Patents

Literature

435 results about "Miniemulsion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A miniemulsion (also known as nanoemulsion) is a special case of emulsion. A miniemulsion is obtained by shearing a mixture comprising two immiscible liquid phases (for example, oil and water), one or more surfactants and, possibly, one or more co-surfactants (typical examples are hexadecane or cetyl alcohol).

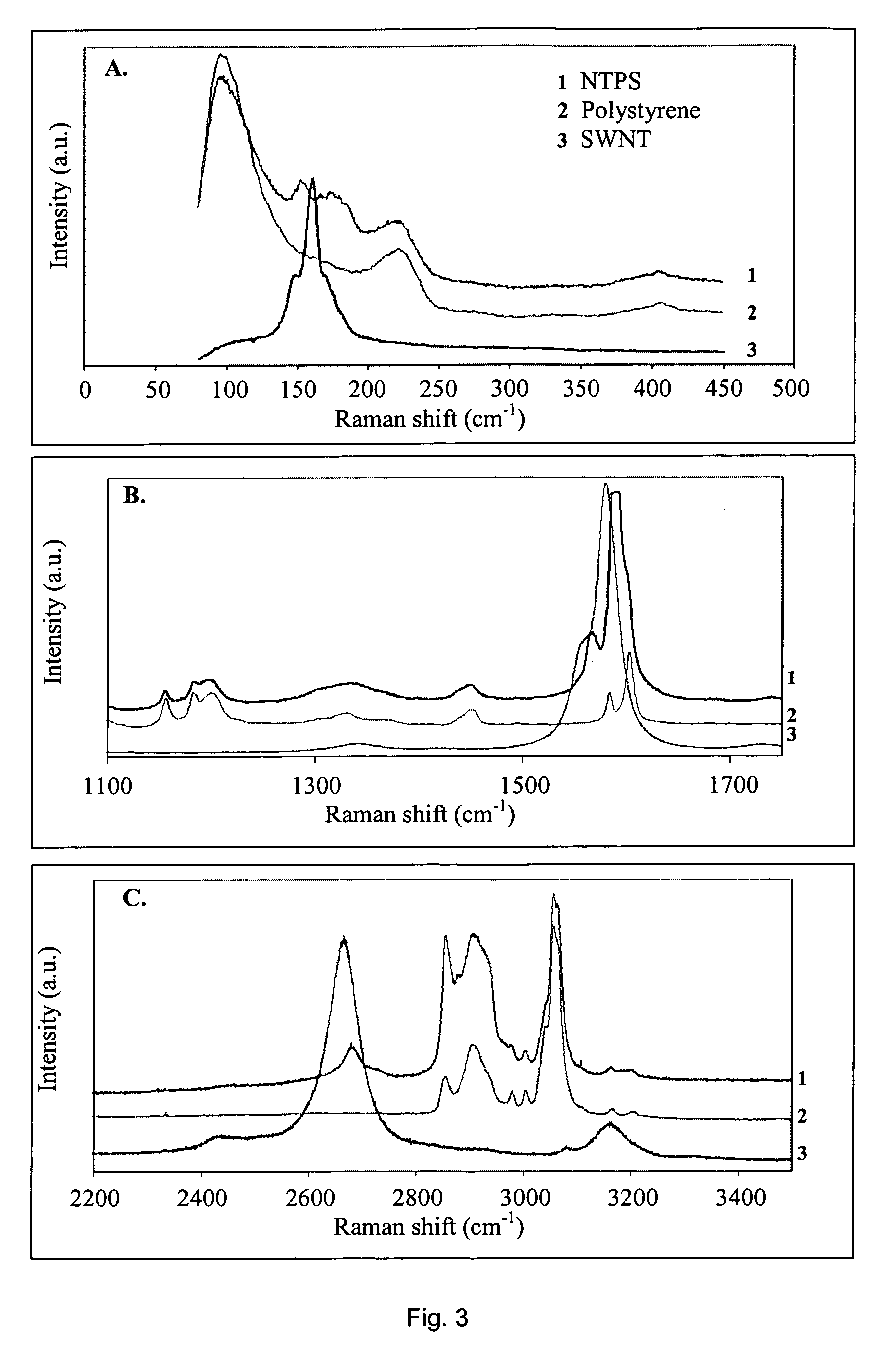

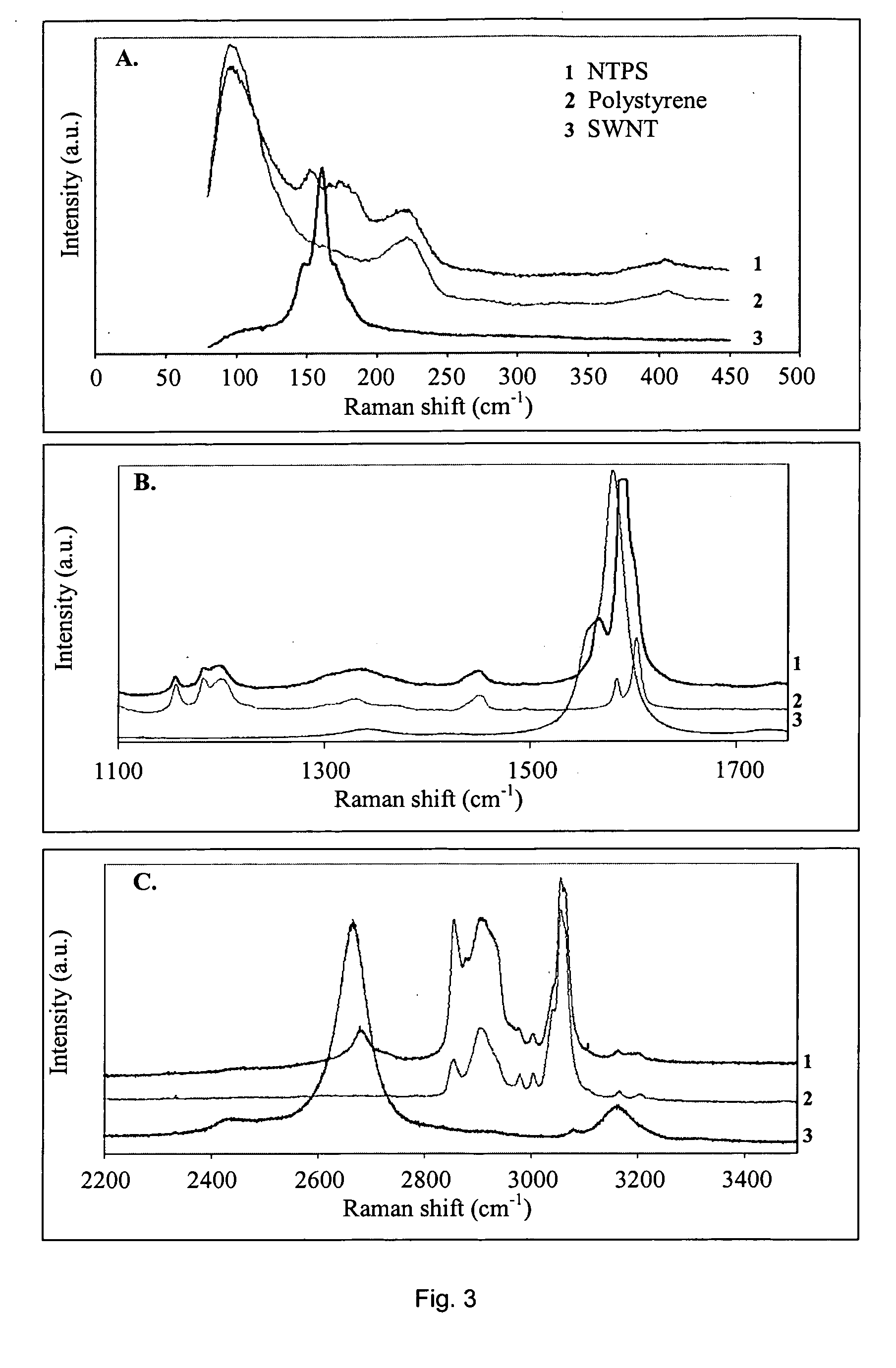

Carbon nanotube-filled composites prepared by in-situ polymerization

ActiveUS7153903B1Material nanotechnologyIndividual molecule manipulationIn situ polymerizationCarbon nanotube

A method of forming carbon nanotube-filled composites using miniemulsion polymerization. The carbon nanotubes are preferably single-walled carbon nanotubes. The carbon nanotubes are highly dispersed within and associated with the polymer comprising the composite.

