Patents

Literature

2316 results about "Emulsion polymerisation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

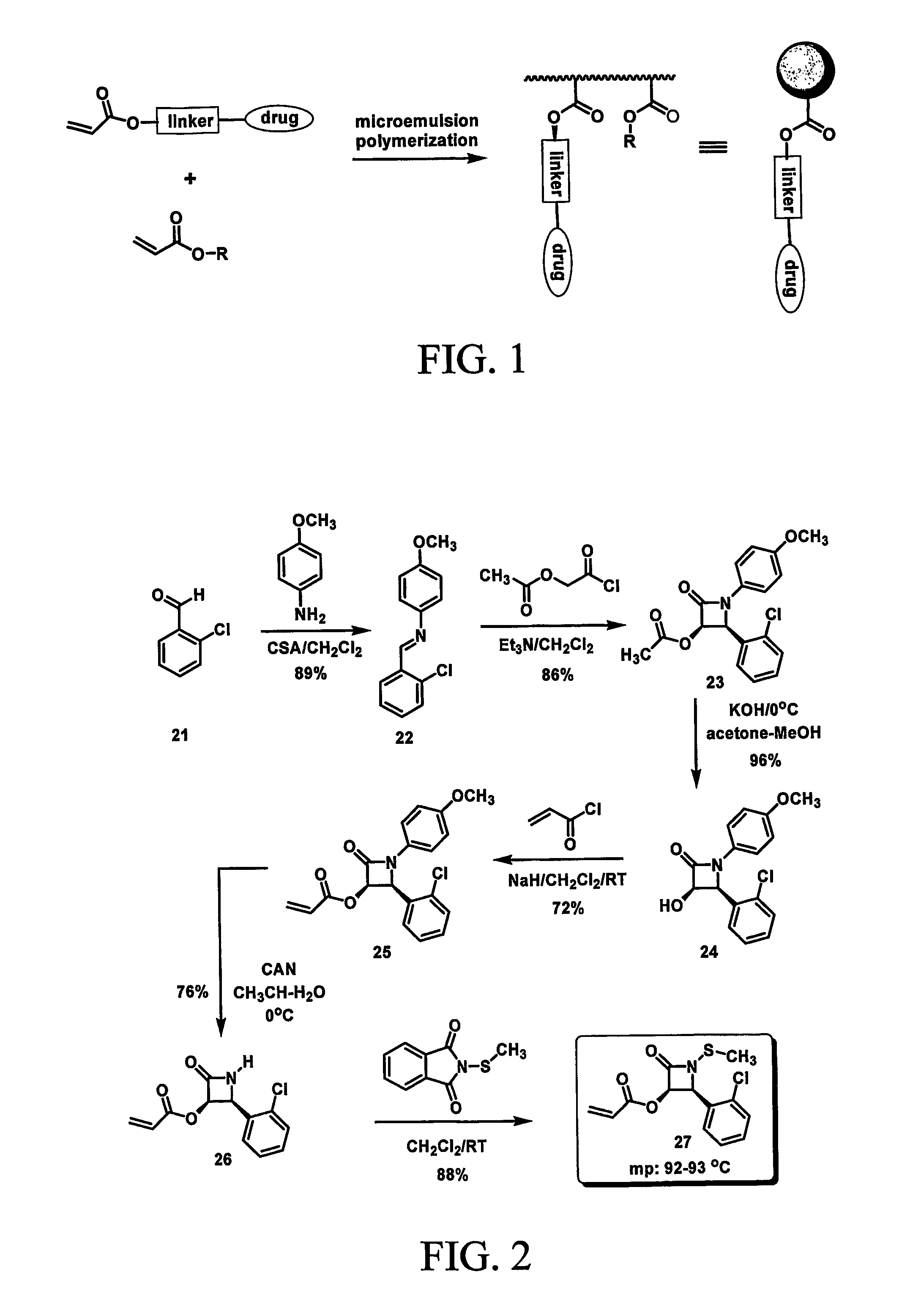

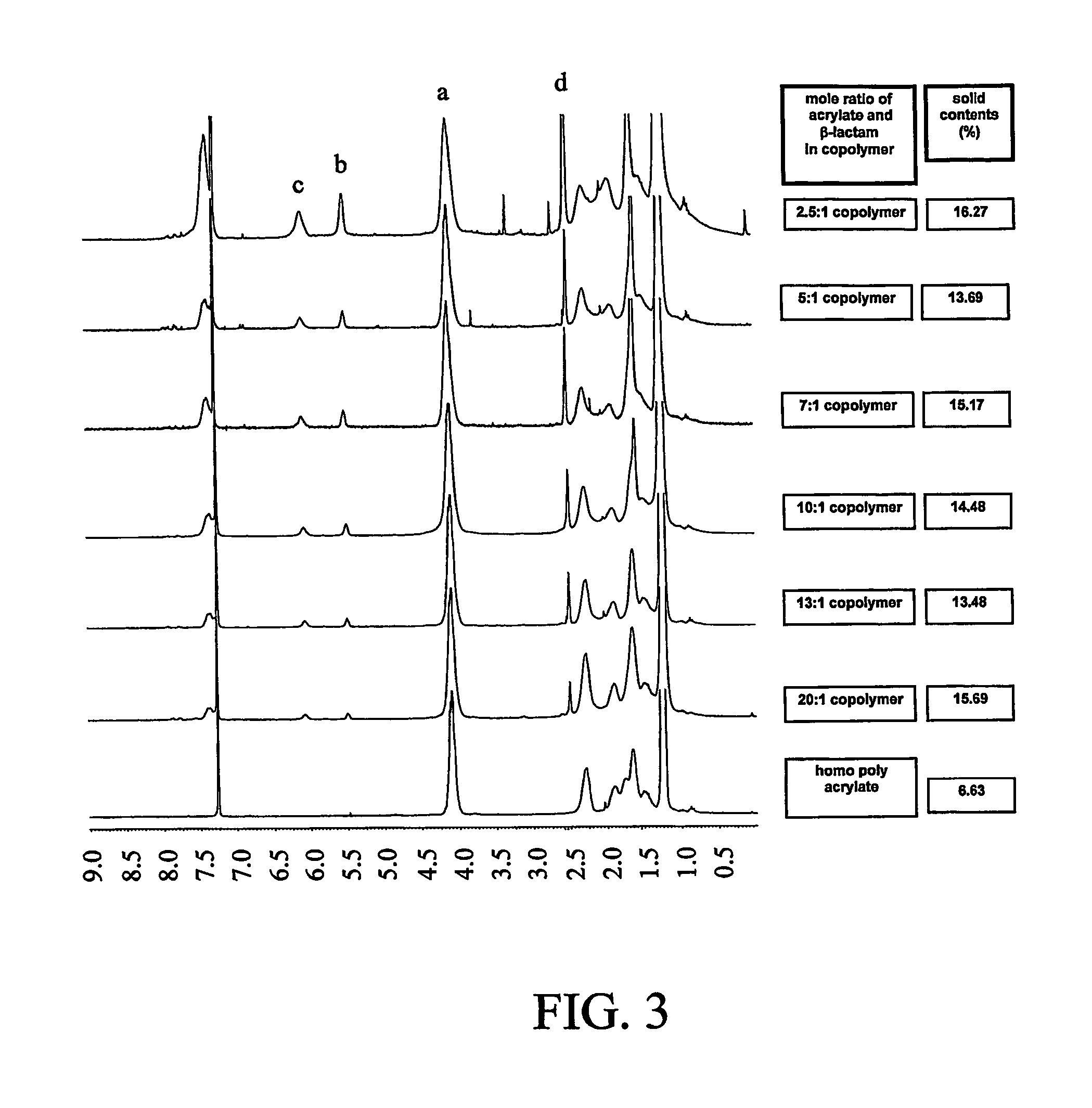

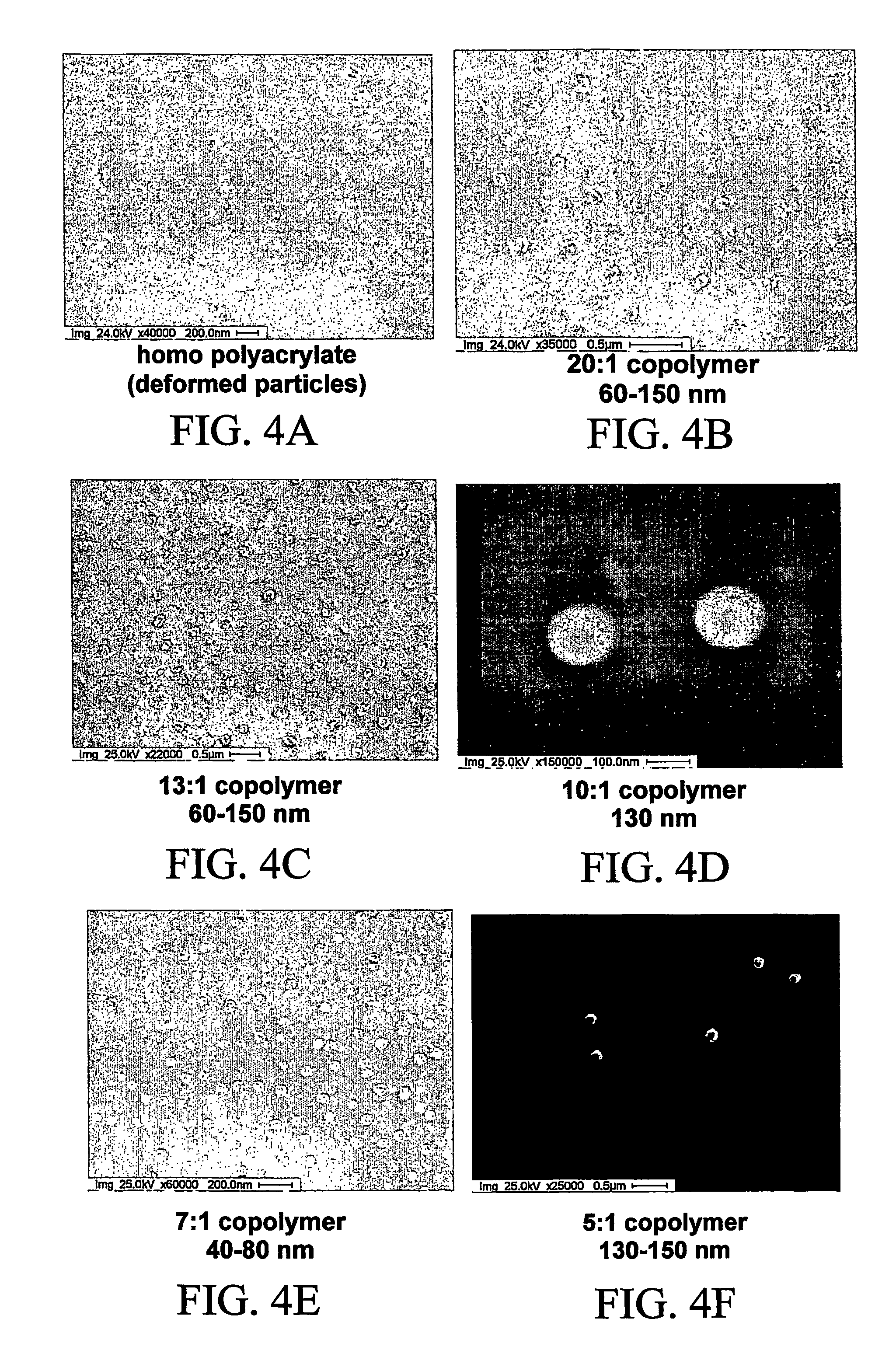

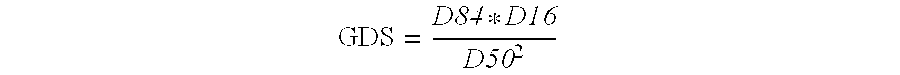

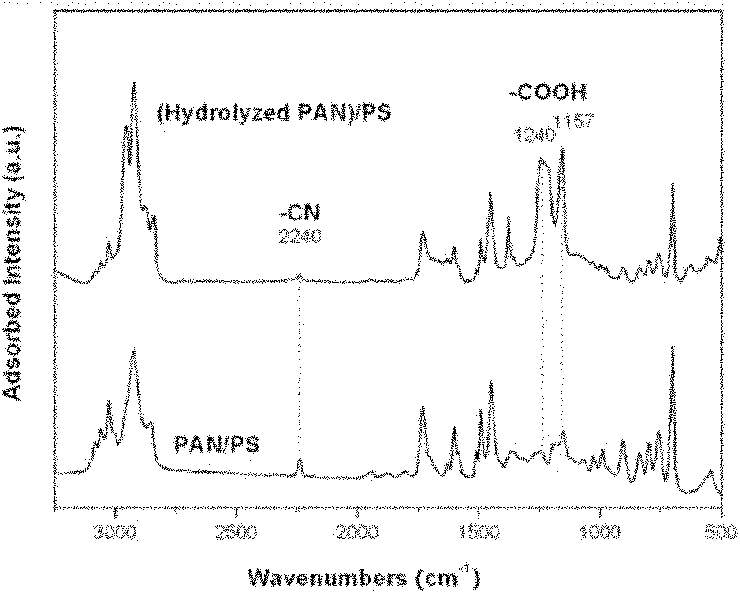

Nanoparticles for drug-delivery

This invention relates to polymeric nanoparticles useful for drug delivery with target molecules bonded to the surface of the particles and having sizes of up to 1000 nm, preferably 1 nm to 400 nm, more preferably 1 nm to 200 nm, that are dispersed homogeneously in aqueous solution. The target drug / target substance is covalently bonded to the novel polymeric nanoparticles to secure them from outer intervention in vivo or cell culture in vitro until they are exposed at the target site within the cell. This invention also relates to microemulsion polymerization techniques useful for preparing the novel nanoparticles.

Owner:UNIV OF SOUTH FLORIDA

Polymerization processes

A process for the preparation of a latex polymer by(i) preparing or providing a water aqueous phase containing an anionic surfactant in an optional amount of less than or equal to about 20 percent by weight of the total amount of anionic surfactant used in forming the latex polymer;(ii) preparing or providing a monomer emulsion in water which emulsion contains an anionic surfactant;(iii) adding about 50 percent or less of said monomer emulsion to said aqueous phase to thereby initiate seed polymerization and to form a seed polymer, said aqueous phase containing a free radical initiator; and(iv) adding the remaining percent of said monomer emulsion to the composition of (iii) and heating to complete an emulsion polymerization thus forming a latex polymer.

Owner:XEROX CORP

Latex for low VOC paint having improved block resistance, open time and water-softening resistance

InactiveUS20080058473A1Good block resistanceImprove open timeCoatingsVolatile organic compoundEmulsion polymerization

The invention is directed to latex compositions comprising sequentially designed polymer having a first stage, a second stage and a third stage corresponding to a seed, a core and a shell. The latex polymer is suitable for aqueous low volatile organic compounds (“VOC”) paint (less than 50 g / L) with good block resistance, improved open time and increased water softening resistance. To attain good block resistance, the seed and the core contain monomers that form polymers with relatively harder characteristics and higher glass transition temperature (“Tg”) while the shell contains monomers that form polymers with softer characteristics and lower Tg. To gain improved open time, the latex polymer contains suitable level of hydrophilic monomers necessary to hold water. To achieve water softening resistance, hydrophobic monomers are grafted on hydrophilic portions of the shell or the core layers. The invention is also directed to the process of making the latex by a sequential emulsion polymerization.

