Microcapsule flame-retardant adsorption resin and preparation method thereof, and flame-retardant composite material

A flame retardant composite material and resin adsorption technology, applied in the field of flame retardants, can solve the problems of easy cracking, affecting the use of flame retardants, etc., to improve migration resistance, inhibit precipitation and migration, improve processing performance and performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

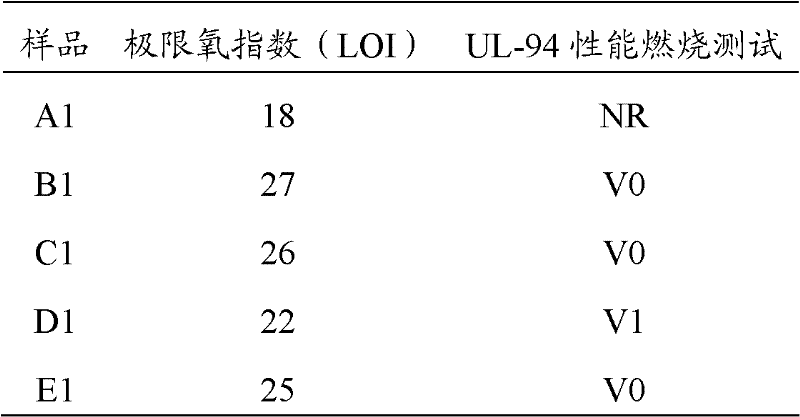

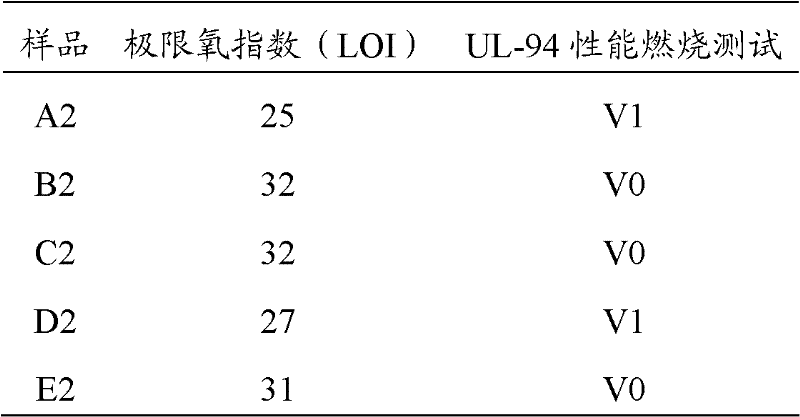

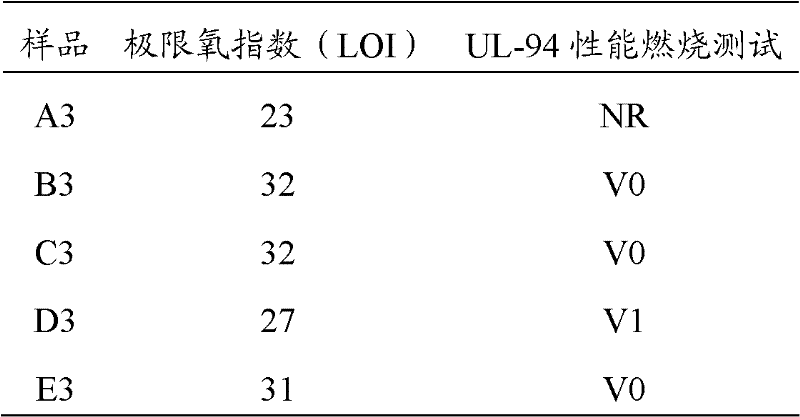

Examples

preparation example Construction

[0043] The present invention also provides a preparation method of microcapsule flame retardant adsorption resin, comprising the following steps:

[0044] The adsorption resin absorbs the flame retardant in the flame retardant or the flame retardant solution to obtain the flame retardant adsorption resin;

[0045] The flame retardant adsorption resin is mixed with the capsule wall material in the solution, and the microcapsule flame retardant adsorption resin is obtained after reaction.

[0046]In the present invention, firstly, the adsorption resin is mixed with the flame retardant solution, so that the flame retardant molecules enter into the adsorption resin. The temperature for the adsorption resin to adsorb the flame retardant is preferably 10°C-200°C, more preferably 30°C-90°C; the time is preferably 20min-90min, more preferably 30min-80min. The flame retardant adsorbing resin can be obtained after drying the adsorbing resin adsorbed with the flame retardant according t...

Embodiment 1

[0057] Put 68g of cyclohexane, 31.5g of a mixture of lauryl acrylate and stearyl acrylate with a mass ratio of 1:1, and a mixture of ethylene glycol diacrylate and divinylbenzene with a mass ratio of 1:1 of 0.5g In the irradiation device, use 40KHz ultrasonic dispersion for 15min, pass high-purity nitrogen gas for 10min, seal it, place it in a 60Co radiation source, and irradiate it for 5h at a dose rate of 50Gy / min, and bake the obtained product at 90°C drying to constant weight to obtain an oil-absorbing resin; pulverizing the oil-absorbing resin into particles with a particle size of 5 μm to 600 μm;

[0058] Add 1 g of the oil-absorbing resin prepared above to 10 g of liquid flame retardant tris(2-chloropropyl) phosphate (TCPP), and heat at 40°C for 20 minutes until the flame retardant completely penetrates into the oil-absorbing resin powder to obtain a flame retardant Burn oil-absorbing resin gel and dry it into powder;

[0059] Add 11g of the flame-retardant oil-absorbi...

Embodiment 2

[0072] 65g of a mixture of n-hexane and n-heptane with a mass ratio of 1:1, 34.8g of a mixture of dodecyl acrylate and butyl acrylate with a mass ratio of 1:1, and 0.2g of ethylene glycol diacrylate with a mass ratio of 1:1 The mixture of acrylate and divinylbenzene is placed in the irradiation device, dispersed by ultrasonic wave at 40KHz for 10 minutes, sealed with high-purity nitrogen gas for 10 minutes, placed in a 60Co radiation source, and irradiated for 4 hours at a dose rate of 40Gy / min. drying the obtained product at 80°C to constant weight to obtain an oil-absorbing resin; pulverizing the oil-absorbing resin into particles with a particle size of 20 μm to 500 μm;

[0073] Add 10 g of the above-prepared oil-absorbing resin to 100 g of an ether solution containing 30% triphenyl phosphate, and heat at 55° C. for 20 minutes until the flame retardant completely penetrates into the oil-absorbing resin powder to obtain a flame-retardant oil-absorbing resin gel. dried into p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com