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA

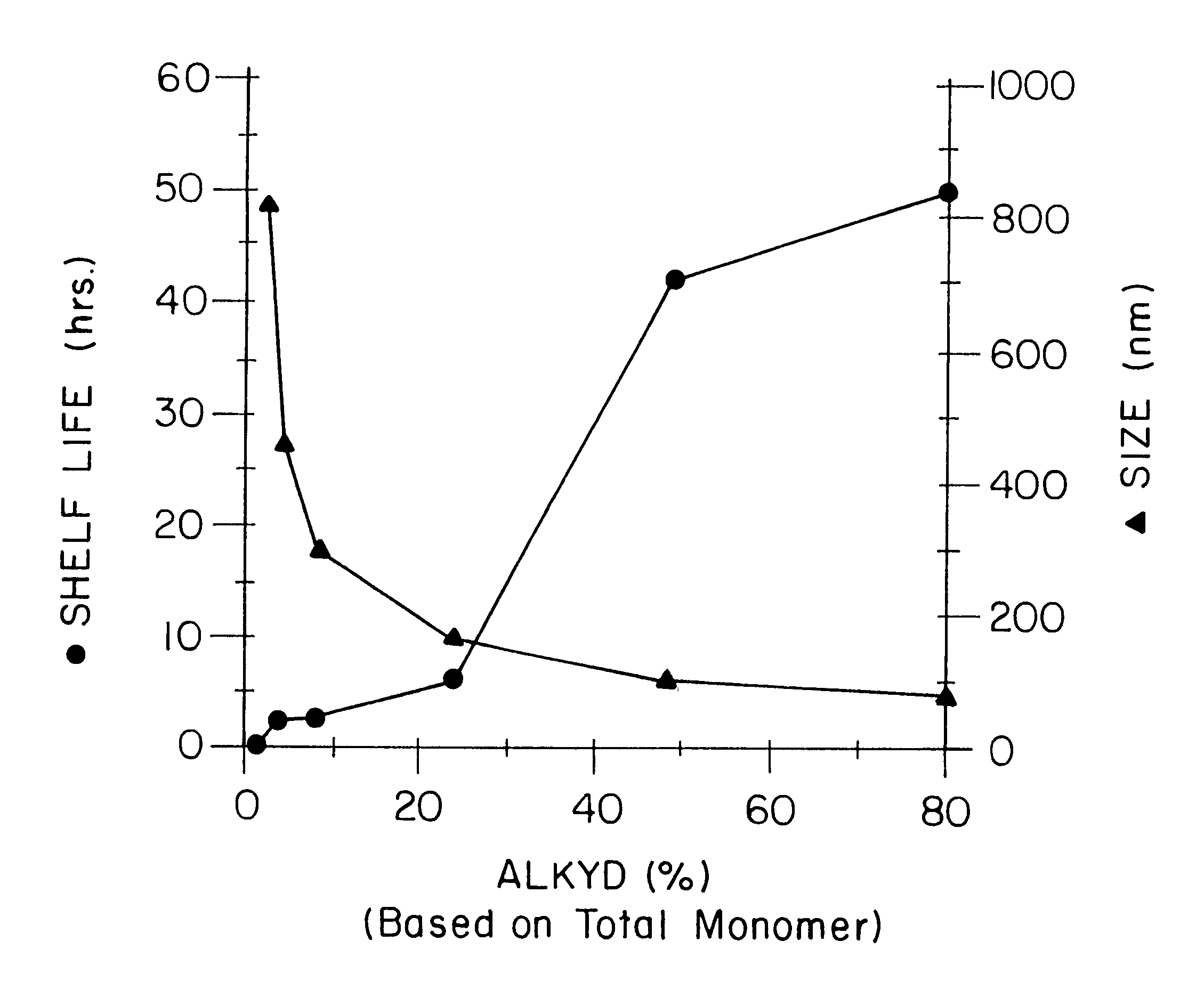

Water-borne alkyd coatings by miniemulsion polymerization

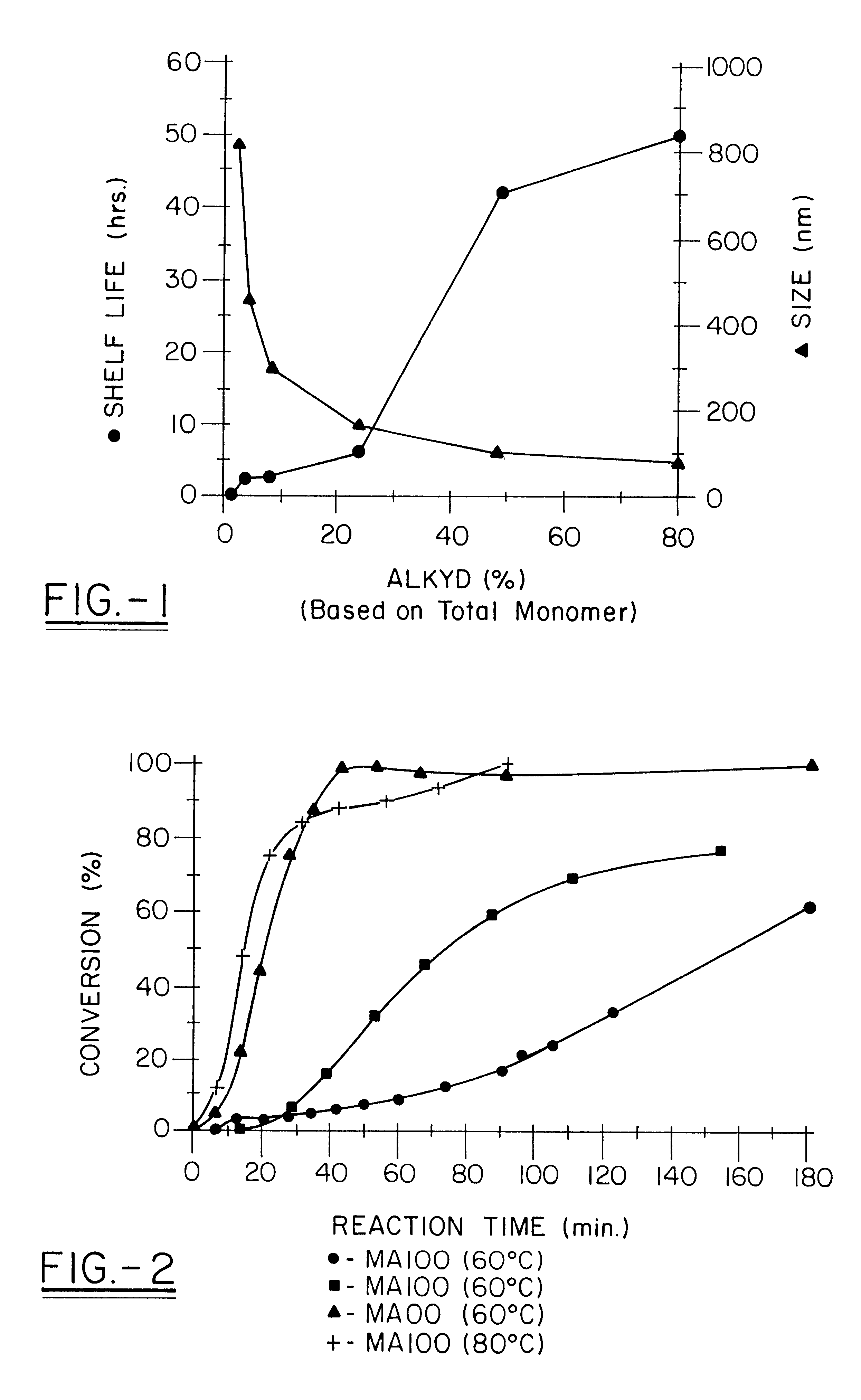

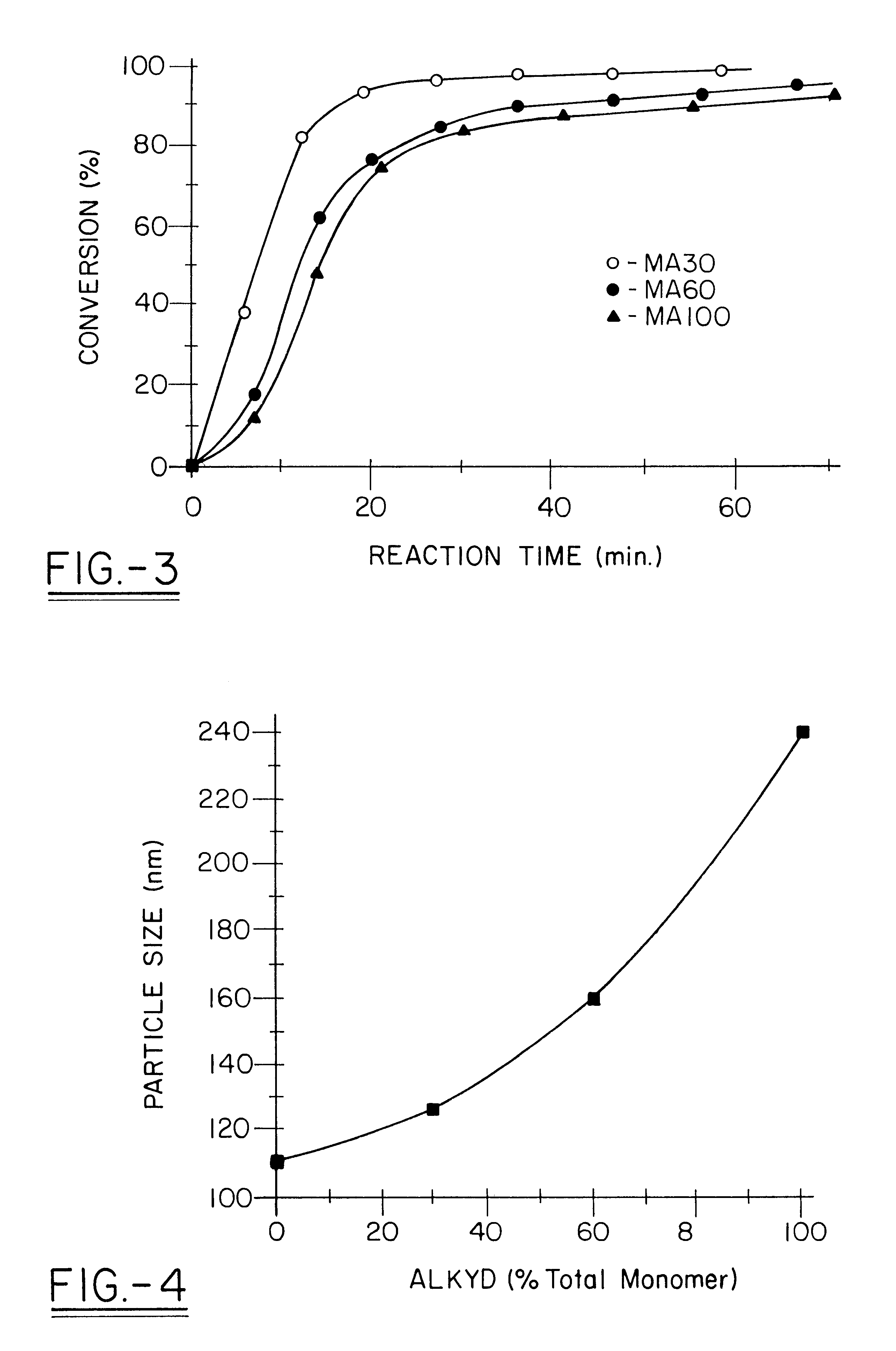

A distinctive graft copolymer is made by dissolving an alkyd resin in various vinyl monomers (methyl methacrylate, styrene, etc.). The monomer / alkyd solution is then miniemulsion polymerized to form a latex consisting of submicron particles of polymer with the alkyd grafted onto the polymer backbone. The latex can be applied to a substrate, which on drying forms a polymeric film with good film properties. The latex can be used in a latex paint formulation in place of an acrylate, acetate or styrene-divinyl benzene latex. In this way it is possible to produce water-borne alkyd coatings which combine the film hardness properties of an oil-based alkyd coating with easy application and cleanup. The coating will beneficially lack organic solvent exposure of typical standard latex coatings.

Owner:GEORGIA TECH RES CORP

Miniemulsion techniques for ink jet inks

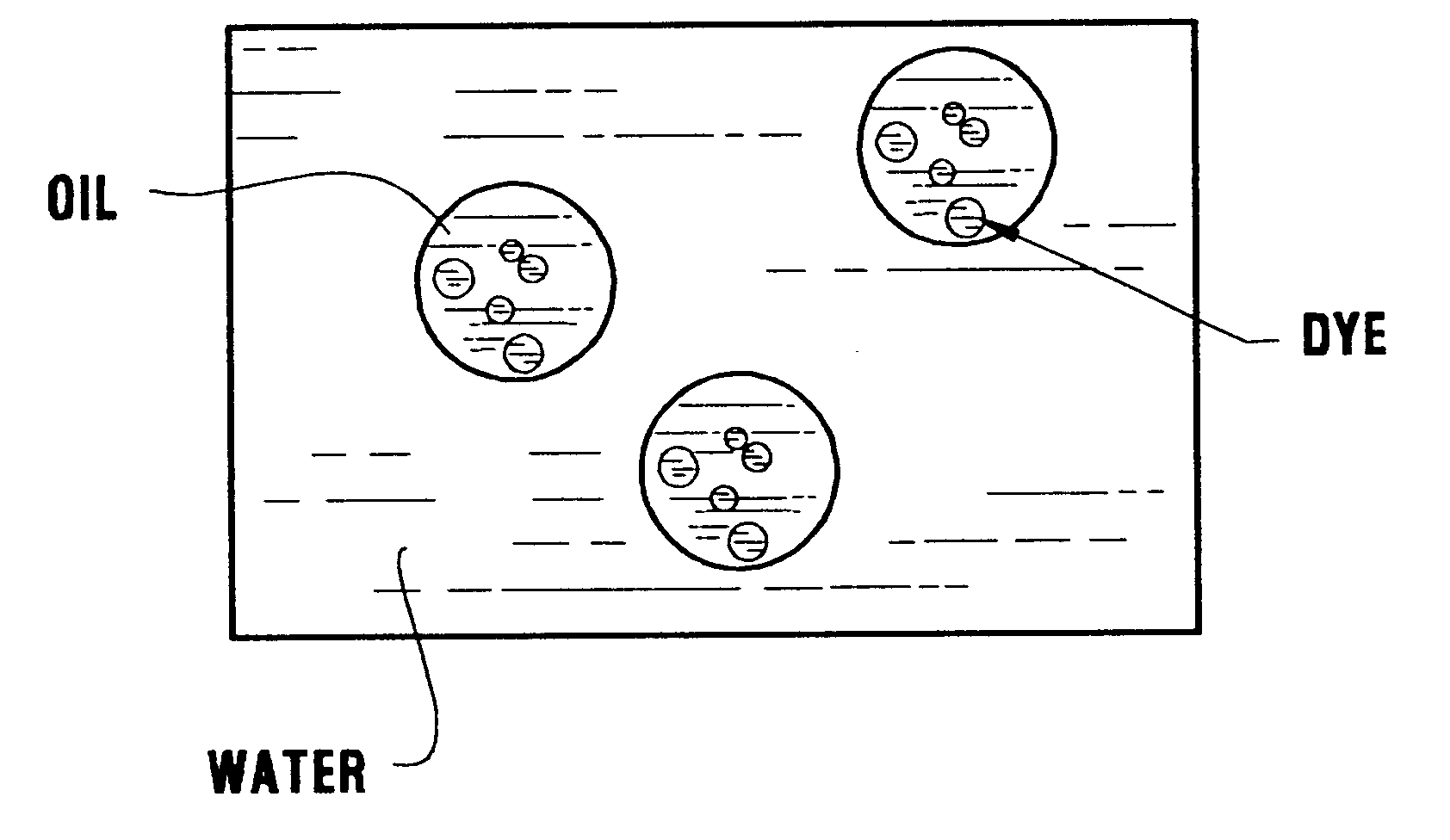

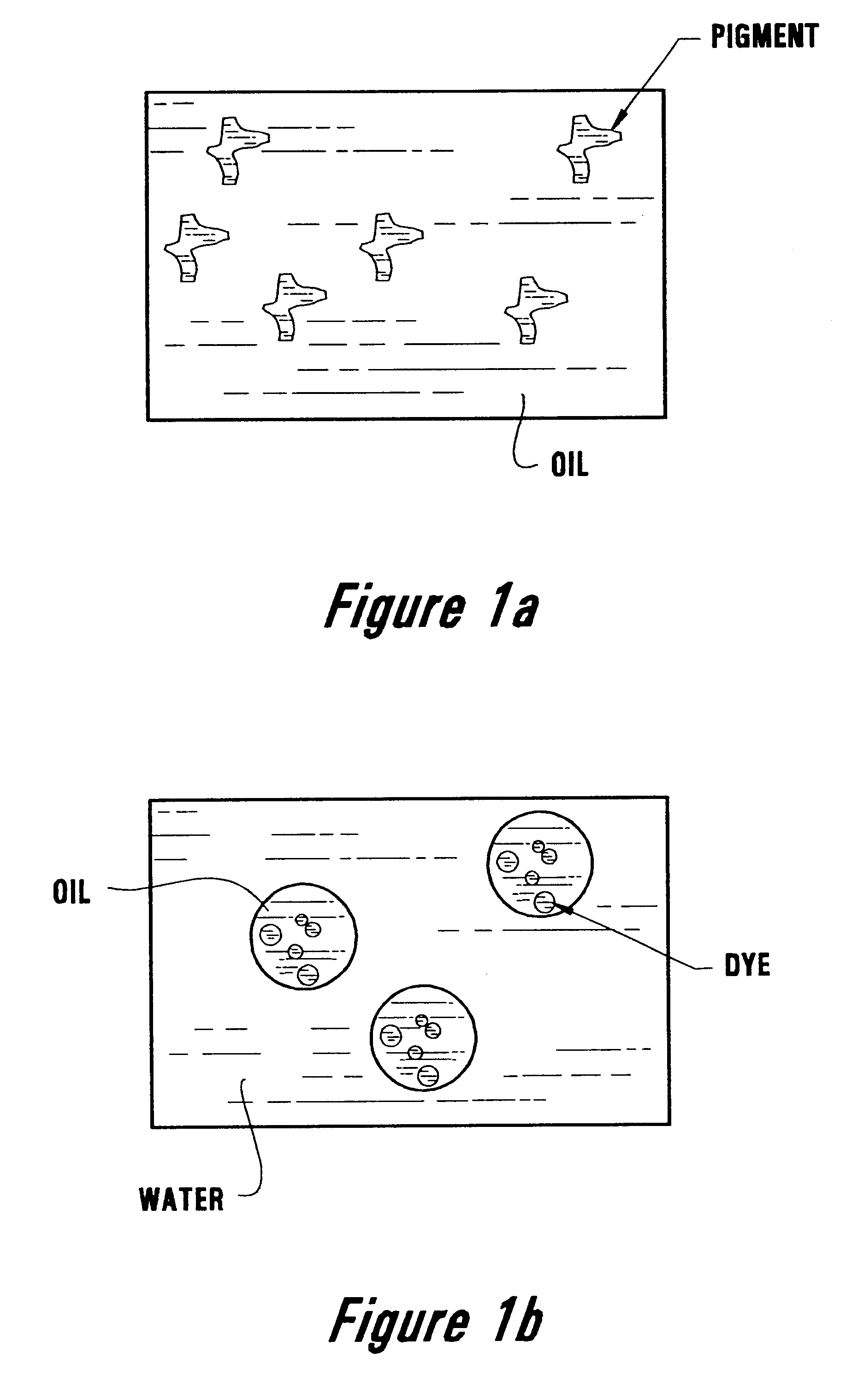

Water-based ink-jet ink compositions and a method of making them, the compositions being miniemulsions, i.e., an aqueous vehicle containing oil particles with dissolved dye molecules, the oil particles having a diameter below 1 mum.

Owner:HEWLETT PACKARD DEV CO LP

Method for preparing microcapsule by miniemulsion polymerization

InactiveUS20060281834A1Improve stabilityLow viscosityCoatingsMicroballoon preparationPolymer scienceSingle-core

Provided is a method for preparing uniformly sized and shaped, mono-dispersed microcapsules using miniemulsion polymerization. In microcapsules prepared by the method, a liquid or solid core encapsulated by a polymer shell has 10 to 80% by volume of the microcapsules. Since miniemulsion particles produced at an early stage of the method are stable, an organic material which is well dissolved in monomer particles and has a higher interfacial tension with water, relative to the polymer shell, can be uniformly positioned in polymer particles. Furthermore, when a crosslinking agent is added during the polymerization, single-core microcapsules can be obtained. In addition, use of an oil-soluble initiator can prevent formation of secondary particles and addition of a secondary initiator during the polymerization can increase the yield of the uniformly sized and shaped microcapsules.

Owner:LG CHEM LTD

Preparation method of sustained-release water reducer microcapsule

ActiveCN102351459AImprove stabilityIncrease concentrationMicroballoon preparationMicrocapsule preparationWater reducerMaterials science

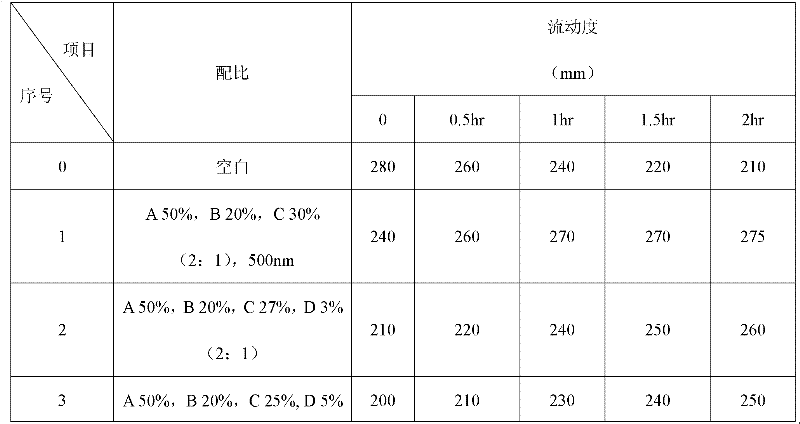

The invention discloses a preparation method of a sustained-release water reducer microcapsules which belong to the technical field of building material additives. By miniemulsion inverse phase polymerization, common water reducer molecules undergo microencapsulation and the water reducer microcapsules which have a pH response function are synthesized. After polymerization is finished, the microcapsules are in an acidic condition. due to the existence of capsule shells, the water reducer molecules can stably stay in the microcapsules. After the microcapsules are mixed with cement, cement concrete is strongly alkaline and the microcapsules perform a response-stimulus behavior under a high pH condition. Large molecular chains of the capsule shells rapidly expand and extend so as to generatethe swelling phenomenon. The compact shell layer becomes loose, and the cladded water reducer molecules slowly release such that the concentration of the water reducer is always high in the cement concrete. Therefore, the fluidity etentivity with time of the water reducer can be raised, and the collapsed slump loss of cement concrete in practical engineering usage can be prevented.

Owner:哈尔滨强石新材料技术开发股份有限公司

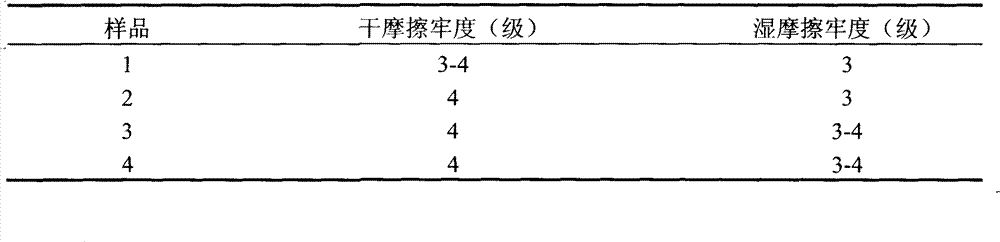

High-color-fastness inkjet printing pigment ink and preparation method thereof

ActiveCN104194494AImprove dispersion stabilityImprove rubbing fastnessInksDyeing processTextile printerPolymer science

The invention discloses high-color-fastness inkjet printing pigment ink, which is characterized by comprising superfine coating pigment color paste, a water-soluble cosolvent, a cross-linking agent, a surfactant, a defoaming agent, a bactericide agent, a pH regulator and water, wherein the superfine coating pigment color paste comprises a polymerizable dispersing agent, a pH regulator, a pigment, a monomer, a water-soluble initiator and water. The surface of pigment particles is coated with a polymer through fine emulsion polymerization, so that the dispersion stability of the pigment particles can be improved, and reaction groups capable of bonding with the crosslinking agent can be provided; when the prepared ink is inkjet-printed onto textiles and roasted for fixation, the cross-linking agent and the polymer on the pigment surface are formed into a continuous, compact and smooth printing film on the surfaces of the textiles, so that the rubbing fastness of the inkjet printing ink can be improved, and the hand feeling of the printed textiles can be improved to certain extent.

