Patents

Literature

365 results about "Hybrid fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

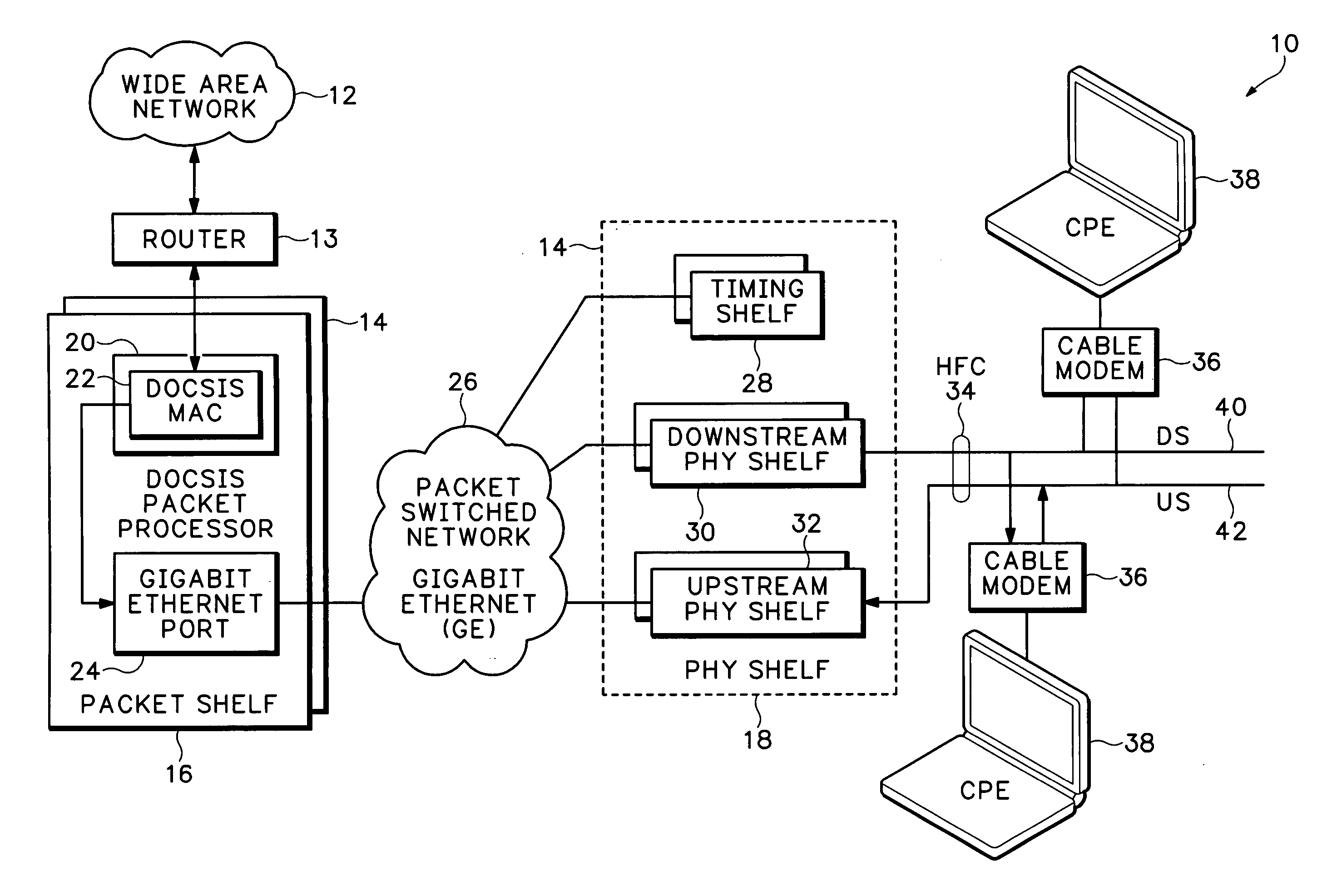

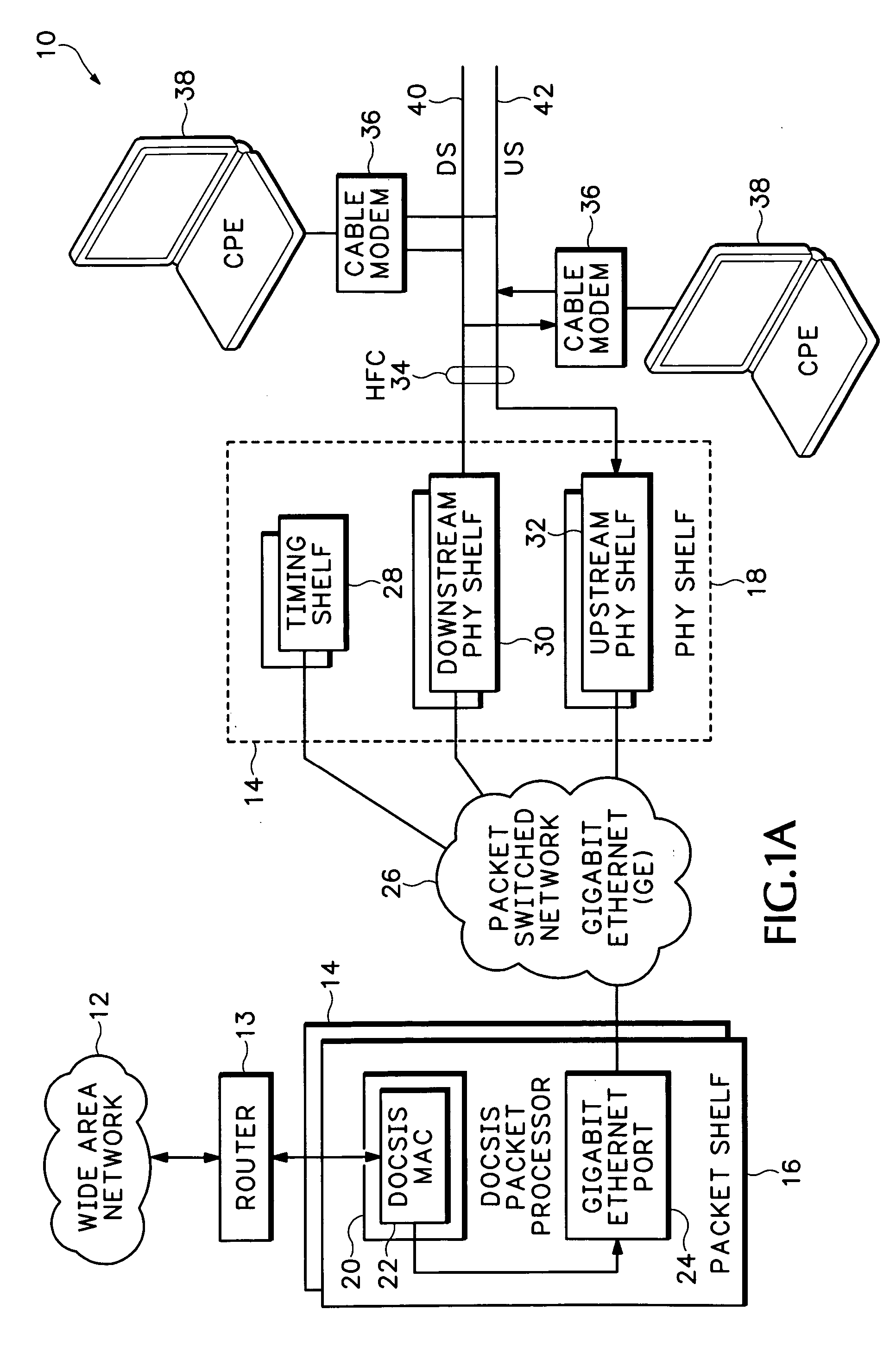

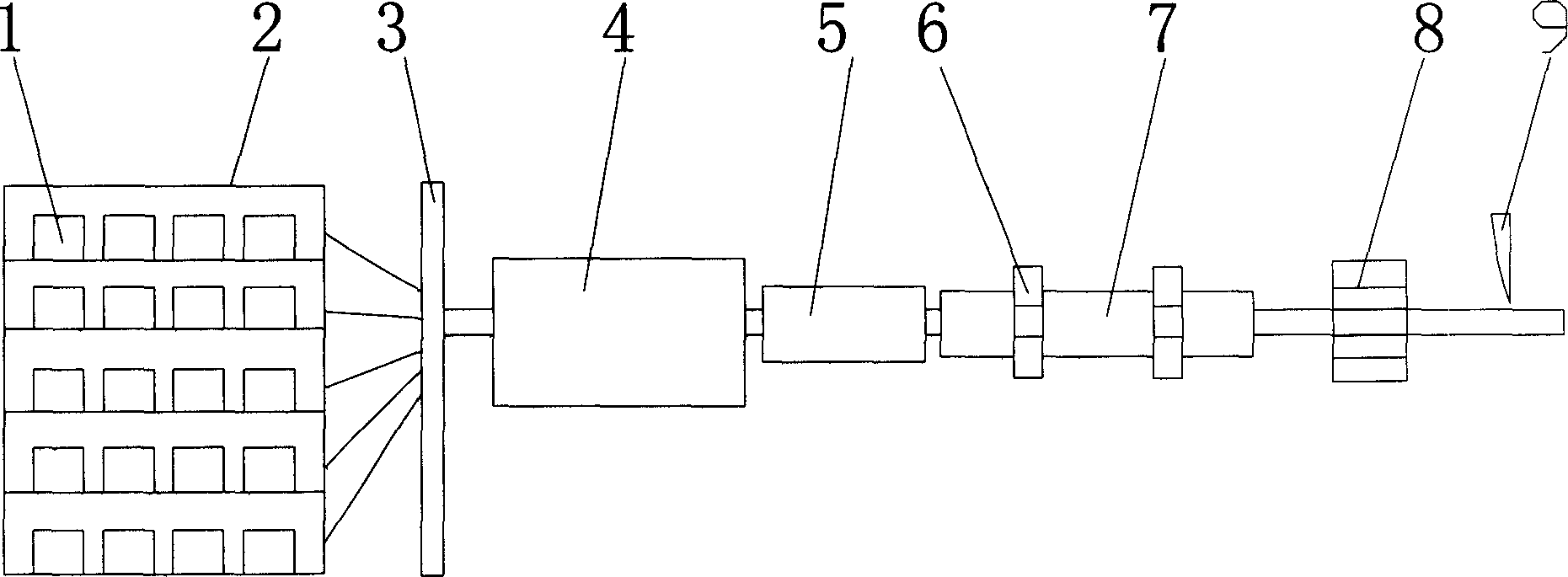

A hybrid fiber coaxial (HFC) network is a telecommunication technology in which optical fiber cable and coaxial cable are used in different portions of a network to carry broadband content (such as video, data, and voice).

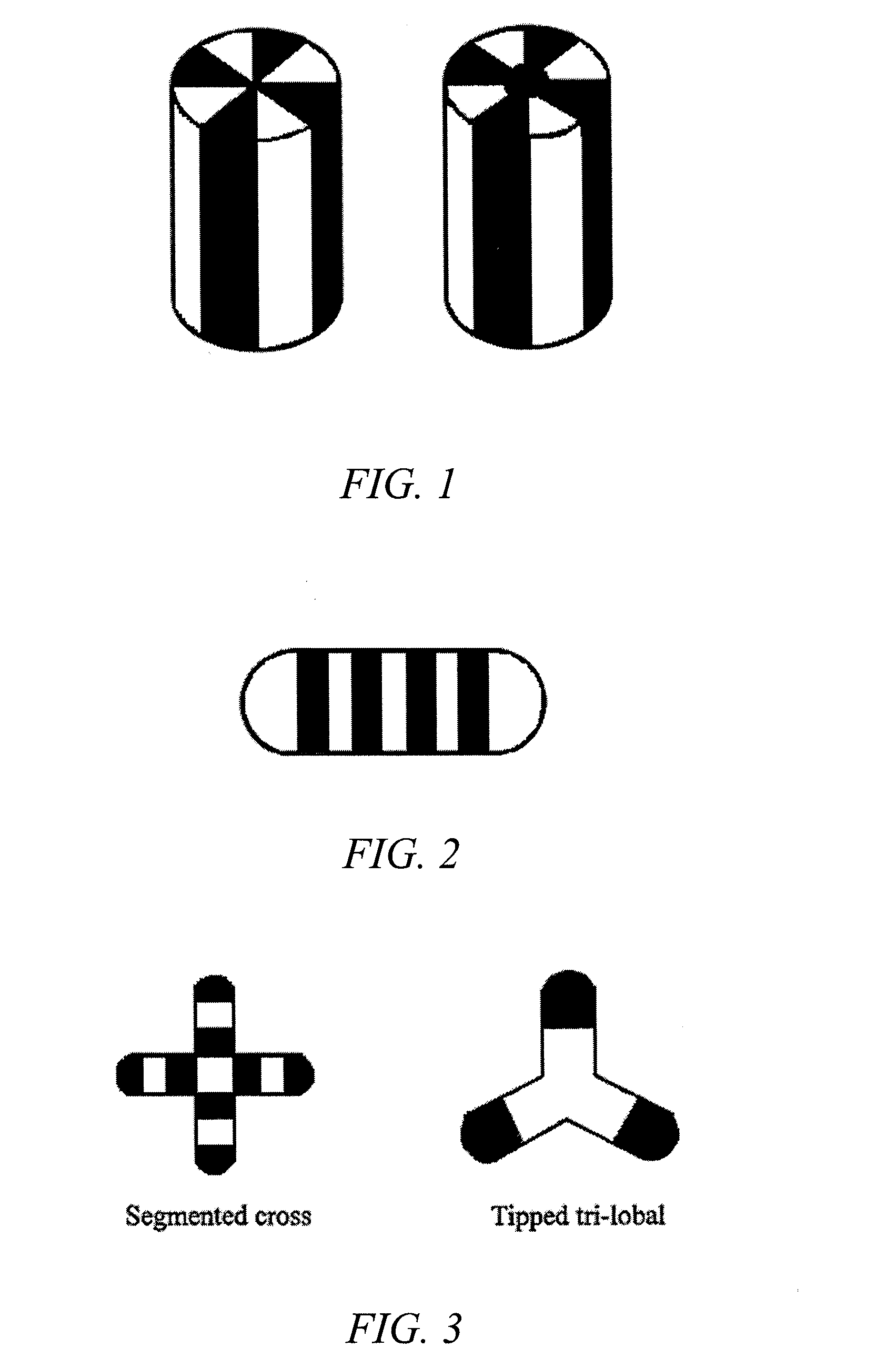

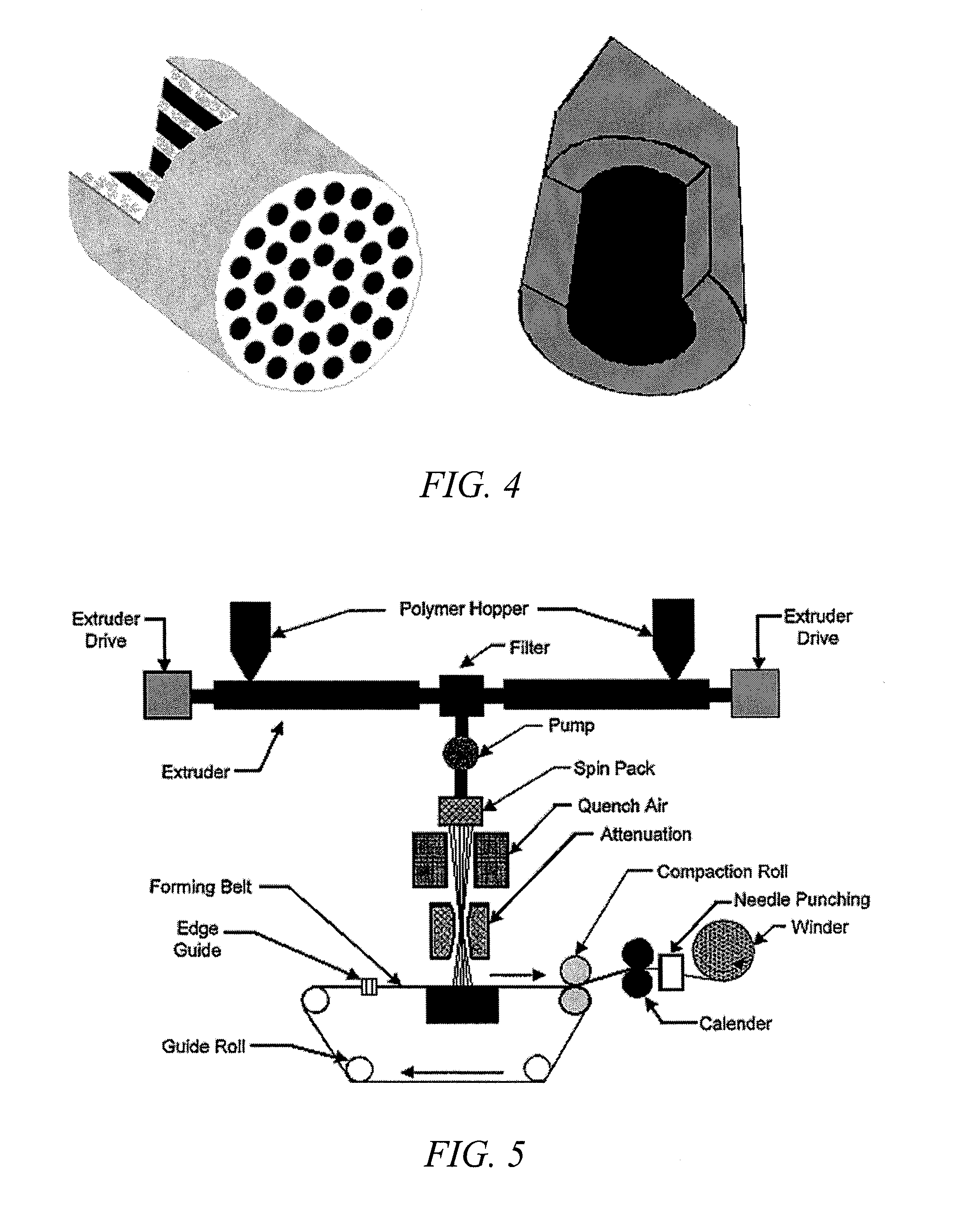

Nonwovens produced from multicomponent fibers

InactiveUS20080311815A1Reduce blockingReduce fusionNon-fibrous pulp additionNatural cellulose pulp/paperPolymer scienceSlurry

A water non-dispersible polymer microfiber is provided comprising at least one water non-dispersible polymer wherein the water non-dispersible polymer microfiber has an equivalent diameter of less than 5 microns and length of less than 25 millimeters. A process for producing water non-dispersible polymer microfibers is also provided, the process comprising: a) cutting a multicomponent fiber into cut multicomponent fibers; b) contacting a fiber-containing feedstock with water to produce a fiber mix slurry; wherein the fiber-containing feedstock comprises cut multicomponent fibers; c) heating the fiber mix slurry to produce a heated fiber mix slurry; d) optionally, mixing the fiber mix slurry in a shearing zone; e) removing at least a portion of the sulfopolyester from the multicomponent fiber to produce a slurry mixture comprising a sulfopolyester dispersion and water non-dispersible polymer microfibers; and f) separating the water non-dispersible polymer microfibers from the slurry mixture. A process for producing a nonwoven article is also provided.

Owner:EASTMAN CHEM CO

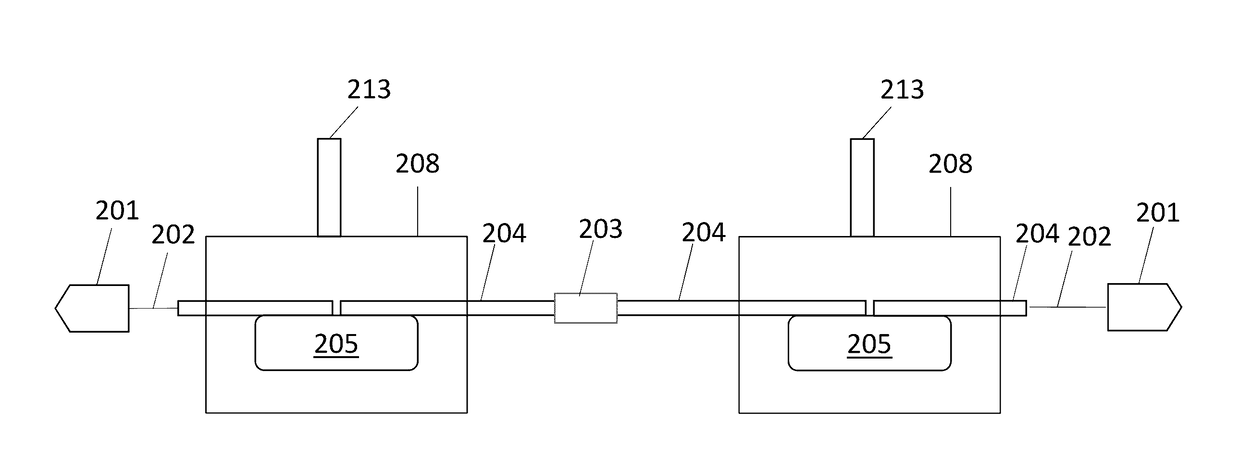

Timing system for modular cable modem termination system

InactiveUS20060168612A1Synchronisation information channelsBroadcast transmission systemsDigital subscriber lineModem device

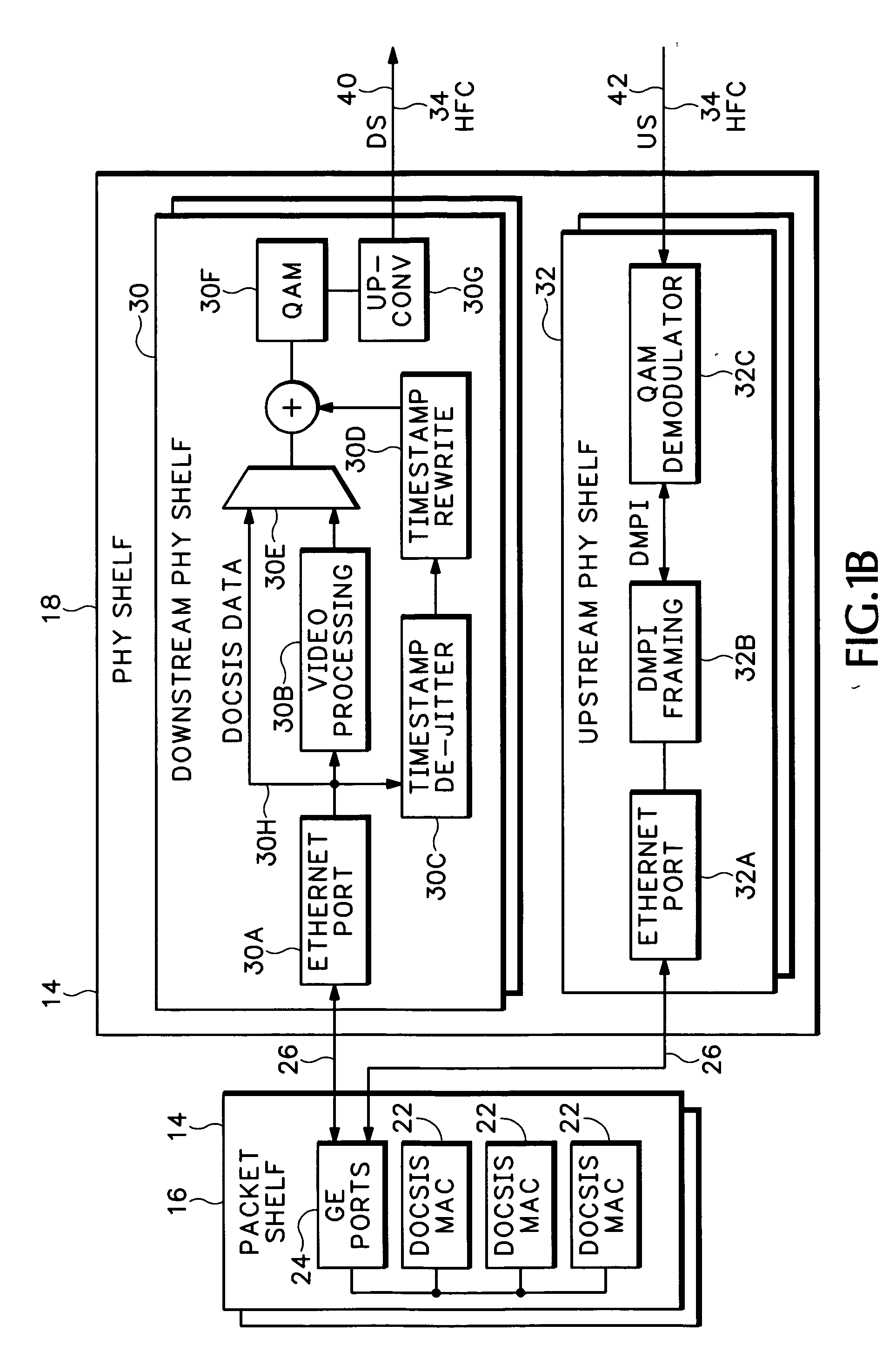

A modular Cable Modem Termination System (CMTS) includes a packet shelf operating a Data Over Cable Service Interface Specifications (DOCSIS) Media Access Control (MAC) framer. One or more downstream Physical Interface (PHY) shelves receive DOCSIS data from the packet shelf over a packet switched network and modulate the DOCSIS data for sending on a downstream path of a cable plant. One or more upstream PHY shelves send DOCSIS data received from an upstream path of the cable plant over the packet switched network to the packet shelf. By separating the PHY components from the MAC and from the system software, the PHY components for a Hybrid Fiber Coax (HFC) plant may be replaced with different PHY components for other access technologies such as wireless, Digital Subscriber Lines (DSL), Ethernet-to-the-Home, Fiber-to-the-Home, or fiber Passive Optical Networks (PONs).