Owner:COLUMBIA INSURANCE CO

Hydrophilic polymeric material and method of preparation

InactiveUS6218440B1Allows preparationStable maintenanceOther chemical processesPharmaceutical non-active ingredientsHydrophilic monomerPolymer science

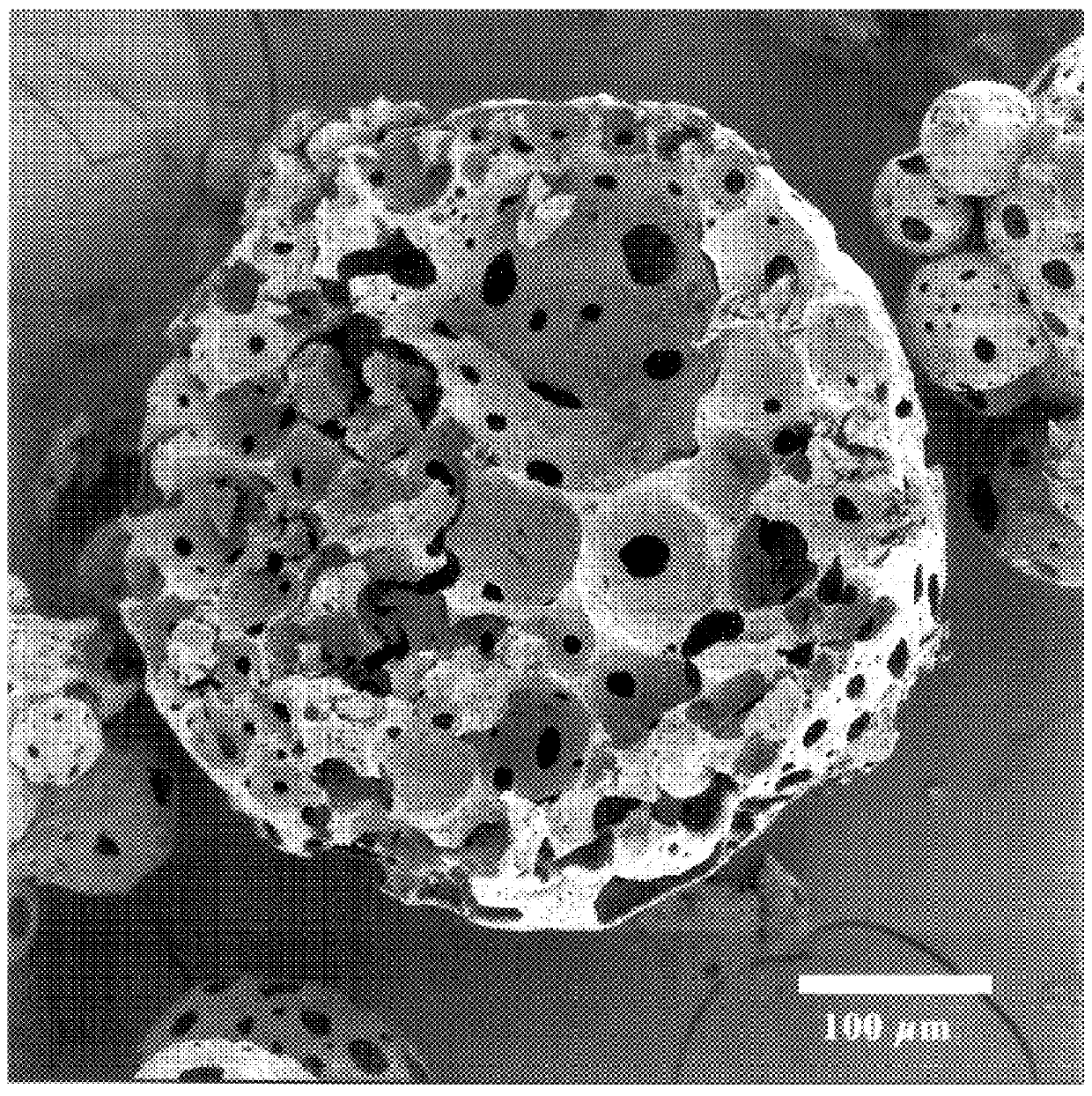

The present invention relates to a porous crosslinked hydrophilic polymeric material having cavities joined by interconnecting pores wherein at least some of the cavities at the interior of the material communicate with the surface of the material. The present invention also relates to a process for producing the polymeric material. This process involves combining a hydrophilic monomer phase with an oil discontinuous phase to form an emulsion, and polymerizing the emulsion. The emulsion can be a high internal phase emulsion (i.e., a "HIPE"). The polymeric material can be produced in a variety of forms. In one embodiment the emulsion is suspended in an oil suspension medium, and emulsion droplets are polymerized to produce polymeric microbeads.

Owner:SUNSTORM RES CORP

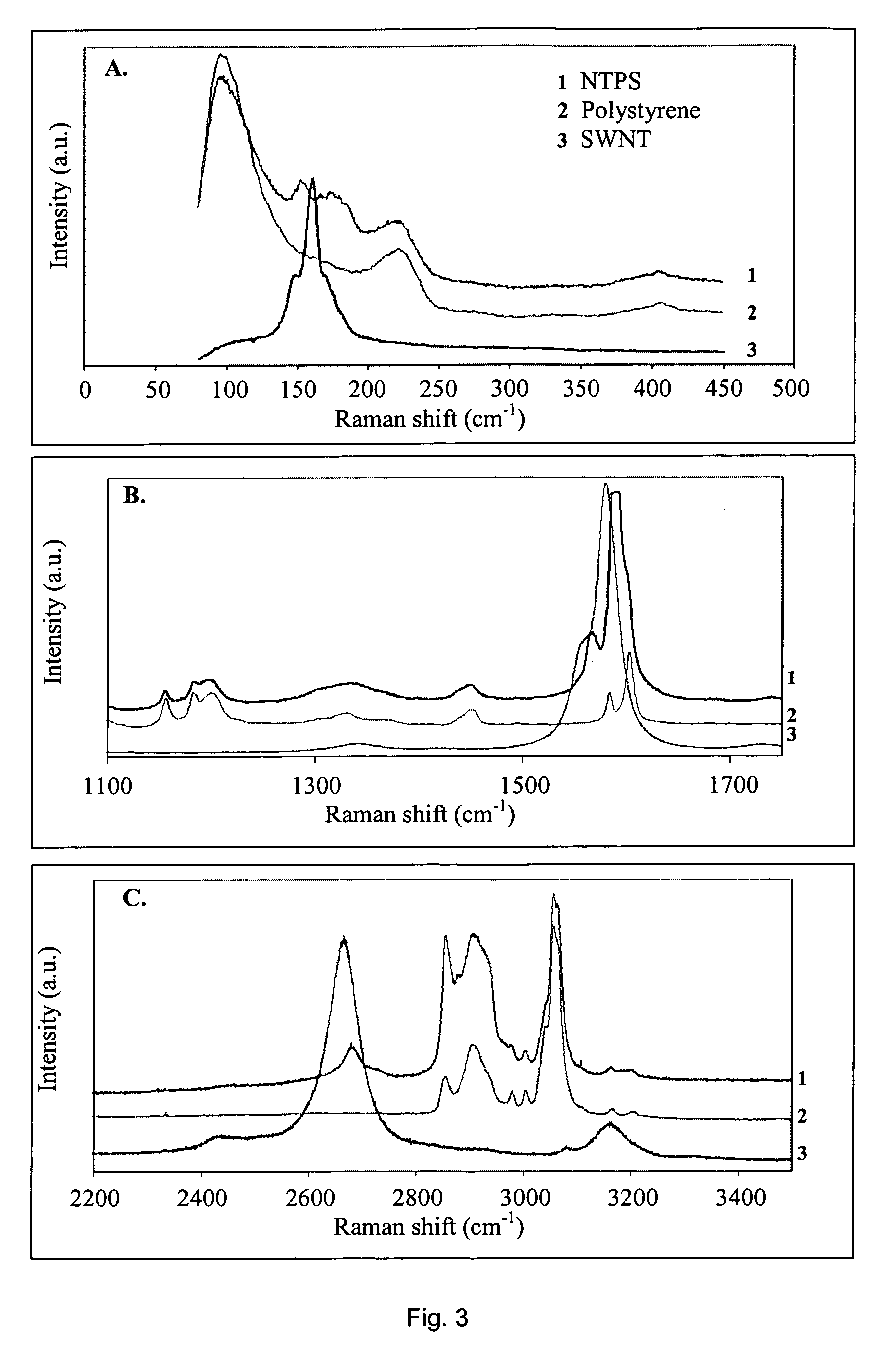

Carbon nanotube-filled composites prepared by in-situ polymerization

ActiveUS7153903B1Material nanotechnologyIndividual molecule manipulationIn situ polymerizationCarbon nanotube

A method of forming carbon nanotube-filled composites using miniemulsion polymerization. The carbon nanotubes are preferably single-walled carbon nanotubes. The carbon nanotubes are highly dispersed within and associated with the polymer comprising the composite.

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA

Method of making electron beam polymerized emulsion-based acrylate pressure sensitive adhesives

InactiveUS6103316AImprove adhesionHigh polymerizable contentFilm/foil adhesivesVacuum evaporation coatingEmulsionElectron

A one-step process using electron beam radiation to polymerize pressure sensitive adhesives on web from acrylate emulsions is disclosed. The radiation may be supplied in a single or multiple dose. Products using such pressure sensitive adhesives are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

