Patents

Literature

786 results about "Dispersion polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In polymer science, dispersion polymerization is a heterogeneous polymerization process carried out in the presence of a polymeric stabilizer in the reaction medium. Dispersion polymerization is a type of precipitation polymerization, meaning the solvent selected as the reaction medium is a good solvent for the monomer and the initiator, but is a non-solvent for the polymer. As the polymerization reaction proceeds, particles of polymer form, creating a non-homogeneous solution. In dispersion polymerization these particles are the locus of polymerization, with monomer being added to the particle throughout the reaction. In this sense, the mechanism for polymer formation and growth has features similar to that of emulsion polymerization. With typical precipitation polymerization, the continuous phase (the solvent solution) is the main locus of polymerization, which is the main difference between precipitation and dispersion.

Nonwovens produced from multicomponent fibers

InactiveUS20080311815A1Reduce blockingReduce fusionNon-fibrous pulp additionNatural cellulose pulp/paperPolymer scienceSlurry

A water non-dispersible polymer microfiber is provided comprising at least one water non-dispersible polymer wherein the water non-dispersible polymer microfiber has an equivalent diameter of less than 5 microns and length of less than 25 millimeters. A process for producing water non-dispersible polymer microfibers is also provided, the process comprising: a) cutting a multicomponent fiber into cut multicomponent fibers; b) contacting a fiber-containing feedstock with water to produce a fiber mix slurry; wherein the fiber-containing feedstock comprises cut multicomponent fibers; c) heating the fiber mix slurry to produce a heated fiber mix slurry; d) optionally, mixing the fiber mix slurry in a shearing zone; e) removing at least a portion of the sulfopolyester from the multicomponent fiber to produce a slurry mixture comprising a sulfopolyester dispersion and water non-dispersible polymer microfibers; and f) separating the water non-dispersible polymer microfibers from the slurry mixture. A process for producing a nonwoven article is also provided.

Owner:EASTMAN CHEM CO

Methods of consolidating formations

InactiveUS6837316B2High mechanical strengthSimple methodLiquid/gas jet drillingFluid removalCross-linkWater soluble

Methods of consolidating formations include drilling a well bore with a drilling fluid that comprises water, a polymeric cationic catalyst which is adsorbed on minerals and rocks in weak unconsolidated zones or formations and then further contacting the unconsolidated formation with a treating fluid comprising a water soluble or dispersible polymer which is cross-linked by a thermoset resin and causes the resin to be hard and tough when cured, and a water soluble or dispersible thermoset resin which cross-links the polymer, is catalyzed and cured by the catalyst and consolidates the weak zone or formation so that sloughing is prevented.

Owner:HALLIBURTON ENERGY SERVICES INC

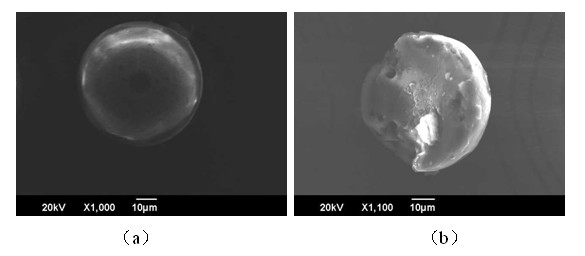

Profile control oil-displacement agent for core-shell type inorganic/organic polymer composite microballoon

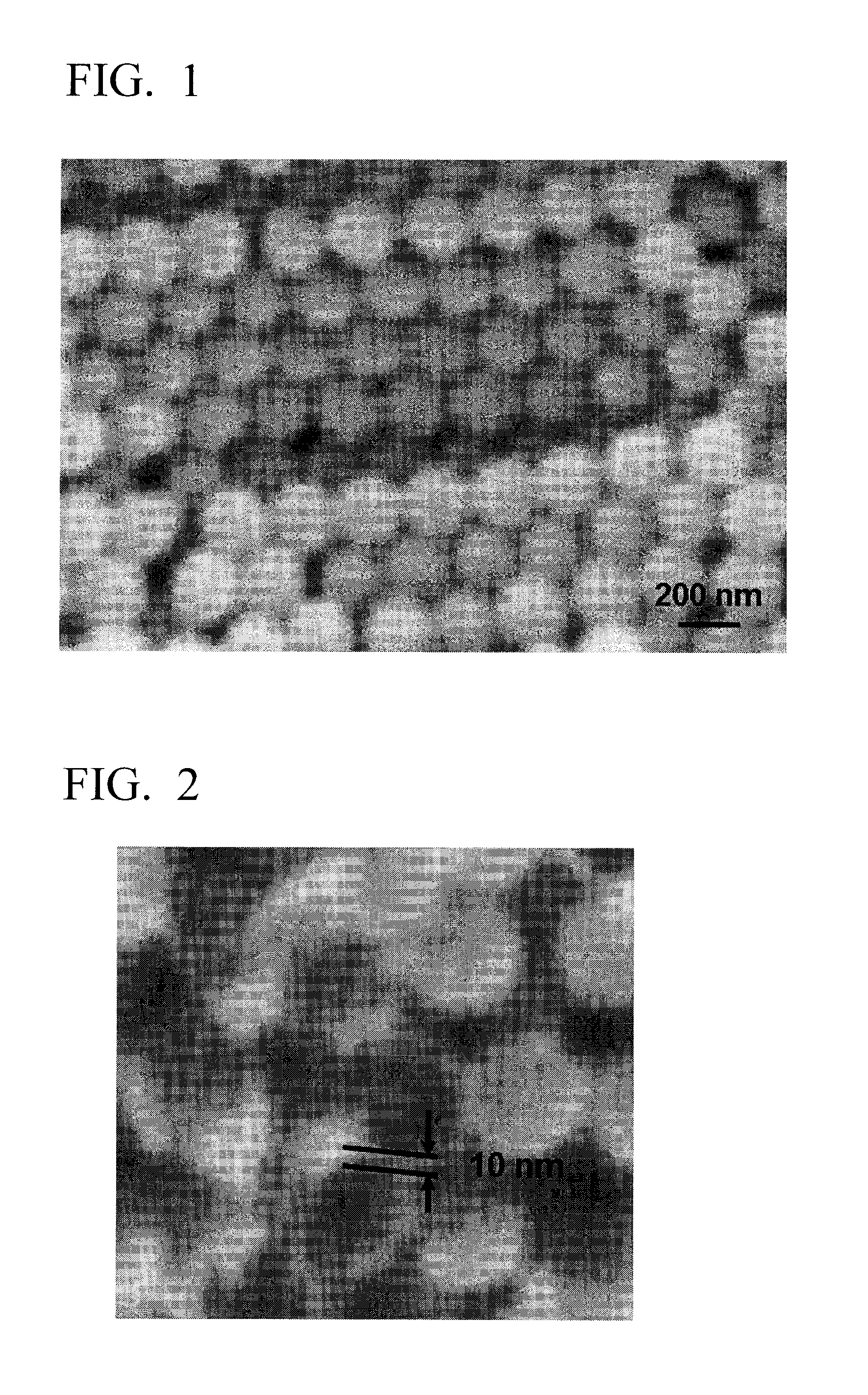

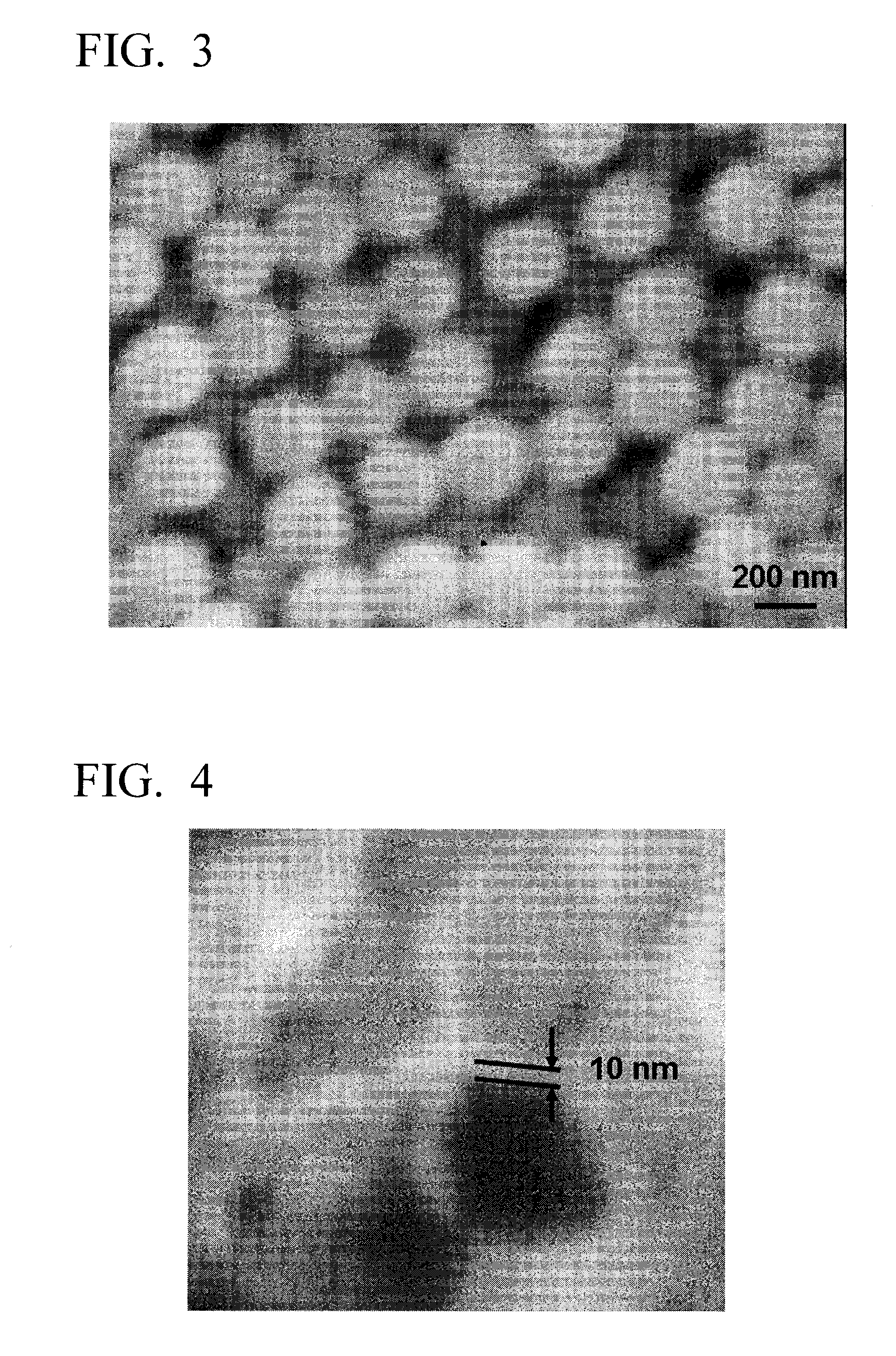

InactiveCN102485830AGood expansion performanceGood temperature and salt resistanceDrilling compositionCross-linkMicrosphere

The invention discloses a profile control oil-displacement agent for a core-shell type inorganic / organic polymer composite microballoon. A preparation method of the core-shell type inorganic / organic polymer composite microballoon comprises the following steps of carrying out surface modification of inorganic cores of inorganic nano-particles such as silica particles and magnetic particles, and carrying out graft polymerisation by a dispersion polymerization method or an inverse emulsion polymerization method to form polymer shells (such as polyacrylamide cross-linked copolymers) on the surfaces of the inorganic cores. The inorganic components and the organic components bind by chemical bonds so that the core-shell type inorganic / organic polymer composite microballoon has very stale structure. The core-shell type inorganic / organic polymer composite microballoon retains the advantages of polymer microballoons and inorganic particles, and has strong heat-resistant and mineralization-resistant capabilities, high plugging strength and good dilatancy. The core-shell type inorganic / organic polymer composite microballoon can move in rock pores and can plug the rock pores. When a plugging pressure difference is improved to a certain degree, elastic deformation of the core-shell type inorganic / organic polymer composite microballoon can be produced and the deformed core-shell type inorganic / organic polymer composite microballoon sequentially moves to a deep rock stratum part so that a liquid flow direction is changed gradually and a crude oil yield is improved. The profile control oil-displacement agent provided by the invention has a large potential.