Owner:JIANGSU GEMEIGAO DEV CO LTD

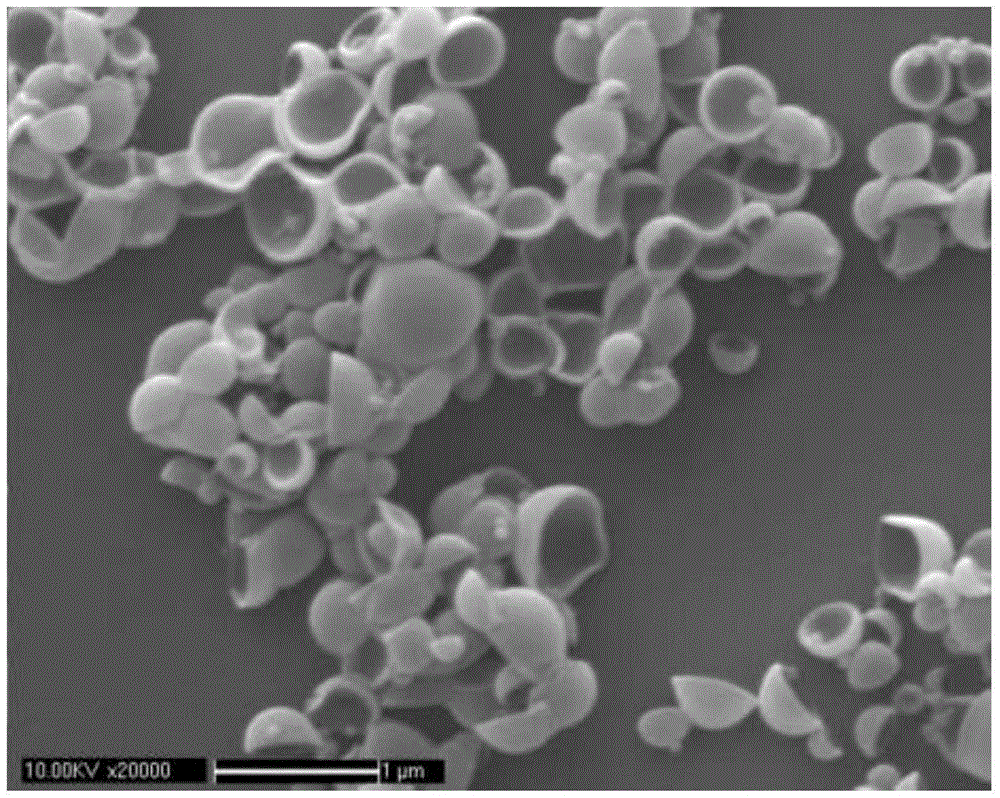

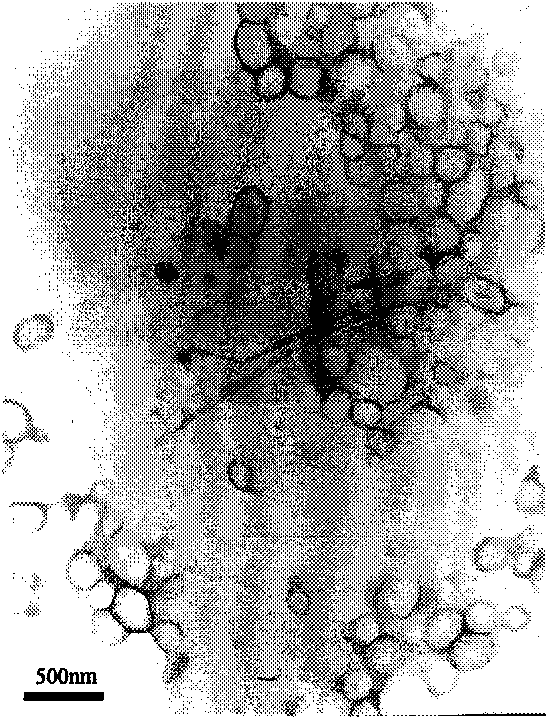

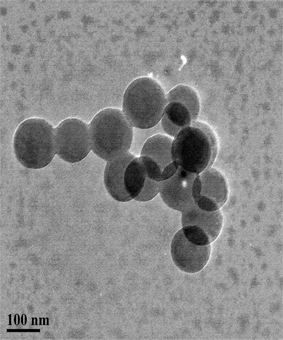

Preparation method for mesoporous silicon oxide hollow microspheres with magnetic nanoparticles embedded in shell layers

ActiveCN102500296AAdjustable sizeAdjust wall thicknessInorganic material magnetismSilicon oxidesPtru catalystSilicic acid

The invention relates to a preparation method for mesoporous silicon oxide hollow microspheres with magnetic nanoparticles embedded in shell layers. In the invention, the magnetic nanoparticles are prepared by using a coprecipitation method, are subjected to oleic acid surface modification and then are dispersed in normal octane; an oil phase constructed by styrene monomer, cetane, normal octane dispersion of the magnetic nanoparticles, alkoxysilane and a silane coupling agent is mixed with a water phase which dissolves a surfactant; a fine emulsion liquid droplet system is obtained through pre-emulsification and fine emulsification processes; controlling formation of silicon oxide and phase separation of organic and inorganic components in the system to obtain a template with a nested structure during free radial polymerization of the liquid droplets by adding a base catalyst; based on the template, generating a raw material by taking long-chain alkyl silane coupling agent and alkoxysilane as mesoporous silicon oxide; performing one-step ablation to remove an inner core of a polymer and a pore forming agent; or by taking a cationic surfactant as the pore forming agent, removing the pore forming agent and the inner core of the polymer through a solvent dissolving method and obtaining the magnetic / mesoporous silicon oxide hollow composite microspheres. The composite microspheres have large specific surface area and good magnetic operability and can be used for application fields of biomedicine, environment, water treatment and the like.

Owner:SUZHOU WIN BIO TECH CO LTD

Carbon nanotube-filled composites prepared by in-situ polymerization

ActiveUS20070004857A1Material nanotechnologyIndividual molecule manipulationIn situ polymerizationCarbon nanotube

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA

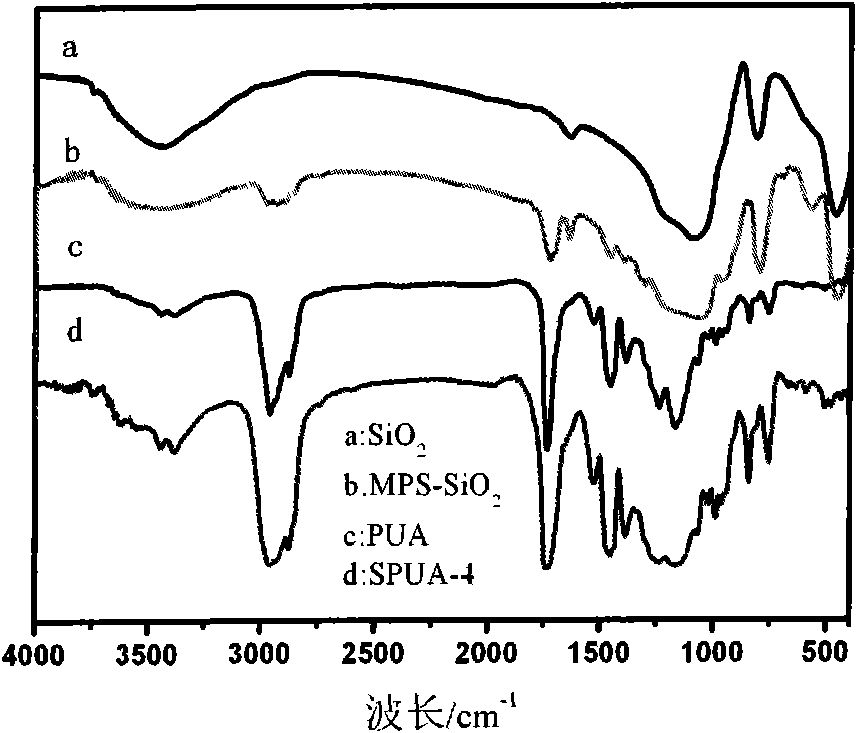

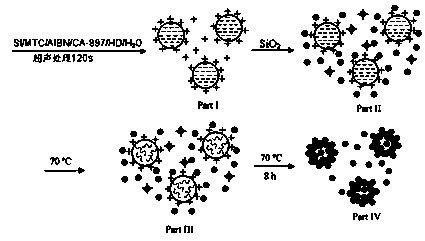

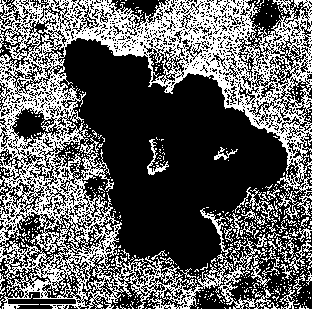

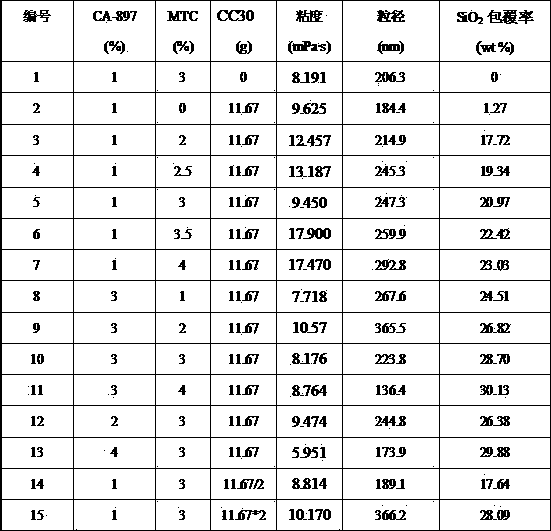

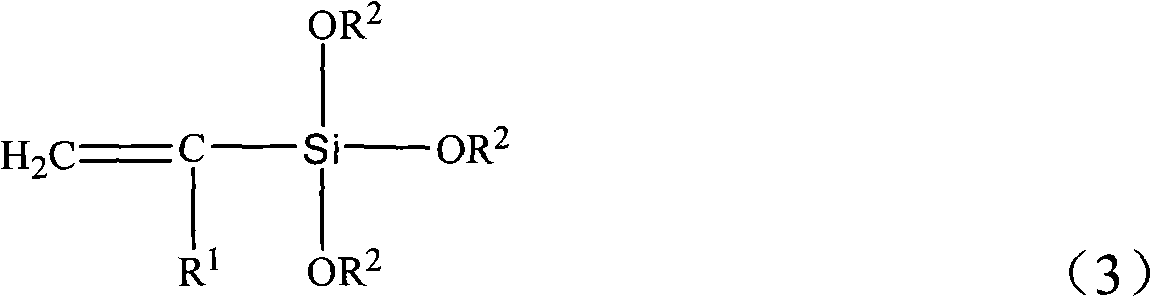

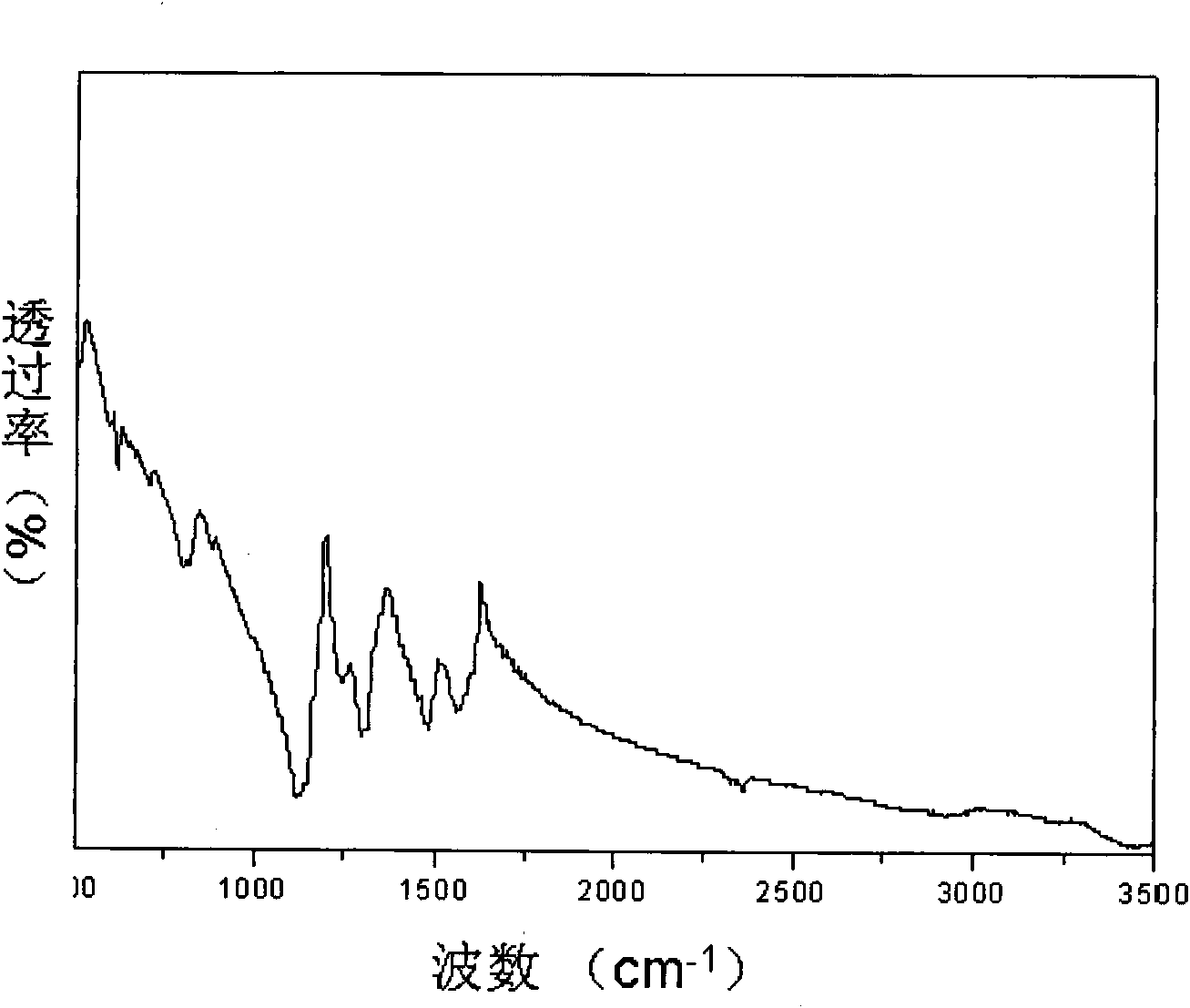

Method for preparing nano SiO2/polyurethane/acrylic ester composite emulsion and miniemulsion polymerization

InactiveCN102010486AGood dispersionHigh strengthPigment treatment with organosilicon compoundsPolymer scienceEmulsion

The invention relates to a method for preparing nano silicon dioxide (SiO2) / polyurethane / acrylic ester composite emulsion and miniemulsion polymerization. The method is characterized in that: the acrylic ester composite emulsion modified by the nano SiO2 and the polyurethane jointly is prepared by a miniemulsion polymerization method. According to the method, SiO2 is modified by using a silane coupling agent KH-570 under an alkaline condition, so that a hydrophilic surface of the composite emulsion is changed into a hydrophobic surface, and the dispersibility of the composite emulsion is improved greatly; stable nano SiO2 / polyurethane / acrylic ester composite emulsion can be prepared by a miniemulsion polymerization process; after the emulsion is formed into a film, the strength of a glue film is greatly improved, the glue film has soft handfeel, and the disadvantage that acrylic ester polymer is sticky in a hot state and is crisp in a cold state is overcome; and the decomposition mechanism of the composite emulsion is not changed.

Owner:ANHUI UNIVERSITY +1

Polymerization processes

InactiveUS6469094B1Cost efficientEasily controlled modalityFilm/foil adhesivesSpecial tyresOligomerPhotochemistry

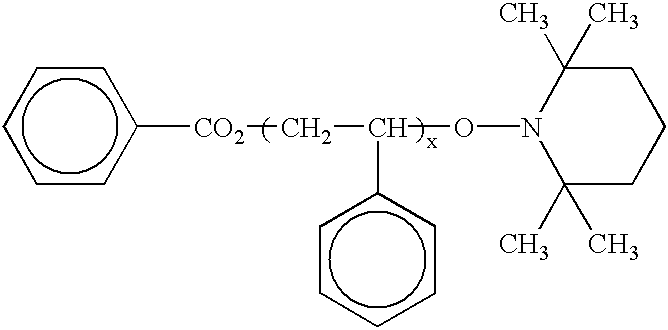

A process for latex preparation including:a first heating of a mixture of at least one free radical polymerizable monomer compound, a free radical initiator compound, and a stable free radical compound to form a latomer mixture with from about 1 to about 8 percent conversion of the monomer compound to an oligomeric compound of the formula I-R'-SFR, wherein R' is an oligomer comprised of from about 1 to about 30 monomer units, I- is a covalently bonded free radical initiator fragment arising from the free radical initiator compound, and -SFR is a covalently bound stable free radical group; dispersing the resulting latomer mixture in water with high shear to form a miniemulsion; and a second heating of the miniemulsion, wherein there results a high stability polymer particle latex which contains a polymer with a high monomer to polymer conversion of from about 98 to about 100 weight percent and a narrow polydispersity of from about 1.1 to about 2.0.

