Patents

Literature

459results about How to "Workability is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

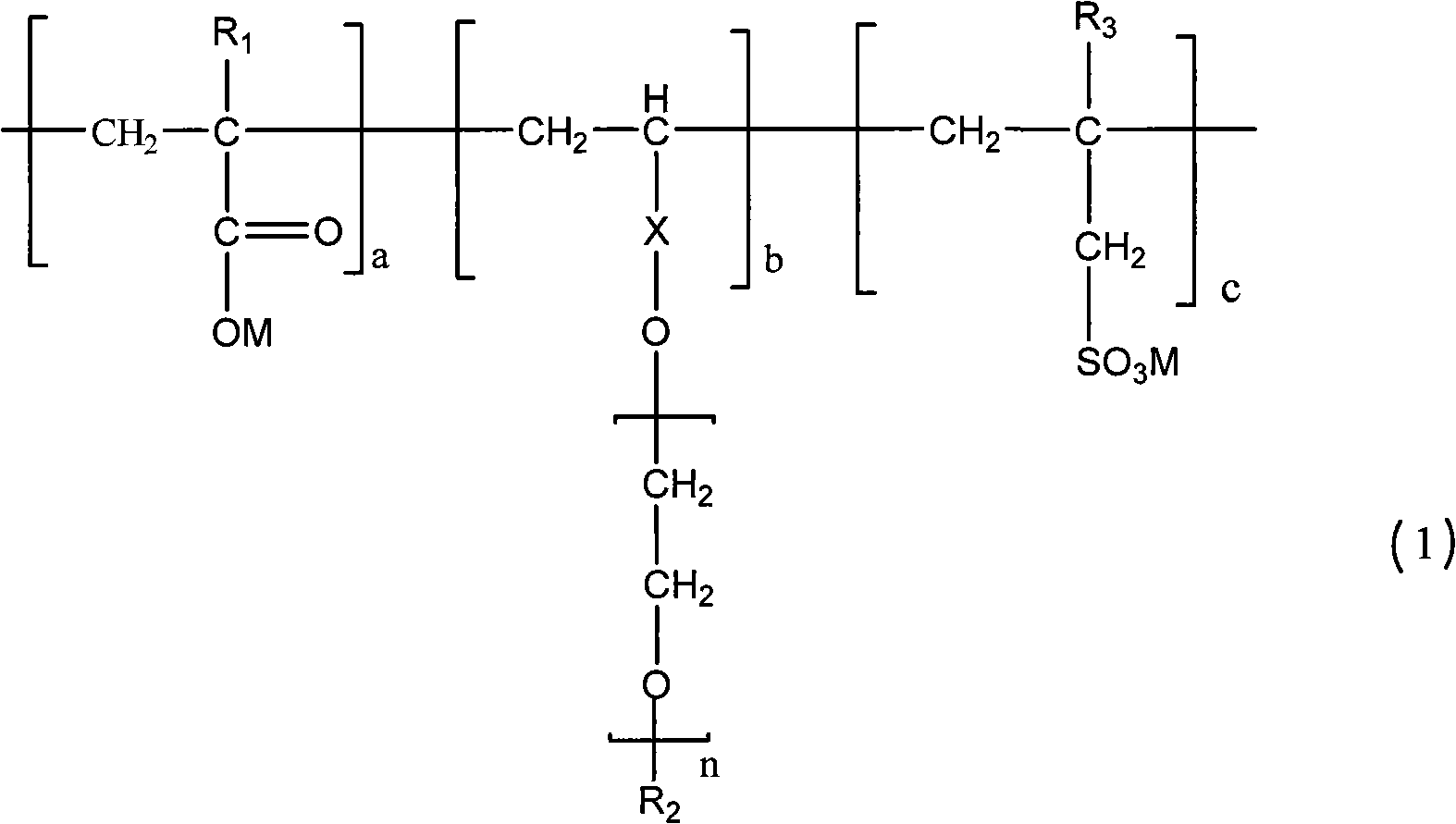

Polycarboxylate composite water reducing agent suitable for low-cementitious material concrete and preparation method thereof

The invention relates to a polycarboxylate composite water reducing agent suitable for low-cementitious material concrete and a preparation method thereof. The polycarboxylate composite water reducing agent suitable for the low-cementitious material concrete is characterized by comprising the following components in percentage by mass: 15 to 25 percent of polycarboxylic high-performance water reducing agent, 1 to 5 percent of retarder, 0 to 0.10 percent of defoaming agent, 0.01 to 0.3 percent of air entraining agent, 0.3 to 0.5 percent of preservative and the balance of water, wherein the mass solid content of the polycarboxylic high-performance water reducing agent is 40 percent. The polycarboxylate composite water reducing agent is applied to the concrete, and has the water reducing rate over 20 percent by comparing the concrete with reference concrete; and the prepared concrete has the advantages of good workability, no dissociation or bleeding, and good freezing resistance and infiltration resistance, and can be used for preparing concrete with various strength grades between C20 and C40.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

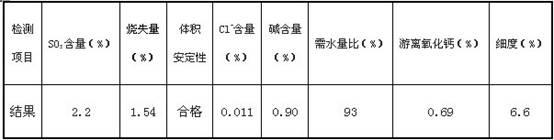

Heat insulating mortar powder and its prepn process

The heat insulating mortar powder contains cementing material, foamed modified polystyrene grain, modified expanded pearlite, cementing material modifier and fiber. The foamed modified polystyrene grain contains foamed polystyrene grain, foamed polystyrene modifier and flyash; the modified expanded pearlite contains expanded pearlite, expanded pearlite modifier and sodium hydroxide; and the cementing material modifier contains polymer adhesive, air entraining and water reducing agent and flyash activator. The preparation process includes preparing foamed modified polystyrene grain, preparing modified expanded pearlite, preparing cementing material modifier, and mixing all the materials in certain proportion. The present invention has the advantages of small heat conducting coefficient, high compression strength, good construction performance, high adhering strength, etc.

Owner:爱福家居(江苏)有限公司

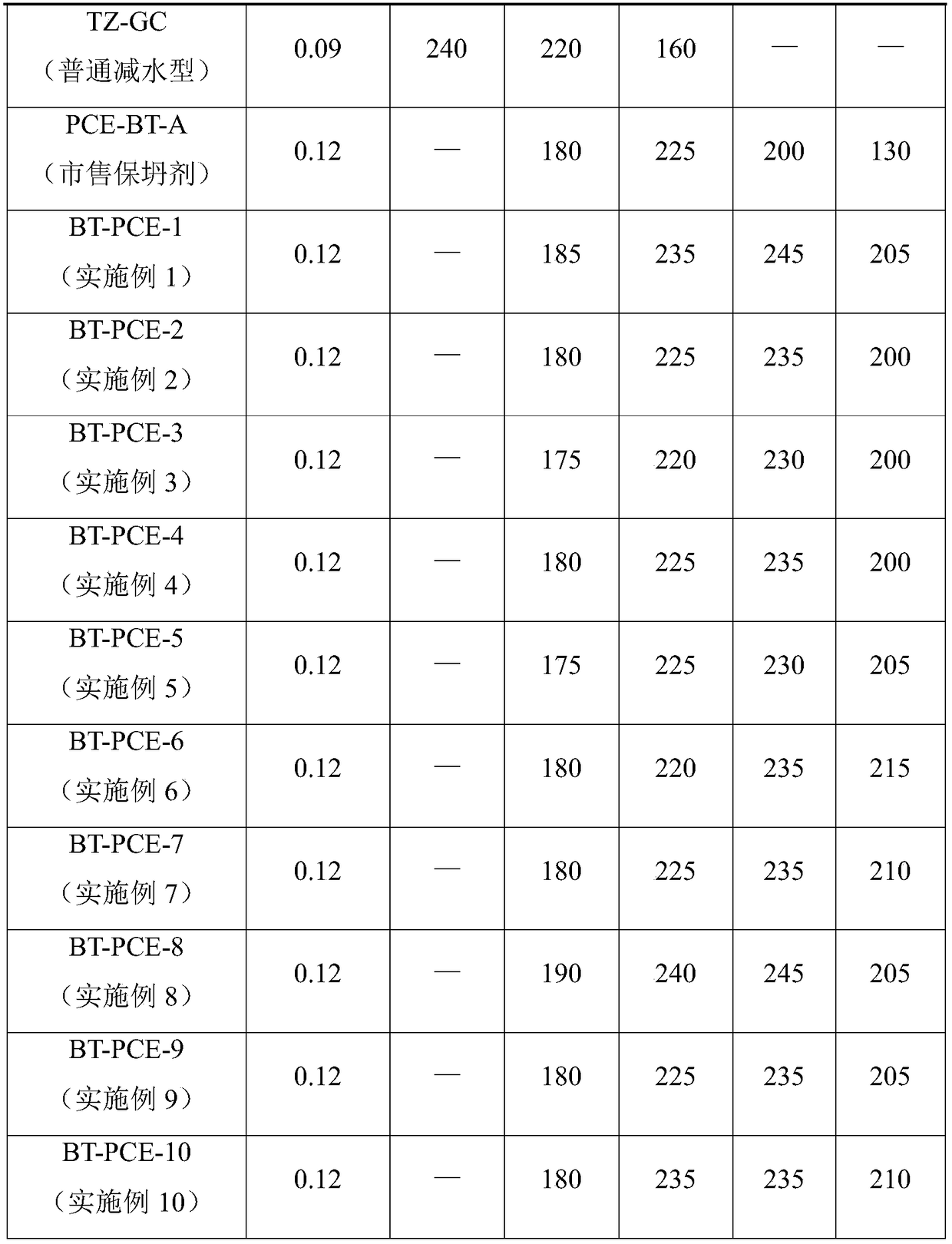

Eco-friendly self-compacting concrete prepared through complete recycling of waste concrete

InactiveCN104788054AWorkability is goodExcellent and workability (liquiditySolid waste managementSuperplasticizerFly ash

The invention discloses eco-friendly self-compacting concrete prepared through complete recycling of waste concrete. The eco-friendly self-compacting concrete comprises components in parts by weight as follows: 100 parts of cement, 10-25 parts of fly ash, 10-25 parts of mineral powder, 20-40 parts of recycled micro-powder, 1-2 parts of a polycarboxylate superplasticizer, 230-380 parts of recycled fine aggregate, 240-400 parts of recycled coarse aggregate and 45-60 parts of water which are mixed. The coarse aggregate only adopts the recycled coarse aggregate, the fine aggregate only adopts the recycled fine aggregate, the recycled micro-powder formed by grinding waste materials produced in production of the recycled aggregate is blended into a mineral admixture, so that complete recycling of the waste concrete is realized, and the eco-friendly self-compacting concrete has a very good eco-friendly effect.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Desulfurization gypsum-based thermal insulation mortar and preparation method thereof

The invention relates to a desulfurization gypsum-based thermal insulation mortar and a preparation method of the mortar, belonging to the technical fields of solid waste comprehensive utilization and building material. The desulfurization gypsum-based thermal insulation mortar comprises the components in parts by weight: 1000 parts of desulfurization gypsum, 3-10 parts of white cement, 350-450 parts of glass beads, 5-15 parts of redispersible latex powder, 1-5 parts of wood fiber, 5-25 parts of sepiolite fiber, 1.5-5 parts of polypropylene (PP) fiber, 1-8 parts of polyvinyl alcohol, 1-5 parts of hydrophobic agent, 0.4-3 parts of retarder, 1-5 parts of water reducing agent and 2-6 parts of thickening agent. The desulfurization gypsum-based thermal insulation mortar is convenient to transport and has very strong thermal insulation performance and fireproof performance.