Owner:BEIJING UNIV OF CHEM TECH

Process for the fractionation of polymers

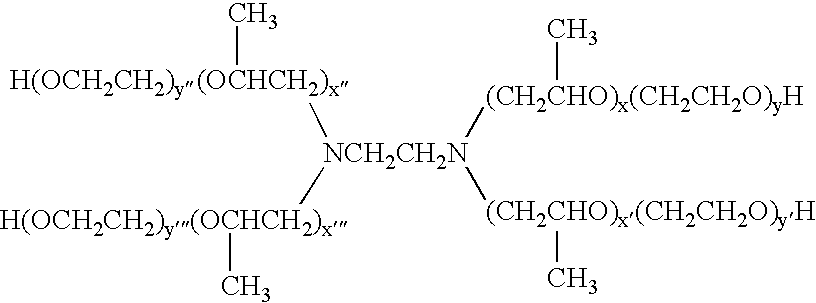

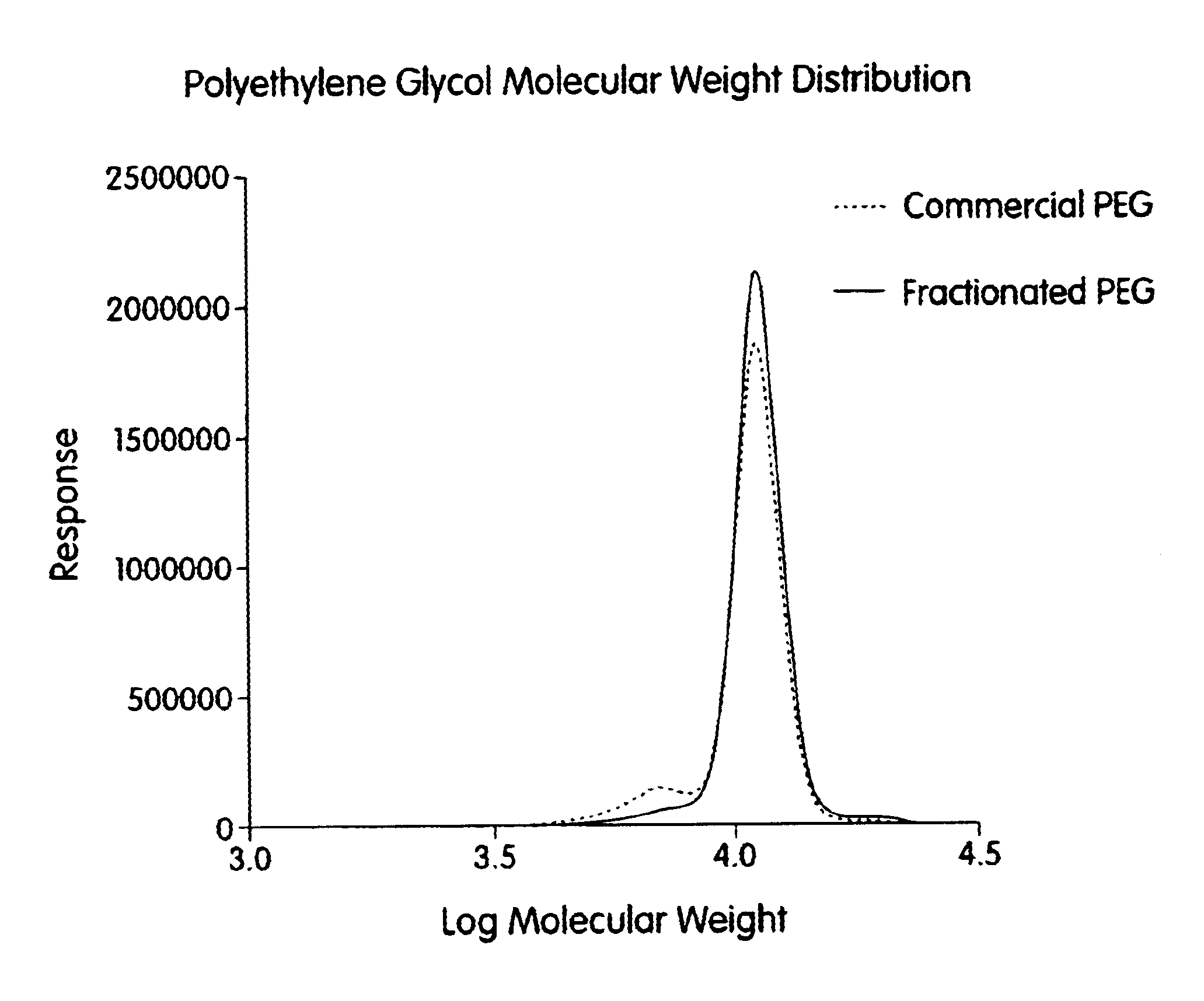

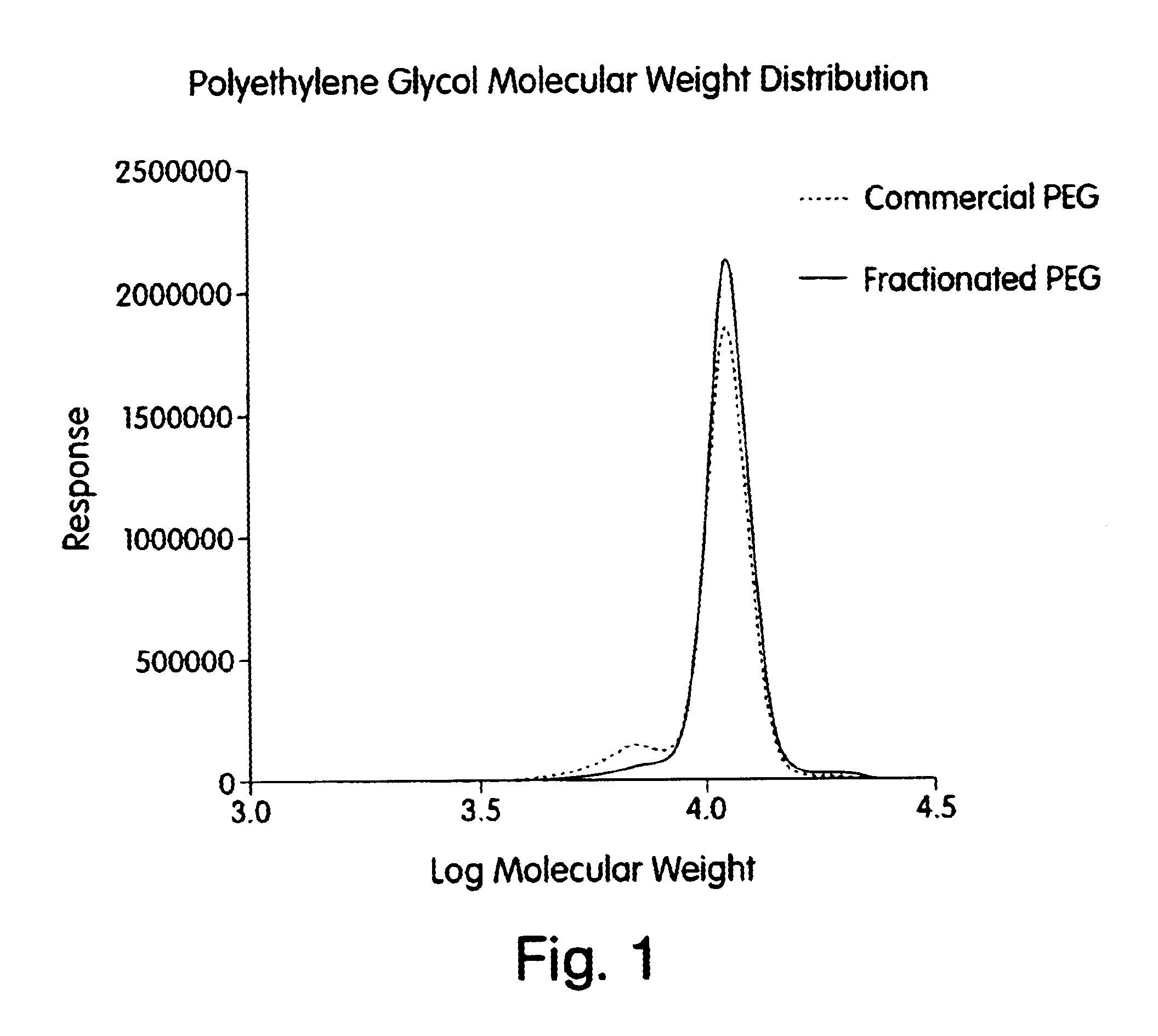

A process for the purification or fractionation of aqueous soluble polymers using an aqueous two-phase system is described. The concentrations of the polymer to be fractionated and of an aqueous soluble salt, and the temperature of the aqueous fractionation medium are adjusted so that two phases form, the lower molecular weight polymer molecules partition into the high salt concentration phase, and the higher molecular weight polymer molecules partition into the low salt concentration phase. The resulting high molecular weight polymers are characterized by a higher average molecular weight and a narrower molecular weight distribution and decreased unsaturation than the unfractionated polymers. After being subjected to the fractionation process, polyol polymers that form hydrogels in aqueous solution exhibited higher viscosities and a liquid to gel transition over a narrower temperature range than the unfractionated polyol polymers.

Owner:HINSBERG MICHAEL G +1

Aqueous dispersion polymers

InactiveUS6020422AOrganic-compounds/hydrides/coordination-complexes catalystsInorganic compound additionEmulsionWater soluble

Water soluable, aqueous salt solution dispersible polymers and aqueous salt solutions containing dispersed polymers are produced by polymerization of ethylenically unsaturated soluble monomers in an aqueous salt solution in the presence of at least one carbohydrate. The polymers and aqueous salt solutions containing the dispersed polymers are useful for paper making, water clarification and emulsion breaking.

Owner:BETZEARBORN INC

Pharmaceutical compositions of dispersions of drugs and neutral polymers

InactiveUS20030091643A1Good chemical stabilityEnhanced aqueous concentrationBiocidePowder deliveryPolymer sciencePharmaceutical Substances

In one aspect, pharmaceutical compositions comprising dispersions of an acid-sensitive drug and a neutral dispersion polymer are disclosed. The acid-sensitive drug has improved chemical stability relative to dispersions of the drug and acidic polymers. In another aspect, pharmaceutical compositions of low-solubility drugs and amphiphilic, hydroxy-functional vinyl copolymers are disclosed.

Owner:BEND RES

Processes for the preparation of a monodisperse polymers, processes for the continuous polymerization of cyclic monomers, and polymers prepared thereby

