Preparation method and application of three-dimensional graphene aerogel load molybdenum disulfide nano-sheet hybridization material

A technology of graphene airgel and molybdenum disulfide, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of surface inert agglomeration, and the excellent performance of materials cannot be effectively brought into play. Potential discounts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment includes the following steps:

[0035] (1) Weigh 100mg of graphene oxide (Go) and dissolve it in 100ml of deionized water, sonicate it for 5-6h to make it evenly dispersed to obtain a 1mg / ml graphene oxide solution;

[0036] (2) Add 200 mg of reduced glutathione to the above solution, then ultrasonicate for 1 hour, and continuously stir to obtain a uniform dispersion solution;

[0037] (3) Place the solution obtained in step (2) in a constant temperature water bath at 85°C for 12 hours to obtain a cylindrical reduced graphene oxide hydrogel ( figure 1 )

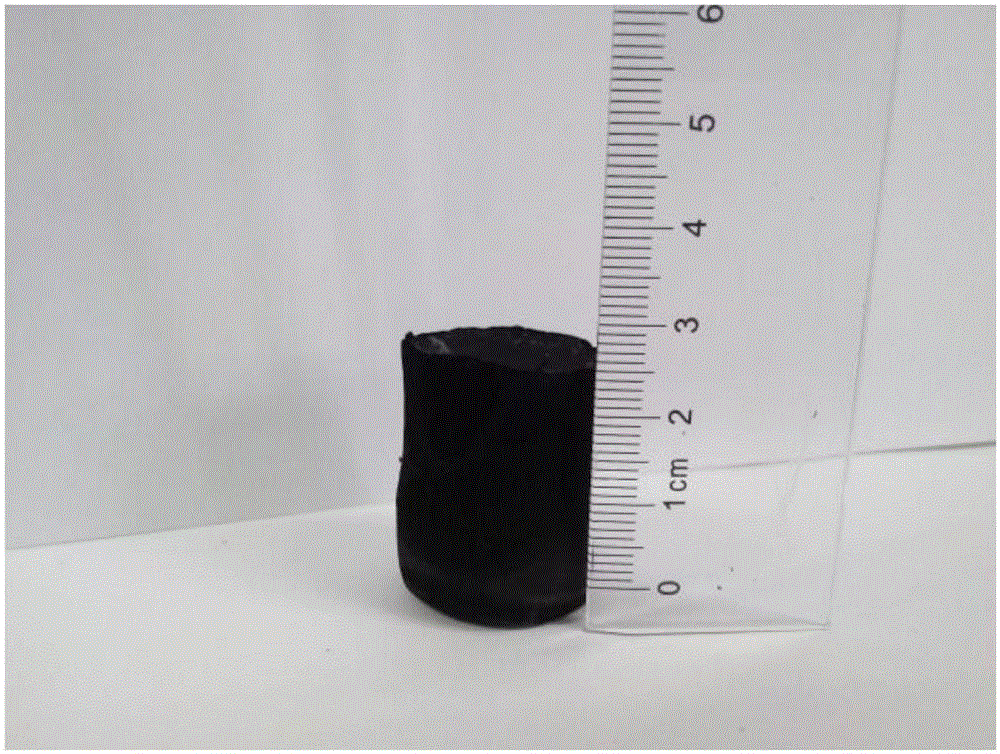

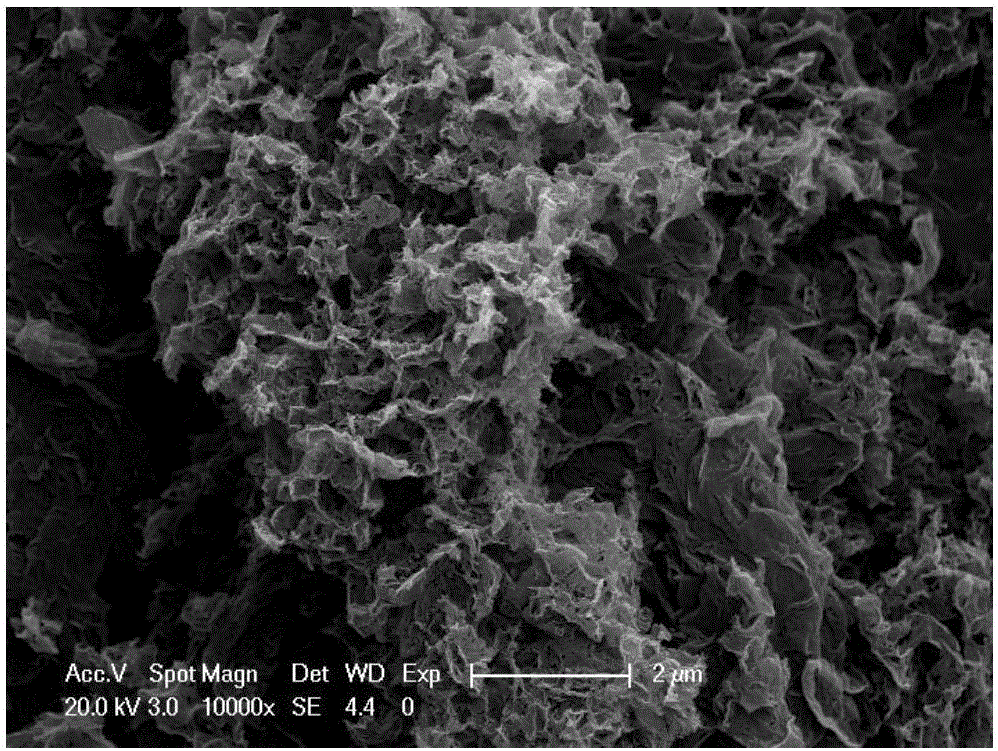

[0038] (4) The reduced graphene oxide hydrogel obtained in step (3) was soaked in tert-butanol for 48 hours, the tert-butanol was replaced twice, and then freeze-dried for 48 hours to prepare graphene aerogel ( figure 2 ),by figure 2 It can be seen that the graphene aerogel maintains the original hydrogel shape well after drying, and then it is annealed under argon and 800℃ for 1h; the morphology of the prepar...

Embodiment 2

[0047] The mass of ammonium tetrathiomolybdate in Example 1 is changed to 10 mg, and the rest are the same as in Example 1. The final hybrid material obtained is labeled MG-1

Embodiment 3

[0049] The mass of ammonium tetrathiomolybdate in Example 1 is changed to 20 mg, and the rest are the same as in Example 1. The final hybrid material obtained is labeled MG-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com