Owner:上海复培新材料科技有限公司

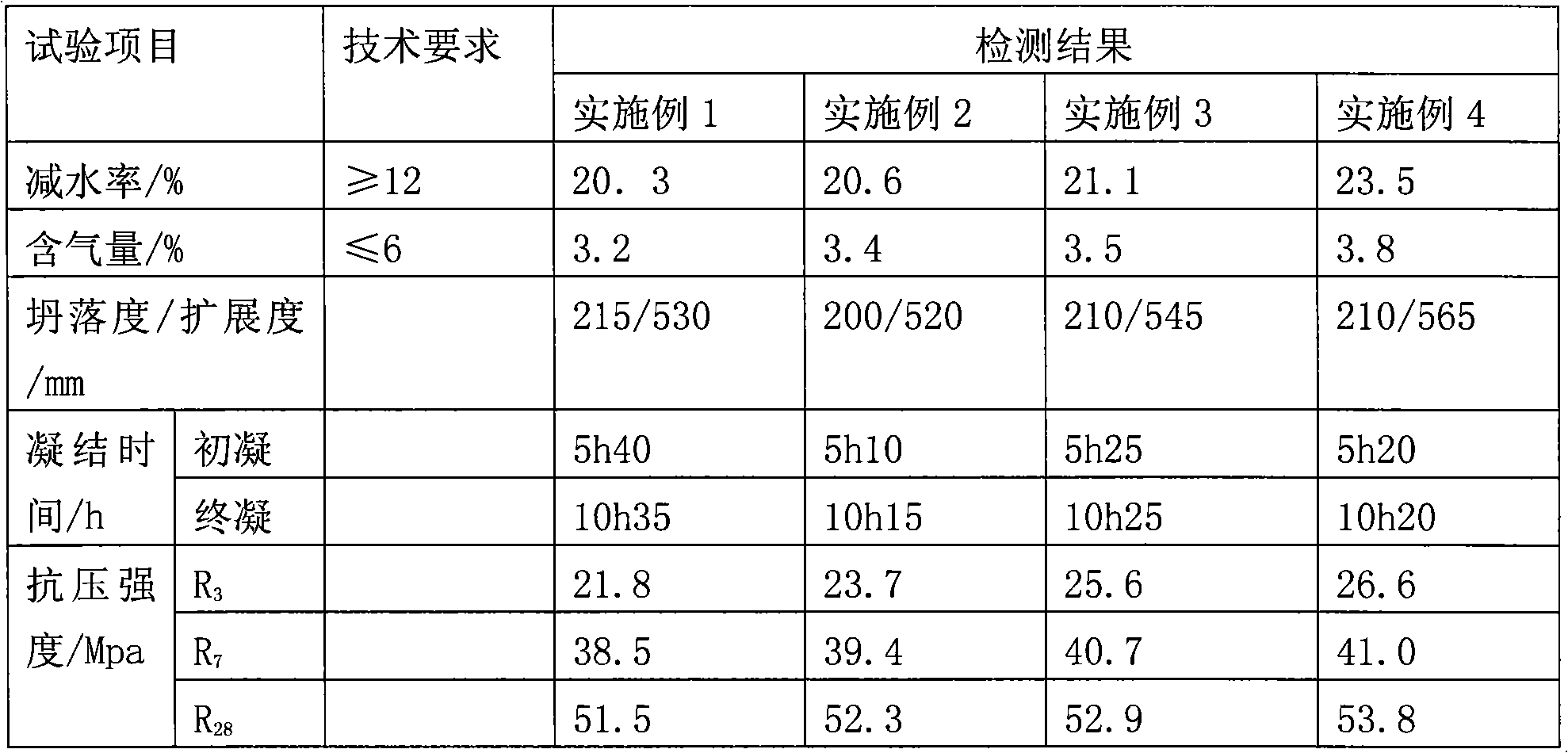

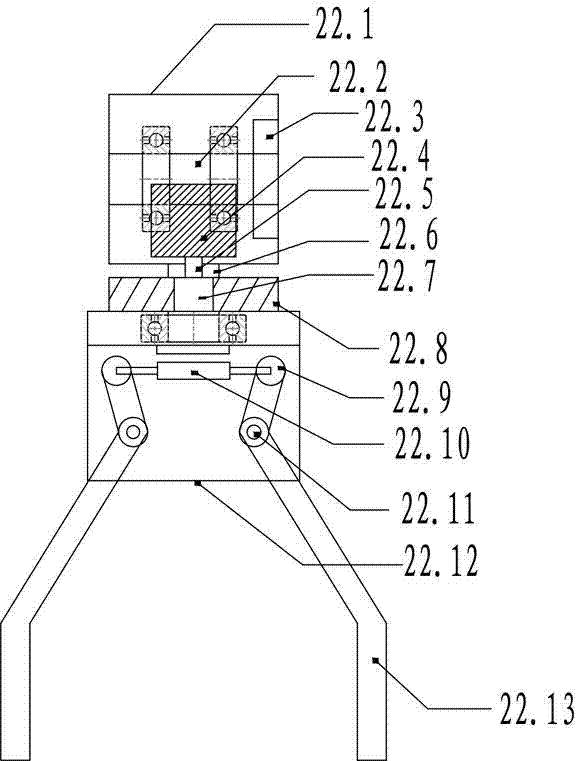

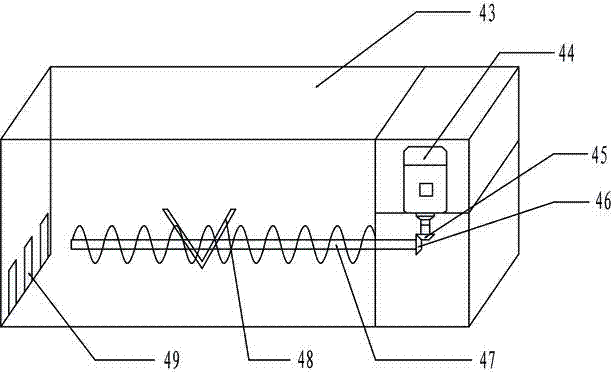

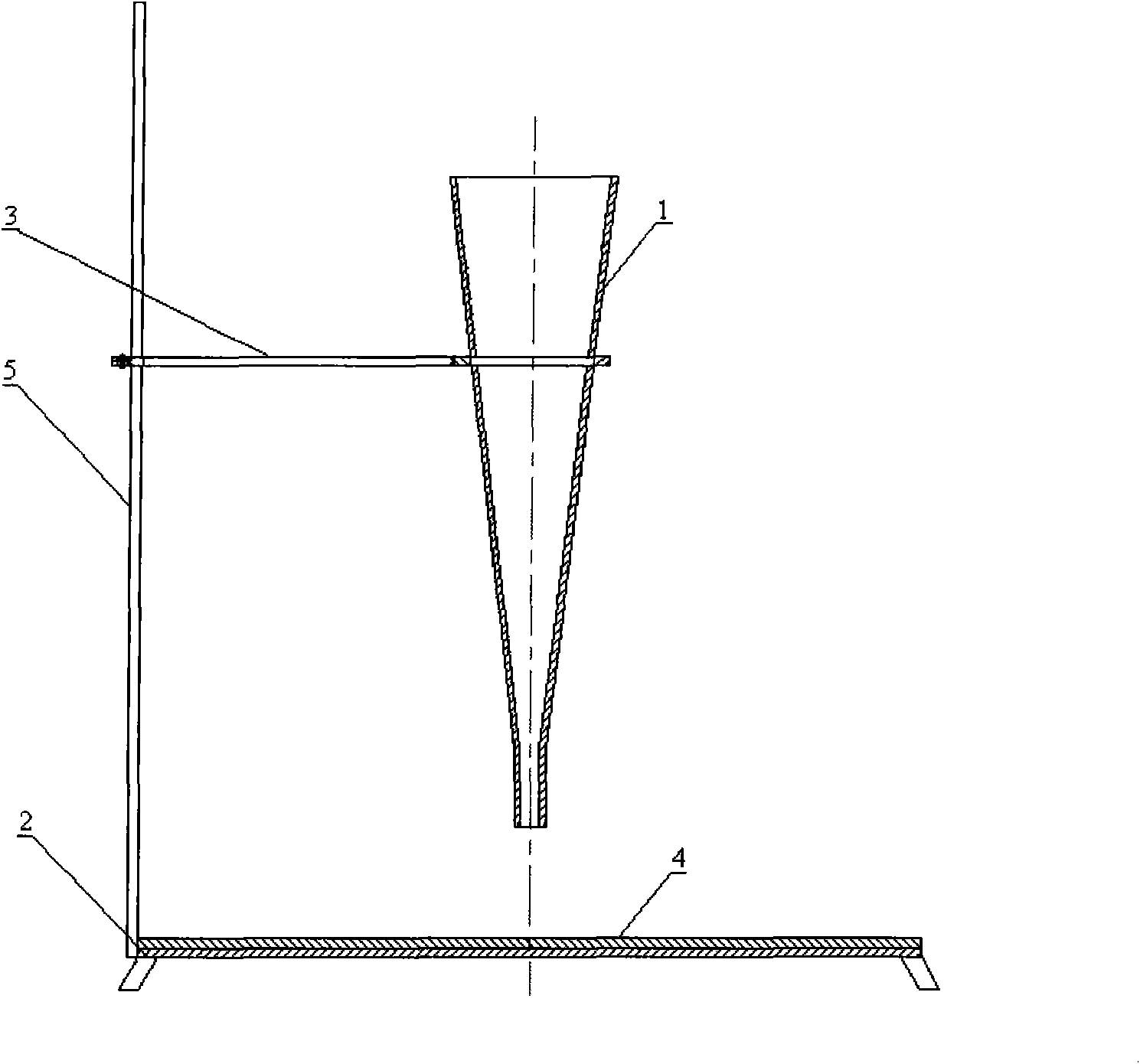

Robot

ActiveCN104493810AAutomate operationsWorkability is goodProgramme-controlled manipulatorBuilding material handlingHydraulic motorArchitectural engineering

The invention discloses a robot. A hollow vertical rod is mounted in a vertical rod sleeve, a lead screw and nuts are mounted in the hollow vertical rod, a gear power motor and a gear mechanism connected with the lower end of the lead screw are mounted in a machine base, a first hydraulic motor inside a big-arm end is connected with a fixed shaft, the lower end of the fixed shaft is fixed on the hollow vertical rod, a second hydraulic motor is arranged inside a transverse swing arm connected with the big-arm end, a rotating arm end is further connected to a first rotating shaft connected with the second hydraulic motor, a longitudinal swing arm is connected to the rotating arm end, a second rotating shaft is connected to a third hydraulic motor inside the rotating arm end, a small-arm end is fixedly connected to the second rotating shaft, and a manipulator device is connected to the small-arm end. The robot has the advantages that the robot meets the requirements on multi-direction and multi-angle composite actions and can complete complex physical labor; when used for building construction, the robot is capable of building a wall, plastering and sticking bricks automatically, so that construction efficiency and quality of bricklaying projects are improved, labor intensity is reduced and construction cost is lowered.