Owner:CISCO TECH INC

Mixed fibers and nonwoven fabrics made from the same

ActiveUS20090042475A1Improve breathabilityIncrease flexibilityLaminationLamination apparatusFiltrationSubject matter

The subject matter disclosed herein relates generally to the production of a predetermined ratio of multicomponent fibers in combination with monocomponent fibers or other multicomponent fibers, preferably through a spunbonding process. After extrusion, these fibers can produce a fiber network that is subsequently bonded to produce a nonwoven fabric comprising multiple types of fibers. The multicomponent fibers within the network may be processed to remove one component by dissolution or to split the individual components into separate fibers. As a result, the fabric will be comprised of fibers with a range of diameters (micro- or nano-denier fibers as well as higher denier fibers) such that the fibers will not pack as tightly as in a homogeneous nonwoven fabric produced from one type of monocomponent or multicomponent fiber. The present invention additionally relates to methods for producing nonwoven fabrics with increased loft, breathability, strength, compressive properties, and filtration efficiency.

Owner:NORTH CAROLINA STATE UNIV

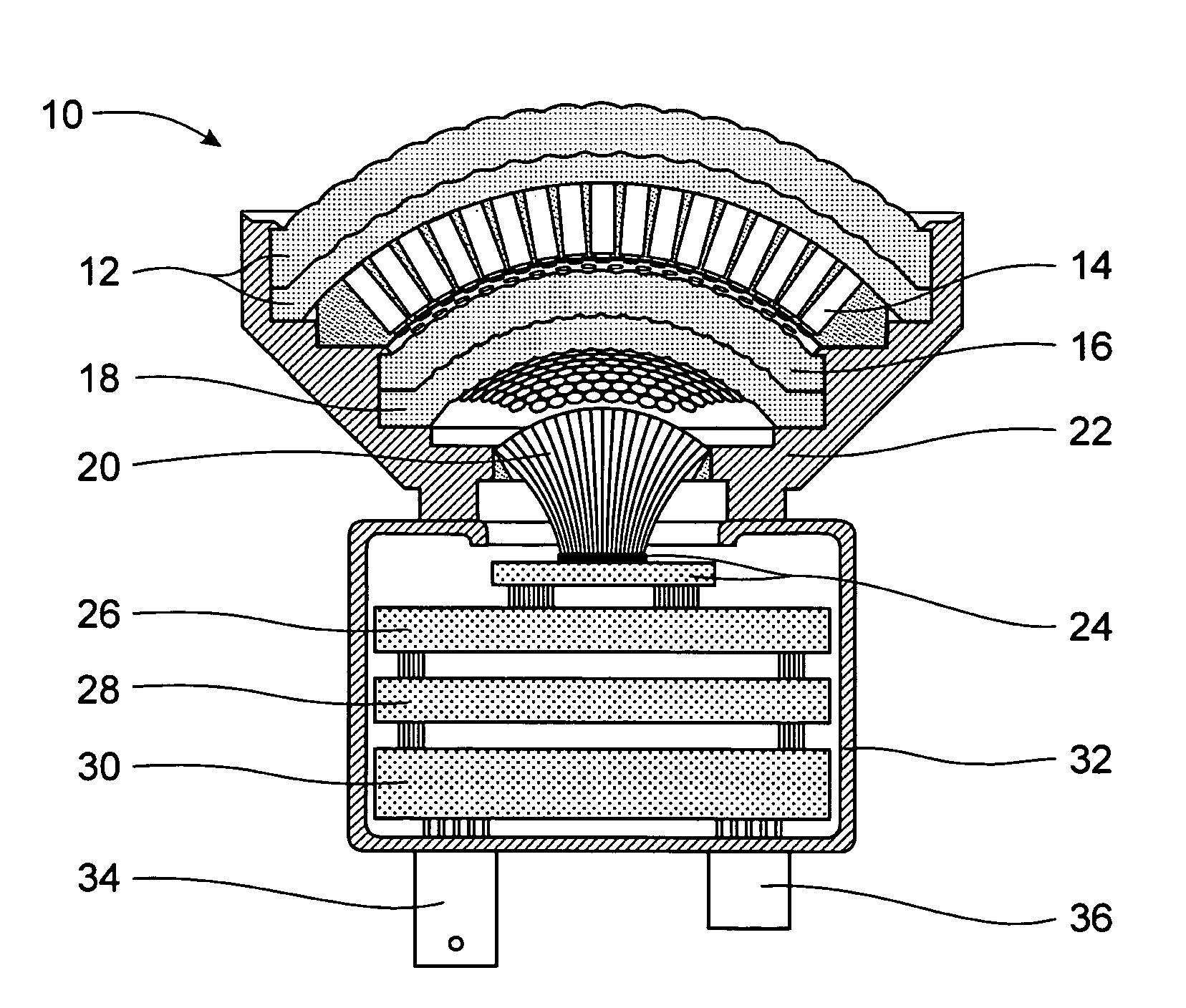

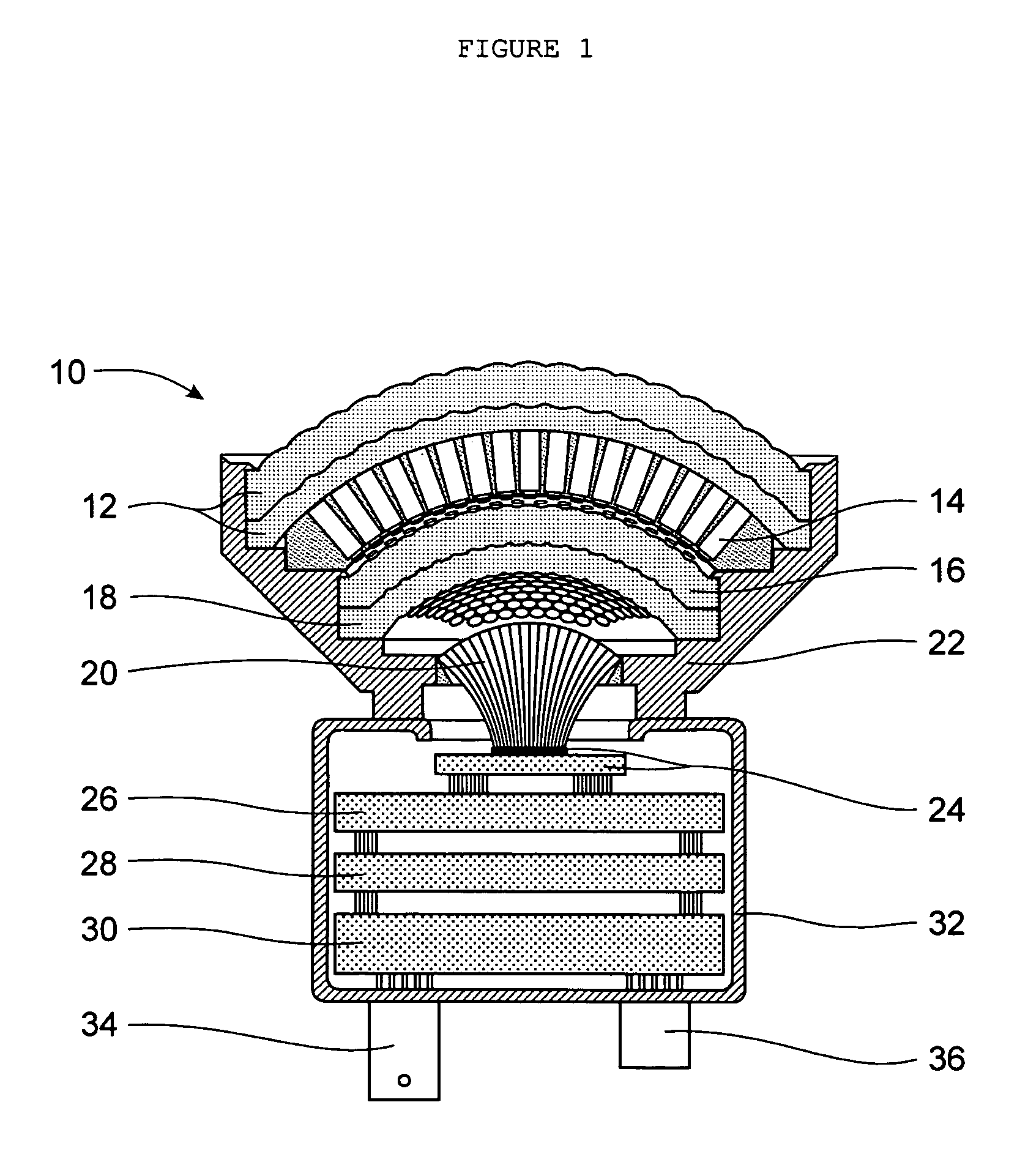

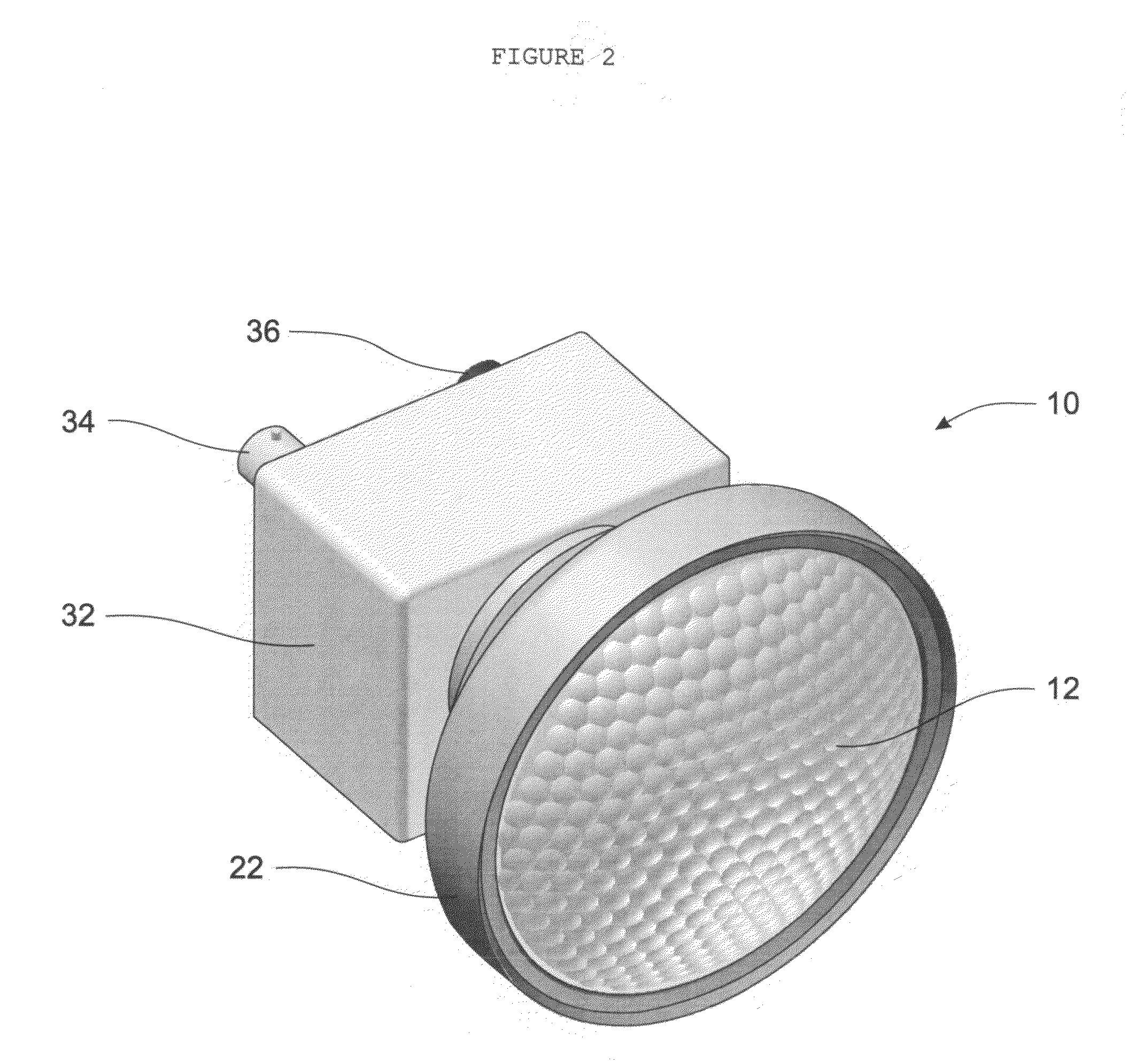

Hybrid fiber coupled artificial compound eye

InactiveUS7587109B1Improve throughputEasy alignmentTelevision system detailsCoupling light guidesCamera lensEyepiece

A hybrid, wide angle imaging system combines high sensitivity superposition arrays with a high resolution apposition array to generate distortion free images with an infinite depth of field. A conformal, superposition array of Keplerian telescope objectives focuses multiple apertures of light through the tubes of a louver baffle. The baffle tubes are terminated by field stops that separate the focused light into inverted, intermediate sub-images. A superposition array of field lenses, positioned immediately after the field stops, reverses the angles of the light beams. An apposition array of erector lenses, linked optically to the superposition arrays and field stops, refocuses and adjoins the beams into a single, upright image. The upright image is formed on the convex surface of a fiber optic imaging taper, which transfers the image to the flat bottom of the taper where it can be viewed through an eyepiece or digitized by a detector array.

Owner:SPECTRAL IMAGING LAB

Mixed fiber and, stretch nonwoven fabric comprising said mixed fiber and method for manufacture thereof

ActiveUS20060121812A1Excellent touch and heat sealing property and productivityLow residual strainWoven fabricsNon-woven fabricsPolymer scienceThermoplastic polyurethane

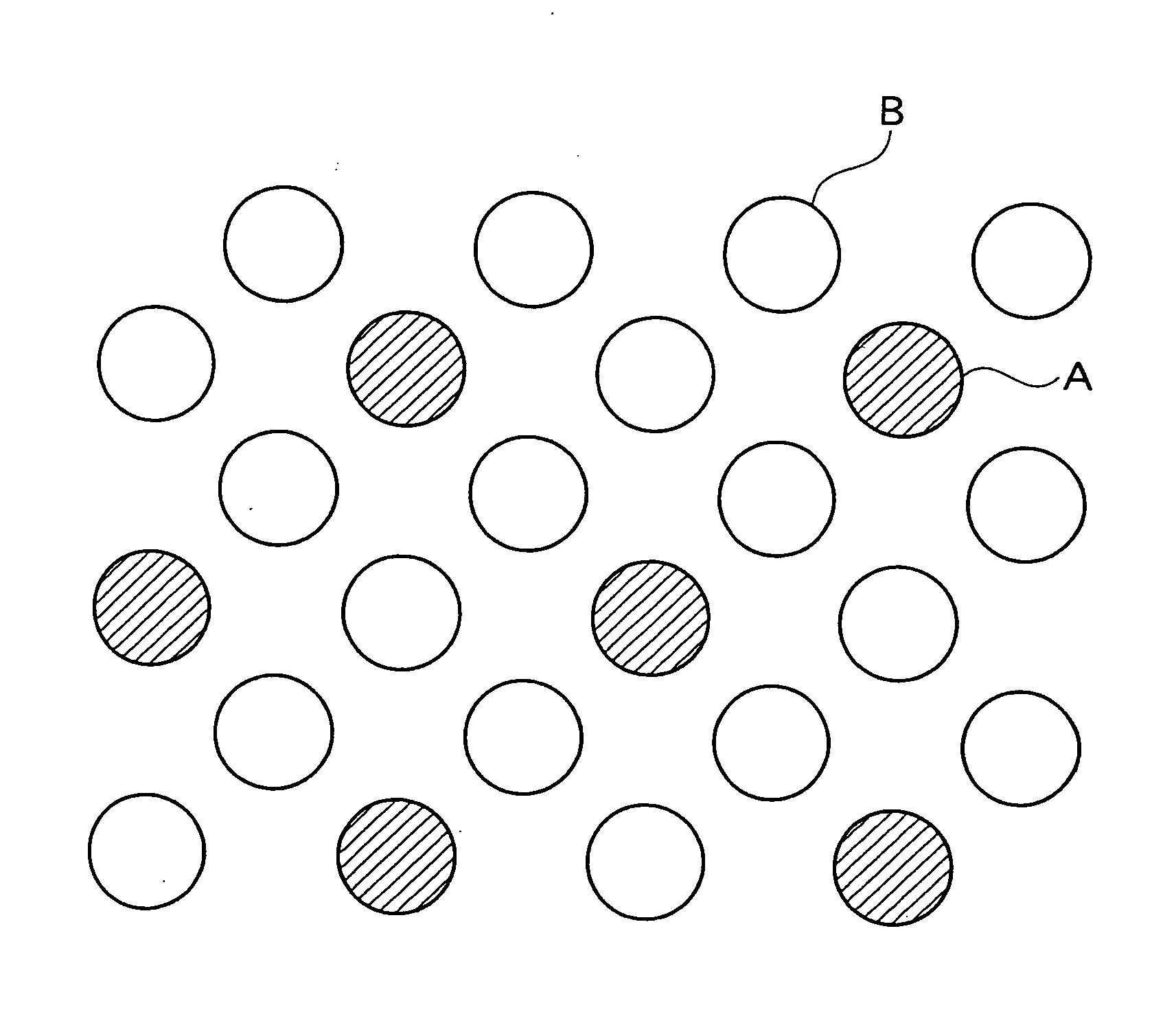

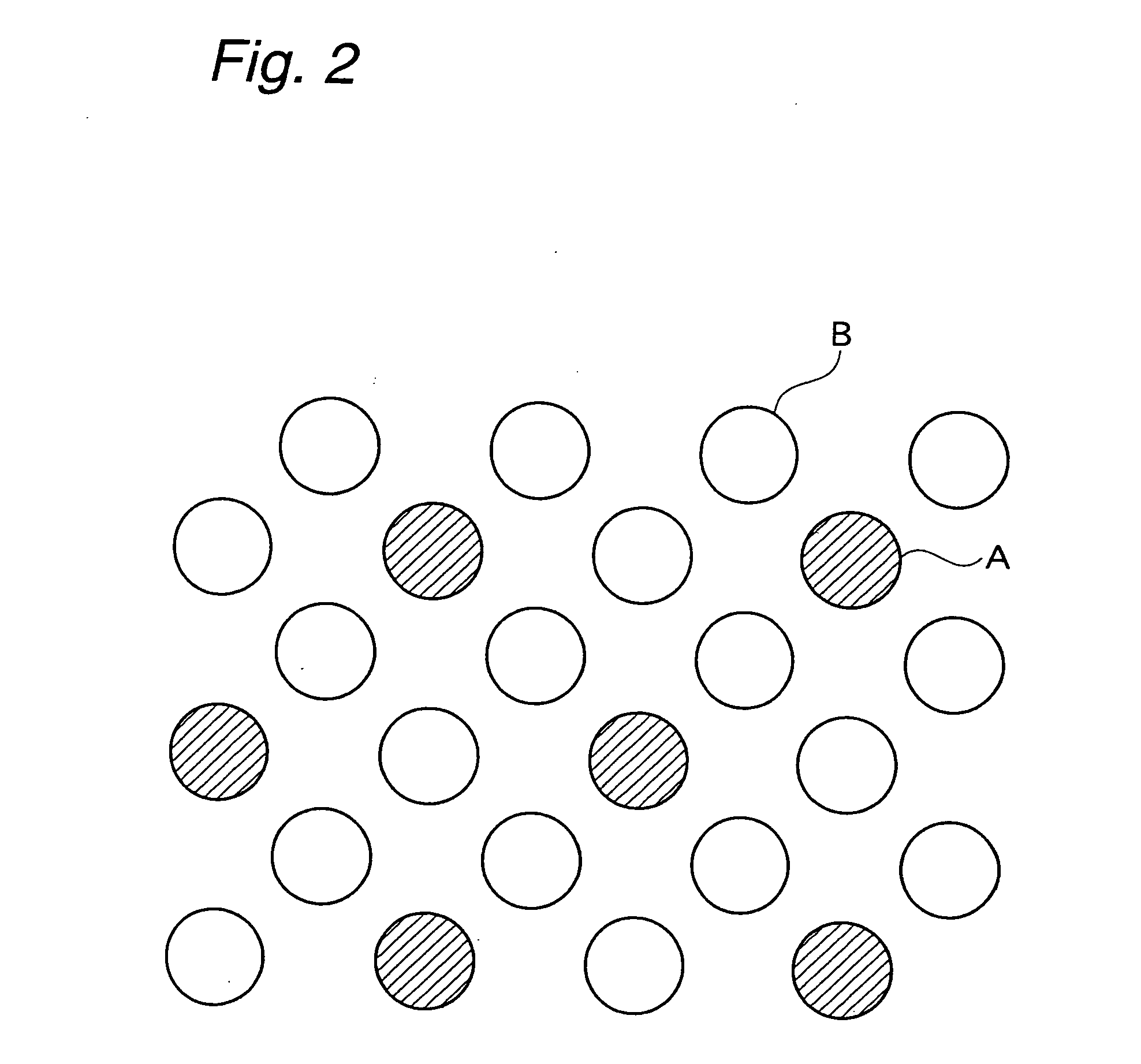

A fiber mixture according to the invention comprises fibers A comprising a polymer A containing a thermoplastic polyurethane elastomer and fibers B comprising a thermoplastic polymer B other than the thermoplastic polyurethane elastomer, said thermoplastic polyurethane elastomer having a solidifying point of 65° C. or above as measured by a differential scanning calorimeter (DSC) and containing 3.00×106 or less polar-solvent-insoluble particles per g counted on a particle size distribution analyzer, which is based on an electrical sensing zone method, equipped with an aperture tube having an orifice of 100 μm in diameter. An elastic nonwoven fabric comprises the fiber mixture.