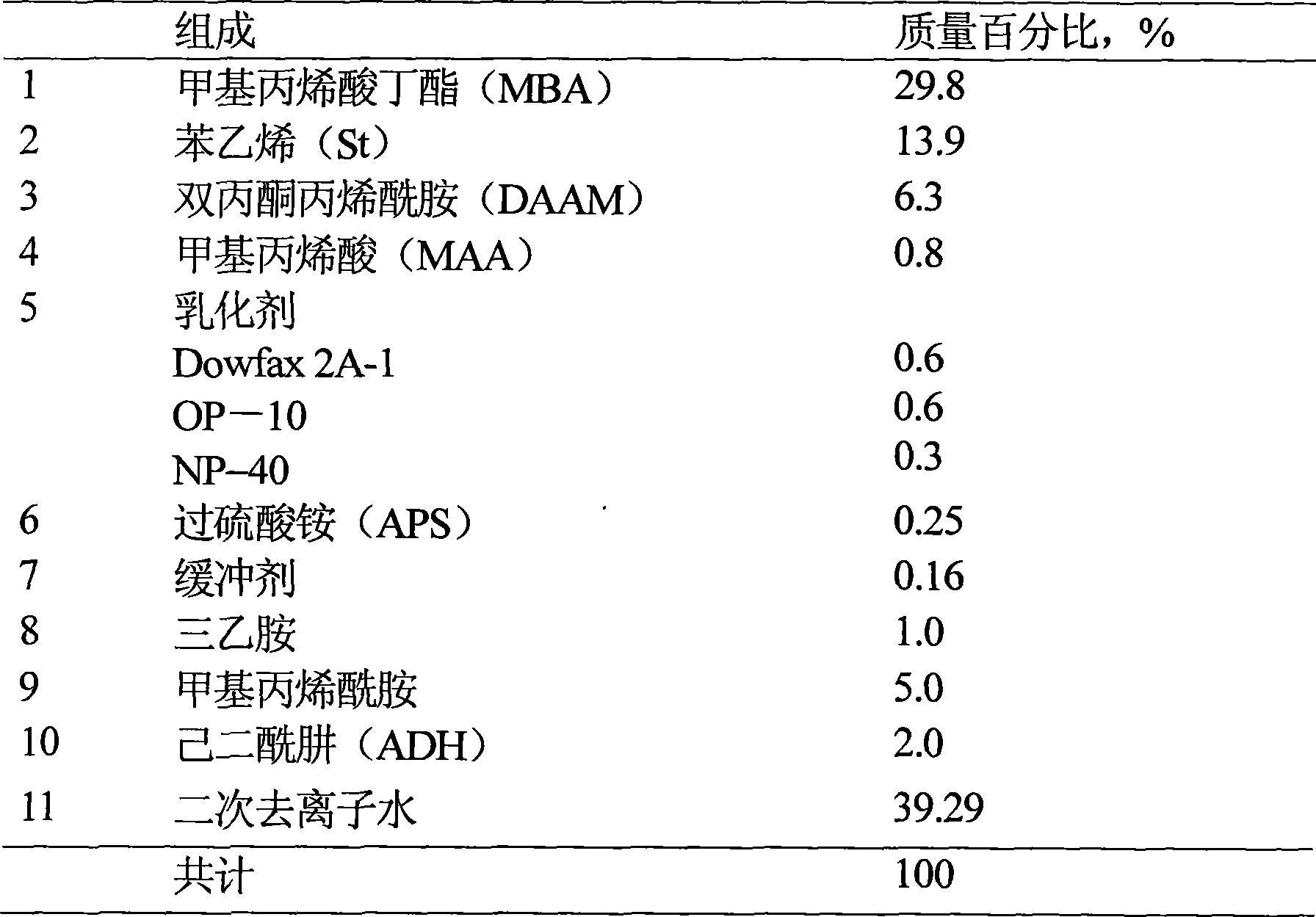

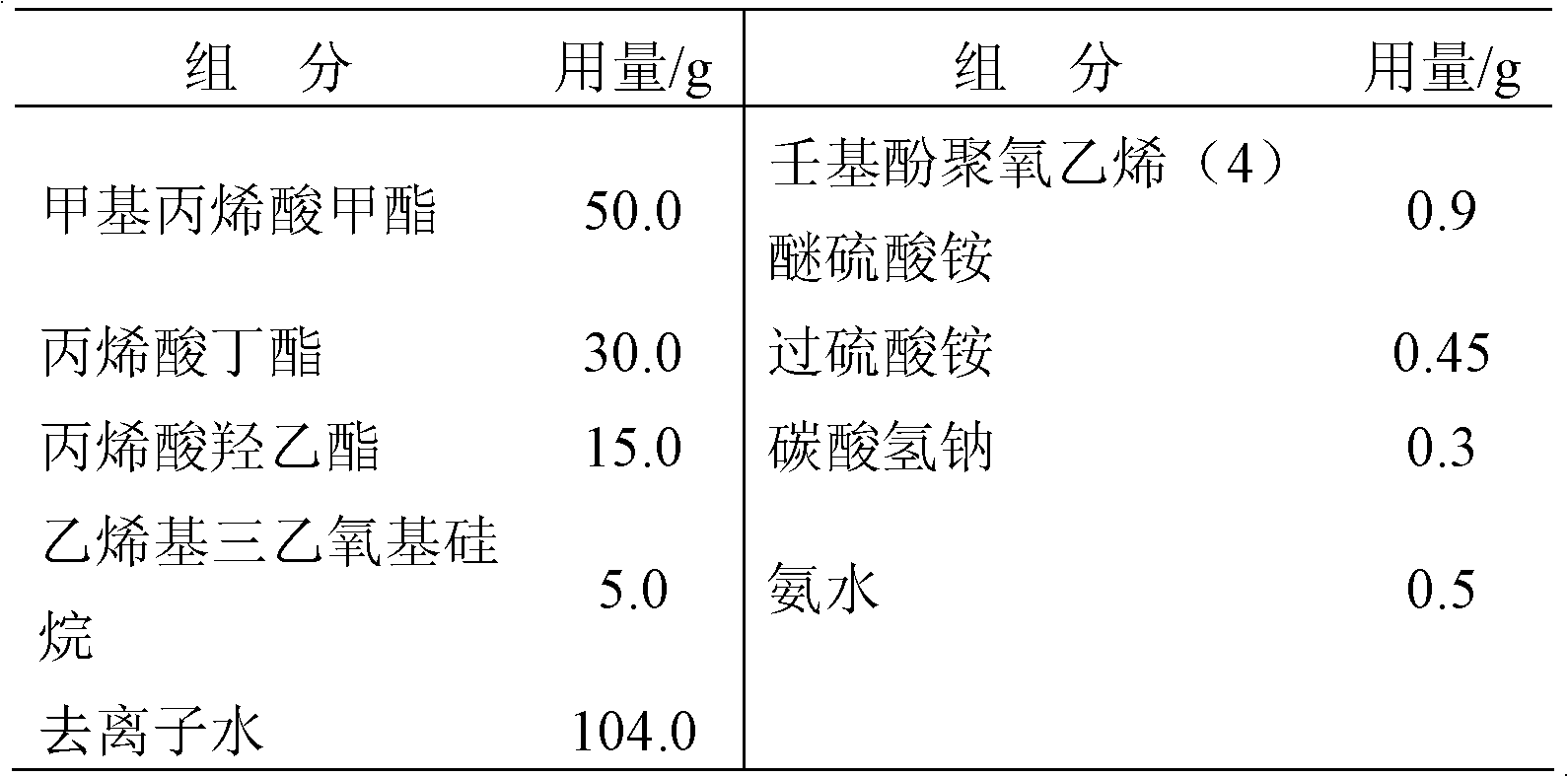

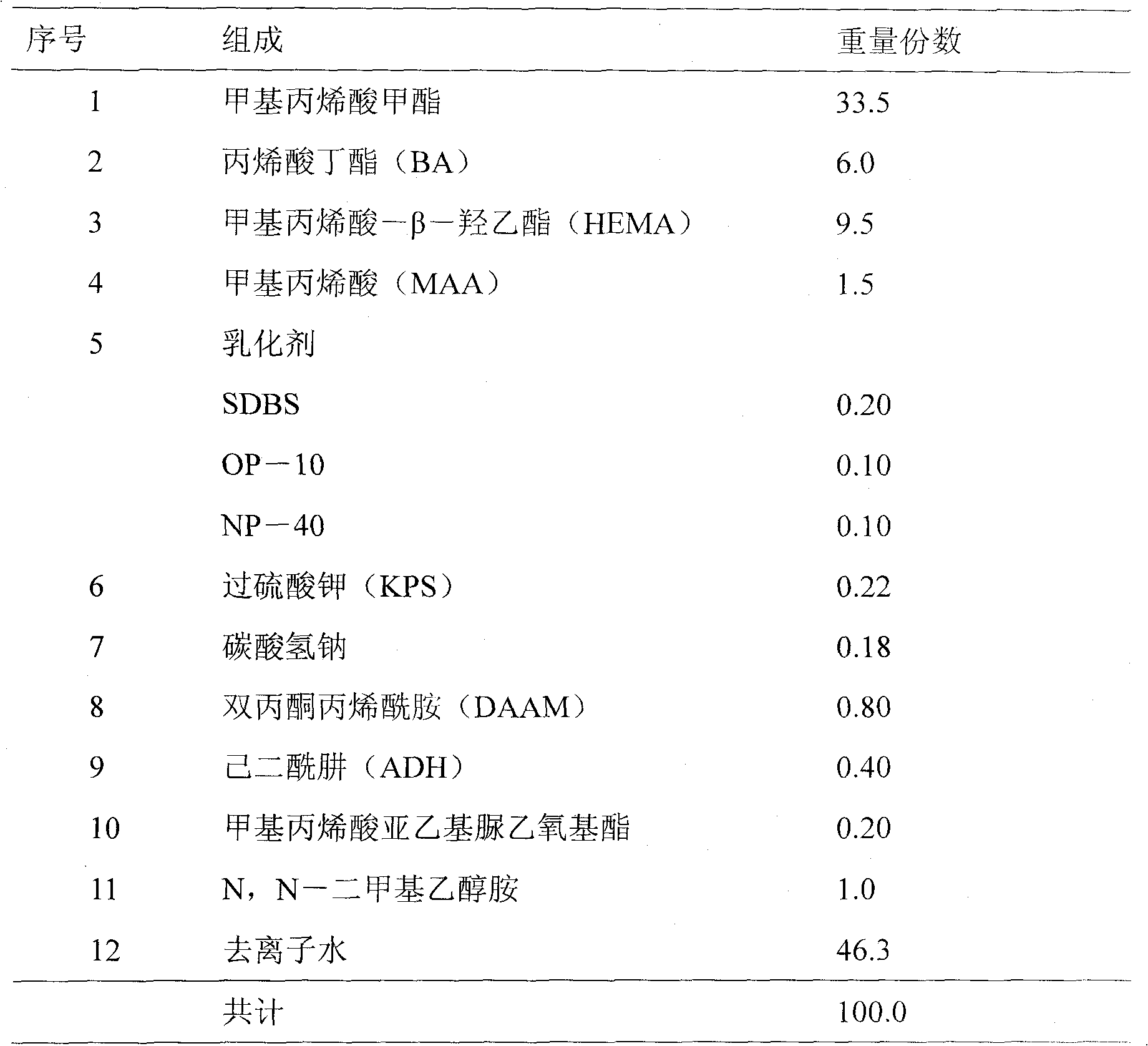

Preparation of high closeness polyacrylacid ester dispersion

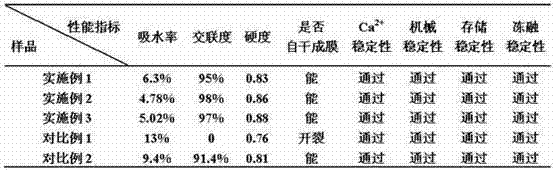

The invention relates to a high-sealing polyacrylic ester dispersoid and a preparation method thereof; a multi-element emulsifier system which consists of an anionic emulsifier and a compound non-ionic emulsifier is adopted for controlling the charging process and components of the emulsifier in different polymerization periods, and the room-temperature self-crosslinking high-sealing polyacrylic ester dispersoid is prepared by a semi-continuous seeding emulsion polymerization process. The dispersoid has small particle size, good electrolyte-resistance (calcium ion) stability and high tolerance to various film forming accessory ingredients (various organic solvents with high boiling point). The dispersoid is used as seal coat of water-based wood coating and has good sealing performance to various woods; harmful volatile organic compounds (VOC) such as formaldehyde, and the like sealed against escaping from plates to pollute indoor environment, and the colored compounds such as turpentine, pine oil and tannin and the like are sealed against dissolving out of the plates to pollute pure top coating and white top coating of a water-based wooden ware; and in addition, the dispersoid can be used in water-based leather finishing agents.

Owner:SOUTH CHINA UNIV OF TECH

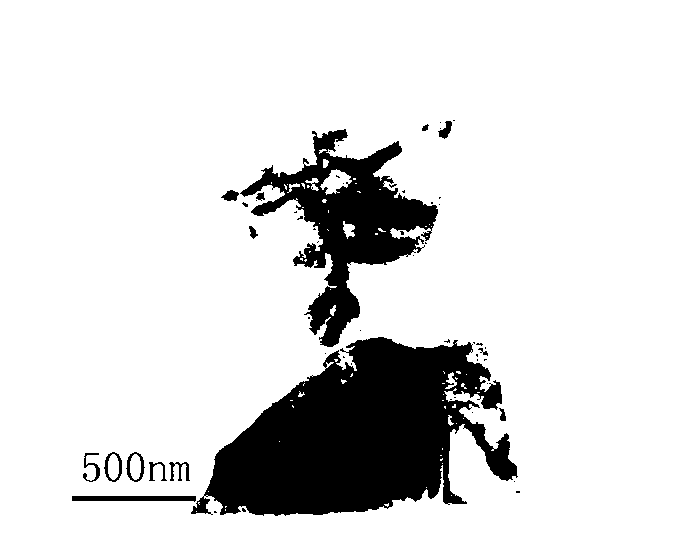

Nano titanium dioxide/ acrylate composite emulsion and preparation method thereof

InactiveCN102516477AAvoid reunionStable structureCoatingsGraft polymer adhesivesPtru catalystPolymer chemistry

The invention discloses nano titanium dioxide / acrylate composite emulsion and a preparation method thereof. The method comprises the following steps of: hydrolyzing butyl titanate to generate nano titanium dioxide sol in absolute ethanol by using hydrochloric acid as a catalyst, adding a vinyl-containing silane coupling agent for modifying the sol, performing centrifugal washing, drying and grinding on the obtained product to obtain nano titanium dioxide, and thus obtaining the nano titanium dioxide / acrylate composite emulsion by using acrylate monomers of methyl methacrylate, butyl acrylate and the like as reaction monomers and adopting a method combining in-situ emulsion polymerization and seed emulsion polymerization. The nano titanium dioxide / acrylate composite emulsion prepared by the method has good storage stability and is stable in a polymerization reaction process; and a film formed by the composite emulsion has good hardness, impact strength and heat resistance.

Owner:SOUTH CHINA UNIV OF TECH

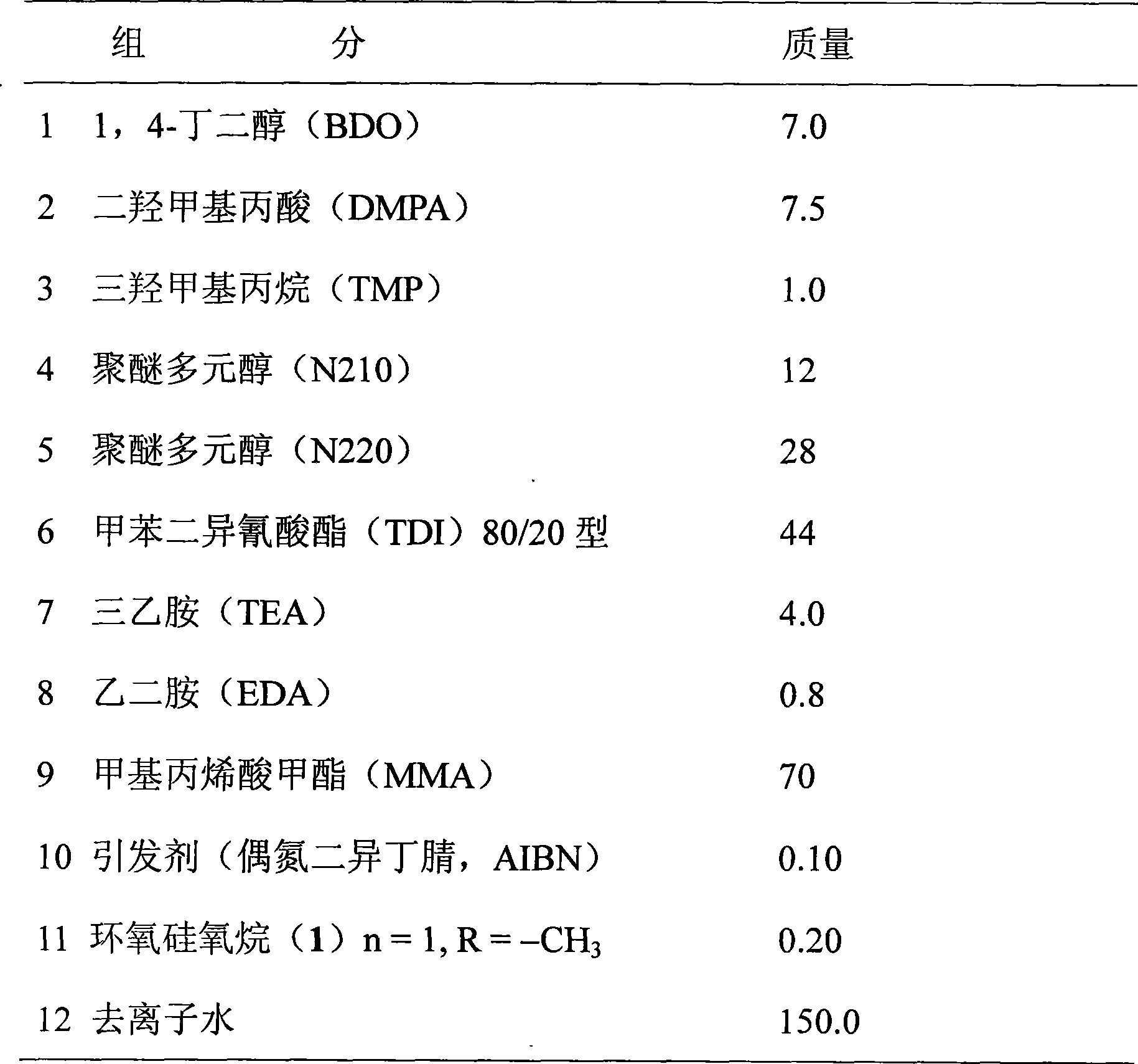

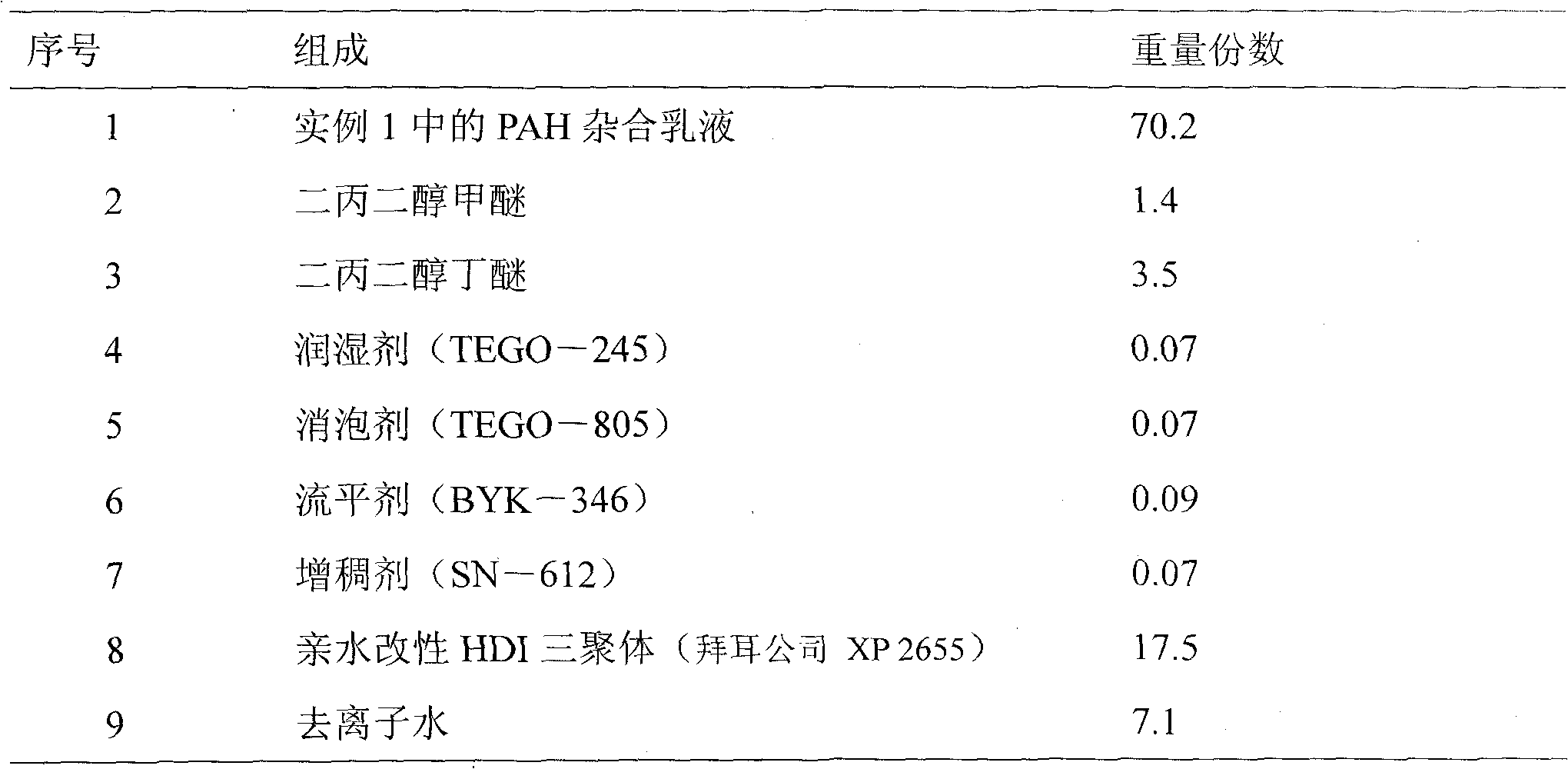

High solid content latent curing polyurethane acroleic acid hybrid emulsion

InactiveCN101481451AHigh solid contentHigh glossPolyurea/polyurethane coatingsPolyesterPolymer science

The invention relates to a method for preparing a high solid content latent cured polyurethane acrylic acid heterozygous latex and an application thereof. The preparation method comprises the following steps: pre-polymerizing polyester polyalcohol, hydrophilic chain extender and diisocyanate monomer to obtain the polyurethane prepolymer containing a hydrophilic group (carboxyl or sulfo group) and a terminal NCO group; then, neutralizing the polymer into salt and dispersing the salt in water to prepare the polyurethane water dispersoid; finally, using the dispersoid as macro molecular emulsifying agent and reactant to emulsify and disperse the acrylic ester monomer, initiating the polymerization by heating, dropping initiator to perform the latex polymerization, and regulating the pH of the latex by adding a latent curing agent to obtain the high solid content latent cured polyurethane acrylic acid heterozygous latex. The high solid content latent cured polyurethane acrylic acid heterozygous latex has a solid content of above 45%; the storage of the high solid content latent cured polyurethane acrylic acid heterozygous latex is stable; and high hardness film coating can be formed at the room temperature. Compared with acrylic acid latex and polyurethane latex, the high solid content latent cured polyurethane acrylic acid heterozygous latex has better film forming performance, water resistance, alcohol resistance, pollution resistance, dry / wet cleaning resistance and chemical solvent resistance, as well as high hardness.