Owner:XEROX CORP

Method for production of polymer-encapsulated pigments

The invention relates to a method for production of an aqueous dispersion of polymer-encapsulated pigments, characterised in that (a) an aqueous pigment dispersion, containing at least one organic pigment (P), selected from the group of azo, isoindolinone, isoindoline, anthanthrone, thioindigo, thiazinindigo, triarylcarbonium, quinophthalone, anthraquinone, dioxazine, phthalocyanine, quinacridone, quinacridonquinone, indanthrone, perylene, perinone, pyranthrone, diketopyrrolopyrrole, isoviolanthrone and azomethine pigments, at least one detergent (T), and water is prepared, (b) a monomer miniemulsion, stabilised by a hydrophobic organic compound with a water solubility at 20 DEG C of at most 5x10<-5> g / l, is prepared from a polymerisable monomer (M) and at least one detergent (T) in water, (c) a monomer pigment emulsion is prepared, whereby the aqueous dispersion from (a) and the monomer miniemulsion from (b) are mixed and homogenised and (d) the pigment-containing monomer from (c) is polymerised in the presence of a polymerisation initiator and / or by heat, whereupon an encapsulation of the pigment with the polymer thus formed occurs.

Owner:CLARIANT PROD DEUT GMBH

Hydrophobic association crosslinked polymer coil and preparation method thereof

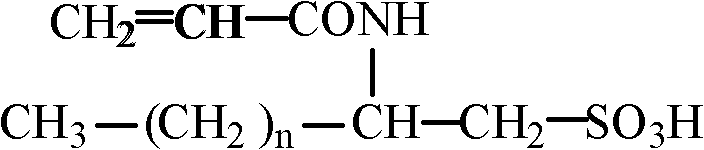

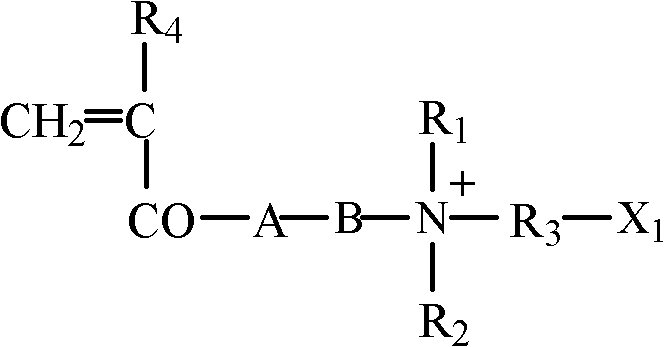

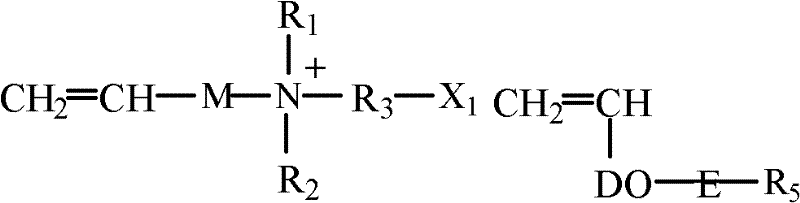

ActiveCN102304201AAdjust and Improve Heterogeneity EffectsEnhanced overall recoveryDrilling compositionOil phaseWater soluble

The invention provides a hydrophobic association crosslinked polymer coil and a preparation method thereof. The preparation method comprises the following steps of: (1) dissolving a surfactant and an oil-soluble initiator in base oil, and taking the base oil in which the surfactant and the oil-soluble initiator are dissolved as an oil phase; (2) dissolving hydrophobic monomer, water-soluble crosslinking monomer, conventional water-soluble monomer and a water-soluble initiator in water to obtain an aqueous solution with total mass percentage content of 20-70 percent, which serves as an aqueousphase; (3) mixing the aqueous phase in the step (2) and an oil phase in the step (1) for emulsification to obtain W / O type miniemulsion of which the dispersed phase is the aqueous phase and the continuous phase is the oil phase; and (4) introducing inert gas into the W / O type miniemulsion formed in the step (3) to initiate polymerization reaction to obtain the hydrophobic association crosslinked polymer coil in the W / O type miniemulsion. The hydrophobic association crosslinked polymer coil miniemulsion profile control agent aqueous solution system is particularly suitable for high permeability oil deposits.

Owner:CHINA NAT OFFSHORE OIL CORP +1

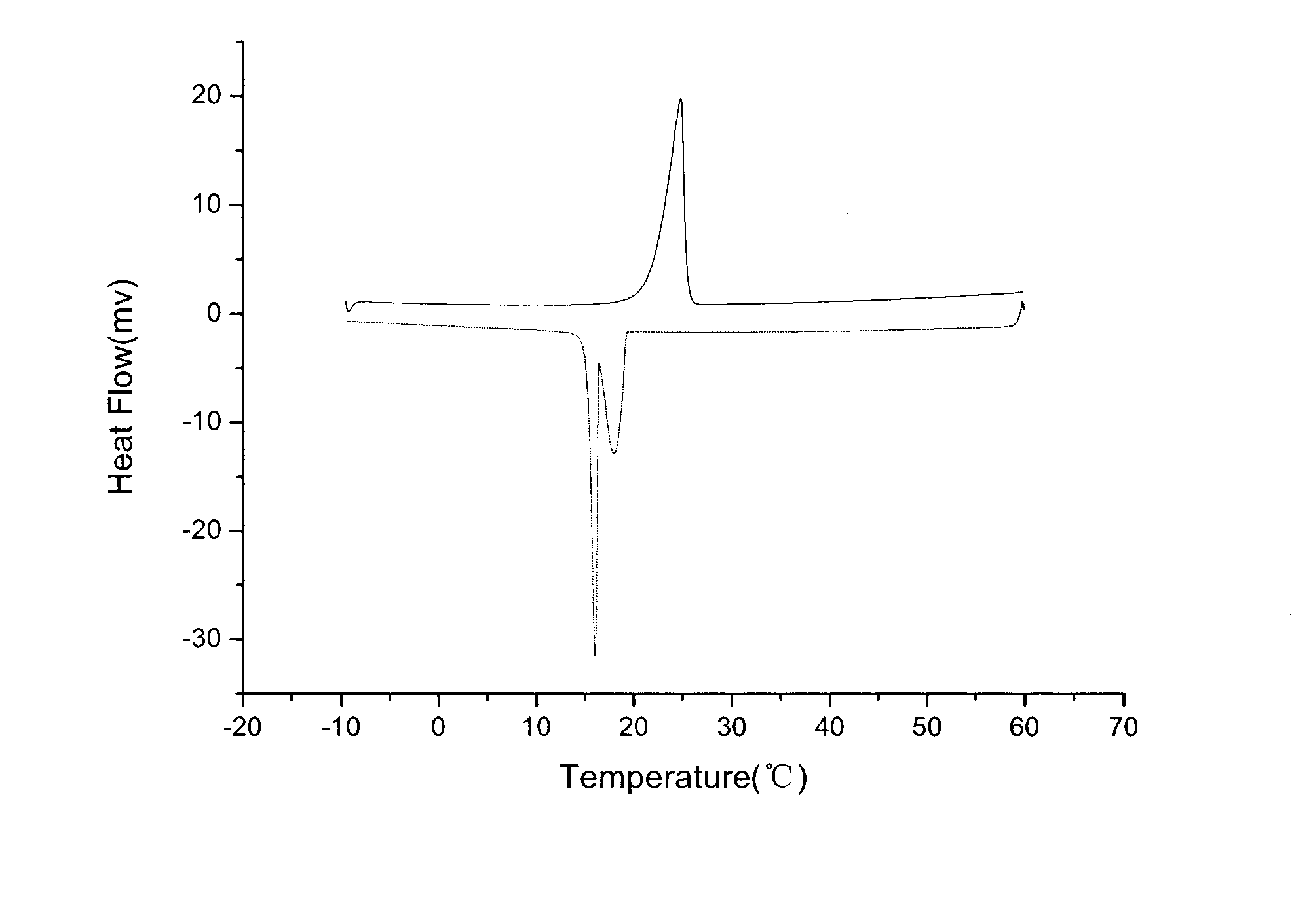

Hybridization wall material nano-capsules made of phase change energy storage material and preparation method of hybridization wall material nano-capsules

ActiveCN105399889AImprove shape regularityEasy to prepareHeat-exchange elementsSilanesHeat stability

The invention discloses hybridization wall material nano-capsules made of a phase change energy storage material and a preparation method of the hybridization wall material nano-capsules. The preparation method specifically comprises the steps of mixing the phase change energy storage material, an alkoxy silane type compound, a vinyl monomer and an initiator to form an oil phase, adding a water phase and an emulsifier, emulsifying, then ultrasonically homogenizing to form miniemulsion, introducing nitrogen to remove oxygen, adding a basic catalyst, and stirring to react under a condition of closing or continuously introducing nitrogen for protection, thus obtaining a mixture of phase change energy storage material nano-capsules and the water phase; filtering the mixture, washing by deionized water, and drying, thus obtaining a powdery product. The product is regular in shape, has a particle size less than 1 mu. m, and is great in specific surface area, high in heat storage / release efficiency, high in enthalpy of phase change and heat stability, and capable of tolerating more than 1000 times of a core material melting-crystallization process; the product can be combined with multiple inorganic materials and organic polymers to prepare a thermoregulation composite material, and is good in compatibility and little in influence to mechanical property.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