Owner:MITSUI CHEM INC

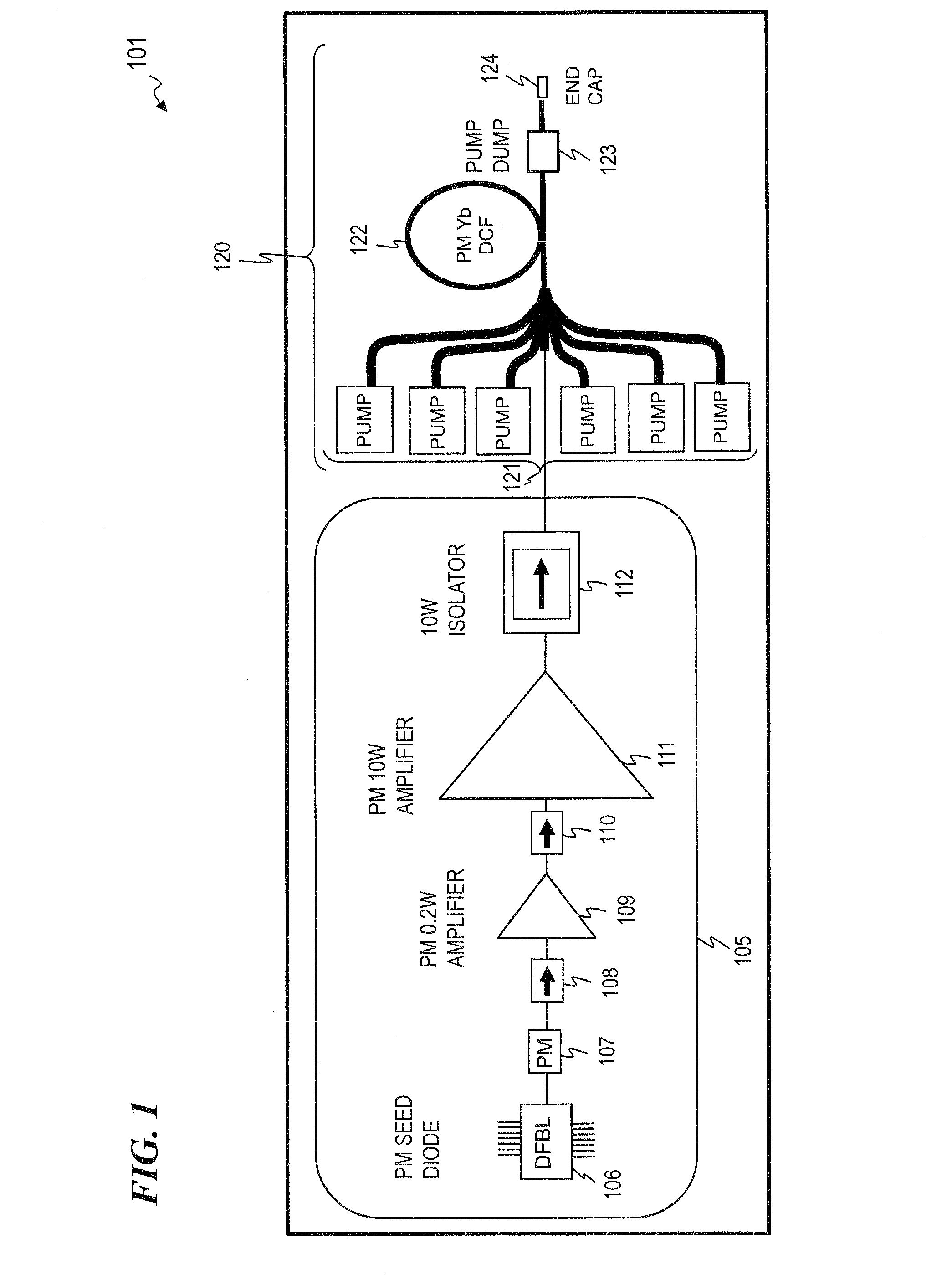

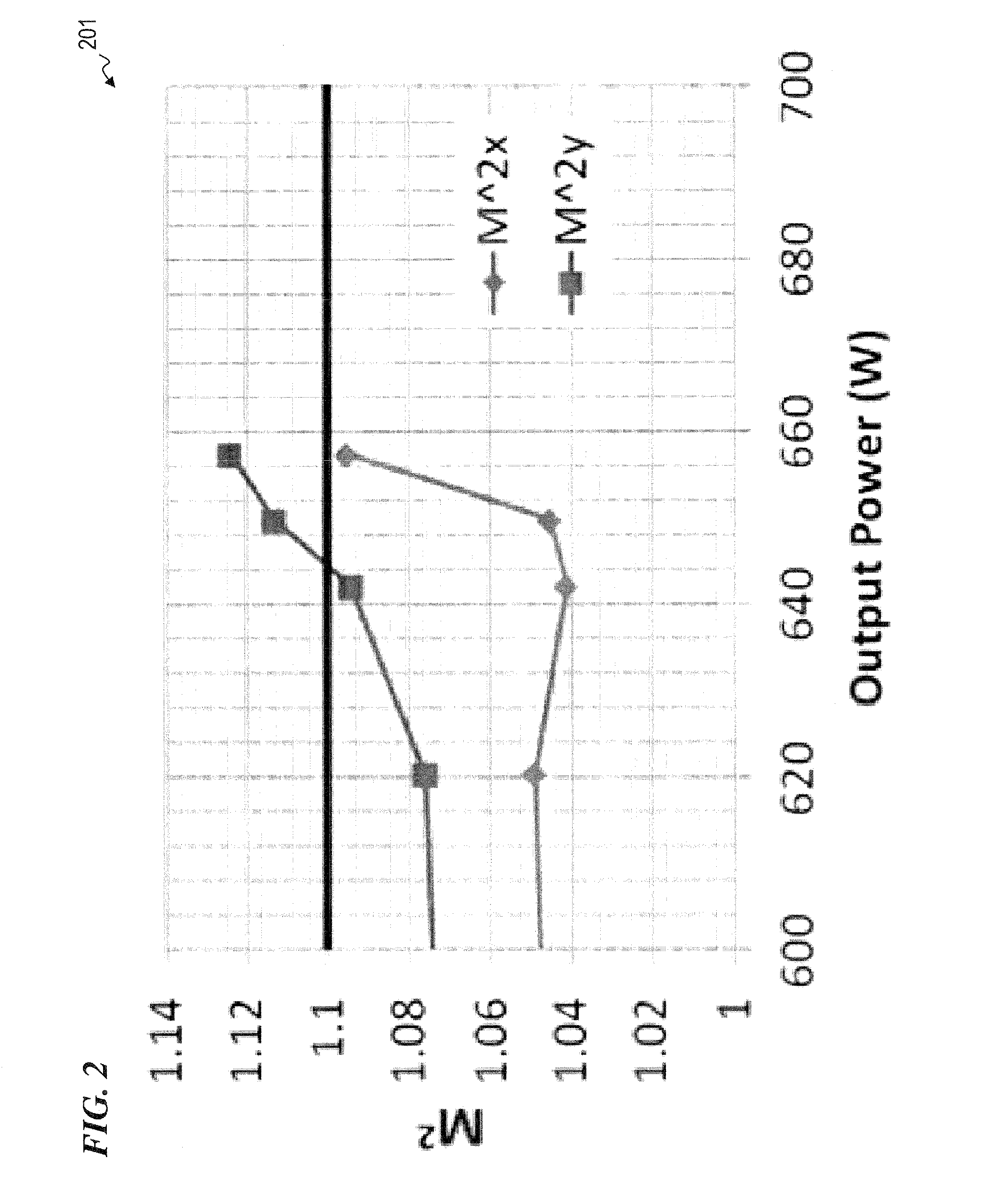

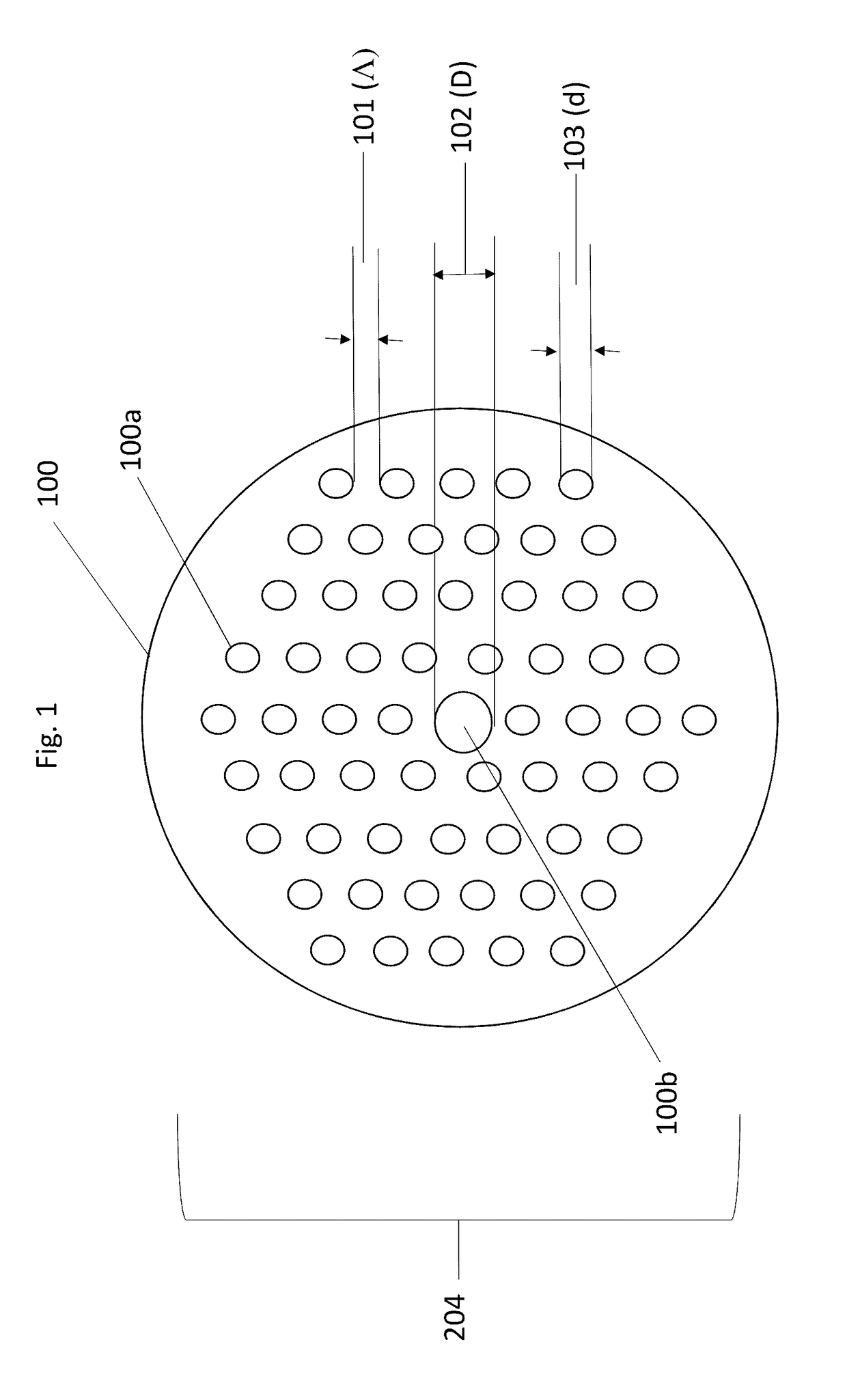

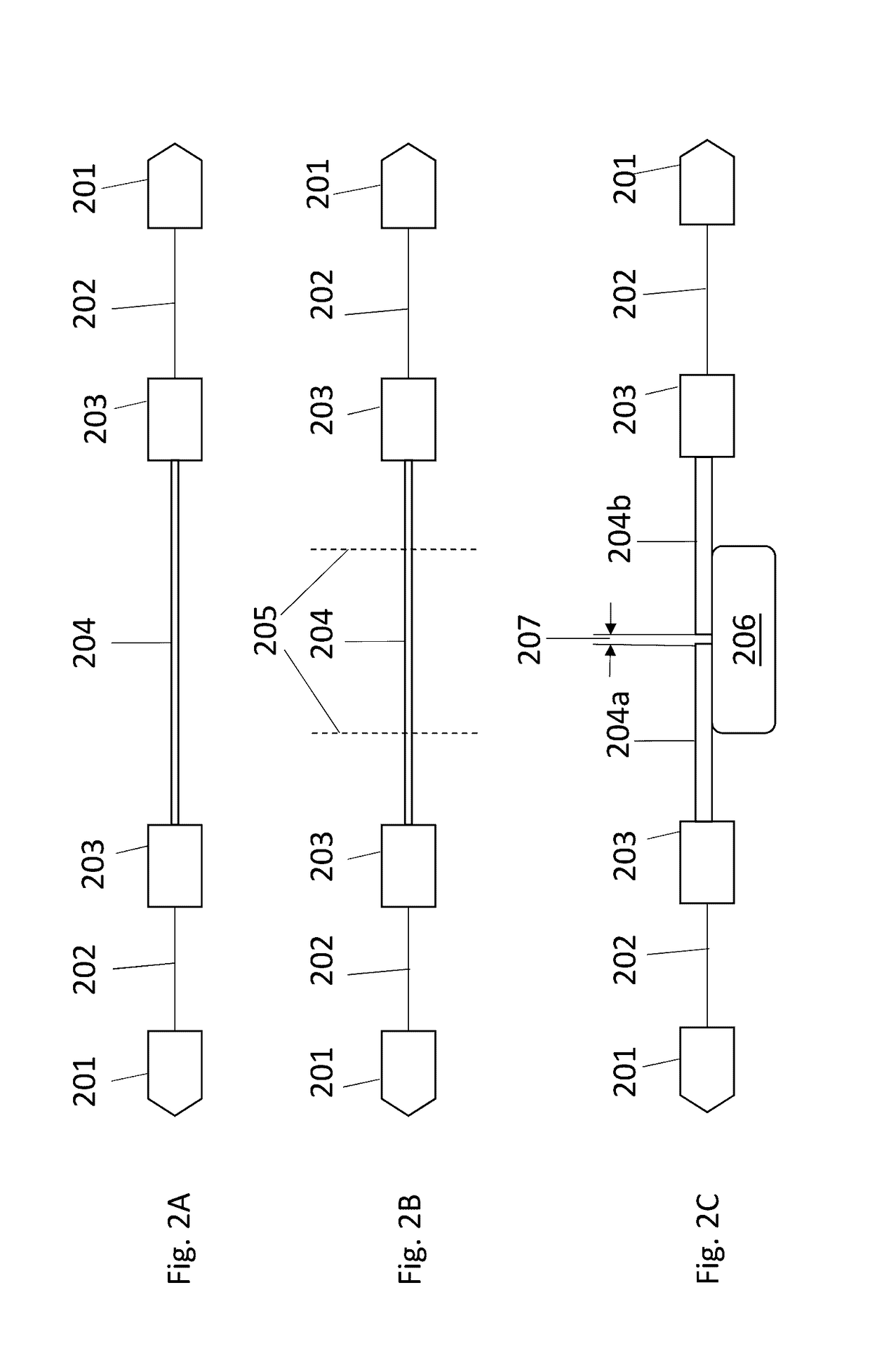

Fiber amplifier system for suppression of modal instabilities and method

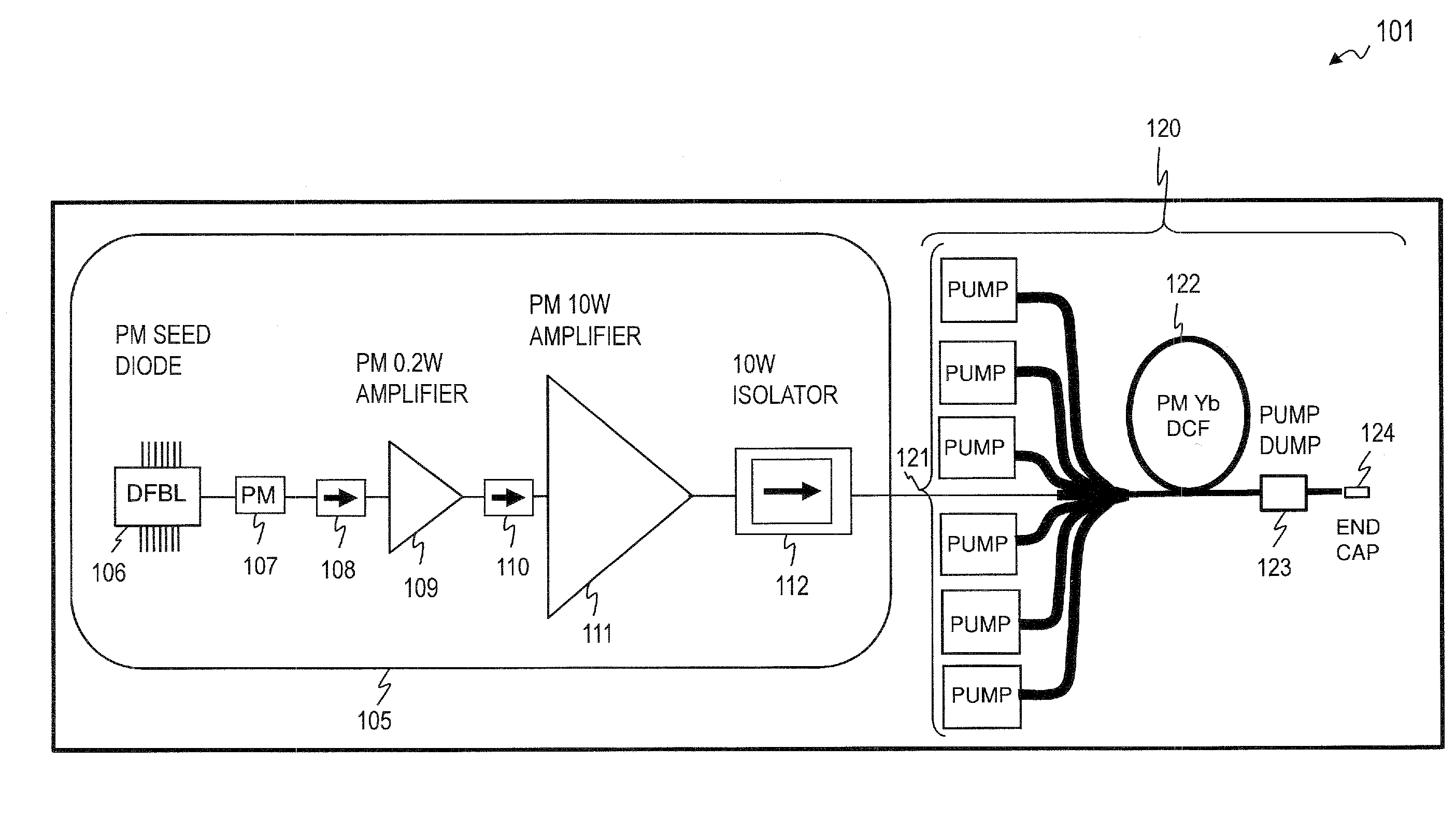

ActiveUS20150138630A1Avoids and minimizes modal instabilitySame performanceLaser detailsFibre transmissionInstabilitySignal beam

Apparatus and method for suppressing modal instabilities (MI) in fiber-amplifier systems. In some embodiments, thermal effects drive the MI process, and in some such embodiments, the present invention provides a plurality of options for mitigating these thermal effects. In some embodiments, the present invention provides a hybrid fiber with a smaller core in the initial length where the thermal loads are highest, followed by a larger-core fiber. In some embodiments the length of the smaller-core section is chosen to keep the core heat-per-unit-length of the second section below a critical value for the onset of MI. In some embodiments, the hybrid fiber of the present invention avoids modal instabilities while yielding almost the same performance as compared to conventional fibers with regard to minimizing fiber nonlinearities such as Stimulated Brillouin Scattering (SBS). In some embodiments, the hybrid fiber outputs a signal beam with at least 1 kW of power.

Owner:LOCKHEED MARTIN CORP

Method for manufacturing high-breathability non-woven wallpaper body paper and product

The invention discloses a method for manufacturing high-breathability non-woven wallpaper body paper and a product. The existing non-woven wallpaper has the disadvantages that the hand feel thereof is not soft enough, the principal plane stereoscopic impression is not strong and the opacity degree is low. The method of the invention comprises the following steps: beating plant fiber containing chemical wood pulp until the beating degree is 20-30OSR, and mixing with non-plant fiber containing chemical fiber; adding chemical addition agent into the mixed fiber; manufacturing the mixed fiber containing the chemical addition agent into body paper semi-finished products by utilizing a fourdrinier wire or inclined wire paper machine; mixing pigment, chemical addition agent and adhesive to form coating liquor, carrying out dip coating on the body paper semi-finished products inside or outside the machine; and drying and finishing the body paper subject to dip coating, and rolling the body paper to form finished paper of body paper, thus obtaining non-woven wallpaper which contains continuous fiber, has high breathability, and can be directly printed. The principal plane has natural lines; and the finished paper has the advantages of soft hand feel, good processability, excellent shape stability, rich color, distinct image and strong stereoscopic impression.

Owner:ZHEJIANG WINBON SPECIALTY PAPER +1

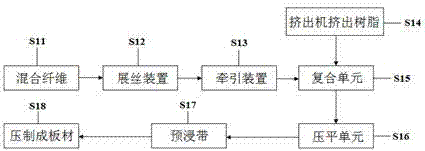

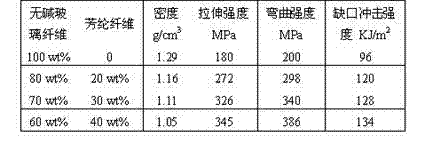

High-performance continuous synthetic fiber reinforced thermoplastic composite and preparation method thereof

The invention discloses a high-performance continuous synthetic fiber reinforced thermoplastic composite and a preparation method thereof. The composite comprises the following components including, by weight, 35-60 parts of reinforcing filler, 35-60 parts of thermoplastic resin and 0.5-5 parts of aids, wherein the reinforcing filler includes synthetic fibers which include, by weight, 55-95% of inorganic fibers and 5-45% of organic fibers. The continuous inorganic fibers and the high-performance organic fibers are mixed to reinforce the thermoplastic resin so as to improve the performance of the composite, and advantages of various fibers are integrated to obtain the continuous fiber reinforced thermoplastic composite which is light in weight, high in strength and high in modulus while impact resistance and fatigue resistance are particularly improved. Mixing a small quantity of expensive high-performance organic fibers with the inorganic fibers can achieve better enhancing effect while cost is effectively reduced, so that higher using requirements of materials can be met.

