Patents

Literature

419 results about "Intermolecular force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intermolecular forces (IMF) are the forces which mediate interaction between molecules, including forces of attraction or repulsion which act between molecules and other types of neighboring particles, e.g., atoms or ions. Intermolecular forces are weak relative to intramolecular forces – the forces which hold a molecule together. For example, the covalent bond, involving sharing electron pairs between atoms, is much stronger than the forces present between neighboring molecules. Both sets of forces are essential parts of force fields frequently used in molecular mechanics.

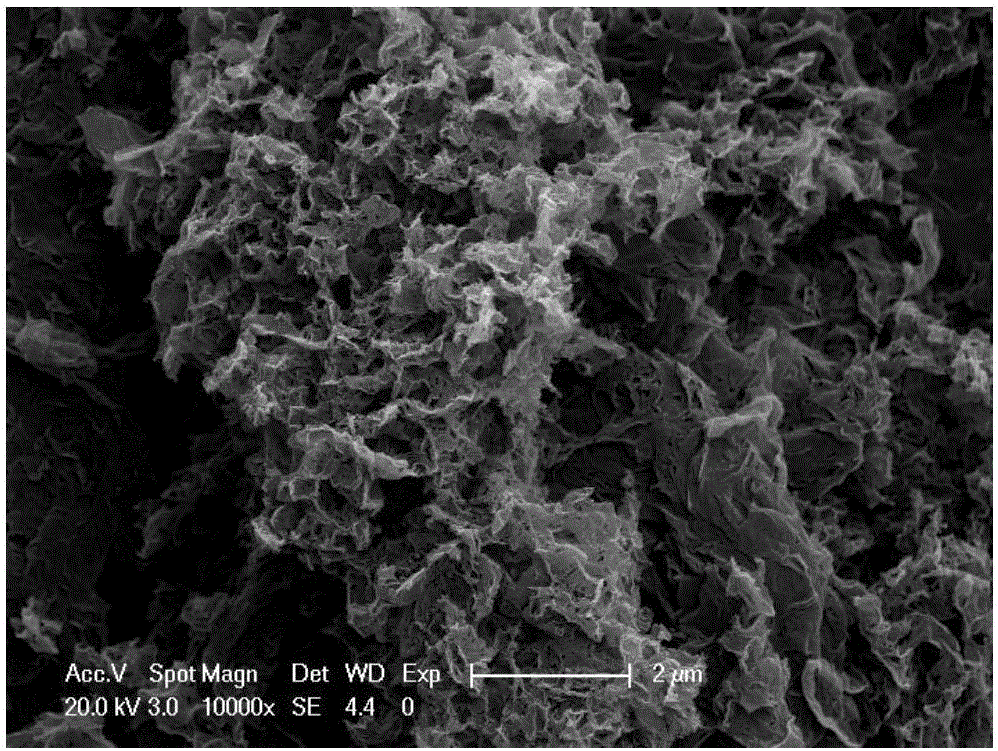

Graphene composite material and preparation method thereof

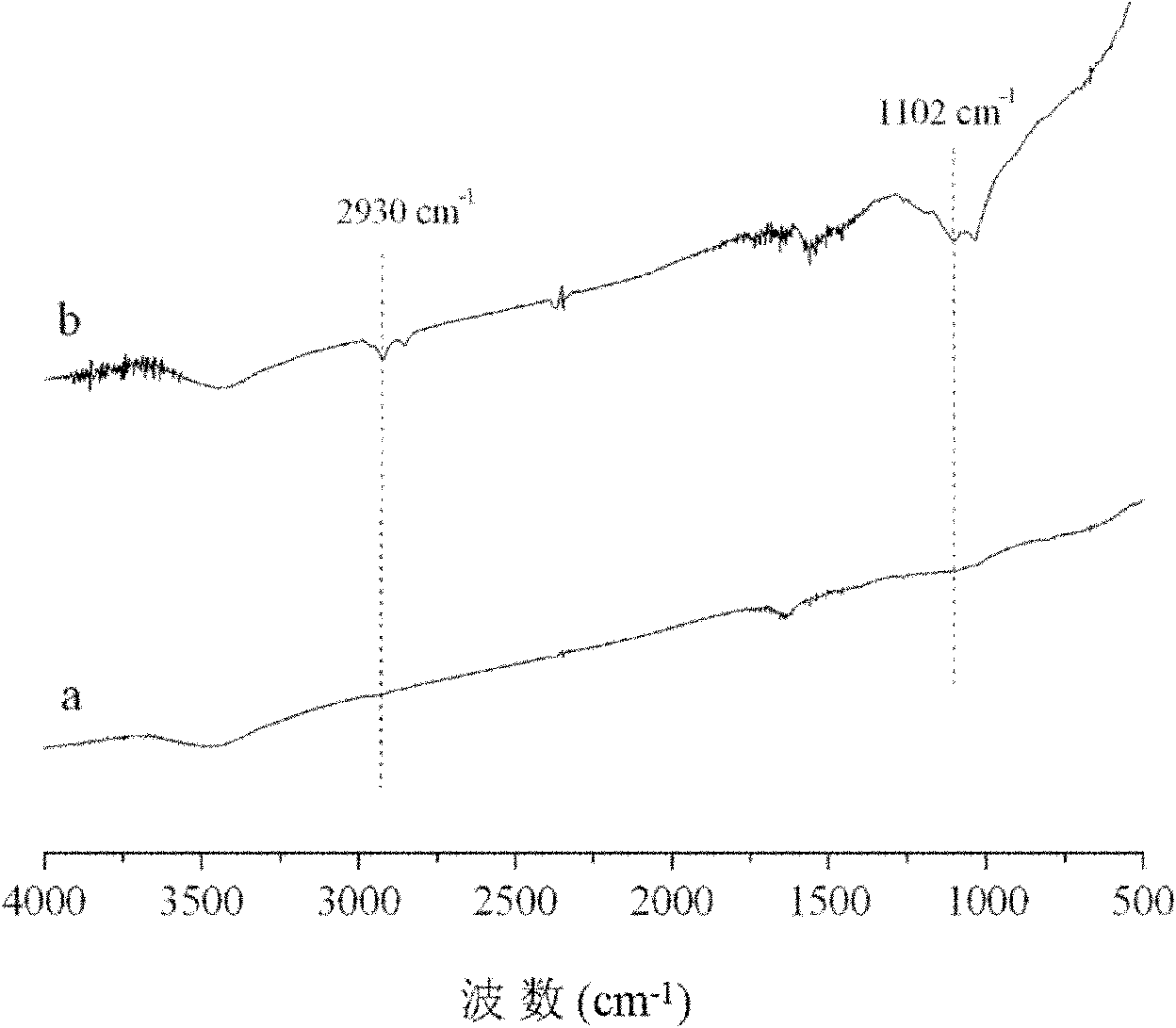

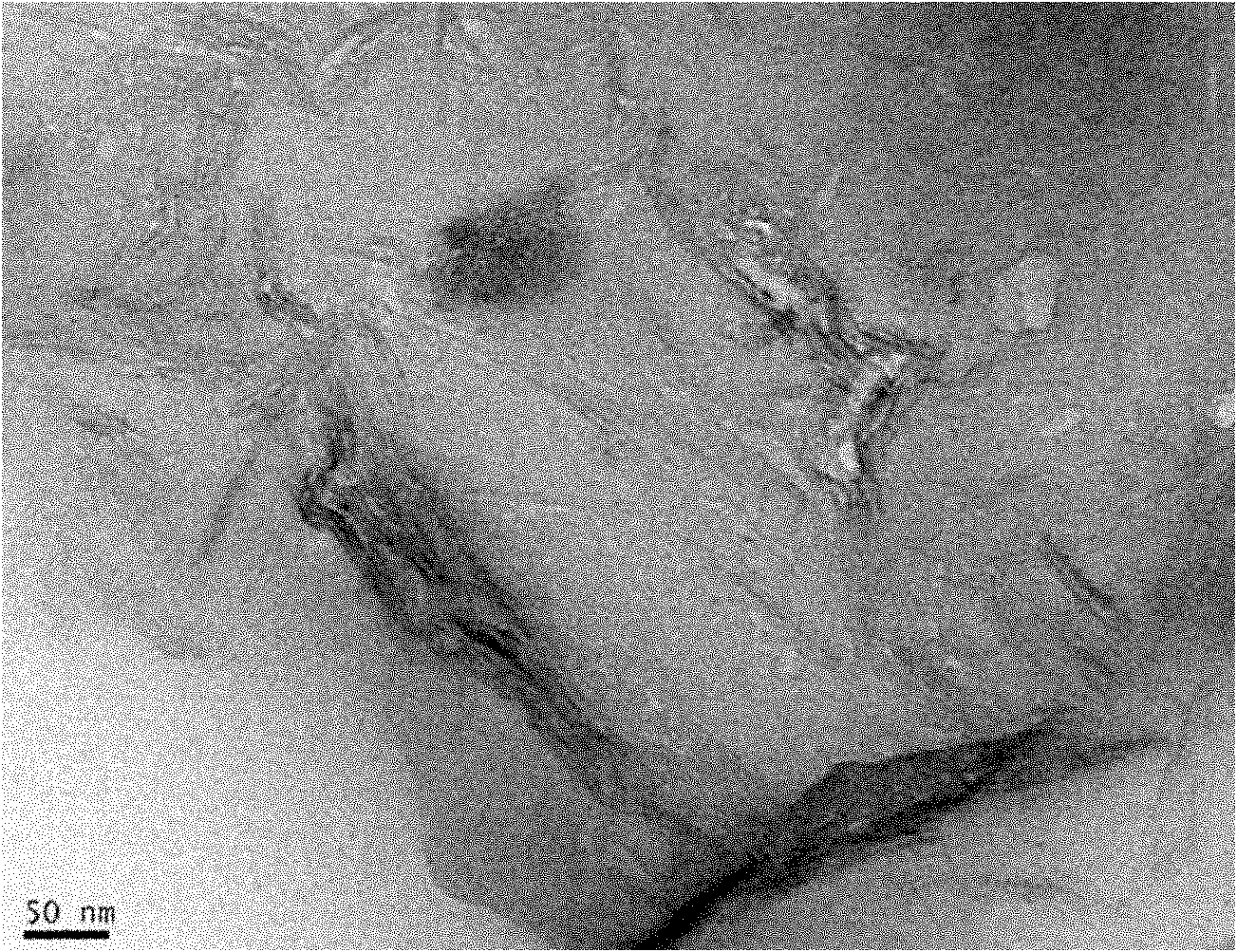

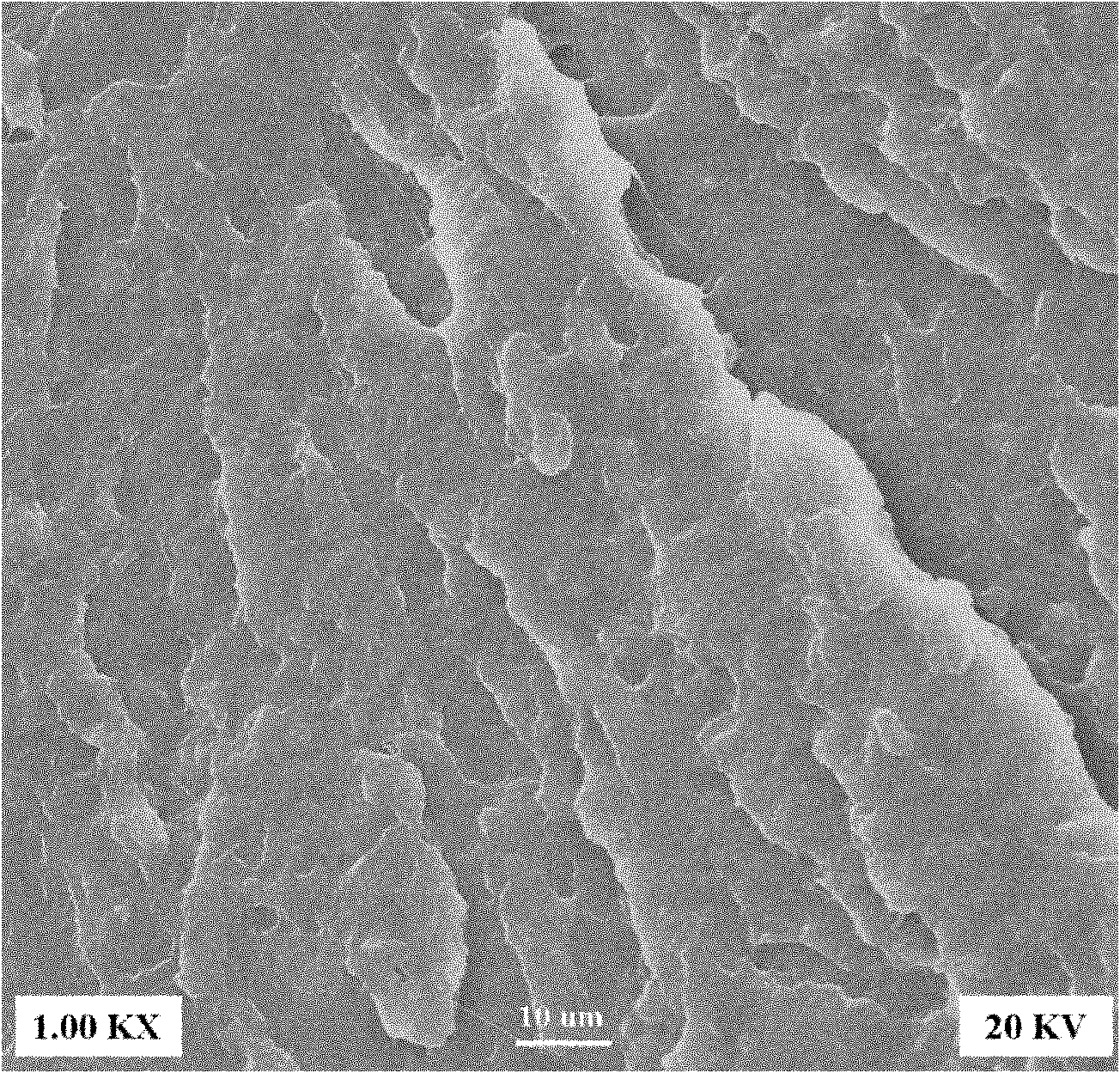

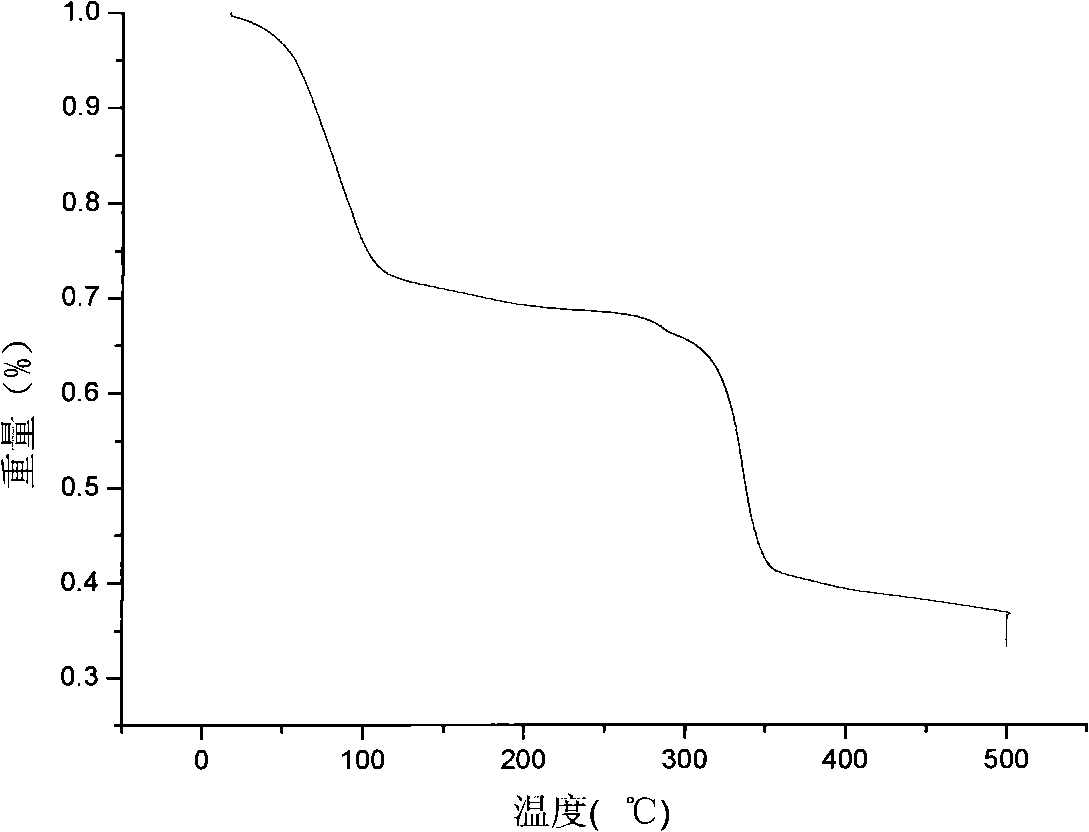

The embodiment of the invention discloses a graphene composite material and a preparation method thereof. In the method, graphene and organosilane are taken as reactants; the organosilane undergoes a hydrolysis reaction, and then undergoes a dehydration condensation reaction with hydroxyl on the graphene so as to obtain organosilane-modified graphene. Compared with the prior art, the organosilane-modified graphene expands the interlayer spacing of graphene, so that the organosilane-modified graphene is difficultly agglomerated when the organosilane-modified graphene is mixed with a polymer, the organosilane-modified graphene is uniformly dispersed in a polymer substrate, and a prepared graphene composite material has an enhanced effect. Moreover, the organosilane-modified graphene undergoes chemical bonding or intermolecular force with the polymer, so that the prepared graphene composite material has excellent interface compatibility. Proved by experiment results, the graphene composite material prepared in the invention has high mechanical property.