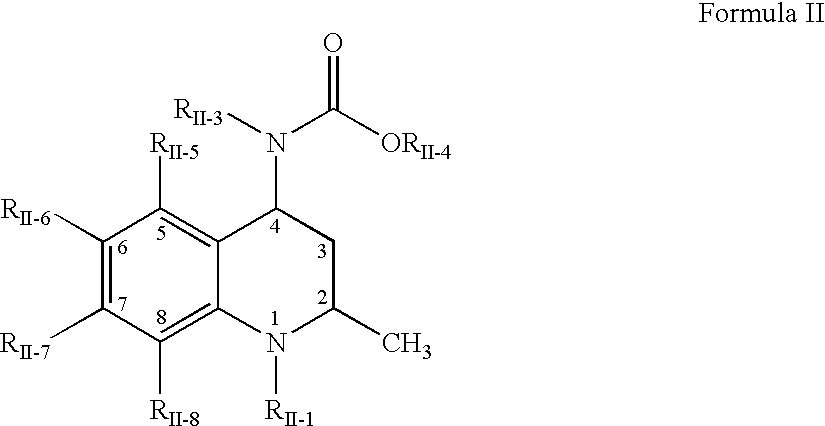

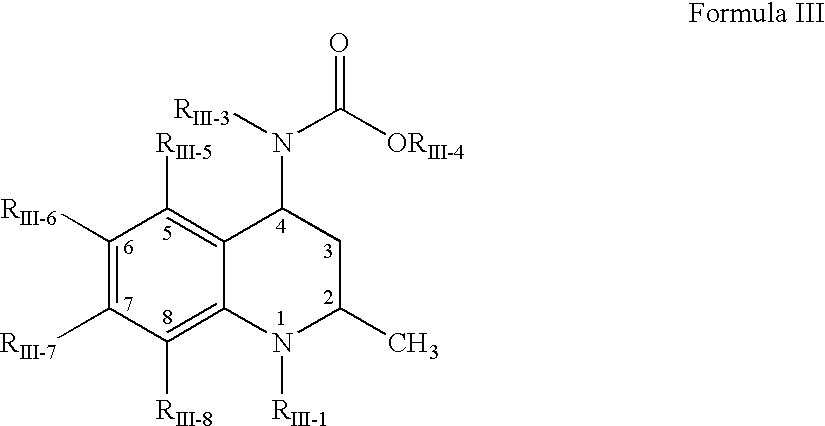

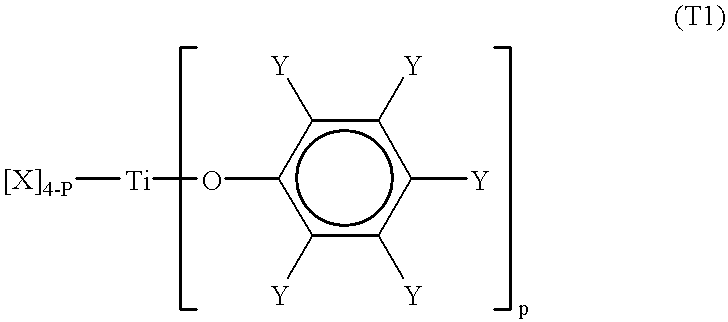

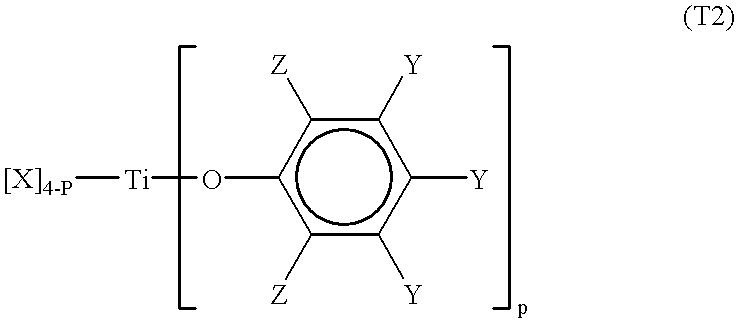

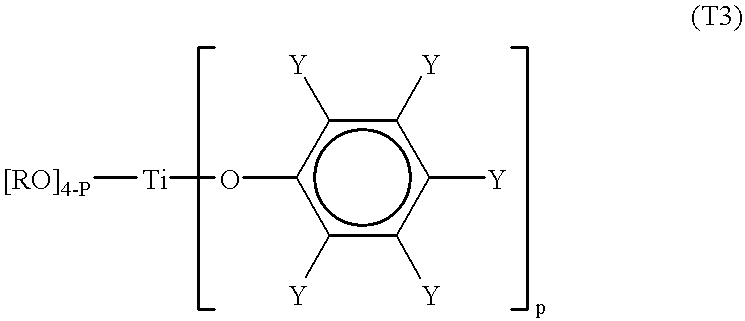

The present invention relates to a method for preparing lactone polymers, carbonate polymers, lactone-carbonate block copolymers and lactone-arbonate random copolymers via a ring-opening addition reaction of a lactone monomer, a cyclic carbonate monomer or a mixture thereof using an initiator and in the presence of a specific titanium-type Lewis acid catalyst. The resulting polymers have a molecular weight distribution (Mw / Mn) approximately equal to 1 or a extremely high purity of single-structure components. The polymer molecules range in an oligomer region to a molecular weight of approximately 200,000. The present invention also relates to a method for preparing lactone polymers, carbonate polymers and lactone-carbonate copolymers having a narrow molecular weight distribution and which can be obtained via a continuous polymerisation of a lactone monomer and / or a cyclic carbonate monomer using an initiator in an extruder in the presence of a specific titanium-type Lewis acid catalyst or an aluminium-type Lewis acid catalyst. The present invention also relates to these resulting polymers.

Owner:DAICEL CHEM IND LTD

Three-dimensional ordered macroporous alumina and preparation method thereof

ActiveCN102838142AGood three-dimensional orderImprove uniformityAluminium oxides/hydroxidesMicrosphereCalcination

Owner:CHINA PETROLEUM & CHEM CORP +1

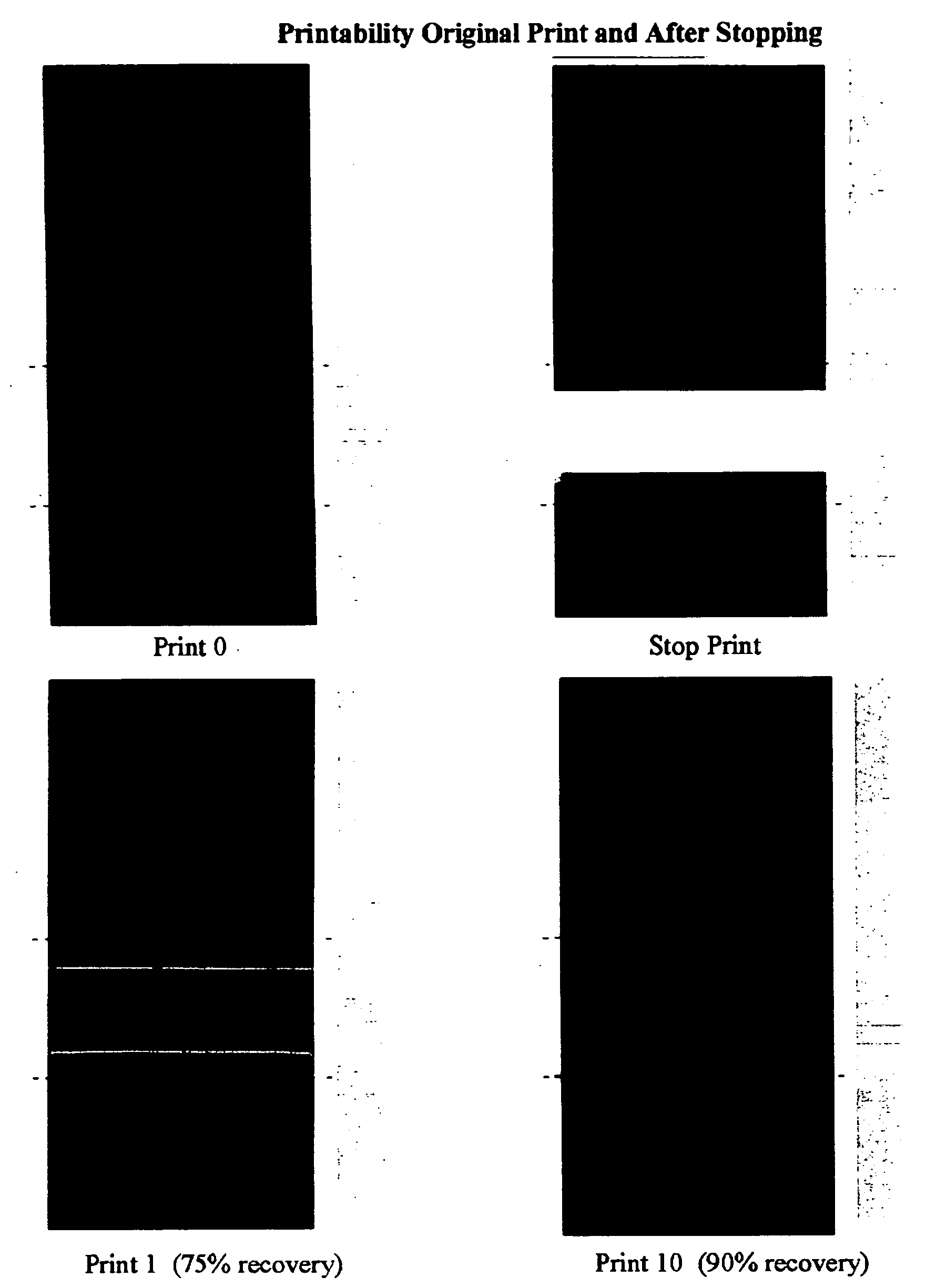

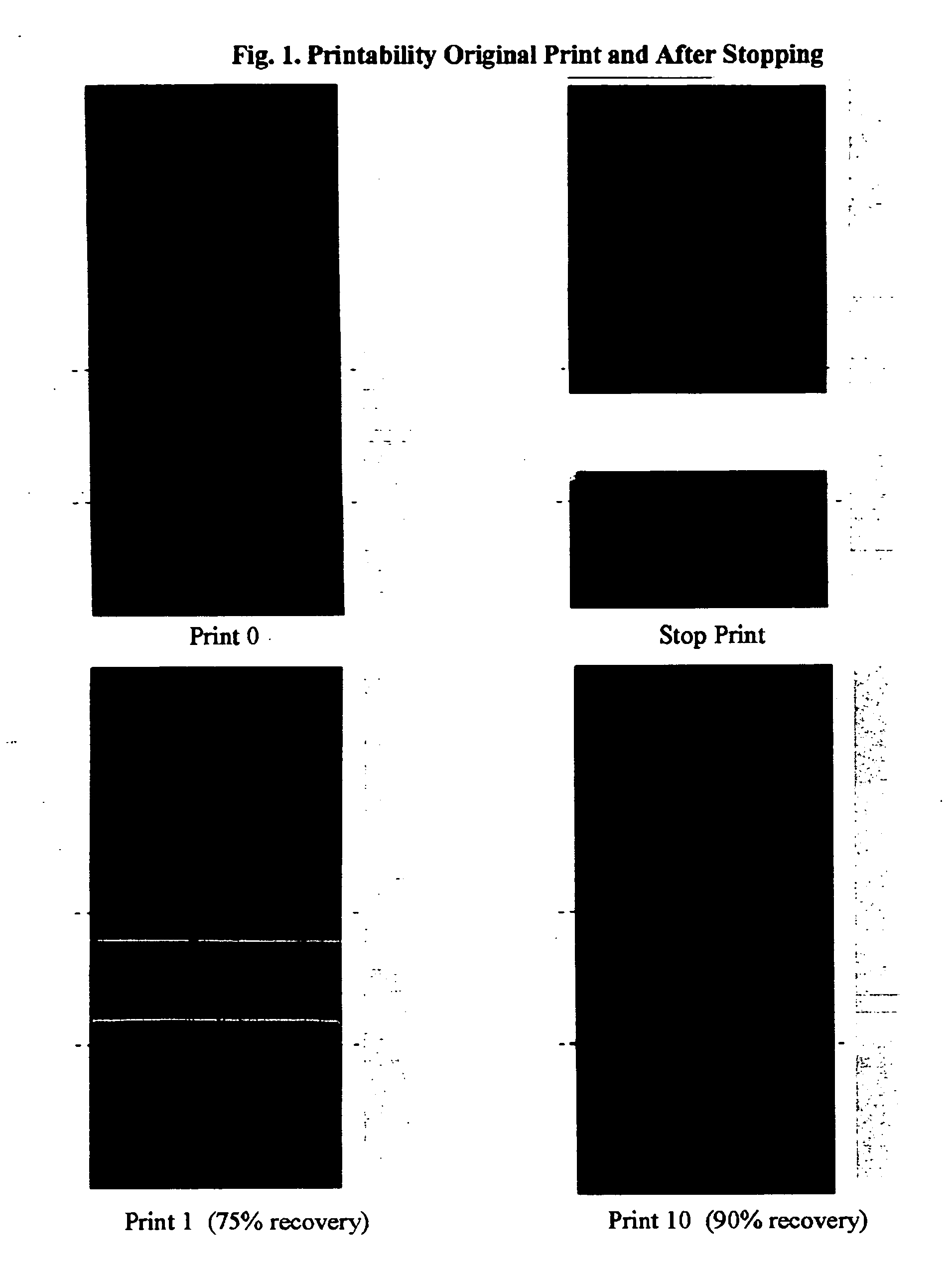

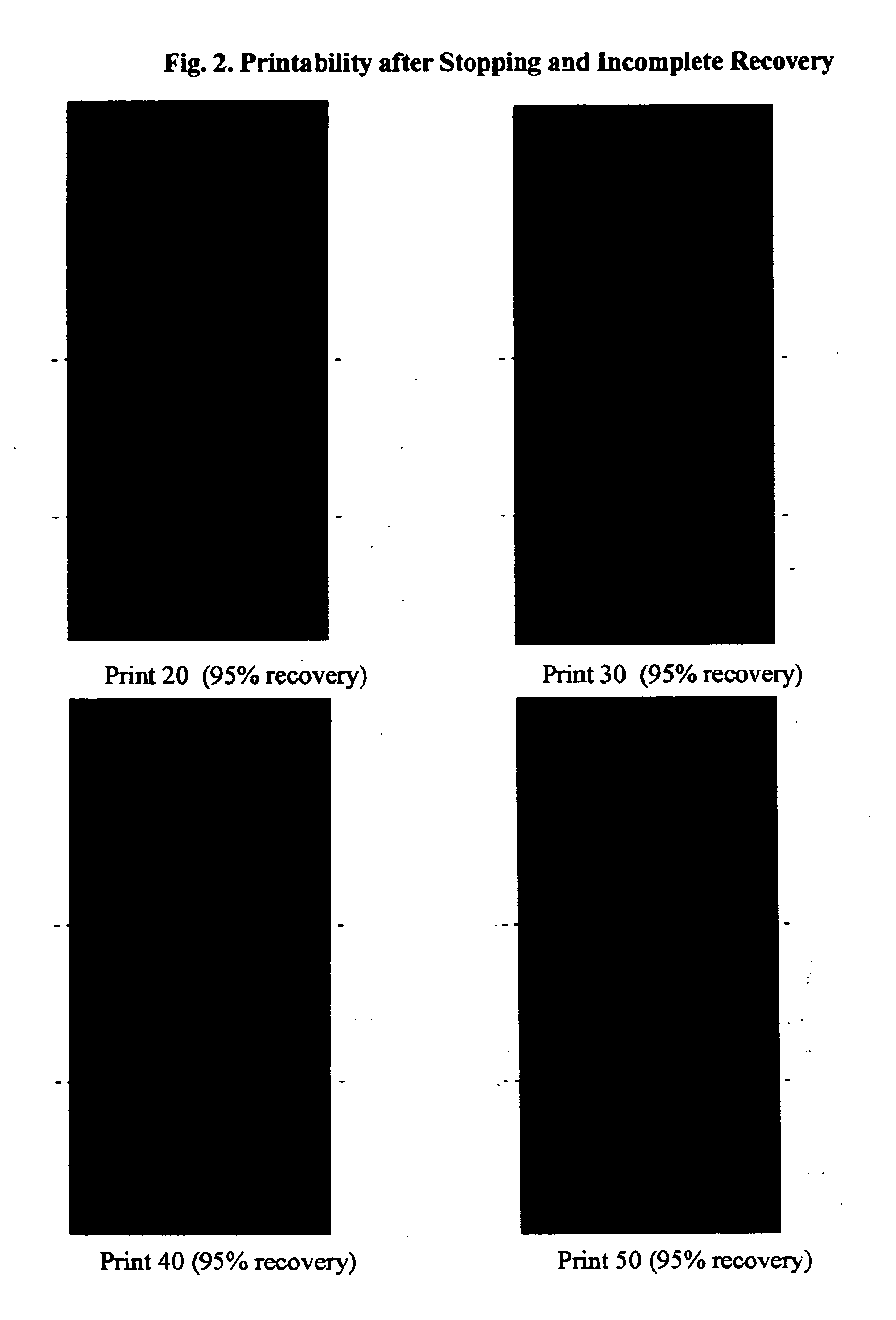

Emulsion compositions for use in printing inks

ActiveUS20060063868A1Good storage stabilityQuality improvementLiquid surface applicatorsInksEmulsionPrinting ink