Owner:LIAONING LIAOJIE SCI & TECH

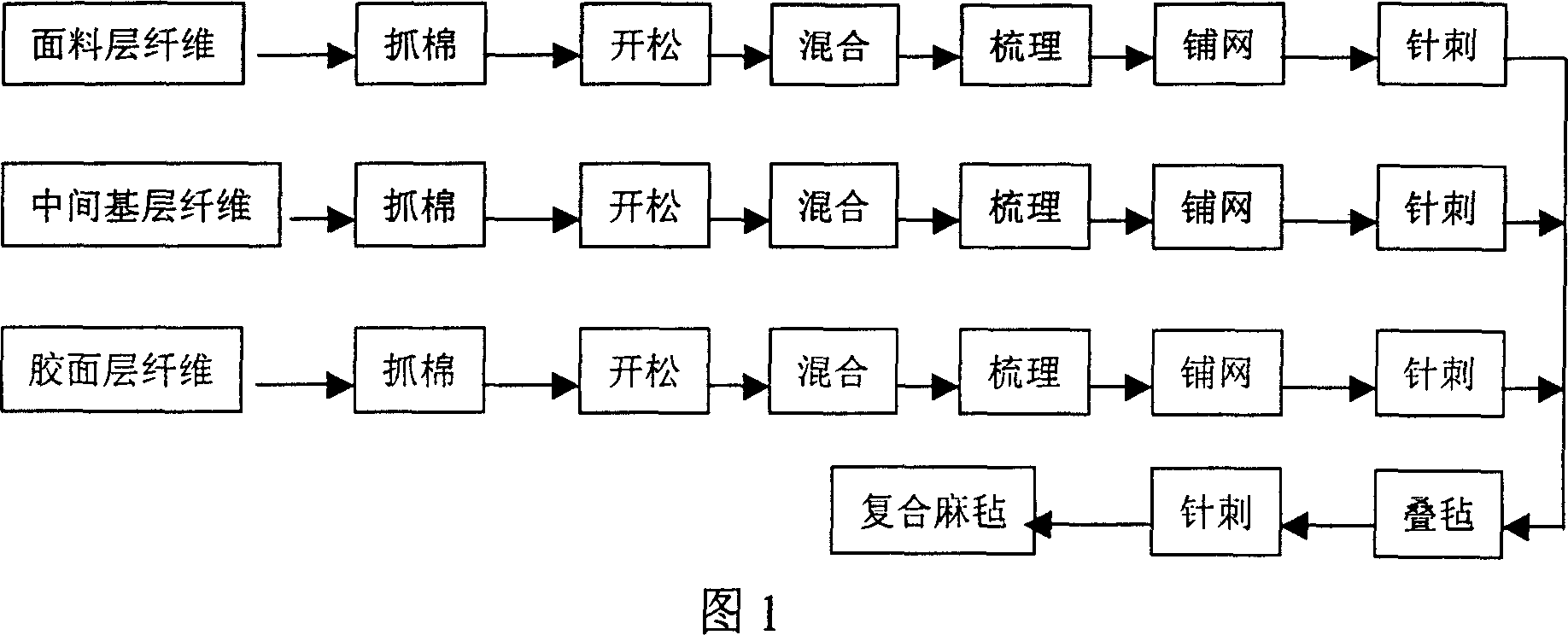

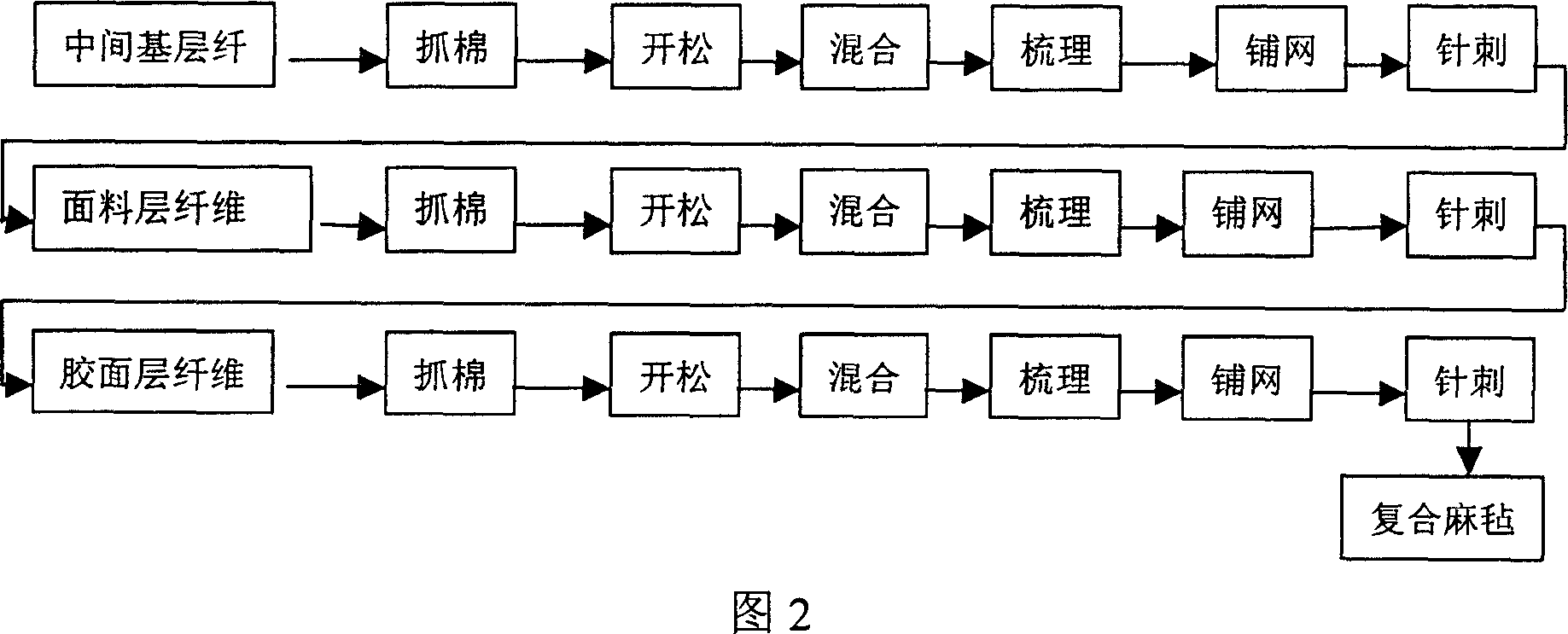

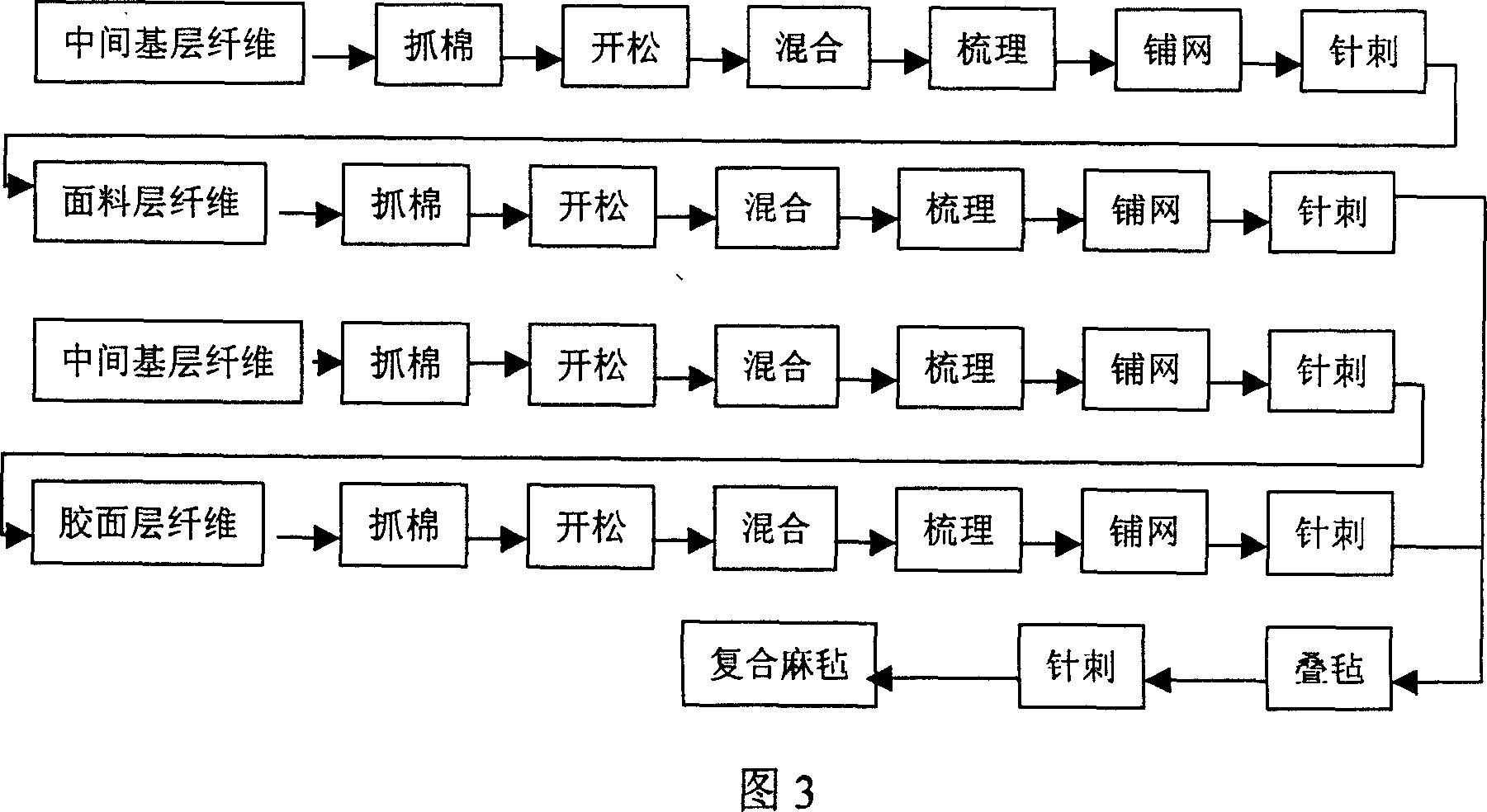

Composite board made of natural firilia for automobile inner decoration use and its producing method

ActiveCN101045310AImprove rigidityAvoid warpingWood working apparatusDomestic articlesPolyesterPolymer science

A composite bast fiber board for the internal decoration of car is composed of adhesive layer, sandwich substrate layer and surface layer, and is prepared through sequentially spreading said three layers, needling to become a composite bast felt, and hot pressing. Said sandwich substrate is made of the mixture of bast fibers (37-45%), polyester fibers (10-20%) and polypropylene fibers (35-53%).

Owner:铜陵华源汽车内饰材料有限公司

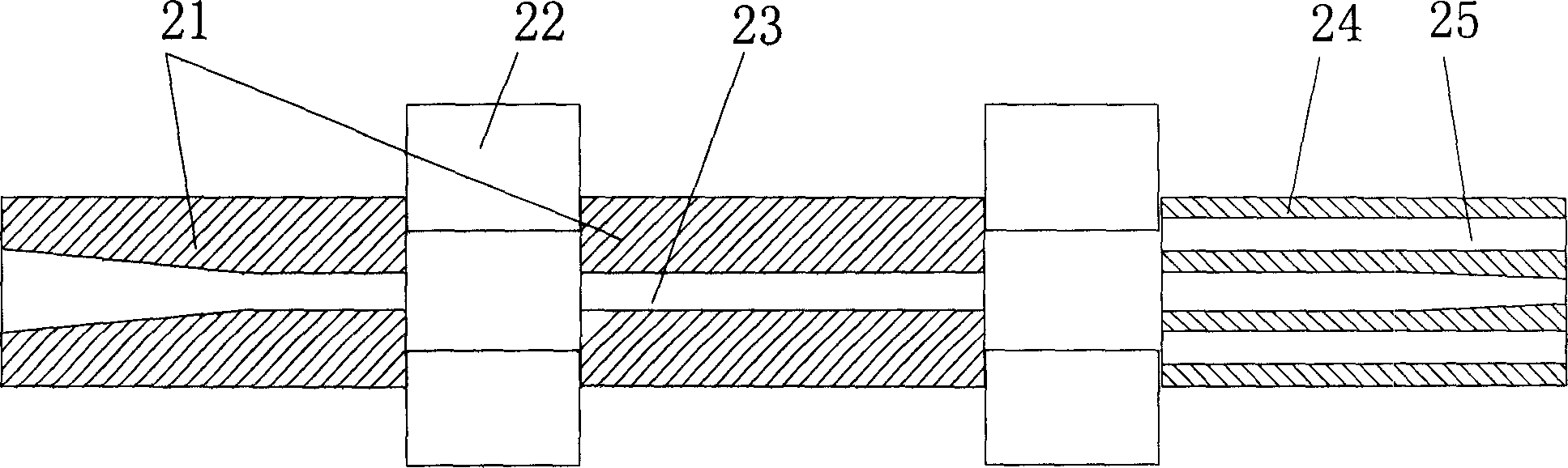

Pultrusion method for thermoplastic composite material and forming die thereof

InactiveCN1730270AImprove impregnation effectImprove mechanical propertiesPolymer scienceFiber bundle

The invention relates to a pultrusion method for thermoplastic composite, which takes fortifying fiber and matrix fiber as raw material, including the following steps: a. placing matrix fiber and fortifying fiber on the creel in the weight ratio of 95-20:5-80; b. loading the fortifying fiber and matrix fiber to demand scale into the preheat chamber by the thread wire and board and preheating them; c. loading the preheated mixed fiber tuft into the preforming die, so the tuft near to the entrance shape of the forming die; d. loading the preformed mixed fiber into the forming die. Certainly the performing die and forming die can be diad, with performing segment and forming segment in one die; e. after loading out from the forming die the section bar cooling and shaping to get products. The invention overcomes the socking problem of high molecular polymer, improving the socking effects of thermoplastic composites, and the mechanical property enhances dramatically.

Owner:SINOMA SCI & TECH

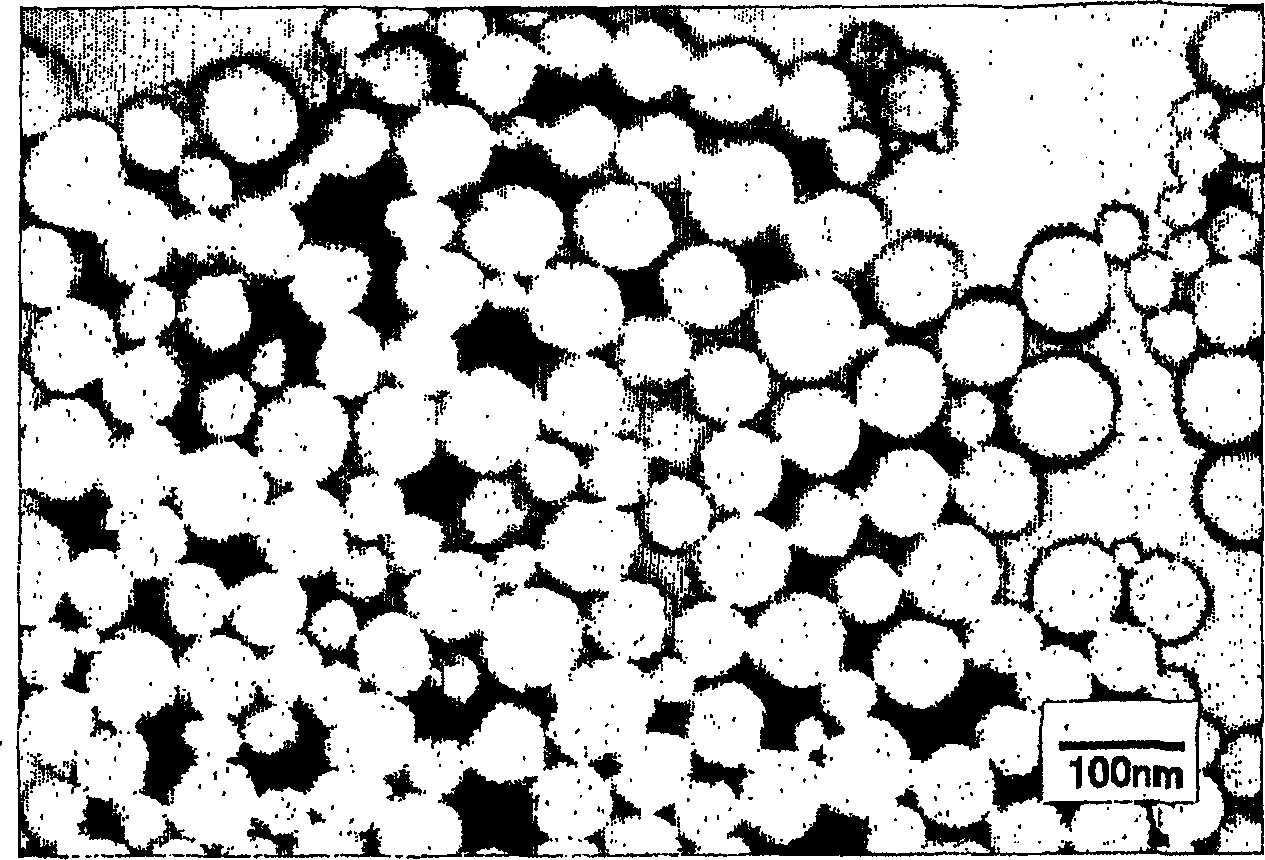

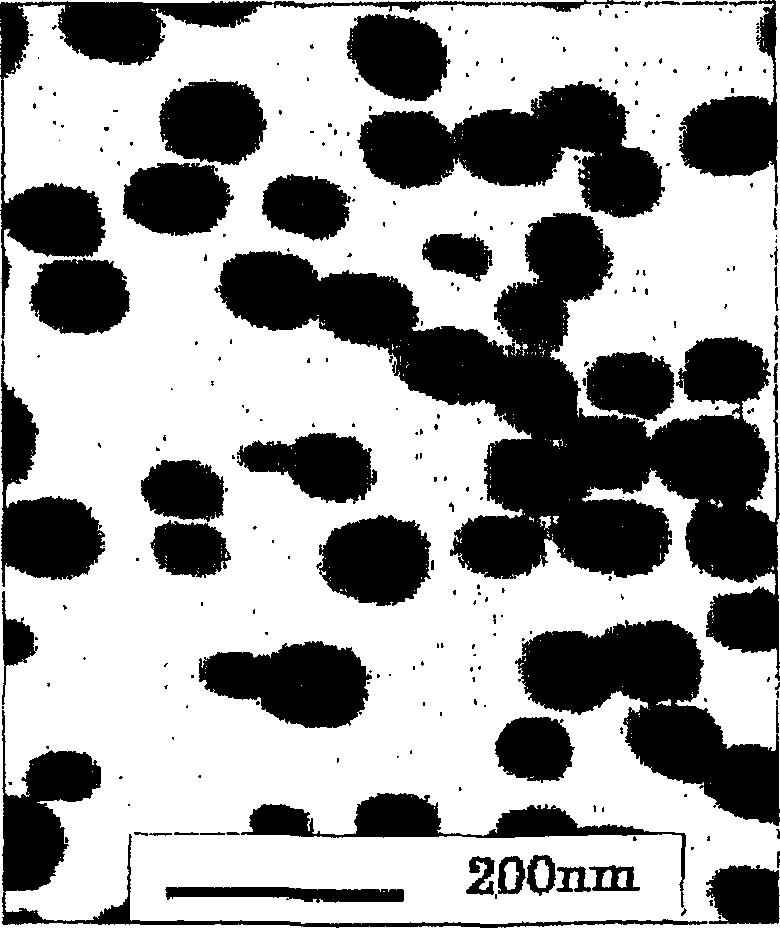

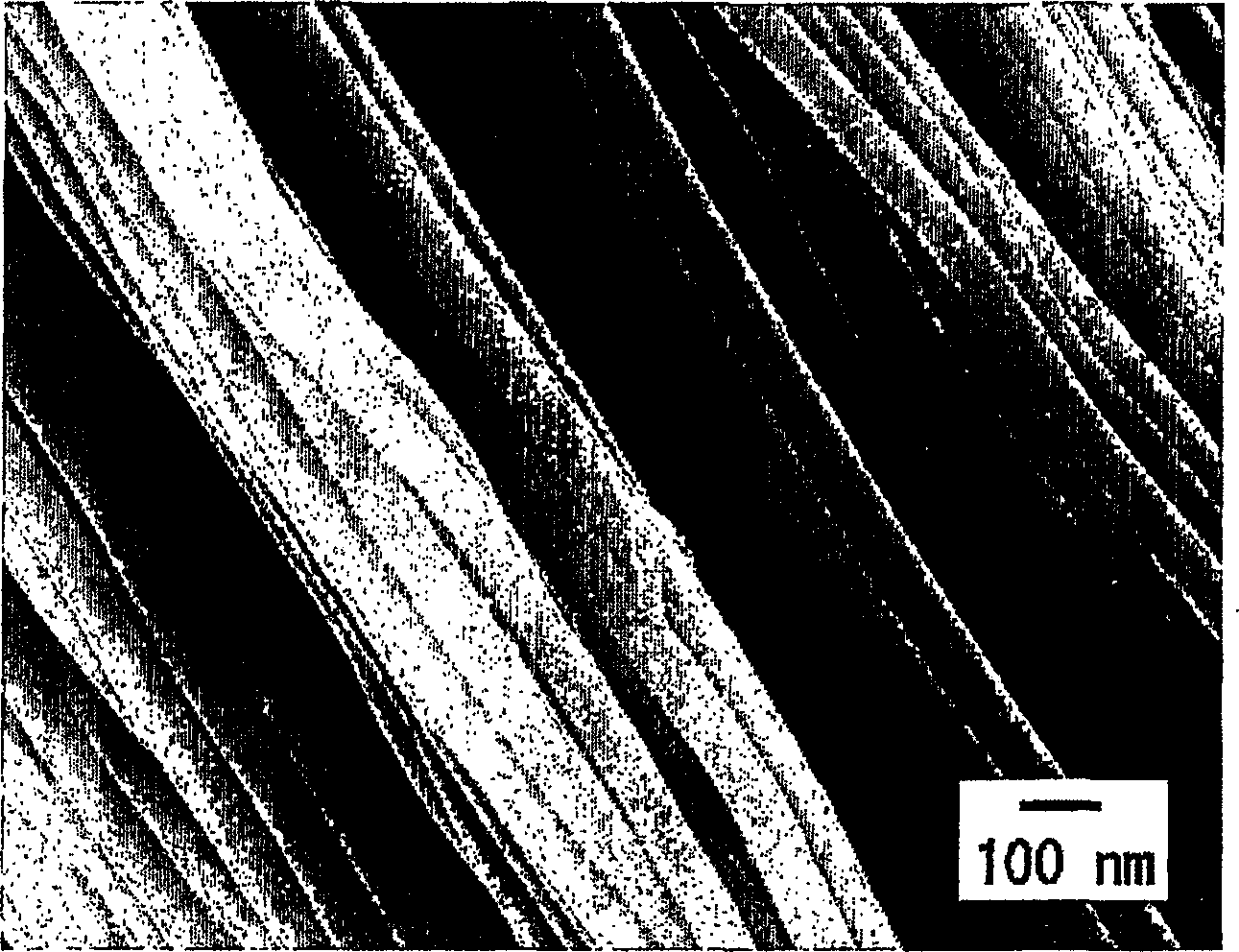

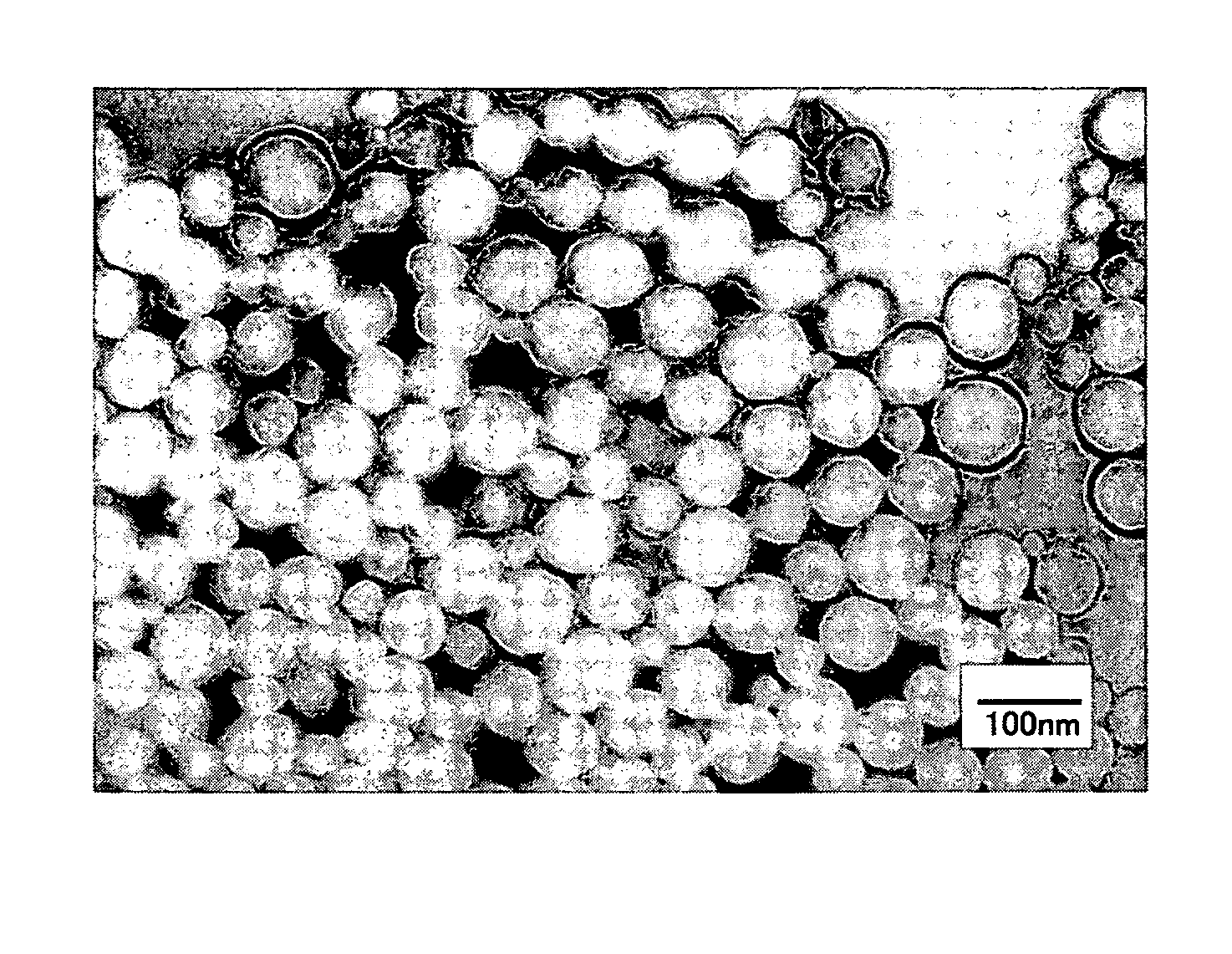

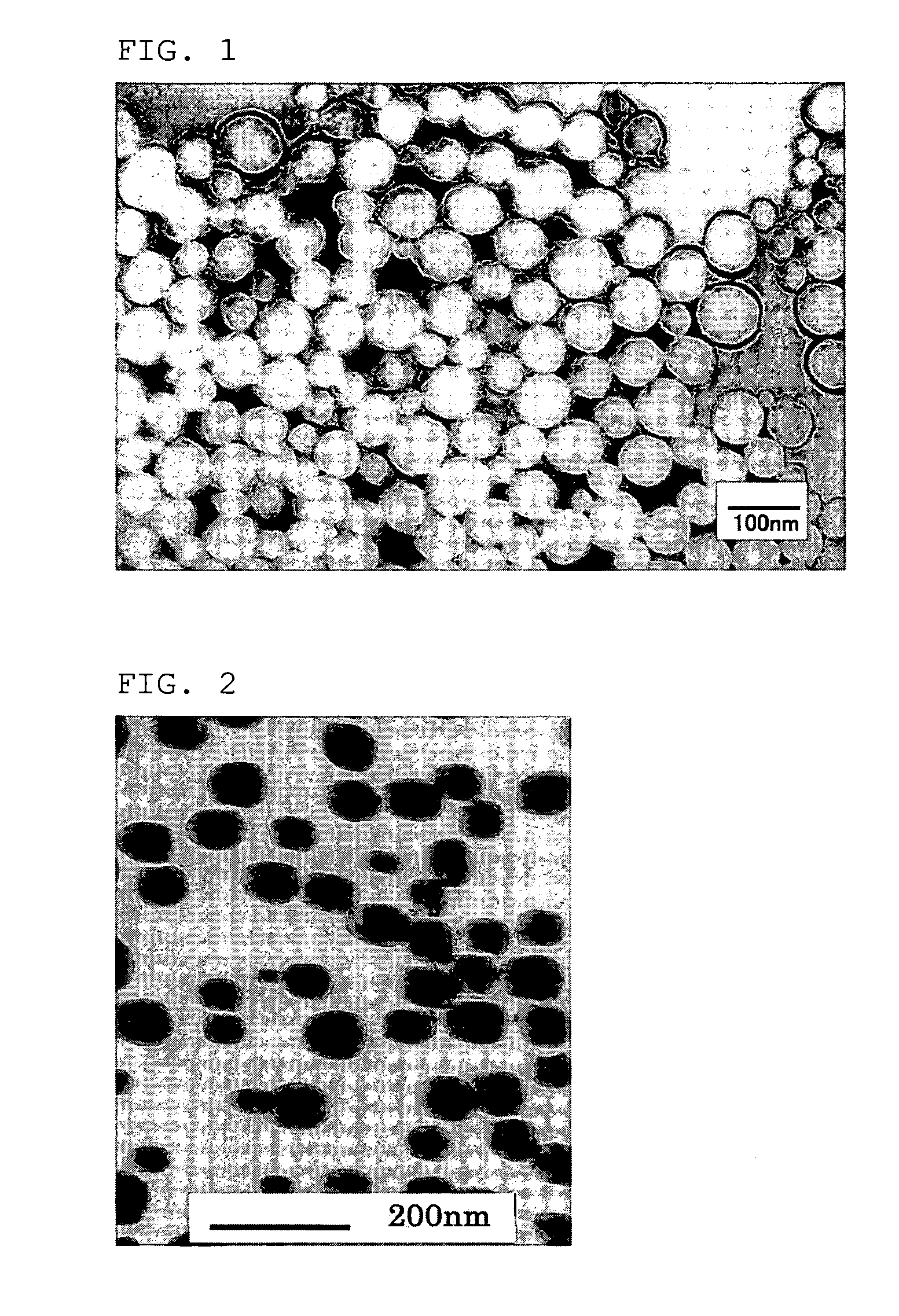

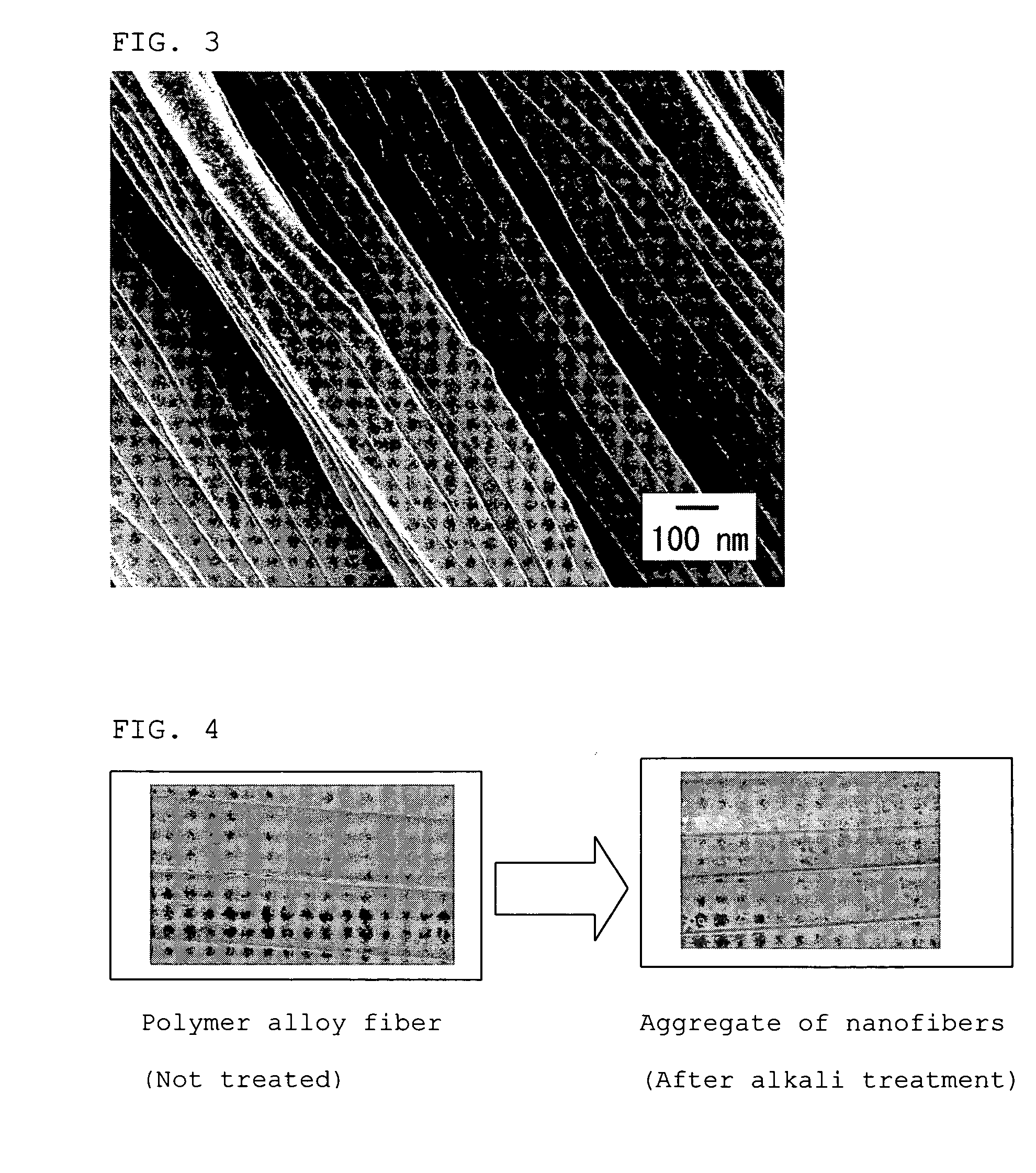

Nanofiber aggregate, polymer alloy fiber, hybrid fiber, fibrous structures, and processes for production of them