Owner:UNIV OF SCI & TECH OF CHINA

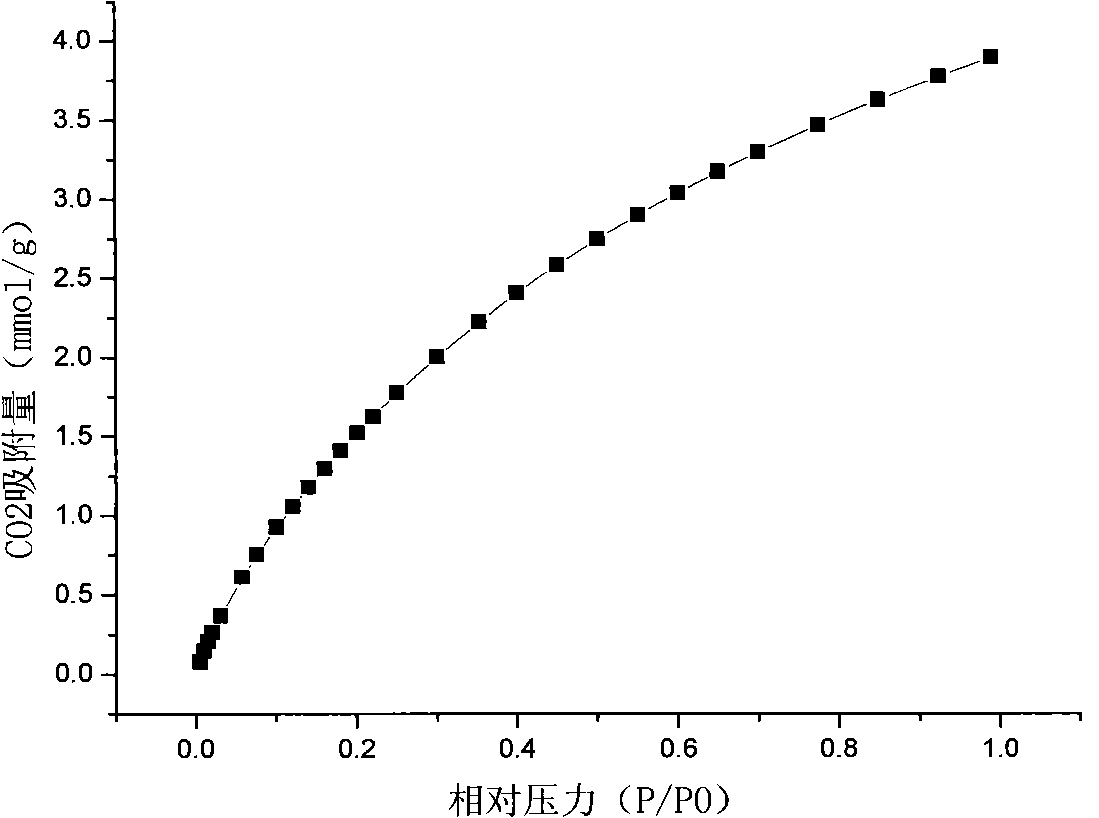

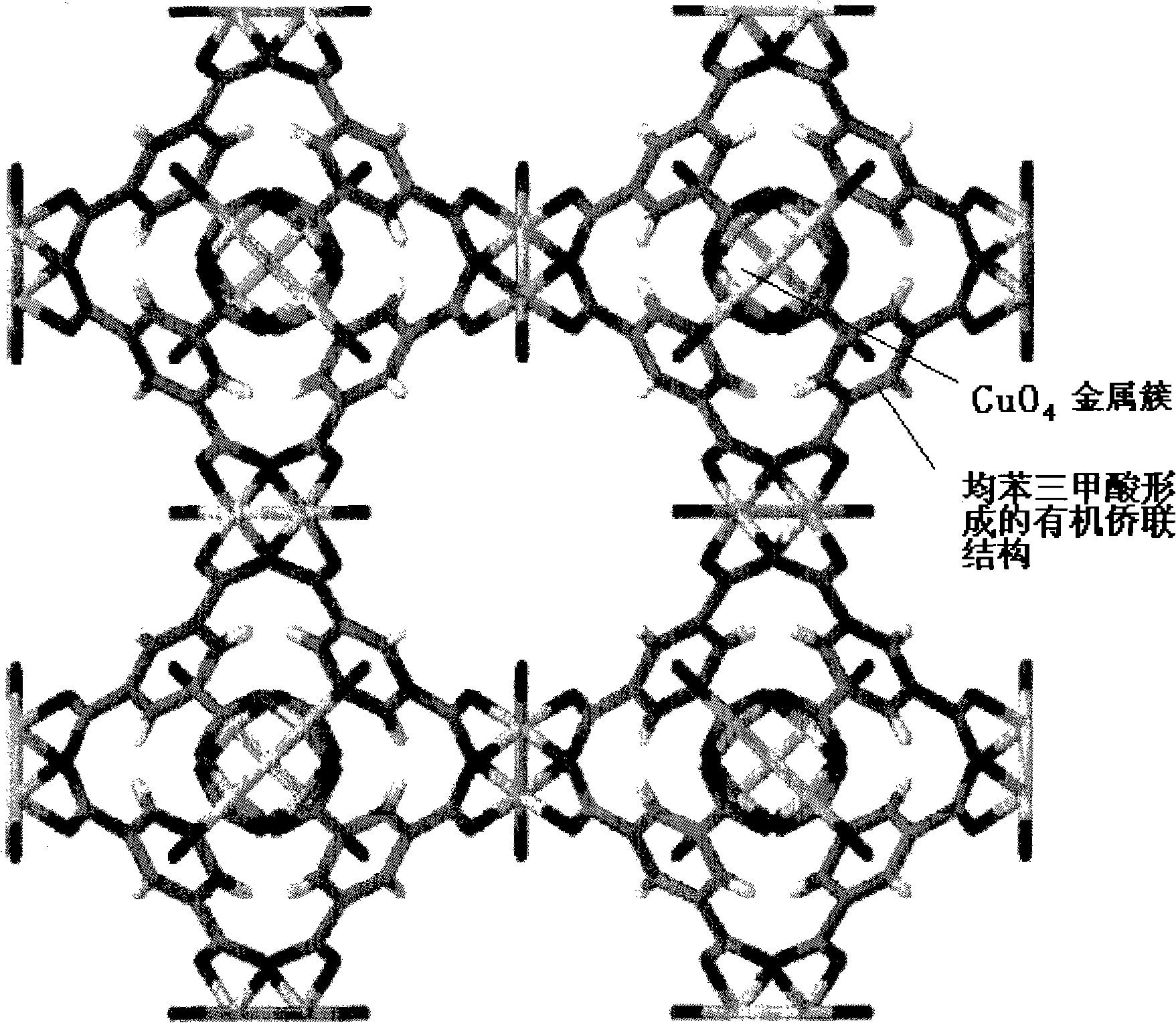

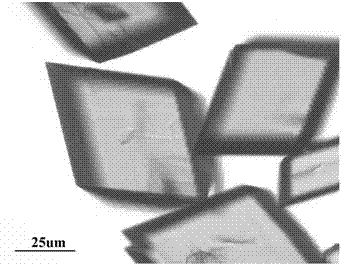

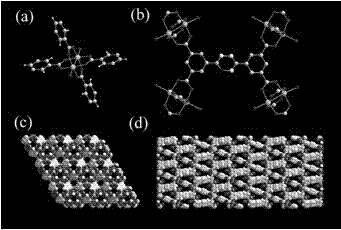

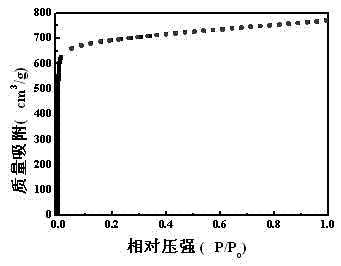

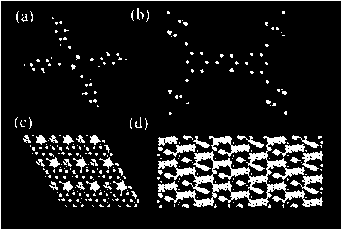

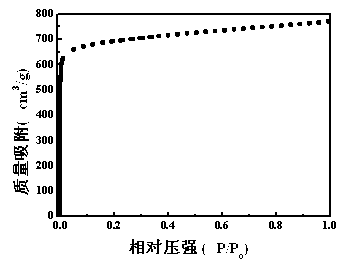

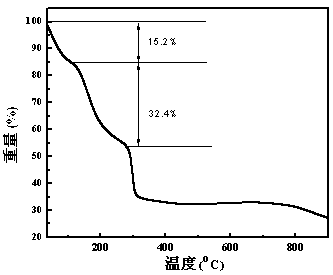

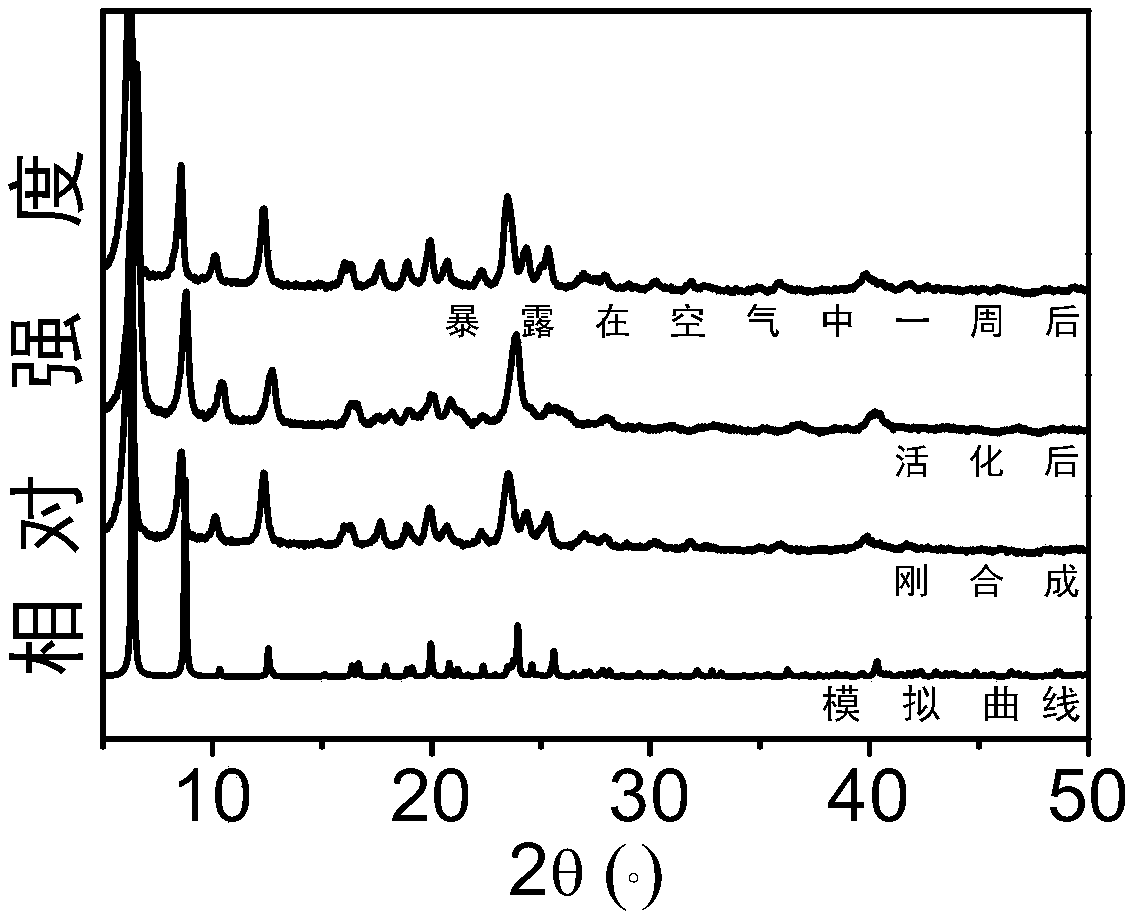

Metal organic framework material used for absorbing and separating CO2 and preparation method thereof

InactiveCN101816924ALarge specific surface areaImprove adsorption capacityProductsCarbon compoundsMetal-organic frameworkChemical measurement

The invention provides a metal organic framework material used for absorbing and separating CO2 and a preparation method thereof. The metal organic framework material is a rigid metal carboxyl compound cluster-like structure which is formed by transition metal ions and multidentate organic ligands through covalent bonds and intermolecular forces. An amine polymer is modified on the metal organic framework material; and the metal organic framework material used for absorbing and separating the CO2 has a specific surface area of 1,000 to 1,200 m<2> / g, and a pore volume of 0.4 to 0.6 cm<3> / g. The preparation method comprises the following steps of: respectively dissolving the nitrate, the chloride or the carbonate of copper or zinc and 1,3,5-trimesic acid together in a stoichiometric ratio in water or an organic solvent; mixing uniformly and sufficiently to react to obtain a BTC bridged complex crystal; and applying a product obtained by reacting an obtained BTC bridged complex crystal with the solution of polyethyleneimine to the metal organic framework material used for absorbing and separating the CO2. The material can realize selective absorption of a gas under a low pressure.

Owner:SOUTHEAST UNIV

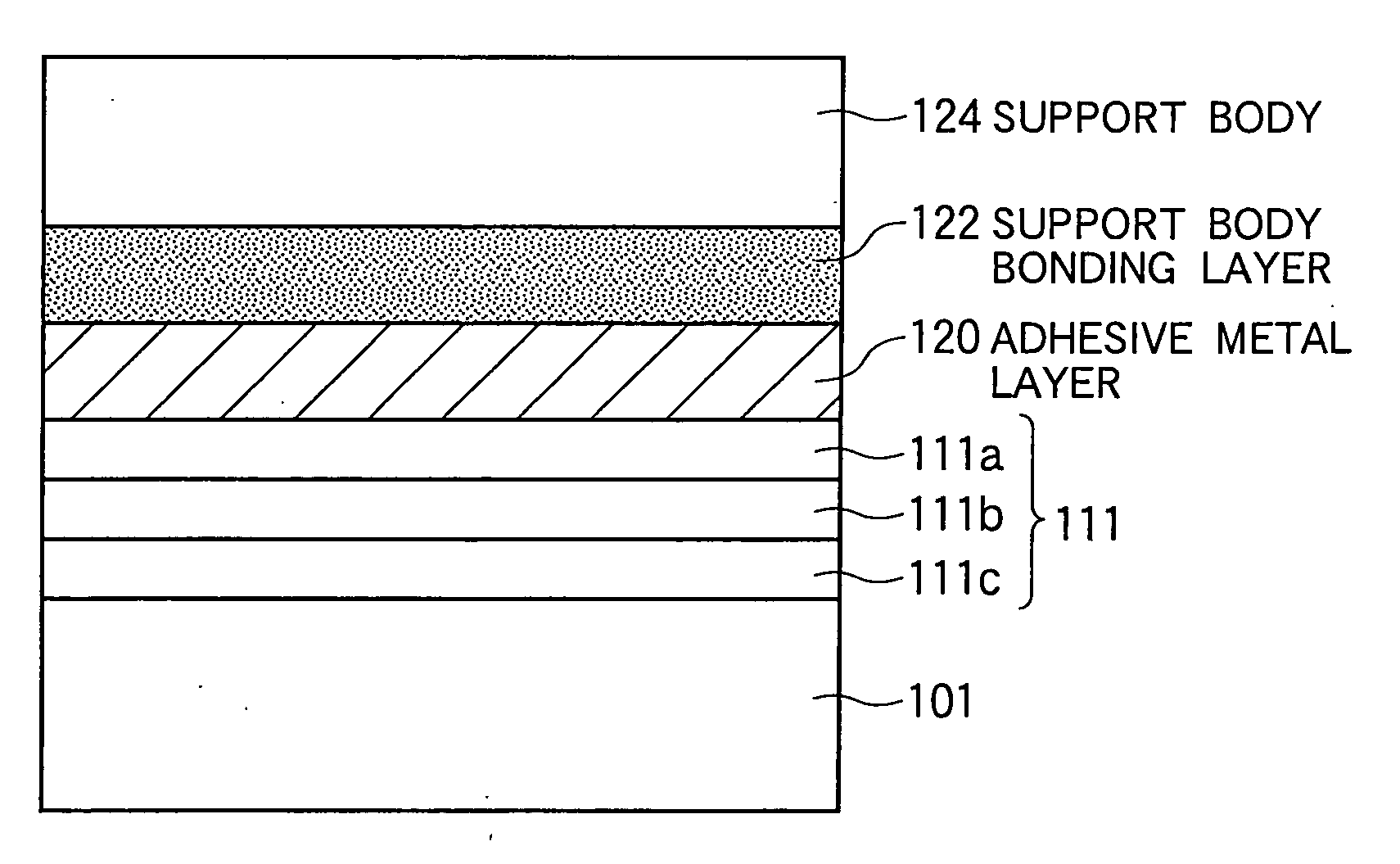

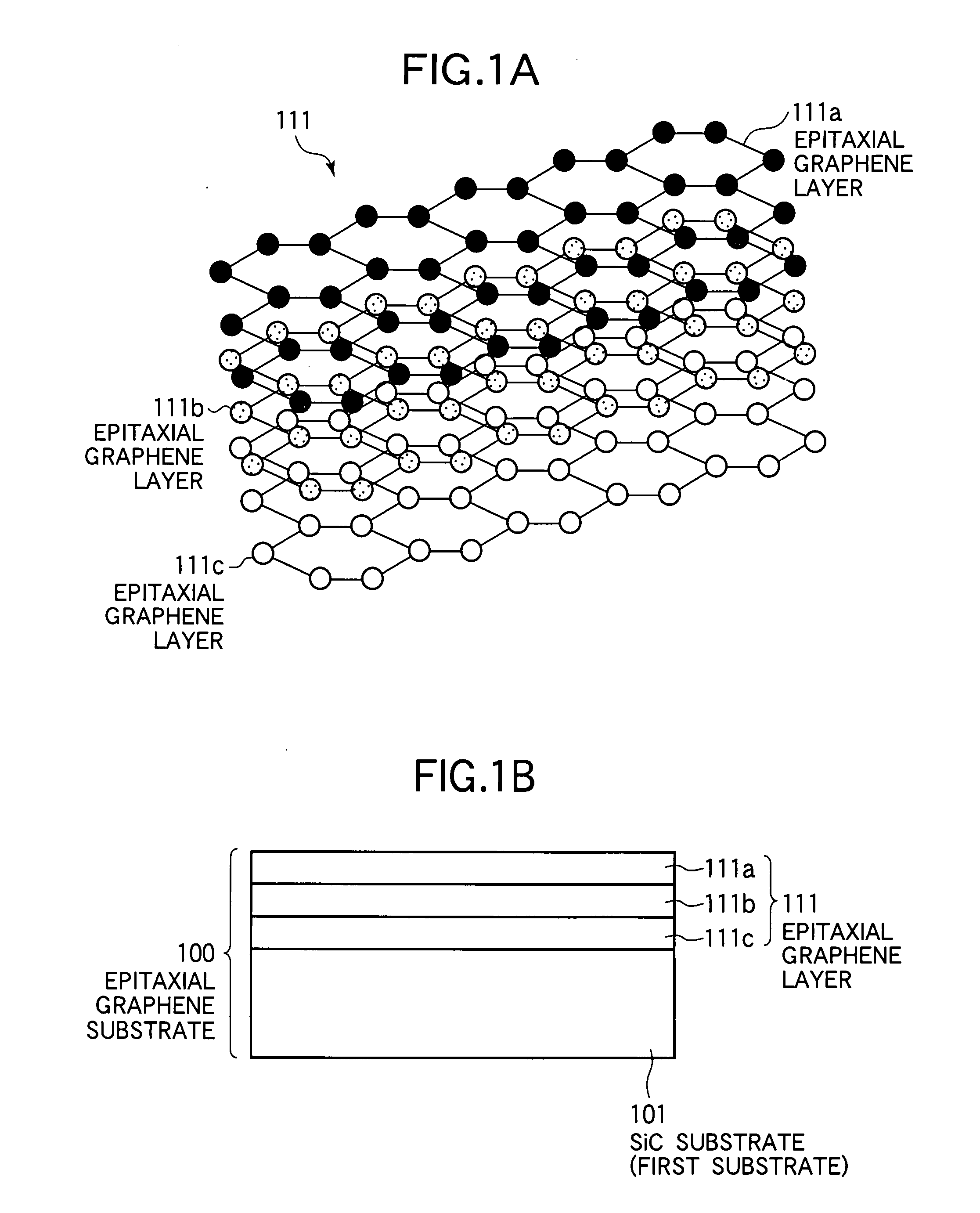

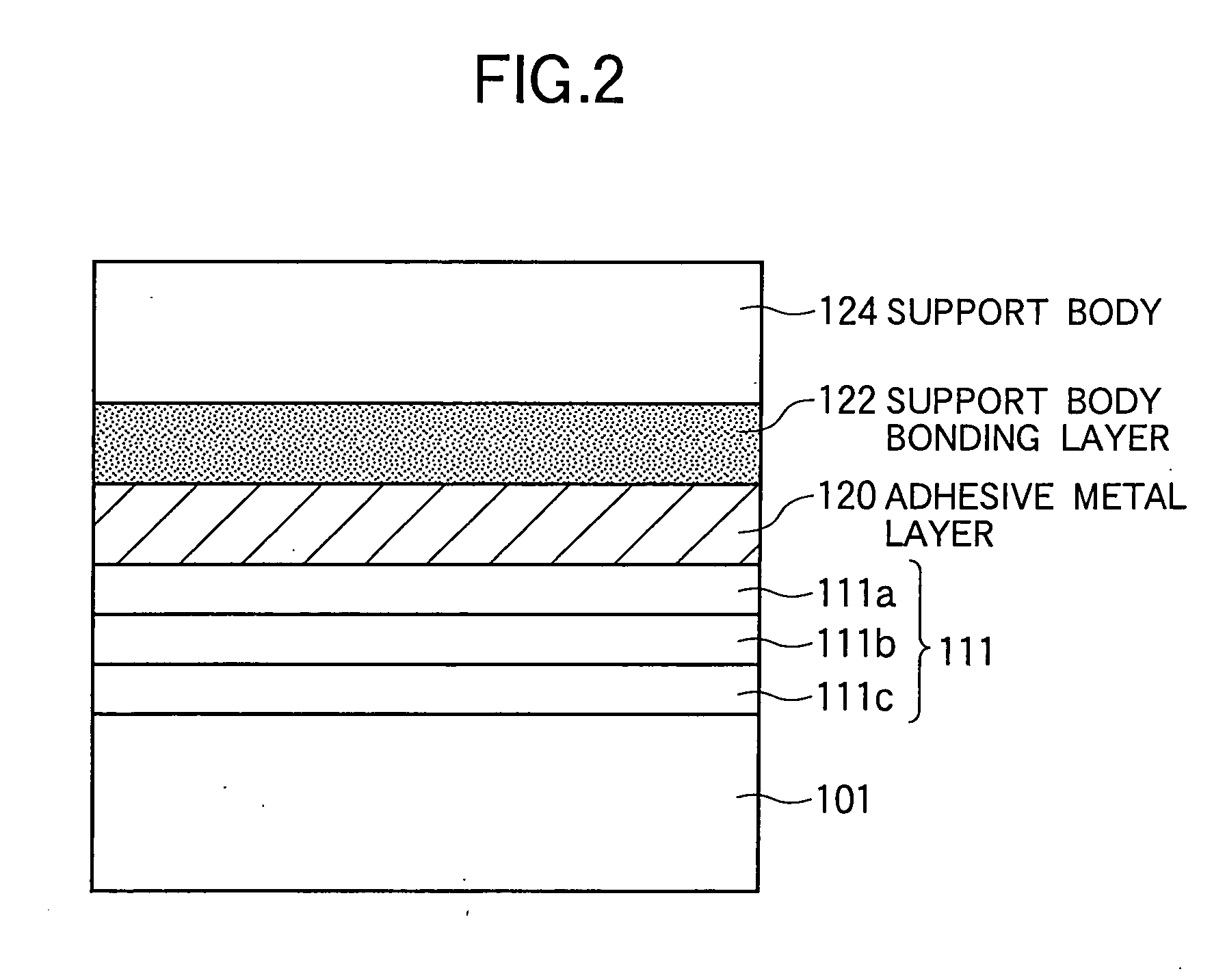

Graphene wafer, method for manufacturing the graphene wafer, method for releasing a graphene layer, and method for manufacturing a graphene device

InactiveUS20100323164A1Good repeatabilityLamination ancillary operationsSemiconductor/solid-state device manufacturingOptoelectronicsCvd graphene

A method is used for releasing a graphene layer from a substrate. A graphene layer is first formed on a surface of a first substrate. A metal layer is then formed on a surface of the graphene layer. A pulling force is then applied to the metal layer to detach the graphene layer from the first substrate. The released graphene layer is bonded by intermolecular force onto a surface of a second substrate separate from the first substrate or onto a surface of a bonding layer formed on the surface of the second substrate. The metal layer is then removed, by for example, etching.

Owner:OKI DATA CORP

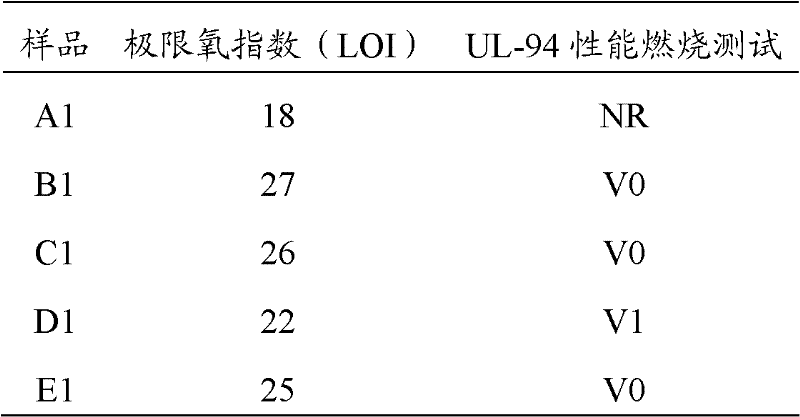

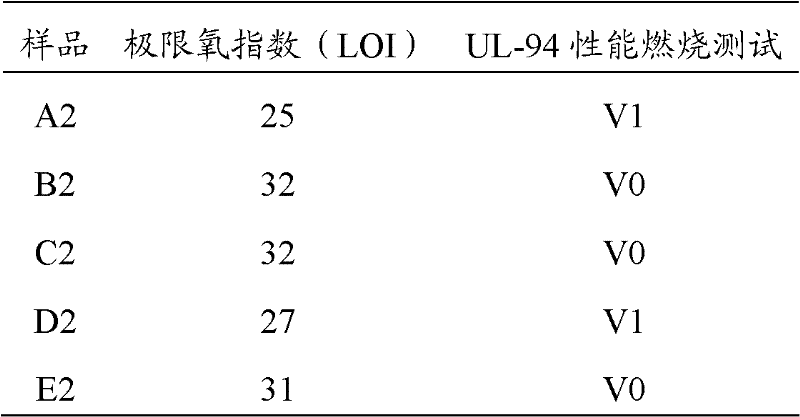

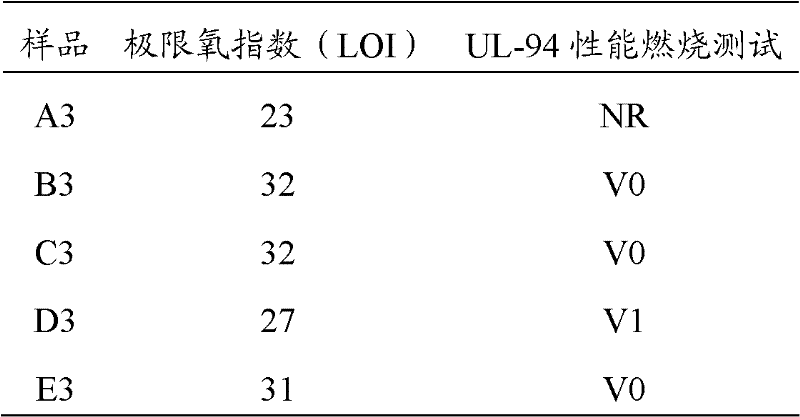

Microcapsule flame-retardant adsorption resin and preparation method thereof, and flame-retardant composite material

ActiveCN102492175AHigh strengthSimple structureMicroballoon preparationMicrocapsule preparationHydrogenFire retardant

The invention provides microcapsule flame-retardant adsorption resin comprising a reservoir wall and a capsule core, wherein the capsule core comprises adsorption resin and flame retardant adsorbed in the adsorption resin. The invention further provides a preparation method of the microcapsule flame-retardant adsorption resin and a flame-retardant composite material. The higher strength adsorption resin with a three dimensional lattice structure is adopted as a support material; the flame retardant or a solution of the flame retardant is adsorbed into resin granules through hydrogen bonding or intermolecular force; and adsorbed flame retardant molecules, in particular to small flame retardant molecules, are very hard to separate out of the adsorption resin owing to the hydrogen bonding orthe intermolecular force, so as to effectively restrain the flame retardant from surface migration. Meanwhile, after microencapsulation of the adsorption resin with the flame retardant, the reservoirwall can further restrain the flame retardant molecules from separation and migration, so as to improve the migration resistance of the microcapsule flame-retardant adsorption resin.