Owner:SOUTH CHINA UNIV OF TECH

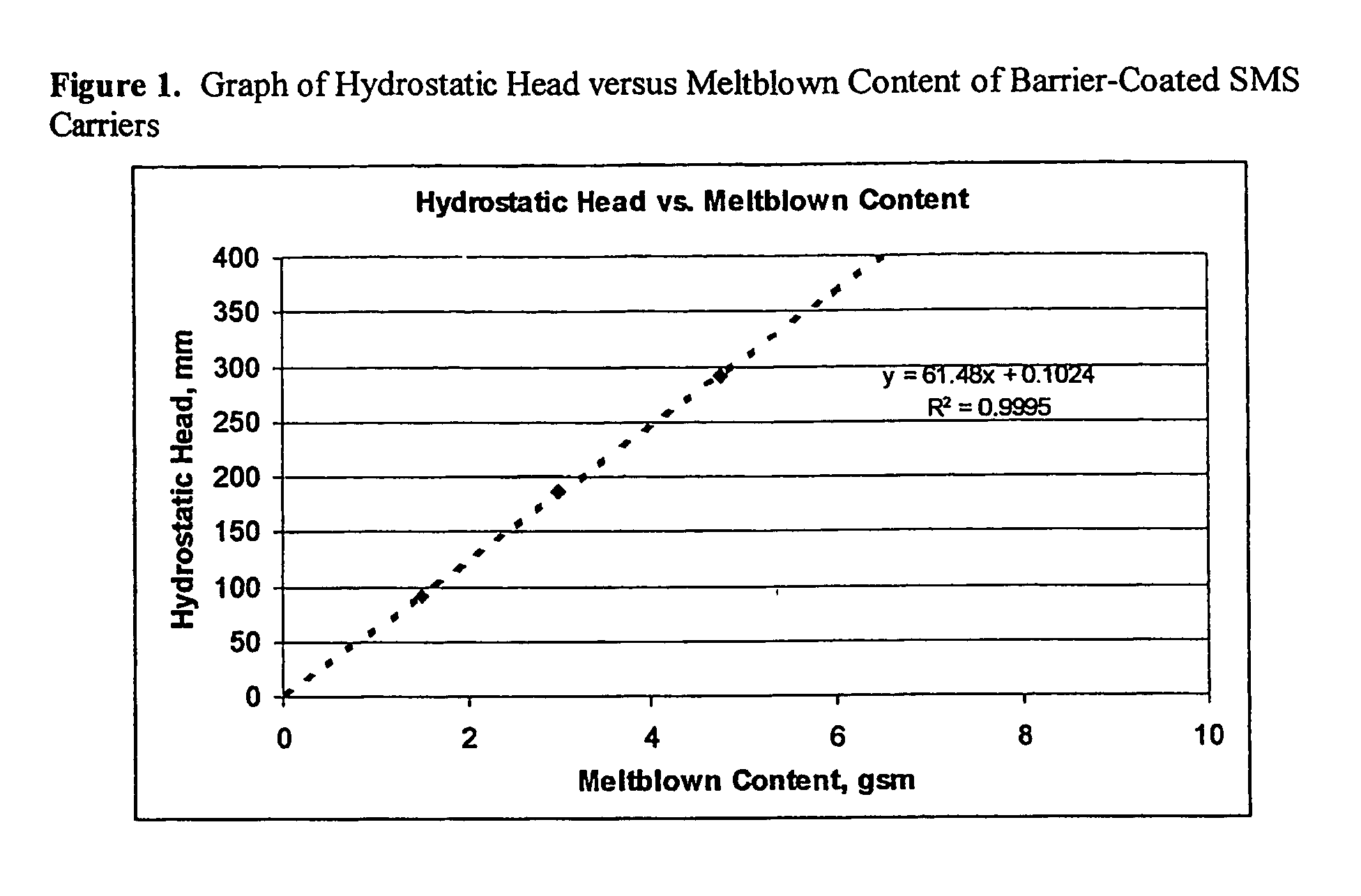

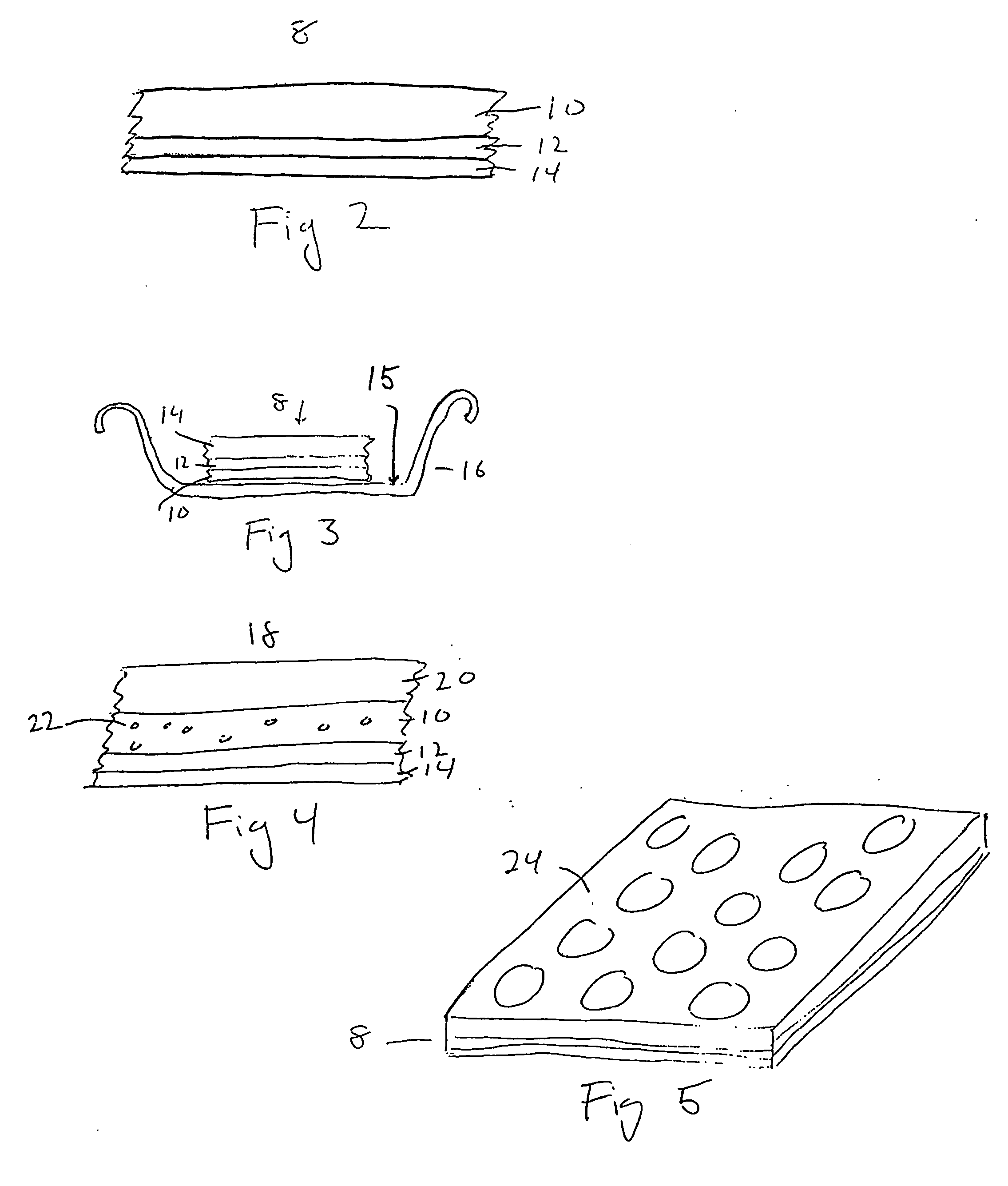

Unitary absorbent multilayered core

The present invention is directed to a unitary absorbent core including a first fibrous absorbent layer of (a) natural fibers, synthetic fibers or a mixture thereof, (b) a binder which is a synthetic binder fiber or powder, a hydrophilic emulsion polymer binder or a mixture thereof, the fibrous absorbent layer having an upper surface and a lower surface, the lower surface in contact, optionally coextensively in contact, with an upper surface of a synthetic carrier which has a lower surface integral with a first hydrophobic vapor-transmissive moisture barrier. The present invention is also directed to a receptacle for food incorporating the unitary absorbent core. The present invention is also directed to a filter element incorporating the unitary absorbent core.

Owner:GLATFELTER CORP

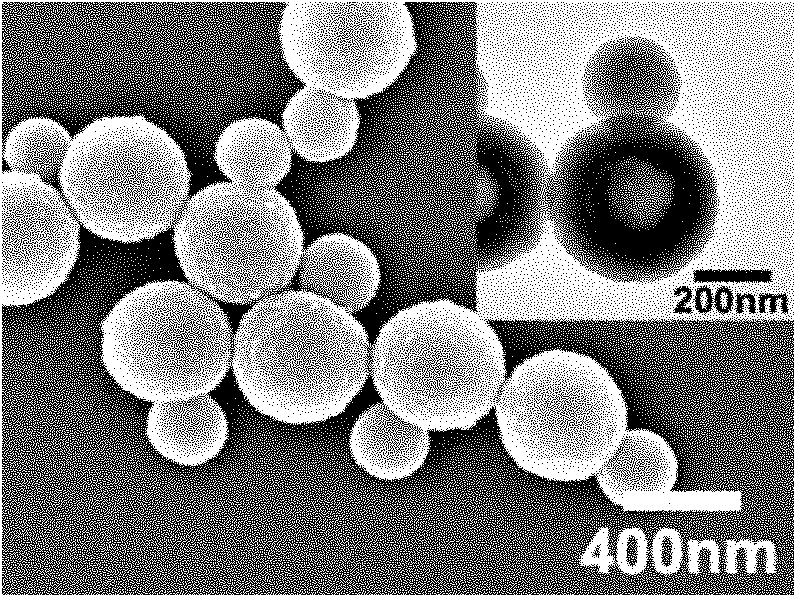

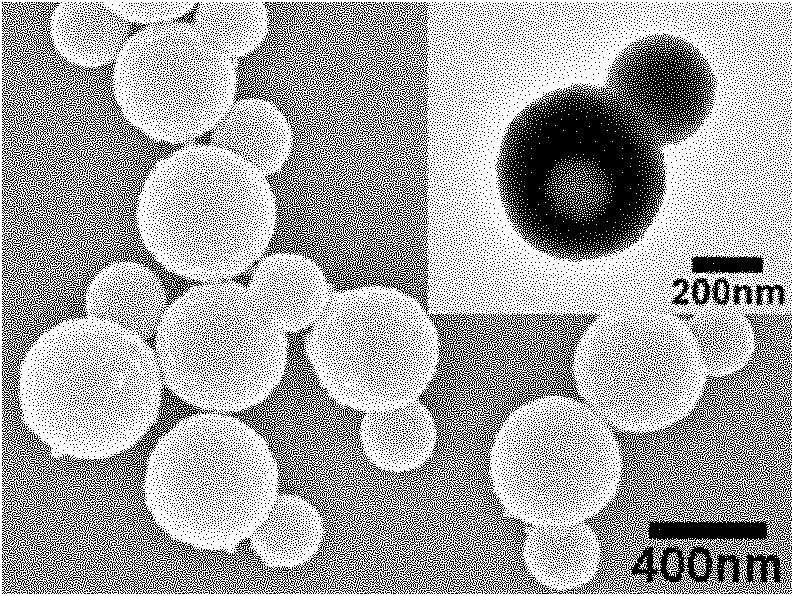

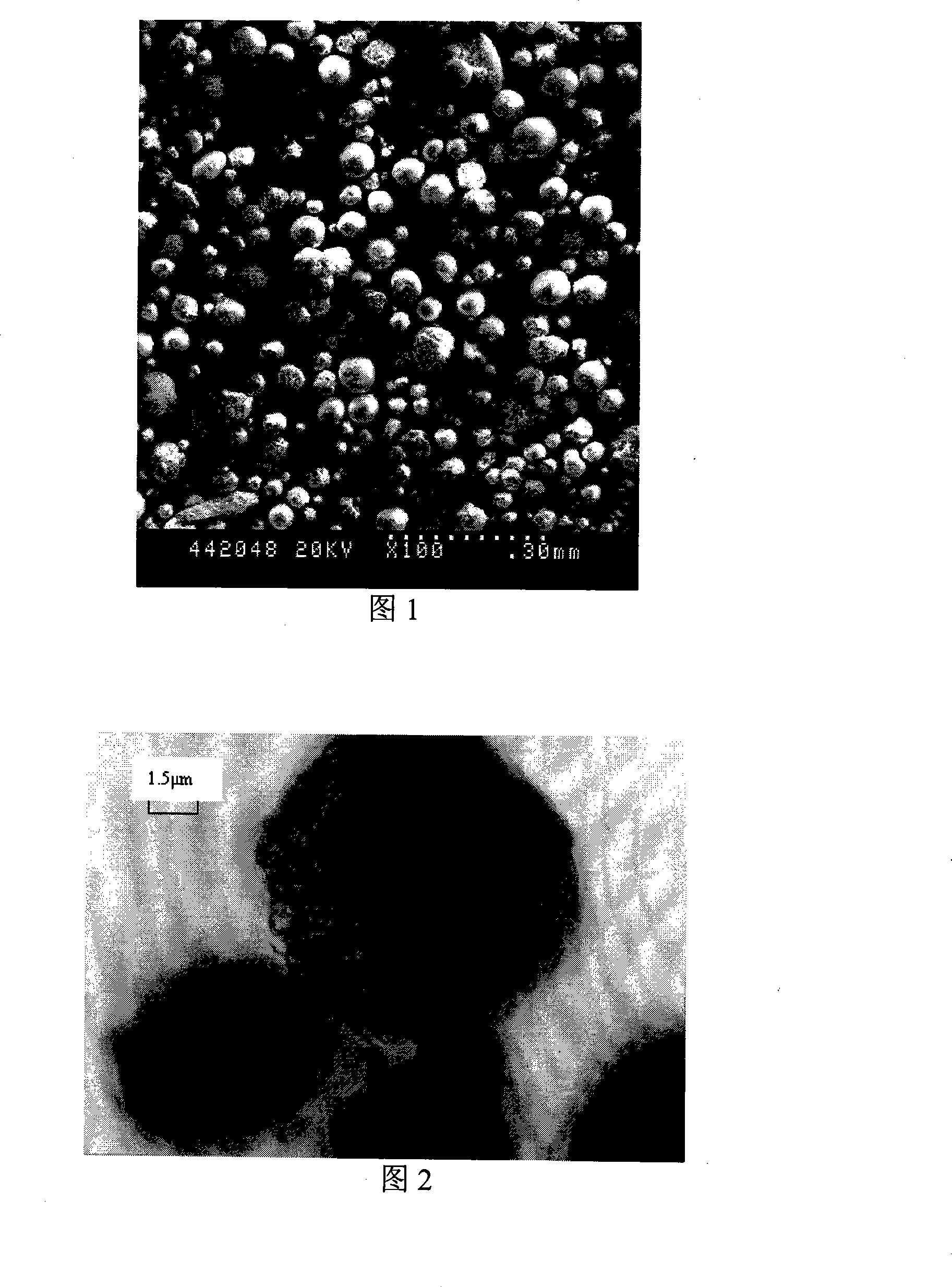

Janus particle with double properties and preparation method thereof

The invention discloses a Janus particle with double properties and a preparation method thereof. By employing cross-linked polymer colloidal particles as seeds and through a seed emulsion polymerization method, Janus particles with double properties are obtained on the basis of a phase separation mechanism; inorganic, metal and metal oxide compounded Janus particles with electrical, magnetic, optical properties are obtained through functional group modification and composition of function materials and can be used for the material field. The Janus particles have an emulsifying property in organic, inorganic dispersed phases or different organic dispersed phases and meanwhile the Janus particles have a great application prospect in the aspects of self-assembly, superhydrophobicity, nanomotor and the like. The preparation method provided by the invention is easy to operate, has the feasibility of mass production and can adapt to different needs by modification and composition of function materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

High-hydroxy silicon-acrylate aqueous glass coating emulsion and synthesis method thereof

InactiveCN102101960ASimple preparation processImprove water resistanceCoatingsPolymer scienceFunctional monomer

The invention discloses high-hydroxy silicon-acrylate aqueous glass coating emulsion and a synthesis method thereof. The high-hydroxy silicon-acrylate emulsion with a particle size between 100 and 180 nanometers and a solid content of 40 to 48 percent is prepared by adopting a monomer pre-emulsification method and a semi-continuous seed emulsion polymerization process and by introducing a hydroxymonomer containing double bonds and organic silicon functional monomer containing double bonds in a polymerization process of acrylate emulsion. The emulsion is low in gel rate and high in stability and can be stored for more than one year. After being added with a curing agent, the emulsion is coated on a glass surface and baked for 2 hours at 20 DEG C to be cured into a film, the film-coated pencil hardness is more than or equal to 2H, the adhesive force of the film is of grade one, the film has high waterproof performance, the cost of the emulsion is low and the preparation process of the emulsion is simple.

Owner:DALIAN POLYTECHNIC UNIVERSITY

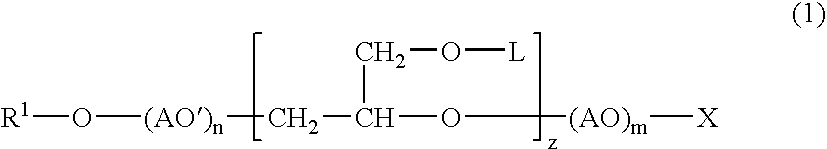

Surfactants

InactiveUS6841655B1No adverse effectsHigh strengthTransportation and packagingMixingPhenyl EthersEmulsion polymerization

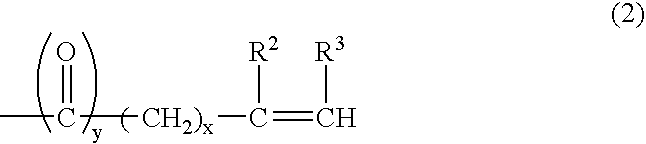

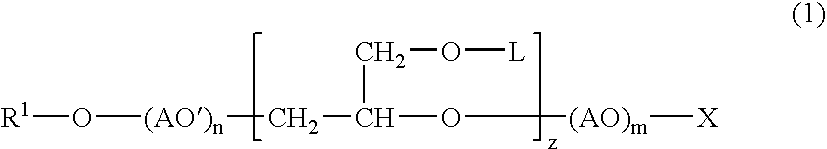

Disclosed are surfactants represented by the following formula (1): wherein R1 represents a branched aliphatic hydrocarbon group, a secondary aliphatic hydrocarbon group or a branched aliphatic acyl group, AO and AO′ each independently represents an oxyalkylene group having 2 to 4 carbon atoms, L represents a group represented by formula (2) to be described below, z stands for a number of from 1 to 10, X represents a hydrogen atom or an ionic hydrophilic group, m stands for a number of from 0 to 1,000, and n stands for a number of from 0 to 1,000. wherein R2 and R3 each independently represents a hydrogen atom or a methyl group, x stands for a number of from 0 to 12, and y stands for a number of 0 or 1. These surfactants do not contain any phenyl ether group considered to have significant effects on the environment, such as a nonylphenyl group, and have performance comparable with reactive surfactants containing one or more phenyl ether groups. Emulsifiers for emulsion polymerization, dispersants for dispersion polymerization and resin modifiers, all of which contain the surfactants, are also disclosed.