InactiveCN1720358AFibre treatmentMonocomponent synthetic polymer artificial filamentPolymer alloyPolymer science

The invention provides an aggregate of nanofibers which is not limited in shape or material polymer, is widely applicable and developable, and has a small dispersion of single fiber fineness, and a process for the production thereof. The invention relates to an aggregate of nanofibers which have a number-average single fiber fineness of 1 x 10<-7> to 2 x 10<-4> dtex and a proportion of single fibers having single fiber fineness ranging from 1 x 10<-7> to 2 x 10<-4> dtex of 60 % or above and which are made of a thermoplastic polymer.

Owner:TORAY IND INC

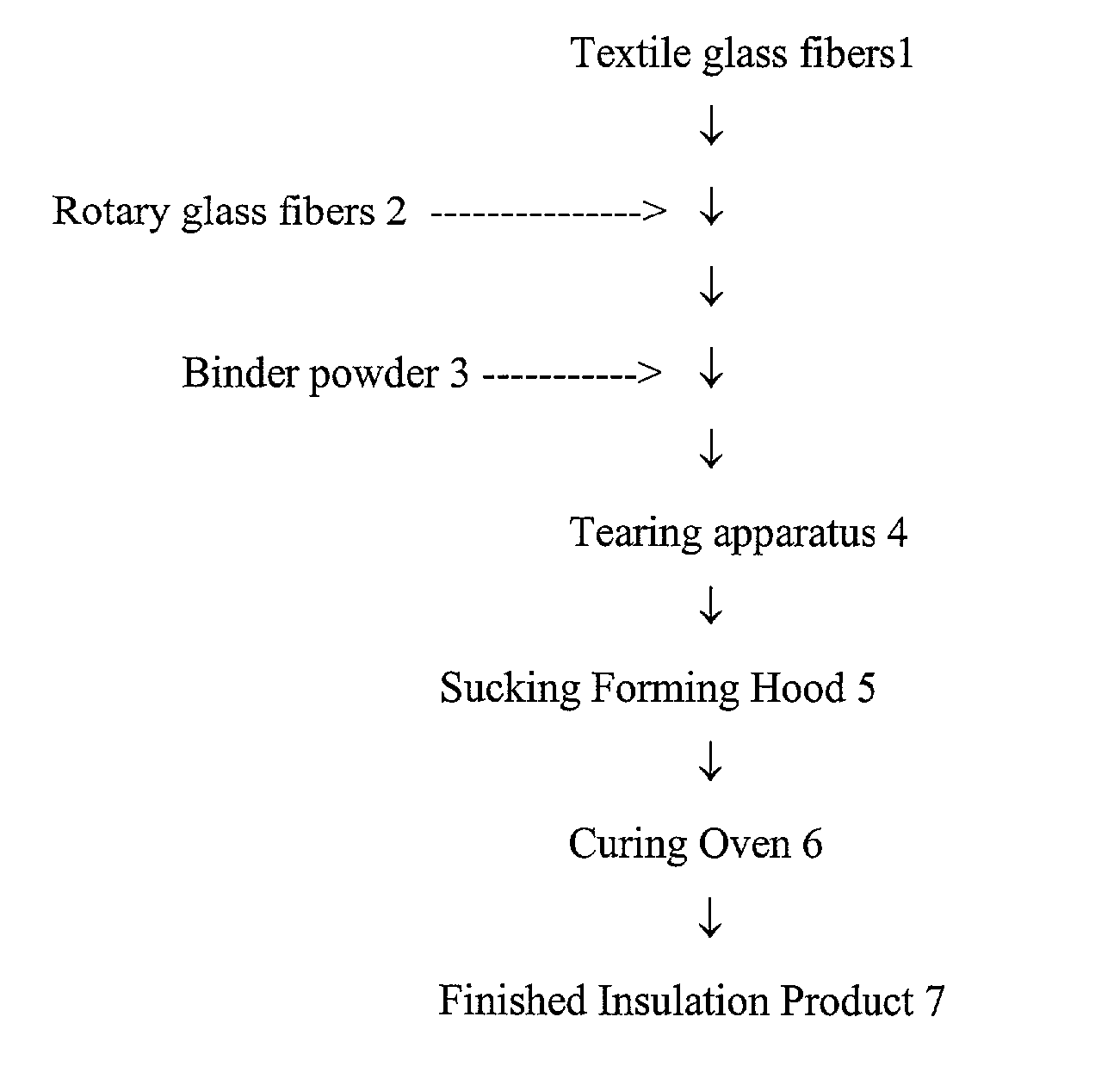

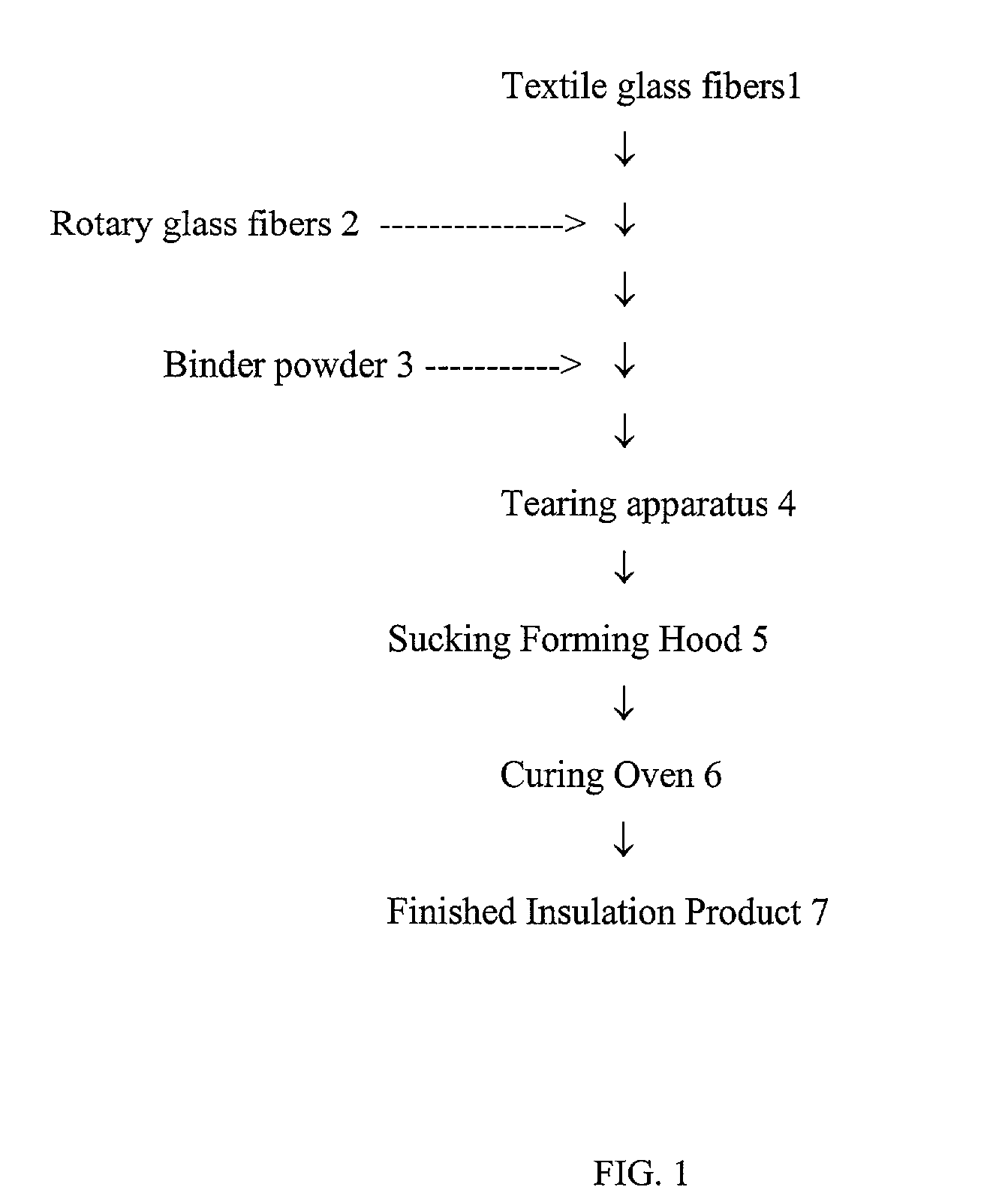

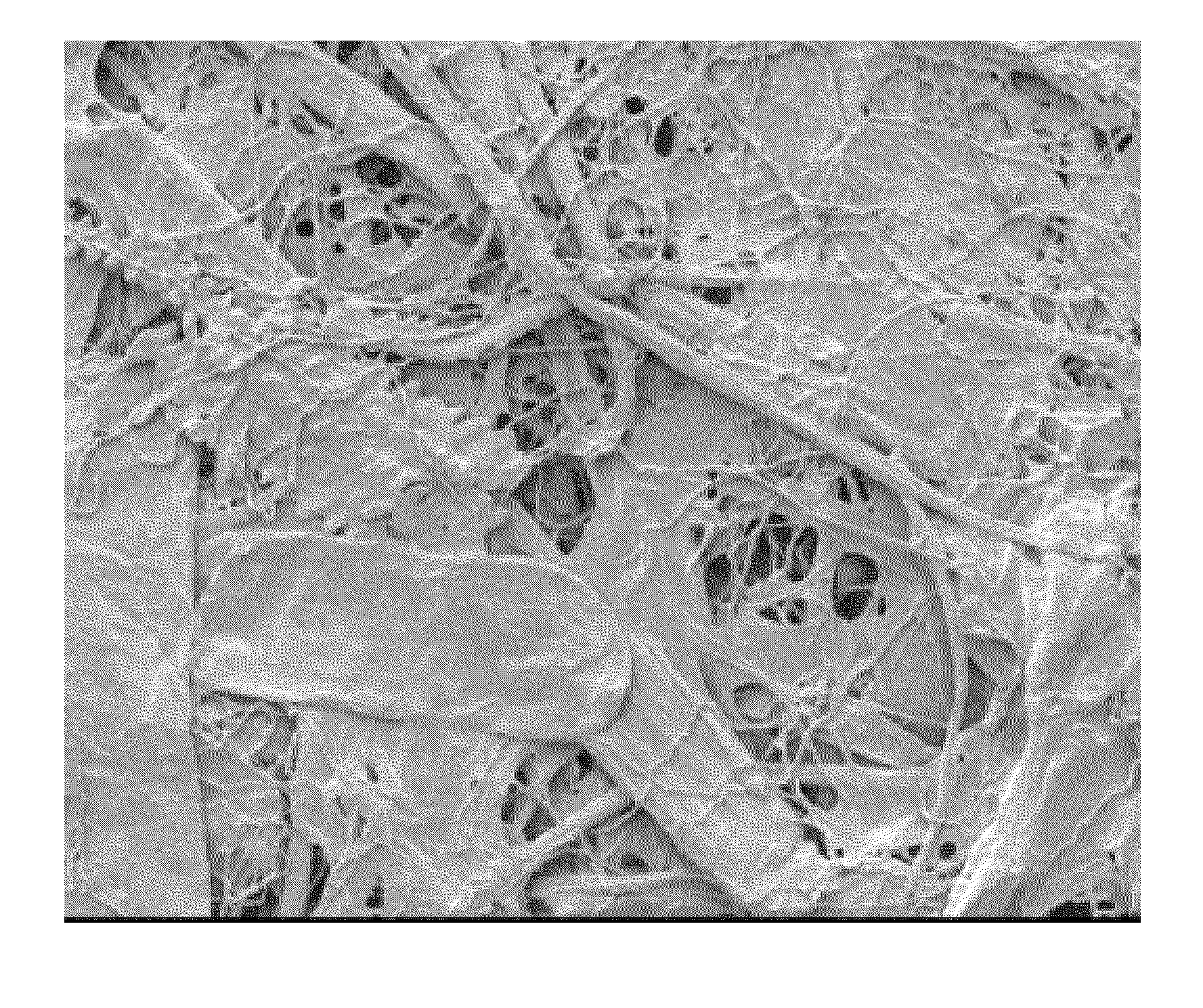

Insulation containing a mixed layer of textile fibers and of rotary and/or flame attenuated fibers, and process for producing the same

An insulation product contains a mixed layer of textile fibers and of rotary and / or flame attenuated fibers. A process for manufacturing the insulation product includes passing fibrous bundles of textile fibers and of rotary and / or flame attenuated fibers together through an apparatus that divides the textile fibers into segments and that mixes the textile fiber segments with the rotary and / or flame attenuated fibers. The bundles of rotary and / or flame attenuated fibers can be in the form of specially manufactured mats and / or can be production scraps. The resulting mixture of fibers is formed into a non-woven batt, mat, blanket, or board. The process provides a mixed fiber product, with an improved combination of thermal and acoustic insulating performance and adequate strength, at a low production cost.

Owner:CERTAINTEED CORP

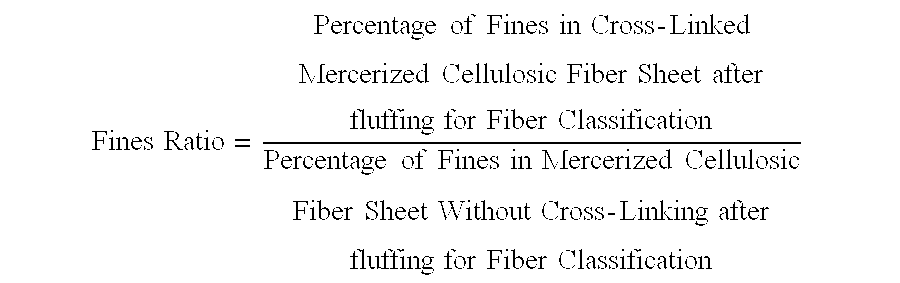

Hybrid Fiber Compositions and Uses in Containerboard Packaging

ActiveUS20140093704A1Cellulosic pulp after-treatmentNon-fibrous pulp additionCardboardFiber composition

The present invention relates to a containerboard packaging material comprising at least one non-wood alternative pulp material wherein said non-wood alternative pulp material is present in an amount of from about 5% to about 100% and wherein said material replaces at least a portion of conventional fiber materials.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Cross-linked pulp and method of making same

InactiveUS20060118255A1Improve featuresPromote absorptionNon-fibrous pulp additionPulp properties modificationPorosityCross-link

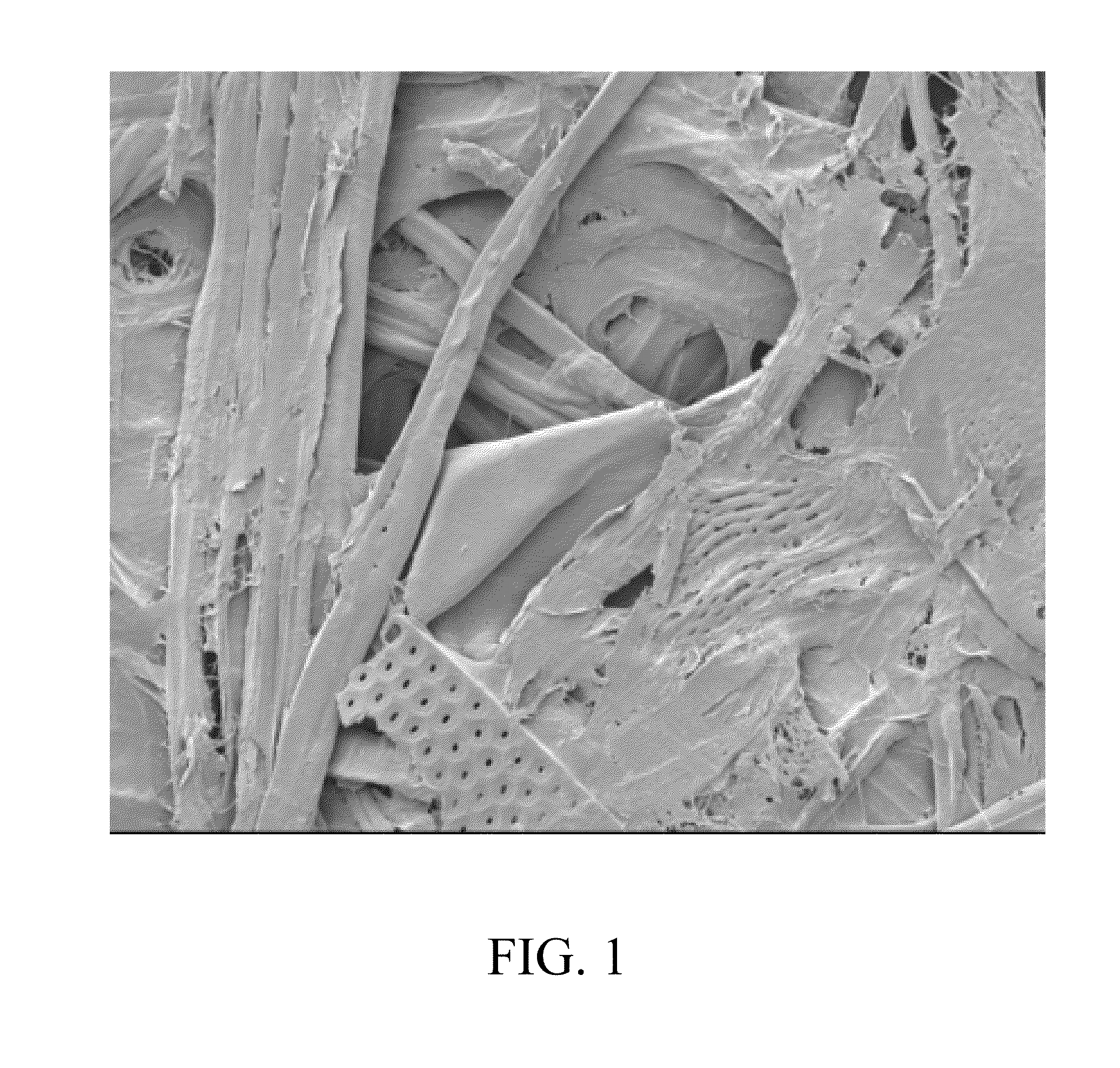

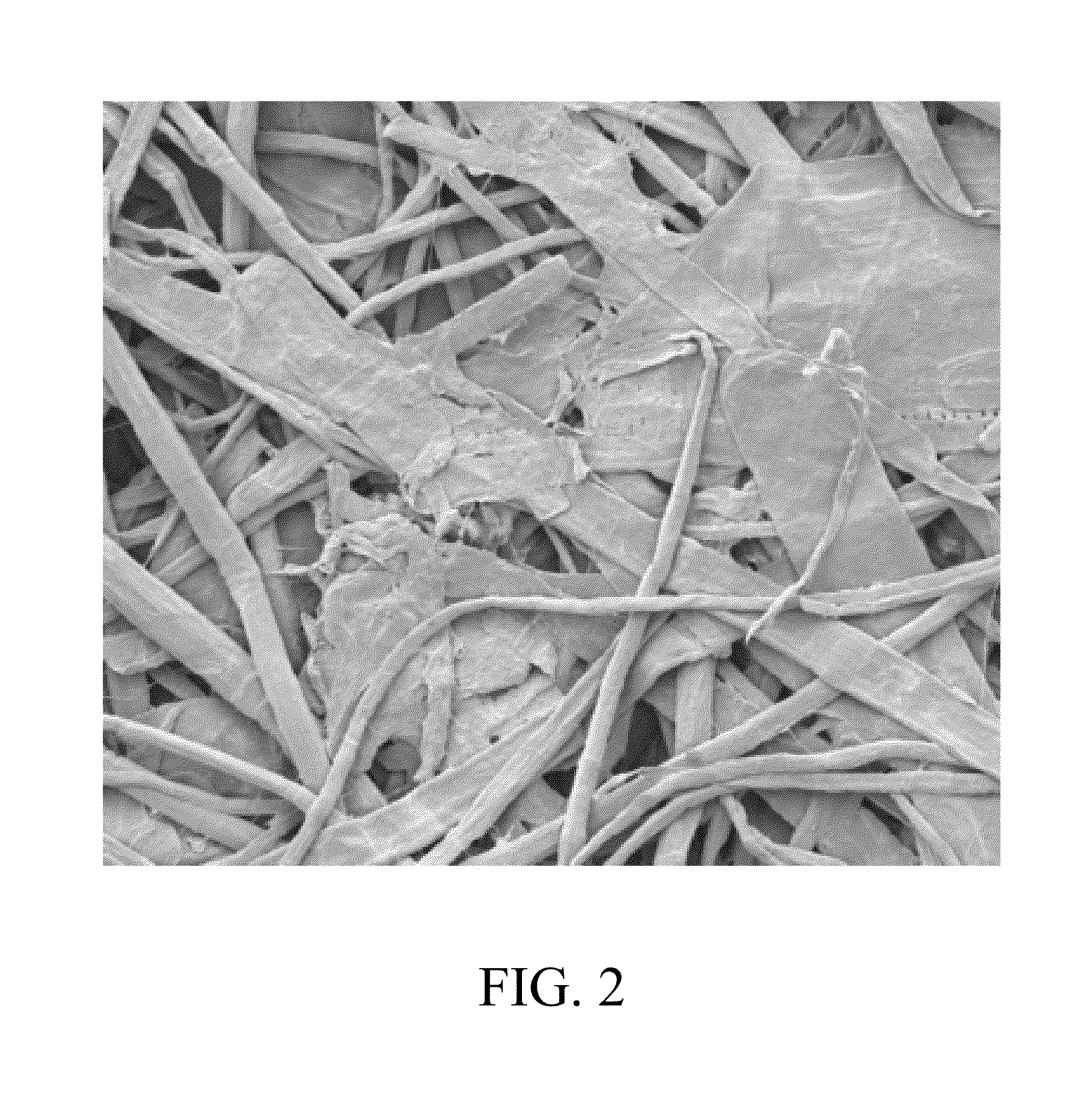

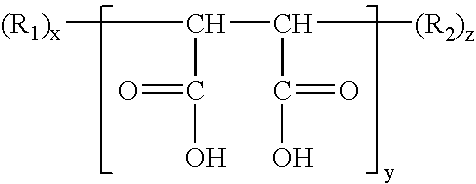

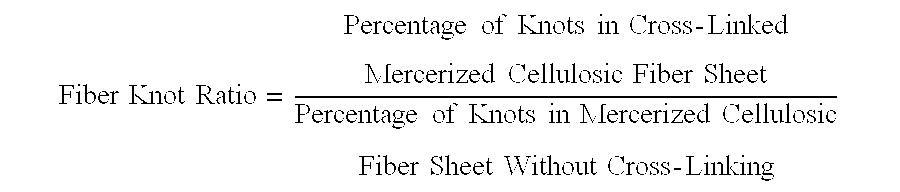

The invention provides a method for preparing cross-linked cellulosic fibers. A sheet of mercerized cellulosic fibers with a purity of at least 95% is treated with a solution containing a carboxylic acid cross-linking agent. The treated cellulosic fibrous material is dried and cured in sheet form to promote intrafiber cross-linking. Cross-linked fiber products produced are economic and possess good porosity, bulking characteristics, wet resiliency, absorption characteristics, low fines, low nits and low knots. The invention also includes blended cellulose compositions comprising a minor proportion of cross-linked mercerized cellulosic fibers and a major proportion of other cellulosic fibers. The invention further provides individualized, chemically cross-linked mercerized cellulosic fibers of high purity.