Owner:苗健

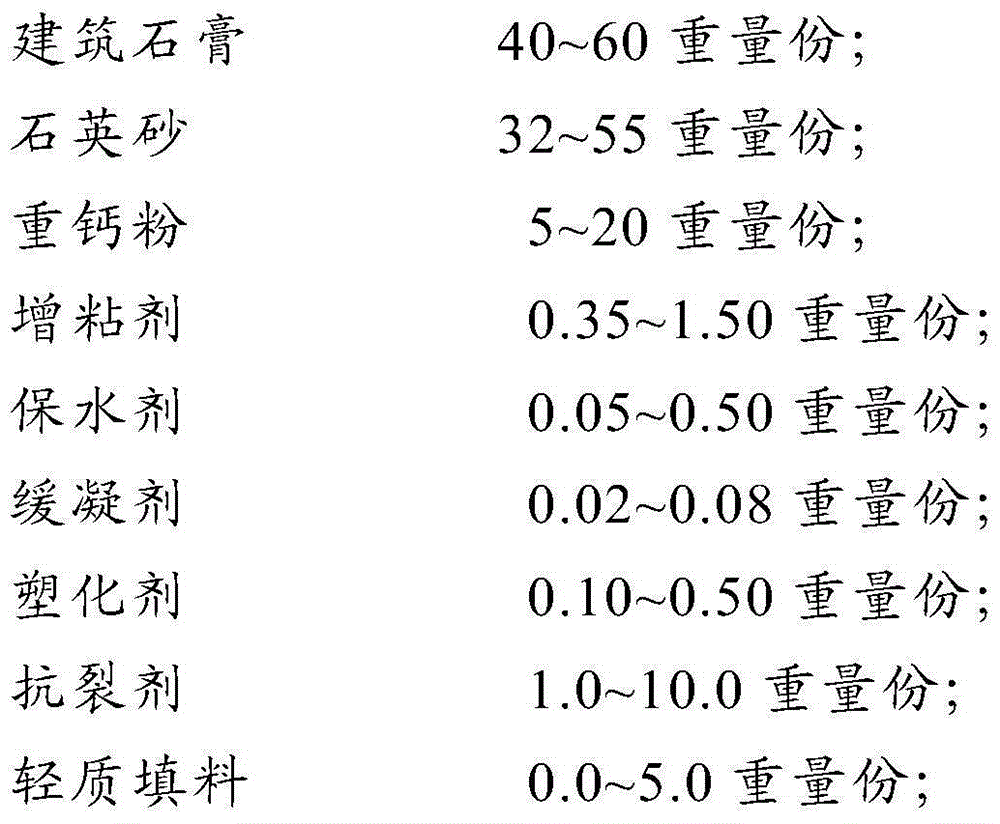

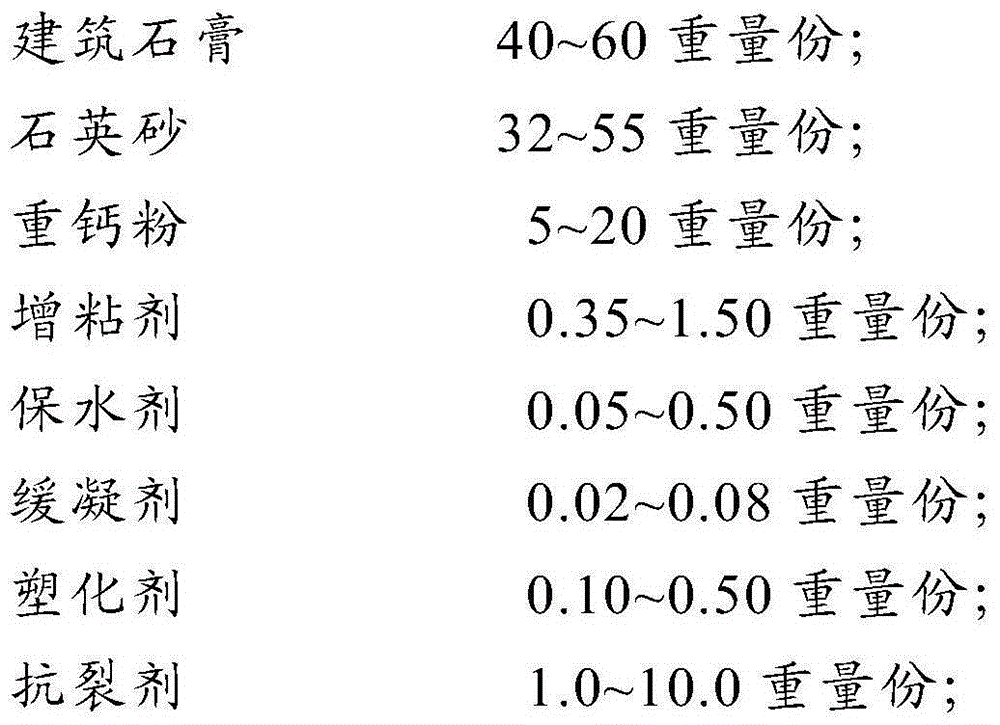

Plastering gypsum and preparation method thereof

The invention provides plastering gypsum which includes, by weight, 40-60 parts of building gypsum, 32-55 parts of quartz sand, 5-20 parts of heavy calcium powder, 0.35-1.50 parts of a tackifier, 0.05-0.50 parts of a water retention agent, 0.02-0.08 parts of a set retarder, 0.10-0.50 parts of a plasticizer, 1.0-10.0 parts of an anti-cracking agent and 0.0-5.0 parts of a light-weight filling material, wherein the anti-cracking agent includes 80-95 wt% of heavy calcium powder and the balanced being aramid fiber. The plastering gypsum is added with the anti-cracking agent, so that the plastering gypsum is improved in anti-crack toughness. In addition, the plastering gypsum is also added with the light-weight filling material, which can dissipate shrinkage stress generated by volume reduction of the plastering gypsum due to moisture volatilization, thereby further ensuring a leveling layer of the plastering gypsum to be free of cracking. The invention also provides a preparation method of the plastering gypsum.

Owner:MEICHAO GROUP

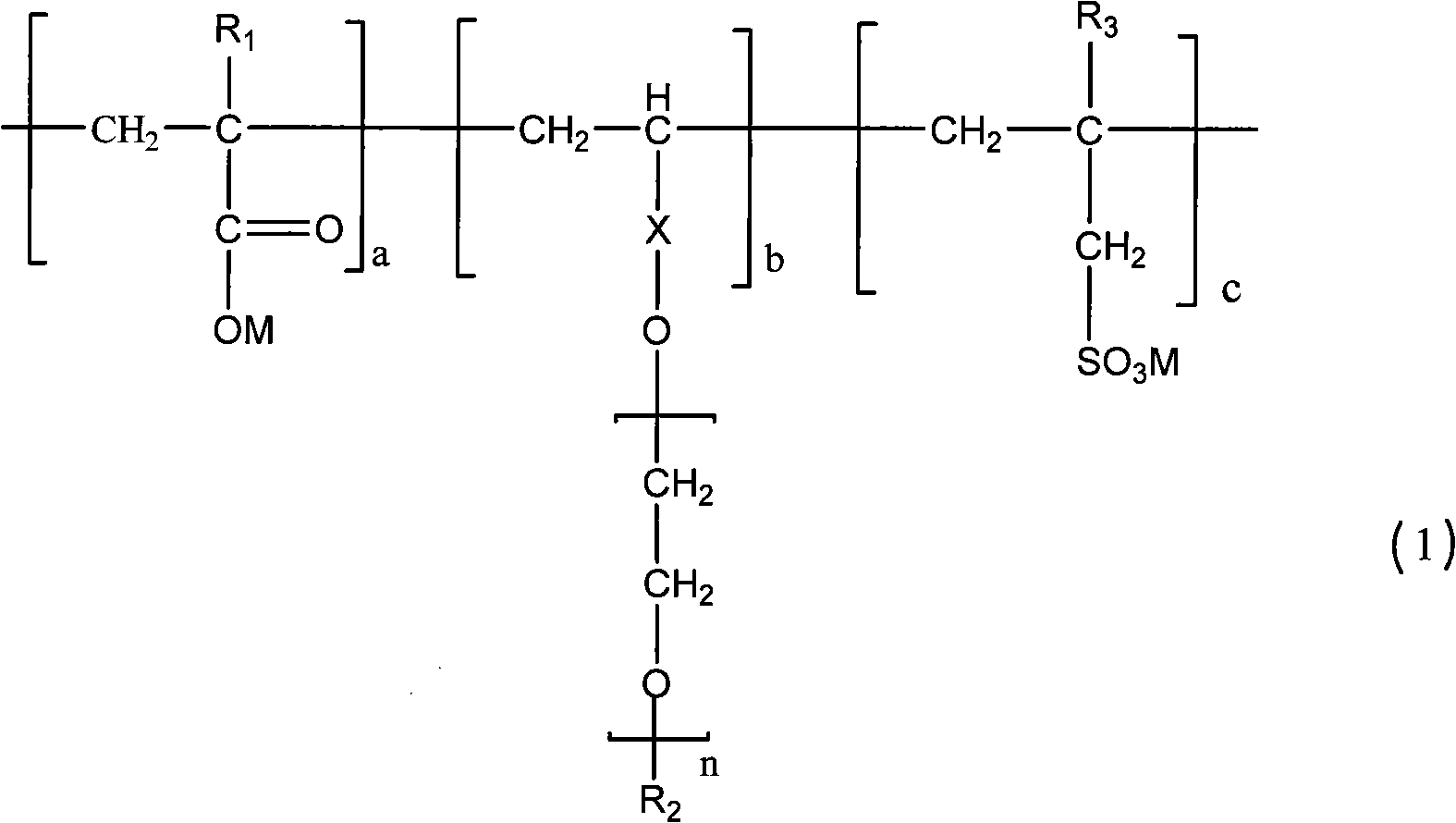

Preparation method of ester early-strength polycarboxylic acid water reducing agent

The invention discloses a preparation method of an ester early-strength polycarboxylic acid water reducing agent. The technical scheme is as follows: the preparation method comprises the following steps: preparing amide small monomer by amidation reaction, preparing esterified big monomer by esterification reaction, and carrying out free radical copolymerization with other unsaturated monomers to obtain the ester early-strength polycarboxylic acid water reducing agent. The product has excellent early-strength property, and can effectively enhance the early strength of the concrete.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Multi-phase combined lightweight aggregate concrete and preparation method thereof

ActiveCN102206096ALow densityImprove toughnessSolid waste managementCeramicwareFiberThermal insulation