Polymer emulsion compositions for use in printing inks and printing inks made from the compositions are provided. The emulsion compositions include an aqueous continuous phase containing water and a dissolved carboxylic acid-functional support polymer. The dispersed phase of the emulsion composition contains crosslinked, dispersed polymer particles. The emulsion compositions also include at least one multivalent metal crosslinker and at least one stabilizing agent. The polymer emulsion compositions display superior printability properties in inks and other coatings formulated with them, yet are stable at elevated temperatures for long periods of time.

Owner:BASF CORP

Green powdered paint and its prepn

The present invention discloses one kind of green powdered paint and its preparation process. The green powdered paint consists of re-dispersible polymer latex powder 5-20 wt%, white cement 20-40 wt%, calcium carbonate 20-45 wt%, titanium white powder 5-25 wt%, diatomite 2-8 wt%, bentonite 1-2 wt%, cellulose ether 0.2-0.5 wt%, defoaming agent 0.2-0.5 wt% and coloring pigment 0-4 wt%. It is prepared through mixing all the components in a stirrer, and packing. It is used after mixing with water in construction site. It has the combined decoration functions of both putty and emulsion paint and may be used widely for decorating inner and outer wall.

Owner:SOUTH CHINA UNIV OF TECH

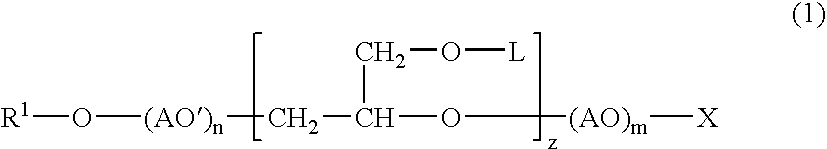

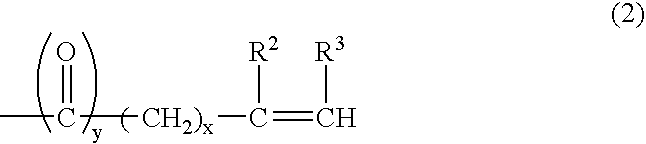

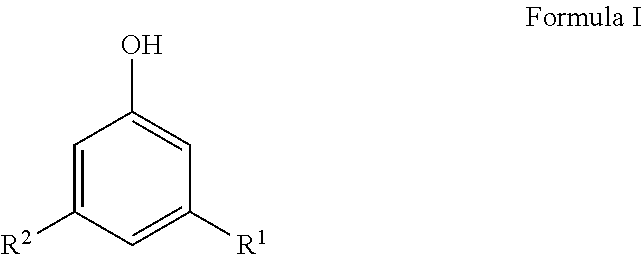

Surfactants

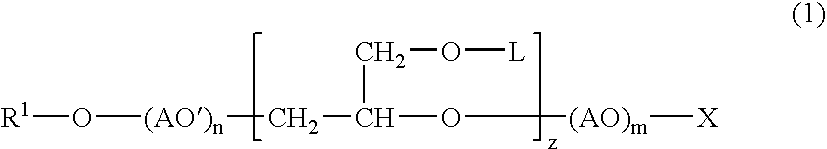

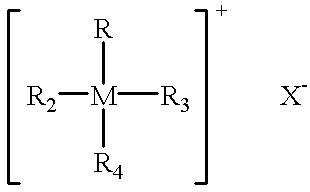

InactiveUS6841655B1No adverse effectsHigh strengthTransportation and packagingMixingPhenyl EthersEmulsion polymerization

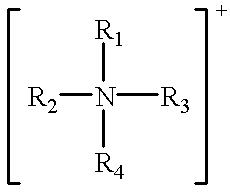

Disclosed are surfactants represented by the following formula (1): wherein R1 represents a branched aliphatic hydrocarbon group, a secondary aliphatic hydrocarbon group or a branched aliphatic acyl group, AO and AO′ each independently represents an oxyalkylene group having 2 to 4 carbon atoms, L represents a group represented by formula (2) to be described below, z stands for a number of from 1 to 10, X represents a hydrogen atom or an ionic hydrophilic group, m stands for a number of from 0 to 1,000, and n stands for a number of from 0 to 1,000. wherein R2 and R3 each independently represents a hydrogen atom or a methyl group, x stands for a number of from 0 to 12, and y stands for a number of 0 or 1. These surfactants do not contain any phenyl ether group considered to have significant effects on the environment, such as a nonylphenyl group, and have performance comparable with reactive surfactants containing one or more phenyl ether groups. Emulsifiers for emulsion polymerization, dispersants for dispersion polymerization and resin modifiers, all of which contain the surfactants, are also disclosed.

