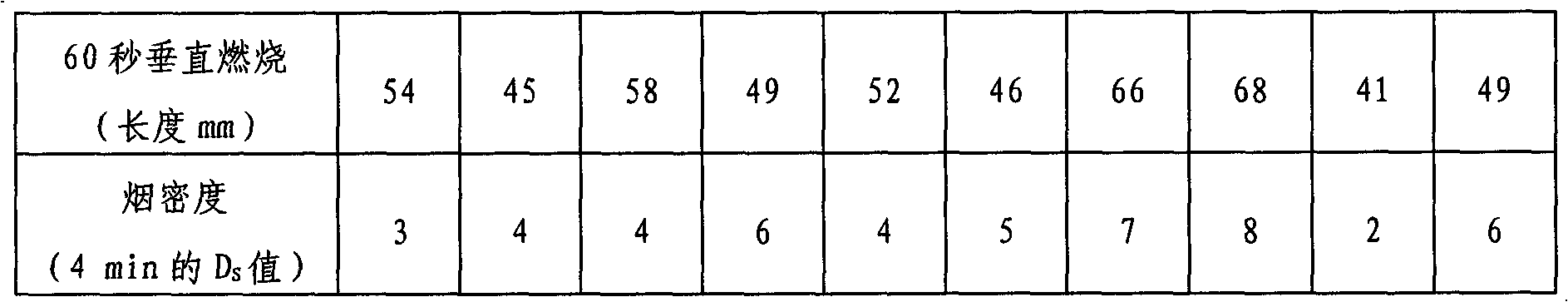

Preparation method of high-toughness flame retardation phenolic prepreg composite material

The invention relates to a high-toughness flame retardation phenolic prepreg composite material, its preparation method and its application, which is characterized in that a reasonable molecular structure design and a synthesis technology are combined for substantially raising the reaction activity of a phenolic resin prepolymer under the low temperature, on the basis of phenolic resin, a thermoplastic polymer and a rubber flexibilizer are introduced, and the toughness of the composite material can be substantially enhanced, a bromine / antimony system fire retardant is introduced for making up the disadvantages of decreased flame resistance performance caused by the addition of a flexibilizer; a preparation technology for regulation and control as well as optimization of the prepreg is used for controlling the solidification degree and the volatile matter content of the prepreg, thereby the soft feeling and moderate viscosity of the phenolic prepreg can be realized, and the composite material possesses good spreading technical performance. The composite material can be use for inner decoration parts of airplane ceilings, luggage compartments and sidewall plates, ship wallboards and cabinets, and high speed train ceilings and sidewall plates and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Synthesis method and application of unsaturated hyperbranched polyimide resin

The invention discloses a synthesis method and application of an unsaturated hyperbranched polyimide resin. The synthesis method comprises the following steps: 1) preparing a monomer, namely uniformlymixing raw materials, namely aromatic tertiary amine A3 and a dianhydride compound B2, adding a high-melting point solvent, and performing a reaction under a set condition so as to obtain an A2B typefunctional monomer; 2) performing a polymerization reaction, namely putting a catalyst into the A2B type functional monomer prepared in the step 1), performing a self-polycondensation reaction so asto obtain a yperbranched resin at the tail end of amino, further adding a free radical polymerization inhibitor and an end-capping reagent, performing a quenching reaction, controlling a branching degree, and performing reduced pressure distillation, thereby obtaining the unsaturated hyperbranched polyimide resin HP-PI. The polyimide resin prepared by using the synthesis method is relatively low in viscosity, good in solubleness, capable of effectively reducing the amount of diluents in the process that an insulating impregnating varnish is prepared, the cost can be reduced, and the toxicity can be degraded.

Owner:CENT SOUTH UNIV

Preparation method of lightning arrester zinc oxide pressure-sensitive valve plate ceramic precursor

ActiveCN111925206AHigh strengthHigh reactivityResistor chip manufactureVaristor coresElectron beam irradiationPyrolysis

The invention belongs to the technical field of zinc oxide materials, and especially relates to a preparation method of a lightning arrester zinc oxide pressure-sensitive valve plate ceramic precursor. The preparation method is simple, polycarbosilane is used for sintering; polycarbosilane is modified and crosslinked by electron beam irradiation so as to obtain a polymer ceramic precursor; and thelightning arrester zinc oxide pressure-sensitive valve plate is obtained through pyrolysis under the protection of pressure-free nitrogen. The precursor has the advantages of being high in surge resistance, high in potential gradient and good in nonlinearity, is suitable for manufacturing valve plates and overvoltage protection pieces of large and small zinc oxide lightning arresters, and is suitable for being applied to lightning arresters.

