Imidazole dinitrile resin based on acid-base co-melting and preparation method thereof

A technology of imidazole dinitrile resin and imidazole dinitrile is applied in the field of thermosetting resin materials to achieve the effects of lowering melting point, lowering initial curing temperature and high nucleophilic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

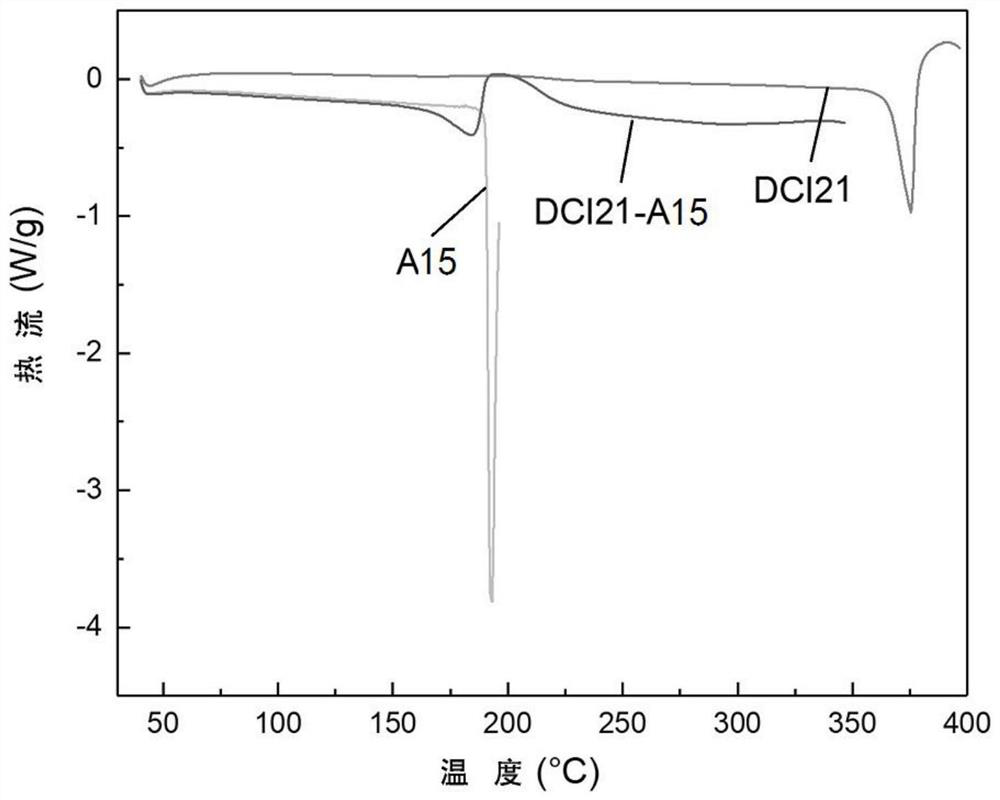

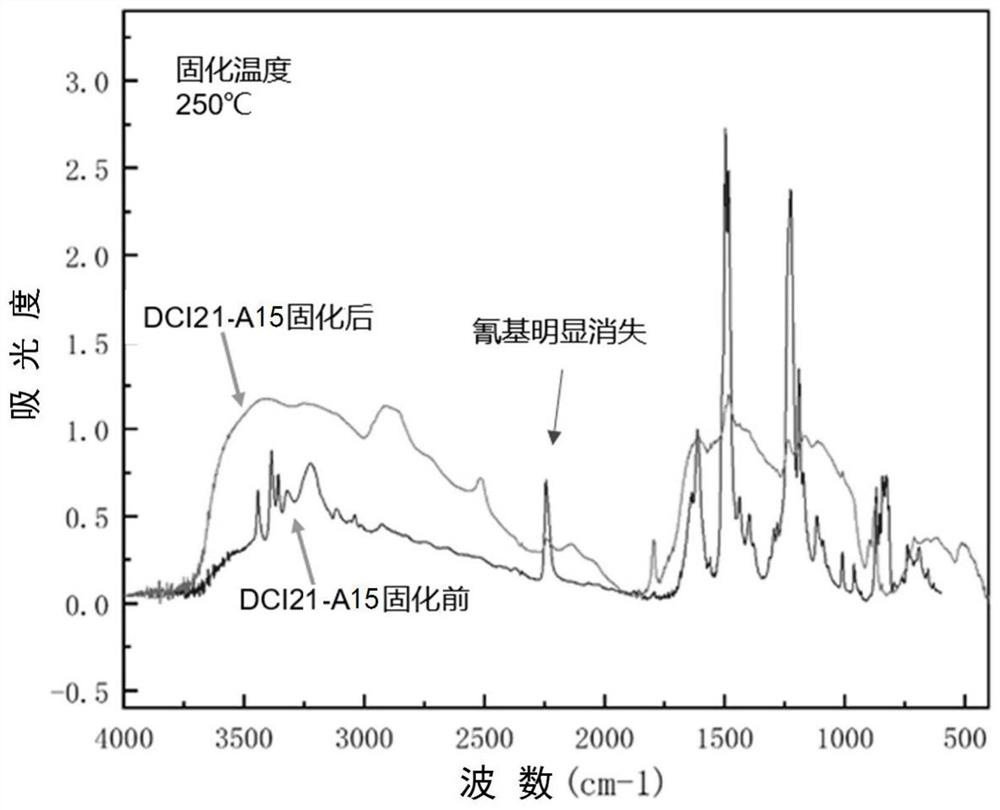

[0071] In this embodiment, DCI1 and A3 Be raw material, the step of preparing co-melting imidazole dinitrile resin is as follows:

[0072] (1) Dissolve 10mmol of DCI1 and 10mmol of A3 in acetonitrile, then stir the reaction at 80°C for 0.1h, then spin the resulting solution to dryness, then add 0.5mL of ethanol to the resulting solid, grind it to a dry state, and then place it in After vacuum drying at 80°C for 3 hours, the acid-base eutectic was obtained; the melting point of the obtained acid-base eutectic was 128°C.

