Patents

Literature

960 results about "Microencapsulations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

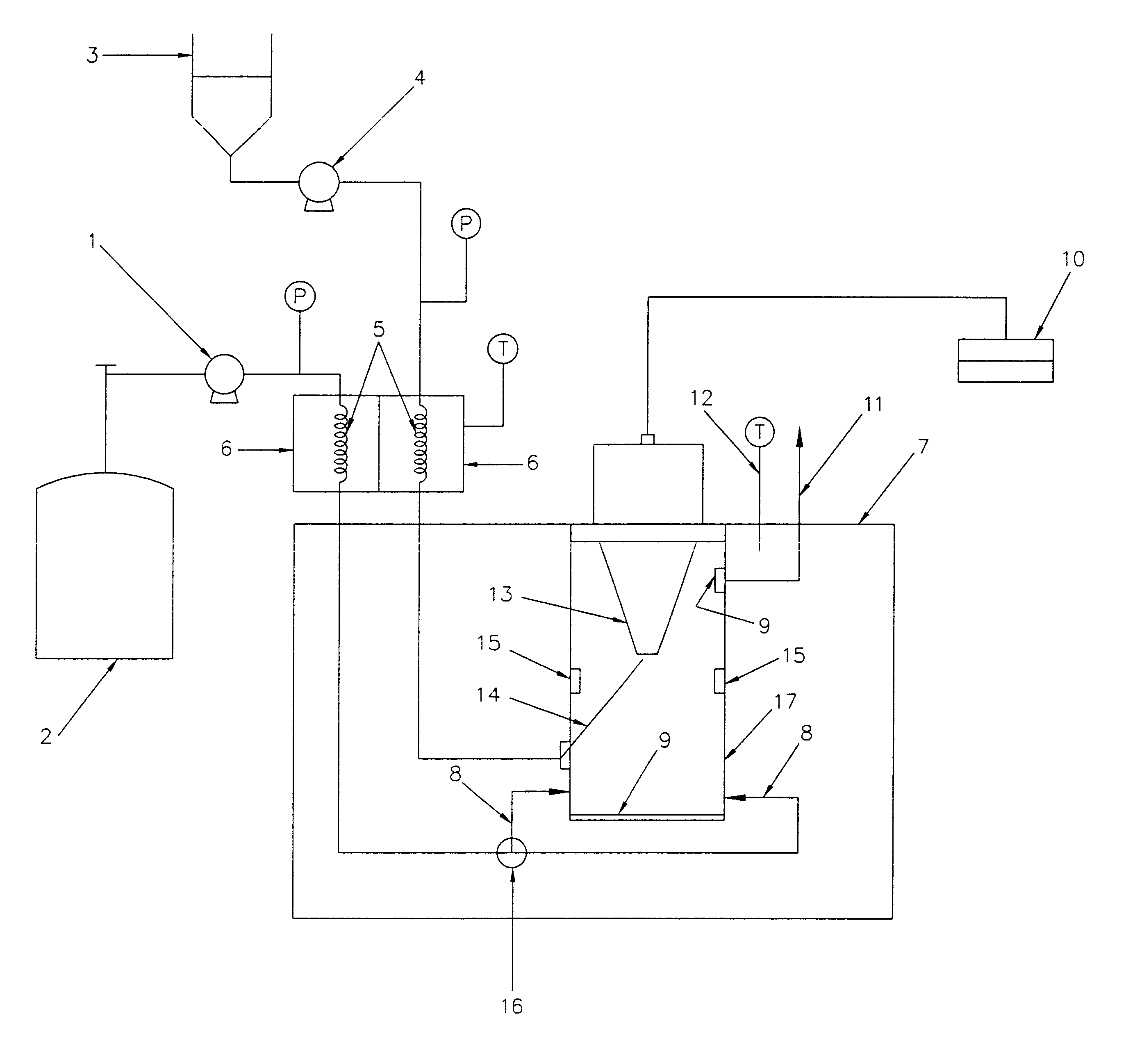

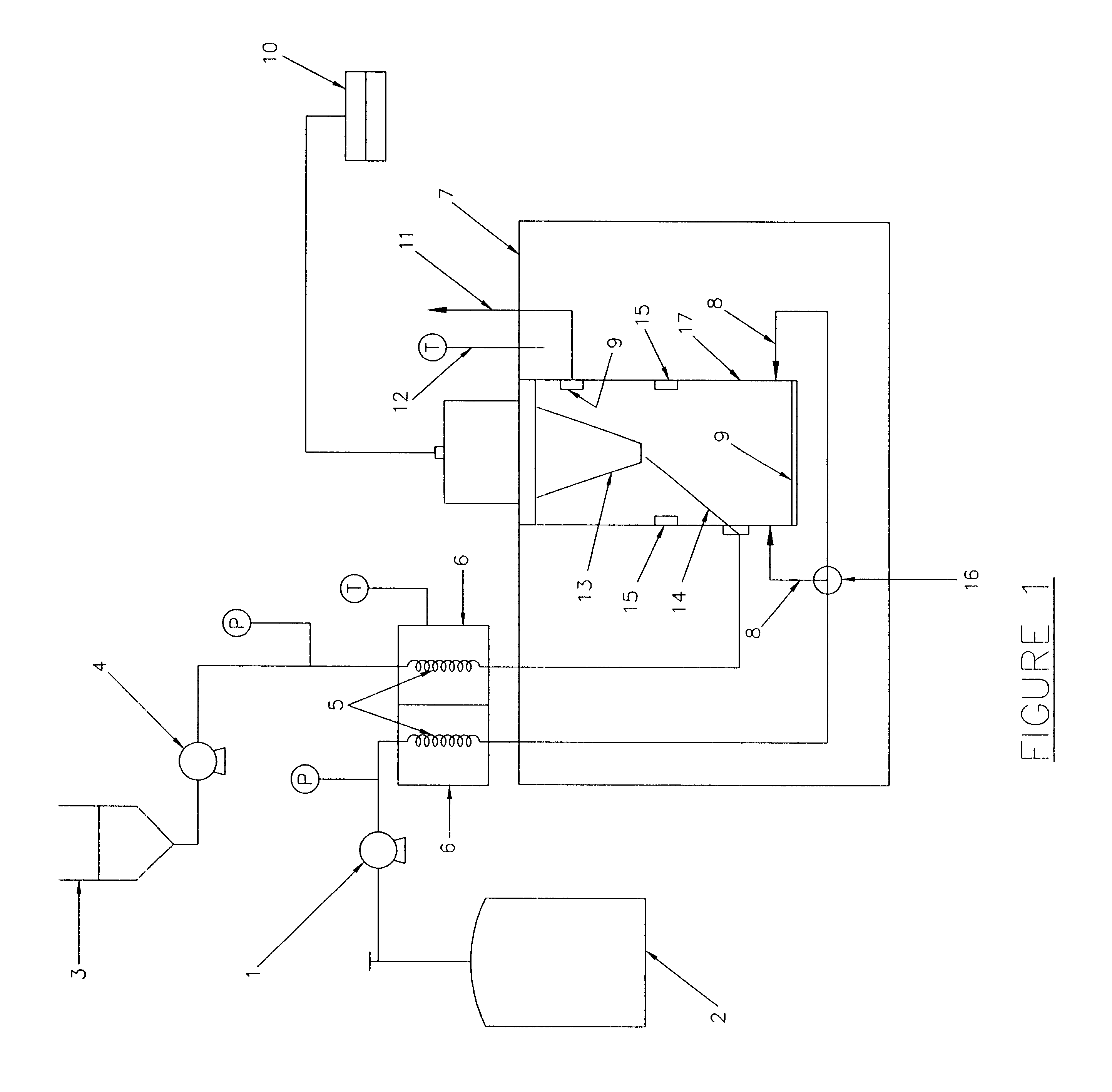

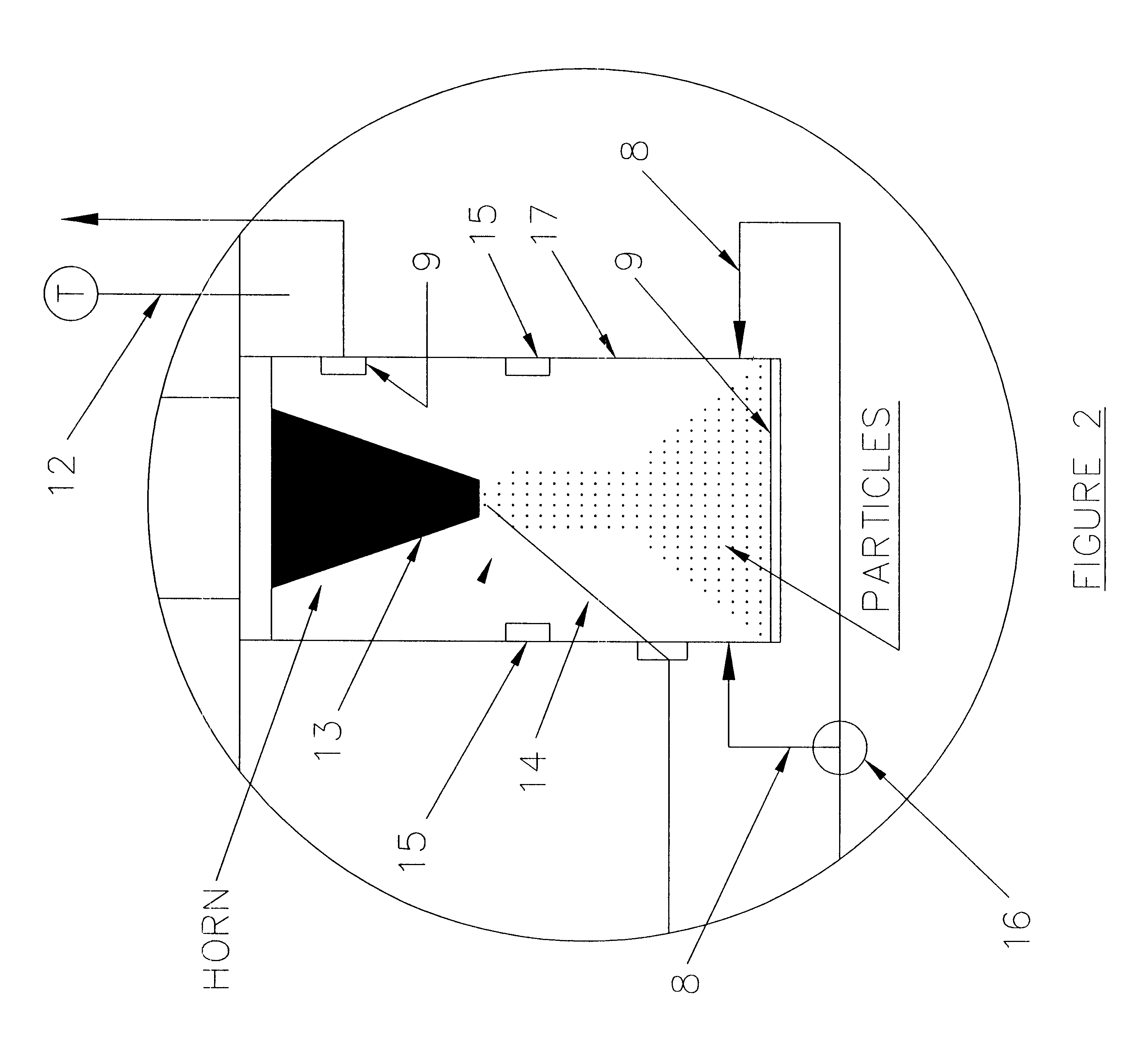

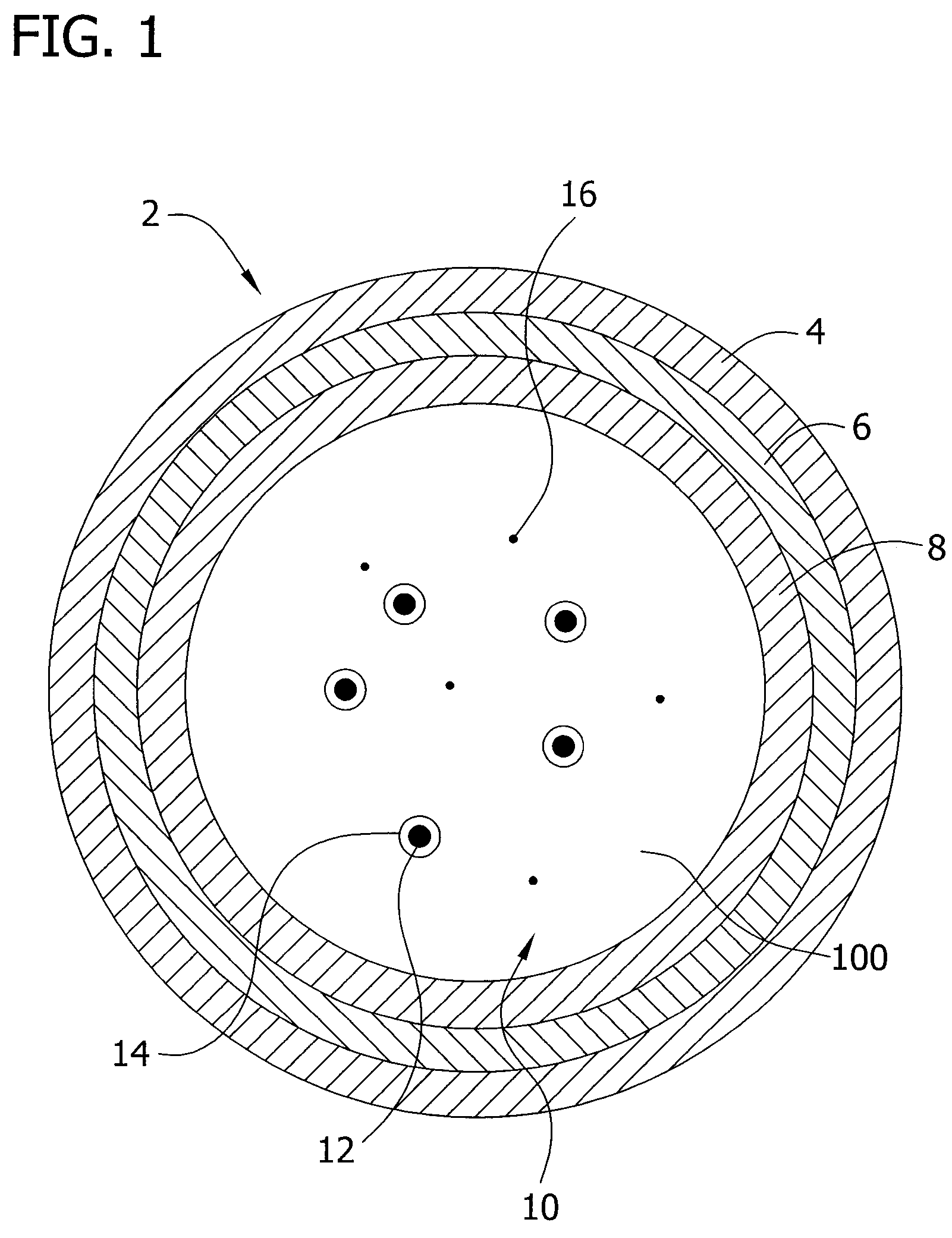

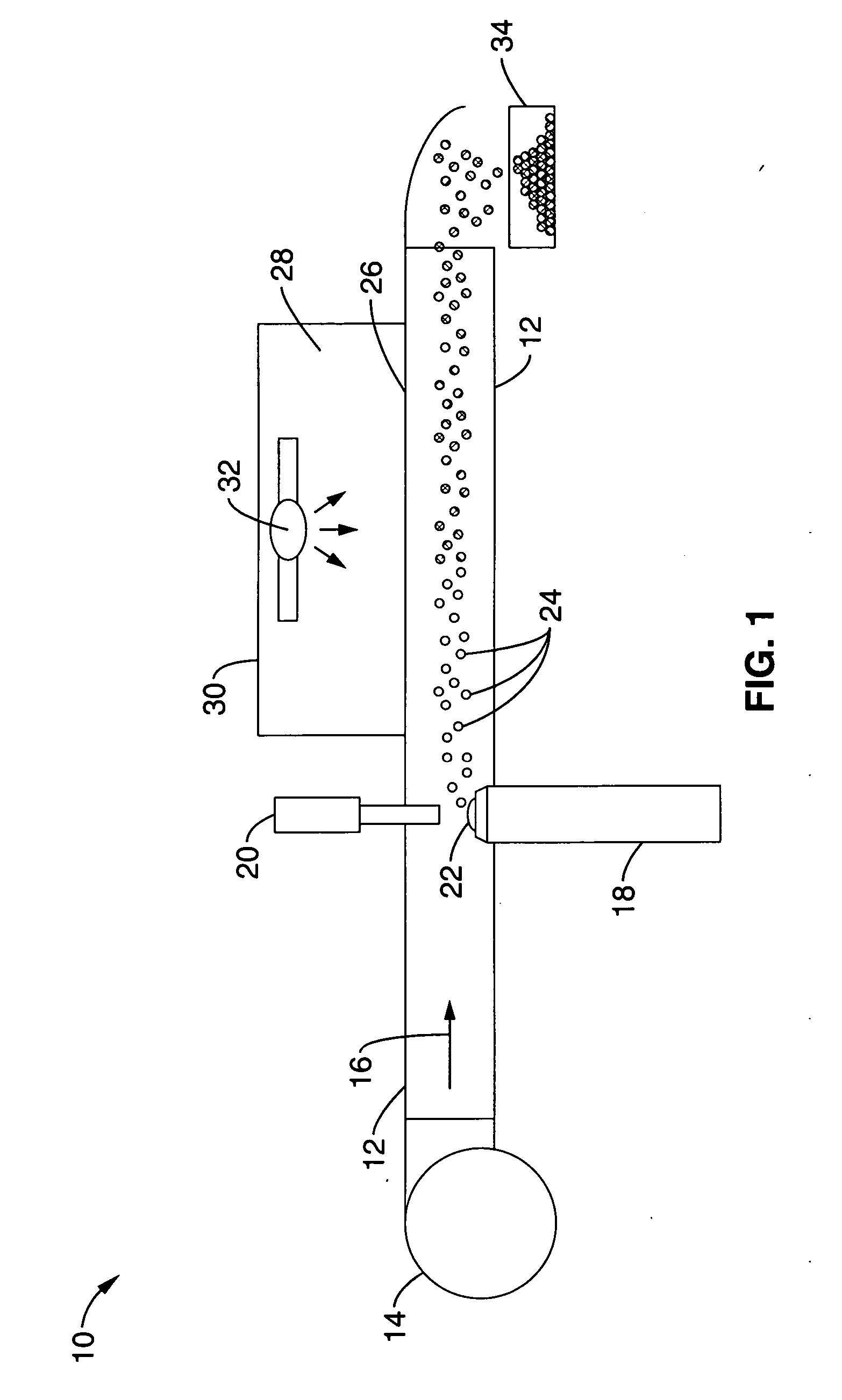

Method of forming nanoparticles and microparticles of controllable size using supercritical fluids with enhanced mass transfer

