High-performance concrete admixture in use of waste ceramic powder and implementing method thereof

A technology of high-performance concrete and waste ceramics, applied in the field of building materials, can solve the problems of lack of systematic technical index theoretical support for new cement-based materials, and achieve the effect of good workability and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0045] Embodiment 1-4: the implementation method of waste ceramic powder as high-performance concrete admixture, comprises the steps:

[0046] 1) Configure the corresponding ceramic powder admixture raw materials according to the percentages in Table 4, and the proportion of each material meets the corresponding technical indicators mentioned above.

[0047] Table 4 Admixture raw material percentage (unit: %)

[0048]

[0049]

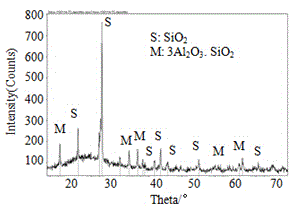

[0050] Preparation of ceramic powder: Mix all kinds of ceramic waste near the Jingdezhen ceramic workshop and waste ceramic bricks on the construction site according to the ratio in Table 4. The mixed material was crushed, screened, cleaned, dried, and ball milled to make waste ceramic powder, which was then placed in an electric heating furnace, heated at 200°C for 4 hours, and then ground by a cement ball mill for 1 hour. The gradation of ceramic powder particles is continuous and reasonable, and the specific surface area is 350m 2 / kg;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com