Owner:ANHUI JINHUA ZINC OXIDE CO LTD

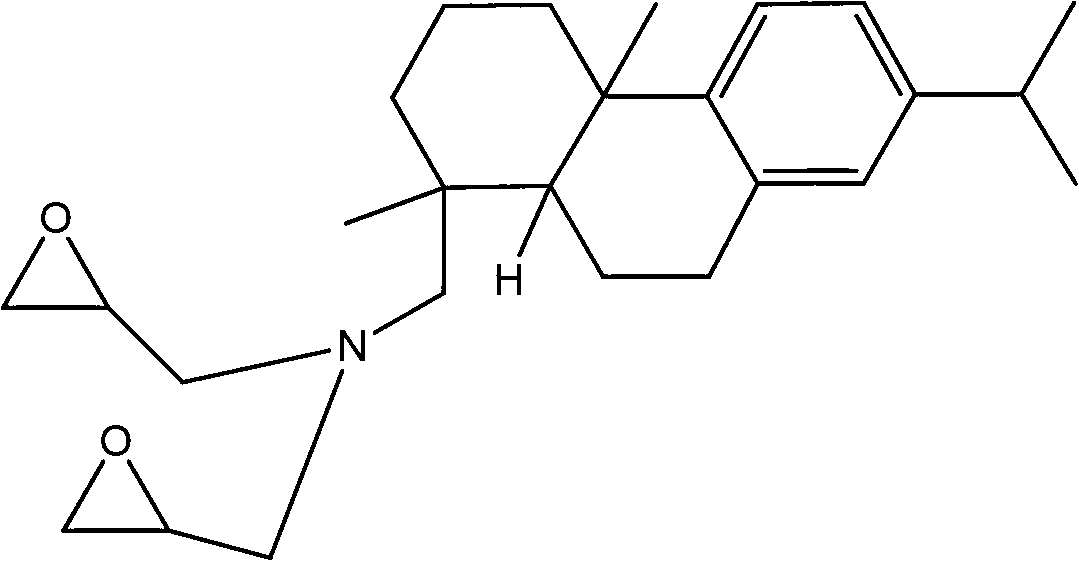

Dehydroabietylamine-based epoxy resin and preparation method and application thereof

ActiveCN102766116AImprove heat resistanceImprove adhesionOrganic chemistryEpoxy resin adhesivesPolymer sciencePolymer chemistry

The invention discloses dehydroabietylamine-based epoxy resin shown as a formula I. The epoxy resin has a large-size hydrophenanthrene ring, high chain segment rigidity after being cured, and high mechanical property and thermal property. The invention also discloses a preparation method and application of the dehydroabietylamine-based epoxy resin. The preparation method is simple and high in operability and process controllability. The epoxy resin is particularly suitable for a composite material, an epoxy adhesive and a coating, and the prepared curing product has high mechanical property and thermal property. The formula I is shown in the specifications.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Solvent-free 180-DEG C-resistant ultralow-viscosity epoxy resin matrix and preparation method thereof

The invention relates to a solvent-free type 180 DEG C-resistant ultralow-viscosity epoxy resin matrix and a preparation method thereof, and aims to solve the problems of short low-viscosity working life, low use temperature, high curing temperature and high hygroscopicity of most existing epoxy resin matrixes for RTMs. The epoxy resin matrix consists of a bifunctional epoxy resin, a polyfunctional epoxy resin and a liquid-state curing system. The preparation method of the epoxy resin matrix comprises the following steps: stirring components at a high speed, fully and uniformly mixing, and defoaming in vacuum to obtain the epoxy resin matrix. According to the invention, the preparation process is simple and convenient, the epoxy resin matrix is low in viscosity, environmentally friendly and long in process window time, and the glass transition temperature (Tg) of the matrix after medium-temperature (150 DEG C) curing is higher than 180 DEG C; and the resin matrix is applied to the technical field of polymer composite materials.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