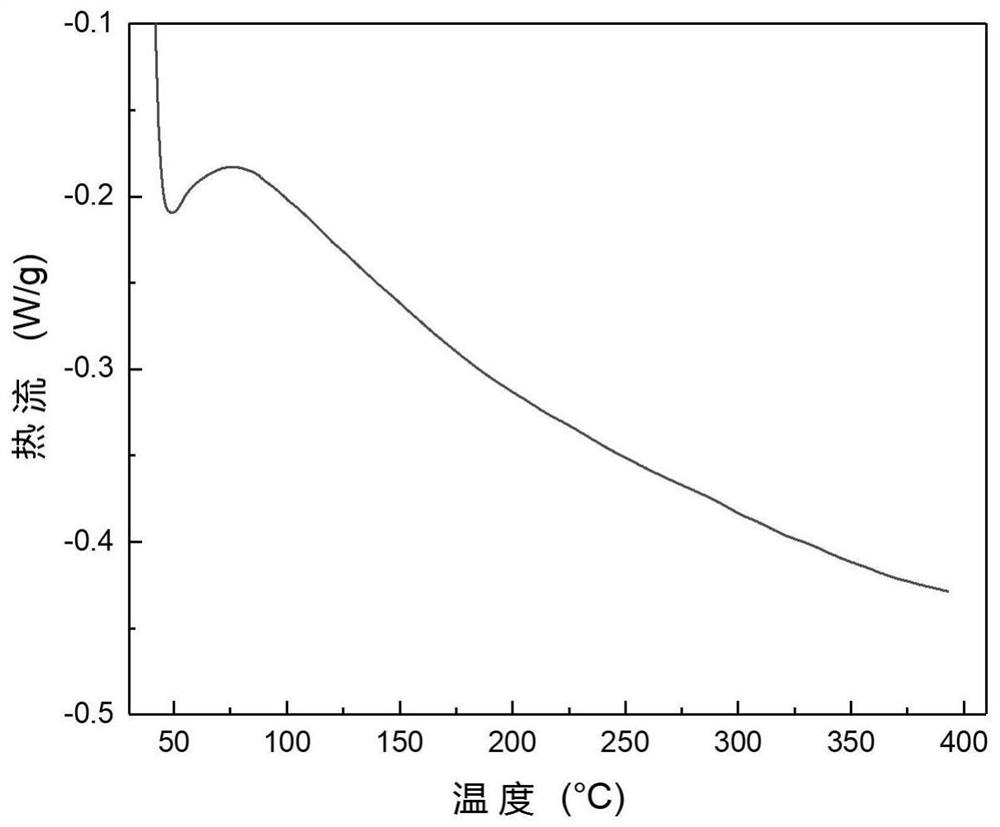

[0073] (2) Place the acid-base eutectic prepared in step (1) under an argon atmosphere, and perform the curing operation according to the following temperature gradient in sequence: heat preservation at 150°C for 5 hours, heat preservation at 200°C for 5 hours, heat preservation at 300°C for 5 hours, After curing, cool to room temperature with the furnace to obtain imidazole dinitrile resin based on acid-base fusion. DSC test data show that the glass tran...

Embodiment 2

[0075] In this embodiment, DCI2 DCI3 and A3 Be raw material, the step of preparing co-melting imidazole dinitrile resin is as follows:

[0076] (1) Dissolve 10mmol each of DCI2 and DCI3 and 10mmol of A3 in tetrahydrofuran, then stir and react at 0°C for 24h, then spin the resulting solution to dryness, then add 1.0mL of ethanol to the resulting solid, grind it to a dry state, and then in 80 °C for 3 hours in vacuum to obtain an acid-base eutectic; the melting point of the obtained acid-base eutectic is 189°C.

[0077] (2) Place the acid-base eutectic prepared in step (1) under a nitrogen atmosphere, and perform the curing operation according to the following temperature gradient in sequence: keep it at 200°C for 1h, keep it at 350°C for 4h, and cool it with the furnace to At room temperature, the imidazole dinitrile resin based on acid-base fusion is obtained. DSC test data show that the glass transition temperature Tg of the acid-base fusion-based fusion imidazole dini...

Embodiment 3

[0079] In this embodiment, DCI3 DCI4 DCI5 and A3 A4 A6 Be raw material, the step of preparing co-melting imidazole dinitrile resin is as follows:

[0080] (1) Add 10mmol each of DCI3, DCI4, DCI5, 20mmol each of A3, A4, and 10mmol of A6 into the grinding body, then add 1.5mL of ethanol, grind until it is dry, and then keep it at 90°C for 3 hours in vacuum to obtain the acid-base Co-melt; the melting point of the acid-base co-melt obtained through testing is 128°C.

[0081] (2) Place the acid-base eutectic prepared in step (1) in an air atmosphere, and perform the curing operation according to the following temperature gradient in sequence: keep warm at 199°C for 3h, keep warm at 300°C for 2h, and cool down with the furnace to At room temperature, the imidazole dinitrile resin based on acid-base fusion is obtained. DSC test data show that the glass transition temperature Tg of the imidazole dinitrile resin based on acid-base fusion is greater than 400°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com