Owner:ADEKA CORP

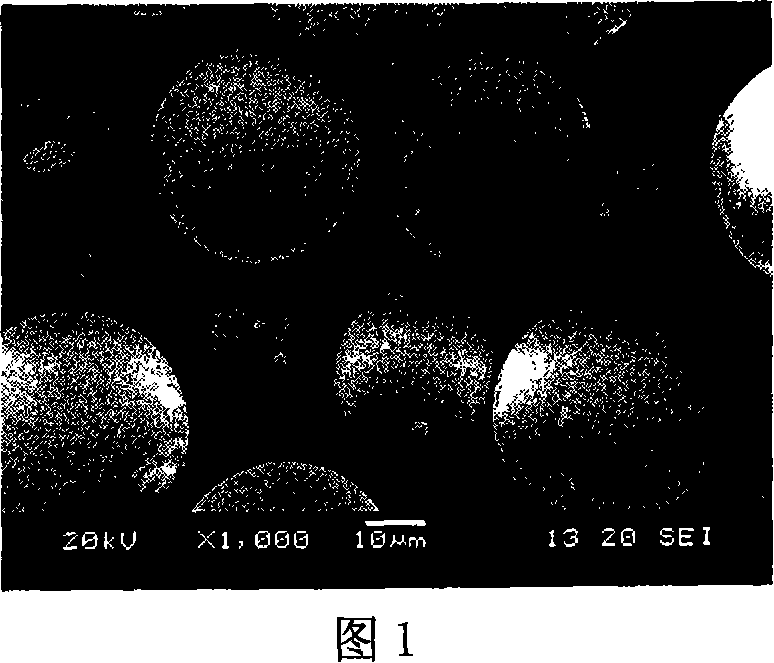

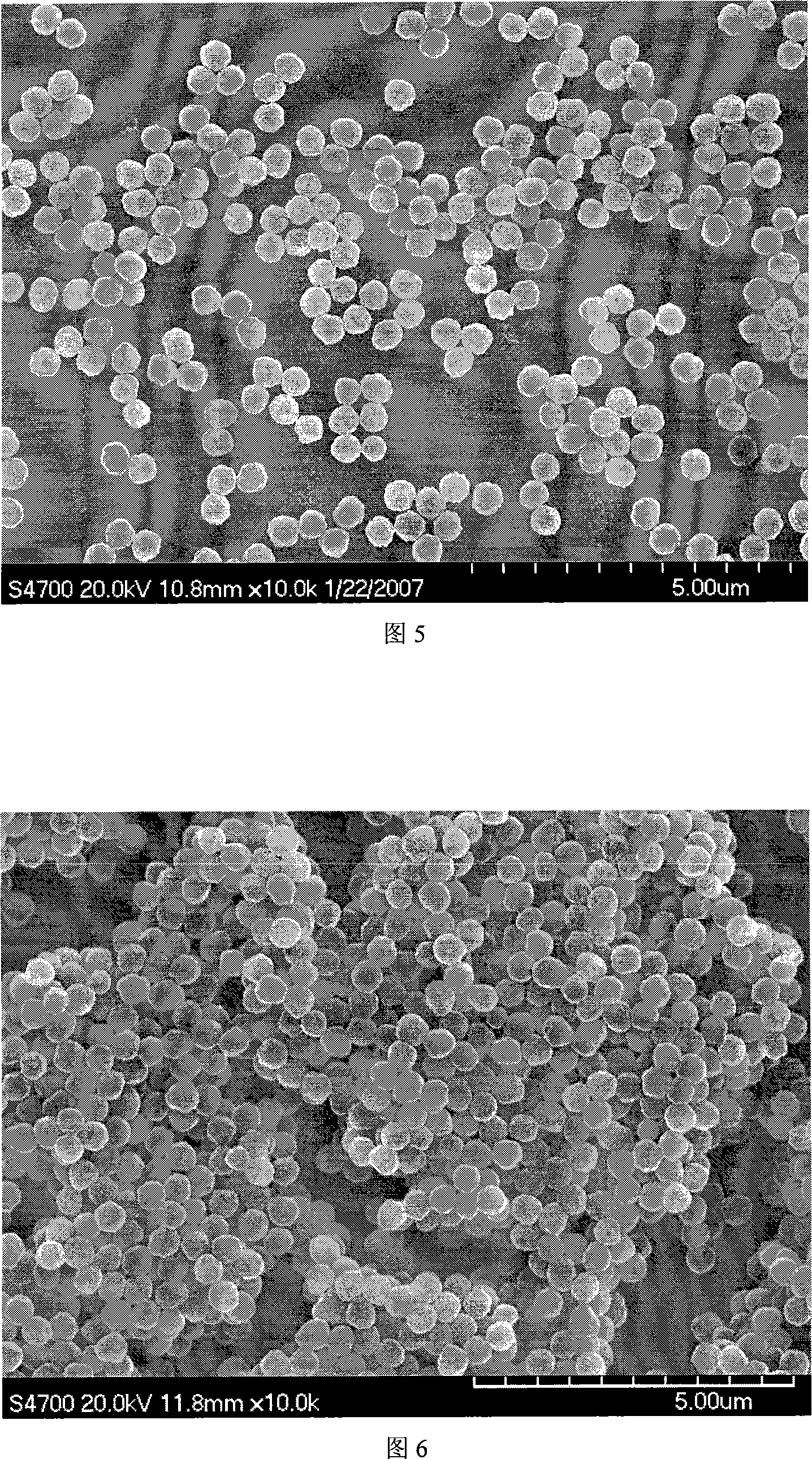

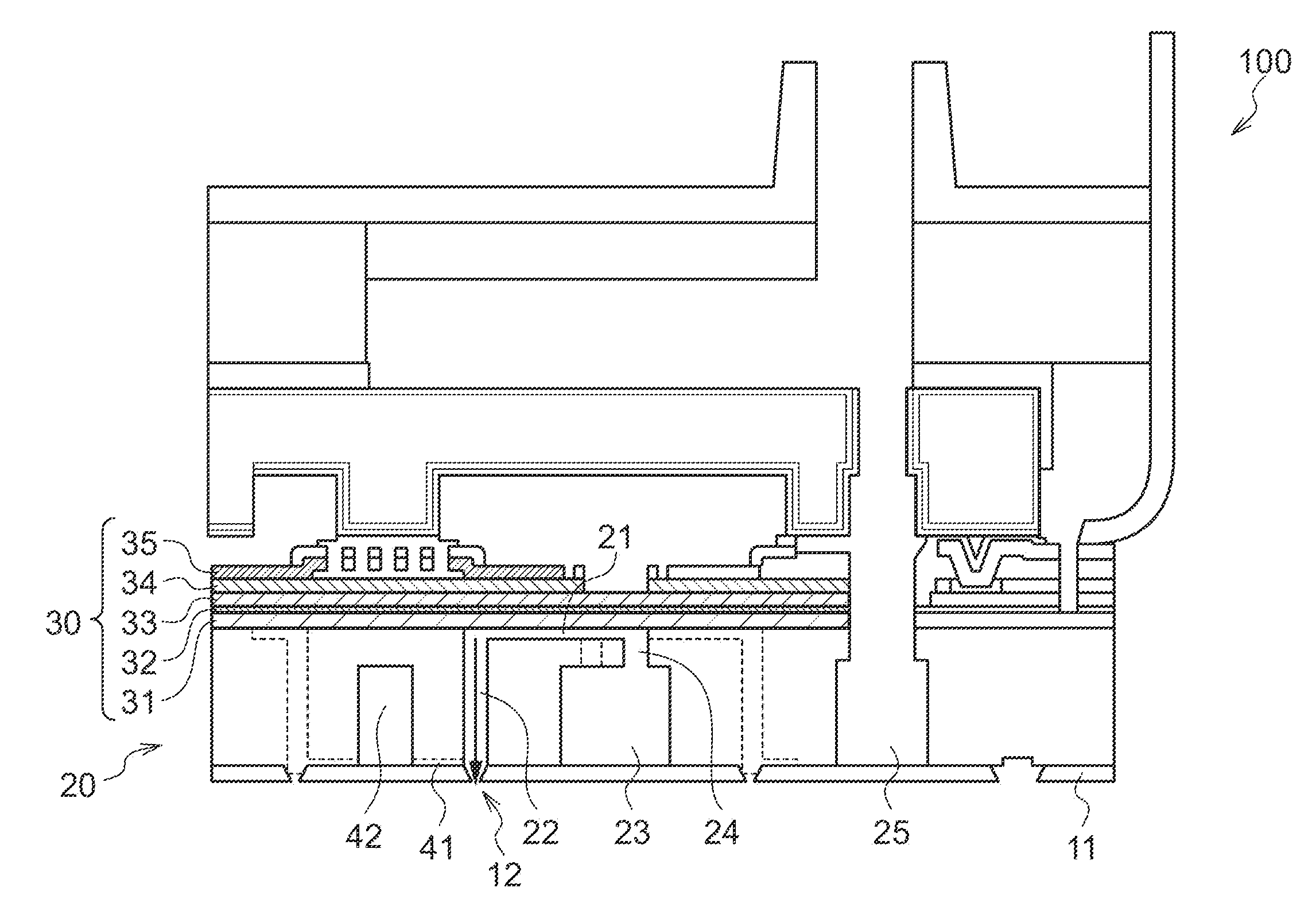

Method for preparing functional composite microsphere with multi-layer core-shell structure and application thereof

InactiveCN101735413ADifferent Surface ElectricityWith strengthDrilling compositionPolymer scienceMicrosphere

The invention discloses a method for preparing functional composite microsphere with a multi-layer core-shell structure and application thereof, and relates to the technical fields of functional macromolecular microsphere preparation and petroleum exploitation, in particular to the technical field of deep profile control water shutoff during high water-cut period of petroleum exploitation. The functional composite microsphere is prepared by a dispersion polymerization method which comprises the following steps: forming a core part by polymerization of a styrene monomer, and forming a cation shell part by copolymerization of acrylamide, the cation monomer and a crosslinking agent; and forming an anion shell part by copolymerization of acrylamide, anion monomer and the crosslinking agent. The functional composite microsphere is characterized in that the size of the microsphere is between 1,500 and 2,000nm and the microsphere is white solid powder or polymer emulsion; the expansion multiplying power of the microsphere is improved by 20 to 50 times after 5-day hydration; and therefore, the functional composite microsphere can be used for effective plugging at the pore throat of a bottom high permeability zone during high water-cut period of the petroleum exploitation.

Owner:JIANGNAN UNIV

Acrylic acid series nucleocapsid polymer emulsion and re-dispersible emulsion powder, and method for producing thereof

InactiveCN101173021AImprove performanceMeet the redispersion performanceAnticaking agentPolymer chemistry

The invention relates to a crylic acid nucleocapsid polymer emulsion and subdividable emulsion powder and the preparation method thereof. The emulsion is prepared by methacrylic acid alkyl ester, crylic acid alkyl ester, hydroxyalkyl ester, methacrylic acid, N-methylol acrylamide, an emulsifying agent and an initiator through the method of emulsion polymerization. The subdividable emulsion powder is prepared by the crylic acid nucleocapsid polymer emulsion, a protective colloid, and an anticaking agent through the spray method of emulsion. The subdividable emulsion powder of the invention has high fixed content (approximating 100 percent) and can reduce the difficulty of transportation and storage, and can be packed by using paper to reduce the packing cost, moreover, the storage stability is good and the storage period is long, and the subdividable emulsion powder of the invention can not go bad due to the water freezing or volatilization; the invention has the important thing that the subdividable emulsion powder can be rapidly dissolved in water and evenly distributed to repeatedly form the emulsion having the same performance as the primary matrix polymer emulsion, thereby being widely applied to zero VOC dry powder paint, terrace patch mortar, artesian flow flat plateau mortar, wall and floor tile bonding agent, sealed mortar, construction luting powder, plastering material, plastering gypsum, heat insulation and heated board bonding material, concrete interface agent, powder binding agent, powder paint, etc.

Owner:SHANGHAI UNIV +1

Non-aqueous dispersions comprising a nonlinear acrylic stabilizer

A non-aqueous dispersion comprising the dispersion polymerization reaction product of an ethylenically unsaturated monomer and a nonlinear, random acrylic polymer stabilizer is disclosed. Related coatings, methods, and substrates are also disclosed.

Owner:PPG IND OHIO INC

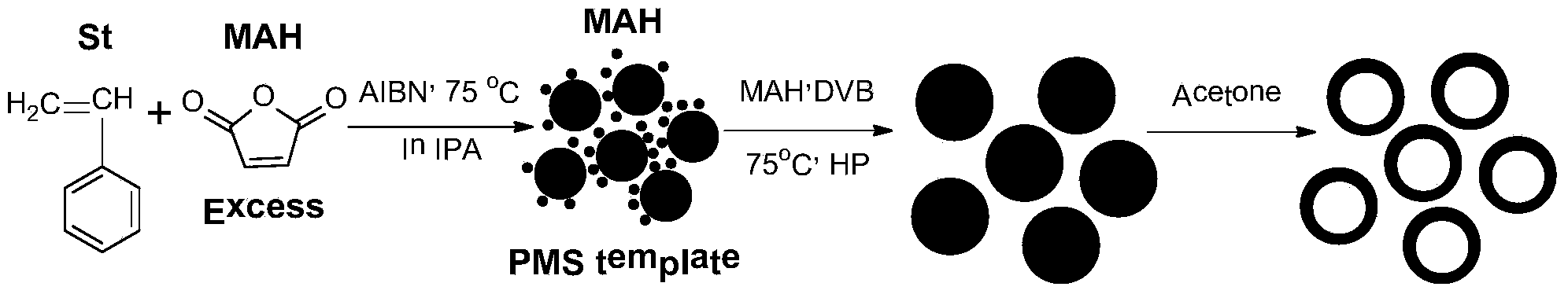

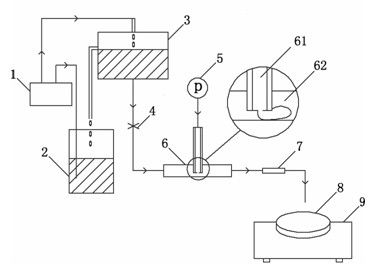

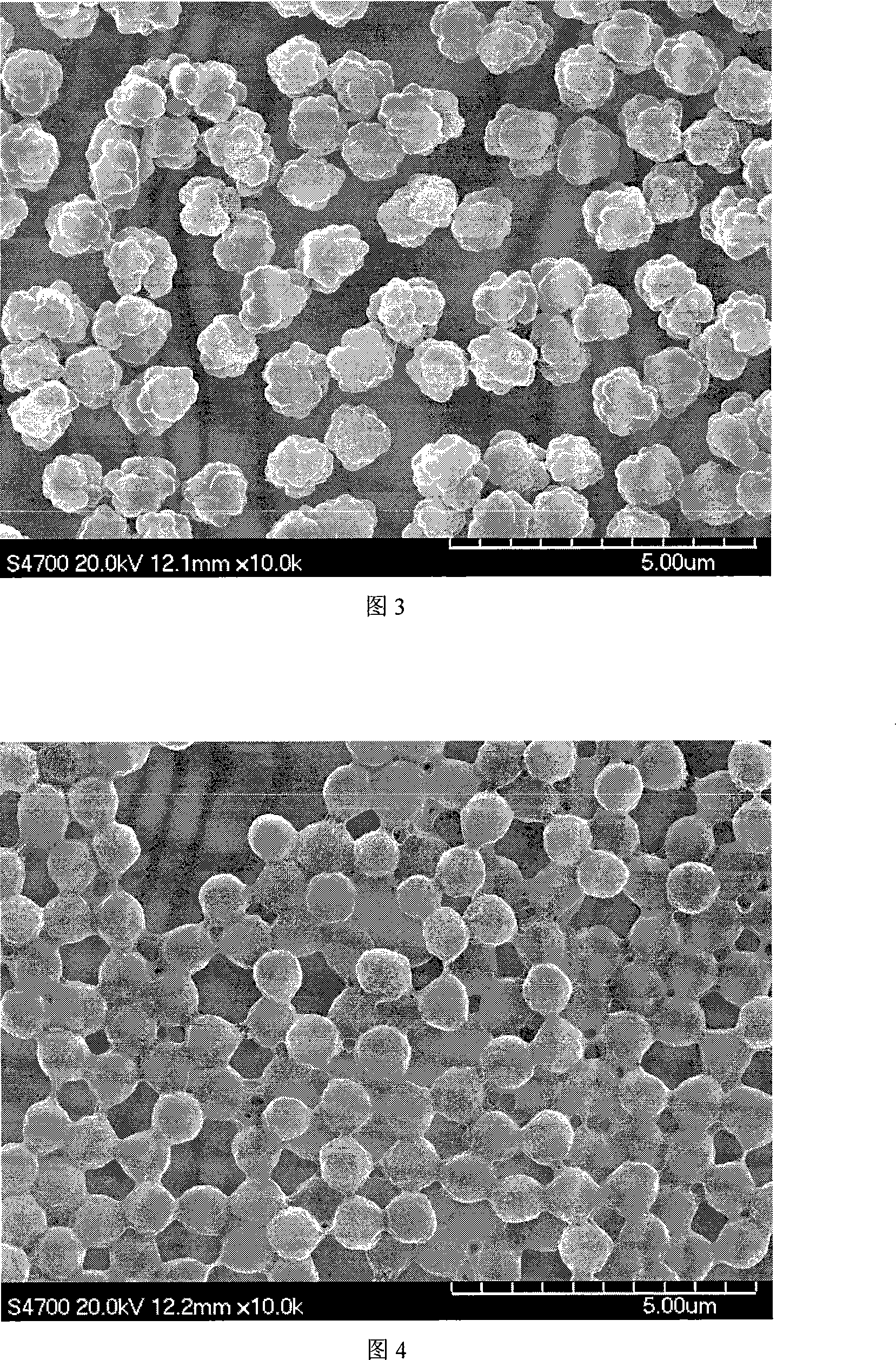

Preparation method of functional hollow polymer microspheres

ActiveCN103554325AMild reaction conditionsEasy to makeOther chemical processesAlkali metal oxides/hydroxidesPolymer scienceFunctional monomer

The invention discloses a preparation method of functional hollow polymer microspheres. The shell of the functional hollow polymer microspheres is prepared by carrying out precipitation polymerization on a functional monomer and a crosslinking agent in different ratios; and the formed crosslinked shell has a mesoporous structure. The preparation method comprises the following steps: preparing a monodisperse polymer microsphere template by self-stabilization precipitation polymerization; directly adding the reaction system into the shell without separation to form the required functional monomer and crosslinking agent, and preparing core-shell polymer microspheres of which the shell has a crosslinked mesoporous structure by precipitation polymerization; and finally, removing the polymer microsphere core by solvent dissolution to obtain the functional hollow polymer microspheres. The technique is simple, and safe and convenient to operate, has the advantages of mild reaction conditions, no need of special equipment, high preparation efficiency, easy microsphere separation, controllable size, and very high functional group content in the polymer microspheres, and lays a foundation for large-scale industrial production of the functional hollow polymer microspheres.