Owner:UNIV OF SCI & TECH OF CHINA

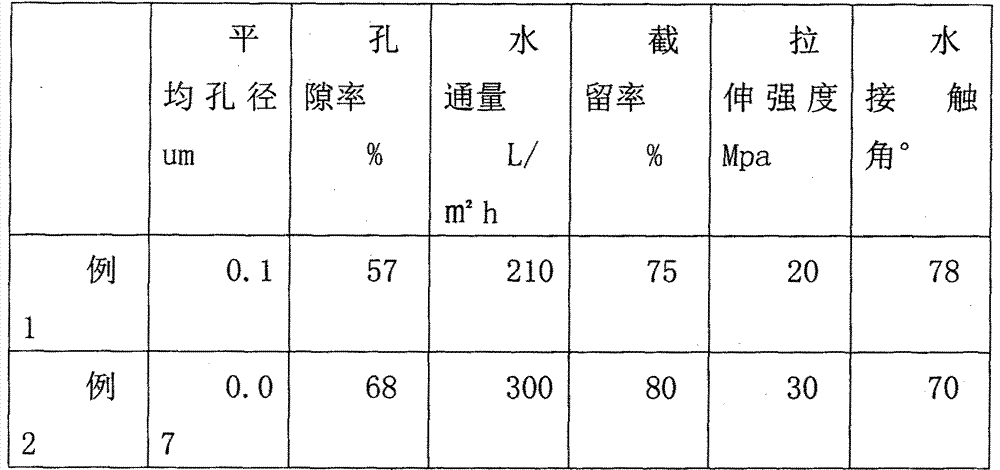

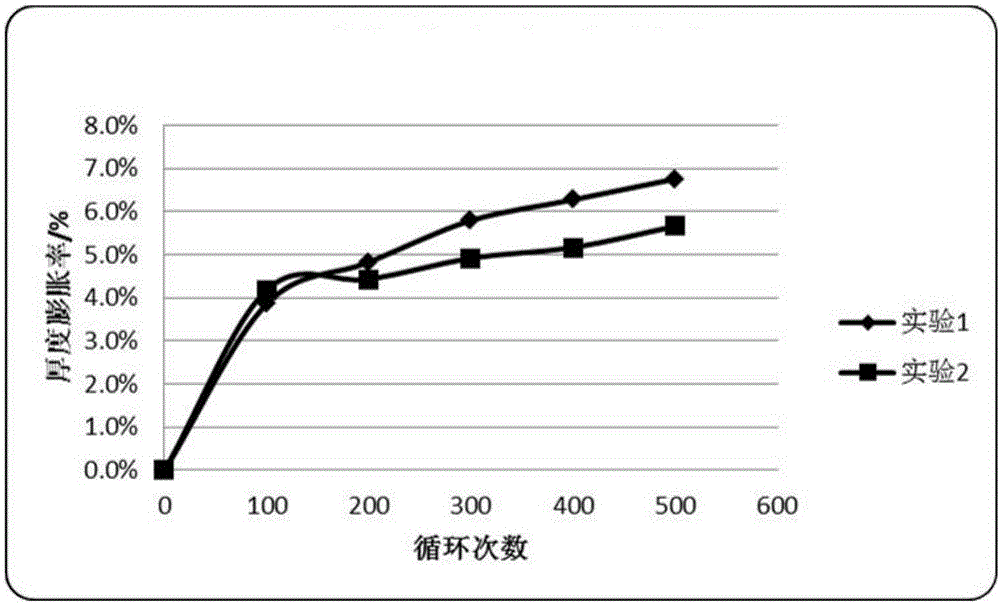

Preparation method of novel MOFs-PVDF (Metal-Organic Frameworks-Polyvinylidene Fluoride) composite film

InactiveCN107020020AAchieve stabilitySmall membrane poresMembranesSemi-permeable membranesPorosityComposite film

The invention discloses a preparation method of a novel MOFs-PVDF (Metal-Organic Frameworks-Polyvinylidene Fluoride) composite film. The preparation method is mainly characterized in that a synthesizing environment of MOFs is controlled to be consistent with a casting solution preparation condition, an organic ligand and metal ions are added into a casting solution by a simple one-step synthetic method, intermolecular acting force between the organic ligand and PVDF is regulated and controlled, the PVDF is chemically combined with the MOFs through a hydrogen bond of an 'F' atom, chemical bonding of a PVDF polymer and the MOFs is realized, and an MOFs-PVDF polymer is synthesized in the casting solution, so that the formation of a chemical bonding hole and the formation of an MOFs-PVDF novel film are performed simultaneously in a spinning process. The method is easy and efficient; moreover, the prepared film combines the advantages of an MOFs and PVDF composite film; the prepared novel MOFs-PVDF composite film has the advantages of high chemical stability, high mechanical strength, controllable aperture, large surface specific area and high porosity.

Owner:TIANJIN POLYTECHNIC UNIV

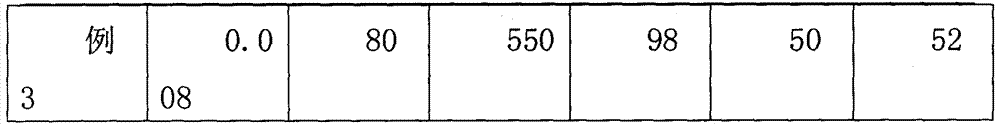

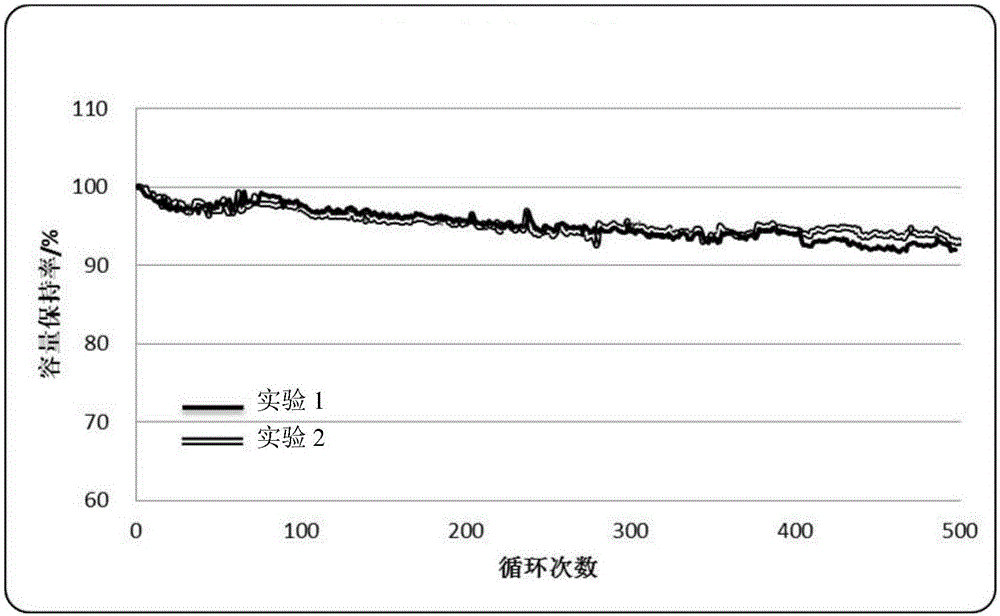

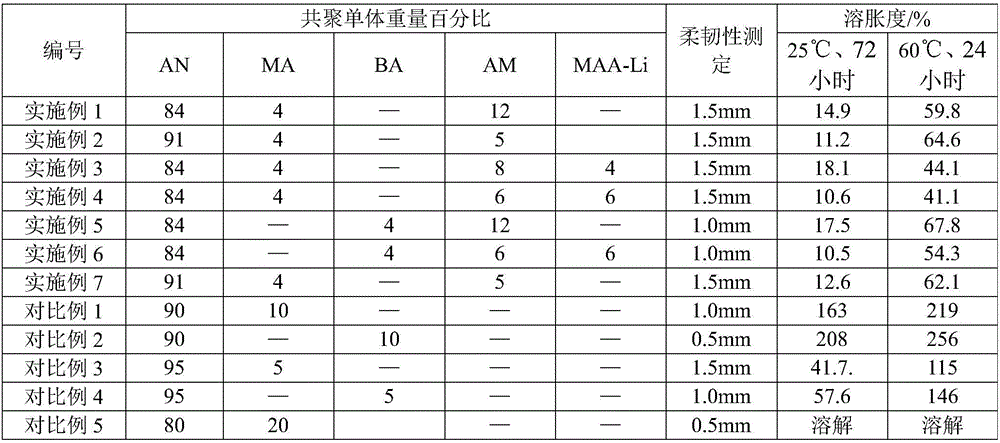

Acrylonitrile copolymer adhesive and application thereof in lithium ion batteries

ActiveCN106220779AImprove flexibilityAppropriate degree of swellingNitrile polymer adhesivesSecondary cellsPolymer adhesivePolymer science

The invention belongs to the field of lithium ion batteries and relates to an acrylonitrile copolymer adhesive and application thereof in lithium ion batteries. The acrylonitrile copolymer adhesive structurally comprises, by weight, 78-95% of an acrylonitrile unit, 1-10% of an acrylate unit and 2-15% of an acrylamide unit. Acrylate monomers, high-polarity acrylamide monomers or acrylate monomers are added into acrylonitrile monomers serving as a main material to implement copolymerization, so that high adhesive power or intermolecular force of acrylonitrile polymer molecules is kept while a polymer adhesive film is given flexibility, electrolyte affinity and appropriate swelling degree in electrolyte to adapt to periodical volumetric changes of electrode active materials along with embedding / escaping of lithium ions in a charging and discharging process, and energy density and cycle performance of the lithium ion batteries are improved.

Owner:SICHUAN INDIGO TECH CO LTD

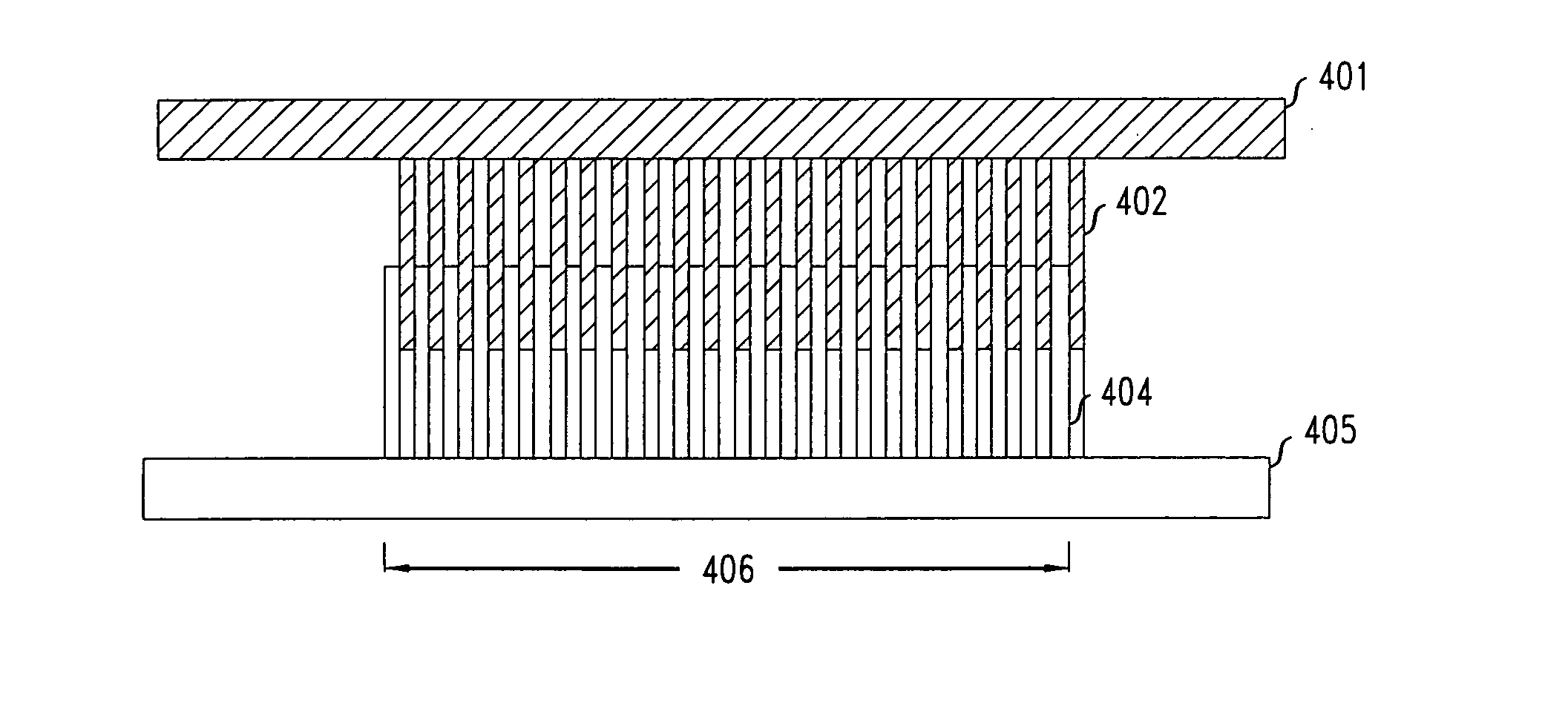

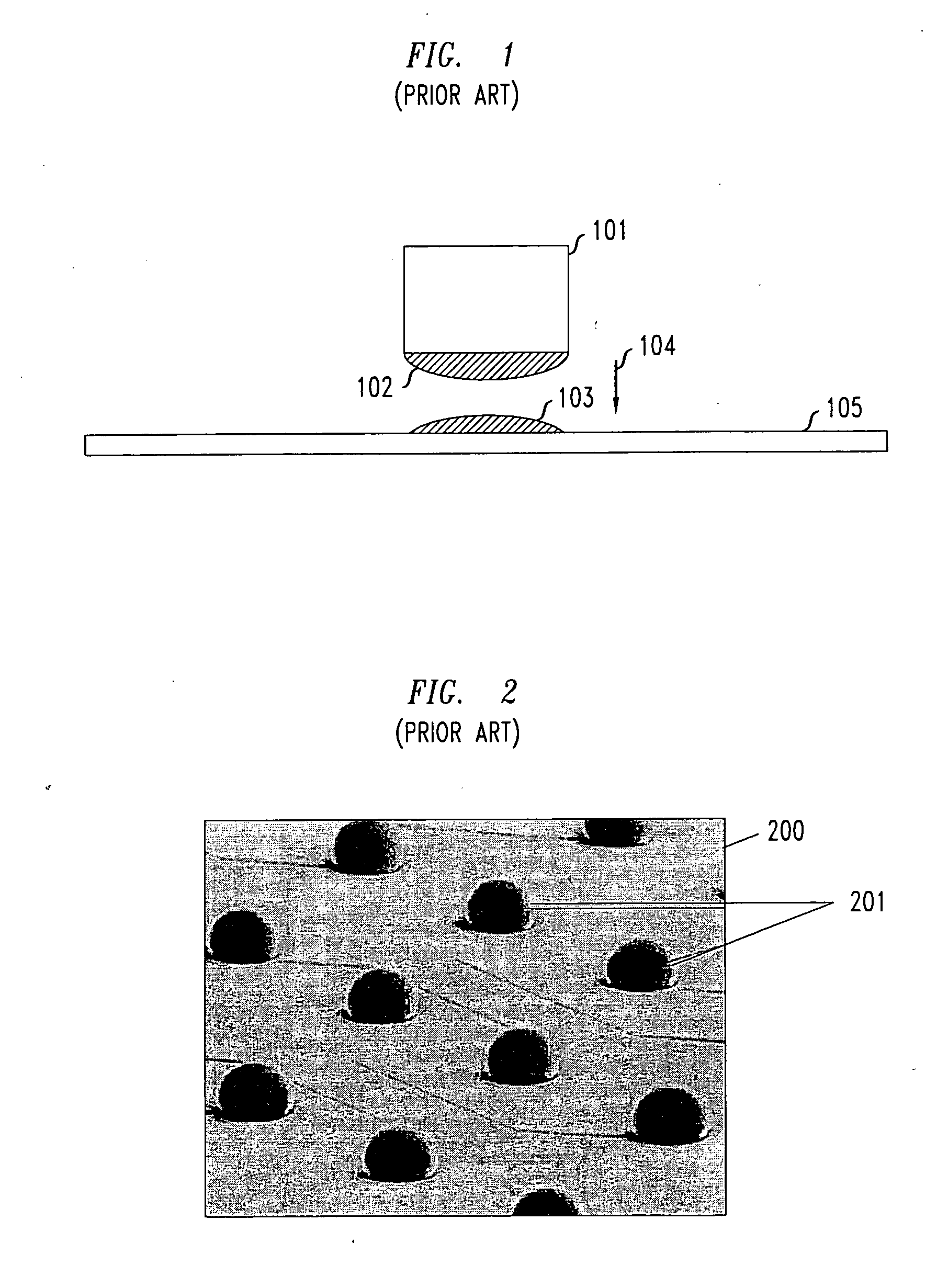

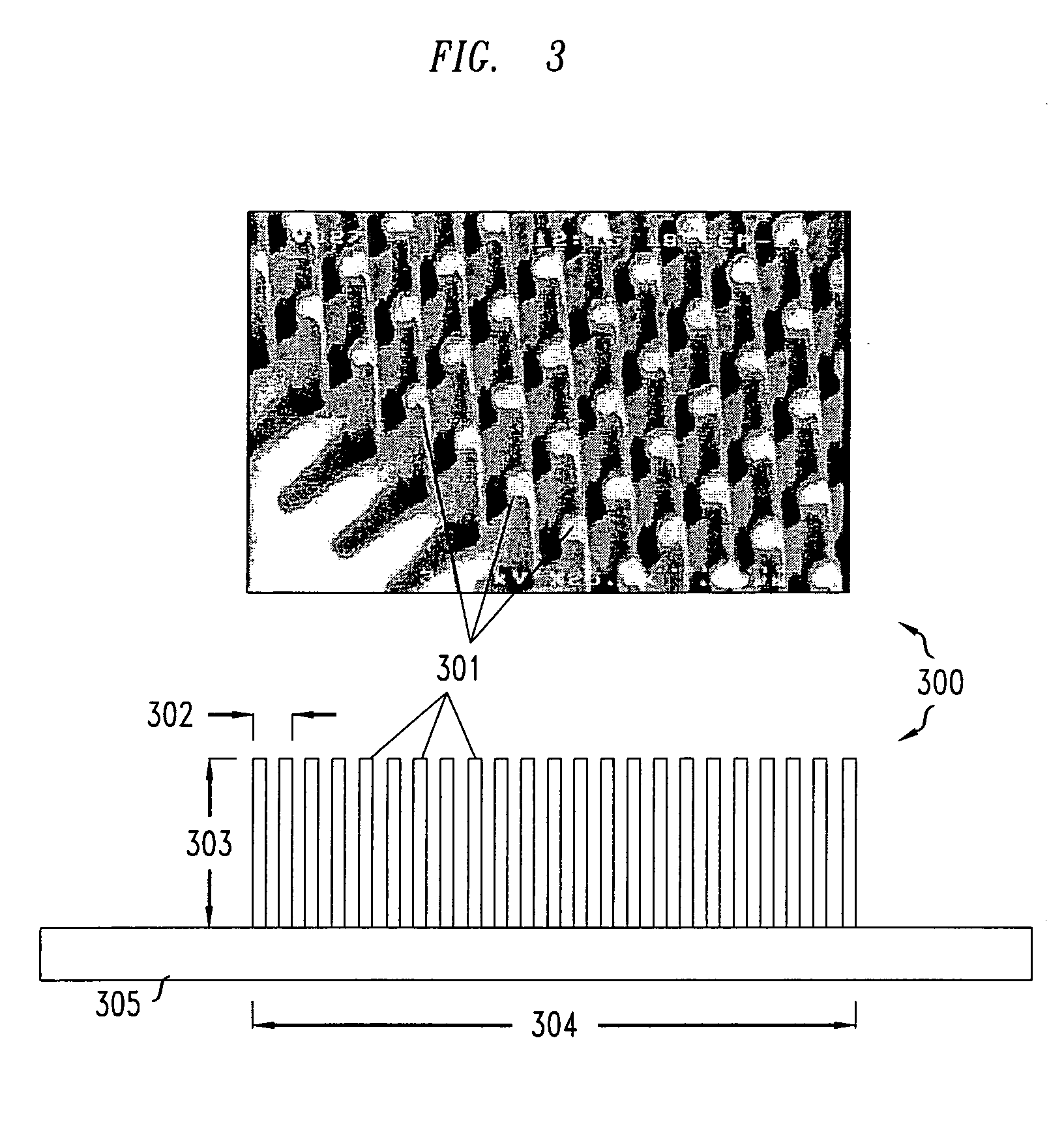

High density nanostructured interconnection

ActiveUS20050224975A1Useful applicationGood adhesionTransistorSemiconductor/solid-state device detailsHigh densityEngineering

A method and apparatus for forming an electrically and / or thermally conducting interconnection is disclosed wherein a first surface and a second surface are contacted with each other via a plurality of nanostructures disposed on at least one of the surfaces. In one embodiment, a first plurality of areas of nanostructures is disposed on a component in an electronics package such as, illustratively, a microprocessor. The first plurality of areas is then brought into contact with a corresponding second plurality of areas of nanostructures on a substrate, thus creating a strong friction bond. In another illustrative embodiment, a plurality of nanostructures is disposed on a component, such as a microprocessor, which is then brought into contact with a substrate. Intermolecular forces result in an attraction between the molecules of the nanostructures and the molecules of the substrate, thus creating a bond between the nanostructures and the substrate.

