Composite transparent conductive thin film and preparation method thereof

A technology of transparent conductive film and treatment film, applied in cable/conductor manufacturing, conductive layer on insulating carrier, conductive material dispersed in non-conductive inorganic material, etc. shedding and other problems, to achieve the effect of cost saving and effective dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

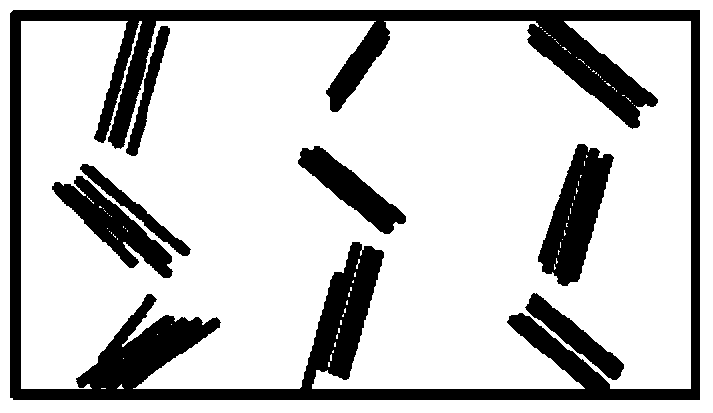

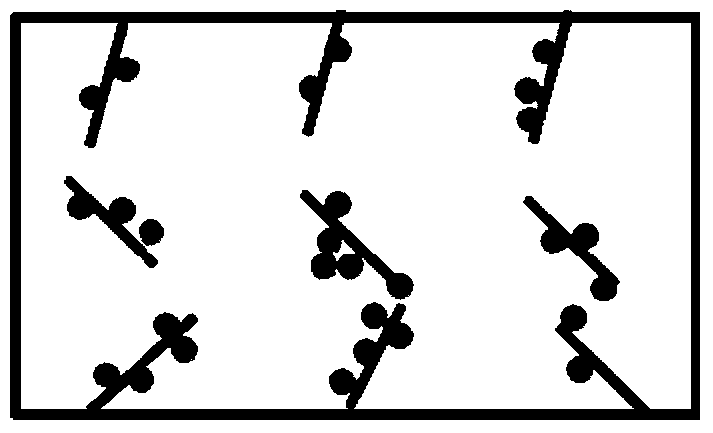

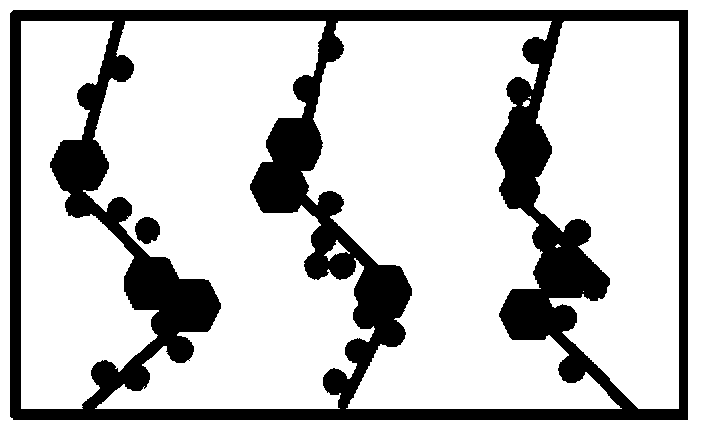

[0028] Such as Figure 4As shown, one embodiment of the present invention is a preparation method of a composite transparent conductive film, which includes the following steps: adding the dispersed silicon-containing nanoparticle solution to the dispersed metal nanowire solution to obtain a primary mixed solution; adding the dispersed conductive flake carbon elemental solution to the dispersed primary mixed solution to obtain the mixed solution to be treated; vacuum filtering the dispersed mixed solution to be treated to obtain the film to be treated and The first filter paper attached to it; the first filter paper is wetted with water, the first substrate, the membrane to be treated and the first filter paper attached thereto, the second filter paper wetted with water, and the second substrate are fixed and then dried, that is , the first substrate, the first filter paper wetted with water and the membrane to be treated, the second filter paper wetted with water, and the sec...

Embodiment 1

[0057] Add acetone to silver nanowires dispersed in aqueous solution or organic solution, centrifuge several times until the infrared spectrum shows that there are no surfactant groups such as PVP on the surface of silver nanowires, and ultrasonically disperse in distilled water for use.

[0058] Disperse silicon nanoparticles in distilled water, sonicate for 30 minutes, slowly drop into the aqueous solution in which silver nanowires are dispersed, stir for 5 minutes, and sonicate for 5 minutes; for example, at a speed of 1 drop per second or 1 drop every 5 seconds, the The dispersed silicon nanoparticle aqueous solution is added dropwise to the aqueous solution in which the silver nanowires are dispersed.

[0059] Then, slowly add the aqueous solution of graphene dispersed in the above mixed solution dropwise, for example, at the speed of 1 drop per second or 1 drop per 5 seconds, the aqueous solution of the dispersed graphene is added dropwise to the above mixed solution; the...

Embodiment 2

[0062] Add acetone to silver nanowires dispersed in aqueous solution or organic solution, centrifuge several times until the infrared spectrum shows that there are no surfactant groups such as PVP on the surface of silver nanowires, and ultrasonically disperse in distilled water for use. Disperse the silicon nanoparticles in distilled water, and after ultrasonication for 30min, slowly add it dropwise into the aqueous solution dispersed with silver nanowires, stir for 5min, and ultrasonicate for 5min; slowly add the aqueous solution dispersed with graphene into the above mixed solution, and stir for 5min, Ultrasound for 10 minutes, wherein the mass ratio of silver nanowires, silicon nanoparticles, and graphene is 12:6:1. Ultrasonic disperse the above mixed solution evenly, vacuum filter to form a film, and the filter paper used is mixed cellulose filter paper. The resulting filter membrane is placed on a copper sheet, wherein the nanowire faces the copper sheet, and after being...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com