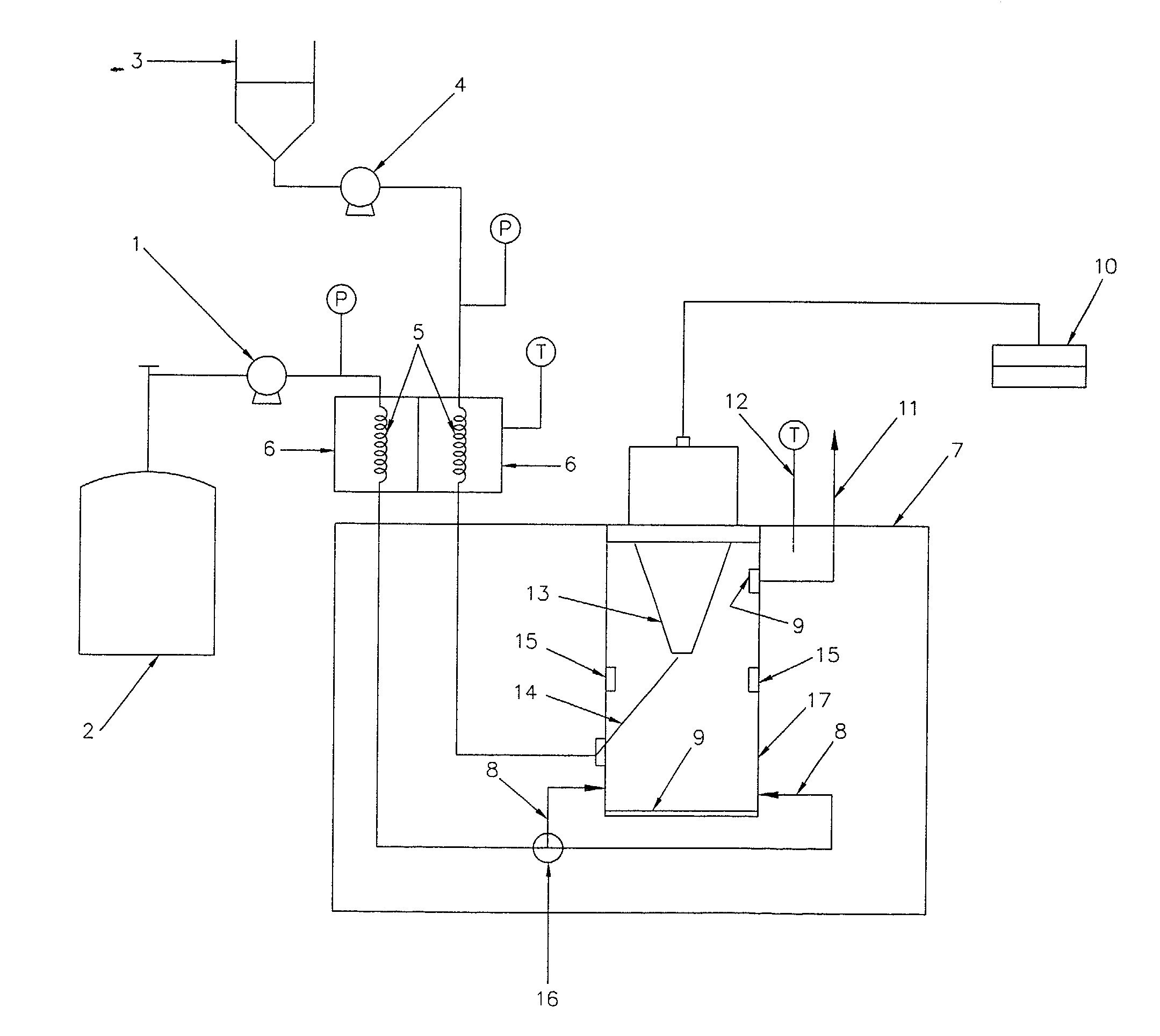

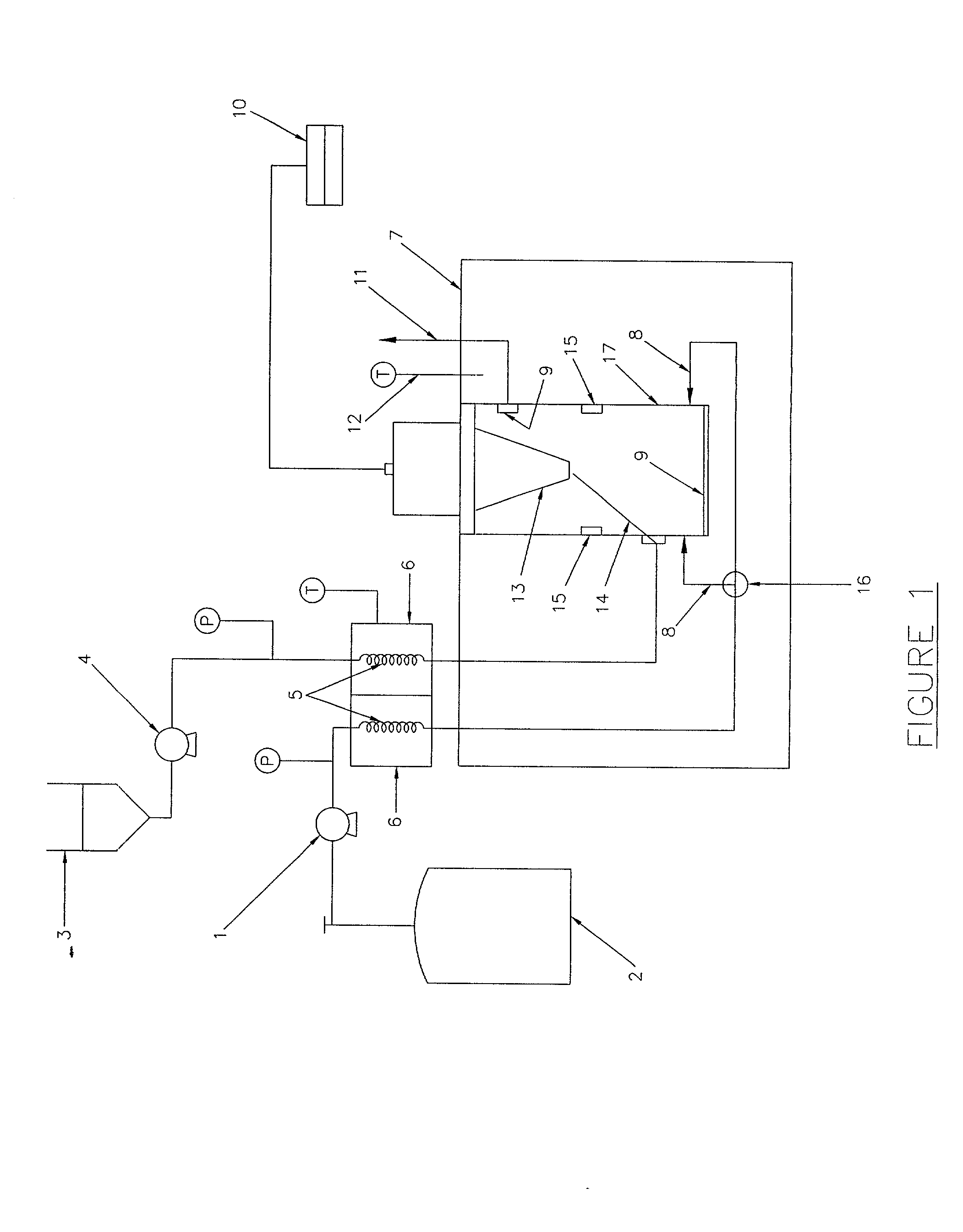

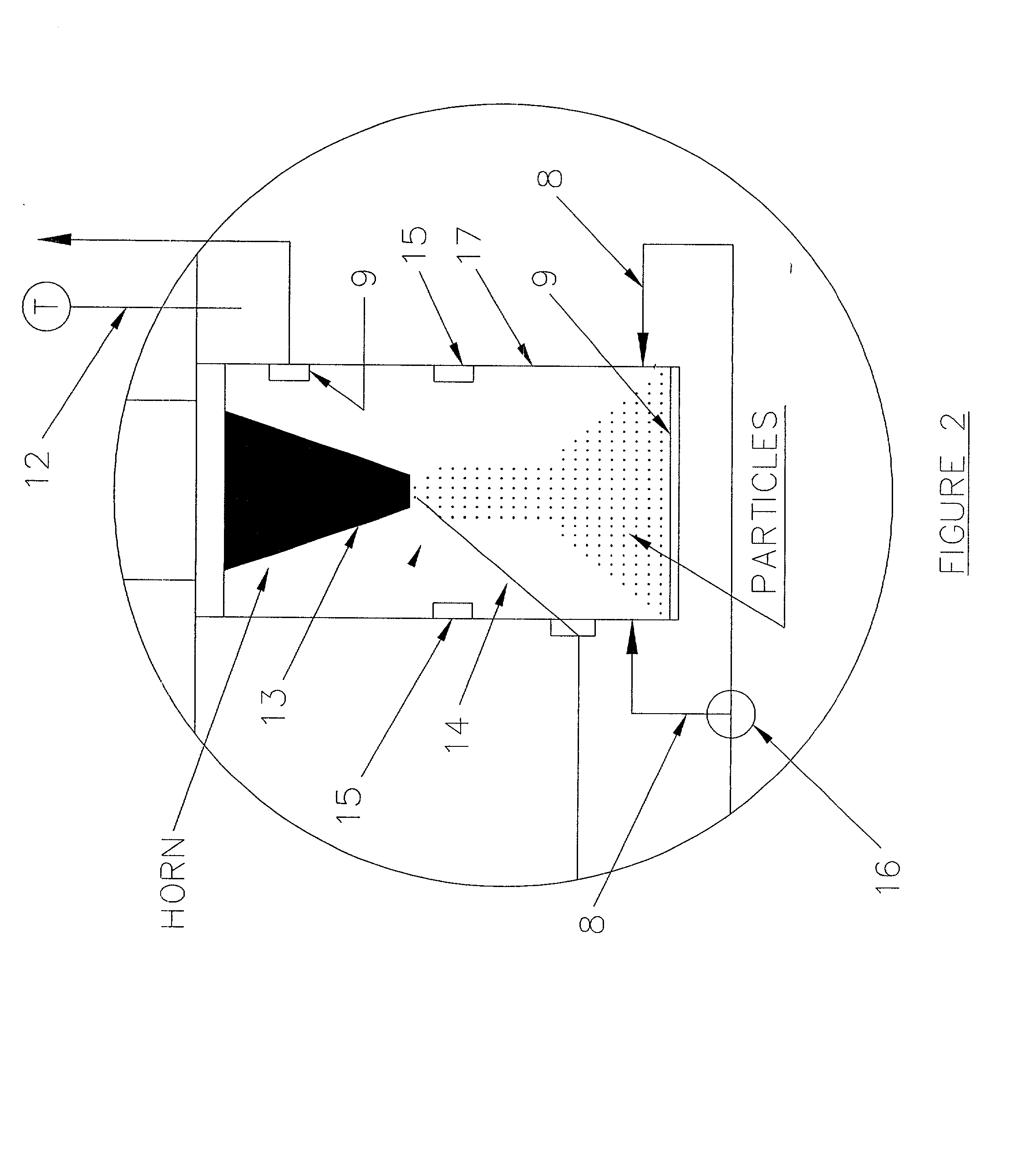

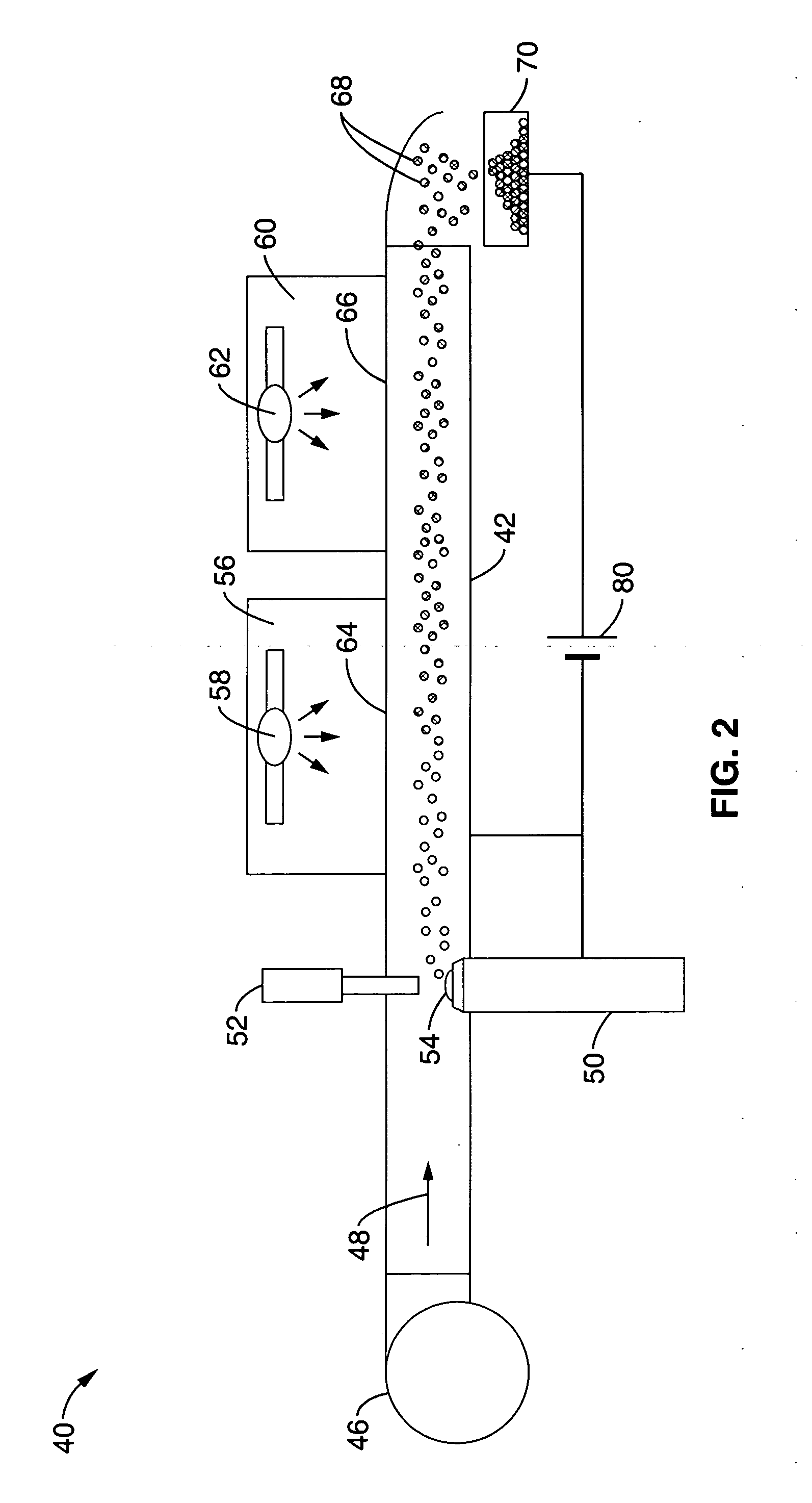

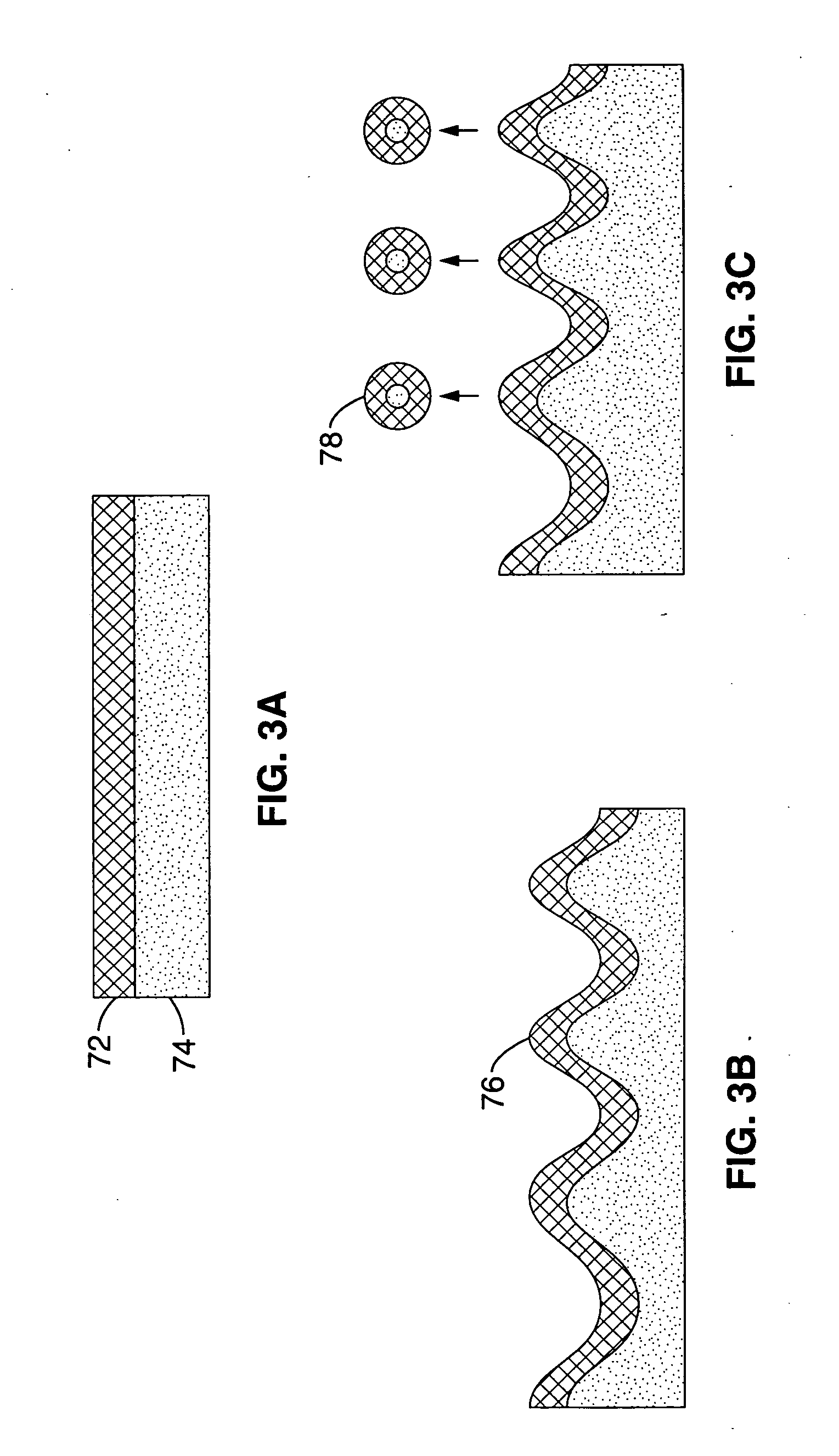

The current invention, Supercritical Antisolvent Precipitation with Enhanced Mass Transfer (SAS-EM) provides a significantly improved method for the production of nano and micro-particles with a narrow size distribution. The processes of the invention utilize the properties of supercritical fluids and also the principles of virbrational atomization to provide an efficient technique for the effective nanonization or micronization of particles. Like the SAS technique, SAS-EM, also uses a supercritical fluid as the antisolvent, but in the present invention the dispersion jet is deflected by a vibrating surface that atomizes the jet into fine droplets. The vibrating surface also generates a vibrational flow field within the supercritical phase that enhances mass transfer through increased mixing. Sizes of the particles obtained by this technique are easily controlled by changing the vibration intensity of the deflecting surface, which in turn is controlled by adjusting the power input to the vibration source. A major advantage of the SAS-EM technique is that it can be successfully used to obtain nanoparticles of materials that usually yield fibers or large crystals in SAS method. Microencapsulation via coprecipitation of two or more materials can also be achieved using the SAS-EM technique.

Owner:UNIV AUBURN

Method of forming nanoparticles and microparticles of controllable size using supercritical fluids and ultrasound

The current invention, Supercritical Antisolvent Precipitation with Enhanced Mass Transfer (SAS-EM) provides a significantly improved method for the production of nano and micro-particles with a narrow size distribution. The processes of the invention utilize the properties of supercritical fluids and also the principles of virbrational atomization to provide an efficient technique for the effective nanonization or micronization of particles. Like the SAS technique, SAS-EM, also uses a supercritical fluid as the antisolvent, but in the present invention the dispersion jet is deflected by a vibrating surface that atomizes the jet into fine droplets. The vibrating surface also generates a vibrational flow field within the supercritical phase that enhances mass transfer through increased mixing. Sizes of the particles obtained by this technique are easily controlled by changing the vibration intensity of the deflecting surface, which in turn is controlled by adjusting the power input to the vibration source. A major advantage of the SAS-EM technique is that it can be successfully used to obtain nanoparticles of materials that usually yield fibers or large crystals in SAS method. Microencapsulation via coprecipitation of two or more materials can also be achieved using the SAS-EM technique.

Owner:UNIV AUBURN

Functional oil microencapsulation and manufacturing method thereof

ActiveCN102550817AGood water solubilityImprove antioxidant capacityMetabolism disorderAlgae medical ingredientsOil and greaseWater baths

The invention provides a functional oil microencapsulation and a manufacturing method thereof and relates to a microencapsulation, and the functional oil microencapsulation has the advantages of high stability and immobilized proteinaceous pellicle. The oil microencapsulation is prepared from the following raw materials: functional oil, plant oil, an antioxidant, aqueous-phase main-wall materials, aqueous-phase auxiliary-wall materials, bio-enzyme protein and water. The plant oil serving as a carrier is mixed with the functional oil, then the antioxidant is added, and then the materials are heated and dissolved in water bath, thus obtaining an oil-phase core material solution; the aqueous-phase main-wall materials and the aqueous-phase auxiliary-wall materials are added into deionized water, and then the materials are heated and dissolved in water bath, thus obtaining an aqueous-phase wall material solution; the oil-phase core material solution is added in the aqueous-phase wall material solution, the mixture is sheared and emulsified by a shearing machine, and then is homogenized by a homogenizer, thus obtaining a nanometer-level solution with uniform oil drop diameter; and bio-enzyme is added into the nanometer-level solution, the mixture is placed in hot-water bath for heating and stirring reaction, temperature is raised after the reaction so as to enable the bio-enzyme to be inactivated, and drying is carried out, thus obtaining the functional oil microencapsulation.