Owner:LUCENT TECH INC

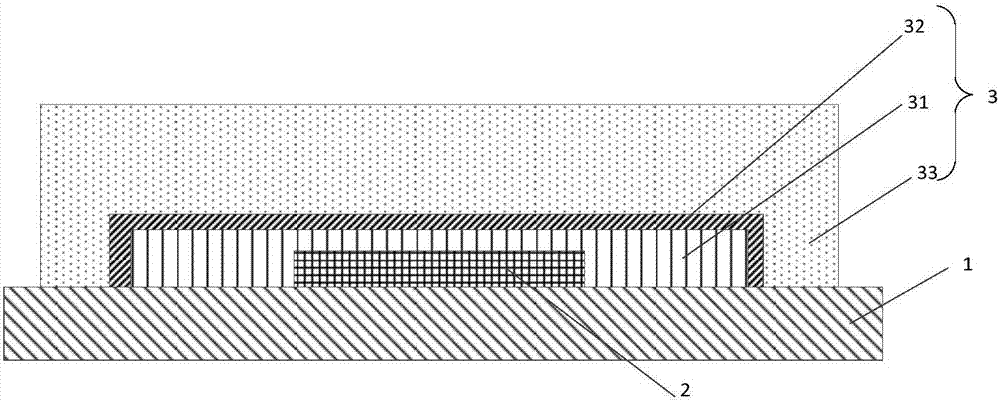

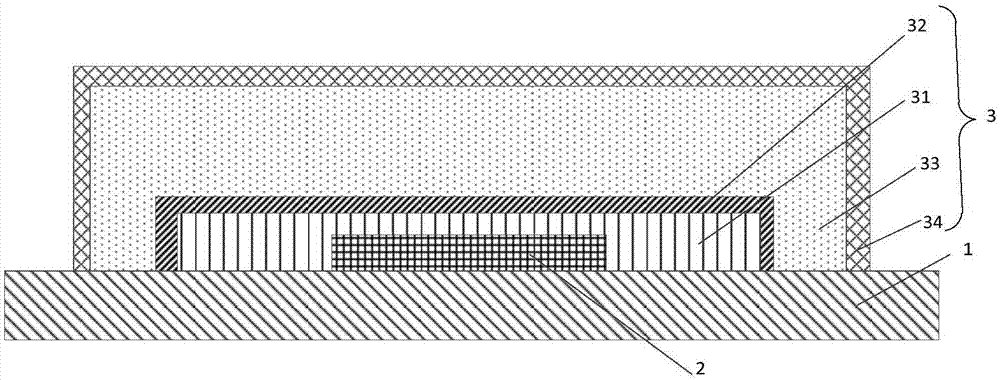

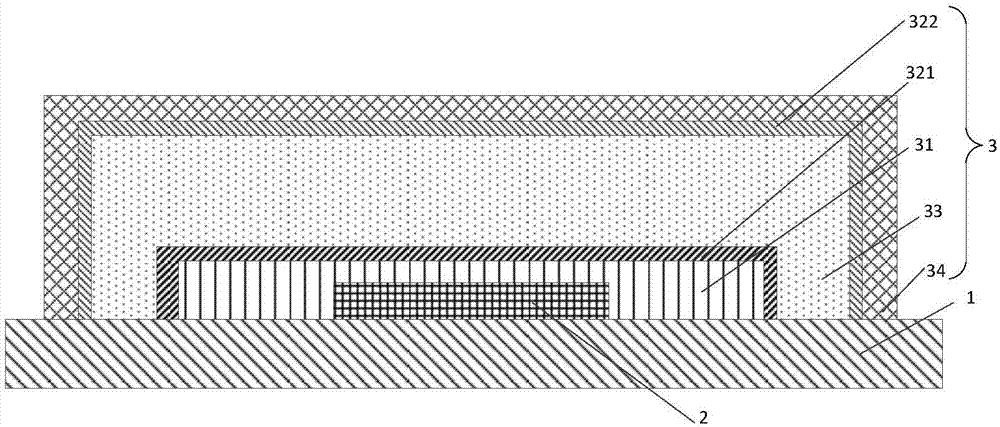

Organic light emitting display panel, display device thereof and manufacturing method thereof

ActiveCN107302014AImprove adhesionPrevent peelingSolid-state devicesSemiconductor/solid-state device manufacturingSurface roughnessDisplay device

The invention relates to the technical field of display and particularly relates to an organic light emitting display panel, a display device thereof and a manufacturing method thereof. The organic light emitting display panel comprises a substrate, a display layer and a package structure. The package structure includes a film encapsulation layer which at least comprises a first inorganic layer and a first organic layer arranged in order. The surface roughness of the first inorganic layer is 0.01nm to 0.99nm. A transition layer is at least arranged between the first inorganic layer and the first organic layer and comprises a connection unit. The connection unit comprises at least one atom in a group consisting of a metal atom and a non-metal atom and a non-polar group, wherein the non-polar group is used for combining the first organic layer through intermolecular force, the metal atom or the non-metal atom is used for connecting the first inorganic layer through a covalent bond, thus the adhesion between the first inorganic layer and the first organic layer is significantly enhanced, and a stripping phenomenon between film layers is avoided.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Hydrophilic super-lubricating coating applied to surfaces of medical apparatuses and preparation method of hydrophilic super-lubricating coating

The invention provides a hydrophilic super-lubricating coating applied to surfaces of medical apparatuses and a preparation method of the hydrophilic super-lubricating coating. The hydrophilic super-lubricating coating comprises a bottom layer and a surface layer, wherein on the basis of the principle of dissolution in similar material structures, the bottom layer and the base material (the surface layer) are firmly bonded; and the surface layer and the bottom layer are firmly connected by virtue of chemical bonds which are formed from ultraviolet grafting and inter-molecular forces. By virtue of a dipping-coating technology, the surfaces of the medical apparatuses are dipped in a bottom layer solution and are subjected to partial curing in ultraviolet radiation; and then, the medical apparatuses that the bottom layer is partially cured are dipped in a surface layer paint and are subjected to complete curing under ultraviolet rays, so that the surface layer is uniformly and stably distributed on the bottom layer. According to the hydrophilic super-lubricating coating and the preparation method provided by the invention, the hydrophilic super-lubricating paint can get rapidly cured under the ultraviolet rays, and the obtained hydrophilic coating is excellent in lubricating performance and durability, and friction and tissue injuries, which are caused in an inserting process, can be effectively relieved; and moreover, the hydrophilic super-lubricating coating is easily available in raw materials and low in cost.

Owner:DALIAN UNIV OF TECH

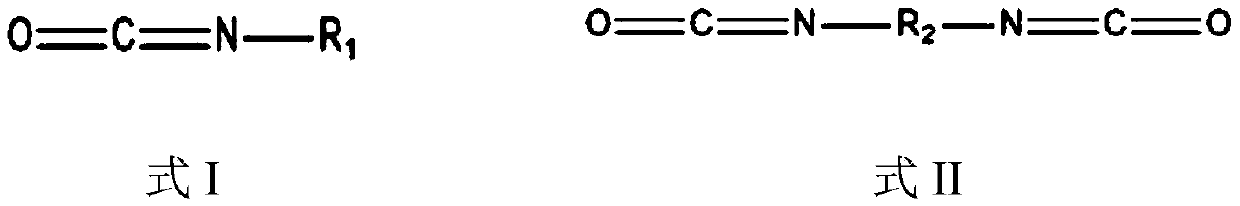

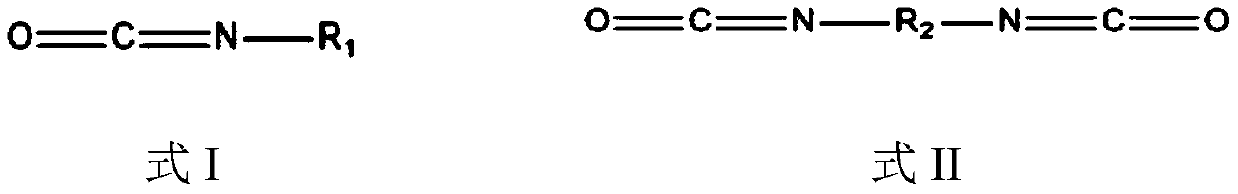

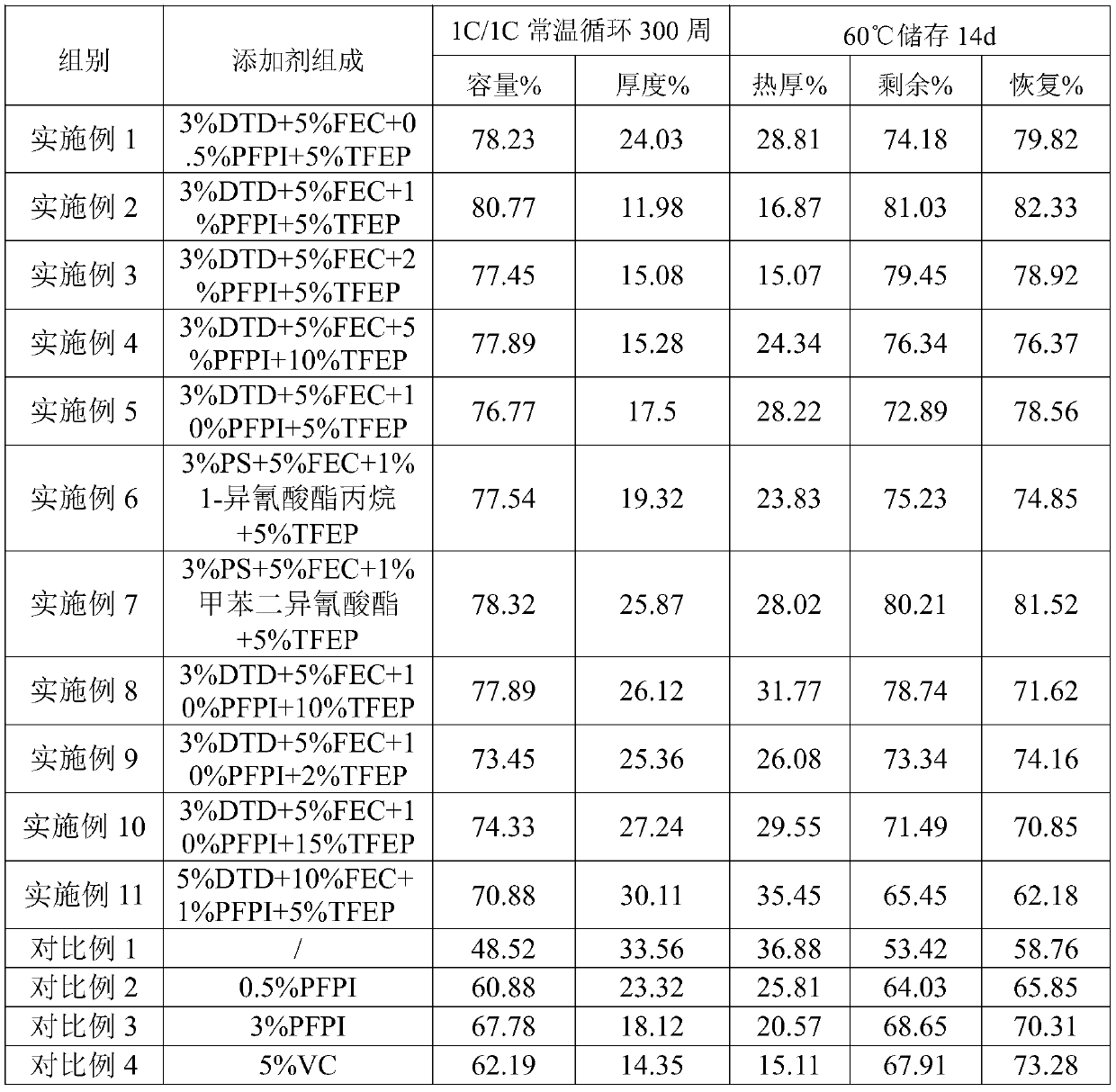

High-temperature high-voltage safety lithium ion battery electrolyte and lithium ion battery

InactiveCN109755636AGood high temperature storage performanceImprove normal temperature cycle performanceSecondary cellsHigh temperature storageElectrical battery

The invention relates to the technical field of lithium ion batteries, and particularly discloses a high-temperature high-voltage safety lithium ion battery electrolyte and a lithium ion battery. Thelithium ion battery electrolyte comprises a lithium salt, a non-aqueous organic solvent and an additive, wherein the additive includes an isocyanate additive, a film forming additive and a fluorinatedflame-retardant additive. According to the lithium ion battery electrolyte, by adding the first type of the isocyanate additive and the second type of the film forming additive, a stable SEI film canbe formed on the surface of an electrode material, so that the ion conduction can be facilitated, and the decomposition of the electrolyte can be inhibited; and by adding the third type of the fluorinated flame-retardant additive, F atoms can form a film on an electrode interface, so that the intermolecular force can be reduced, the viscosity of the electrolyte can be reduced, and the conductivity of the electrolyte can be improved. All the components cooperate, so that the battery has good high-temperature storage performance, normal temperature cycling performance and high-temperature cycling performance under a high voltage, and does not have potential safety hazards.

Owner:SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

Preparation method and application of three-dimensional graphene aerogel load molybdenum disulfide nano-sheet hybridization material

The invention belongs to the technical field of a new energy nano function material, and specifically relates to a preparation method and application of a three-dimensional graphene load molybdenum disulfide nano-sheet hybridization material. A three-dimensional graphene aerogel macroscopic body is prepared through a hydrothermal reduction self-assembly method, and nano-sheet layer crystal-phase molybdenum disulfide grows on a three-dimensional graphene aerogel skeleton through adoption of a H<2> reduction method. According to the three-dimensional graphene load molybdenum disulfide nano-sheet hybridization material prepared in the invention, a large specific surface of three-dimensional graphene provides more active sites for growth of molybdenum disulfide nano sheets, the nano-sheet layer crystal-phase molybdenum disulfide as an active catalyst disperse on a surface of a three-dimensional graphene aerogel, heterojunction structure is formed between the molybdenum disulfide nano sheet and the three-dimensional graphene aerogel through intermolecular forces, and edge activity of the molybdenum disulfide nano sheet is fully exposed. The high catalytic property of molybdenum disulfide is combined with the high specific surface area and excellent eectrical conductivity of the three-dimensional graphene. The hybridization material is applied to fuel cell counter electrode preparation to perform cell assembly so that photoelectric conversion efficiency is improved.

Owner:TONGJI UNIV

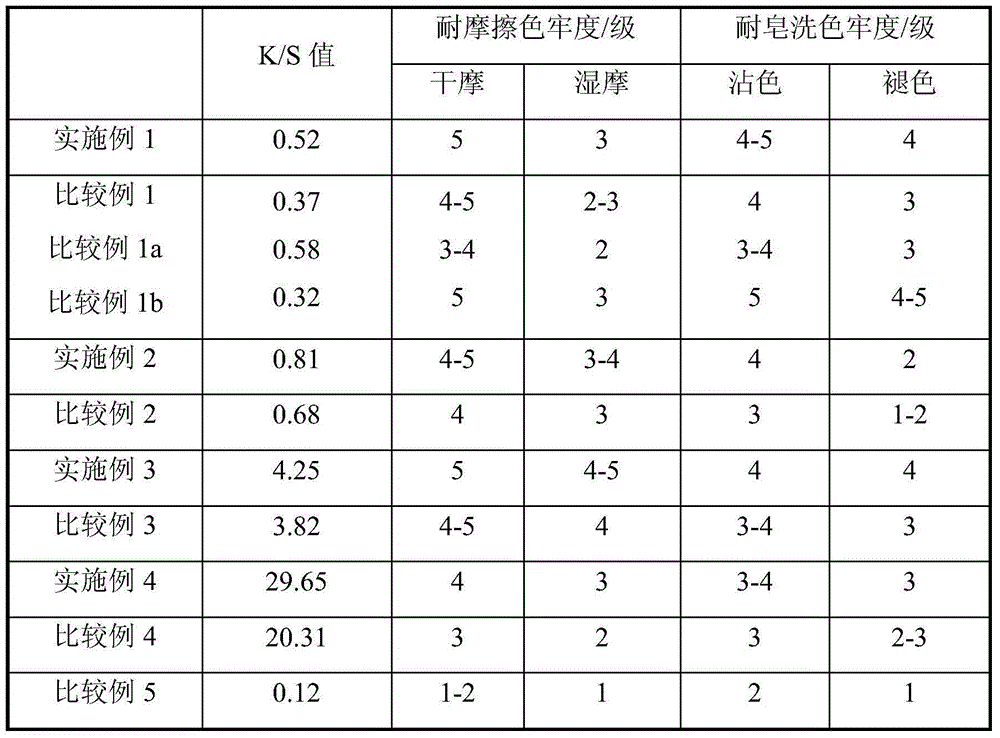

Preparation method and application of chitosan-natural plant pigment macromolecular dye solution

ActiveCN104087020AImprove adsorption capacityAchieve purificationOrganic dyesDyeing processColour fastnessCellulose fiber

The invention belongs to the field of new materials, and particularly relates to a preparation method and application of a chitosan-natural plant pigment macromolecular dye solution. The preparation method comprises the following steps: firstly purifying a natural plant dye by utilizing the electrostatic attraction and the intermolecular force between the amido of chitosan and a negative ion natural plant pigment to obtain a chitosan-natural plant pigment macromolecular dye; and then preparing the chitosan-natural plant pigment macromolecular dye into a dye solution for textile coloration. Compared with the original natural plant dye, the obtained chitosan-natural plant pigment macromolecular dye has heavier molecular weight and has very high coloring capacity on natural fibers, such as cotton, hemp, silk and fur, because the chitosan has high affinity with cellulose fibers and protein fibers; a dyed fabric obtained by the chitosan-natural plant pigment macromolecular dye solution not only has deep color, but also has good color fastness.

Owner:临泉县嘉鸿装饰工程有限公司

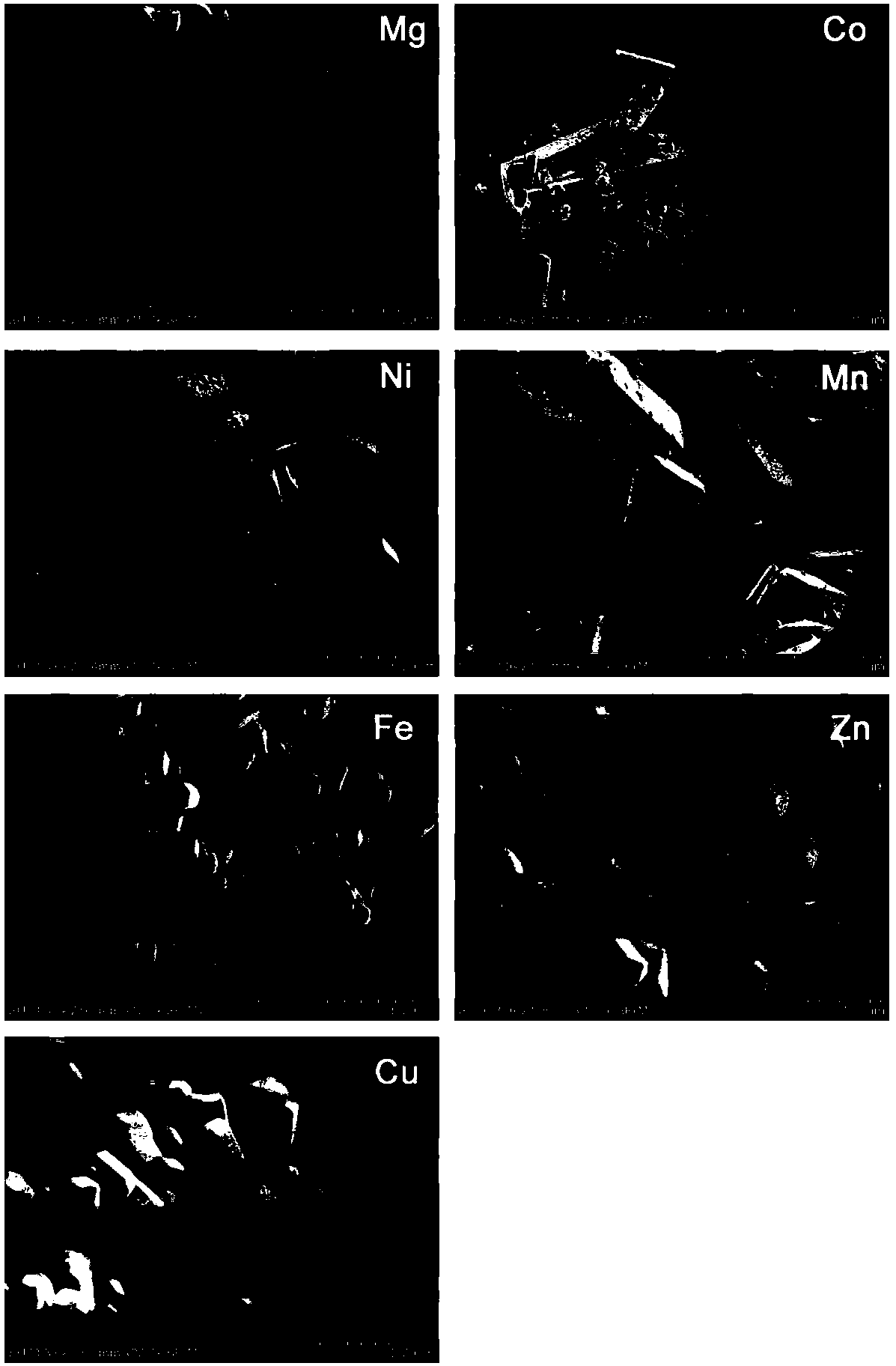

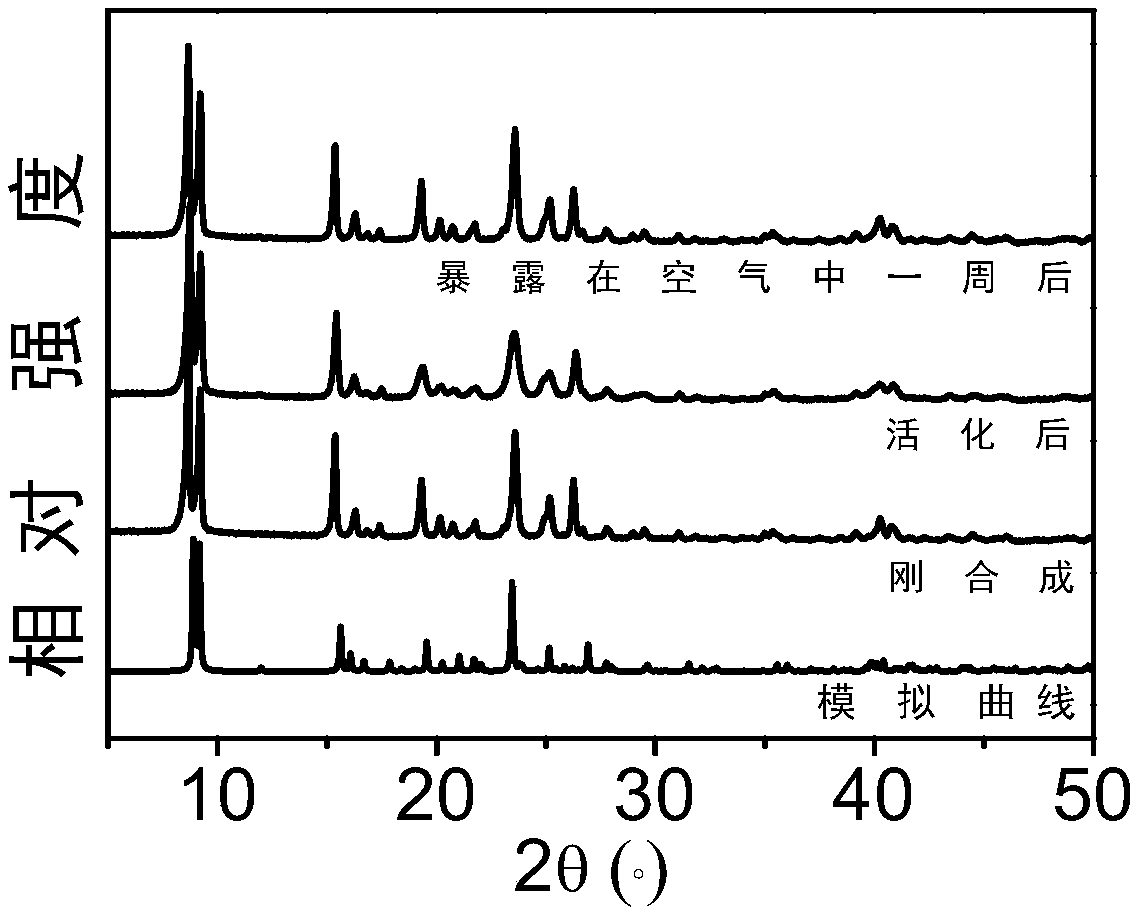

Metal-organic frame material for absorbing and storing acetylene and preparation method thereof