Owner:RAYONIER PERFORMANCE FIBERS

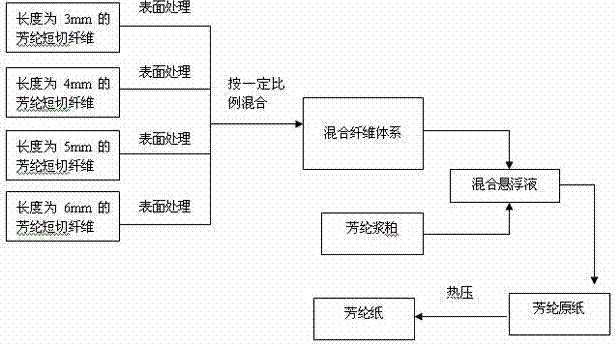

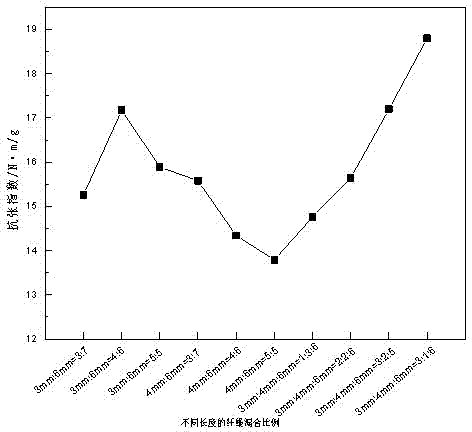

Preparation method of mixed fiber system aramid paper

ActiveCN103485234AReduce the ratioPrevent flocculationSynthetic cellulose/non-cellulose material pulp/paperPolymer scienceAramid

The invention discloses a preparation method of mixed fiber system aramid paper. The mixed fiber system aramid paper comprises the following components in parts by mass: (1) 30-50 parts of aramid chopped fiber with different average lengths, which is compounded by the aramid chopped fiber with the lengths of 3mm, 4mm, 5mm and 6mm; and (2) 50-70 parts of aramid pulp. The preparation method of the aramid paper comprises the following steps: (1) performing surface treatment on the aramid chopped fiber with the different lengths; (2) mixing the aramid chopped fiber with the different lengths according to different proportions to obtain a mixed aramid chopped fiber system; (3) mixing the aramid chopped fiber system with the aramid pulp; (4) preparing wet-formed aramid raw paper; and (5) performing hot-pressing on the aramid raw paper. The preparation method disclosed by the invention can solve the problems of fiber flocculation, poor evenness of the formed paper and poor paper strength in an existing aramid preparation process.

Owner:SHAANXI UNIV OF SCI & TECH

Composite material section bar as well as preparation method and application thereof in preparation of solar photovoltaic module

InactiveCN103205004AHigh mechanical strengthImprove bending strengthPhotovoltaicsPhotovoltaic energy generationHigh concentrationElectricity

The invention discloses a composite material section bar as well as a preparation method and an application thereof in preparation of a solar photovoltaic module. The composite material section bar comprises fiber reinforcement and resin, wherein the mass ratio of the fiber reinforcement to the resin is (6-9): (1-4), and the fiber reinforcement is the mixture of mixed fibers and mixed fabrics. The composite material section bar can be used for preparing the solar photovoltaic module, has the advantages of lightness, hardness, high mechanical strength, good bending strength, high temperature resistance, low cost, low energy consumption, and very good corrosion resistance and can be applied to regions with environments such as high air temperature, high humidity and high concentration of salt and alkali. The composite material section bar is little influenced by the environments, has good electrical insulation property and can not be subjected to earthing treatment.

Owner:天津顺御科技有限公司 +1

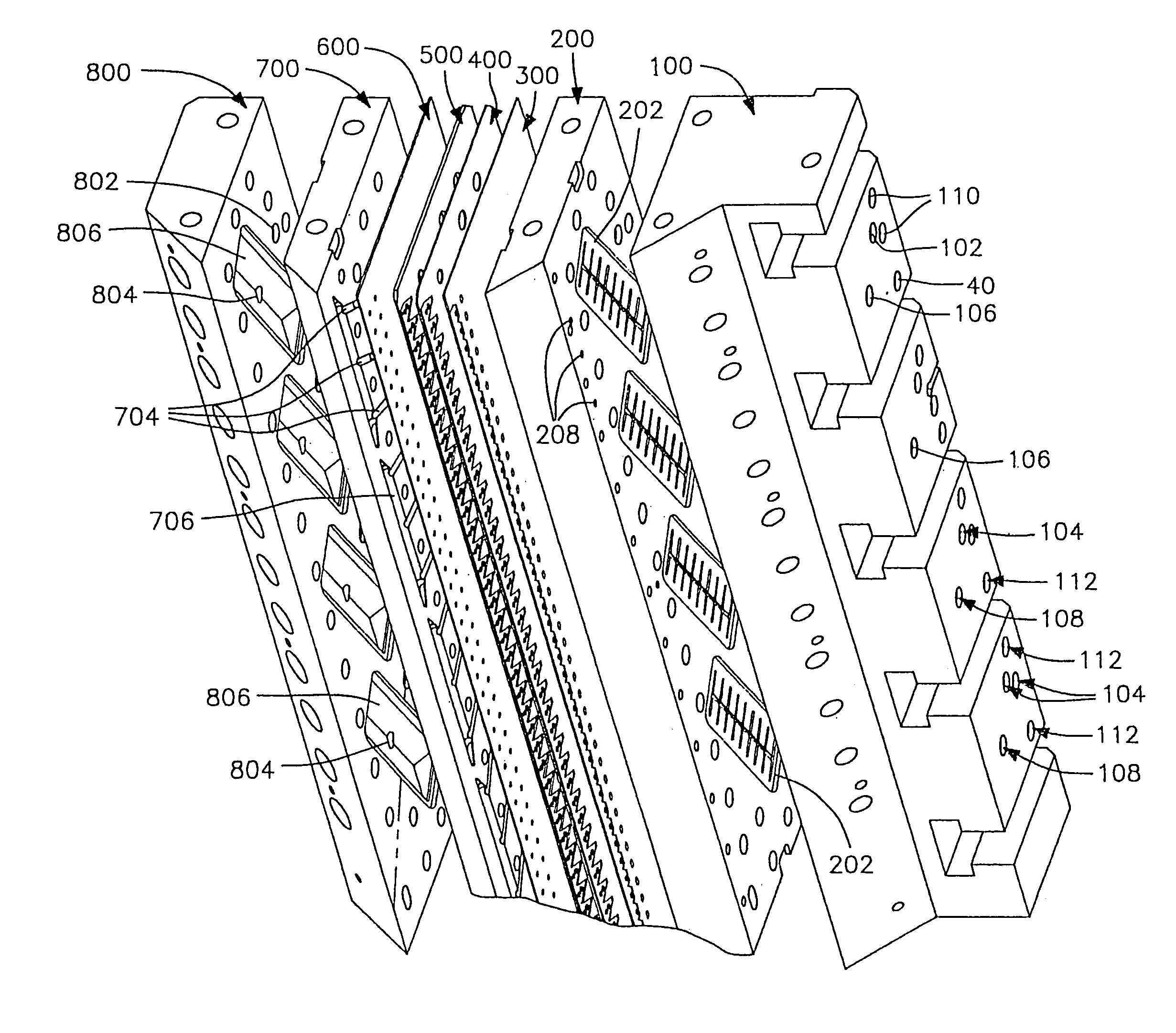

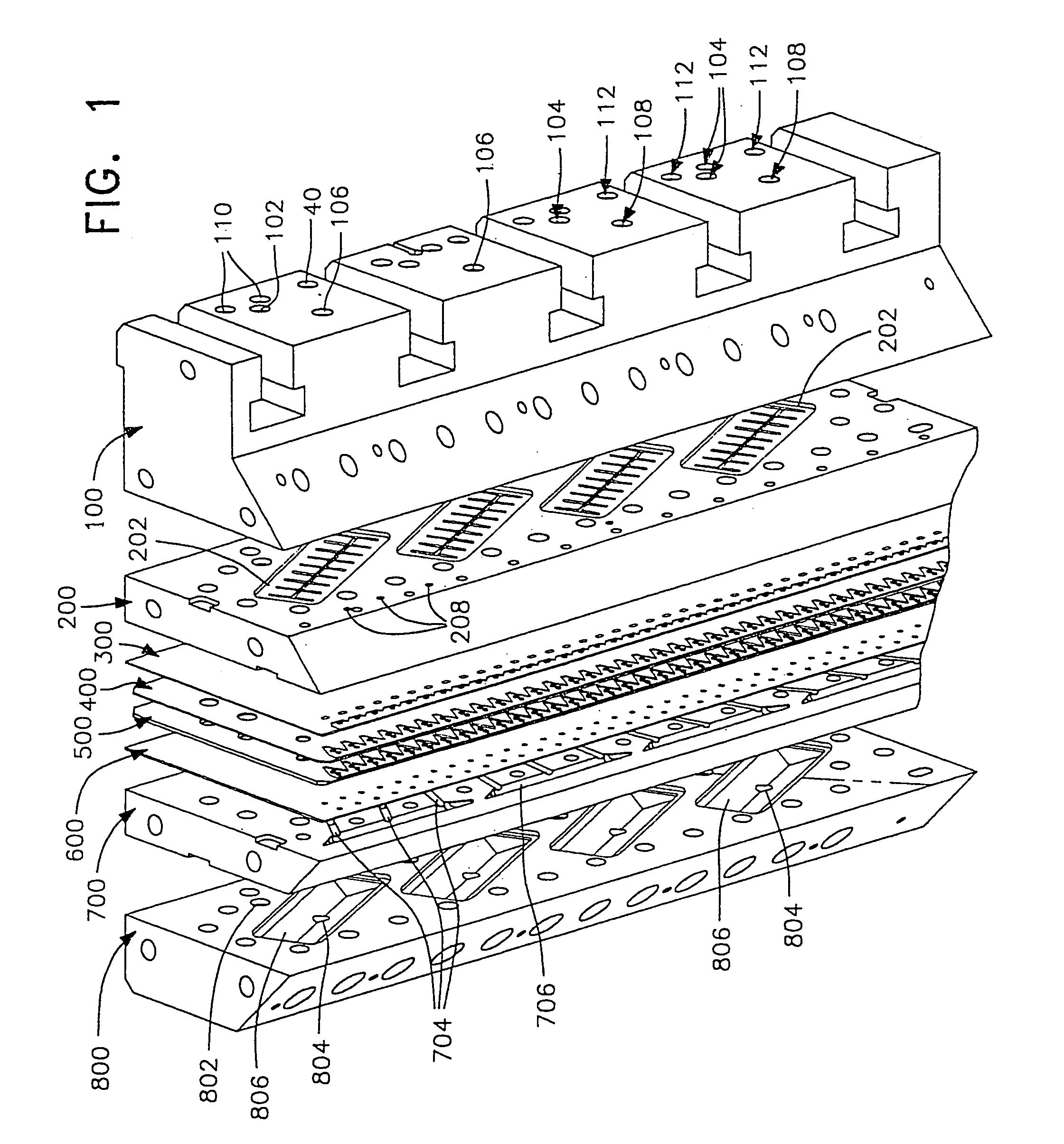

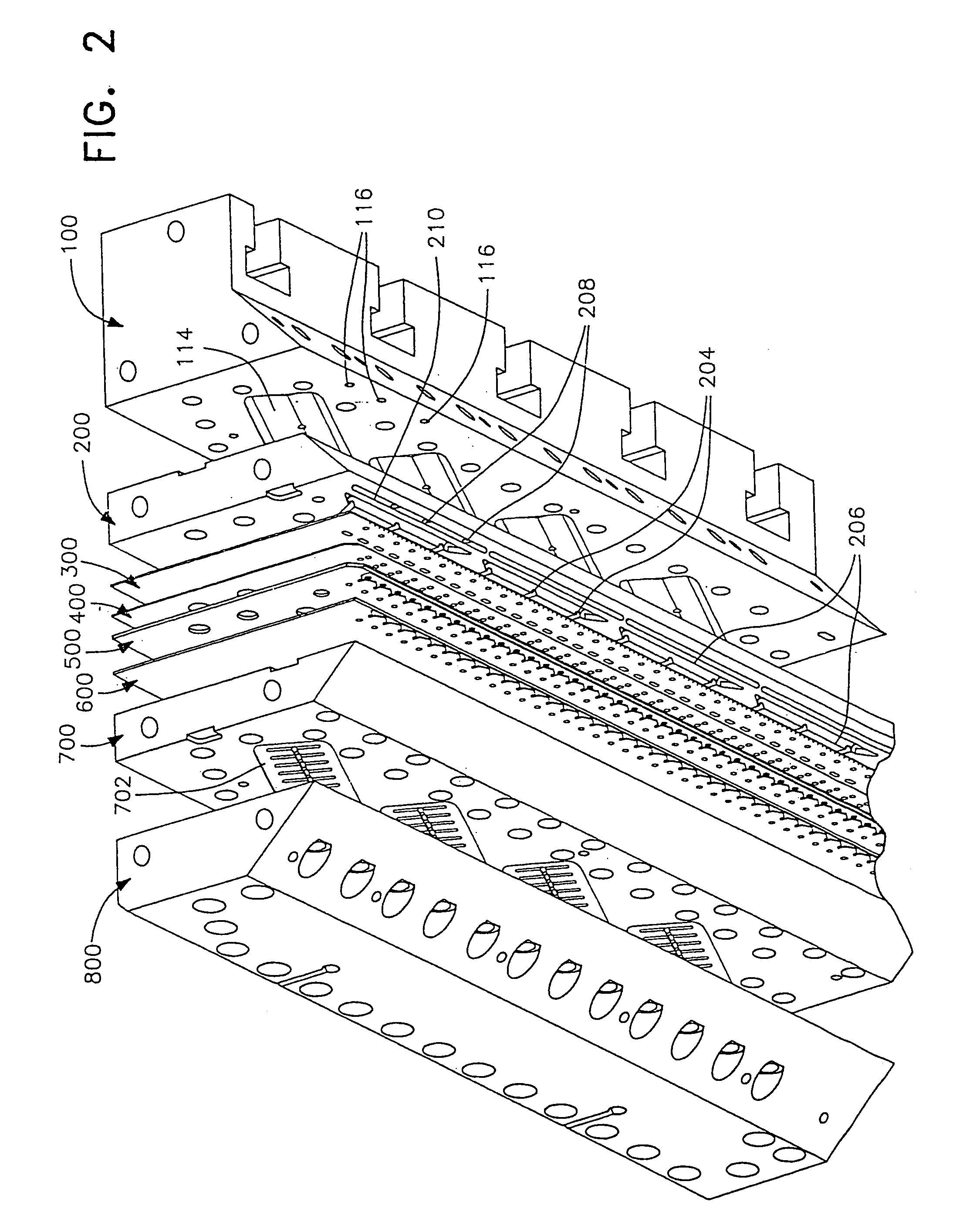

Method and apparatus for spinning a web of mixed fibers, and products produced therefrom

InactiveUS7192550B2Inexpensively formedEffective bonding agentConfectioneryTobacco smoke filtersFiberEngineering

A device and method for spinning polymer fibers utilizes one or more independent sources of polymer materials, pumps for feeding polymer material from each of the sources, and a series of distribution plates with surface grooves, through holes and / or slots together defining separated distribution paths, each of which receives polymer material from one of said independent sources. The surface grooves are defined to a depth less than the thickness of the distribution plate. At least one distribution plate contains spinneret orifices defined by outlet surface grooves extending from the distribution path to the edge of that plate, whereby fibers are extruded from the spinneret orifices edgewise from the plate. The spinneret orifices may be defined by overlayed outlet surface grooves or slots defined in abutting plates.

Owner:HILLS CO

Nanofiber aggregate, polymer alloy fiber, hybrid fiber, fibrous structures, and processes for production of them

InactiveUS8460790B2Less spreadingWide applicationSynthetic resin layered productsFilament/thread formingPolymer alloyPolymer science

The present invention provides an aggregate of nanofibers having less spread of single fiber fineness values that can be used in wide applications without limitation to the shape and the kind of the polymer, and a method for manufacturing the same. The present invention is an aggregate of nanofibers made of a thermoplastic polymer having single fiber fineness by number average in a range from 1×10−7 to 2×10−4 dtex and single fibers of 60% or more in fineness ratio have single fiber fineness in a range from 1×10−7 to 2×10−4 dtex.

Owner:TORAY IND INC

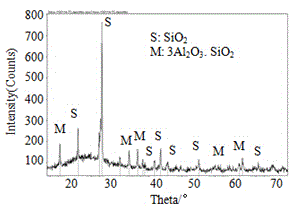

Anti-permeability anti-corrosion concrete

InactiveCN106365556AStrong aging and weather resistanceGood insulation performanceCeramicwareMicrosphereSlag

The invention discloses anti-permeability anti-corrosion concrete. The anti-permeability anti-corrosion concrete is prepared from the following components: silicate cement, coarse sand, medium-coarse sand, broken stone, water, steel slag, siliceous iron tailing powder, plaster, high calcium ash, ganister sand, vitrified microspheres, polycarboxylic water reducer, sodium molybdate, sodium nitrite, stannous chloride, ultrafine natural zeolite powder, hybrid fibres, an air entraining agent, urea and triethanolamine. According to the anti-permeability anti-corrosion concrete disclosed by the invention, the components are reasonable and act synergistically; the anti-permeability anti-corrosion concrete has high strength and high durability, such as freezing resistance, permeability resistance and corrosion resistance, and also has the advantage of preventing noise.

Owner:蚌埠市宝运商品混凝土有限公司

High-durability concrete

The invention discloses a high-durability concrete which comprises the following raw materials: cement, river sand, macadam, water, fly ash, nano microbead, natural zeolite micropowder, aluminum oxide, sodium sulfate, diethanolamine, sodium hydroxide, methyl trichlorosilane, ethanol, an air entraining agent, a lignosulfonate water reducing agent, polyvinyl alcohol, mixed fiber, sodium nitrate and polyvinylpyrrolidone. The mixed fiber is the combination of carbon fiber, steel fiber, polypropylene fiber and polyvinyl alcohol fiber in a weight ratio of 1:(2-5):(3-7):(3-6). The high-durability concrete has the advantages of high strength, favorable water impermeability, favorable freezing resistance and favorable durability, and has long service life when being applied to hydrotechnics, harbors, roads and other projects.

Owner:WUWEI HENGJI COMML CONCRETE

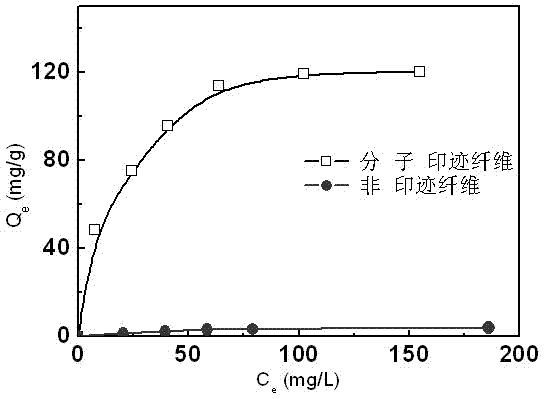

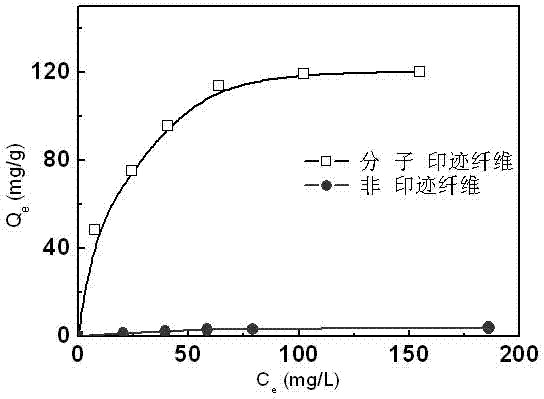

A molecularly imprinted fiber material and its preparation method

InactiveCN102294231AImprove adsorption capacityHigh selectivityOther chemical processesFibre treatmentPolymer scienceFunctional monomer

The invention discloses a molecularly imprinted fiber material and a preparation method thereof. The matrix of the molecularly imprinted material is an organic fiber, specifically polypropylene, polytetrafluoroethylene, viscose, polyacrylonitrile or polyvinyl alcohol. The preparation method comprises the following steps of: radiating the matrix fibers after being preprocessed using cobalt 60 gamma rays, mixing the radiated fibers with a graft monomer, and after a grafting reaction, removing homopolymers from the fibers through extraction filtration, and then drying the fibers in vacuum, thereby obtaining grafted modified fibers; reacting the grafted modified fibers with a functional polymer or a functional monomer, after the completion of the reaction, washing away the non-reacted functional polymer or functional monomer on the surface of the fibers, and then adding the fibers to the solution of template ions or template molecules to absorb the template ions or the template molecules;after the absorption is saturated, performing cross-linking using a cross-linking agent, and after the reaction is ended, removing the template ions or the template molecule through desorption using a desorbent, thereby obtaining the molecularly imprinted fiber material. The fiber material of the invention has high mechanical strength, high thermal stability, high chemical stability, high absorption capacity and high selectivity.