Owner:XIAMEN KINGDOMWAY BIOTECH CO LTD +1

Method of microencapsulation

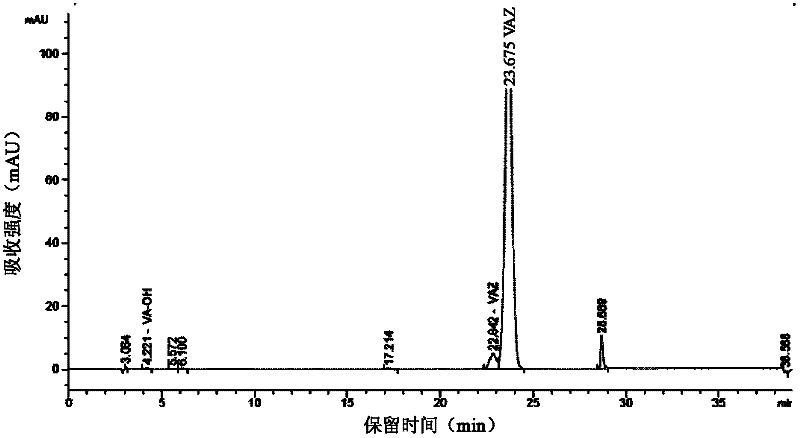

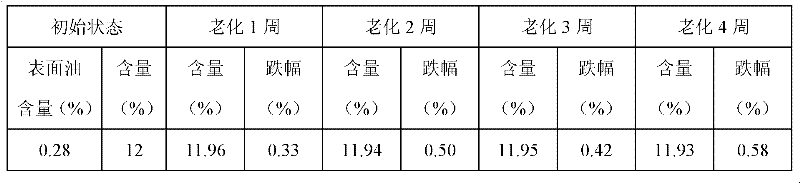

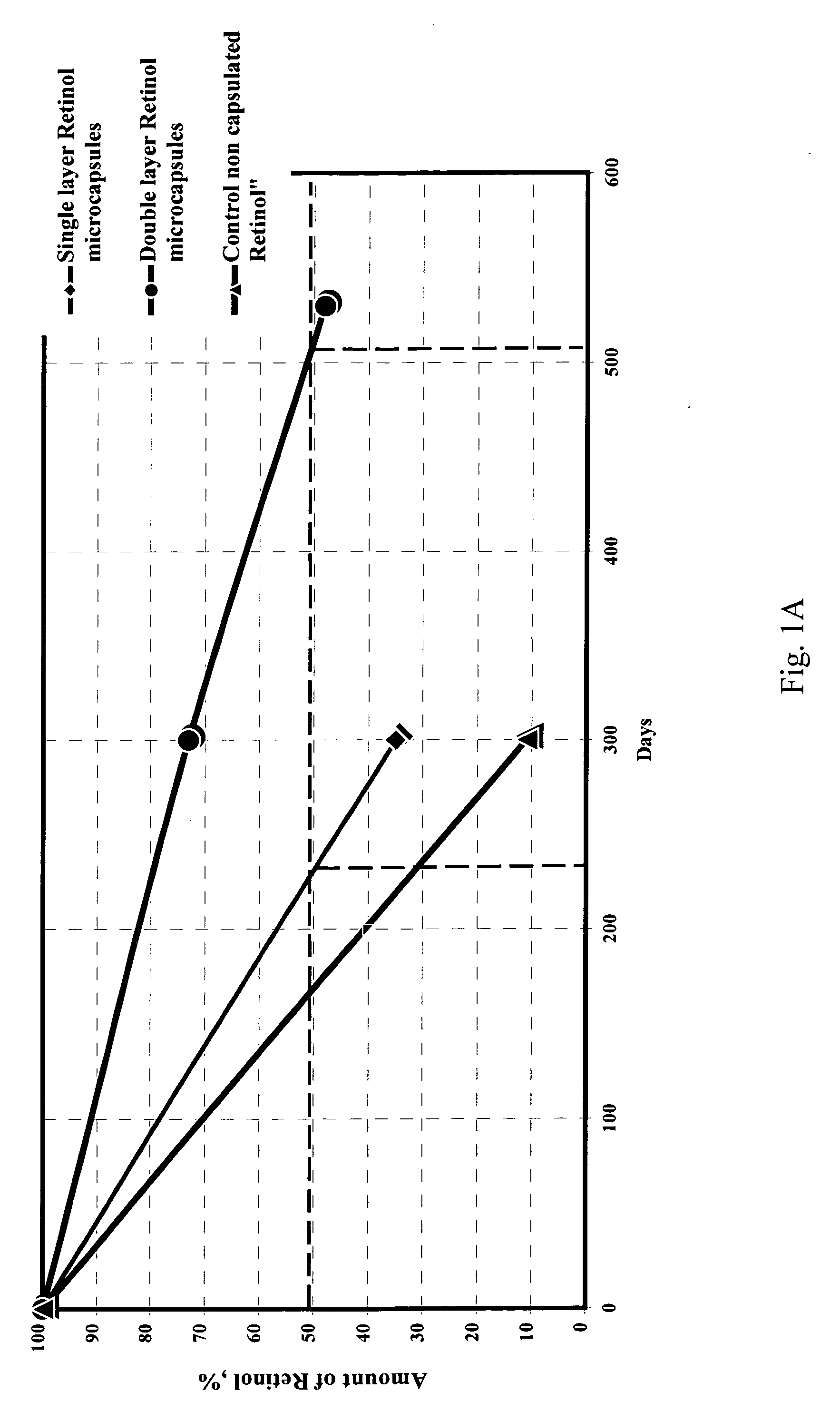

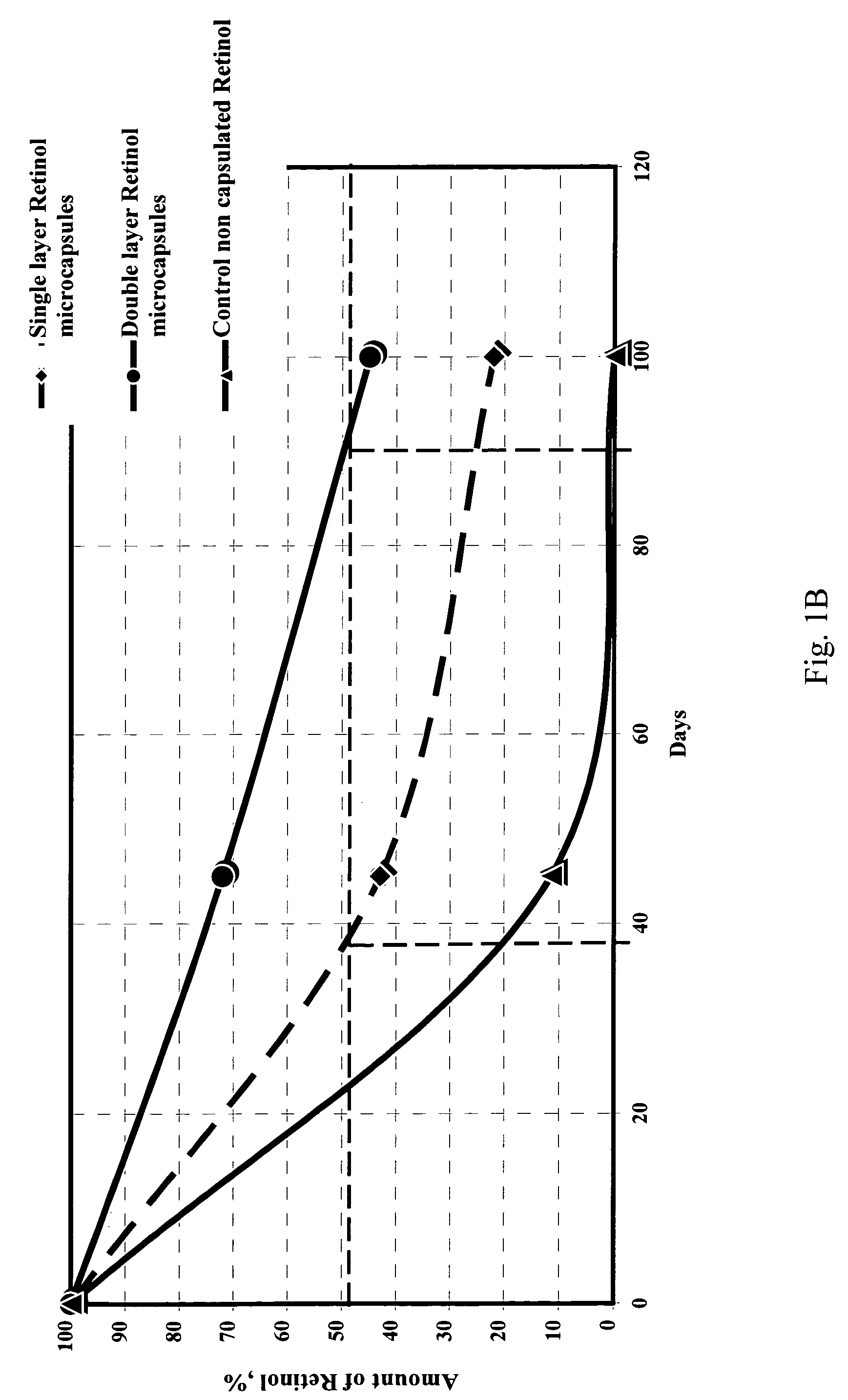

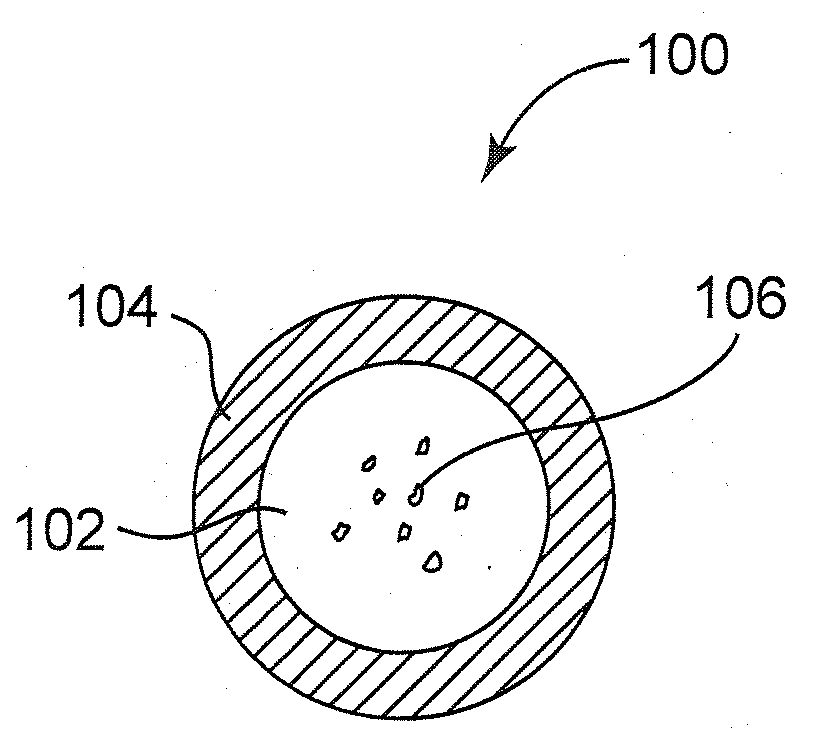

InactiveUS20060051425A1Improve stabilityPrevent undesirable releasePowder deliveryCosmetic preparationsControl releaseBiochemistry

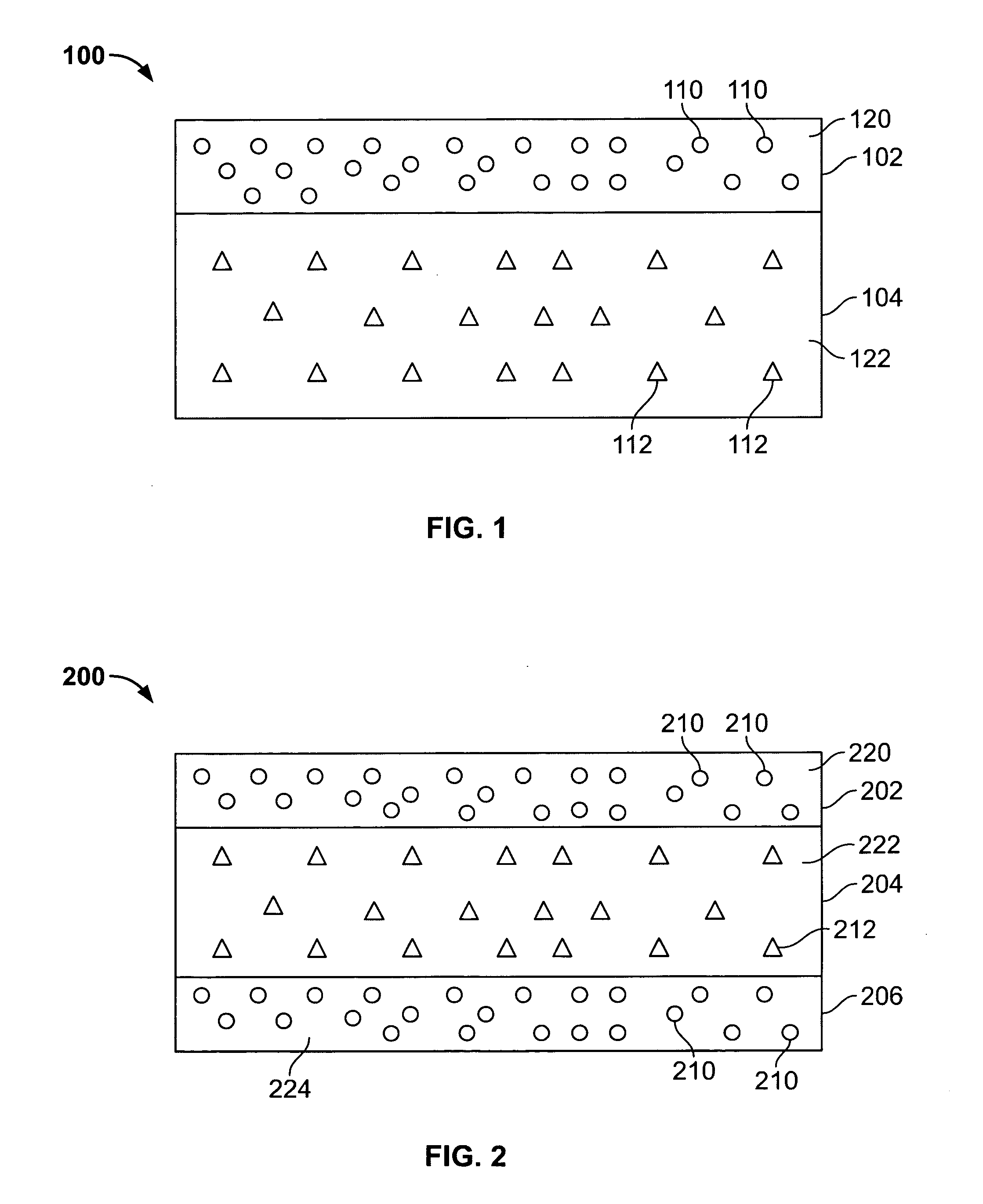

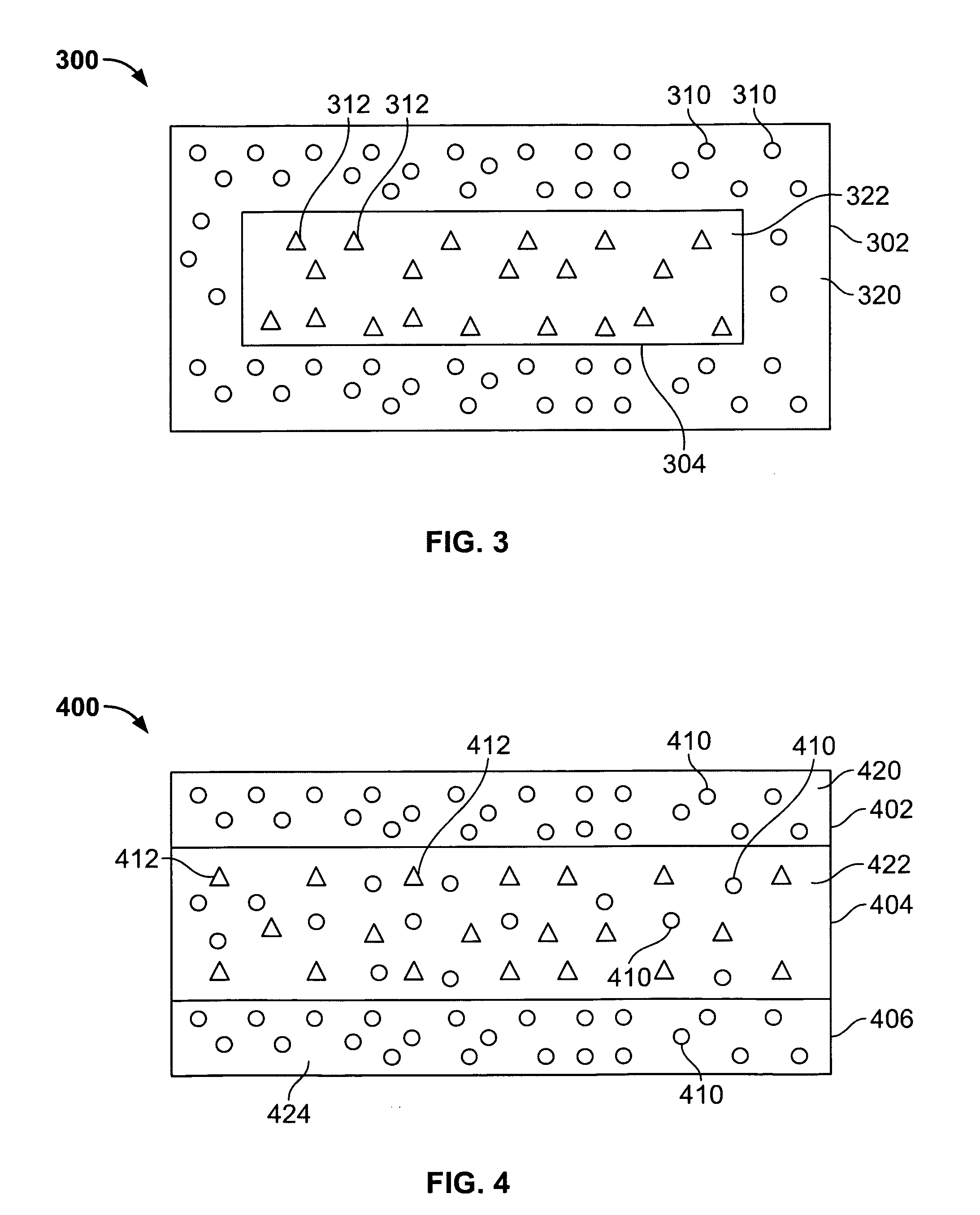

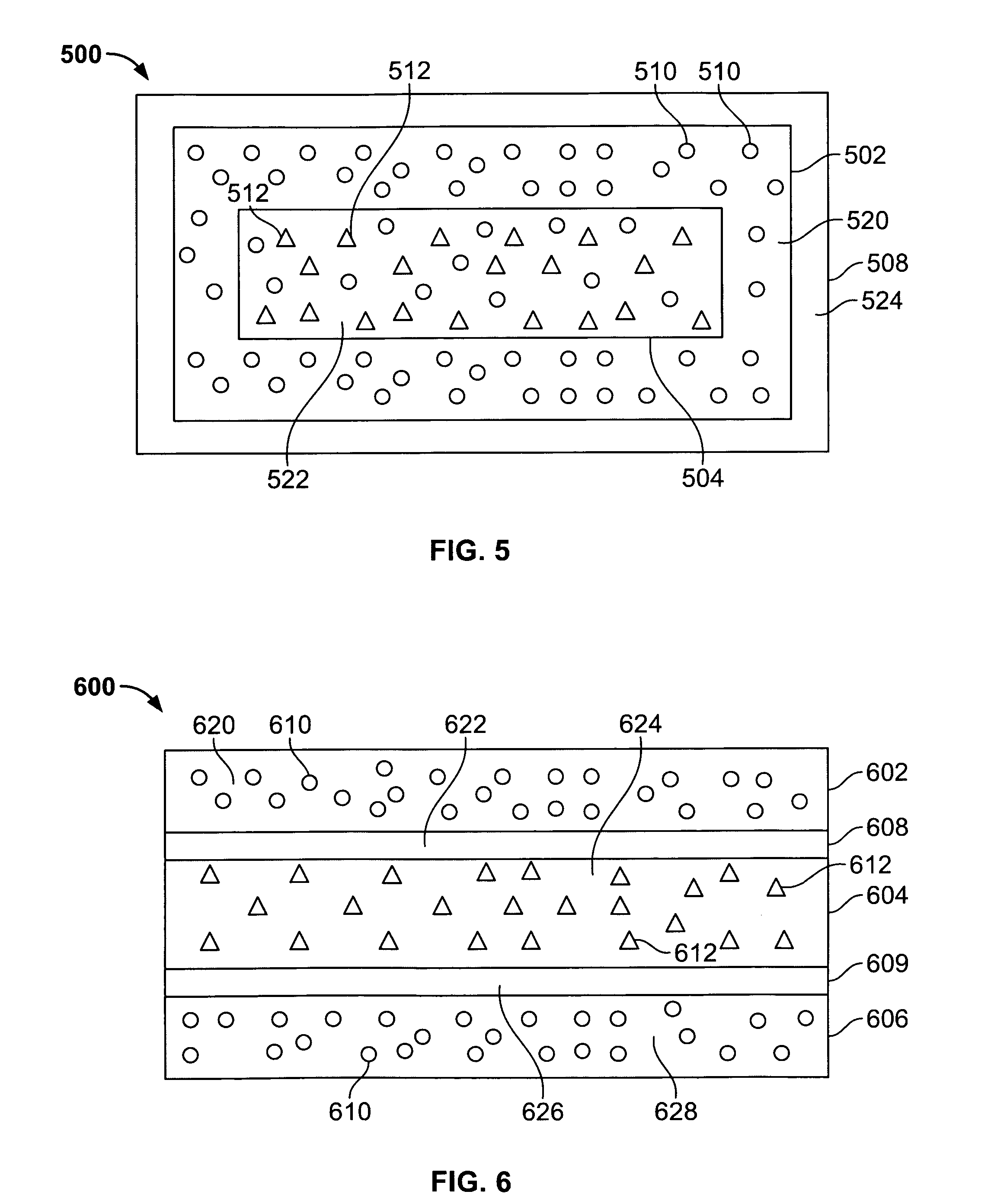

The present invention provides methods for microencapsulation of active ingredients for topical application, whereby single-layer and multi-layer, preferably double-layer, microcapsules, are obtained. The microcapsules protect the active ingredients, maintain their original activity throught processing, formulation and storage, and enable controlled release of the active ingredient only upon application onto the skin.

Owner:TAGRA BIOTECH

Microencapsulated acetochlor herbicidal composition

Microencapsulated compositions containing haloacetanilide herbicides, i.e., acetochlor, are produced by microencapsulation process. The microencapsulated composition performs comparably to nonencapsulated compositions of the same herbicide applied at the same application rates.

Owner:ZENECA AG PROD INC

Means of delivering drugs in an ascending zero order release pattern

Disclosed are dosage forms and methods for sustained release of a drug including: a delay layer comprising a polymeric matrix, and microencapsulated drug, wherein the delay layer is substantially free of non-microencapsulated drug; and a second layer including a polymeric matrix, and non-microencapsulated drug matrix; wherein the second layer is located adjacent to the delay layer.