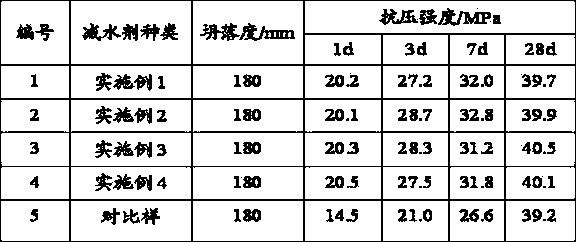

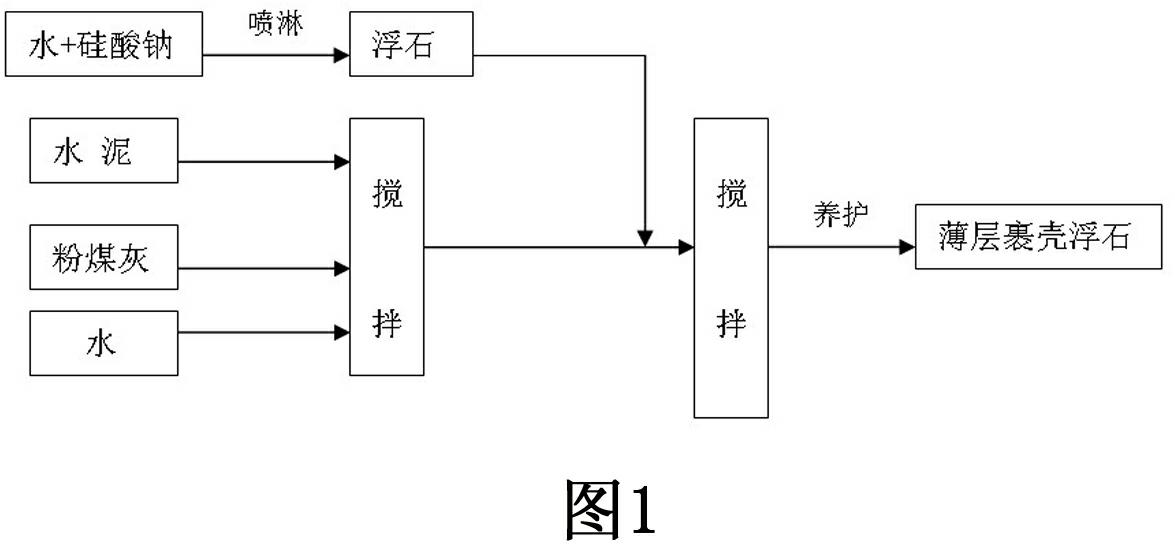

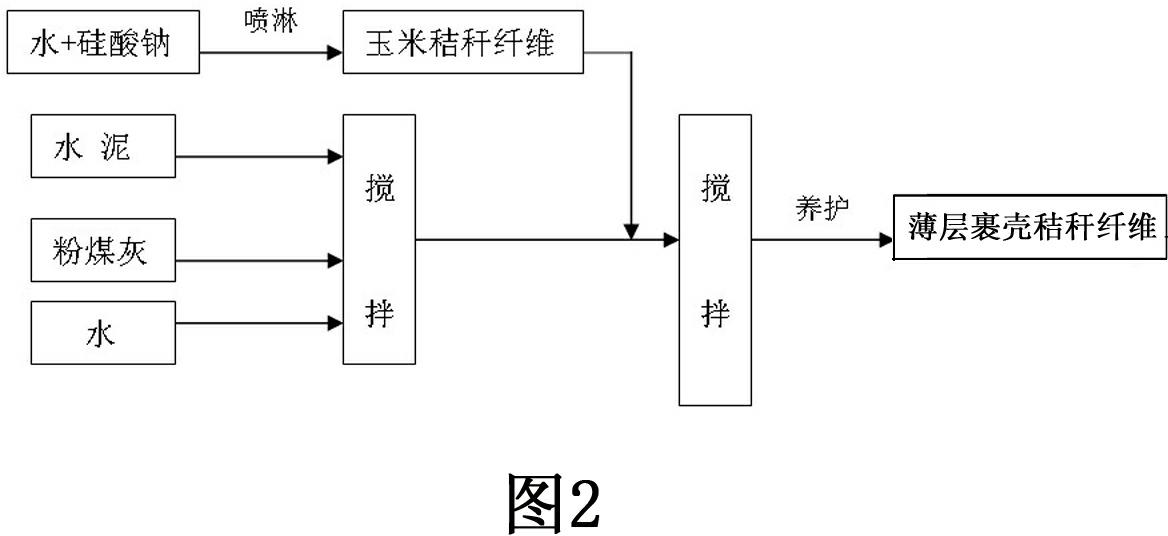

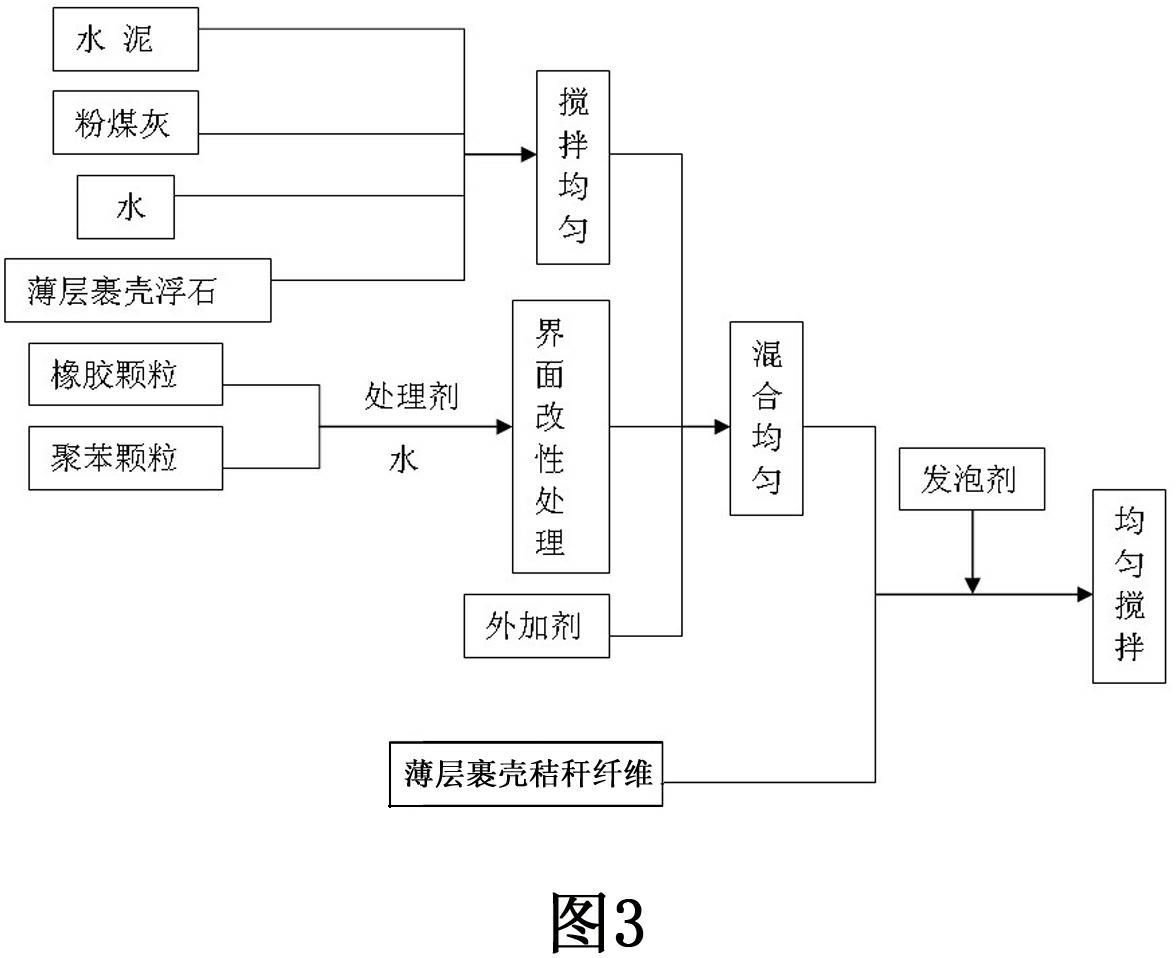

The invention discloses multi-phase combined lightweight aggregate concrete and a preparation method thereof. The multi-phase combined lightweight aggregate concrete is prepared from the following raw materials in part by weight: 1 part of cement, 0.40 to 0.50 part of fly ash, 1.836 to 2.219 parts of pumice sand, 0.028 to 0.043 part of corn straw fibers, 0.006 to 0.008 part of polyphenyl particles, 0.23 to 0.33 parts of rubber particles, 0.010 to 0.015 part of additive, 0.005 to 0.007 part of foaming agent, and 0.50 to 0.55 parts of water. The preparation method comprises the following steps:1, preparing thin-coating pumice sand and thin-coating straw fibers; 2, performing interference treatment of polyphenyl particles and rubber particles; 3, uniformly stirring the cement, fly ash, water, additive and thin-coating pumice sand; and 4, adding the polyphenyl particles, rubber particles and thin-coating straw fibers in turn, and continuing to stir. When the method is used, the mechanical performance of the lightweight aggregate concrete can be improved effectively, the thermal-insulation and heat-preservation performance is enhanced, and production cost is lowered.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