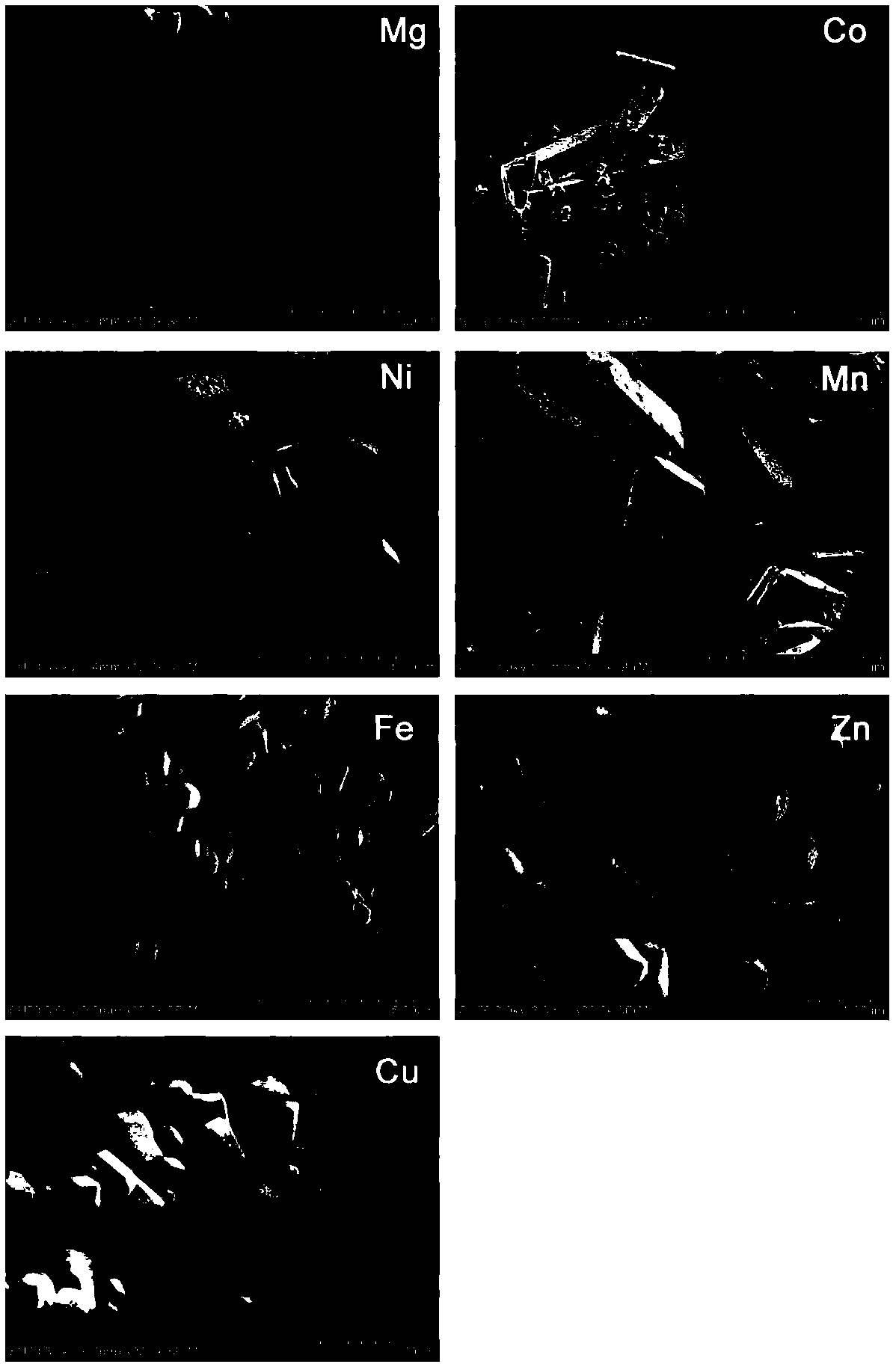

ActiveCN103041778AImprove adsorption capacityIncrease storage capacityOther chemical processesCopper organic compoundsAbsorption capacityCobalt

The invention discloses a metal-organic frame material for absorbing and storing acetylene and a preparation method thereof. The metal-organic frame material adopts a three-dimensional network structure which is formed by transition metal ions and multitooth organic ligands 5,5'-(pyridine-2,5-dibase)-isophthalic acid through coordinate bonds or intermolecular forces. Bivalent copper, zinc, cobalt, nickel and cadmium ions are preferably selected as the transition metal ions. The metal-organic frame material has a simple preparation process and has higher specific surface area being 2000-2200m2 / g and pore volume being 1.0-1.3cm<3> / g. The multitooth organic ligands used by the material introduce an alkaline unit containing pyridine, so that the absorption and storage capacity of acetylene can be effectively increased. The materials has a higher acetylene absorption capacity under the 273-298K temperature condition, can be used under lower pressure, and can be used as a novel efficient acetylene absorption and storage material.

Owner:ZHEJIANG UNIV

Amphoteric water soluble color-fixing agent and its application

The present invention relates to one kind of amphoteric water soluble polymer color-fixing agent and its synthesis and use. The amphoteric water soluble color-fixing agent is suitable for color fixing of direct active dye, and can form cation radical, reactant anion radical, hydrogen bond and some radical capable of increasing the intermolecular force in water solution. It can combine with dye anion and cellulose anion through electrostatic force like cationic color fixing agent, and has active cross-linking radical, structure unit with affinity to dye and molecular weight great enough to form protecting film combining with dye and fiber to close the hydrophilic radical, lower the water solubility of dye molecule and strengthen the force between dye molecule and cellulose molecule simultaneously, so as to raise color fastness in several aspects.

Owner:DONGHUA UNIV

Alcohol-soluble composite film adhesive and preparation method thereof

InactiveCN101818033AThe impact of small resource pricesNo waste problemMonocarboxylic acid ester polymer adhesivesMineral oil hydrocarbon copolymer adhesivesPolymer scienceComposite film

The invention discloses an alcohol-soluble composite film adhesive and a preparation method thereof, belonging to the field of an adhesive. The adhesive is prepared from the following components in percentage by weight: acrylate polymer, tackifying resin and solvent, wherein the acrylate polymer is polymerized from 20-50wt% of acrylate hard monomer, 40-70wt% of acrylate soft monomer and 1-10wt% of acrylate functional monomer by a solution polymerizing method under the actions of an initiator and the solvent. The glass transition temperature of the acrylate polymer is -10 to -40 DEG C. As the acrylate hard monomer and the acrylate soft monomer are reasonably matched, and a certain acrylate functional monomer is matched to participate into the polymer, the molecular chain of the acrylate polymer in the composite film adhesive has multiple chemical bond structures of -COH, -OH, -NH and the like, multiple intermolecular action force can be formed, the adhesive can be adhered to various composite materials with good adhesion property and wide adhesion range. The prepared composite film adhesive can use the alcohol as the main solvent and has the advantages of little toxicity and low cost.

Owner:BEIJING COMENS NEW MATERIALS

Metal-organic framework material for methane adsorption and storage and preparation method thereof

ActiveCN103100372AImprove thermal stabilityImprove adsorption capacityOrganic chemistryOther chemical processesManganeseMetal-organic framework

The invention discloses a metal-organic framework material for methane adsorption and storage and a preparation method thereof. The metal-organic framework material is of a three-dimensional network structure formed by transition metal ions, an organic ligand, namely, 5,5'-(pyridine-2,5-diyl)-isophthalic acid, and derivatives of the ligand through coordinate bonds or intermolecular forces. The transition metal ions are preferentially selected from bivalent ions of copper, zinc, cobalt, nickel, cadmium and manganese. The metal-organic framework material is higher in specific surface area and pore volume and good in thermal stability. Pyridine, fluorine, methyl, amino, methoxy, hydroxyl, nitro and other functional groups which do not participate in coordination are introduced into the organic ligand used in the material, can effectively improve the capacity of methane adsorption and storage. The metal-organic framework material is simple in preparation process and low in cost, can be used repeatedly, has high capacity of methane adsorption and storage under variable-temperature and variable-pressure conditions, and is expected to be used as a novel high-efficiency methane adsorption and storage material.

Owner:ZHEJIANG UNIV

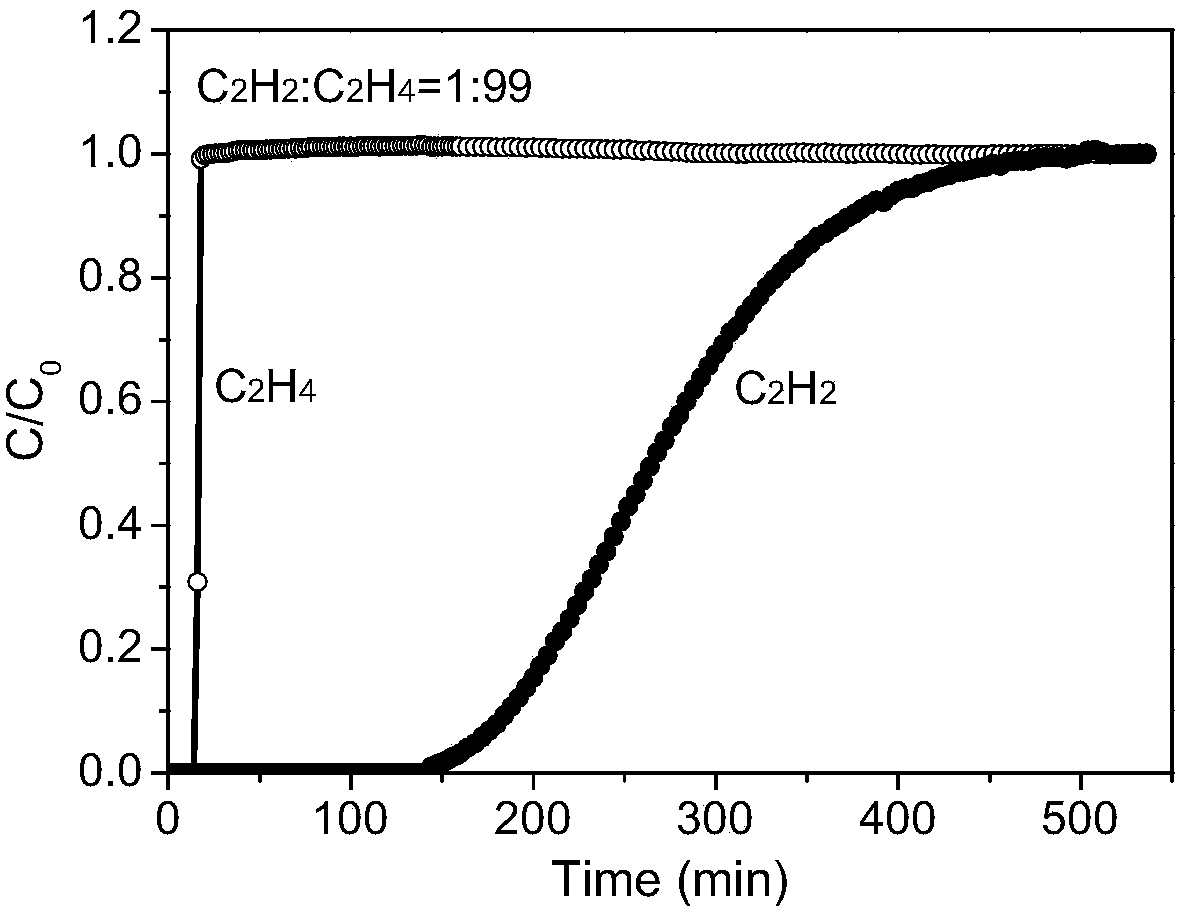

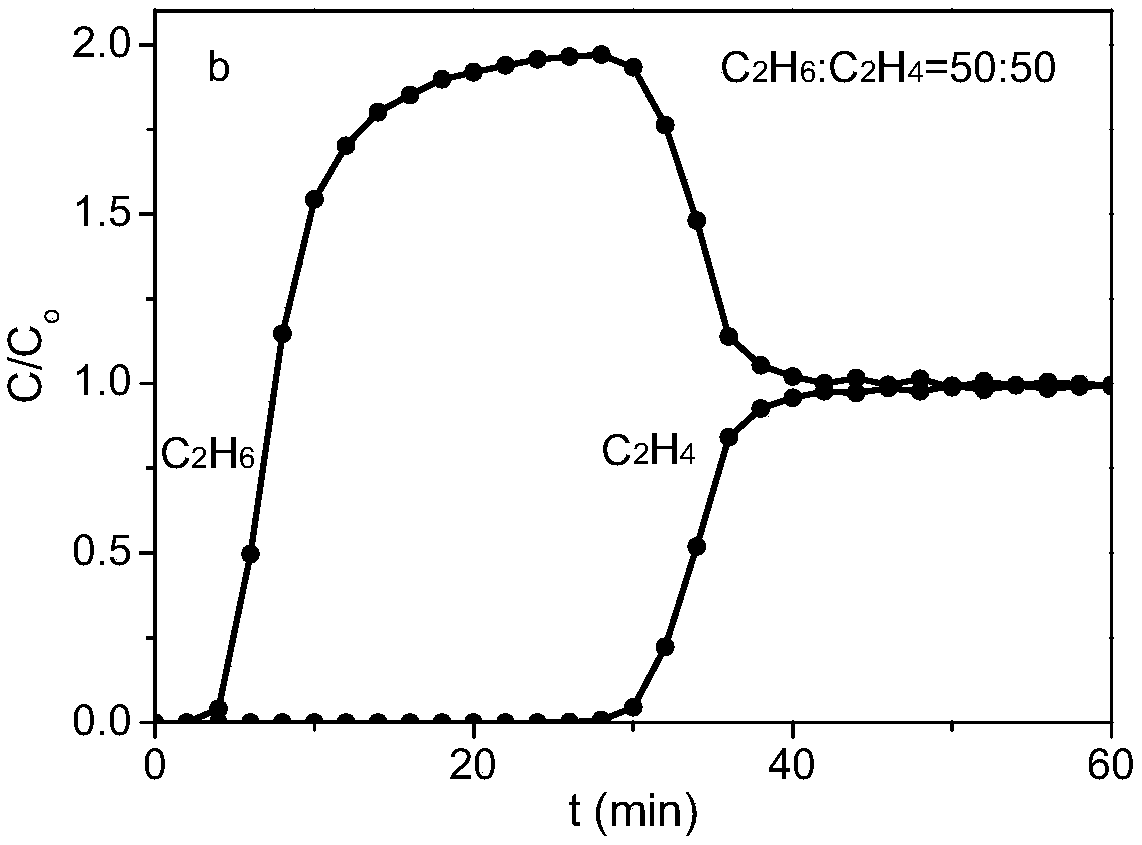

Method for separating ethylene and acetylene from mixed gas

ActiveCN108014751AEasy synthesis costLower synthesis costOther chemical processesAdsorption purification/separationAlkaline earth metalGallic acid ester

The invention discloses a method for separating ethylene and acetylene from a mixed gas. The method comprises the step of using a metal organic frame material as an adsorbent for separating the ethylene and the acetylene from the mixed gas containing the ethylene and the acetylene; the metal organic frame material has a structural formula of M(C7O5H4).2H2O, wherein M is a metal ion, and the metalorganic frame material is a three-dimensional network structure formed by coordination bonds or intermolecular forces from a transition metal ion or alkaline earth metal ion and gallic acid. The metalorganic frame material has a large adsorption capacity for the acetylene and an excellent selectivity for adsorption and separation of ethylene / acetylene. The materials for the synthesis of the material is cheap and easy to obtain, the material preparation process is simple, and the cost is low; and the material has good regeneration and repetition performance, can still maintain the original adsorption effect after vacuum or heating regeneration, and has broad industrial application prospects.

Owner:ZHEJIANG UNIV

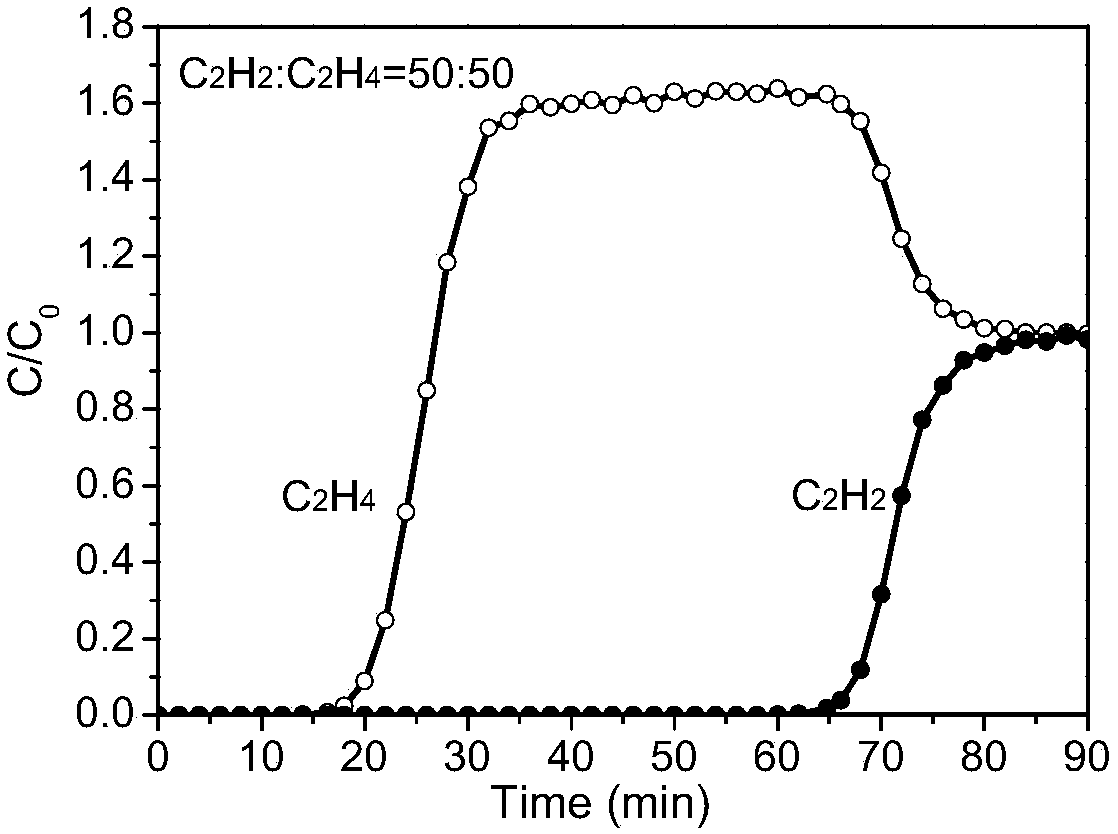

Metal-organic framework material for separating ethylene and acetylene, and method for separating ethylene and acetylene

ActiveCN108671893AImprove stabilityImprove adsorption capacityOther chemical processesDispersed particle separationSorbentPyrazine

The invention provides a metal-organic framework material for separating acetylene and ethylene, and a method for separating ethylene and acetylene. The metal-organic framework material has the advantages of good stability, high adsorption capacity, good adsorption separation selectivity, simple preparation method and low preparation cost. The structural general formula of the metal-organic framework material is Cu2(pzdc)2L.2H2O, pzdc in the formula is pyrazine-2,3-dicarboxylic acid, and the material is a three-dimensional network structure formed by copper ions, the pyrazine-2,3-dicarboxylicacid and an organic ligand A through a coordination bond or an intermolecular action force. The preparation method comprises the following steps: (1) mixing and reacting an inorganic salt, the pyrazine-2,3-dicarboxylic acid, an alkali and the organic ligand in proportion, wherein the inorganic salt is chloride, nitrate, acetate, sulfate or perchlorate of the copper ions; and (2) sequentially washing a product obtained after the reaction is finished with ionized water and anhydrous methanol, and then carrying out vacuum drying to obtain the metal-organic framework material. The metal-organic framework material is used as an adsorbent to adsorb and separate a mixed gas containing ethylene and acetylene.