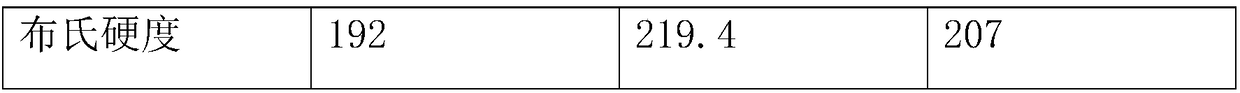

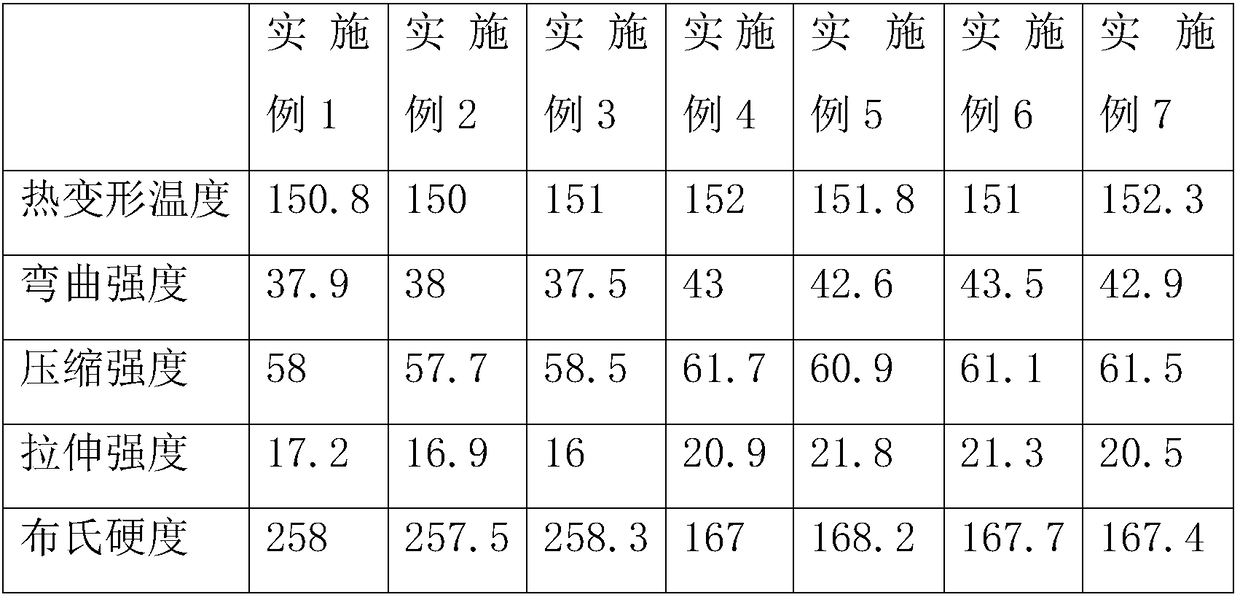

Epoxy resin composite board for vacuum plastic film mould

ActiveCN109438924AImprove temperature resistanceImprove deformation resistanceHeat deflection temperaturePolyamide-imide

The invention relates to the technical field of vacuum plastic film moulds, and provides an epoxy resin composite board for a vacuum plastic film mould so as to solve the problem that the surface of aplastic board is not resistant to high temperature. The epoxy resin composite board comprises the following components in parts by mass: 93-124 parts of epoxy resin, 16-21 parts of a curing agent, 15-20 parts of polyamideimide and 0.5-0.6 part of a defoamer, wherein the epoxy resin is bisphenol A-type epoxy resin and comprises one or more of bisphenol A-type epoxy resin, epoxy resin comprises E-51 epoxy resin, E-55 epoxy resin and E-44 epoxy resin. Through addition of the polyamideimide, due to high heat deformation temperature and high tensile strength of the polyamideimide, improvement on the temperature resistance and the deformation resistance of the epoxy resin composite board is facilitated, so that the heat deformation temperature and the tensile strength of the epoxy resin composite board are enhanced, the prepared vacuum plastic film mould is not easily deformed, and thus reduction in the frequency of mould replacement is facilitated and the production cost is lowered.