Owner:ADEKA CORP

Preparation method and application of acrylate heterozygotic emulsion

ActiveCN101787098ASmall particle sizeWide particle size distributionPolyurea/polyurethane coatingsPolymer scienceLacquer

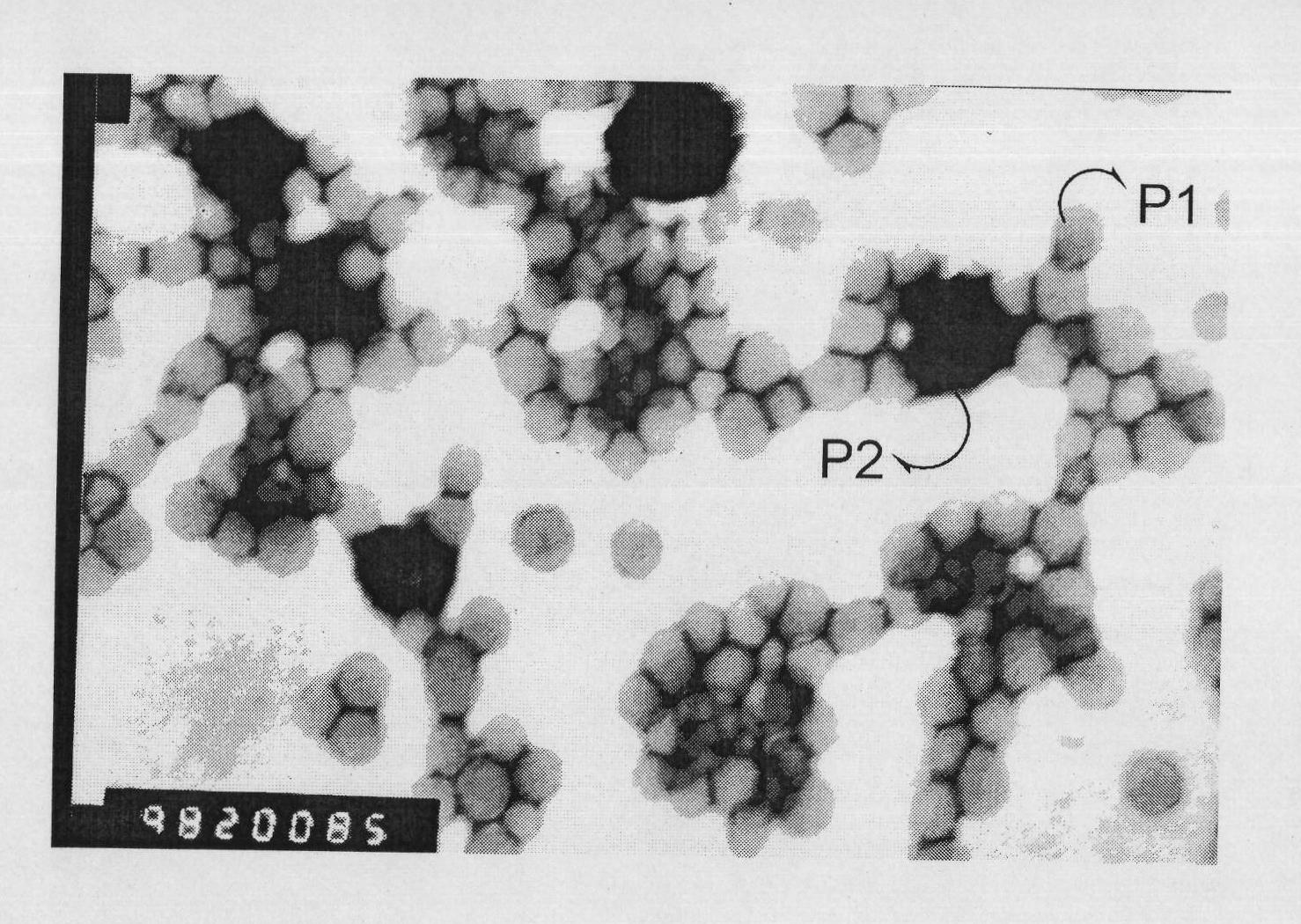

The invention discloses a preparation method and an application of an acrylate heterozygotic emulsion. In the invention, the acrylate heterozygotic emulsion is synthesized by adopting a seed emulsion polymerization process and combining a process of instantly neutralizing and segmentally adding polar monomers. The acrylate heterozygotic emulsion comprises macroparticles consisting of polymers P2 rich in hydroxyl groups on a surface layer and microparticles consisting of polymers P1 rich in carboxylate on the surface layer. Compared with a conventional hydroxy acrylate emulsion, the acrylate heterozygotic emulsion has smaller mean grain size and wider grain size distribution on emulsion particles. The acrylate heterozygotic emulsion can be adopted to prepare aqueous bi-component polyurethane wood coatings, and a coating layer of the coating has excellent property of resisting water and solvents, high crosslinking density and hardness, good mechanical property, scratching resistance and wear resistance. The acrylate heterozygotic emulsion has compact coating structure, high glossiness and better combination property, and not only can be applied to high-grade wood coatings, but also can be applied to automotive refinish paint, metallic anti-corrosion paint, other industrial protective paint, and the like.

Owner:SOUTH CHINA UNIV OF TECH

Fluorine-silicon modified self-crosslinking acrylic ester emulsion and preparation thereof

InactiveCN101348595ASimple preparation processReaction conditions are easy to controlCoatingsPolymeric surfacePolymer science

The invention provides a fluorine-silicon modified self-crosslinking acrylic ester emulsion and a preparation method thereof, belonging to the technical field of polymer synthesis. The emulsion is a product formed by organosilicon monomers, fluoride-containing acrylic monomers, (methyl) acrylic monomers and self-crosslinking monomers through core-shell emulsion polymerization. The preparation method adopts a core-shell emulsion polymerization method, thereby ensuring that the fluoride-containing acrylic monomers tend to surface polymerization, and fluorine atoms tend to polymer surface in emulsion film forming process; moreover, the monomers capable of self-crosslinking is added to a shell layer, so as to utilize the crosslinking of the monomers to fixedly limit the migration of the fluorine atoms towards the inside of latex particles, as well as the swing of chains, thereby ensuring that the performances of the fluoride-containing emulsion are completely embodied. The preparation method improves the water resistance, stain resistance, solvent resistance, weather resistance and other comprehensive performances of the emulsion. The fluorine-silicon modified self-crosslinking acrylic ester emulsion prepared through the preparation method can be widely applied to high-grade building paint, industrial paint and wooden ware varnish. Moreover, the preparation method has the characteristics of simple manufacturing process, easy reaction condition control, good emulsion stability and environment-friendly property.

Owner:PEKING UNIV +1

Synthesizing microcapsules of storing energy through phase change by using method of emulsion polymerization

A process for synthesizing the phase-change energy-accumulating microcapsules by emulsion polymerizing method features that the liposoluble organic phase-change material, vinyl or bivinyl monomers, water, non-ionic or anionic surfactant and the persulfate, percarbonate, perborate, hydrogen peroxide, or their redox pair take part is core-shell polymerizing reaction in emulsion to obtain said microcapsules.

Owner:DONGHUA UNIV

Silicone resin-containing emulsion composition, method for making same, and article having a cured film of same

InactiveUS6114440AGroup 4/14 element organic compoundsPretreated surfacesPolymer scienceOrganic solvent

A silicone resin-containing emulsion composition is prepared by emulsion polymerizing a solution containing a water-insoluble silanol group-bearing silicone resin and a radical polymerizable vinyl monomer and substantially free of an organic solvent. The emulsion may further contain a film-forming assistant having a boiling point of at least 100 DEG C. and soluble or uniformly dispersible in water. The emulsion can be coated and cured into a film having mar resistance, weather resistance, and chemical resistance.

Owner:SHIN ETSU CHEM IND CO LTD

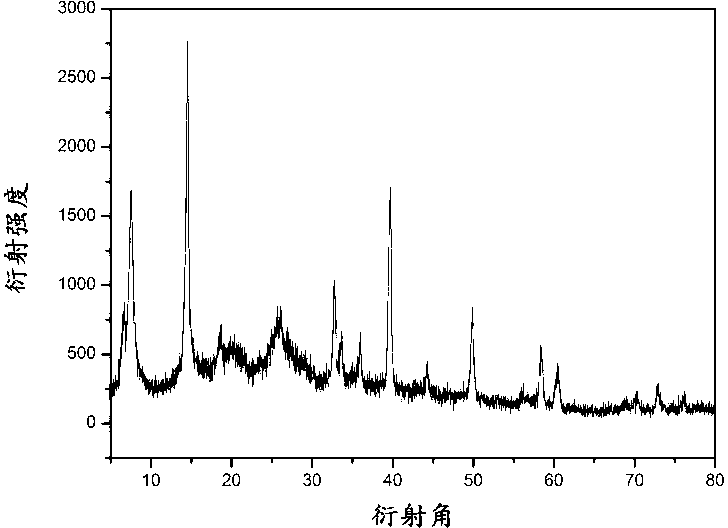

Preparation method of polyaniline and molybdenum disulfide intercalated composite material

The invention discloses a preparation method of a polyaniline and molybdenum disulfide intercalated composite material. The preparation method comprises the steps of preparing suspension of graphene molybdenum disulfide from molybdenum disulfide powder through a chemical intercalation process, adding an aniline monomer, an oxidizing agent and organic acid dopants, and implementing in-situ emulsion polymerization to prepare the polyaniline / molybdenum disulfide intercalated composite material. The preparation method is simple and convenient, controllable and environment-friendly; the material is in emulsion or solid powder, and can be formed by coating, deposition, or pressing powder thereof, and other methods; the material is uniform in texture, stable in performance, and excellent in both photoelectrical performance and thermal stability; and the composite material is applicable to the fields of photoelectronic devices such as a secondary battery, a super-capacitor, an electromagnetic shielding device, an antistatic device, a field effect transistor, a sensor, an organic electroluminescence device and the like.

Owner:HEFEI UNIV OF TECH

Waterborne paper or paperboard coating composition

InactiveUS20010036990A1Trend downHigh molecular weightMaterial nanotechnologyNon-fibrous pulp additionEmulsionPolymer science

A waterborne pigmented paper or paperboard coating composition containing as pigment 50% to 100%, by weight based on pigment weight, calcium carbonate and from 1% to 25%, as dry weight based on pigment weight, of an aqueous polymeric dispersion including (a) 95-25% by weight, based on the weight of the solids of the aqueous polymeric dispersion, of a first emulsion polymer having an average particle diameter of 150 to 3000 nanometers and (b) 5-75% by weight, based on the weight of the solids of the aqueous polymeric dispersion, of a second emulsion polymer having an average particle diameter of 40 to 600 nanometers wherein the ratio of the average particle diameter of the first emulsion polymer to the average particle diameter of the second emulsion polymer is from 1.2 to 60, wherein at least the first emulsion polymer particles, when dry, contain at least one void, and wherein the first emulsion polymer is prepared in the presence of the second emulsion polymer or the second emulsion polymer is prepared in the presence of the first emulsion polymer is provided, as is a method for improving the sheet gloss of paper or paperboard coated with the coating composition.

Owner:BOBSEIN BARRETT RICHARD +2

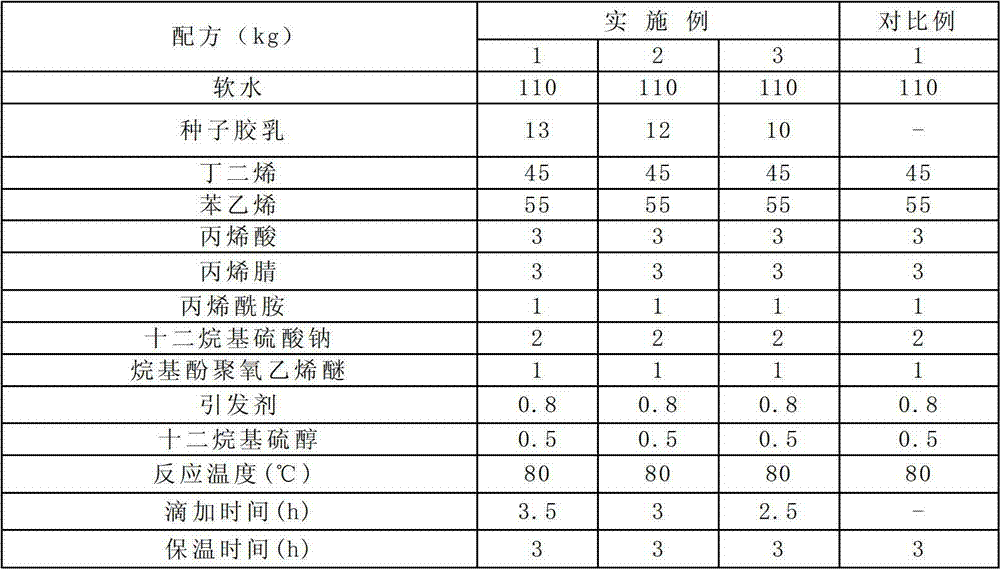

Small-particle-size carboxylic styrene-butadiene latex and its preparation method

ActiveCN102786620AAdjustable particle sizeSimple processPaper coatingCoatingsPolymer scienceFunctional monomer

The invention belongs to the technical field of seed emulsion polymerization, relates to a preparation of a high polymer material, and especially relates to a small-particle-size carboxylic styrene-butadiene latex and its preparation method. Technical problems comprising unadjustable particle size, bad mechanical stability, bad chemical stability and the like of latexes in the prior art are solved in the invention. The preparation method which adopts a seed emulsion polymerization technology and adopts butadiene and styrene as monomers comprises the following steps: adding soft water, a seed latex, an electrolyte, a chelating agent and a pH buffering agent; heating; adding functional monomers, unsaturated carboxylic acid, a molecular weight adjustment agent, a composite emulsifier and an initiator; degassing when the conversion rate reaches above 98%; cooling; and synthesizing the carboxylic styrene-butadiene latex. Compared with the prior art, the preparation method of the small-particle-size carboxylic styrene-butadiene latex has the advantages of realization of the adjustment of the particle size of the latex, and simple operation; and compared with present carboxylic styrene-butadiene latexes, the carboxylic styrene-butadiene latex prepared in the invention has the advantages of narrow monodispersion, good fluidity, excellent mechanical stability and excellent chemical stability.

Owner:WEIFANG LANLI NEW MATERIAL CO LTD

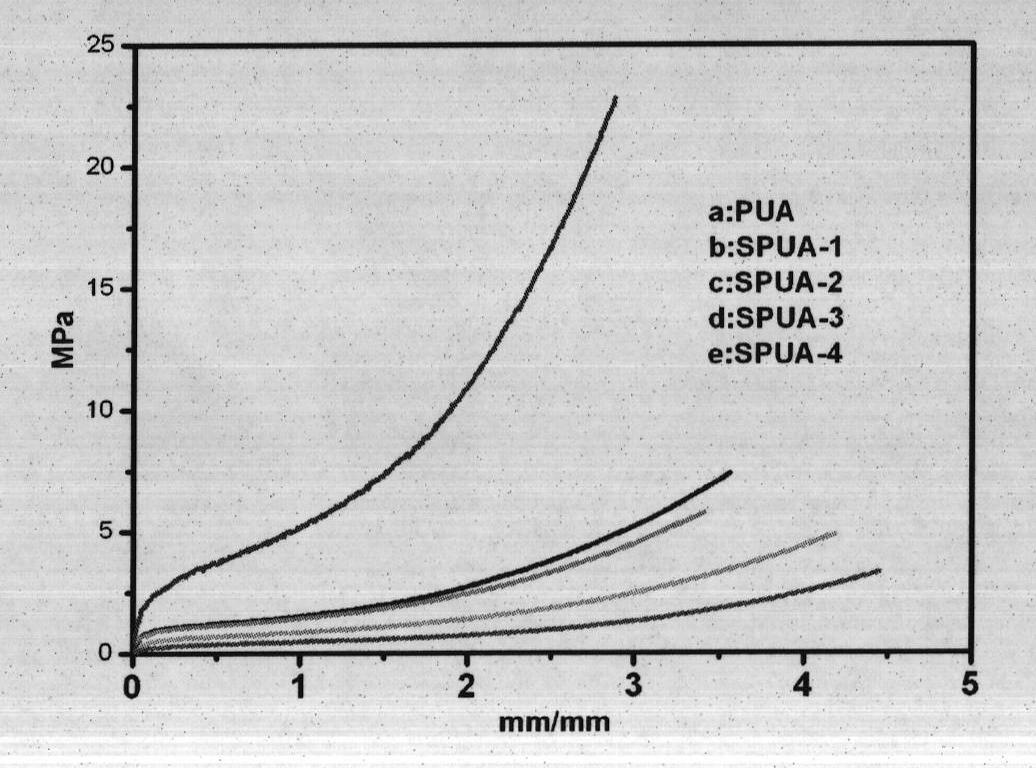

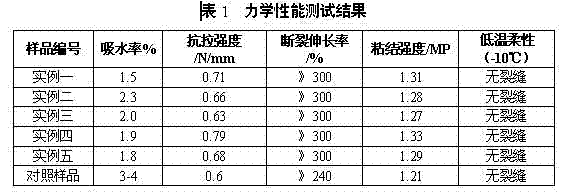

Nano silicon dioxide/acrylate composite emulsion and process for preparing same

The present invention discloses one kind of nanometer composite silica / acrylate emulsion and its preparation process. The present invention is superior to available technology, and the composite emulsion has dispersed nanometer inorganic silica phase in 0.1-5 % of the total weight of monomers for the acrylate copolymer emulsion. The preparation process includes the surface treatment of nanometer inorganic silica phase, and synthesizing nanometer inorganic phase / polymer emulsion in molecular level compounding through in-situ polymerization process or seed emulsion polymerization process. The composite emulsion of the present invention can form film with doubled tensile strength and breaking elongation. Adding nanometer silica in 0.2 % results in tensile strength of 5.25 MPa and breaking elongation of 1300 %.