Owner:SUN YAT SEN UNIV

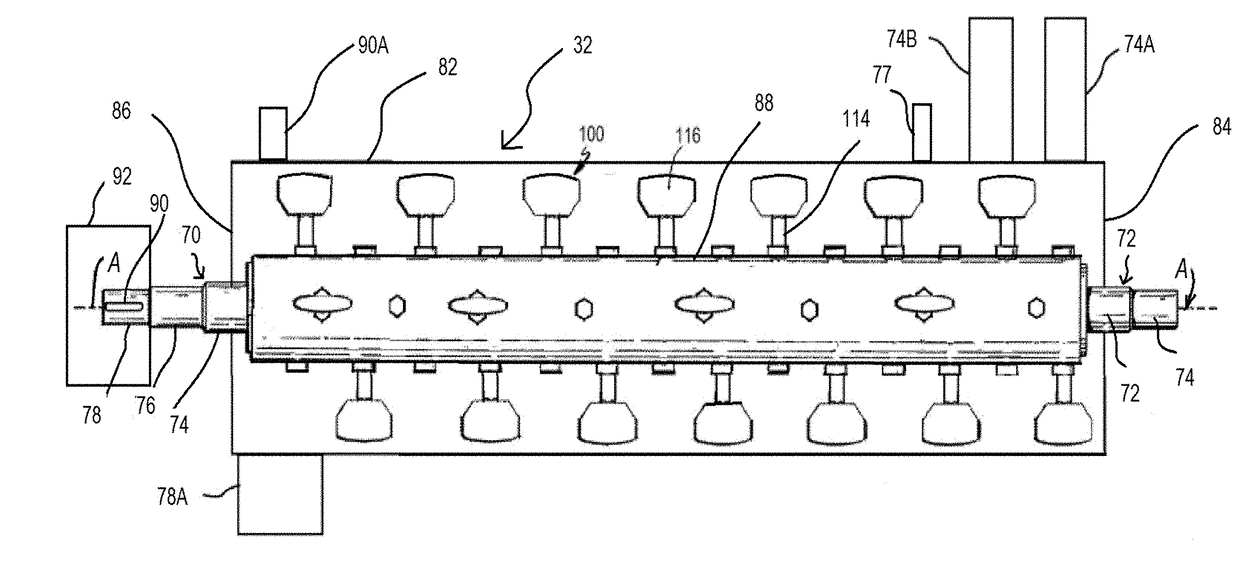

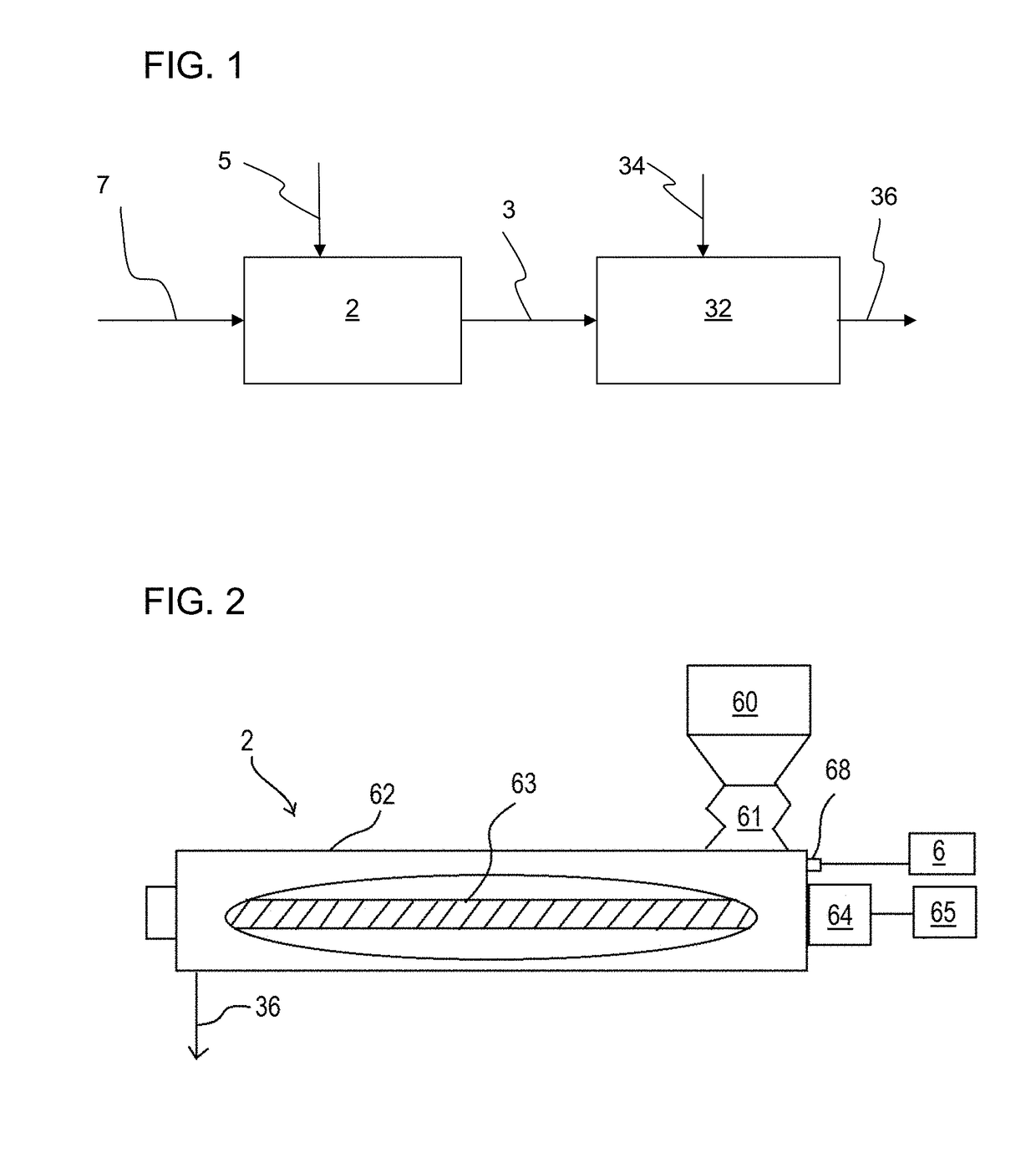

Continuous methods of making fiber reinforced concrete panels

ActiveUS20180036912A1Promote formationEasy to processLiquid surface applicatorsRotary stirring mixersStructural engineeringSlurry

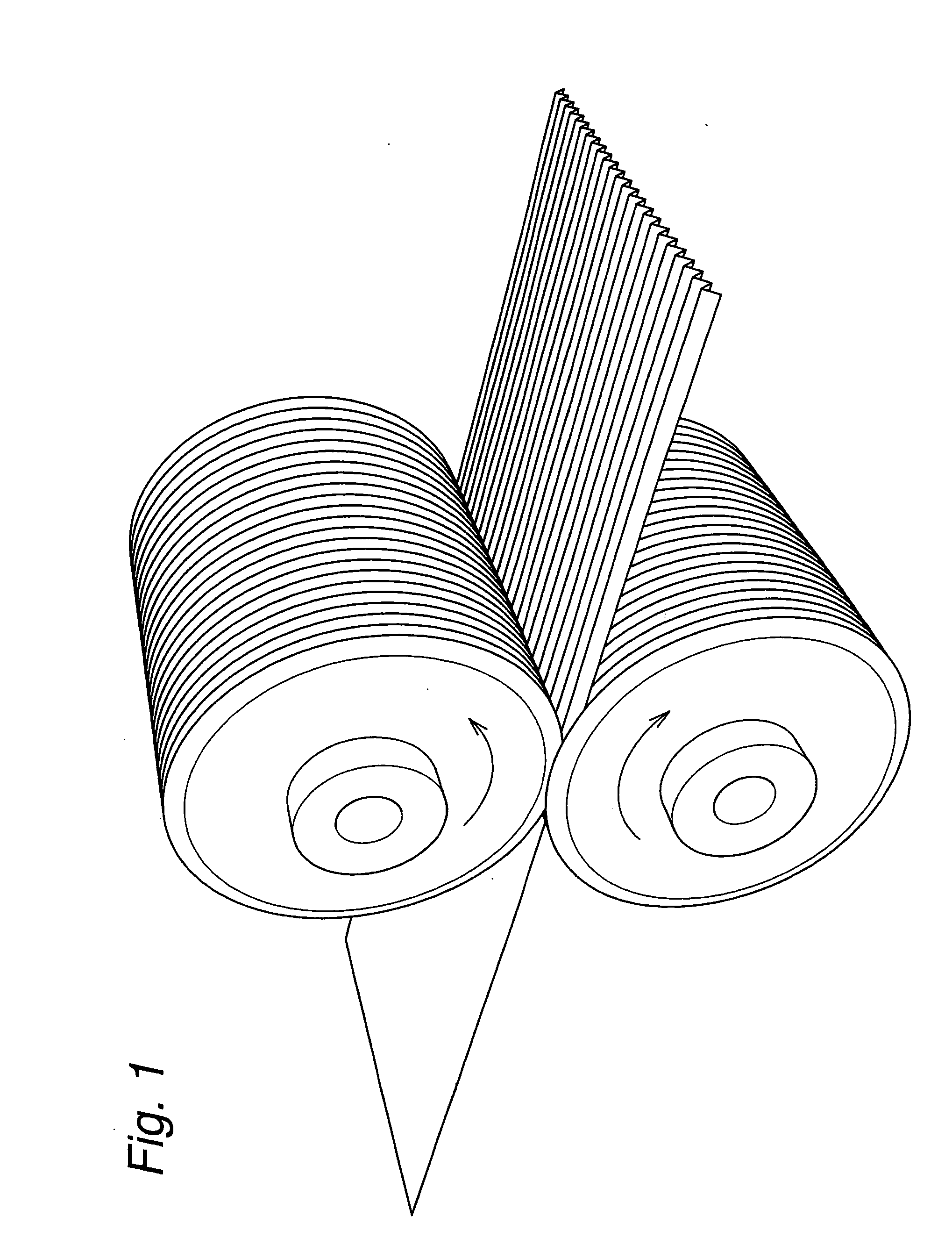

Continuous method including:mixing water and cementitous powder to form slurry;mixing the slurry and reinforcement fibers in a single pass horizontal continuous mixer to form fiber-slurry mixture,the mixer includingan elongated mixing chamber having a reinforcement fiber inlet port, andupstream of the fiber inlet port is an inlet port to introduce water and cementitous powder together as one stream or at least two inlet ports to introduce water and dry cementitous powder separately as separate streams into the chamber,a rotating horizontal shaft / s within the chamber,part of the chamber for mixing the fibers and slurry and moving the fiber-slurry mixture to a mixture outlet;discharging the fiber-slurry mixture from the mixer outlet;forming and setting the fiber-slurry mixture on a moving surface;cutting the set mixture into fiber reinforced concrete panels and removing the panels from the moving surface.

Owner:UNITED STATES GYPSUM CO

Hybrid fiber-reinforced plastic

InactiveUS6306474B1Easy to makeMaintain good propertiesSynthetic resin layered productsCeramic shaping apparatusFiber bundleCarbon fibers

The present invention relates to a carbon fiber reinforced plastic member provided with high-elongation fiber bundle regions, which are uni-directionally aligned and separately disposed within the plastic member. The plastic member provides a carbon fiber reinforced plastic of lightweight, high strength and high modulus that is safe. Even if it breaks, it shows little scatter of fragments or exposure of dangerous fracture surfaces. Preferably, the high-elongation fiber at break has an elongation exceeding about 10%.

Owner:TORAY IND INC

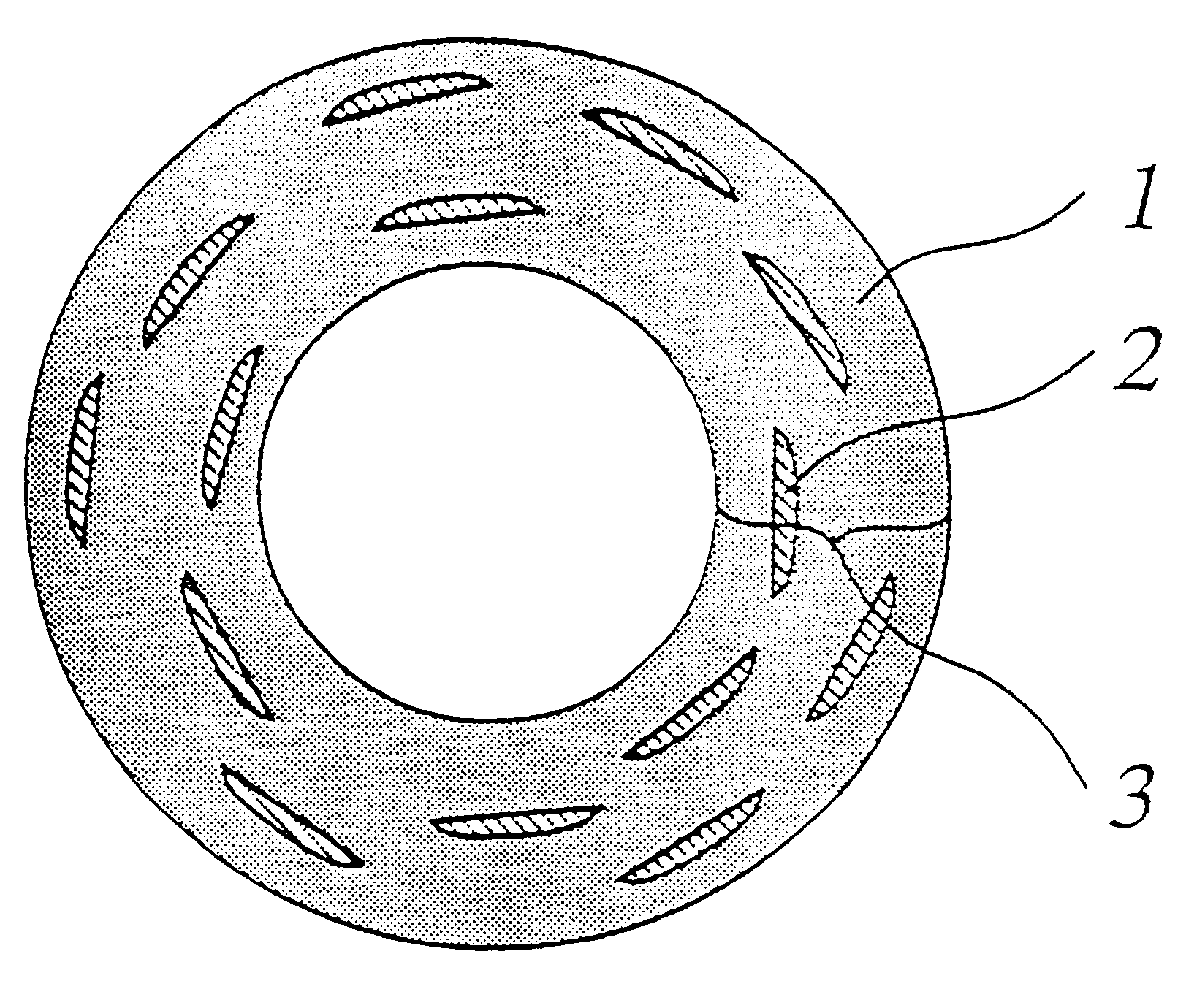

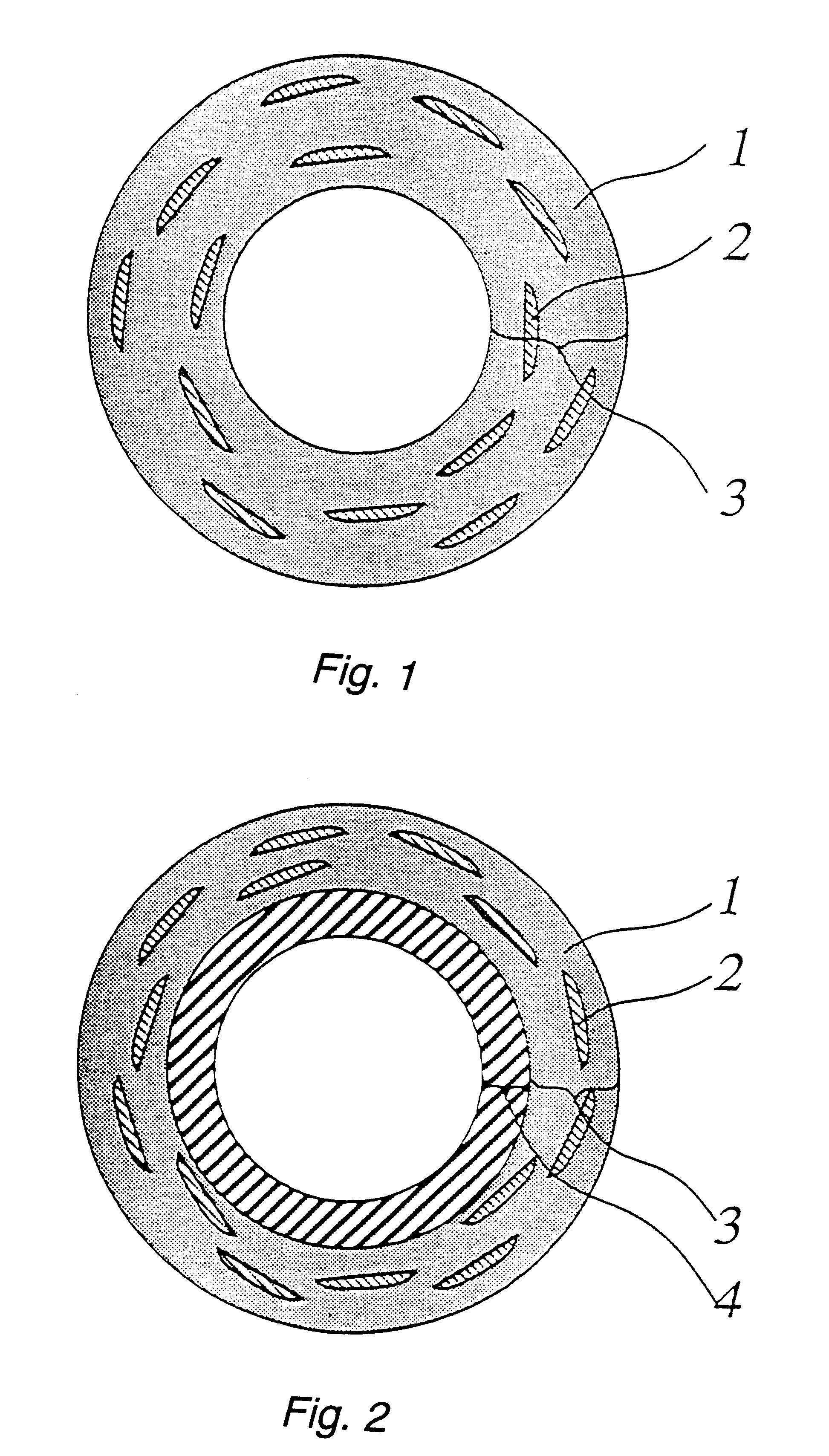

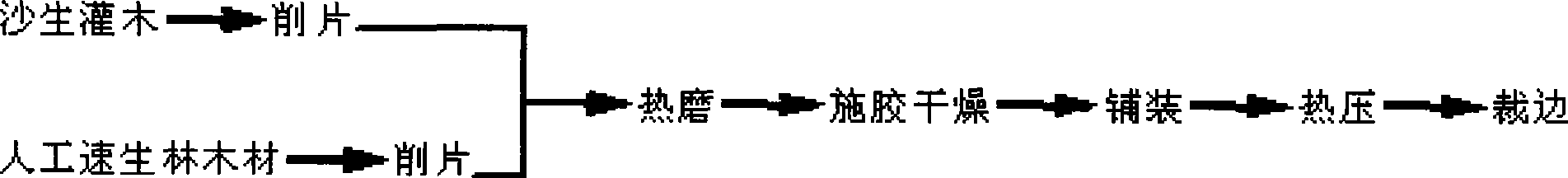

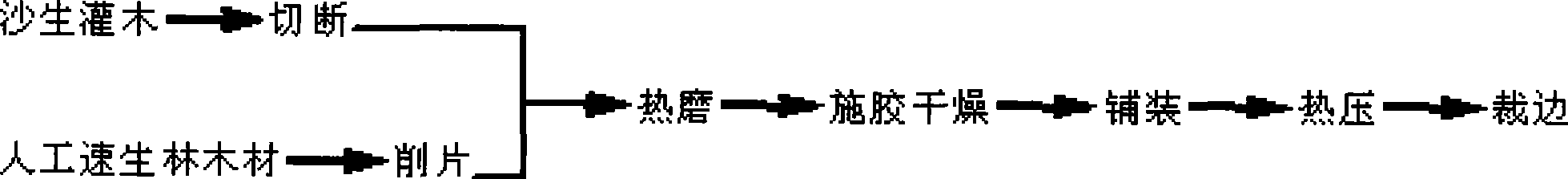

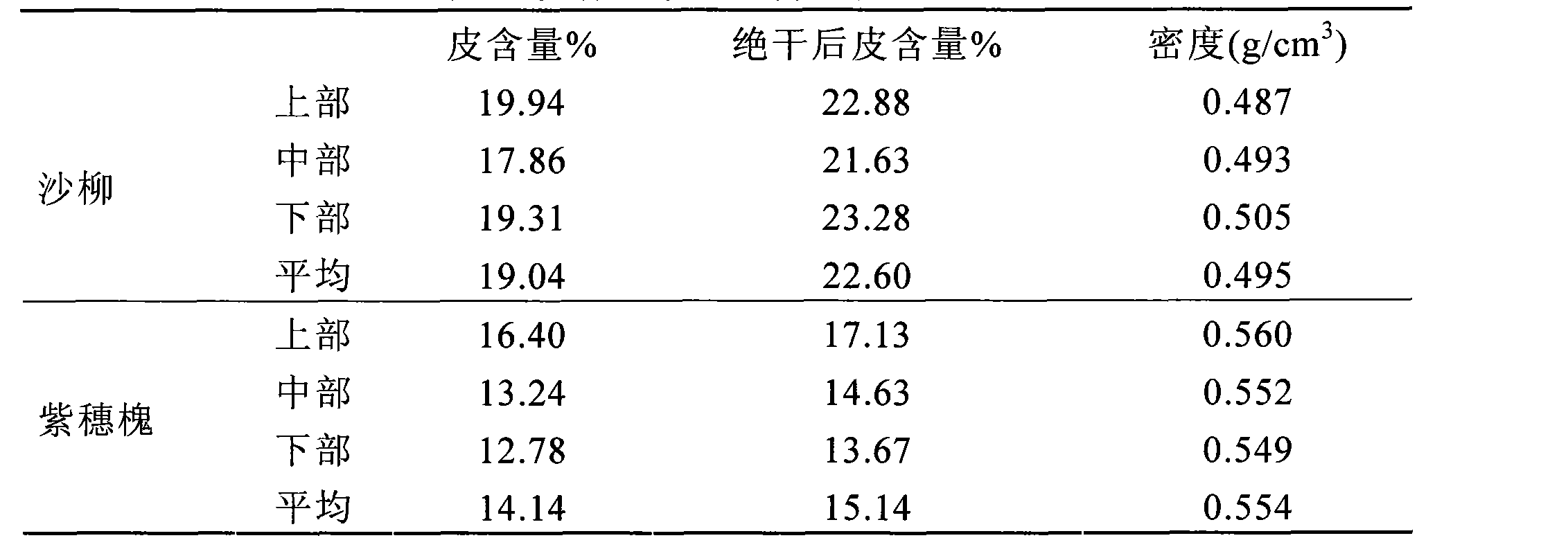

Desert shrub composite fibre board and method of manufacturing the same

InactiveCN101486216AReduce skin contentQuality improvementDomestic articlesFlat articlesFiberMaterials preparation

The invention discloses a composite fibreboard of psammophyte bush. A manual fast-growing forest timber is mixed in the psammophyte bush to prepare mixed fibre by a mixed jordaning method; and the mixed fibre reduces the bark content of the psammophyte bush and improves the fibre quality of the psammophyte bush, thereby improving the quality of the fibreboard. The invention also provides a method for manufacturing the composite fibreboard of the psammophyte bush; the method comprises the main steps: (1) material preparation; (2) hot grinding; (3) adhesive application and drying; (4) pavement; (5) hot pressing; (6) edge trimming, and other working procedures; in the material preparation section, wooden chips of the psammophyte bush with length of more than 10 cm are controlled within 5 percent; or the psammophyte bush is cut into small sections of crabsticks with the length of between 1.5 and 5.0 cm; and the wood chips or the crabsticks and the wood chips of the fast-growing forest timber are mixed to solve the problems that uncut strips of the psammophyte bush wind a cutter wheel of a drum-type chipper and block a tub wheel and a screen, and the like.

Owner:张琪

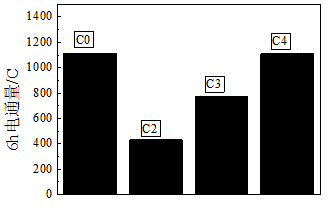

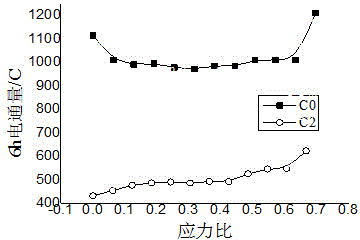

High-performance concrete admixture in use of waste ceramic powder and implementing method thereof

InactiveCN104817287AThe stability result is qualifiedImprove liquiditySolid waste managementEnvironmental resistanceFiber

The invention discloses a high-performance concrete admixture in use of waste ceramic powder and an implementing method thereof. The high-performance concrete admixture is prepared by the following steps: utilizing waste ceramics as a main material and utilizing active seed crystals and a modified enhancer as auxiliary materials; performing modified treatment and high-temperature smelting on various materials, then putting into a cement mill to mill the materials to be pre-finished products with specific area of 300-450 m2 / kg, and finally, doping mixed fibers. The high-performance concrete admixture comprises the raw materials in parts by weight: 80-100 parts of waste ceramic powder, 6-9 parts of active seed crystal, 2-6 parts of modified enhancer and 5-10 parts of mixed fibers. By adopting mixed ceramic powder, density of cement mortar is effectively increased; strength of concrete is improved and durability of concrete is remarkably improved. Energy problems are solved, and meanwhile, an environmental protection purpose is considered; the high-performance concrete admixture has remarkable technical, economic and social benefits.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Wet-process substrate non-woven fabric used for reverse osmosis membrane and preparation method thereof

ActiveCN105040275AImprove bonding fastnessTroubleshooting Curl's Technical DifficultiesNon-woven fabricsPolymer scienceReverse osmosis

The invention discloses wet-process substrate non-woven fabric used for a reverse osmosis membrane and a preparation method thereof. The manufactured substrate non-woven fabric is formed by integrating three layers of fibers through hot-melting rolling compaction, wherein the upper layer comprises ES composite fibers, the lower layer comprises COPET / PET dacron composite fibers, and the intermediate layer comprises synthetic fibers composed of PET fibers, ES fibers and COPET / PET composite fibers. The fabric is mainly characterized in that the entire fabric is of a single-layer structure. The preparation method of the fabric comprises the steps of hydrophilic treatment of the fibers serving as raw materials, processing and netting, drying treatment, first hot melting rolling compaction, cooling shrinkage treatment, second hot melting rolling compaction and quality inspection and rolling-up, and the preparation method is mainly characterized in that the seven steps are conducted in a continuous and synchronized mode. The wet-process substrate non-woven fabric used for the reverse osmosis membrane and the preparation method thereof have the advantages that the manufactured product quality is good, the preparation method and process are advanced and reasonable, energy is saved, consumption is reduced, and the process cost is low.