Owner:ALZA CORP

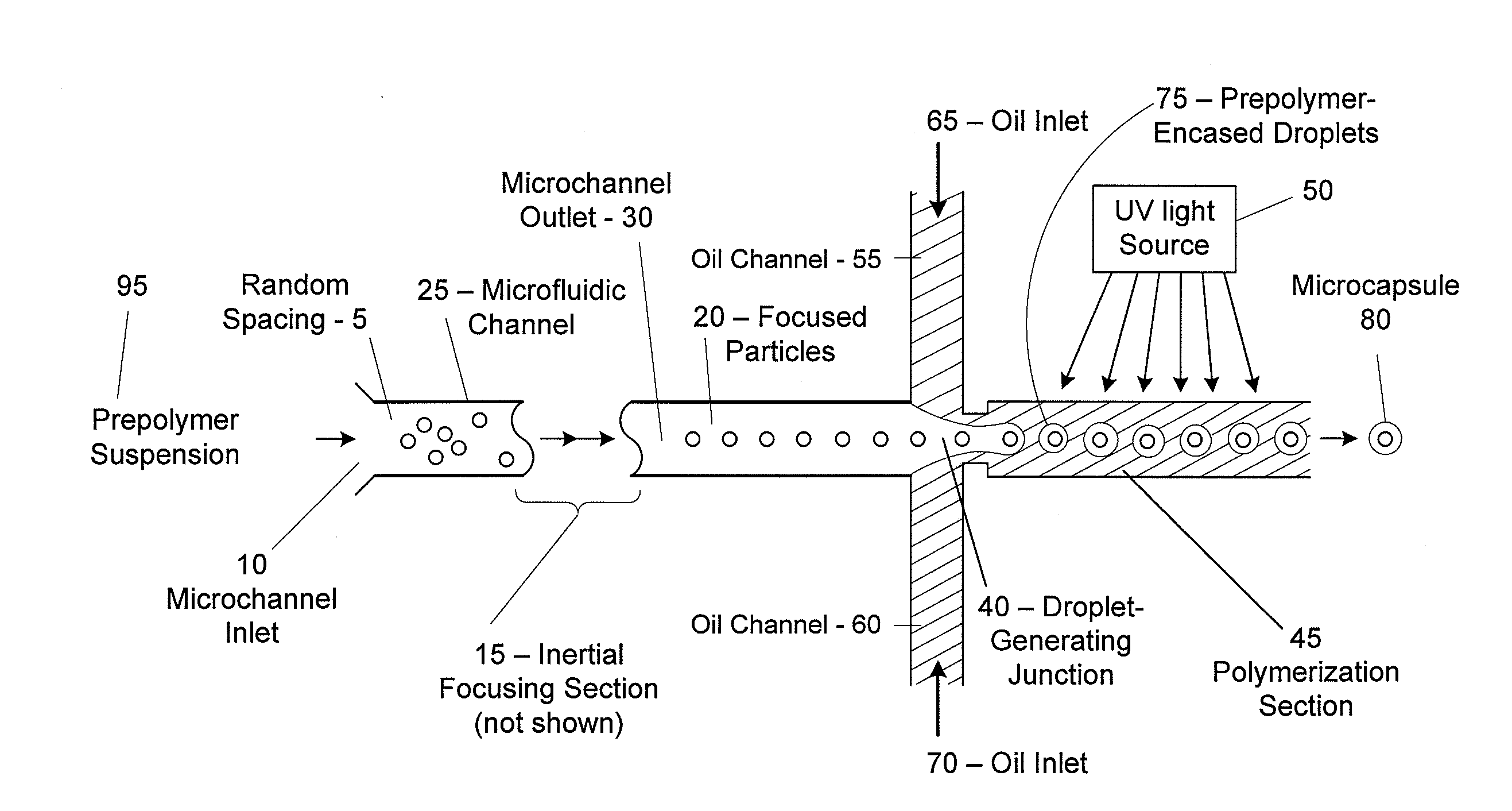

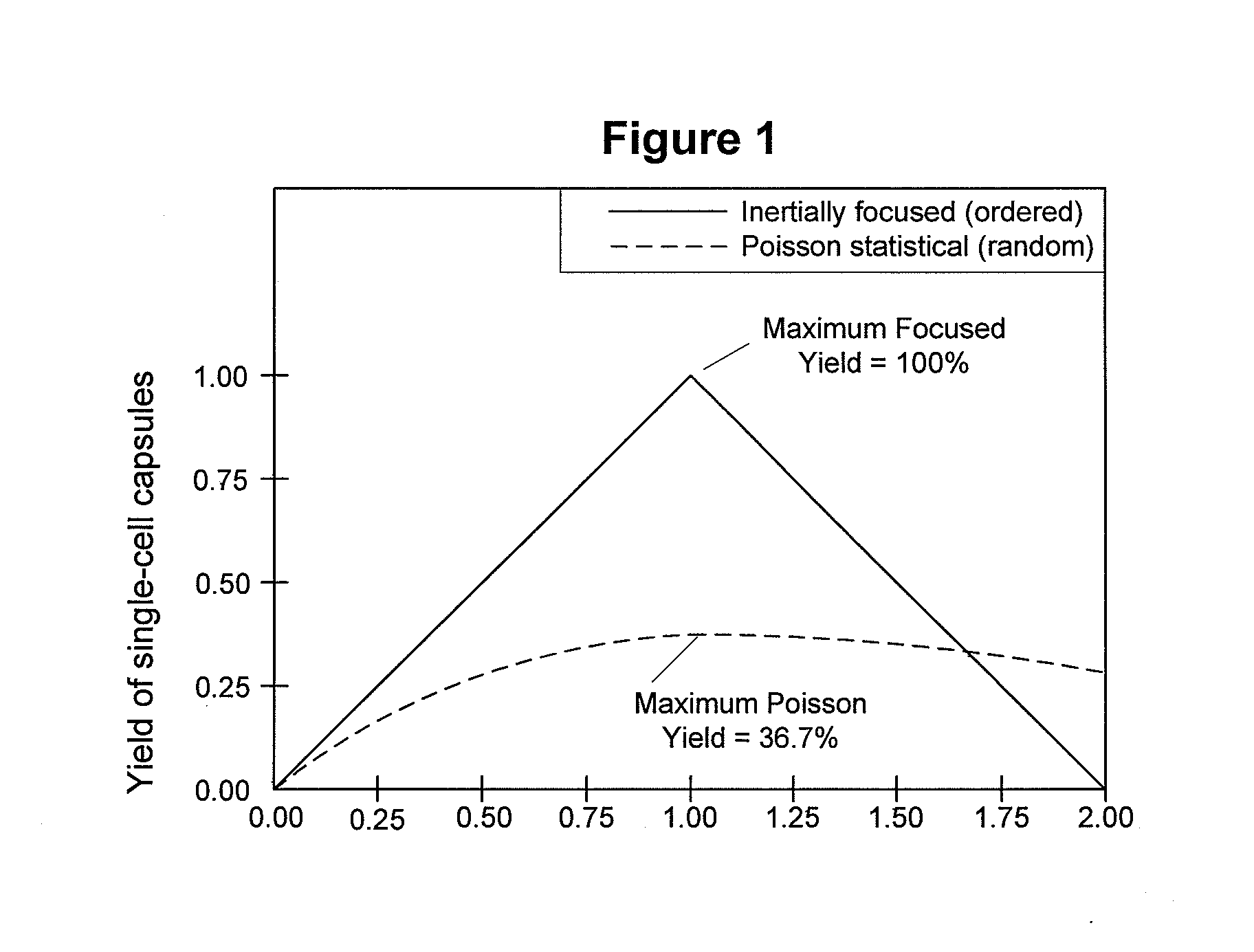

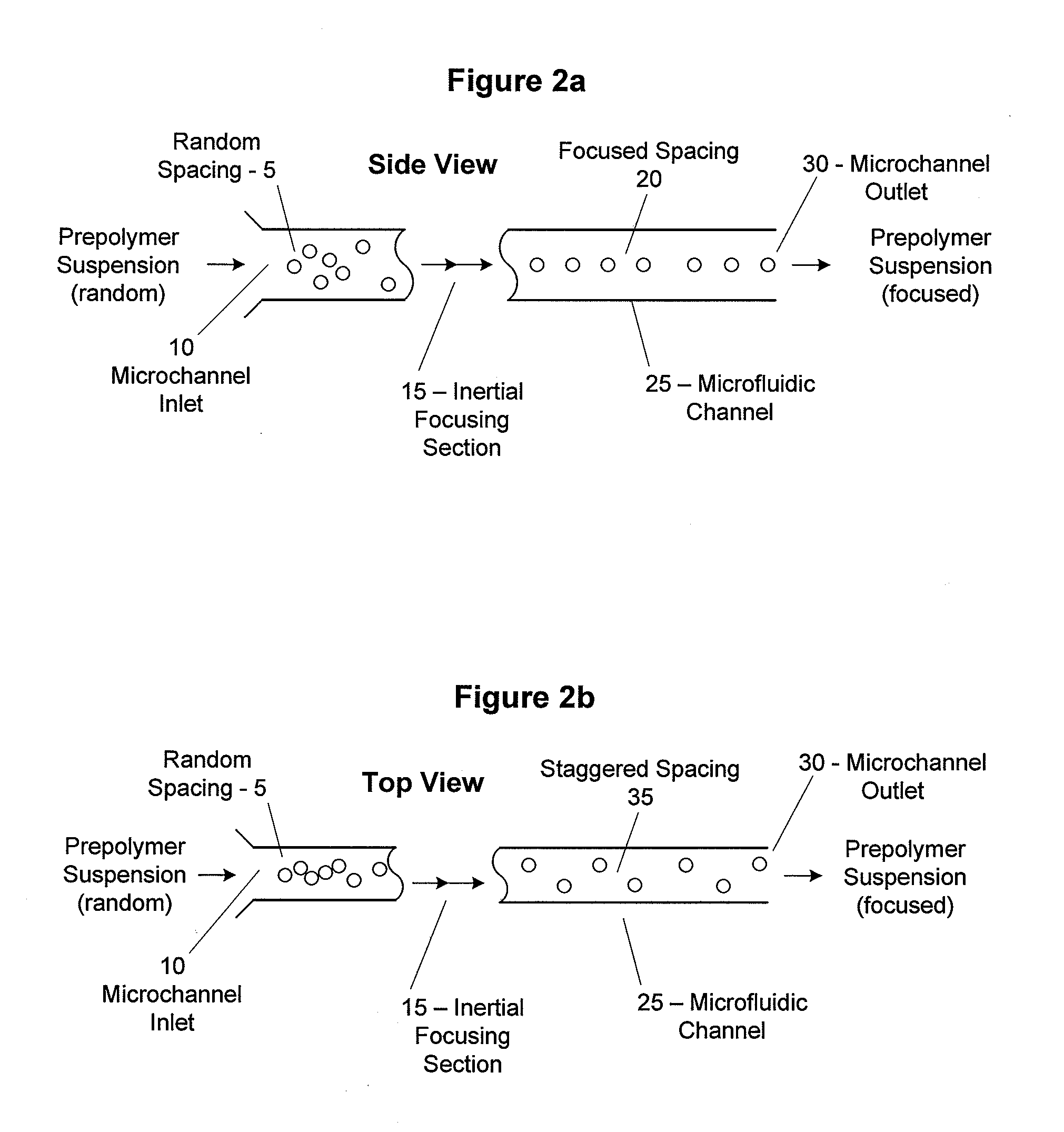

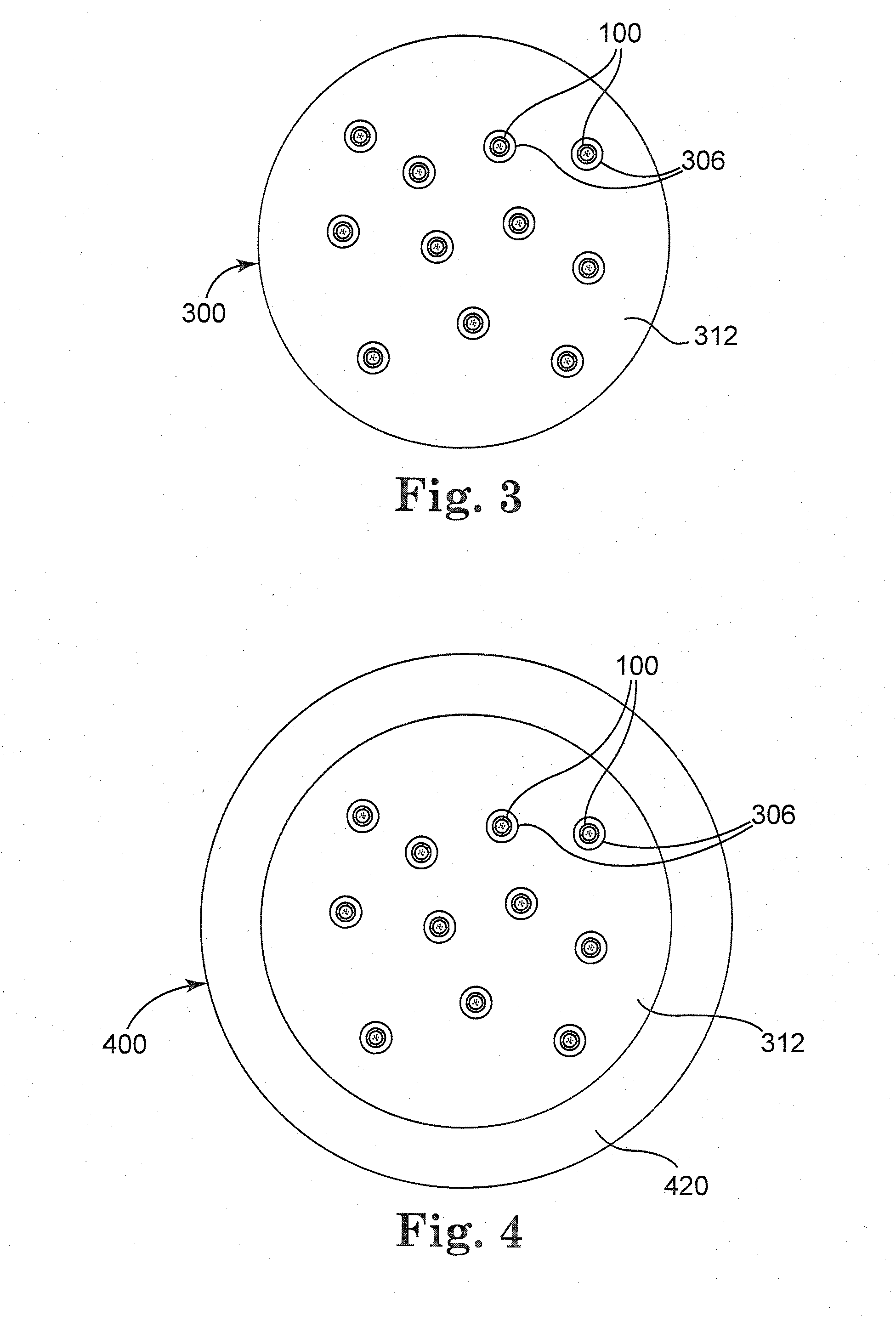

Efficient microencapsulation

InactiveUS20110223314A1Increase radiusChannel widthMixersPharmaceutical containersPolymer scienceDiacrylate ester

A device and method for generating microcapsules employs an inertial-focusing channel for introducing particles dispersed in a prepolymer suspension fluid, a droplet-generating junction for introducing oil evenly onto the flow of particles to create separated droplets of prepolymer suspension fluid encapsulating respective particles in a streamline flow, and a polymerization section for exposing the droplets to UV light or heat to cause polymerization of a polymer coating on separate microcapsules each containing a respective particle. Preferred suspension fluids may be aqueous solution of poly(ethylene-glycol)-diacrylate (PEGDA), or poly(N-isopropyl-acryalmide) (PNIPAAM). The preferred device may employ a curved or linear inertial-focusing microchannel. Functional tags and / or handles may be added to the microcapsules allowing easy detection, measurement and handling of the microcapsules.