Owner:江苏汉德纳米材料科技有限公司

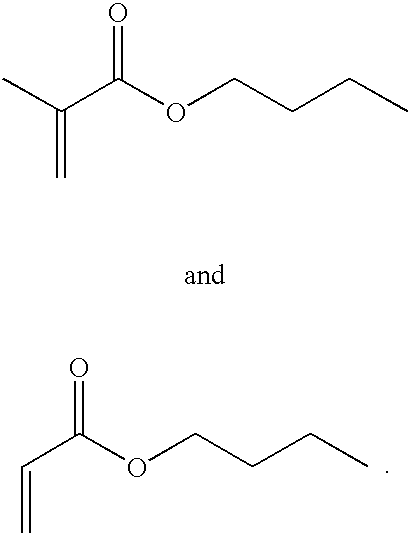

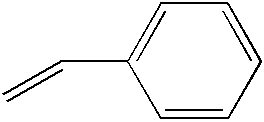

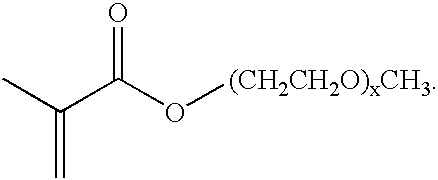

Water-based acrylic emulsion dispersants utilized as grind resins for pigments and method of preparing the same

The present invention is directed to a water-based acrylic emulsion dispersant to be used as a grind resin to incorporate inorganic pigment into a pigment dispersion for a coating composition. The acrylic emulsion dispersant is the reaction product of butyl methacrylate, butyl acrylate, styrene, methyl ether polyethylene glycol methacrylate, polyethylene glycol methacrylate, and polyphosphoric acid. The present invention is also directed to a method of preparing the acrylic emulsion dispersant. In this method, the butyl methacrylate, butyl acrylate, and styrene are combined with water to establish a first reaction blend. Similarly, the methyl ether polyethylene glycol methacrylate and the polyethylene glycol methacrylate are combined with water to establish a second reaction blend. Next, the first and second reaction blends are polymerized to form an intermediate emulsion polymer containing a hydroxyl group from the functionality of the polyethylene glycol methacrylate. Finally, the hydroxyl group from the polyethylene glycol methacrylate is reacted with polyphosphoric acid to form the acrylic emulsion dispersant which is utilized for efficient wetting and grinding of the pigment.

Owner:BASF CORP

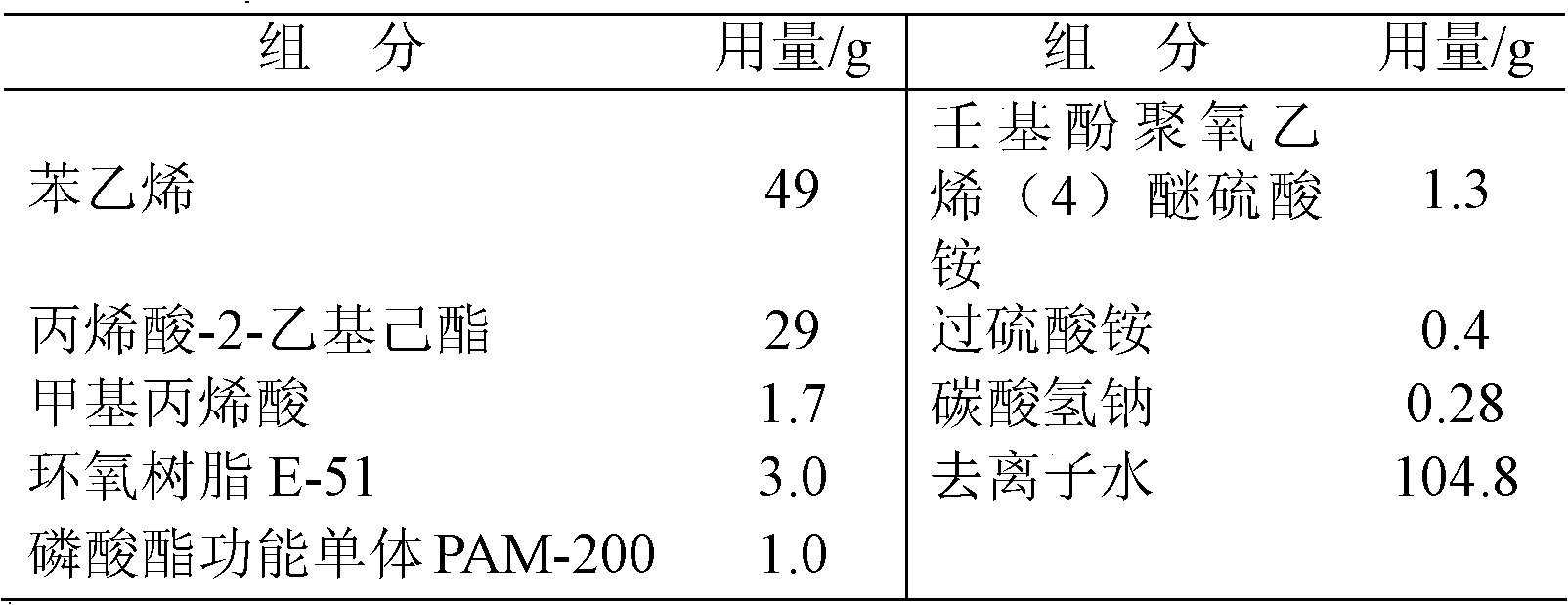

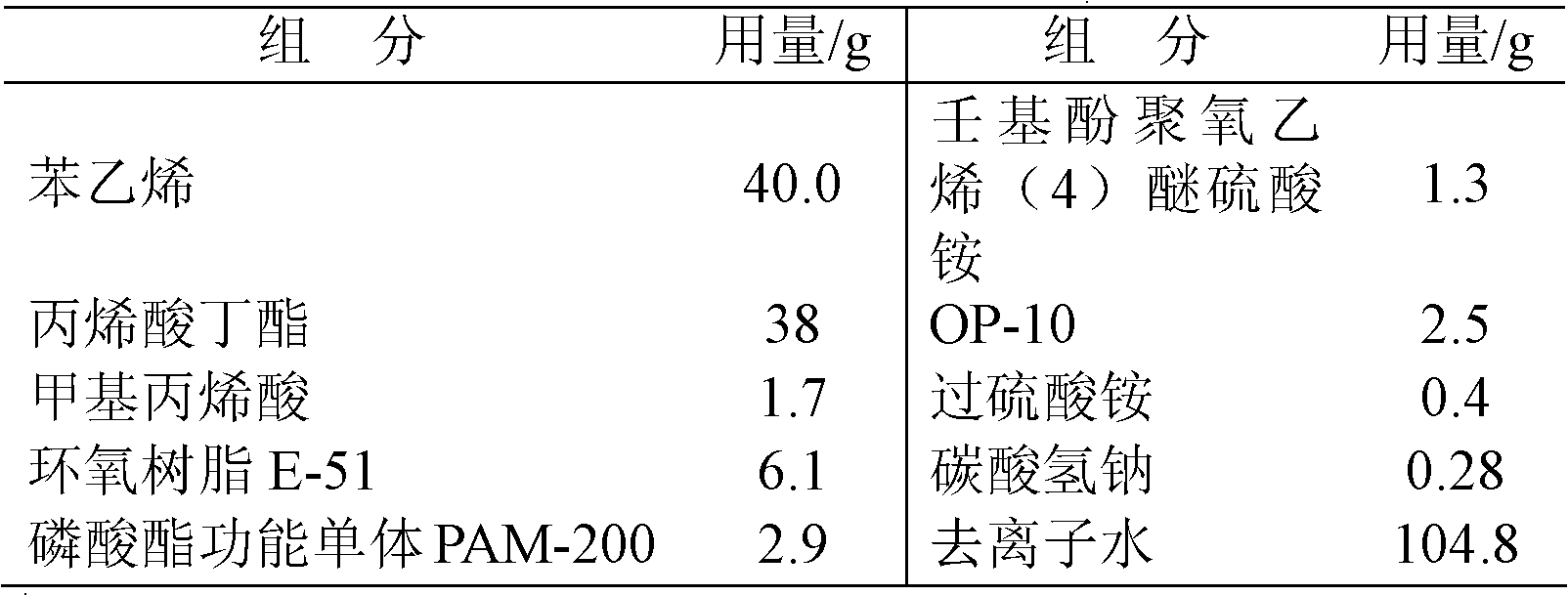

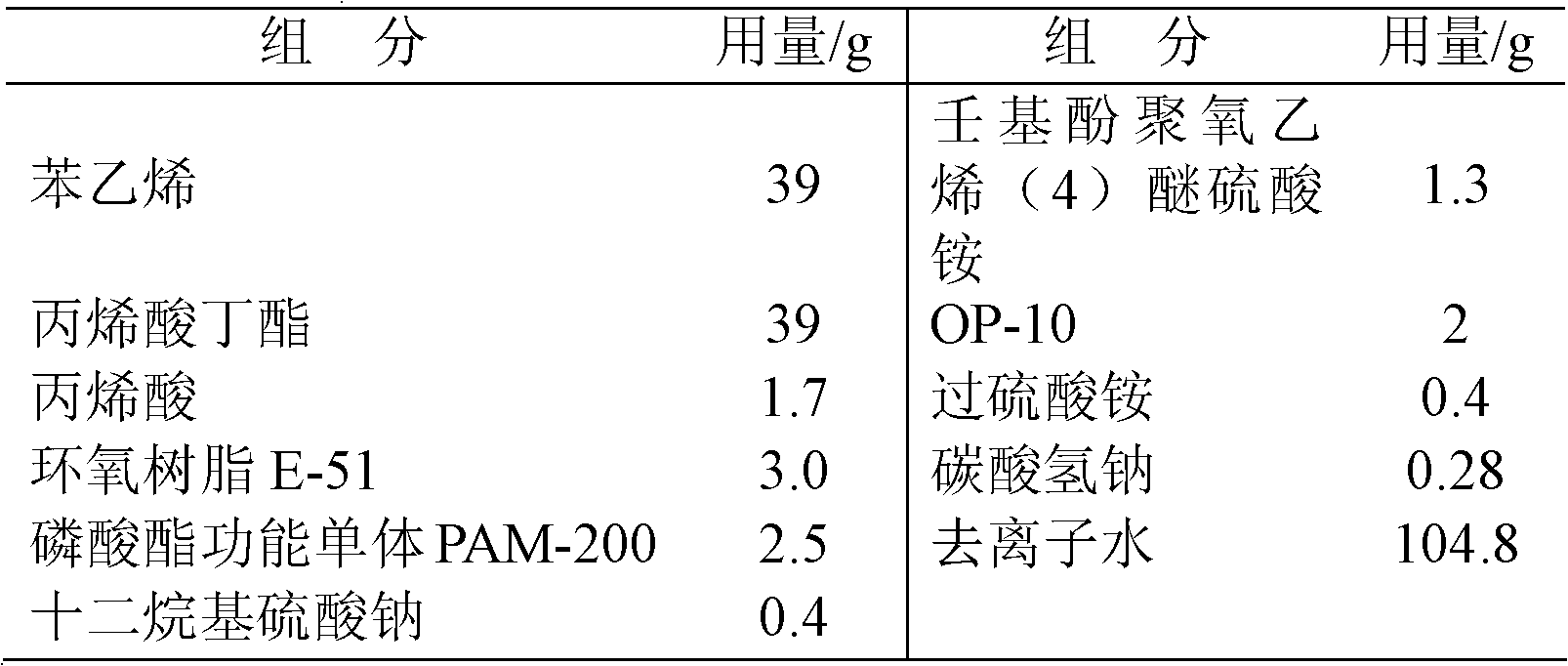

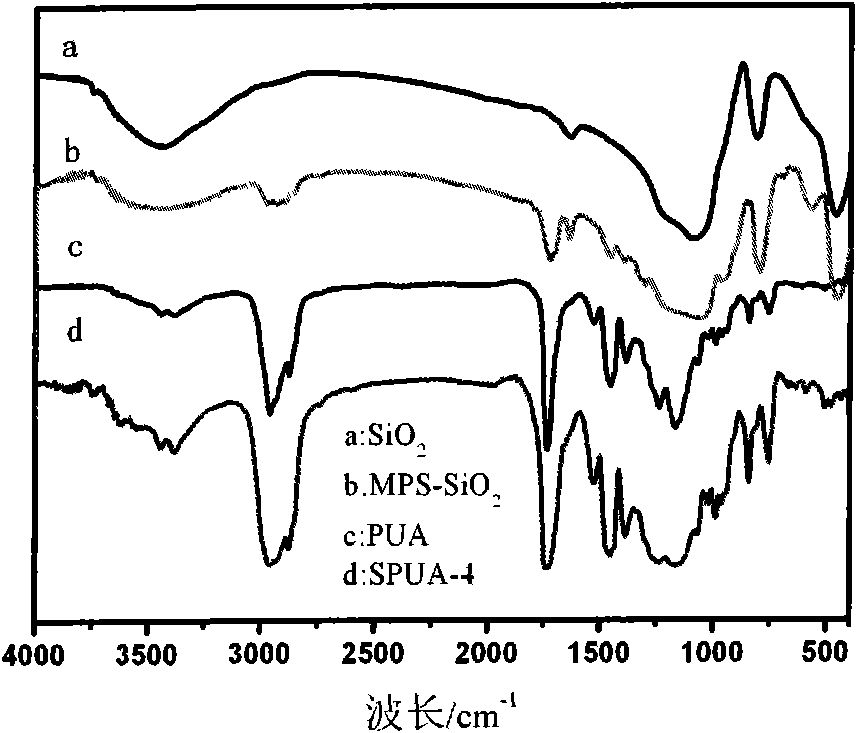

Water-based epoxy modified phosphorus-containing styrene-acrylic antirust emulsion and synthesis method thereof

InactiveCN102127271ASmall sizeControl particle diameterAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention relates to a water-based epoxy modified phosphorus-containing styrene-acrylic antirust emulsion and a synthesis method thereof. The water-based epoxy modified phosphorus-containing styrene-acrylic antirust emulsion is prepared by a conventional emulsion polymerization method, and can be crosslinked with a crosslinking agent and cured at room temperature; and the particle size of thewater-based epoxy modified phosphorus-containing styrene-acrylic antirust emulsion is 80-140nm, the solid content is 40-50%, and the minimum filming temperature is not higher than 35 DEG C. The emulsion is prepared by introducing epoxy-group-containing epoxy resin and phosphate functional monomer with flash-etching-resistant function into the conventional emulsion polymerization process of acrylate. The polymerization technique is simple and practical, almost no gel is generated in the polymerization process, and the storage stability of the emulsion can reach more than 1 year. When the synthesized emulsion is crosslinked with the curing agent to form a film, a three-dimensional network structure is generated, and an efficiently-antirust paint film with high adhesive force can be formed after the emulsion is completely cured. When the water-based epoxy modified phosphorus-containing styrene-acrylic antirust emulsion is used as water-based antirust paint, the adhesive force can reach Level 1, and the water absorptivity is smaller than or equal to 10%; and the water-based epoxy modified phosphorus-containing styrene-acrylic antirust emulsion does not bubble after being soaked in a 3% NaCl solution for 450 hours, and has favorable corrosion resistance.