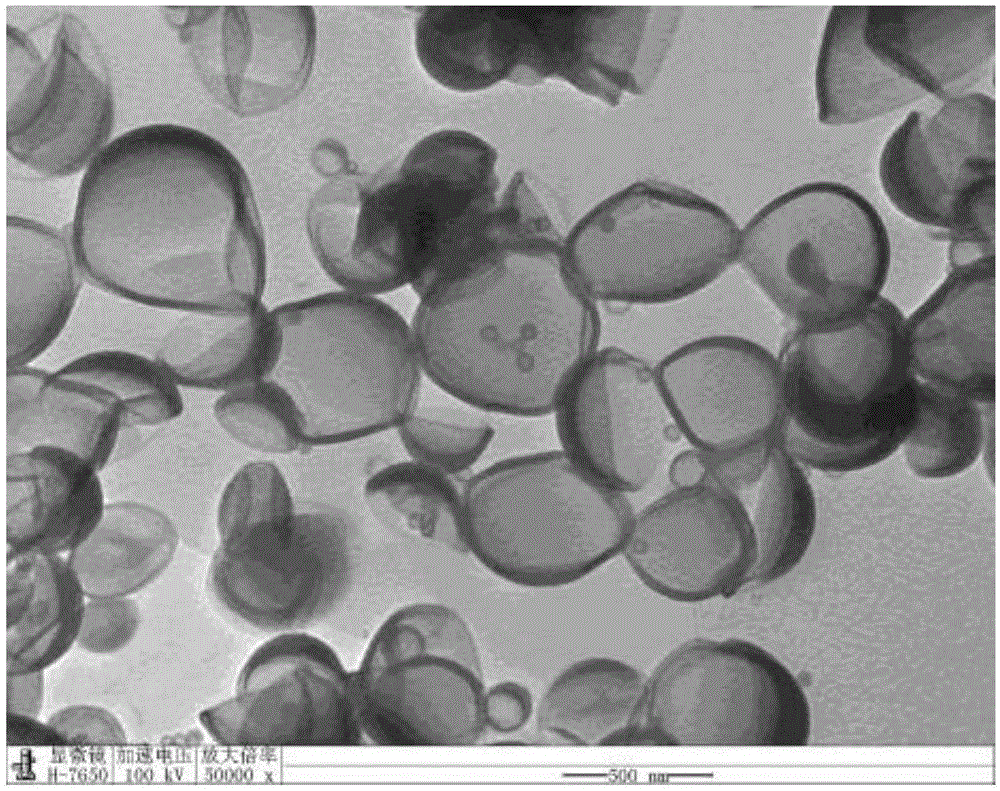

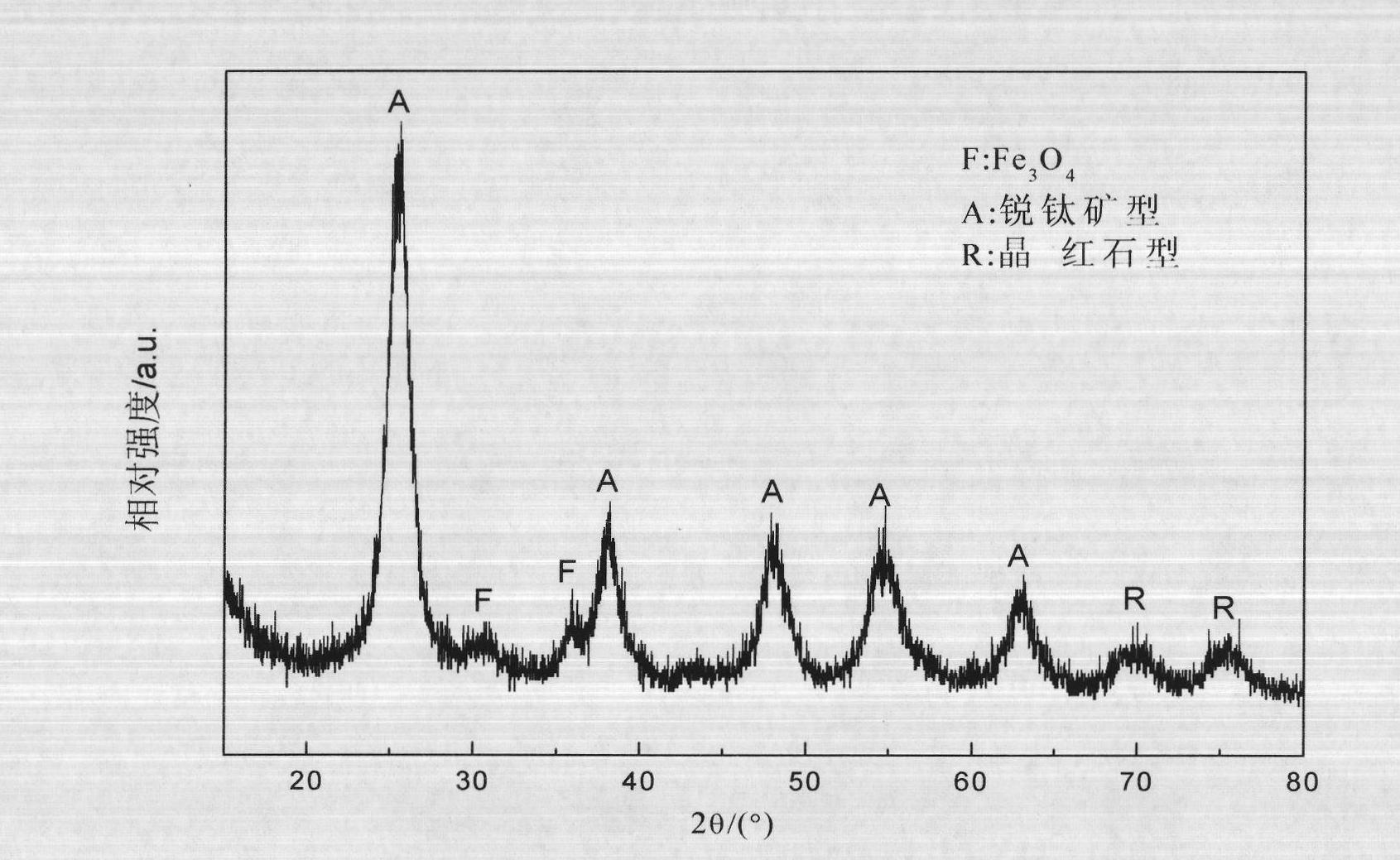

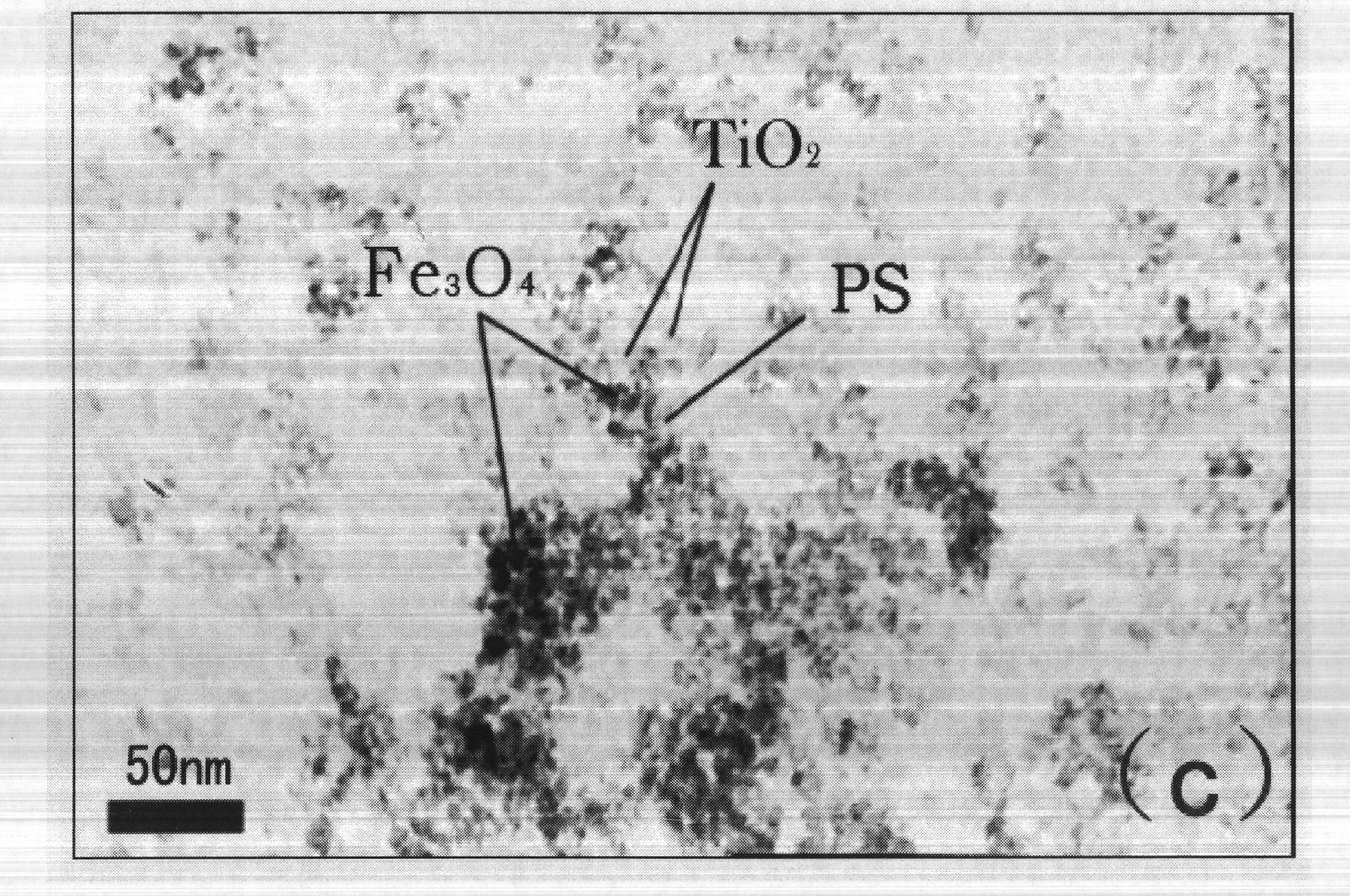

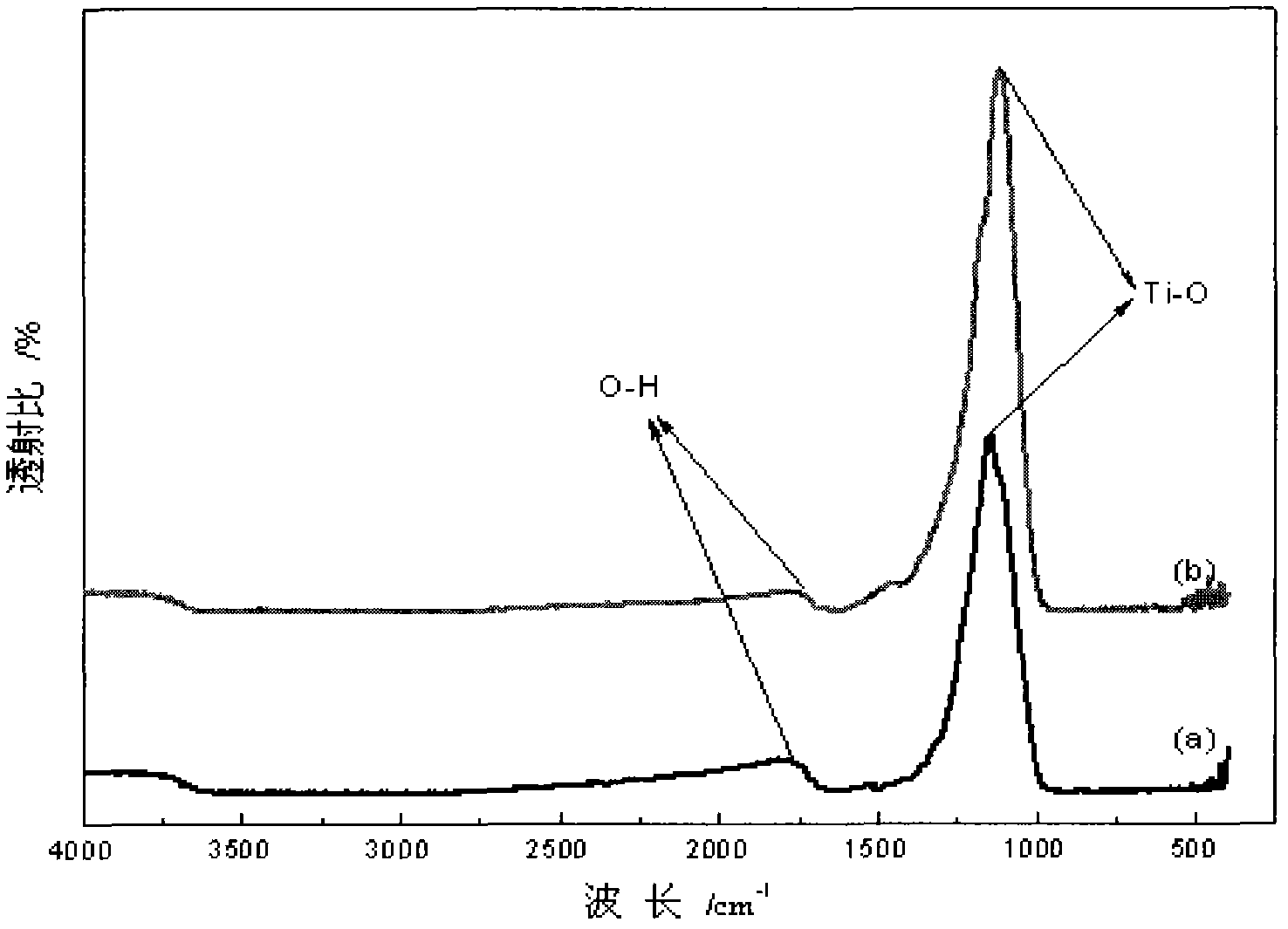

Method for preparing TiO2/PS/Fe3O4 magnetic nanoparticle photocatalyst

InactiveCN102580783ANot corrosiveNo secondary pollutionWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsWater bathsPolystyrene bead

The invention relates to a method for preparing a TiO2 / PS / Fe3O4 magnetic nanoparticle photocatalyst, comprising the following steps of: (1) preparing oleic acid modified Fe3O4 nanoparticles; (2) preparing an aqueous-phase magnetic fluid; (3) preparing styrene miniemulsion; (4) preparing magnetic polystyrene beads PS / Fe3O; and (5) preparing the magnetic photocatalyst TiO2 / PS / Fe3O4, which specifically comprises the following steps of: mixing absolute ethyl alcohol with tetra-n-butyl titanate, and performing magnetic stirring to form a solution A; adding the magnetic polystyrene beads PS / Fe3O to de-ionized water and performing ultrasonic treatment to form a solution B; under magnetic stirring, adding the solution A to the solution B, thereby obtaining sol after 30-40 min, wherein TiO2 covers the PS / Fe3O at the moment; after condensing and refluxing the sol in a water bath, filtering the sol to obtain the TiO2 / PS / Fe3O4, washing the TiO2 / PS / Fe3O4 by using ethanol, filtering, washing by using distilled water and filtering, thus obtaining a solid; and drying the solid until the weight thereof is constant, thereby obtaining the magnetic photocatalyst TiO2 / PS / Fe3O4 with the polystyrene PS as an isolating layer, the Fe3O4 as a magnetic core and the TiO2 as a shell. The product obtained by using the method is low in energy consumption, high in catalytic activity and recyclable.

Owner:LANZHOU JIAOTONG UNIV

Preparation method of pigment ink for inkjet printing of non-adhesive textile

InactiveCN102926224AGood storage stabilityLittle impact on hand feelingDyeing processColour fastnessAdhesive

The invention discloses a preparation method of pigment ink for inkjet printing of a non-adhesive textile, and belongs to the technical field of fine chemical engineering and material science. Different from the conventional ink for inkjet printing, the ink is obtained by adopting ultrafine coated pigment color paste obtained by a miniemulsion polymerization method as a coloring agent, adding substances such as a water-soluble cosolvent, a surface active agent and deionized water, stirring, mixing and filtering. The ink does not contain the adhesive, has the advantages of small particle diameter, high storage stability and good jetting smoothness and the like; and the inkjet printed textile prepared by the ink has the advantages of good color fastness and color brightness and good hand feel.

Owner:JIANGNAN UNIV

Phase change energy storage microcapsule material and its preparation method

InactiveCN103509527AUniform particle sizeImprove stabilityHeat-exchange elementsMicroballoon preparationWater bathsUltrasonic emulsification

The invention relates to a phase change energy storage microcapsule, which takes n-dodecanol as a phase change material and adopts methyl methacrylate-acrylic acid copolymer as a capsule wall material. Ultrasonic-assisted emulsification is adopted, and interfacial polymerization is employed to perform microcapsule packaging. The preparation method of the phase change energy storage material includes: firstly mixing n-dodecanol with an emulsifier, performing ultrasonic emulsification, then conducting mechanical stirring, adding methyl methacrylate and an initiator under 80DEG C water bath to react for certain time, then adding acrylic acid to react, and completing polymerization; and carrying out cooling, filtering, and drying so as to obtain a sample. According to the invention, n-dodecanol is adopted as the phase change material, the phase change temperature can be controlled in the vicinity of room temperature. The methyl methacrylate-acrylic acid copolymer is taken as the capsule wall, which has very good chemical stability and strong adaptability to the environment. Ultrasonic assisted emulsification is employed to form a miniemulsion, and the reaction undergoes more easily. The phase change energy storage microcapsule material provided by invention has the advantages of simple process, low cost, and good stability, and can effectively improve the energy storage effect of a phase change material.

Owner:NANJING UNIV OF TECH

Method for preparing microcapsule by miniemulsion polymerization

Provided is a method for preparing uniformly sized and shaped, mono-dispersed microcapsules using miniemulsion polymerization. In microcapsules prepared by the method, a liquid or solid core encapsulated by a polymer shell has 10 to 80 % by volume of the microcapsules. Since miniemulsion particles produced at an early stage of the method are stable, an organic material which is well dissolved in monomer particles and has a higher interfacial tension with water, relative to the polymer shell, can be uniformly positioned in polymer particles. Furthermore, when a crosslinking agent is added during the polymerization, single-core microcapsules can be obtained. In addition, use of an oil-soluble initiator can prevent formation of secondary particles and addition of a secondary initiator during the polymerization can increase the yield of the uniformly sized and shaped microcapsules.

Owner:LG CHEM LTD

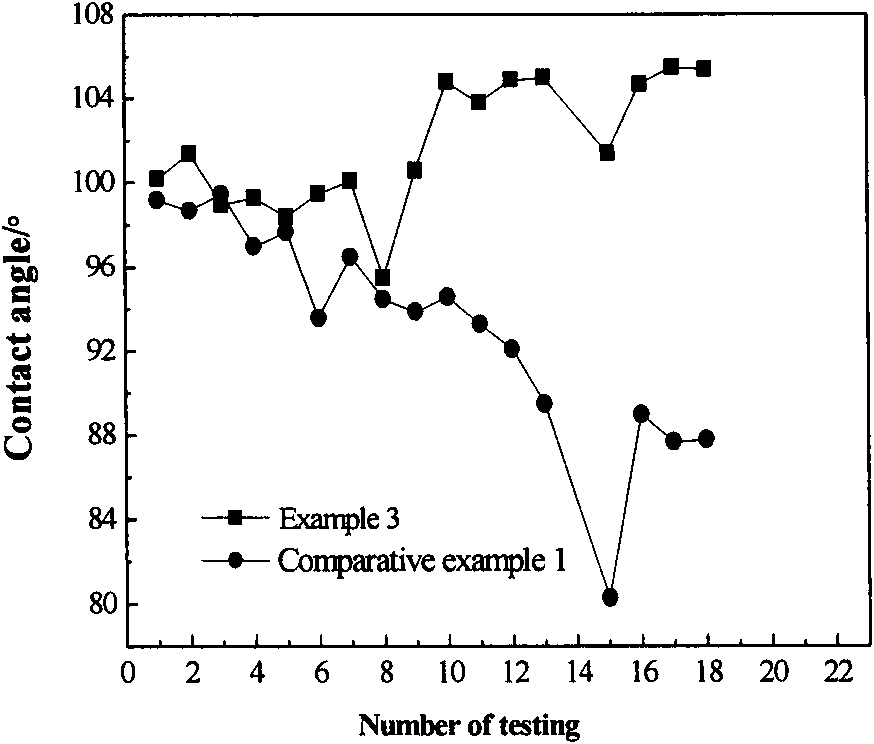

Silicone oil microcapsule with slow-release characteristics and preparation method thereof

InactiveCN102030990AStrong persistenceImprove waterproof performanceCoatingsUltrasonic emulsificationOil phase

The invention provides a silicone oil microcapsule with slow-release characteristics and a preparation method thereof, relating to the field of new chemical materials. In the invention, ethyl orthosilicate or methyl orthosilicate, non-functional linear silicone oil and silane coupling agents with long-chain alkyl are used as oil phases, silicone oil microcapsule dispersion liquid taking silicon dioxide as a shell is prepared by the following steps of: compounding anionic surface active agents with nonionic surface active agents into emulsifying agents; carrying out ultrasonic emulsification to obtain miniemulsion; stirring at room temperature for hydrolysis; and finally regulating pH value; wherein the silicone oil microcapsule dispersion liquid taking silicon dioxide has grain diameter of 140-260 nanometers and solid content of 13%-20%. The silicone oil microcapsule has high storage stability and good slow-release characteristics and can be directly used for the preparation of high-durability hydrophobic coating.

Owner:FUDAN UNIV

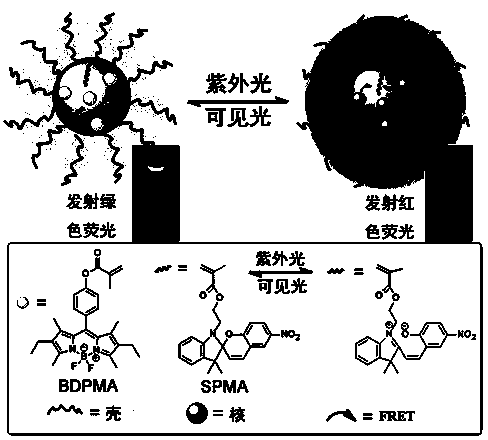

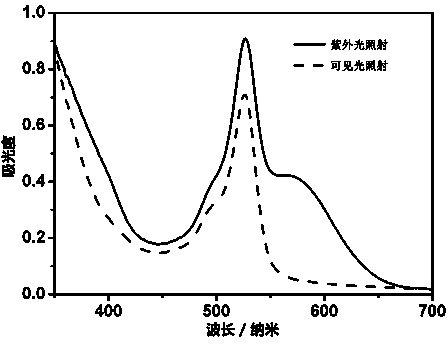

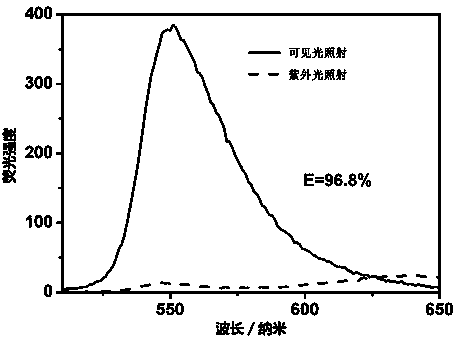

Amphipathy photoswitch fluorescent polymer nano particles and preparing method thereof

The invention discloses amphipathy photoswitch fluorescent polymer nano particles and a preparing method of the amphipathy photoswitch fluorescent polymer nano particles. Methyl methacrylate, polymerizable green fluorescence dye and a polymerizable photochromic compound are taken as monomers, hexadecane is taken as hydrophobe, a polyoxyethylene macromolecular chain transfer reagent is taken as a surface active agent, a one-step reversible addition-fragmentation chain transfer (RAFT) miniemulsion polymerization method is adopted for preparing the novel amphipathy photoswitch fluorescent polymer nano particles. The amphipathy photoswitch fluorescent polymer nano particles can emit intense macroscopic green or red fluorescence under irradiation of visible light and ultraviolet light, and have fast photoresponse capacity and good repeated fluorescence reversible switch performance. The amphipathy photoswitch fluorescent polymer nano particles have wide application prospects in the fields of cell imaging, bioanalysis, optical storage and the like.