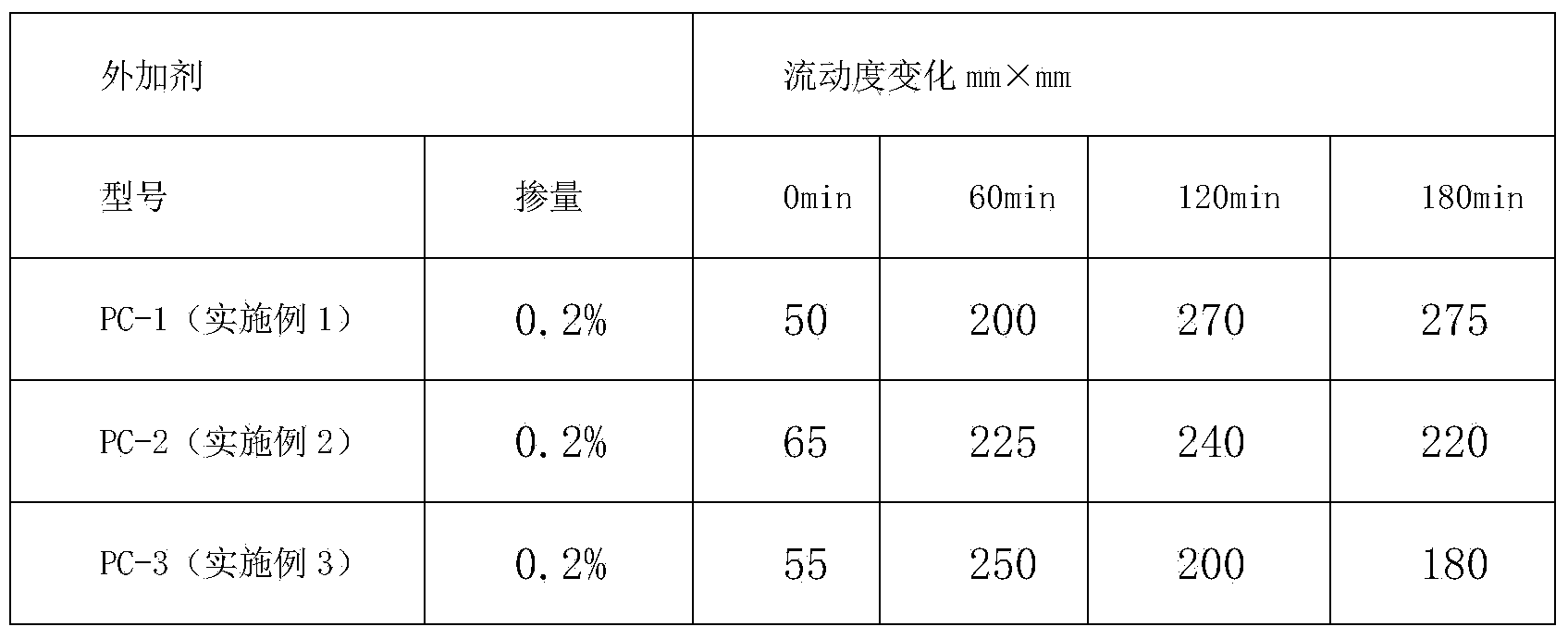

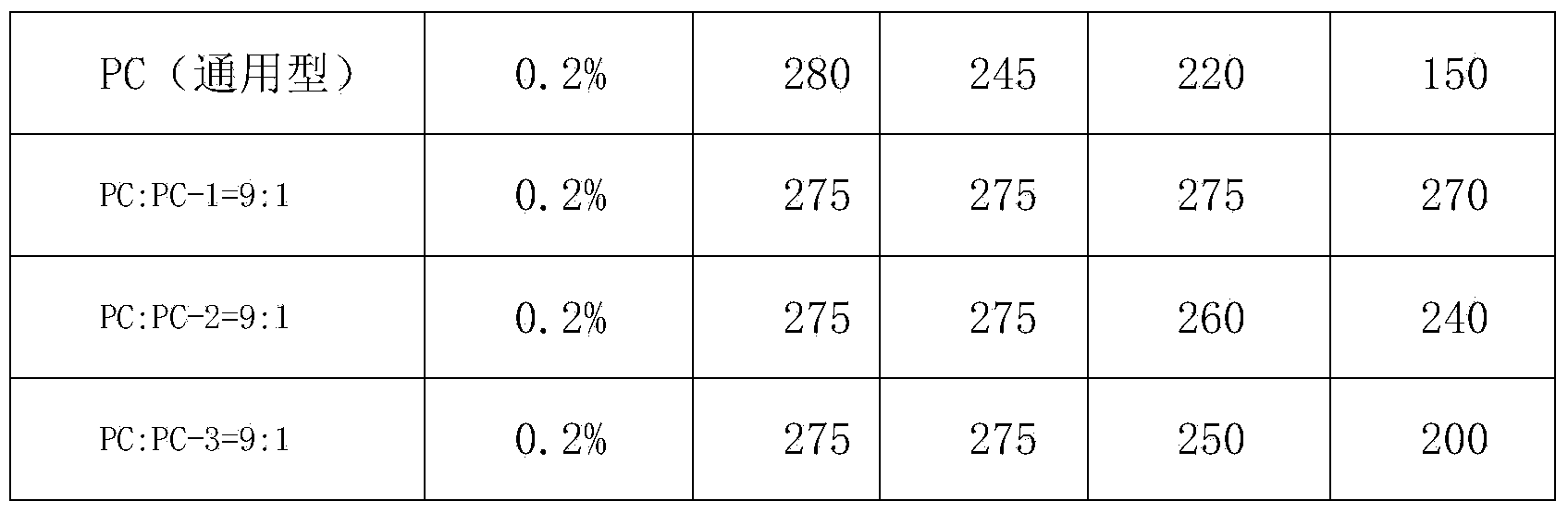

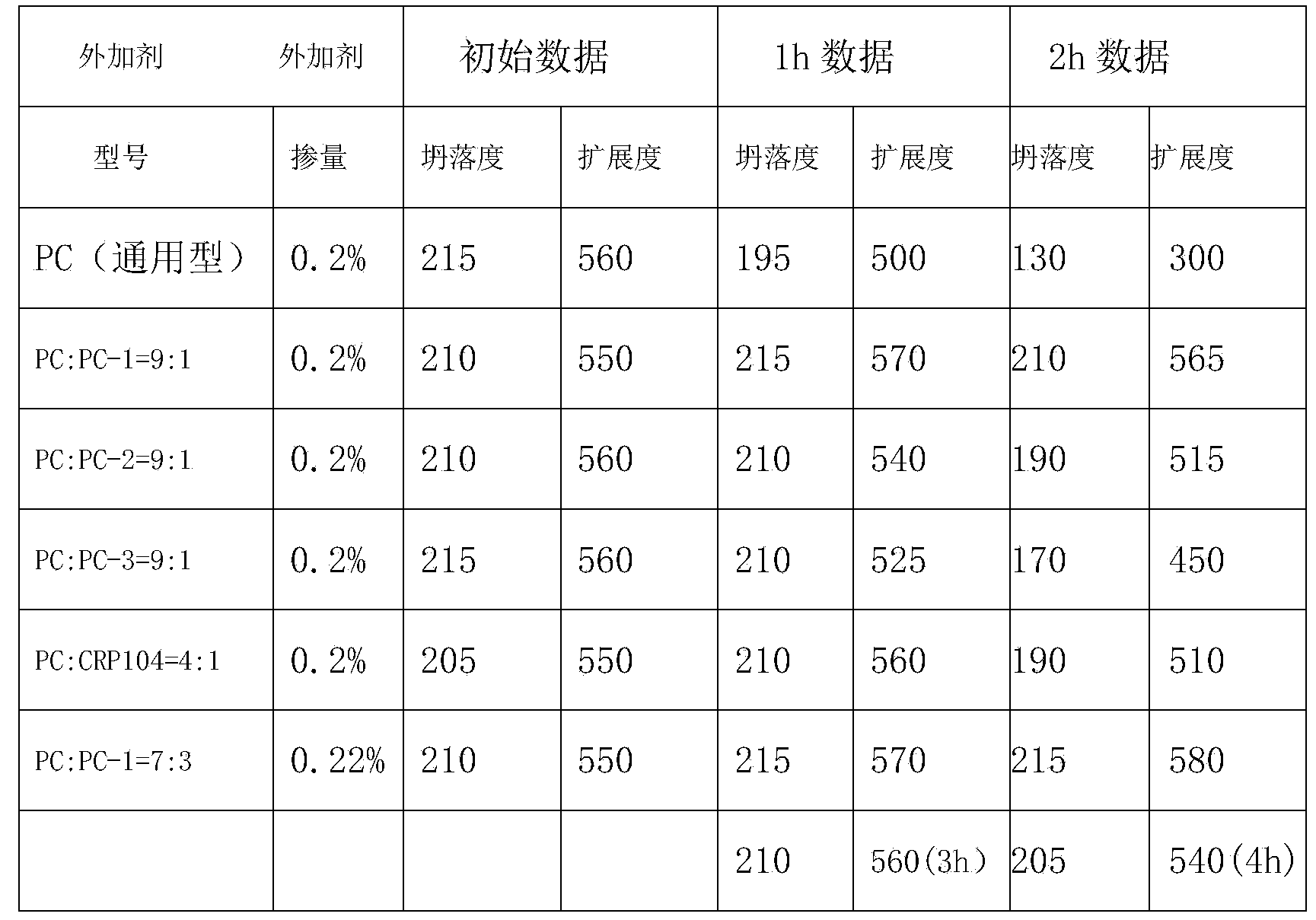

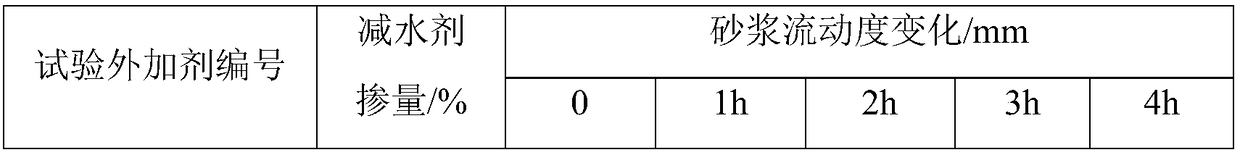

Super controlled release type polycarboxylate slump retention agent and preparation method thereof

The invention discloses a super controlled release type polycarboxylate slump retention agent and a preparation method thereof. The preparation method of the polycarboxylate slump retention agent comprises the following steps: carrying out free radical polymerization on a monomer A, namely polyoxyethylene ether (TPEG), a monomer B, namely maleic anhydride or polyethylene glycol maleic acid esters, a monomer C, namely acrylic acid, a monomer D, namely hydroxyalkyl acrylate or vinyl acetate, an initiator, a chain transfer agent and water, adding an alkaline liquor to neutralize the mixture, wherein a molar ratio of the monomer A to the monomer B to the monomer C to the monomer D is 1 to (1.0-2.5) to (1.0-2.5) to (2.0-4); the dosage of the initiator accounts for 1%-8% of the total mole number of the monomer A, the monomer B, the monomer C and the monomer D; the dosage of the chain transfer agent is 1%-3% of the total mole number of the monomer A, the monomer B, the monomer C and the monomer D. The super controlled release type polycarboxylate slump retention agent disclosed by the invention is in a liquid state, has solid content of 50%, and has performances of low alkaline content, a low water-reducing rate and excellent slump retention performance. Besides, the production process is simple, the reaction conditions are easy to control, and the environmental pollution is avoided.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH +1

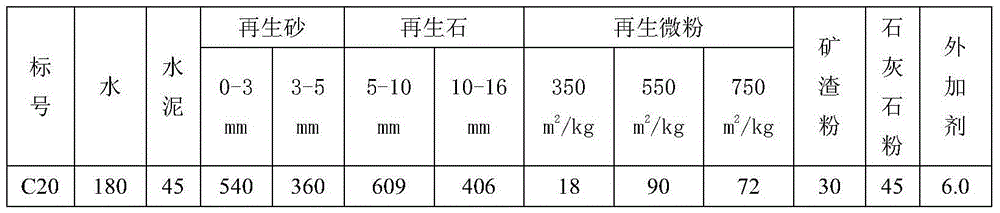

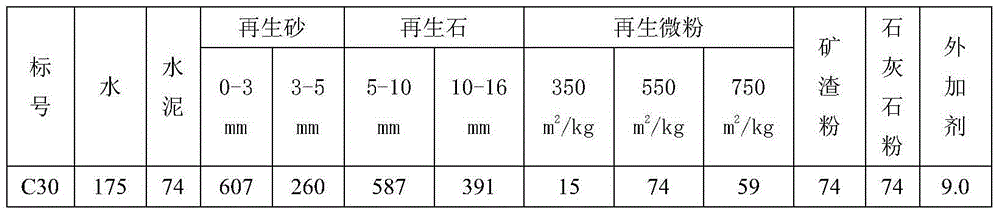

Recycled green concrete with low cement content and preparation method thereof

ActiveCN103553395AOvercoming small dosageOvercoming the drawbacks of high cement contentSolid waste managementSlagNatural sand

The invention relates to recycled green concrete with low cement content. The recycled green concrete is the concrete prepared through reclaimed sand and recycled stone instead of natural sand and stone, and recycled micro powder, slag and limestone powder instead of most of the cement, wherein the reclaimed sand and recycled stone are obtained by treating construction wastes taking waste concrete as major by cleaning, crushing, grading and mixing in a certain proportion.

Owner:北京联绿技术集团有限公司

Highly adaptive ultralong-slow release slump-retaining agent and normal and low temperature preparation method thereof

The invention discloses a highly adaptive ultralong-slow release slump-retaining agent and a normal and low temperature preparation method thereof. Mainly, polyether macromonomer, unsaturated carboxylic acid monomer, unsaturated carboxylic ester monomer, unsaturated phosphate ester monomer, unsaturated amide monomer, oxidant, reducing agent, chain transfer agent and deionized water carry out freeradical polymerization by aqueous solution at the temperature of 5-25 DEG C, after sodium hydroxide solution is then added to regulate pH value, water is then replenished, and thereby the slump-retaining agent is prepared. The preparation method does not need a heat source, reaction is carried out under normal and low temperatures, equipment is simple, the operability is high, the production efficiency is high, the prepared slump-retaining agent has ultralong slow release capability, slump can be retained for a long time, the adaptability is high, and the performance is excellent.

Owner:SICHUAN TONGZHOU CHEM TECH

Foaming concrete for foam agent

The invention discloses a foaming agent for foam concrete. The foaming agent is prepared by uniformly mixing and stirring the following raw materials at room temperature, by weight : 5-10 parts of sodium dodecyl benzene sulfonate, 2-4 parts of sodium alcohol ether sulphate, 1-2 parts of sodium lauroyl sarcosinate, 1-2 parts of cocamidopropyl betaine, 0.2-0.6 part of polyethylene glycol (120) methyl glucoside dioleate, 0.3-0.5 part of triethanolamine, 0.5-1 part of polyacrylamide, 1-2 parts of hydroxyethyl cellulose, and 60-70 parts of water. The invention has advantages of easily available raw materials, low cost and simple preparation process; and the produced foaming agent has advantages of good stability, no deterioration, easiness for long-term preservation, prolonged shelf-life, good foaming power, good peaceability with various foam concrete substrates, no defoaming and unrestricted range of usage.

Owner:安徽艾柯泡塑股份有限公司

Foaming agent used in ultra-low density anti-seepage foamed concrete, and preparation method thereof

The invention relates to a foaming agent used in ultra-low density anti-seepage foamed concrete, and a preparation method thereof. The foaming agent comprises components of, by mass: 8 to 18 parts of sodium polyoxyethylene fatty alcohol sulfate, 0.1 to 7 parts of sodium dodecylsulfate, 0.5 to 7 parts of sodium dodecylbenzene sulfonate, 4 to 15 parts of pure acrylic emulsion or styrene-acrylate emulsion, 3 to 6 parts of fatty alcohol polyoxyethylene ether, 0.5 to 2 parts of hydroxyethyl cellulose or hydroxy propyl methylcellulose, 0.1 to 5 parts of modified silicon resin or modified nano-gradebentonite, 0.1 to 0.5 parts of a thickener, and balance of water. The anti-seepage foamed concrete foaming agent provided by the invention has stable property, high foaming multiple, and good workability with a substrate. The agent can be used in a foamed concrete product with a density of 100 to 600kg / m<3>. The raw materials are easy to obtain, and the cost is low. The foaming agent can be stored for a long term with out deteriorating. With the agent, foamed concrete properties such as strength and softening coefficient can be improved.

Owner:梁材

Industrial waste residue dry-mixed mortar

The invention discloses an industrial waste residue dry-mixed mortar. The industrial waste residue dry-mixed mortar takes cement, phosphorus slag powder, fly ash, composite activators, composite additives and sand as raw materials and is prepared after all the raw materials are mixed evenly. The industrial waste residue dry-mixed mortar comprises, by weight, 18-22 parts of cement, 35-45 parts of phosphorus slag powder, 35-45 parts of fly ash, 0-20 parts of composite activators, 0.1-7.5 parts of composite additives and 65-85 parts of sand. The industrial waste residue dry-mixed mortar can take a large number of phosphorus slag and fly ash as raw materials and is advantaged by low production cost, low energy consumption, less pollution, good workability, good mechanical properties, good durability, reliable quality and wide adaptability.

Owner:GUIZHOU UNIV

Light masonry mortar with heat insulation and preservation

InactiveCN101643349AImprove insulation effectAvoid "Cold Bridge" PhenomenonSolid waste managementFiberSlag

The invention discloses a light masonry mortar with heat insulation and preservation, comprising the following components by weight percent: 20 percent to 65 percent of portland cement, 5 percent to 50 percent of fly ashes, 0 percent to 50 percent of furnace bottom slag, 0 percent to 55 percent of slag, 10 percent to 23 percent of vitrified microspheres, 0.1 percent to 1.0 percent of water retention and thickening materials, 0.1 percent to 0.5 percent of lignocellulose and 0.1 percent to 1.0 percent of water reducing agent. The mortar has the dry density of 750 to 1000 kg / m<3>, the thermal conductivity of 0.15 to 0.20 w / m k, the lowest compressive strength of 5 Mpa and the liner shrinkage rate of less than 0.1 percent, satisfies the requirements of heat insulation and preservation of an energy-saving building, has the advantages of favorable heat insulation and preservation performance, favorable water retention, favorable workability, high adhesion strength of a wall body, simple construction, energy saving, environmental protection and the like, completely avoids the occurrence of the phenomenon of cold bridge, and efficiently prevents dry-shrinkage cracking and the phenomenon ofmoisture absorption of the wall surface.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Multi-strength regeneration brick aggregate fiber concrete and preparing method thereof

The invention relates to multi-strength regeneration brick aggregate fiber concrete and a preparing method thereof. The multi-strength regeneration brick aggregate fiber concrete is prepared from cement, fine aggregate, natural coarse aggregate, regeneration brick coarse aggregate, polyolefin fiber, steel fiber and water according to the weight ratio of 1: (0.780-1.309) : (0-1.830) : (0.390-1.568) : (0-0.019) : (0-0.161) : (0.33-0.48). The regeneration brick aggregate fiber concrete with the target strength grade of CF30-CF50 can be prepared by means of the raw materials, strength grade is high, and application range is wide. The obtained regeneration brick aggregate fiber concrete has high working performance including peaceability and water-retaining property, compressive strength and splitting-tension strength are high, the preparing process is simple and environmentally friendly, and construction is easy.