Owner:BEIJING UNIV OF CHEM TECH

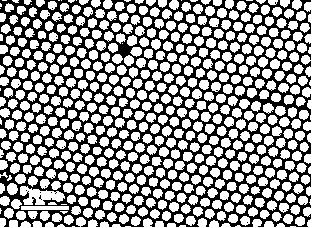

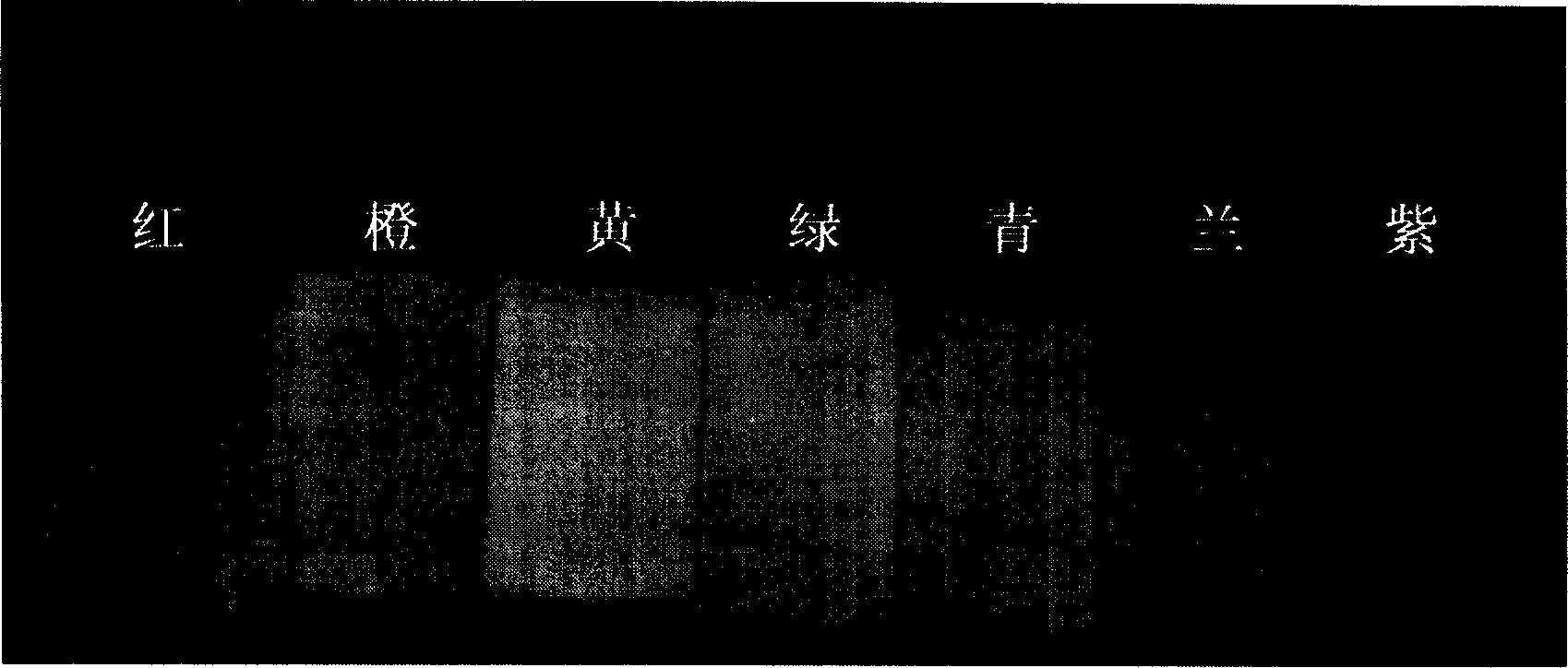

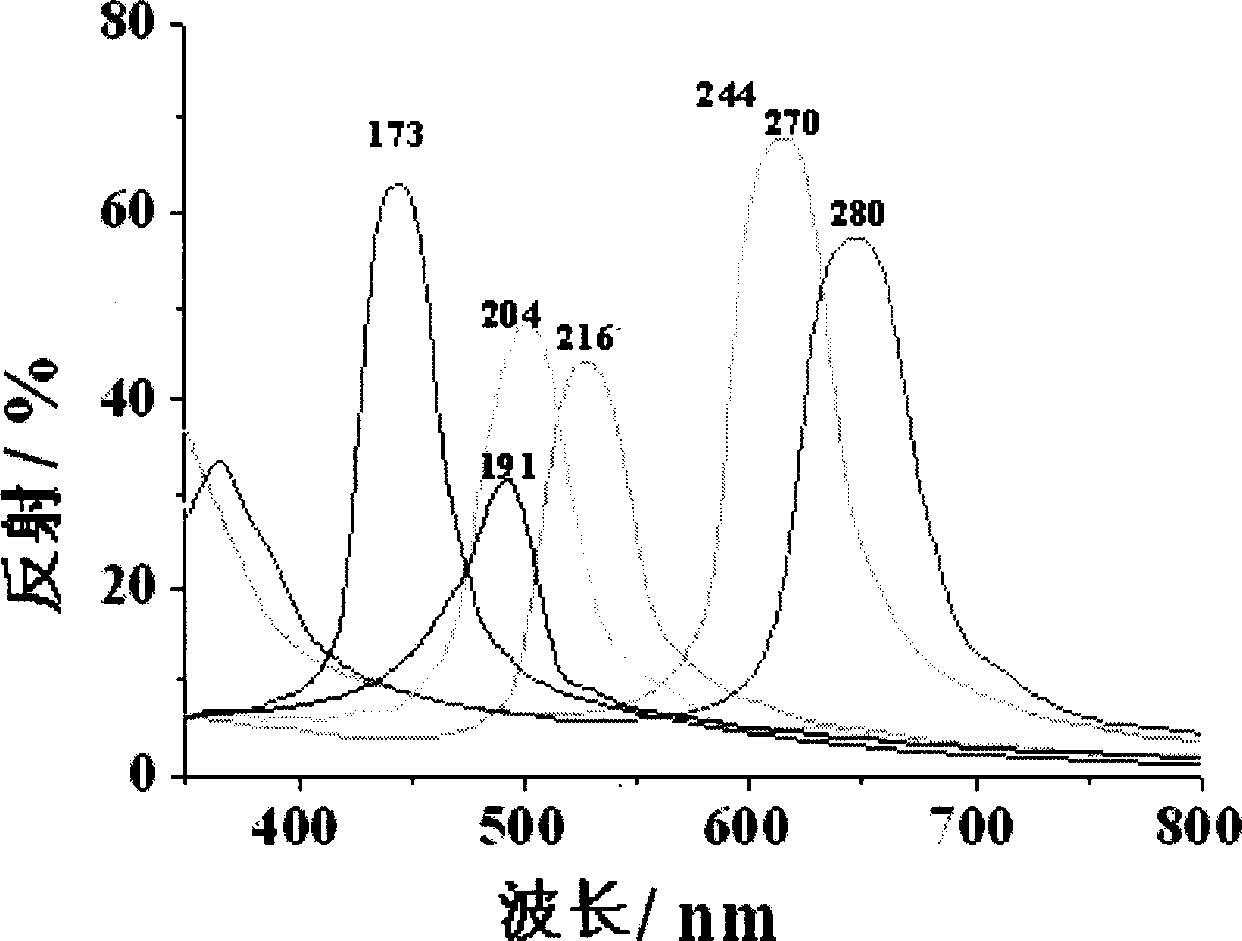

Full-color colloid photonic crystal film and its preparation method and use

ActiveCN1808214AThe monodispersity index is smallThe size is easy to controlNon-linear opticsPolymer chemistryPolymer

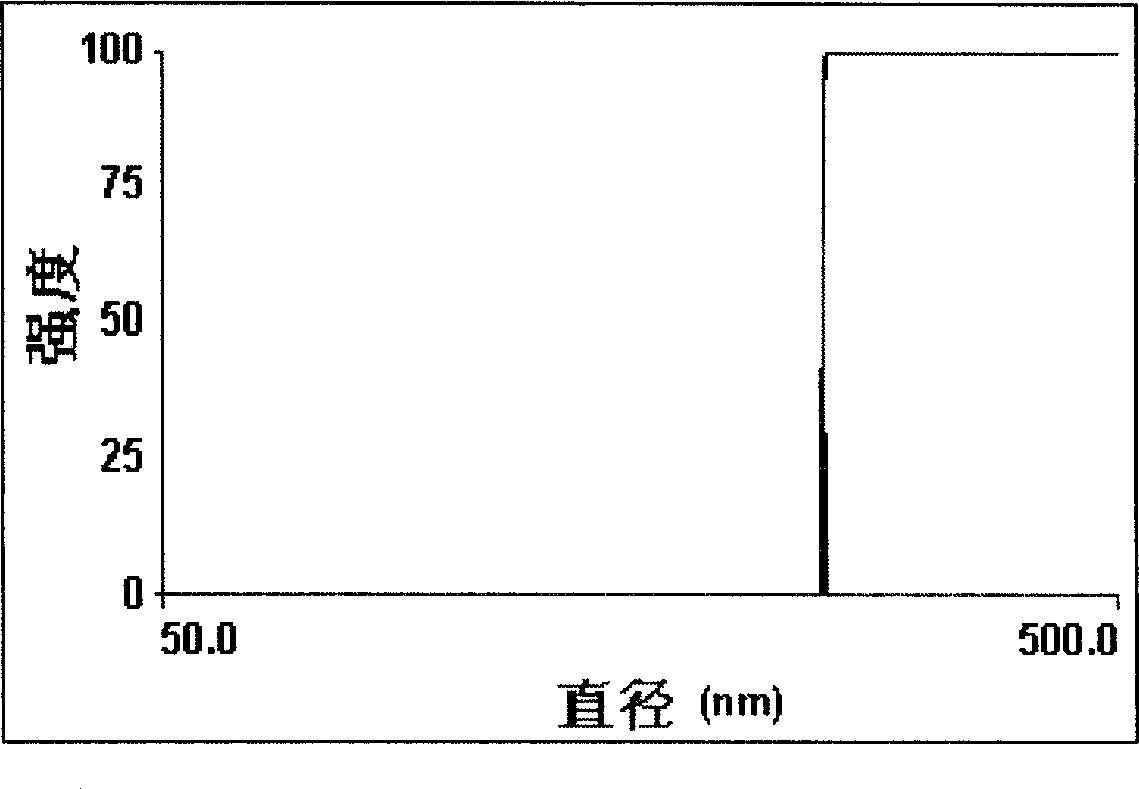

The invention relates to a large size full color colloid photon crystal membrane and the method for making the same. The method comprises: covering monodisperse polymer emulsion particle with hard shell-soft shell structures on the flat base material to form full color colloid photon crystal membrane after dispersion volatilizing, the model having cellular structure; the thickness of the single dispersion polyaromatics emulsion particle shell is 20-50nm, the range of the diameter of emulsion particle is 170í½300nm, and the multi dispersion index is less or equal to 0.005.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Polyester/platelet particle compositions displaying improved dispersion