Owner:DALIAN POLYTECHNIC UNIVERSITY

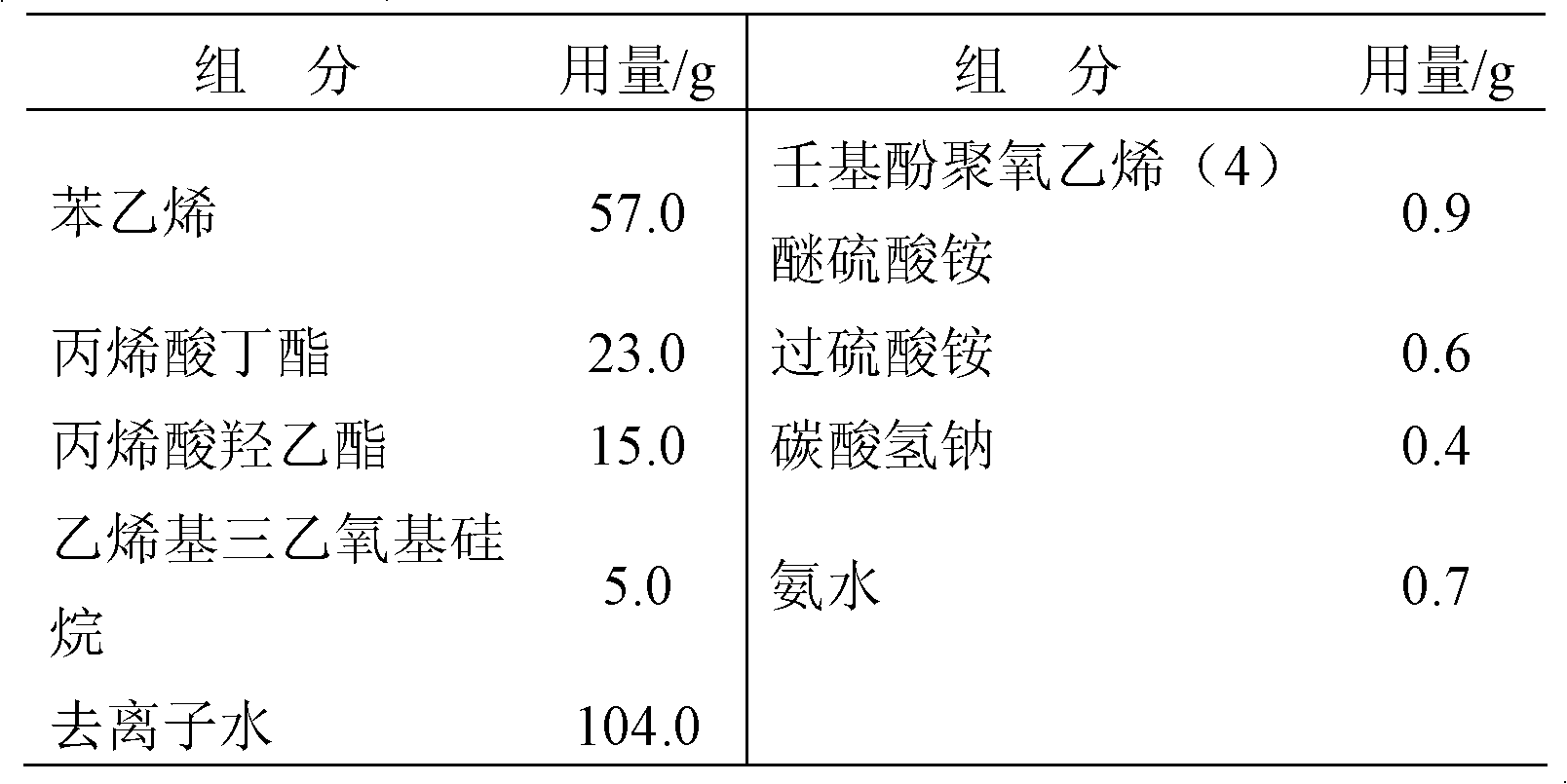

Organic siloxane modified phenylethylene-acrylic ester nano-emulsion and preparing method thereof

InactiveCN1456577AHigh glass transition temperatureLow minimum film forming temperatureHigh resistanceSolid component

An organic siloxane modifier nano-class styrene-acrylate emulsion used for paint or adhesive is prepared from the functional silane monomer with multifunctional vinylalkoxy groups and the monmers of styrene, alkyl methylacrylate, hydroxyalkyl methylacrylate, alkyl acrylate and (methyl) acrylic acid through copolymerization in the manner that under the action of organic silaxane as hydrolysis inhibitor the emulsion polymerizing is inhibited. Its advantages are low content of emulsifier, high content of solid component and storage stability (more than one year), high resistance to weather, dirt, water, chemical solvent and alkali, and high adhesion and tension strength.

Owner:SOUTH CHINA UNIV OF TECH

Room-temperature self-crosslinking water-soluble polyurethane acrylic resin and preparation method and application thereof

InactiveCN101544738ALow viscosityImprove conversion ratePolyureas/polyurethane adhesivesInksPolymer scienceAcrylic resin

The invention discloses a room-temperature self-crosslinking water-soluble polyurethane acrylic resin and a preparation method and an application thereof. The preparation method adopts an in-situ emulsion polymerization method and improves the prior preparation method, introduces tetramethyl benzene dimethylene diisocyanate or 2, 4 methyl cyclohexyl diisocyanate, and dipropylene glycol or neopentyl glycol functioning as chain extendor in raw materials, thereby lowering the viscosity of polyurethane prepolymer, and achieving the purpose of performing the synthetic reaction without organic solvent; oil-soluble evocating agent and water-soluble evocating agent are adopted to together evocate radical copolymerization so that oil-soluble monomer and water-soluble monomer can more effectively perform the radical copolymerization, thereby improving the reaction conversion rate. In addition, the combination of the two evocating agents also leads emulsion in the reaction to keep stable without easily jellifying and layering. The resin can be used for preparing plastics, aluminum foil package compound gel, paper-plastics compound gel, water color ink, water oil polish, water wooden ware paint or water plastic paint.

Owner:SUN YAT SEN UNIV

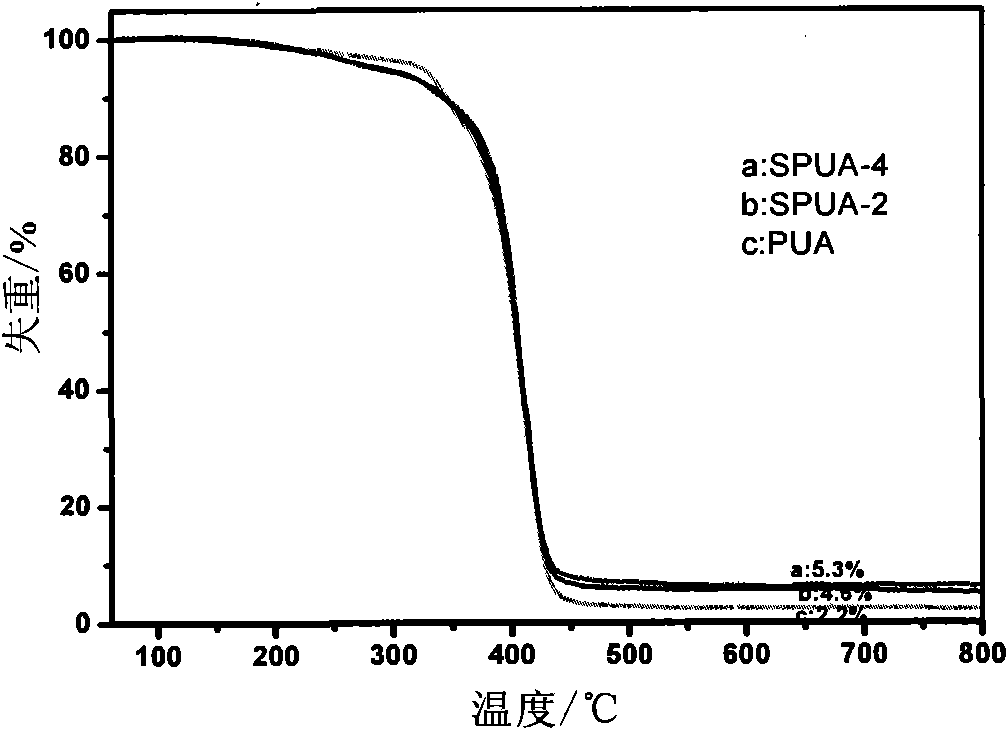

Method for preparing nano SiO2/polyurethane/acrylic ester composite emulsion and miniemulsion polymerization

InactiveCN102010486AGood dispersionHigh strengthPigment treatment with organosilicon compoundsPolymer scienceEmulsion

The invention relates to a method for preparing nano silicon dioxide (SiO2) / polyurethane / acrylic ester composite emulsion and miniemulsion polymerization. The method is characterized in that: the acrylic ester composite emulsion modified by the nano SiO2 and the polyurethane jointly is prepared by a miniemulsion polymerization method. According to the method, SiO2 is modified by using a silane coupling agent KH-570 under an alkaline condition, so that a hydrophilic surface of the composite emulsion is changed into a hydrophobic surface, and the dispersibility of the composite emulsion is improved greatly; stable nano SiO2 / polyurethane / acrylic ester composite emulsion can be prepared by a miniemulsion polymerization process; after the emulsion is formed into a film, the strength of a glue film is greatly improved, the glue film has soft handfeel, and the disadvantage that acrylic ester polymer is sticky in a hot state and is crisp in a cold state is overcome; and the decomposition mechanism of the composite emulsion is not changed.