Owner:ZHEJIANG UNIV

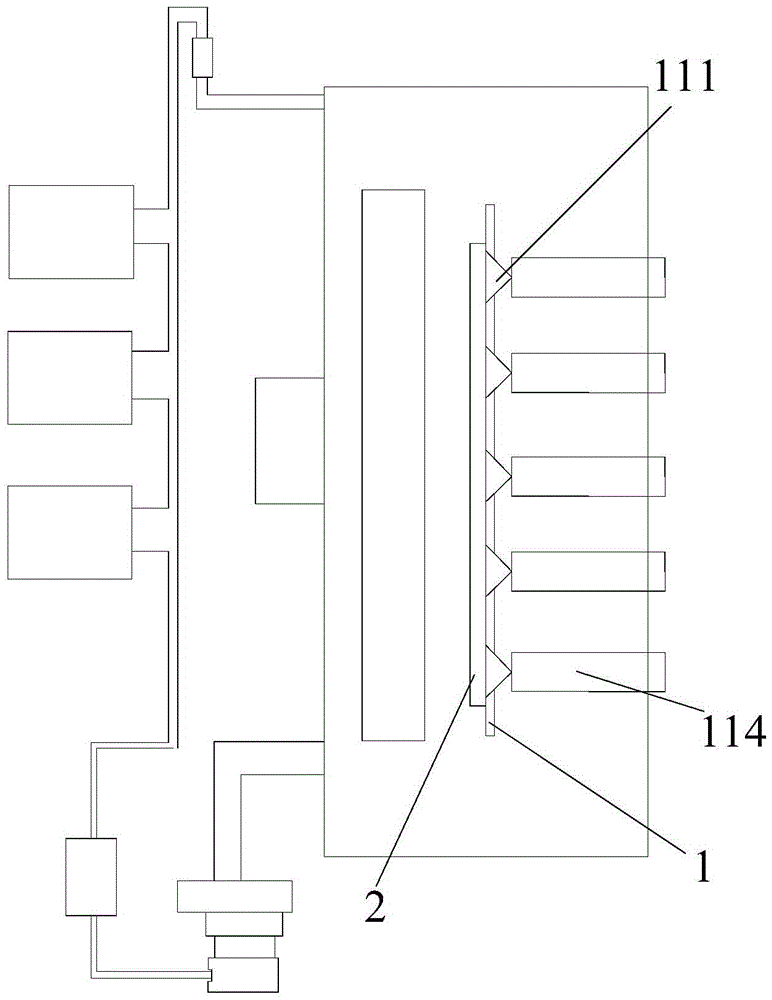

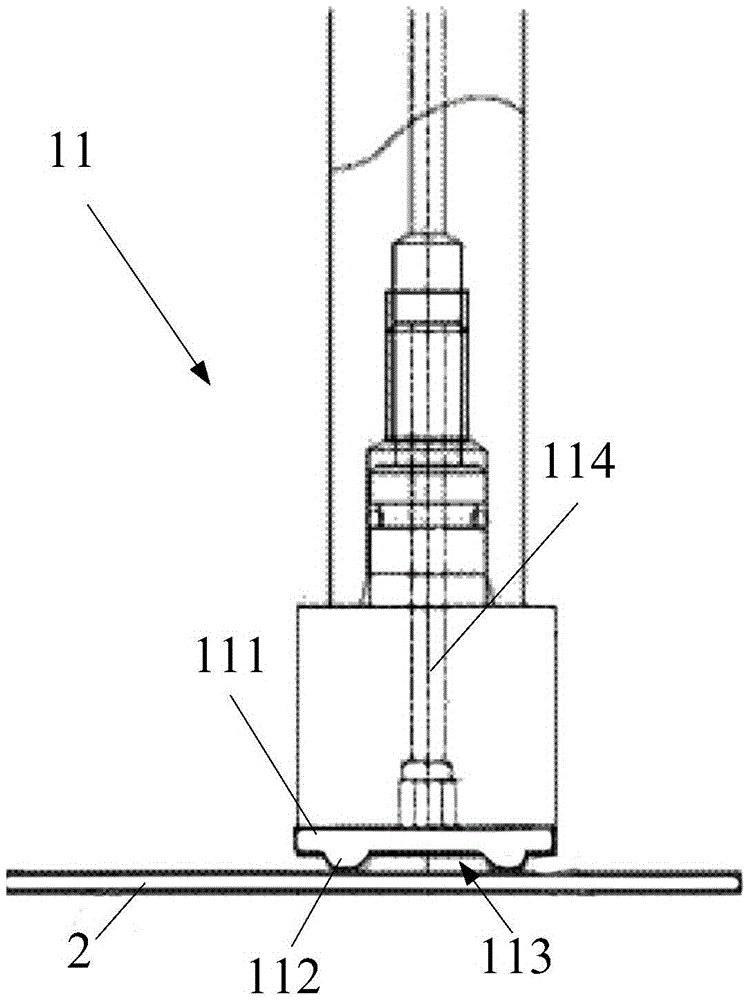

Base plate bearing device

ActiveCN105572925AEasy to fixReduce deformationNon-linear opticsManufacturing technologyLiquid-crystal display

The invention relates to the technical field of liquid crystal display design and manufacturing, in particular to a base plate bearing device which comprises a base platform, a press fit sucking mechanism and an adhesive sucking mechanism, wherein the press fit sucking mechanism and the adhesive sucking mechanism are arranged on the base platform; the adhesive sucking mechanism is made of an adhesive material; the press fit sucking mechanism is used for enabling the base plate to be tightly pressed to the adhesive sucking mechanism. When being placed on the base platform by using a manipulator, the base plate can be sucked by the adhesive sucking mechanism made of the adhesive material through action force of molecules, and can be fixed on the base platform, so that the problems that the base plate can be deformed and is relatively poor in coating uniformity when being fixed by using a clamp are solved; compared with a conventional fixation mode of a triangular clamp, the base plate bearing device is relatively stable and solid, the deformation quantity of the base plate is relatively low, the coating uniformity is greatly improved, and meanwhile the defects that the base plate is deformed and dropped are also solved.

Owner:BOE TECH GRP CO LTD +1

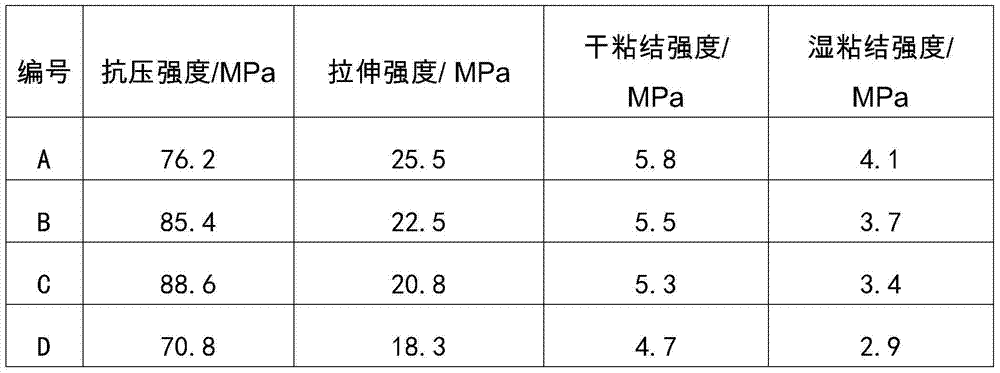

Preparation method of polyurethane modified epoxy resin and grouting material based on resin

The invention provides a preparation method of polyurethane modified epoxy resin. The preparation method comprises the following steps: firstly performing reaction on isocyanate and a hydroxyl group on epoxy resin to obtain polyurethane graft epoxy resin, further terminating isocyanate on the polyurethane graft epoxy resin with monohydric alcohol, and further grafting a polyurethane short branch chain on the epoxy resin by utilizing the unit termination of isocyanate so as to increase the intermolecular distance of the epoxy resin, reduce the intermolecular action force, improve the motion ability of a chain segment and simultaneously realize the effects of reducing viscosity of slurry and toughening; furthermore, a grouting material based on the polyurethane modified epoxy resin provided by the invention can effectively reduce the intermolecular physical crosslinking and realize strong permeability and good toughness; data shows that the compressive strength exceeds 70MPa, the tensile strength is more than 20MPa, the dry bonding strength is more than 5MPa, and the wet bonding strength is more than 3MPa.

Owner:BEIJING TIEKE SHOUGANG RAIL TECH CO LTD

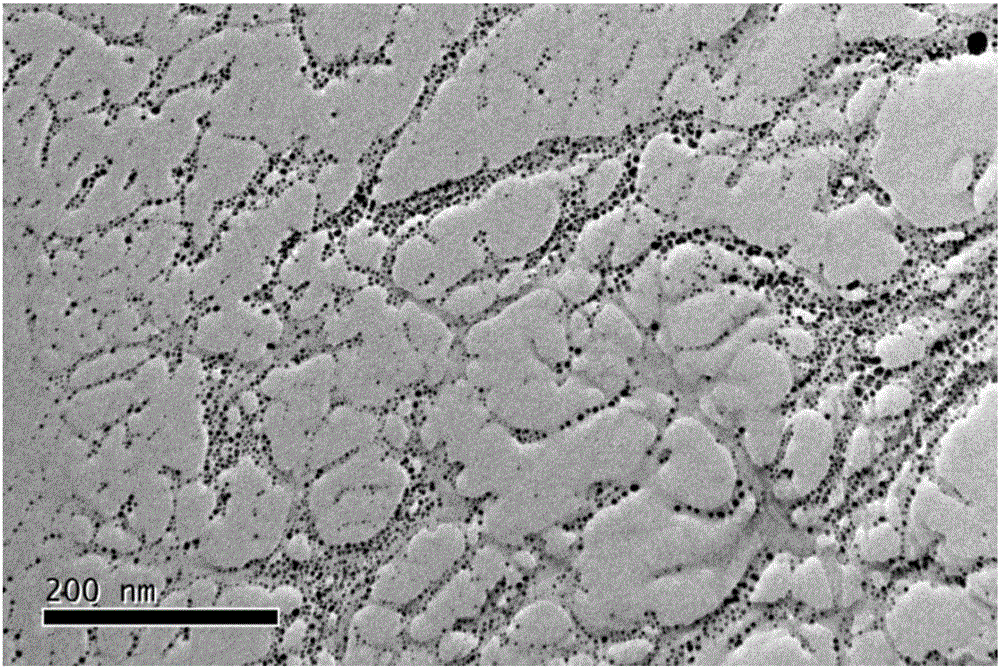

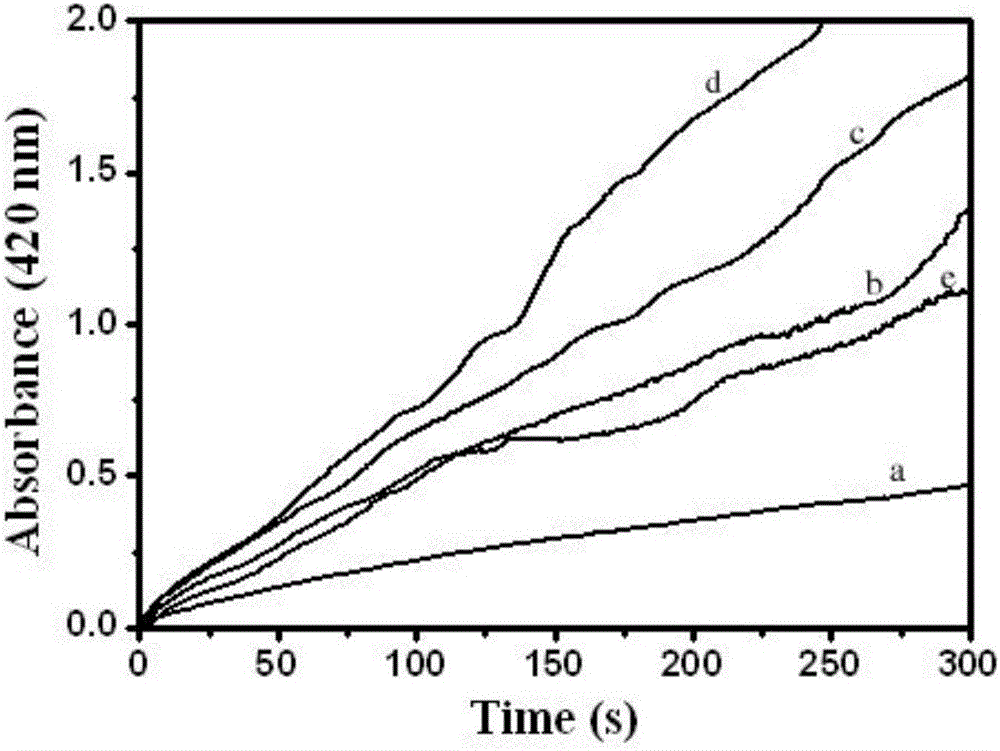

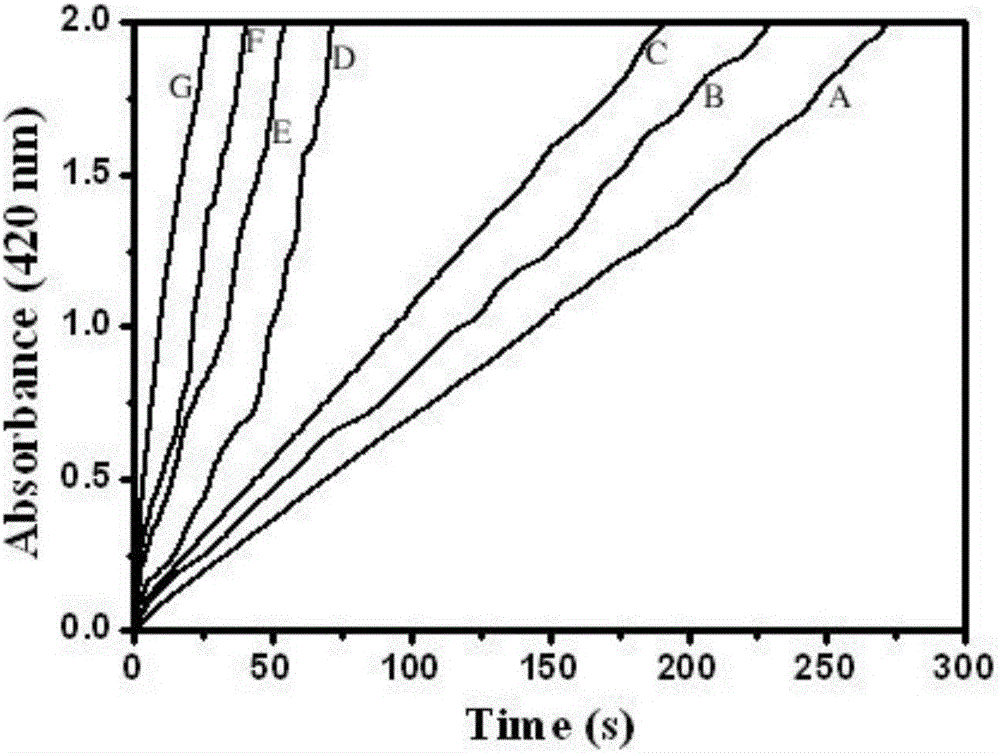

Mimic enzyme based on self-assembly structure as well as preparation method and application thereof

InactiveCN105798324AIncreased peroxidase activityThe synthesis conditions are mild and convenientMaterial nanotechnologyTransportation and packagingPeroxidaseReducing agent

The invention discloses a preparation method for a mimic enzyme based on a self-assembly structure. The preparation method comprises the following steps: (1) dissolving chemical substances capable of carrying out a self-assembly behaviour into water; (2) adding an active metal salt solution and a reducer in the solution in the step (1), and stirring to obtain the mimic enzyme based on the self-assembly structure. In the preparation method provided by the invention, two previously prepared chemical substance aqueous solutions capable of carrying out the self-assembly behaviour are mixed, two types of molecules are assembled together through an action force among weak molecules, and metal salt ions are adsorbed on the surfaces of the molecules and generate metal nanoparticles in situ under the action of the reducer; and the obtained metal nanoparticles based on the self-assembly structure have a great peroxidase activity under the conditions of wide pH and temperature ranges, high ion strength and the like. The synthesis conditions of the material are moderate, simple and convenient, the price of raw materials is low, and business development is facilitated. The metal nanoparticle material based on the self-assembly structure, which is disclosed by the invention, can also be applied to many fields of electro-catalysis, water treatment, biomedicine and the like, and has a wide application prospect.

Owner:SUN YAT SEN UNIV

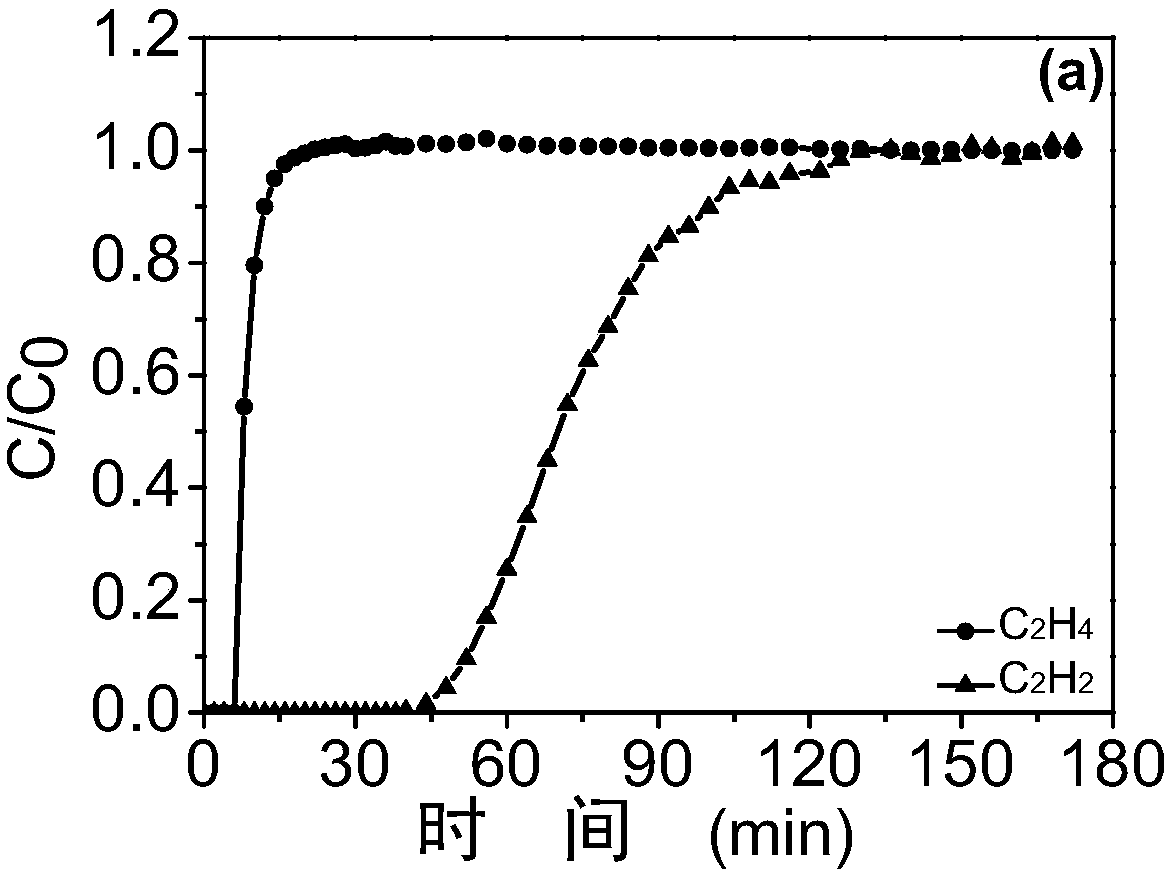

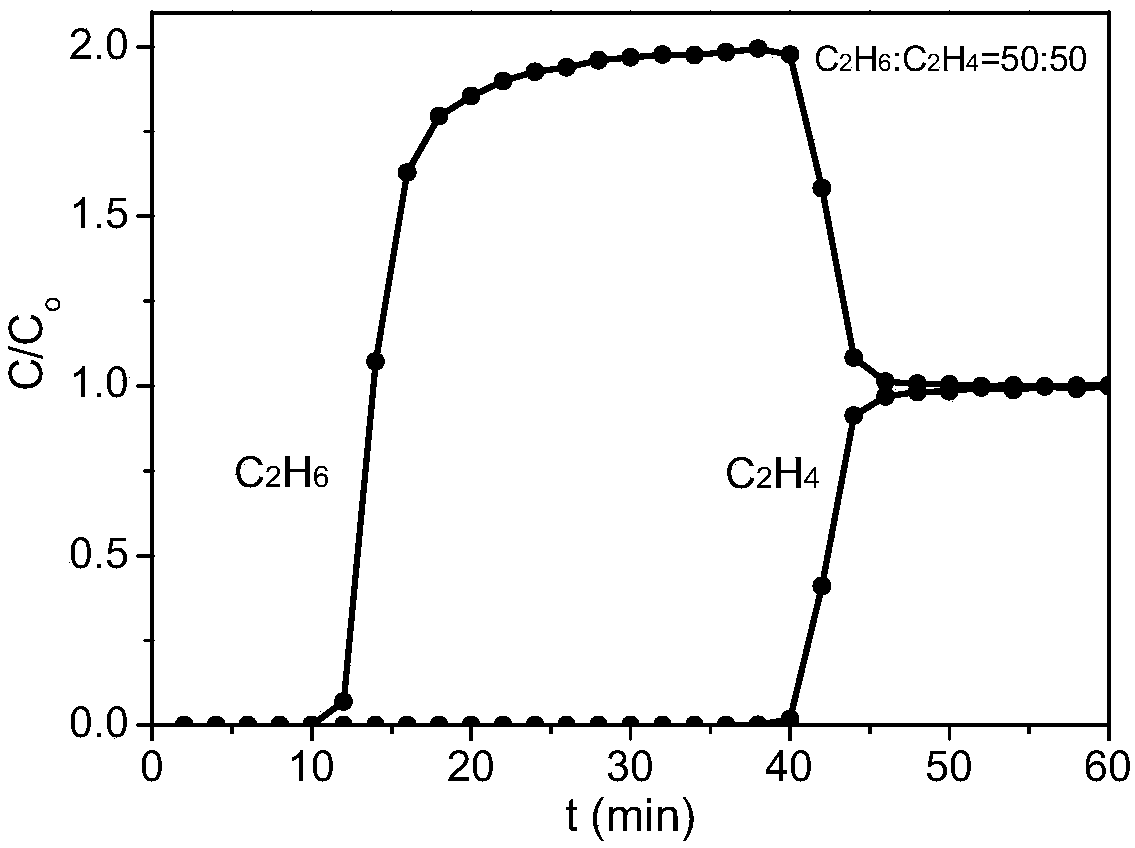

Metal organic frame material for separating ethane and ethylene and separation method of ethylene and ethane

ActiveCN108014752AStable structureImprove performanceOrganic chemistryOrganic compound preparationGallic acid esterAlkaline earth metal

The invention discloses a metal organic frame material for separating ethane and ethylene and a separation method of the ethylene and the ethane .The metal organic frame material has the advantages ofgood stability, high adsorption capacity, good adsorption and separation selectivity, simple preparation method and low preparation cost. The general structural formula of the metal organic frame material is M(C7O5H4).2H2O, wherein M is a metal ion, and the structure of the metal organic frame material is a three-dimensional network structure formed from a transition metal ion or an alkaline earth metal ion and gallic acid through coordinate bonds or intermolecular forces. A preparation method is as follows: (1) an inorganic salt, the gallic acid, an alkali, and deionized water are mixed according to a ratio, stirred and dissolved, and then put into a reaction kettle for hydrothermal reaction; the inorganic salt is a chloride salt, a nitrate salt, an acetate, a carbonate, a sulphate or aperchlorate of the metal ion; and (2) after the end of the hydrothermal reaction, the deionized water and absolute ethanol are in turn used for washing, and vacuum drying is performed. The metal-organic frame material is used as an adsorbent to perform adsorption separation of a mixed gas containing the ethylene and the ethane.