Owner:东莞市艾博龙新型材料有限公司

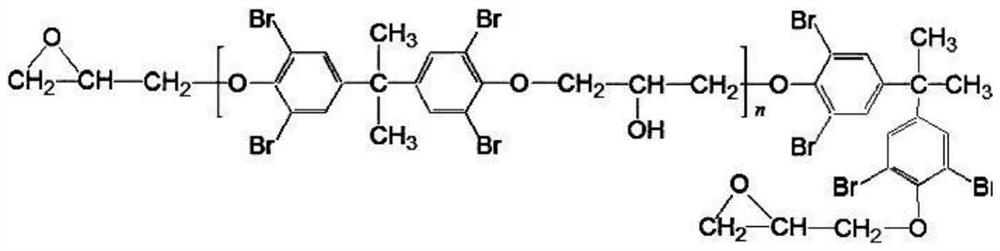

A kind of underwater epoxy resin curing agent and preparation method thereof

The invention relates to an underwater epoxy resin curing agent, which consists of the following components: amine curing agent, difunctional glycidyl ether, high brominated DGEBA, activity accelerator, plasticizer and hydrophobic agent. Utilize the highly active hydrogen atoms in the amine curing agent to undergo ring-opening reactions with the epoxy groups in the difunctional glycidyl ether and highly brominated DGEBA to form a new curing agent structure; at the same time, provide a system based on the accelerator High reactivity, plasticizer improves the viscosity of the system and the mechanical properties of the cured product, and the hydrophobic agent improves the underwater adhesiveness of the system, which effectively solves the problems of long curing time in water, poor adhesive performance and poor mechanical properties of the current curing agent. And improve the weather resistance and environmental protection of the curing agent.