Owner:UNIV OF HAWAII

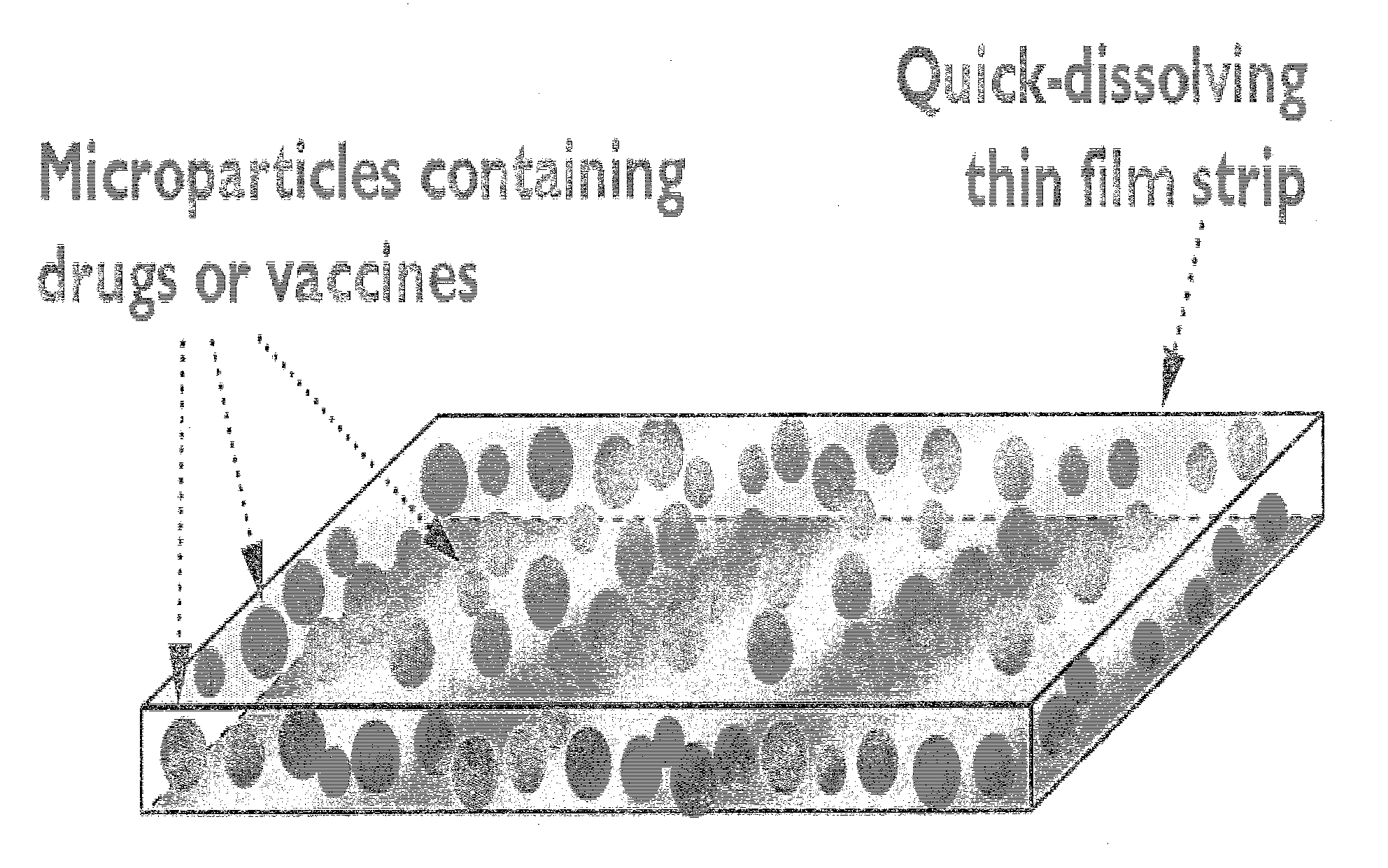

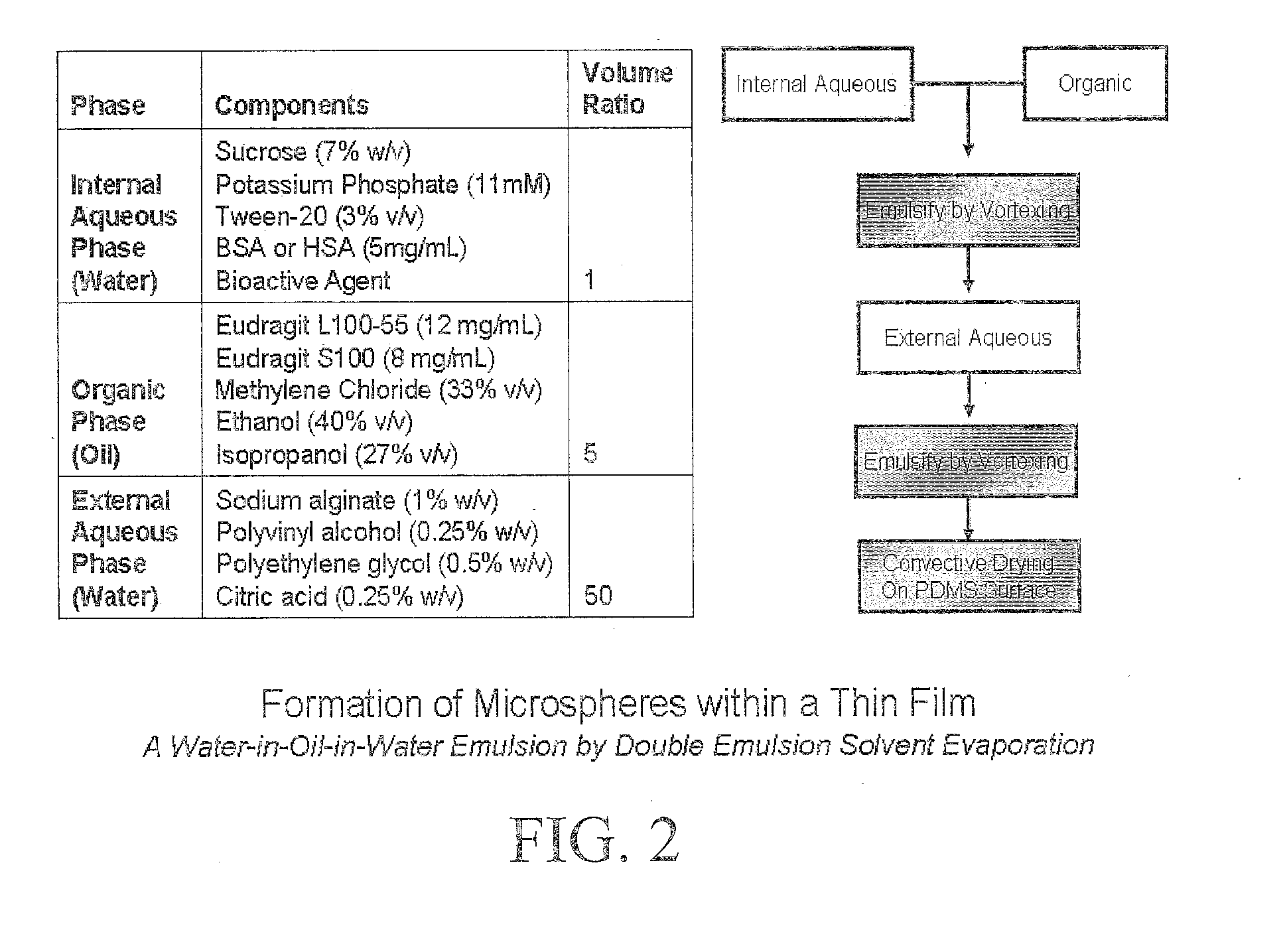

Quick-dissolving oral thin film for targeted delivery of therapeutic agents

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

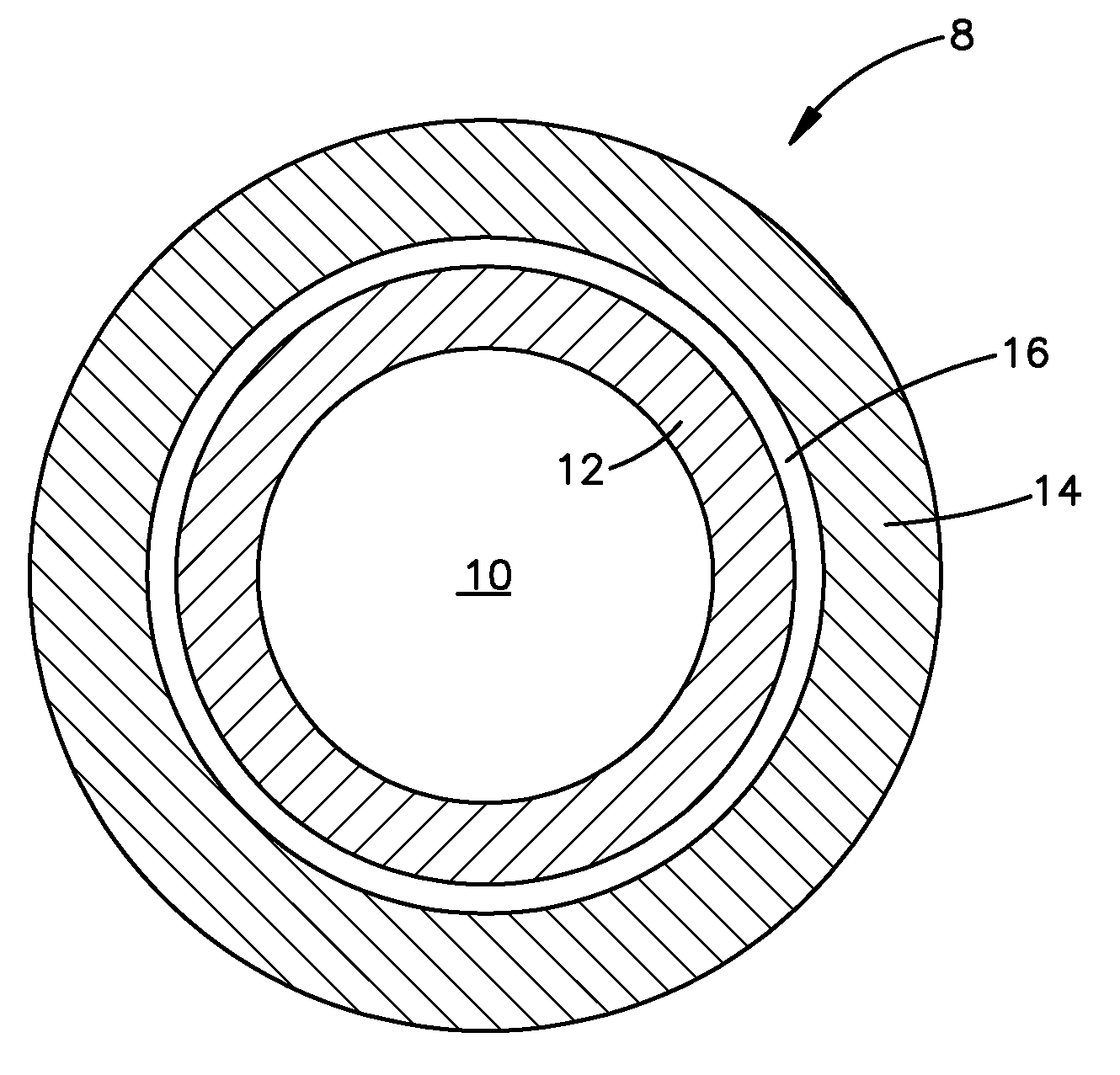

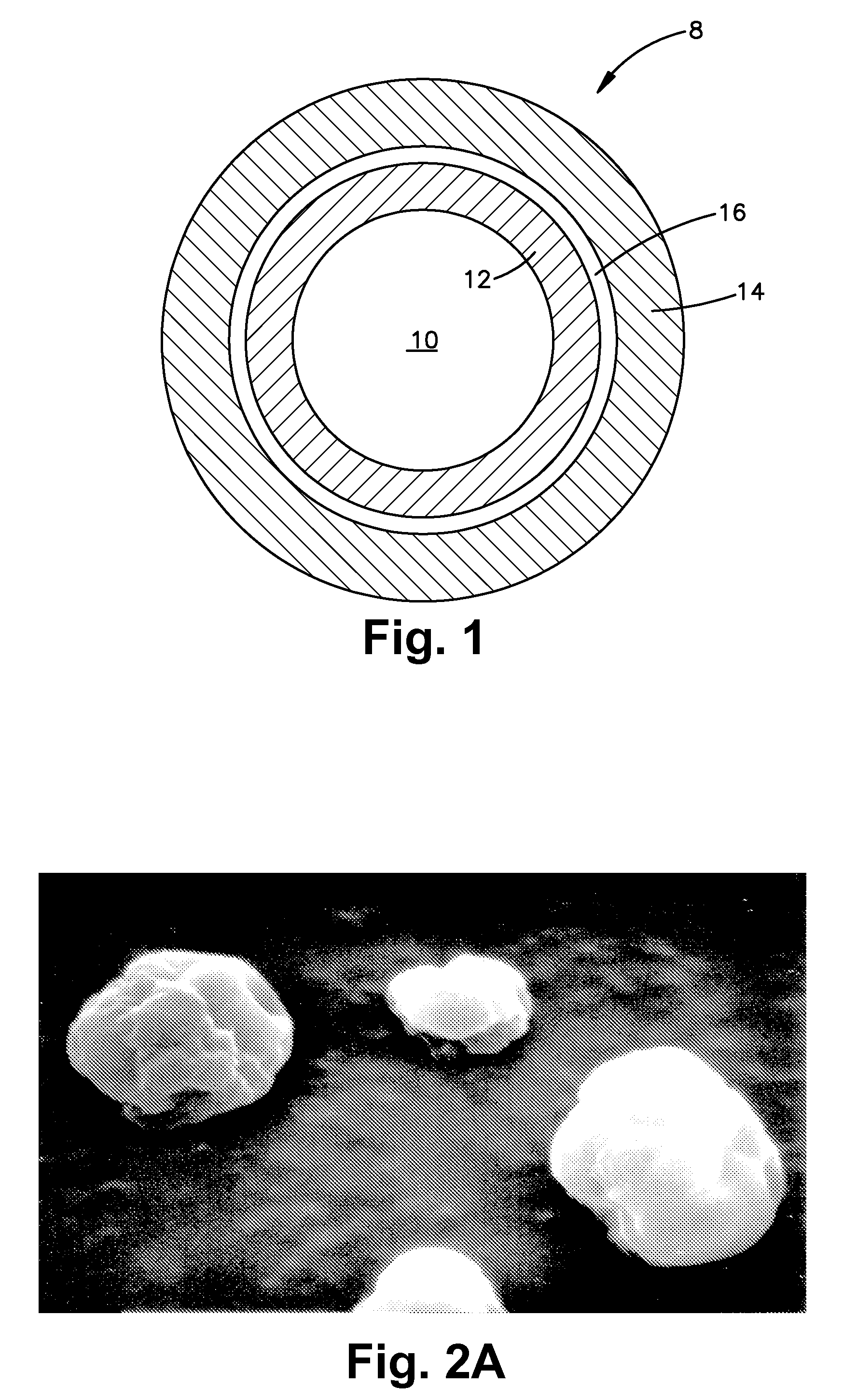

Microencapsulated Oil Product and Method of Making Same

ActiveUS20090004333A1Increase loadAvoid excessive shear and damageDough treatmentConfectionerySolid shellProtein free

A microencapsulated product comprises a core, a first shell comprising a protein and being substantially carbohydrate-free, and a second shell comprising a carbohydrate and being substantially protein-free. The double shell structure provides a strong shell that makes the microcapsule suitable for use in food products. The core can be a lipid, and in particular a structured lipid with nutritional benefits, such that the nutritional benefits can be passed on to the consumer. The microcapsules of the present invention can be used in making foods products, beverage products, and mixes for making such food and beverage products.

Owner:BUNGE OILS INC

Microencapsulated compositions and methods for tissue mineralization

ActiveUS20100272764A1Increase contentHigh densityCosmetic preparationsImpression capsActive agentP phosphate

The present invention is directed to compositions, products and methods useful for bone and tooth mineralization. The compositions comprise polymer microcapsules containing aqueous salt solutions. The shells of the microcapsules can be semi-permeable or impermeable. Solutions of calcium, fluoride and phosphate salts are particularly useful in the compositions of the invention. The microcapsules are preferably prepared by surfactant free inverse emulsion interfacial polymerization. Bone products include cements, scaffolds and bioactive glass. Dental products include pastes, gels, rinses and many other dental materials.

Owner:PREMIER DENTAL PRODS

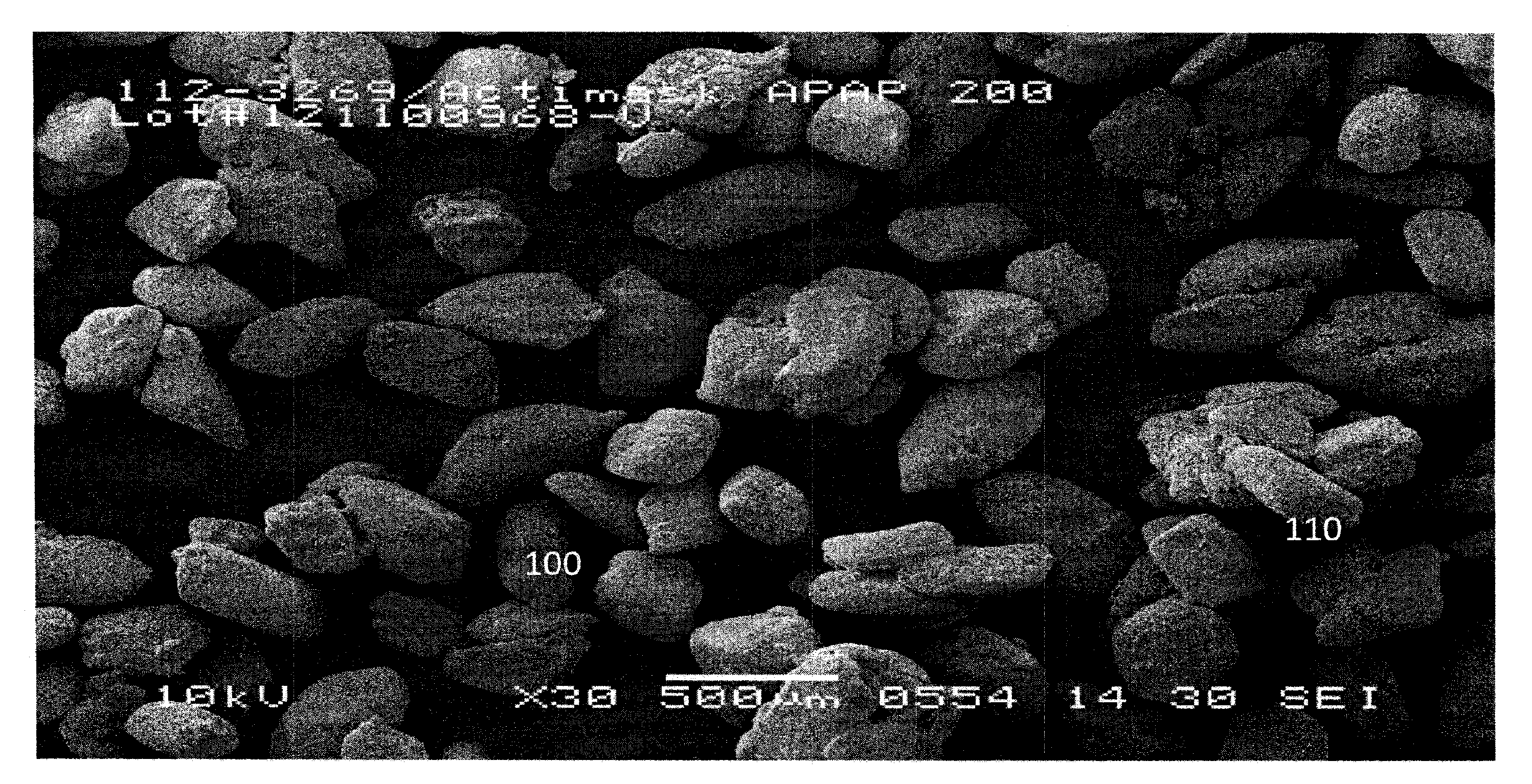

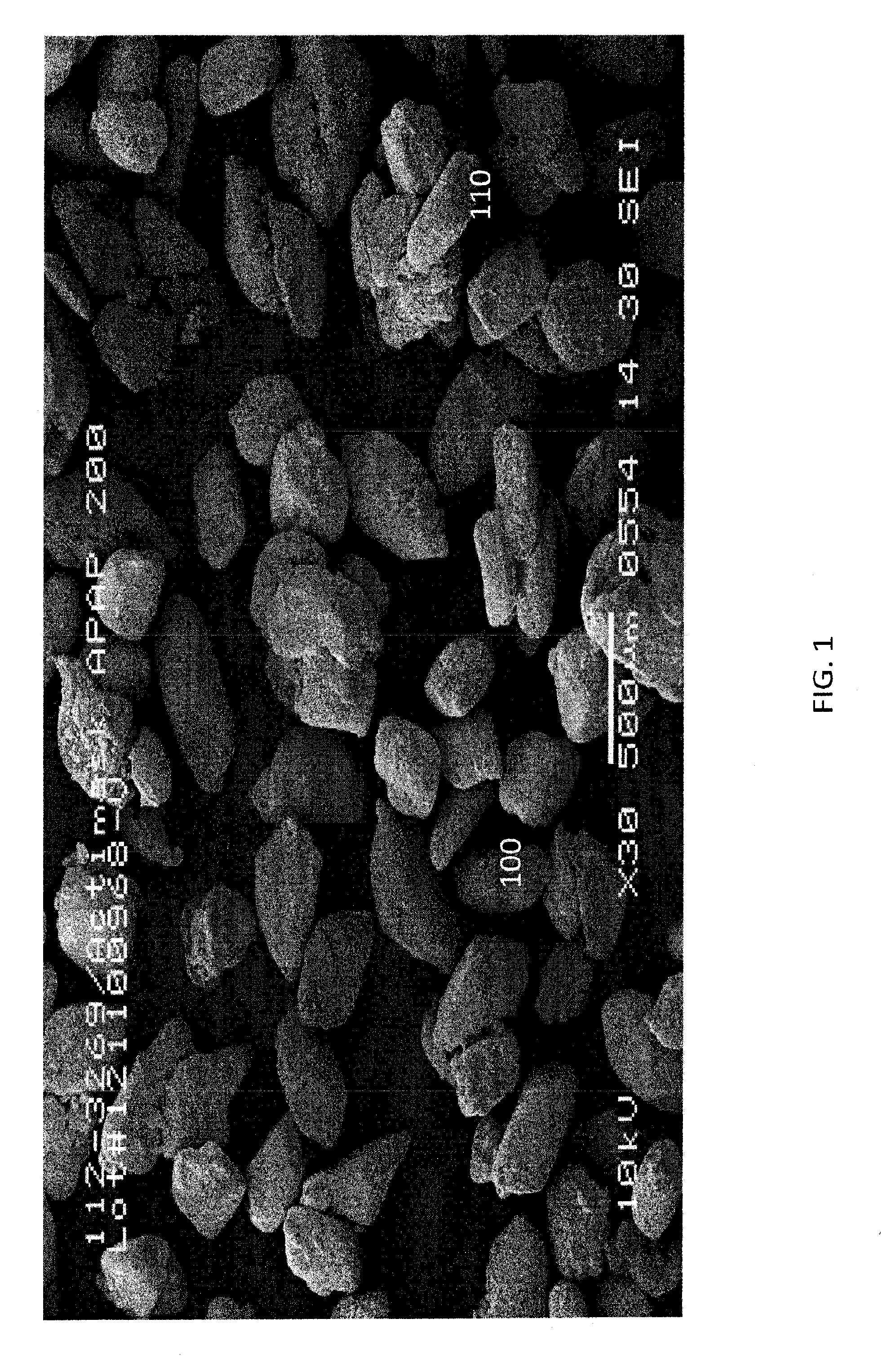

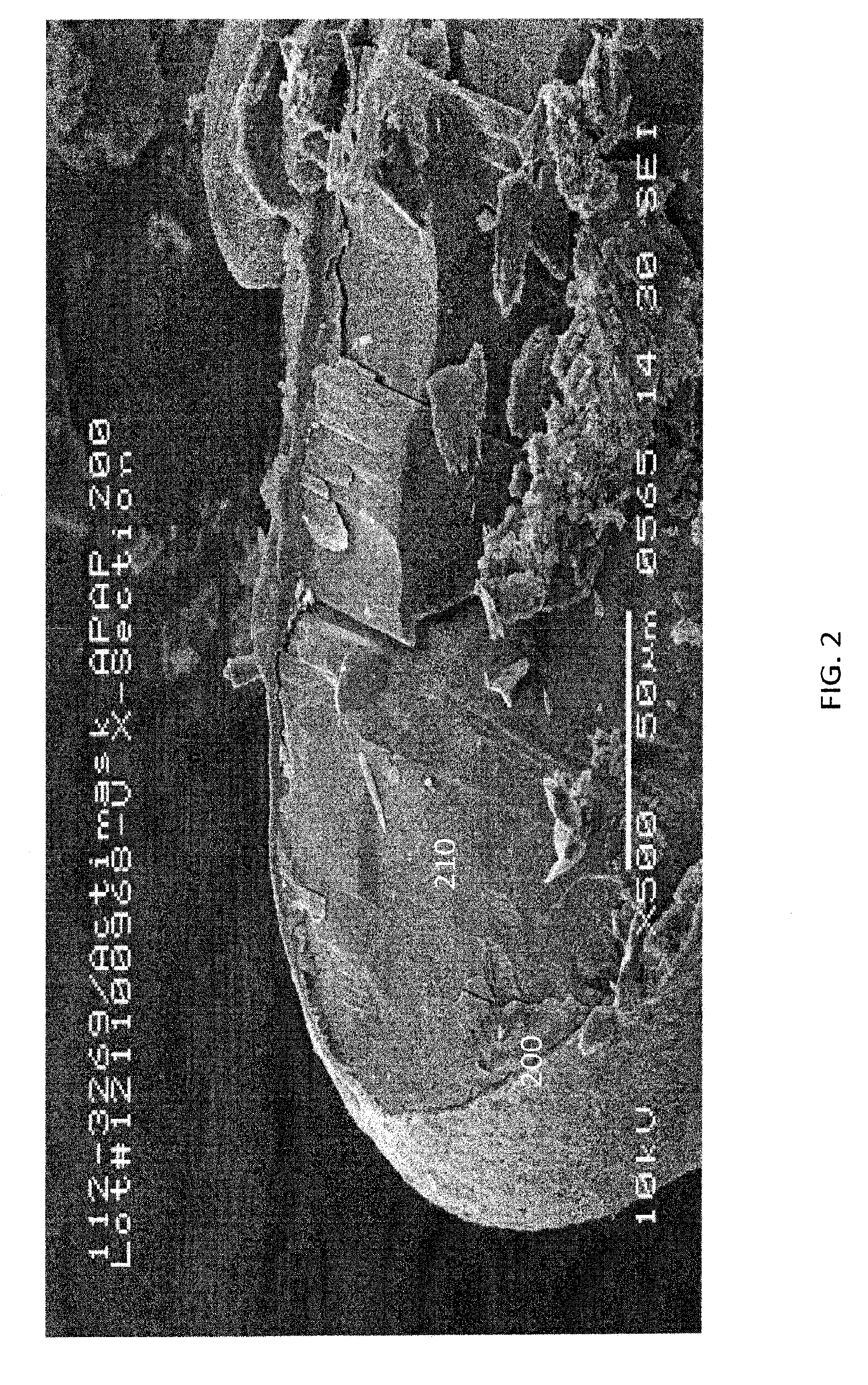

Microencapsulation process and product

A composition comprising a core material, having a taste value and a polymeric coating. The polymeric coating substantially surrounds the core material and comprises a cationic polymer and optionally an anionic polymer. The polymeric coating has a uniform thickness ranging from 2 μm to 20 μm. The composition provides release of a portion of the core material which is taste masked over a time period ranging from 0.5 minute to 2 minutes in the oral cavity and provides a modified-release of the remaining core material in a gastrointestinal tract.

Owner:SPI PHARMA

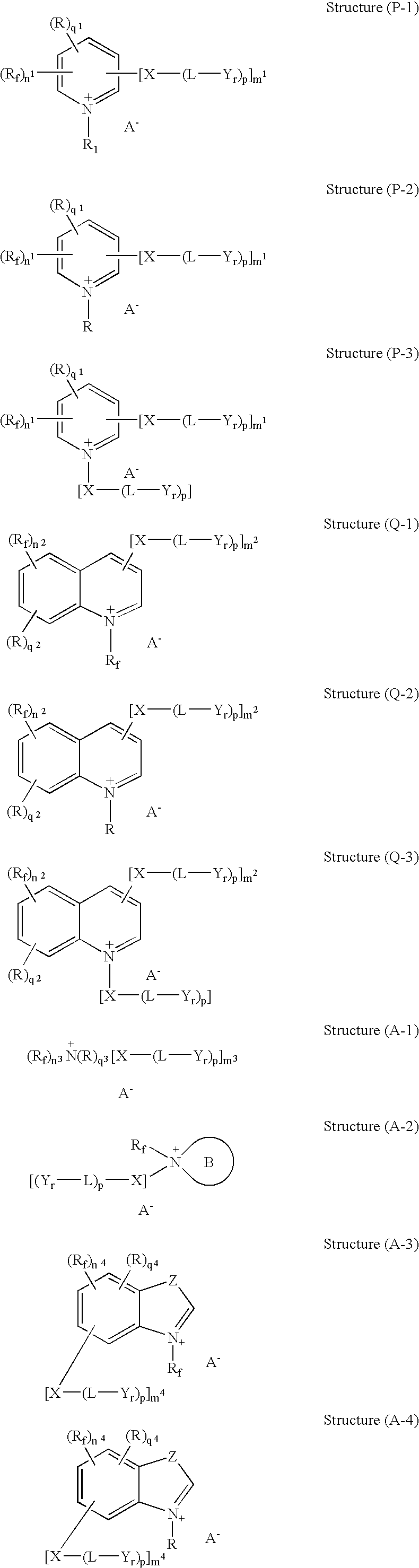

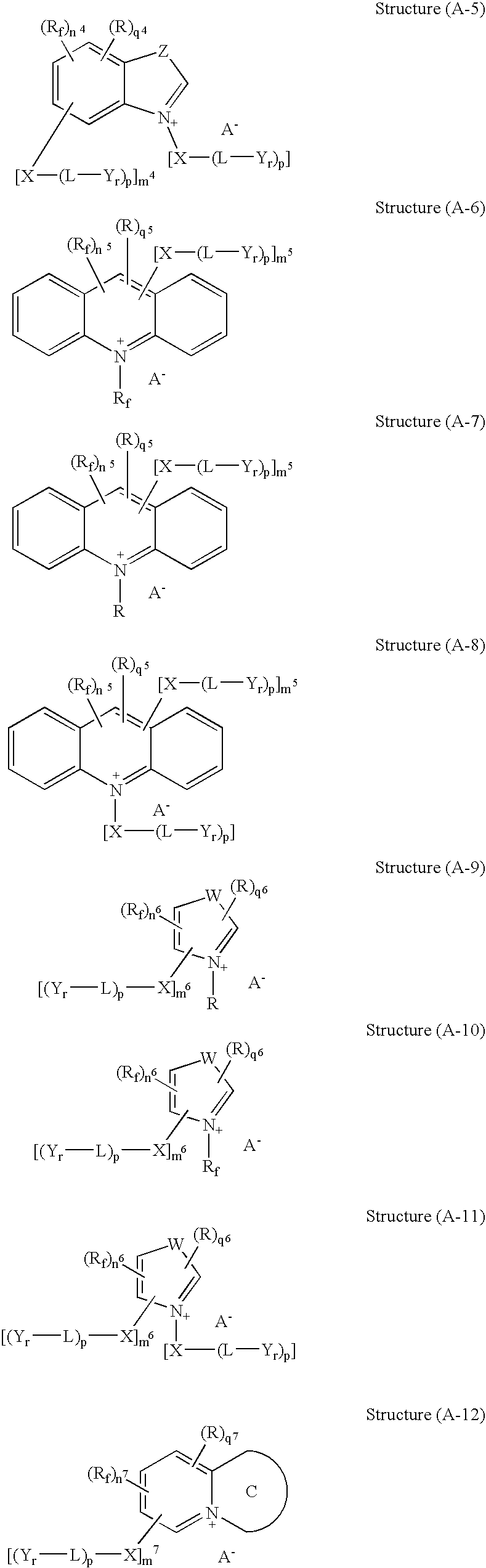

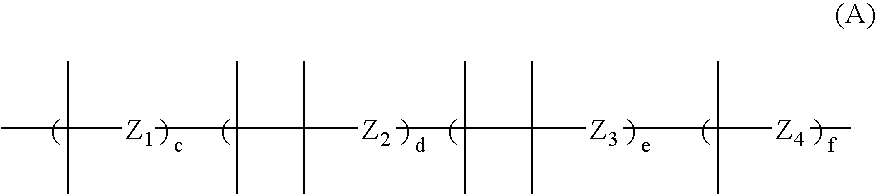

Microencapsulation processes and compositions for electrophoretic displays

ActiveUS7286279B2Improve responseImprove performanceDevelopersNon-linear opticsDisplay deviceMicroparticle

The present invention is directed to a method for improving the performance of an electrophoretic display, which method comprises adding a fluorinated quaternary nitrogen salt in either the internal phase or the continuous phase in a microencapsulation process for the formation of pigment-containing microparticles. One or more of the following materials may be further added to the internal phase or continuous phase in the microencapsulation process: a fluorinated protective colloid, a second charge controlling agent or a second monomer or oligomer.