Owner:ZHEJIANG UNIV

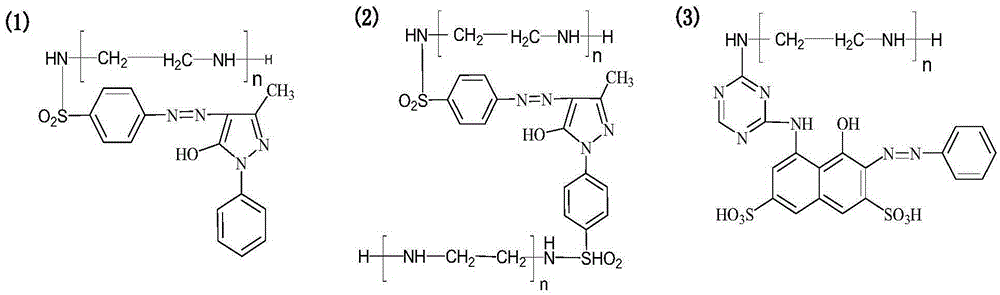

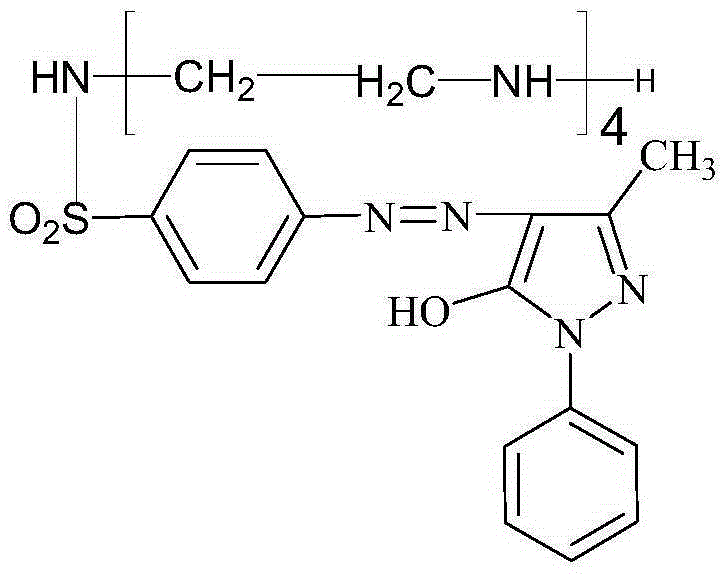

Dyeing method for calcium alginate fibers

The invention belongs to the technical field of fiber dyeing, and particularly relates to a dyeing method for calcium alginate fibers. According to the dyeing method for the calcium alginate fibers, dye containing polyethylene polyamine framework structures is adopted to dye the calcium alginate fibers; the defect that the fibers are damaged due to the fact that inorganic salt needs to be added for dyeing accelerating in the dyeing process of traditional dye is fundamentally overcome, and the strength loss of the fibers after dyeing is small; meanwhile, compared with the weaker intermolecular force and hydrogen-bond interaction between general direct dye and the fibers, the acting force between molecules of the dye and the fibers is higher, and then the advantages of being higher in dye-uptake rate and soaping fastness and the like are achieved; the dyed fibers are uniform and bright in color and meet the dyeing requirements of the calcium alginate fibers, and the dyeing method is economical in energy and environmentally friendly.

Owner:SHANDONG UNIV OF TECH

Composite transparent conductive thin film and preparation method thereof

ActiveCN104299681AEffective dispersionLow costConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialNanowireElectromagnetic shielding

The invention discloses a piece of composite transparent conductive thin film and a preparation method thereof. The composite transparent conductive thin film comprises metal nanometer wires, silicon-contained nanometer particles and conductive sheet carbon elementary substances, wherein a conductive grid of the composite transparent conductive thin film is composed of all the metal nanometer wires, the silicon-contained nanometer particles are adsorbed to the peripheries of all the metal nanometer wires under the intermolecular forces and are used for dispersing all the metal nanometer wires, the conductive sheet carbon elementary substances are used for connecting all the metal nanometer wires in an electric conduction mode. The composite transparent conductive thin film can be used as a flexible transparent electrode and can be widely applied to the photoelectric field of solar cells, touch screens, electroluminescence displays, electronic paper, liquid crystal displays, plasma displays, electromagnetic shielding material and the like.

Owner:SHENZHEN SMART SECURITY & SURVEILLANCE SERVICE ROBOT CO LTD

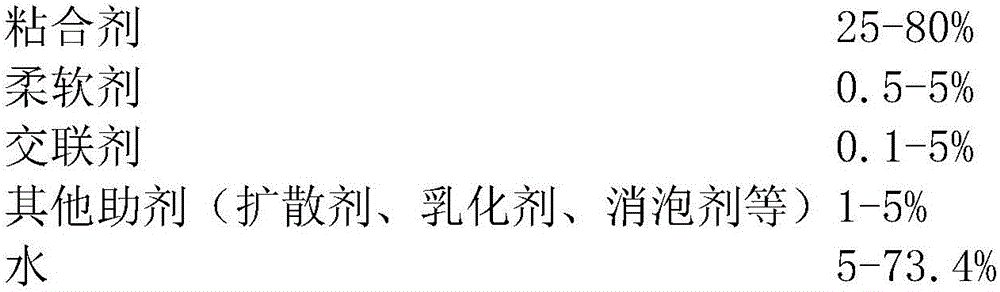

Single-component water-based adhesive for evaporative cooling wet curtain and preparation method thereof

ActiveCN102516904AAvoid performance conflictsImprove wetting and levelingNon-macromolecular adhesive additivesMacromolecular adhesive additivesWater basedAdhesive

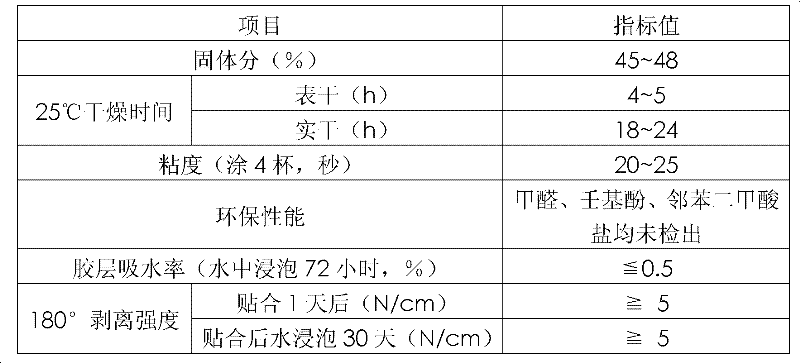

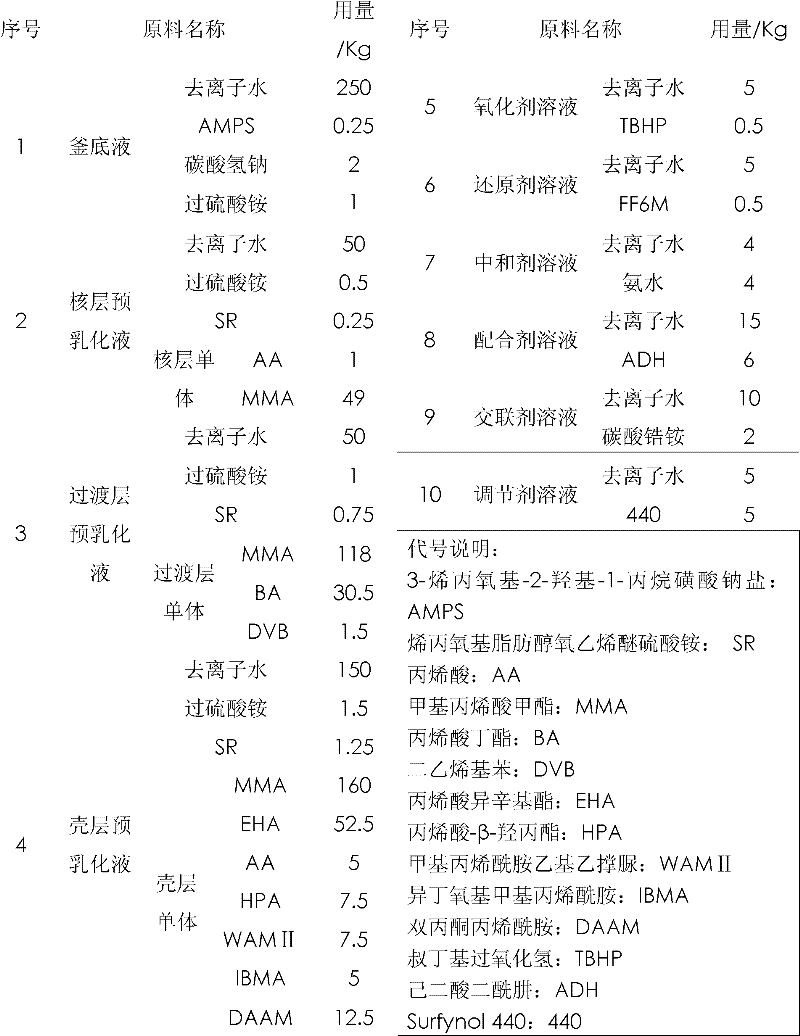

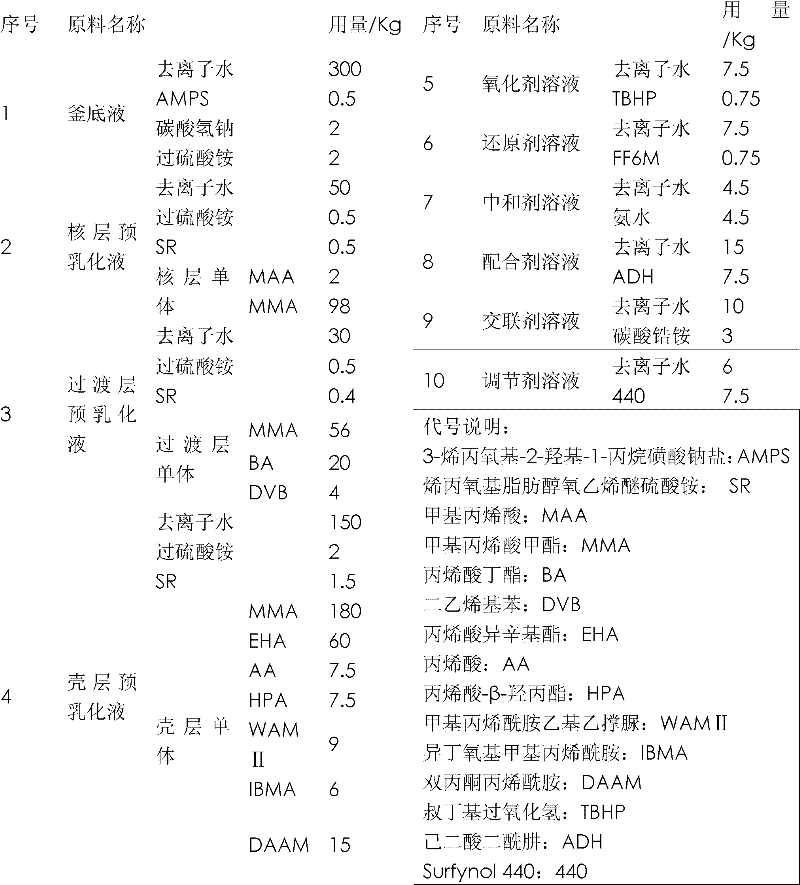

The invention discloses a single-component water-based adhesive for an evaporative cooling wet curtain and a preparation method thereof. The method comprises the following steps of: firstly preparing kettle bottom liquid and adding into a polymerization reaction kettle; then respectively preparing nuclear layer pre-emulsion, transition layer pre-emulsion and shell layer pre-emulsion; removing possibly-caused free formaldehyde through carrying out nuclear layer-transition layer-shell layer gradient emulsion polymerization, by adopting an environmentally-friendly and highly-efficient reactive emulsifier and through replacing hydroxymethyl acrylamide with a novel self-crosslinking monomer and replacing sodium formaldehyde sulphoxylate with a macromolecule polymerization type reducing agent; and introducing carbamido or nitrogen heterocycle into an acrylate structure to provide a higher intermolecular hydrogen bond and an intermolecular acting force and improve the wet adhesive force and the scrub resistance of an adhesive layer. The invention has the beneficial effects that the adhesive force and the water resistance of the adhesive layer are ensured through ion crosslinking and in cooperation with diacetone acrylamide / adipic dihydrazide crosslinking; and by adopting an adjusting agent with the super-strong defoaming and wetting functions, the adhesive is ensured to satisfy higher coating rate in the gluing process and not to generate tiny bubble residues.

Owner:DONGGUAN STAR COSM POLYMER

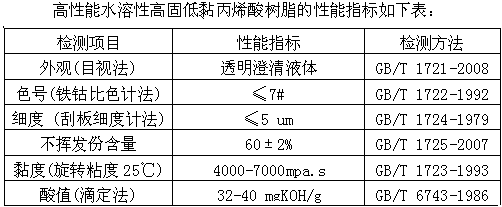

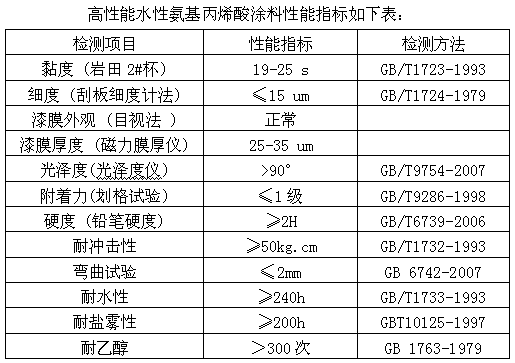

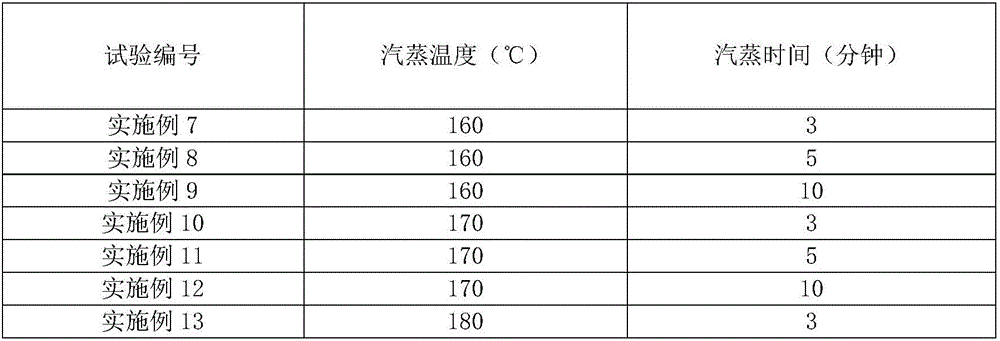

Preparation method of high-performance water-soluble high-solid low-viscosity acrylic resin

ActiveCN108864359AImprove performanceHigh reactivityAntifouling/underwater paintsPaints with biocidesSolubilityWater based

The invention relates to a preparation method of a high-performance water-soluble high-solid low-viscosity acrylic resin. In a compound solvent system, a continuous-process free radical solution polymerization is adopted for preparing the acrylic resin, and the resin is endowed with water solubility. Modification is carried out by utilizing a tertiary carbonate ester, and a large branch structureis introduced, so that the intermolecular force is reduced, the resin viscosity is reduced, and the high-solid resin has lower viscosity. Through a tertiary carbonic acid group, the water resistance and the alcohol resistance of a paint film are remarkably increased, the performances such as the toughness and the impact resistance of the paint film are remarkably improved, and the influence on thehardness of the paint film is less. According to the preparation method of the high-performance water-soluble high-solid low-viscosity acrylic resin provided by the invention, organosilicone is usedfor modifying the acrylic resin, so that the performances such as humidity resistance and corrosion resistance of the paint film are improved; an amino resin is used as a curing agent for directly preparing a water-based amino acrylic acid baking paint, so that the performances such as hardness, fullness, water resistance, alcohol resistance and salt tolerance of the paint film are good, and the paint film is suitable for industrial coating in the industries of automobiles, bicycles, agricultural machinery and the like, an can be used for coating in the industries of fishing rods, wine bottles, dining tables and other industries with a certain humidity resistance and pollution resistance requirements.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI +1

Dyeing and printing process

The invention relates to a textile dyeing and printing process, in particular to a hydrophobic textile material dyeing and printing process. The process comprises the steps that a textile to be treated is sequentially subjected to printing, drying, color development and aftertreatment, and then a printed finished product is obtained, wherein washing and drying can be performed again in the color development and finishing process. The process before printing is similar to traditional dye printing, a slurry-like composition can be printed on the surface of the textile material through round screen and flat screen printing machines. In the high temperature color development process, most of disperse dyes combine with hydrophobic fiber materials through intermolecular forces, a printing additive in printing slurry assists dye dispersion and high temperature color development ad meanwhile crosslinking curing is performed to form a film, so that surface dyes which do not combine with the fibers attach to the fiber surface. The washing water COD of the textile treated by adopting the dyeing and printing process is 30-2000 PPM, the chromaticity of partial varieties is smaller than 200 ppm, the chromaticity of partial varieties is smaller than 50 ppm, the chromaticity (diluted multiples) is smaller than 200, the chromaticity of partial varieties (diluted multiples) is smaller than 80, and the chromaticity of partial varieties (diluted multiples) is smaller than 30.