Owner:ZHENGZHOU UNIV

Low-creep C60 high-performance concrete

InactiveCN101891426AReduce usageImprove economySolid waste managementPortland cementSuperplasticizer

The invention discloses a low-creep C60 high-performance concrete material. Economic and reasonable 42.5 normal portland cement or portland cement is selected, and technologies of mixing grade I fly ash and grade S95 mineral powder, adding a polycarboxylic acid superplasticizer, and the like are adopted, thereby optimizing the proportioning of concrete, ensuring the economy and good placeability and mechanical property of concrete with low water to binder ratio, avoiding concrete cracking caused by low water to binder ratio, ensuring high durability of the concrete, effectively reducing the creep of concrete, reducing the prestressing loss, and ensuring the safety of the concrete structure.

Owner:CHINA RAILWAY HI TECH IND CORP LTD +1

Preparation method of polycarboxylic acid water reducer with high workability

The invention discloses a preparation method of a polycarboxylic acid water reducer with high workability. The preparation method comprises the following steps: mixing acrylic acid with active monomers with high workability, adding an oxidant and co-initiator into the mixture, dropwise adding a mixed solution of unsaturated monomers, chain transferring agent, reducing agent, and water at a low temperature; carrying out reactions to obtain segmented copolymer (intermediate), finally adding methoxy polyethylene glycol and a catalyst to carry out esterification and grafting, and finally neutralizing the products. Through molecular structure design, active monomers with good workability are introduced into polycarboxylic acid water reducer; low temperature polymerization is performed at first, then high temperature esterification is carried out, damage rate of double bonds can be reduced, copolymerization degree is high, and the produced water reducer has good workability and high water reducing rate. The industrial production technology is simple, the production period is largely reduced, and production process is green, environment-friendly, and pollution-free.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Desulfurized-gypsum-base lightweight spraying gypsum mortar

Disclosed desulfurized-gypsum-base lightweight spraying gypsum mortar is composed of the following compositions in parts by weight: 50-65 parts of desulfurized gypsum, 20-30 parts of building sand, 3-5 parts of vitrified microsphere, 10-20 parts of stone powder, 0.1-0.5 part of a retarder, 0.1-0.3 part of cellulose ether, 0.02-0.04 part of an air-entraining agent, and 0.05-0.1 part of starch ether. The desulfurized-gypsum-base lightweight spraying gypsum mortar employs mechanical spraying for construction, possesses the dry density less than 1000 Kg / m<3>, the heat-conduction coefficient of 0.20 W / (m*K) and the compressive strength lager than 4.0 MPa, and possesses the characteristics of being light in weight, low in heat-conduction coefficient, high in strength and suitable for mechanical spraying construction, and the like.

Owner:JIANGSU NIGAO SCI & TECH +1

Plastic stabilizer for wet-mixed mortar

InactiveCN104556812AImprove performanceShorten the setting timeWater soluble polysaccharidesProcess engineering

The invention discloses a plastic stabilizer for wet-mixed mortar. The plastic stabilizer comprises the following components in parts by weight: 0.1-5 parts of a water retention agent, 0.1-5 parts of an air entraining agent, 0.1-1 part of a defoaming agent, 0.01-1 part of water soluble polysaccharide, 1-10 parts of a special effect retarder, 1-10 parts of a water reducing agent and 68-98 parts of water. The plastic stabilizer for the wet-mixed mortar, provided by the invention, is liquid, is beneficial for automatic feeding and metering, and overcomes the defects that most mortar additives on the market are solid powder products and cannot realize automatic metering. Meanwhile, the water retention rate of the plastic stabilizer for the wet-mixed mortar, provided by the invention, can reach 98%, so that the setting time of the mortar can be deferred to 10-72 hours.

Owner:JIANGSU ZHONGKAI NEW MATERIALS

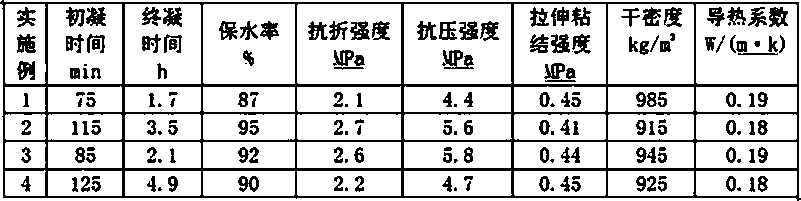

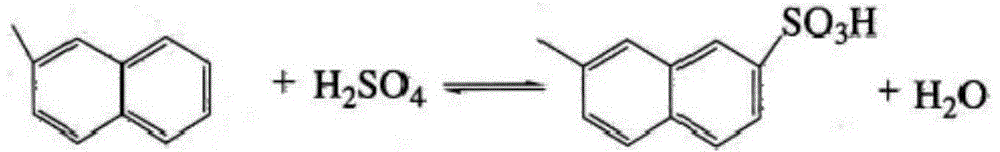

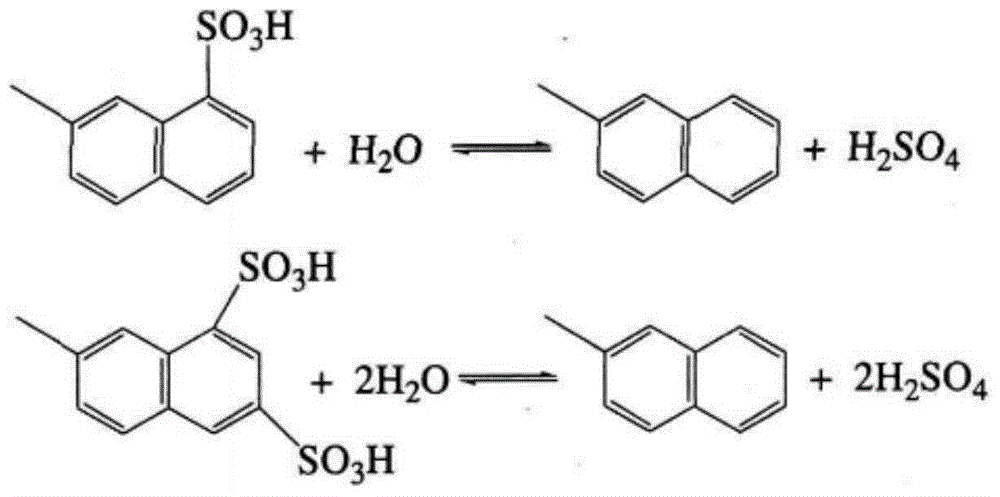

Preparation method of naphthalene-series water reducing agent

ActiveCN105236798ASolve the defect of poor plastic retention performanceHigh densityMethyl groupPhenol

The invention relates to a preparation method of a naphthalene-series water reducing agent. The method comprises the following steps: (1) methylnaphthalene and phenol are separately sulfonated, such that a sulfonated methylnaphthalene material and a p-hydroxybenzenesulfonic acid material are obtained; (2) the sulfonated methylnaphthalene material is subjected to a hydrolysis reaction; un-reacted methylnaphthalene or homologs thereof are removed through zeotropy; the rest of the sulfonated methylnaphthalene material enters a reaction in the step (3); (3) the sulfonated methylnaphthalene material obtained in the step (2) and the p-hydroxybenzenesulfonic acid material obtained in the step (1) are subjected to a condensation reaction with formaldehyde acidified with concentrated sulfuric acid, such that a condensed material is obtained; and (4) alkali liquid is added into the condensed material obtained in the step (3), such that a neutralization reaction is carried out, until the pH value is 7.5-9; and the naphthalene-series water reducing agent is obtained when the reaction is finished. The naphthalene-series water reducing agent provided by the invention has the excellent performances of good adaptability to cement, good concrete workability, high plasticity-maintaining performance, low concrete gradual loss, high water reducing rate, and the like. The preparation method has the advantages of simple process and easy-to-control reaction conditions. With the method, naphthalene-series water reducing agent production cost can be reduced.

Owner:ZHEJIANG JISHENG CHEM BUILDING MATERIALS

Beta-naphthol produced waste liquid modified amido sulfoacid series high-efficiency water reducer and preparation method thereof

The invention relates to a beta-naphthol produced waste liquid modified amido sulfoacid series high-efficiency water reducer and a preparation method thereof, wherein the preparation method comprises the following preparation steps of: a. sulfonation reaction: firstly adding a beta-naphthol produced waste liquid into a reaction kettle, heating to the temperature of 105-110 DEG C, dropwise adding concentrated sulfuric acid for 15-30 minutes and preserving heat for 1.5-2.5 hours to obtain naphthol sulfonate; b. polycondensation reaction: heating water to the temperature of 65-75 DEG C, adding sodium p-aminobenzenesulfonate, a phenol compound and a pH value regulator which accounts for about three fourths of the gross amount into the reaction kettle and increasing the temperature to 80-90 DEG C while stirring; dropwise adding formaldehyde for 10-30 minutes, keeping the temperature at 85-95 DEG C and preserving heat for 2-5 hours; and adding the residual pH value regulator and the naphthol sulfonate obtained in step a, reacting at the temperature of 85-95 DEG C for 1.5-2.5 hours, then reducing the temperature and discharging to prepare a liquid product. When the doped amount of the prepared modified amido sulphate high-efficiency water reducer is 0.3-0.8 percent (calculated by solids) of the mass of a cementing material, the corresponding water reducing rate is 16-24 percent.

Owner:NANJING RUIDI HIGH TECH

Thermal insulation material and its preparing process and usage

The invention discloses a thermal insulating material which is prepared from the following raw materials: construction gypsum 75-79 parts, thickening agent 1.9-2.3 parts, rubber powder 1.7-2.0 parts, water-loss reducer 0.4-0.5 part, gypsum retarder 0.3-0.5 part, reinforcing agent 0.5-0.7 part, filler 16-19.5 parts, vitreous beads 49-51 parts through a step of blending.

Owner:SHANGHAI KENAI NEW MATERIAL TECH CO LTD

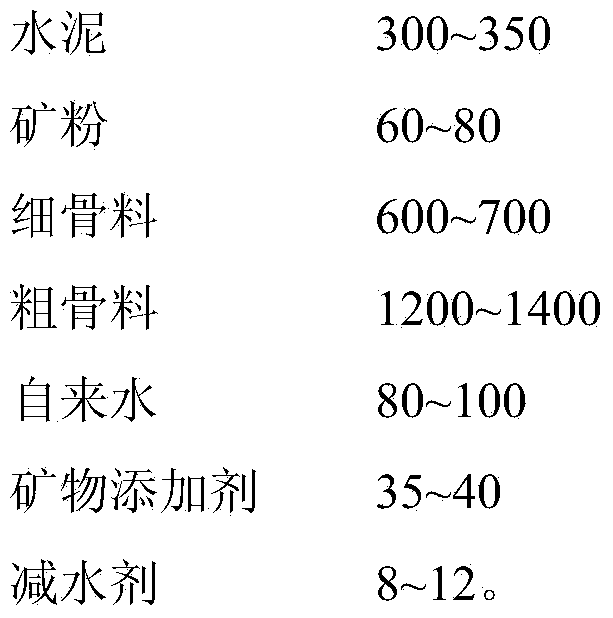

Production method of non-residual slurry non-autoclaved prestressed concrete pipe pile

ActiveCN103434020AReduce pollutionReduce energy consumptionShaping reinforcementsLow speedPre stress

The invention relates to a production method of a non-residual slurry non-autoclaved prestressed concrete pipe pile. The production method comprises the following steps: (1) sequentially adding fine aggregate, coarse aggregate, cement, mineral powder, a mineral additive, water and a water reducing agent into a reaction kettle, and evenly stirring to obtain a concrete mixture; (2) prestressed tensioning the concrete mixture after material distribution and die assembling; (3) centrifuging the concrete mixture after prestressed tensioning, and sequentially carrying out low speed, low medium speed, medium speed and high speed centrifugation steps in centrifugation without producing residual slurry in the centrifugation process; (4) placing the centrifuged concrete mixture into a steam maintenance pool for steam maintenance. According to the production method, after multiple experiments, through contrastive analysis, the nanoscale mineral additive is added, and by matching with the compound high-performance water reducing agent and adjusting existing pipe pile centrifugation and steam maintenance steps, the non-residual slurry centrifugation and one-time demoulding strength of C80 are realized, so that the working procedures of pouring residual slurry and steam maintenance are eliminated, and the environmental pollution and energy consumption of enterprises are greatly reduced.