Owner:ANHUI UNIVERSITY +1

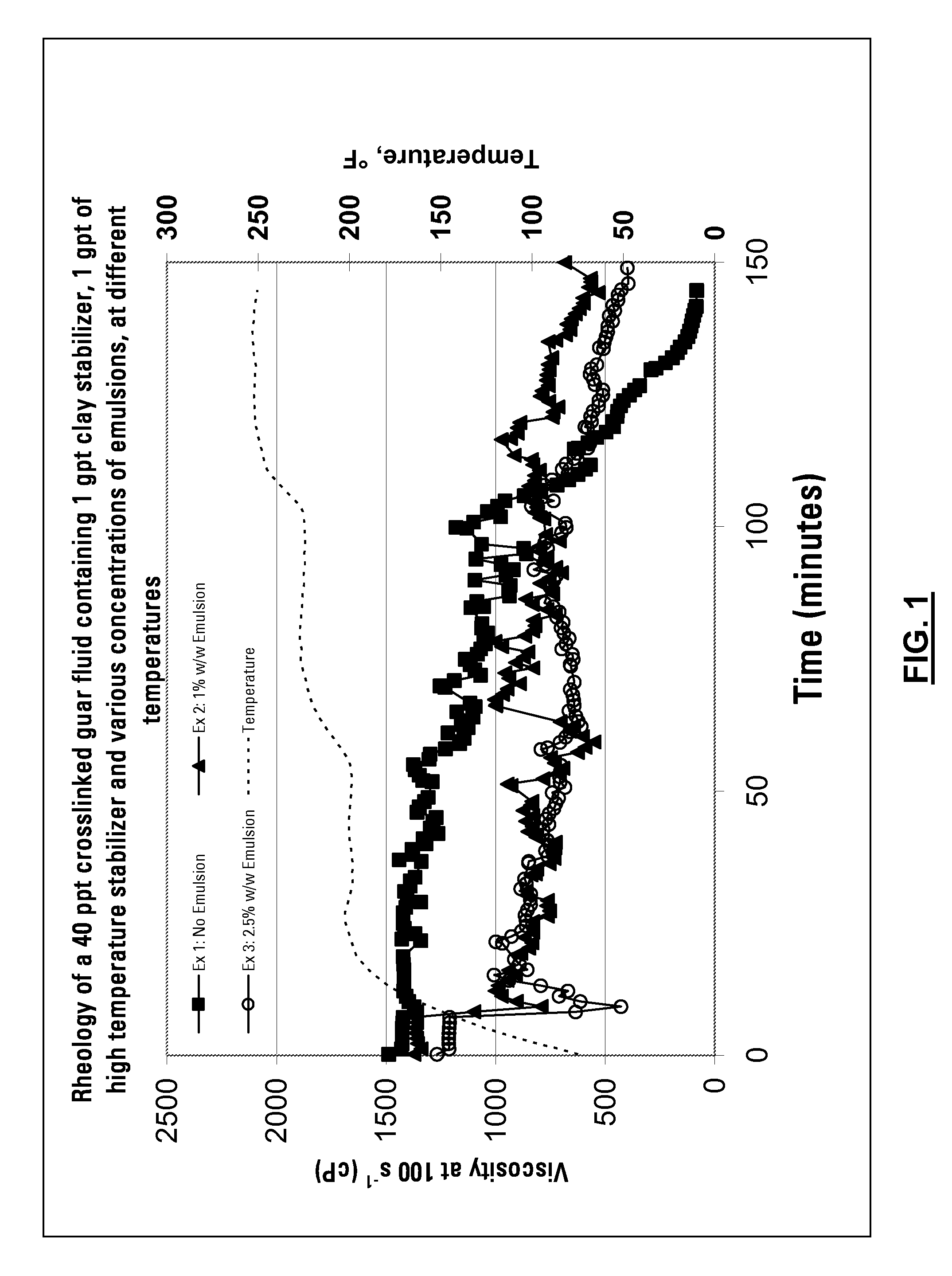

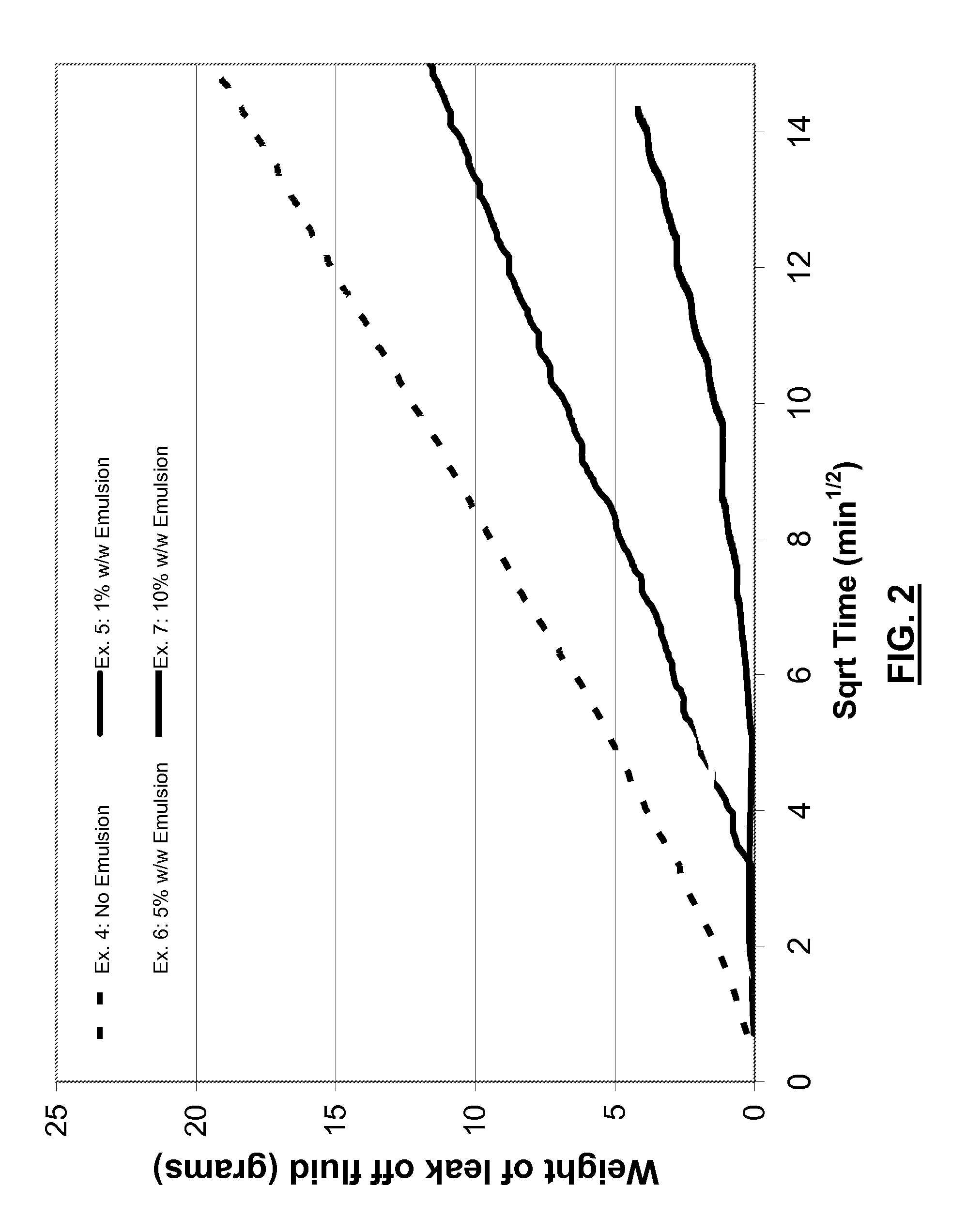

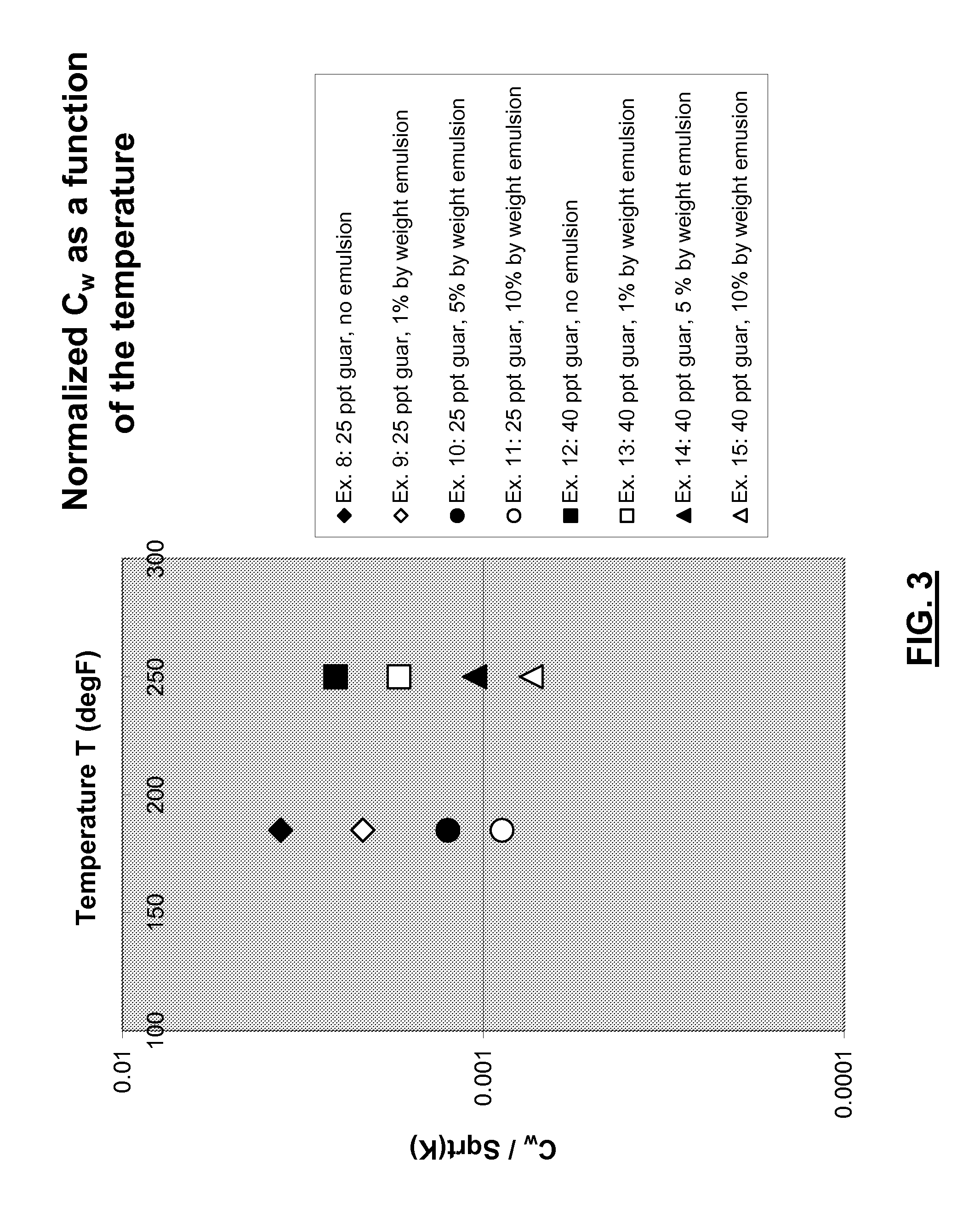

Methods of limiting leak off and damage in hydraulic fractures

Methods for treating a formation penetrated by a wellbore which improves fluid loss control during treatment. In some aspects, the treatments include preparing an aqueous fluid including one or more water inert polymers and an optional viscosifier, injecting the aqueous fluid into the wellbore at a pressure equal to or greater than the formation's fracture initiation pressure, and thereafter injecting into the wellbore a proppant laden fluid at a pressure equal to or greater than the formation's fracture initiation pressure. The water inert polymer may be a polymer such as an emulsion polymer or a latex polymer. Some methods of the invention use a fluid which may have a normalized leak off coefficient (Cw / sqrt(K)) equal to or less than about 0.0022, 0.0014, or 0.0010. A conventional fluid loss additive may or may not be used in conjunction with the treatment fluid and / or the proppant laden fluid. The water inert polymer may or may not substantially enter formation pores. In another aspect, methods for reducing matrix damage to a formation during a treatment operation include preparing an aqueous treatment fluid formed of at least one water inert polymer, and injecting the fluid at a pressure equal or greater than the formation's fracture initiation pressure.

Owner:SCHLUMBERGER TECH CORP

Method for preparing chitosan magnetic micro-sphere and method for immobilizing yeast by using the magnetic micro-sphere

InactiveCN101240075AGood biocompatibilityUniform particle sizeOrganic/organic-metallic materials magnetismOn/in organic carrierMicrosphereEmulsion polymerization

Preparation of chitosan magnetic microsphere and preparation of immobilized yeast for magnetic microsphere. The invention adopts suspended emulsion polymerization to prepare chitosan magnetic microsphere. The invention immobilize yeast cell to magnetic microsphere by swelling absorption. The inventive chitosan magnetic microsphere has characteristics of both magnetic particle and macromolecular material. Immobilized yeast cell is not discharged out of the system with fermentation broth, so that consumption is avoided, concentration of yeast cell in the fermentor is kept, rate of alcoholic fermentation is enhanced, fermentation time is shorten, resource consumption is reduced, while reducing discharge of waste water, and hardness to process the waste water.

Owner:HARBIN INST OF TECH

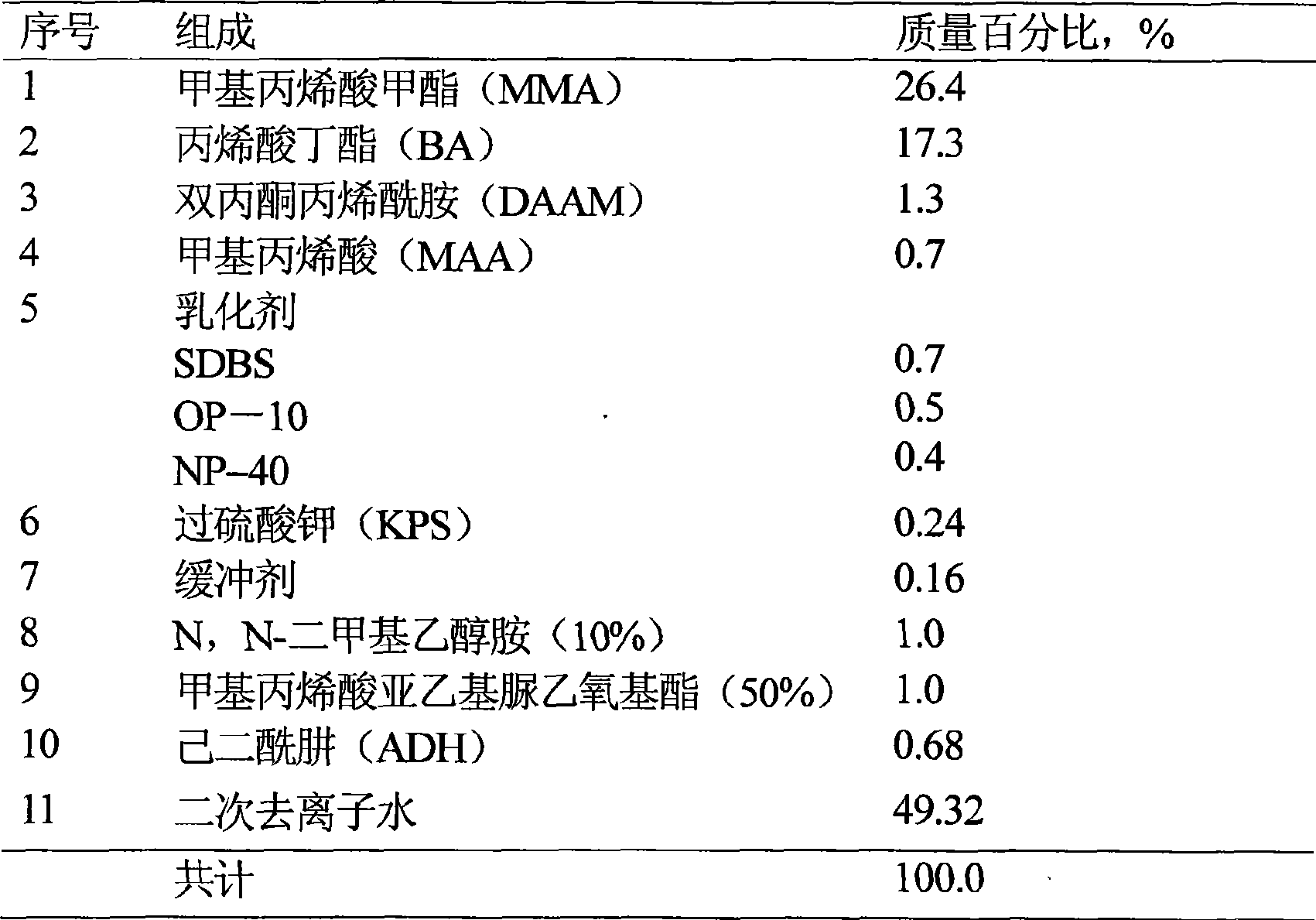

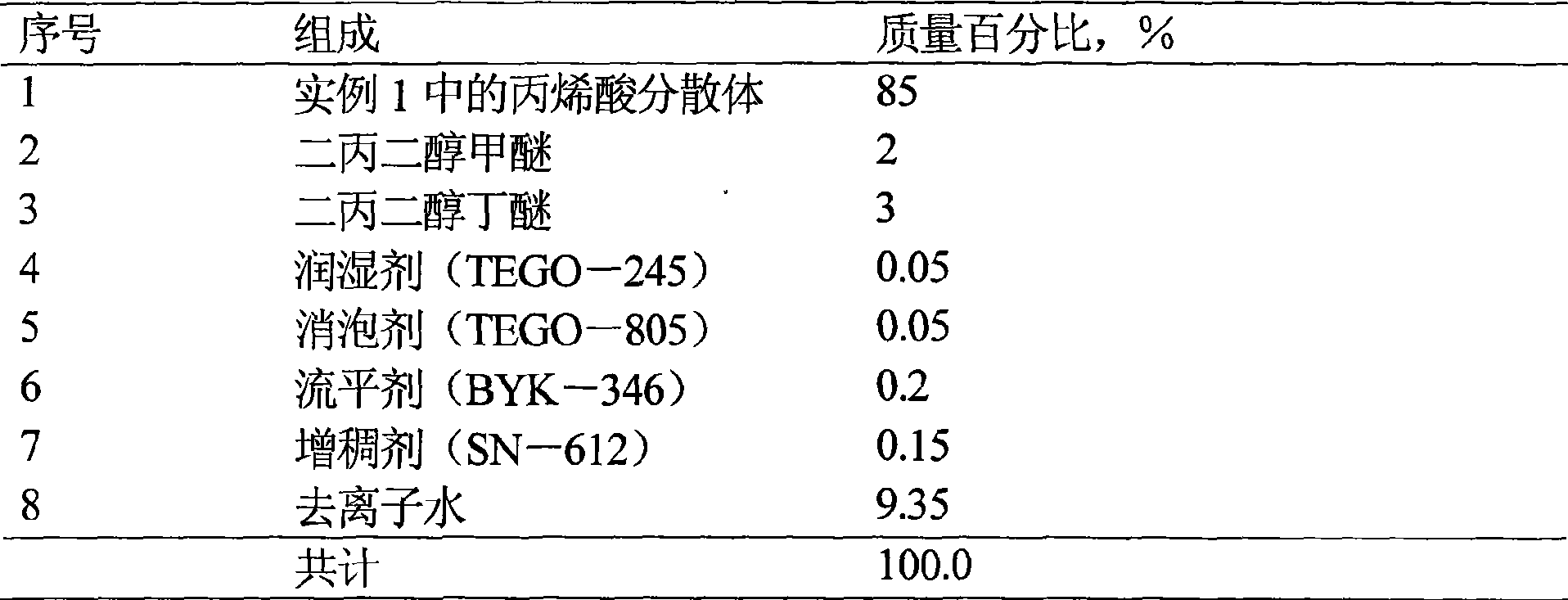

Preparation method and application of internal-external dual cross-linked core-shell structured acrylic acid emulsion

The invention discloses a preparation method and application of internal-external dual cross-linked core-shell structured acrylic acid emulsion. The method employs a multi-step pre-emulsification and polymerization process for seed emulsion to prepare the acrylic acid emulsion and mainly comprises a first step of preparation of seed monomers, a second step of seed emulsion polymerization, a third step of core emulsion polymerization and a fourth step of shell emulsion polymerization; after polymerization is finished, the pH value of the emulsion is adjusted, and adipic dihydrazide is added so as to obtain the internal-external dual cross-linked core-shell structured acrylic acid emulsion. According to the invention, polymerization stability and minimum film-forming temperature of the core-shell structured acrylic acid emulsion prepared in the invention are greatly improved; the acrylic acid emulsion is applied in the field of water-borne wood paints and can improve the cross-linking degree, density and hardness of a paint film and reduce water absorption and a glass transition temperature of the paint film.

Owner:SOUTH CHINA UNIV OF TECH

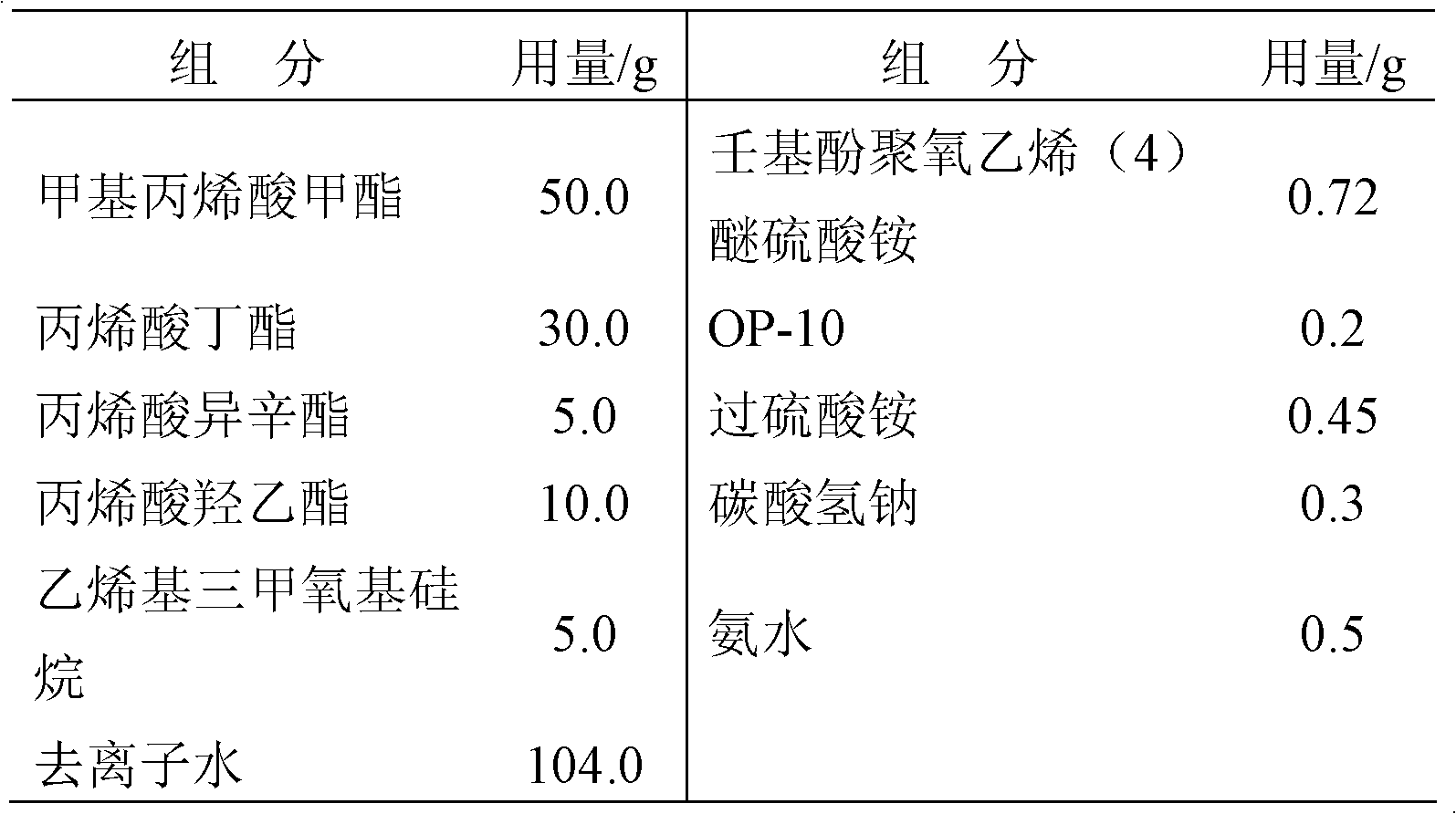

Preparation method of polyacrylate emulsion containing silicon, fluorine and phosphate group

The invention relates to a preparation method of polyacrylate emulsion containing silicon, fluorine and a phosphate group. The polyacrylate emulsion is widely applied in the fields of leather, paper and architectural decoration and finishing paint due to excellent caking property, film-forming property and mechanical properties. According to the preparation method provided by the invention, butyl acrylate, methyl methacrylate, styrene, hydroxypropyl methacrylate, vinyl triethoxy silane, phosphate functional monomer and dedecafluoroheptyl methacrylate are taken as polymerization monomers, lauryl sodium sulphate and fatty alcohol-polyoxyethylene ether are taken as emulsifiers, peroxysulphate is taken as an initiator, and a pre-emulsification seeded emulsion polymerization process is adopted for preparing the polyacrylate emulsion. According to the polyacrylate emulsion obtained by adopting the preparation method provided by the invention, fluorine, silicon and the phosphate group are introduced into a molecular structure, flame retardance, low temperature resistance, corrosion resistance, water resistance, anti-scouring property, mechanical properties and adhesiveness with materials such as metal and cement of a polymer emulsion film are obviously improved, and the obtained polyacrylate emulsion can be applied to leather, textile, metal antirust paints and decorative finish paints for an internal wall and an external wall of a building material and has good development prospect.

Owner:南京紫鸿生物科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com