Owner:E INK CORPORATION

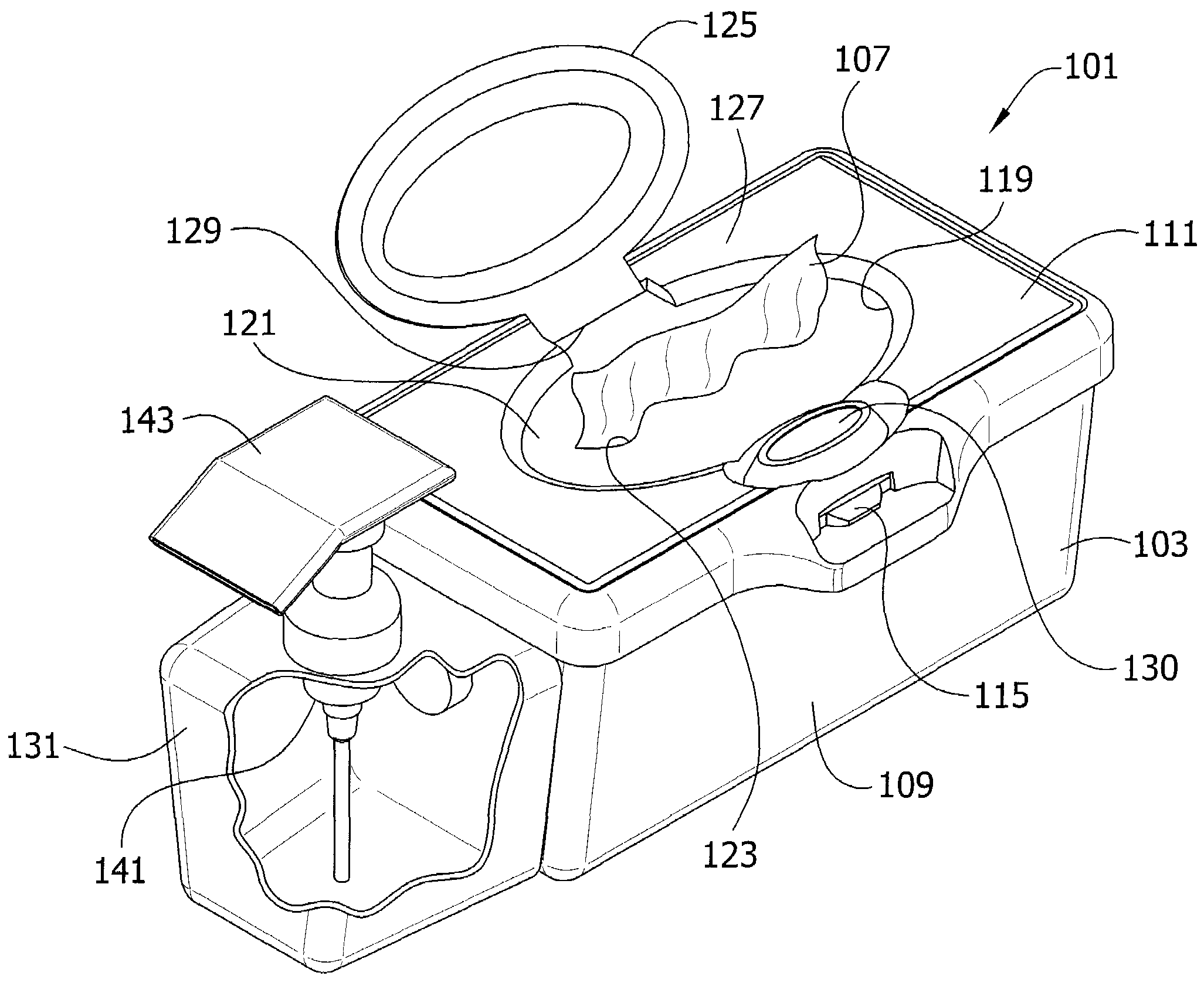

Wet wipe dispensing system

Owner:KIMBERLY-CLARK WORLDWIDE INC

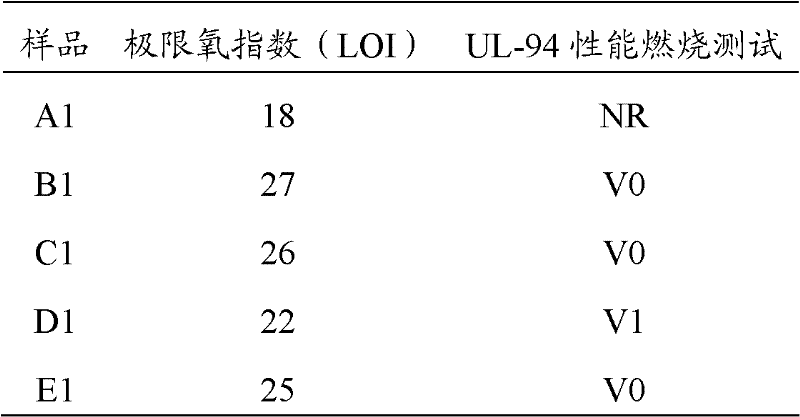

Microcapsule flame-retardant adsorption resin and preparation method thereof, and flame-retardant composite material

ActiveCN102492175AHigh strengthSimple structureMicroballoon preparationMicrocapsule preparationHydrogenFire retardant

The invention provides microcapsule flame-retardant adsorption resin comprising a reservoir wall and a capsule core, wherein the capsule core comprises adsorption resin and flame retardant adsorbed in the adsorption resin. The invention further provides a preparation method of the microcapsule flame-retardant adsorption resin and a flame-retardant composite material. The higher strength adsorption resin with a three dimensional lattice structure is adopted as a support material; the flame retardant or a solution of the flame retardant is adsorbed into resin granules through hydrogen bonding or intermolecular force; and adsorbed flame retardant molecules, in particular to small flame retardant molecules, are very hard to separate out of the adsorption resin owing to the hydrogen bonding orthe intermolecular force, so as to effectively restrain the flame retardant from surface migration. Meanwhile, after microencapsulation of the adsorption resin with the flame retardant, the reservoirwall can further restrain the flame retardant molecules from separation and migration, so as to improve the migration resistance of the microcapsule flame-retardant adsorption resin.

Owner:UNIV OF SCI & TECH OF CHINA

Detergent compositions for cleaning and fabric care

InactiveUS20070293414A1Increase depositionOrganic detergent compounding agentsNon-surface-active detergent compositionsPolyolefinPolymer science

Detergent compositions comprising selected deposition polymers for improved deposition of fabric care benefit agents, such as organosilicones, polyolefin dispersions, polymer latexes, microencapsulated fabric care actives, onto fabrics through the laundering operation.

Owner:THE PROCTER & GAMBLE COMPANY

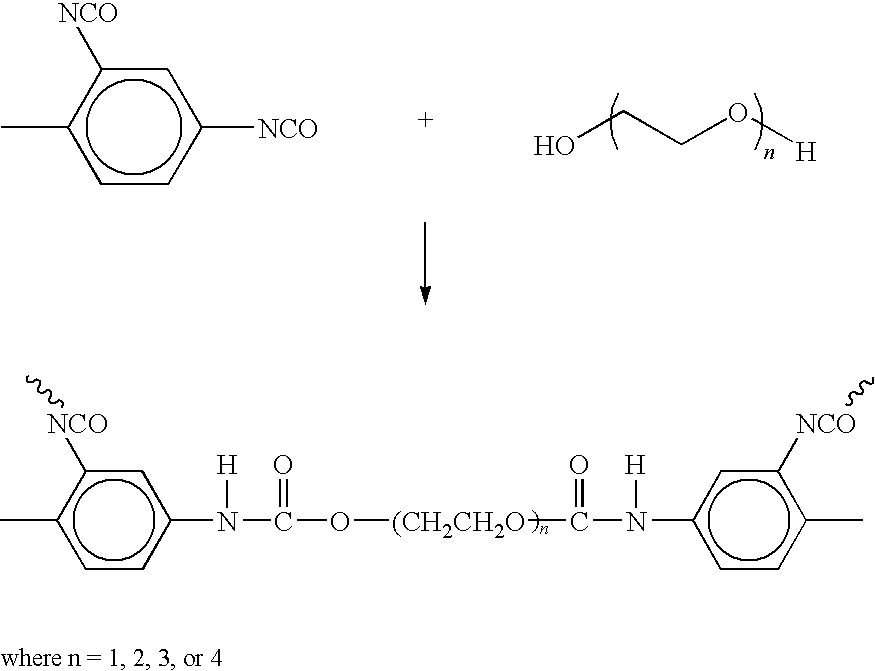

Microencapsulation of reactive diisocyanates and the application to self-healing anticorrosion coatings

InactiveUS20130196071A1Prevent downgradePreventing and slowing corrosionPretreated surfacesAnti-corrosive paintsSelf-healingPrepolymer

The disclosure provides a polyurethane microcapsule consisting of a polymerization product of methylene diphenyl diisocyanate (MDI) prepolymer with a polyol, the polyurethane microcapsule comprising a liquid isocyanate compound encapsulated within the microcapsule. The disclosure also provides self-healing coating compositions comprising such polymeric microcapsules and methods of preventing or slowing corrosion using such coating compositions.

Owner:NANYANG TECH UNIV

Laminating adhesives containing microencapsulated catalysts

InactiveUS20060078741A1Improve curing speedImprove effective working timePolyureas/polyurethane adhesivesSynthetic resin layered productsHydrogenAdhesive

The curing rate of a two component laminating adhesive is effectively accelerated by incorporating in at least one component a microencapsulated catalyst. When the laminating adhesive is subjected to an effective amount of pressure (for example, the pressure applied when laminating flexible films together using nip rollers), the catalyst (which may be, for example, a dialkyl tin dicarboxylate) is released from encapsulation and is made available to catalyze the polyurethane-forming reaction between the isocyanate groups and the active hydrogen-functionalized groups in the adhesive mixture.

Owner:HENKEL CORP

Core-shell synergistic flame retardant polyurethane microencapsulation expandable graphite and application thereof in rigid polyurethane foaming plastic

InactiveCN103554428AImprove flame retardant performanceReduce smoke productionMicroballoon preparationMicrocapsule preparationPolyesterDecomposition

The invention discloses a core-shell synergistic flame retardant polyurethane microencapsulation expandable graphite and the application of the expandable graphite in rigid polyurethane foaming plastic. The core-shell synergistic flame retardant polyurethane microencapsulation expandable graphite comprises polyether and / or polyester polyol, a foaming agent, a foam stabilizer, a catalyst, an organic phosphorus-based flame retardant, a halogen-free intumescent flame retardant, an organic modified nano inorganic filler, core-shell synergistic flame retardant polyurethane microencapsulation expandable graphite, polyisocyanate compound and isocyanate index, wherein the polyisocyanate compound has two or more isocyanate groups; the core-shell synergistic flame retardant polyurethane microencapsulation expandable graphite takes expandable graphite particles as a capsule core and takes cyclodextrin or polyurethane as a capsule shell, wherein the cyclodextrin or polyurethane is formed by crosslinking cyclodextrin / modified resin and toluene diisocynate. The expandable graphite microcapsule can effectively improve the initial decomposition temperature, the heat stability and the flame retardant effect of a material and remarkably reduces the heat release rate and the total heat release quality during combustion.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

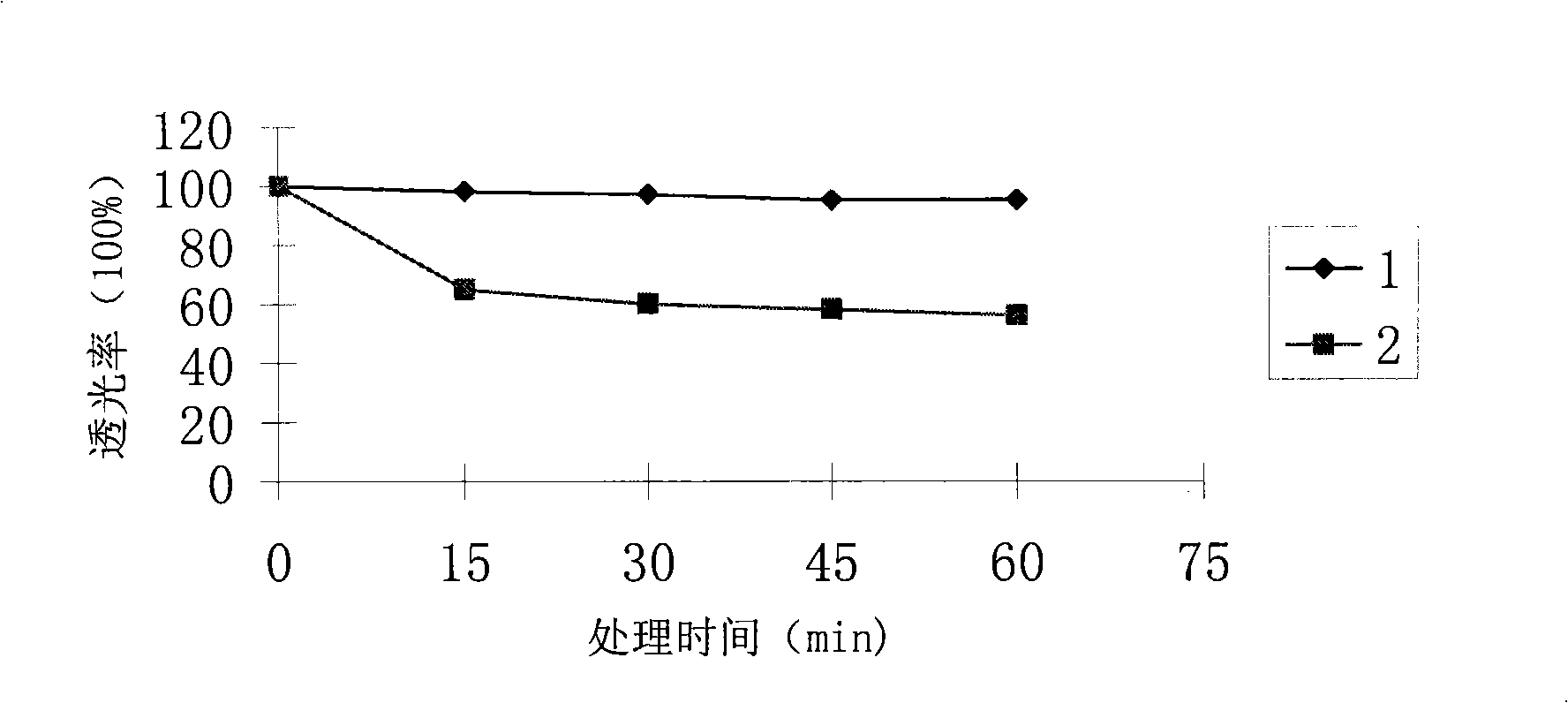

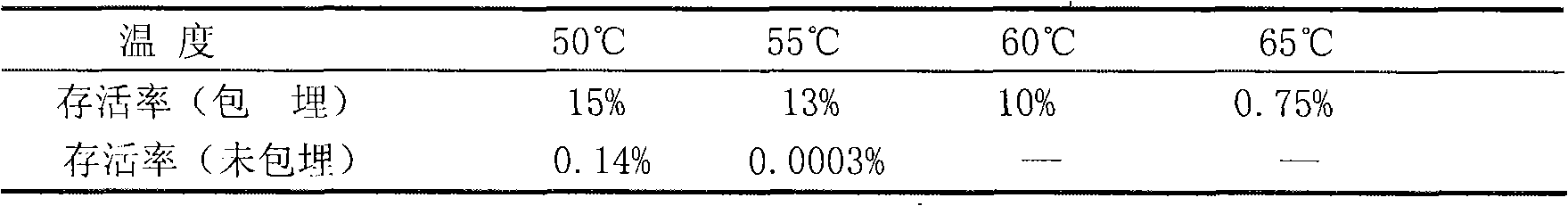

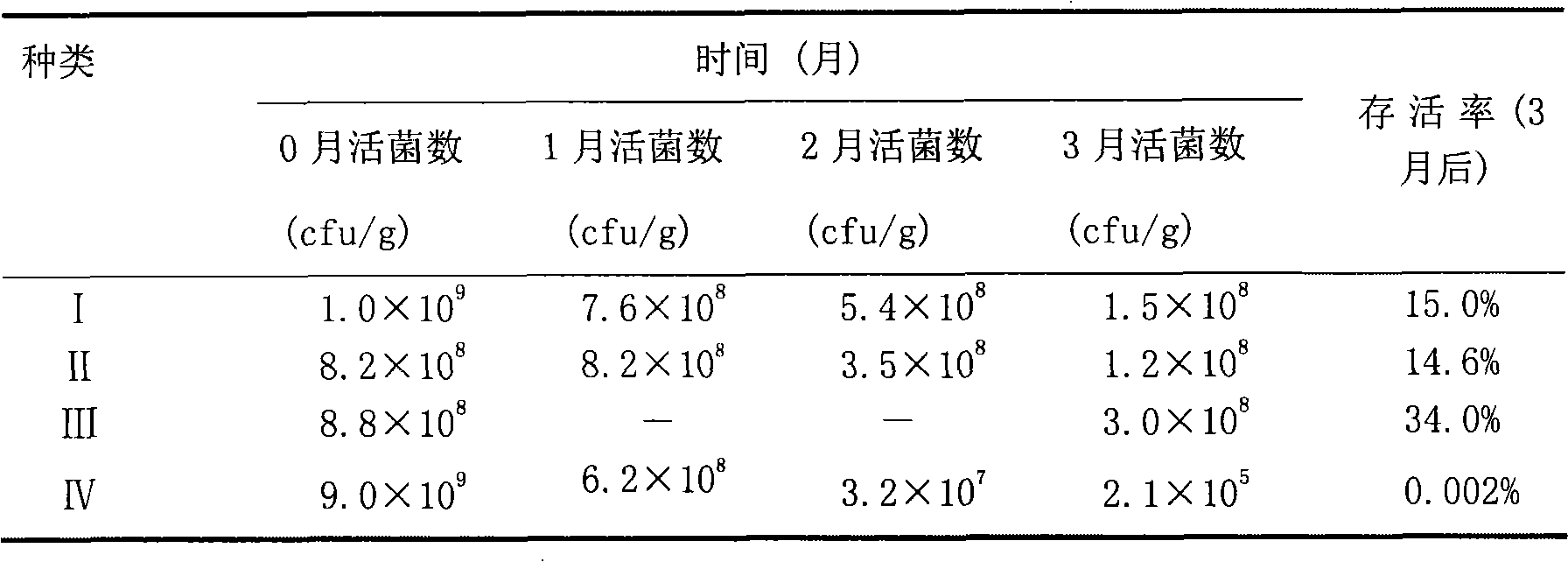

Lactobacillus helveticus microcapsule, preparation and use thereof

InactiveCN101323850AOvercoming the problem of low survival rate of freeze-dryingImprove efficiencyMilk preparationMetabolism disorderFreeze-dryingDietary supplement

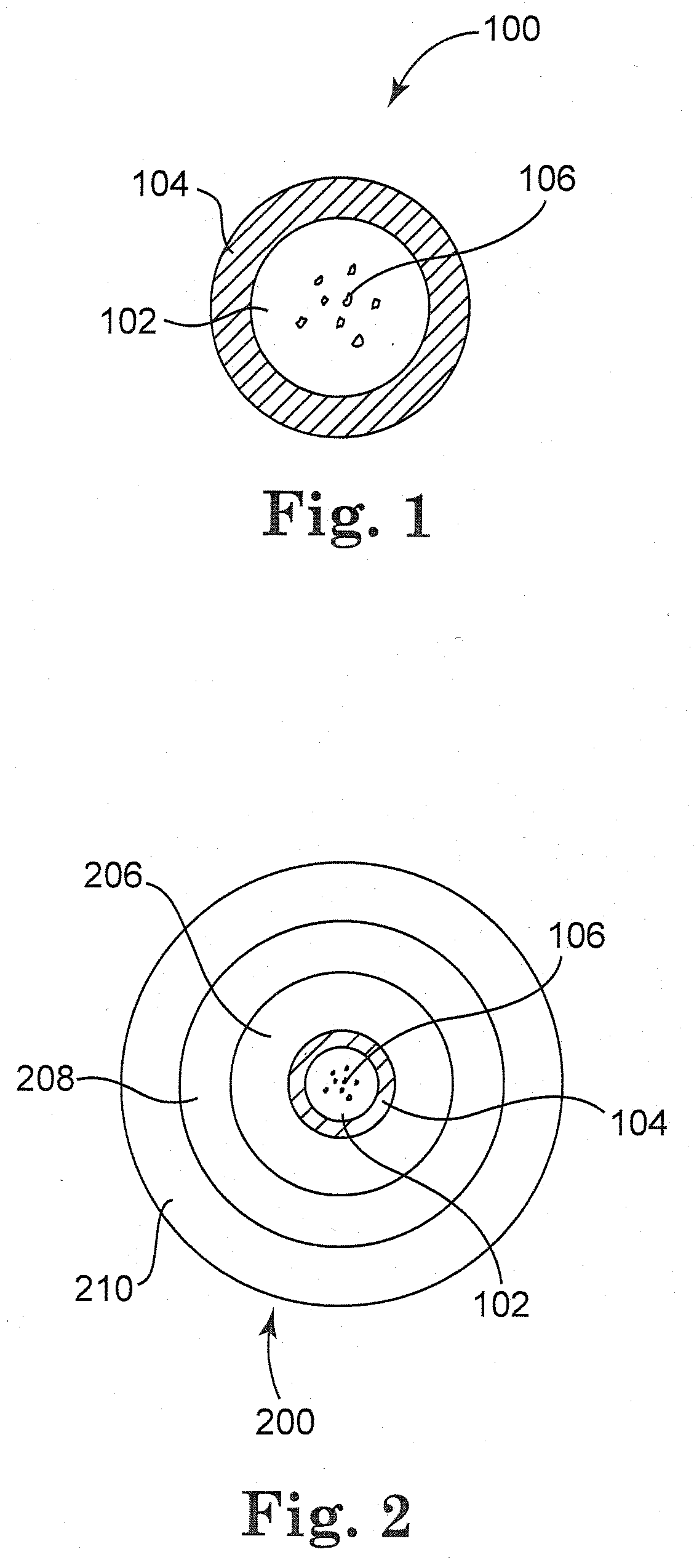

The invention provides a lactobacillus helveticus microcapsule as well as the preparation and application thereof, pertaining to the embedding technology of lactobacillus helveticus and aiming at microencapsulating the lactobacillus helveticus so as to solve the problems of low embedding efficiency and embedding yield in single-layer or double-layer embedment. The technical proposal adopted by the invention is that isolated soy protein, microporous starch and sodium alginate are respectively taken as the first, the second and the third layers of wall materials for microencapsulation; the three-layer embedment is carried out to the lactobacillus helveticus for the first time, wherein, in the process of preparing bacterial suspension, an orthogonal optimization protective agent is adopted to improve the livability after freeze drying. The microcapsule of the invention has strong heat resistance and acid resistance, solves the inactivation problem caused by gastric acid, digestive enzyme and antibiotic, etc. to active bacillus, is capable of releasing when reaching large intestine, and balances intestinal flora. The reusability of fermented milk is good. The lactobacillus helveticus used by the invention enriches the variety of probiotic bacteria microcapsule and is a good dietary supplement.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