Owner:TIANJIN YONGSHENG XINHE PILE

Ether type polycarboxylic acid concrete water reducer containing chitosan and preparation method thereof

The invention provides an ether type polycarboxylic acid concrete water reducer containing chitosan and a preparation method thereof. The concrete water reducer is a polymerization product, and is obtained by a polymerization reaction of the following components in percentage by mass: 0.02-12.6% of chitosan, 3-65% of a polyoxyalkylene based ether type unsaturated macromonomer, 1-40% of unsaturated carboxylic acid and / or unsaturated acid anhydride, 0.02-8% of an unsaturated carboxylic acid derivative and / or unsaturated ether, and 25-95% of water. The ether type polycarboxylic acid concrete water reducer provided by the invention has a simple synthetic process and a relatively low production cost; and the obtained water reducer not only has a high water reducing rate but also can obviously improve phenomena of easy segregation and easy bleeding of concrete to obviously improve workability and fluidity of concrete, and has a very significant effect of improving the long-term strength of concrete.

Owner:HUAQIAO UNIVERSITY

Cold-mixing repairing material SBS pitch liquid for pit or slot of pitch road surface, and its producing technology

InactiveCN1640939ATo overcome the construction affected by the climate environmentOvercoming many factors such as construction affected by climate and environmentIn situ pavingsBuilding insulationsGasolineRepair material

The present invention discloses SBS pitch fluid for repairing road pits and holes after cold mixing and its production process. The SBS pitch fluid has the material comprising diesel oil 7-10 wt%, glycol 4-5 wt%, gasoline 8-10 wt%, SBS 6-8 wt%, antiager 5-10 wt% and stripping resisting agent 0.3-0.4 wt% except pitch. The production process of the SBS pitch fluid is also disclosed. The SBS pitch fluid is liquid at normal temperature and low temperature and may be mixed directly before being used, so that it may be used conveniently all the year round without environmental pollution caused by heating pitch.

Owner:张坚

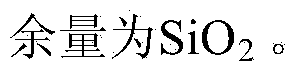

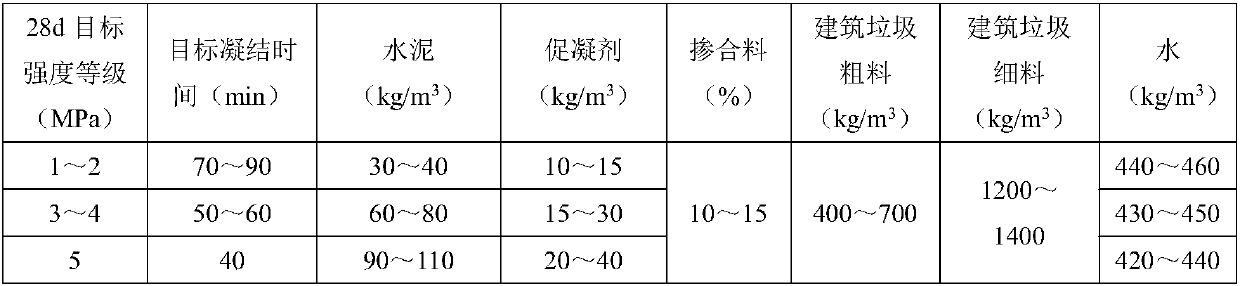

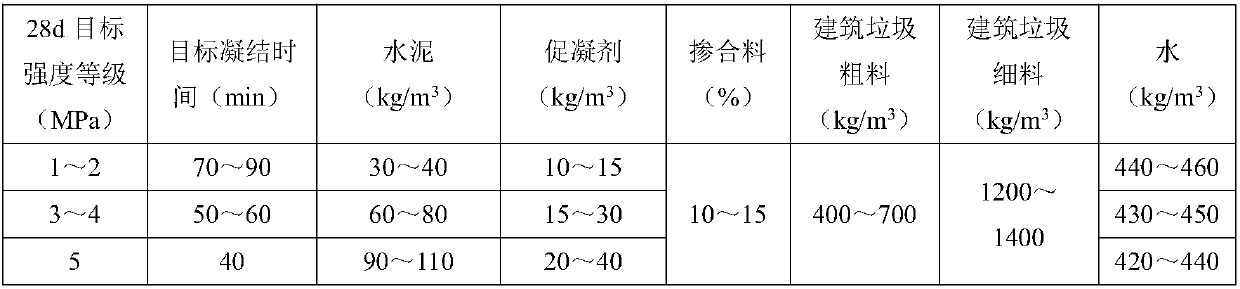

Road pipe trench quick backfill material produced with building wastes and construction technology thereof

The invention discloses a road pipe trench quick backfill material produced with building wastes and a construction technology thereof. The backfill material is prepared by mixing a building waste renewable coarse material, a building waste renewable fine material, cement, sprayed concrete coagulator shrinkage reducing agent, admixture and water. Building waste renewable products are classified and managed strictly in specification and quality, and are treated with other engineering technologies, so that the material fully utilizes building waste renewable aggregates of various specifications,and meets the technological requirements of pipe trench backfill and requirement of quick setting and hardening at the same time; the hardened material is adjusted in mechanical strength according toengineering need, 2h strength adjustment range is 0.2-1.0MPa, and 28d strength adjustment range is 1.0MPa-6.0MPa. The material utilizes building waste renewable materials generated in city construction to the maximum degree and is quick hardening, early strengthening low-strength concrete suitable for backfilling of city road pipe trenches and grooving.