Owner:CHANGZHOU KANGJIE SPECIAL NON WOVEN FABRICS CO LTD

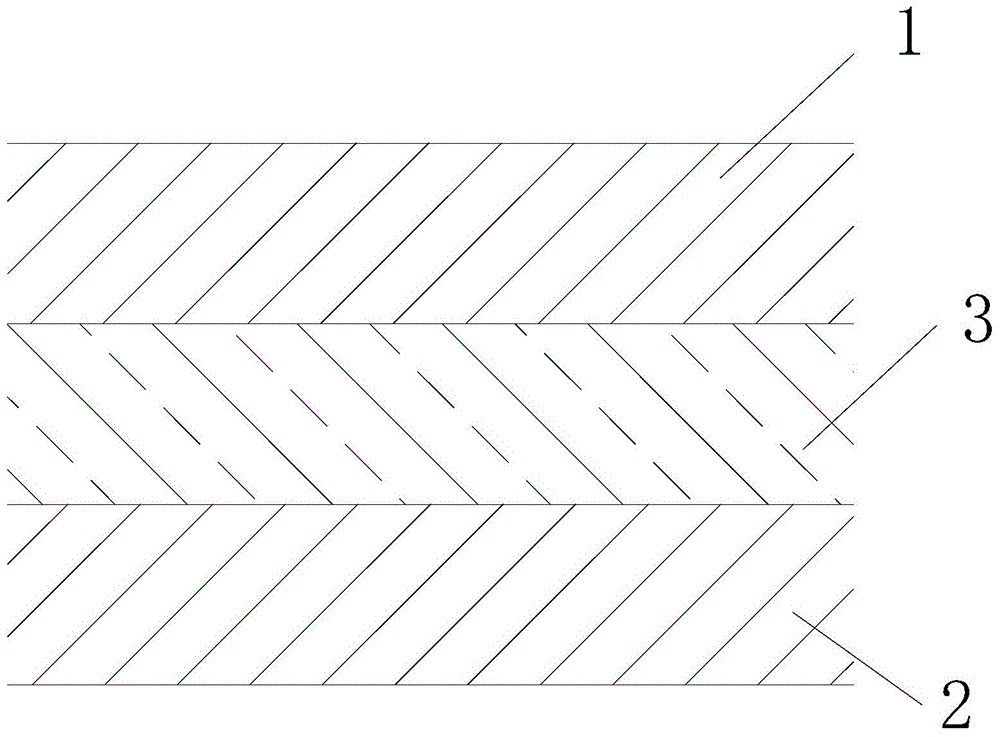

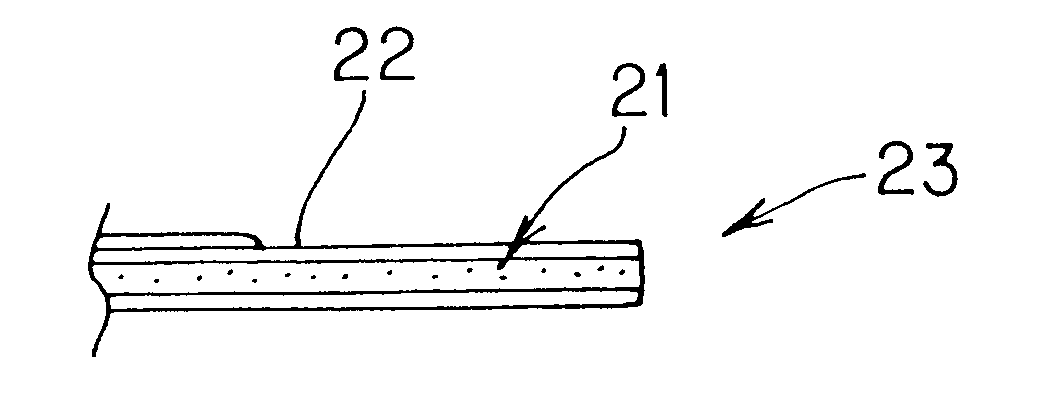

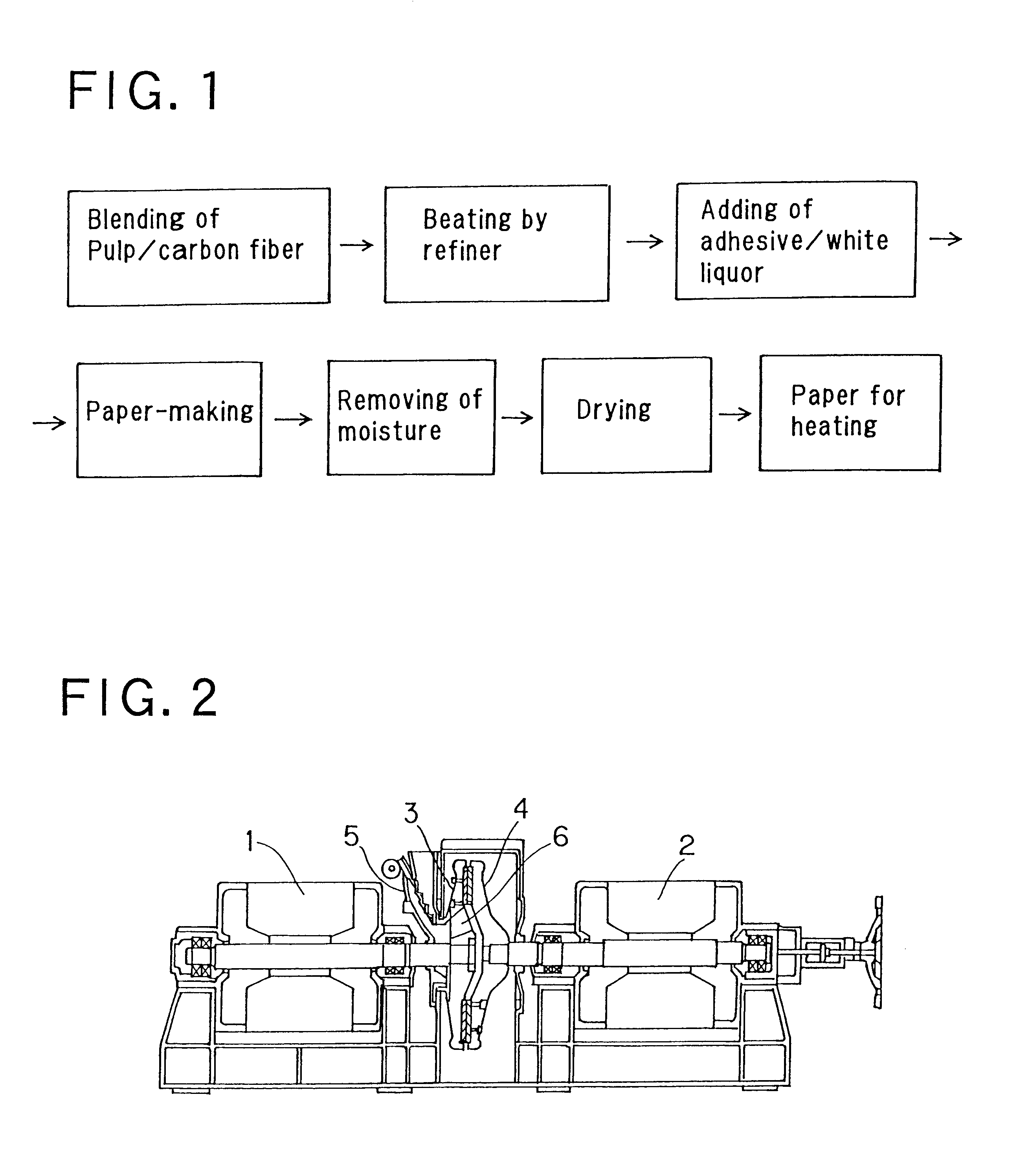

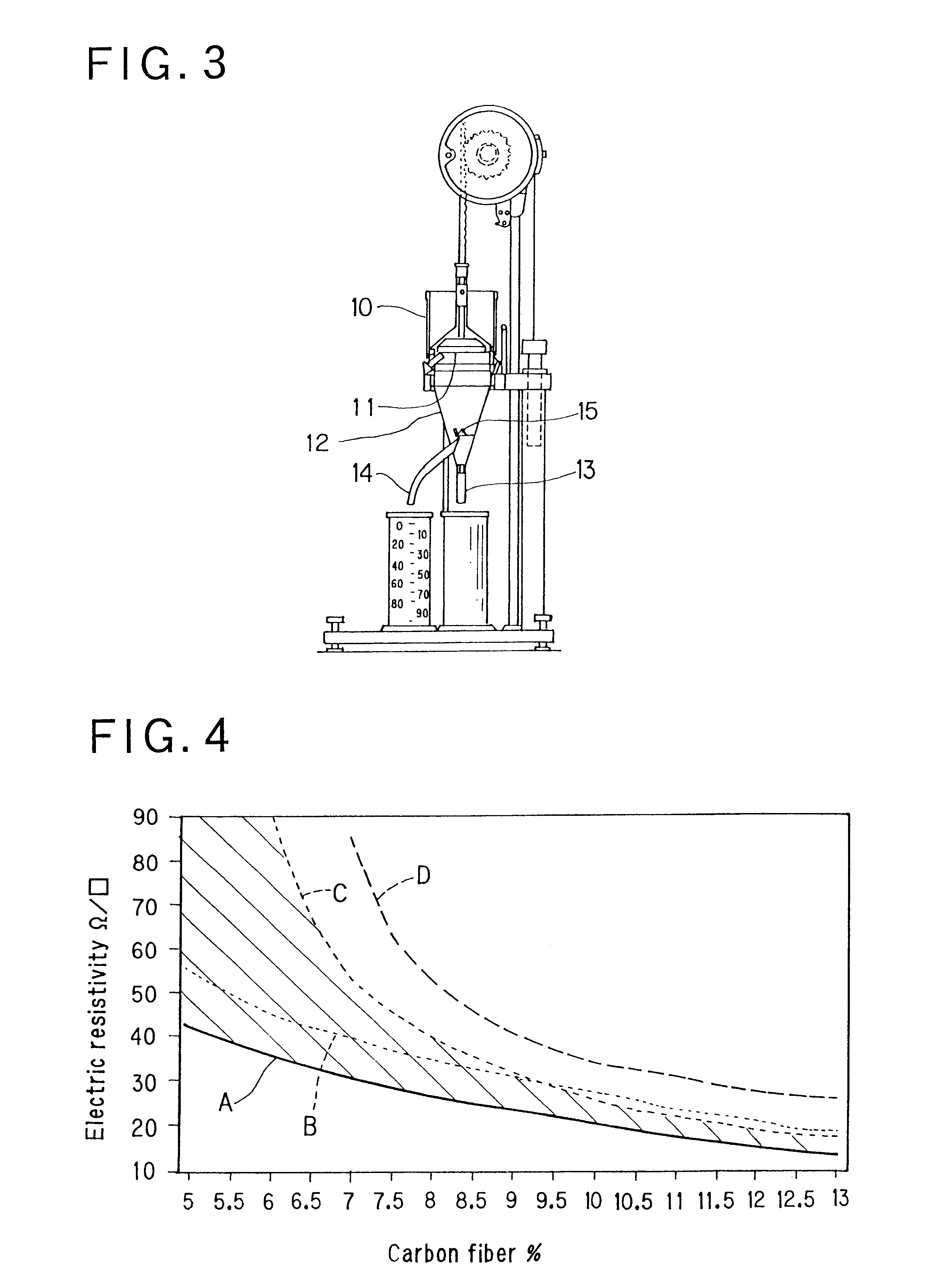

Heating unit of carbon fiber-mixed sheet

InactiveUS6593555B2Resistance actionHeating element shapesHeating element materialsCarbon fibersPolymer science

The purpose is to provide a heating unit of a carbon fiber-mixed sheet with a low price in which sheet carbon fibers are equally dispersed and a member on the surface of which sheet is not subjected to such change of properties as discoloration and the like. The constitution is characterized in that a sizing agent covers a part of the carbon fiber-mixed sheet which sheet is made by the mixed fiber-making of 5~10 wt. % of a carbon fiber having a length of 5~10 mm and 95~90 wt. % of a pulp containing a bast fiber and in that the sheet has a thickness of 150 mum or less, a basis weight of 50 g / m2 or less and a degree of beating of 30~70° SR.

Owner:HAYASHI KYOKO

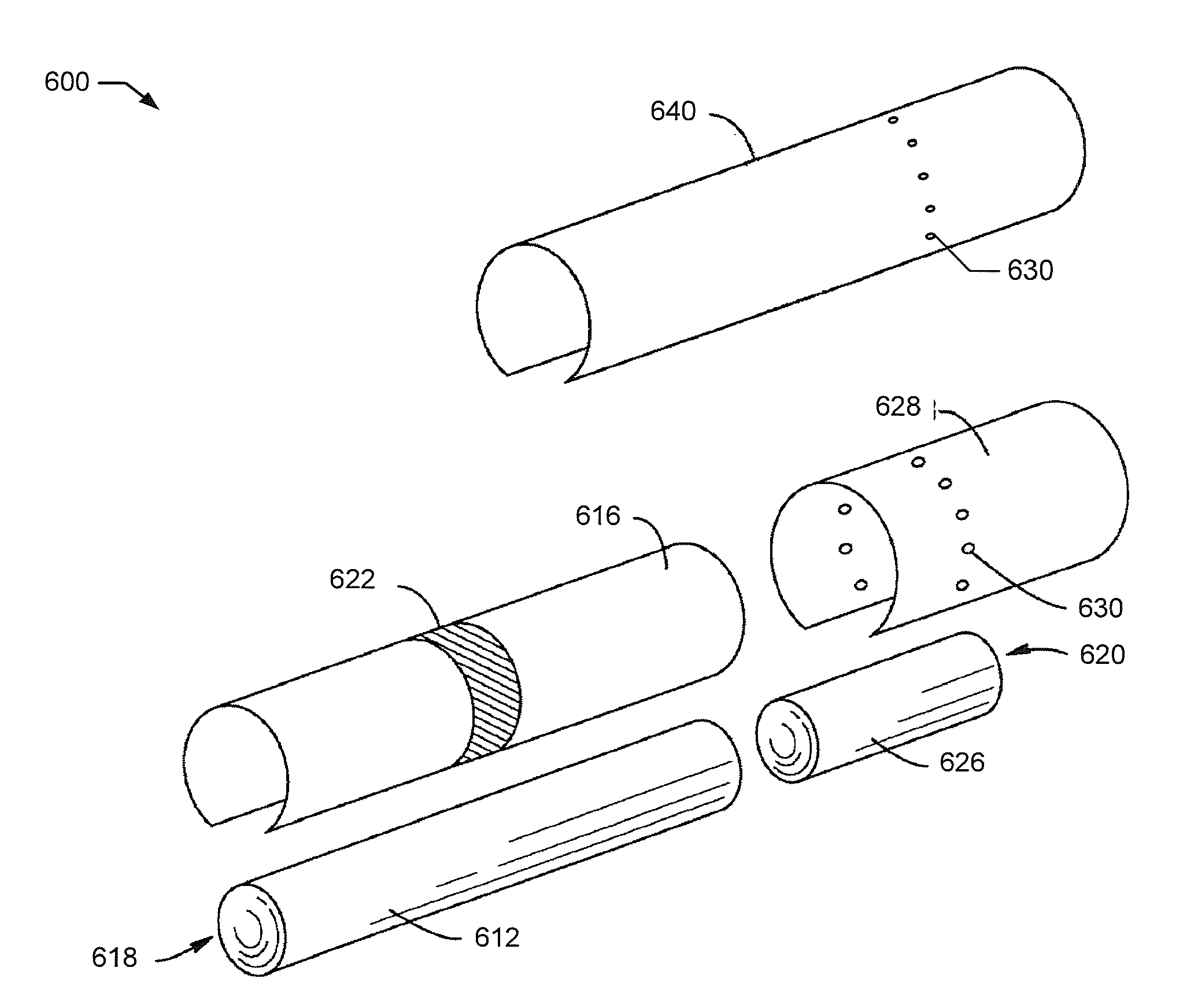

Robust Fiber Cell for Atomic and Molecular Sensing

ActiveUS20170123147A1Cladded optical fibreColor/spectral properties measurementsPhotonic bandgapLength wave

A robust, rugged, and small hybrid fiber for use in reference chambers was created using a Hollow-Core Photonic Bandgap Fiber (HCPBF). The hybrid fiber and associated chamber apparatus is amenable to mass production and can be used for wavelengths of light from 400 nm to 2000 nm. The apparatus and method of making thereof is described herein.

Owner:TRIAD TECH

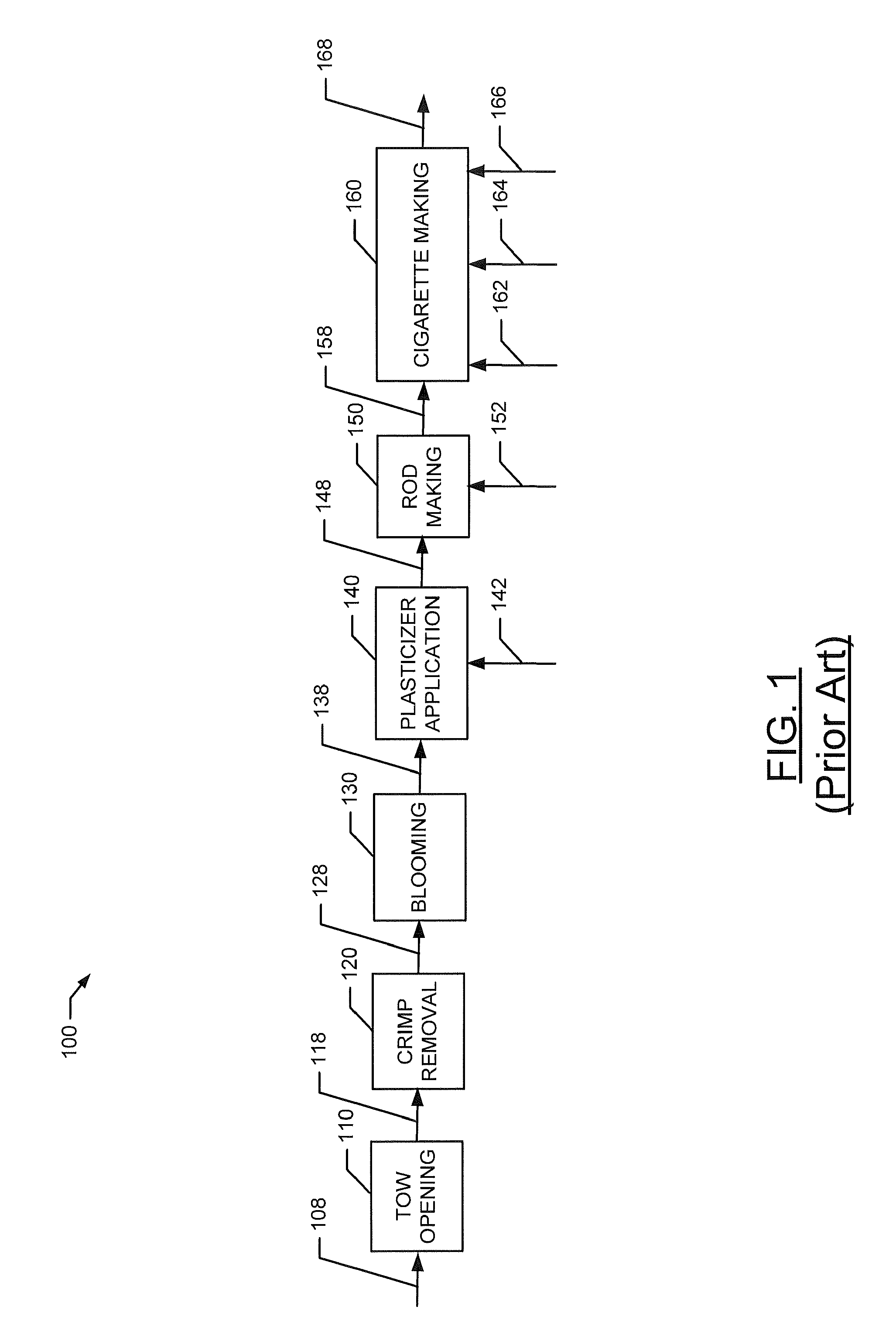

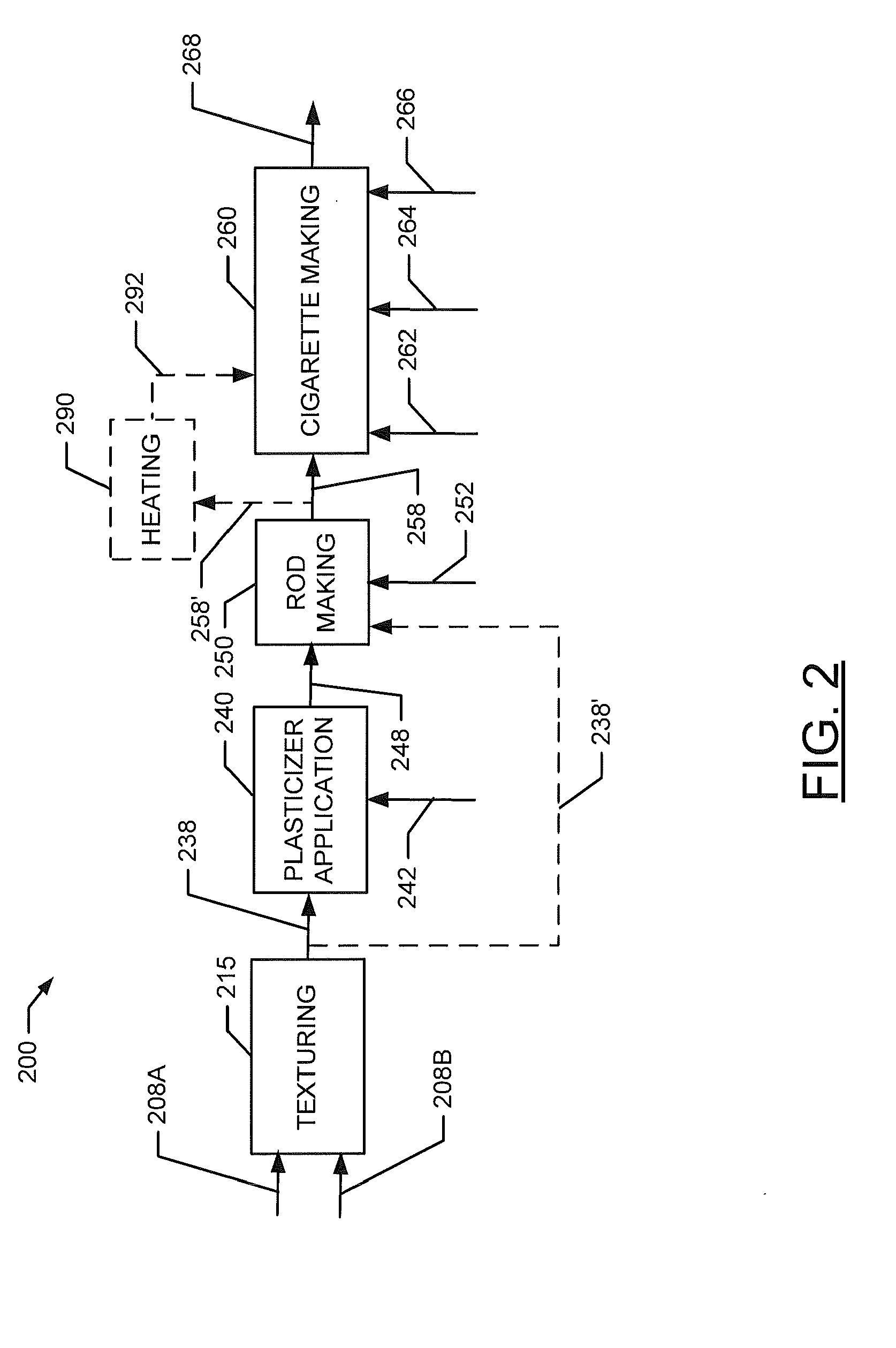

Mixed fiber product for use in the manufacture of cigarette filter elements and related methods, systems, and apparatuses

A system configured to produce smokable products including filter elements formed from multiple fibers is provided. The system includes a texturing apparatus configured to combine the fibers such that the fibers are at least partially entangled with each other and form a mixed fiber product. The entangled fibers may be sufficiently separated from one another such that plasticizer may be applied to the mixed fiber product without necessarily performing tow opening, crimp removal, or blooming operations. The fibers combined to form the mixed fiber product may define characteristics that differ or which are the same. Accordingly, filter elements may be produced that include different fibers that have respective desirable properties associated therewith. Related methods, apparatuses and mixed fiber products are also provided by the disclosure.

Owner:R J REYNOLDS TOBACCO COMPANY

Self-fragrant nonwoven fabric and application thereof

ActiveCN106283406ALong lasting fragranceImprove stabilitySynthetic resin layered productsMedical devicesAbsorption ratioNonwoven fabric

The invention relates to a self-fragrant nonwoven fabric which is prepared from bicomponent fibers. The self-fragrant nonwoven fabric is prepared from the following components in percentage by mass: 10-50 percent of the bicomponent fibers and 50-90 percent of self-fragrant fibers and is prepared by the following steps of metering and carding the bicomponent fibers and the self-fragrant fibers, randomly arranging the bicomponent fibers, the self-fragrant fibers and natural anti-bacterial deodorizing fibers in the longitudinal direction and the transverse direction, laying a mixed fiber net by vertically and horizontally interlacing, winding and cohering the bicomponent fibers, the self-fragrant fibers and the natural anti-bacterial deodorizing fibers, and then heat setting and to compounding the mixed fiber net into the self-fragrant nonwoven fabric. The self-fragrant nonwoven fabric has no stimulation on skins of a human body, can inhibit invasion and breeding of bacteria, is high in absorption ratio to ammonia, is very prominent in the antibacterial effect, the antifungal effect and the deodorizing effect, has the characteristics of uniformity in releasing fragrance and long fragrance keeping time and is high in added value of a product.

Owner:漳州市鼎鑫电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com