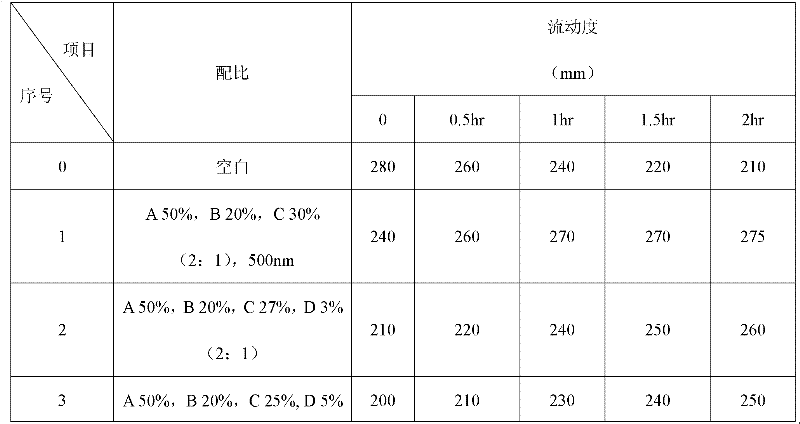

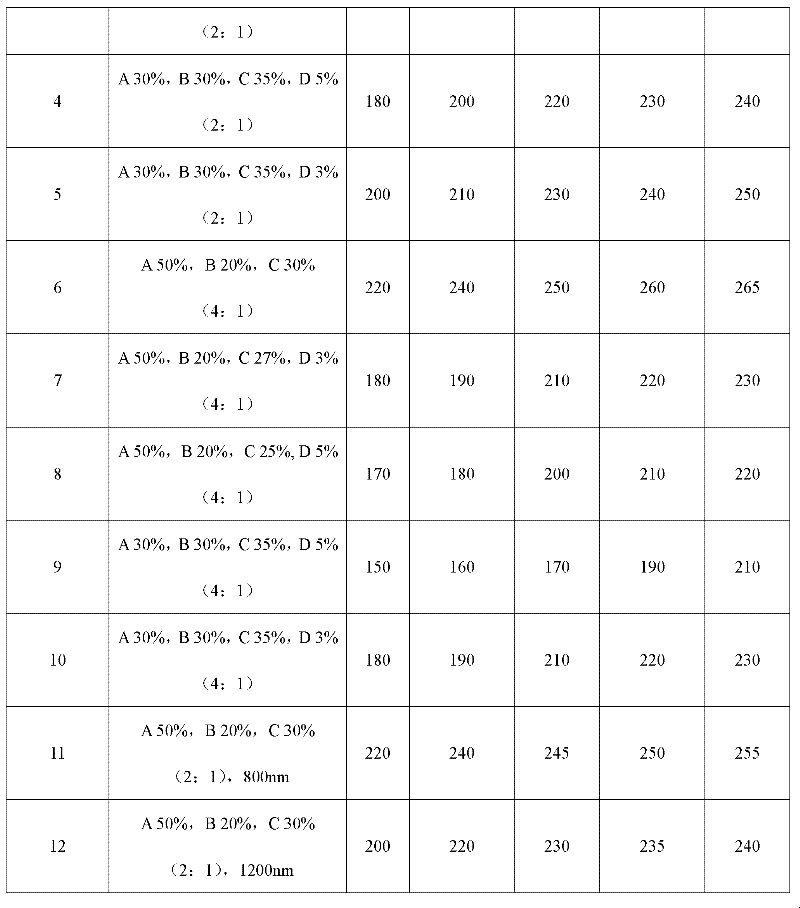

Preparation method of sustained-release water reducer microcapsule

ActiveCN102351459AImprove stabilityIncrease concentrationMicroballoon preparationMicrocapsule preparationWater reducerMaterials science

The invention discloses a preparation method of a sustained-release water reducer microcapsules which belong to the technical field of building material additives. By miniemulsion inverse phase polymerization, common water reducer molecules undergo microencapsulation and the water reducer microcapsules which have a pH response function are synthesized. After polymerization is finished, the microcapsules are in an acidic condition. due to the existence of capsule shells, the water reducer molecules can stably stay in the microcapsules. After the microcapsules are mixed with cement, cement concrete is strongly alkaline and the microcapsules perform a response-stimulus behavior under a high pH condition. Large molecular chains of the capsule shells rapidly expand and extend so as to generatethe swelling phenomenon. The compact shell layer becomes loose, and the cladded water reducer molecules slowly release such that the concentration of the water reducer is always high in the cement concrete. Therefore, the fluidity etentivity with time of the water reducer can be raised, and the collapsed slump loss of cement concrete in practical engineering usage can be prevented.

Owner:哈尔滨强石新材料技术开发股份有限公司

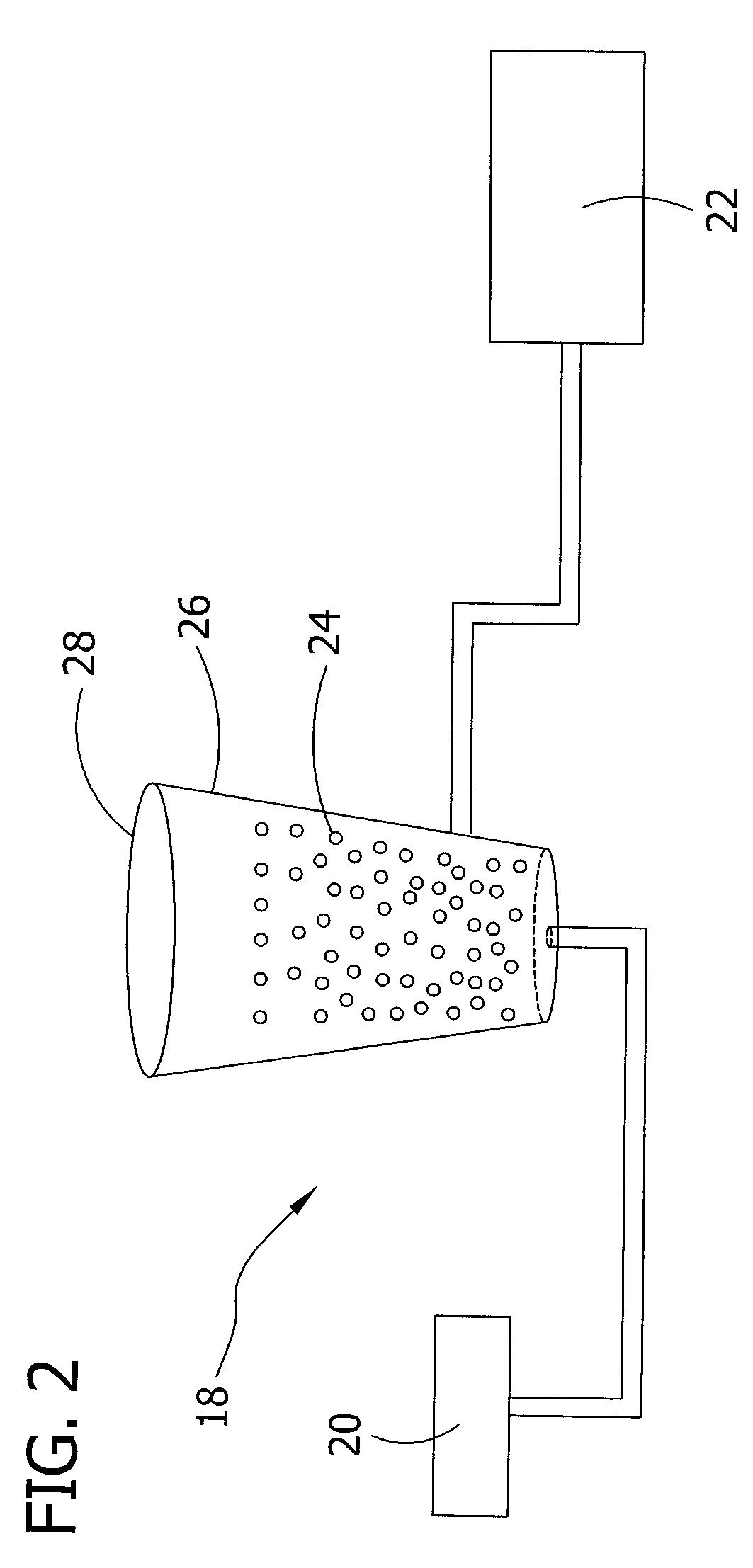

Method and apparatus for liquid microencapsulation with polymers using ultrasonic atomization

InactiveUS20060071357A1Minimize surface depositionEasy to collectPharmaceutical product form changeMicroballoon preparationEmulsionUltraviolet lights

An apparatus and method for encapsulating a liquid or suspension within a polymeric shell to form a microcapsule of a selected size ranging from approximately 0.1 μm to 1000 μm in diameter. The apparatus preferably has a laminar flow of air through a channel and ultrasonic atomizer with the head oriented at approximately ninety degrees from the laminar flow. Emulsions, liquids or thin films of core and shell materials are atomized and the formed microcapsules are exposed to ultraviolet light or additionally infrared light to cure the polymer shell and then are collected. A variety of capsule morphologies can be created by the choice of materials and process conditions to achieve desired controlled or programmed release kinetics. Surface functionalization of the outer shell of the microcapsules capsules can also be achieved to facilitate targeted delivery.

Owner:RGT UNIV OF CALIFORNIA

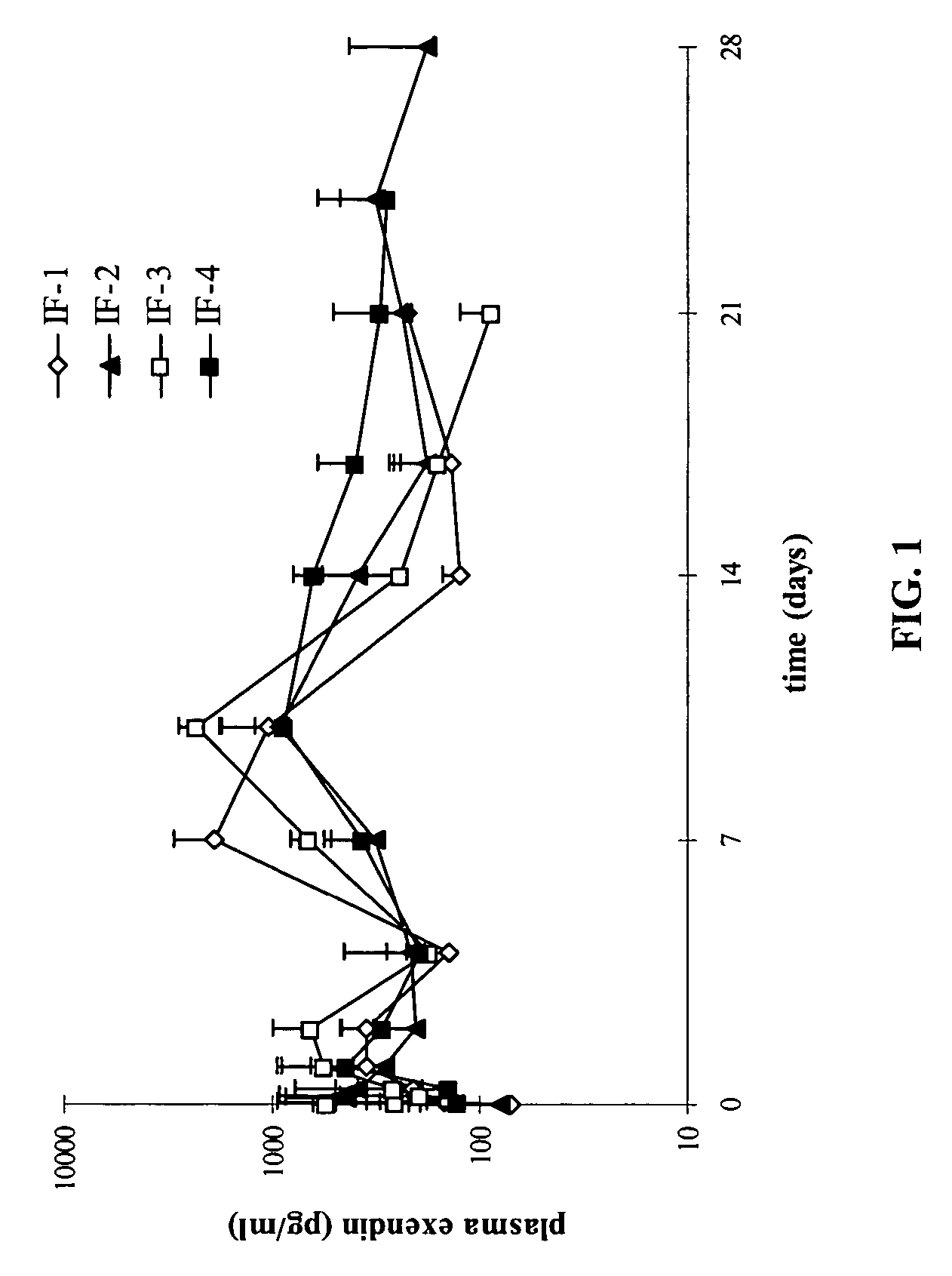

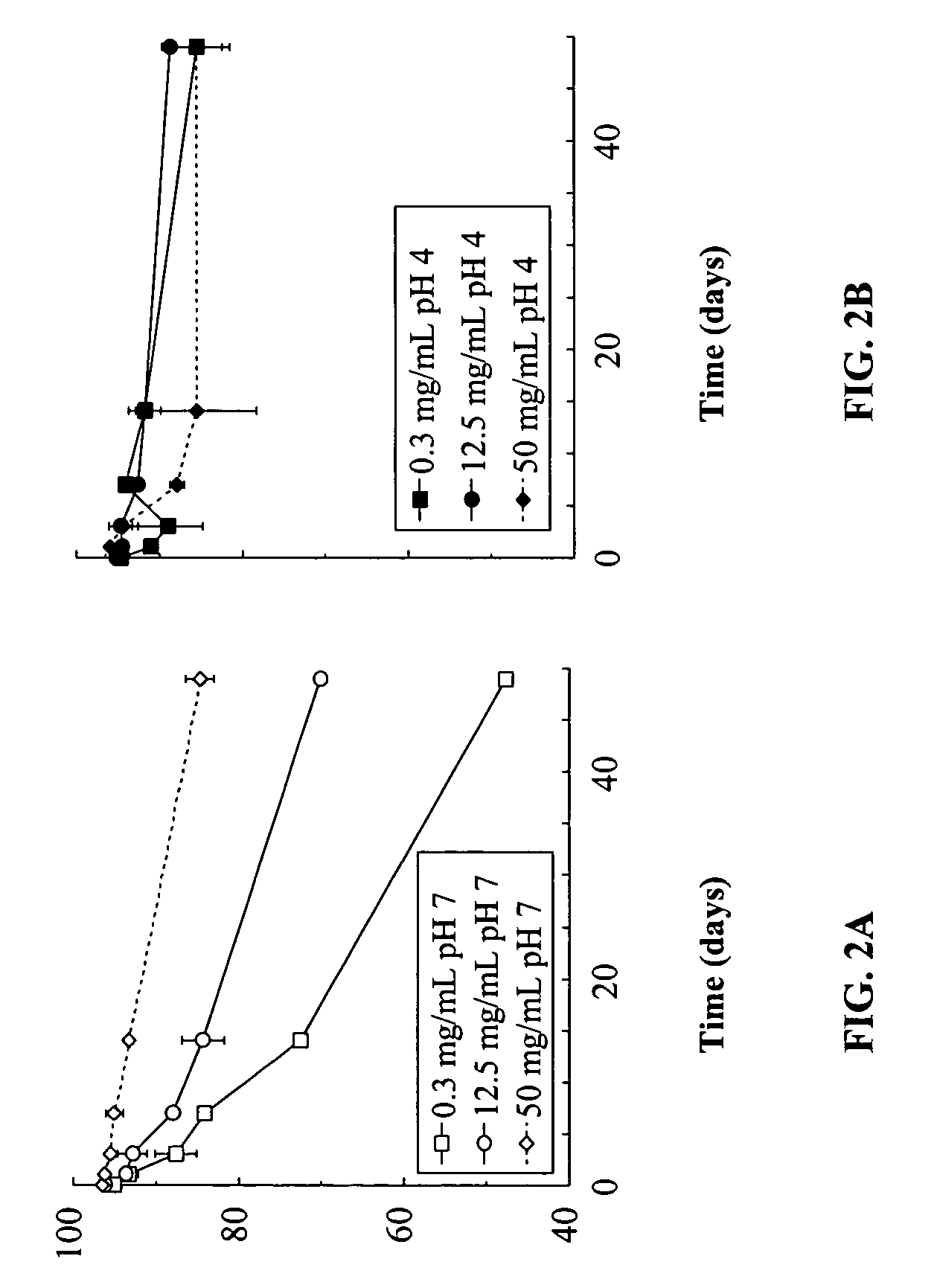

Microencapsulation and sustained release of biologically active polypeptides

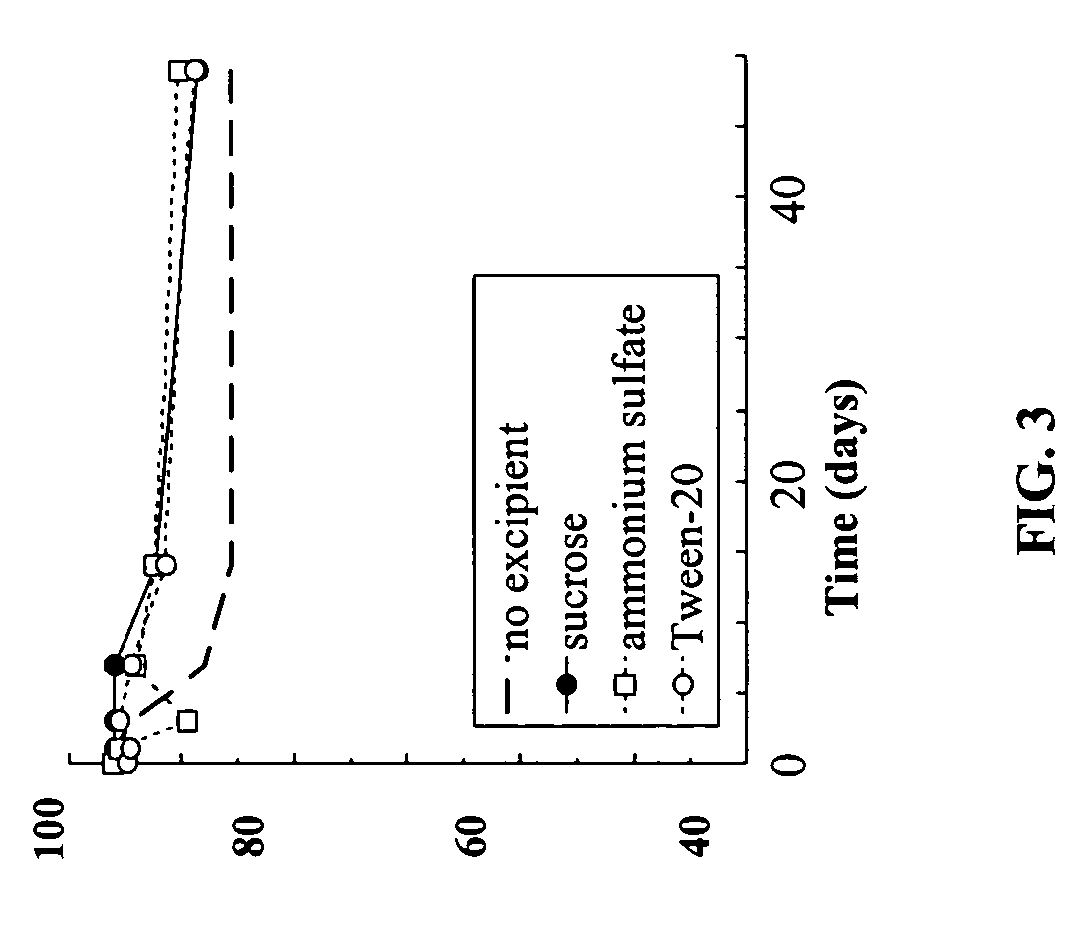

ActiveUS7164005B2Avoid a lot of problemsIncrease acceptancePowder deliveryOrganic active ingredientsMedicineSugar

This invention relates to compositions for the sustained release of biologically active polypeptides, and methods of forming and using said compositions, for the sustained release of biologically active polypeptides. The sustained release compositions of this invention comprise a biocompatible polymer having dispersed therein, a biologically active polypeptide, a sugar and a salting-out salt.