Owner:BEIJING UNIV OF TECH

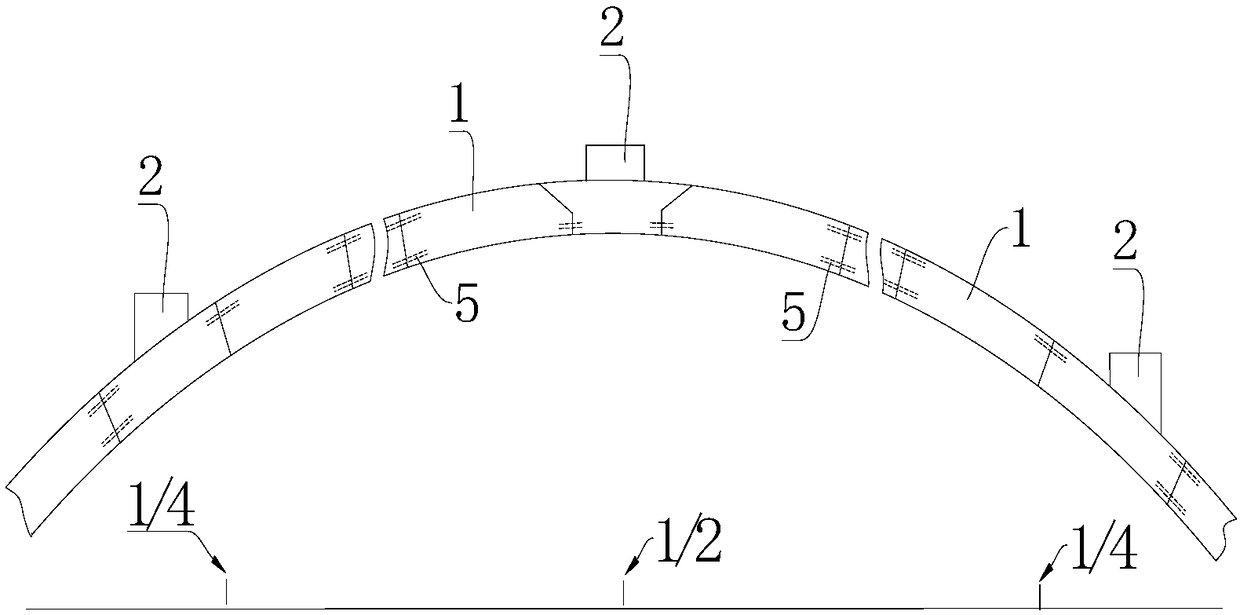

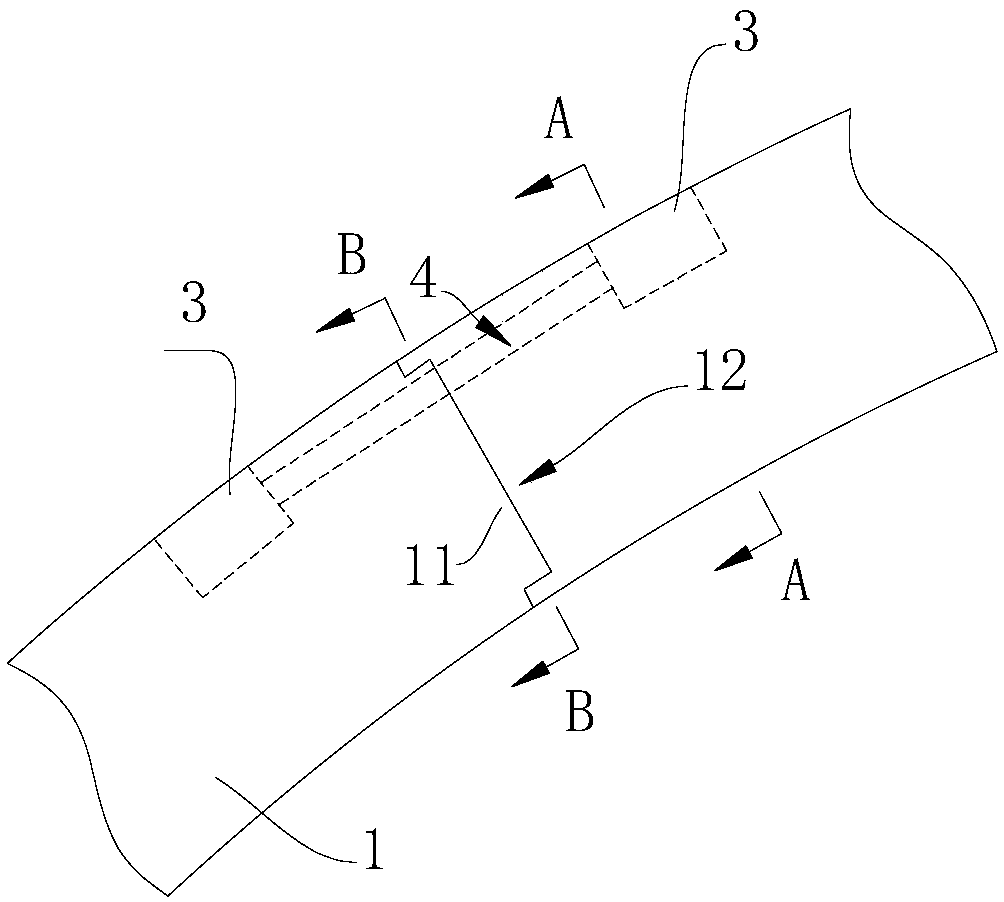

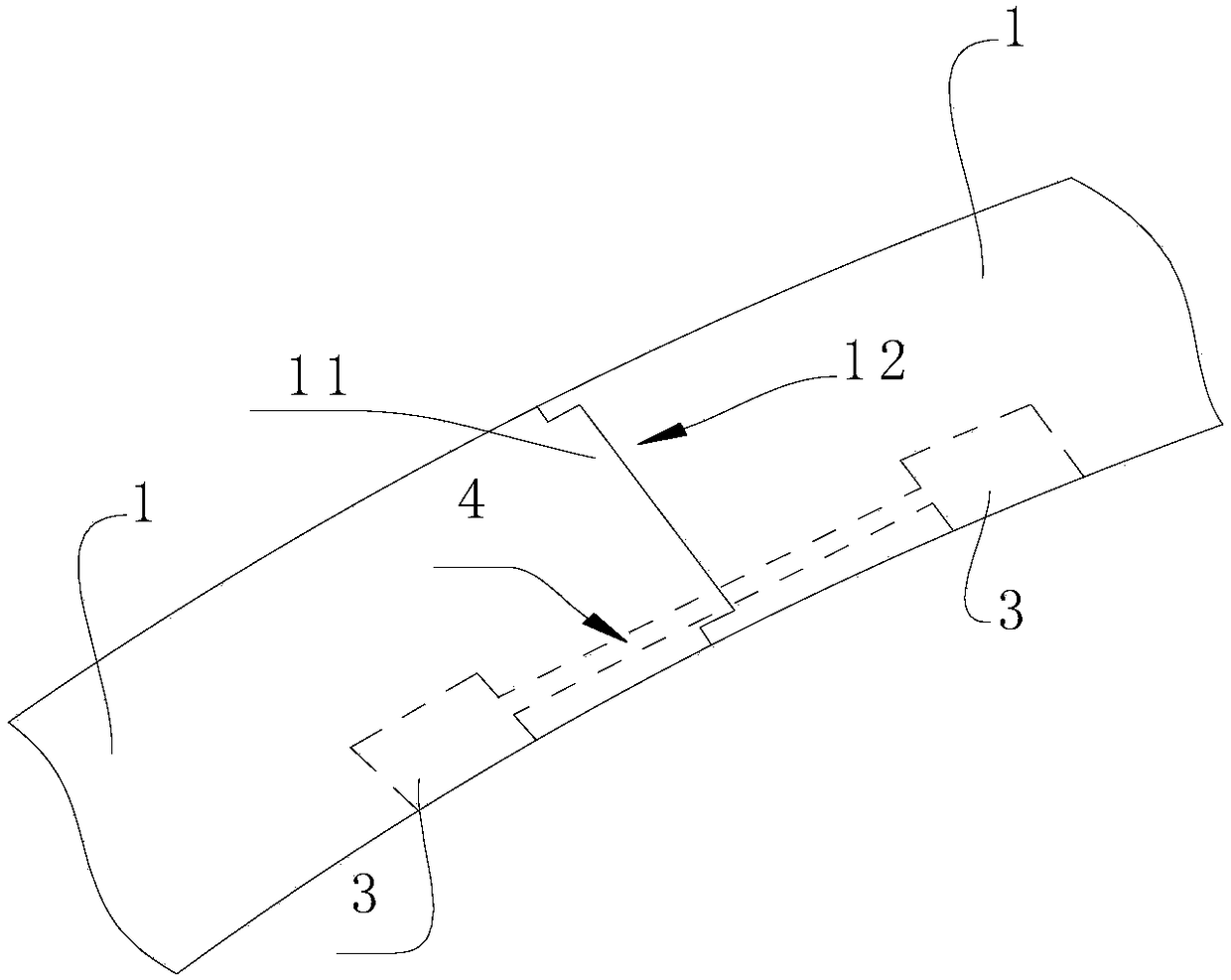

Pre-casting and mounting method for super-high performance concrete deck type slab arch bridge segments

ActiveCN108179700ALight structureStructural thinningBridge erection/assemblyBridge materialsCopperSpandrel

The invention provides a pre-casting and mounting method for super-high performance concrete deck type slab arch bridge segments, and belongs to the technical field of bridge construction methods. According to the pre-casting and mounting method for the super-high performance concrete deck type slab arch bridge segments, each of the slab arch segments of the deck type slab arch bridge is pre-casted by using the super-high performance concrete. Plush coppers are arranged on a joint between the two ends of the slab arch segments in a matched and abut-joint mode, and grooves are formed in the joint between the two ends of the slab arch segments in a matched and abut-joint mode. Tensioning cable channels and grooves are formed in the inner portions of the two ends of the slab arch segments. The slab arch segments are hoisted by a hoisting device to the own positions, the abut-joint plush coppers and grooves of the two adjacent slab arch segments are abut-joint with each other, and tensioning cables are installed in channels in a penetrating mode and are fixed in the grooves in a tensioning mode. Tensioning pintle cables and guy-cables are arranged on the slab arch segments to adjust elevation and arch axes of the slab arch segments, and an arch ring is formed by the splicing of the slab arch segments in sequence. Spandrel columns and bent caps are arranged, so that the ancillary works of the slab arch bridge are completed, and the construction is completed. According to the pre-casting and mounting method for the super-high performance concrete deck type slab arch bridge segments, the speed and quality of the construction can be improved, the cost of the super-high performance concrete arch bridge is reduced, and a thinner and more attractive bridge shape is generated.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD +1

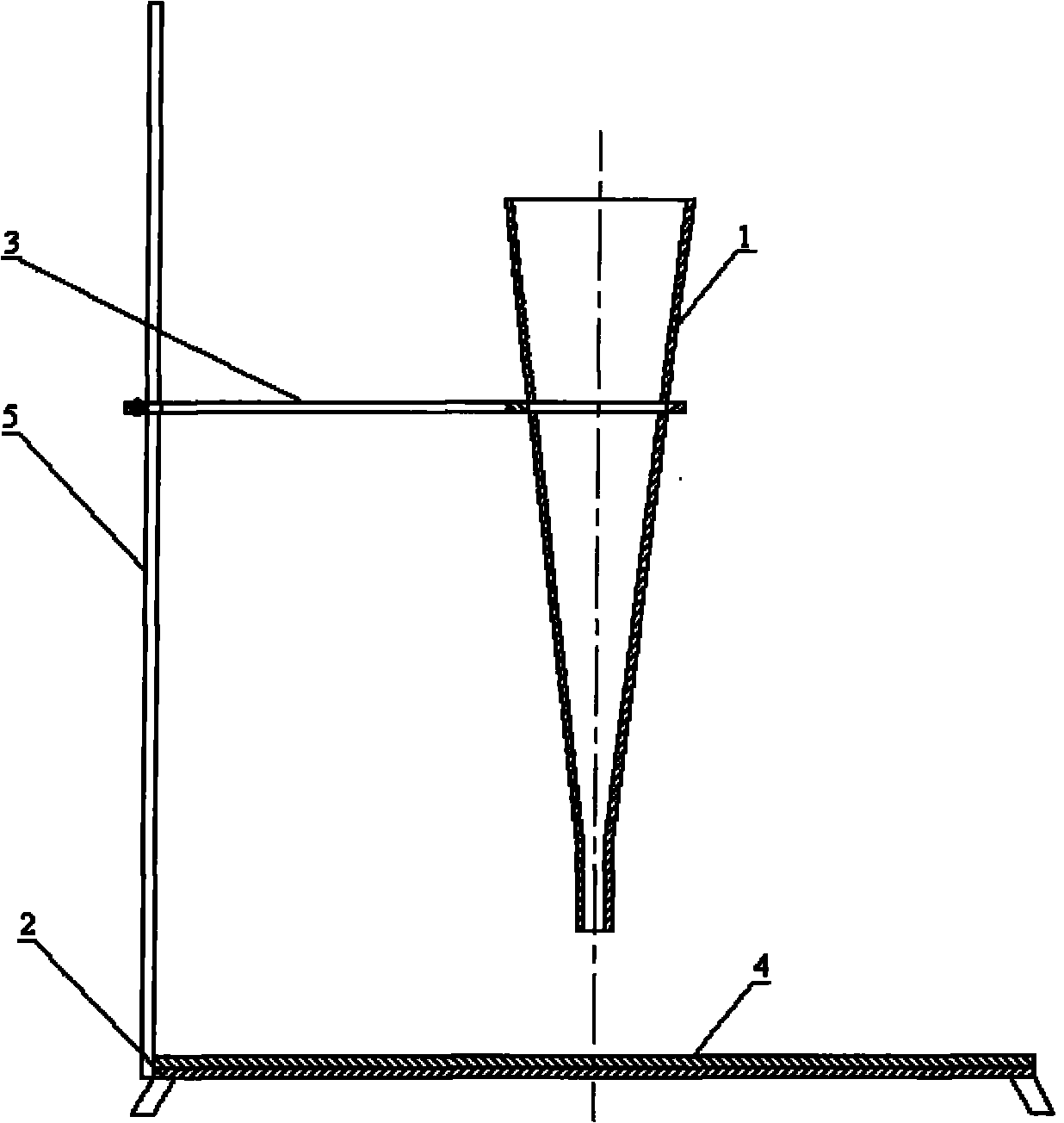

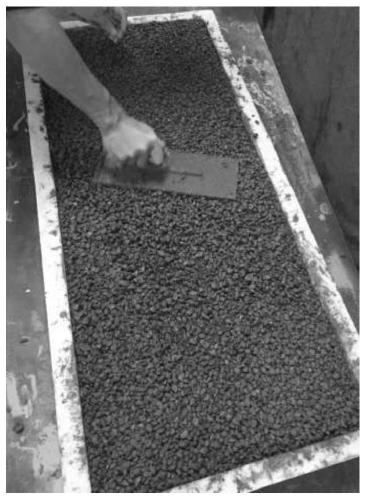

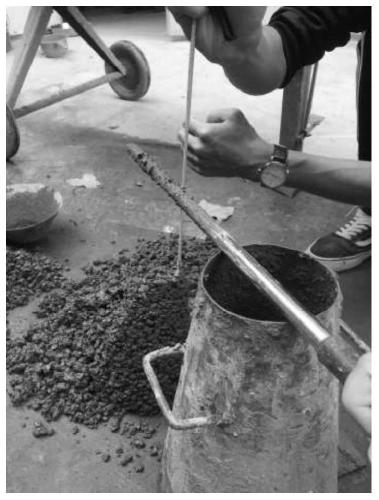

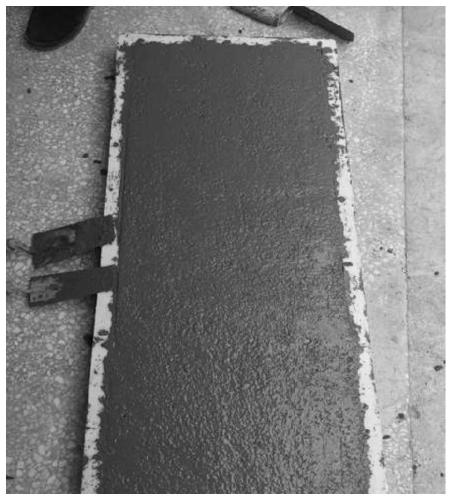

Method for testing adaptability of polycarboxylic water reducer and cement

ActiveCN101980014ASimple methodEasy to operateFlow propertiesMaterial testing goodsWater reducerCement mortar

The invention discloses a method for testing the adaptability of a polycarboxylic water reducer and cement. The method comprises the following steps of: proportioning according to a ratio of each raw material in concrete during the actual construction; blending mortar by using a cement mortar blender, and detecting the mortar by using a device for testing the adaptability of the polycarboxylic water reducer and the cement; and evaluating the workability of the mortar according to the time that the detected mortar overflows from a mortar funnel completely and the extensibility of the mortar ona glass plate so as to determine the adaptability of the polycarboxylic water reducer and the cement. The method has the advantages of simplicity, convenience of operation, accurate measuring, strongrelevance with the workability of the concrete and comprehensive reflection on the adaptability.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD

Full-lightweight ceramsite concrete and preparation method thereof

The invention relates to full-lightweight ceramsite concrete and a preparation method thereof. The full-lightweight ceramsite concrete is prepared from, by weight, 278-339 parts of cement, 318-344 parts of ceramsite, 334-382 parts of pottery sand, 50-55 parts of coal ash, 35-42 parts of silica fume, 0.001-3 parts of triisopropanolamine, 0.5-3 parts of a water reducing agent and 0.001-3 parts of athickening agent. The method includes steps: subjecting ceramsite and pottery sand to surface pretreatment through alkyl alkoxy silane, prewetting ceramsite and pottery sand to achieve a saturated surface dry state, then sequentially feeding lightweight aggregates, cement, silica fume and coal ash into a forced mixer, and well mixing to obtain the full-lightweight ceramsite concrete. The full-lightweight ceramsite concrete prepared according to the method has advantages of light weight, high peaceability and effectiveness in inhibition of ceramsite floating and has a promising application prospect in the field of energy-saving construction engineering.

Owner:CHINA THREE GORGES UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com