Owner:SHENYANG RES INST OF CHEM IND

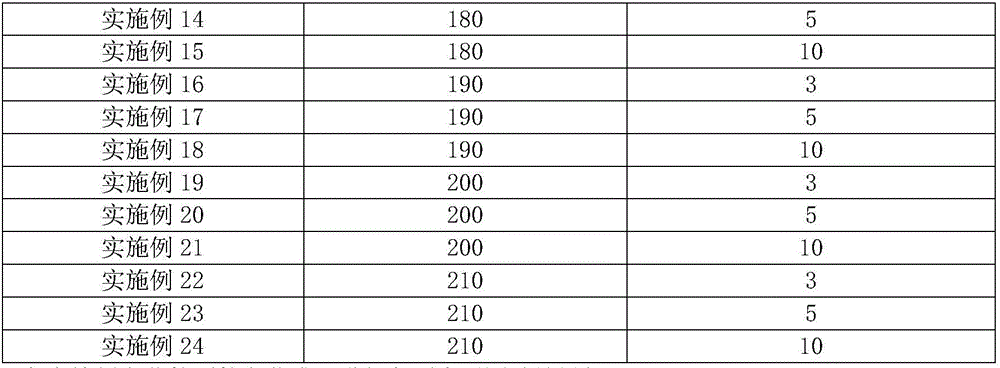

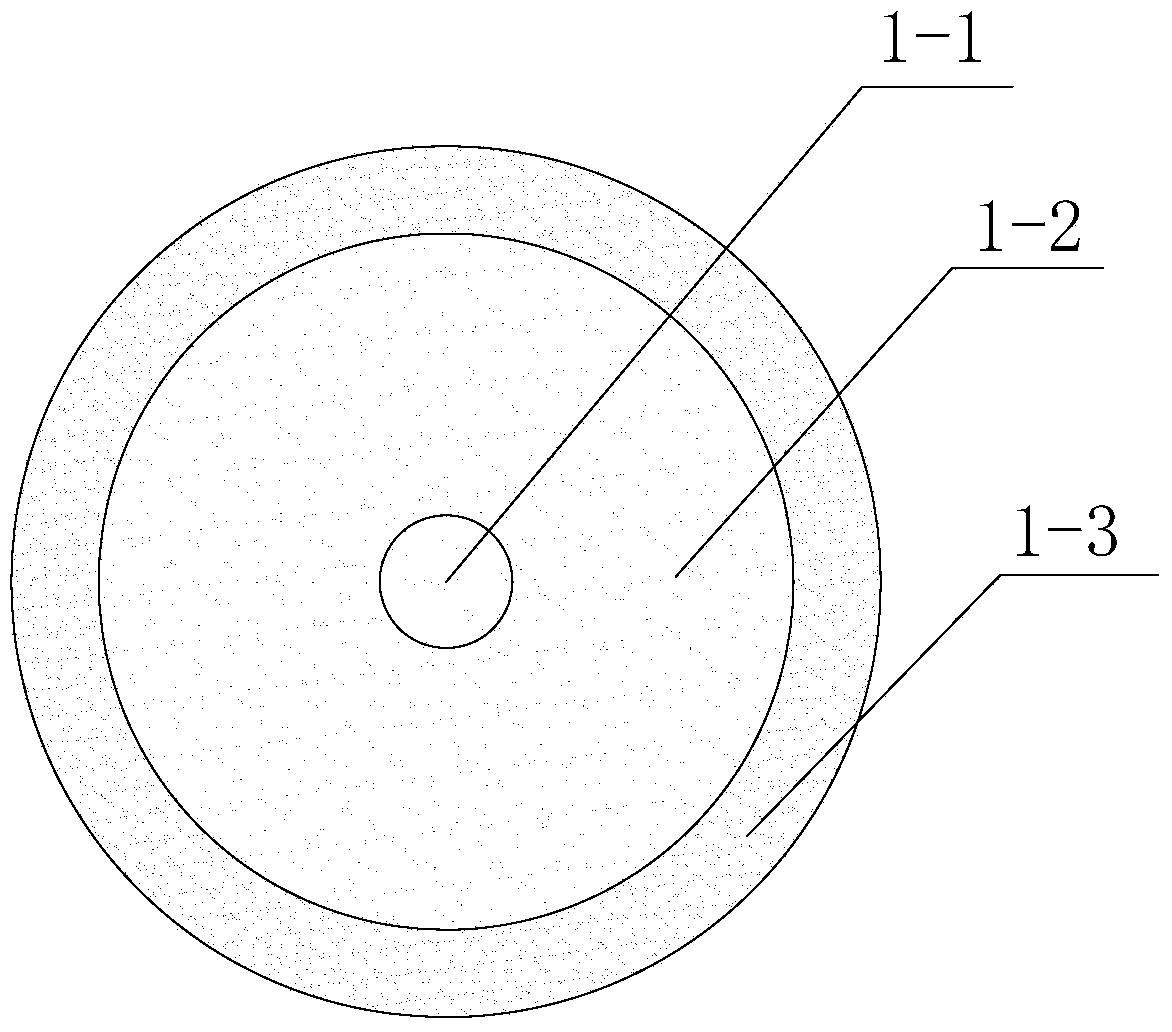

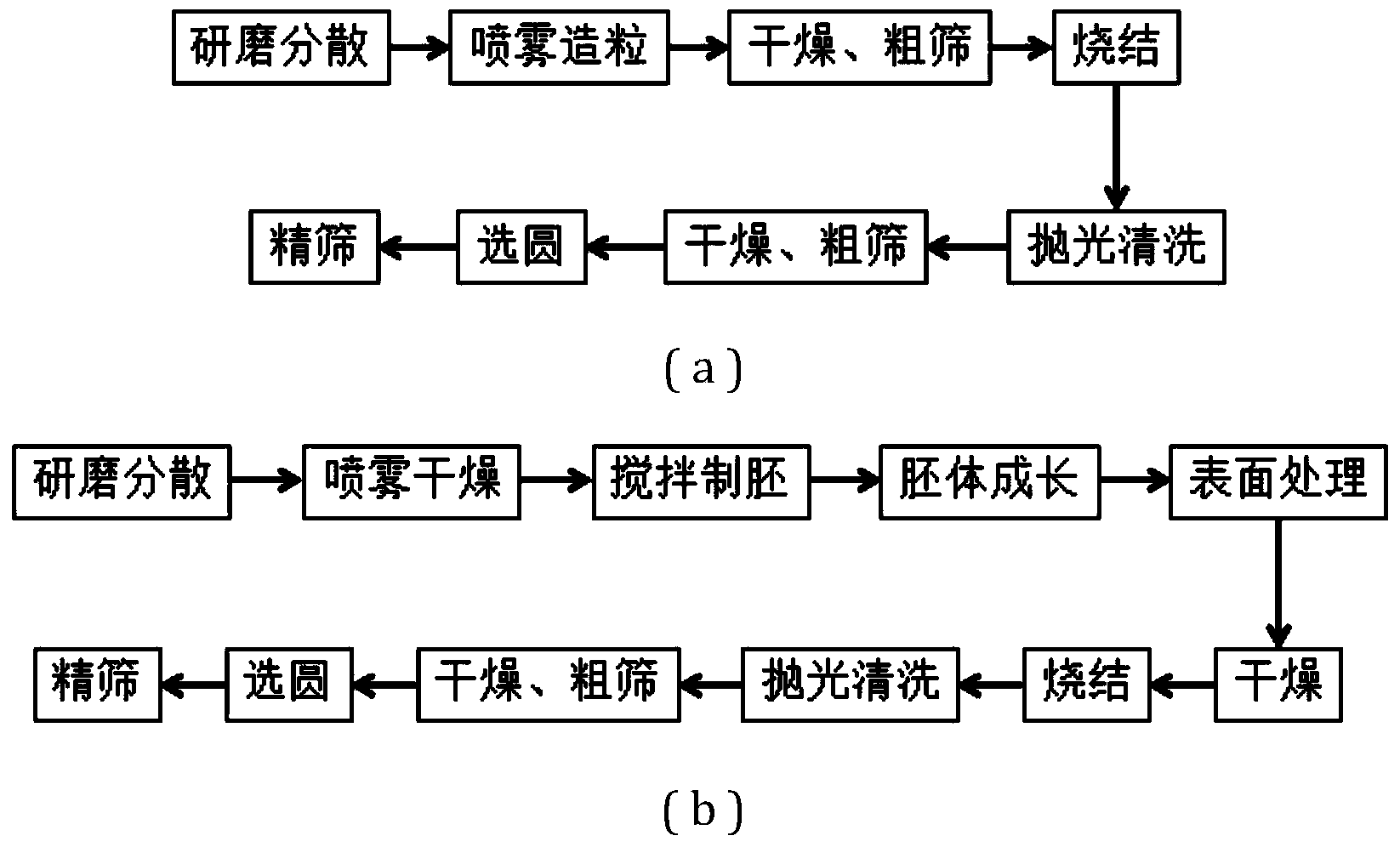

Uniformly-composite spherical ceramic particles and preparation method thereof

The invention relates to the technical field of ceramic-based powder materials and especially relates to uniformly-composite spherical ceramic particles and a preparation method thereof. The uniformly-composite spherical ceramic particles are high-sphericity degree nanoscale and submicron-scale powder aggregates, the aggregate is prepared from at least two different inorganic powder, the inorganic powder particles are bonded by sintering or intermolecular action, local density values of the uniformly-composite spherical ceramic particle from the center to the outer surface are gradually or stepwisely increased and the local density value of the outer surface of the uniformly-composite spherical ceramic particle is maximal The uniformly-composite spherical ceramic particle obtained by the preparation method has the advantages that in a mean volume diameter of 10-500 microns, the difference between the single-particle ingredients and particle total average ingredients is less than 3%, and more than 80% of the particles have a sphericity degree more than 0.92. The preparation method has no pollution and does not discharge toxic gas. The uniformly-composite spherical ceramic particle can be widely used for metal surface frosting treatment, member surface residual stress elimination treatment, strengthening treatment and fatigue-resistance treatment, and can be used for fine processing of nano-powder and preparation of a ceramic coating.

Owner:CHANGZHOU FUNDANT SPECIAL MATERIAL TECH

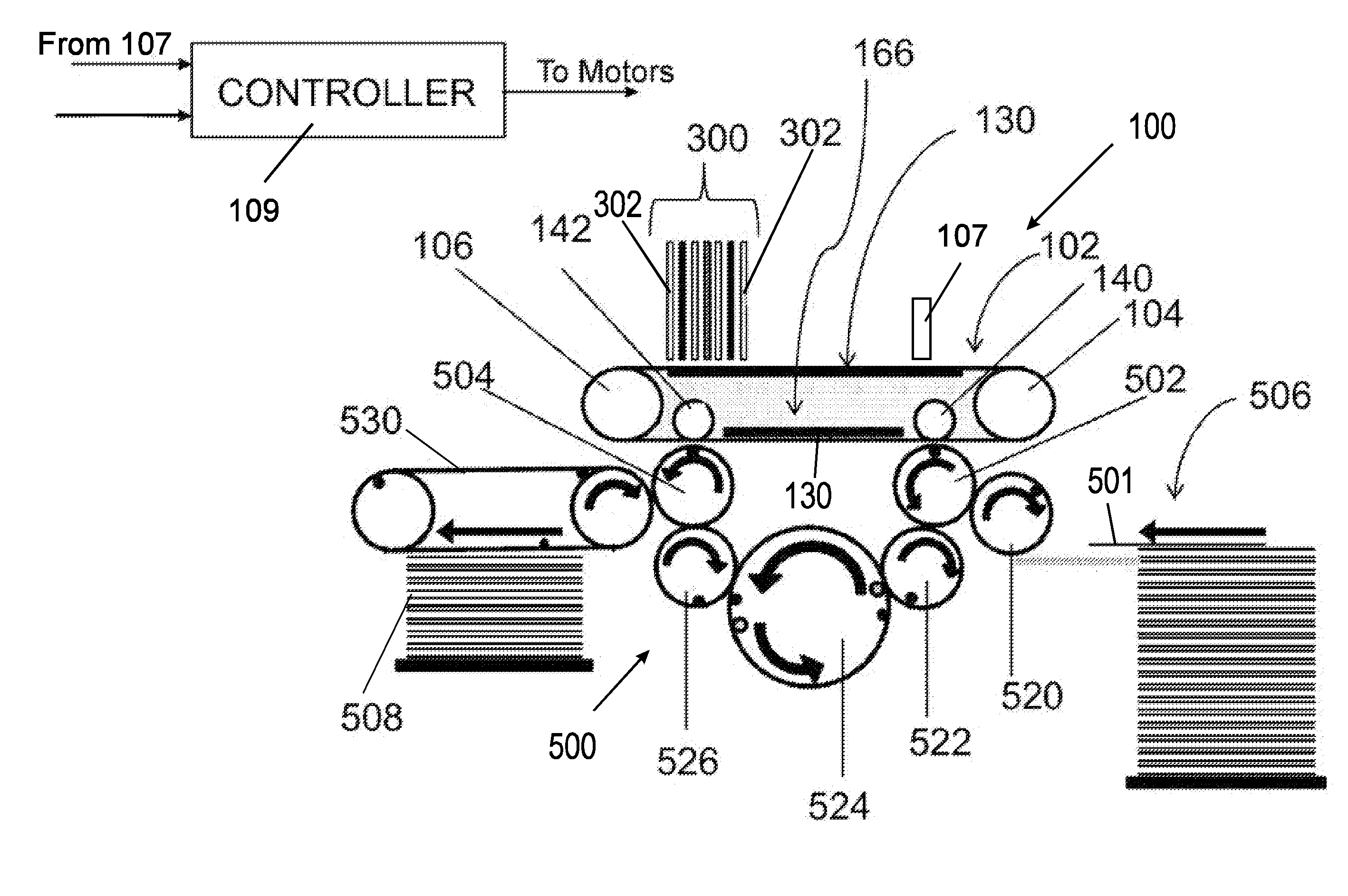

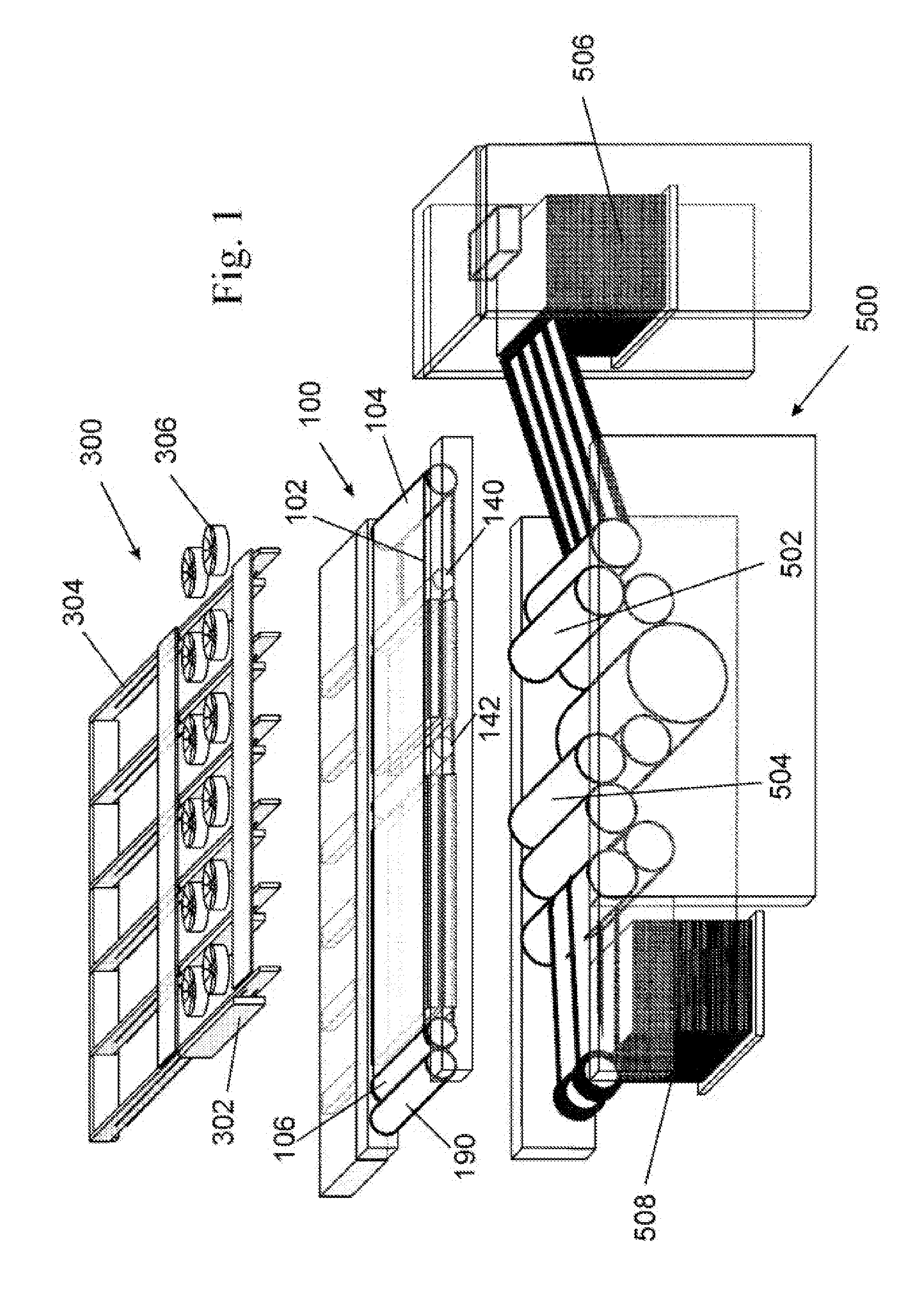

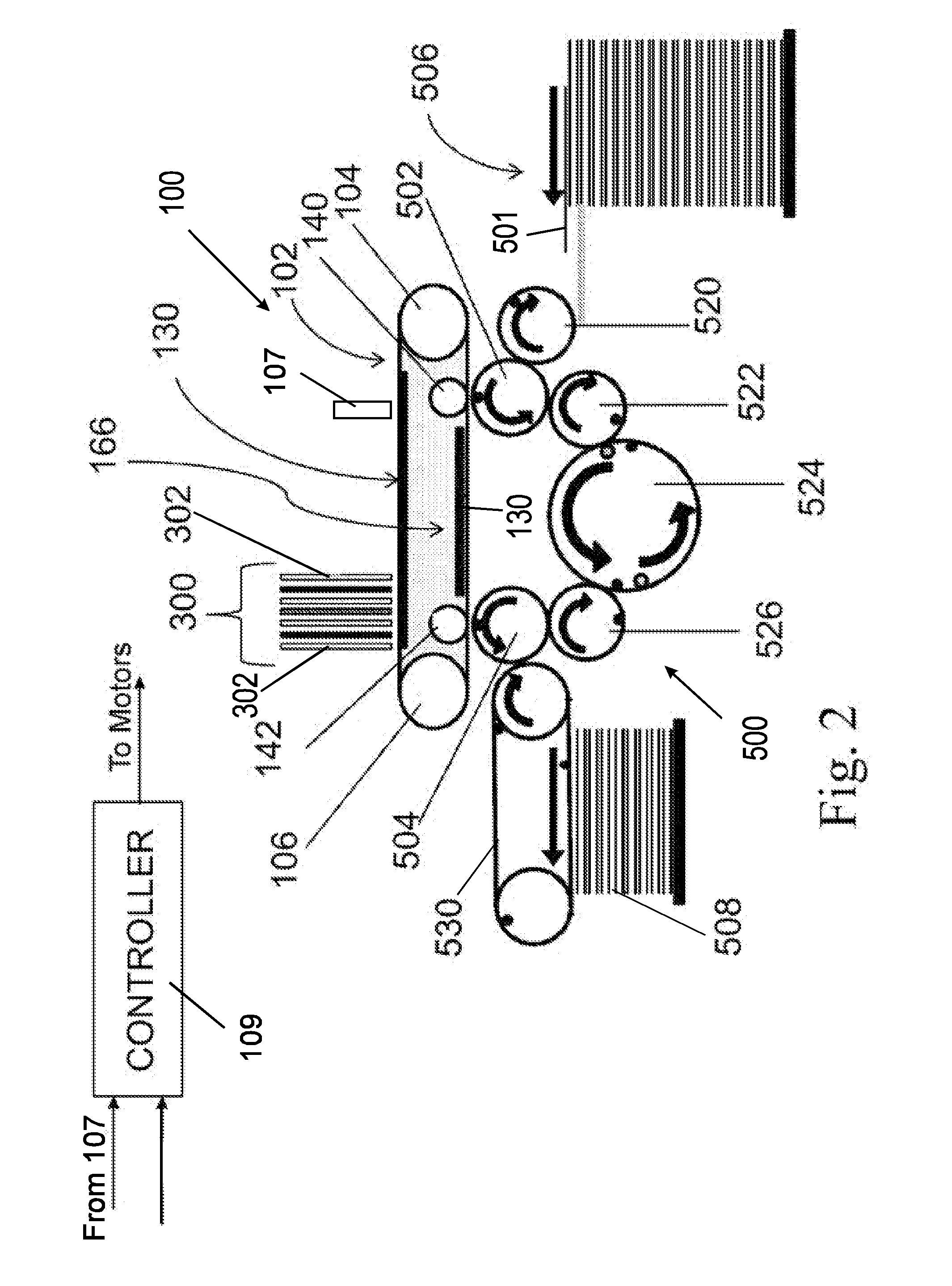

Digital printing process

A printing process is disclosed which comprises directing droplets of an ink onto an intermediate transfer member to form an ink image, the ink including an organic polymeric resin and a coloring agent in an aqueous carrier, and the transfer member having a hydrophobic outer surface so that each ink droplet in the ink image spreads on impinging upon the intermediate transfer member to form an ink film. The ink is dried while the ink image is being transported by the intermediate transfer member by evaporating the aqueous carrier from the ink image to leave a residue film of resin and coloring agent. The residue film is then transferred to a substrate. The chemical compositions of the ink and of the surface of the intermediate transfer member are selected such that attractive intermolecular forces between molecules in the outer skin of each droplet and on the surface of the intermediate transfer member counteract the tendency of the ink film produced by each droplet to bead under the action of the surface tension of the aqueous carrier, without causing each droplet to spread by wetting the surface of the intermediate transfer member.

Owner:LANDA

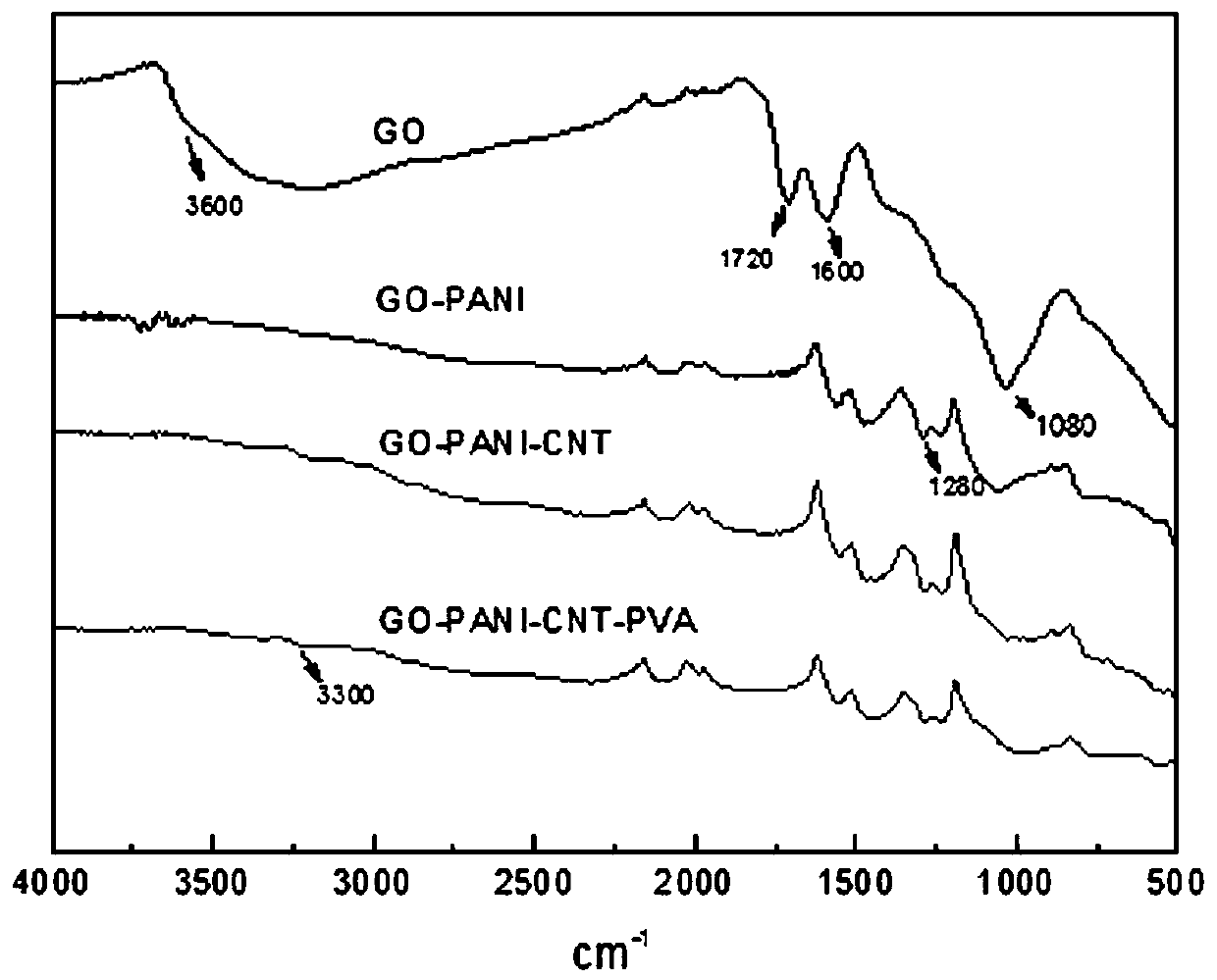

Preparation method of flexible lithium ion battery negative electrode material

ActiveCN110034279AHigh bonding strengthNot easy to fall offElectrode rolling/calenderingElectrode thermal treatmentElastomerConductive polymer composite

The invention discloses a preparation method of a flexible lithium ion negative electrode. The method includes the following steps of: taking graphene oxide as an active substance, firstly adding a conductive polymer monomer, performing polymerization to obtain a graphene oxide / conductive polymer composite material, and then sequentially adding an elastomer, a conductive agent and a binder that are capable of bonding with active sites of graphene oxide, performing reduction to obtain an RGO / conductive polymer / conductive agent / binder / elastomer integrated composite material, and finally performing vacuum suction filtration, drying and rolling to obtain an integrated flexible electrode sheet. The flexible electrode sheet prepared by the invention is bonded by chemical bonds and has strong intermolecular force, the active material is not easy to fall off in the process of bending or charging / discharging the electrode sheet, and various parts are in close contact by vacuum suction filtration and rolling to play a cooperation role. The flexible electrode prepared by the invention has good flexibility and electrochemical performance, and still maintains good rate performance and cycle performance after bending tests.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com