Owner:UNIVERSITY OF SOUTH CAROLINA

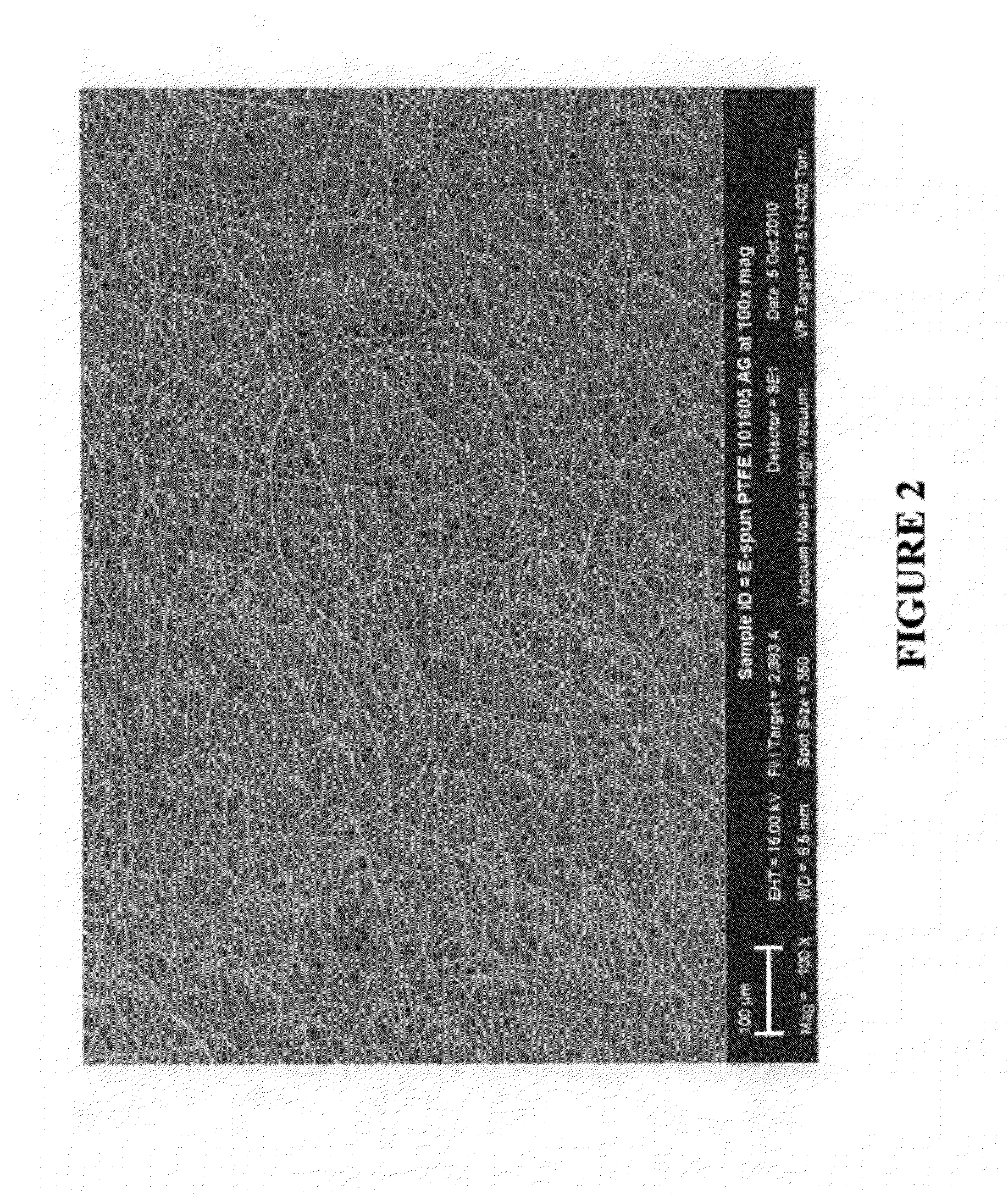

Antimicrobial substrate

Owner:ZEUS COMPANY INC

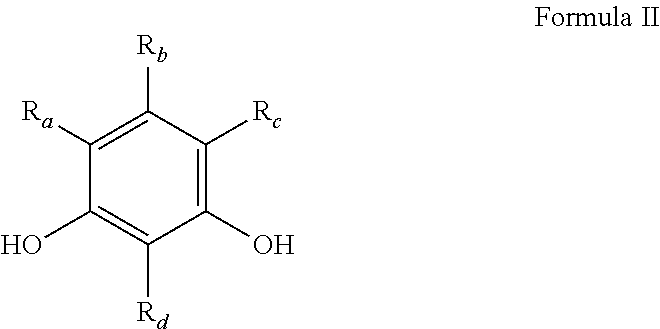

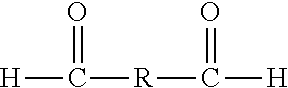

Preparation of phenol-formaldehyde resin beads using suspension or emulsion polymerization

Methods for making polymer particles in gel form via an emulsion and / or suspension polymerization are provided. In at least one specific embodiment, the method can include reacting a first reaction mixture comprising a phenolic monomer, an aldehyde monomer, and a first catalyst to produce a prepolymer. The method can also include combining the prepolymer with a carrier fluid and a second catalyst to produce a second reaction mixture. The second catalyst can include a dicarboxylic acid, an anhydride, a dihydroxybenzene, or any mixture thereof. The method can also include polymerizing the prepolymer to form polymer particles in gel form.

Owner:GEORGIA PACIFIC CHEM LLC

Process for the stabilization of dusting surfaces

InactiveUS20060128839A1Avoids environmental disadvantageAvoid disadvantagesSpecial tyresEmulsion paintsGypsumPolymer

The invention relates to a process for the stabilization of dusting surfaces characterized in that the dusty ground is tilled or scarified and mixed with polymers in form of water-redispersible polymer powders, which are optionally re-emulsifiably modified, or reemulsifiable modified aqueous polymer dispersions, which are optionally sprayed on to the untreated dusty ground. In a preferred embodiment the redispersible polymer powder, respectively the reemulsifiable modified redispersible polymer powder or the reemulsifiable modified aqueous polymer dispersion, is combined with hydraulically setting compounds, preferably cement and / or gypsum.

Owner:WACKER POLYMER SYST

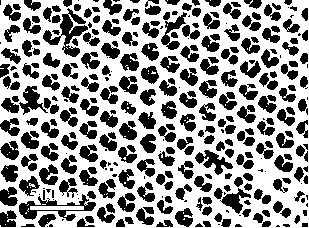

Structural color film material and method for preparing same

The invention belongs to fields of chemical industry, materials and optics, and relates to a structural color film material used in a large area and a method for preparing the same. Water-based inorganic nano-particles, monodisperse polymer emulsion and a non-essential addition agent are compounded by an in-situ polymerization method or blending method to obtain nano-composite emulsion, and the obtained emulsion is coated on the surface of a substrate; and moisture is volatilized, the three-dimensional ordered nano-structural color film material is prepared, and the color of the material can be regulated in a visible light area without adding any pigments. The structural color film material has the advantages of simple preparation, complete aquosity, safety, innocuity, easy large-area construction, good transparency, strong adhesive force and high heat resistance, can be directly coated on surfaces of glass, metal, ceramic, concrete, plastic and the like, and is used for bionics, decoration, printing, color display, photonic crystals, wave filtering, personal care, fabric fibers, coating, anti-counterfeit, optical sensors, photoelectric conversion materials and the like.

Owner:FUDAN UNIV

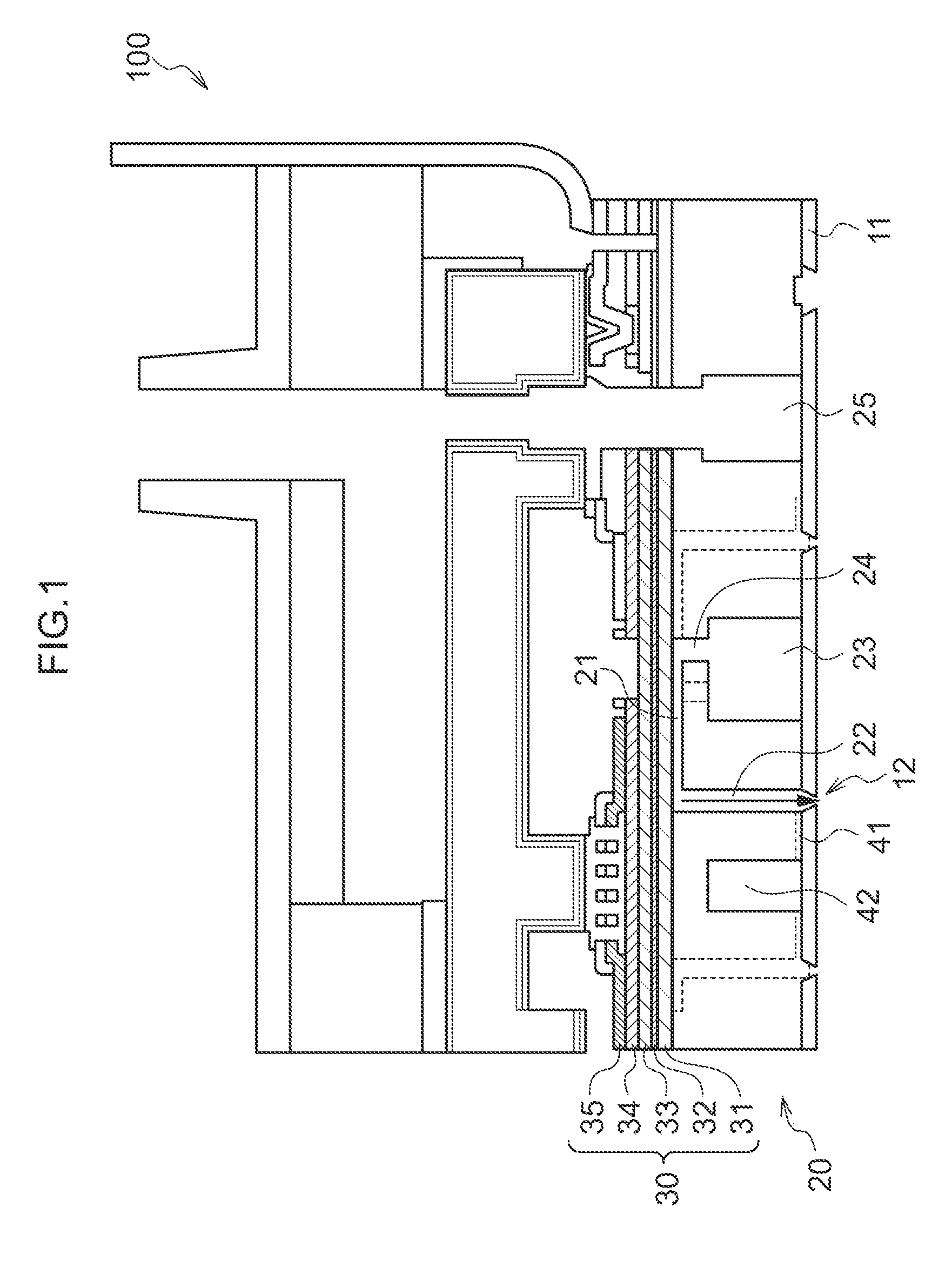

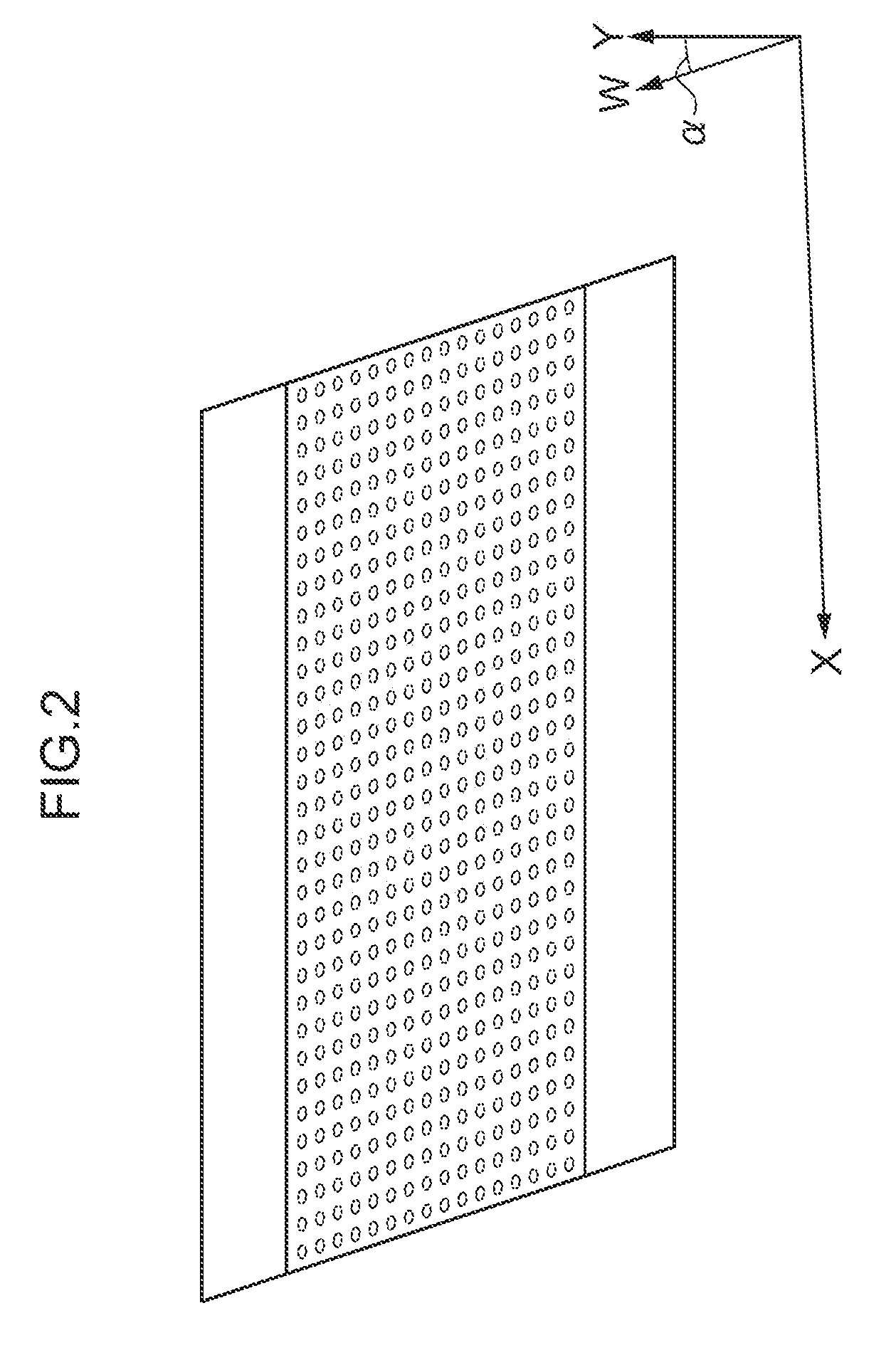

Organic/inorganic composite coating film, structural color film using the same, and preparation methods thereof

InactiveUS20100104810A1Easy to prepareSuitable for useRoof covering using sealantsLayered productsMetal alkoxidePolymer chemistry

An organic / inorganic composite coating film comprising an inorganic material as a matrix and an organic material combined therewith. The coating film has a regular hollow structure therein, and the coating film surface has a rugged pattern with semispherical protrusions. Also provided is a large-area structural color film obtained by burning the composite coating film. The organic / inorganic composite coating film is obtained by applying an aqueous coating composition comprising a metal alkoxide, an aqueous dispersion of monodisperse polymer particles, and an acid catalyst to a substrate and curing the coating composition. Burning the organic / inorganic composite coating film gives the structural color film.