Owner:CNBM ZHONGYAN TECH

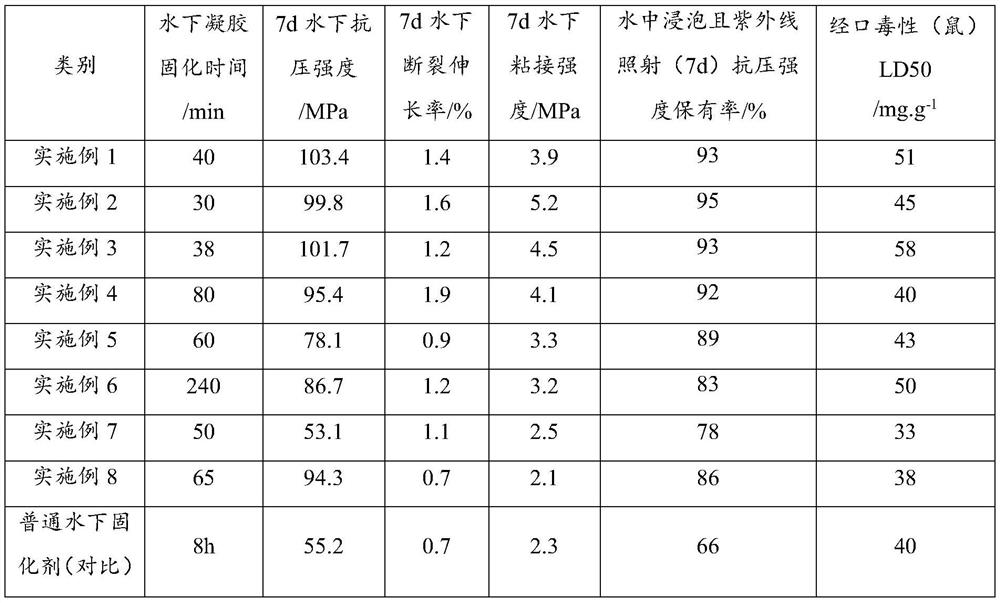

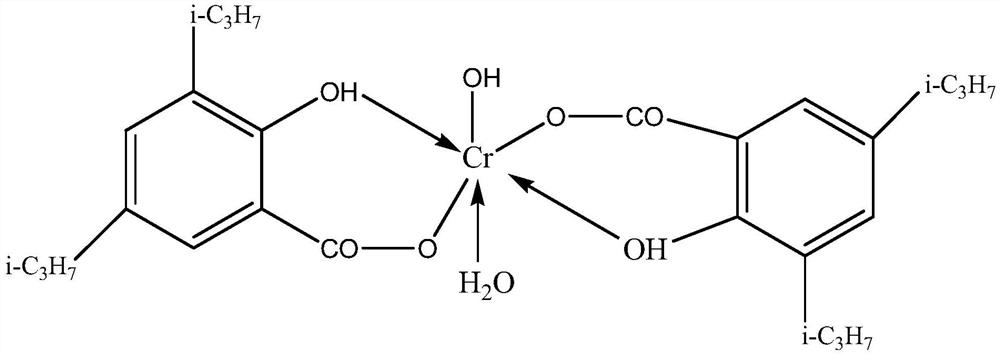

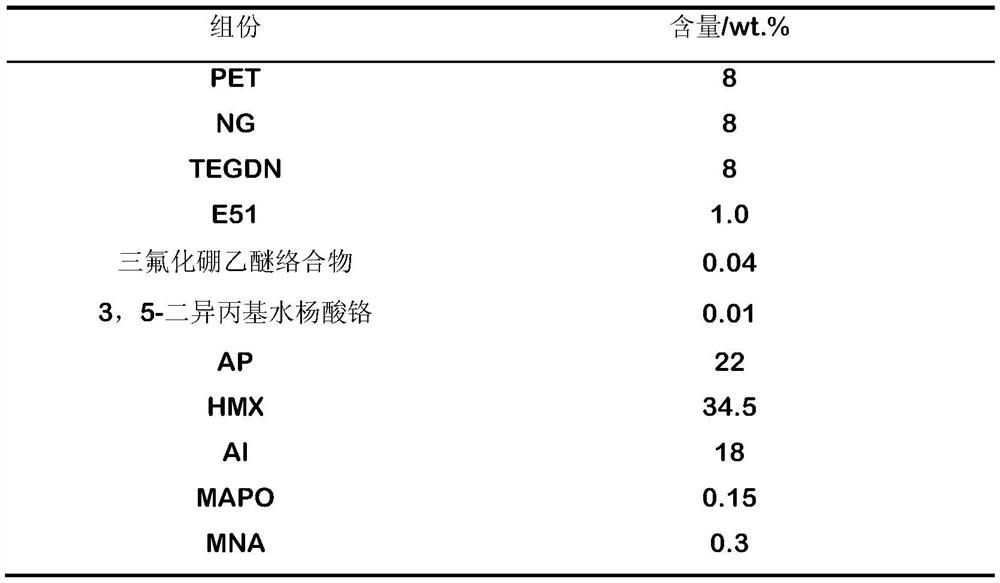

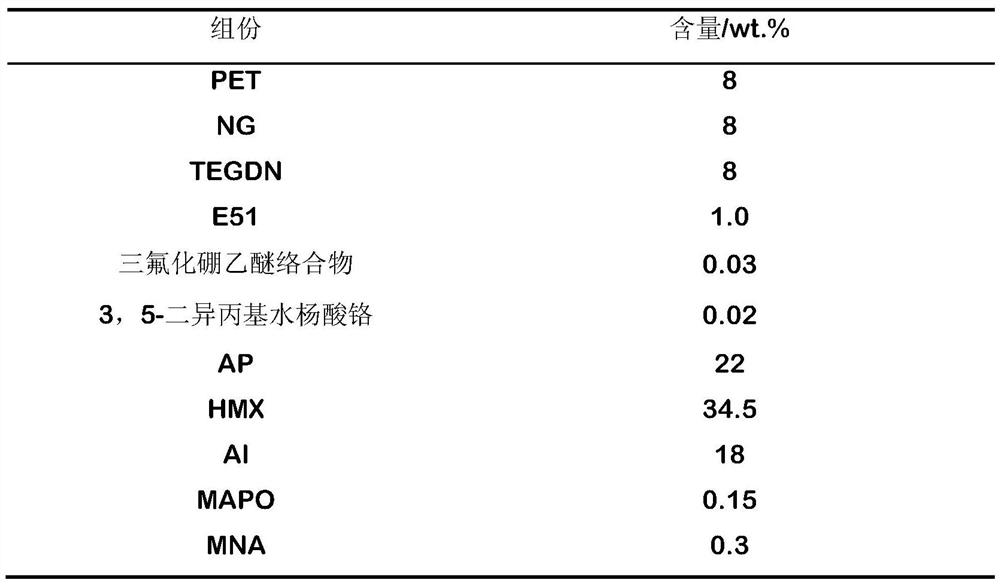

A kind of curing system and solid propellant containing the curing system and preparation method

ActiveCN109748766BEliminate Stability IssuesStable mechanical propertiesExplosive working-up apparatusNon-explosive/non-thermic compositionsPlasticizerReaction rate

The invention relates to a curing system, a solid propellant containing the curing system and a preparation method, and belongs to the technical field of solid propellant preparation. The curing process of the curing system is not affected by moisture, which can reduce the influence of environmental humidity and raw material moisture on the performance of the propellant, which is conducive to improving the performance stability and reliability of the propellant; and the curing system also has high curing reactivity and high reaction rate. Controllable, good chemical compatibility with high-energy components such as nitrate plasticizers, and excellent mechanical properties.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Popular searches

Improve liquidity Improve flame retardant performance Low softening point Improve moisture resistance Good high temperature resistance and flame retardant effect The preparation method is simple and controllable The control method is simple and convenient Suitable for industrial production Reduce melt viscosity Improve water absorption

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com