Owner:HUNAN UNIV OF SCI & TECH

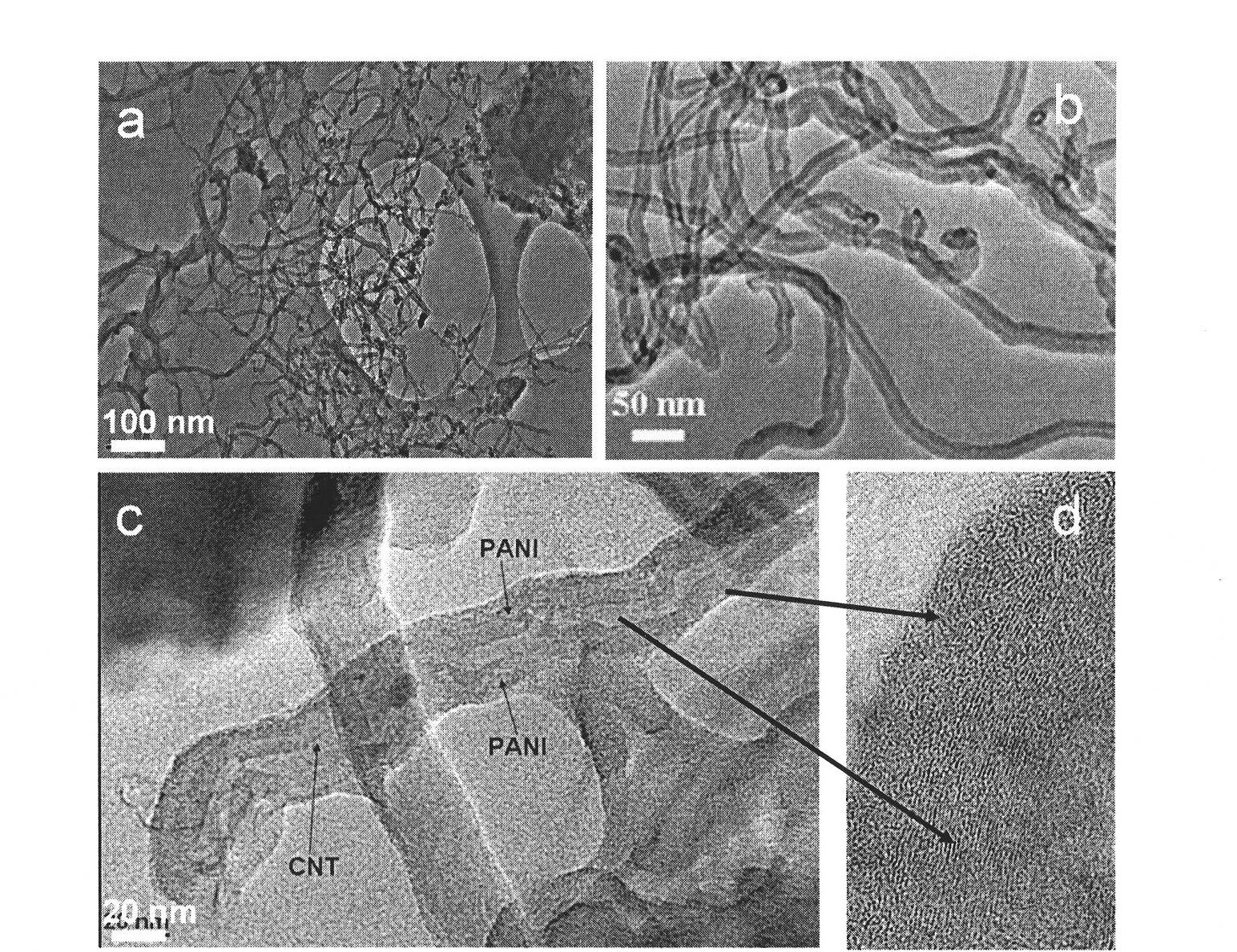

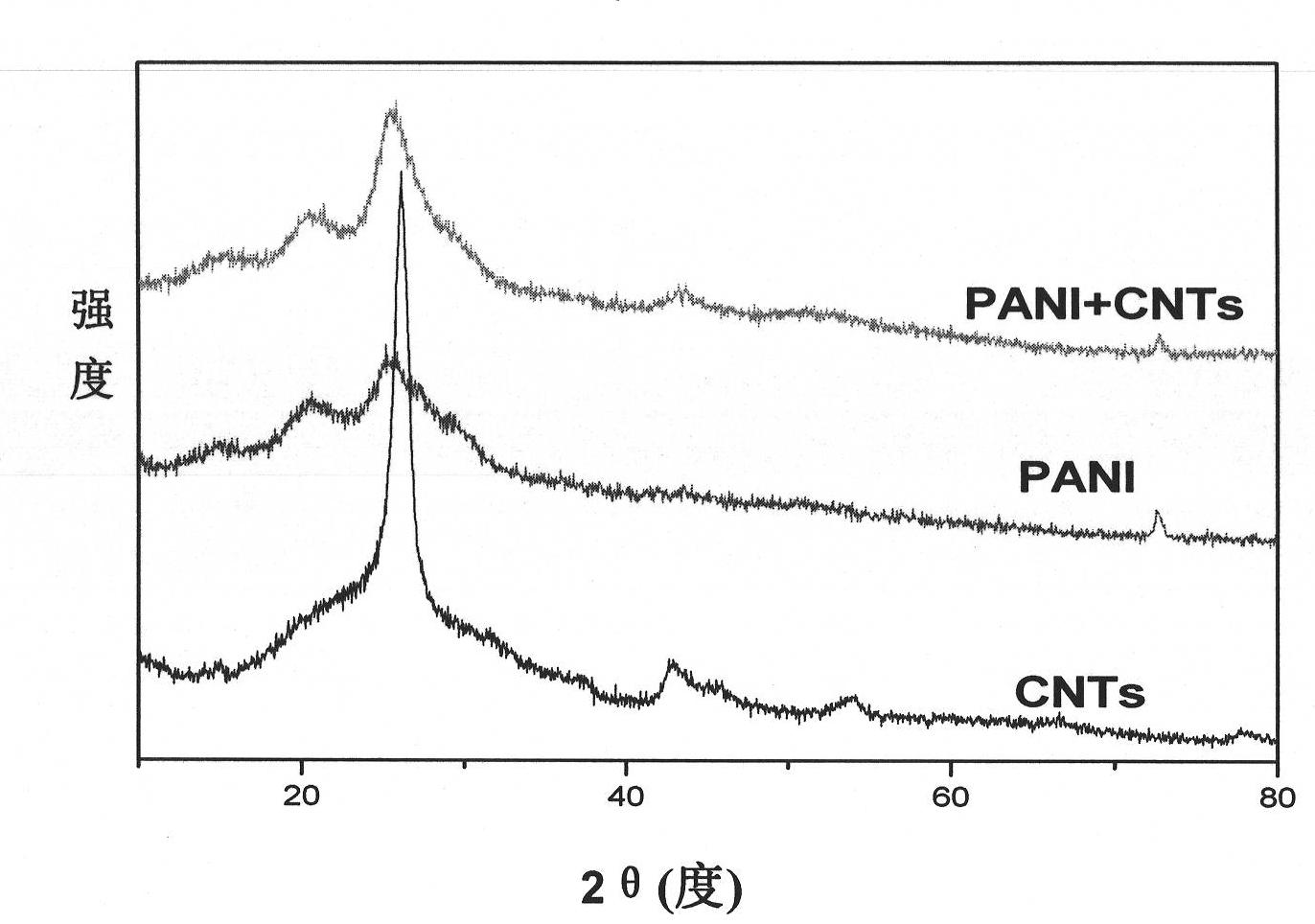

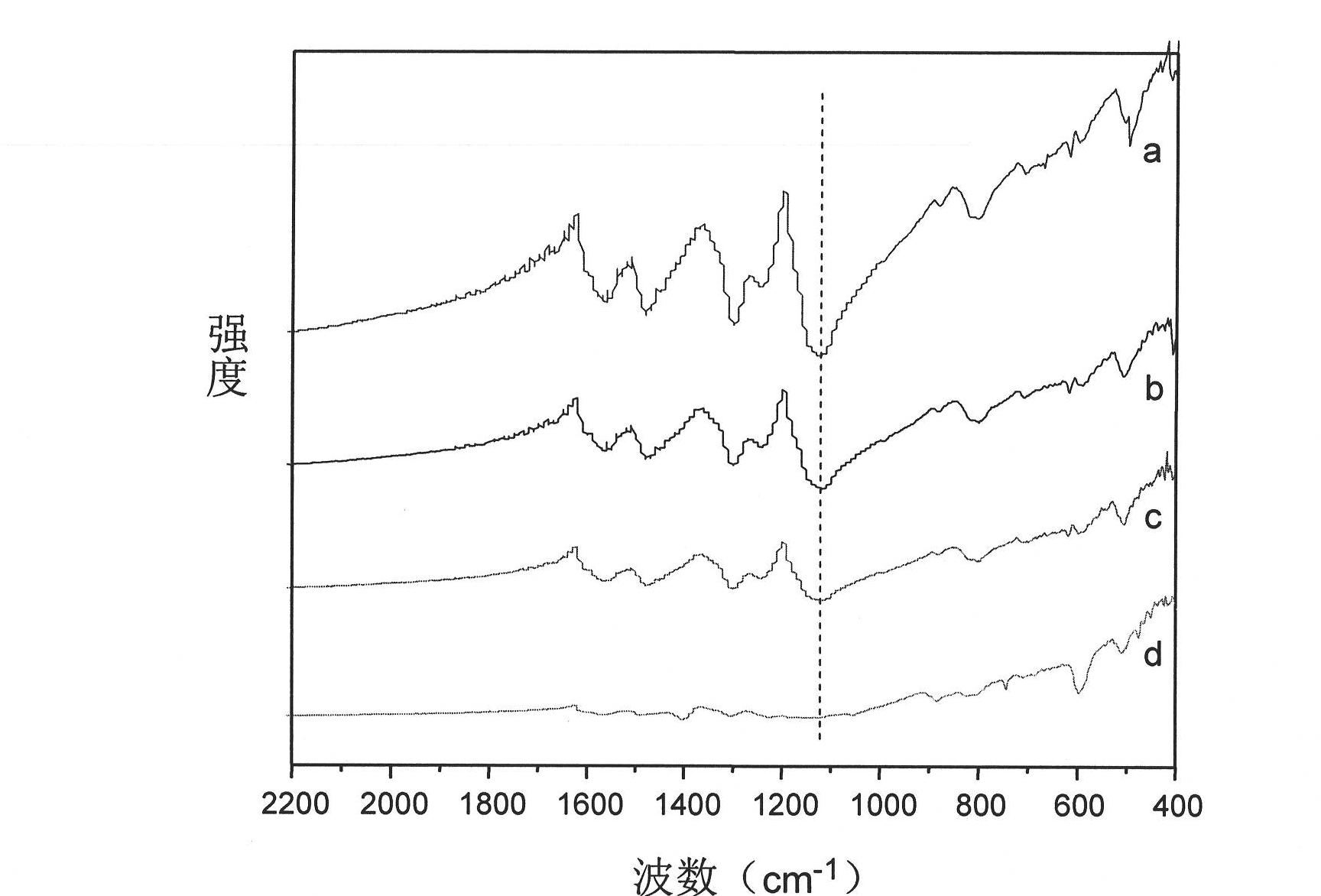

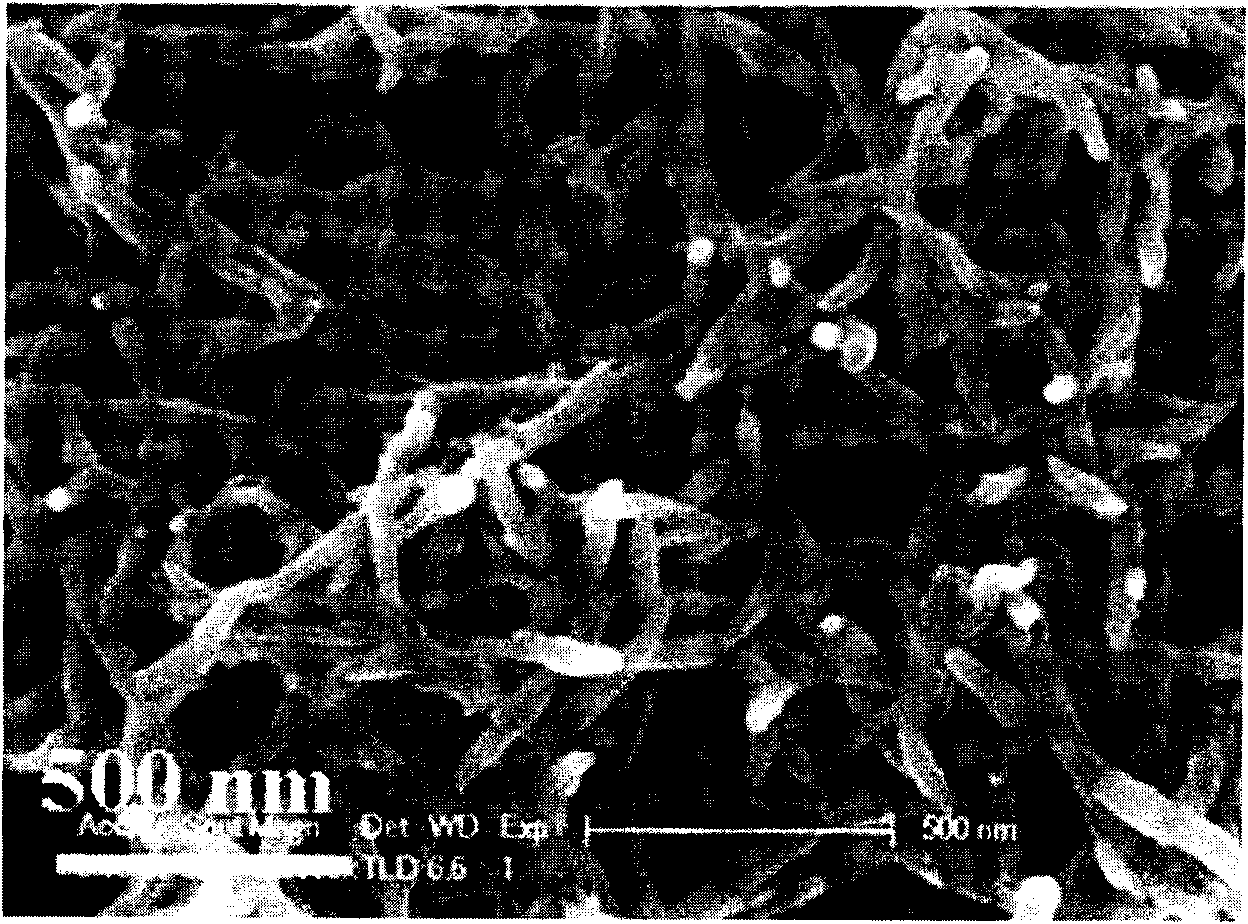

Preparation method of carbon nano tube/polyaniline nano composite conductive powder

The invention discloses a preparation method of carbon nano tube / polyaniline nano composite conductive powder. The method comprises the following steps: mixing a carbon nano tube, aniline and protonic acid, and adding an assistant stabilizing agent into the mixture to obtain an oil phase solution; mixing an emulsifier with water to obtain an aqueous phase solution; mixing the oil phase solution and the water phase solution and then carrying out homogenization on the mixture in ultrasonic wave to obtain a miniemulsion; adding the protonic acid solution into the miniemulsion and then stirring to obtain a doping solution; dropwise adding an oxidant aqueous solution into the doping solution and carrying out a reaction for at least 4 hours to obtain the reaction solution; and finally carrying out centrifugalization to obtain a precipitate, washing the precipitate with ethanol and water, and drying the precipitate after washing to obtain carbon nano tube / polyaniline nano composite conductive powder, wherein the core is the carbon nano tube and a shell is polyaniline, and the thickness of polyaniline is 10-30nm. The product prepared by the method can be used as a conductive material or an enhanced filling material to be added into the polymer matrix, so as to prepare the new materials for light-to-electricity conversion, photoelectrocatalysis and electromagnetic shielding and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

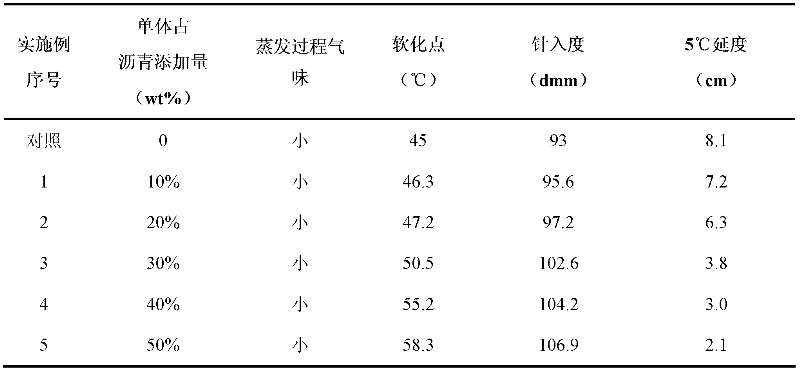

Preparation method for polymer microcapsule modified emulsified bitumen

ActiveCN102352113AImprove stabilityImprove performanceBuilding insulationsPolymer modifiedCrack resistance

The invention discloses a preparation method for polymer microcapsule modified emulsified bitumen, which belongs to the technical field of modification of bitumen. A polymer shell layer is formed through microcapsule in-situ cladding and crosslinking on the surface of bitumen microballoons by using the method of miniemulsion polymerization, and an organic / inorganic composite core-shell structure is formed. After the polymer microcapsule modified emulsified bitumen becomes a film, an interpenetrating polymer network of a polymer and bitumen is formed; the polymer microcapsule modified emulsified bitumen has the characteristics of an organic / inorganic composite, better heat resistance and a high softening point; a mixture fabricated with the polymer microcapsule modified emulsified bitumen has good resistance to permanent deformation, can prevent harmful damage like formation of ruts on a pavement in high temperature seasons and better adapts to needs for pavement construction and maintenance in hot areas. Since the polymer microcapsule modified emulsified bitumen has the characteristic of modification by the polymer, the emulsified bitumen has improved toughness and good crack resistance, and can be extensively used in the fields like emulsified bitumen cement mortar for plate type ballastless tracks of high-speed railways or urban light rails.