Owner:ALKERMES PHARMA IRELAND LTD

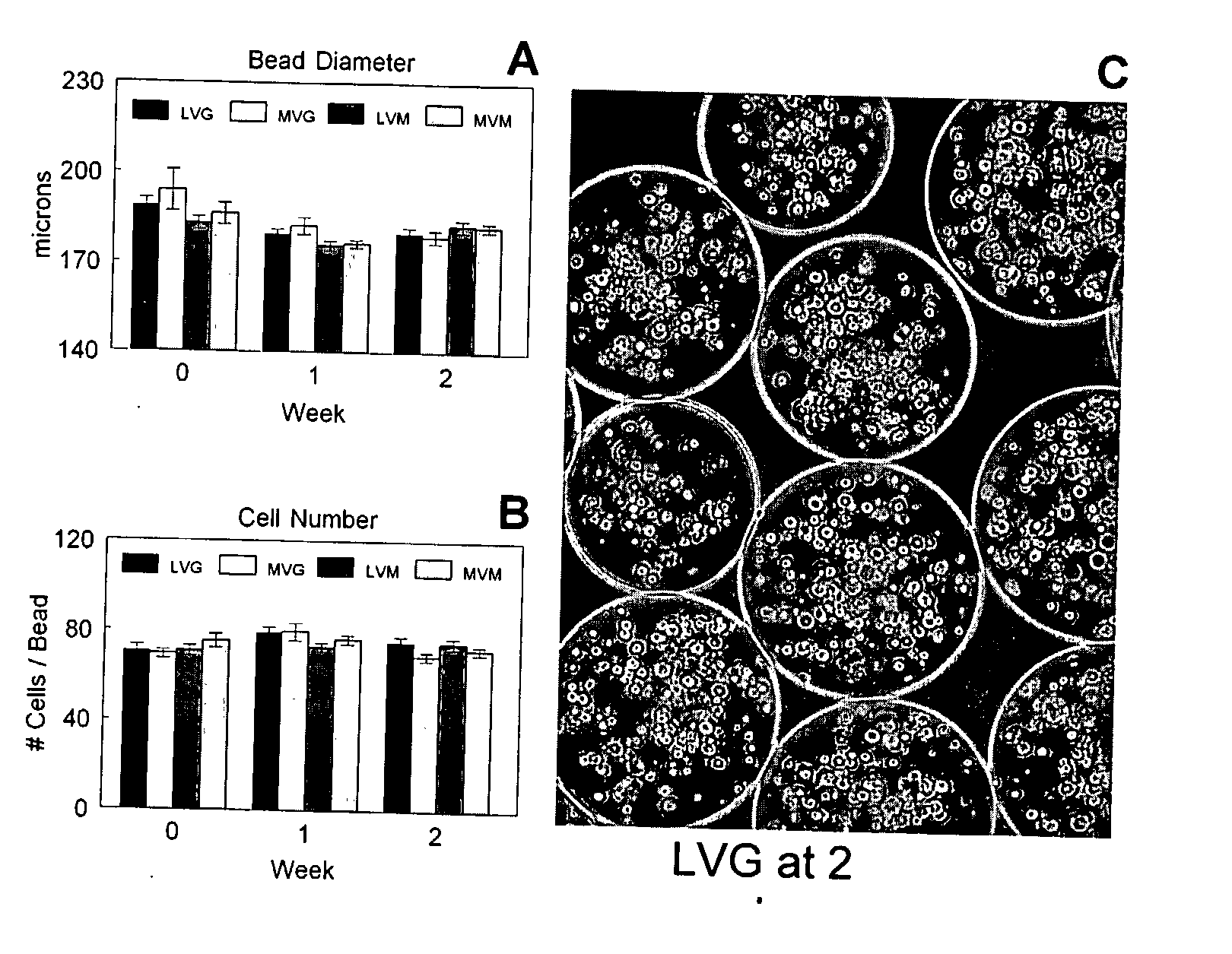

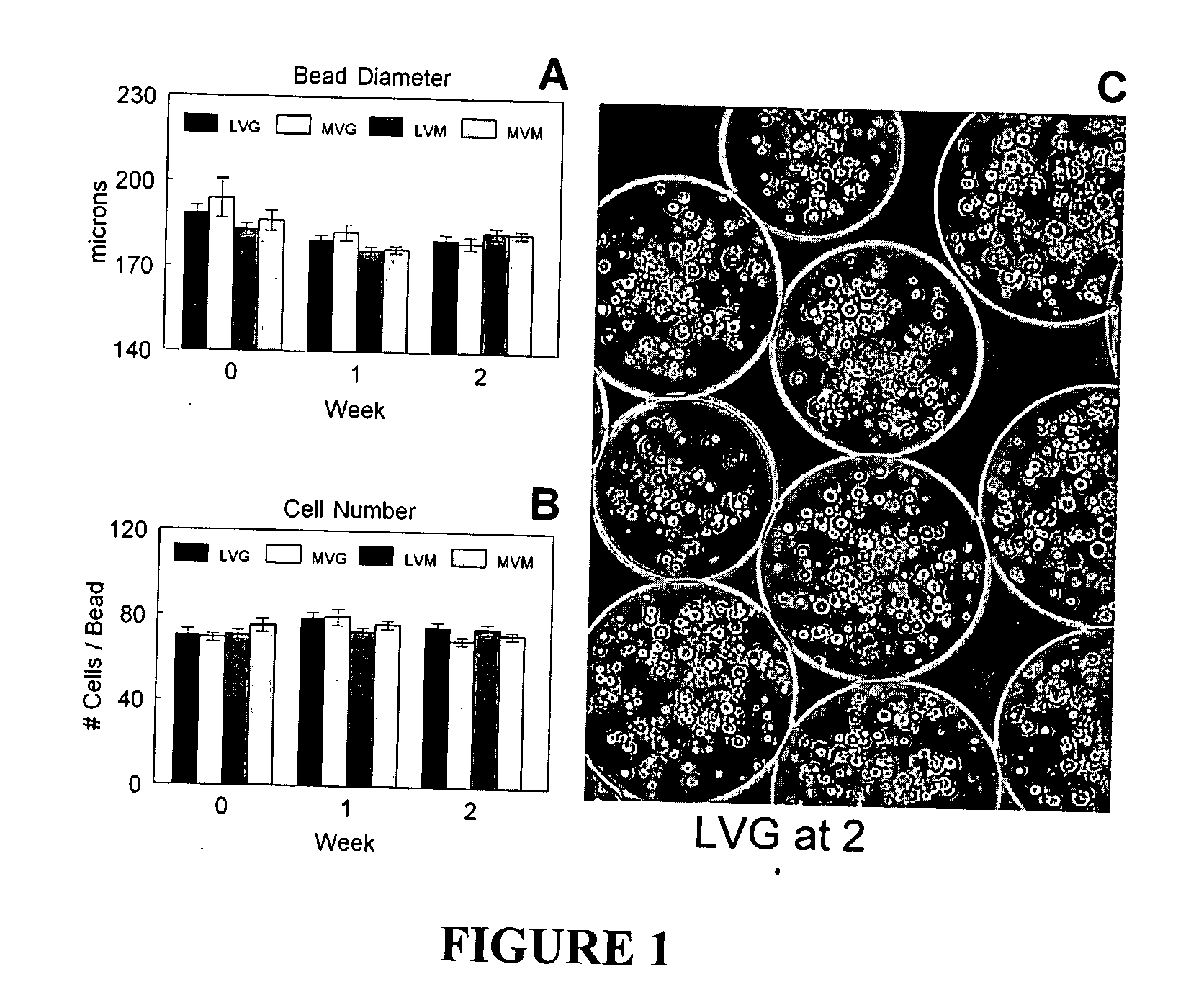

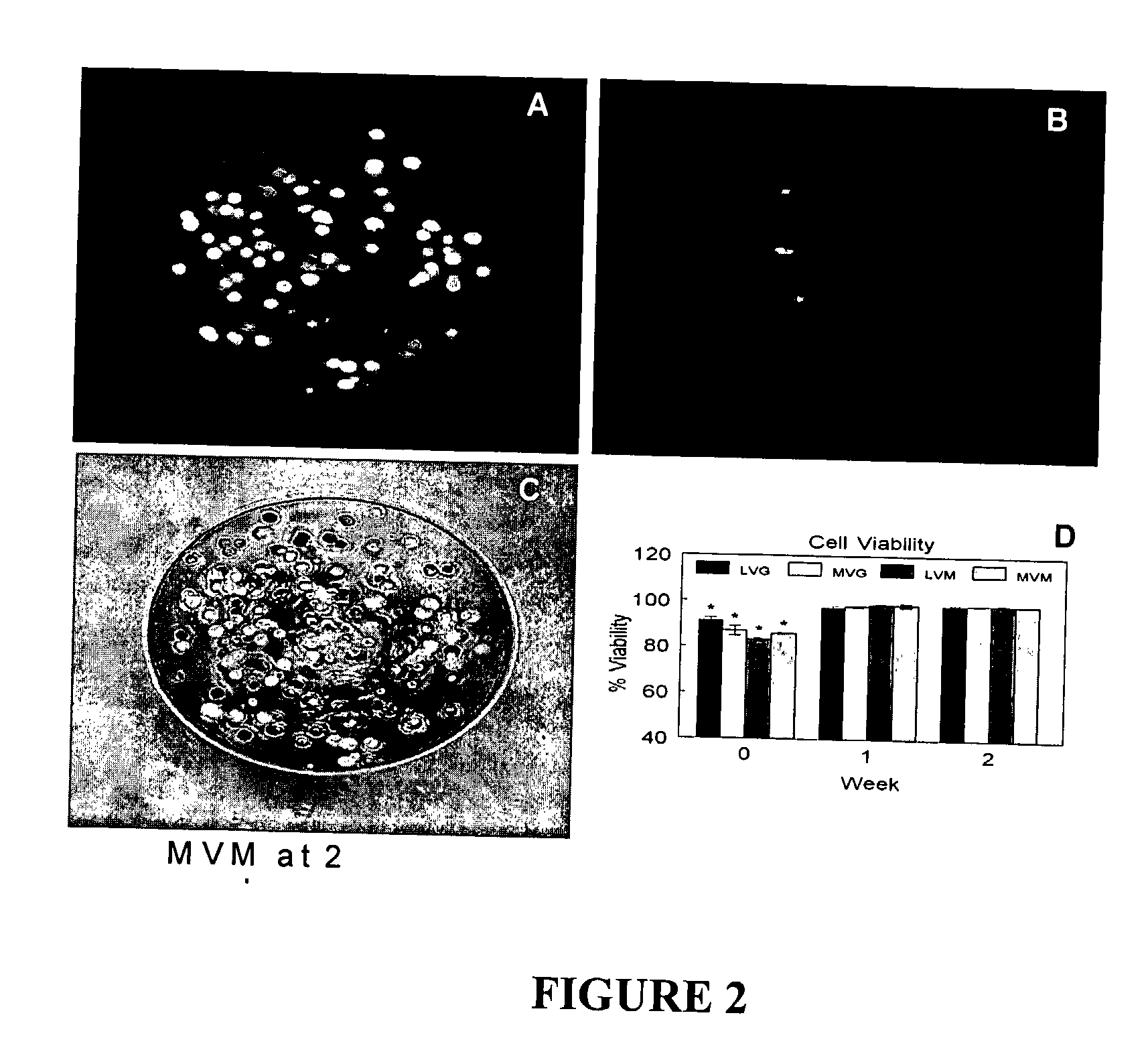

Microencapsulation of Cells in Hydrogels Using Electrostatic Potentials

Compositions and methods for producing encapsulated cells having an average diameter of less than about 200 μm are provided. Methods for using the disclosed encapsulated cells are also provided

Owner:GEORGIA TECH RES CORP

Encapsulation of oxidatively unstable compounds

InactiveUS20110052680A1Improve Oxidation StabilityDry powder formImmobilised enzymesOrganic active ingredientsPhospholipidPhytosterol

An encapsulated material containing an oxidation-sensitive core is covered by at least a dried phospholipid layer, and contains at least one phytosterol in the core, the phospholipid layer or in a further layer or layers. By using microencapsulation, oxidatively unstable materials may be provided with a synthetic protective barrier and rendered less susceptible to oxidative degradation.

Owner:AVEKA INC

Method for preparing artificial graphite cathode material of lithium ion battery

ActiveCN1691374AEasy to implementGood coating effectElectrode manufacturing processesNon-aqueous electrolyte accumulatorsGraphiteSodium-ion battery

The invention discloses a making method for lithium ion battery negative materials, comprising the steps of: (1) mixing the black lead, clad material and solvent, evacuating, stripping solvent and cladding the natural black lead in the clad materials; (2) polymerizing the materials and the surface of the natural black lead will get the microencapsulation cladding layer; (3) charring or charring the products of step (2) to get the carbon negative materials with the artificial black lead layer coated on the surface, this is the lithium ion battery negative materials. The detecting results of the battery negative materials are: tap density is more than 1.02, specific surface area is lese than 2.0, the first discharging capacity is more than 350mAh / g (non-reversible capacity is less than 25mAh / g), the first charging efficiency is more than 93%, after circulating 460 times, the rest first capacity is more than 90%.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

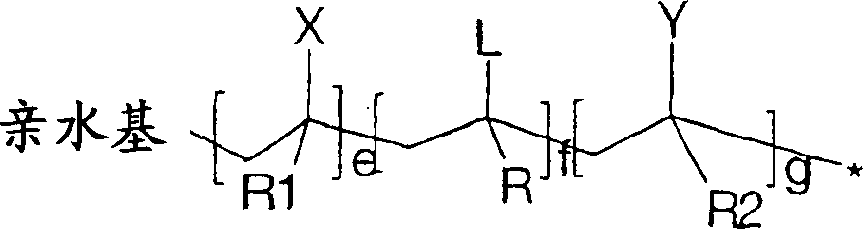

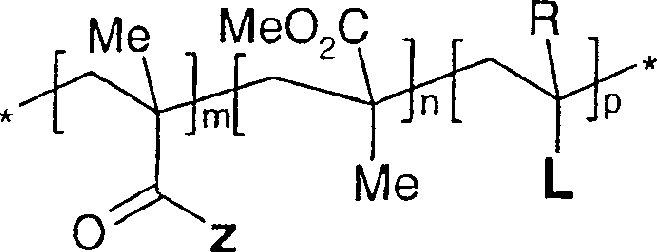

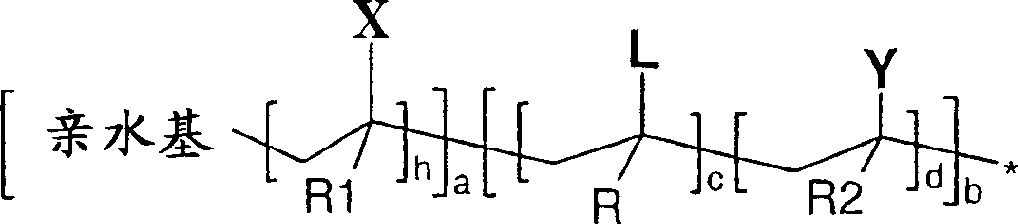

Use of reactive polymeric surfactants in formation of emulsions

Reactive polymeric surfactants are disclosed, and their use in processes for preparation of microcapsules, and in stabilising emulsions. The surfactants are random graft polymers or block copolymers which contain both hydrophobic and hydrophilic units and in which the hydrophobic unit includes a hydrophilic cross-linking unit which reacts with (a) a wall forming ingredient in a microencapsulation process, or (b) an ingredient in the disperse phase of an emulsion.

Owner:SYNGENTA LTD

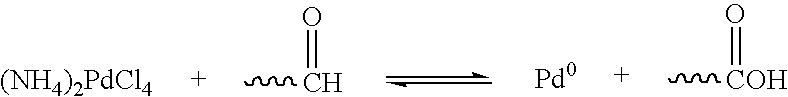

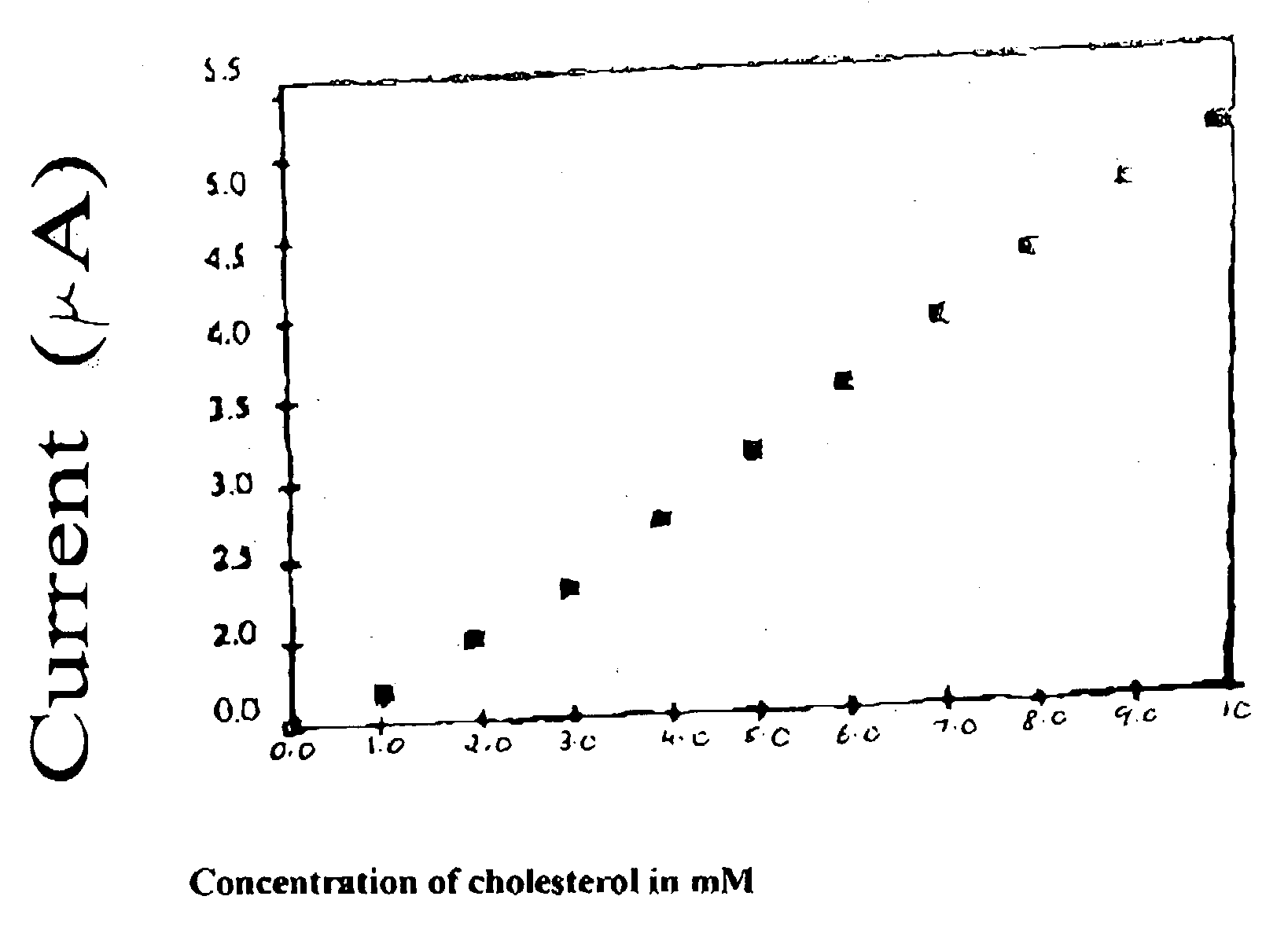

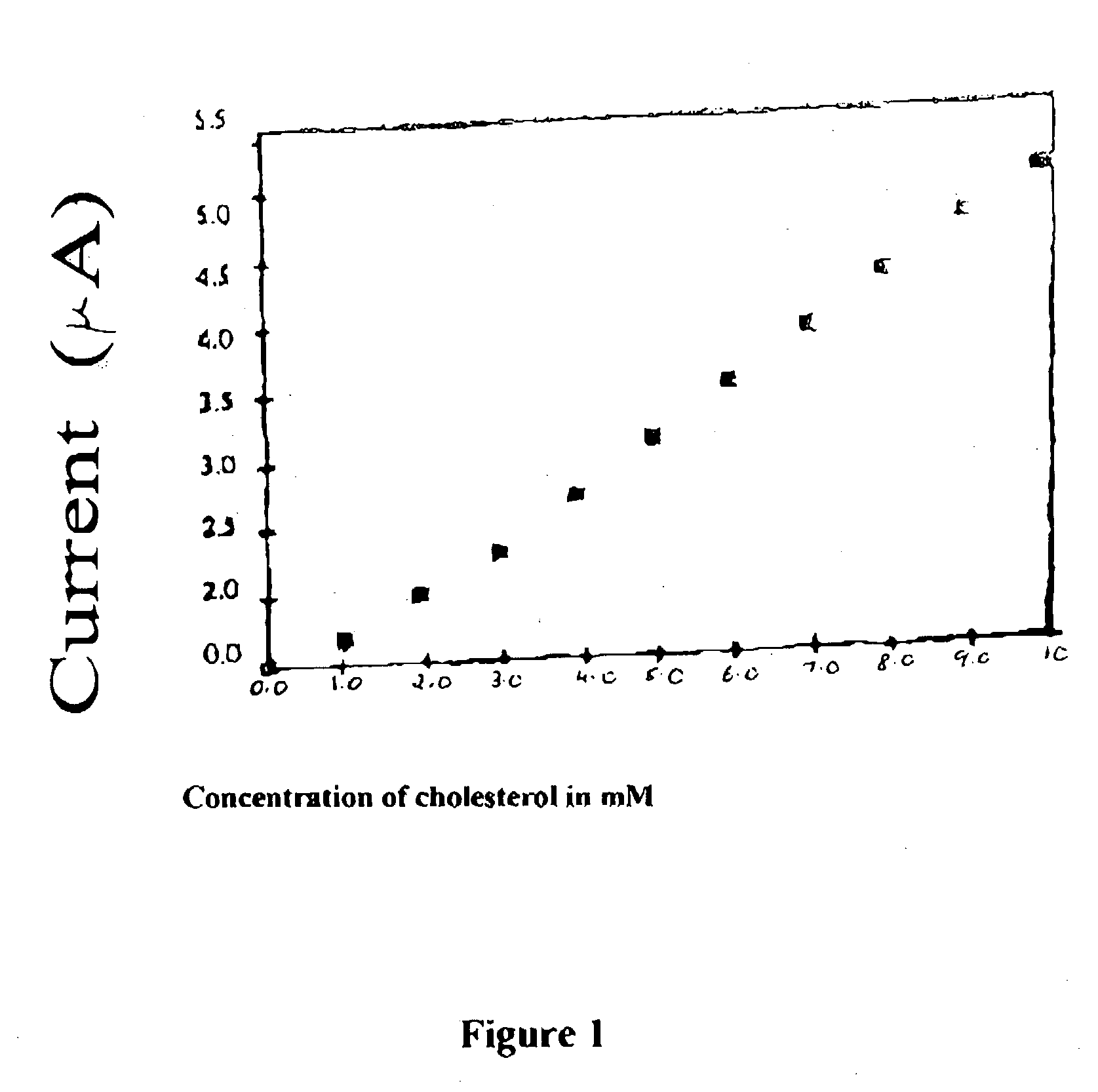

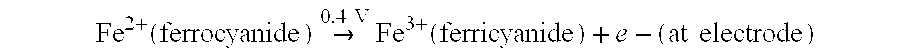

Enzyme electrode and process for preparation thereof

ActiveUS20040149577A1Accurate measurementShort timeImmobilised enzymesBioreactor/fermenter combinationsEnzyme ElectrodesPhysical chemistry

The present invention relates to an enzyme electrode useful for estimation of cholesterol in aqueous medium, said electrode comprising: i. an electrically conductive base plate, ii. a film of sol gel derived material deposited thereon, said sol gel derived material of step b) being microencapsulated cholesterol oxidase with an electron mediator. The present invention also relates to a process for the preparation of an enzyme electrode by coating an immobilized cholesterol oxidase (ChOx) and mediator on a silicate sol gel by microencapsulation.

Owner:KUMAR ARUN +2

Vitamin powder and preparation method thereof

ActiveCN102716087AHigh mechanical strengthGood dispersionPowder deliveryHydroxy compound active ingredientsEmbedding rateAntioxidant

The invention mainly discloses vitamin powder and a preparation method of the vitamin powder. The vitamin comprises the following components in mass percentage: 5-60% of fat soluble vitamin, 30-70% of wall material, 5-30% of assistant wall material, 0.5-2% of emulsifier, 0.1-2% of antioxidant and 0.1-3% of cross linking agent. The invention further relates to a preparation method of the vitamin powder. By using a microencapsulation technique, the fat soluble vitamin oil (e.g. vitamin A, vitamin D3, vitamin E and vitamin K) is embedded to a micro-capsule, the wall material used in the embeeding process is starch sodium octenylsuccinate, the vitamin oil is embeeded in the wall and then the micro-capsule is subjected to cross linkage, mist spraying and drying are carried out to form the vitamin powder, and the embedding rate of the vitamin is more than 95.3%. According to the invention, the process is simple, the cost is low, the obtained vitamin powder is not soluble in water, high in oil loading amount and good in flowability, and can be used in the fields such as foods, daily-used industrial chemicals and medicines.

Owner:ZHEJIANG ZHONGTONG TECH

Water-in-oil microencapsulation process and microcapsules produced thereby

A suspension of microcapsules in an organic liquid, the microcapsules containing an aqueous phase, is produced by interfacial polymerization in the presence of a proton transfer catalyst of a water-in-oil emulsion in which the aqueous phase contains a urea / formaldehyde or melamine / formaldehyde prepolymer.

Owner:ZENECA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com