Owner:DAINIPPON INK & CHEM INC +1

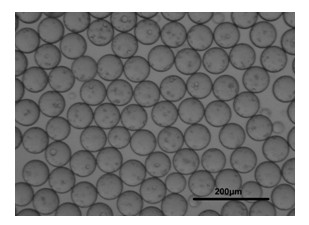

Detachable T-shaped microchannel device and method for preparing monodisperse polymer microspheres by same

InactiveCN102211008AEasy to unblockNarrow particle size distributionPharmaceutical non-active ingredientsChemical/physical/physico-chemical processesOrganic solventMicrosphere

The invention discloses a detachable T-shaped microchannel device and a method for preparing monodisperse polymer microspheres by the same. The method comprises the following steps of: performing heat treatment on a needle tube serving as a disperse phase flowing channel, and processing a duct with the same outer diameter as the needle tube on a pipeline serving as a continuous phase flowing channel to make the disperse phase needle tube and the continuous phase tube form a T-shaped channel; under the stable operating condition, making dispersed fluid form uniform micro liquid drops at a T-shaped tube orifice through the shearing force of continuous phase fluid to the disperse phase fluid; and under the action of a shaker, diffusing an organic solvent out of the liquid drops, and curing the liquid drops to form the polymer microspheres with uniform particle size. The T-shaped microchannel device is simple in equipment and can be detached, and pipelines are easy to dredge after being blocked; and the prepared polymer microspheres have uniform particle size, the particle size distribution coefficient of less than 15 percent, the minimum particle size distribution coefficient of 3 percent, and smooth surfaces without adhesion.

Owner:ZHEJIANG UNIV

Prepn process of polyimide microsphere

The present invention relates to dispersive polymerization process of preparing polyimide microsphere in monomer solution. The process includes the following steps: dissolving monomer diamine and dispersant in organic solvent through stirring; stage adding monomer diamine and heating for polymerizing to prepare polyamic acid solution; adding catalyst and dewatering agent successively for chemical imination; dropping water solution of dispersant to separate out solid grains, centrifugally filtering, washing and stoving to obtain polyimide microsphere. Thus prepared polyimide microsphere has glass transition temperature Tg of 200-300 deg.c, and grain size of 0.1-100 micron. The process has high polyimide yield, low cost and controllable grain shape and size distribution.

Owner:NANJING UNIV OF TECH

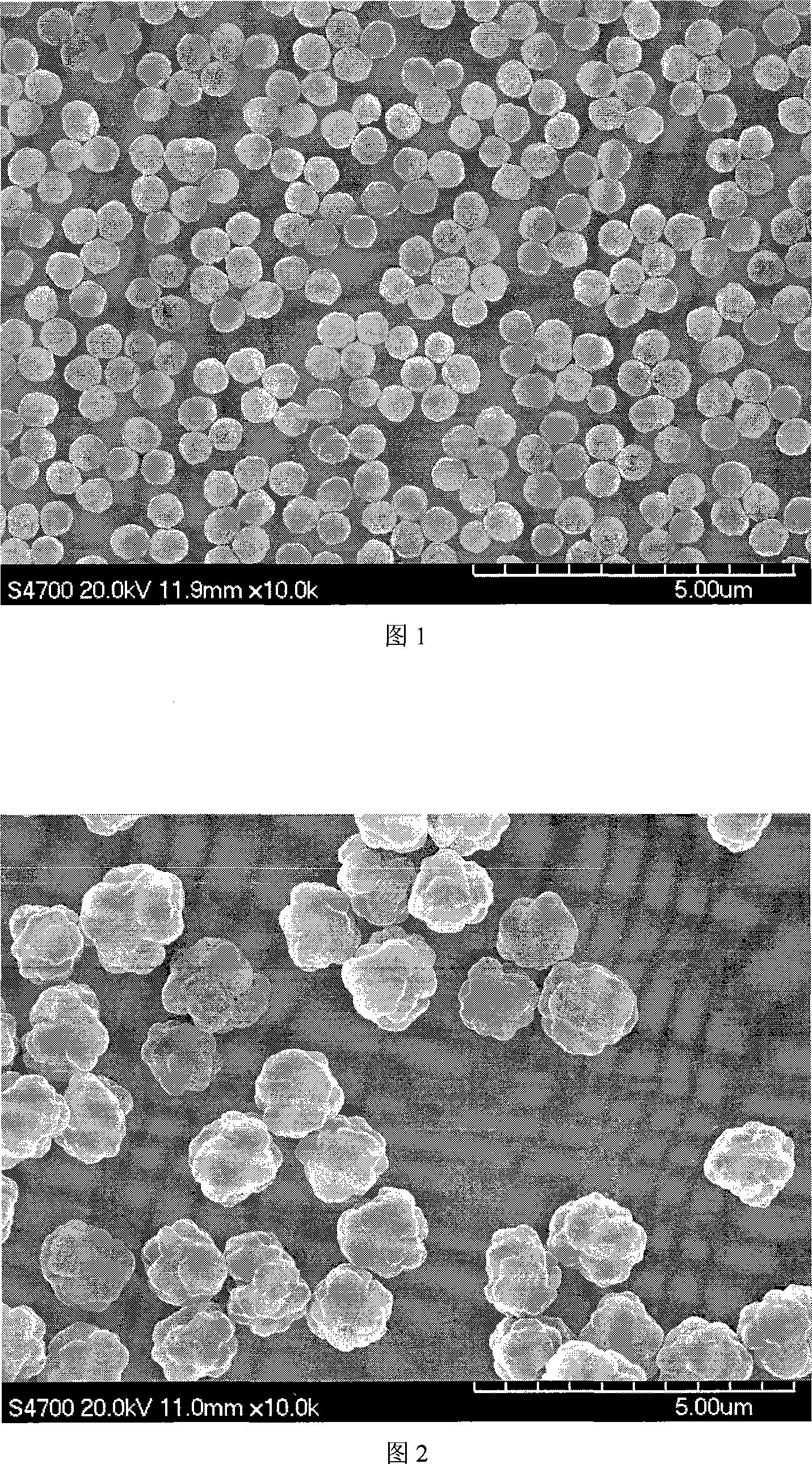

Core-shell polyacrylamide microsphere profile controlling oil displacement agent and preparation method thereof

ActiveCN103739778AEfficient recyclingAchieving a green cycleDrilling compositionMicrosphereMicrometer

The invention discloses a core-shell polyacrylamide microsphere profile controlling oil displacement agent and a preparation method thereof. The method comprises the following steps: fully stirring and dissolving acrylamide, cationic monomer, a crosslinking agent and an initiator to synthetize a core part by adopting a dispersion polymerization method; fractionally adding a mixed solution of the acrylamide, anionic monomer, third monomer, the crosslinking agent and the initiator into a reaction device, controlling reaction conditions to be invariant, and reacting on the surface of the core to generate a shell part, thereby obtaining the core-shell polyacrylamide microsphere profile controlling oil displacement agent taking the cationic polyacrylamide as the core and taking the anionic polyacrylamide polymerized on the surface of the core as the shell, wherein the particle size range of the microsphere profile controlling oil displacement agent is from 1micrometer to100 micrometers. The microsphere profile controlling oil displacement agent has the advantages that the microsphere has an interpenetrating polymer network system and is capable of forming a viscoelastic body after absorbing water and forming a gel body after a certain time, so that the oil displacement agent is long in plugging time and little in leakage and is capable of bearing the pressure of more than 5MPa.

Owner:TIANJIN UNIV

Copolymerization reaction method for styrene/maleic anhydride

A copolymerization method of phenylethene / maleic anhydride belongs to polymer preparation technical field, for resolving the defect caused by stabilizer in traditional disperse polymerization system, which comprises under nitrogen gas protection, dissolving monomer Man and St, inducer organic hyperoxide or azocompound of suitable ratio in organic acid alkyl ester, the mixture of aromatics and organic acid alkyl ester or the mixture of ketone and alkane to react for 1 / 4-12h at 60-90 DEG C to obtain the disperse system of polymer microballoon, wherein the average particle diameter of microballoon in the disperse system is 90-1715mm, the disperse factor is 1.04-1.004 and the number average molecular weight is 80000-300000g / mol. The invention has the advantages of eliminated stabilizer, simple process, low cost, clean polymer microballoon or particle surface, controllable particle diameter, controllable shape and narrow granularity distribution.

Owner:BEIJING UNIV OF CHEM TECH

Dry mortar formulations modified with water-redispersible polymer powders

Dry mortar formulations comprising a) from 0.5 to 80% by weight of hydraulic binder, b) from 0 to 97% by weight of fillers, c) from 0 to 3.5% by weight of thickeners, d) from 1.0 to 80% by weight of redispersible polymer powder, and e) from 0.0001 to 1.0% by weight of antioxidants exhibit improved tensile strength and other set mortar properties, particularly after storage of the dry mortar composition.

Owner:WACKER CHEM GMBH

Ink composition, ink set and inkjet image forming method

ActiveUS20110069110A1Improve discharge performanceSuppression problemMeasurement apparatus componentsDuplicating/marking methodsHydrophilic monomerColloidal silica

The present invention provides an inkjet ink composition including: self-dispersing polymer particles, each of the self-dispersing polymer particles including a structural unit derived from a hydrophilic monomer and a structural unit derived from a hydrophobic monomer; colloidal silica; and colorant particles, the inkjet ink composition having excellent dischargeability and suppressing the deterioration of the liquid repellency of an inkjet head member.

Owner:FUJIFILM CORP

High oil absorption polyurethane foam and preparation method thereof

ActiveCN101987884AHigh oil absorptionFast oil absorptionOther chemical processesChemical recyclingChlorobenzeneKerosene

The invention relates to a high oil absorption polyurethane foam which comprises the following components in parts by weight: 20 to 40 parts of isocyanate, 35 to 60 parts of polyol, 0.5 to 3 parts of catalyst, 0.5 to 3 parts of foam stabilizer, 5 to 10 parts of foaming agent, 2 to 10 parts of opening agent,5 to 20 parts of flame retardant, 5 to 15 parts of silicon rubber spherical micro powder and 0.5 to 2 parts of coupling agent. The preparation method comprises the following technology steps of weighing, prepolymerization, dispersing, polymerization foaming reaction, curing and peeling at room temperature and cutting. The high oil absorption polyurethane foam can be used for the absorption and recycle of various oil products (crude oil, engine oil, diesel fuel, gasoline, kerosene and the like) on water surfaces, ground or surfaces of other objects, and various oil soluble organic compounds (benzene, methylbenzene, dimethylbenzene, chloroform, nitrobenzene, chlorobenzene and the like). The invention has the advantages of simple technology and low cost, obviously improves the dispersing effect of the silicon rubber spherical micro powder in a polymerization system by using ultrasonic technique, and greatly increase the oil absorption quantity and oil absorption rate of the polyurethane foam by adding the silicon rubber spherical micro powder.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

Dry powder latex paint for inner wall and preparation thereof

The invention relates to an environment-friendly inner wall dry powder latex coating and a preparation method thereof. The compositions according to weight percentages are as follows: 10-40% of re-dispersible polymer latex powder, 10-40% of titanium dioxide, 10-40% of ground calcium carbonate, 5-20% of calcined kaolin, 5-10% of talcum powder, 0.1-0.5% of cellulose ether, 0.2-0.6% of solid defoamer, 0.2-1.0% of multifunctional auxiliary agent, and 0.01-10% of tinting pigment. The inner wall dry powder latex coating formed in the invention can have scumble construction after thinning by being added with two to three times of water, and the thickness of dry film is 20 microns to 200 microns; the color is tunable; the storage is stable, and the transportation is convenient; the VOC thereof cannot be detected (real zero VOC), and the coating film performances meet the technical requirements of national standard of inner wall latex coating; and the combination properties of products can reach international most advanced level of similar products.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com