Owner:TSINGHUA UNIV

Method for preparing polymer-zinc oxide nano composite microspheres

InactiveCN101955613AParticle size controllableControllable morphology of nano ZnOCoatingsMicroballoon preparationPhoto catalyticMicrosphere

The invention discloses a method for preparing polymer-zinc oxide nano composite microspheres and belongs to the technical field of preparation of organic-inorganic nano composite microspheres. The method comprises the following steps of: firstly, copolymerizing a vinyl monomer and organosiloxane to prepare polymer microspheres of which the surfaces are provided with active silicon hydroxyl through miniemulsion polymerization; and secondly, generating nano ZnO on the surfaces of the polymer microspheres by reacting an organic amine alkali source with the active silicon hydroxyl function on the surfaces of the polymer microspheres so as to prepare the polymer / ZnO nano composite microspheres. The prepared polymer / ZnO nano composite microspheres have the advantages of controllable grain size and nano ZnO shape on the surfaces of the polymer microspheres, capacity of overcoming the defects of easy agglomeration and poor dispersibility of nano ZnO grains, and wide application to the fields of UV-resistant coatings, photo-catalytic environment-friendly materials, and the like.

Owner:JIANGNAN UNIV

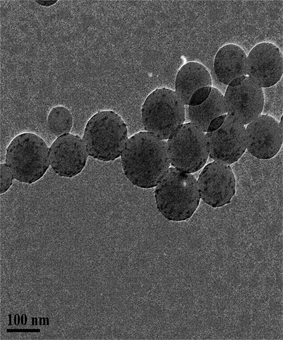

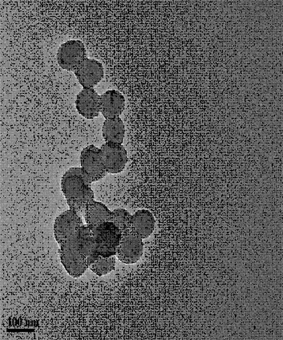

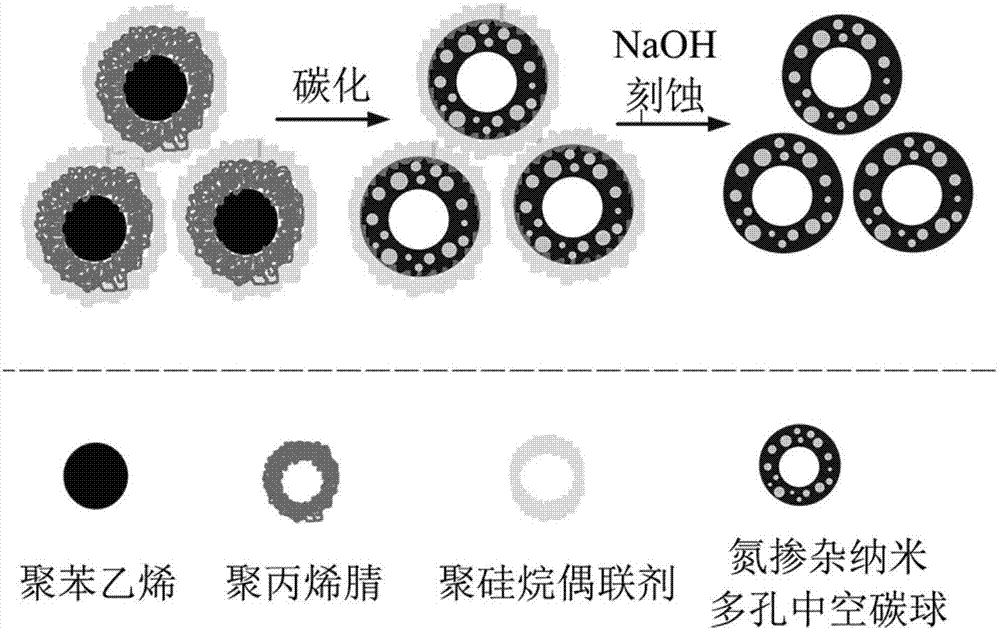

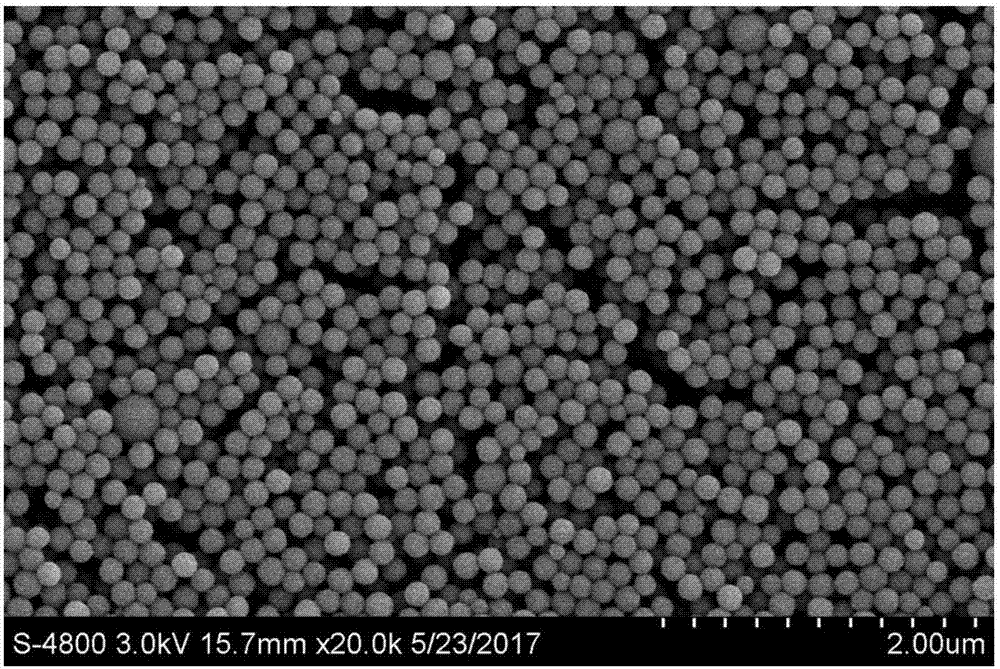

Preparation method of nitrogen-doped nano porous hollow carbon spheres

ActiveCN107311144AHigh densityLarge specific surface areaOther chemical processesNanotechnologyDispersityMicrosphere

The invention discloses a preparation method of nitrogen-doped nano porous hollow carbon spheres. The preparation method comprises the following steps: preparing polystyrene / polyacrylonitrile core-shell structural composite microspheres by adopting styrene and acrylonitrile as monomers by virtue of miniemulsion polymerization; dropwise adding a silane coupling agent, and continuously polymerizing to form polystyrene / polyacrylonitrile / polysilane coupling agent dual-layer core-shell composite microspheres; and then pre-oxidizing, carbonizing and removing core-layer silicon dioxide to prepare the nitrogen-doped nano porous hollow carbon spheres. The polystyrene / polyacrylonitrile / polysilane coupling agent dual-layer core-shell composite microspheres prepared by adopting a seed miniemulsion polymerizing method are used as a precursor of the carbon spheres and have the characteristics of narrow distribution of particle size, good single dispersity, controllability in particle size and the like.

Owner:ANHUI UNIVERSITY

Method for preparing nano colouring matter aqueous dispersions

The invention discloses a preparing method for a water dispersoid of a nanometer colouring matter which is obtained by a miniemulsion polymerization-nucleocapsid copolymerization reaction with a common dye or a common pigment. The preparation method includes the steps as follows: A, preparing the seed of a preformed polymer; B, preparing a shell copolymerization emulsion; C nucleocapsid copolymerization reaction. The average grain diameter of the water dispersoid of the colouring matter is less than 100nm and the polydispersity index is less than 0.1; the water dispersoid of the colouring matter has high granularity equality. The invention adopts the miniemulsion polymerization-nucleocapsid copolymerization to prepare, leads the dye or the pigment to be firmly combined together with a proper nanometer polymer by a chemical mode and has an excellent storage stability. As the polymer of organic silicon / acrylic acid is led in; the water dispersoid of the colouring matter has the advantages of excellent water-resistance, light-resistance, weatherability and heat resistance. The water dispersoid of the nanometer colouring matter is suitable for coloring toning agents used by color ink-jet printing ink, colorful coat of the colorful filter of a colorful display, water-based ink, water-based UV color paste, cosmetics, high-grade products, and the like.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +3

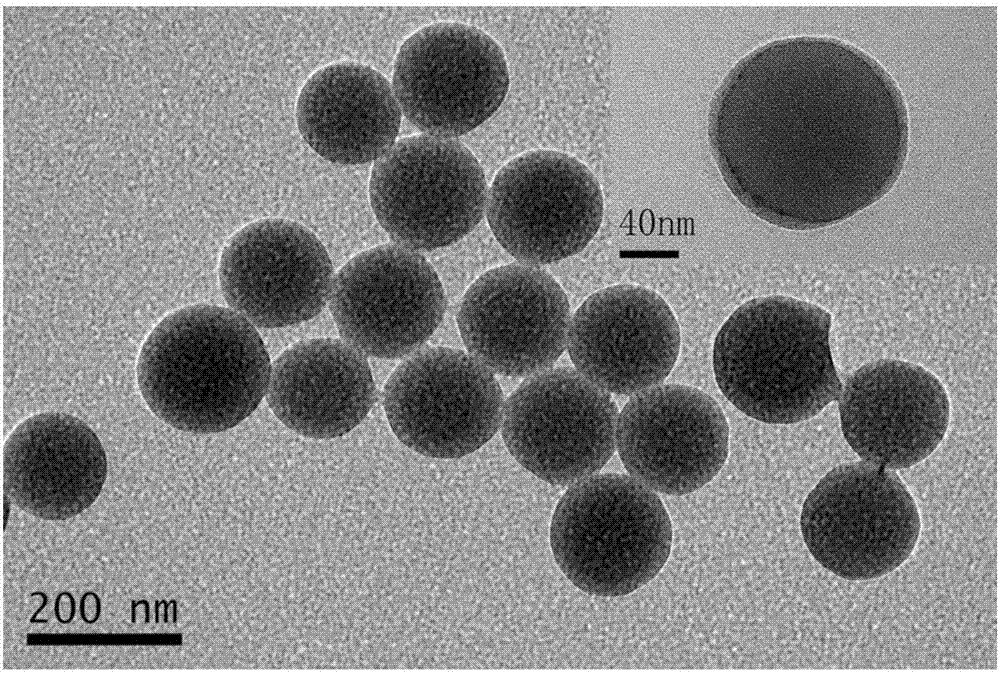

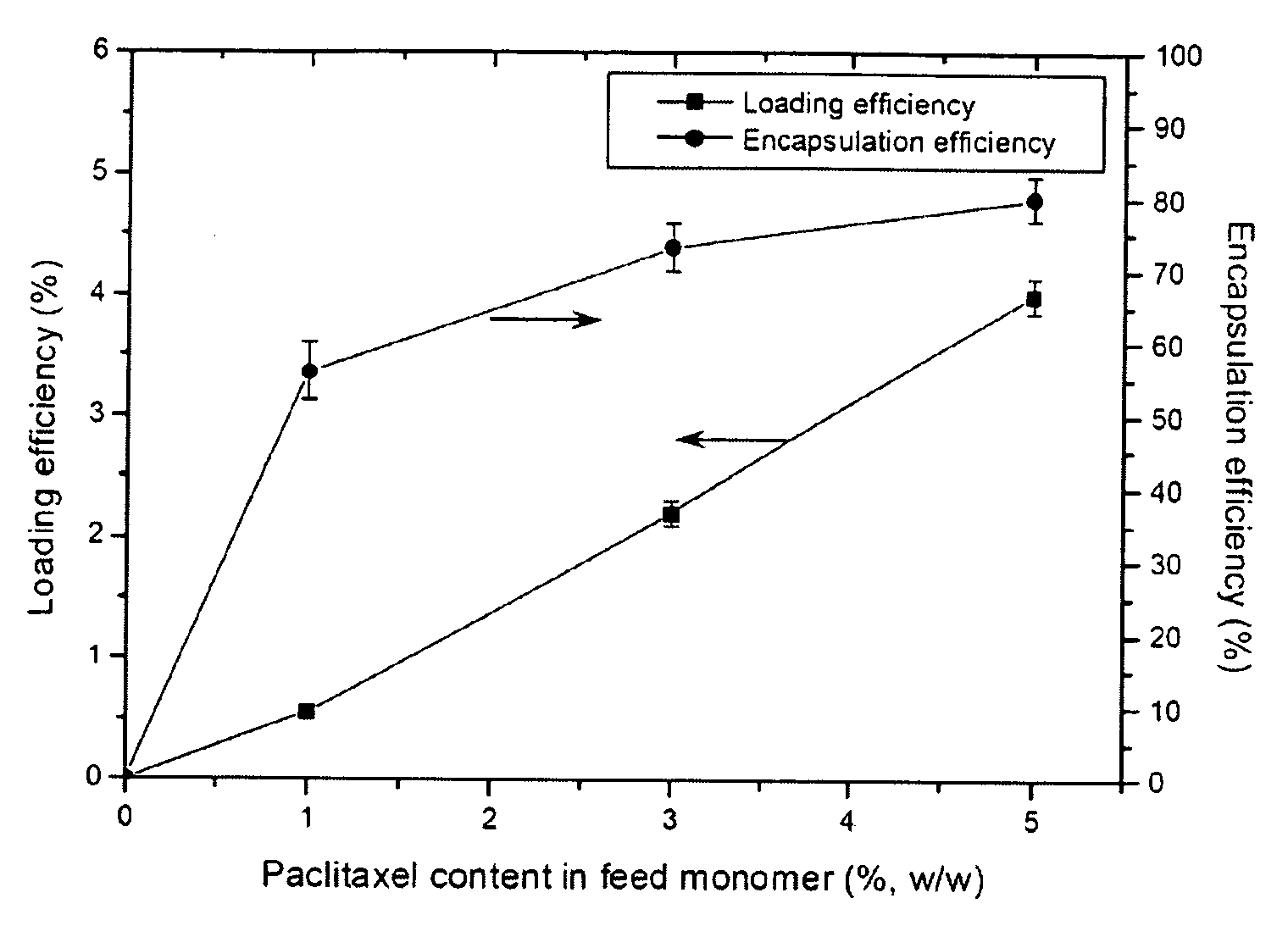

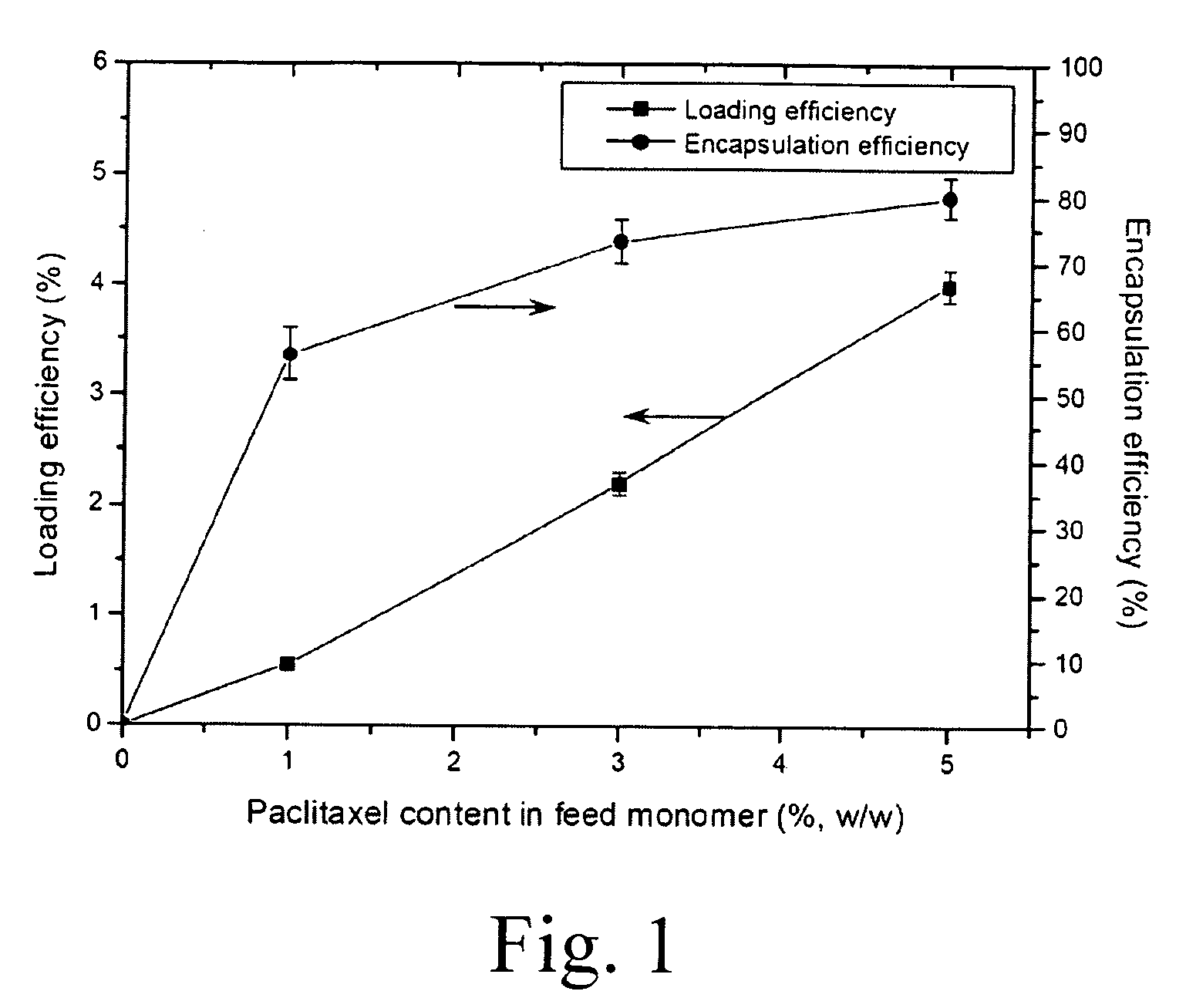

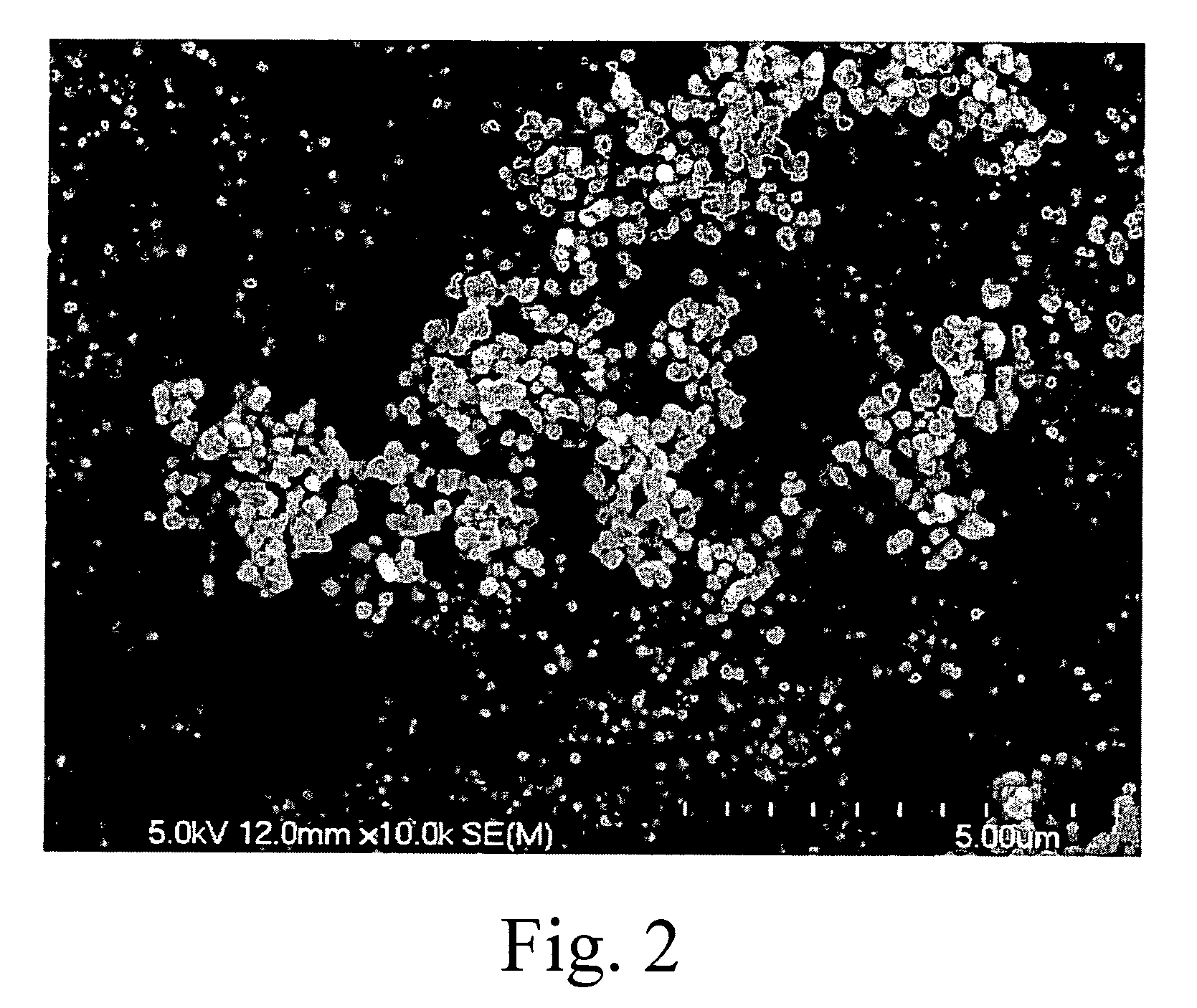

Drug-loaded poly (alkyl-cyanoacrylate) nanoparticles and process foe the preparation thereof

ActiveUS20080182776A1Increase loadImprove encapsulationAntibacterial agentsPowder deliveryCyanoacrylateActive agent

A process for preparing the drug-loaded cyanoacrylate nanoparticles is described. The cyanoacrylate nanoparticles which effectively deliver biological and therapeutic agents are synthesized by miniemulsion polymerization with surfactant, pluronic F127 or F68. Before initiation of polymerization, active agents with particularly highly hydrophobicity are dissolved in cyanoacrylate monomer. Compared with the drug-loaded polyalkylcyanoacrylate nanoparticles produced by emulsion polymerization, those produced by miniemulsion polymerization possess higher loading and encapsulation efficiencies. While the content of dissolved agents increases, furthermore, the loading and encapsulation efficiencies increase concurrently.

Owner:TONG SHEN ENTERPRISE

Preparation method of strawberry-type polystyrene-silicon dioxide nanocomposite microspheres

The invention relates to a preparation method of strawberry-type polystyrene-silicon dioxide nanocomposite microspheres. The preparation method comprises the following steps: in a nitrogen atmosphere, mixing methacryloyloxyethyl trimethyl ammonium chloride, octaphenyl polyoxyethyiene and deionized water to obtain a water-phase mixture; dissolving azodiisobutyronitrile into styrene and n-hexadecane through ultrasonic wave to obtain an oil-phase mixture; dropping the oil-phase mixture into the water-phase mixture by using a constant-pressure dropping funnel to obtain mixed liquid; performing ultrasonic treatment on the mixed liquid under an ice-water mixed bath condition to obtain miniemulsion; dropwise adding silicon dioxide nanosol into the miniemulsion, and heating to obtain milky dispersion liquid; collecting and cooling the dispersion liquid, and centrifugating and dispersing until no free SiO2 particles exist under a transmission electron microscope, so as to obtain the strawberry-type polystyrene-silicon dioxide nanocomposite microspheres finally. The preparation method is simple and relatively low in cost and the SiO2 cladding rate is relatively high.

Owner:HUBEI UNIV

Method for preparing inorganic nano microcapsule by one-step method

InactiveCN101259399AGood chemical stabilityImprove mechanical stabilityMicroballoon preparationMicrocapsule preparationInorganic compoundMechanical stability

The invention relates to a method for preparing a nanometer microcapsule and aims at providing a method for preparing an inorganic nanometer microcapsule by one step. The method includes that an emulsification agent and a PH regulator are dissolved into water; a monomer, a small molecular hydrocarbon template compound and a co-stabilizer are mixed and added into the mixed solution obtained above, and then ultrasonic dispersion is carried out to obtain a stable miniemulsion; the temperature of the obtained miniemulsion is adjusted to 30 to 80 DEG C; the inorganic nanometer microcapsule with an inorganic compound as a shell layer and the small molecular hydrocarbon as a core is obtained after reaction for 3 hours to 5 days. The method has simple preparing process and can stably obtain the inorganic nanometer microcapsule which has high thermal, chemical and mechanical stabilities; simultaneously the porous structure of the shell layer is more beneficial to the substance exchange between the covered object and the outside environment; besides, the size of the microcapsule and the thickness of the shell layer can be conveniently realized by adjusting the proportion of the monomer and the small molecular hydrocarbon, the water-oil ratio and the categories and concentration of the emulsification agent when the invention is used for preparing the microcapsule.

Owner:ZHEJIANG UNIV

Method for preparing nano colouring matter aqueous dispersions

The invention discloses a method for preparing a nanometer coloring material watercraft dispersoid which is prepared by the miniemulsion polymerization-core shell copolymerization of common dyes or common pigments. The specific steps are that: A. preparing prepolymer seeds; B. preparing shell polymerization emulsion; and C. carrying out core shell polymerization reaction. The average granular size of the dispersoid is less than 100nm, the polydispersity index is less than 0.1 and the granularity uniformity is high; by adopting miniemulsion polymerization-core shell copolymerization for preparation, the method firmly combines pigments or dyes with proper nanometer polymer in a chemical manner, consequently, the dispersoid has excellent storage stability; as organic silicon / acrylic acid polymer are introduced, the dispersoid has fine water resisting property, light resistance, weather resistance and heat resistance. The nanometer coloring material watercraft dispersoid of the invention is applicable for colorized ink jet marking ink, colorized monitors, colored filters, colored coatings, water color ink, watercraft UV color sizing, cosmetics and coloring toner for high-grade products, and the like.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +3

Miniemulsion polymerization method of high-solid-content self-crosslinking type styrene-acrylate emulsion surface sizing agent

InactiveCN102225982AImprove water resistanceLow viscosityWater-repelling agents additionEmulsionAqueous solution

The invention provides a miniemulsion polymerization method of a high-solid-content self-crosslinking type styrene-acrylate emulsion surface sizing agent. The method comprises the following steps: mixing a composite emulsifier with a mixed monomer and then pre-emulsifying so as to obtain pre-emulsion, and carrying out ultrasonic processing so as to obtain a monomer miniemulsion; mixing an composite emulsifier, a buffer and an initiator and deionized water and then stirring, adding the monomer miniemulsion in the presence of noble gas for polymerization so as to obtain seed miniemulsion; dissolving an initiator in deionized water so as to obtain an initiator aqueous solution; simultaneously dropwise adding the seed miniemulsion and 80% of the initiator aqueous solution in a reactor, and adding a molecular weight regulator at the middle and later periods of dropwise addition; after dropwise addition is finished, replenishing residual 20% of the initiator aqueous solution and insulating heat; and filtrating reactant after the reaction is finished, so as to obtain the self-crosslinking surface sizing agent with the solid content of 48%-68%. The styrene-acrylate emulsion surface sizingagent obtained by the method has the characteristics of high solid content, proper viscosity, good stability and the like. In addition, the method has a simple process and low cost.

Owner:SOUTH CHINA UNIV OF TECH

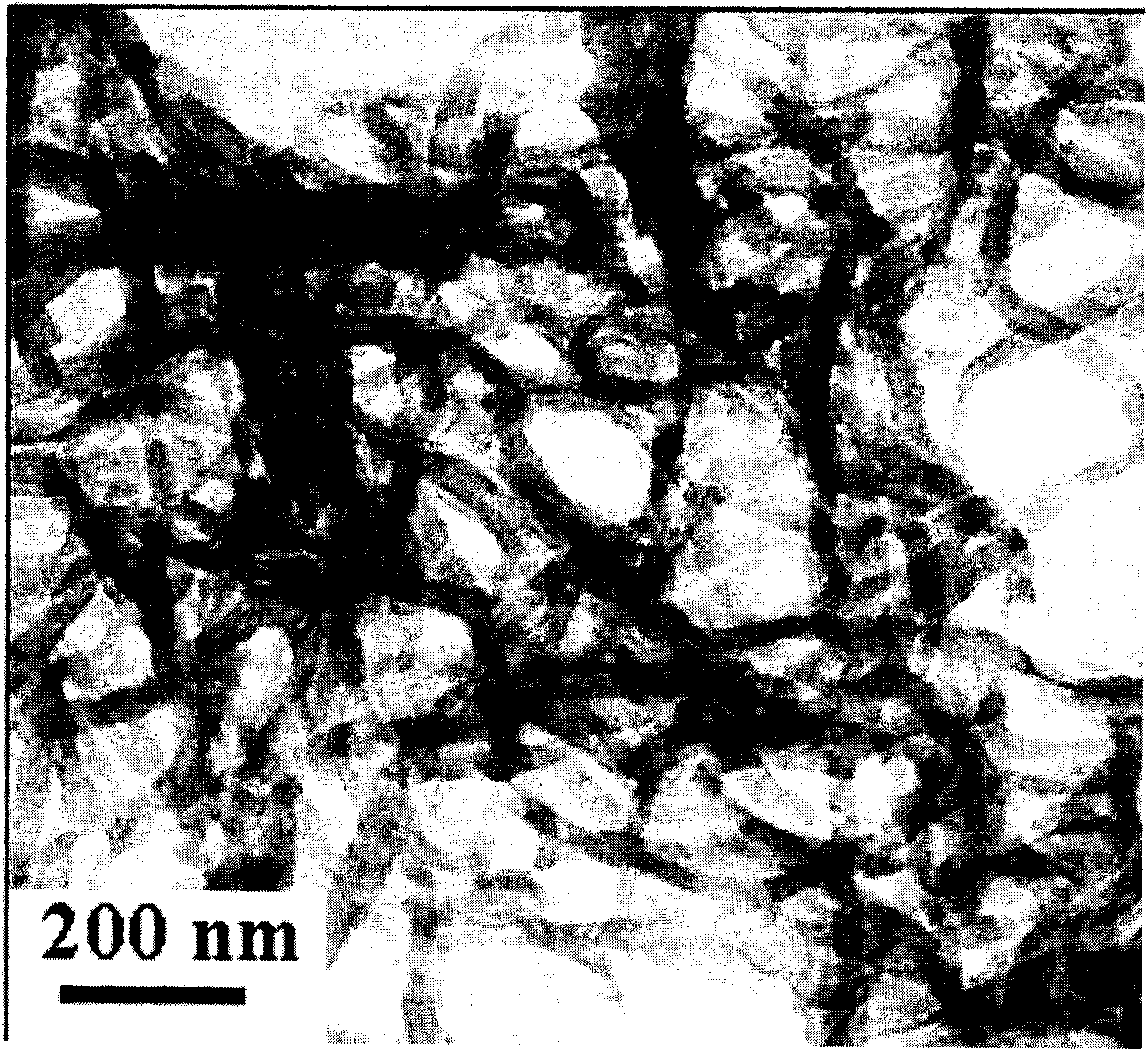

Soluble polyaniline conductive nanofiber and preparation method thereof

The invention discloses a soluble polyaniline conductive nanofiber and a preparation method thereof. The fibers have smooth surfaces and uniform shapes, are crossed and automatically assembled to form a regular nanoscale three-dimensional net, and have the solubility of more than or equal to 10 mg / ml in a solvent which may be water, ethanol, ethylene glycol, N,N-dimethylformamide or dimethyl sulfoxide. The method comprises the following steps of: first mixing aniline with an auxiliary stabilizer with stirring to obtain oil phase liquid, mixing an emulsifier with the water with stirring to obtain water phase liquid, mixing the oil phase liquid with the water phase liquid with stirring and placing the mixture in ultrasonic waves for homogenization to obtain miniemulsion; then adding protonic acid solution into the miniemulsion for stirring to obtain mixed solution, and adding the aqueous solution of oxidant dropwise into the mixed solution for reaction to obtain dark green solution; and finally performing centrifugation treatment on the dark green solution to obtain precipitates, washing the precipitates with the ethanol and the water, and drying the washed precipitates to obtain the soluble polyaniline conductive nanofibers. The polyaniline conductive nanofiber and the preparation method thereof can be widely used for the connection, functional units and the like of nanoscale electronic devices, photoelectronic devices, electrochemical devices and electromechanical devices.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com